Patents

Literature

46results about How to "Many tricks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

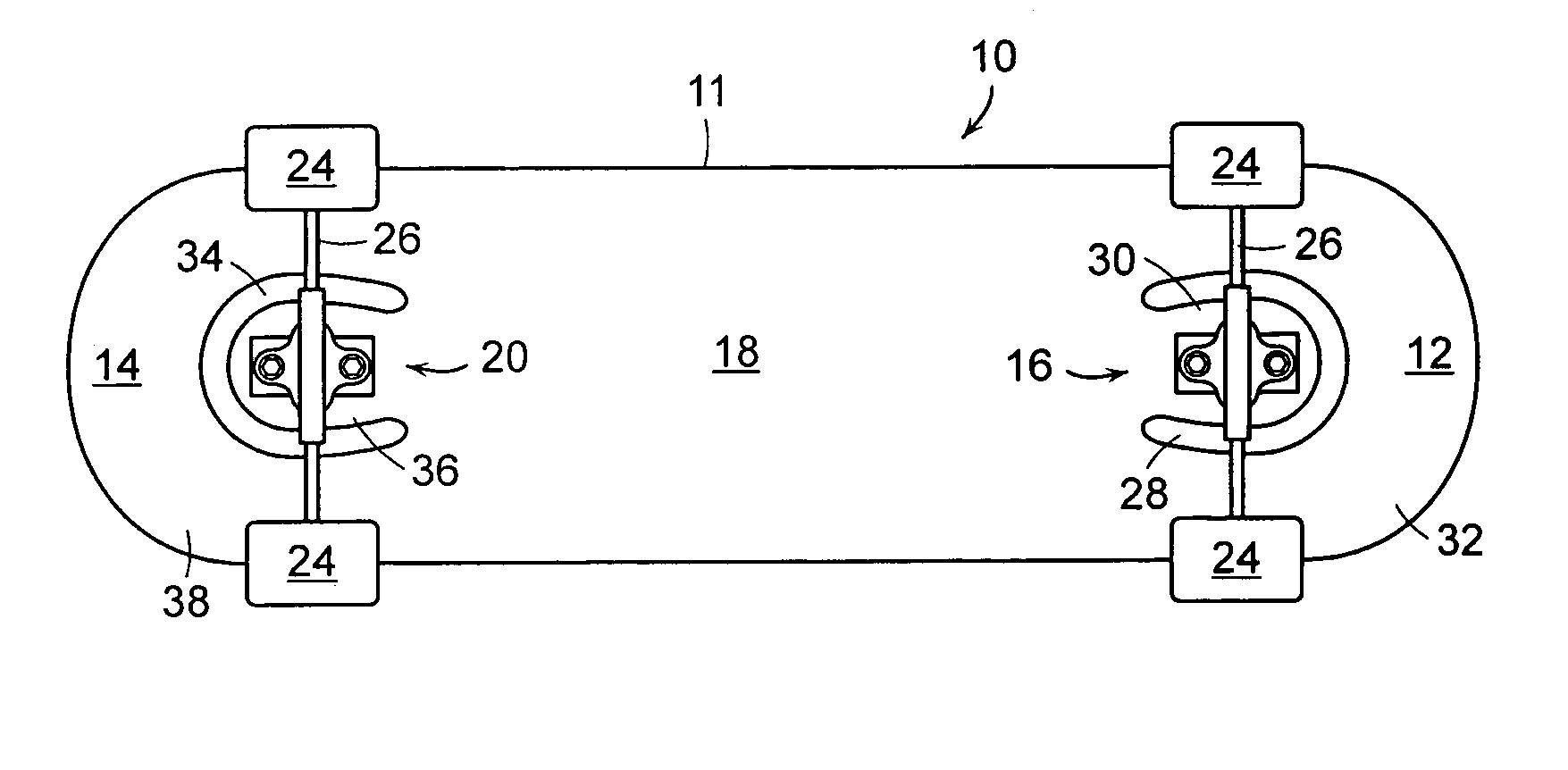

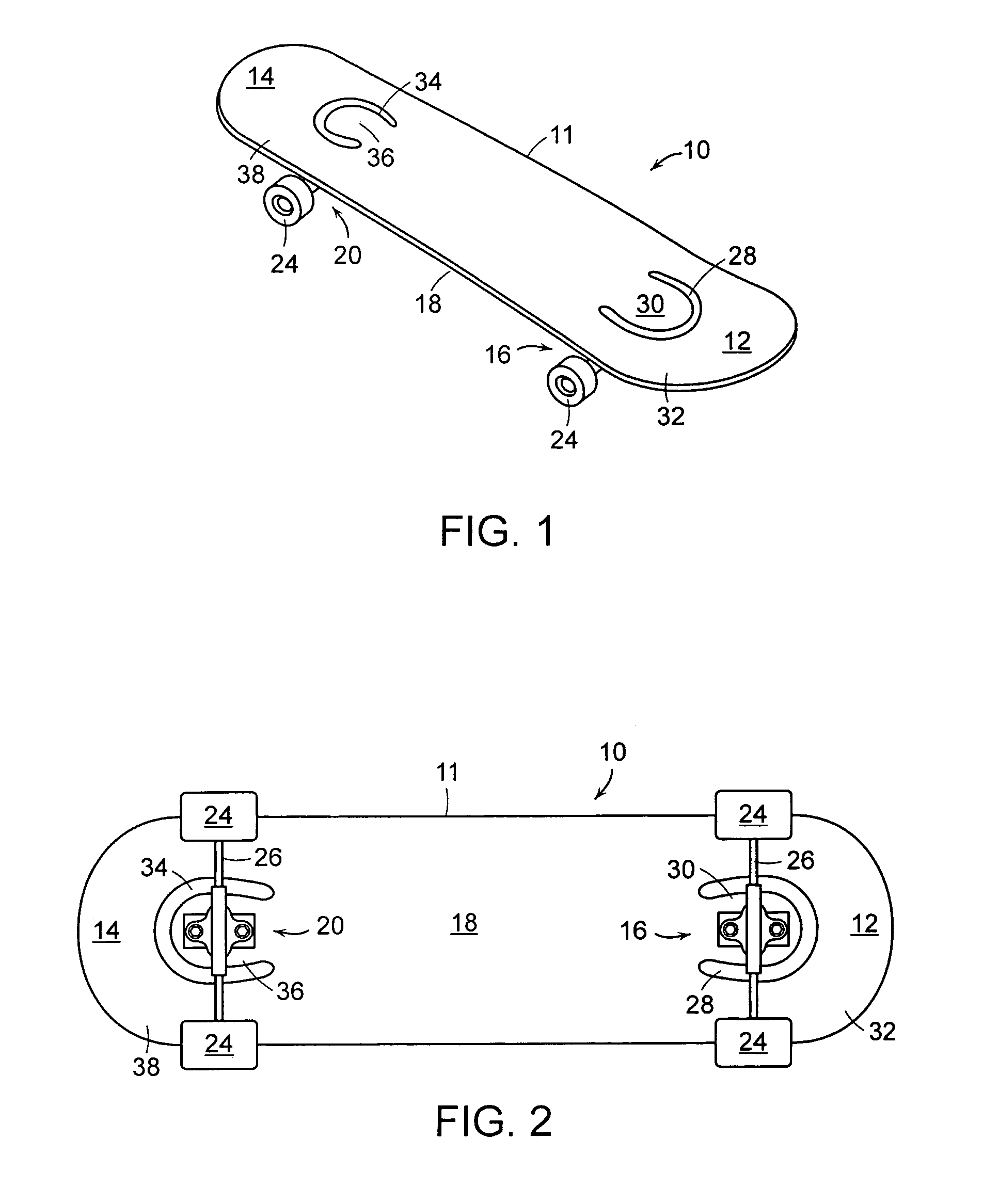

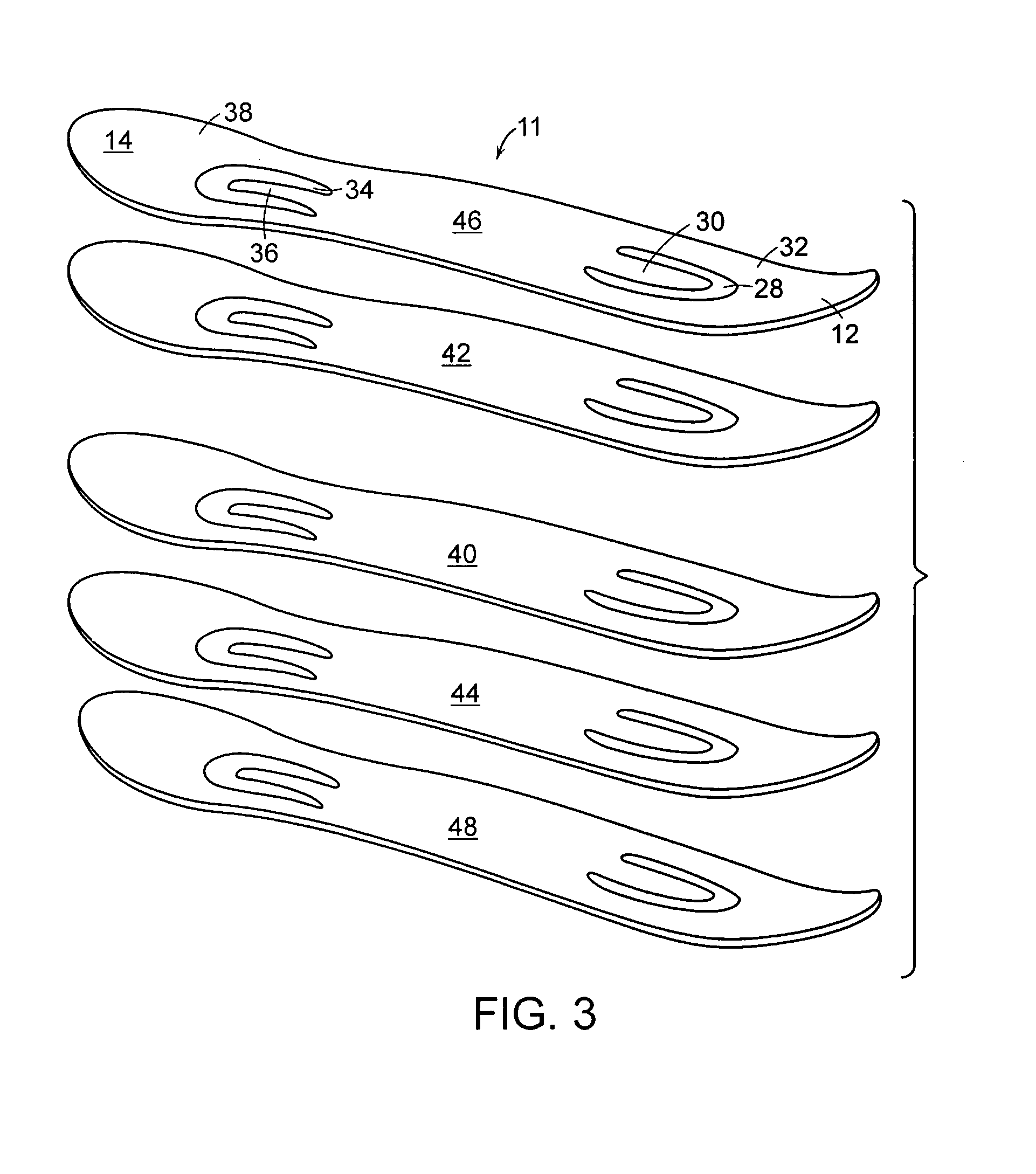

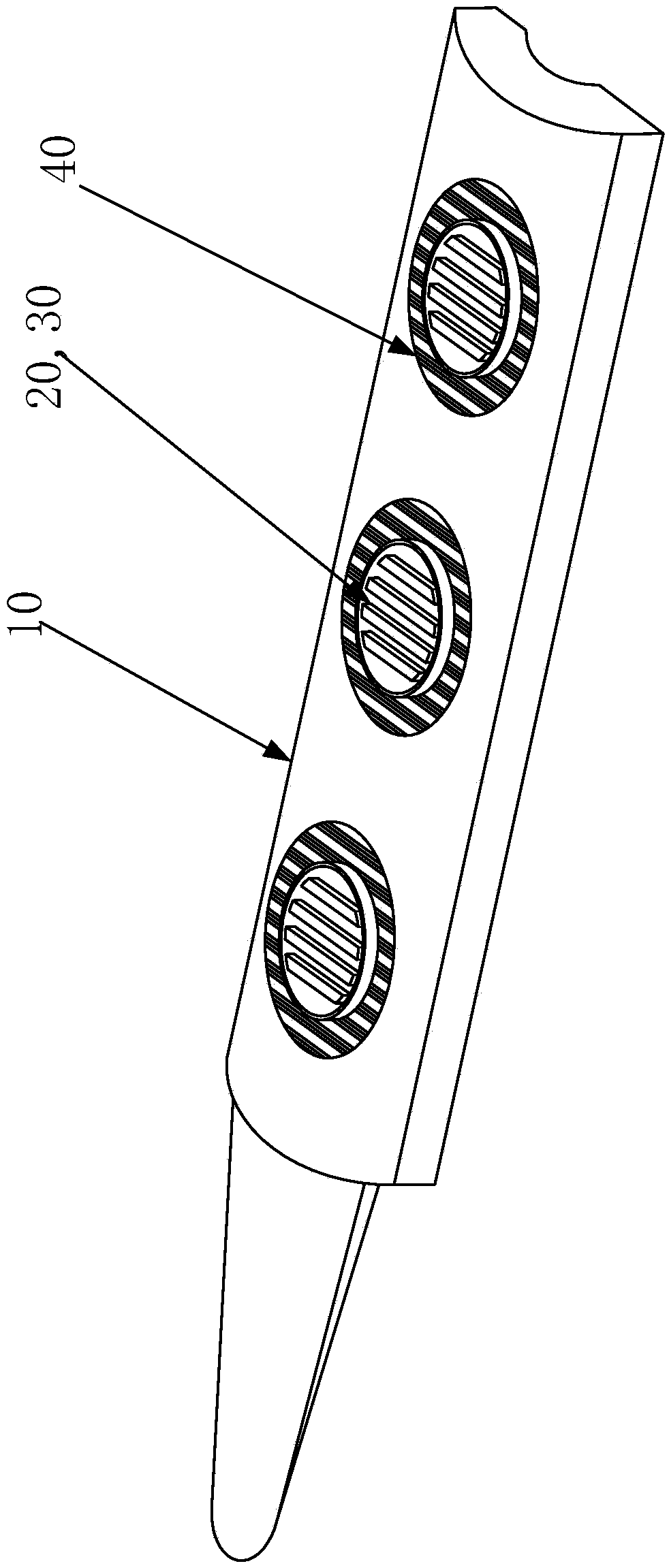

Skateboard with suspension system

InactiveUS7044486B2Improved suspension systemIncrease flexibilityRider propulsionSkate-boardsEngineeringMechanical engineering

A skateboard includes a board having a tip portion and a tail portion. A substantially U-shaped first aperture is formed in the tip portion, with an open end of the first aperture opening toward a central portion of the board. A substantially U-shaped second aperture is formed in the tail portion, with an open end of the second aperture opening toward a central portion of the board.

Owner:NIKE INC

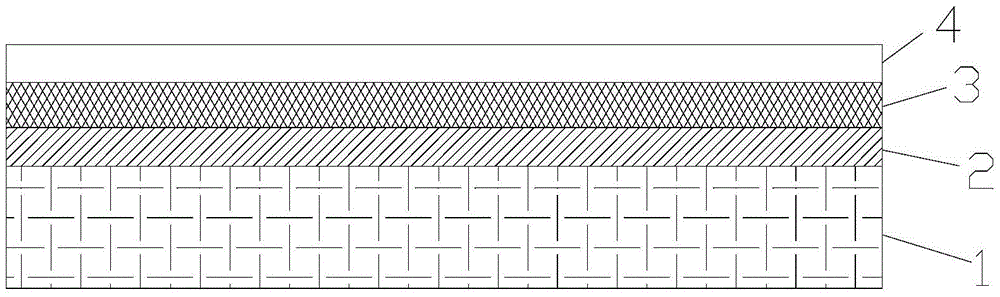

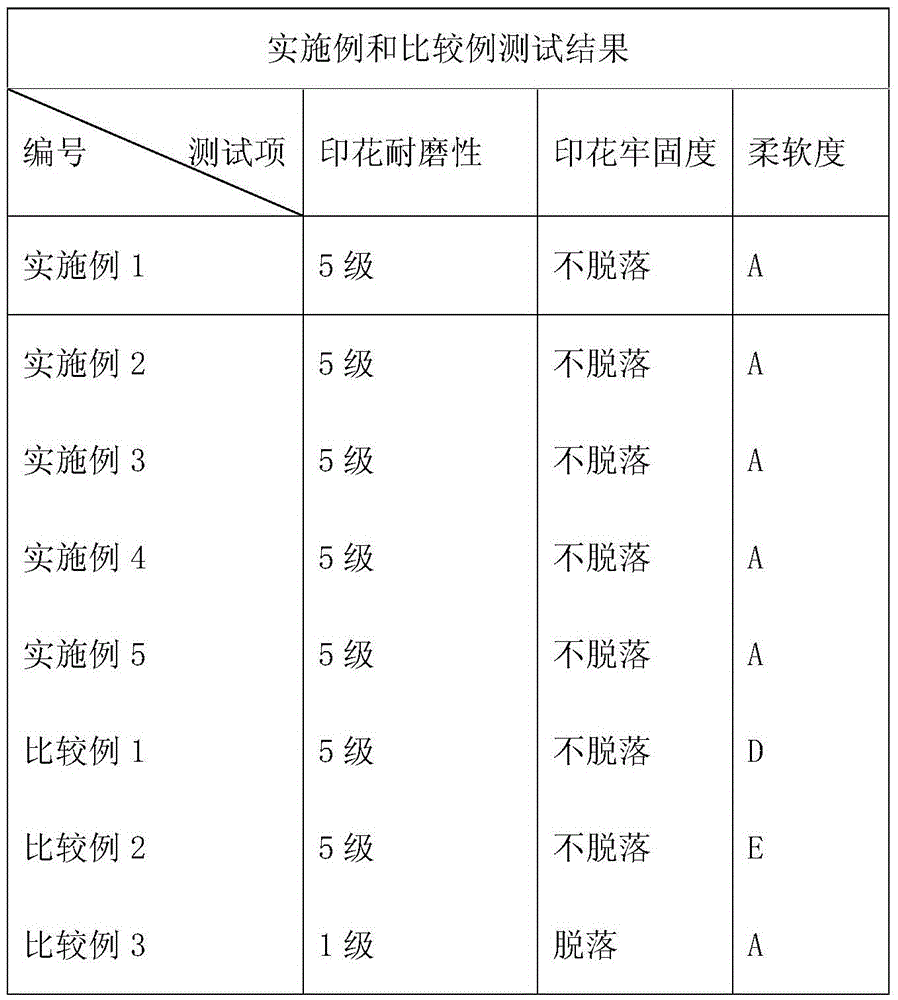

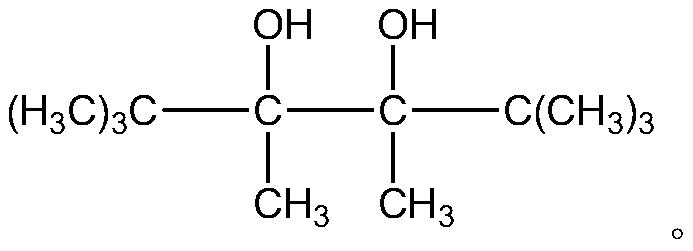

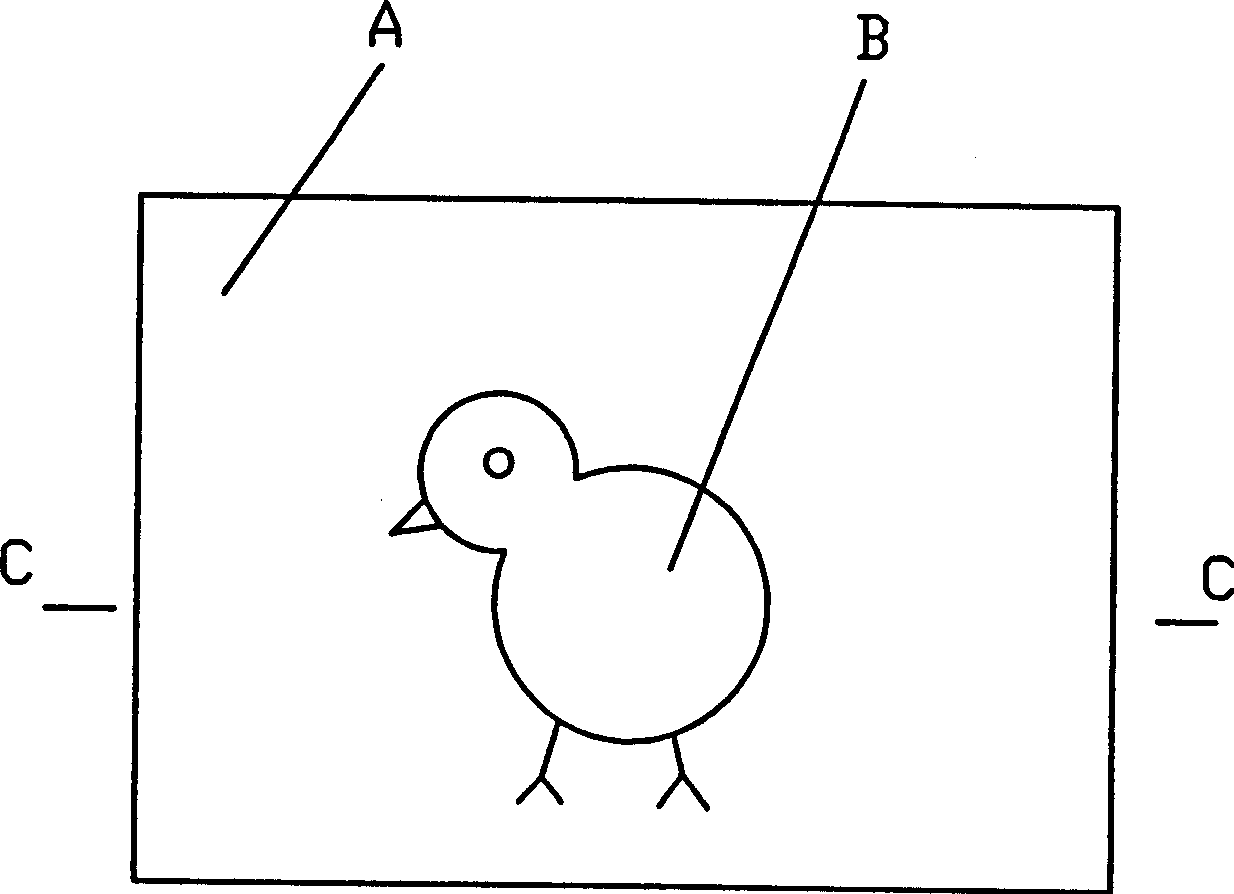

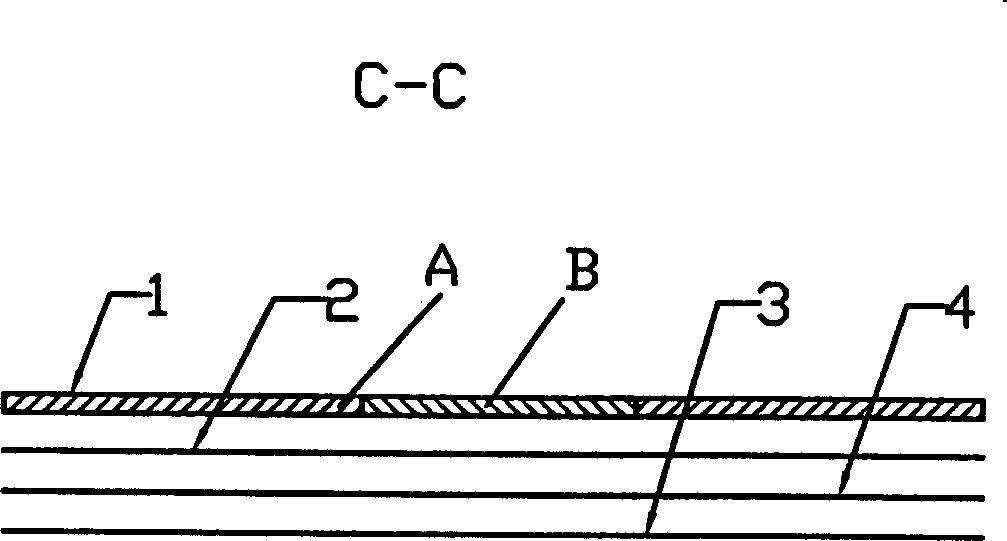

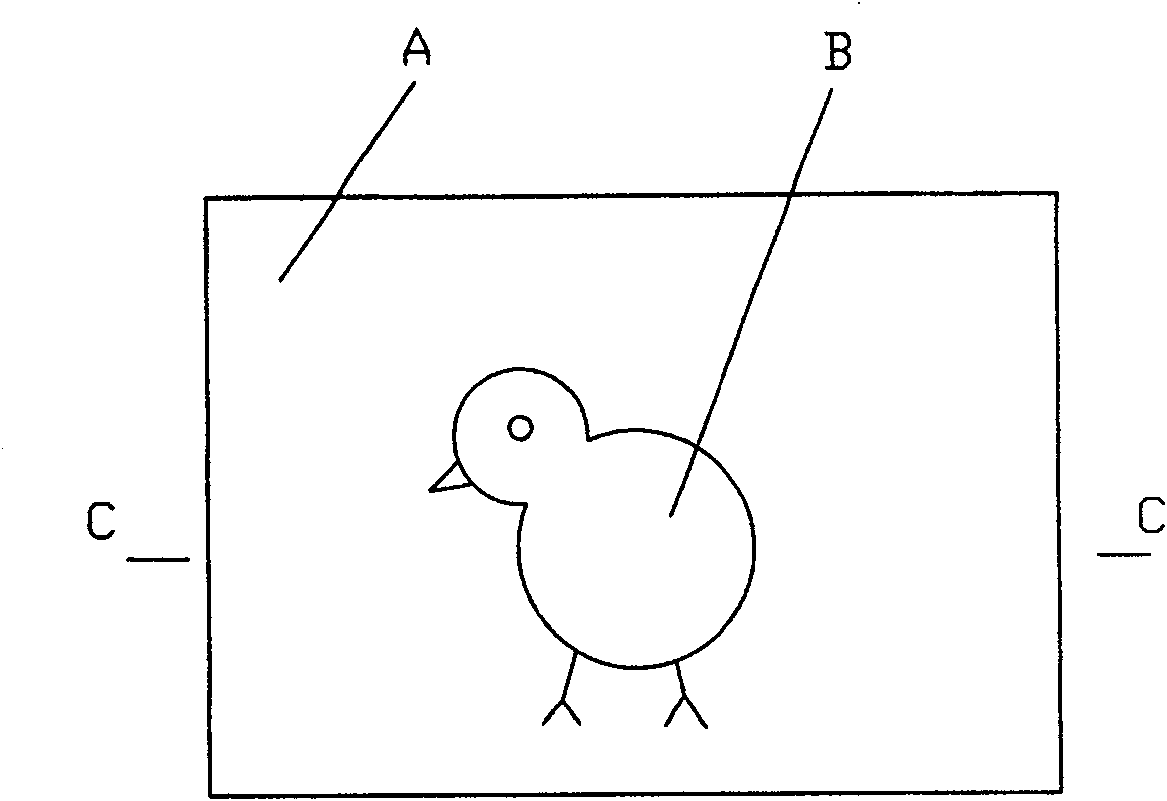

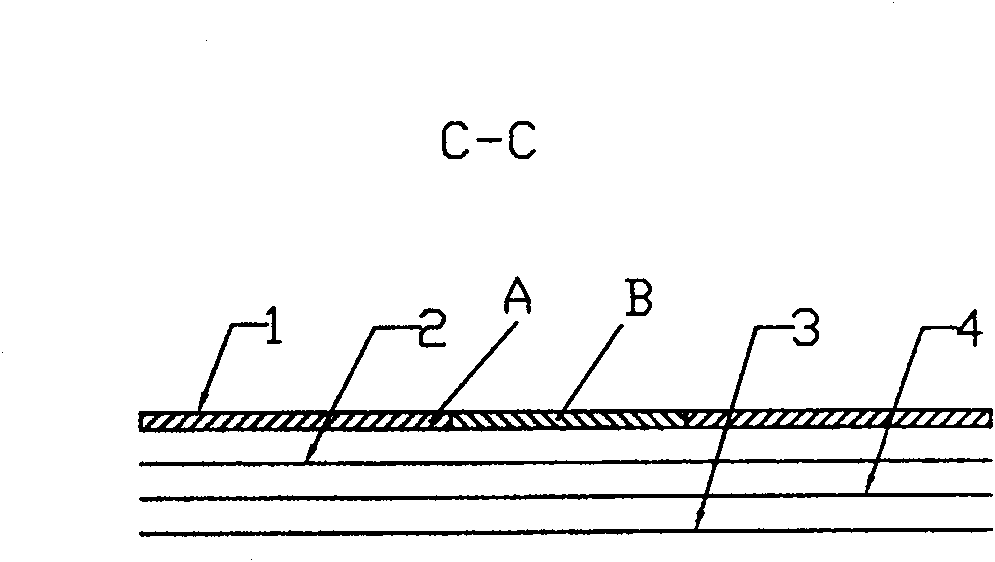

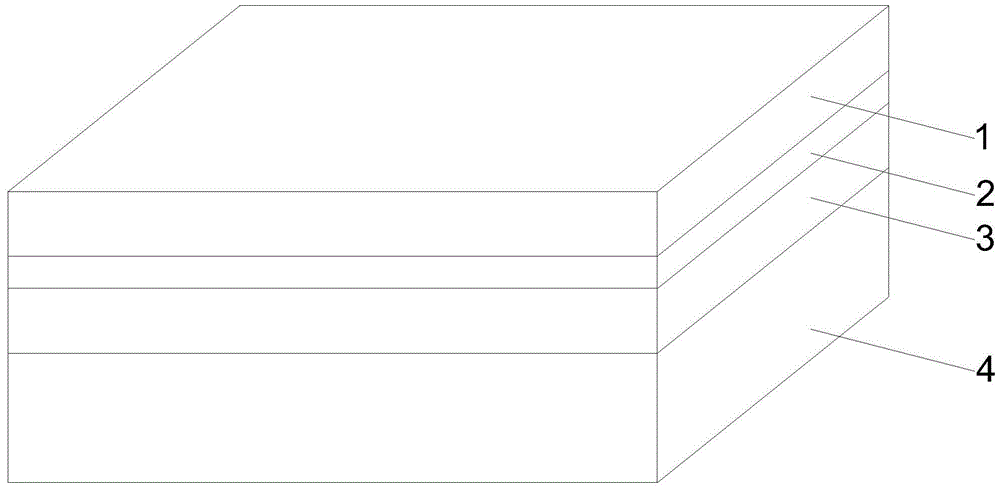

Printed organic silicone synthetic leather and preparation method thereof

The invention discloses printed organic silicone synthetic leather and a preparation method thereof. The printed organic silicone synthetic leather comprises a silica gel layer (4), an ink layer (3), a colored silica gel layer (2) and a base material (1) in sequence from top to bottom. The preparation method includes the steps that blended silica gel layer adhesive is arranged on release paper or a release film in a coated mode and vulcanized to form the silica gel layer (4), blended ink layer adhesive is utilized to form a printed pattern on the cured silica gel layer (4) in a spraying or coating mode, blended colored silica gel layer adhesive is arranged on the vulcanized ink layer (3) in a coated mode to be attached to the base material (1), after vulcanization is conducted, the release paper or the release film is stripped, and the printed organic silicone synthetic leather is obtained. According to the printed organic silicone synthetic leather and the preparation method thereof, the release film or the release paper is utilized to cover the silica gel ink layer with a transparent layer, so that a bonding layer and a surface protection layer are additionally arranged on silica gel ink, it is difficult to remove the printed pattern from the organic silicone synthetic leather, diversity can be achieved, and the layered feeling is obvious.

Owner:SALIRONE INC HUIZHOUCAMPUS

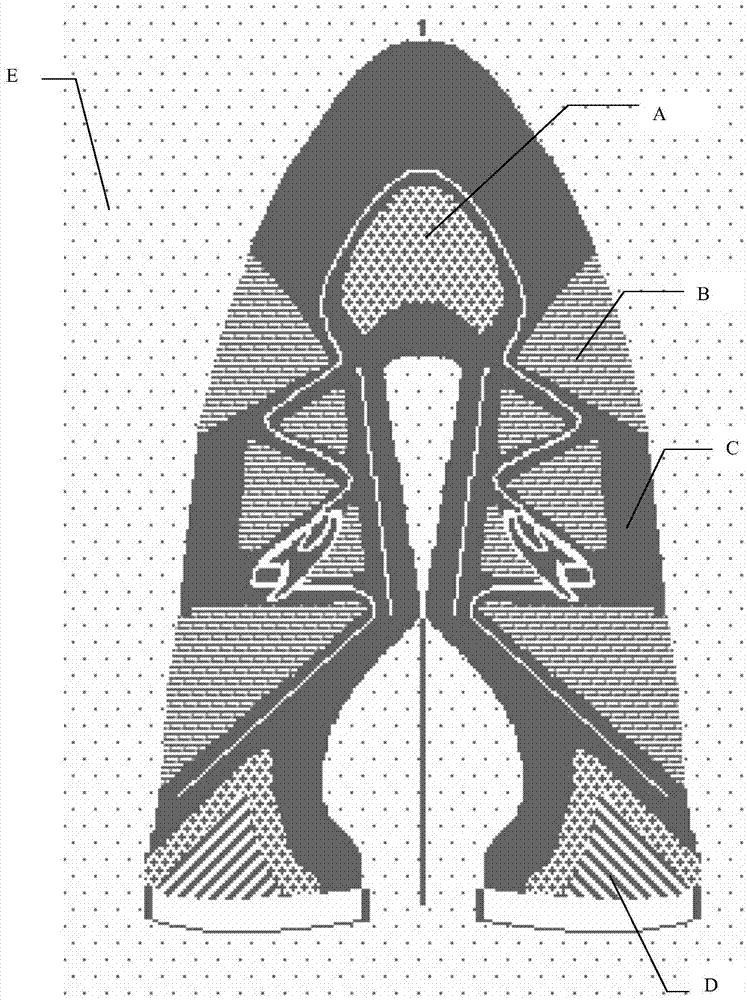

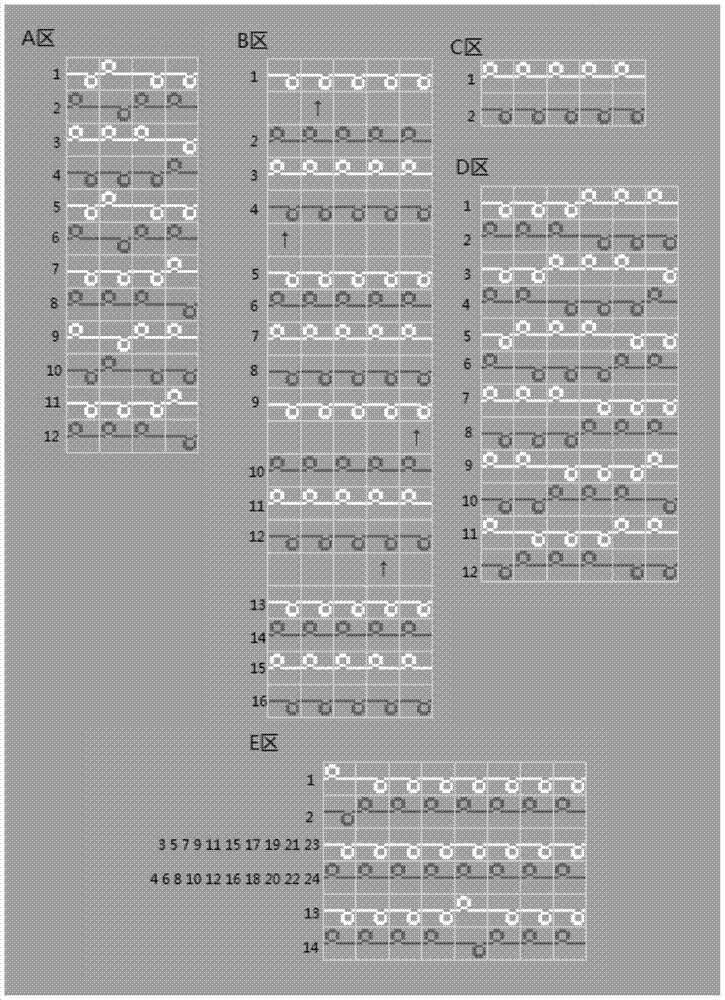

Structure and production method of weft-knitted jacquard shoe upper material

ActiveCN104562401AImprove breathabilityComfortable to wearWeft knittingHeating/cooling textile fabricsEngineeringAir layer

The invention belongs to the field of textiles and provides a structure and a production method of a weft-knitted jacquard shoe upper material. According to the weft-knitted jacquard shoe upper material, terylen low-melting-point color filaments with skin-core structures are adopted, the meshes, esthetic appearance and air permeability of the shoe upper material are realized by utilizing air-layer jacquard tissues as fundamental tissues, loop accumulation tissues or loop transfer tissues on a dual-way jacquard dual-side loop transfer round weft machine; by virtue of cooperation between colors and structural jacquards, functional sections of the shoe upper material are realized; during aftertreatment, a skin layer is fused at a certain temperature under a certain pressure, so that dual-side weft-knitted jacquard shoe upper fabric loops are mutually glued, then cooled and solidified, so that the shoe upper material with appropriate rigidity and hand feeling is obtained; spandex can also be added, so that the elasticity and the density of the fabric are enhanced. The weft-knitted jacquard shoe upper material is variable in pattern, color and style, beautiful in appearance, portable and flexible, favorable in air permeability and comfort in wear; traditional working procedures of cutting, sewing, bonding and the like for shoe materials are not needed, so that the equipment investment and the labor cost are lowered.

Owner:JIANGNAN UNIV

Cookie biscuit and preparation method thereof

InactiveCN101313688AEasy to eatEasy to controlBakery productsFood preparationSodium bicarbonateVegetable oil

The invention relates to a butter cookie and a preparation method thereof. The formula of the butter cookie comprises 15 to 18 percent of coarse grain special flour, 30 to 38 percent of gluten flour, 8 to 15 percent of edible vegetable oil, 12 to 20 percent of white granulated sugar, 2 to 3 percent of dried whole milk, 0.2 to 0.25 percent of sodium bicarbonate, 0.2 to 0.35 percent of ammonium bicarbonate, 0.1 to 0.25 percent of edible salt, 0.1 to 0.25 percent of coarse grain essence, 2 to 3.5 percent of egg and the balance being water. The preparation method comprises the following steps that: needed raw materials are taken and mixed in advance by means of dry powder; a prepared dough is extruded and is cut into a biscuit dough by a steel wire, thereby forming biscuit dough in different shapes; and the biscuit dough is roasted, and roasted butter cookies undergo cooling in a natural state. The butter cookie has easily controlled mixture ratio of raw materials, low production cost and stable product quality, and is suitable for large-scale production.

Owner:田丰

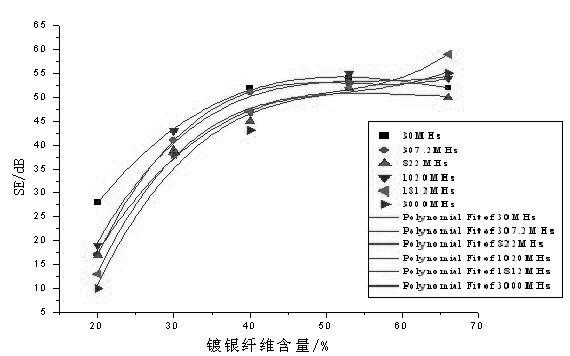

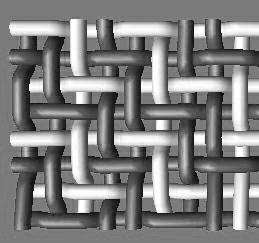

Multifunctional compound fabric resisting electromagnetic radiation and ultraviolet ray

InactiveCN102181989AEfficient radiation protectionReduce manufacturing costFibre typesWoven fabricsFiberUltraviolet

The invention discloses a multifunctional compound fabric resisting electromagnetic radiation and ultraviolet ray. The warp and the weft are formed by mixing silver-coated fiber and uvioresistant terylene; the arranging proportion of the silver-coated fiber to the unioresistant terylene in the warp and the weft is 1:1, or 1:2 or 1:3: the silver-coated fiber is distributed in a warp network and weft network type in the fabric so as to form a closed conductive loop; and the fabric has a double-tissue structure, or a double-layer exchanging structure, and double-layer tying tissue structure or multi-layer filing and multi-layer tying tissue structure. The multifunctional compound fabric has the advantages that under the condition of relatively low preparing cost, the fabric with high-efficiency effects of resisting electromagnetic radiation, ultraviolet ray, bacterium and the like can be produced, the production method is simple and convenient. The multifunctional compound fabric can be widely applied to daily life and daily production of people.

Owner:ZHEJIANG SCI-TECH UNIV

Glue-free PVC (polyvinyl chloride) floor board and preparation method thereof

The invention relates to a glue-free PVC (poly vinyl chloride) floor board, comprising a surface wear-resistant layer, a fabric layer and a bottom layer, wherein the bottom layer comprises an upper layer, a middle layer and a lower layer, the upper layer is prepared from the following raw materials in parts by weight: 140-170 parts of PVC powder, 700-900 parts of plasticizer and 5-7 parts of stabilizer, the middle layer is prepared from the following raw materials in parts by weight: 400-600 parts of PVC powder, 300-400 parts of plasticizer, 800-1000 parts of mountain flour and 9-13 parts of stabilizer, and the lower layer is prepared from the following raw materials in parts by weight: 800-1000 parts of PVC powder, 600-750 parts of plasticizer, 200-300 parts of mountain flour and 20-30 parts of stabilizer. The glue-free PVC floor board provided by the invention has skid resistance and good elasticity, is easy to construct and has low construction cost, and no glue is used. The invention also discloses a preparation method of the glue-free PVC floor board.

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

Sesame oil-free glue pudding and manufacturing method thereof

The invention relates to a sesame oil-free glue pudding which is manufactured by the following materials by weight percent: 15%-25% of cooked black sesame, 40%-60% of skin jelly, 20%-40% of rock candy as well as 1%-5% of sugar osmanthus. The manufacture method includes the following steps of: 1) preparing the skin jelly; 2) preparing glue pudding stuffing; 3) preparing glue padding blanks; 4) boiling and processing; and 5) packaging and freezing finished products. The sesame oil-free glue pudding and the manufacturing method thereof have the advantages of low oil, low heat, richness of various natural collagen nutrition and hairdressing elements, fragrant and sweet as well as soft and glutinous taste, and multi-juices. The sesame oil-free glue pudding and the manufacturing method thereof innovate boldly according to the modern nutrition principle and health diet, consider the integrated demands of delicious food and health, and propagate the traditional Chinese snacks. The stuffing ofthe finished products can also be prepared into sesame cakes manufactured by glutinous rice served cold in summer by properly reducing the proportions of partial black sesame and rock candy, can be prepared into frozen food like double-flavor and double-layer cakes manufactured by glutinous rice served cold in summer by increasing less cooked walnut powder. The sesame oil-free glue pudding has a plurality of types, is simple and convenient, and is suitable for public needs.

Owner:童跃斌

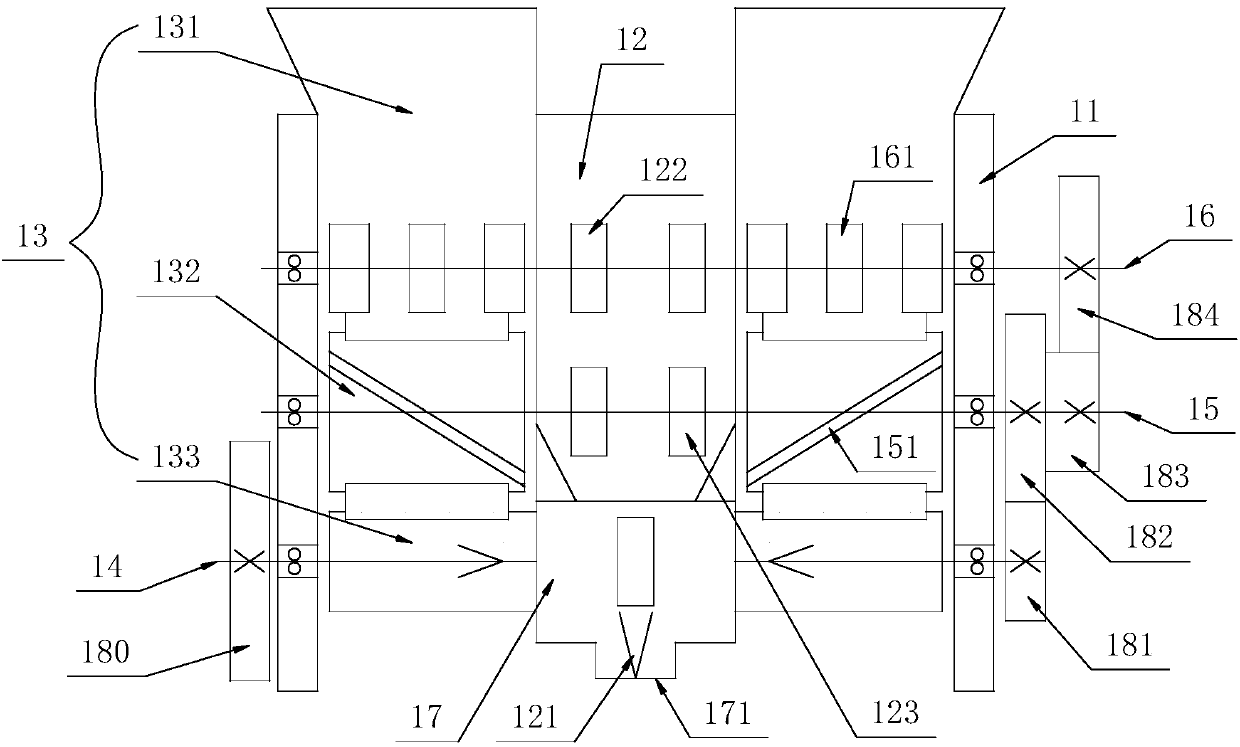

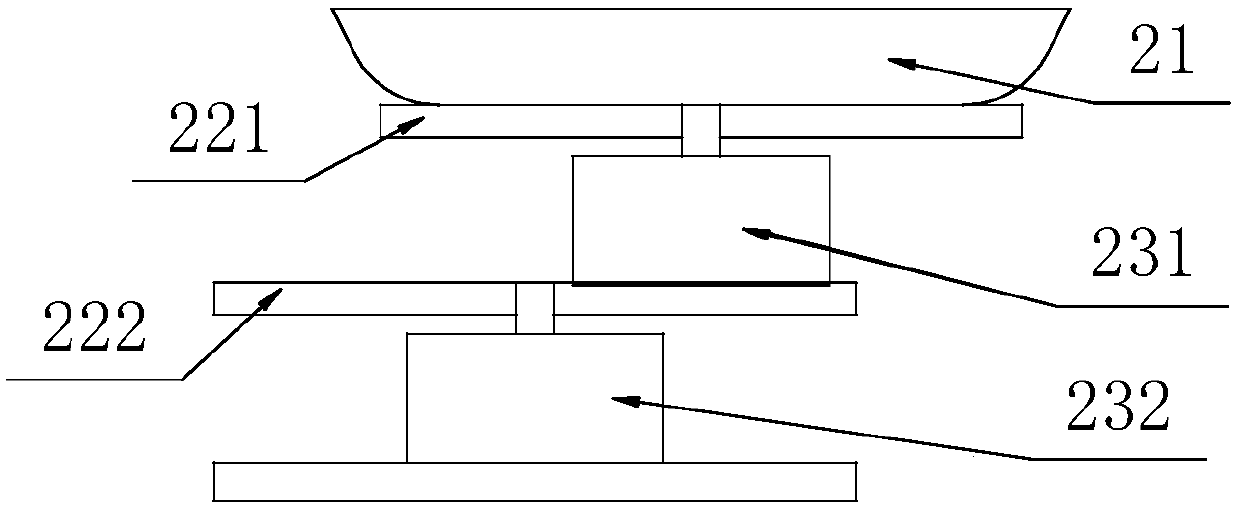

Cooked wheaten food processing equipment and method for making cooked wheaten foods through cooked wheaten food processing equipment

ActiveCN107581205ARealize mechanized processingImprove work efficiencyMixing/kneading structural elementsBakery productsEngineeringFood item

The invention provides cooked wheaten food processing equipment. The cooked wheaten food processing equipment comprises a food strip processing device, a food shaping device and a food cooking device,wherein the food strip processing device comprises a stuffing barrel and dough kneading devices, and the operations of dough mixing, dough kneading, stuffing stirring and food strip extrusion are realized by simultaneous rotation of a first shaft, a second shaft and a third shaft; as for the food shaping device, a driving device is used for driving a food plate to move in the horizontal directionto realize food shaping; and the food cooking device realizes continuous food cooking by electric heating. The invention also provides a method for making cooked wheaten foods through the cooked wheaten food processing equipment. The cooked wheaten food processing equipment disclosed by the invention is used for making stuffed cooked wheaten foods, so that making of the stuffed cooked wheaten foods is mechanized, the limitation of manual operation is broken through and the work efficiency is improved.

Owner:李才生

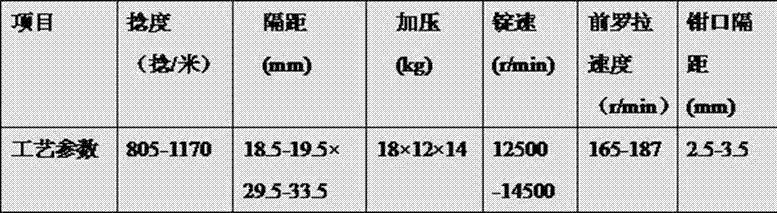

Semi-worsted porous segment color slub yarn and preparation method thereof

The invention relates to a semi-worsted porous segment color slub yarn. The semi-worsted porous segment color slub yarn is prepared from base yarn and decorative yarn, wherein the base yarn is prepared from prolivon fibers, spun silk fibers and wool fibers, and the decorative yarn is prepared from aloe viscose fibers and antibacterial hollow polyester fibers. The slub yarn prepared through the method is colorful, rich in color, changeable in pattern, unique in style, rich in layer change and special in shape, and can generate a flash effect after the fibers in different colors are combined into threads; due to the fact that the yarn is rich in color and diversified in shape change, a fabric manufactured through processing is antibacterial, capable of diminishing inflammation, protecting skin and beautifying the face, good in moisture absorption and good in dyeing property and elasticity, does not generate adverse reactions when making contact with the human body, and is not easy to damage by worms or rot, unique in appearance, good in drapability, good in comfort degree, good in abrasion resistance, natural in color and wide in application range; the processed fabric is strange in style and has the health-care functions of resisting bacteria, protecting the skin, strengthening the body, beautifying the face, moisturizing the skin, being good in comfort degree and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Color wainscot base paper for wood-based plate wainscot

ActiveCN101148844AIncrease coverageStrong coloring powerSpecial paperPaper/cardboardPulp and paper industryPigment

The present invention is one kind of color raw paper for making artificial board veneer, and belongs to the field of artificial board veneer paper making technology. The color raw paper includes stuffing, assistant, heat resistant inorganic and organic pigment and dyeing. It has low cost, no pollution, pure and bright color and other advantages. It is applied in making fireproof board, furniture, office article, etc.

Owner:SHANDONG QIFENG SPECIAL PAPER

Production technology for easily torn cloth with satin weaves

The invention discloses a production technology for easily torn cloth with satin weaves. The production technology comprises the following steps: cationic FDY and cationic DTY are selected for standby application; the cationic DTY serving as warp yarn is soaked in size, taken out and dried; upper and lower parts of the warp yarn are separated, sheds are formed, and the cationic DTY serving as weft yarn is introduced into the sheds formed by the warp yarn; the warp yarn and the weft yarn are subjected to shedding with a textile machine, and the easily torn cloth with the satin weaves is formed. The production technology for the easily torn cloth with the satin weaves adopts a simple preparation method, the cationic FDY with high spinnability, good uniformity and extremely low shrinkage and end breakage rate is taken as the warp yarn and can be wound on a high-speed warping machine, the spinning efficiency is high, an aqueous acetic acid solution is used as slashing size, and the corrosion resistance of the easily torn cloth is improved greatly; the produced easily torn cloth is good in breathability, soft, comfortable, attractive in appearance, convenient to use and low in cost, can be widely applied to various industries, and can be used for treating superficial fungal infection of skin when taken as medical easily torn cloth.

Owner:HUZHOU XINXI FIVE STAR SILK CO LTD

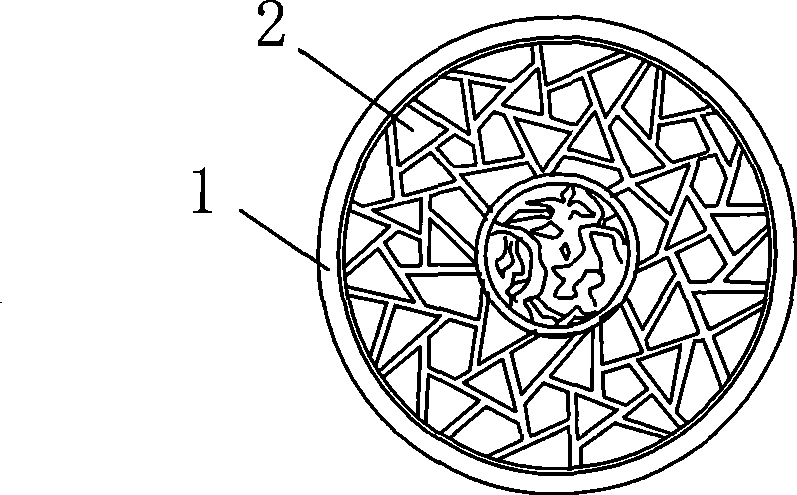

Method for preparing paper-cut artwork

InactiveCN101531115AImprove textureUniform densityOutline designsDecorative surface effectsGraphicsEngineering

The invention discloses a method for preparing paper-cut artwork, comprising the following preparation steps of: a. processing photos by a computer, drawing line drawings and printing the drawn line drawings; b. selecting plates according to the size of the figure; c. attaching the printed figure on the plate, removing large blocks around and removing the hollow-out position of the figure; d. repairing thorn by sand paper and a file; e. bonding the two semi-finished products with the thorn repaired together by chloroform; f. coloring: coating grounding by a spraying gun and coating second layer of wood-grain color by a brush pen; g. spraying oil: coating the artwork by the spraying gun after attempering the essence and bright oil; and h. completing the paper-cut artwork after cooling. Compared with the prior art, the method for preparing the paper-cut artwork has the advantages of environmental-protection, fine grain, uniform density, various designs, high impact strength and the like, is not cracked even when the carving degree is considerably exquisite, has simple but precise process, low cost and high preparation efficiency and has excellent generalization values.

Owner:李前政

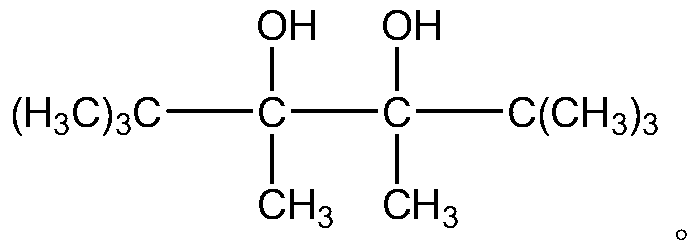

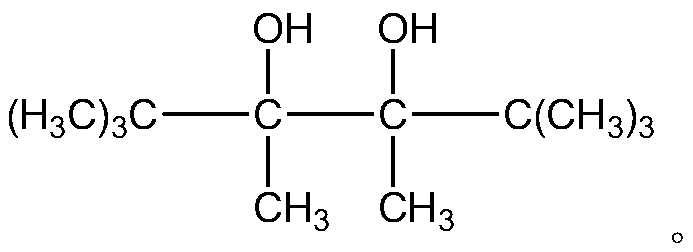

Cationic dyed polyester composite differential dyed yarn and preparation method thereof

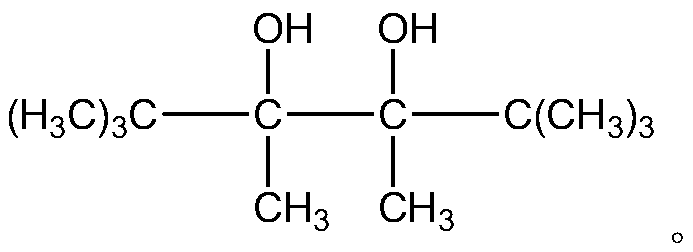

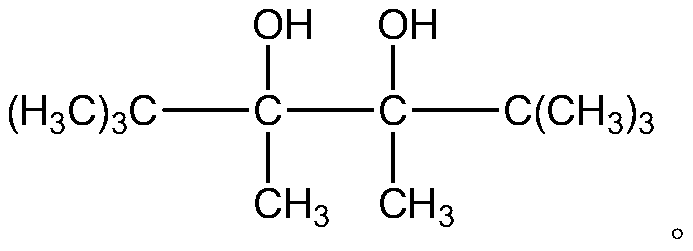

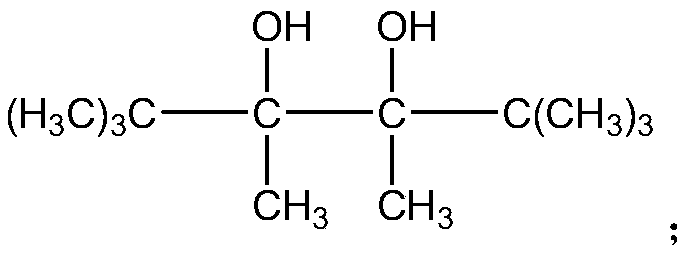

ActiveCN109750377AIncrease the free volume of spaceIncrease the void free volumeMelt spinning methodsMonocomponent polyesters artificial filamentYarnSulfonate

The invention relates to cationic dyed polyester composite differential dyed yarn and a preparation method thereof. The preparation method comprises the steps that terephthalic acid, ethanediol, isophthalic acid gylcol ester sodium sulfonate and 2,2,3,4,5,5-hexamethyl-3,4-heptandiol are evenly mixed, then an esterification reaction and a polycondensation reaction are conducted successively to prepare modified cationic dyed polyester (CDP), then polyester pre-oriented yarn (POY) and modified CDP POY are prepared from a polyester melt and a modified CDP melt correspondingly according to a POY process, finally, the POY and the modified CDP POY are doubled and then processed according to a DTY process, and thus the cationic dyed polyester composite differential dyed yarn is prepared. The dye-uptake of the cationic dyed polyester composite differential dyed yarn at the temperature of 125 DEG C is 89.7-94.3%, the soaping-resistant color fastness reaches the fifth level, the dry friction fastness reaches the fourth level, and the wet friction fastness reaches the fourth level. The preparation method of the cationic dyed polyester composite differential dyed yarn is simple in process and low in cost; and a prepared product is excellent in dyeing performance, various in pattern, attractive and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Embedded surface ornament and its making process

InactiveCN1810525AFully reflect the textureCombined bonding is firmDecorative surface effectsSpecial ornamental structuresMaterials scienceOrnaments

Owner:王吉祥

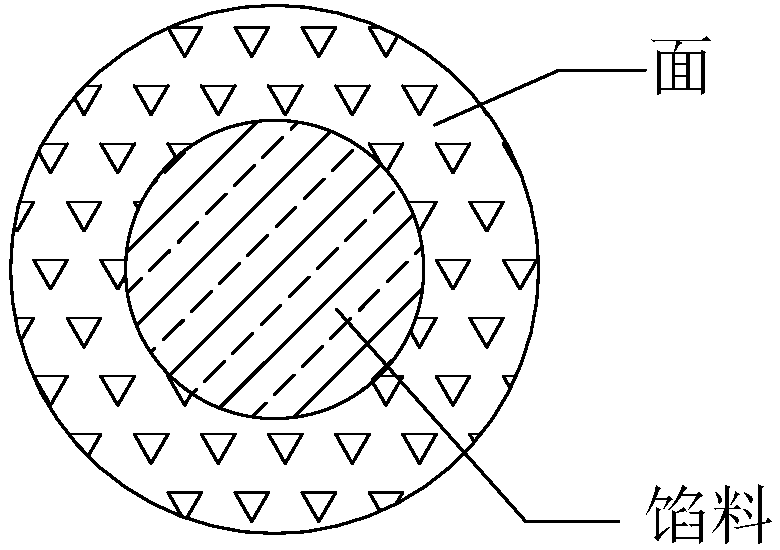

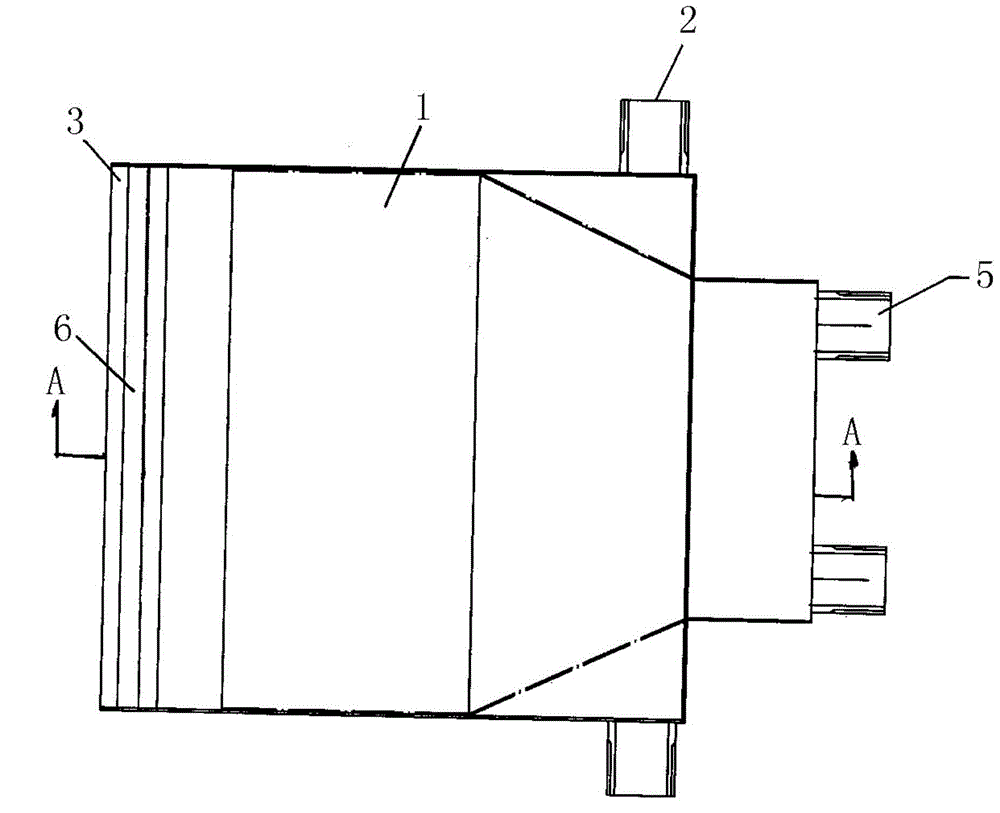

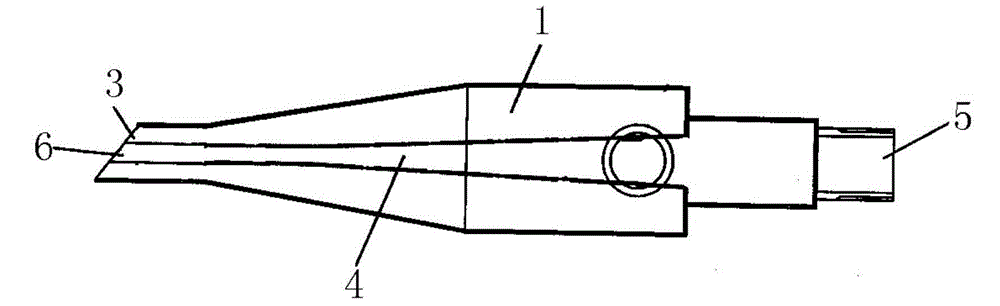

A forming mould for fish tofu with fillings

The present invention discloses a forming mould for fish tofu with fillings. The forming mould is characterized in that wrapping layer feed ports are arranged at one end of a box body (both sides), wrapping layer discharge ports are arranged at the other end of the box body (both sides), a filling feed hopper is arranged in the middle part of the inner space of the box body, one end of the filling feed hopper is connected with a filling feed pipe arranged at the other end of the box body, a filling discharge port is arranged at the other end of the filling feed hopper, and arranged in the middle part of the wrapping layer discharge port. The forming mould can be used to produce the fish tofu with fillings through the above settings, and the formation of middle inherent levels achieves the purpose of filling, making the fish tofu has more abundant varieties and a great variety of devices or patterns to exploit the market.

Owner:SHANDONG JIASHIBO FOOD

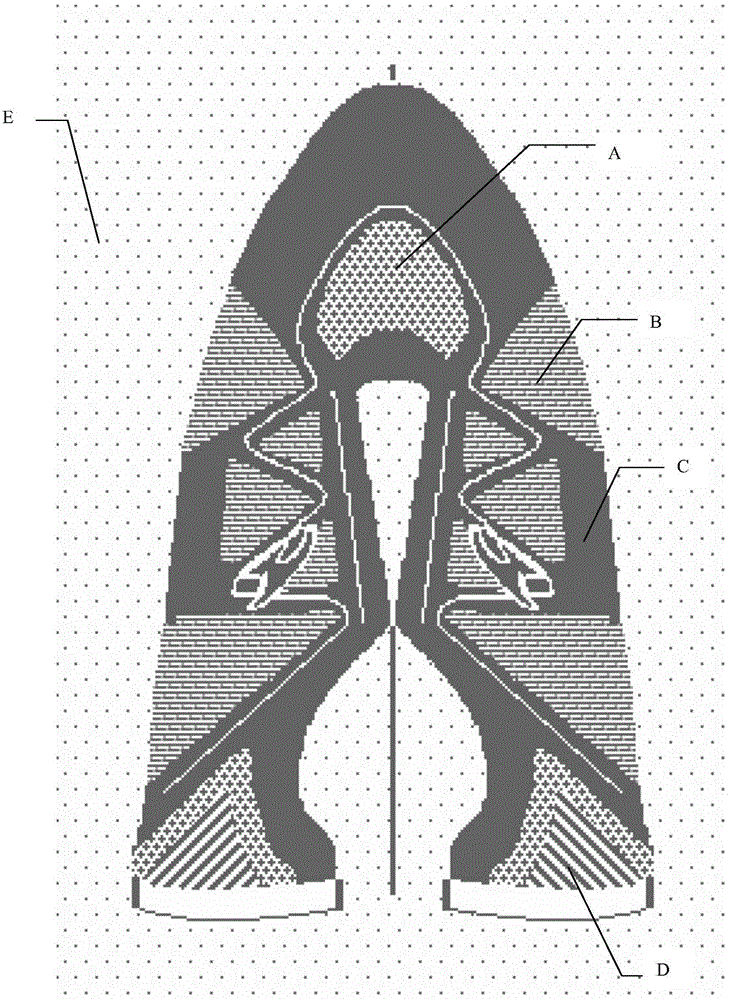

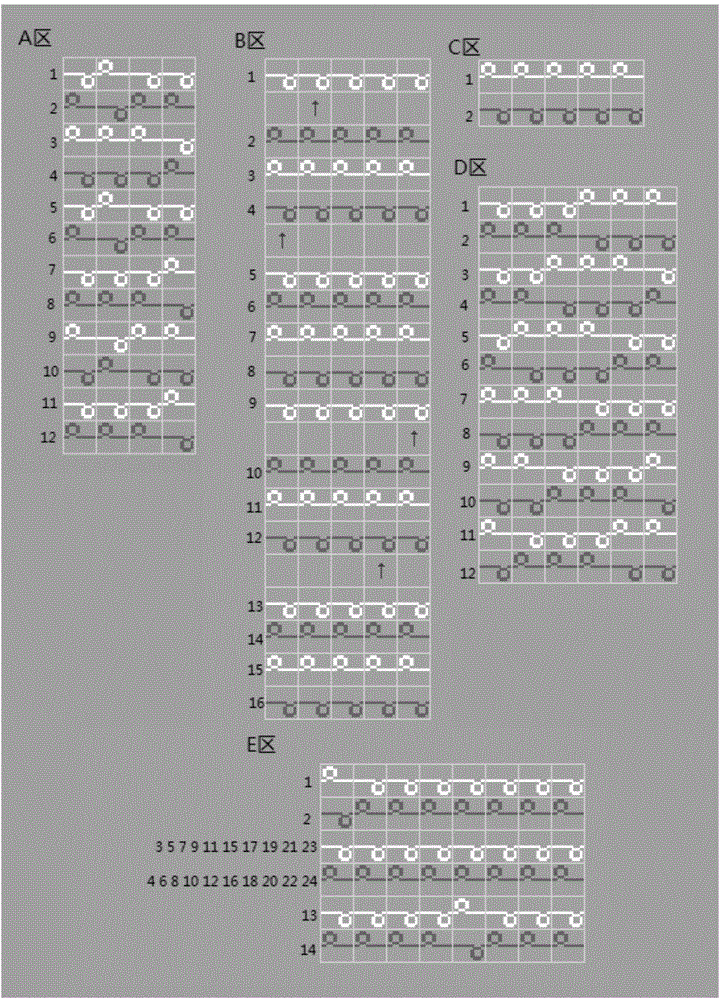

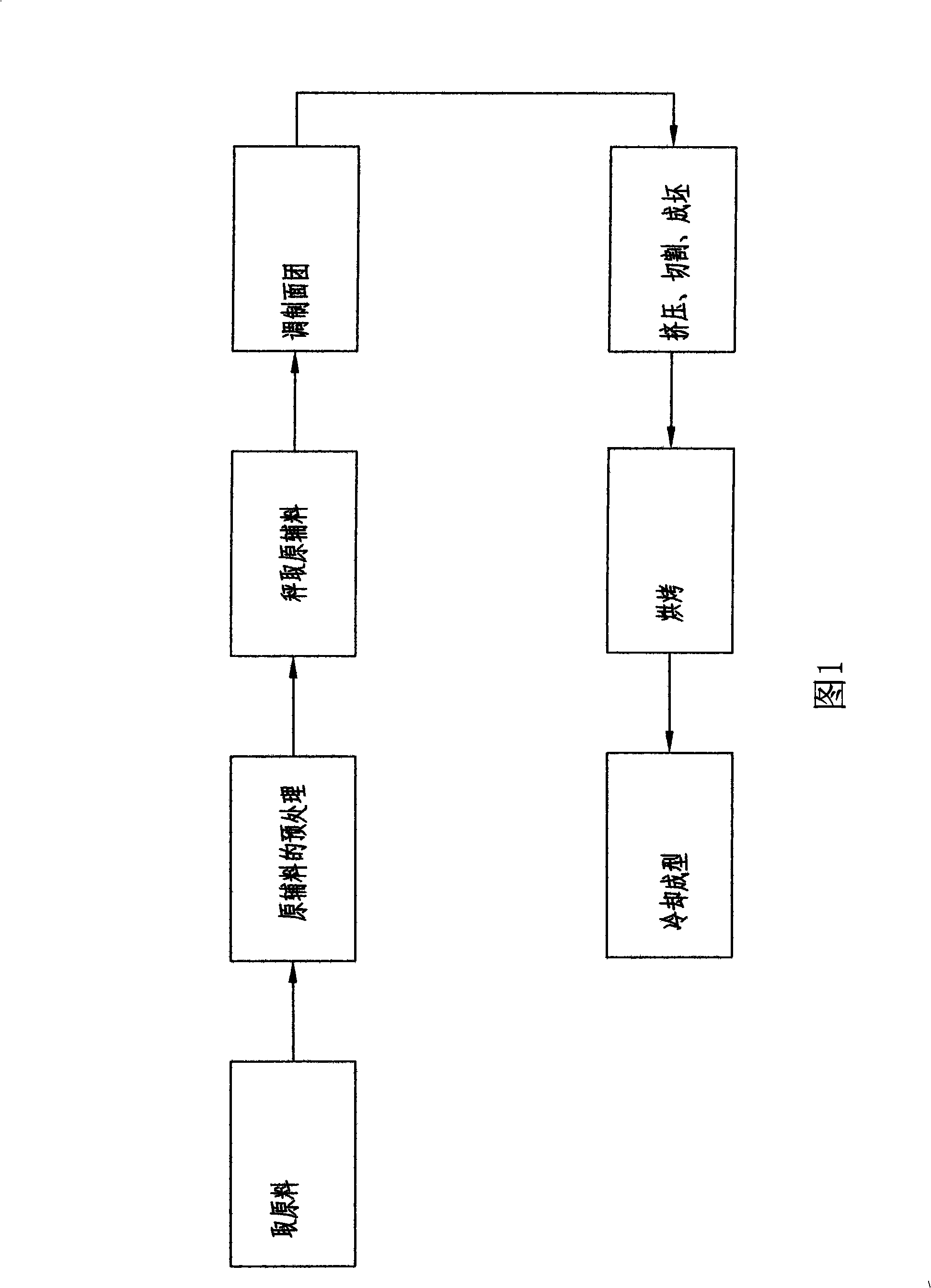

Structure and production method of a weft-knitted jacquard upper material

ActiveCN104562401BMany tricksChangeable colorWeft knittingHeating/cooling textile fabricsEngineeringVolumetric Mass Density

The invention belongs to the field of textiles and provides a structure and a production method of a weft-knitted jacquard shoe upper material. According to the weft-knitted jacquard shoe upper material, terylen low-melting-point color filaments with skin-core structures are adopted, the meshes, esthetic appearance and air permeability of the shoe upper material are realized by utilizing air-layer jacquard tissues as fundamental tissues, loop accumulation tissues or loop transfer tissues on a dual-way jacquard dual-side loop transfer round weft machine; by virtue of cooperation between colors and structural jacquards, functional sections of the shoe upper material are realized; during aftertreatment, a skin layer is fused at a certain temperature under a certain pressure, so that dual-side weft-knitted jacquard shoe upper fabric loops are mutually glued, then cooled and solidified, so that the shoe upper material with appropriate rigidity and hand feeling is obtained; spandex can also be added, so that the elasticity and the density of the fabric are enhanced. The weft-knitted jacquard shoe upper material is variable in pattern, color and style, beautiful in appearance, portable and flexible, favorable in air permeability and comfort in wear; traditional working procedures of cutting, sewing, bonding and the like for shoe materials are not needed, so that the equipment investment and the labor cost are lowered.

Owner:JIANGNAN UNIV

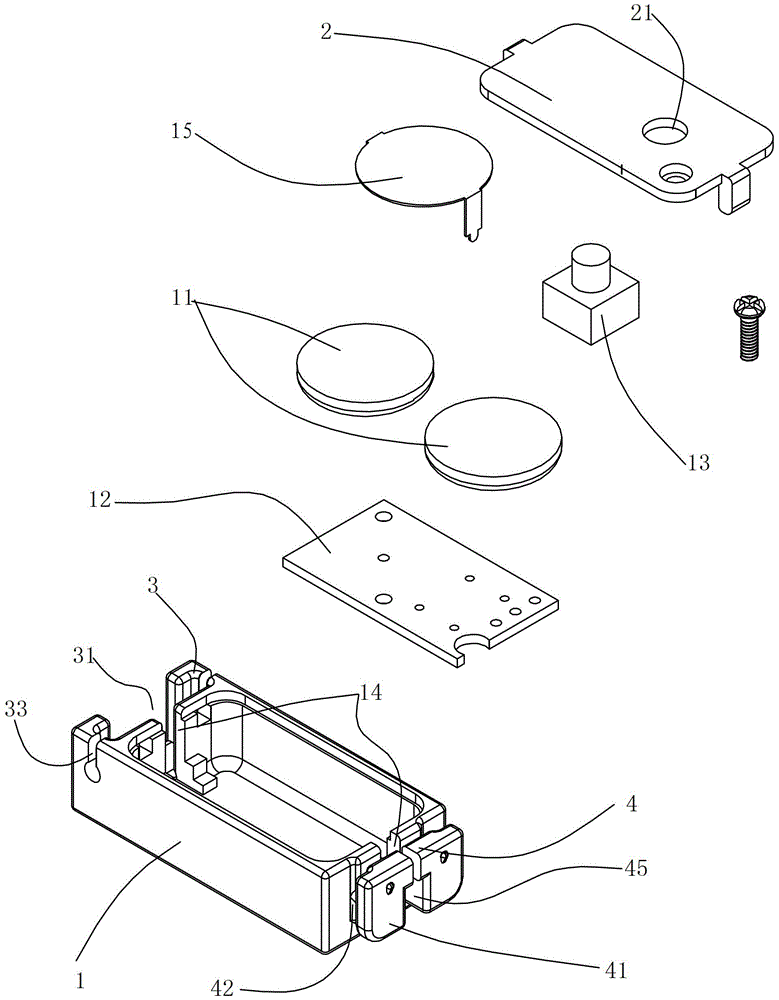

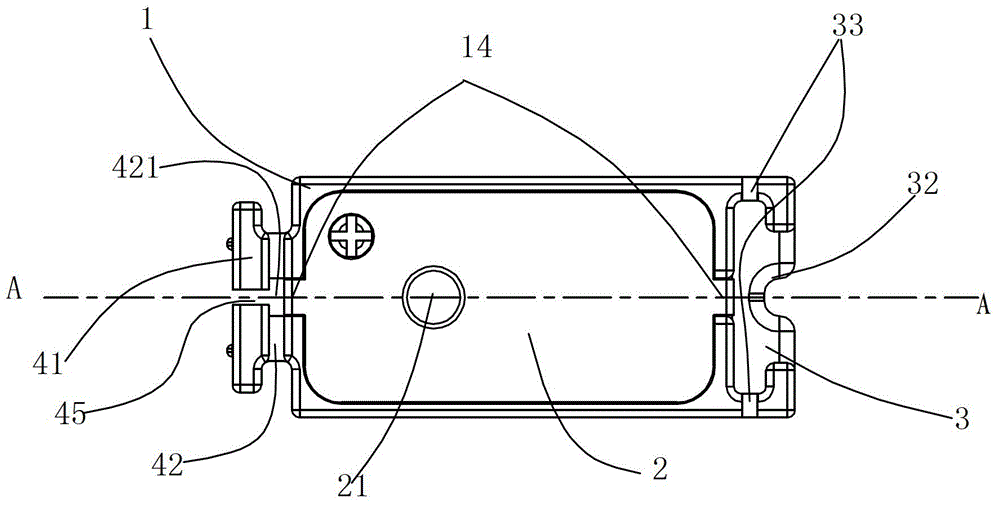

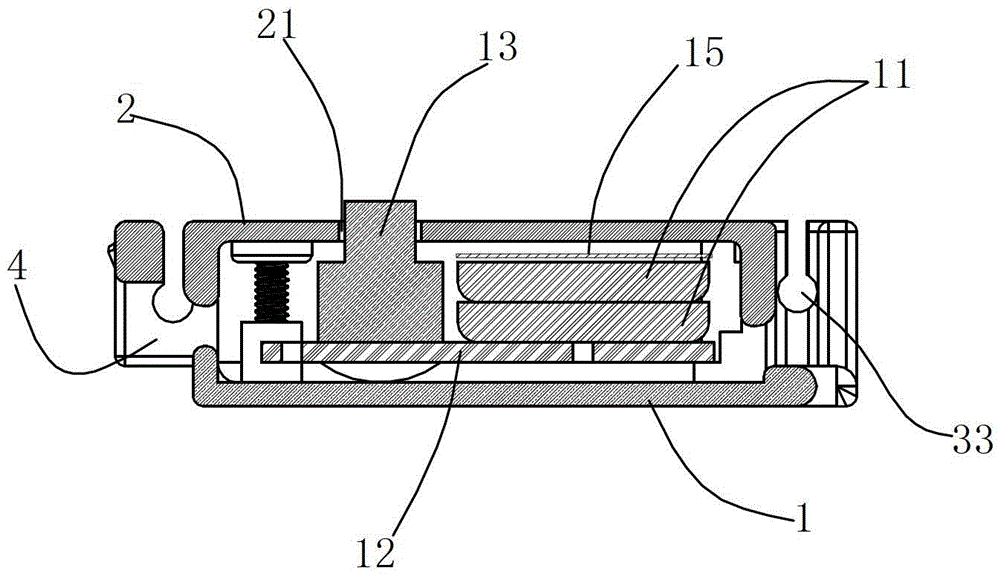

Connection lock catch and necklace provided with same

ActiveCN103431585BAchieve connectionFirmly connectedLighting elementsWatch chainsElectricityEngineering

The invention relates to a connection lock catch and a necklace provided with same. The connection lock catch comprises a shell body and a shell cover which match with each other; the shell body is provided with an accommodating space, and a battery pack, a circuit board and a switch are disposed in the accommodating space; the two ends of the shell body are respectively provided with a clamping buckle and a clamping groove which match with each other; the clamping buckle is provided with clamping plates, and the clamping plates are parallel to the end face of the shell body, disposed at intervals and connected with the bottom of the shell body via a connection piece; the clamping groove is provided with a notch matching with the connection piece; and the clamping groove is provide with a concave opening and side notches. The necklace provided with the connection lock catch comprises one or more connection lock catches which are in buckling connection, and also comprises a necklace chain capable of being charged with electricity and a necklace sinker capable of being lightened by controlling the switch. The winding and connecting among the necklace chains are convenient by using the connection lock catch with the structure of the clamping buckle and the clamping groove; the circuit board disposed in the connection lock catch is convenient for the connection of the switch control circuit, and the switch control circuit is stable and reliable; additionally-installed clips are convenient for clamping and arrangement of the multiple necklace chains, and the clips are neat and beauty.

Owner:ACE GIFT&CRAFTNINGBOCO LTD

Glue-free PVC (polyvinyl chloride) floor board and preparation method thereof

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

Cushion manufacturing method

InactiveCN103767393AMany tricksImprove skid resistanceStuffed mattressesSpring mattressesWear resistantEngineering

A cushion manufacturing method comprises the following steps: scissoring a plastic framework material made by arranging rectangular frame arrays into the shape of a cushion; transversely punching in acrylic thin sheets, allowing connecting wires to penetrate the holes to wind on the small rectangular frames of the plastic framework material, and fixing the acrylic thin sheets on the surface of the plastic framework one by one to form an acrylic thin sheet decorative layer on the surface of the plastic framework; tailoring or sticking bottom lining cloth on back sides of the plastic framework; winding ice silks at the edge of the plastic framework to form a decorative strip. The cushion made by the method has different patterns through arranging the acrylic thin sheets or different colors of the acrylic thin sheets, is diverse in pattern and is attractive. Meanwhile, with the design of a framework layer, the cushion has favorable firmness and air permeability; with the bottom lining layer at the back of the plastic framework, the cushion has improved anti-slip effect; with the wear-resistant outer edge, the cushion has enhanced wearing resistance and can prevent damage of trousers.

Owner:QUWO BEILEI ART & CRAFT

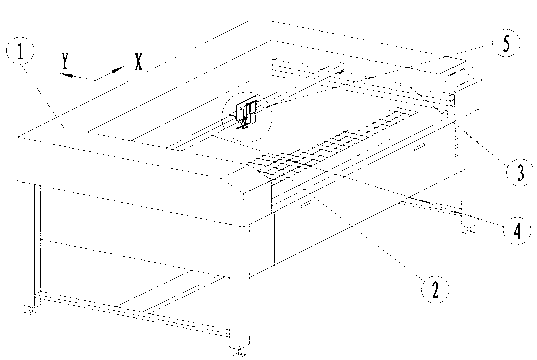

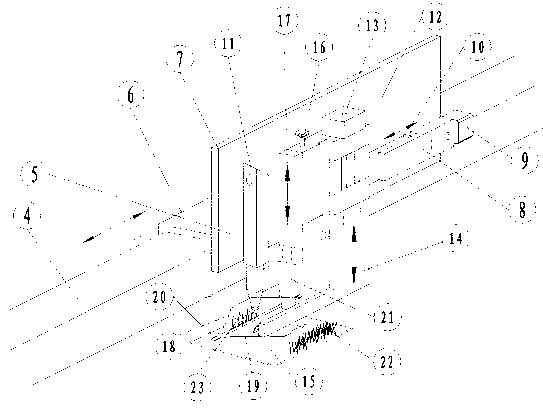

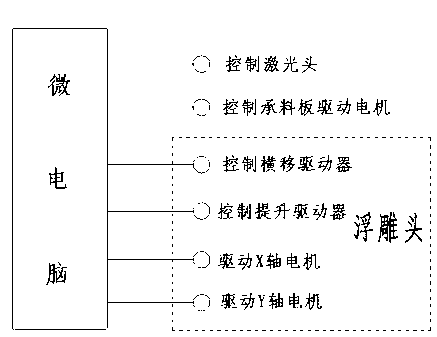

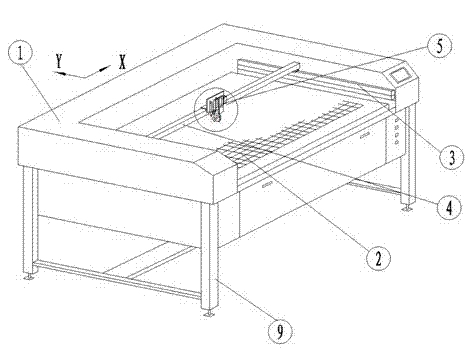

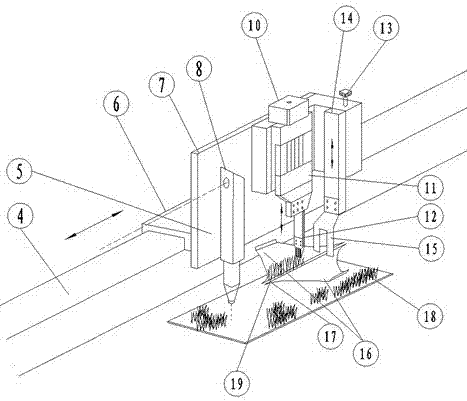

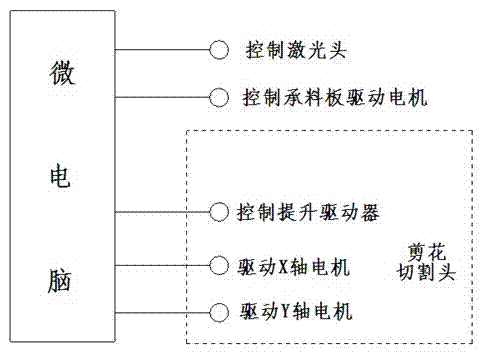

Plush laser embossing machine

The invention discloses a plush laser embossing machine which comprises a working platform, a microcomputer and an embossing head, wherein the embossing head is arranged on the working platform in a sliding way; the microcomputer is connected with the embossing head; the embossing head comprises an embossing head bottom plate, a laser head, a reflecting mirror and a plush divider; one side of the embossing head bottom plate is arranged on the working platform in the sliding way, and the other side of the embossing head bottom plate is provided with the laser head, the reflecting mirror and the plush divider; the reflecting mirror is arranged on the embossing head bottom plate in a way of being capable of sliding up and down; the plush divider is arranged on the embossing head bottom plate in the sliding way. According to the plush laser embossing machine, the embossing head is controlled to move along the X axis and the Y axis of the working platform by the microcomputer, and a lifting driver and a transverse movement driver are controlled to process plushy fabric by the microcomputer; multiple embossed patterns can be preset, so that the plush laser embossing machine has multiple types of patterns; the plush laser embossing machine is convenient to operate, thus being suitable for embossment processing of the plushy fabric in small batches.

Owner:CHUZHOU SEEK ELECTRONICS

Functional health raindrop yarn and preparation method thereof

The invention provides functional health raindrop yarn. The functional raindrop yarn is prepared from, by weight, 0-50% of aloe viscose fiber, 0-50% of emerald pearl fiber, 0-50% of soft silk fiber, 0-50% of natural mint fiber, 0-50% of sarcandra glabra fiber and 10-50% of anti-bacteria polyester fiber. The raindrop yarn not only has a unique form, but also has rich yarn colors, is good in moisture absorption and air permeability, good in dyeing property and elasticity, soft in hand-feeling, noble and elegant and bright in color; fabric processed by using the raindrop yarn has the advantages of bright color, good air permeability, unique pattern and the like, it is represented on the surface of the fabric that raindrops seem to run and fly in air, and the fabric is high in stereoscopic impression, stiff and smooth in quality, unique in style, rich in color, diverse in pattern and rich in level change. The fabric woven by the raindrop yarn is comfortable in wearing, is ideal fabric forindoor decorative fabric and the like and is suitable for production of top-grade fabric, decorative cloth, bedding and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Making method of opening type finger ring with concave-convex patterns on surface as well as finger ring

PendingCN109602128AEasy to processMany tricksDecorative surface effectsFinger-ringsAfter treatmentEngineering

The invention relates to an opening type finger ring with concave-convex patterns on the surface. Patterns which are concave-convex on the surface of the finger ring are arranged on the finger ring. The making method comprises the following steps: engraving concave-convex patterns on a stamping die; putting a finger ring material into the stamping die, stamping to form a strip-shaped finger ring blank and forming the concave-convex patters on the surface of the finger ring; and performing after-treatment on the finger ring blank to form the opening finger ring. Due to the adoption of the technical scheme, the opening type finger ring is simpler to process, has rich patterns and has three-dimensional feeling.

Owner:SHENZHEN RIFDA JEWELRY

Mutton soup bowl seasoning

The invention relates to a mutton soup bowl seasoning composed of the following components in parts by weight: 200 parts of cloves, 200 parts of cinnamon seeds, 10 parts of interior eardamom, 10 partsof Xiangsha, 10 parts of rhizoma kaempferiae, 20 parts of pericarpium zanthoxyli, 20 parts of quilled cinnamon, 10 parts of myrcia, 10 parts of magnolia liliflora, 10 parts of red branches and 3 parts of cordyceps sinensis. By using mutton soup bowl seasoning, mutton soup can be as white as fat and as bright as milk, diversified, delicious in taste and fragrant, but not greasy and has the characteristic of smelling fragrant and tasting delicious.

Owner:周通

Catalyst composite dyed yarn and its preparation method

ActiveCN109750377BImprove dyeing effectSimple processMelt spinning methodsMonocomponent polyesters artificial filamentYarnSulfonate

The invention relates to cationic dyed polyester composite differential dyed yarn and a preparation method thereof. The preparation method comprises the steps that terephthalic acid, ethanediol, isophthalic acid gylcol ester sodium sulfonate and 2,2,3,4,5,5-hexamethyl-3,4-heptandiol are evenly mixed, then an esterification reaction and a polycondensation reaction are conducted successively to prepare modified cationic dyed polyester (CDP), then polyester pre-oriented yarn (POY) and modified CDP POY are prepared from a polyester melt and a modified CDP melt correspondingly according to a POY process, finally, the POY and the modified CDP POY are doubled and then processed according to a DTY process, and thus the cationic dyed polyester composite differential dyed yarn is prepared. The dye-uptake of the cationic dyed polyester composite differential dyed yarn at the temperature of 125 DEG C is 89.7-94.3%, the soaping-resistant color fastness reaches the fifth level, the dry friction fastness reaches the fourth level, and the wet friction fastness reaches the fourth level. The preparation method of the cationic dyed polyester composite differential dyed yarn is simple in process and low in cost; and a prepared product is excellent in dyeing performance, various in pattern, attractive and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

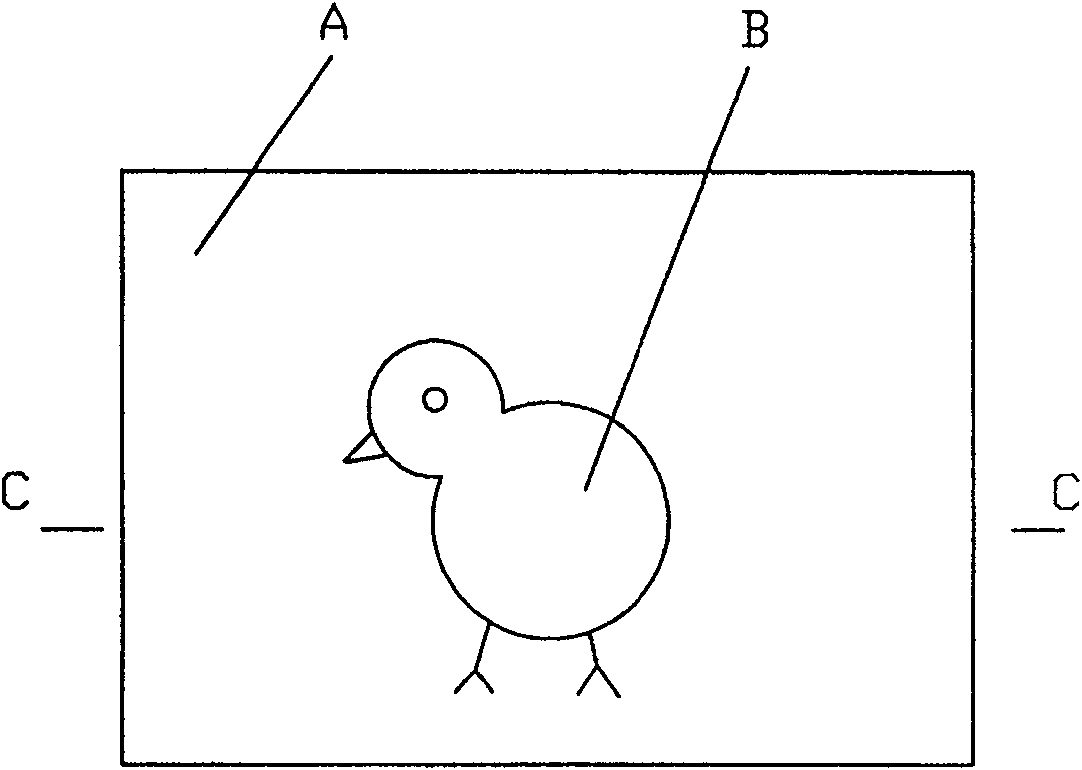

Plush flower-shearing cutting machine

The invention discloses a plush flower-shearing cutting machine which comprises a working platform, a microcomputer and a flower-shearing cutting head, wherein the flower-shearing cutting head is arranged on the working platform in a sliding way; the microcomputer is connected with the flower-shearing cutting head; the flower-shearing cutting head comprises a flower-shearing cutting head bottom plate, a laser head, a pair of electric shears and a plush divider; one side of the flower-shearing cutting head bottom plate is arranged on the working platform in the sliding way, and the other side of the flower-shearing cutting head bottom plate is provided with the laser head, the electric shears and the plush divider; the electric shears and the plush divider are arranged on the flower-shearing cutting head bottom plate in a way of being capable of sliding up and down. According to the plush flower-shearing cutting machine, the flower-shearing cutting head is controlled to move along the X axis and the Y axis of the working platform by the microcomputer, and a lifting driver and a plush dividing height adjuster are controlled to process plushy fabric by the microcomputer; multiple embossed patterns can be preset, so that the plush laser embossing machine has multiple types of patterns; the plush flower-shearing cutting machine is convenient to operate, thus being suitable for embossment processing of the plushy fabric in small batches.

Owner:CHUZHOU SEEK ELECTRONICS

Embedded surface ornament and its making process

InactiveCN1810525BFully reflect the textureCombined bonding is firmDecorative surface effectsSpecial ornamental structuresEngineeringStructural engineering

Owner:王吉祥

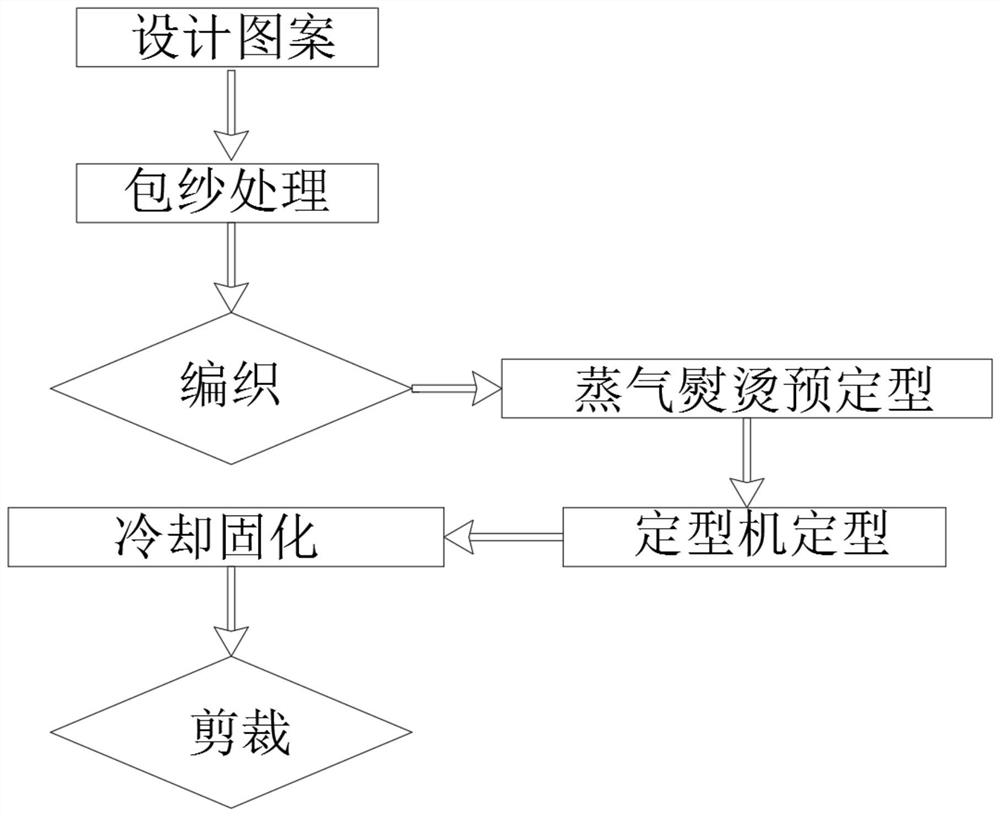

Preparation method of double-faced jacquard knitted vamp

PendingCN113756001AFor precise cuttingImprove efficiencyWeft knittingFootwearYarnIndustrial engineering

The invention relates to the technical field of double-faced jacquard, and discloses a preparation method of a double-faced jacquard knitted vamp. The method comprises the following steps of S1, designing a pattern: performing computer plate-making of the double-faced jacquard knitted vamp, and designing the surface pattern of a jacquard knitted fabric; S2, performing yarn covering treatment: performing yarn covering treatment on spandex by using thermal fuses by adopting a conventional yarn covering process, so as to obtain a thermal fuse pulling frame; and S3, performing knitting: feeding the thermal fuse pulling frame obtained in the S2 and conventional knitting yarn into a computerized flat knitting machine together for knitting a semi-finished double-faced jacquard knitted vamp with the preset pattern. According to the invention, the front face and the back face of the produced vamp fabric are provided with patterns through a double-faced jacquard process, so that the functions and the purposes of the fabric are diversified; and meanwhile, the vamp can be cut accurately, quickly and efficiently through laser cutting, and the woven vamp can be light, soft and high in viscosity through the thermal fuse pulling frame, so that the vamp is more durable.

Owner:泉州市达和丰针织有限公司

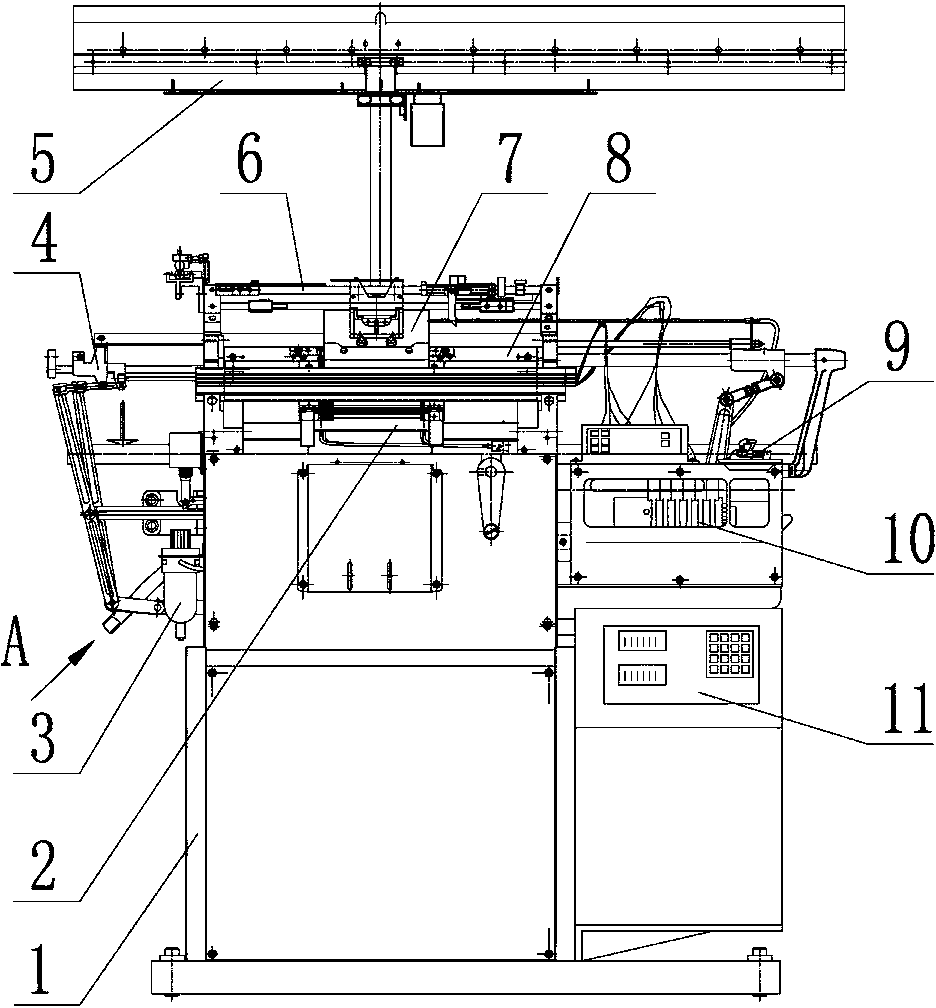

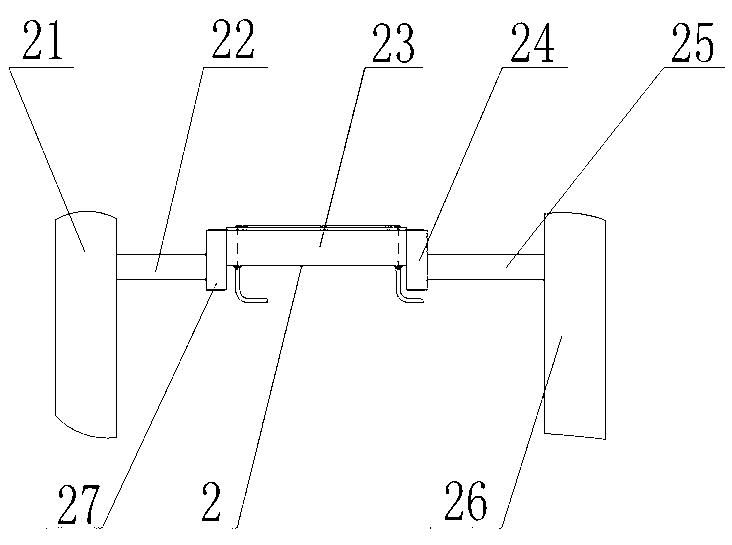

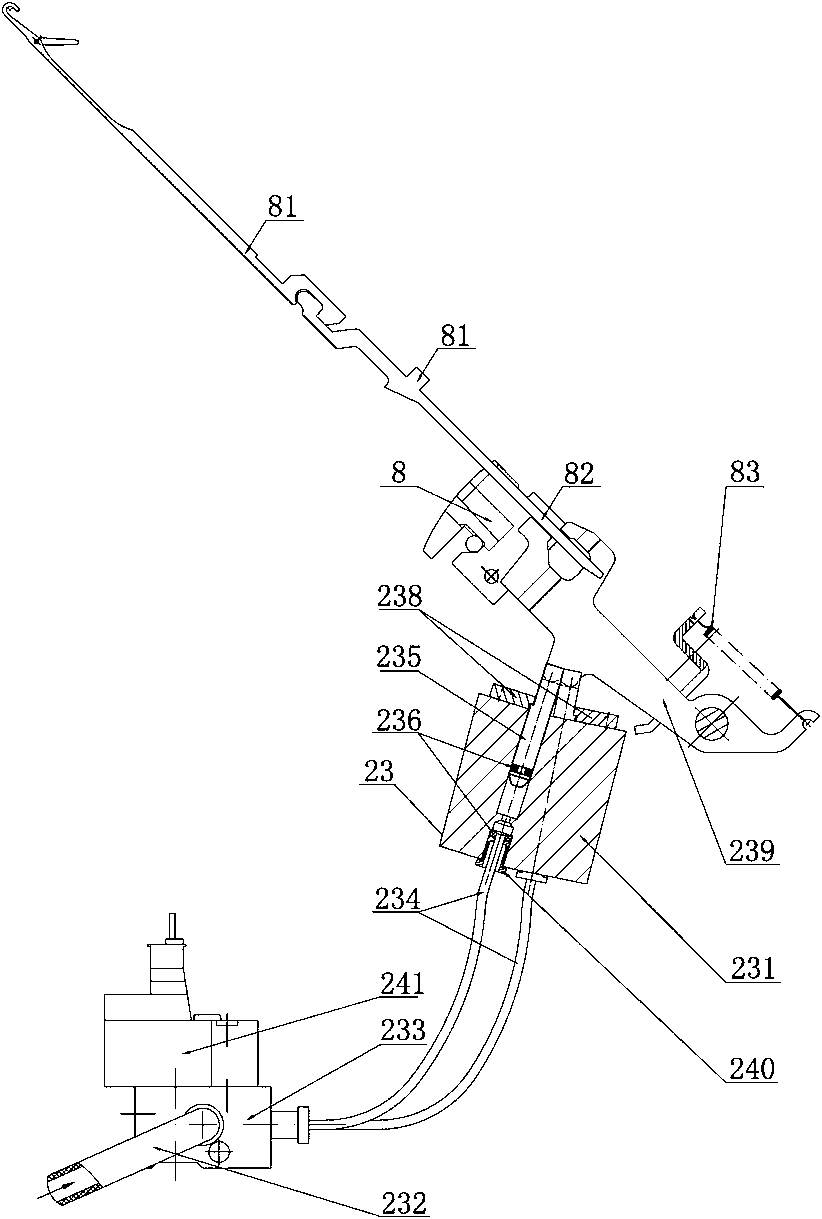

Glove knitting machine with electronic pneumatic control type piston needle selection device

InactiveCN102493113BMany tricksUnaffected by operationFlat-bed knitting machinesEngineeringMechanical engineering

The invention relates to a glove knitting machine with an electronic pneumatic control type piston needle selection device, which is composed of a frame component, a needle selection component, a pneumatic control component, a creel component, a machine head component, a needle plate component, a computer control component and the like. A needle selection device is arranged on the needle selection component and comprises a needle selection seat, a main air pipe, a converging body, a plurality of branch air pipes, pistons, a stopping plate and a bird sheet. A plurality of hole groups are arranged on the needle selection seat, one end of the converging body is connected with the main air pipe, the other end of the converging body is connected with the plurality of branch air pipes, each branch air pipe is connected with the bottom of each hole group through a fixing connector, the pistons are contained in the hole groups, the tops of the pistons abut against the bird sheet and push the bird sheet to rotate, and the stopping plate is arranged on the needle selection seat and can adjust the rising height of the pistons. The glove knitting machine can conduct irregular needle selectionunder control of electronic pneumatic control, enables fabric and fabric patterns of the machine to be diversified, and enables the needle selection to be rapid, stable, reliable and free of influences of running of a machine head.

Owner:丁原章

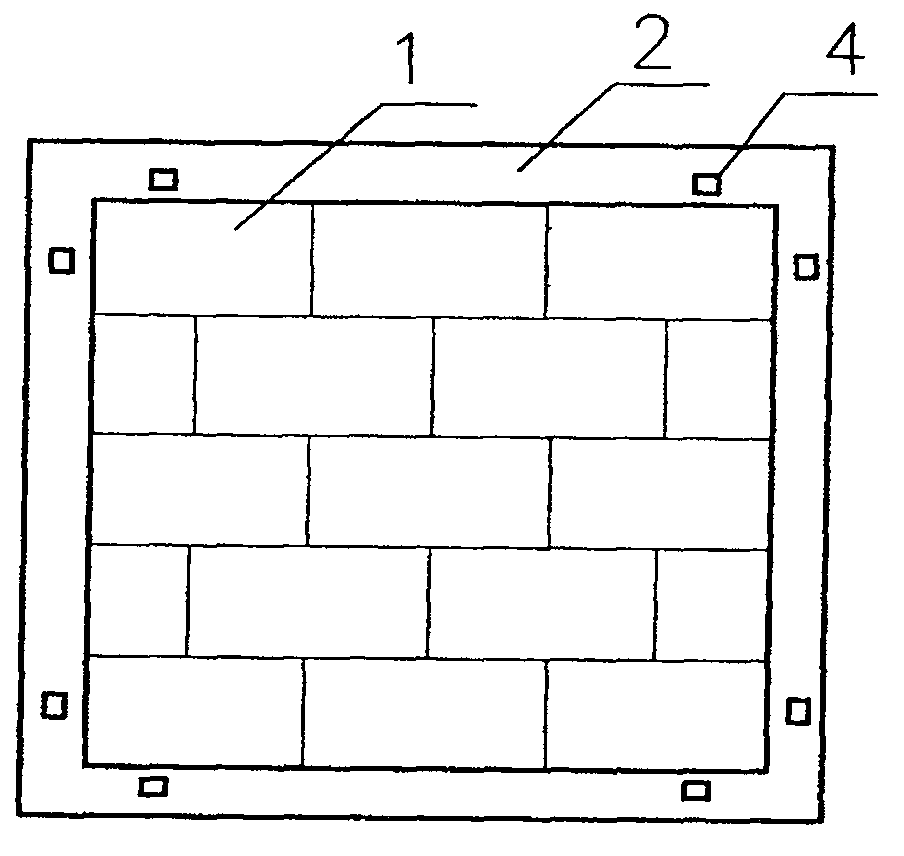

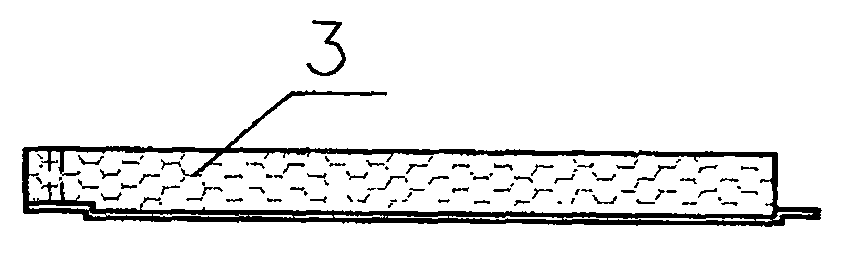

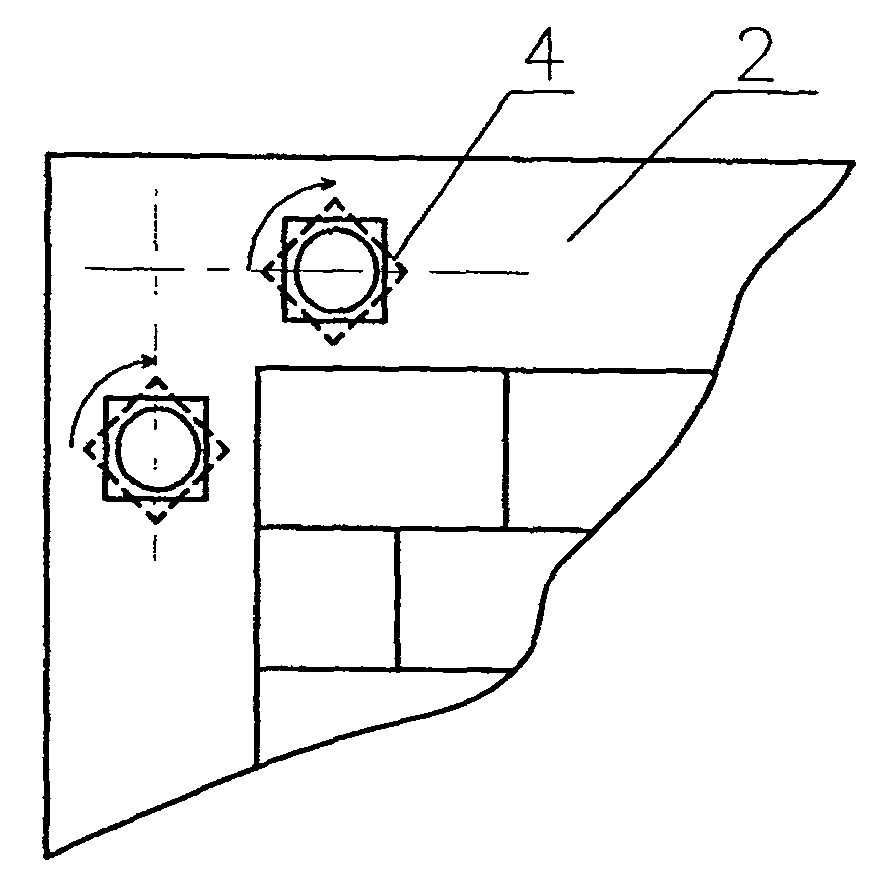

Polystyrene composite decorative plate

InactiveCN100549343CLow costShort construction periodCovering/liningsArchitectural engineeringPolystyrene

The invention discloses a polystyrene composite decorative board which is laminated by a decorative board and a polystyrene board. The outer surface of the decorative board is provided with a paint coating and the inner surface thereof is adhesive to the polystyrene board. An L-shaped margin frame is circumferentially arranged on the decorative board and has screw bolt holes each with a fixing bolt. The inventive novel energy-saving building material has both heat-insulating and decorative effects, and is suitable for the use in construction of new buildings and the reconstruction of old buildings. The invention has the advantages of rapid and easy construction, wide application range, low construction cost, short construction cycle, long use life, various patterns, long service life, low cost, suitability for renovation and reconstruction, and decorative and energy-saving effects.

Owner:刘成金

A kind of embedded nylon pet glasses plate and preparation method thereof

InactiveCN104597614BStable chemical propertiesNo effectSynthetic resin layered productsFlat articlesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to an embedded type nylon PET (Polyethylene Terephthalate) glasses sheet material which has good safety, large mechanical strength and various patterns, and can be individually customized, and a preparation method thereof. The embedded type glasses sheet material sequentially comprises a transparent layer, an embedding layer, a background layer and a base layer in sequence from outside to inside, wherein the transparent layer is made of nylon; and the background layer and the base layer are made of PET. The embedded type nylon PET glasses sheet material has the beneficial effects that the glasses sheet material adopts an embedded type interlayer decorative design and the embedding layer can use various decorative materials, so that the patterns of glasses are greatly enriched; and the patterns of the sheet materials are more stereoscopic and the individualized requirements of people can be met.

Owner:黄永忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com