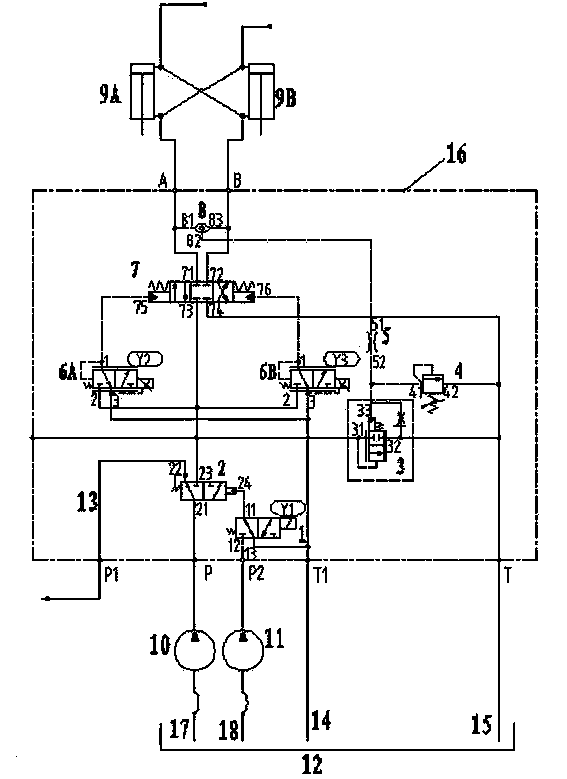

Steering electrohydraulic control system for remote control loading machine

A technology of electro-hydraulic control system and hydraulic control reversing valve, which is applied to the components of fluid pressure actuating system, mechanical equipment, fluid pressure actuating device, etc. Problems such as high heat generation and oil leakage of steering hydraulic system can improve system reliability, reduce installation size and reduce oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] 1. Use the steering quantitative pump 10 of the loader as the power source.

[0034] 2. The steering pressure oil output by the steering quantitative pump reaches the first oil inlet 21 of the first hydraulic control reversing valve 2 from the oil port P, and the loader also has a pilot oil with constant pressure (about 3MPa) from the oil port P2 It reaches the oil inlet 12 of the electromagnetic reversing valve 1. When there is no remote control steering signal, the steering pressure oil output by the steering quantitative pump passes through the first oil inlet 21 of the first hydraulic control reversing valve 2 to the first oil outlet 22, reaches the oil port P1, and finally leads to the loader engine. Vehicle steering valve; when the loader switches to the remote control state, the electromagnet Y1 of the electromagnetic reversing valve 1 is always energized, and the pilot oil passes through the oil inlet 12 to the oil outlet 11, and reaches the first hydraulic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com