Patents

Literature

73results about How to "Commutation is reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

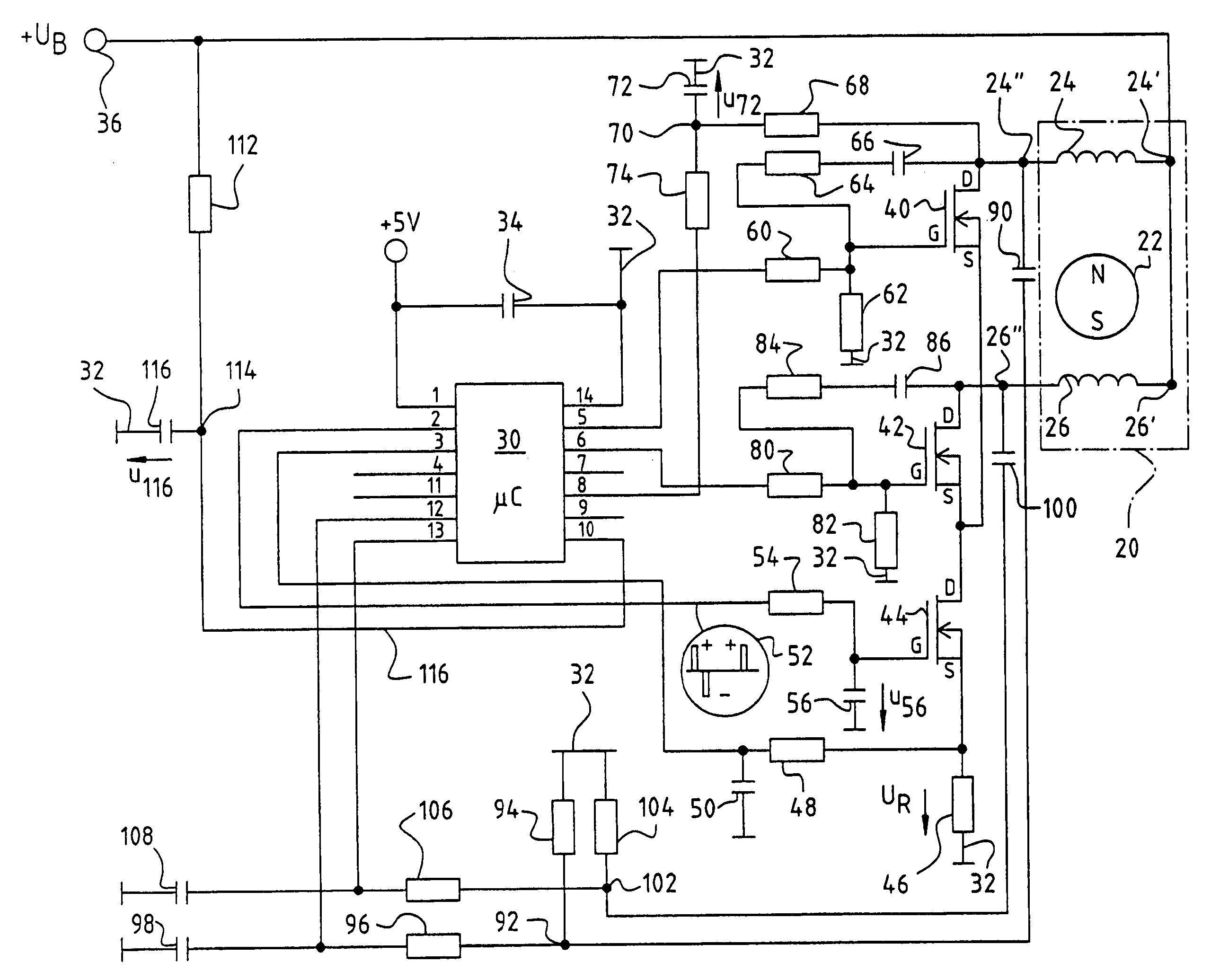

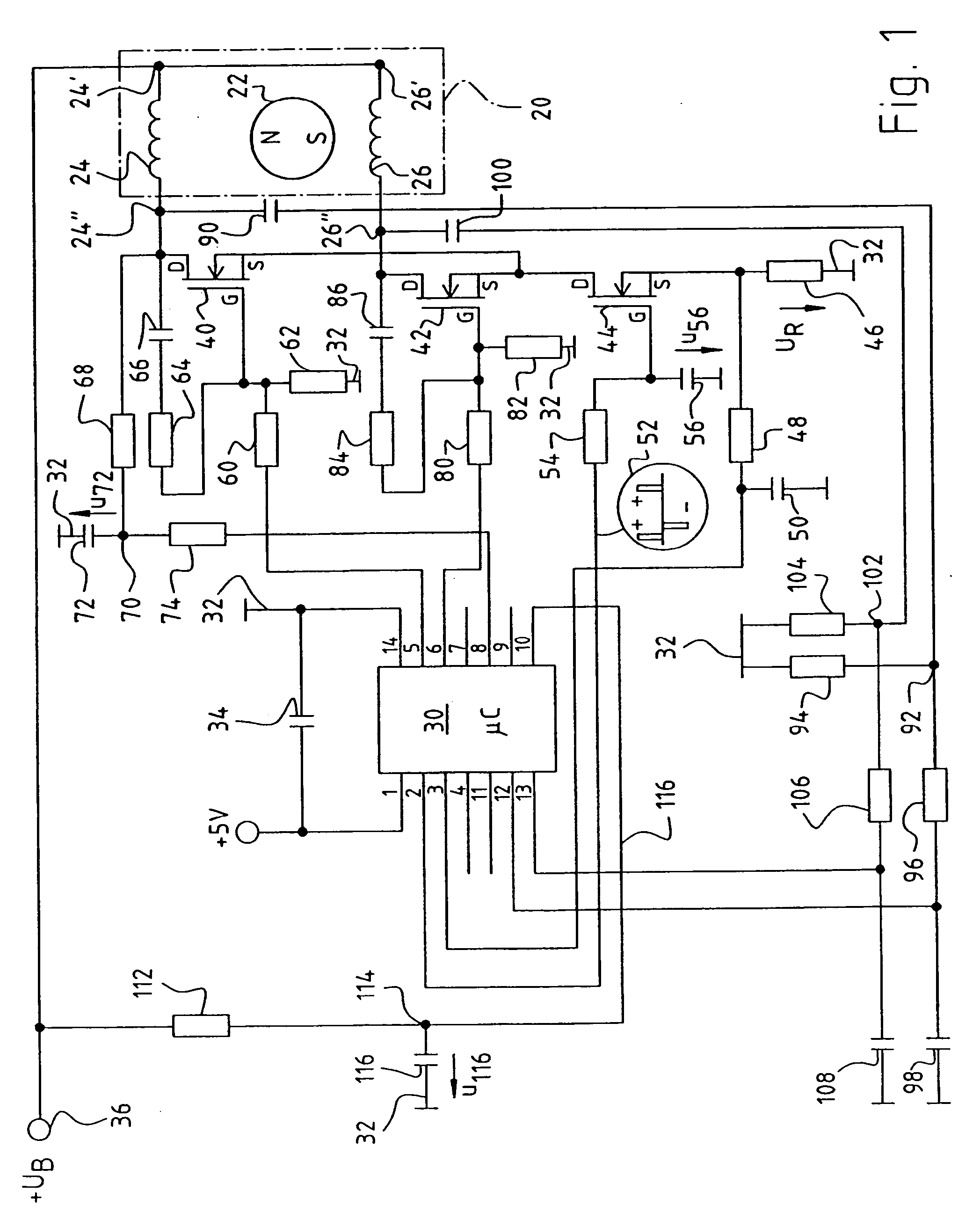

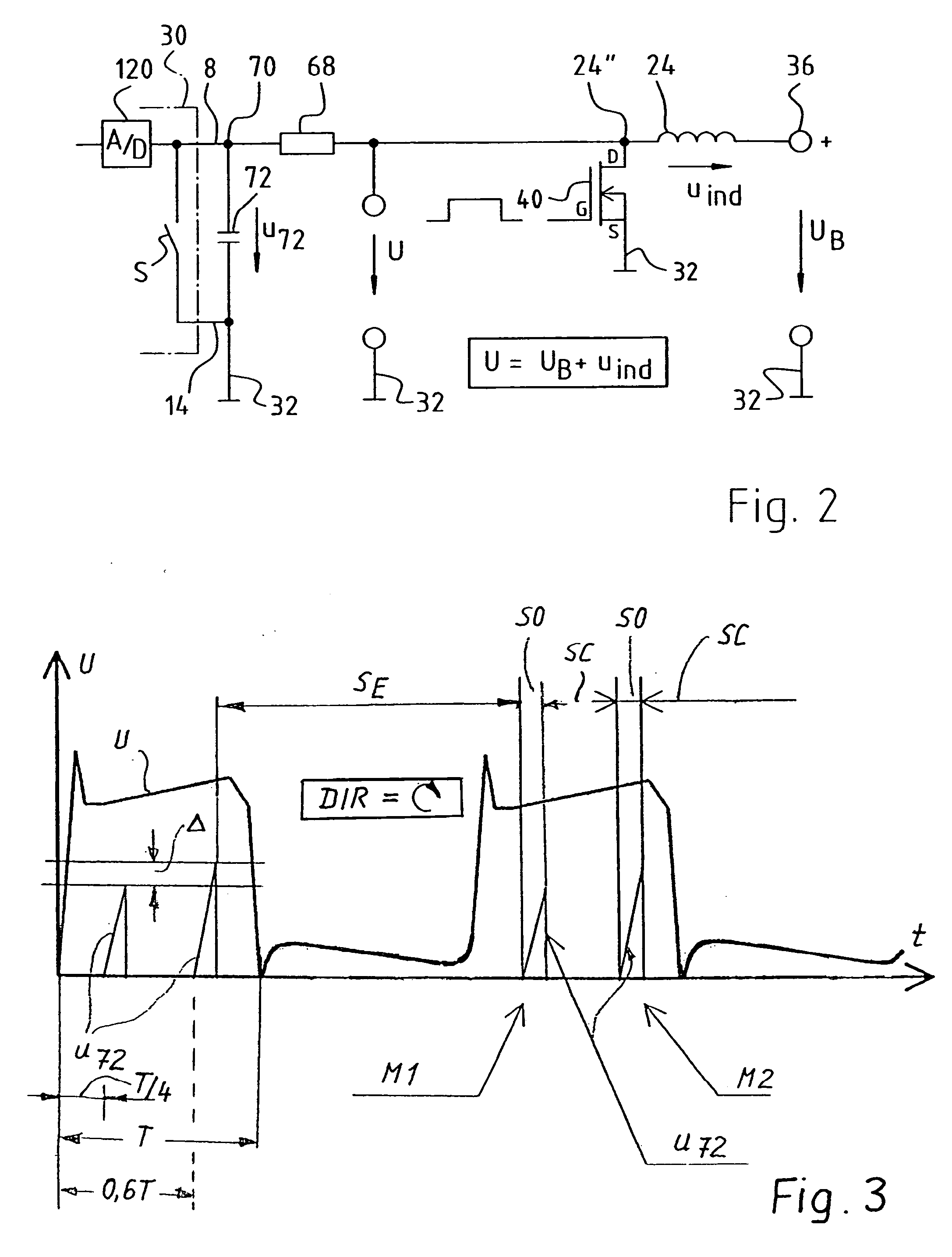

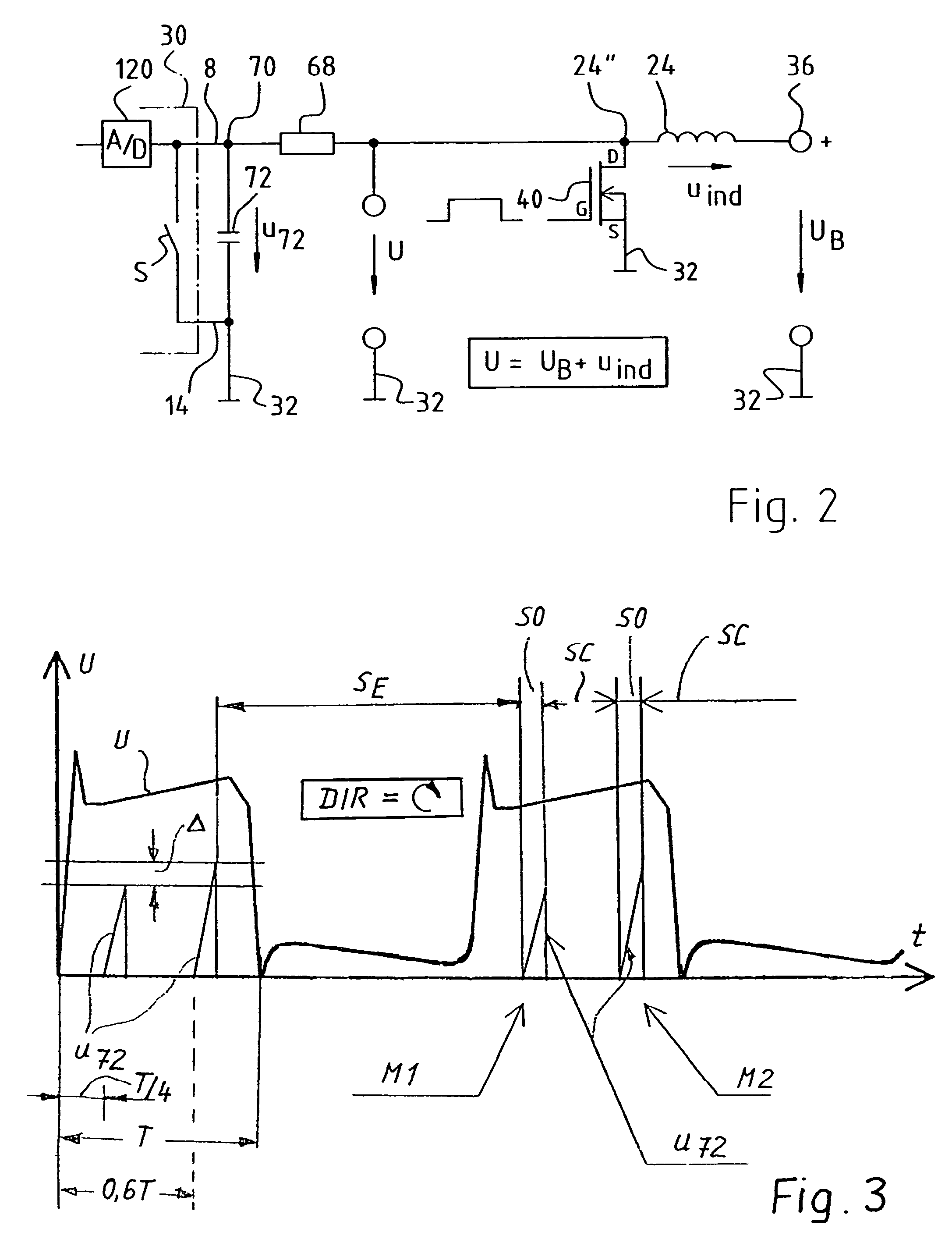

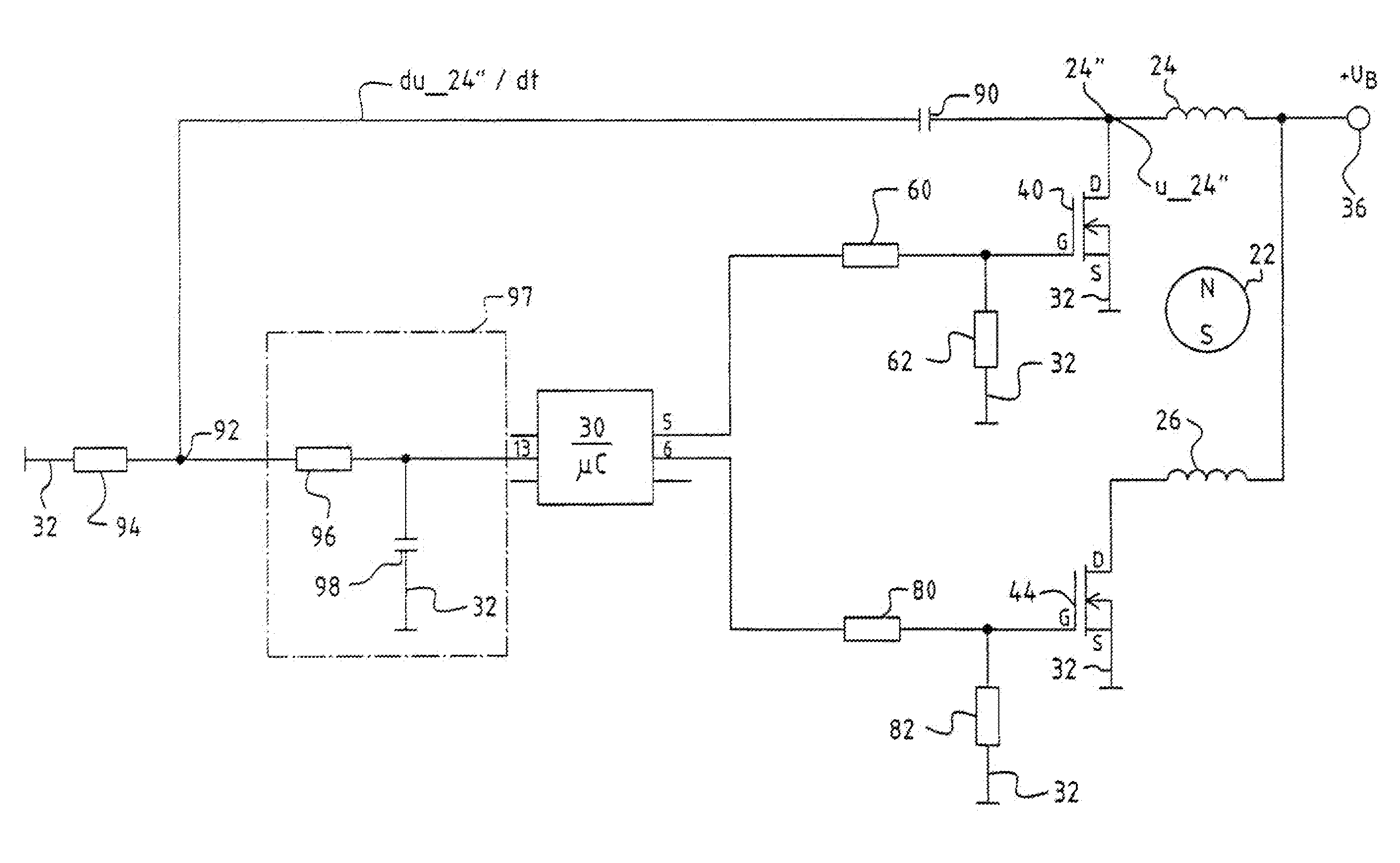

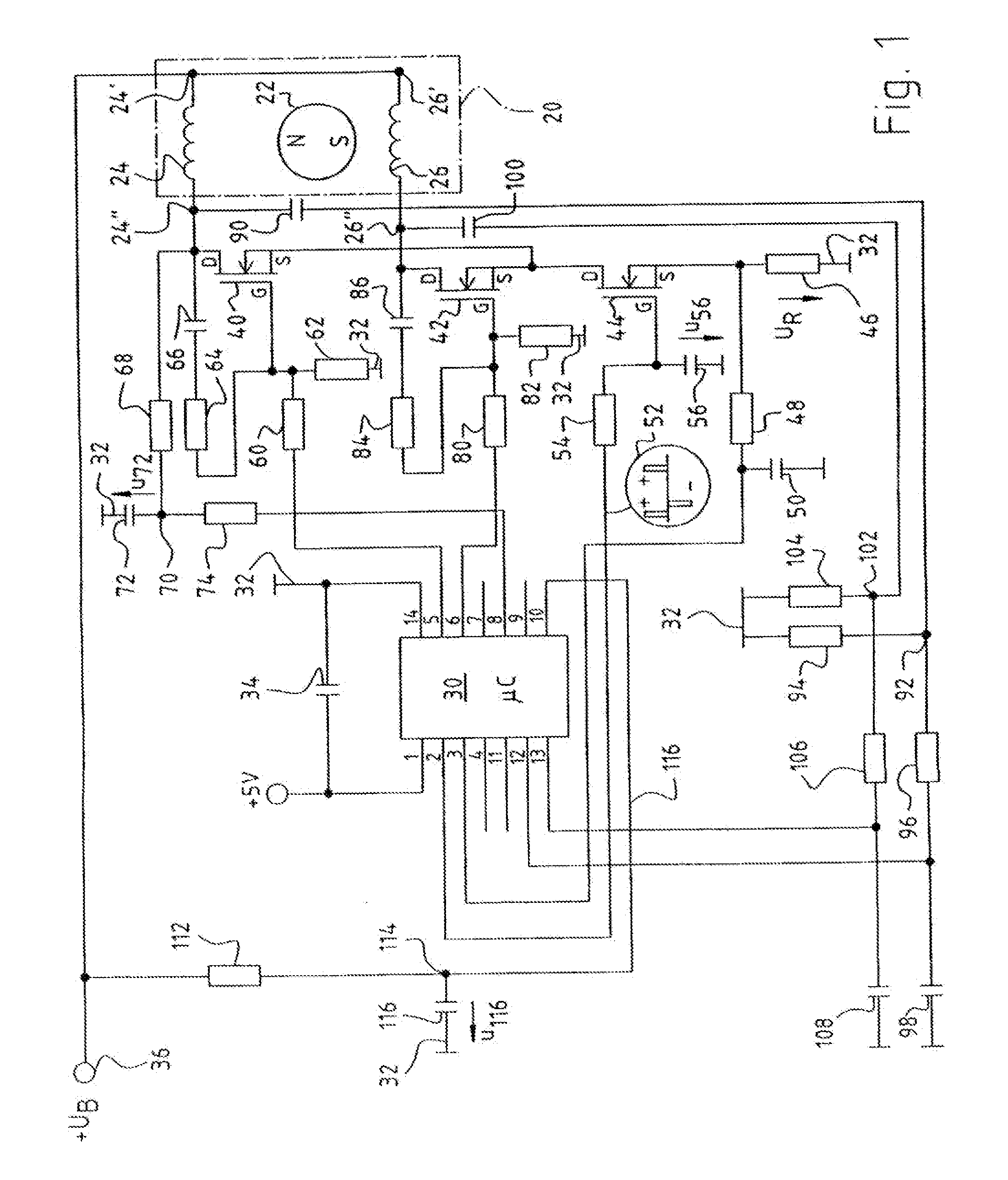

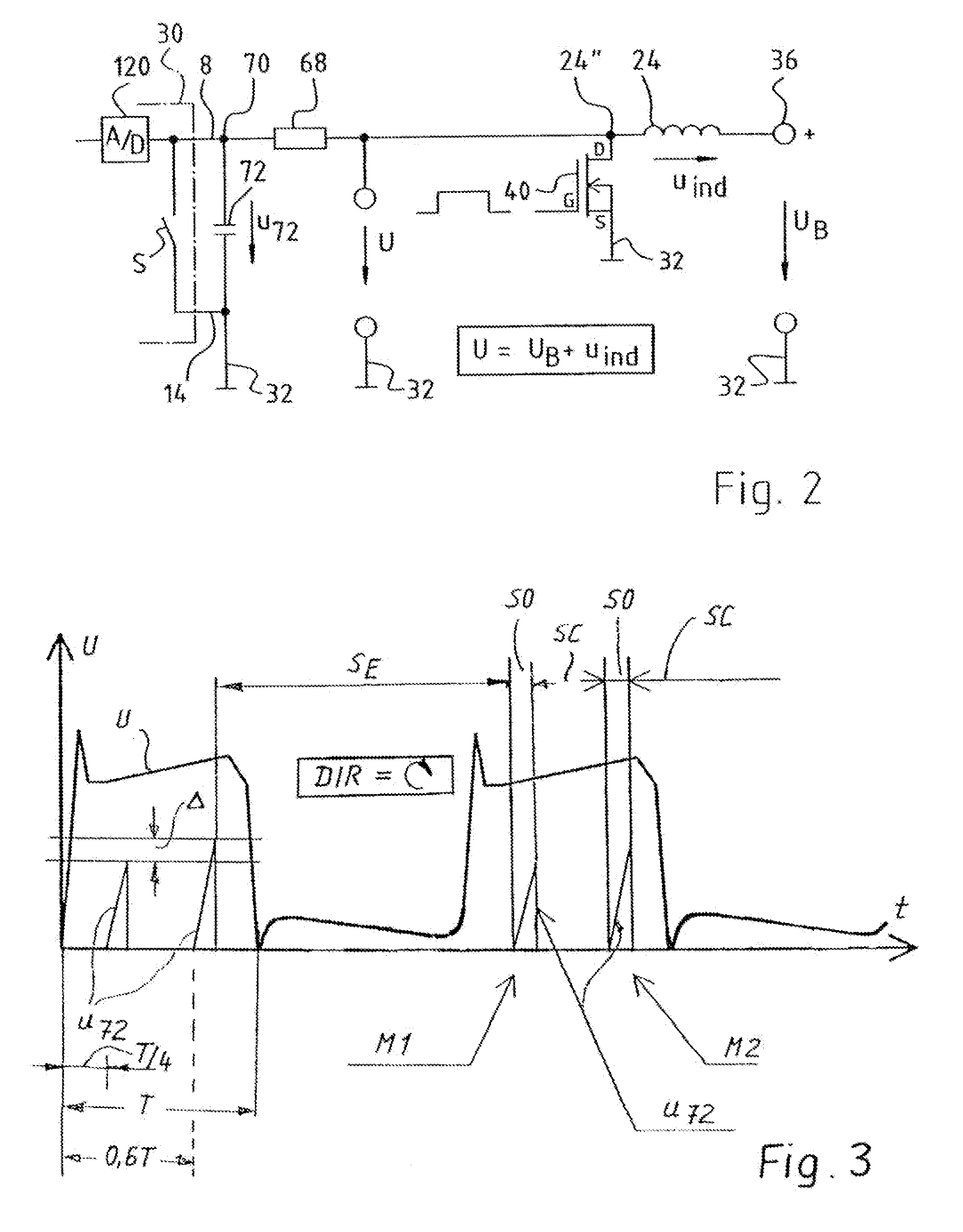

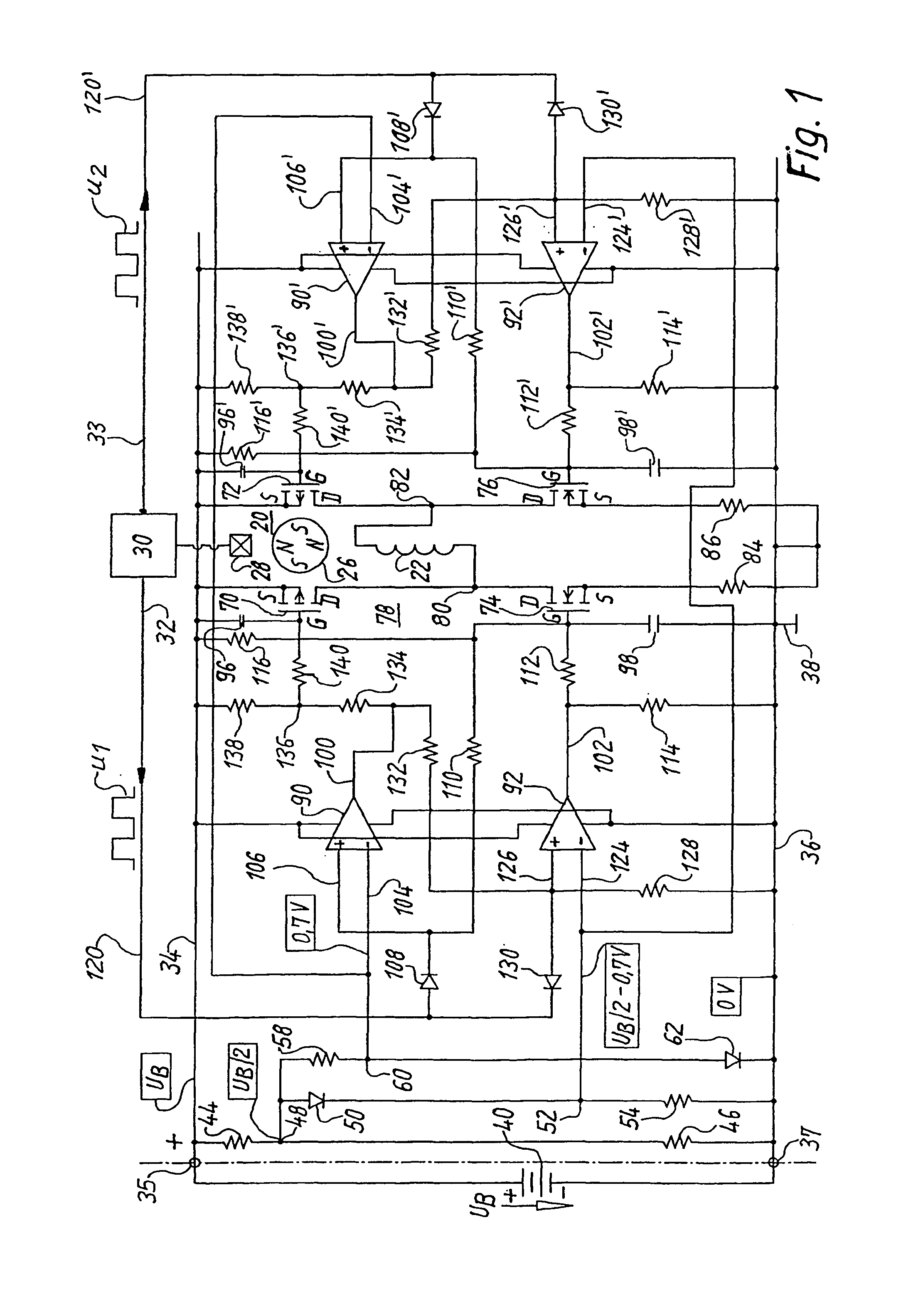

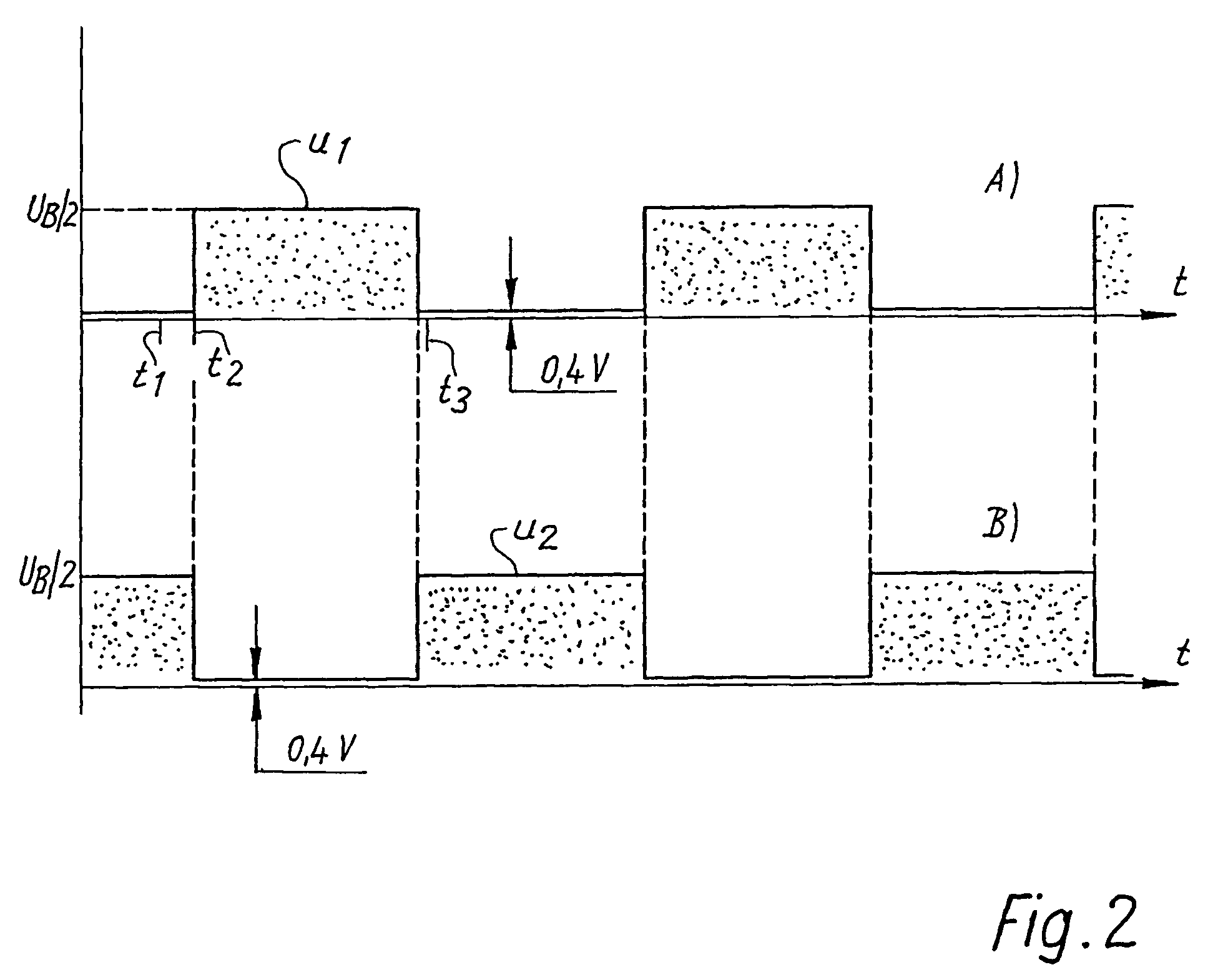

Method for sensorless operation of an electronically commutated motor and motor for carrying out such a method

ActiveUS20050253546A1Commutation is reliableSimplified generationAC motor controlSynchronous motors startersPermanent magnet rotorVoltage drop

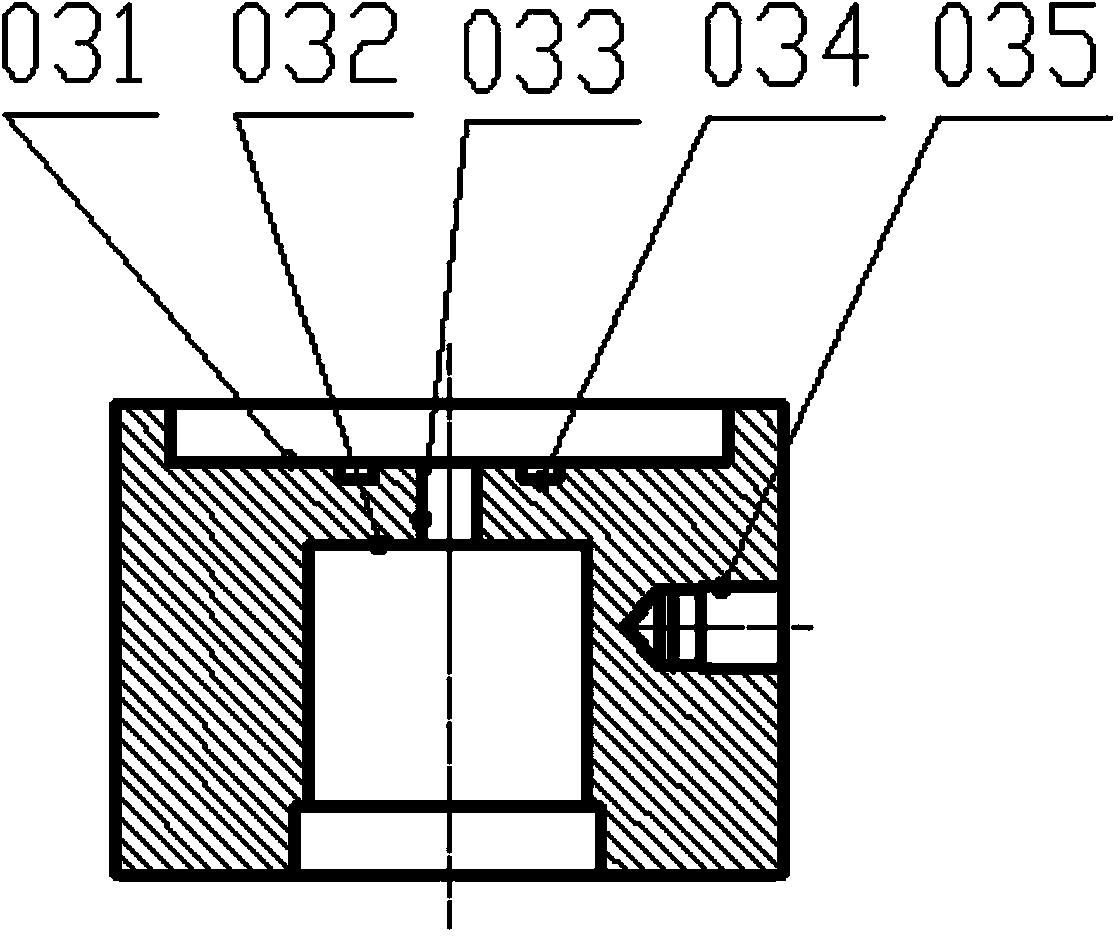

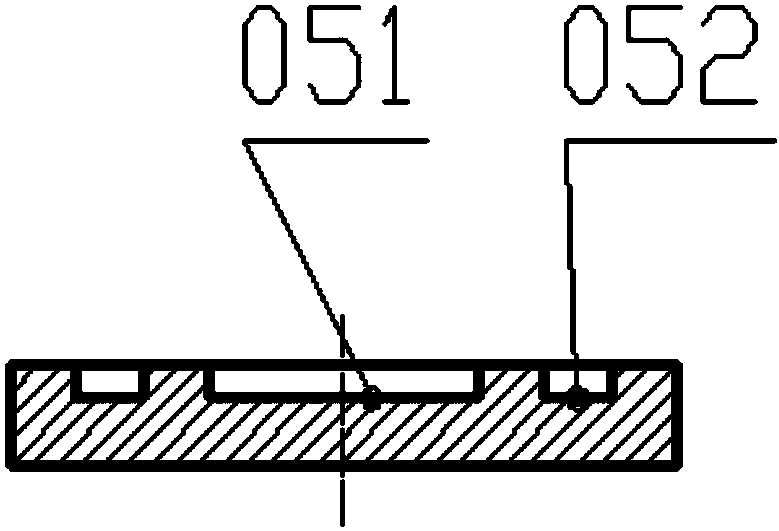

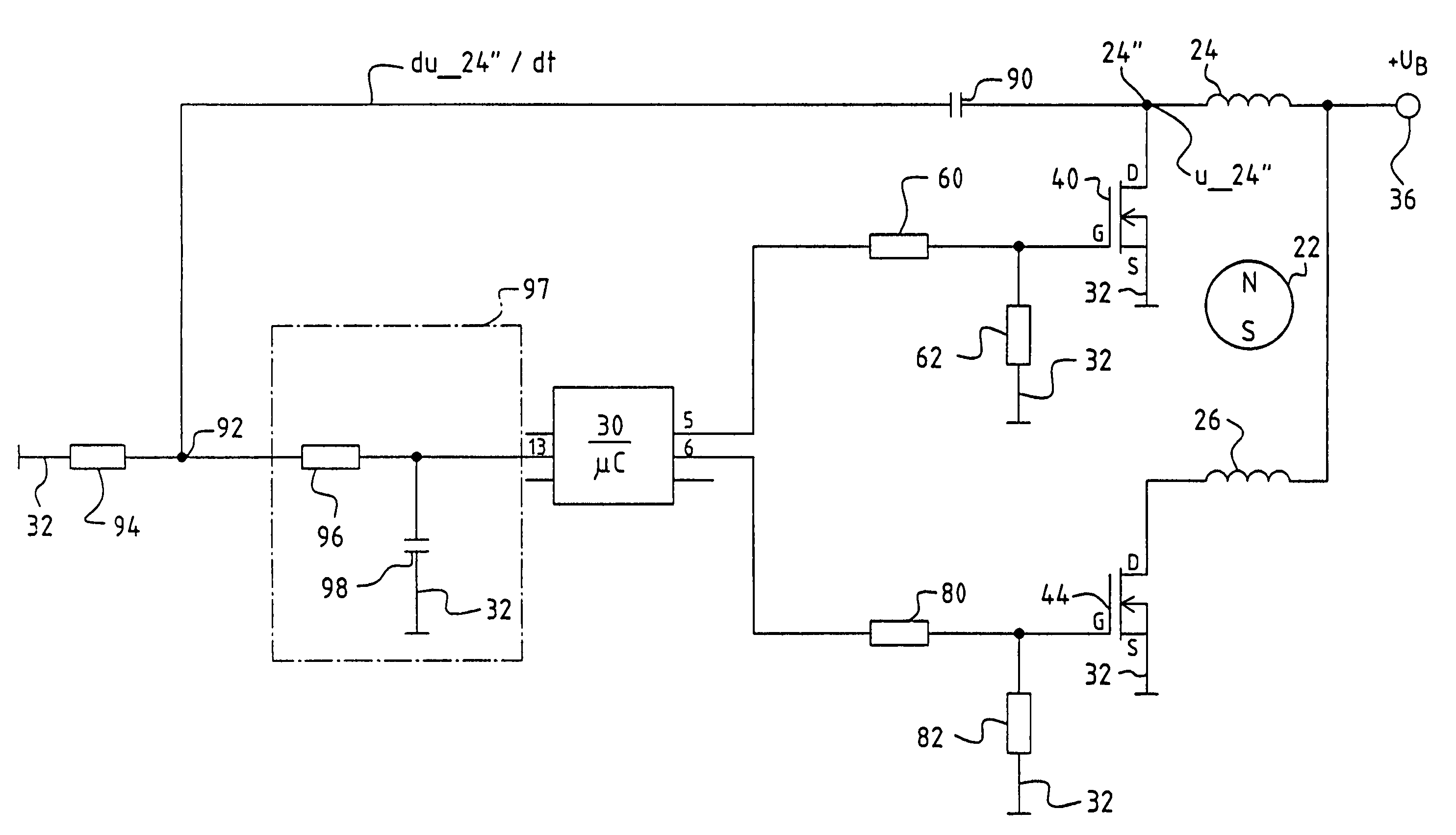

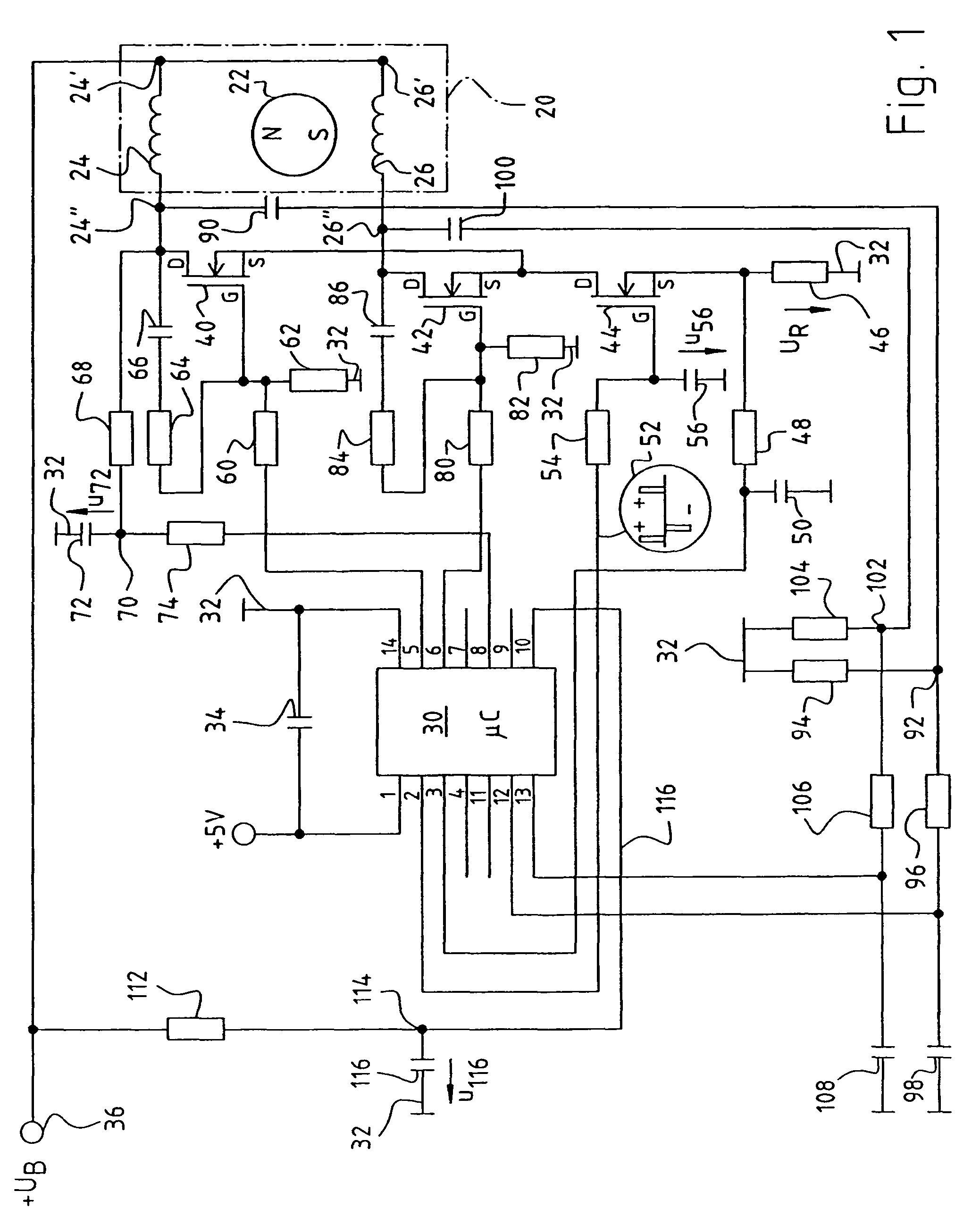

An electronically commutated motor (ECM) often employs a Hall sensor for reliable operation. Even when a Hall sensor is omitted from a motor having a plurality of stator winding phases (24, 26) and a permanent-magnet rotor (22), one can reliably detect direction of rotation of the rotor by the steps of: (a) differentiating a voltage profile obtained by sampling either (1) induced voltage in a presently currentless phase winding or (2) voltage drop at a transistor, through which current is flowing to a presently energized phase winding, and (b) using such a differentiated signal (du_24″ / dt, du_26″ / dt) to control current flow in an associated phase winding. In this manner, one obtains reliable commutation, even if the motor is spatially separated from its commutation electronics.

Owner:ELEKTROSIL SYST DER ELEKTRONIK

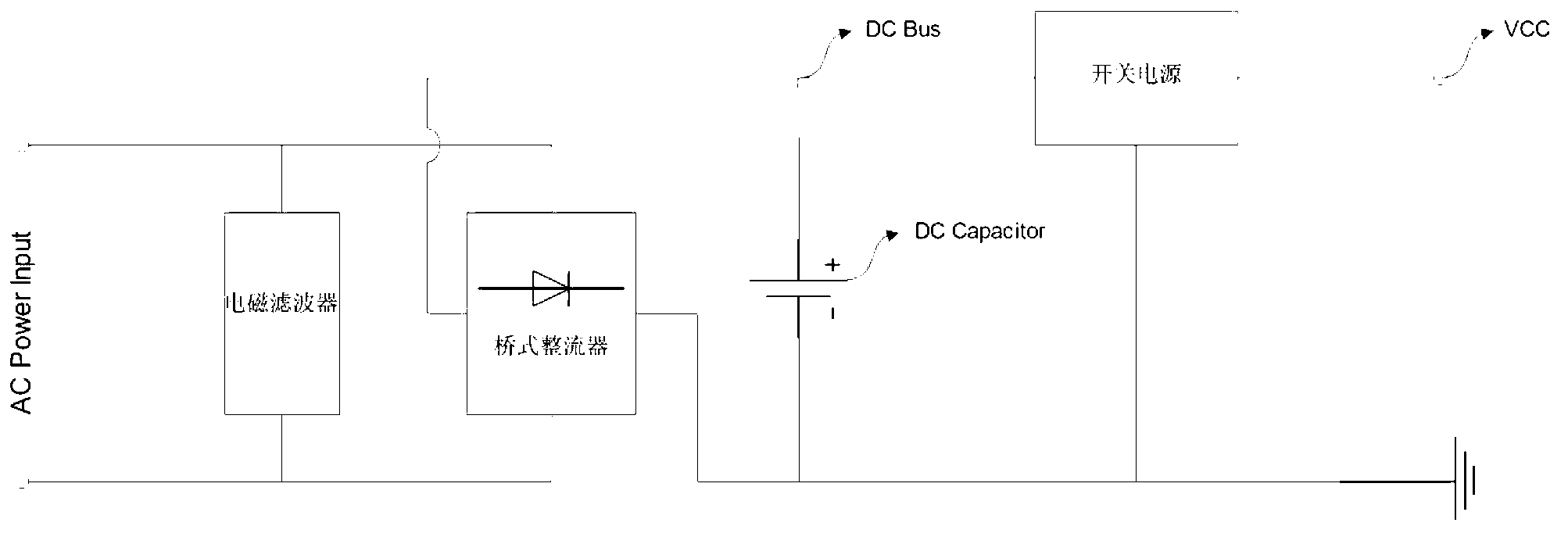

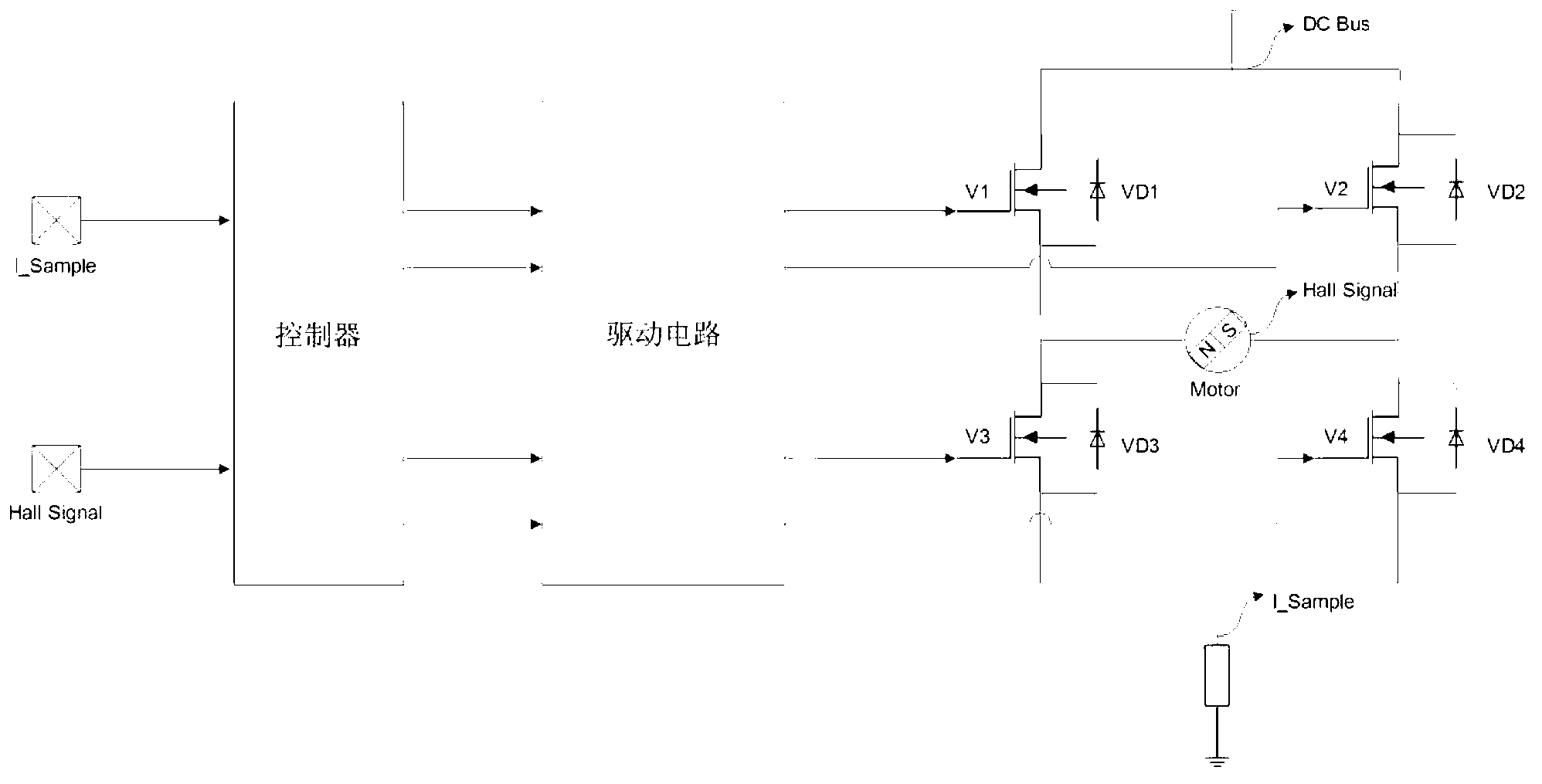

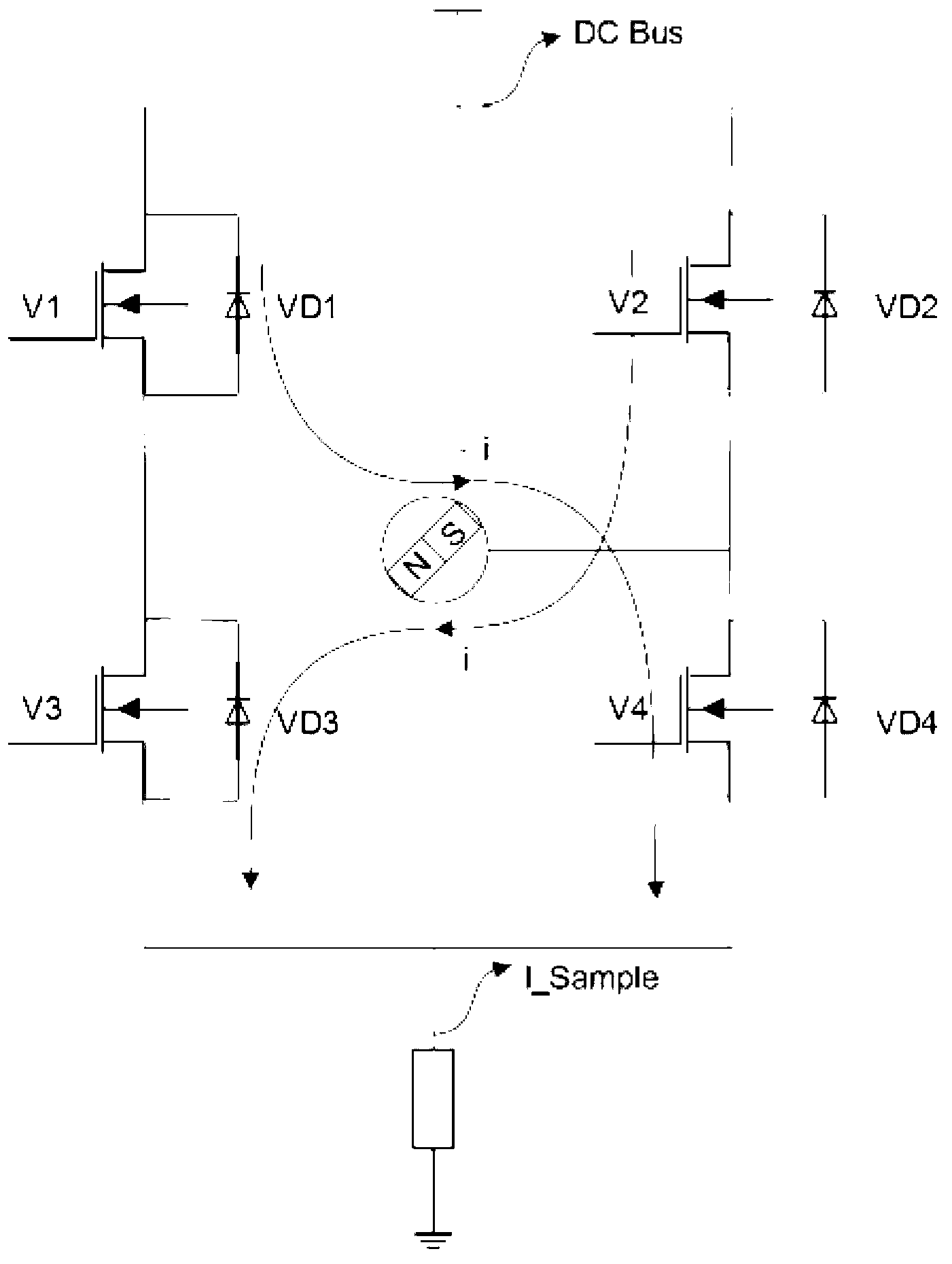

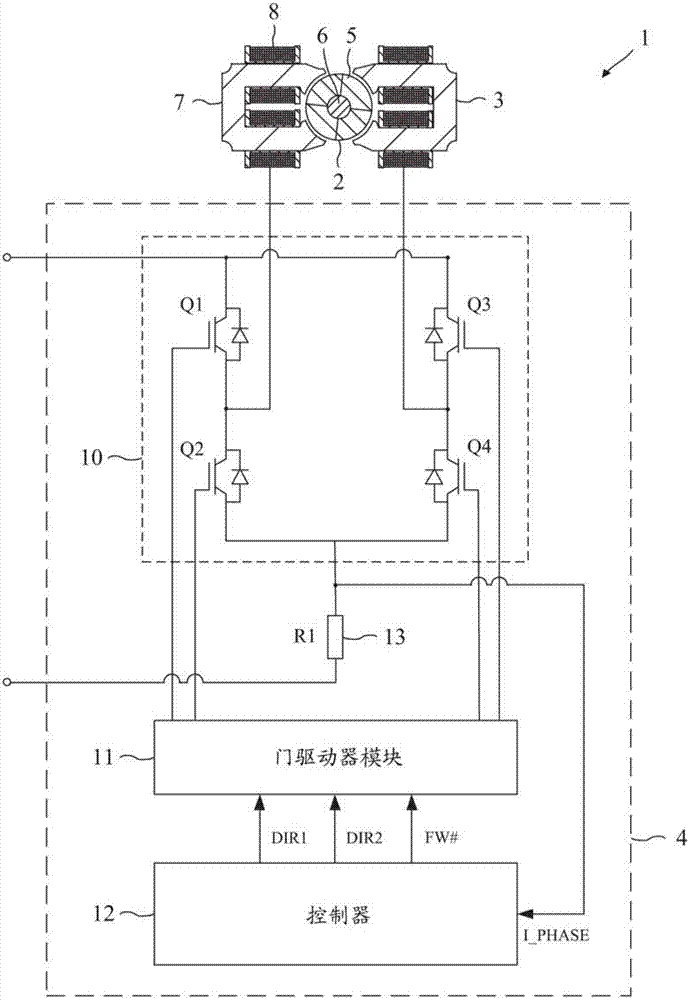

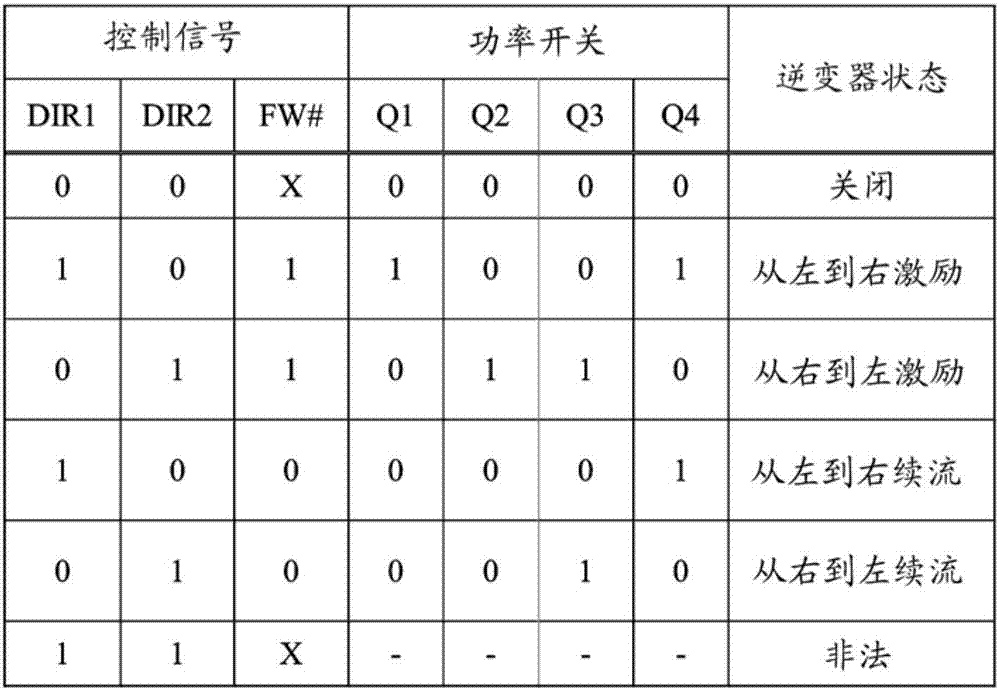

Electronic commutation brushless direct current and single phase fan circuit and control method thereof

InactiveCN103259469ACommutation quietReduce lossField or armature current controlElectronic commutatorsSingle phaseSwitched-mode power supply

The invention discloses an electronic commutation brushless direct current and single phase fan circuit and a control method thereof. The electronic commutation brushless direct current and single phase fan circuit comprises an alternating current rectifying circuit, a switching power supply, an inverting commutation circuit, rotor-position sensor, a current sampling circuit and a controller, wherein the switching power supply is used for supplying power to a motor and the switching power supply, the switching power supply is used for generating low-voltage power supply and supplying the low-voltage power supply to an external component, the inverting commutation circuit is used for controlling motor current alternation, the rotor-position sensor is used for supplying the position information of the current rotor, the current sampling circuit is used in winding current feedback, and the controller is used for fulfilling motor commutation and circuit regulation. The electronic commutation brushless direct current and single phase fan circuit and the control method thereof have the advantages that due to the fact electronic switch components are adopted, the motor is quiet and reliable in commutation processes without any mechanical movement. Due to the fact that permanent magnet rotors are adopted, the magnet winding of an ordinary direct current motor is not needed, and loss is reduced. In addition, the whole circuit and the control method of the circuit are simple and reliable, and the performance and reliability of a whole machine are improved.

Owner:HANGZHOU WEIGUANG ELECTRONICS

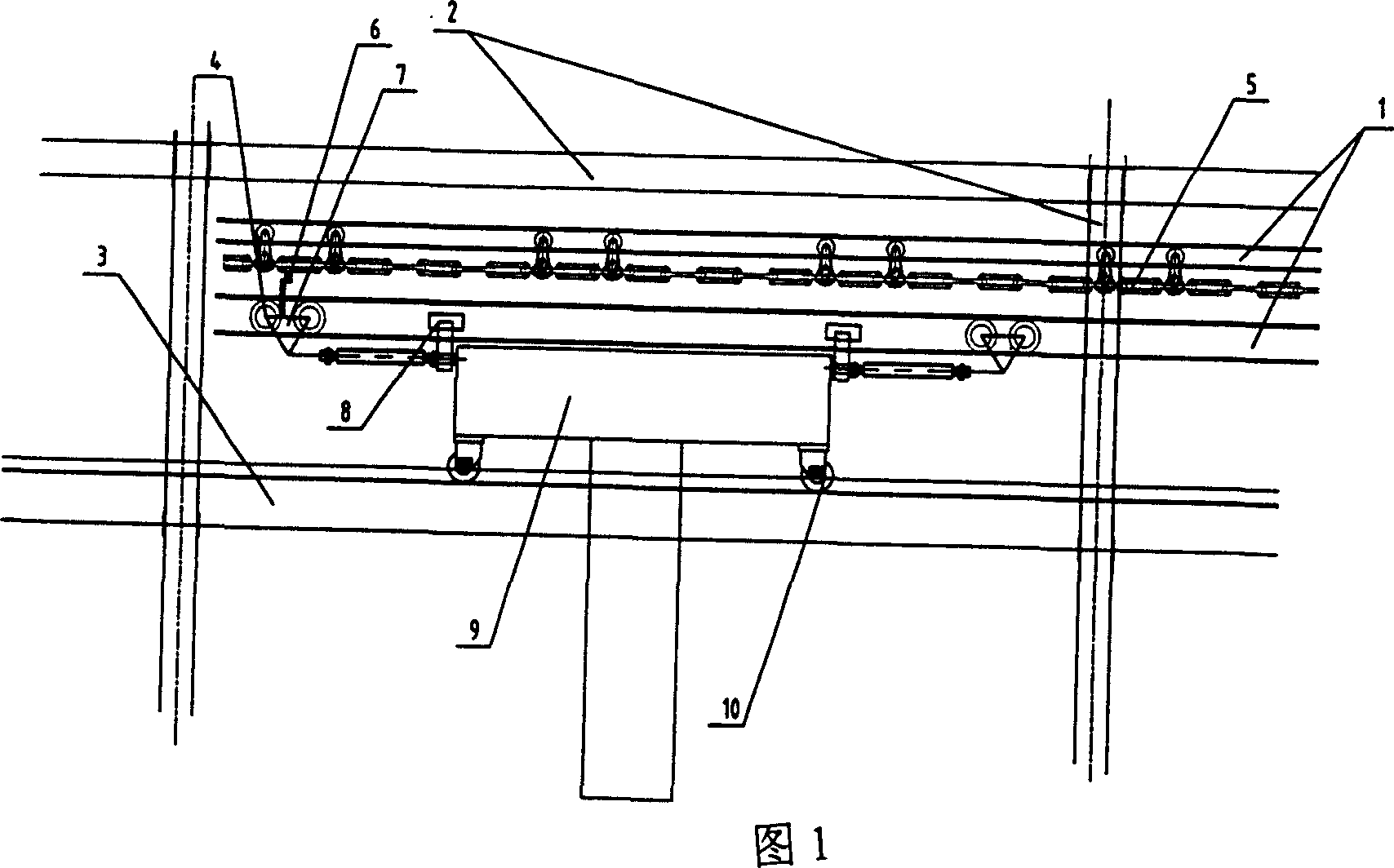

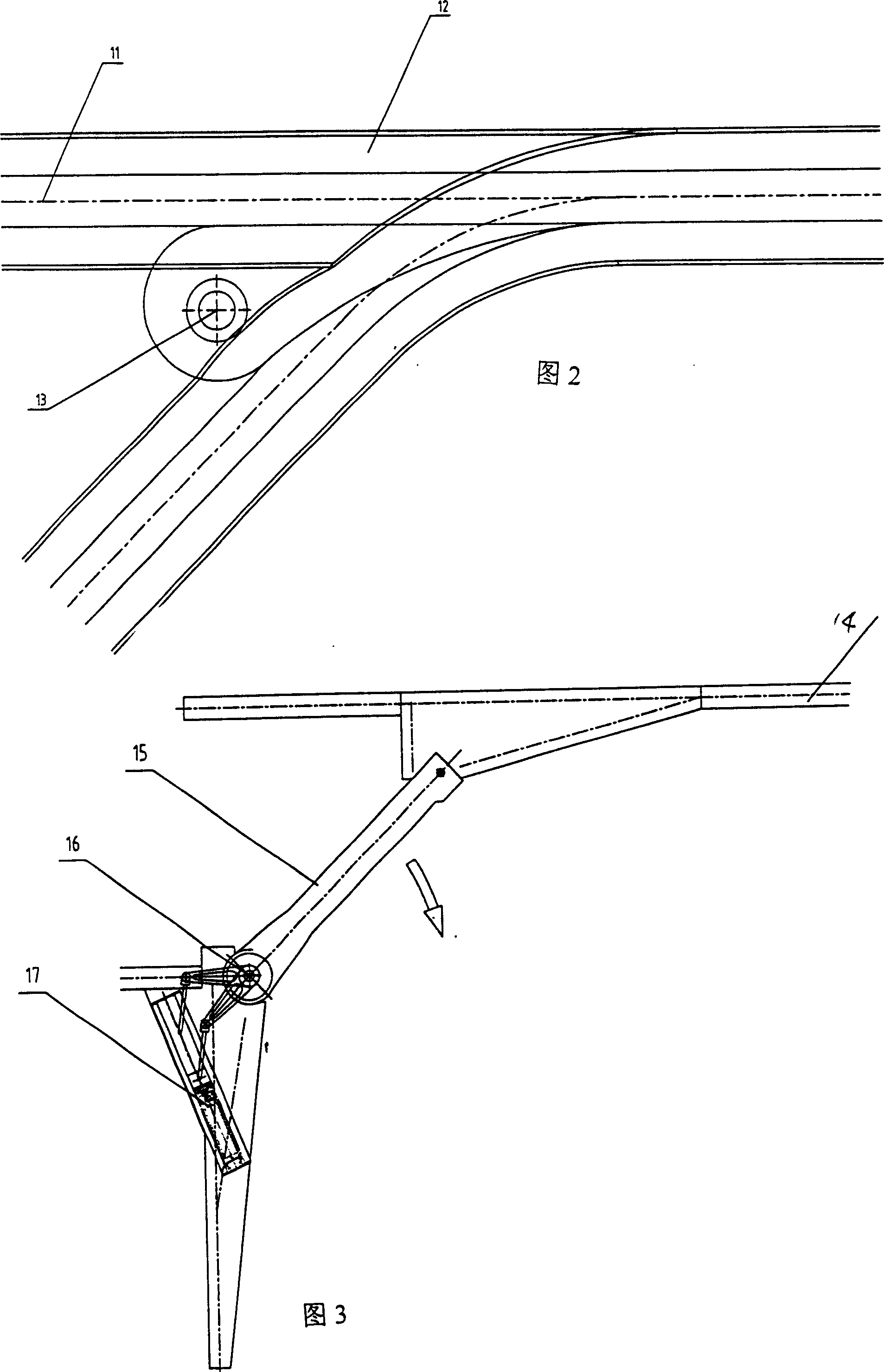

Double bearing track turnout

The invention discloses a double-bearing rail switch, it is characterized by: the conventional switch is installed on the upper layer position, and the multifunctional carriage bearing switch rail is installed right below the conventional switch and is welded by steel structure; the conventional switch includes the upper layer H-bar, the switch of the tail for carrying the lower layer guiding carriage is two channel bars embracing each other. The multifunctional carriage bearing switch rail, its switch is installed on the multifunctional carriage rail surface and is butted with the fore and rear tails, the central switch tongue encircles one end of rotary device and cylinder pushing device is connected with the central switch tongue, when turn the switch, the switch tongue butt joints with tail head in different direction, then realize the role of changing tail direction. The advantages of the invention: using the similar mode with train replacing rail, reversing and transporting the self-carriage and rapidly, it can realizes flexible transmission and rapid, steady and reliable reversing in the transportation of examining and repairing trains and rail vehicles.

Owner:郑卫星

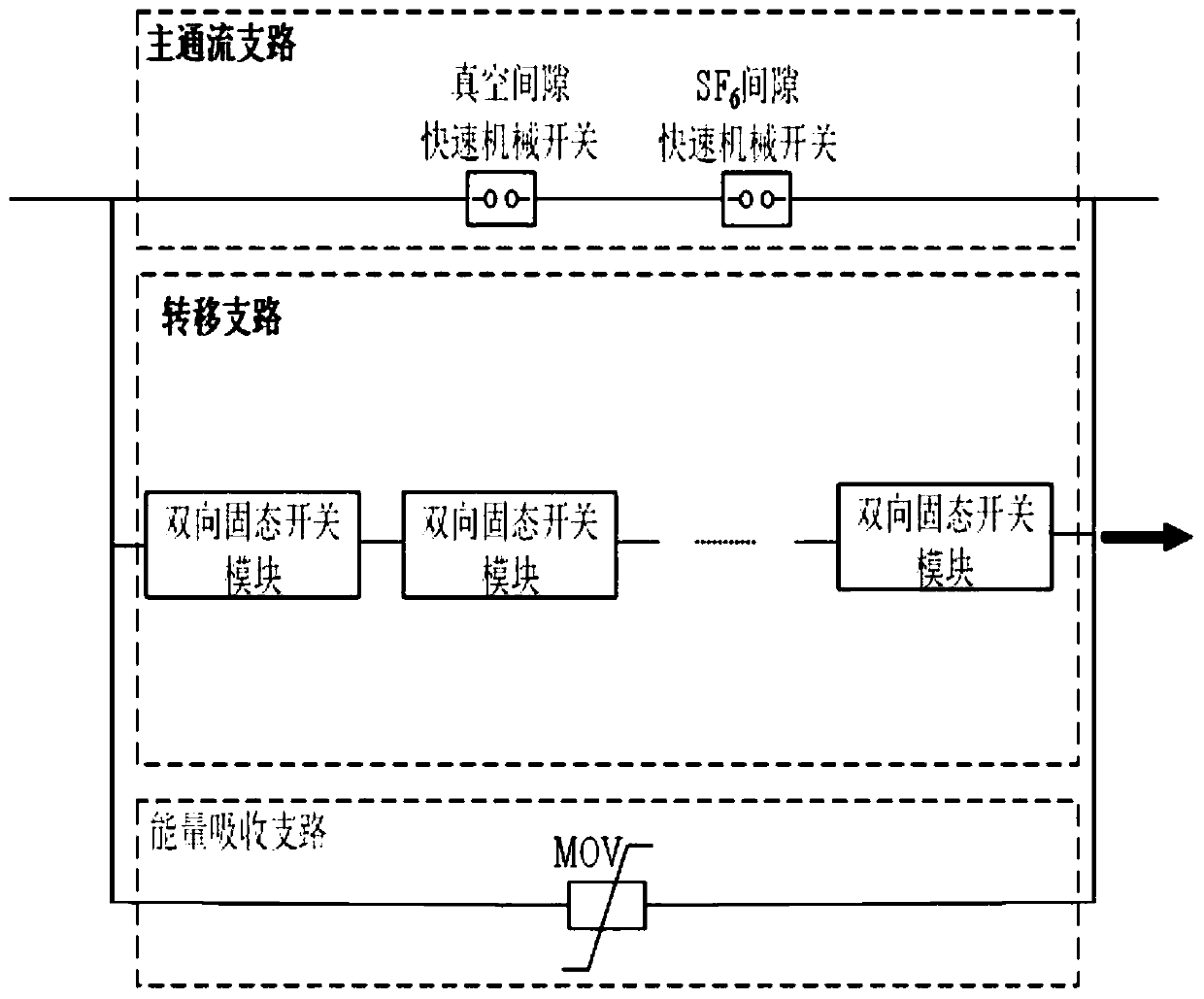

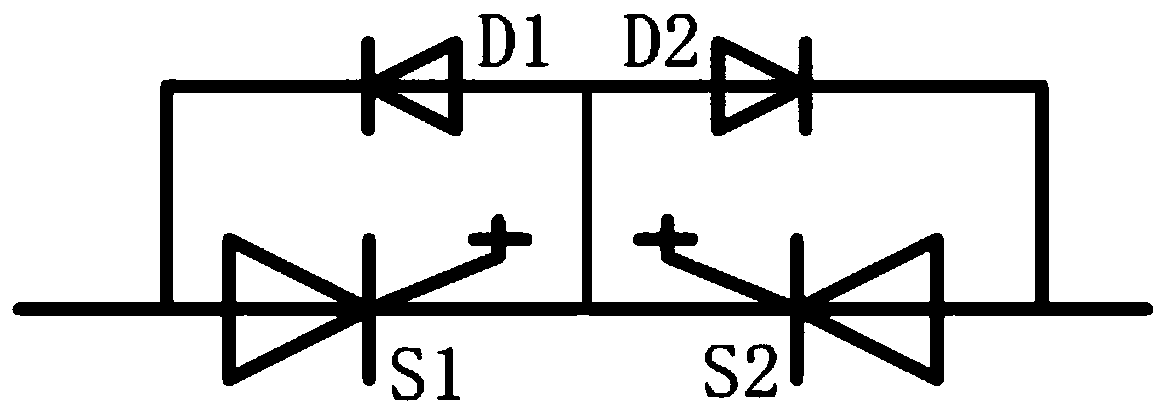

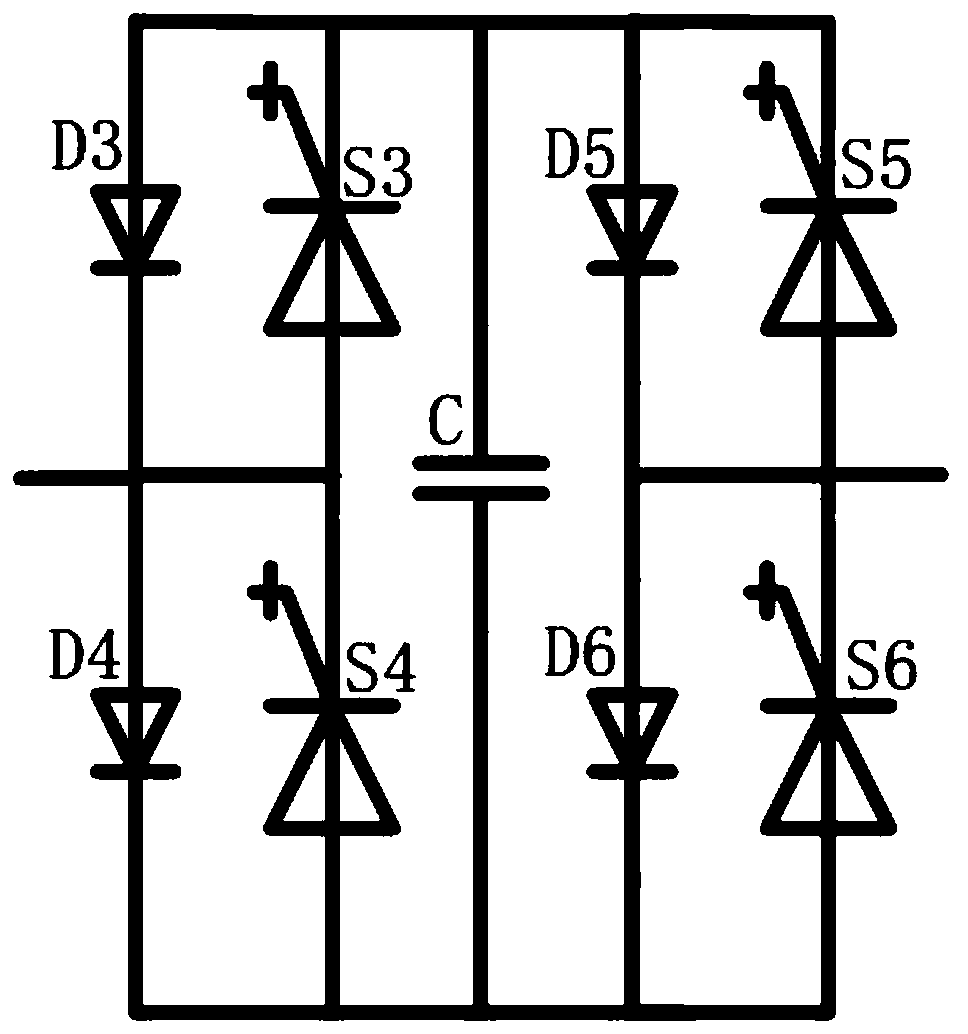

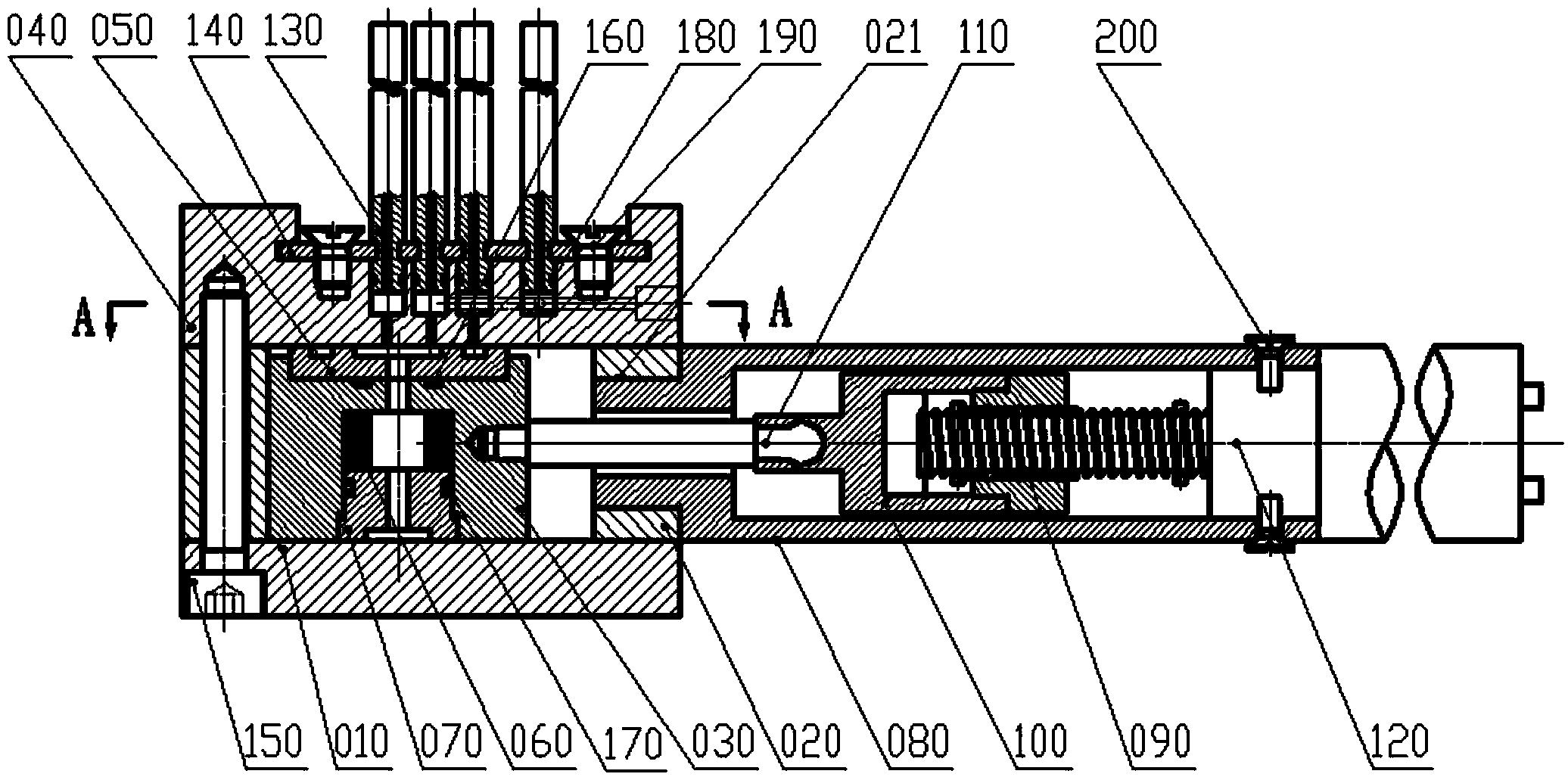

Natural commutation type hybrid DC circuit breaker and current turn-off method of DC system

PendingCN111404127AReduce lossStrong reliability and controllabilityEmergency protective arrangements for limiting excess voltage/currentVacuum gapElectrical current

The invention provides a natural commutation type hybrid DC circuit breaker and a current turn-off method of a DC system, the natural commutation type hybrid DC circuit breaker is composed of a main through-flow branch, a transfer branch and an energy absorption branch, and the main through-flow branch, the transfer branch and the energy absorption branch are connected in parallel; and the main through-flow branch is formed by connecting a vacuum gap rapid mechanical switch and a gas gap rapid mechanical switch in series. The natural commutation type hybrid DC circuit breaker has the characteristics of near zero on-state loss, reclosing and current differentiation support, reliable commutation, high controllability, compact size, small occupied area, low cost and the like.

Owner:TSINGHUA UNIV

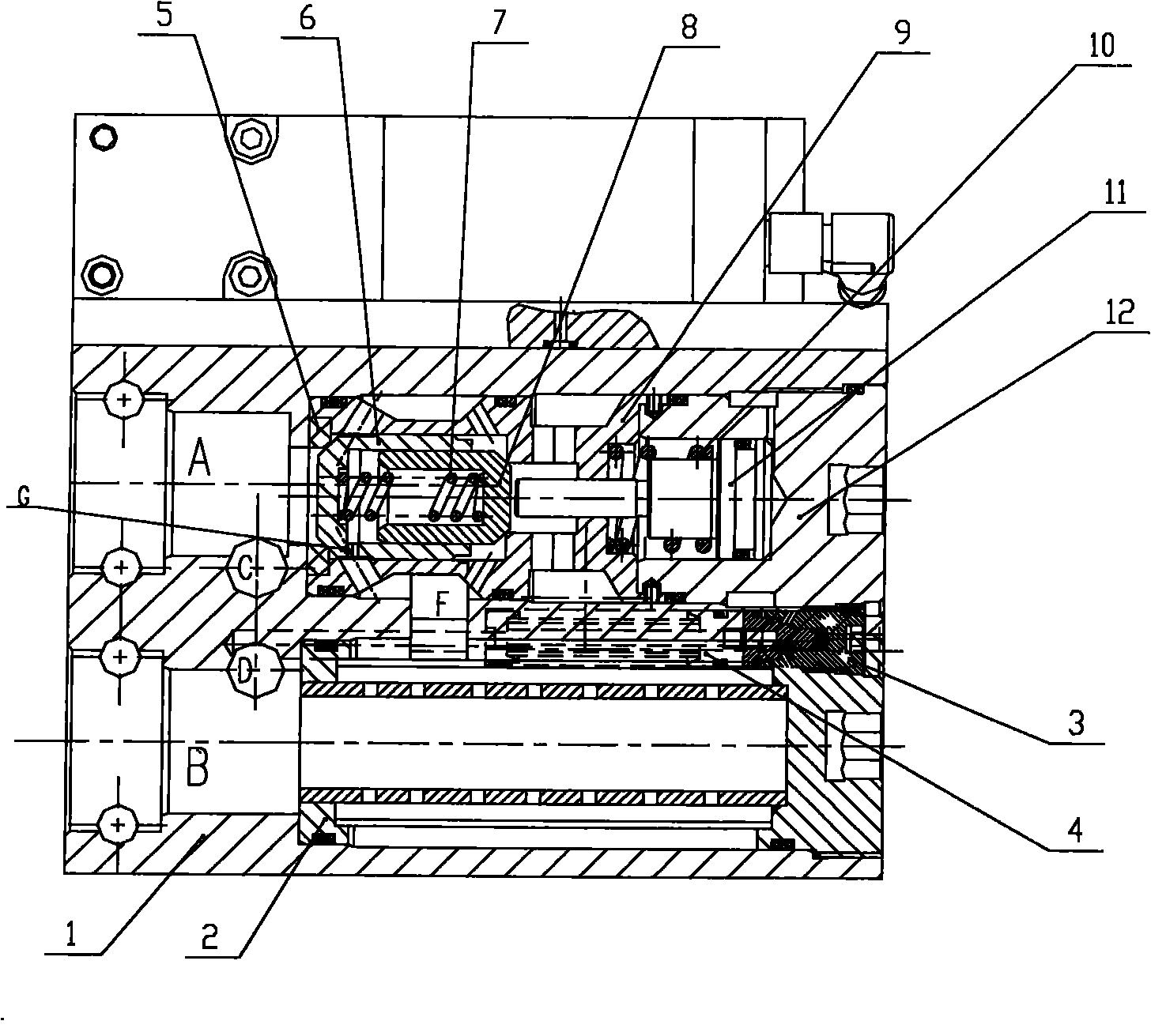

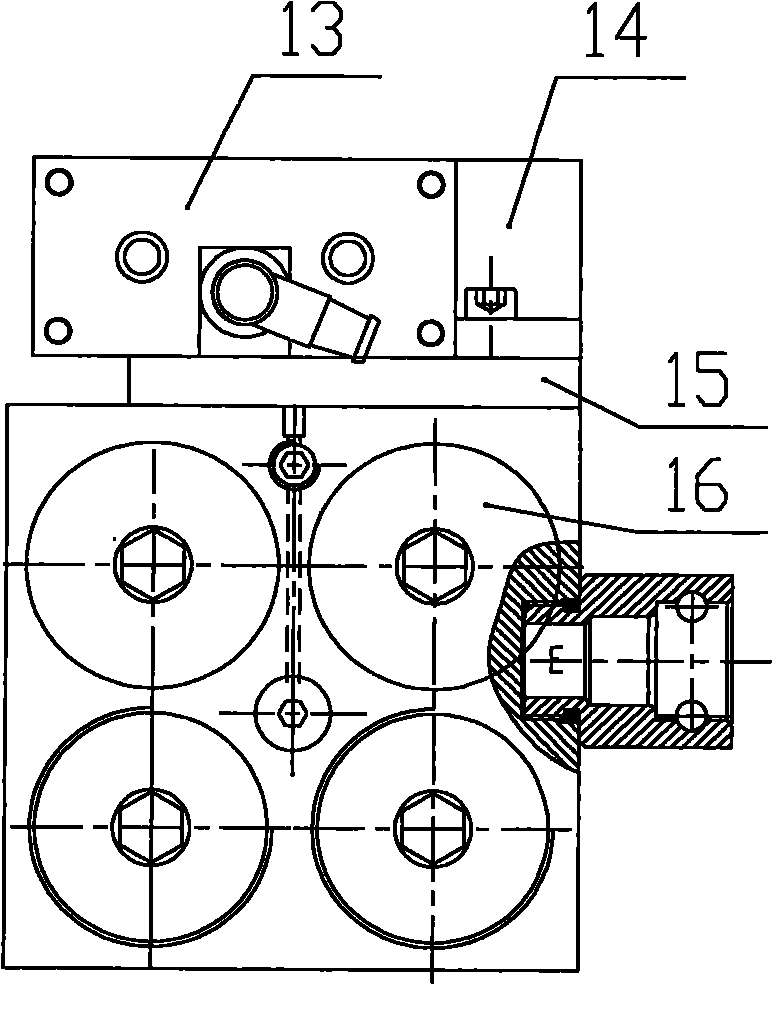

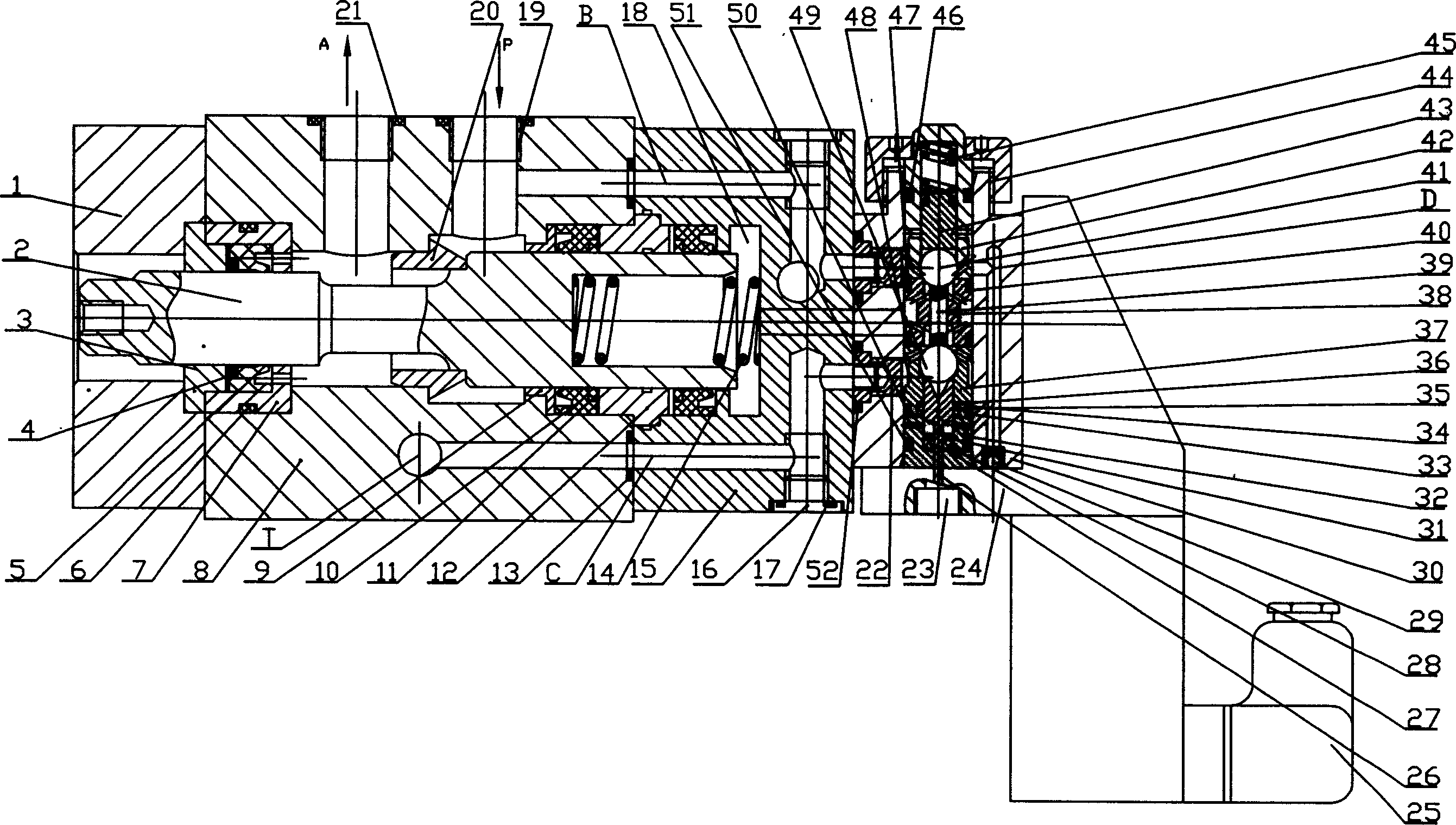

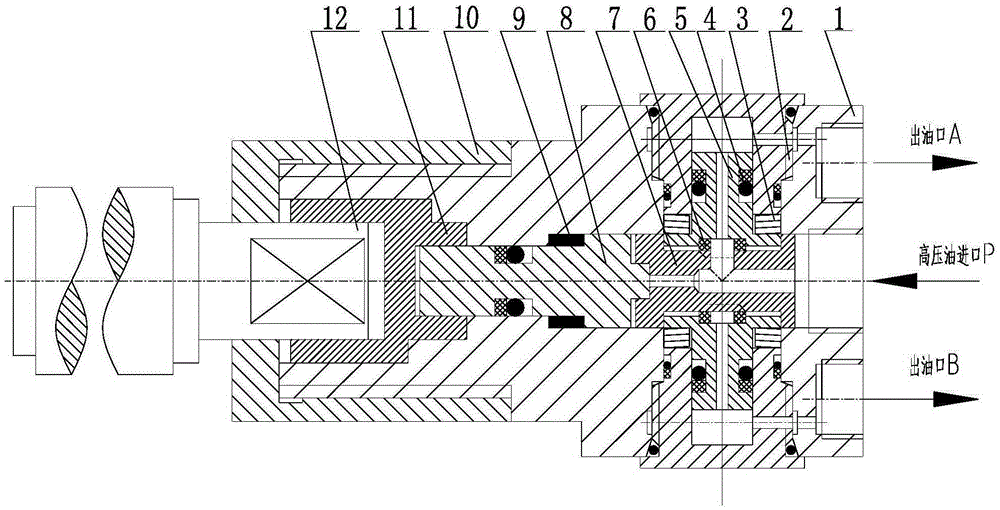

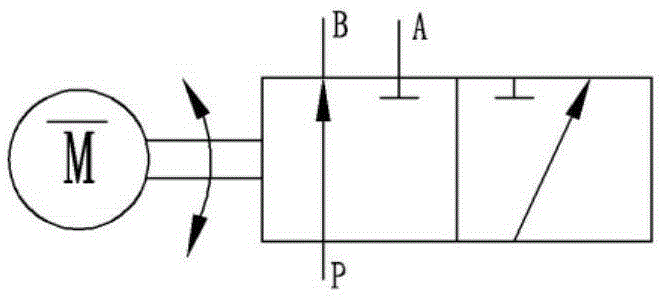

Plane sealing type reversing valve

ActiveCN104344017ACommutation is reliableAchieving Zero LeakageServomotor componentsMultiple way valvesFluid controlBall screw

The invention discloses a plane sealing type reversing valve which belongs to hydraulic control valves and is used for the fluid switching of a plurality of channels and solving the problem that the reversing valves at present are relatively large in reversing operation force, bad in anti-pollution capacity, high in processing difficulty and high in cost. The plane sealing type reversing valve comprises a lower valve seat, a support seat, a sliding block, an upper valve seat, a fixed valve element, a disc spring, a floating valve element, a sleeve, a ball screw assembly, a connection threaded sleeve, a push rod and a gear motor. According to the plane sealing type reversing valve, plane sealing is used, and the small rotary gear motor with the ball screw assembly is used for linear driving to drive the sliding block to move straightly and control the reversing of the oil path. The plane sealing type reversing valve is simple in structure, convenient in interface form and good in manufacturability, is capable of reliably realizing the sealing of the entire life cycle and ensuring the reliable reversing of the hydraulic systems, is suitable for standard and serial production and suitable for the high-temperature high-pressure severe environments and working conditions such as petroleum and natural gas extraction, and can be used for the fluid control of various hydraulic systems.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for sensorless operation of an electronically commutated motor and motor for carrying out such a method

ActiveUS8058825B2Commutation is reliableSimplified generationMotor/generator/converter stoppersAC motor controlPermanent magnet rotorDifferential signaling

An electronically commutated motor (ECM) often employs a Hall sensor for reliable operation. Even when a Hall sensor is omitted from a motor having a plurality of stator winding phases (24, 26) and a permanent-magnet rotor (22), one can reliably detect direction of rotation of the rotor by the steps of: (a) differentiating a voltage profile obtained by sampling either (1) induced voltage in a presently currentless phase winding or (2) voltage drop at a transistor, through which current is flowing to a presently energized phase winding, and (b) using such a differentiated signal (du—24″ / dt, du—26″ / dt) to control current flow in an associated phase winding. In this manner, one obtains reliable commutation, even if the motor is spatially separated from its commutation electronics.

Owner:ELEKTROSIL SYST DER ELEKTRONIK

Back washing filter

ActiveCN101816847AProtection lifeReduce damage rateGravity filtersStationary filtering element filtersCore componentPilot valve

The invention discloses a back washing filter which comprises a valve body, wherein the valve body is provided with a liquid inlet, a liquid outlet and a drain outlet; a plurality of valve core components and a plurality of filter core components are arranged in the valve body; communicating channels are arranged between the valve core components and the filter core components; each valve core component comprises a liquid valve core and a drain valve core which are arranged back to back; small springs are arranged between liquid valve cores and drain valve cores; the rear ends of the drain valve cores are provided with push rods. The back washing filter also comprises a filter guide core, a non return valve and a pilot valve; the liquid outlet is communicated with liquid cavities at the rear ends of the pushing rods sequentially though the filter guide core, the non return valve and the pilot valve and is used for controlling conversion between a normal operating position and a back washing position. The invention has the advantages of convenient use and effect prolonging of the service life of the filter core.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

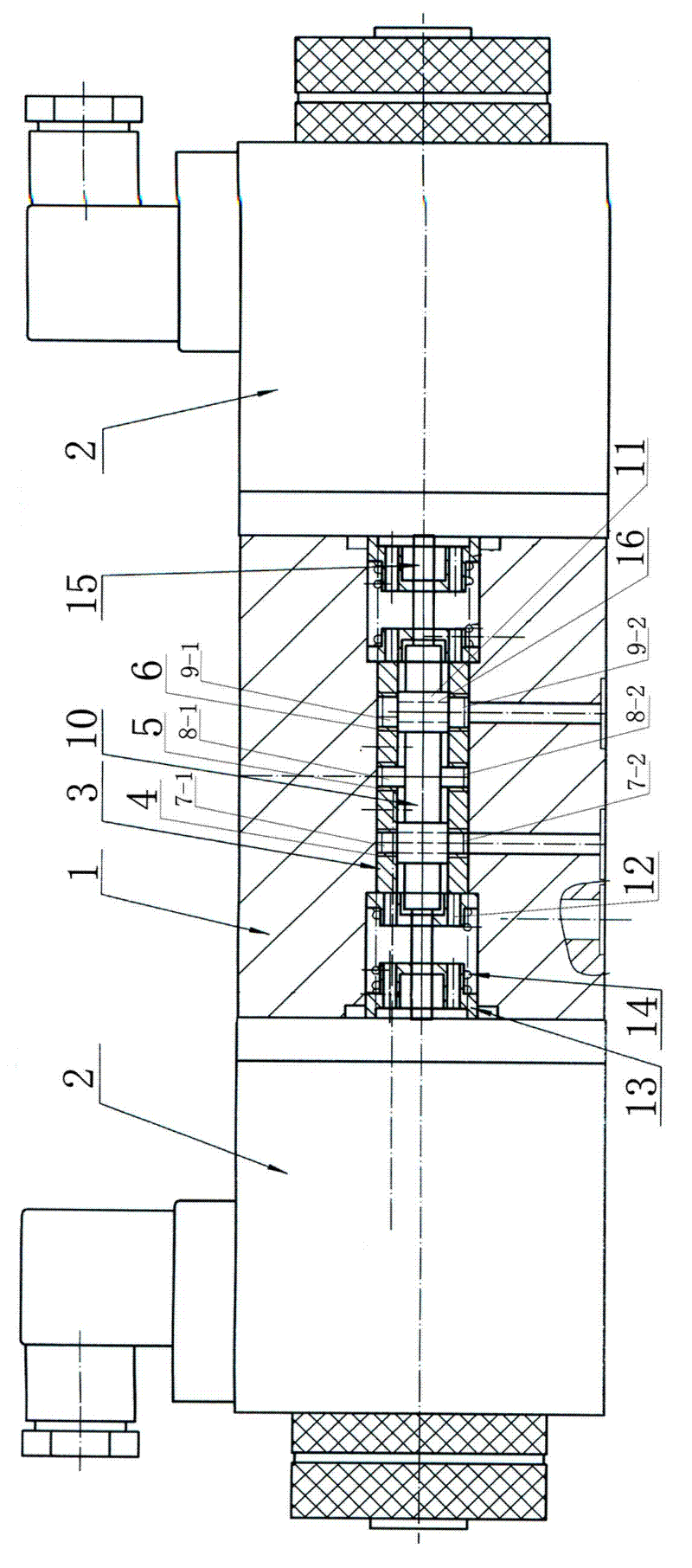

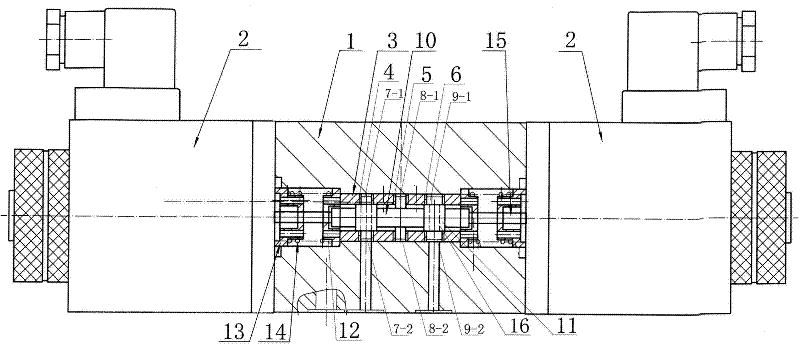

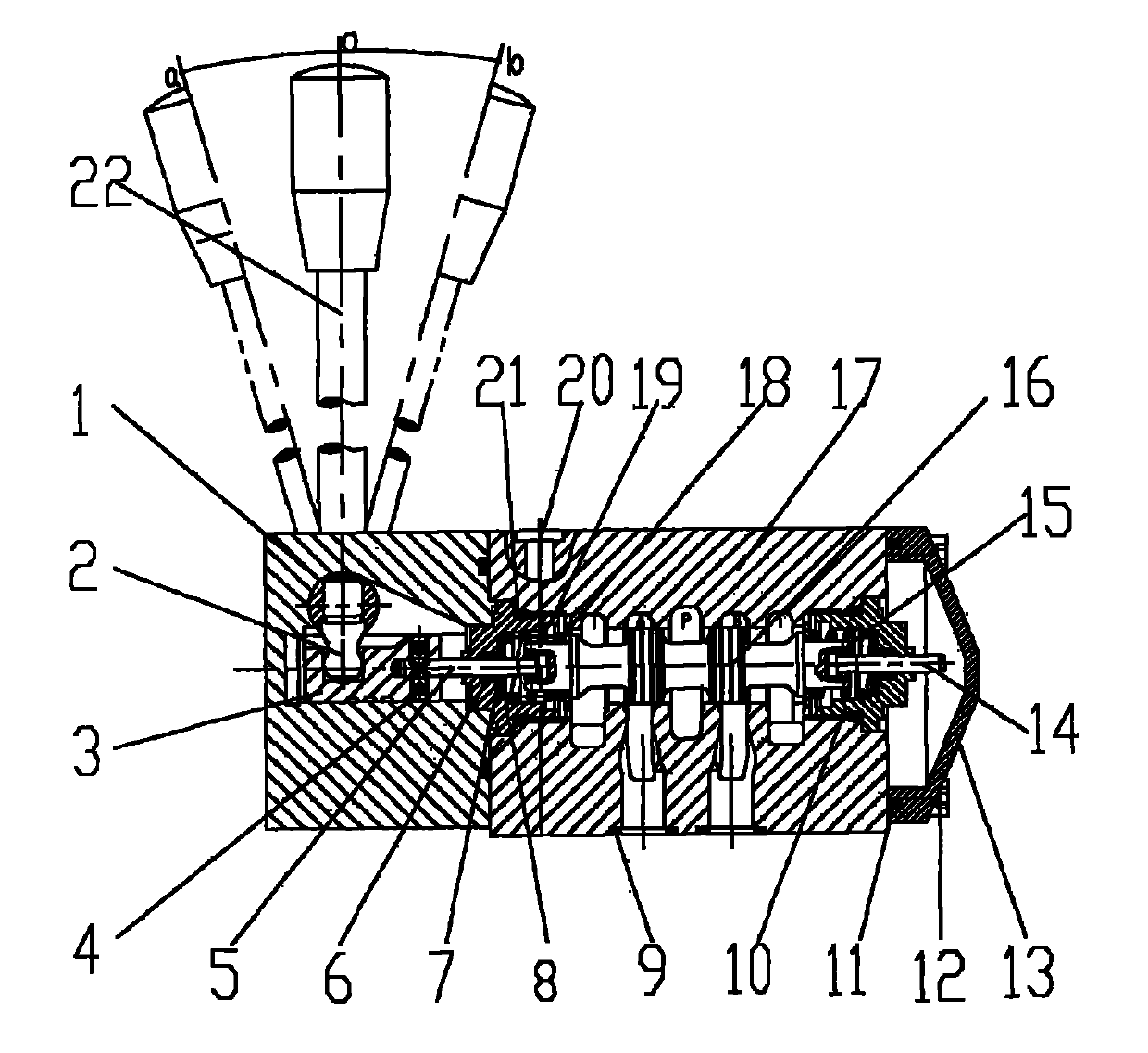

Ultrahigh-pressure three-position four-way electromagnetic reversing valve

InactiveCN102364179ARestore mutual closureIncrease bearing pressureOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

The invention discloses an ultrahigh-pressure three-position four-way electromagnetic reversing valve and relates to the technical field of fluid pressure executing mechanisms. The ultrahigh-pressure three-position four-way electromagnetic reversing valve comprises a valve body, wherein a through hole is formed in the valve body; electromagnets are connected at two ends of the through hole; an oil distributing sliding sleeve is sleeved in the through hole; a first annular undercut groove, a second annular undercut groove and a third annular undercut groove are formed on the outer periphery of the oil distributing sliding sleeve; an oil inlet is formed on the second annular undercut groove; a first oil outlet is formed on the first annular undercut groove; a second oil outlet is formed on the third annular undercut groove; a valve core is arranged in the oil distributing sliding sleeve; annular blocks matched with the first oil outlet and the second oil outlet are arranged in the length direction of the valve core; spring bases are arranged in the through hole and between the two ends of the oil distributing sliding sleeve and the two electromagnets; each spring base is provided with an inner base body and an outer base body; and a spring is connected and a push rod is arranged between each group of the inner base body and the outer base body. A slide valve structure is easy to reverse under high pressure.

Owner:张家庆

Manual reversing valve for ship

InactiveCN102563120ASmall rotational frictionStrong rust resistanceOperating means/releasing devices for valvesMultiple way valvesEngineeringCopper

The invention discloses a manual reversing valve. A valve core is driven to move by rotation of a handle, so that connection and disconnection of oil ports are determined, and the required functions are obtained; and the oil sealing reliability of the valve core in the moving process is ensured by an effective sealing form. Leakage of oil and intrusion of dust and moisture are effectively prevented by a sealing ring at each position. A valve body, a front cover and a rear cover of the valve are obtained by casting, so that the machining time is greatly reduced. Parts such as a copper bush, a hinge shaft, a pin, a push rod, a locking screw and the like for forming a manual mechanism are placed in the front cover. The valve core, a retainer ring, a spring, a gasket, a sealing element, an end face screw cover and the like are arranged in the valve body. The rear cover plays a role in water proofing and dust resistance.

Owner:SHANGHAI LIXIN HYDRAULIC

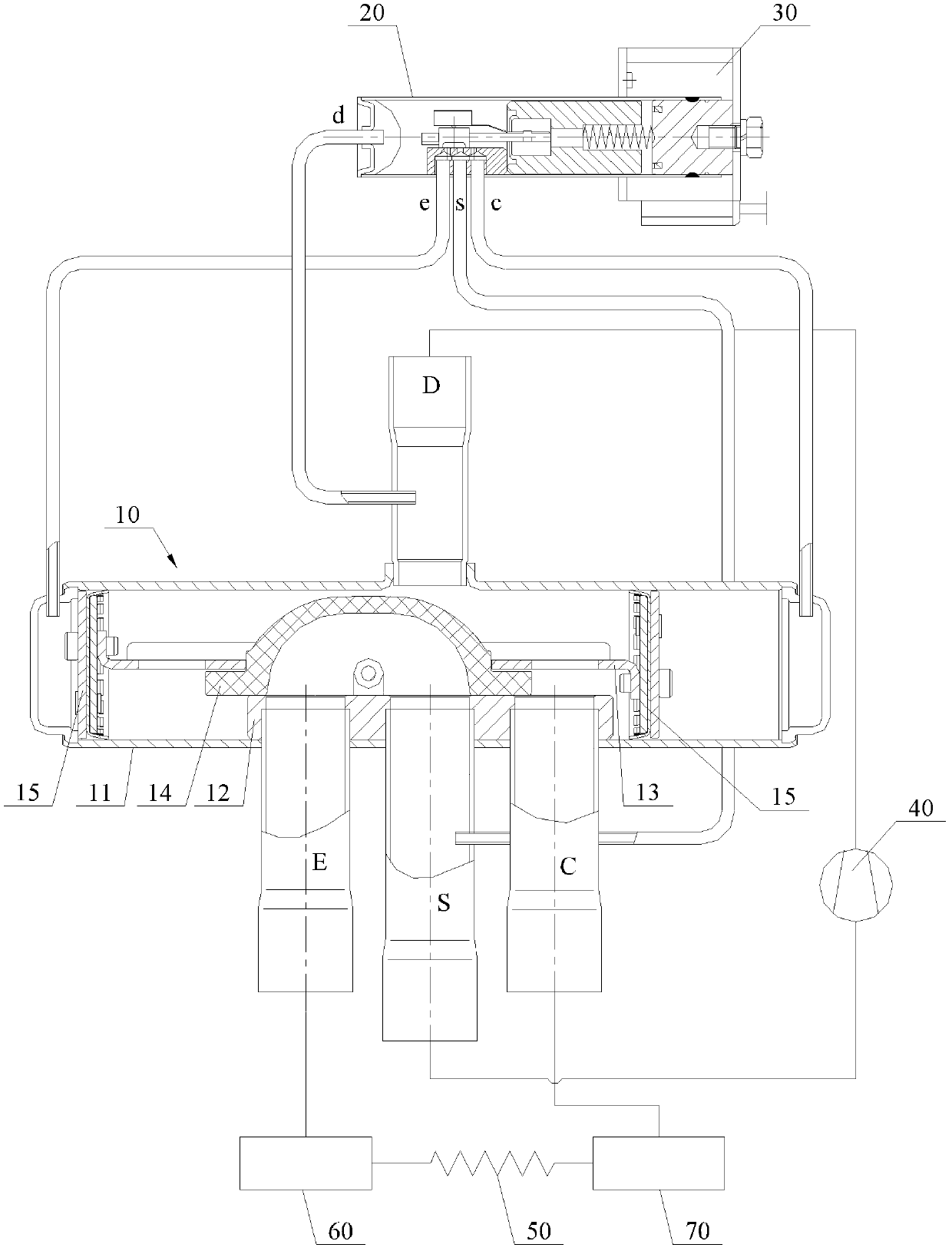

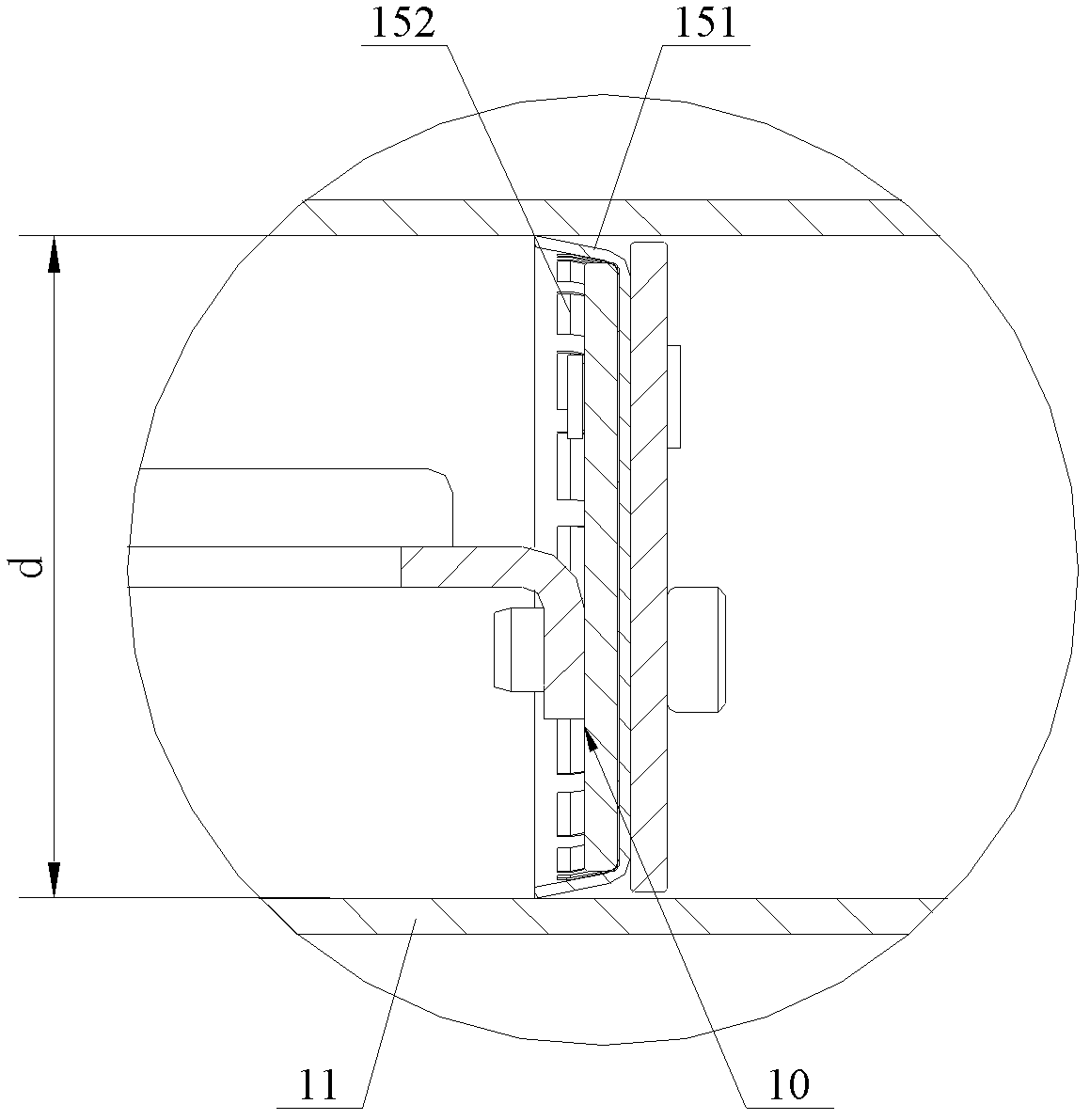

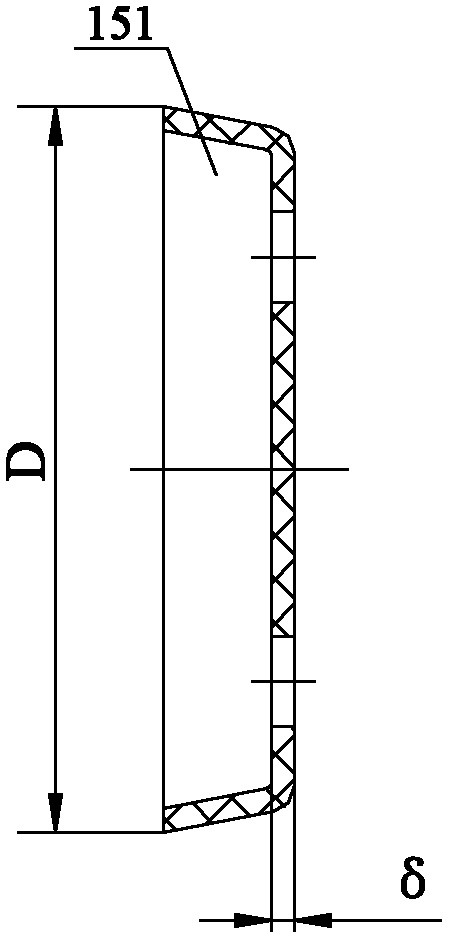

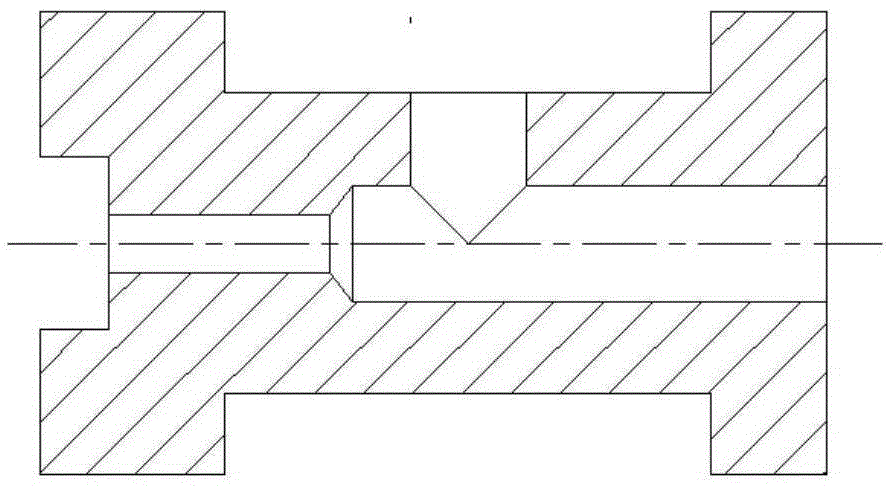

Main valve of four-way reversing valve and four-way reversing valve provided with main valve

InactiveCN103291957AOptimize structure sizeReduce coefficient of frictionOperating means/releasing devices for valvesMultiple way valvesEngineeringAir conditioning

The invention discloses a main valve of a four-way reversing valve. The main valve comprises a valve body, two piston devices and sliding blocks, wherein the piston devices are arranged in the valve body and connected through a connecting rod; the sliding blocks and the piston devices move synchronously; piston cups and piston spring pieces are arranged in the piston devices, the piston cups are glidingly matched with the inner wall of the valve body, and the piston spring pieces are arranged in the piston cups and provide radial action force; the thickness of each piston cup is 0.55-0.65mm, and the thickness of each piston spring piece is 0.11-0.15mm; and the piston cups are made of materials by weight of 85%-95% of a polytetrafluoroethylene base material and 5%-15% of an additive capable of reducing friction coefficients. By means of optimization and improvement in two aspects of structure dimension and material selection, the adaptability of the four-way reversing valve is effectively improved, and configuration requirements of different air conditioning systems can be met. On the basis, the invention further provides a four-way reversing valve provided with the main valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

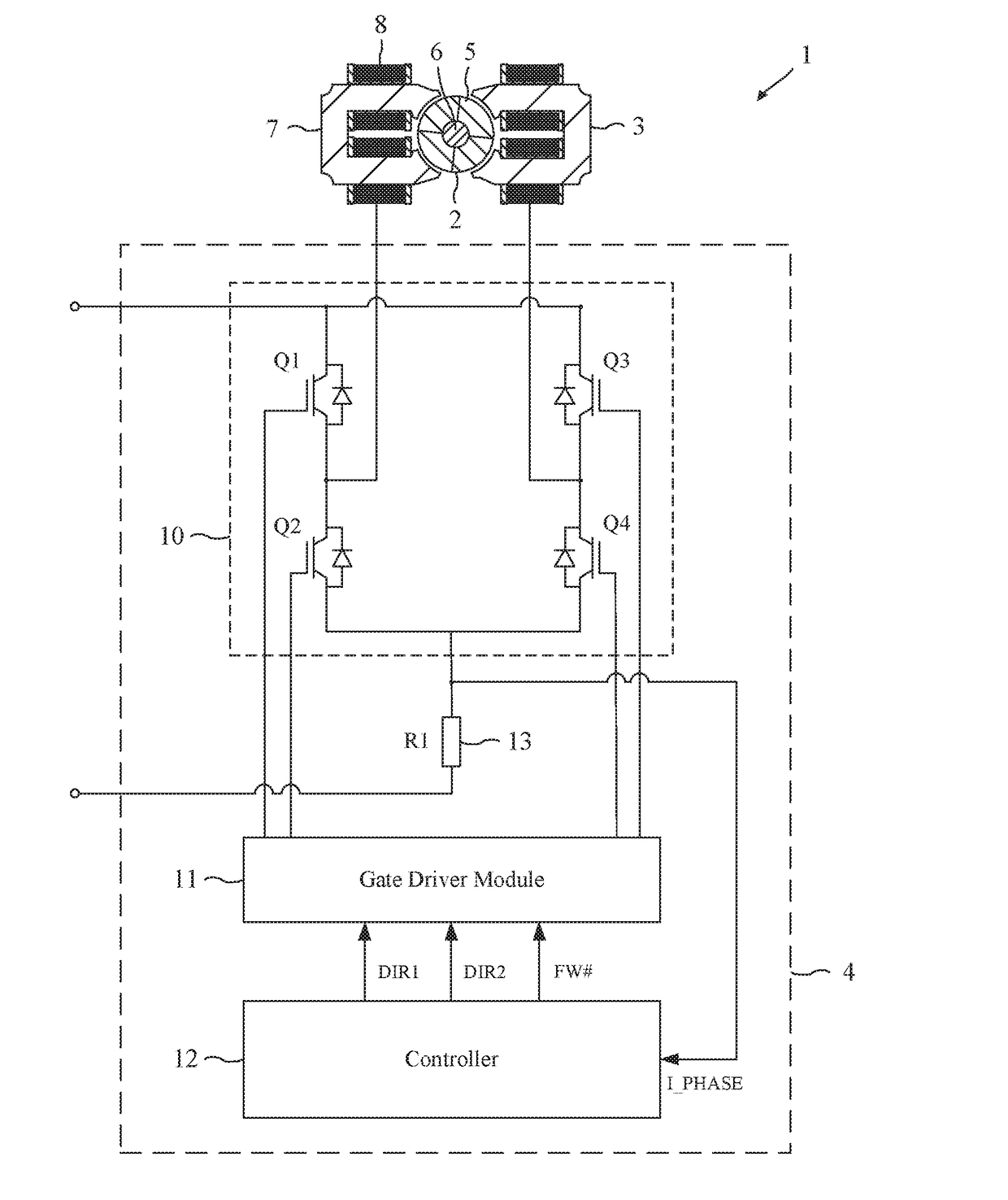

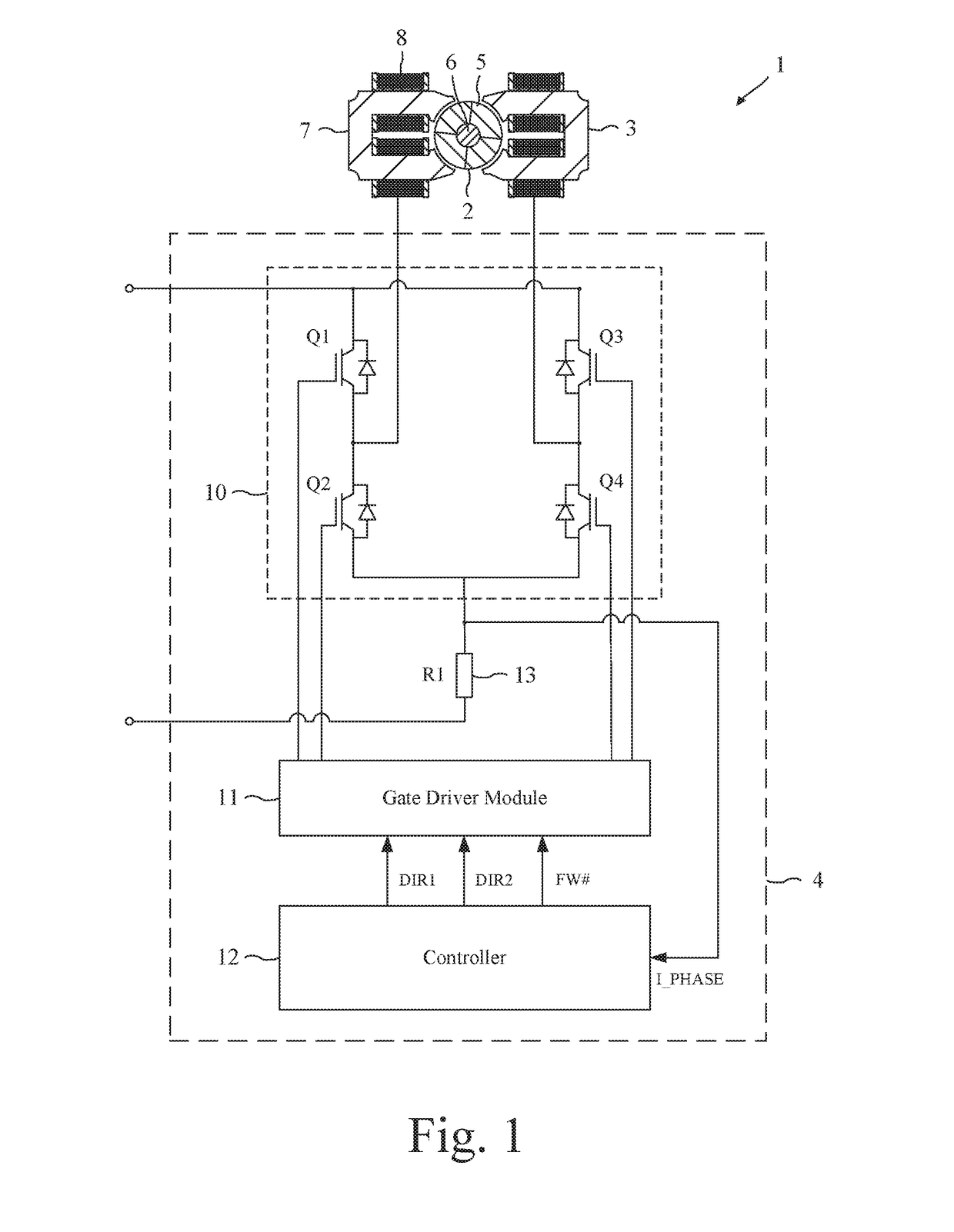

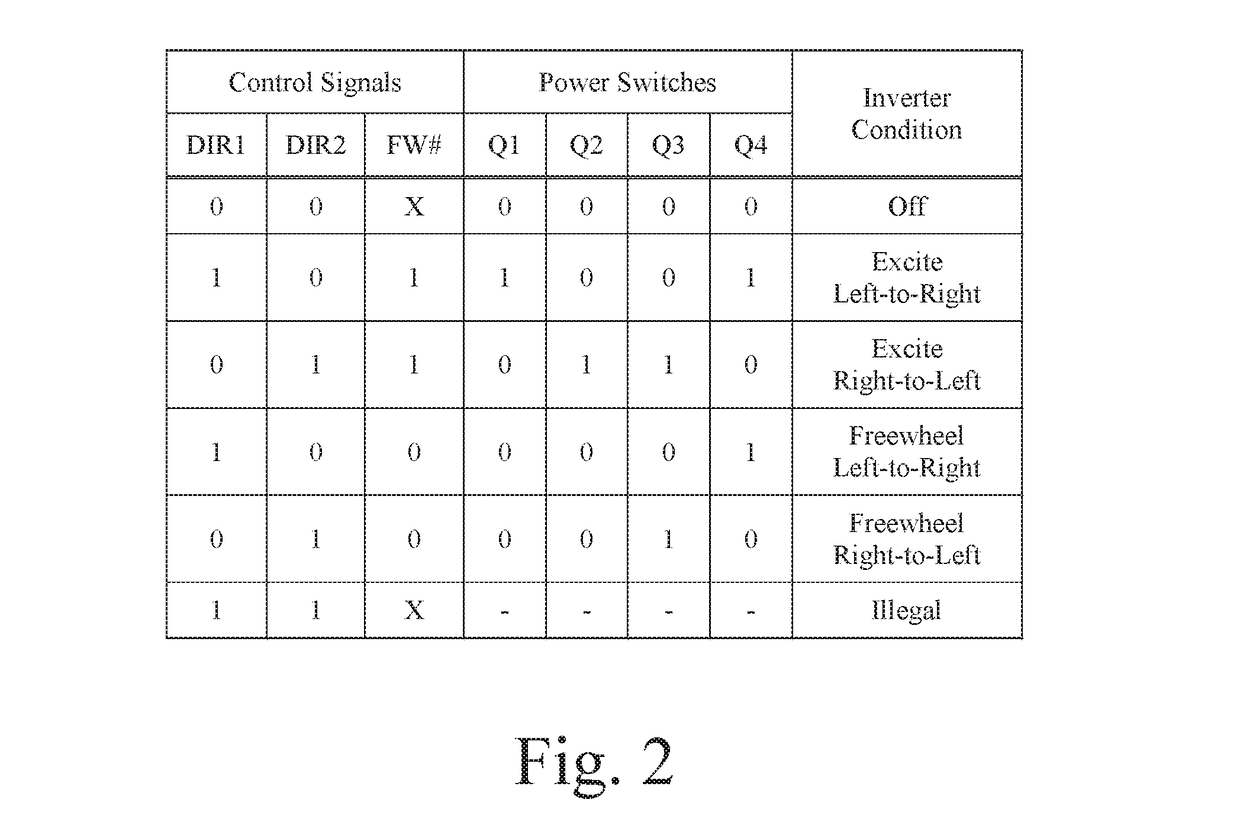

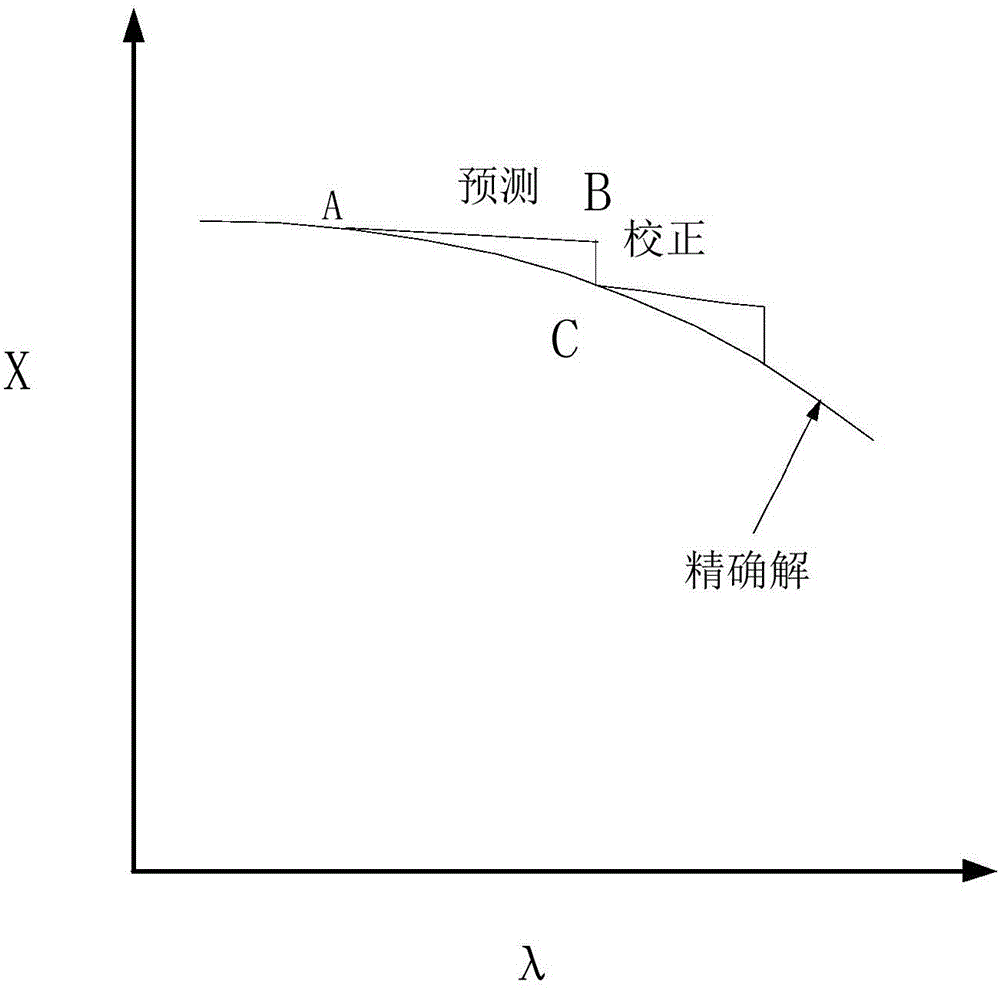

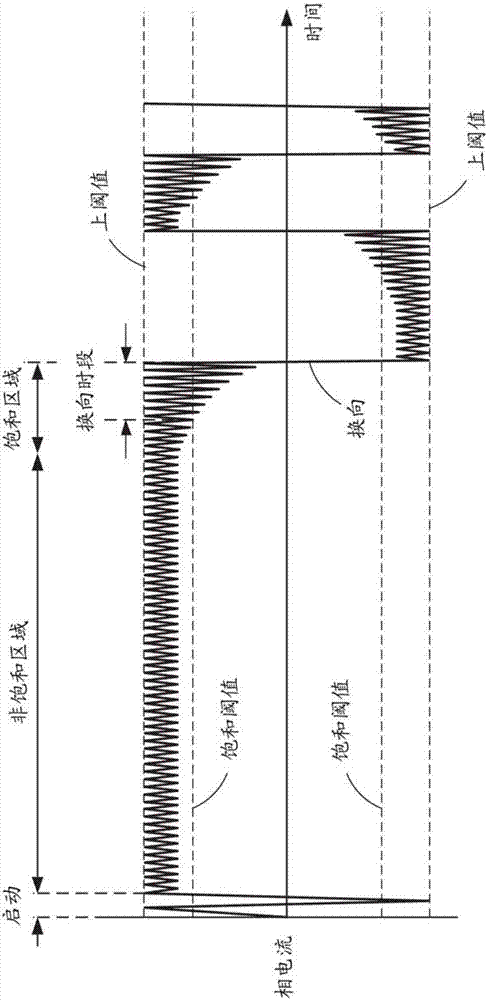

Method of determining the rotor position of a permanent-magnet motor

ActiveUS20170310255A1Reduce inductanceIncrease ratingsAC motor controlSingle phase motor controlPhase currentsElectric machinery

A method of determining the position of a rotor of a brushless permanent-magnet motor is provided. The phase winding is freewheeled when a phase current exceeds an upper threshold. The method further includes measuring a parameter that corresponds to either: (i) the magnitude of the phase current during or at the end of freewheeling when the phase winding is freewheeled for the fixed period of time, or (ii) the time interval between the start and end of freewheeling or the start and end of excitation when the phase winding is freewheeled until the phase current falls below the lower threshold. The measured parameter is then used to define a saturation threshold. The phase winding is subsequently excited and freewheeled in the same manner, and the parameter is measured again. The method then compares the measured parameter against the saturation threshold, and determines that the rotor is at a predetermined position.

Owner:DYSON TECH LTD

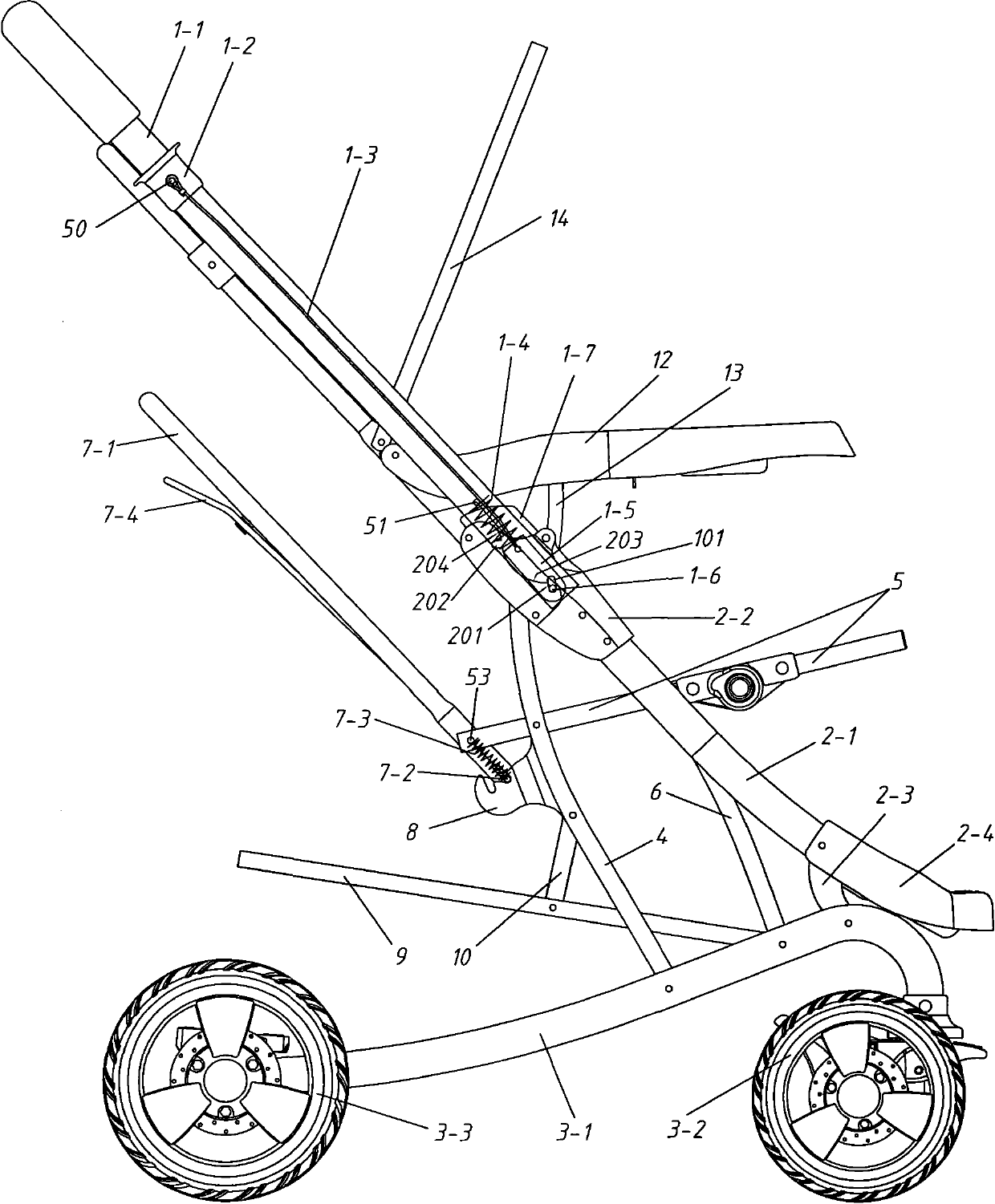

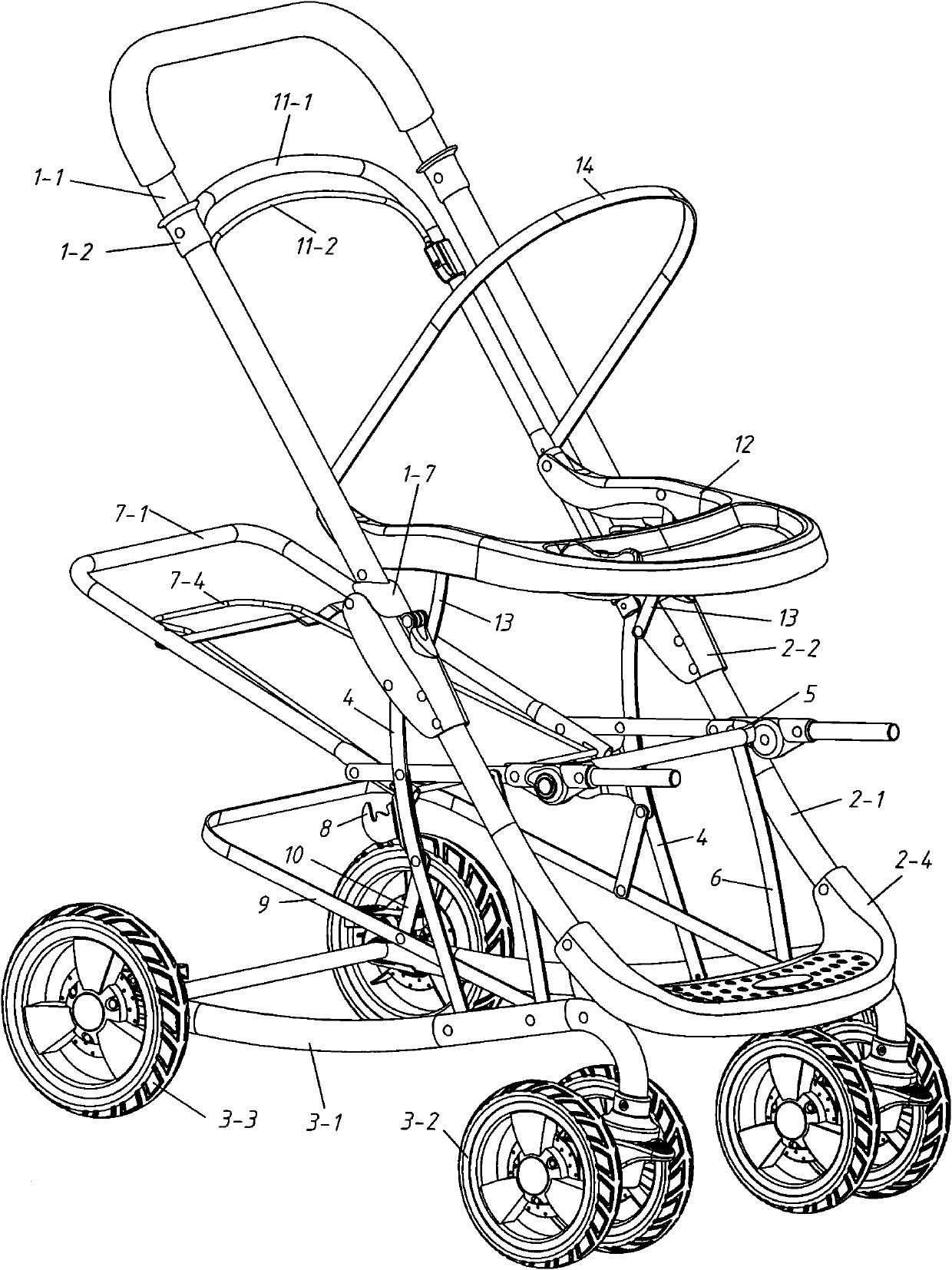

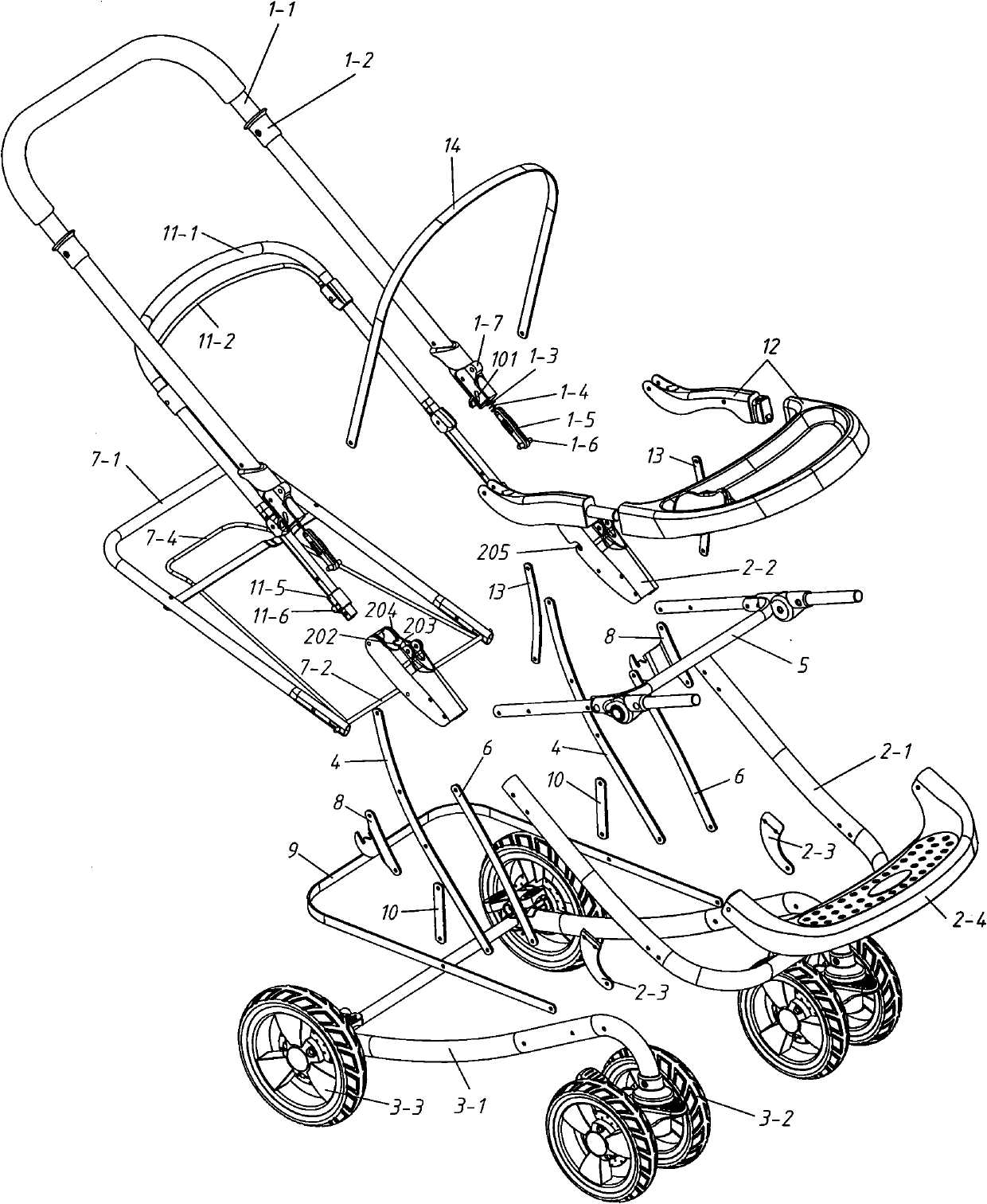

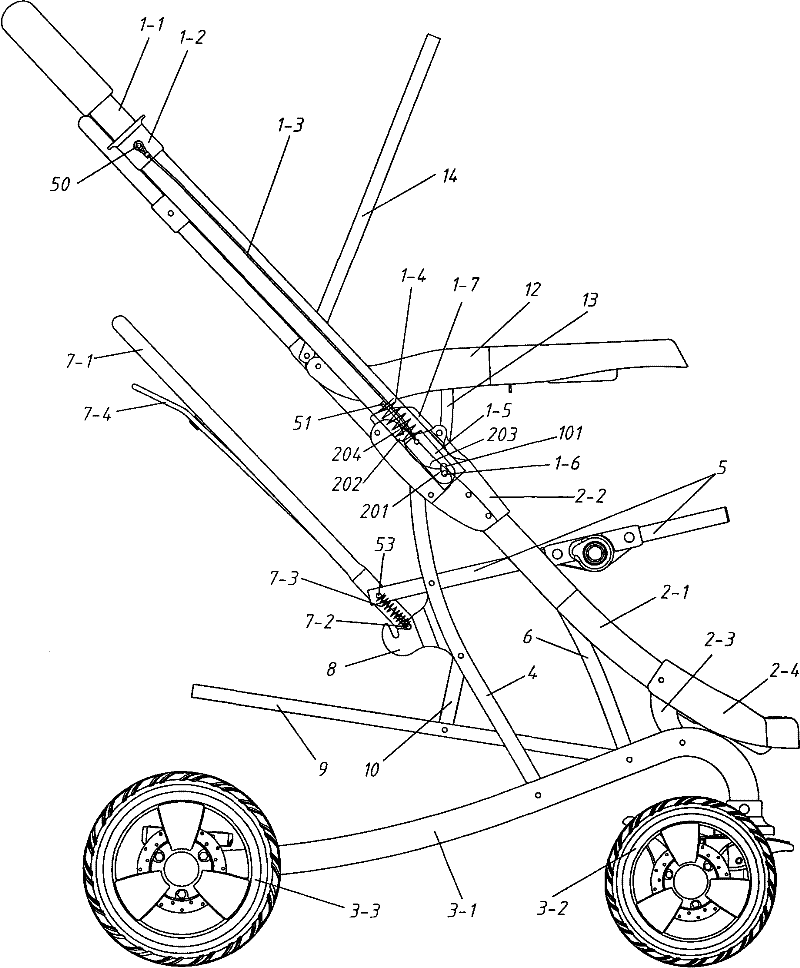

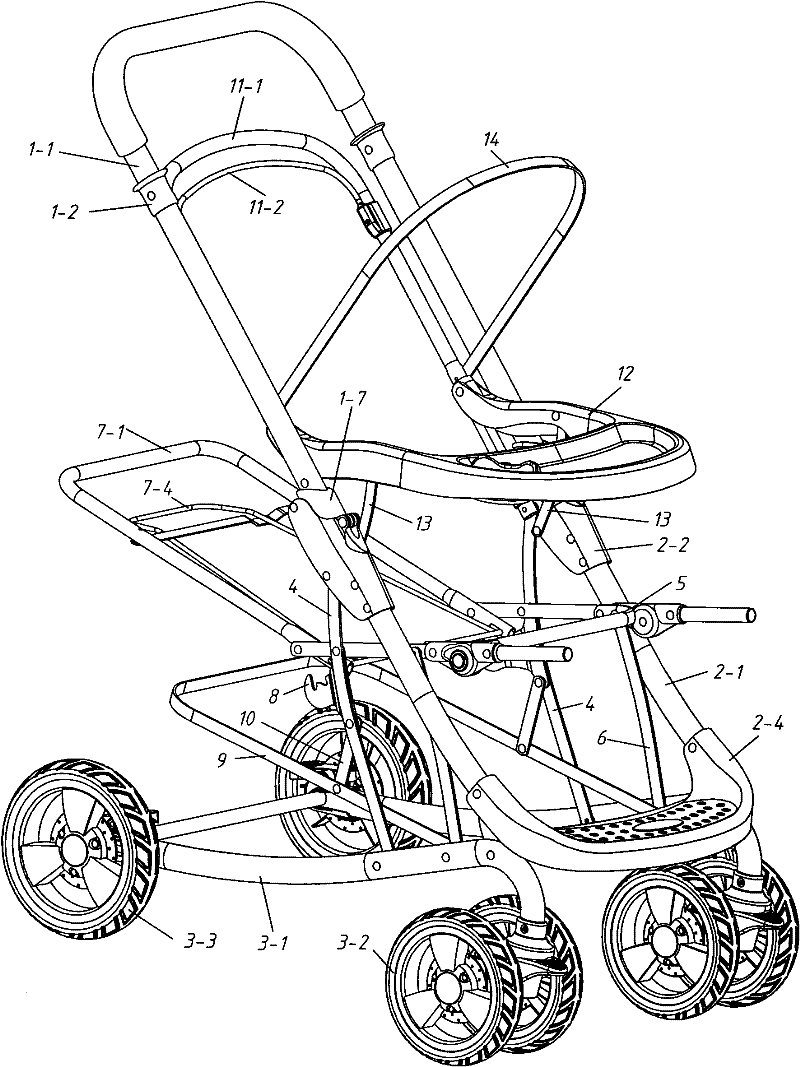

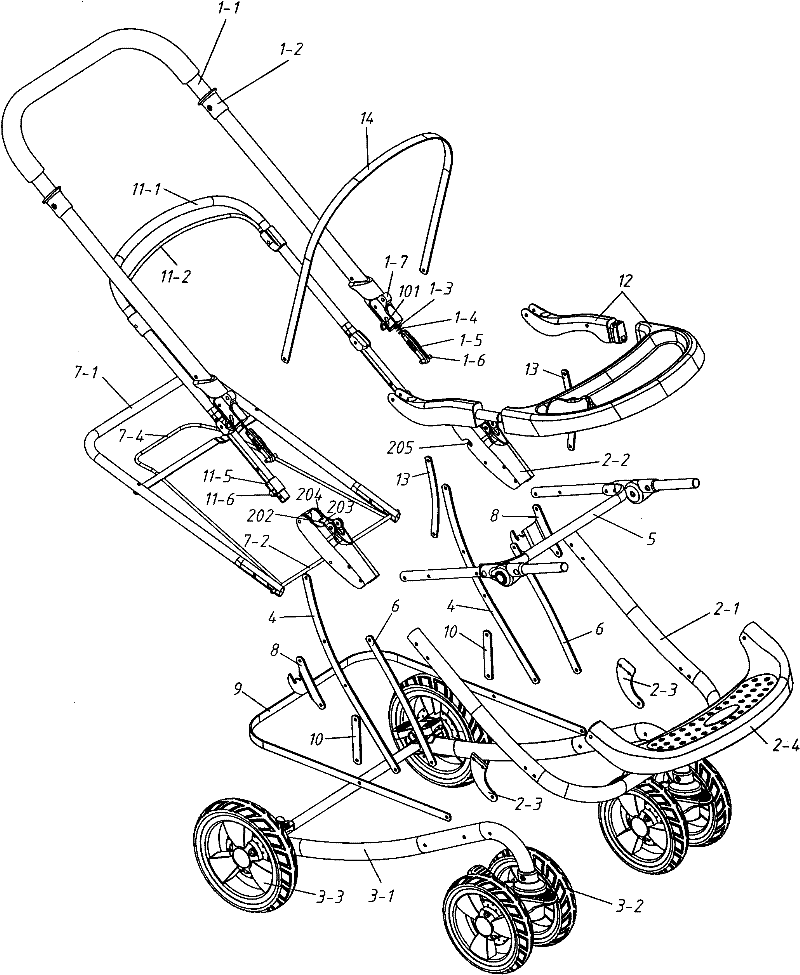

Foldable baby carriage capable of being pushed in reverse direction

InactiveCN101767600AReasonable structureStable supportCarriage/perambulator with multiple axesEngineeringMechanical engineering

The invention discloses a foldable baby carriage capable of being pushed in a reverse direction. The invention is characterized in that a push-hold frame is provided with an inverting handle interlocked with a pulling cable; the pulling cable is connected with a positioning piece connecting seat which forms a positioning piece; the upper end of the connecting seat jacks up an offsetting spring; the other end of the offsetting props against the inside of the push-hole frame upwards; the side of an upper inverting seat is provided with a kidney-shaped hole and the positioning piece penetrates through the hole; a first positioning part and a second positioning part are formed at a lower inverting seat and are matched with the positioning piece; a first guide surface is formed between the two positioning parts for transition; when the push-hold frame is pushed in a forward direction, the positioning component penetrates through the kidney-shaped hole and is clamped at the first positioning part; the positioning component slides to be clamped at the second positioning part along the first guide surface, and by this time, the push-hold frame is pushed in a reverse direction; both ends of a rear hood frame are rotatably connected with the lower inverting seat; and a retracting device is arranged between the rear hood frame and the lower inverting seat. The invention has the advantages of high strength of the reverse mechanism, reliable inverting and folding operation, smooth conversion, adjustable angle of the backrest and small volume because front wall components are retracted inwards after being folded.

Owner:NINGBO SHENMA GROUP

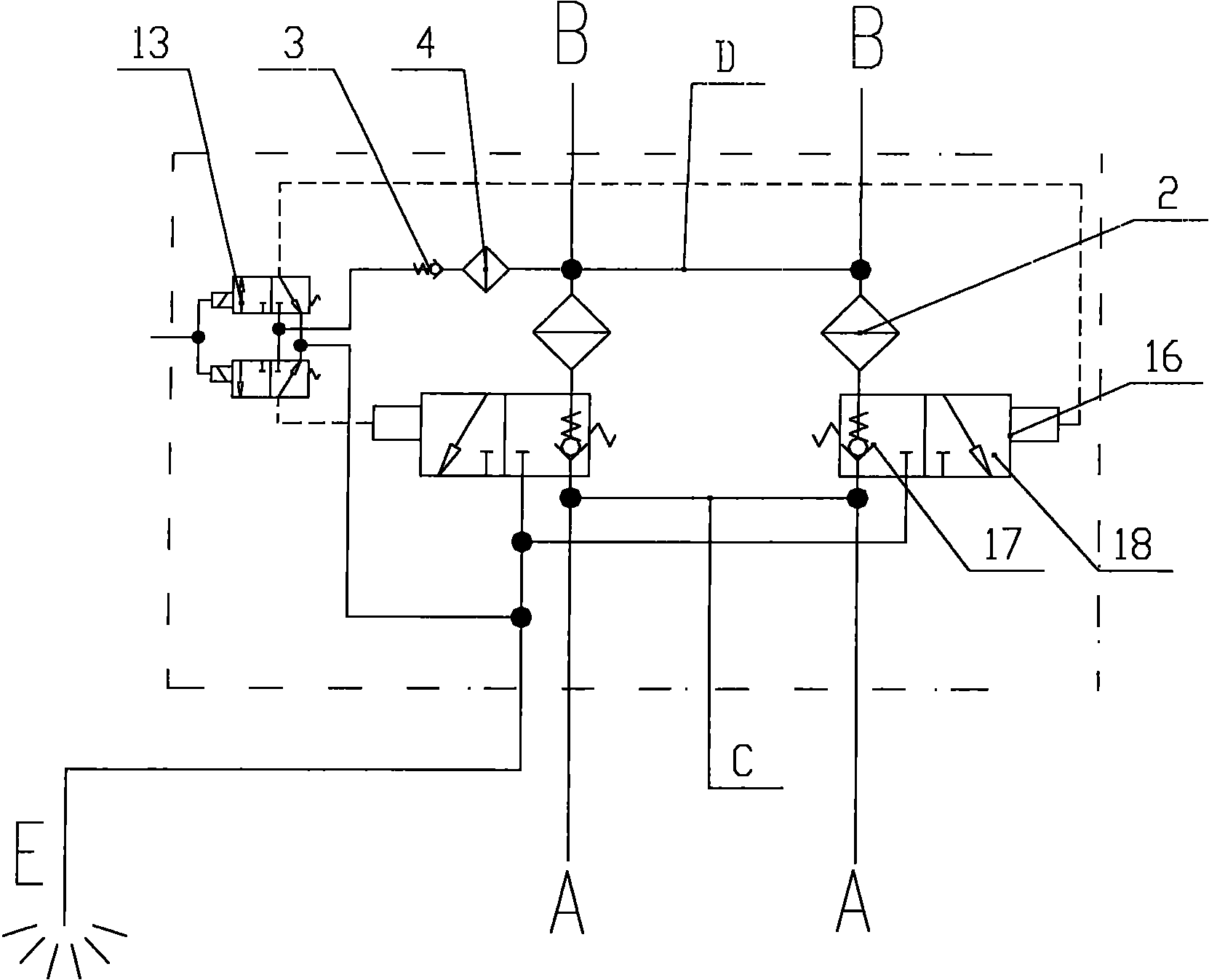

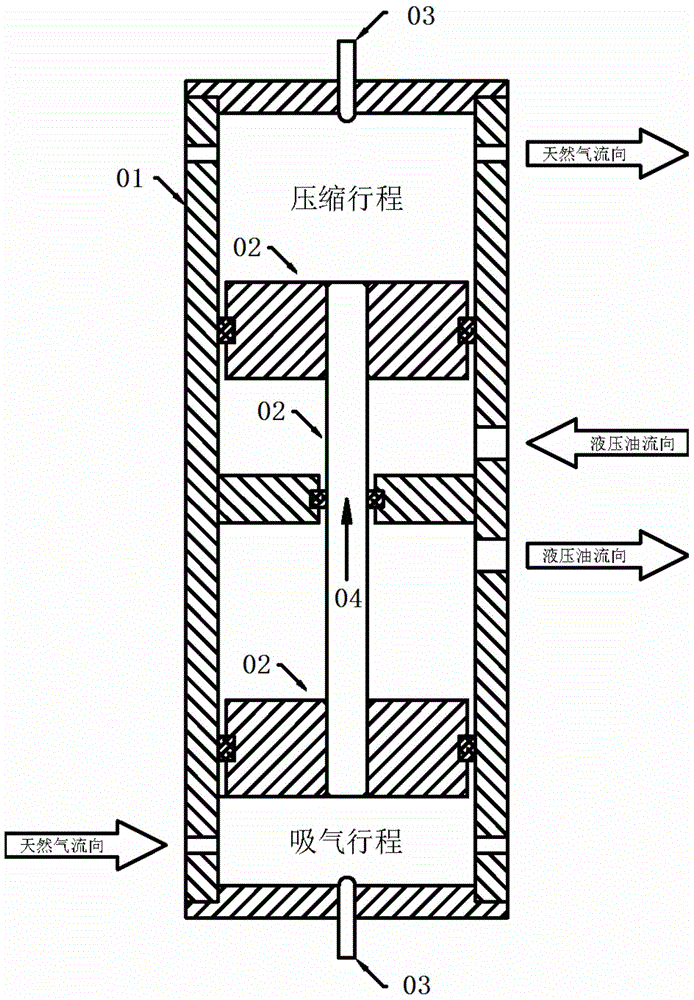

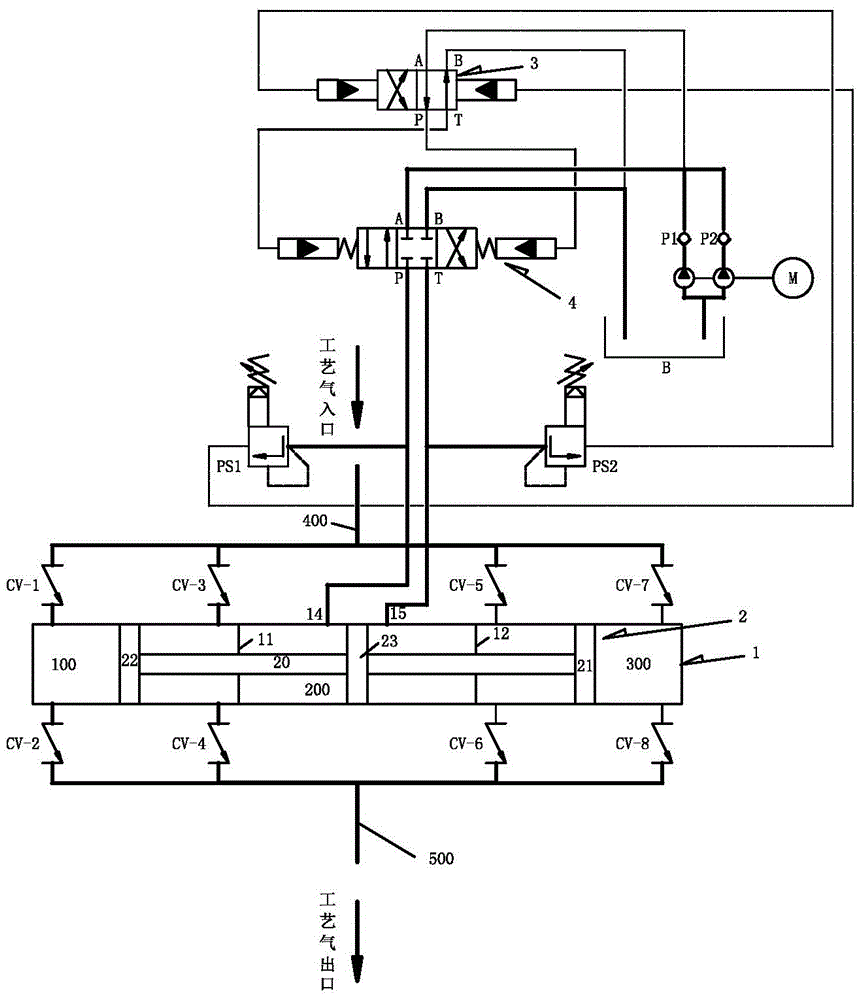

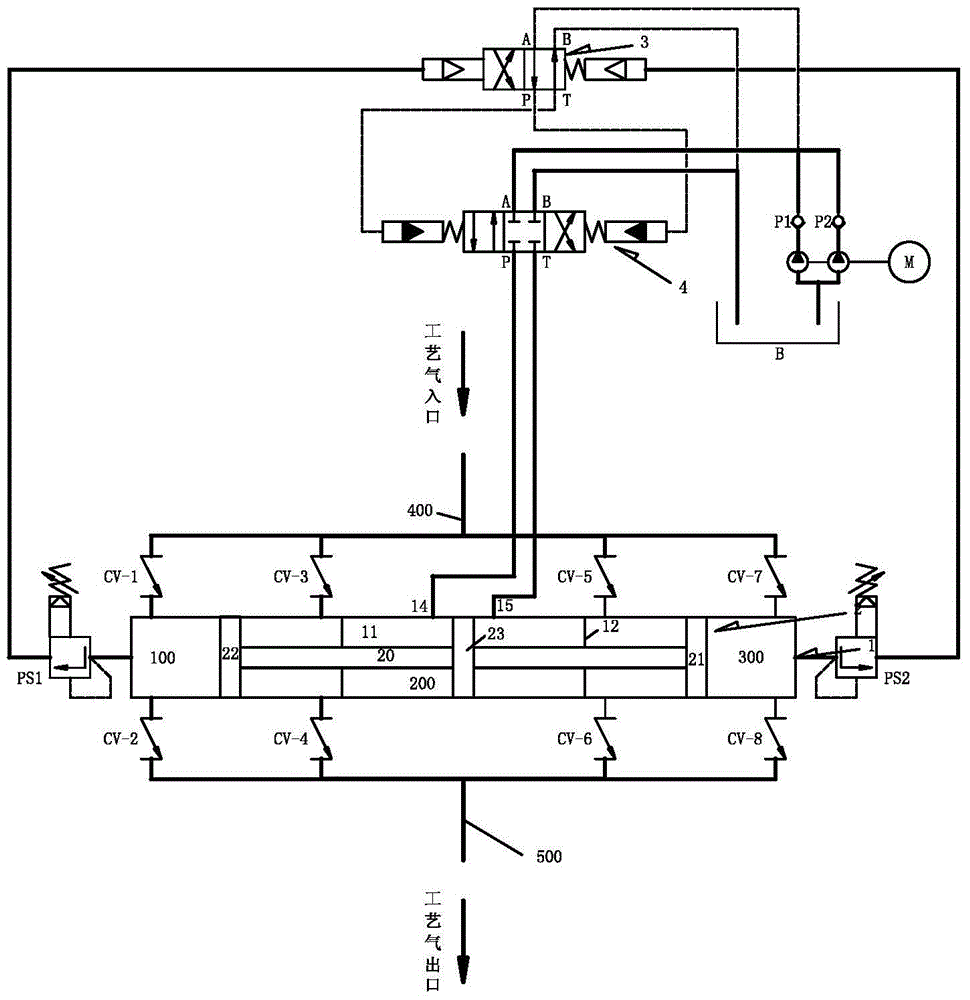

Pressure self-adaptive hydraulic reversing system

ActiveCN104533853ACommutation is reliableCommutation smoothServomotor componentsServomotorsReciprocating motionHydraulic pump

The invention provides a pressure self-adaptive hydraulic reversing system. The pressure self-adaptive hydraulic reversing system is used for piston reserving in a fluid compressing and delivering double-acting compressor and comprises a power drive hydraulic system, wherein the power drive hydraulic system is connected to two hydraulic oil ports formed in the double-acting compressor and used for driving a piston to perform reciprocating motion to form a power drive hydraulic loop, a hydraulic pump and a reversing device are arranged in the power drive hydraulic loop, and the reversing device is correlated with a reversing control device. The reversing control device comprises a pressure detection control device, wherein the pressure detection control device can detect pressure in the power drive hydraulic loop and / or delivery pressure of a fluid compressing delivery pipeline and is correlated with the reversing device so as to achieve the purpose of achieving piston reversing when the pressure of the fluid compressing delivery pipeline and / or the power drive hydraulic system reaches set pressure. The pressure self-adaptive hydraulic reversing system can perform hydraulic reversing according to the pressure of a delivered medium and / or the power drive hydraulic system.

Owner:BEIJING PROVA ENERGY DEV

Method of controlling a brushless permanent-magnet motor

ActiveUS20170310256A1High saturation thresholdLack of saturationElectric motor controlCurrent controllersPhase currentsElectric machine

A method of controlling a brushless permanent-magnet motor that includes sequentially exciting and freewheeling a phase winding of the motor is provided. The phase winding is freewheeled when the phase current exceeds an upper threshold. The method further includes measuring a parameter that corresponds to either: (i) the magnitude of the phase current during or at the end of freewheeling when the phase winding is freewheeled for the fixed period of time, or (ii) the time interval during freewheeling or during excitation when the phase winding is freewheeled until the phase current falls below the lower threshold. The measured parameter is then compared against a saturation threshold, and the rotor is determined to be at a predetermined position. In response to determining that the rotor is at the predetermined position, the phase winding is commutated after a commutation period has elapsed.

Owner:DYSON TECH LTD

METHOD FOR SENSORLESS OPERATION OF AN ECM, and MOTOR FOR CARRYING OUT

ActiveUS20120126730A1Commutation is reliableSimplified generationMotor/generator/converter stoppersAC motor controlPermanent magnet rotorElectric machine

An electronically commutated motor (ECM) often employs a Hall sensor for reliable operation. Even when a Hall sensor is omitted from a motor having a plurality of stator winding phases (24, 26) and a permanent-magnet rotor (22), one can reliably detect direction of rotation of the rotor by the steps of: (a) differentiating a voltage profile obtained by sampling either (1) induced voltage in a presently currentless phase winding or (2) voltage drop at a transistor, through which current is flowing to a presently energized phase winding, and (b) using such a differentiated signal (du—24″ / dt, du—26″ / dt) to control current flow in an associated phase winding. In this manner, one obtains reliable commutation, even if the motor is spatially separated from its commutation electronics.

Owner:ELEKTROSIL SYST DER ELEKTRONIK

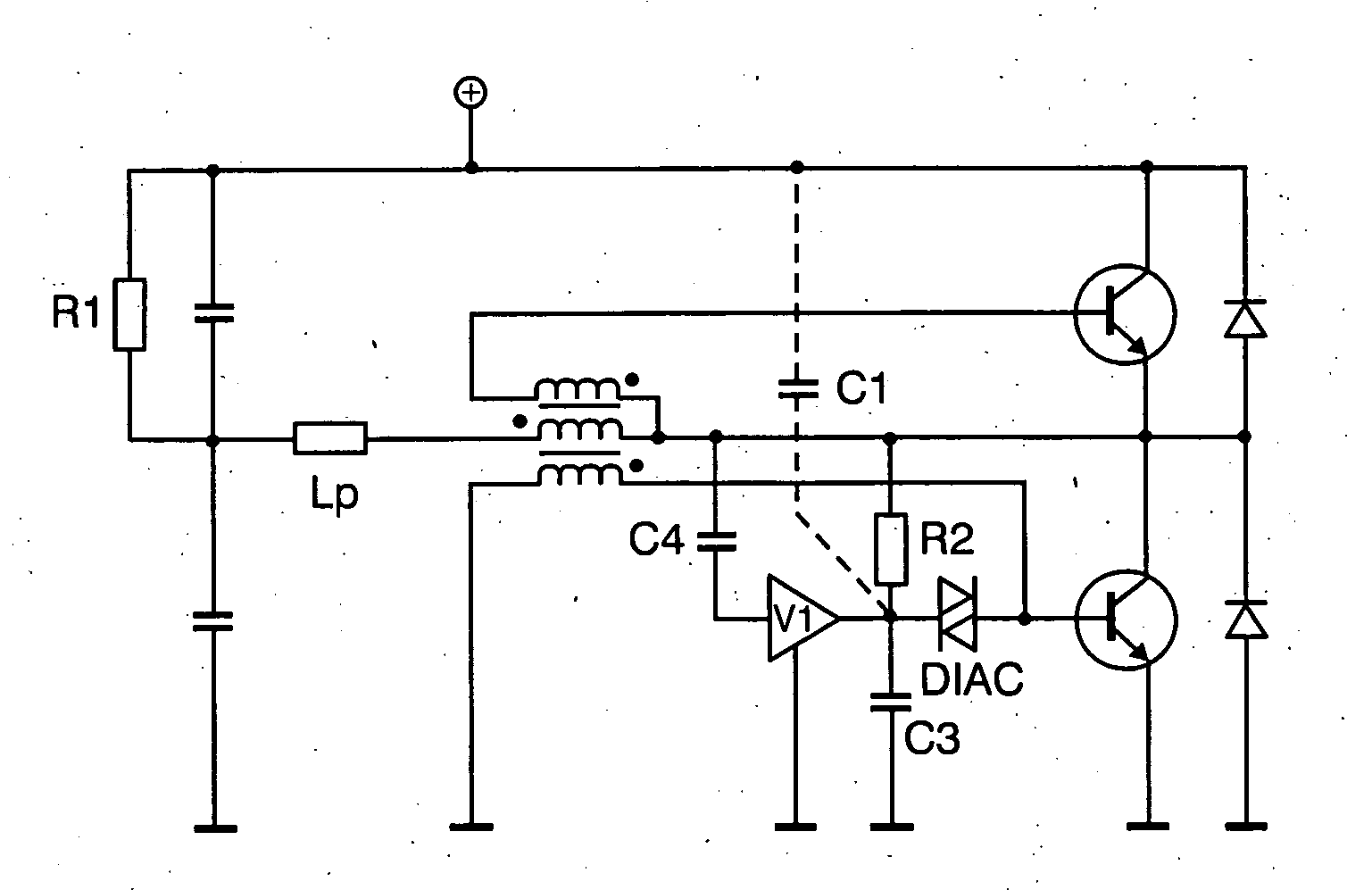

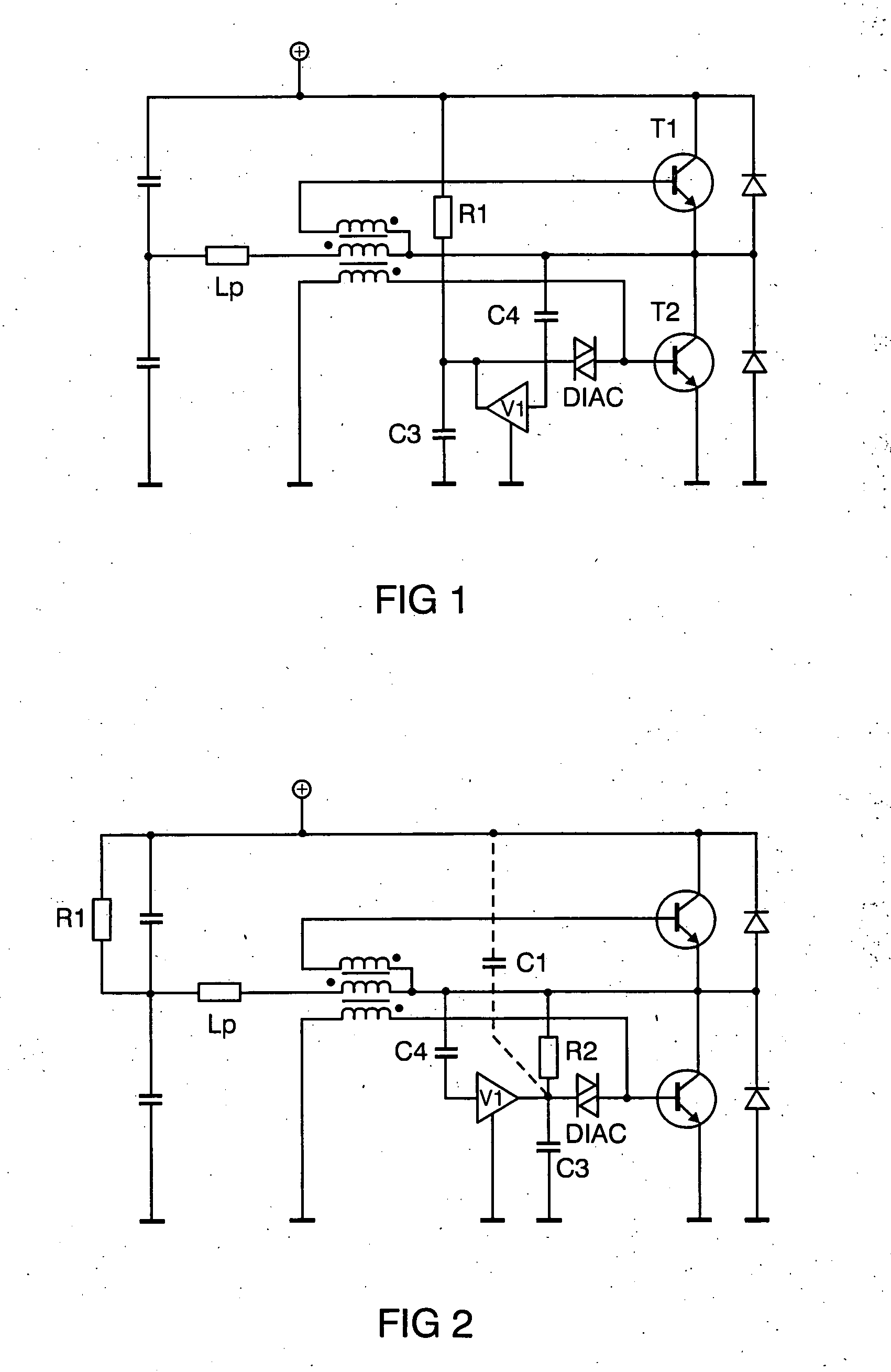

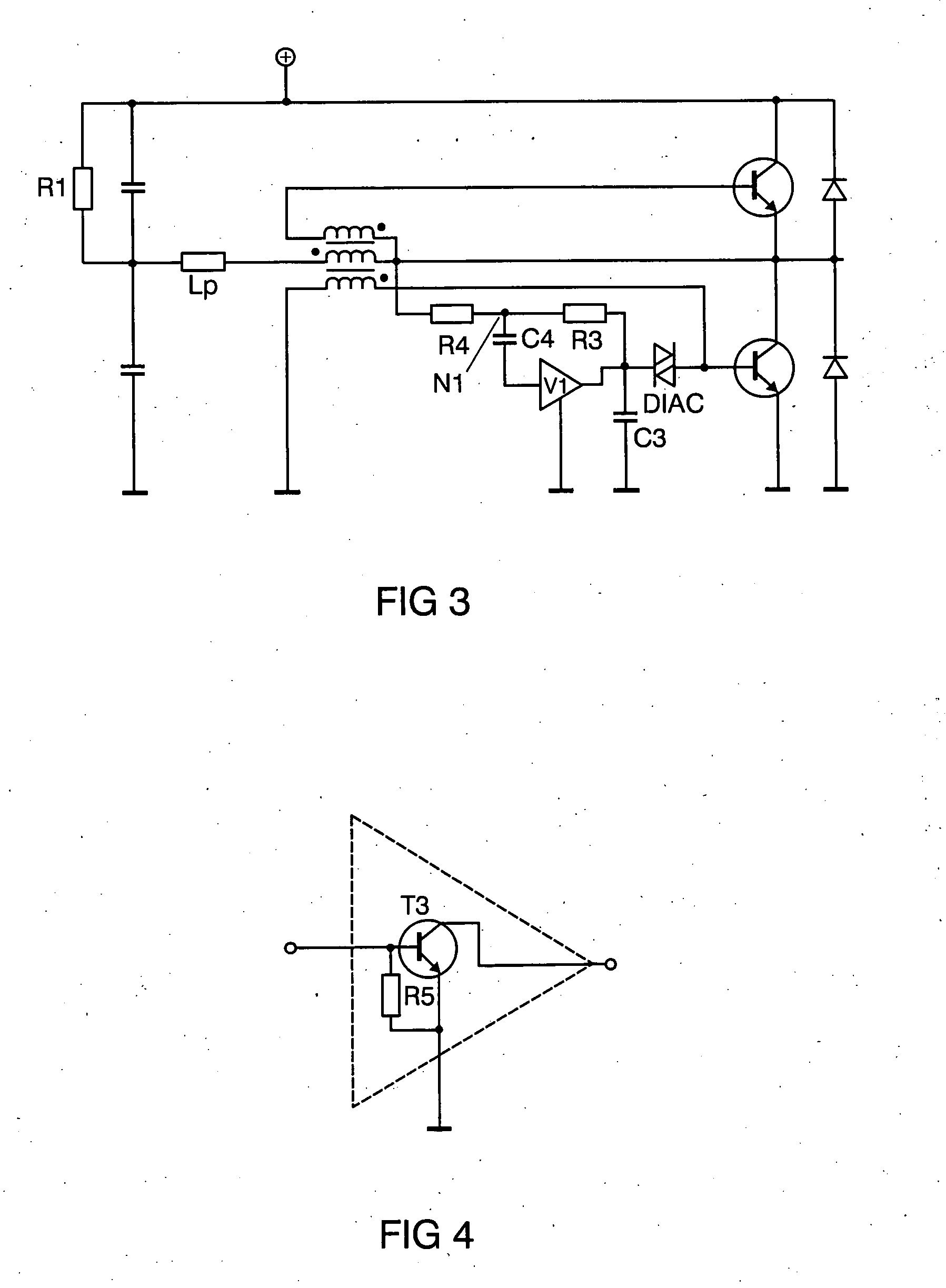

Circuit for the operation of light sources

InactiveUS20050275353A1Reliable startCommutation is reliableElectrical apparatusElectric light circuit arrangementTransformerHemt circuits

An electronic transformer for halogen incandescent lamps is equipped with a self-commutated half-bridge inverter. The half-bridge inverter contains a start circuit with a start capacitor (C3), which starts commutation of the half-bridge inverter after each mains half-wave by driving a lower half-bridge transistor (T2). The start circuit has to be suppressed while the half-bridge inverter is commutating. This is achieved according to the invention by discharging the start capacitor (C3) whenever an upper half-bridge transistor is turned on (T1). This is done by an amplifier element (V1), which is driven via a high-pass filter (C4) from the half-bridge midpoint (M).

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

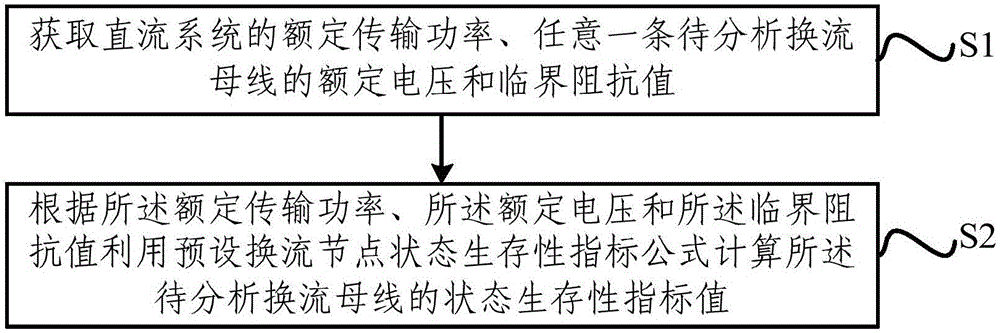

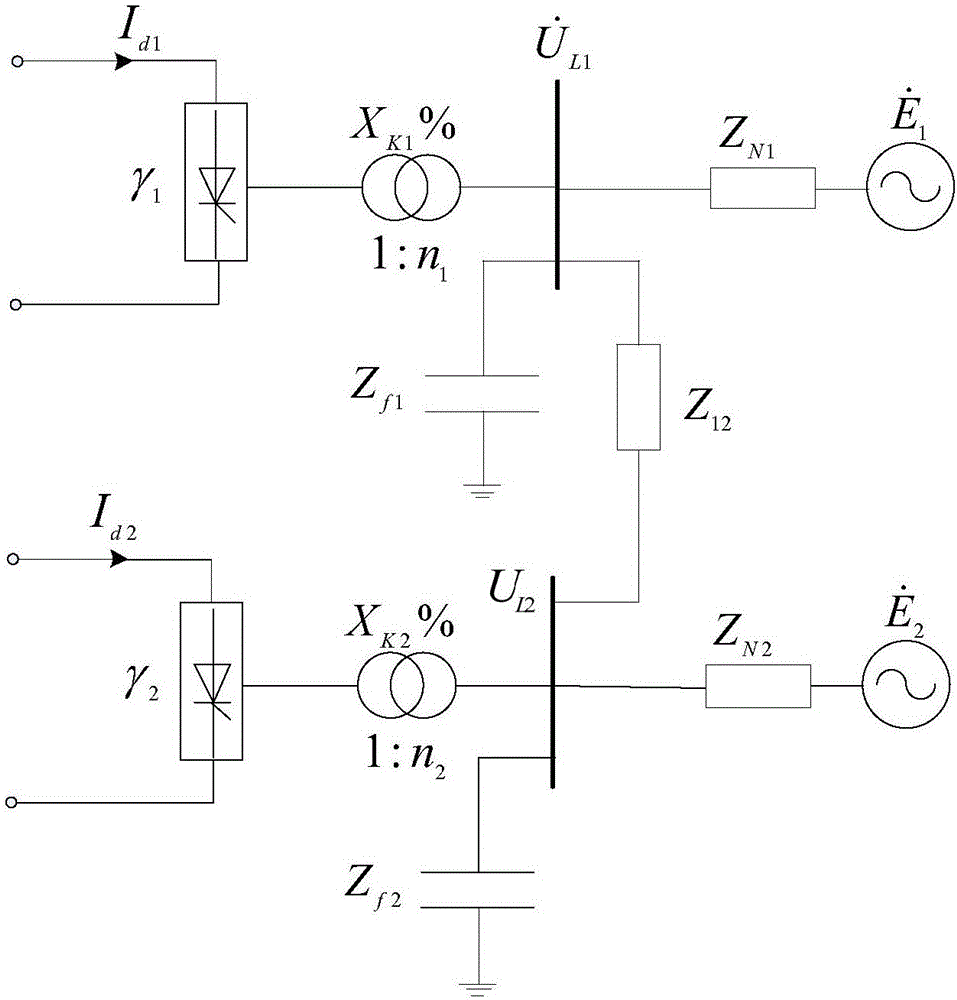

Low voltage current limiting controller-based multiple feed-in current converting bus survivability analysis method

InactiveCN106374542ACommutation is reliableImprove effectivenessElectrical apparatusCurrent limitingPower grid

The invention relates to a low voltage current limiting controller-based multiple feed-in current converting bus survivability analysis method comprising the following steps: rated transmission power of a direct current system and rated voltage and critical impedance value of any one current converting bus to be analyzed are obtained; according to the rated transmission power, the rated voltage and the critical impedance value, a preset current converting node state survivability index formula is used for calculating state survivability index value of the current converting bus to be analyzed. Via the multiple feed-in current converting bus survivability analysis method disclosed in an embodiment of the invention, state survivability of a multiple feed-in direct current converting bus can be effectively detected, and operation capability of power grid current converting nodes can be improved in low voltage conditions.

Owner:STATE GRID CORP OF CHINA +2

Method of determining the rotor position of a permanent-magnet motor

ActiveCN107317524AReliable determinationCommutation is reliableAC motor controlSingle phase motor controlPhase currentsPermanent magnet motor

The present invention provides a method of determining the position of a rotor of a brushless permanent-magnet motor, the method comprising: exciting and freewheeling a phase winding of the motor, wherein the phase winding is freewheeled when a phase current exceeds an upper threshold and freewheeling comprises one of: (i) freewheeling for a fixed period of time, and (ii) freewheeling until the phase current falls below a lower threshold. The method further comprises measuring a parameter corresponding to one of: (i) the magnitude of the phase current during or at the end of freewheeling when the phase winding is freewheeled for the fixed period of time, and (ii) the time interval between the start and end of freewheeling or the start and end of excitation when the phase winding is freewheeled until the phase current falls below the lower threshold. The measured parameter is used to define a saturation threshold. The phase winding is sequentially excited and freewheeled in the same way and the parameter is measured in the same way. The method then comprises comparing the measured parameter against the saturation threshold; and determining that the rotor is at a predetermined position when the measured parameter is less than the saturation threshold.

Owner:DYSON TECH LTD

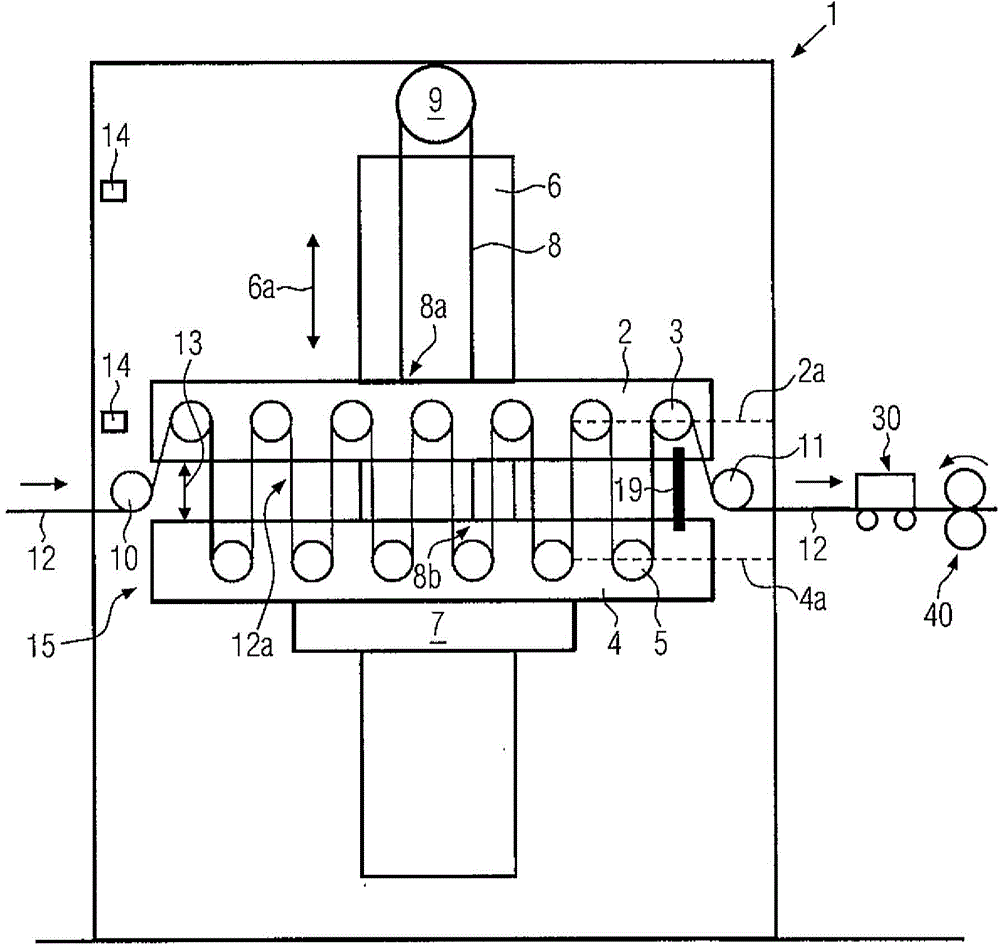

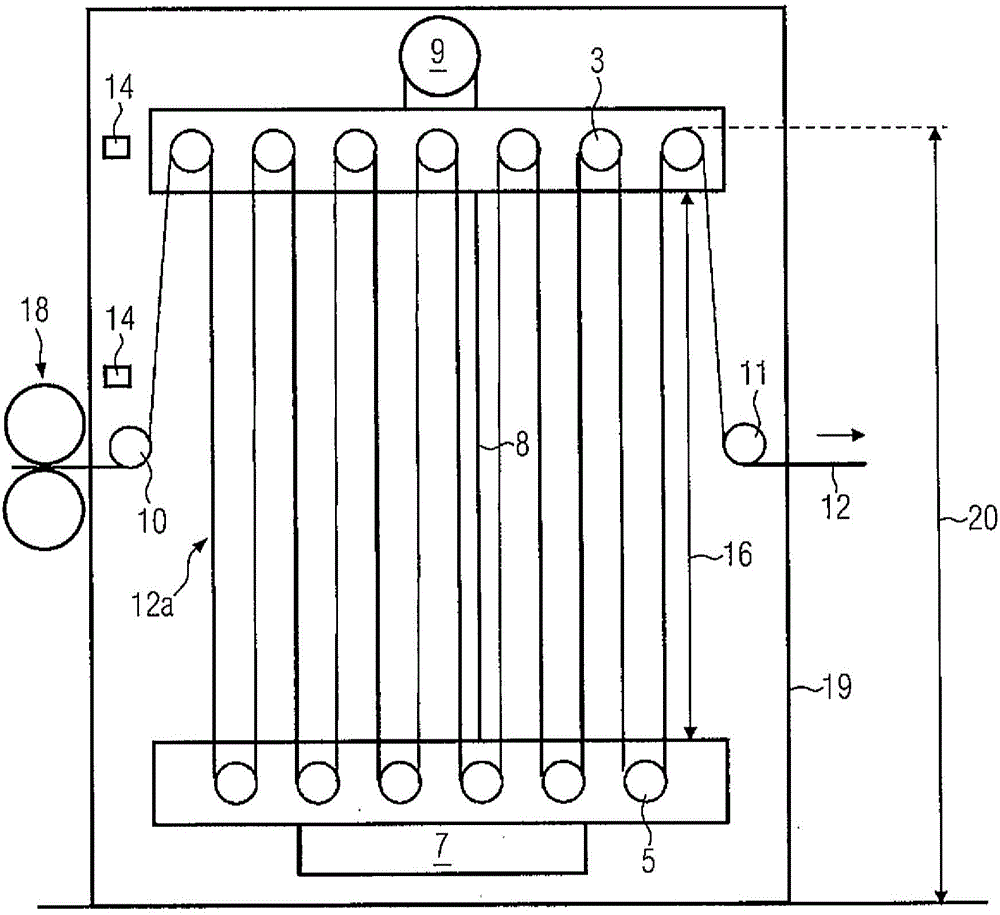

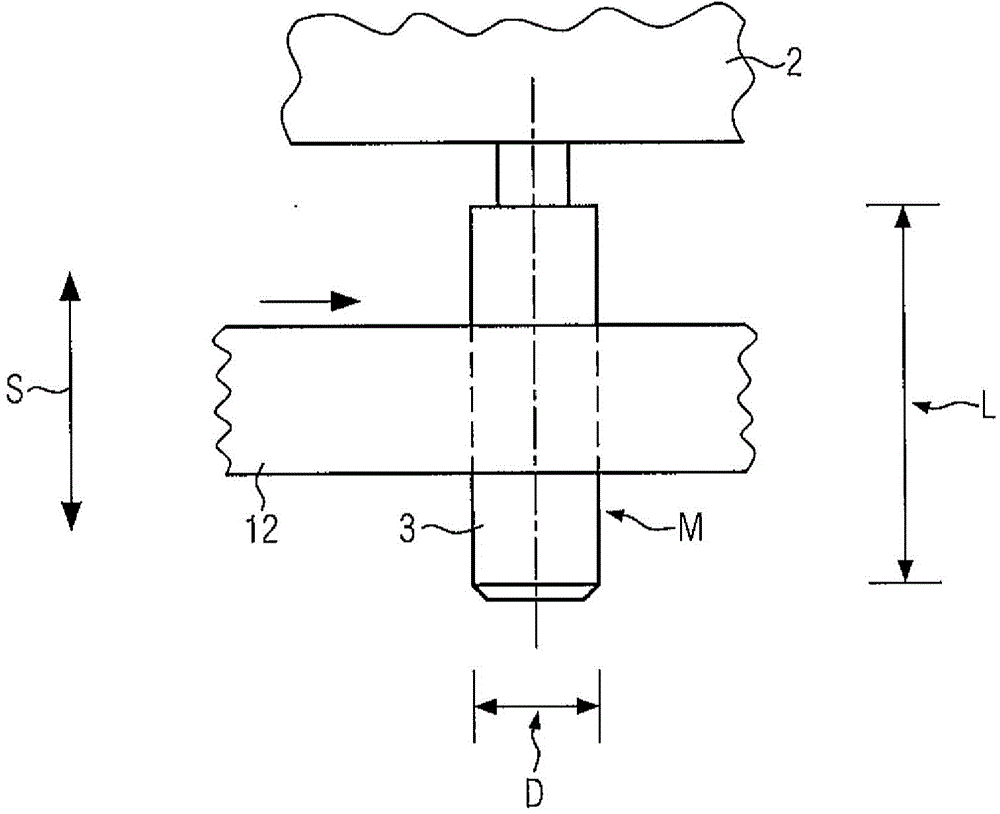

Film storage device for endless films

ActiveCN104909219ACommutation is reliableSufficient tensile stressWebs handlingElectrical and Electronics engineeringMechanical engineering

The present invention provides a film storage device for endless films. The film storage device comprises a commutative roller, wherein, the commutative roller is mounted on an upper carrier and a lower carrier in the following method, namely, the endless films commutate along the winding and zigzagging transmission track extended between the upper and lower carriers during the period of the memory running, the distance between the upper and lower carriers is variable for processing quantity matching to the film storage device. Hereon, the vertical positions of the upper and lower carriers are variable. Thus, the upper carrier can decline to the position benefiting for ergonomics to thrill through the endless films and / or aim at maintenance measurement. Accordingly, the upper carrier can occupy a higher position during the normal process of storage device running, which reaches a more acceptable level than the condition of fixedly-mounting the upper layer from a point of ergonomics.

Owner:KRONES AG

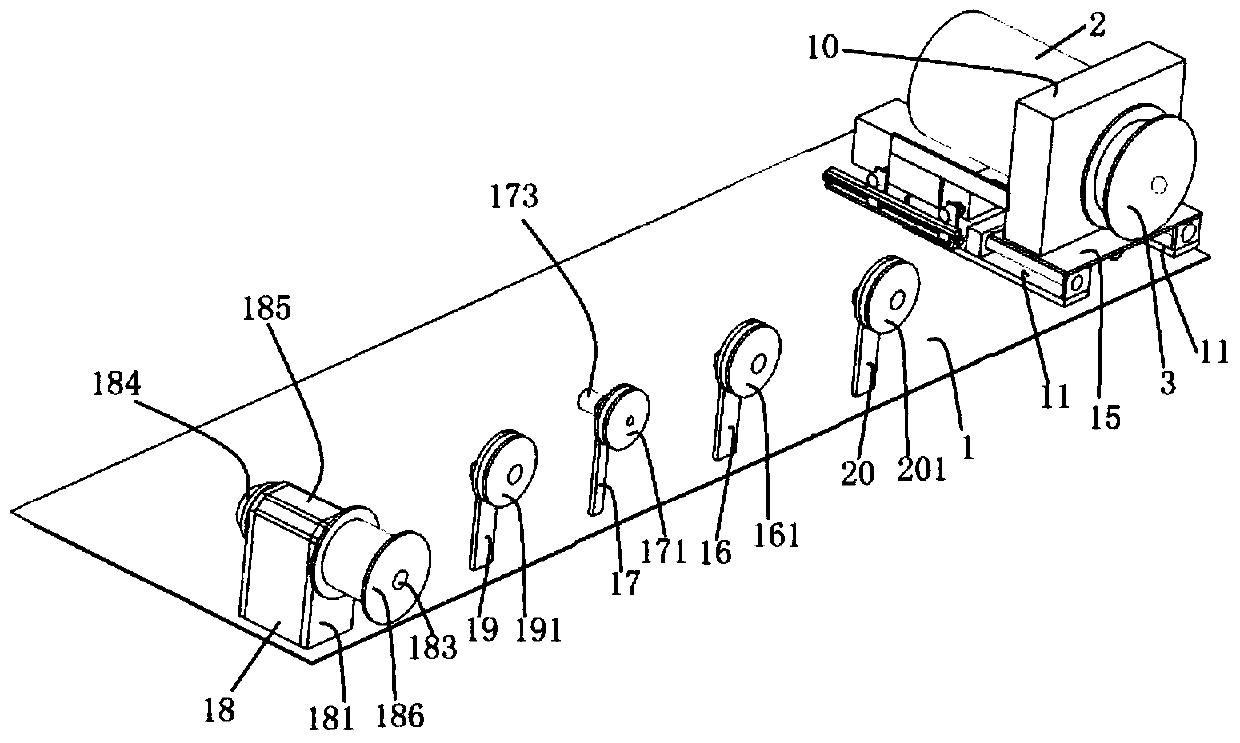

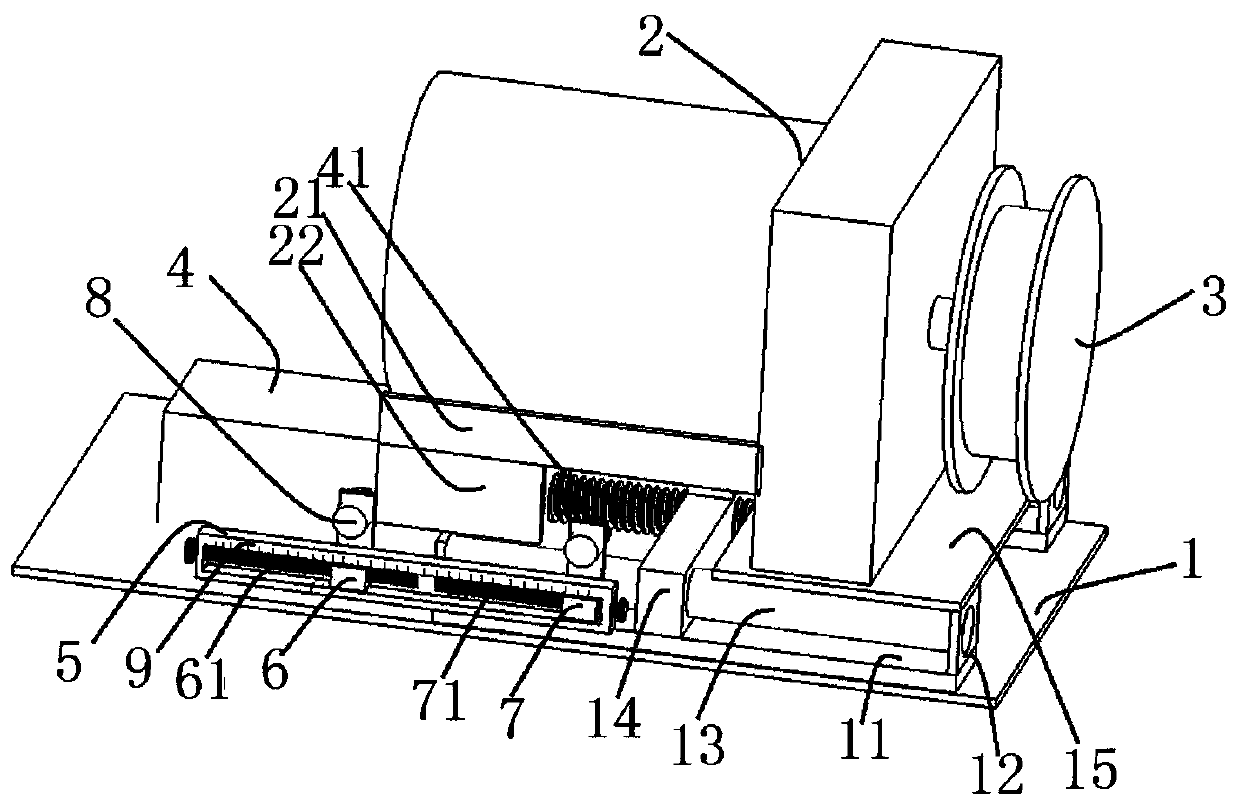

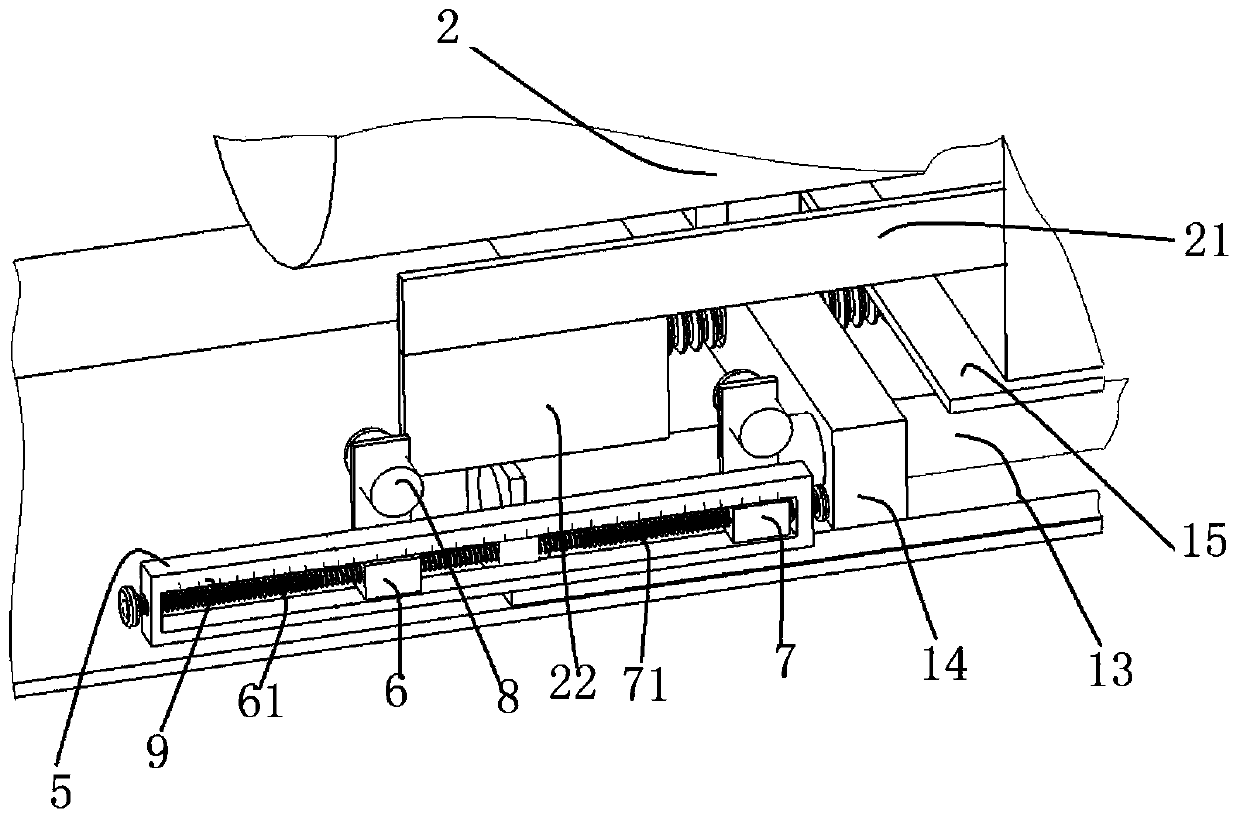

Full-automatic wire tension control rewinding machine

PendingCN110155808AReduce the difficulty of process operationImprove product qualityFilament handlingWire tensionEngineering

The invention discloses a full-automatic wire tension control rewinding machine. The machine comprises a bottom plate, wherein the bottom plate is provided with a wire pay-off device, the wire pay-offdevice is provided with a material wire coil in an inserting mode, and a material wire in the material wire coil winds around a positioning mechanism, a tension sensor mechanism, a speed measuring mechanism and a flat cable positioning mechanism in a sequential mode, and then wound on a wire take-up device. The wire take-up device, the tension sensor mechanism and the speed measuring mechanism ismatched with the wire pay-off device. The real-time tension of the wire material is detected through a tension sensor, thus transiting the data to a tension controller, and then the tension controller controls a real-time output torque of a magnetic powder brake, so that the wire pay-off tension can be stably controlled; in addition, by using the tension sensor and the magnetic powder brake, thetension, stress, straightness and flatness of the wire material can be realized; further more, with the tension sensor and the magnetic powder brake matched with the speed measuring mechanism, the arrangement of winding wire of the material wire coil is compact with the tension and stress being uniform, thus improving production efficiency as well as product quality, and the problems of messed wire, broken wire, pressed wire, over looseness of wire take-up, coil explosion and the like occurring during stop of turning and coil separation can be solved.

Owner:CHENGDU HONGBO INDAL

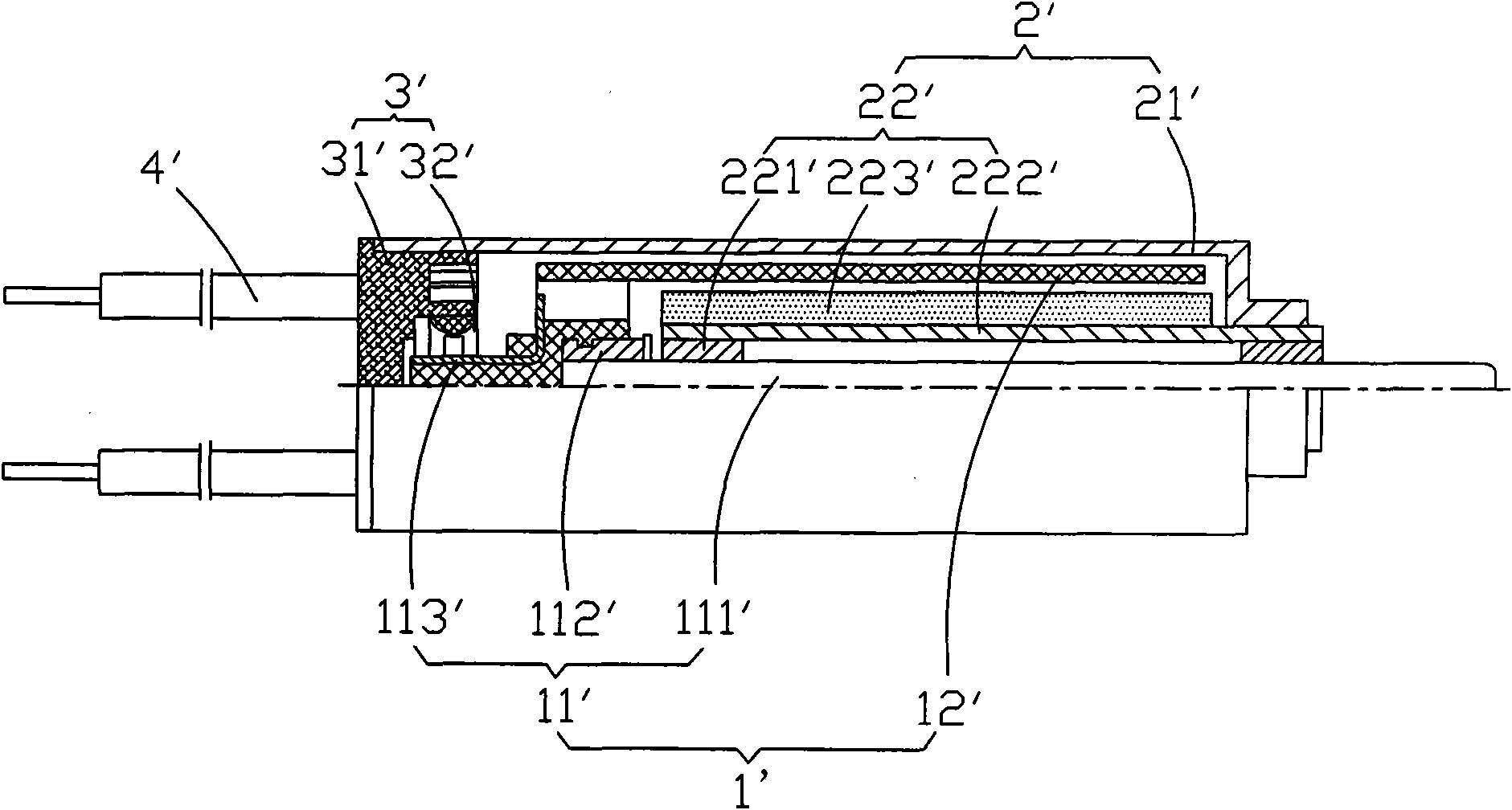

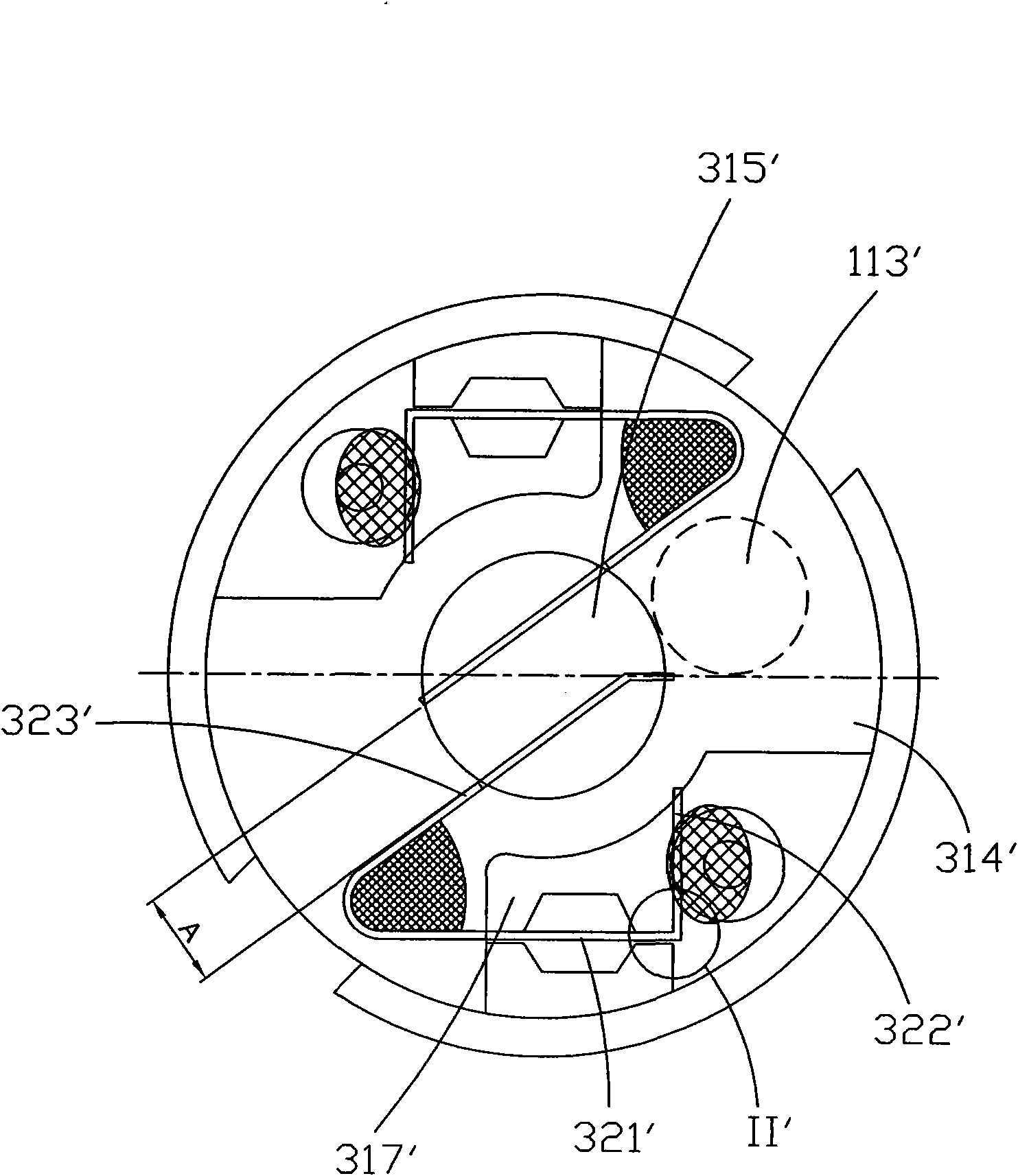

Ultraminiature continuous current dynamo for facilitating commutator installation

ActiveCN101789668AControl installation locationConsistent brush distanceDC commutatorSupports/enclosures/casingsConductor CoilDynamo

The invention relates to an ultraminiature continuous current dynamo for facilitating commutator installation, comprising a rotor, a stator and a brush group. The rotor comprises a rotor support and a winding; while the rotor support comprises a revolving shaft, a fixed ring sheathed at one end of the revolving shaft and a commutator located at one end of the revolving shaft. The brush group comprises a base plate at one end of a machine shell and an upper electric brush and a lower electric brush which are arranged on the base plate; the central part of the base plate, which is close to the machine shell is provided with center holes; each electric brush is provided with a straight panel part, a vertical part which vertical extends out from one end of the straight panel part and a slant part which slantly extends out from the other end of the straight panel part in a bent manner. Wherein, an end surface of the base plate, which is close to the machine shell is provided with a commutator installation slide rail, one end of the slide rail is communicated with the center holes, the lower edge of the slide rail is contacted with the edges of the center holes and the spacing between the lower edge of the slide rail and the slant part of the electric brush is equal to allowed deformation of the electric brush. With the structure adopted, when being installed, the commutator can slide along the lower edge of the slide rail to the center of the base plate, thus effectively avoiding deformation of the electric brush.

Owner:SHENZHEN SHUANGHUAN QX MOTOR

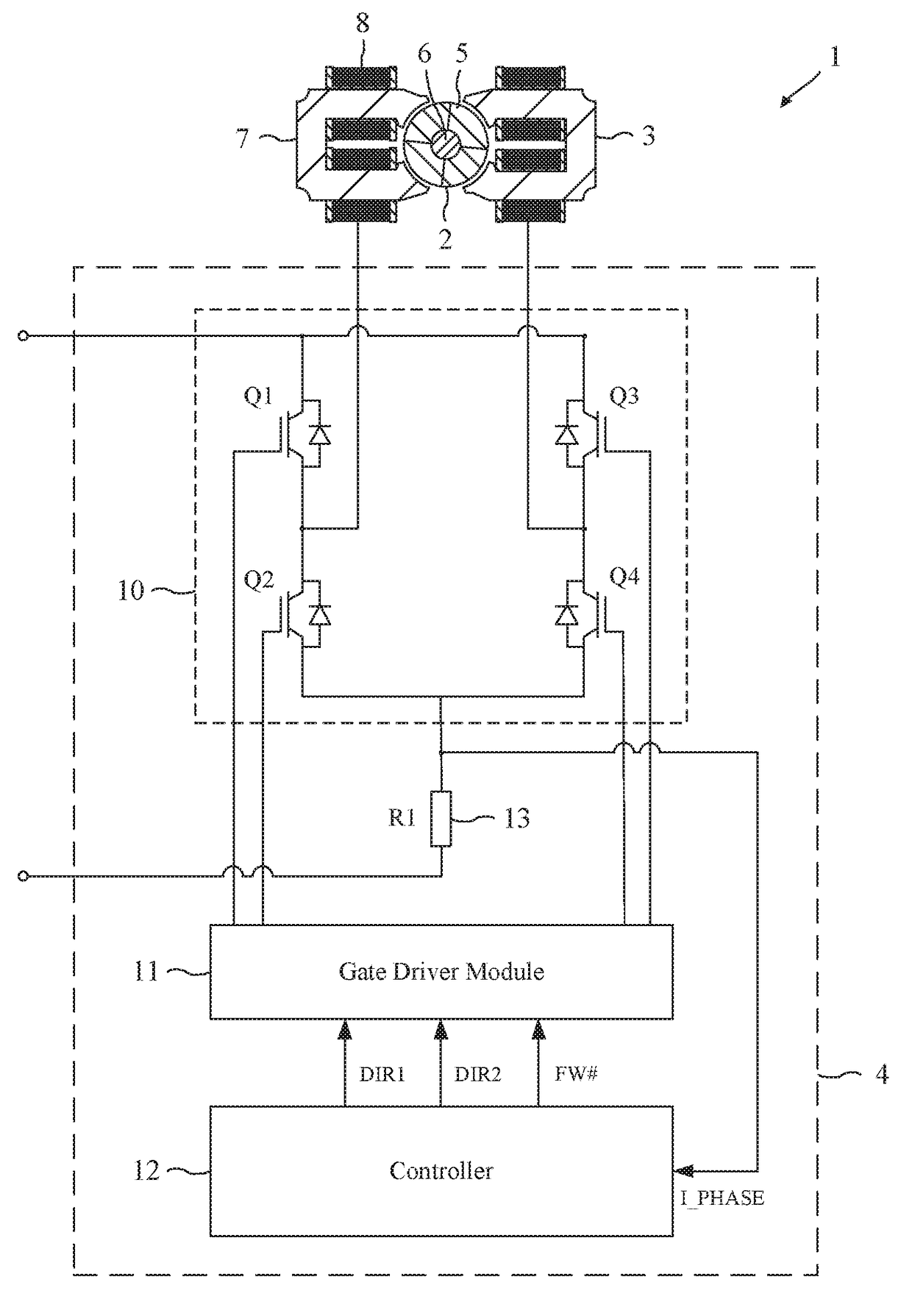

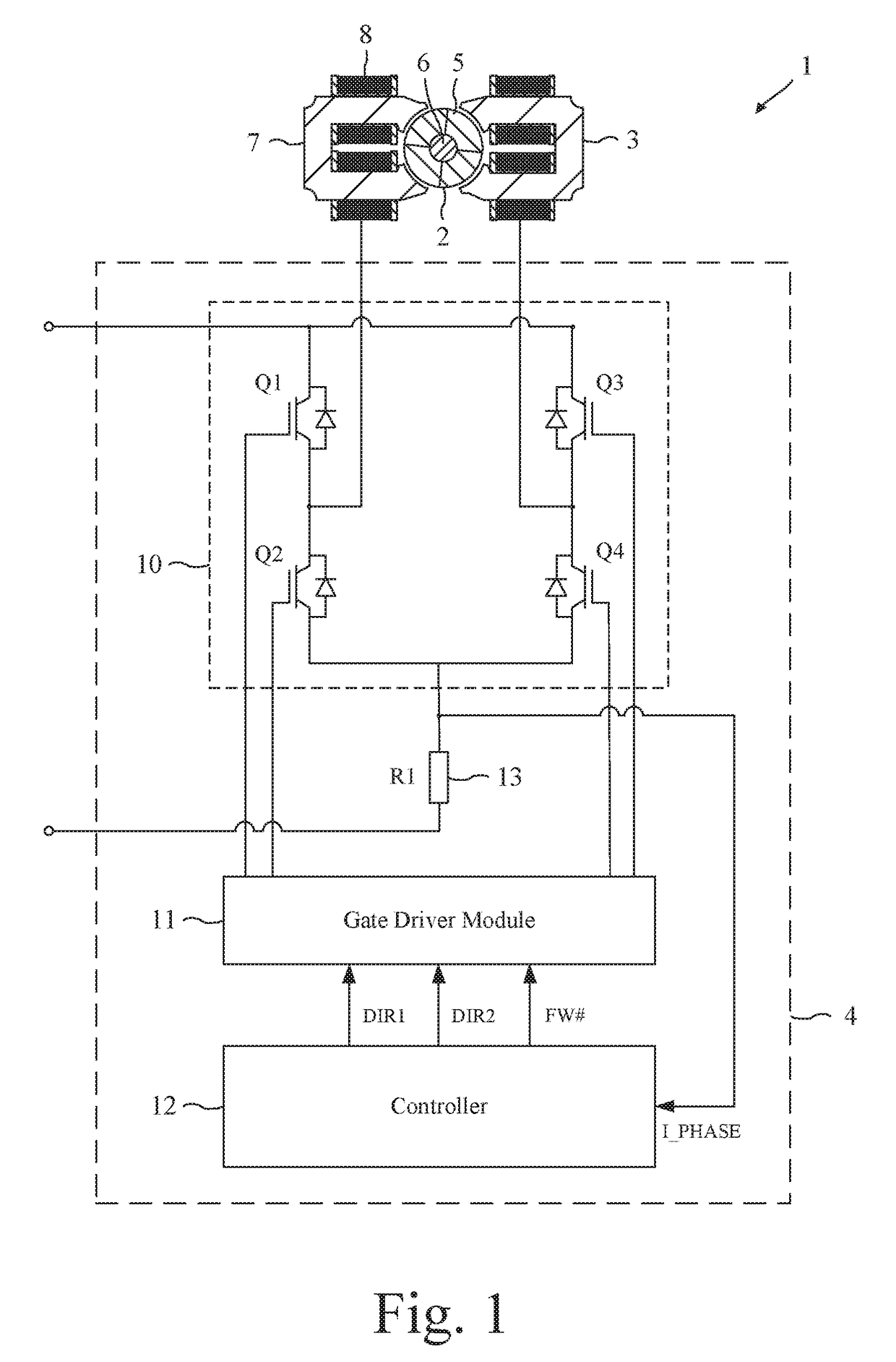

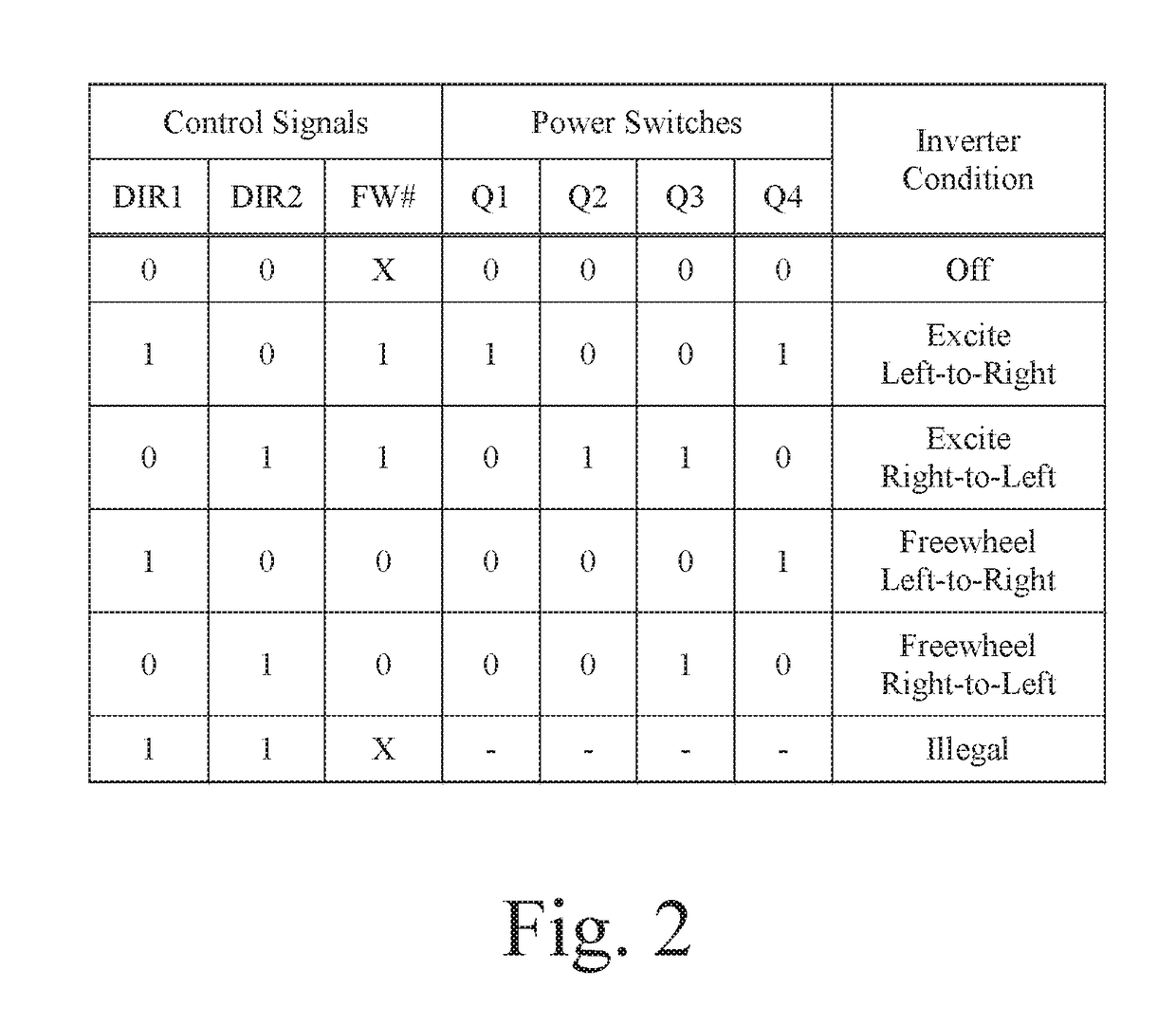

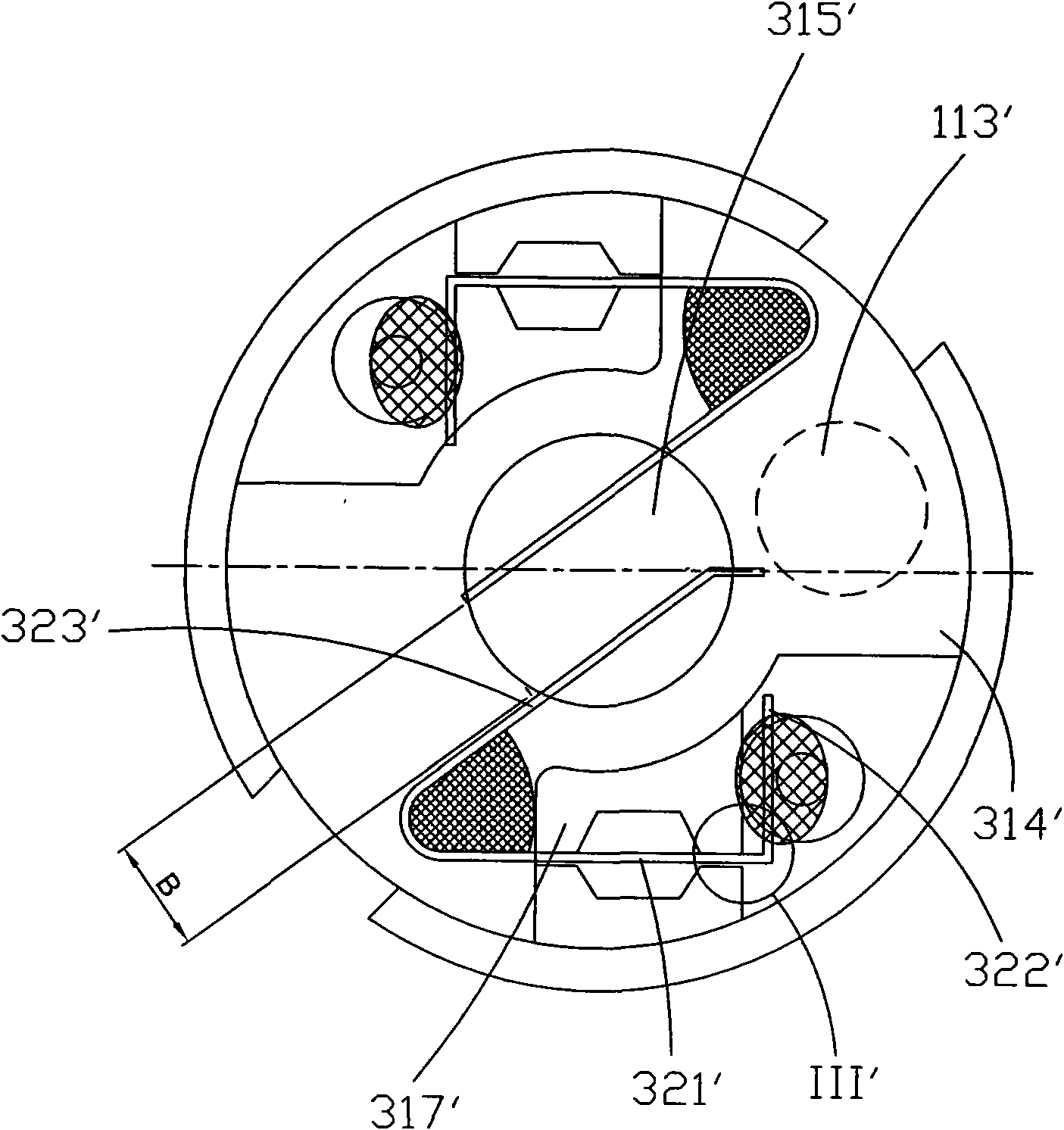

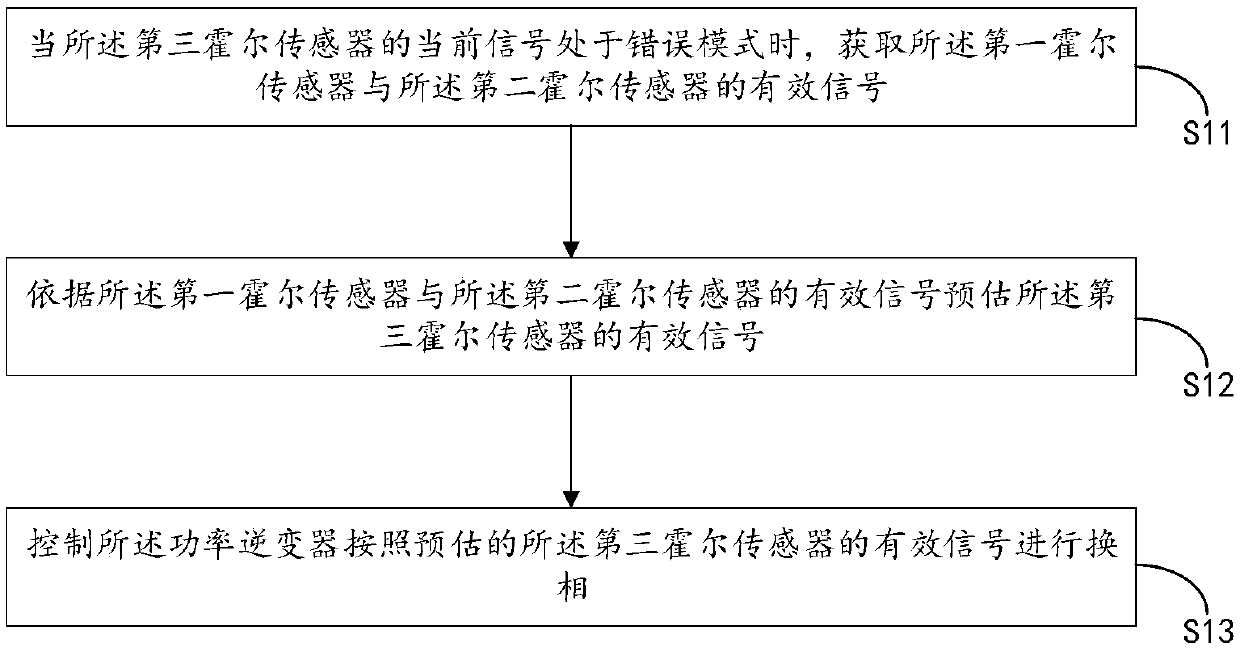

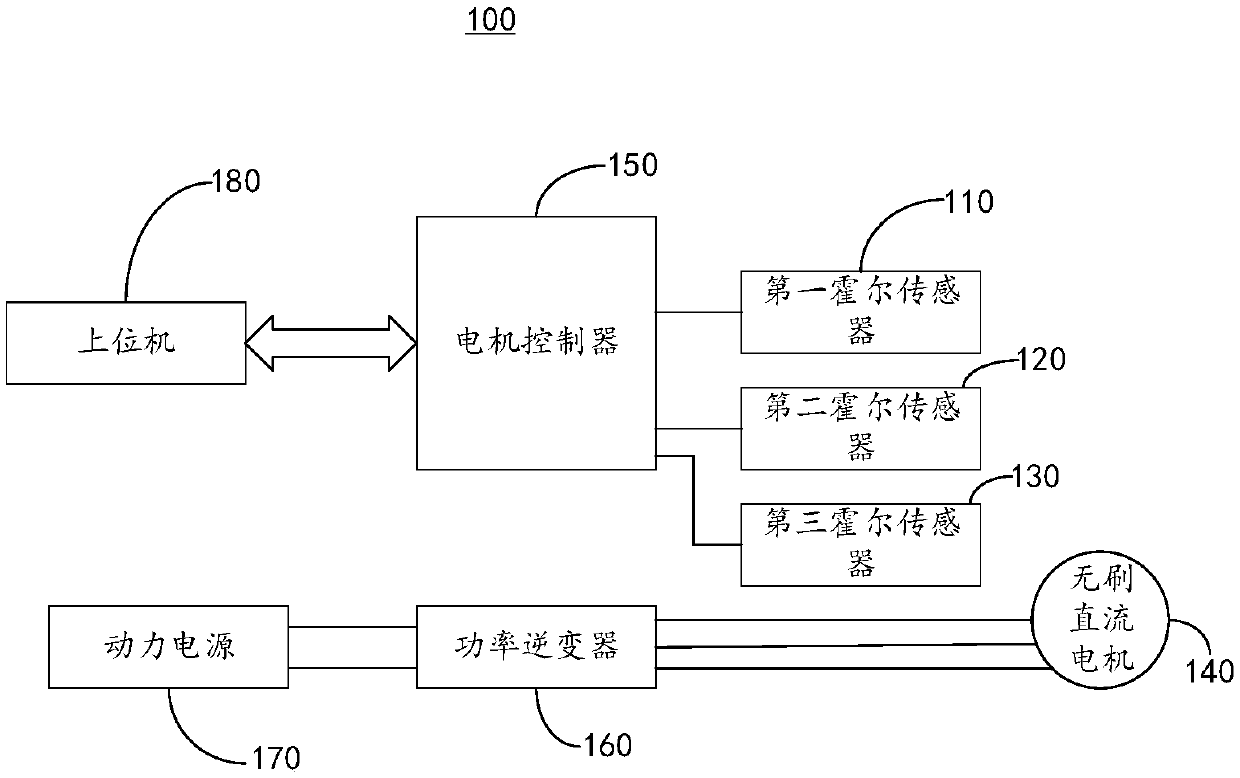

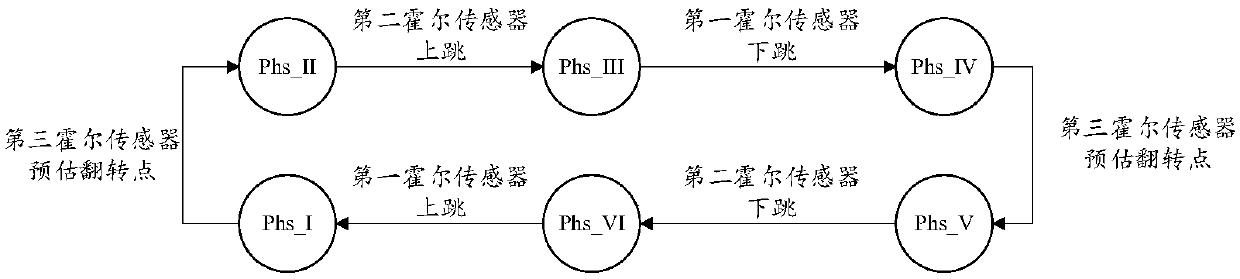

Commutation control method and apparatus for power inverter

ActiveCN109546902AReliable commutationWork not affectedElectric motor controlElectronic commutatorsPower inverterControl theory

The invention provides a commutation control method and apparatus for a power inverter, and relates to the technical field of brushless direct current motors. The commutation control method and apparatus for a power inverter are characterized in that when a current signal of a third Hall sensor is in an error mode, valid signals of a first Hall sensor and a second Hall sensor are acquired; and according to the valid signals of the first Hall sensor and the second Hall sensor, the valid signal of the third Hall sensor is estimated, and the power inverter is controlled to perform commutation according to the estimated valid signal of the third Hall sensor. The commutation control method and apparatus for a power inverter have the advantages of being higher in stability of working of the system.

Owner:CHENGDU JOUAV AUTOMATION TECH

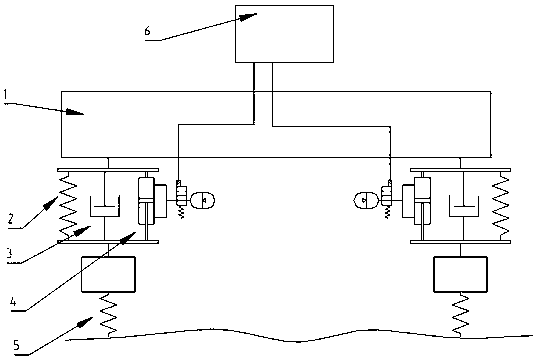

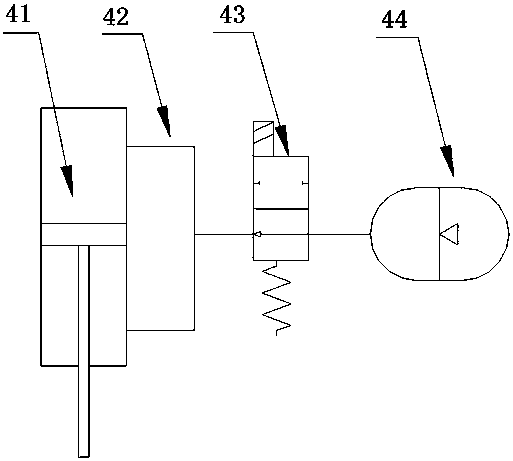

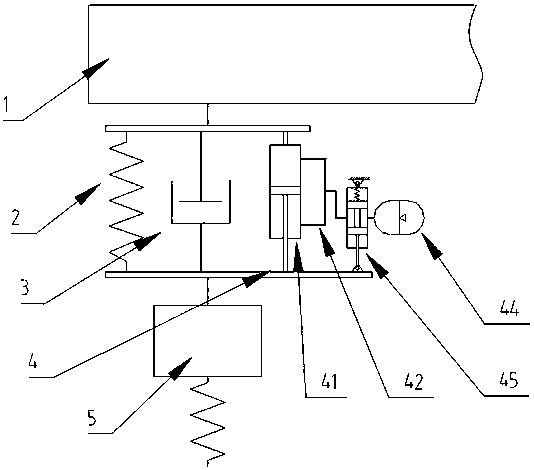

Anti-rollover vehicle and suspension system thereof

PendingCN109703314ARollover resistanceRollover activeResilient suspensionsHydraulic cylinderRollover

The invention provides an anti-rollover vehicle and a suspension system thereof, which relate to the technical field of vehicle safety, and have the advantages of simple structure and high reliability. The anti-rollover vehicle comprises a suspension system, including an elastic element and a damping element, and a locking structure for locking a suspension. The locking structure comprises a hydraulic cylinder, including a cylinder body and a piston rod, one of which is connected to a vehicle rack and the other of which is connected to a vehicle wheel. The cylinder body is provided with a rodchamber and a non-rod chamber, communicated through a connection path. The connection path is connected to an energy-storing machine through a control path, and the control path is provided with a control valve for controlling the connection and disconnection. When the vehicle rolls over, the hydraulic cylinder can be controlled. Due to the incompressibility of hydraulic oil, the pressure of hydraulic oil in the hydraulic cylinder can be quickly changed, and the force for resisting the further deformation of the suspension can be generated, and thereby vehicle rollover can be resisted, and safe driving of the vehicle can be ensured.

Owner:ZHENGZHOU YUTONG BUS CO LTD

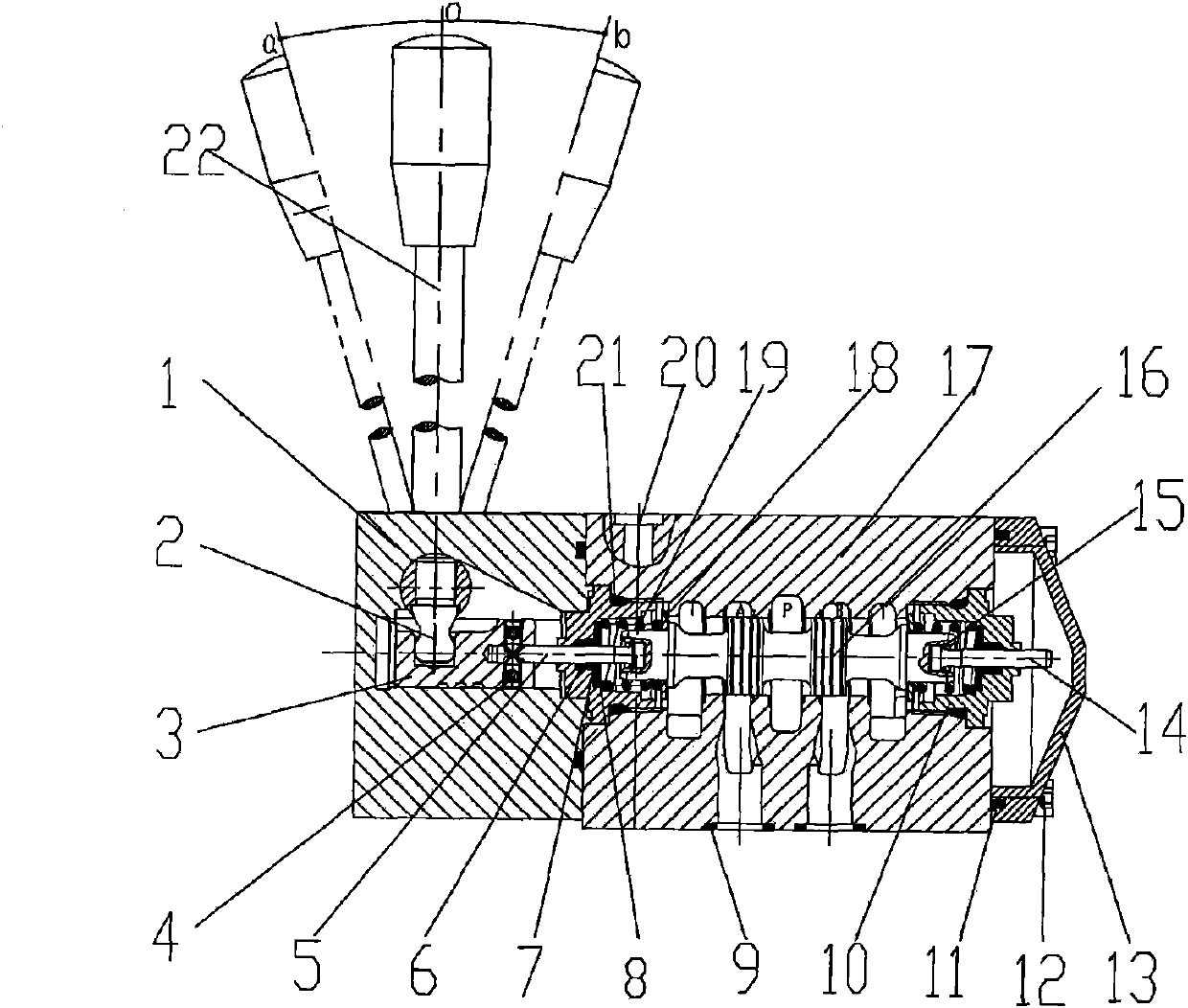

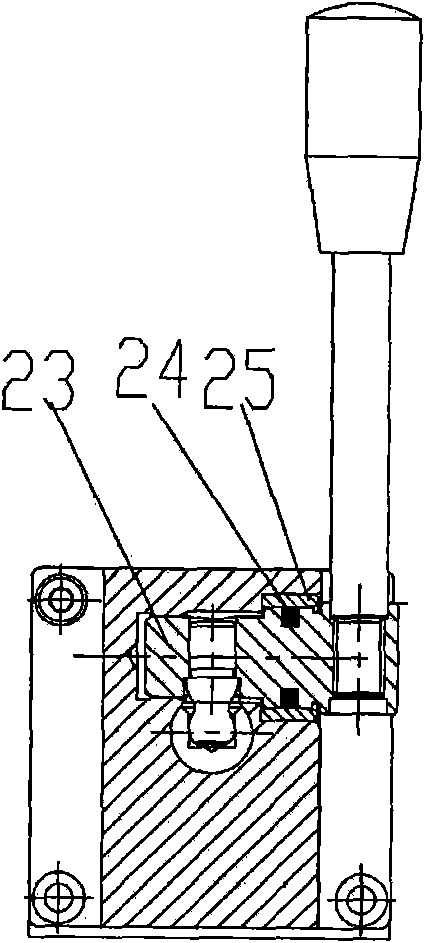

Leakless plane type pure water electrohydraulic change valve

InactiveCN1587720ASmall control forceCommutation is reliableOperating means/releasing devices for valvesServomotor componentsElectro hydraulicEngineering

The invention discloses a kind of no leakage and pure water flat electro-hydraulic directional control valve. A king valve cover is in the heart of the king valve and flat king valve core compacted by a spring lies in the cavity of axial of the king valve body; on the upper of king valve body there is a water inlet and a water outlet connected by the king valve's channel; in the king valve there is a sensitive cavity connected with electromagnetic ball valve by tunnels; a valve port damper installed at the valve entrance of electromagnetic ball valve matches with the sensitive cavity of king valve in order to control the flow velocity of fluid and reduce directional strike at the same time diverting fast. The invention adopt flat king valve core set on the packing force of the king valve cover and increase dramatically valve covers, adopt direct seal to realize zero leakage; divert fast and steadily through matching the sensitive cavity of king valve with the damper at the entrance of the electromagnetic ball valve; not change the structure of the king valve and only change structural form of electromagnetic ball valve in order to have different functions and fit to work under conditions of middle and high pressure water medium.

Owner:ZHEJIANG UNIV

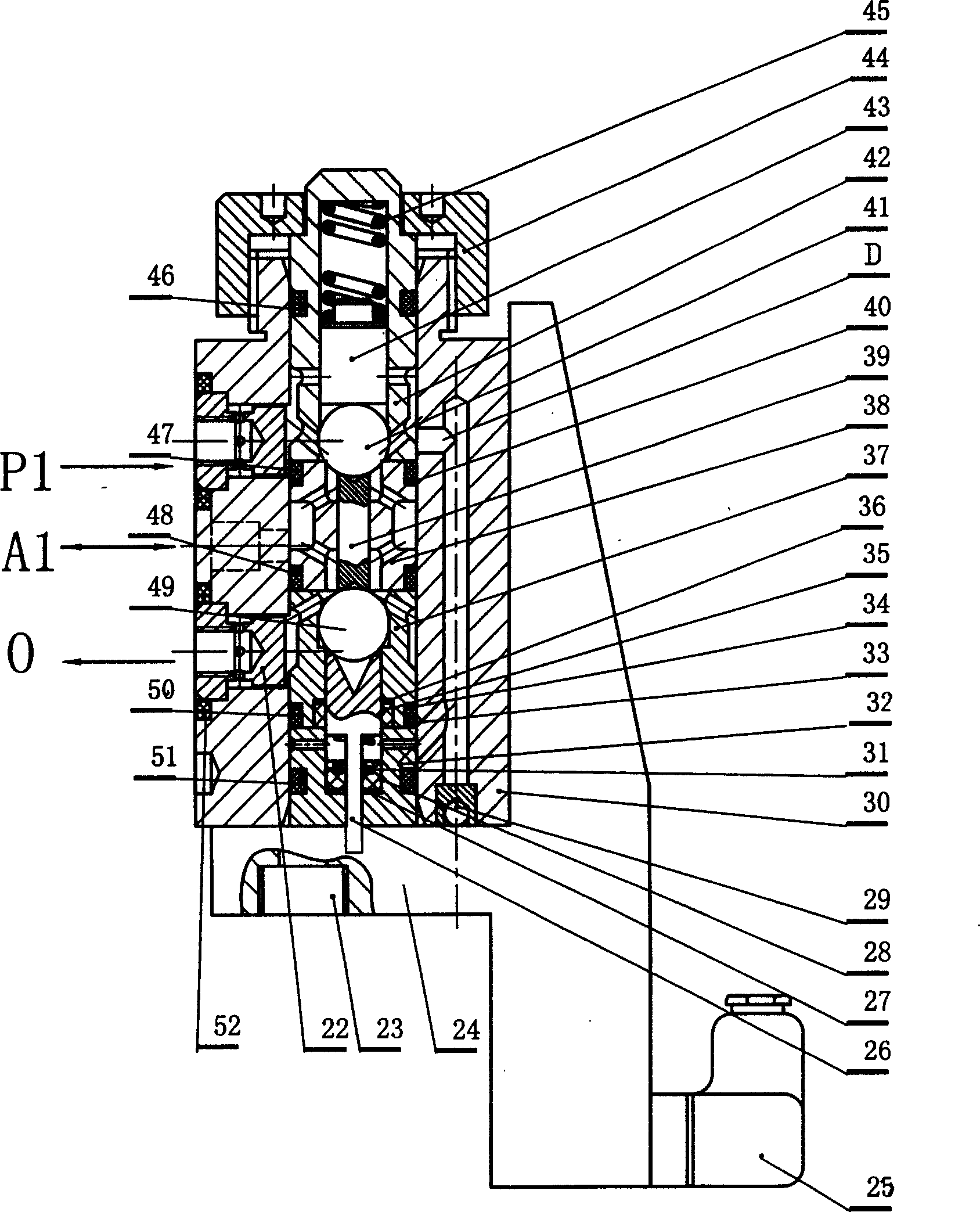

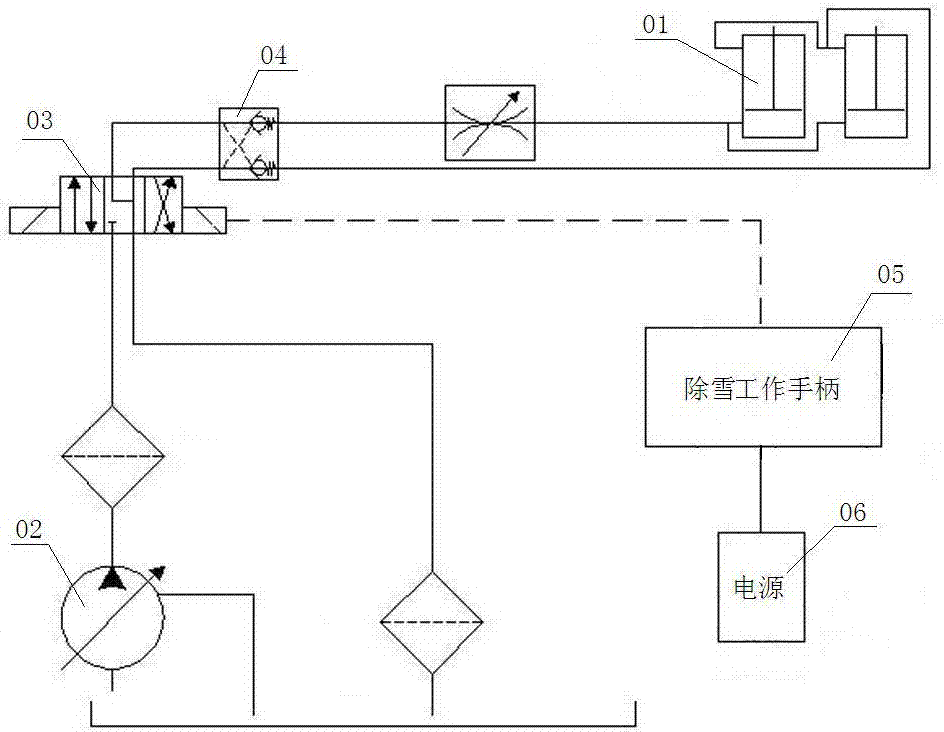

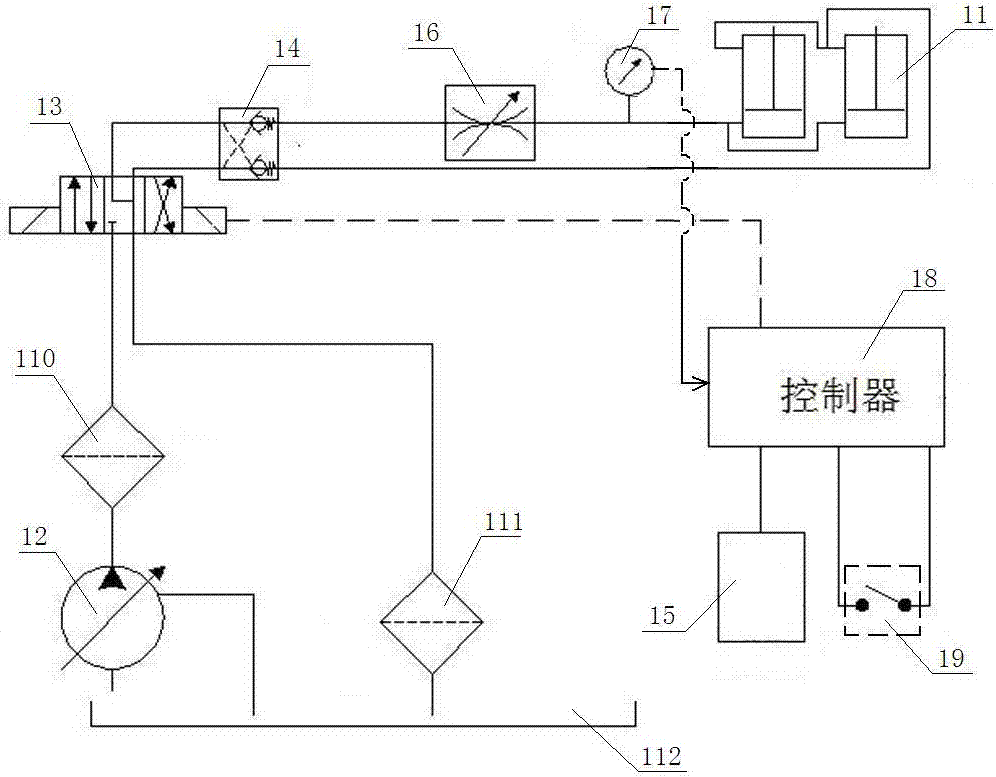

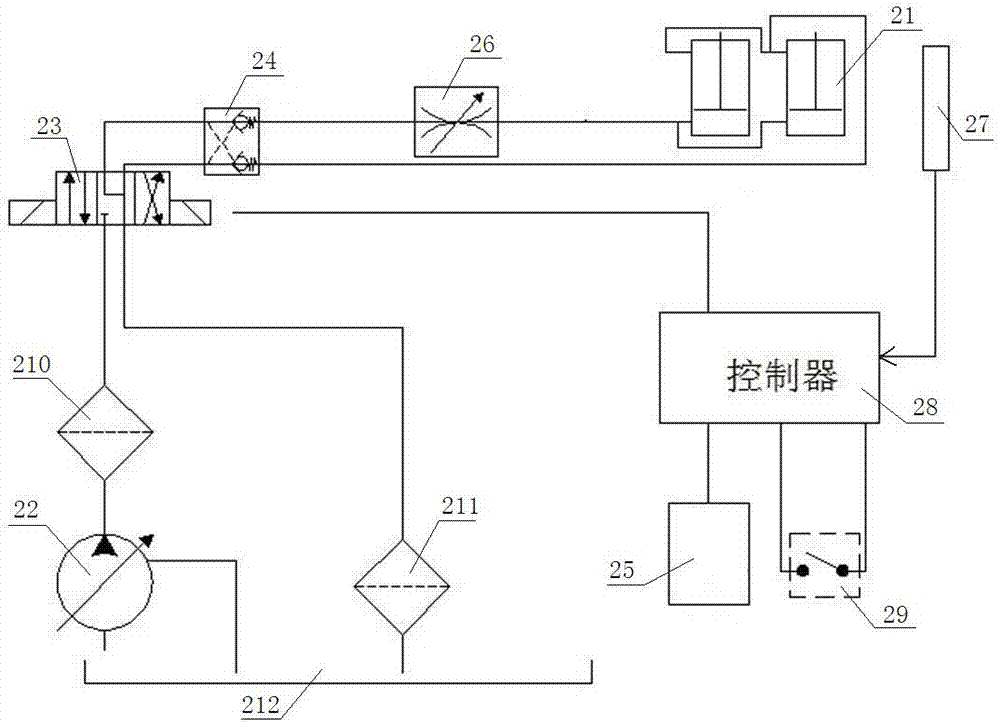

Rolling brush regulating device for snow sweeper

The invention discloses a pressing control device for a rolling brush of a snow sweeper and belongs to the technical field of engineering machinery. The device comprises a lifting cylinder and a hydraulic pump, wherein the lifting cylinder is used for driving the rolling brush to press down; the hydraulic pump is used for supplying pressure oil to the lifting cylinder; a solenoid directional valve is arranged between the lifting cylinder and the hydraulic pump; a sensor used for sensing the abrasion of the rolling brush is also arranged on the device; the sensor is connected with an electric control end of the solenoid directional valve through a controller; an automatic pressing switch for the rolling brush and a snow sweeping operation handle are arranged at a control end of the controller. The pressing control device is capable of solving the problem of easy abrasion of the rolling brush or incomplete snow sweeping caused by the difficulty in controlling the contact pressure between the rolling brush of the snow sweeper and the ground within the optimal scope.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

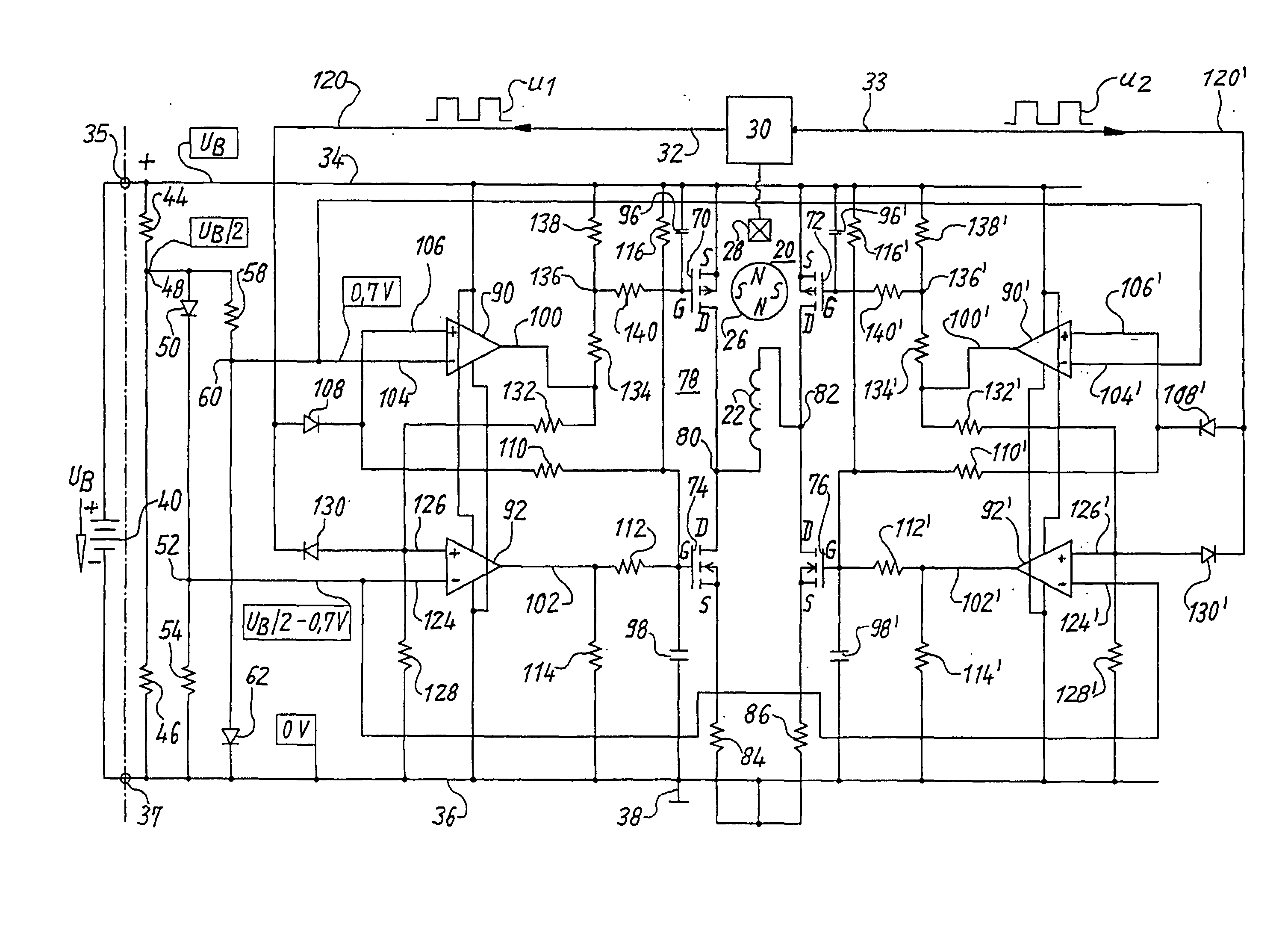

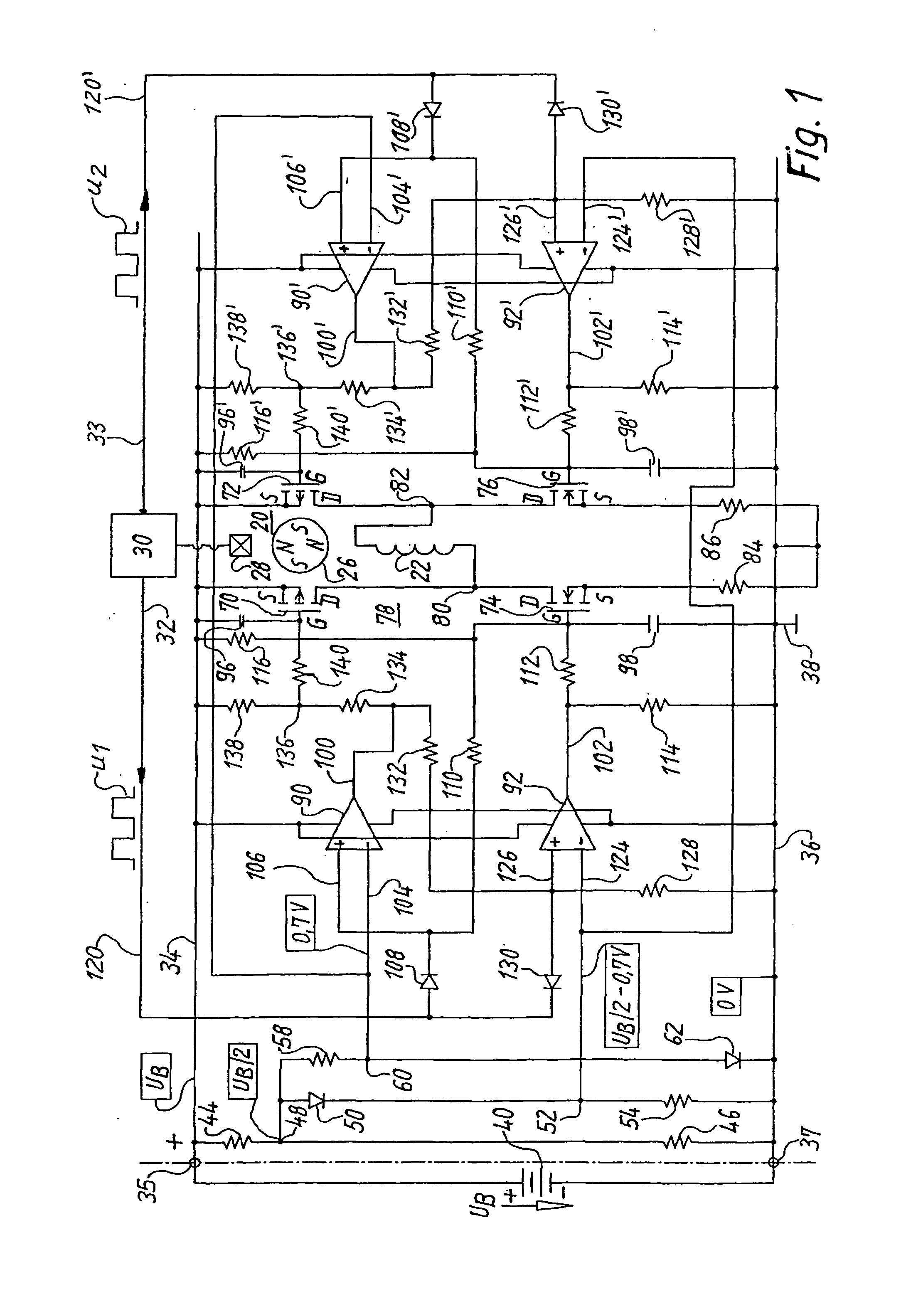

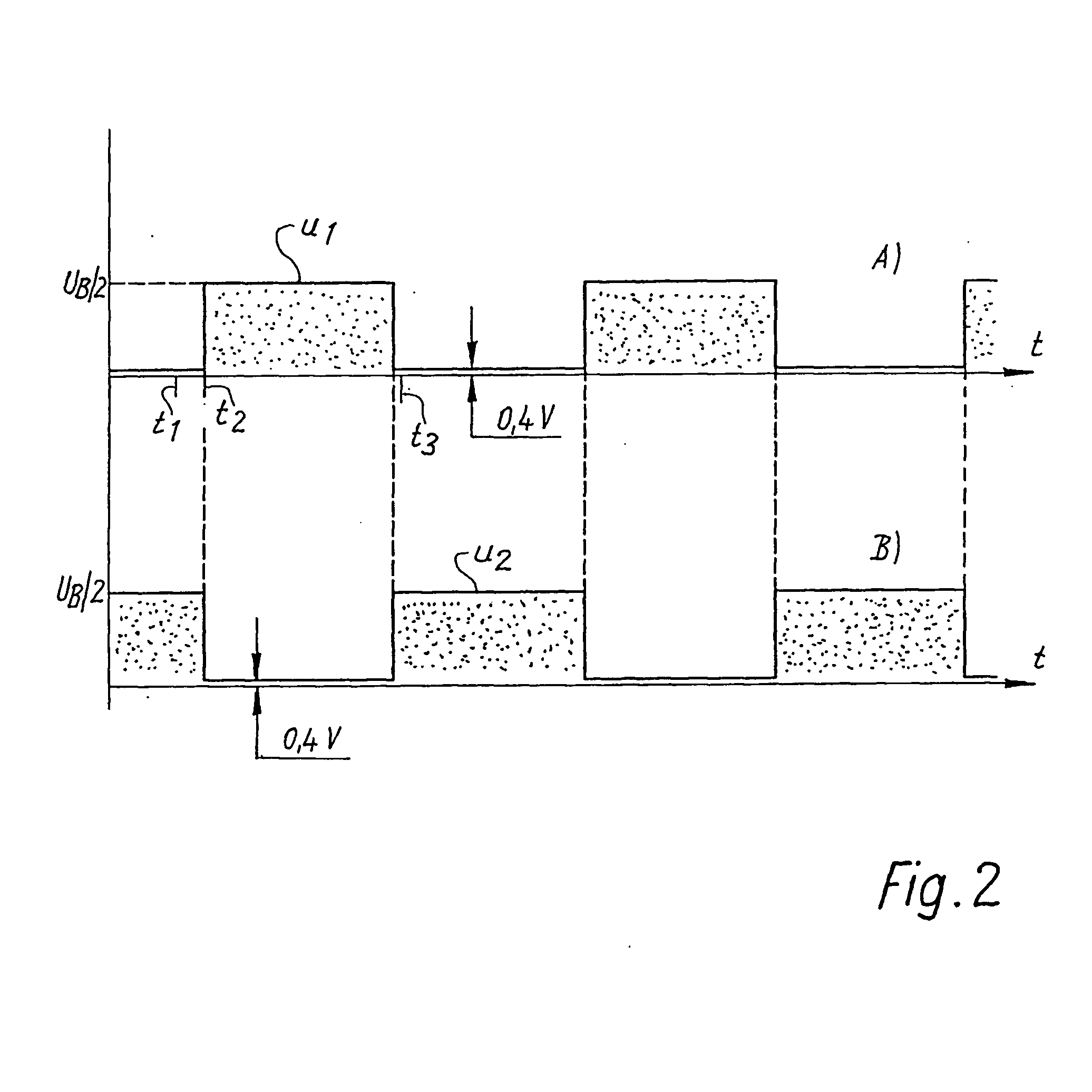

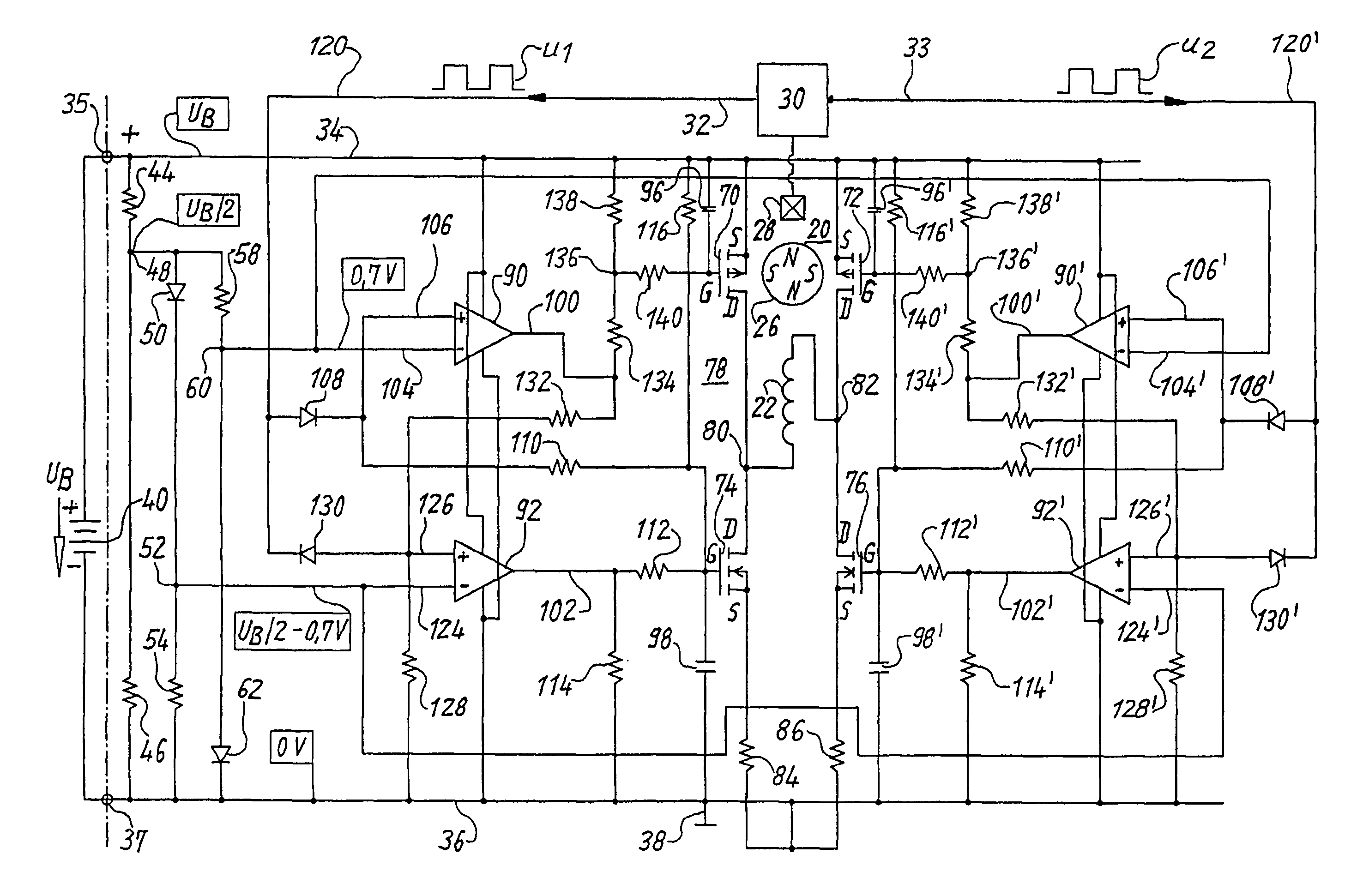

Method for commutating an electronically commutated motor and motor for carrying out said method

InactiveUS20050083002A1Increased power outputHigh power outputMotor/generator/converter stoppersDC motor speed/torque controlOxide semiconductorMOSFET

An improved method of commutating an electronically commutated motor (20) is disclosed. The motor has a positive (34) and a negative connecting lead (36), a stator having at least one winding phase (22), a permanent-magnet rotor (26), a rotor-position sensor (28) for producing a rotor position signal (u1, u2), and a full bridge circuit (78), comprising a pair of Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) coupled to each end of each winding phase (22). In order to prevent current shoot-through and prolong the service life of the MOSFETs, without employing a microprocessor, a respective-comparator (90, 90′, 92, 92′) is coupled to the gate of each MOSFET, in order to assure that the MOSFET is switched ON and OFF at an optimum time.

Owner:EBM PAPST ST GEORGEN & -

Method for commutating an electronically commutated motor and motor for carrying out said method

InactiveUS7015668B2High power outputSimple and inexpensive configurationMotor/generator/converter stoppersAC motor controlMOSFETPermanent magnet rotor

An improved method of commutating an electronically commutated motor (20) is disclosed. The motor has a positive (34) and a negative connecting lead (36), a stator having at least one winding phase (22), a permanent-magnet rotor (26), a rotor-position sensor (28) for producing a rotor position signal (u1, u2), and a full bridge circuit (78), comprising a pair of Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) coupled to each end of each winding phase (22). In order to prevent current shoot-through and prolong the service life of the MOSFETs, without employing a microprocessor, a respective-comparator (90, 90′, 92, 92′) is coupled to the gate of each MOSFET, in order to assure that the MOSFET is switched ON and OFF at an optimum time.

Owner:EBM PAPST ST GEORGEN & -

Miniature high-temperature and high-pressure electric rotary valve

InactiveCN105351557ACommutation is reliableReduce volumePlug valvesOperating means/releasing devices for valvesRotary valveEngineering

The invention discloses a miniature high-temperature and high-pressure electric rotary valve. The miniature high-temperature and high-pressure electric rotary valve comprises a cylindrical valve body, a valve core, a valve rod and a limiting connecting shaft, wherein valve seat holes are symmetrically formed in both sides of a valve core hole in the valve body, floating valve seats are arranged in the valve seat holes, the floating valve seats are matched with the valve core through curved surfaces, a port P, a port A and a port B are formed in the right end of the valve body, the three oil ports are all axially formed and are positioned in the same end surface, a part, which is communicated with the port P, of the valve core forms a cavity P, parts, which are respectively communicated with the port A and the port B, of the two floating valve seats form a cavity A and a cavity B, and the valve core is driven to reverse leftwards or rightwards by a motor, so that the port A is communicated with the port A or the port B to form a two-position three-way reversing valve. The miniature high-temperature and high-pressure electric rotary valve has the advantages of small size, compact structure and reliable sealing performance and is compatible with the small installation space of an annular pipeline, the reliable reversing of an oil system can be guaranteed, and the miniature high-temperature and high-pressure electric rotary valve can be applied in high-temperature and high-pressure severe environments such as power plants, petroleum and natural gas exploitation and the like.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

Foldable baby carriage capable of being pushed in reverse direction

InactiveCN101767600BReasonable structureStable supportCarriage/perambulator with multiple axesEngineeringMechanical engineering

The invention discloses a foldable baby carriage capable of being pushed in a reverse direction. The invention is characterized in that a push-hold frame is provided with an inverting handle interlocked with a pulling cable; the pulling cable is connected with a positioning piece connecting seat which forms a positioning piece; the upper end of the connecting seat jacks up an offsetting spring; the other end of the offsetting props against the inside of the push-hole frame upwards; the side of an upper inverting seat is provided with a kidney-shaped hole and the positioning piece penetrates through the hole; a first positioning part and a second positioning part are formed at a lower inverting seat and are matched with the positioning piece; a first guide surface is formed between the twopositioning parts for transition; when the push-hold frame is pushed in a forward direction, the positioning component penetrates through the kidney-shaped hole and is clamped at the first positioning part; the positioning component slides to be clamped at the second positioning part along the first guide surface, and by this time, the push-hold frame is pushed in a reverse direction; both ends of a rear hood frame are rotatably connected with the lower inverting seat; and a retracting device is arranged between the rear hood frame and the lower inverting seat. The invention has the advantages of high strength of the reverse mechanism, reliable inverting and folding operation, smooth conversion, adjustable angle of the backrest and small volume because front wall components are retracted inwards after being folded.

Owner:NINGBO SHENMA GROUP

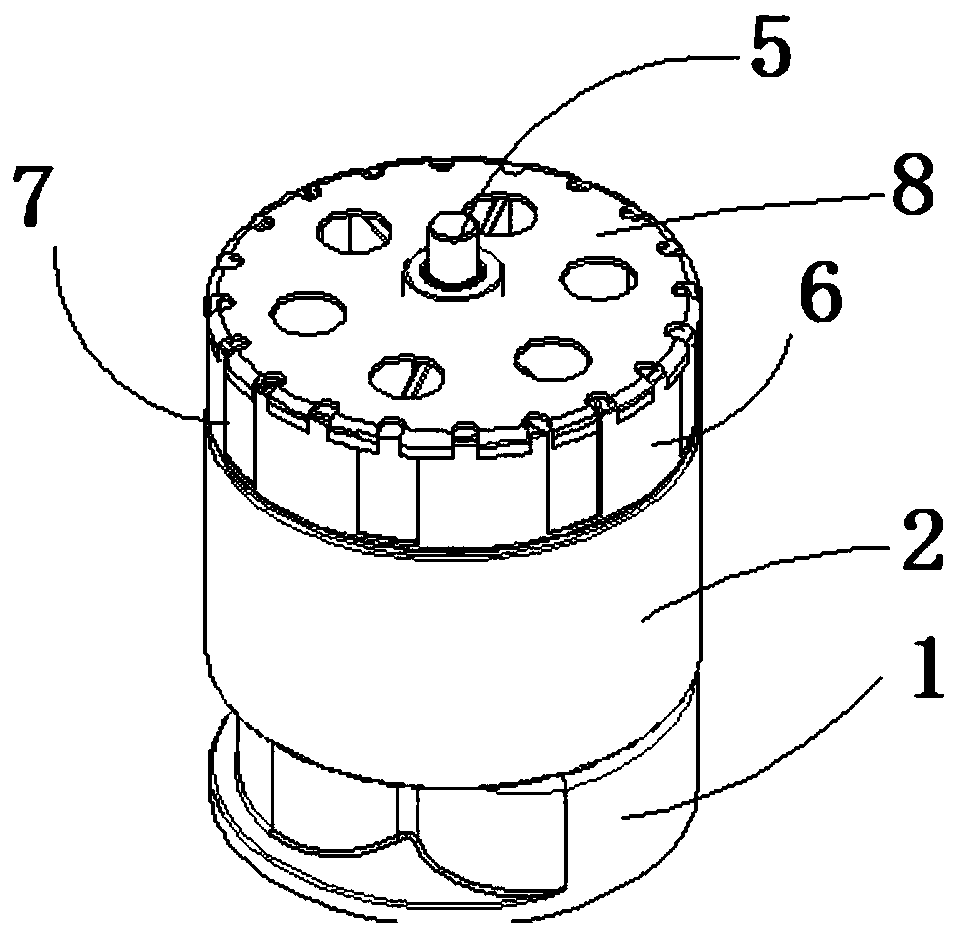

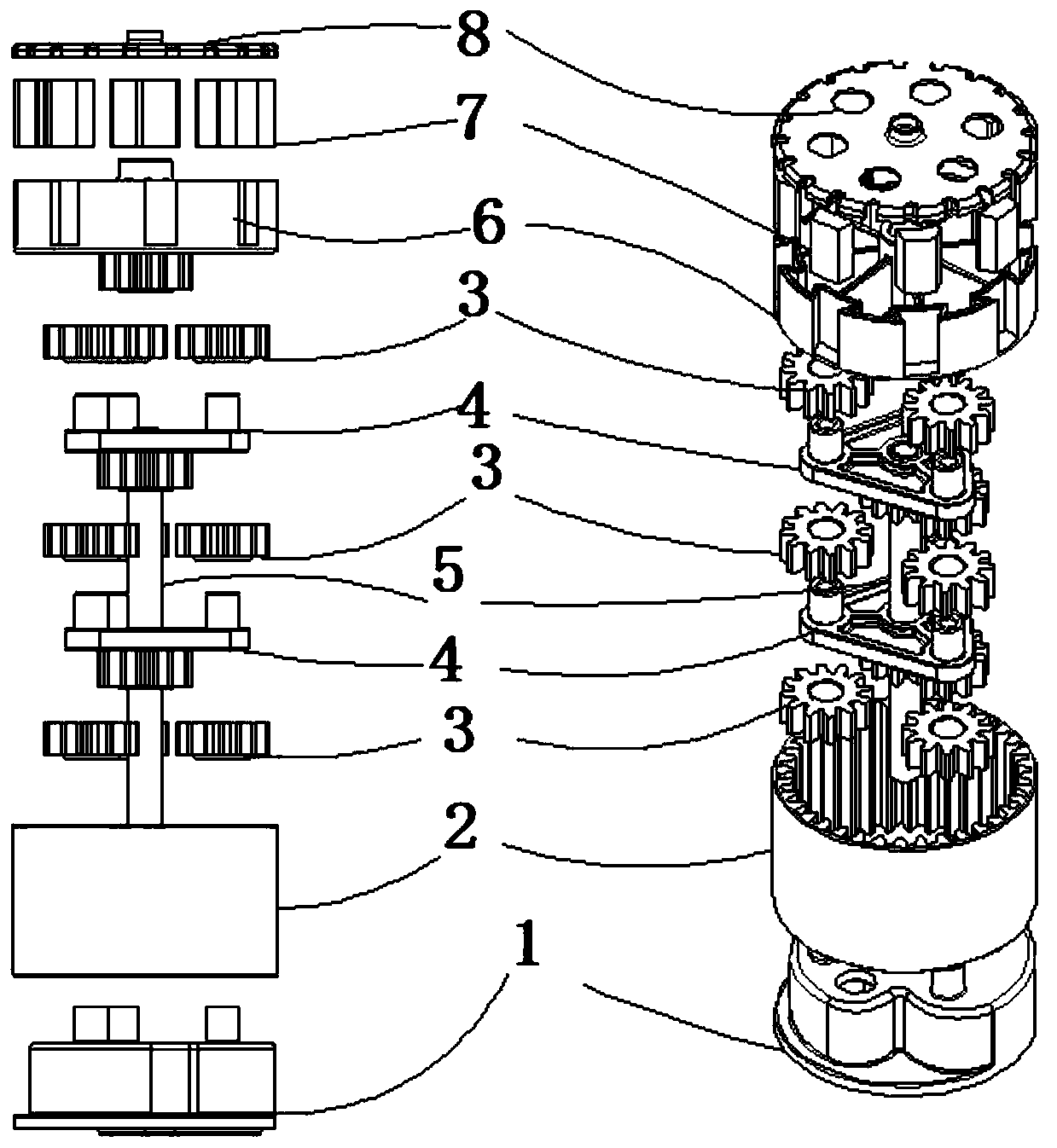

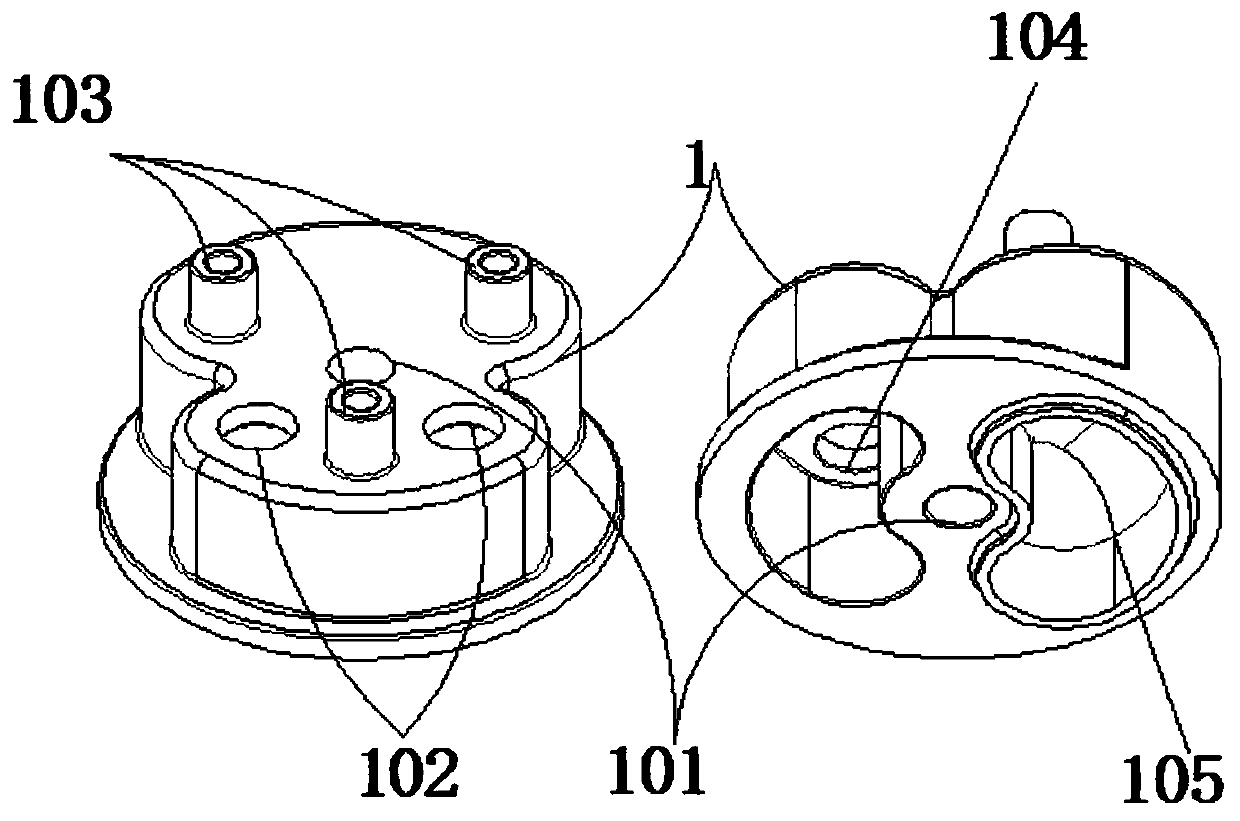

Planetary reducing mechanism for four-way switching valve

PendingCN110131370ALow processing priceCommutation is reliableOperating means/releasing devices for valvesToothed gearingsMechanical engineeringStatics

The invention discloses a planetary reducing mechanism for a four-way switching valve. The mechanism comprises a switching valve disc, a first planetary gear, a planetary gear disc, an inner driving wheel, an inner gear ring, a central shaft and a bearing disc, and the central shaft sequentially penetrates through a first through hole of the switching valve disc, a second through hole of the planetary gear disc and a third through hole of the inner driving wheel to be connected with a through hole of the bearing disc; the first planetary gear is installed on a first positioning shaft of the switching valve disc and a second positioning valve of the planetary gear disc, the planetary gear disc and the first planetary gear are embedded in the inner gear ring, and the inner gear ring is fixedand static and arranged between the switching valve disc and the inner driving wheel. The planetary reducing mechanism has the advantages that large torque can be achieved, so that reliable switchingis ensured, the assembly is simple, the cost of materials is low, the processing cost is low, and therefore the cost is reduced.

Owner:ZHUJI YIBA ELECTRONICS VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com