Great-torque miniature DC permanent-magnet synchronous servo motor

A permanent magnet synchronous and servo motor technology, applied in the field of servo motors, can solve the problems of high transportation costs, large motor volume, and unattractive appearance, and achieve the effects of easy transportation and packaging, reduced installation size, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

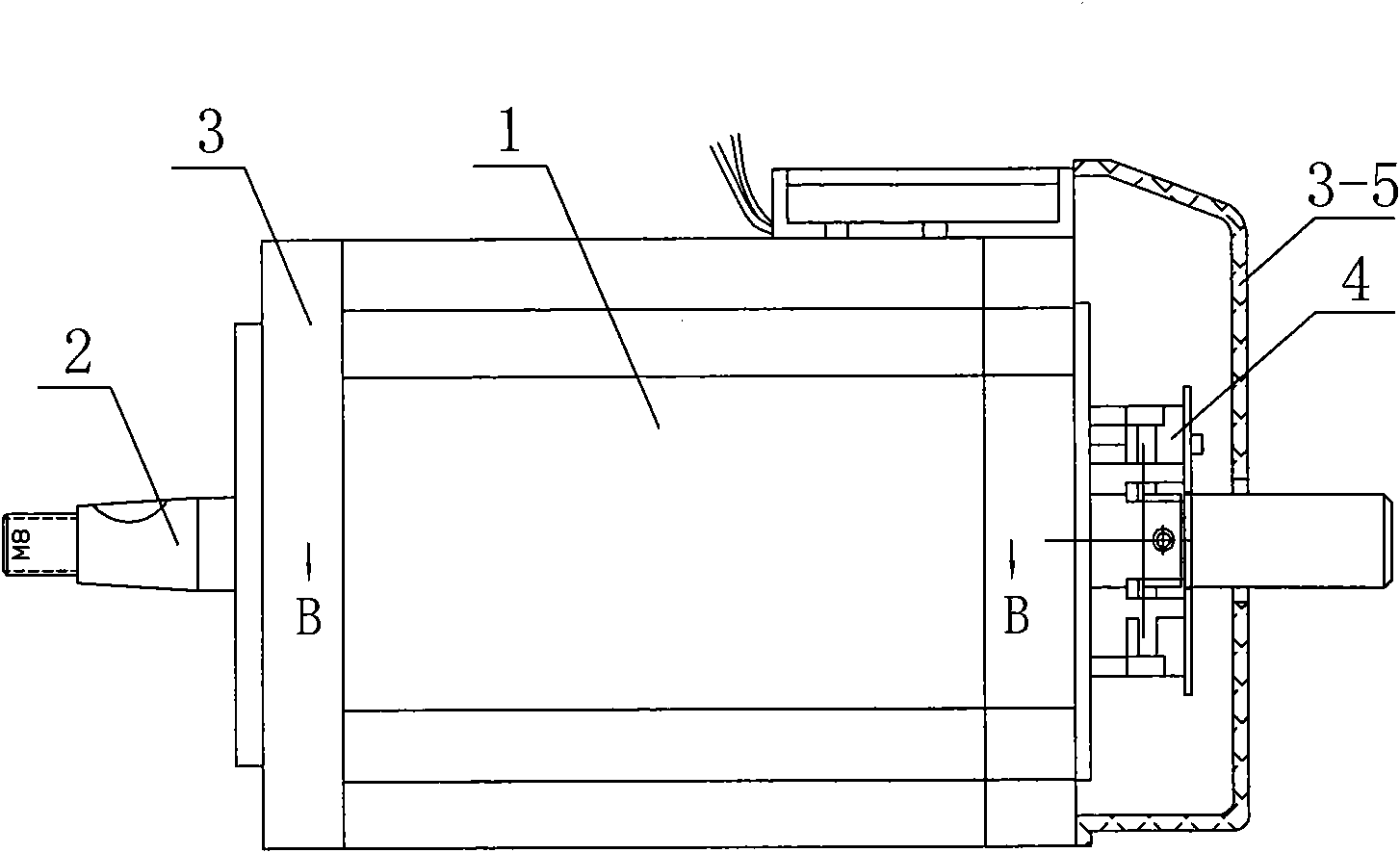

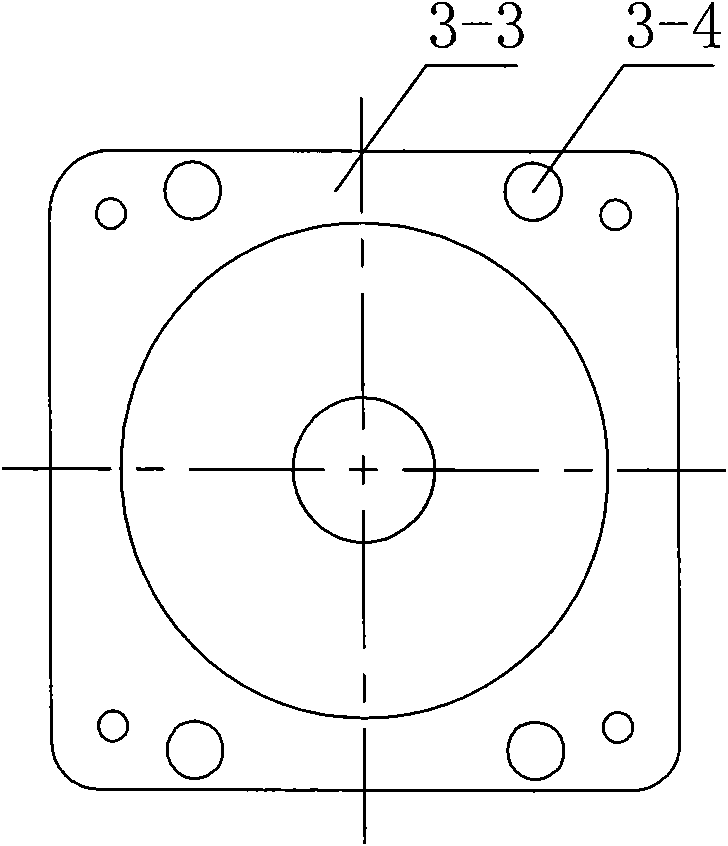

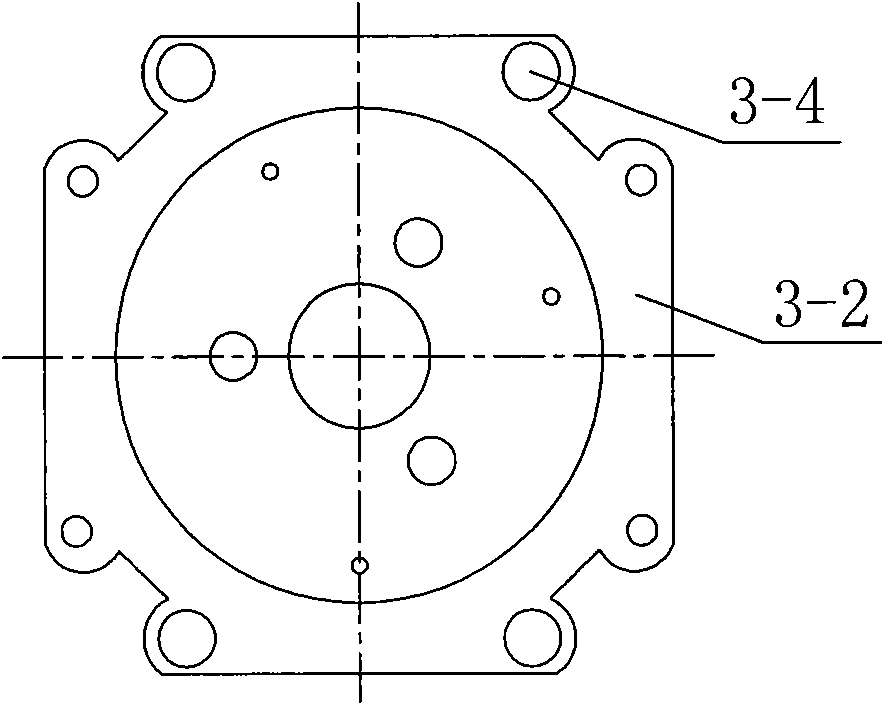

[0032] Such as Figure 1-Figure 3 As shown, this embodiment includes a casing 3, the inner wall of which is fixed with a stator 1, the stator is coaxially embedded with a rotor 2 that can rotate around its axis, and a photoelectric encoder 4 is installed on the output shaft of the motor as a speed and phase signal detector. . The casing 3 includes a hollow body 3-1, a front end cover 3-2 and a rear end cover 3-3, wherein the outer shell 3-1 is a stretched aluminum profile, and the front end cover 3-2 and the rear end cover 3-3 are die-cast aluminum , has the characteristics of light weight and good heat dissipation. The three are tightly connected by through-hole screws 3-4 to form a sealed cavity, and its length, width, and height are 10.8cm, 8cm, and 8cm, respectively.

[0033] Such as Figure 4-Figure 6 As shown, the stator 1 is used to generate a magnetic field, and it includes a sleeve-shaped stator core formed by a group of stator punches 1-3 (silicon steel sheets) tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com