Patents

Literature

152results about How to "Commutation smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

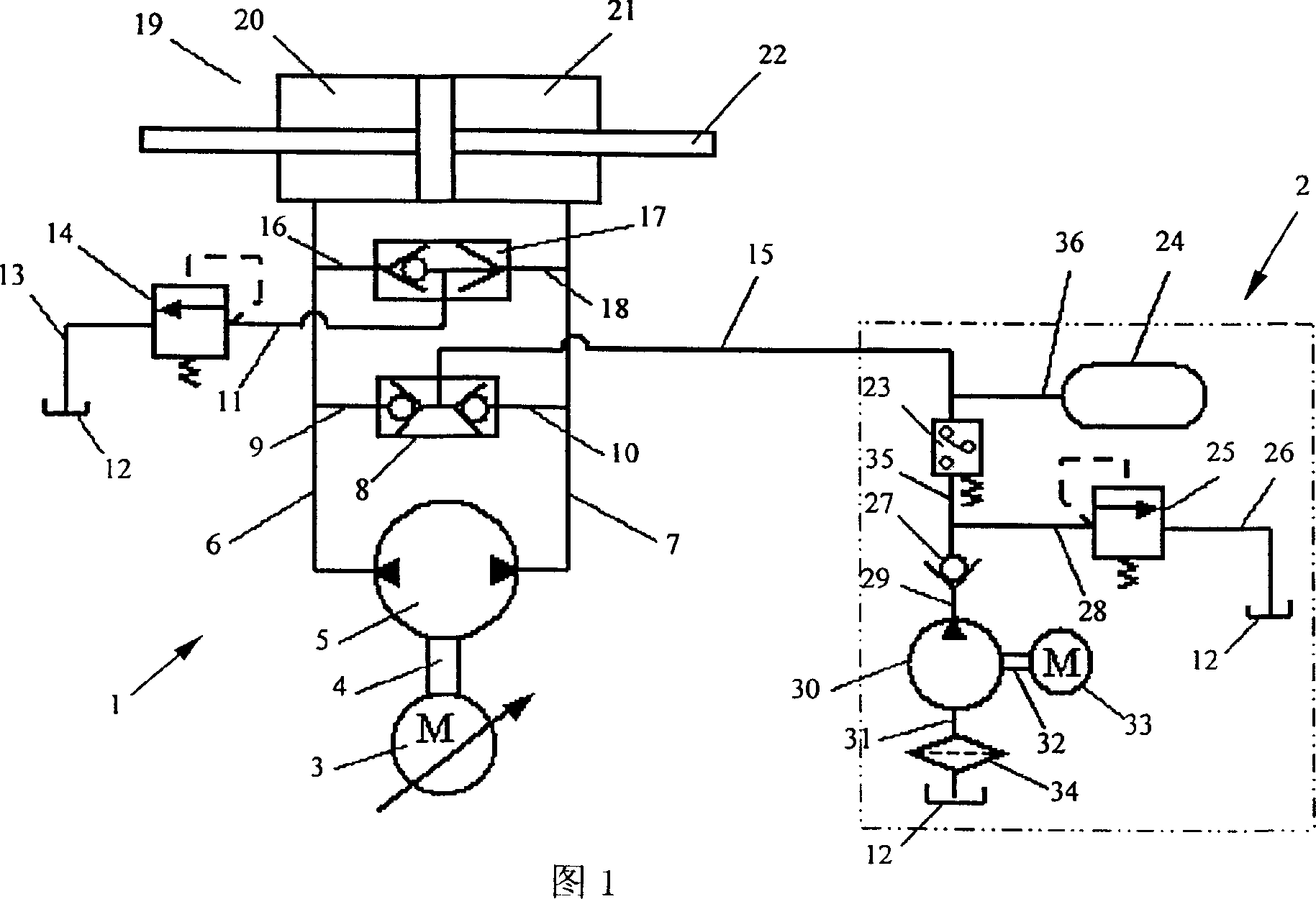

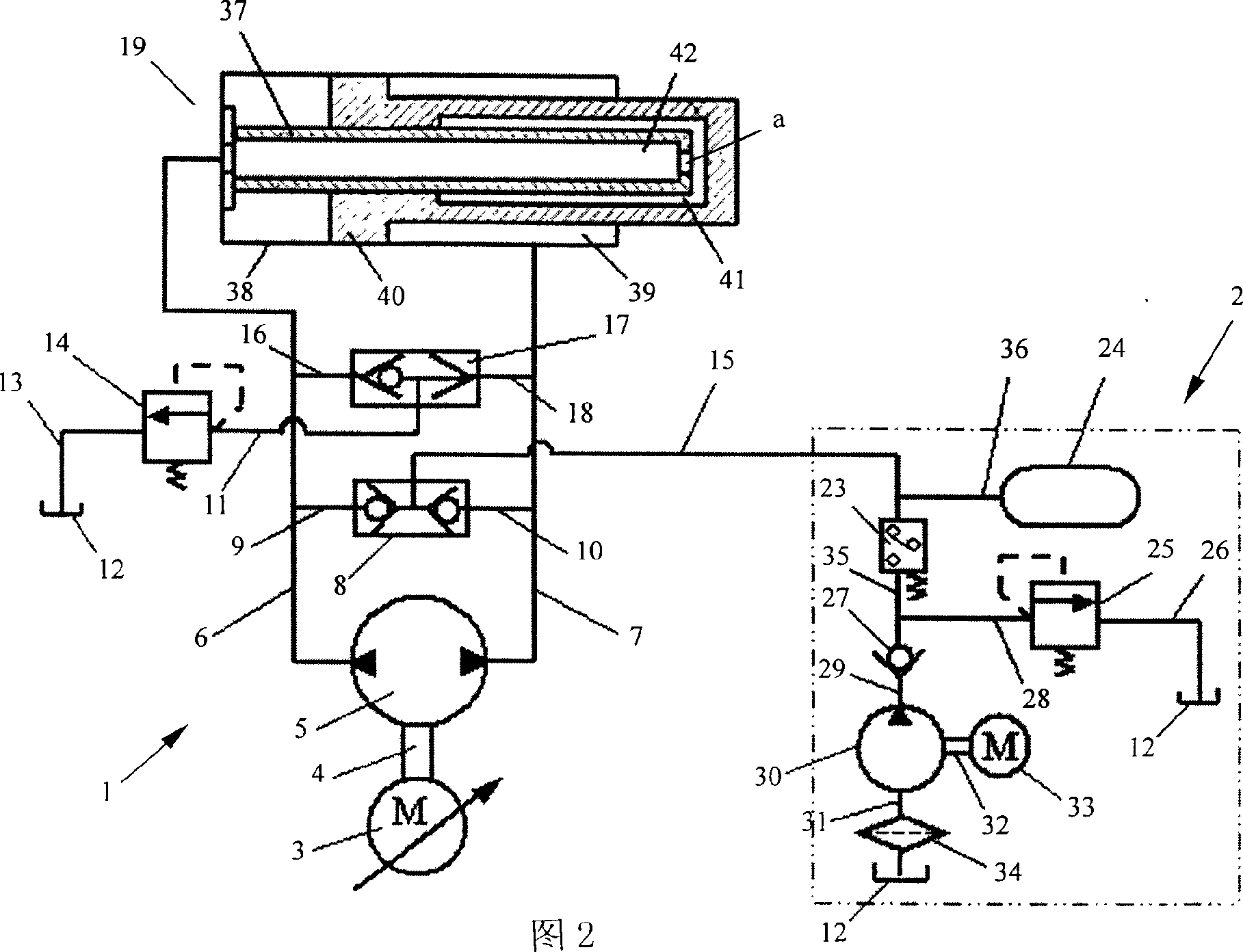

Frequency converter volume variable speed closed hydraulic control systems

InactiveCN1439814AImprove transmission efficiencySave energyServomotorsHydraulic control unitHydraulic motor

A closed hydraulic control system with frequency-varying volumetric speed regulation for high-power and high-speed fields is composed of primary hydraulic loop and oil-supplementing loop for said primary hydraulic loop. A frequency-varying technique is used to control the rotation speed of three-phase AC asynchronous motor and in-turn the output flow of hydraulic pump or hydraulic motor. Its advantages are small volume of oil in hydraulic loop, and high energy-saving effect.

Owner:ZHEJIANG UNIV

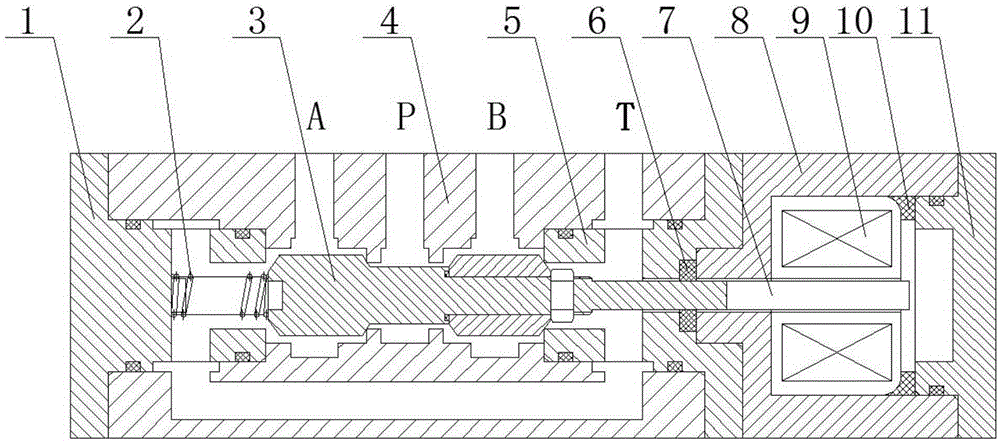

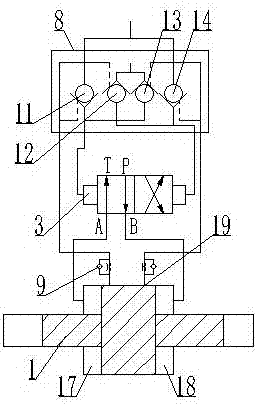

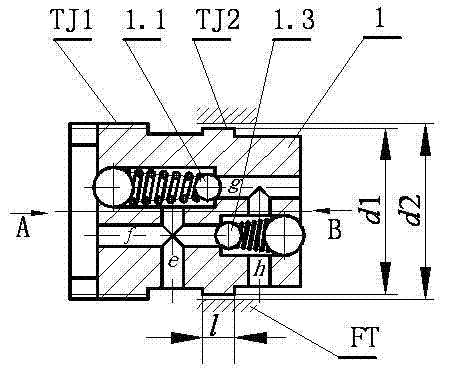

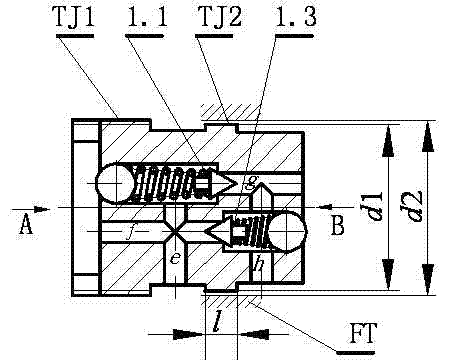

Double-cone type two-position four-way electromagnetic reversing valve

InactiveCN105422911AWork lessGuaranteed reliabilityOperating means/releasing devices for valvesMultiple way valvesWater basedAtmospheric air

The invention discloses a double-cone type two-position four-way electromagnetic reversing valve and belongs to a water hydraulic control valve. The double-cone type two-position four-way electromagnetic reversing valve is mainly applicable to a direction control valve of a medium and high-pressure deep sea operating device which takes seawater, fresh water, a high-water base and the like as a working medium and is also applicable to a working condition in an atmospheric environment. The double-cone type two-position four-way electromagnetic reversing valve disclosed by the invention is based on deep sea application and is capable of solving the problems met by a traditional electromagnetic reversing valve working in a deep sea environment at the aspects of overall sealing, pressure compensation, underwater control and the like of the reversing valve; an electromagnetic control device is integrally sealed so as to be isolated from external seawater; meanwhile, a valve opening is sealed by adopting a cone valve, so leakage of the valve opening is reduced; by adopting a separated type double-cone valve structure, the sealing reliability of the valve opening of the reversing valve is guaranteed, and a valve core of the reversing valve is also ensured not to be affected by the value of ambient pressure. The reversing valve disclosed by the invention is small in size, rapid in response, small in leakage, high in work reliability, long in service life, good in economical efficiency, free of pollution, applicable to work under seawater environments different in water depth and quite high in practical application value.

Owner:BEIJING UNIV OF TECH

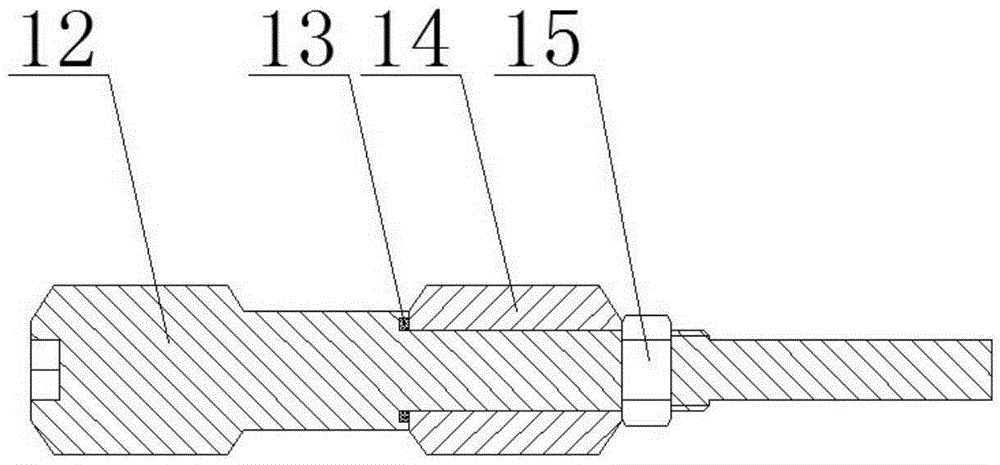

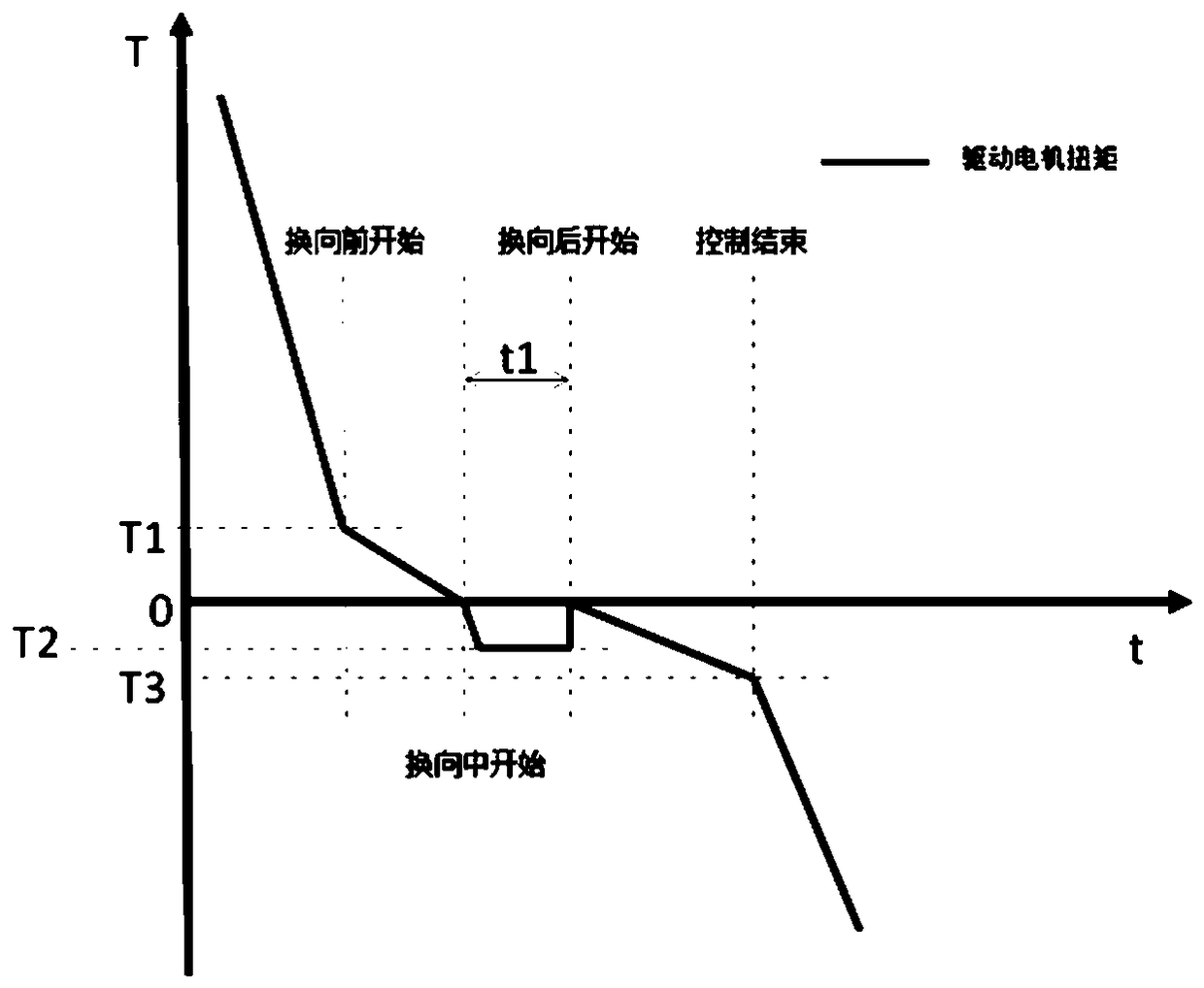

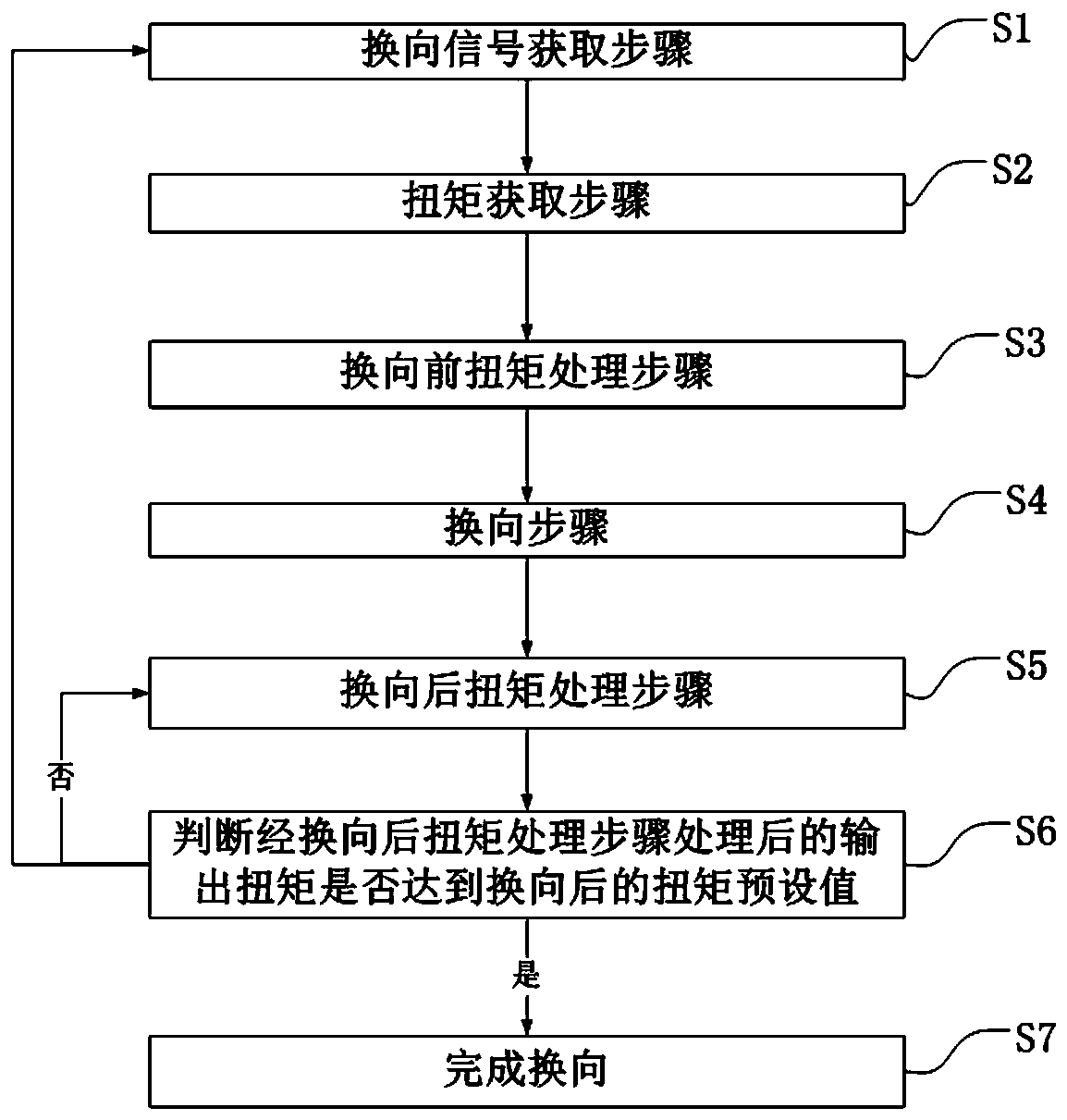

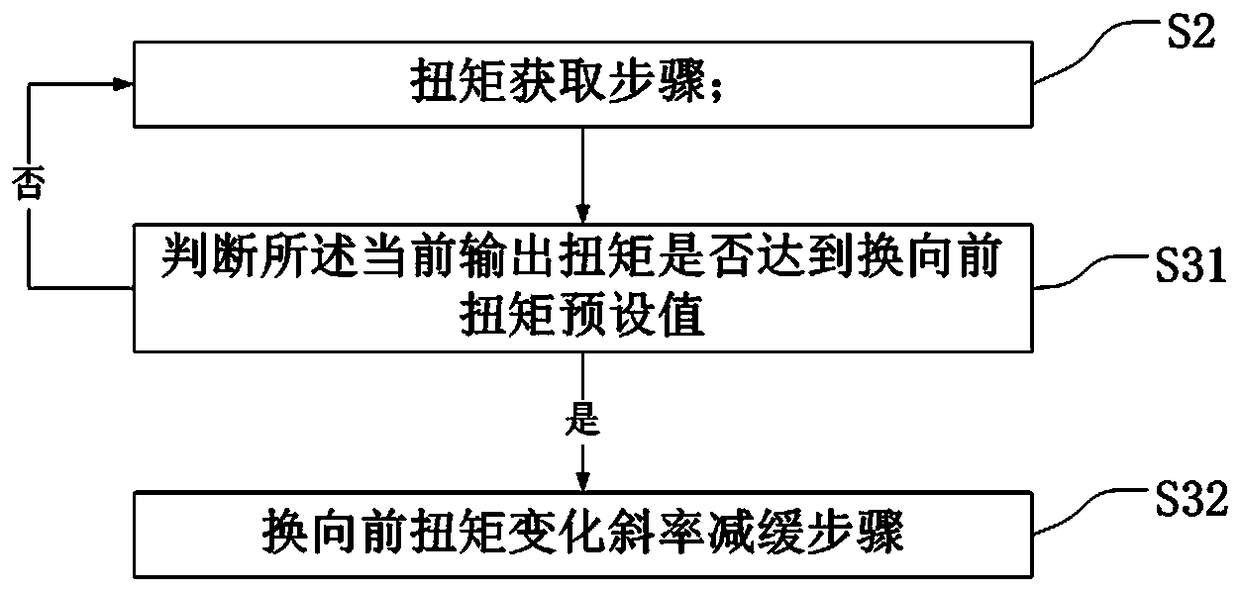

Tooth surface reversing anti-shake control method for electric vehicle

ActiveCN108583365ACommutation smoothImprove comfortSpeed controllerElectric energy managementElectric vehicleControl theory

The invention discloses a tooth surface reversing anti-shake control method for an electric vehicle. The tooth surface reversing anti-shake control method for the electric vehicle comprises the stepsof a reversing signal obtaining step, a torque obtaining step, a reversing step, a step of processing a torque after reversing and a step of judging a torque value after reversing; and the tooth surface reversing anti-shake control method for the electric vehicle further comprises the steps of judging whether an output torque processed in the step of processing the torque after reversing reaches atorque preset value after reversing or not; and if so, finishing reversing and returning to the reversing signal obtaining step; and otherwise, returning to the step of processing the torque after reversing. According to the tooth surface reversing anti-shake control method for the electric vehicle, tooth surface reversing is realized during smoother running, the tooth surface reversing anti-shake control method for the electric vehicle is more in line with characteristics of pure electric logistics vehicles, and the comfort of the whole vehicle is improved.

Owner:上海伊控动力系统有限公司

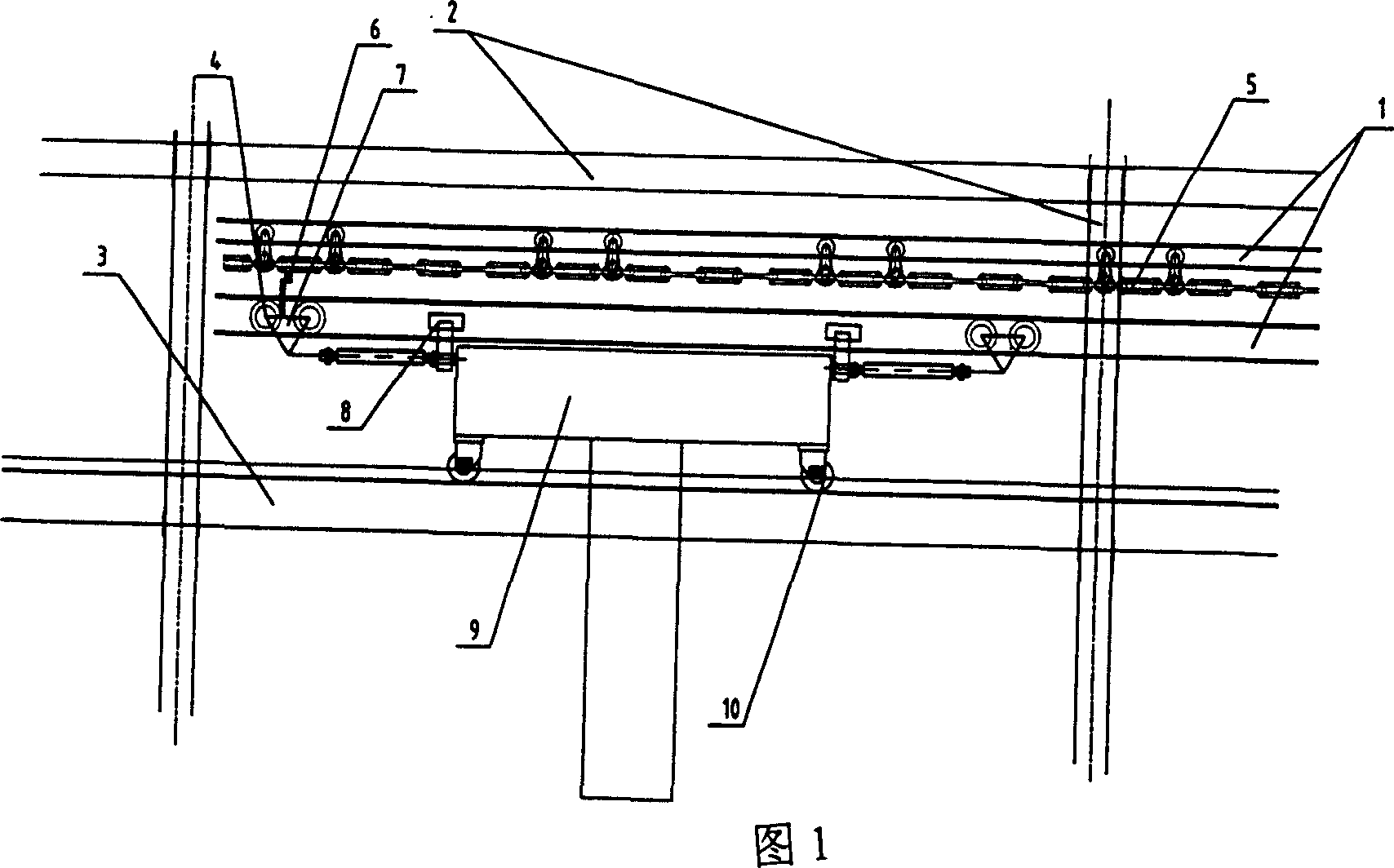

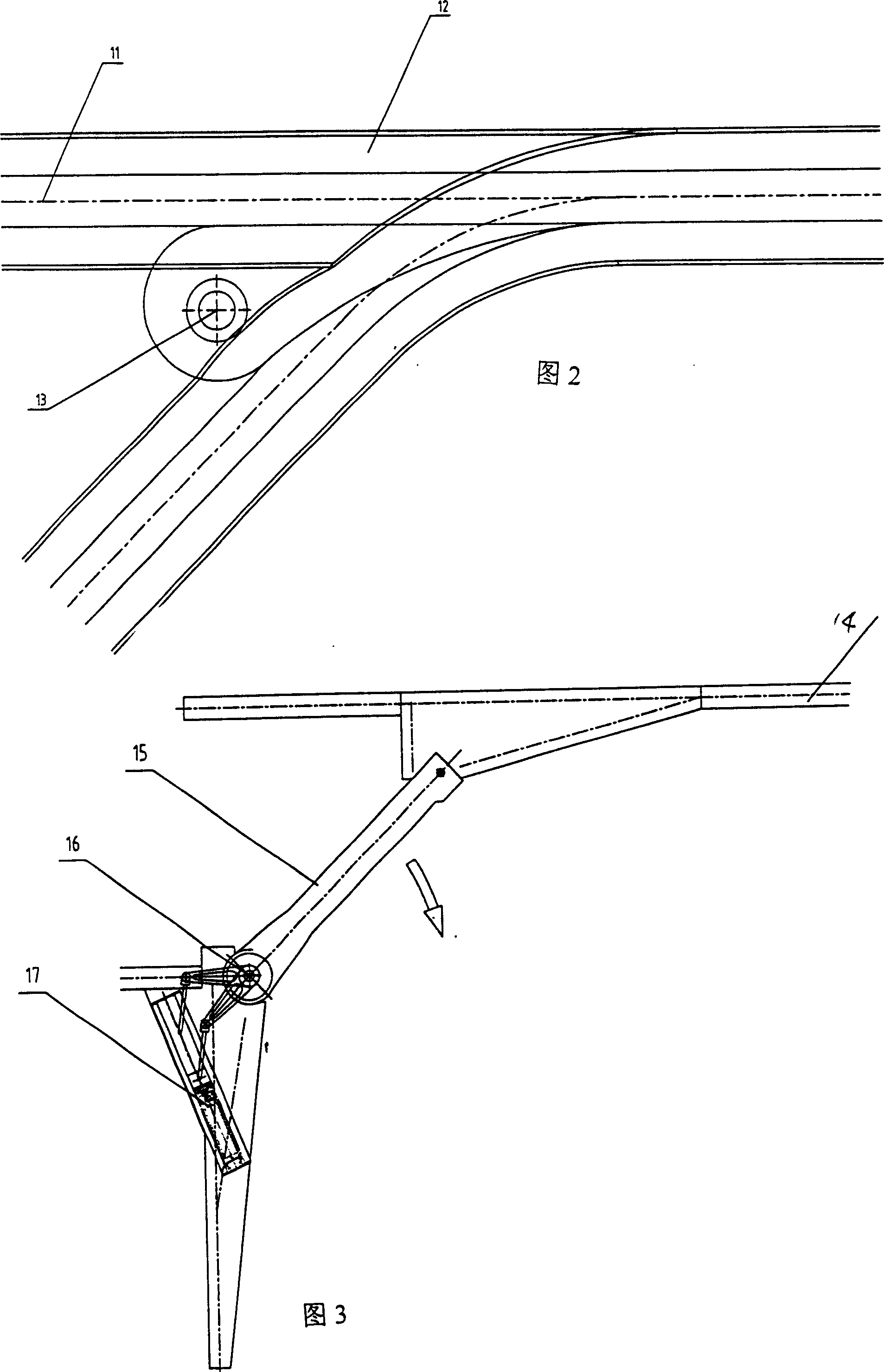

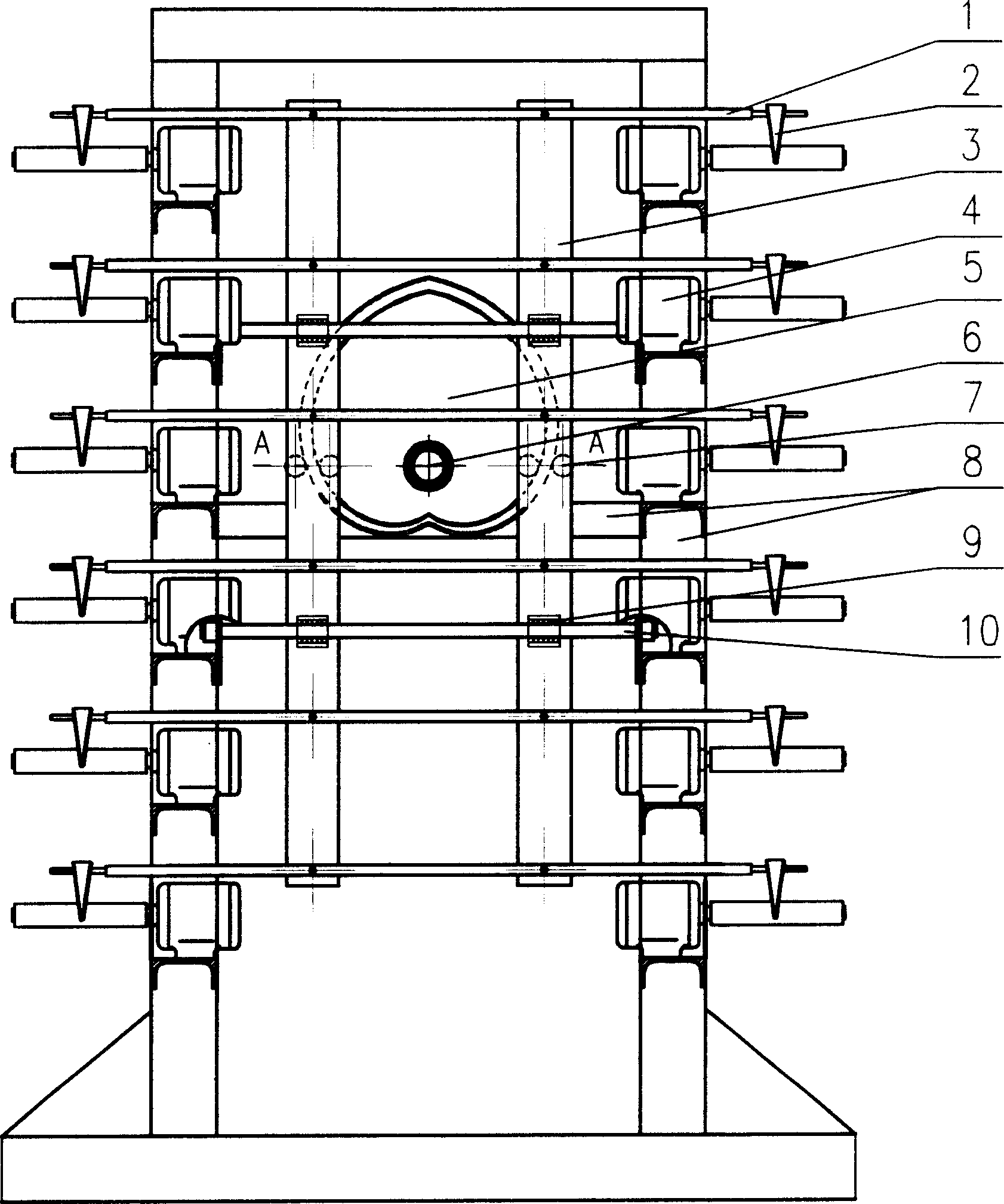

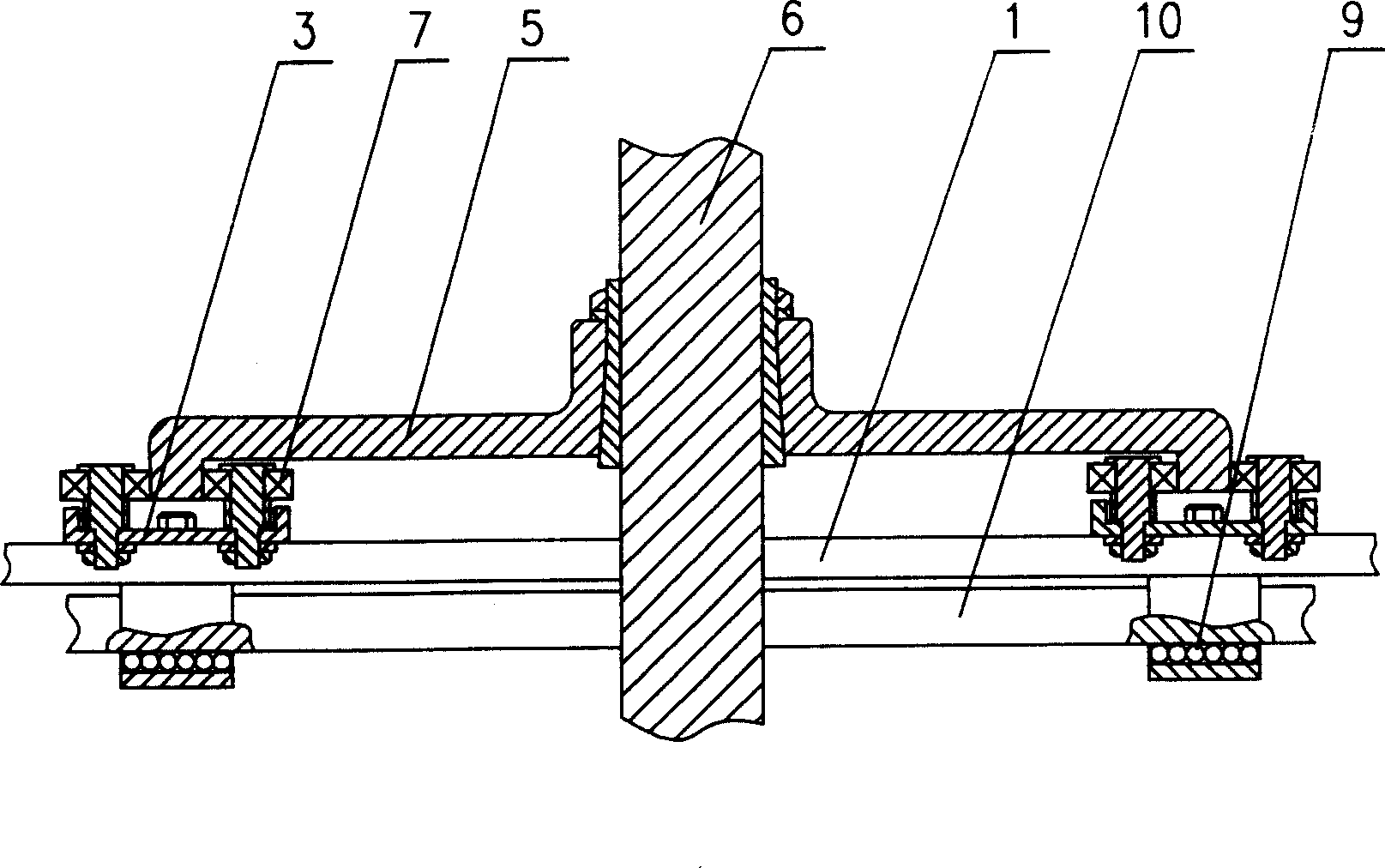

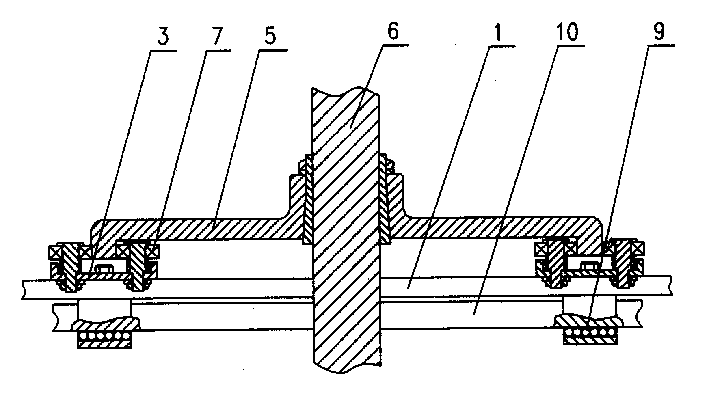

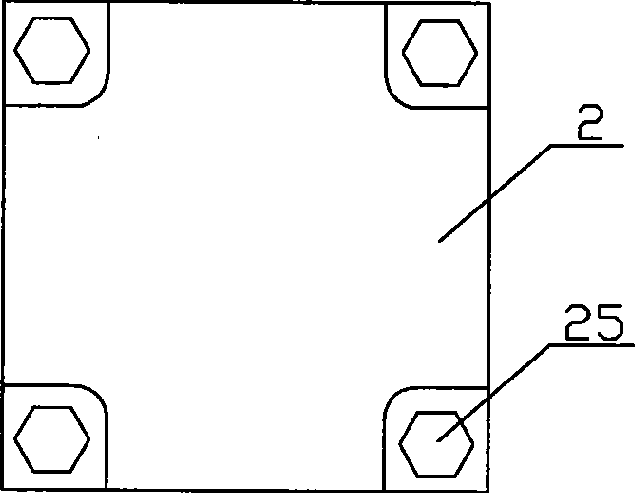

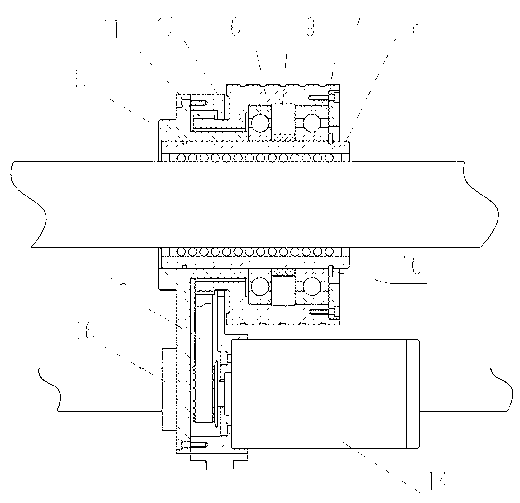

Double bearing track turnout

The invention discloses a double-bearing rail switch, it is characterized by: the conventional switch is installed on the upper layer position, and the multifunctional carriage bearing switch rail is installed right below the conventional switch and is welded by steel structure; the conventional switch includes the upper layer H-bar, the switch of the tail for carrying the lower layer guiding carriage is two channel bars embracing each other. The multifunctional carriage bearing switch rail, its switch is installed on the multifunctional carriage rail surface and is butted with the fore and rear tails, the central switch tongue encircles one end of rotary device and cylinder pushing device is connected with the central switch tongue, when turn the switch, the switch tongue butt joints with tail head in different direction, then realize the role of changing tail direction. The advantages of the invention: using the similar mode with train replacing rail, reversing and transporting the self-carriage and rapidly, it can realizes flexible transmission and rapid, steady and reliable reversing in the transportation of examining and repairing trains and rail vehicles.

Owner:郑卫星

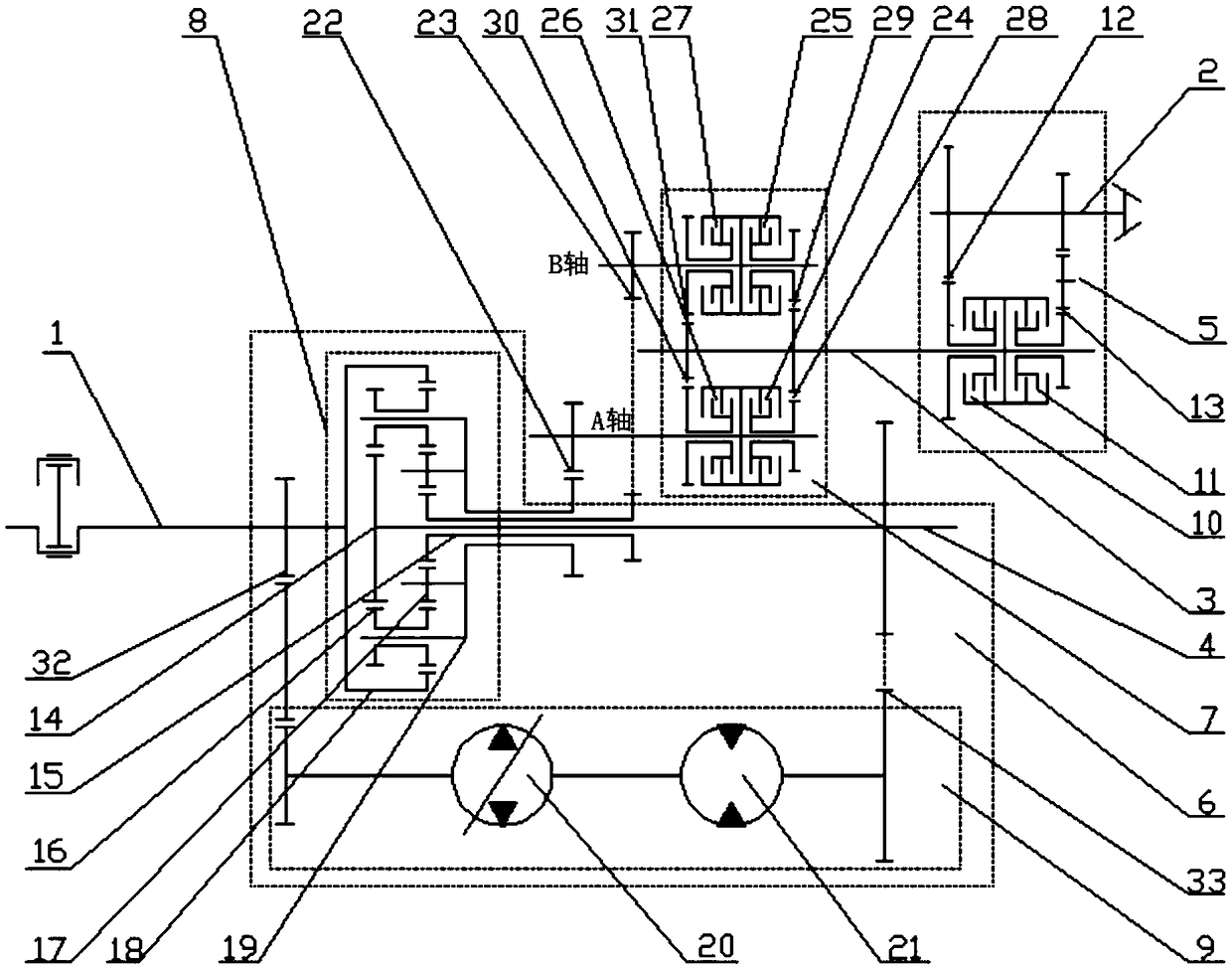

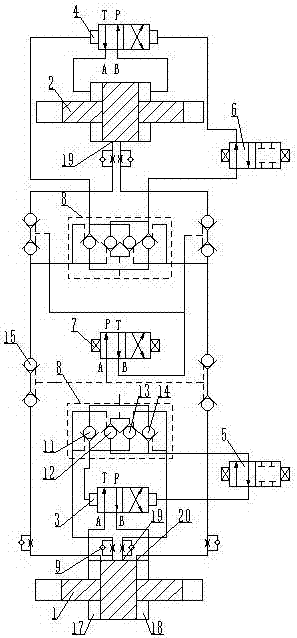

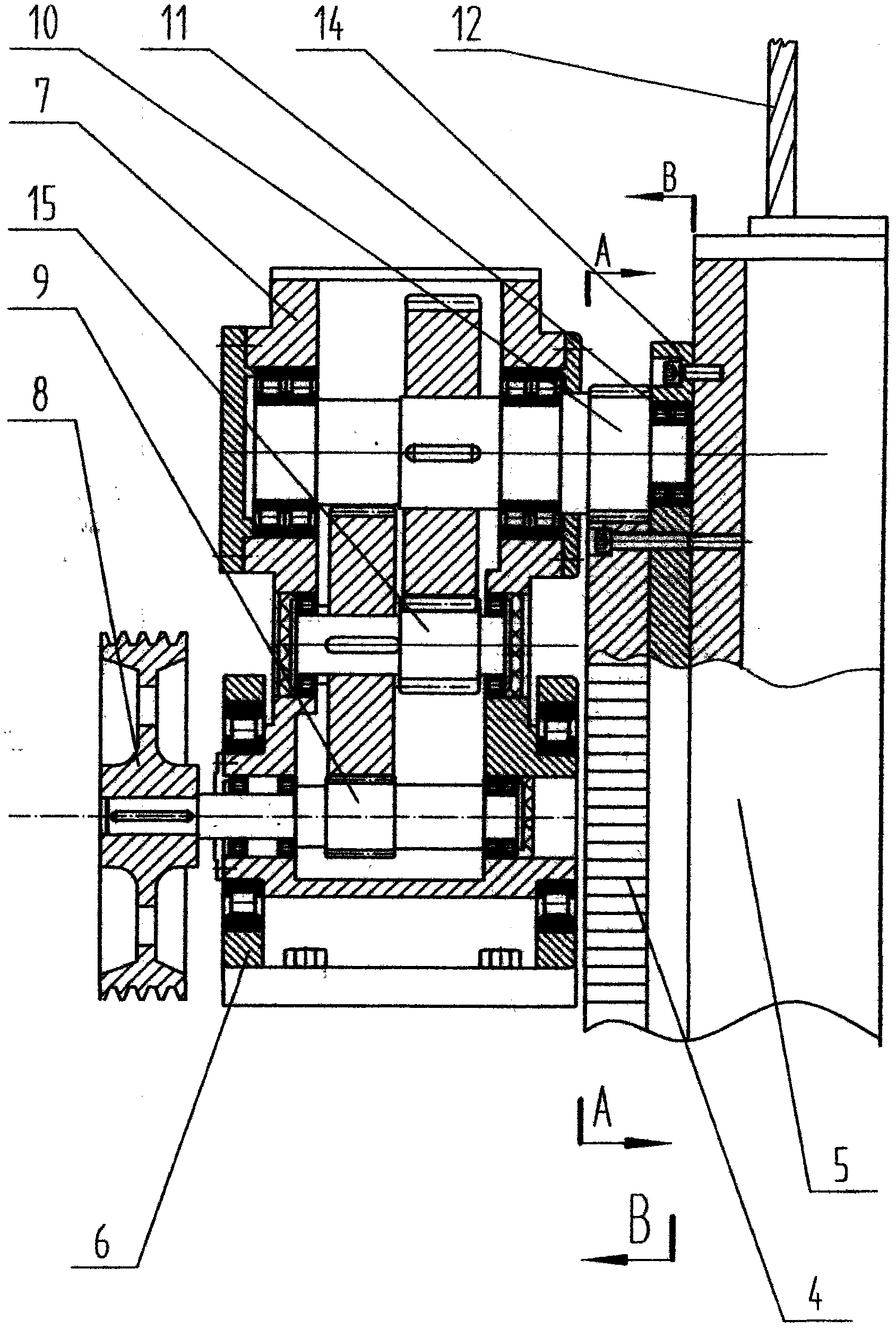

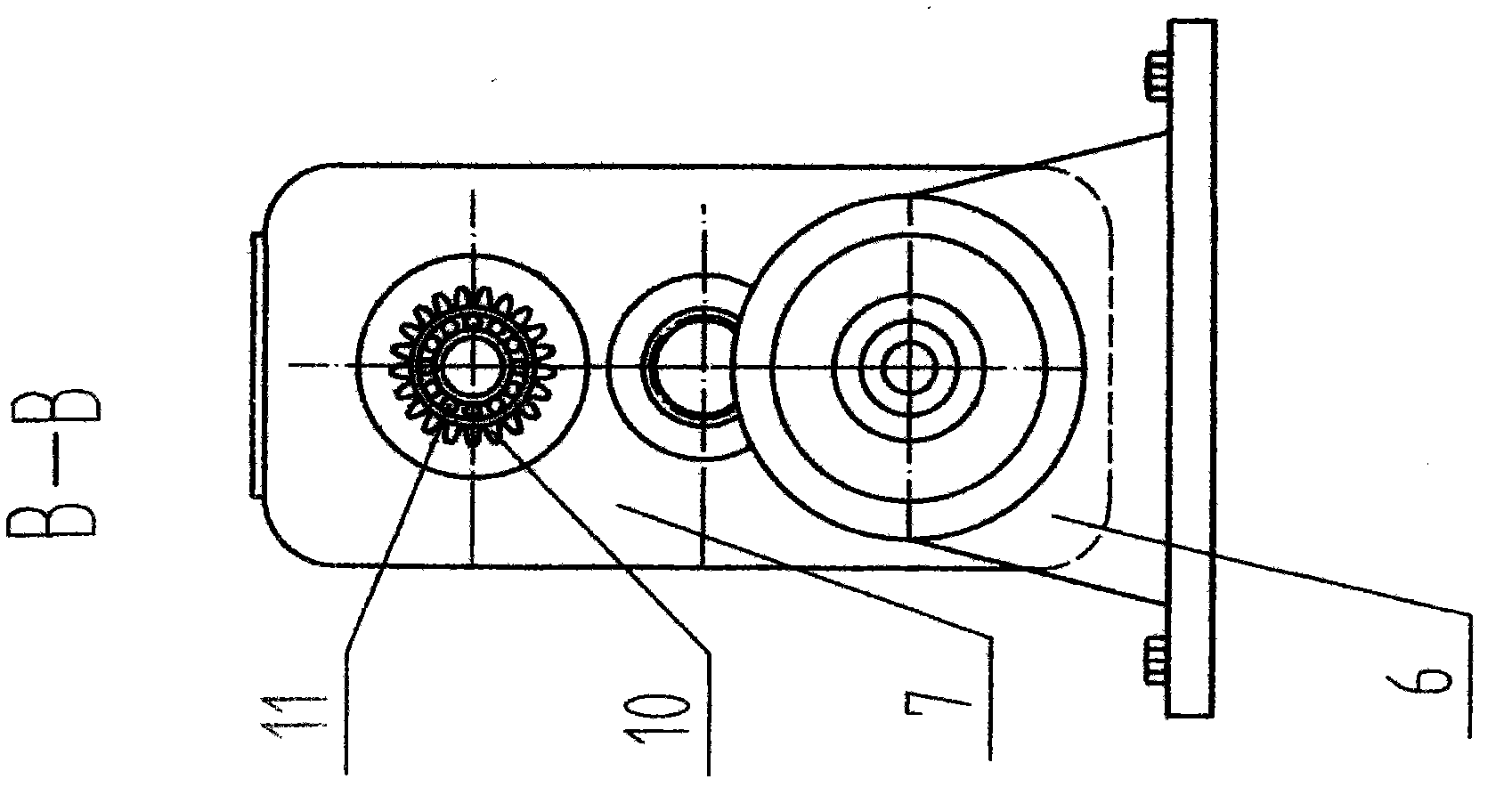

Continuously variable transmission of quick reversing power division hydraulic machinery

ActiveCN109185417AStart fastCompact structureFluid gearingsGearing detailsHydraulic machineryEngineering

The invention discloses a continuously variable transmission of quick reversing power division hydraulic machinery. The continuously variable transmission comprises a transmission main body mechanism,a transmission gear shifting mechanism and an advancement-retreating switching mechanism; the transmission main body mechanism comprises a planet gear mechanism and a hydraulic transmission mechanism; the hydraulic transmission mechanism comprises a variable pump and a quantitative motor; an input shaft of the transmission divides engine power through the planet gear mechanism and the hydraulic transmission mechanism; mechanical power and hydraulic power are collected through a long planet gear; and the collected power is output to the transmission gear shifting mechanism through a small sungear shaft or a planet carrier, and is transferred to an output shaft of the transmission for outputting through the transmission gear shifting mechanism and the advancement-retreating switching mechanism. The transmission is more compact in structure and higher in economical benefit.

Owner:JIANGSU UNIV

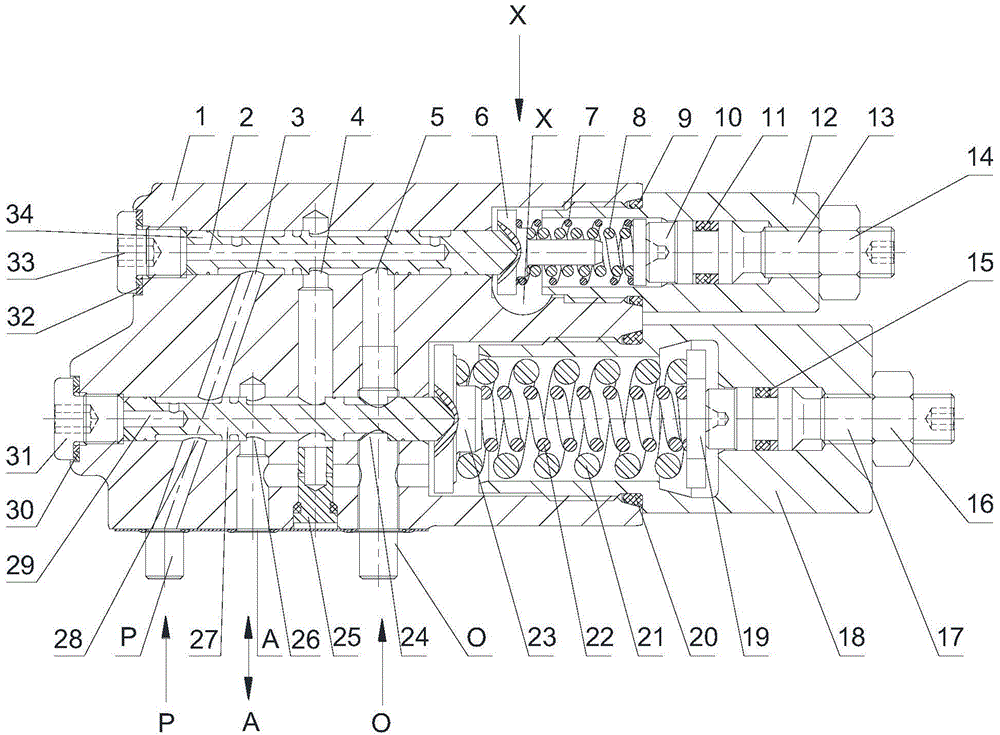

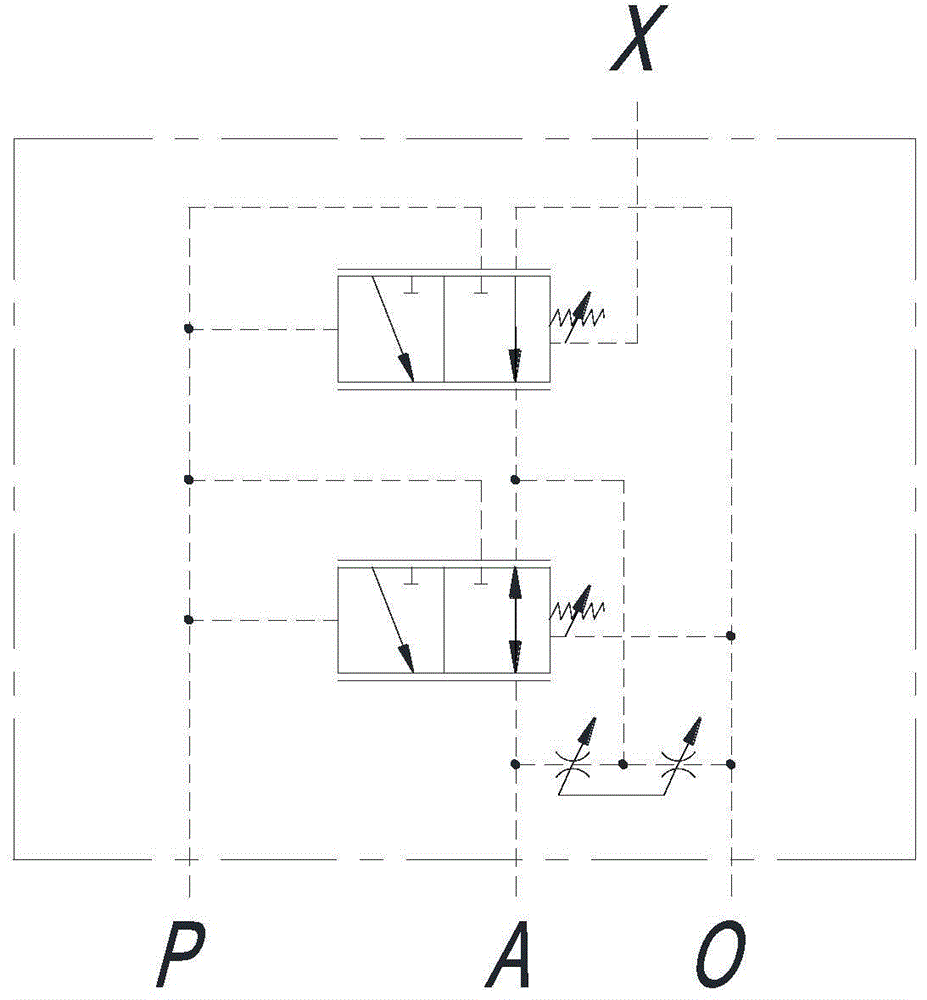

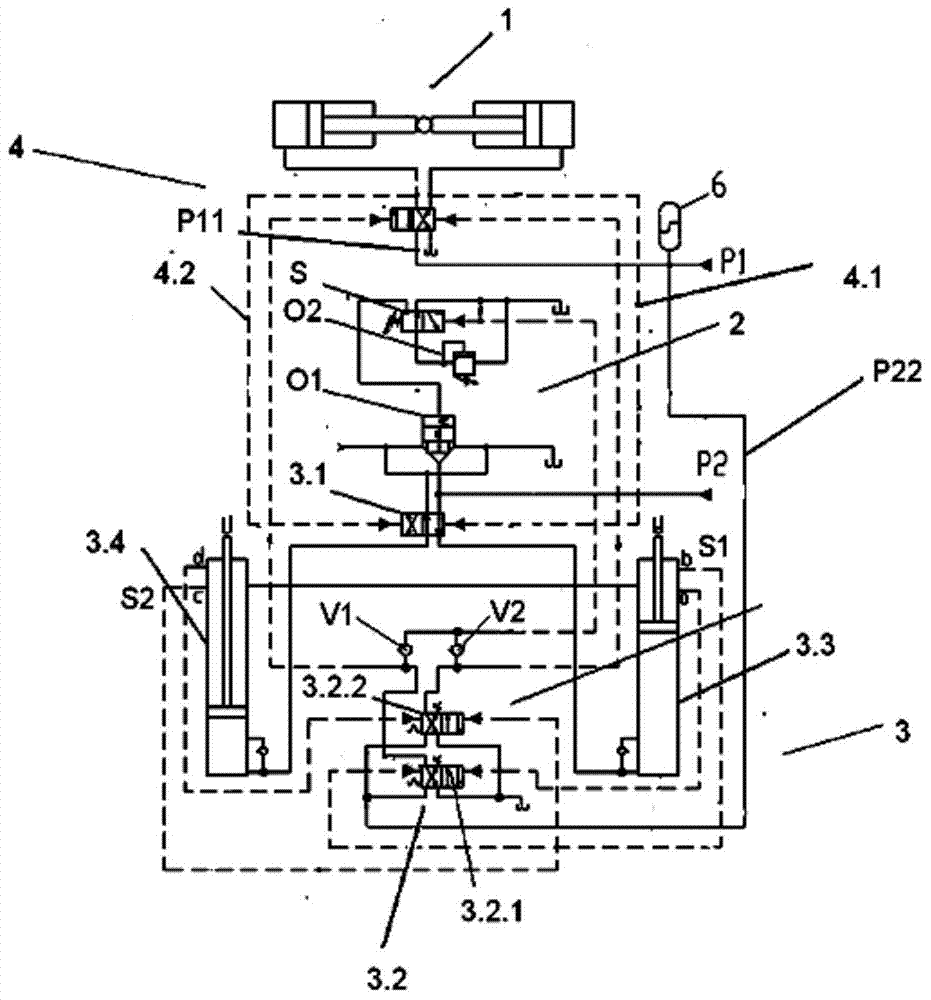

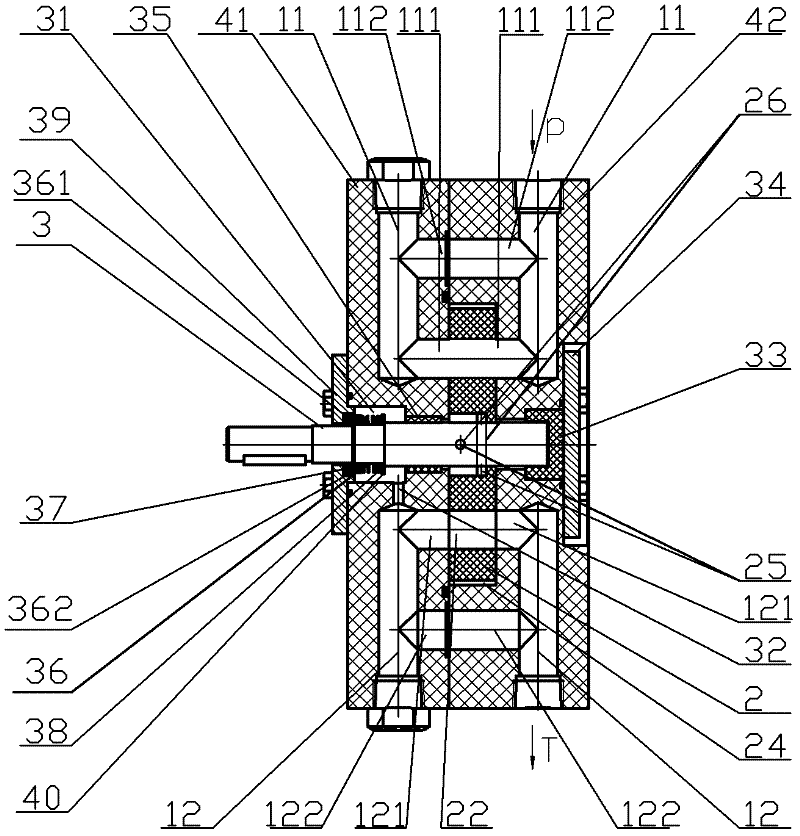

Reciprocating type pressurizer reversing device and application thereof

PendingCN107246422ACommutation smoothReversing valve reversing smoothlyServomotor componentsFluid-pressure convertersHydraulic cylinderChamber pressure

The invention discloses a reciprocating type pressurizer reversing device. The reciprocating type pressurizer reversing device comprises hydraulic control reversing valves and further comprises a hydraulic control one-way valve set; pilot ports in the two sides of the hydraulic control reversing valves communicate with an oil supply pipeline through the hydraulic control one-way valve set; pilot ports of hydraulic control one-way valves in the hydraulic control one-way valve set are connected to control ports of piston cavities of pressurization cylinders; and the control ports of the pressurization cylinders are each provided with a one-way throttling valve. According to the reciprocating type pressurizer reversing device, hydraulic cylinders indirectly control reversing of the hydraulic control reversing valves through the hydraulic control one-way valve set, due to the fact that the amount of oil liquid required by the pilot ports of the hydraulic control one-way valves is small, the pressure loss in the piston cavities of a pressurizer is extremely small, and normal pressure output of the piston cavities of the pressurizer cannot be affected; and the control ports of the piston cavities are provided with the one-way throttling valves, on the premise that the opening speed of the hydraulic control one-way valves is not affected, the pilot ports of the hydraulic control one-way valves are enabled to return oil normally and smoothly so that the phenomenon that the hydraulic control one-way valves are closed prematurely due to the fact that the piston cavities are in a negative pressure state can be effectively avoided, and therefore smooth reversing of the hydraulic control reversing valves can be realized.

Owner:JINZHONG HAOPU HYDRAULIC EQUIP

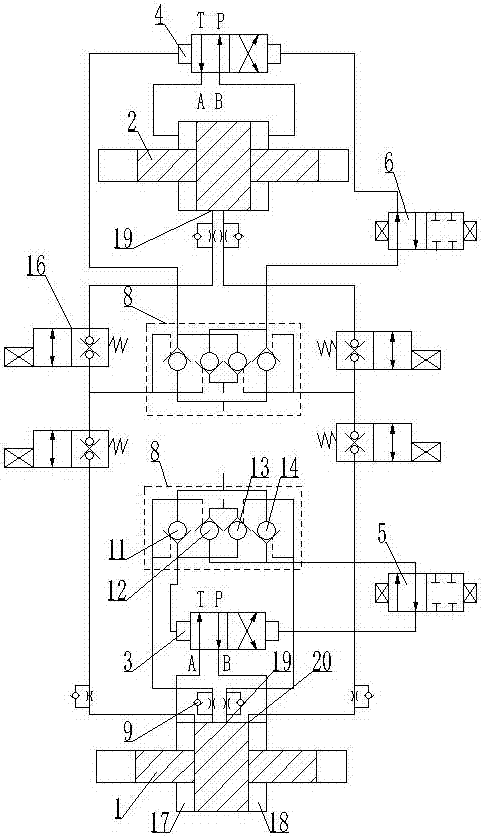

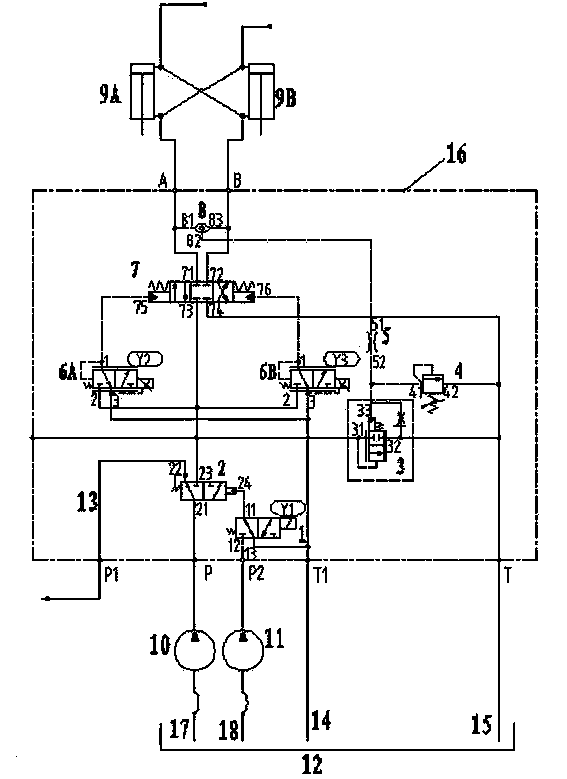

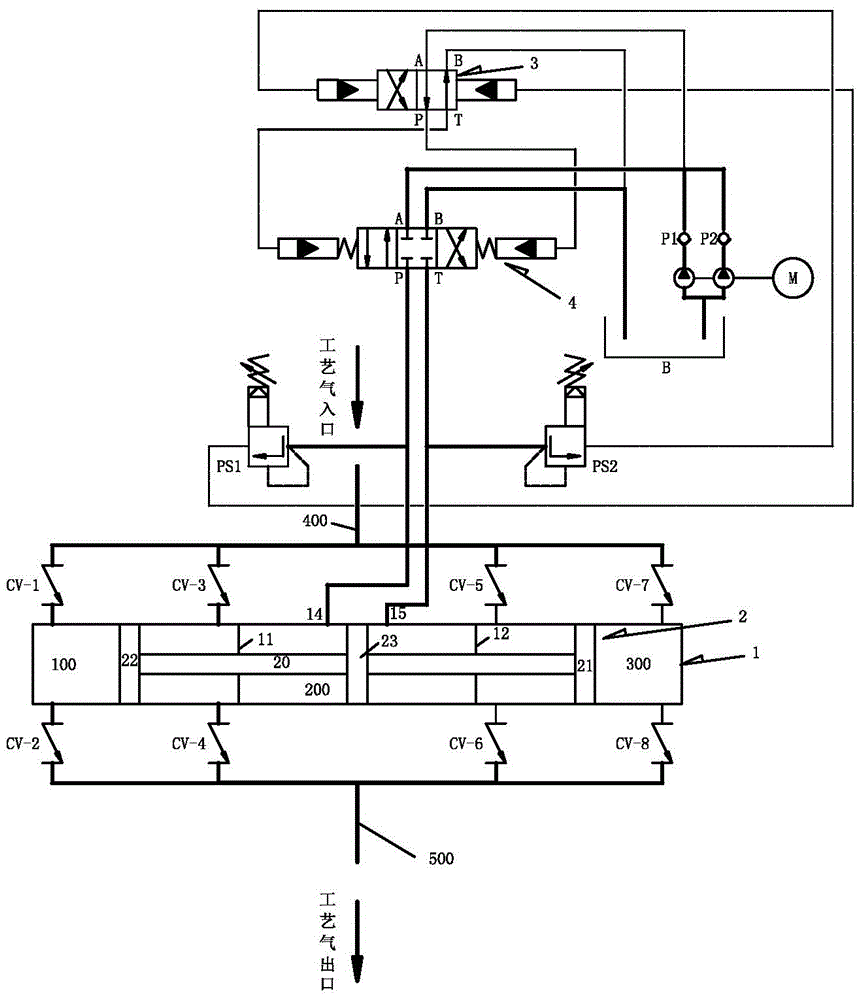

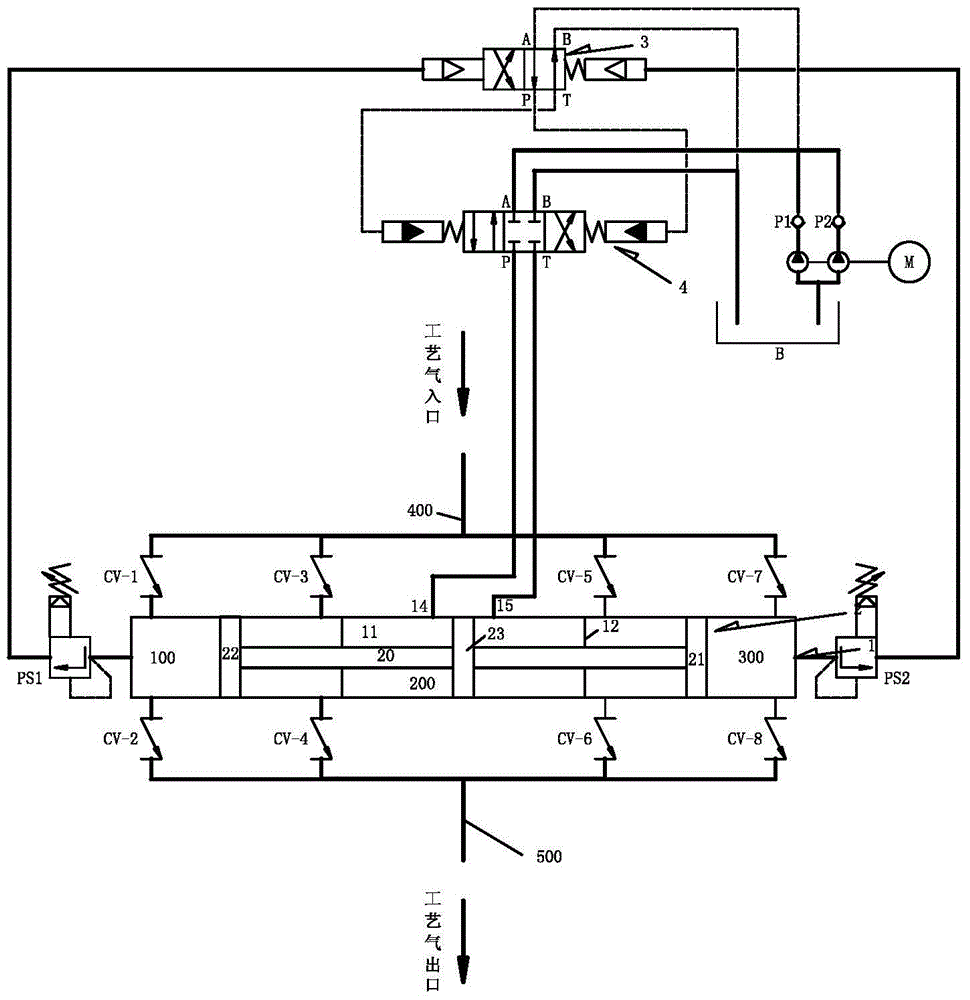

Pumping reversal hydraulic control system, control method and concrete conveying pump

ActiveCN102734236ARealize rational utilizationEnable recyclingMechanical apparatusMaster cylinderControl theory

The invention provides a pumping reversal hydraulic control system comprising a pressure oil source, a master oil cylinder, a master cylinder reversal valve, a swinging oil cylinder, a swinging cylinder reversal valve, a pressure sensor, a first directional valve, an accumulator and a controller, wherein when the master oil cylinder reaches a reversing position or a preset position in front of the reversing position, at least part of pressure oil in the pressure oil source enters the accumulator through the first directional valve; when the pressure in the accumulator reaches a preset valve and the master oil cylinder is in the reversing position, the controller controls the swinging cylinder reversal valve to change the direction, and pressure oil in the accumulator enters the swinging oil cylinder through the swinging cylinder reversal valve; and when or after the direction of the swinging cylinder reversal valve is changed, the controller controls the master cylinder reversal valveto change the direction. Accordingly, the invention also provides a pumping reversal hydraulic control method and a concrete conveying pump. According to the invention, when the direction of the master oil cylinder is changed, the impact of a piston in the master oil cylinder on a cylinder barrel can be reduced, so that stable direction change of the pumping system is achieved, and the working efficiency of the system is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

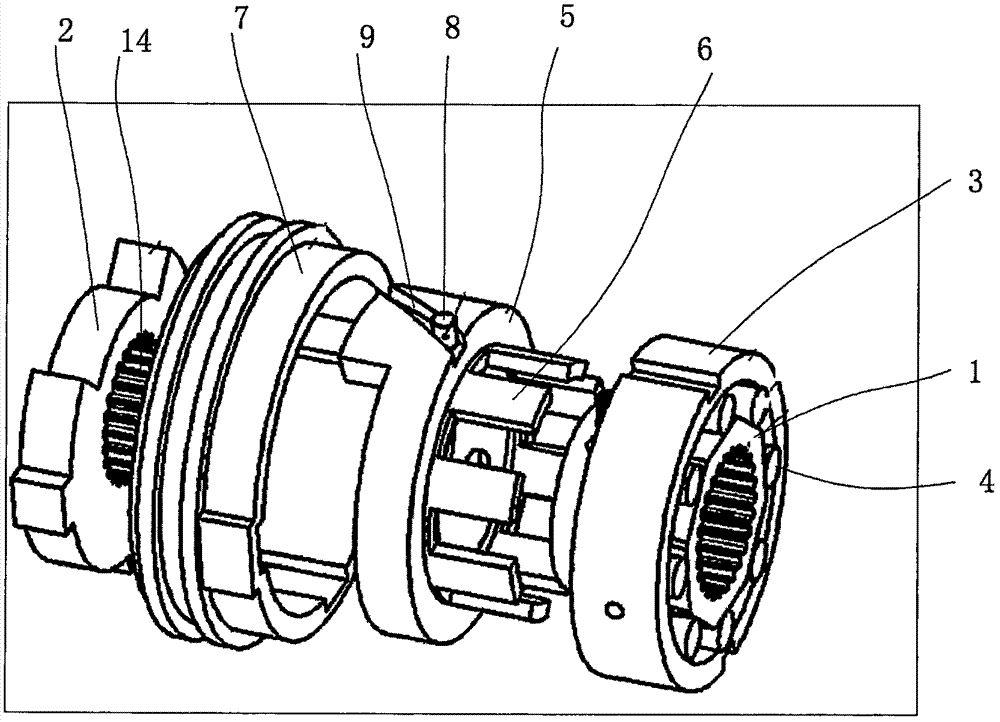

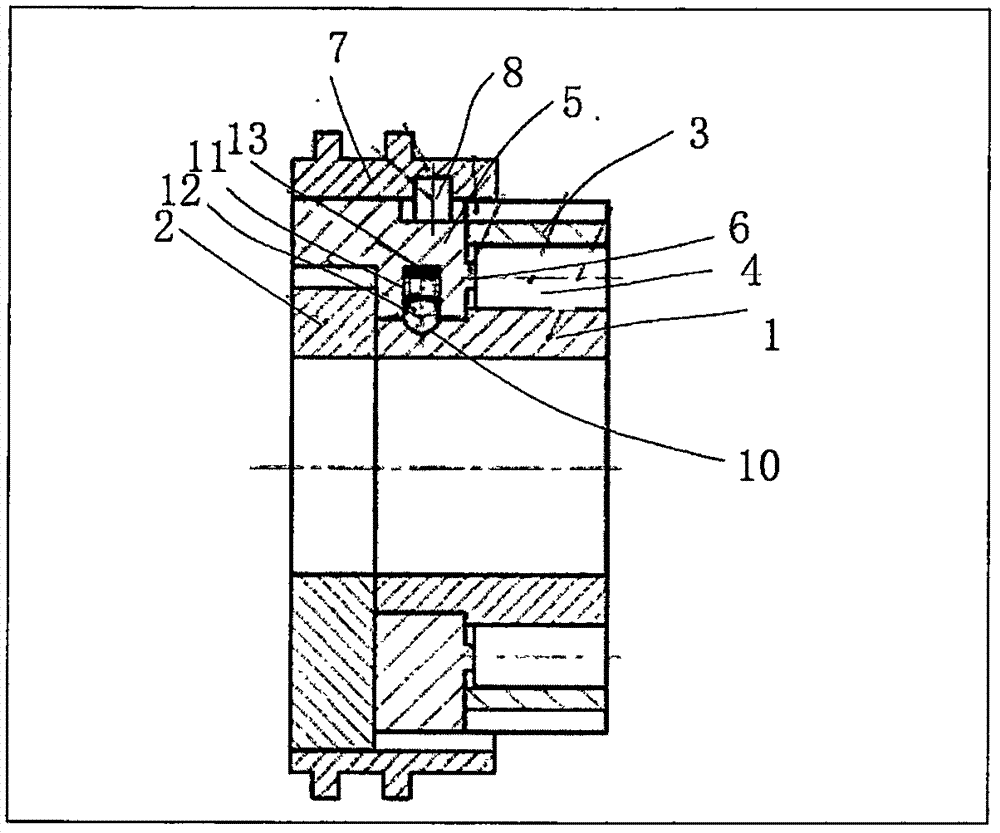

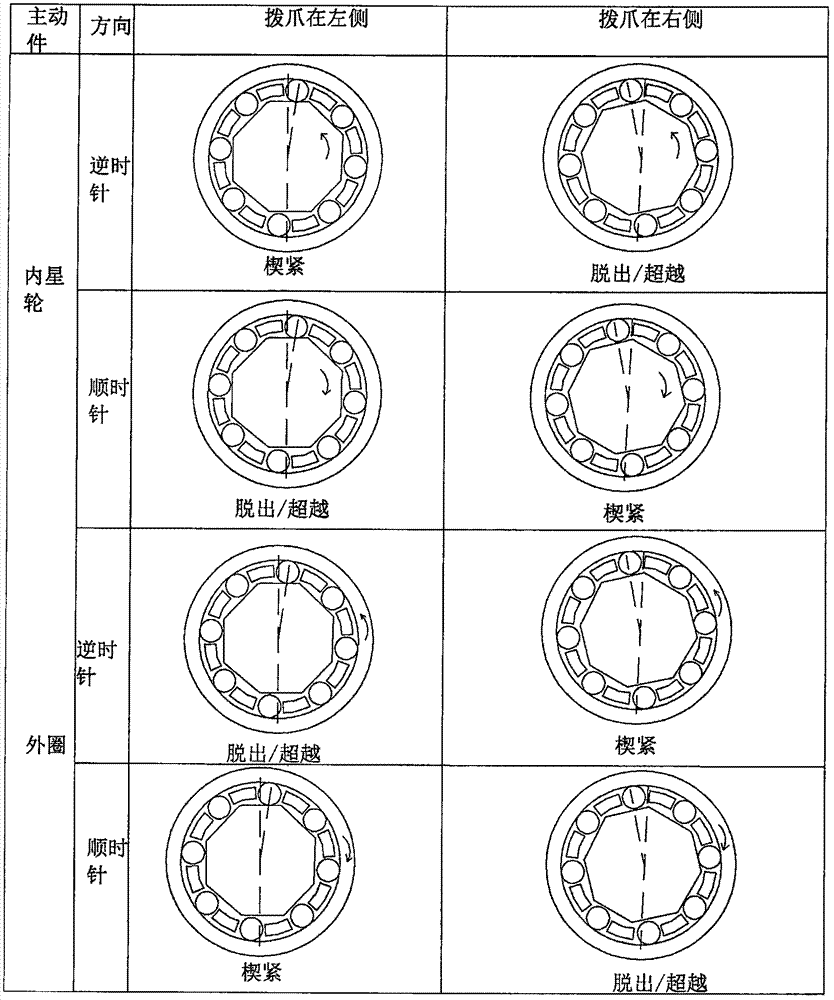

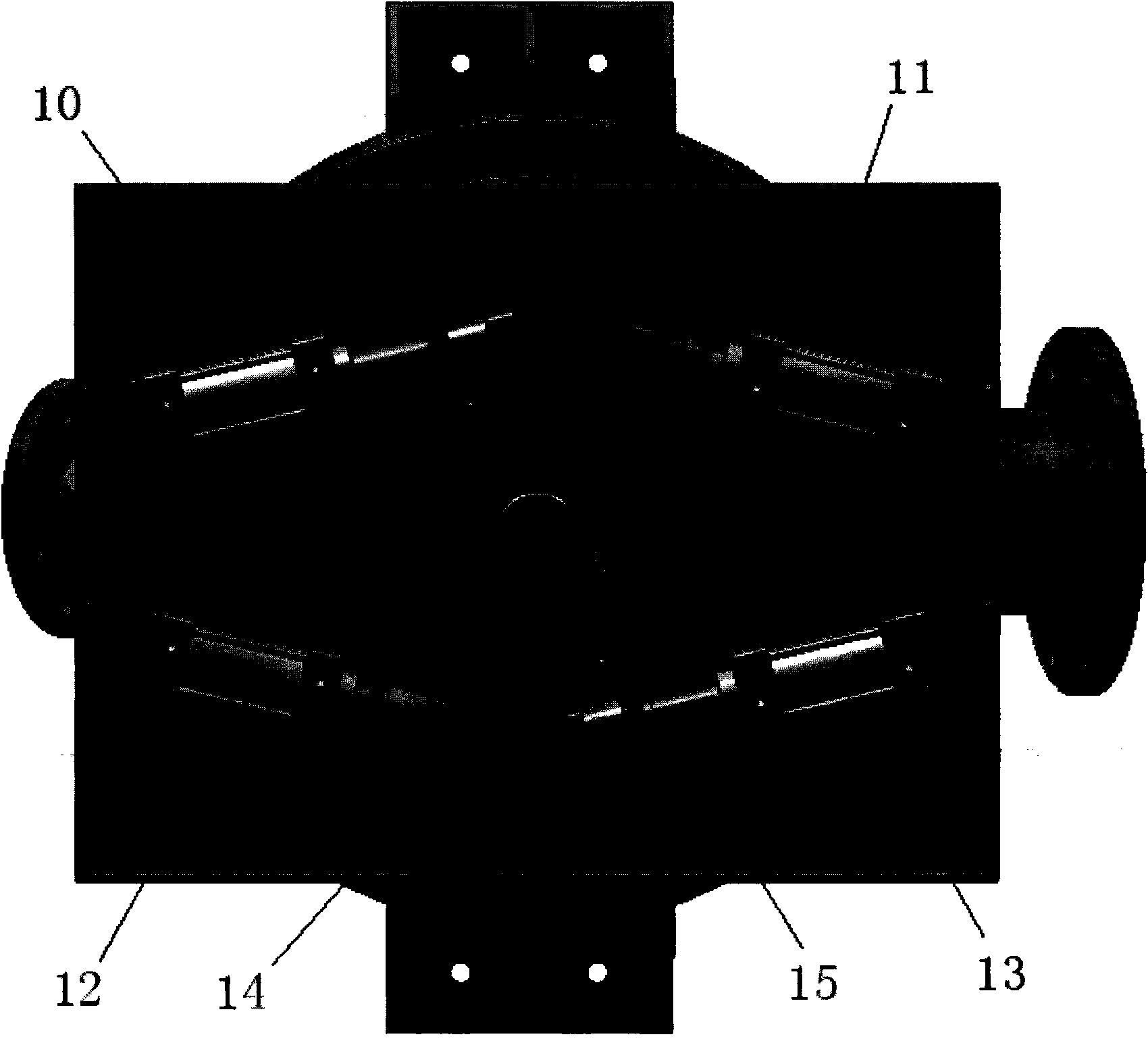

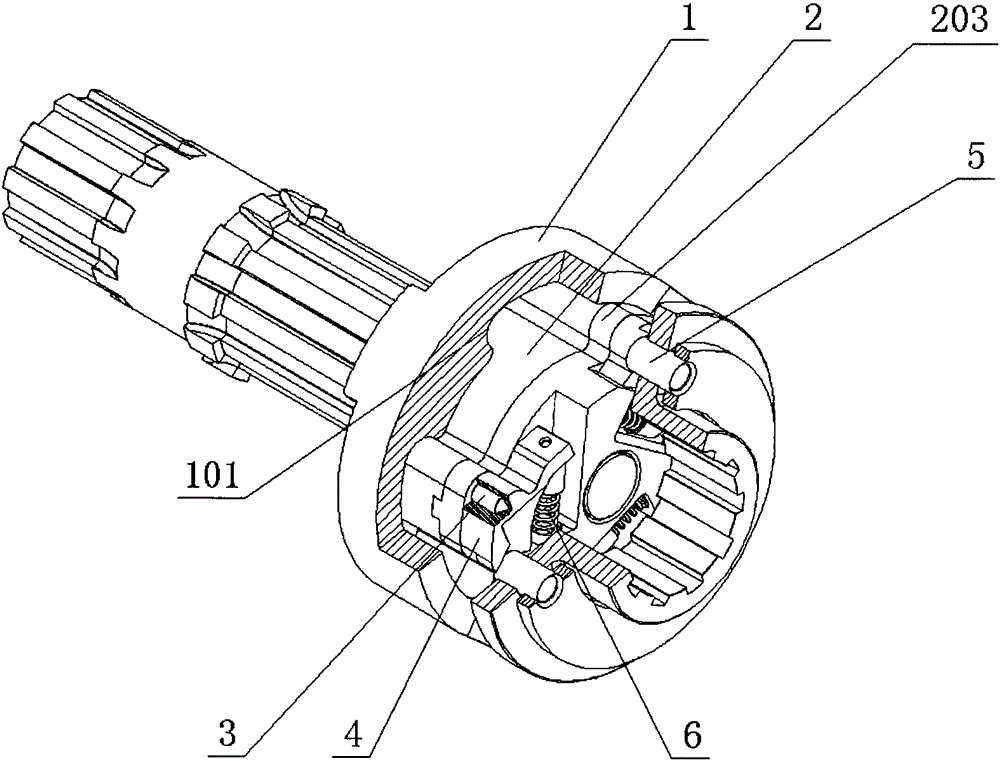

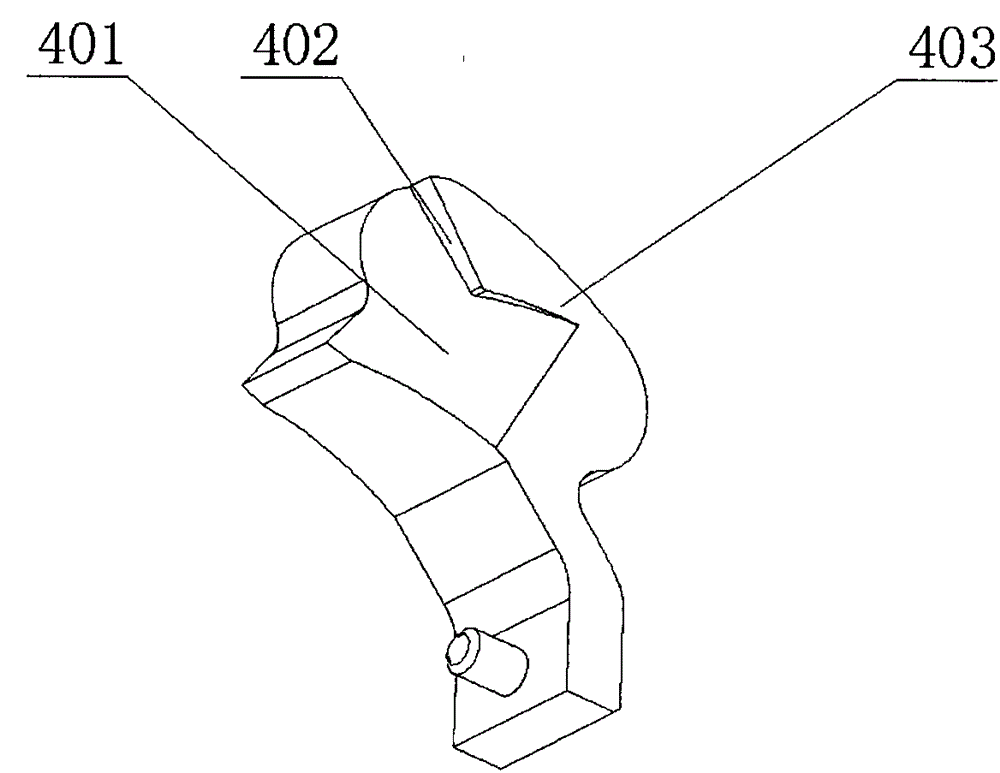

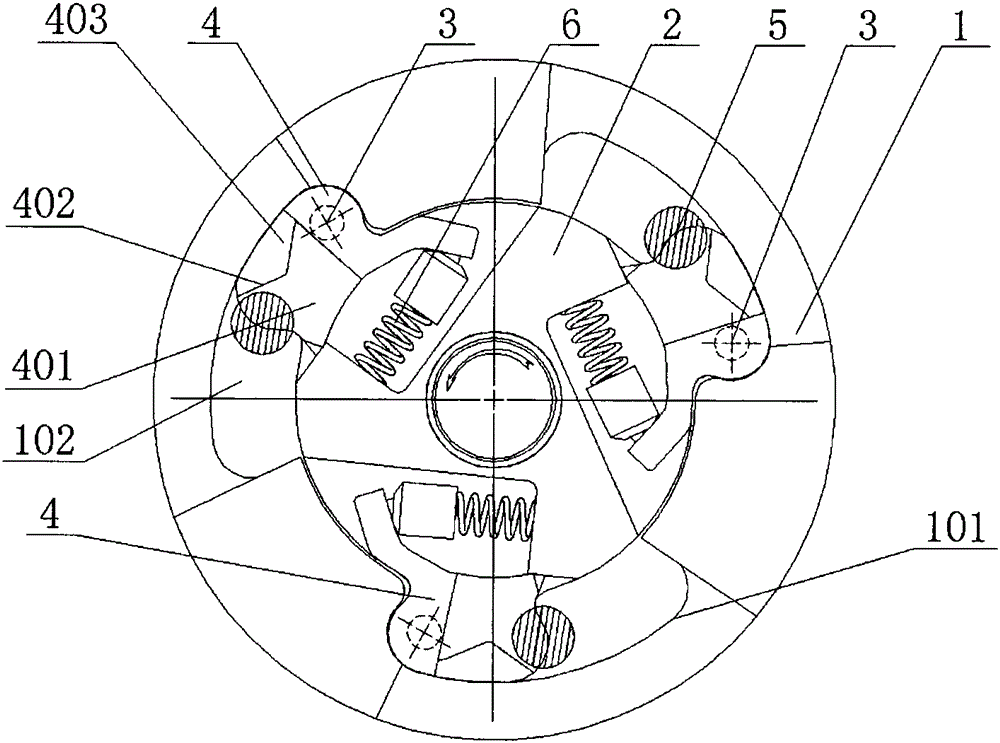

Two-way overrunning clutch with pusher dog

PendingCN107299943AReasonable structureReduce axial sizeFreewheel clutchesStructural engineeringClutch

The invention discloses a two-way overrunning clutch with a pusher dog. The two-way overrunning clutch with the pusher dog comprises an inner star wheel and a reversing guide block, wherein an outer ring is arranged at the outer side of the inner star wheel, and a roller is arranged evenly between the outer ring and the outer side surface of the inner star wheel; the pusher dog is arranged between the reversing guide block and the inner star wheel, and a pawl is fixed on the side surface of the pusher dog; the pawl is arranged on the side surface close to the inner star wheel, and a reversing sleeve is arranged on the outer side of the reversing guide block; a reversing plug pin is fixed on the reversing sleeve, and an oblique groove is formed in the pusher dog; the pusher dog is arranged between the reversing sleeve and the inner star wheel, and the reversing plug pin is arranged in the oblique groove; the surface of the inner star wheel is a regular polygon, and when the pusher dog moves to the inner star wheel, the pawl is arranged between the outer side surface of the inner star wheel and the outer ring. Since the arranged structure of the two-way overrunning clutch with the pusher dog is reasonable, requirements for different transmission torque can be met; the two-way overrunning clutch with the pusher dog has the advantages of smooth reversing, a compact structure, high integration and good stability, adaptability and practicability.

Owner:中汽院智能网联科技有限公司

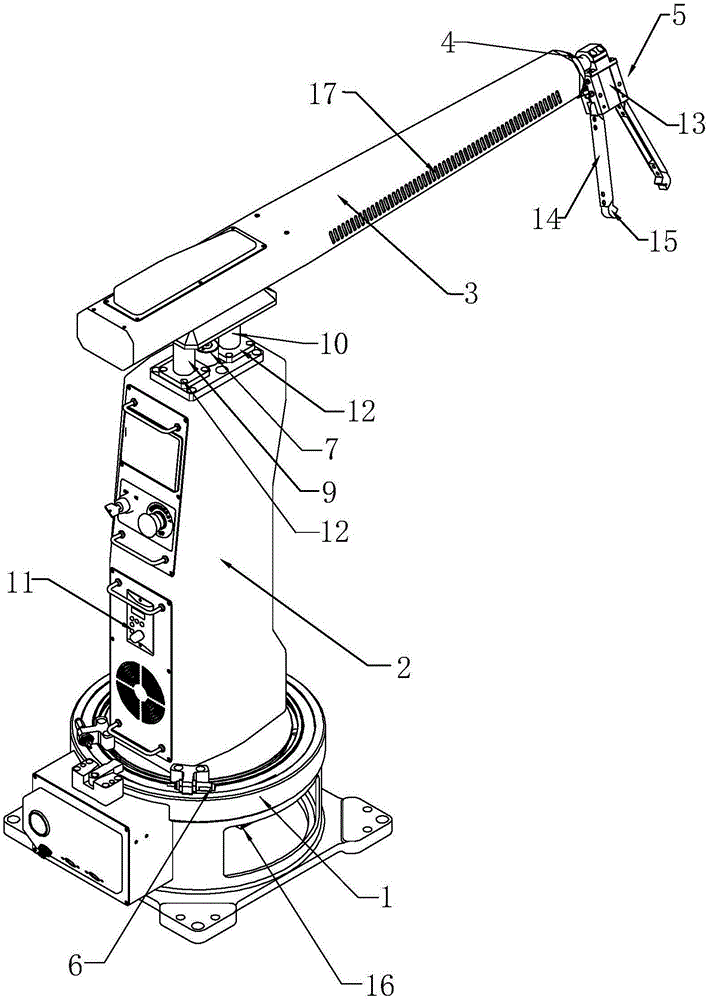

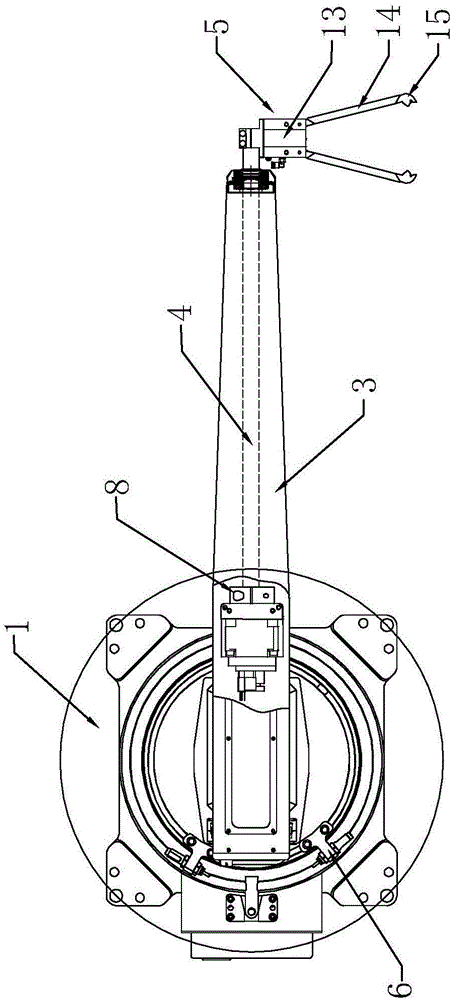

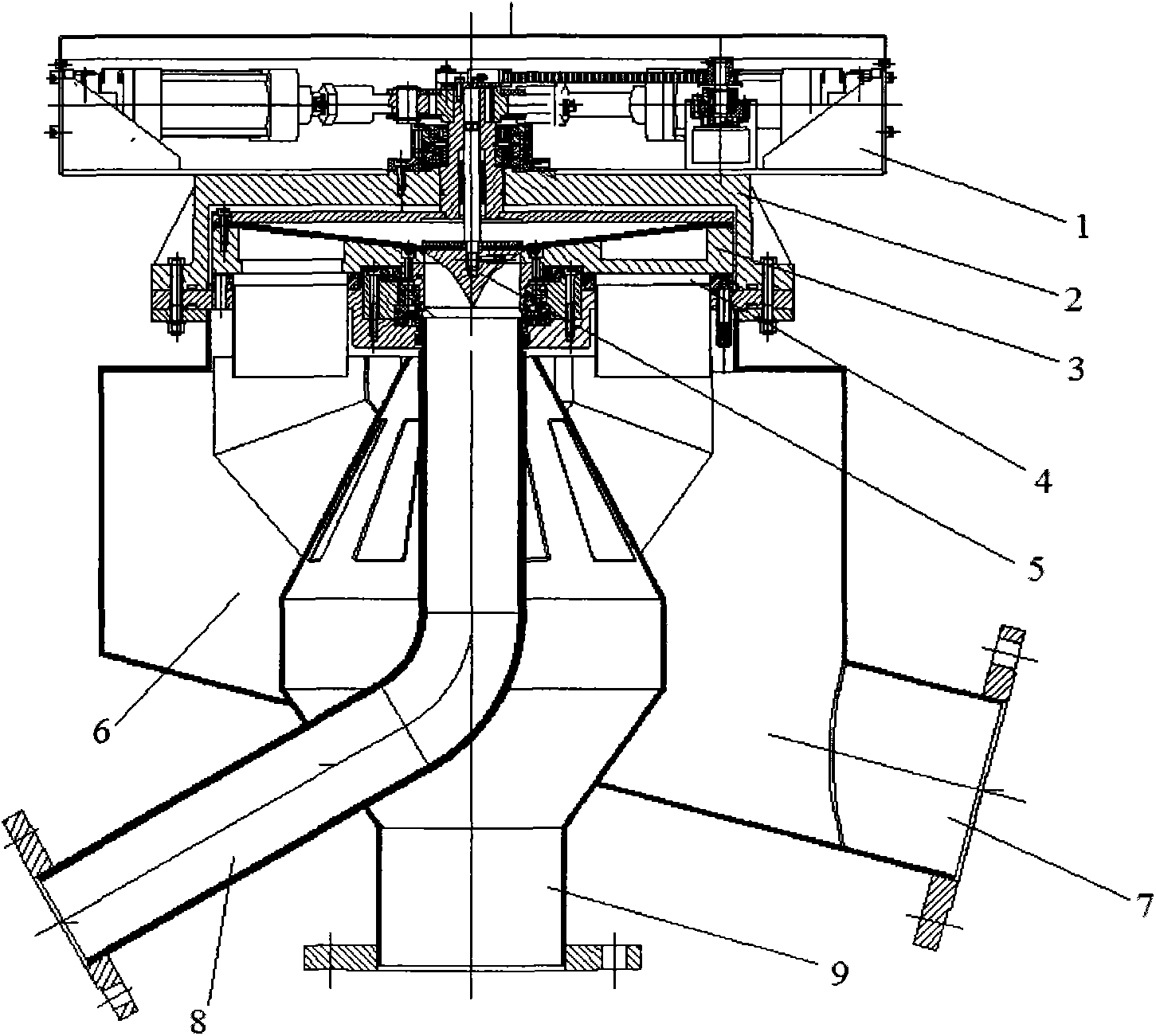

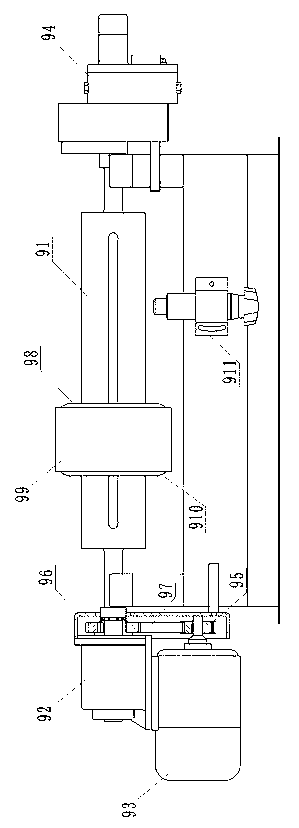

Forging loading robot

ActiveCN105033148APlay a buffer roleTurn fasterForging/hammering/pressing machinesHandling devicesEngineeringMechanical engineering

The invention relates to a forging loading robot. The forging loading robot comprises a rotating base, a rotating arm, a swing arm, a swing shaft and a clamping mechanism, wherein the rotating arm is mounted on the rotating base; two hydraulic dampers are arranged on the rotating base for limiting a rotating angle of the rotating arm within +-145 degrees; a lifting cylinder is arranged at the top end of the rotating arm; the back end of the rotating arm is fixed on the lifting cylinder; a blade type swing cylinder is arranged in the swing arm; the swing shaft is inserted in the swing arm; one end of the swing shaft is connected with a blade type swing cylinder, and is controlled by the blade type swing cylinder; and the other end of the swing shaft is connected with the clamping mechanism. The hydraulic dampers are arranged on the rotating base for limiting the rotating range of the rotating arm in a range of +-145 degrees, so that the rotating arm can rotate fast, and can achieve a buffer effect to effectively prevent the machine damage. Meanwhile, materials are carried by adopting a mechanical clamping mode, so that the carrying requirements of the materials with various shapes can be adapted to, and the safety is excellent.

Owner:江苏华普泰克石油装备有限公司

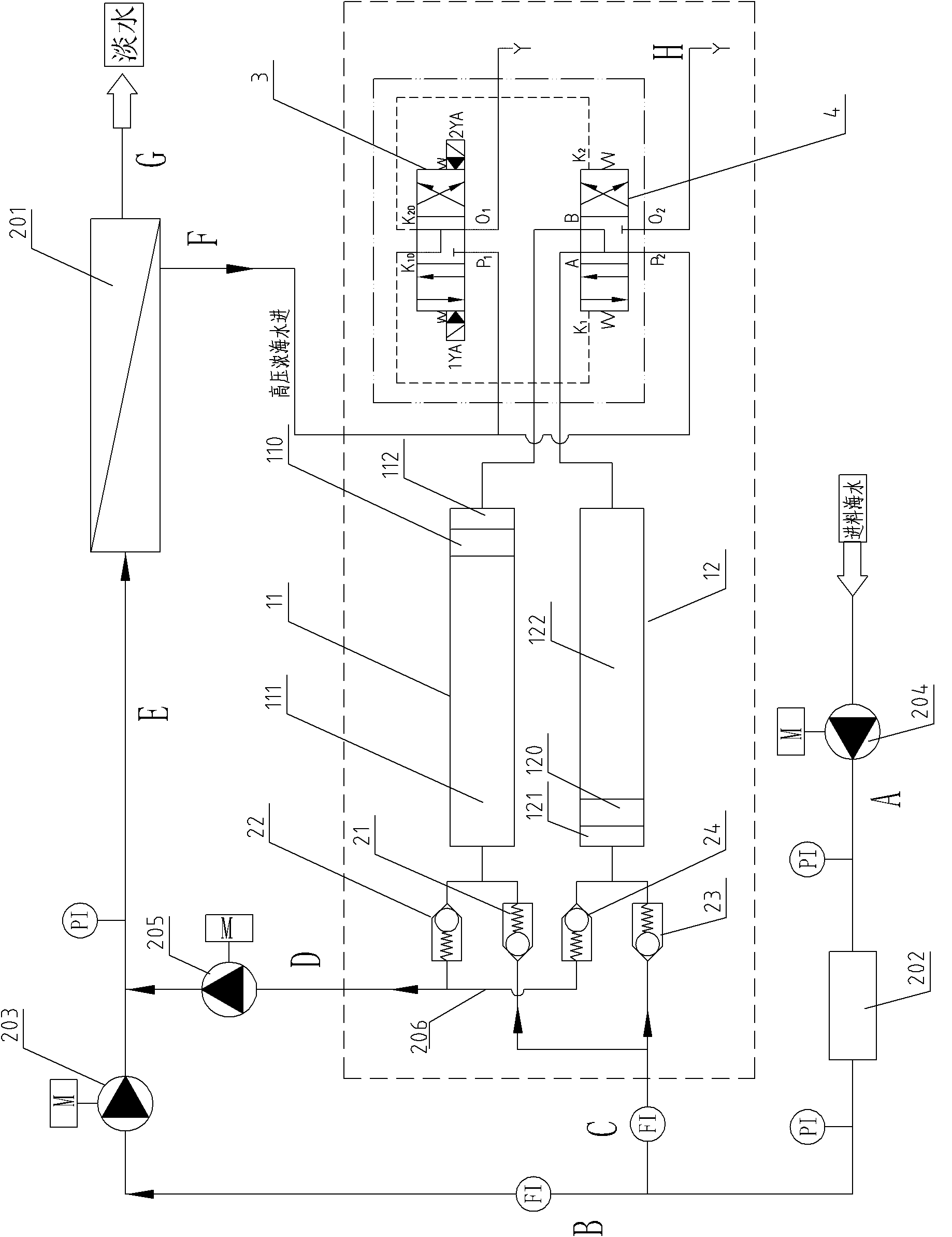

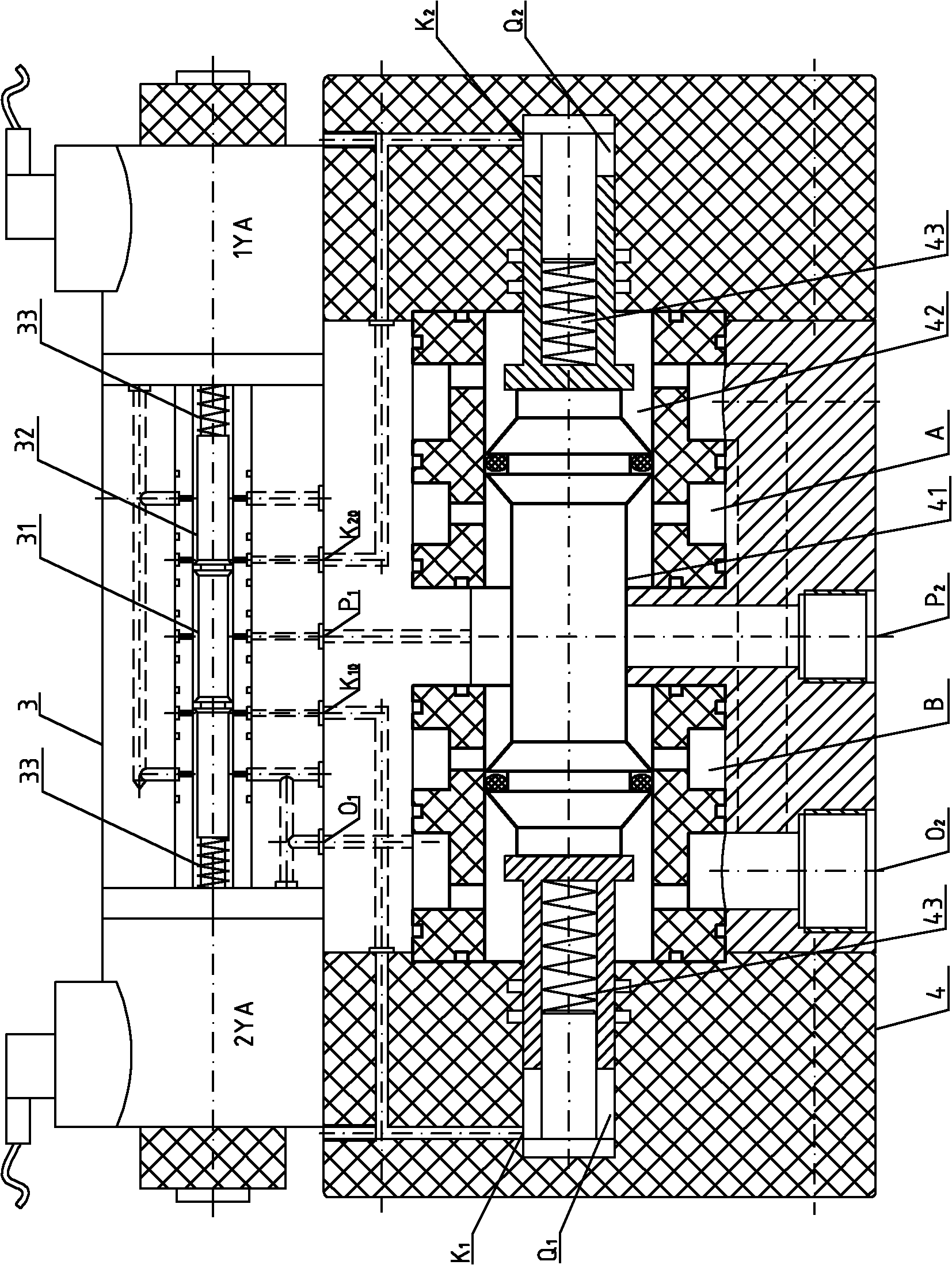

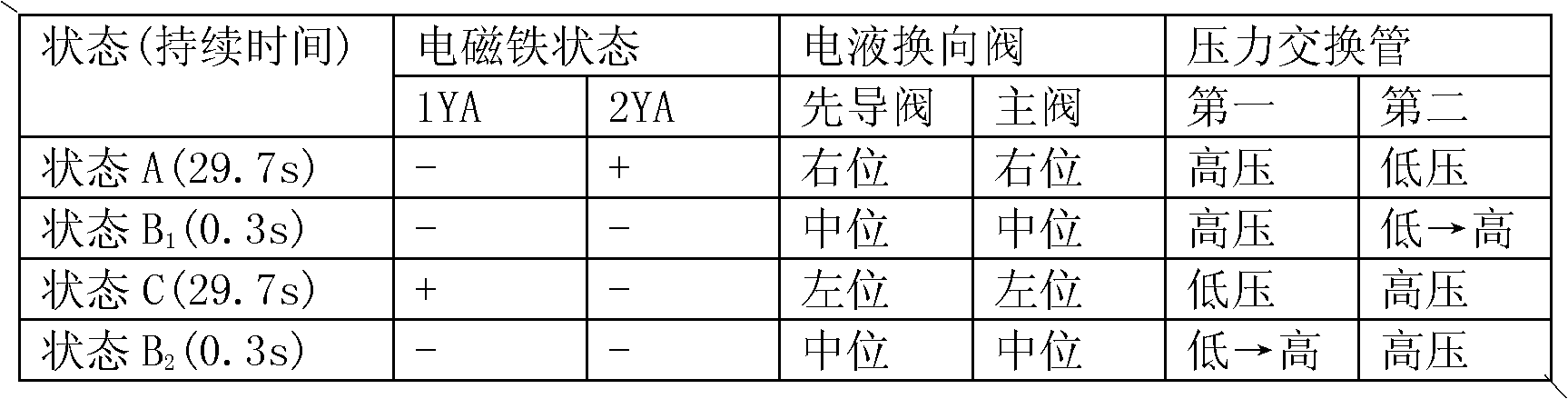

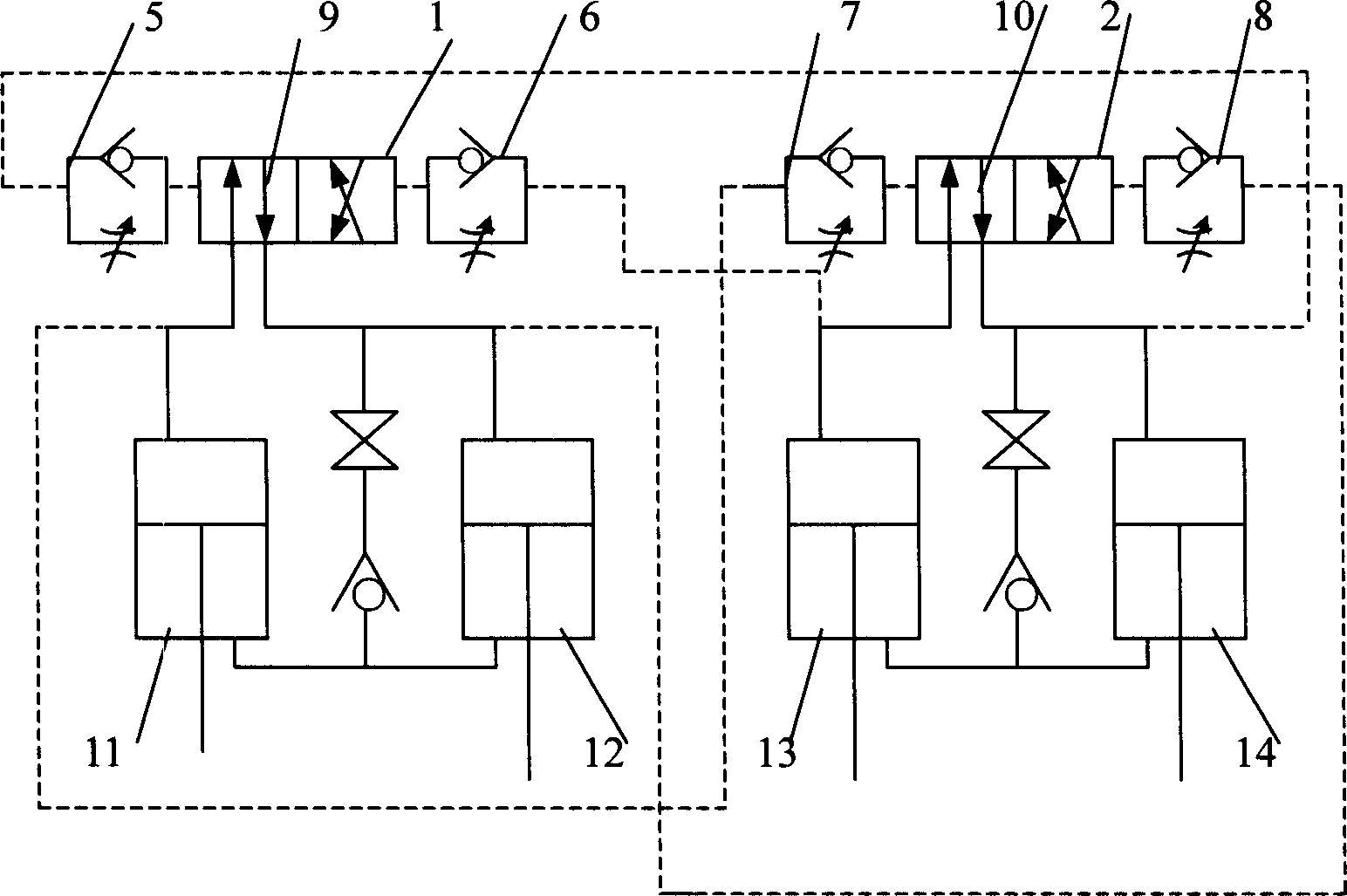

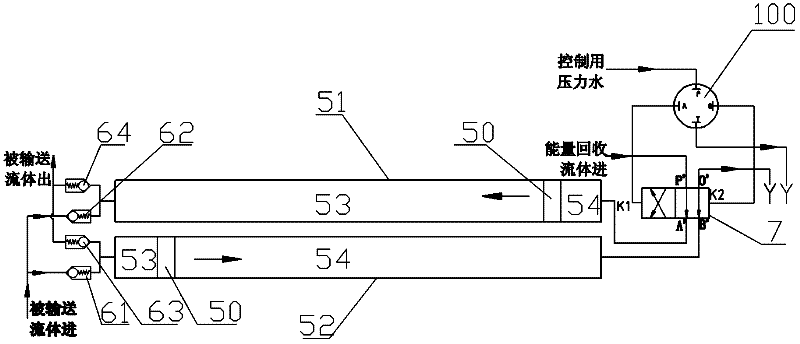

Electric-hydraulic reversing energy recovery device

ActiveCN101985951ALarge thrustEasy to operateFluid-pressure actuator componentsControl systemEngineering

The invention provides an electric-hydraulic reversing energy recovery device, which is simple in control and less in pressure oscillation. The device comprises an electric-hydraulic reversing valve, two pressure exchanging pipes and four unidirectional check valves. A free piston is arranged in each pressure exchanging pipe to divide the pressure exchanging pipe into two working cavities which are a transmitted liquid working cavity and a waste liquid working cavity. The device has the following beneficial effects that because the electric-hydraulic reversing valve is piloted by using a magnetic pilot valve, and the main valve is pushed by the high pressure waste liquid which is manipulated and controlled by the magnetic pilot valve in the system pipeline, the pushing power can be very large, the operation is simple, and the reversing is stable and fast. The electric-hydraulic reversing energy recovery device is suitable for a reverse osmosis desalination system with high pressure and large flow rate.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Steering electrohydraulic control system for remote control loading machine

InactiveCN103671364ALow calorific valueCommutation smoothServomotor componentsFluid-pressure actuator componentsRemote controlControl system

The invention relates to a steering electrohydraulic control system for a remote control loading machine. The steering electrohydraulic control system for the remote control loading machine comprises an oil tank, a steering metering pump, a pilot pump, a solenoid directional valve, a three-way pressure compensator, an overflow valve, a throttling valve, a shuttle valve, two hydraulic directional valves, two three-way solenoid proportional reducing valves and two steering oil cylinders. An inlet of the steering metering pump is connected with an oil outlet of the oil tank, the outlet of the steering metering pump is connected with a first oil inlet of the first hydraulic directional valve, the first hydraulic directional valve is respectively connected with the three-way pressure compensator and the two three-way solenoid proportional reducing valves, and the two three-way solenoid proportional reducing valves are connected with the second hydraulic directional valve, the shuttle valve and the two steering oil cylinders in sequence. The steering electrohydraulic control system for the remote control loading machine is stable in steering and free of impact and clamping stagnation phenomena, reduces the heat emitting amount and reduces waste of power of an engine, and thus the purposes of reducing oil consumption and saving energy are achieved finally.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

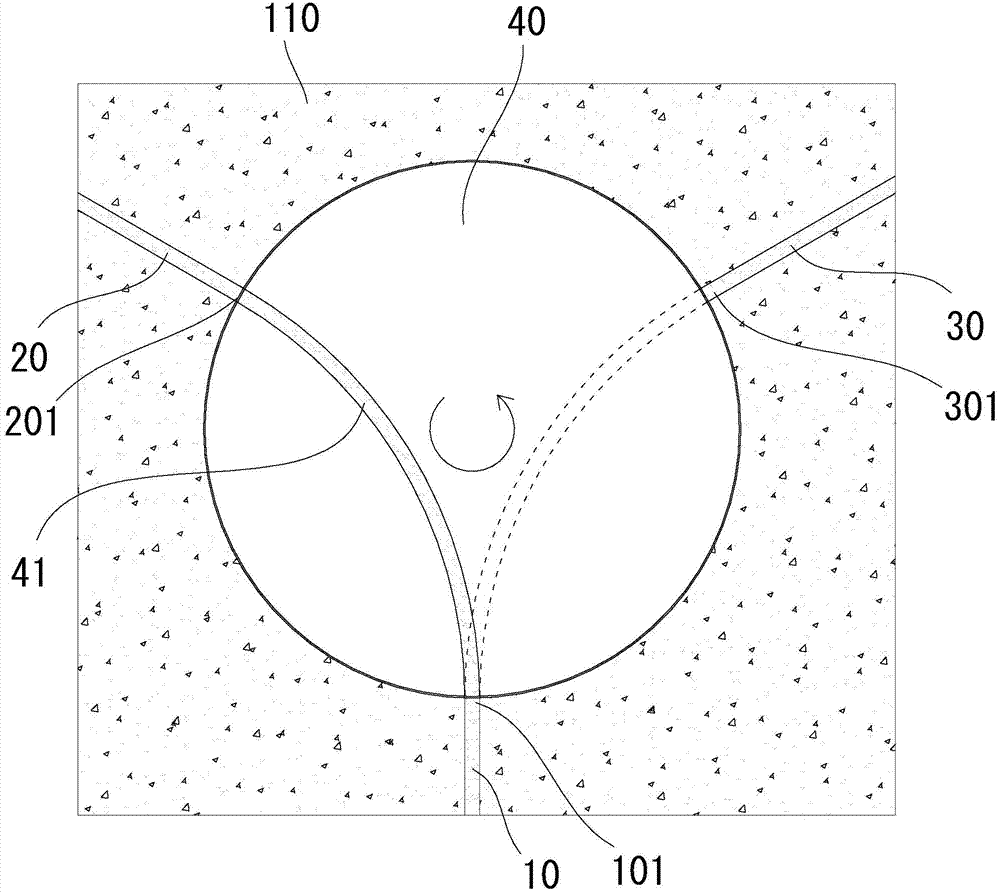

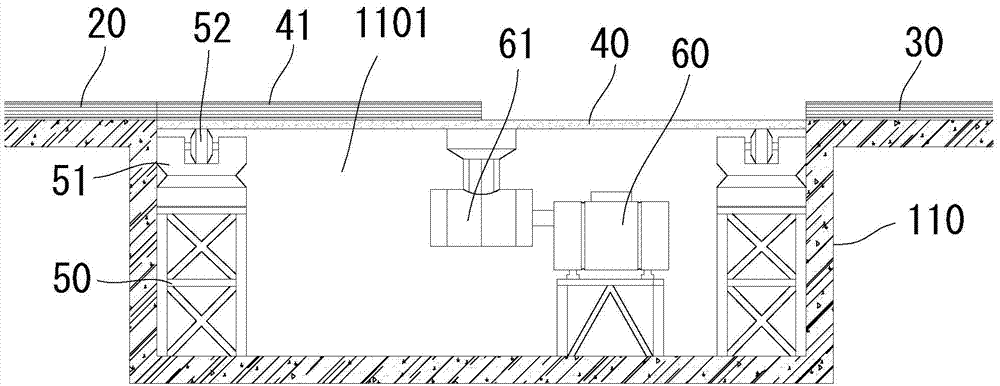

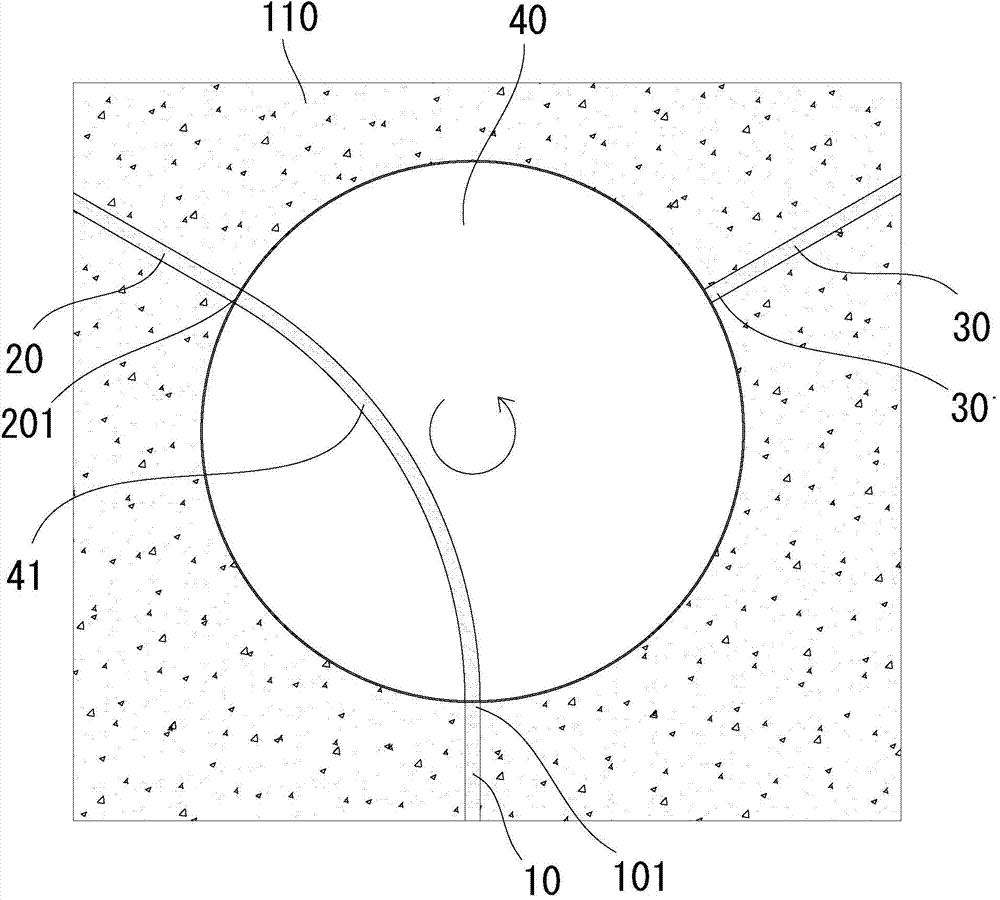

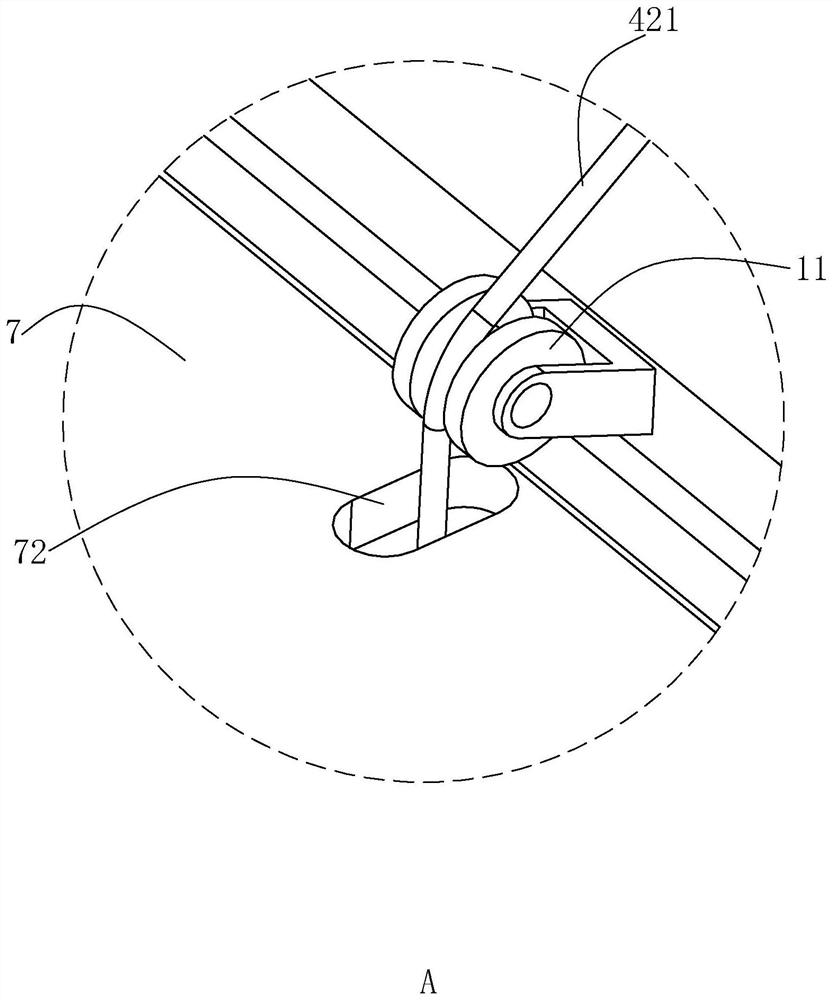

Rotary rail reversing device and rail with reversing device

InactiveCN104328716ARealize free reversingSimple structureRail switchesEngineeringMechanical engineering

Owner:杨兵

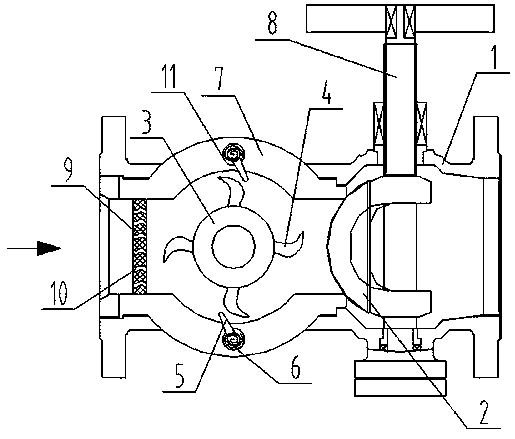

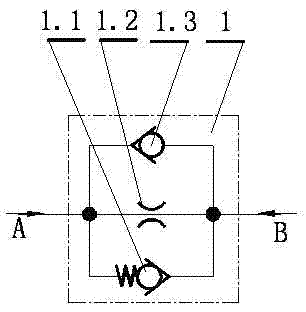

Closed type open commutator

ActiveCN103438964ACommutation smoothGood symmetryTesting/calibration apparatusSpray nozzleEngineering

The invention discloses a closed type open commutator which comprises a control box provided with a component for supplying power for commutation, a rotating disk which is positioned below the control box and is provided with a plurality of nozzles, a floating disk which is matched with the rotating disk and is provided with diversion holes corresponding to the nozzles, and a water feeding pipe positioned at the center of the open commutator, wherein a diversion cone is arranged above the water feeding pipe. The commutator disclosed by the invention has a steady commutation process and is high in symmetry and repetitiveness; the flowing state of fluid is stable and symmetric as much as possible at outlets of the nozzles; water sputtering and internal leakage of the commutator are avoided, and interference caused by the commutation process on the flow of a flow device system is also avoided.

Owner:NAT INST OF METROLOGY CHINA +1

Valve buffer device

PendingCN108869868APlay the role of rotation bufferReduce rotation speedPlug valvesValve members for absorbing fluid energyImpellerBlock effect

The invention relates to a valve buffer device. The valve buffer device comprises a valve body, wherein a valve element, a valve seat and a valve rod are arranged in the valve body, the valve rod is connected with the valve element, the valve element corresponds to an inner cavity of the valve seat, an elastic die and a roller are arranged in the valve seat in sequence from left to right, a plurality of through holes are formed in the elastic die, a plurality of impellers are uniformly distributed on the roller, a rolling shaft is arranged on the inner wall of the valve seat, the rolling shaftis connected to the valve seat by virtue of a shaft, a torsion spring is directly connected to the rolling shaft and the valve seat, and a rocking rod is arranged on the rolling shaft. Through the elasticity of the elastic die and the impact of the impellers arranged on the roller on liquid, when liquid enters the valve seat, the liquid impacts on the impellers and pushes the impellers to rotate,a blocking effect is achieved on the rotation of the impellers by virtue of the rocking rod, so that the rotating speed of the impellers is reduced, and the third-stage buffer is performed on the impact of the liquid, so that direct impact of high-pressure liquid in a liquid inlet of the valve body on the valve element is prevented, the reversing is smooth, and the performance is reliable.

Owner:DEYANG DIXINJIA VALVE MFR

Cam type plastic flat filament coiling machine

The present invention relates to a cam type plastic flat yarn rolling-up machine, in particular, it is a flat yarn rolling-up machine for plastic wire-drawing operation. It is characterized by that on the structure of original flat yarn rolling-up machine the cam can be made into a boss whose edge has curve, the rolling bearings respectively fixedly mounted on left and right moving frames can be rolling fit with said curve boss, and the left and right two boss edges are respectively equipped with one rolling bearing. The described bearing is linear rolling bearing. Said invention can make the reciprocating movement and reversing motion of moving frame more stable and smooth, and can greatly raise flat yarn rolling-up quality.

Owner:雁峰集团有限公司

Hydraulic damping device

The invention relates to a hydraulic damping device for controlling and adjusting a dynamic process of a reversing motion of a valve core of a hydraulic controlled slide valve type hydraulic control valve. The device is of an integrated structure, and consists of a first one-way valve, a damping hole and a second one-way valve. An external screw thread is processed at the outer end of the device and the external screw thread can be inserted, screwed and installed in the hydraulic control valve. The first one-way valve, the damping hole and the second one-way valve are connected in parallel, and the first and second one-way valves are arranged opposite to each other. The hydraulic damping device is compact in structure and convenient to arrange, and the damping effects in positive and reverse motions of the valve core of the hydraulic controlled slide valve type hydraulic control valve can be respectively controlled and adjusted, and the valve core of the slide valve reveres stably and quickly.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Flow and pressure control valve

InactiveCN105114665AEasy to useSimple structureServomotor componentsMultiple way valvesBrake torqueControl flow

The invention relates to a flow and pressure control valve. The flow and pressure control valve comprises a valve body in which a flow control valve and a pressure control valve are arranged; the flow control valve comprises a first valve element, a first spring cavity and a first-stage spring; the pressure control valve comprises a second valve element, a second-stage spring cavity and a second-stage spring. According to the flow and pressure control valve, by arranging the two control valves, stepping control over oil pressure is achieved, the first-stage flow control valve is mainly used for controlling flow through flow diversion, the second-stage pressure control valve is mainly used for controlling pressure through oil return unloading, the problem that after pressure is out of control, the pressure continuously rises, and consequently braking torque and oil liquid temperature fast raise is efficiently solved, and use is reliable.

Owner:SUZHOU SABO IND DESIGN

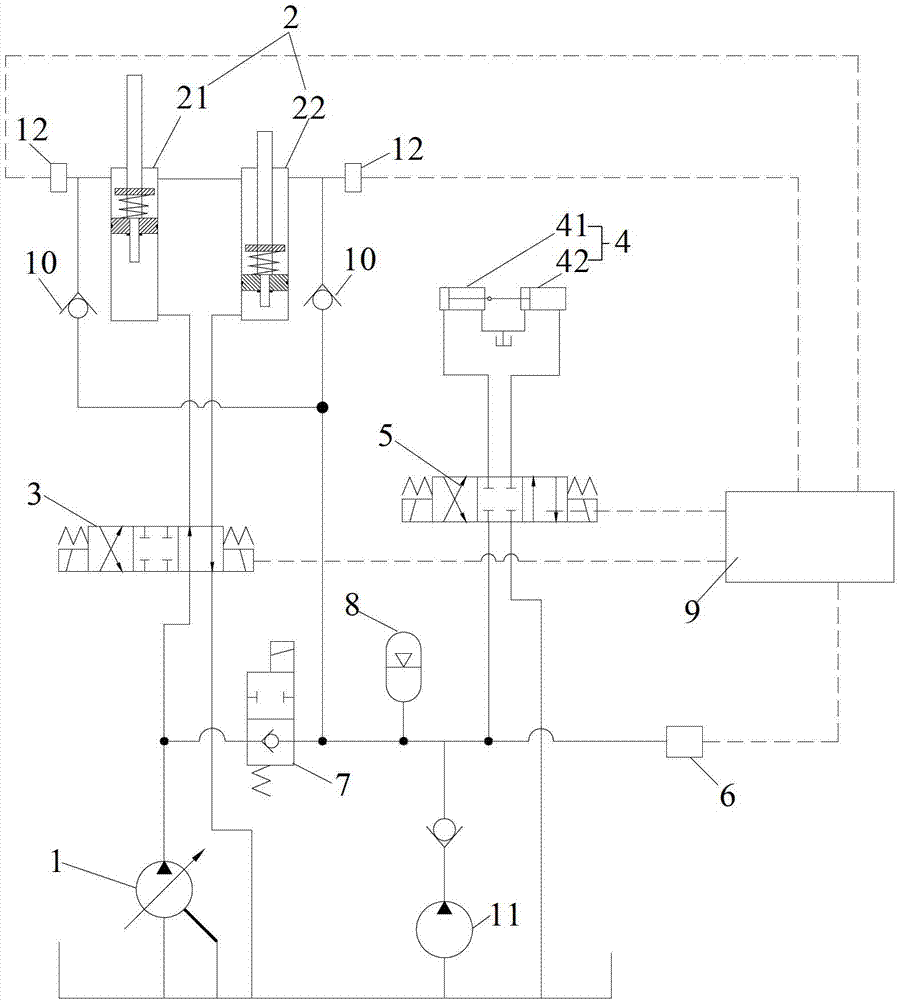

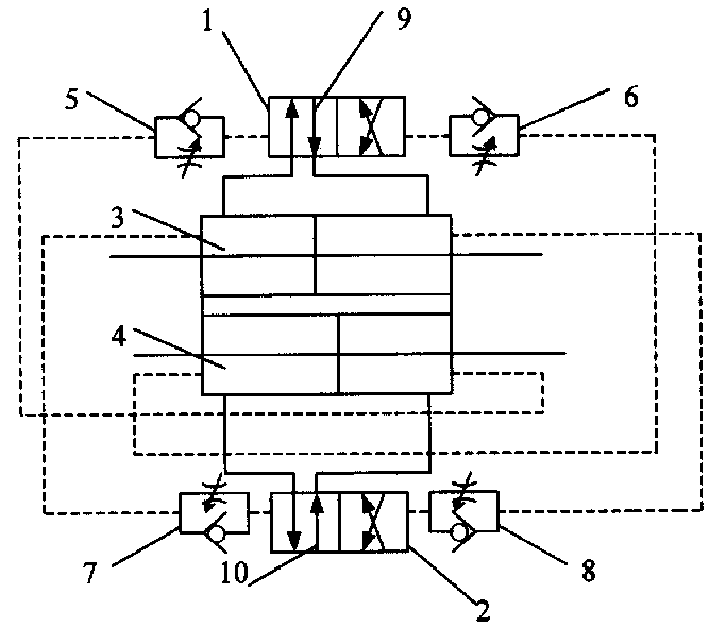

Hydraulic control system and method as well as pump

ActiveCN104329306ACommutation smoothSlow downServomotor componentsServomotorsSystem impactReciprocating motion

The invention relates to a hydraulic control system. The hydraulic control system comprises an oscillating oil cylinder, a first pressure oil source, a pumping main oil cylinder, an oscillating oil cylinder reversing valve set, a pumping system combination and a reversing buffering valve set, wherein the oscillating oil cylinder reversing valve set is used for reversing a piston of the oscillating oil cylinder; the pumping system combination is used for realizing reciprocating motion of the pumping main oil cylinder and providing a reversing signal for the oscillating oil cylinder reversing valve set; the reversing buffering valve set is used for reducing reversing impact of the pumping main oil cylinder. The invention further relates to a control method of the hydraulic control system and a pump containing the hydraulic control system. According to the hydraulic control system, when a pumping system is reversed, the displacement of the hydraulic pump does not need to be adjusted and part flow of the system is overflowed at the moment of reversing, so that the flow of the system is reduced, the movement speed of the pumping main oil cylinder is reduced and the system impact is reduced, and furthermore, the stable reversing of the pumping system is realized; the working efficiency of the system is improved and the fault rate is reduced.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

Hydraulic oscillating machine

InactiveCN1417487AWork reliablyCommutation smoothServomotor componentsPumpsHydraulic cylinderHydraulic circuit

The hydraulic oscillating machine includes a hydraulic loop comprising change-over valve, throttle valve and hydraulic cylinder. The hydraulic change-over valve controls the motion of the hydraulic cylinder; the single-way throttle valve is connected to the control port of the hydraulic chagne-over valve to control the change-over time of the change-over valve in outlet throttle mode; and the twocavities of the hydraulic cylinder are connected via the single-way throttle valve to the two control ports of the hydraulic change-over separately. The pressure oil inlet of the hydraulic change-over valve is connected to the oil source parallel. On starting hydraulic pump to provide pressure oil, the hydraulic cylinder will move alternately, the motion speed of the hydraulic cylinder is regulated by the variable hydraulic pump of oil source and the stroke of the hydraulic cylinder is regulated by the single-way throttle valve.

Owner:BEIHANG UNIV

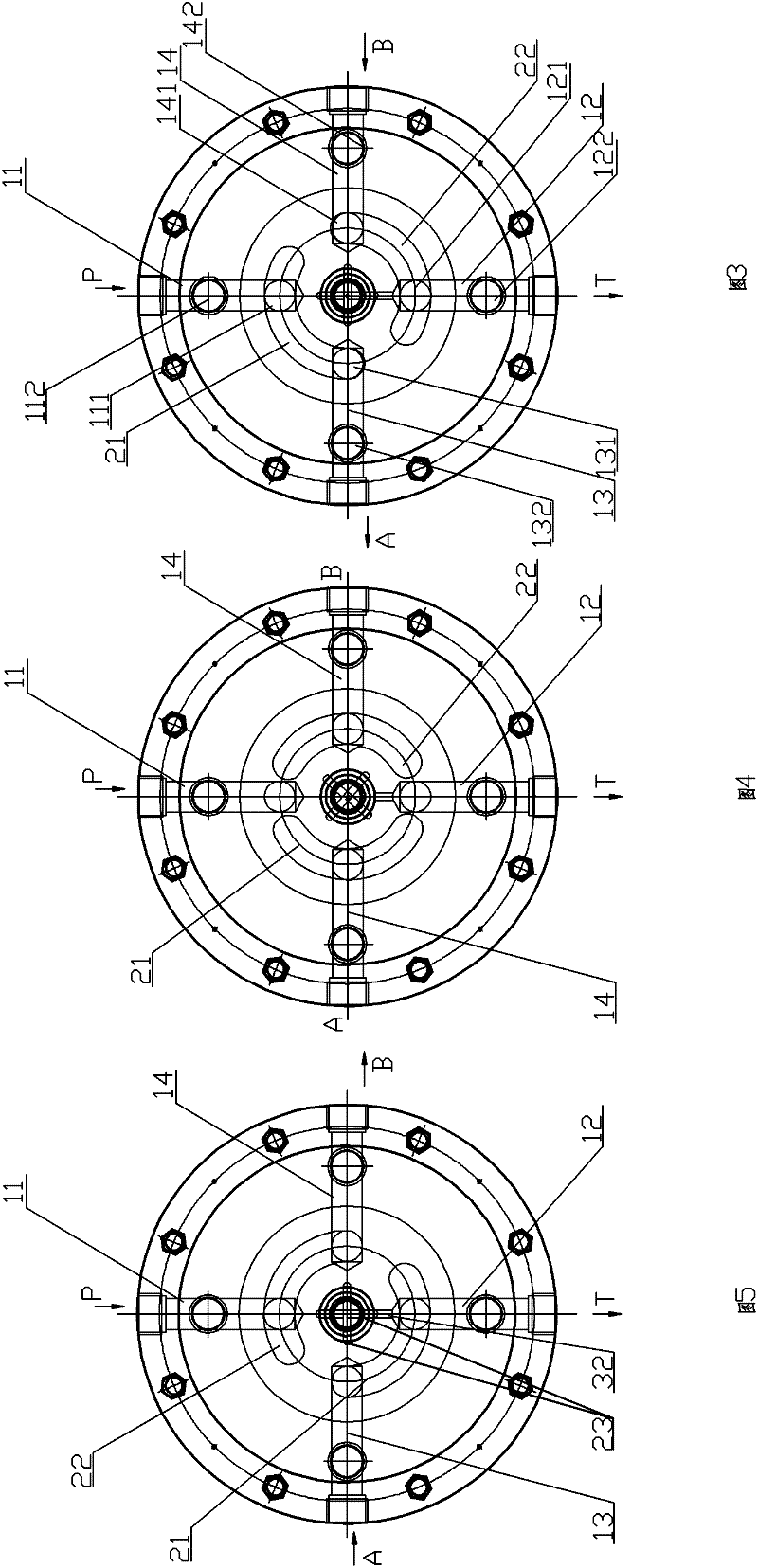

Valve control type energy recovery unit device

ActiveCN102442716ALarge thrustEasy to operateSeawater treatmentWater/sewage treatment bu osmosis/dialysisLow noiseHigh concentration

The invention provides a valve control type energy recovery unit device, comprising a four-way sliding valve, four-way rotary valves, a group of two pressure exchange tubes and four one-way check valves; the four one-way check valves are uniformly divided into two groups, and are respectively arranged on one side of the pressure exchange tube; and the other side of the pressure exchange tube is connected with a four-way reversing valve. The valve control type energy recovery unit device can adopt one group or more groups of pressure exchange tubes according to requirements, and the four-way rotary valves can be overlapped. The invention adopts an isobaric change exchange principle, uses the own high-pressure operation conditions of a reverse osmosis processing system, and fully recycles the excessive pressure energy of reverse osmosis high-concentration seawater under the high-pressure condition, so as to realize the purpose of saving energy. The valve control type energy recovery unit device is simple and reliable to control, is stable to operate, has excellent adaptability to the system flow and pressure, and has low noise; and the energy recovery rate of the device reaches up to more than 95%, so the device is easy to standardize and upsize. Through the valve control type energy recovery unit device, the water making energy consumption of the reverse osmosis system and the investment in high-pressure pumps are greatly reduced, and the device has an important significance for reducing the water making cost of reverse osmosis projects and reducing the project investment.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

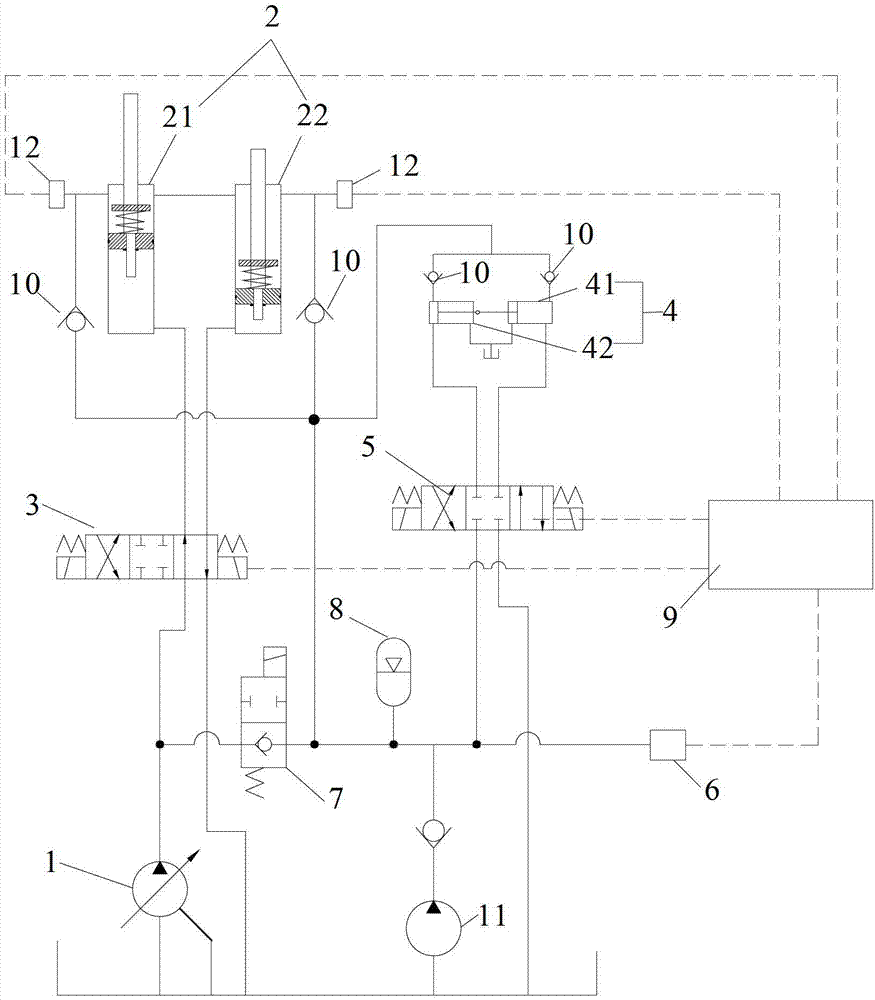

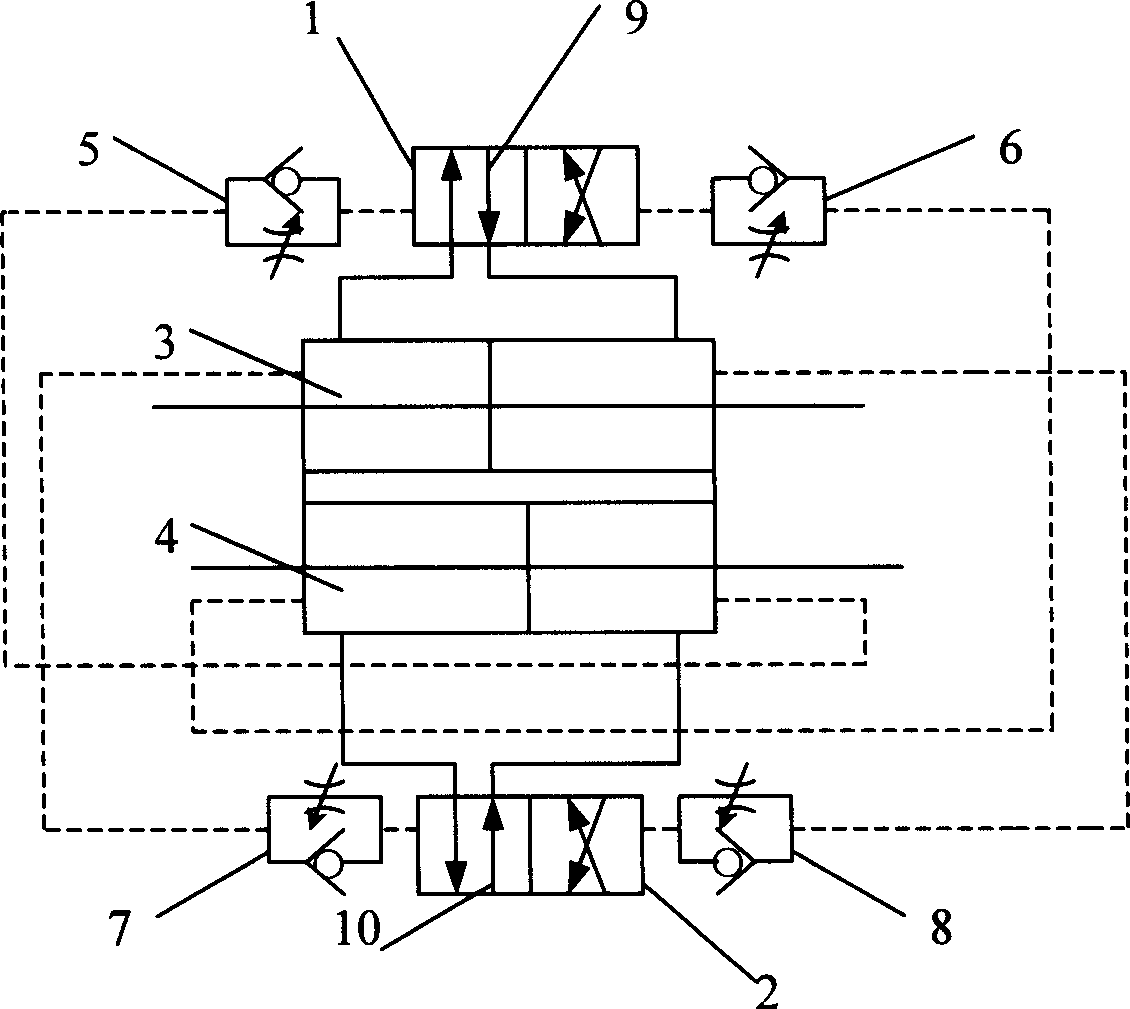

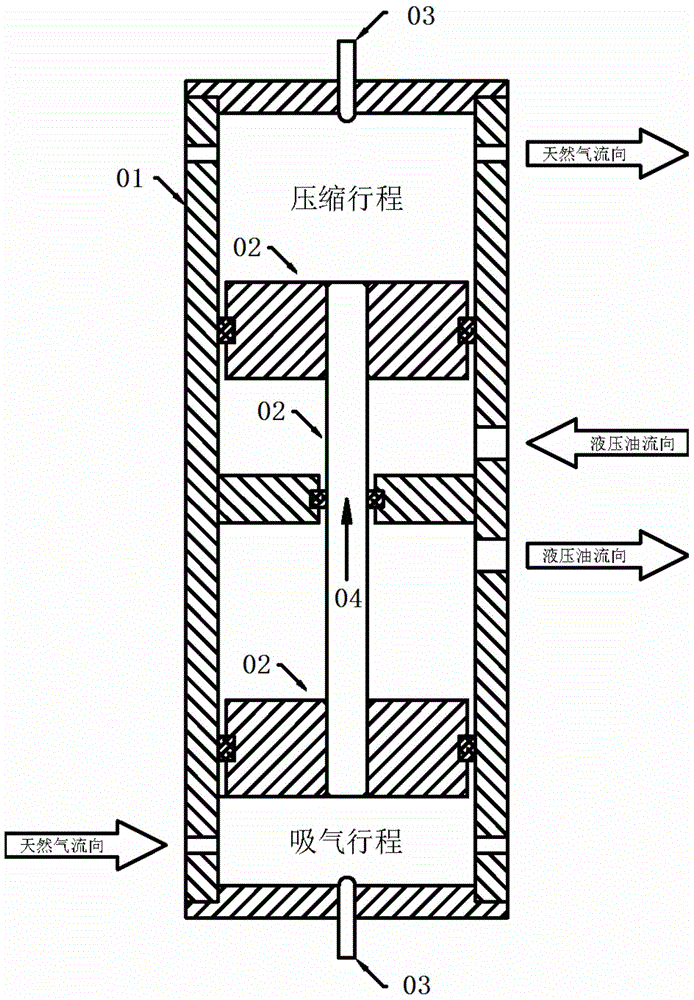

Pressure self-adaptive hydraulic reversing system

ActiveCN104533853ACommutation is reliableCommutation smoothServomotor componentsServomotorsReciprocating motionHydraulic pump

The invention provides a pressure self-adaptive hydraulic reversing system. The pressure self-adaptive hydraulic reversing system is used for piston reserving in a fluid compressing and delivering double-acting compressor and comprises a power drive hydraulic system, wherein the power drive hydraulic system is connected to two hydraulic oil ports formed in the double-acting compressor and used for driving a piston to perform reciprocating motion to form a power drive hydraulic loop, a hydraulic pump and a reversing device are arranged in the power drive hydraulic loop, and the reversing device is correlated with a reversing control device. The reversing control device comprises a pressure detection control device, wherein the pressure detection control device can detect pressure in the power drive hydraulic loop and / or delivery pressure of a fluid compressing delivery pipeline and is correlated with the reversing device so as to achieve the purpose of achieving piston reversing when the pressure of the fluid compressing delivery pipeline and / or the power drive hydraulic system reaches set pressure. The pressure self-adaptive hydraulic reversing system can perform hydraulic reversing according to the pressure of a delivered medium and / or the power drive hydraulic system.

Owner:BEIJING PROVA ENERGY DEV

Combined wedge block mechanism, lever-type anti-exceeding lock catch and automobile anti-reversed sliding device

The invention relates to a combined wedge block mechanism, a lever-type anti-exceeding lock catch and an automobile anti-reversed sliding device. Provided is the automobile anti-reversed sliding device which is provided with the combined wedge block mechanism and the lever type anti-exceeding lock catch. The automobile anti-reversed sliding device cannot be affected by the rotation speed of a driving shaft, can effectively prevent the rotation speed of a driven rotation member from exceeding the rotation speed of a driving rotation member, can ensure the situation that an overload automobile stopped on a ramp can smoothly turn a direction, back up and head downhill, and can ensure normal driving of the automobile in advancing. The combined wedge block mechanism and the lever-type anti-exceeding lock catch are simple in structure and are reliable in working; a novel mechanical driving member is provided in the mechanical engineering general technical field; and the provided automobile anti-reversed sliding device is substantially improved in working performance.

Owner:甘亚冰

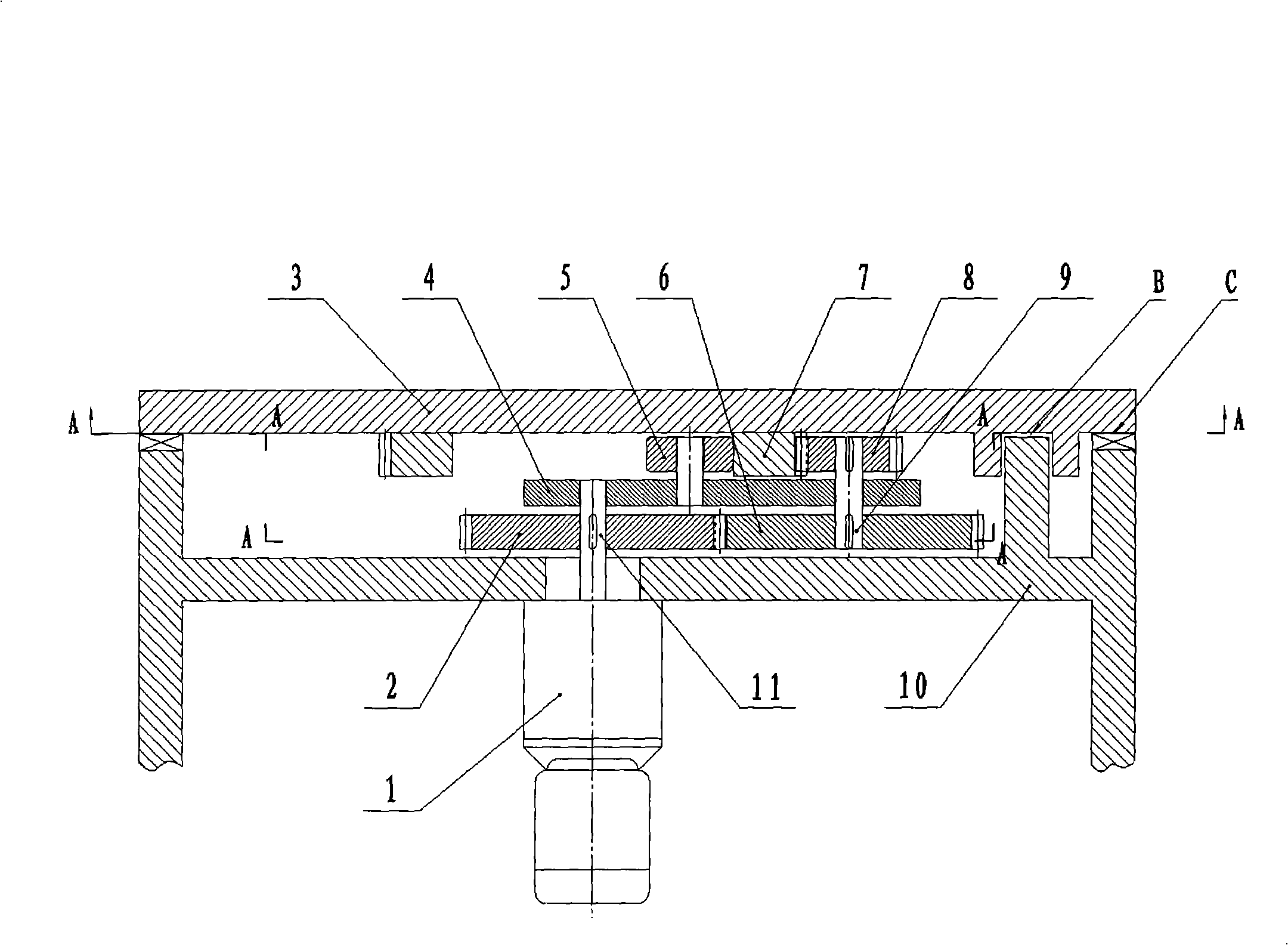

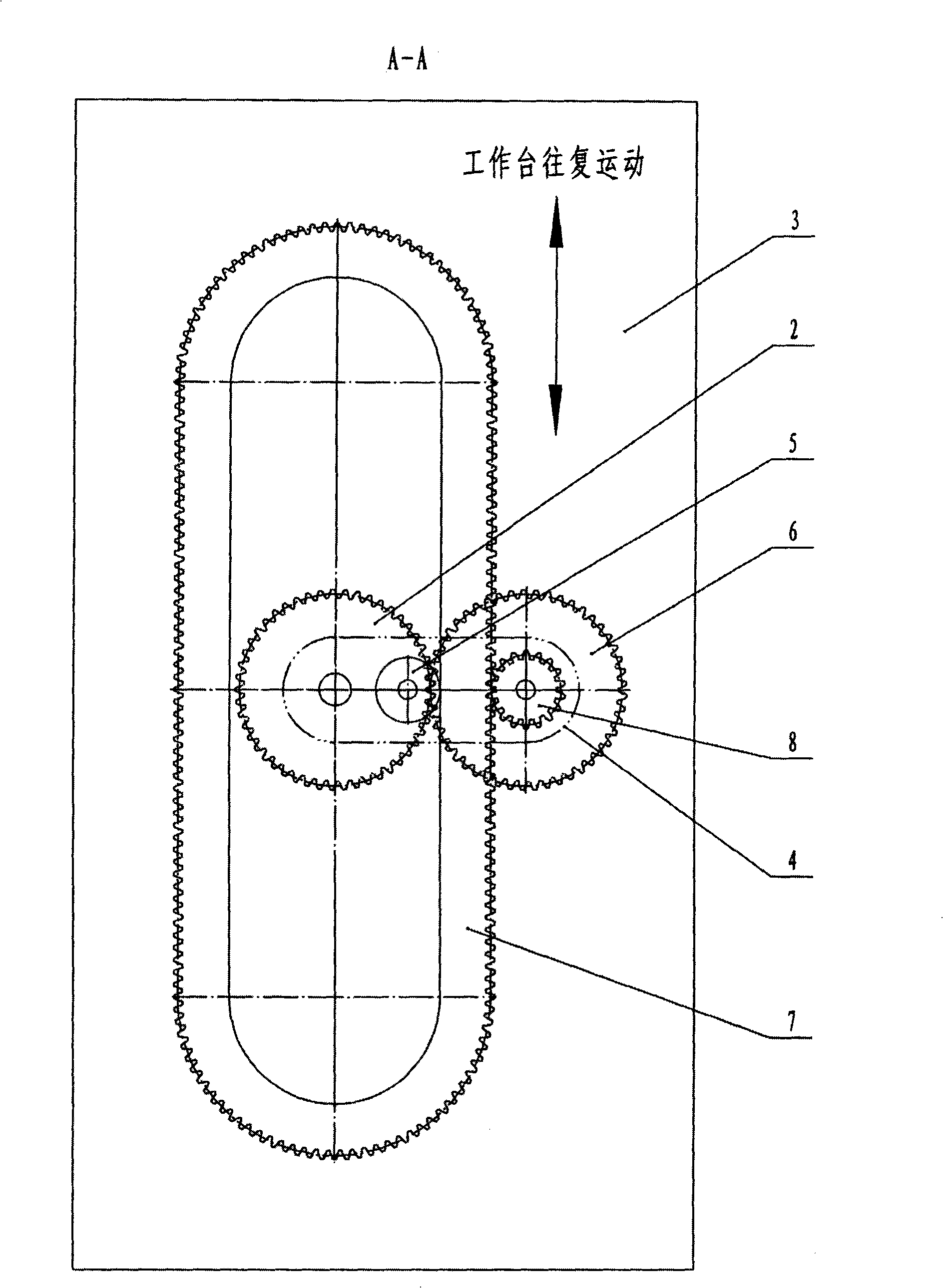

Reciprocating linear motion mechanism

InactiveCN101294620ALarge stroke rangeUniform speedLarge fixed membersFriction gearingsLinear motionDrive shaft

The invention relates to a reciprocating linear motion mechanism. A closed externally-toothed guide rail consists of two toothed racks and two semi-circular externally-toothed rings and is fixed on a work bench with a linear guide rail. A driving gear is fixedly connected with a driving shaft. A wheel axle support frame is connected with the driving shaft, a guide wheel and an intermediate gear shaft. Two intermediate gears are fixedly connected with two ends of the intermediate gear shaft and engages with the external teeth of the driving gear and the closed externally-toothed guide rail respectively. The guide wheel is matched with the internal rail of the closed externally-toothed guide rail. The driving mechanism supplies power to the driving gear via the driving shaft and then to the intermediate gear II via the intermediate gear I and the intermediate gear shaft and acts on the closed externally-toothed guide rail. Under the limitation of the guide wheel, the intermediate gear II makes cyclic motion along the closed externally-toothed guide rail, thereby driving the work bench to make reciprocating linear motion. The mechanism is characterized in large travel range, uniform velocity, smooth turning and no need of limit switch; and is suitable for mechanical equipment in need of uniform-velocity and large-travel reciprocating linear motion.

Owner:冯志晶

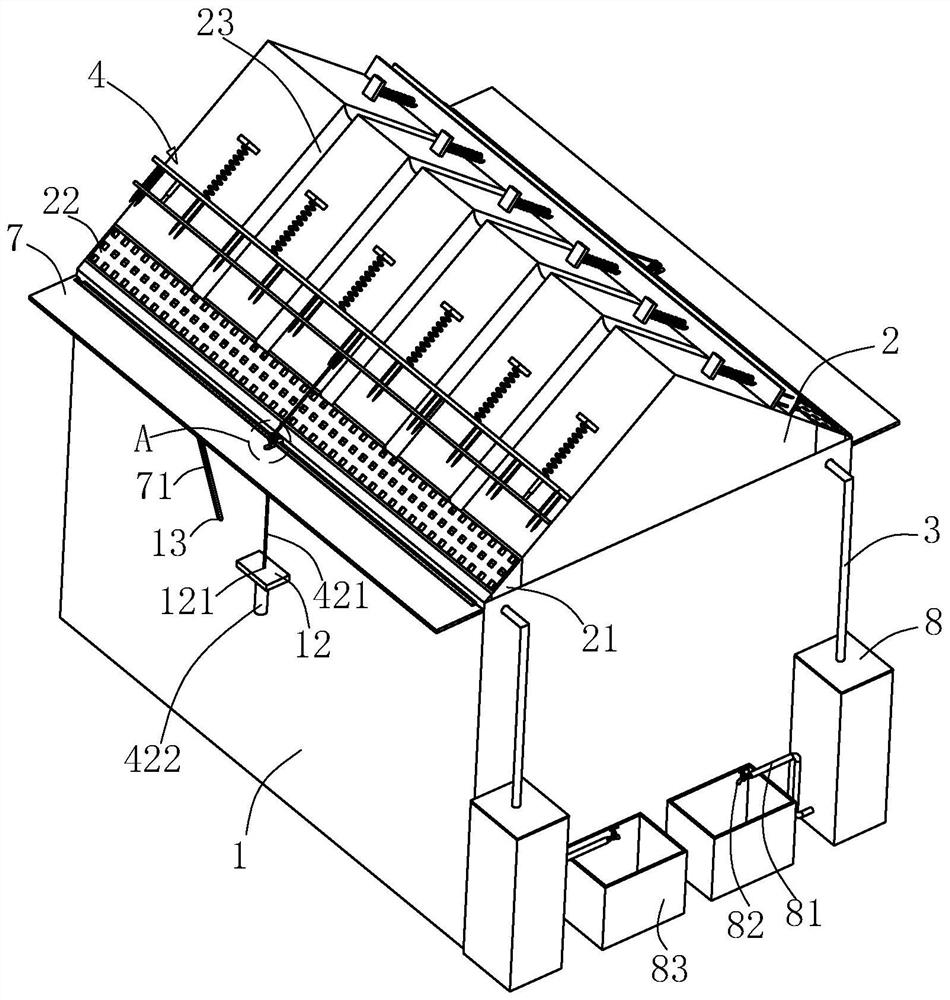

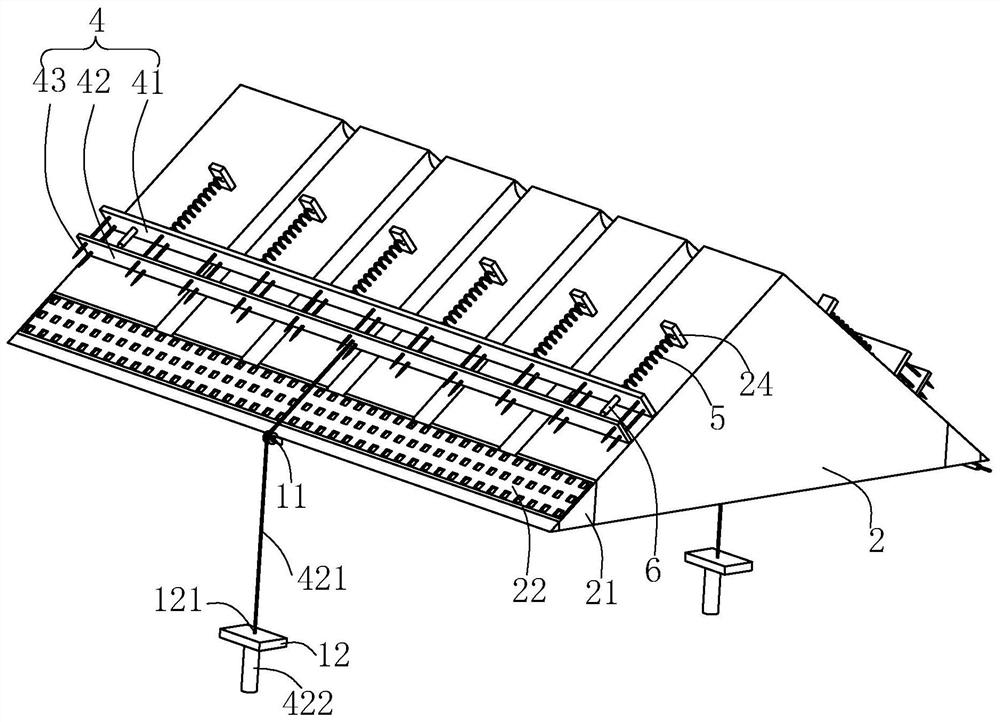

Environment-friendly and energy-saving building water supply and drainage system

ActiveCN112538937AEasy to cleanReliable cleaningGeneral water supply conservationRoof drainageCleaning needleArchitectural engineering

The invention relates to an environment-friendly and energy-saving building water supply and drainage system. The system comprises a house body, an inclined roof is arranged at the top of the house body, a water collecting tank is arranged at the inclined bottom end of the roof, a filter screen is fixedly arranged on the upper surface of the water collecting tank, the bottom end of the water collecting tank communicates with a water diversion pipe, and a cleaning assembly for cleaning the surface of the filter screen is arranged on the roof surface; the cleaning assembly comprises a mounting plate, a cleaning plate and a cleaning needle, the cleaning plate is located on the side, facing the filter screen, of the mounting plate, a first elastic piece is fixedly connected between the side, deviating from the cleaning plate, of the mounting plate and the roof, and the cleaning needle is fixed to the mounting plate and penetrates through the cleaning plate in the roof inclination direction; and a second elastic piece is fixedly connected between the cleaning plate and the mounting plate, the elastic force of the second elastic piece is larger than that of the first elastic piece, and apull rope is fixedly connected to the side, deviating from the mounting plate, of the cleaning plate and extends downwards along the house body. The system has the effect of improving the cleaning convenience of the filter screen.

Owner:深圳市星中恒建筑工程有限公司

Directional control valve driven by hydraulic pressure

InactiveCN101398020ALight in massShort tripOperating means/releasing devices for valvesServomotor componentsWater basedWater flow

The invention provides a hydraulic driving directional control valve which is provided with a valve base. The valve base is provided with a first water intake, a second water intake, a pressure water inlet, a third water intake and a forth water intake respectively from left to right. The directional control valve adopts the hydraulic drive of pressure water which is guided into a hydraulic driving chamber by a pilot control opening to drive a piston to act, cause a valve stem to move, and further control the on-off and the flowing direction of water flow so as to control the action of an actuator, thereby saving energy and protecting the environment; in addition, the valve stem is light in weight, short in stroke, and smooth, quick and liable in switching. Simultaneously, the technical proposal adopted by the directional control valve has good sealing effect and long service life, and needs no valve core or valve sleeve of expensive ceramic materials, thereby greatly reducing the cost on elements. The directional control valve is particularly applicable to sea water, fresh water and a hydraulic medium with high water base and low viscosity.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Reversing machine and reversing method thereof

The invention discloses a reversing machine. The reversing machine comprises a machine frame, a jacking mechanism, a transition rail and a reversing rail in perpendicular butt joint with the transition rail, the reversing rail is arranged on the machine frame, the transition rail is located on the upper side of the jacking mechanism and is connected with the jacking mechanism, a base and a movablesupporting device used for supporting the transition rail are arranged on the machine frame, and the jacking mechanism is arranged on the base. The invention further discloses a reversing method of the reversing machine. The reversing method of the reversing machine comprises the following steps that S1, the movable supporting device extends out to support the transition rail; S2, a to-be-reversed material is transferred to the transition rail; S3, the movable supporting device retracts to provide a descending space for the transition rail; S4, the to-be-reversed material is transferred to the reversing rail; S5, reversing is completed, wherein the reversing rail operates to convey the to-be-reversed material towards the downstream portion. The reversing machine and the reversing method thereof have the advantage that reversing is smooth and stable and the like.

Owner:TRUKING TECH LTD

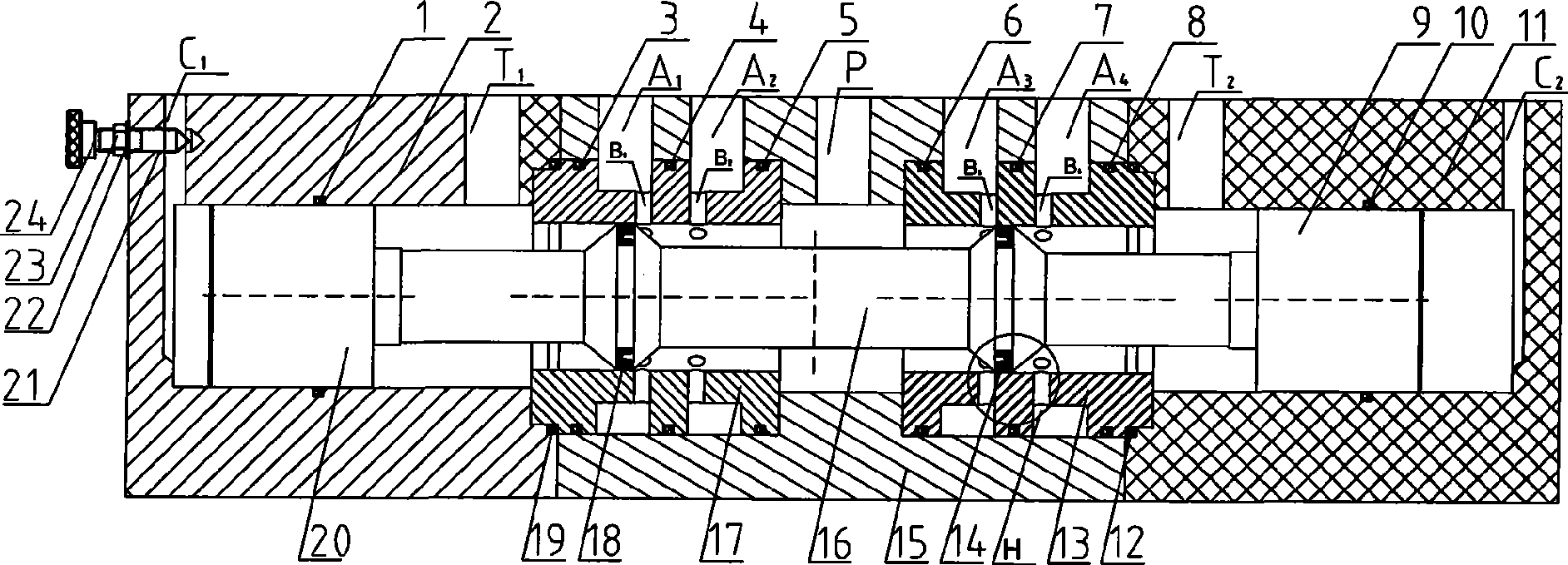

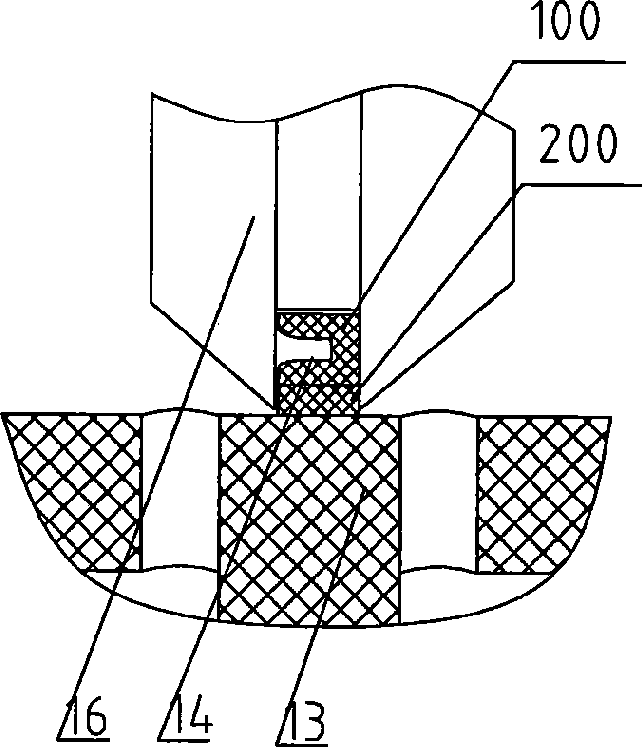

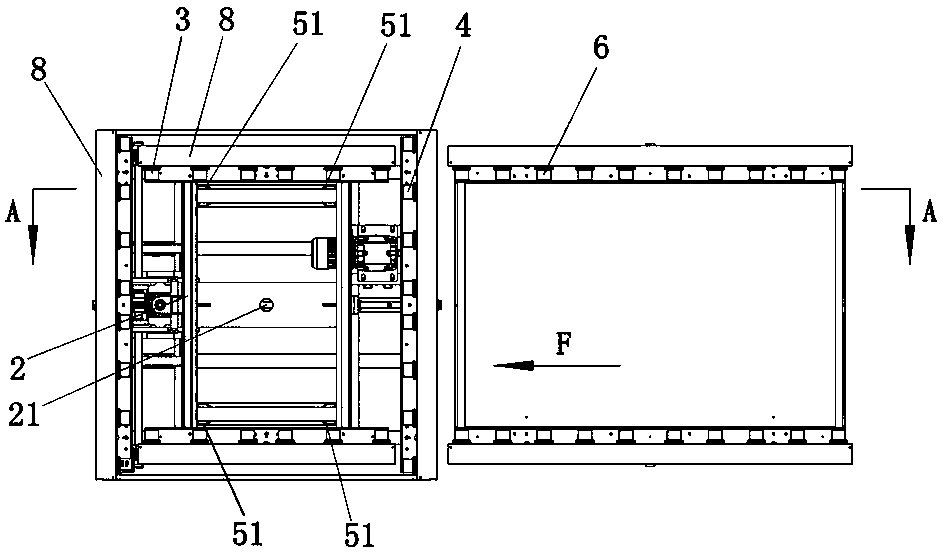

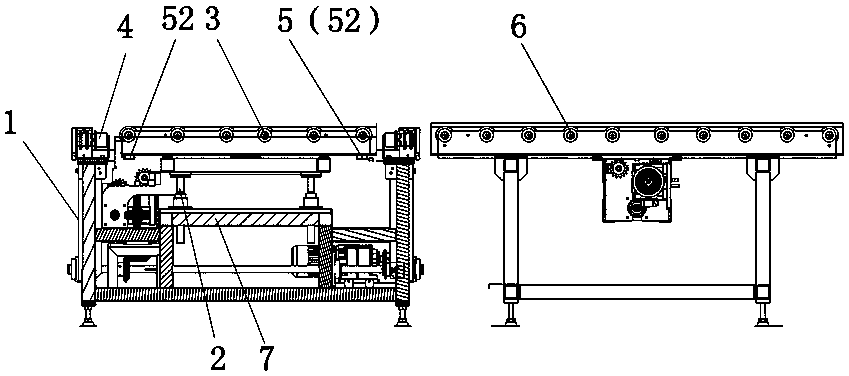

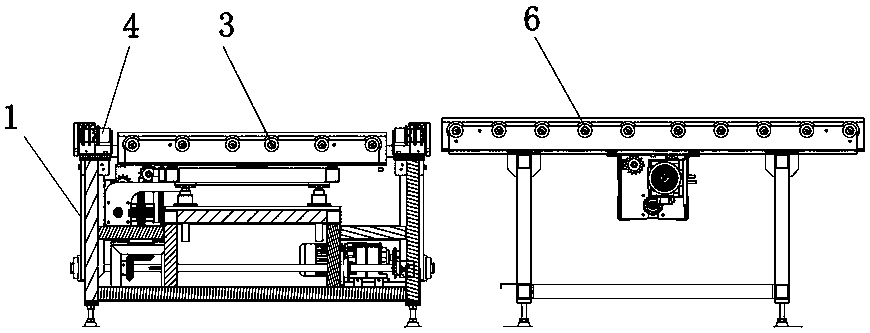

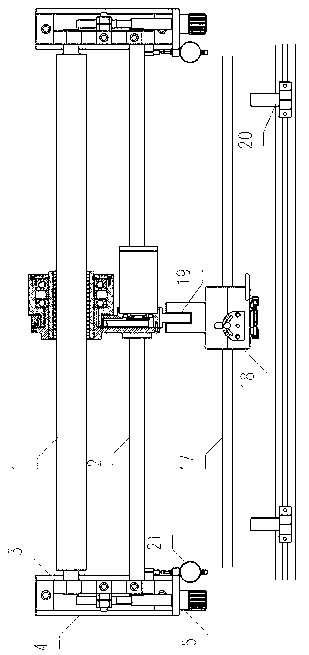

Grinding device of licker-in grinding and covering machine

ActiveCN103264326AHigh rotation accuracyImprove grinding qualityRevolution surface grinding machinesGrinding drivesFailure rateBall bearing

The invention discloses a grinding device of a licker-in grinding and covering machine. The grinding device comprises a grinding head unit, a roller unit and a power device, wherein the roller unit comprises a main roller, a guide rod, a grinding roller support and a grinding roller seat bottom plate; the main roller is in parallel to the guide rod; both ends are respectively arranged on the grinding roller seat bottom plate through the grinding roller support; the grinding head unit comprises a grinding head, a high-precision ball bearing, a high-precision linear bearing and linear bearings; the grinding head unit is arranged on the main roller and the guide rod through the two linear bearings, and is driven by the power unit to perform reciprocating motion along the main roller and the guide rod; the grinding head is directly arranged on the high-precision ball bearing; the high-precision ball bearing is also directly arranged on the high-precision linear bearing, and is driven by the power unit so that rotary motion is performed on the grinding head by taking the main roller as an axle center. The grinding device has the beneficial effects that the equipment is high in precision during rotary motion and reciprocating motion, adjustable in stroke, smooth in reversing and extremely low in failure rate; and the whole equipment is high in grinding quality, simple in structure and convenient to operate, and is free of amending a grinding wheel during the using process.

Owner:无锡立达纺织机械器材有限公司

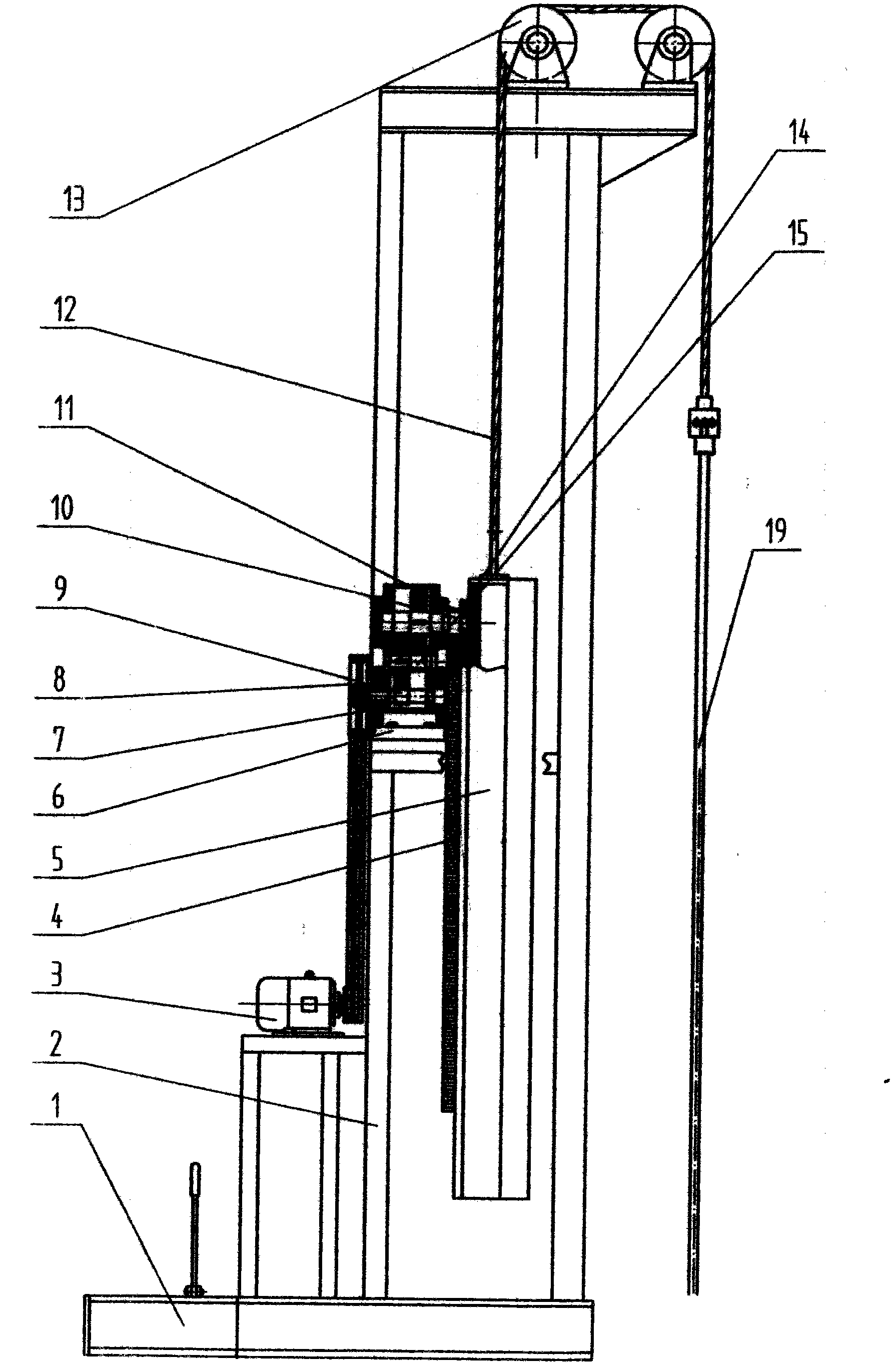

Planet gear ring oil pumping unit

InactiveCN102828726AGuaranteed meshing accuracyGuaranteed bearing capacityFluid removalFriction gearingsGear wheelRack and pinion

The invention discloses a planet gear ring oil pumping unit comprising a rack, a motor, a support, a gear box, a sun wheel gear shaft, a planet gear shaft, speed reduction gears, an annular rack and a rope suspending system. The planet gear ring oil pumping unit disclosed by the invention is characterized in that the middle part of the rack is provided with a support, the support is provided with the gear box, the gear box is provided with the sun wheel gear shaft, the speed reduction gear shaft and the planet gear shaft, and the speed reduction gear shaft and the planet gear shaft are respectively provided with one speed reduction gear. The planet gear shaft is meshed with the annular rack and does linear movement, and the two ends of the rack are semi-circular long rings, so that the oil pumping unit operates to an annular gear surface and enters into a guide ring, a planet gear is meshed with a semi-circular gear and moves from the left side of the rack to the right side of the rack under the action of the guide ring, the annular rack starts to operate in an inverted manner at the moment, reciprocation of the rack is realized, the rope suspending system at the top of the rack is driven, and the aim of pumping oil is achieved. The planet gear ring oil pumping unit disclosed by the invention has the characteristics of simple structure, reliable operation, high efficiency, stable reversing, economical efficiency and durability.

Owner:陈建武

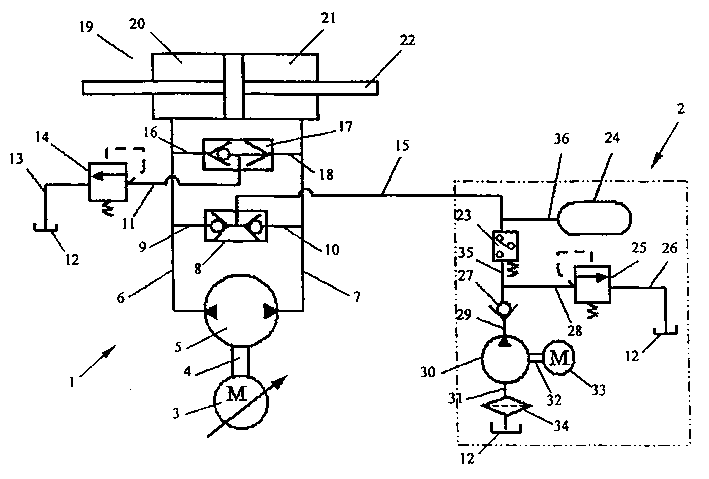

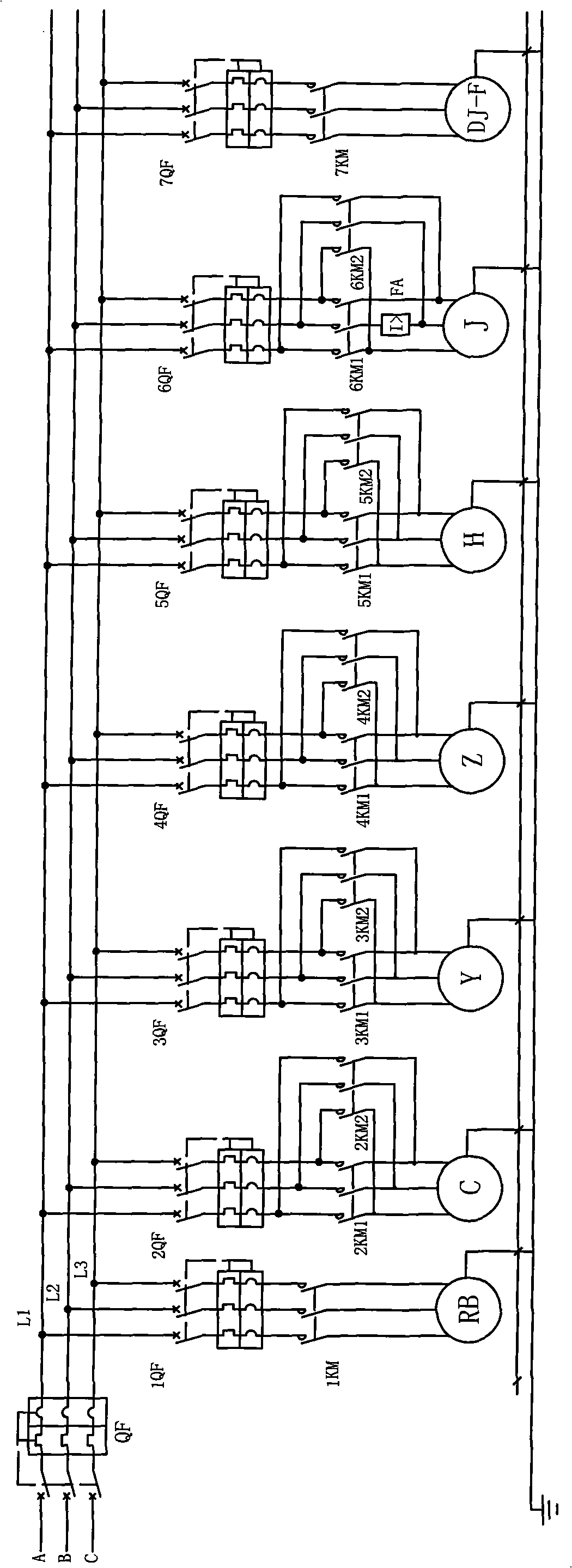

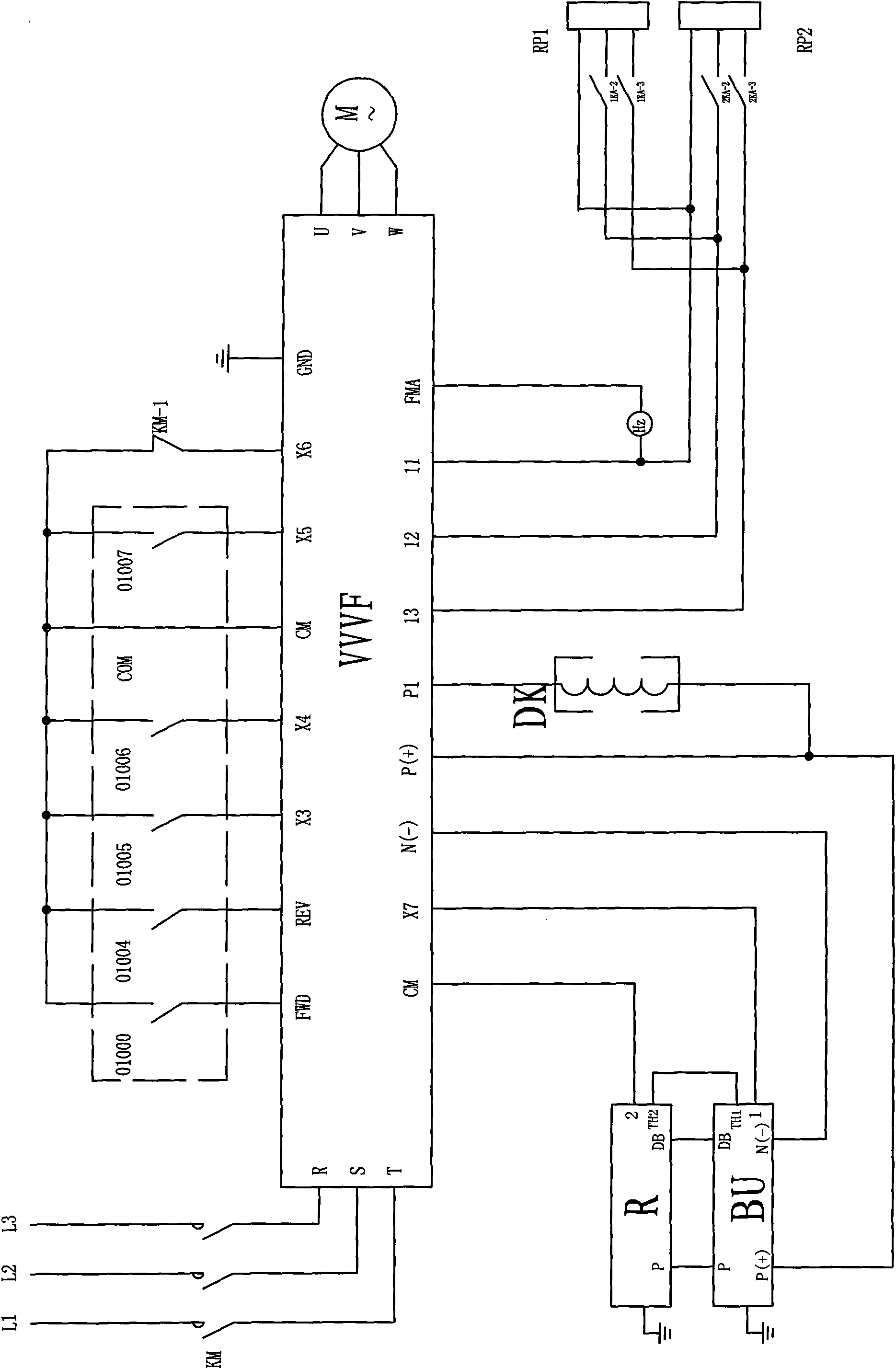

Power-saving control system of double housing planer

InactiveCN101829806ASimple and convenient speed adjustmentRealize stepless speed regulationAttachable planing devicesControl systemElectric machinery

The invention discloses a power-saving control system of a double housing planer, which comprises a cabinet body, a main loop unit, a frequency converter VVVF control unit, a programmable controller (PLC) input and output unit, a cutter lifting and indicating lamp unit and a relay protection unit, wherein all the units are arranged in the cabinet body; a main circuit is connected with a lubricating motor RB, a vertical turret motor C, a right turret motor Y, a left turret motor Z, a cross beam lifting motor H and a cross beam clamping motor J through circuit breakers 1QF-7QF and contactors 1KM respectively; the frequency converter VVVF output is connected to a main motor M; and the PLC input and output unit consists of an input part and an output part. The power-saving control system of the double housing planer has the advantages of simple structure, strong reliability, convenient speed adjustment, energy conservation, running speed improvement and cutting efficiency improvement, and can be widely applied to cutting mechanical equipment.

Owner:SHENYANG LIGONG UNIV

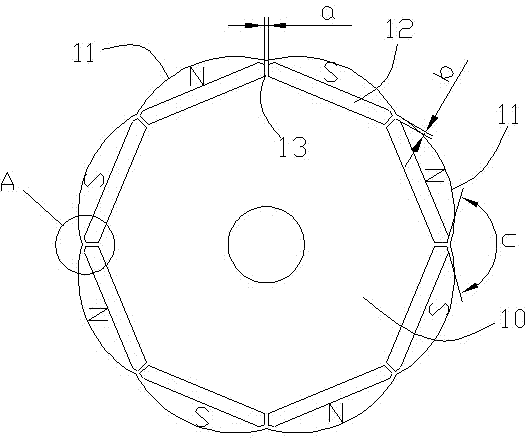

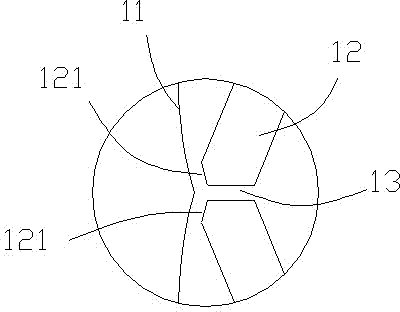

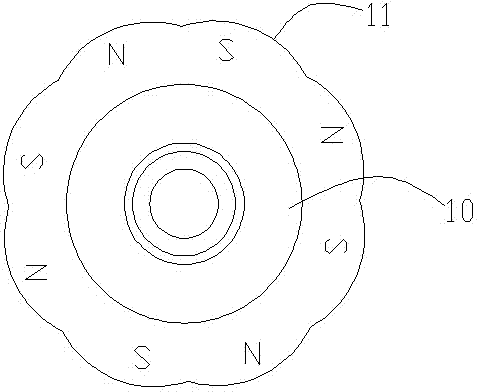

Novel rotor of brushless direct current motor

InactiveCN104734383AImprove air gap flux density waveformSmall moment of inertiaMagnetic circuit rotating partsEngineeringElectromotive force

The invention discloses a novel rotor of a brushless direct current motor. The peripheral face of the rotor is composed of an even number of eccentric arcs, the contour of the rotor is in a quincunx shape, a permanent magnet groove corresponds to each eccentric arc, a magnetism isolating bridge is arranged between every two adjacent permanent magnet grooves, and magnetic blocks are imbedded in each permanent magnet groove in sequence from N to S; the two ends of each magnetism isolating bridge are parallel, the width a of each magnetism isolating bridge is 0.3-3 mm, and the eccentric distance of each eccentric arc is 0.5-3mm; the two ends, close to an end face of the corresponding eccentric arc, of each magnetism isolating bridge are provided with oblique planes which are approximately parallel to the two ends of the corresponding eccentric arc, and the included angle c between the oblique planes on every two adjacent permanent magnet grooves ranges from 75 degrees to 160 degrees. The eccentric arcs and the permanent magnet grooves of the novel rotor are designed to be mutually matched, the air-gap magnetic field and the winding counter electromotive force wave form are improved, the magnetic field cutting inside the motor is effectively improved, and the rotation inertia moment of the rotor is decreased, so that the commutation noise and commutation vibration generated when the motor rotates are reduced, and an obvious effect for meeting the operating requirements of silence and slight vibration is achieved for the motor.

Owner:FOSHAN CITY NANHAI POPULA FAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com