Rolling brush regulating device for snow sweeper

A technology of snow removal vehicles and rolling brushes, which is applied in snow surface cleaning, construction, cleaning methods, etc. It can solve the problems of difficult control of contact pressure, easy wear of rolling brushes, and incomplete snow removal, so as to achieve the goal of not being easy to wear and ensuring accuracy , The effect of reliable commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

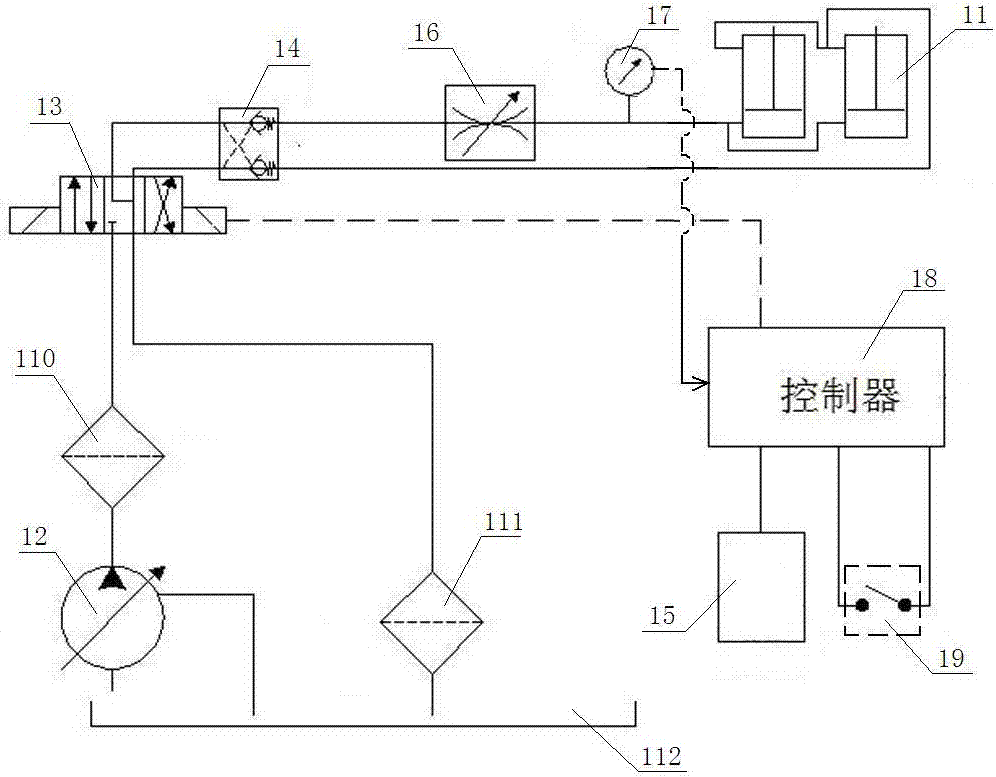

[0020] figure 2 The shown snow removal vehicle rolling brush down pressure control device includes a lifting cylinder 11 that drives the roll brush down and a hydraulic pump 12 that provides pressure oil for the lifting cylinder 11. One-way hydraulic pressure is sequentially arranged between the lifting cylinder 11 and the hydraulic pump 12 Lock 14 and solenoid reversing valve 13, solenoid reversing valve 13 is a three-position four-way valve; there is an adjustable flow valve 16 between the rodless cavity of the lifting cylinder 11 and the one-way hydraulic lock 14, and the lifting cylinder 11 has no rod A pressure sensor 17 is provided between the cavity and the adjustable flow valve 16; a first filter element 110 is provided between the electromagnetic reversing valve 13 and the hydraulic pump 12, and a second filter element 111 is provided between the electromagnetic reversing valve 13 and the oil tank 112; pressure The sensor 17 is connected to the electric control end of ...

Embodiment 2

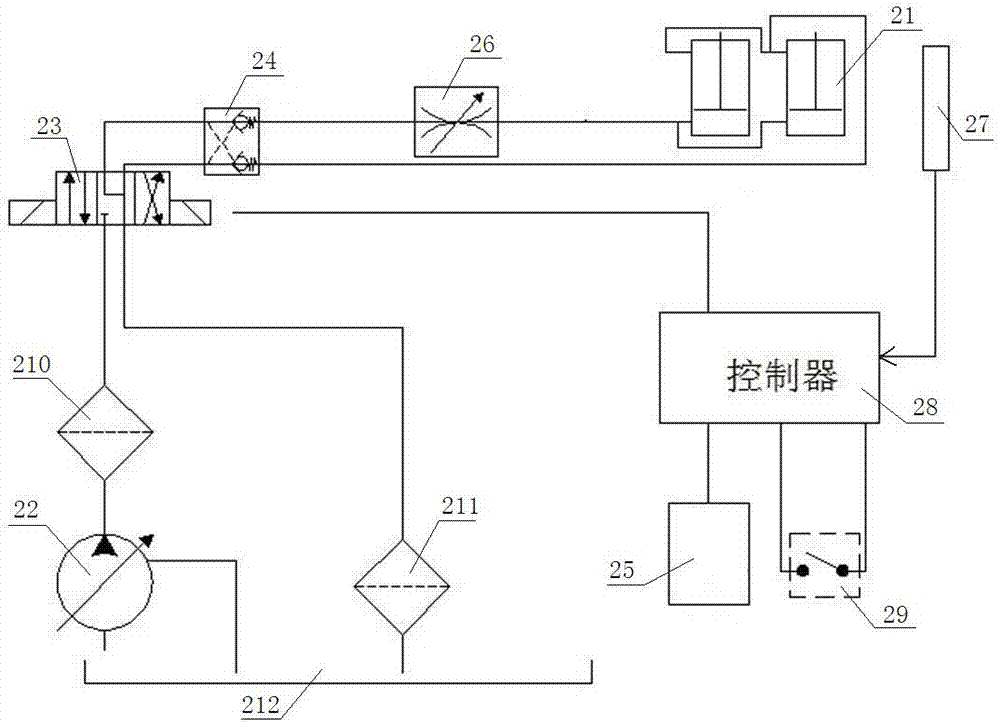

[0023] image 3 The shown snow removal vehicle rolling brush downward pressure control device includes a lifting oil cylinder 21 that drives the rolling brush downward and a hydraulic pump 22 that provides pressure oil for the lifting oil cylinder 21. One-way hydraulic pressure is sequentially arranged between the lifting oil cylinder 21 and the hydraulic pump 22. The lock 24 and the electromagnetic reversing valve 23, the electromagnetic reversing valve 23 is a three-position four-way valve; an adjustable flow valve 26 is arranged between the rodless cavity of the lifting cylinder 21 and the one-way hydraulic lock 24; the electromagnetic reversing valve 23 and A first filter element 210 is provided between the hydraulic pump 22, and a second filter element 211 is provided between the electromagnetic reversing valve 23 and the oil tank 212; a displacement sensor 27 is provided at the piston rod corresponding to the lifting cylinder 21; the displacement sensor 27 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com