Patents

Literature

32results about How to "Does not affect cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

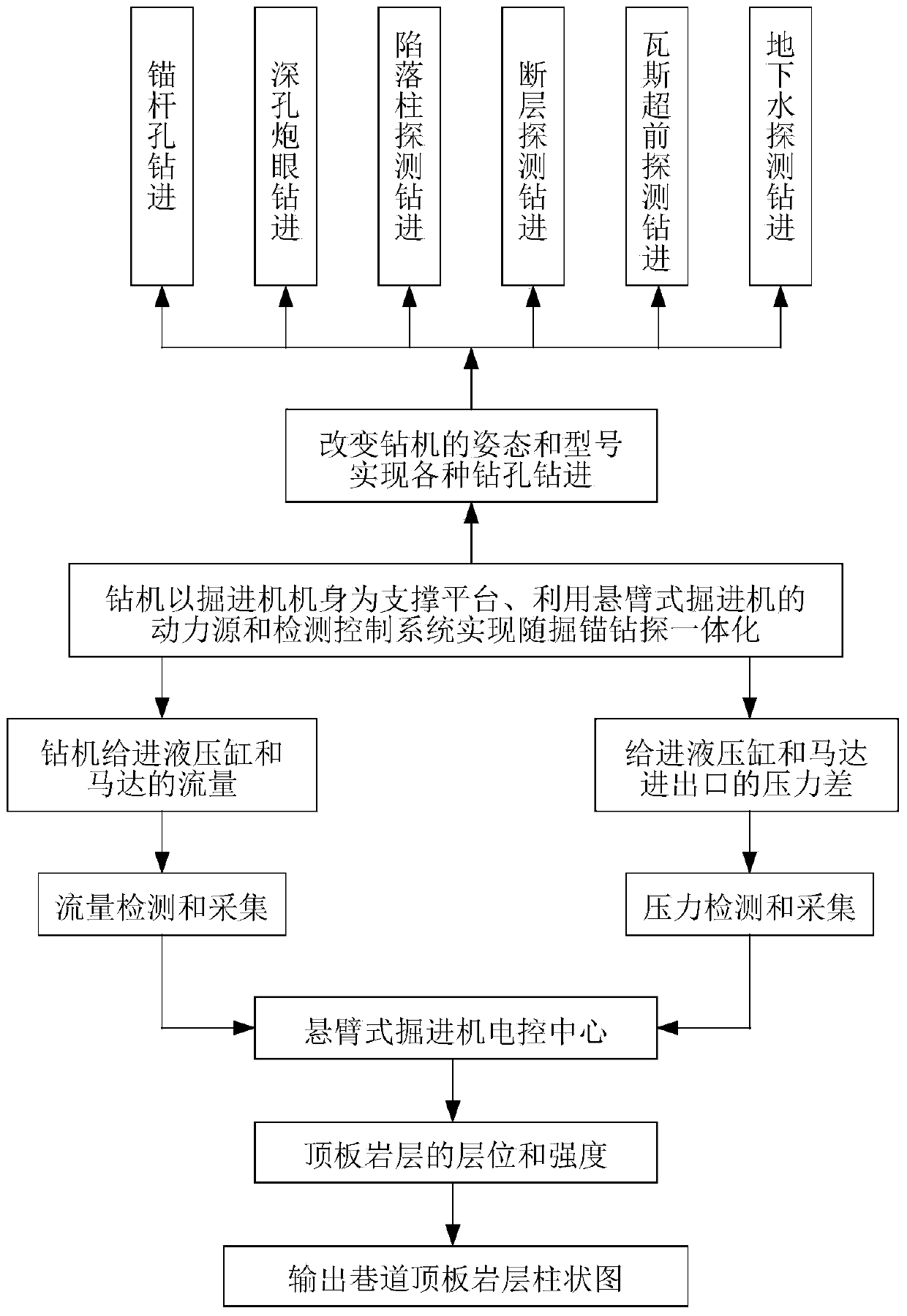

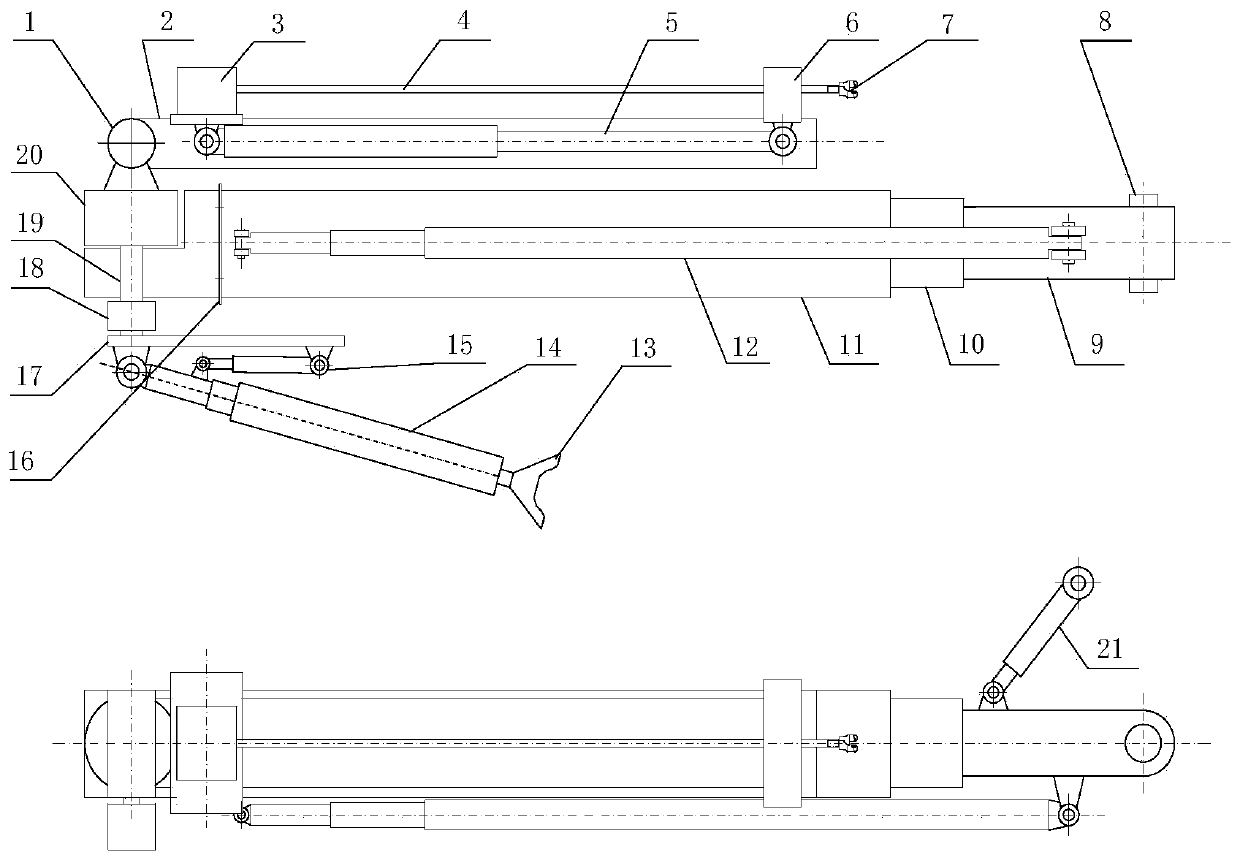

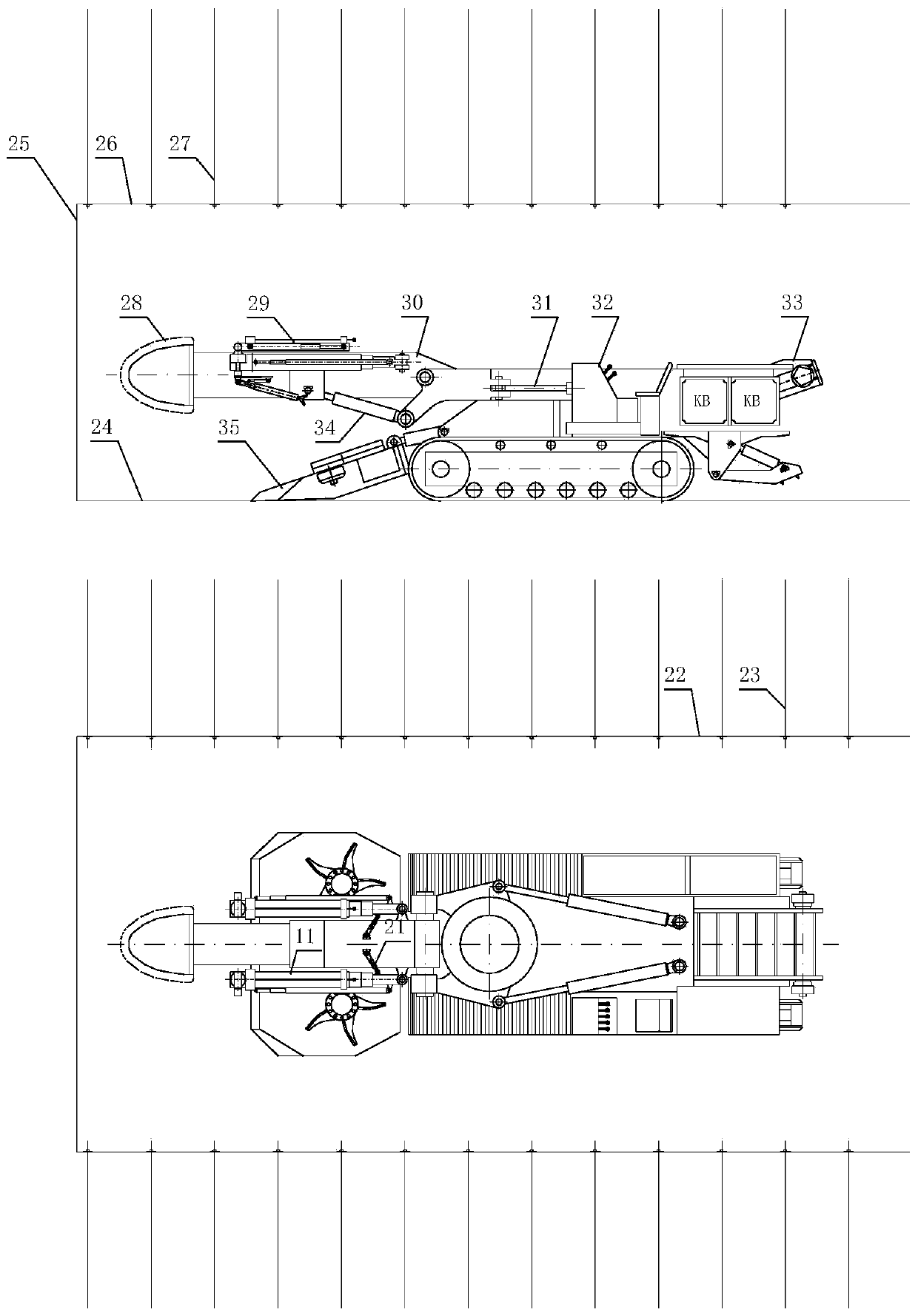

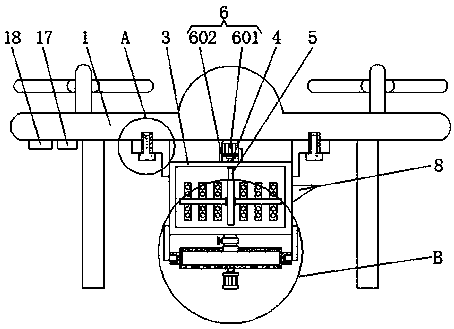

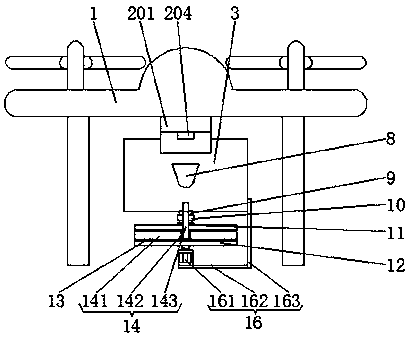

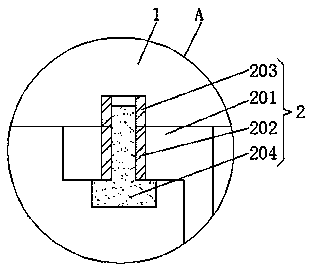

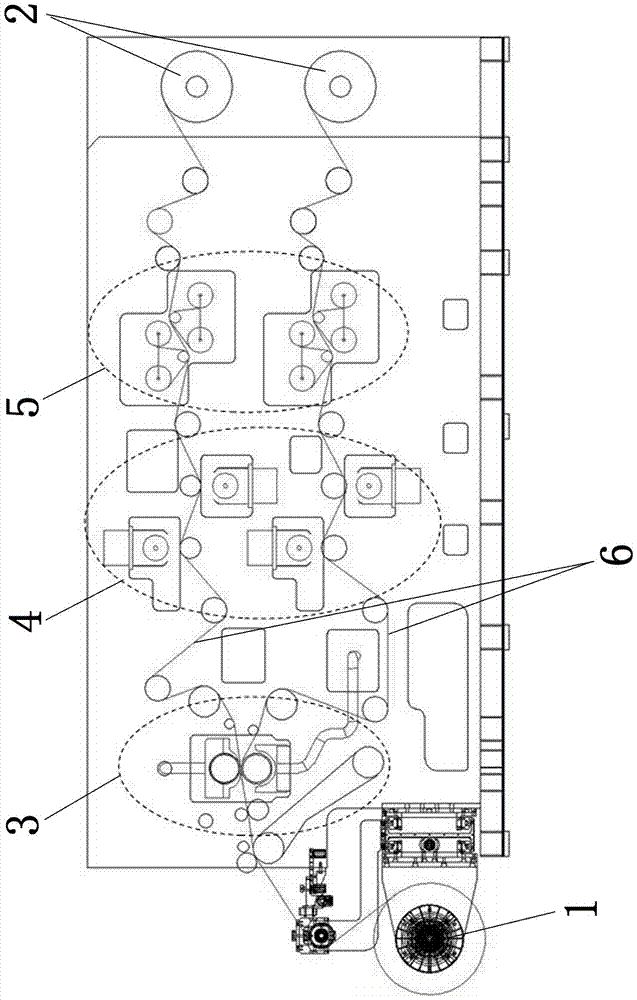

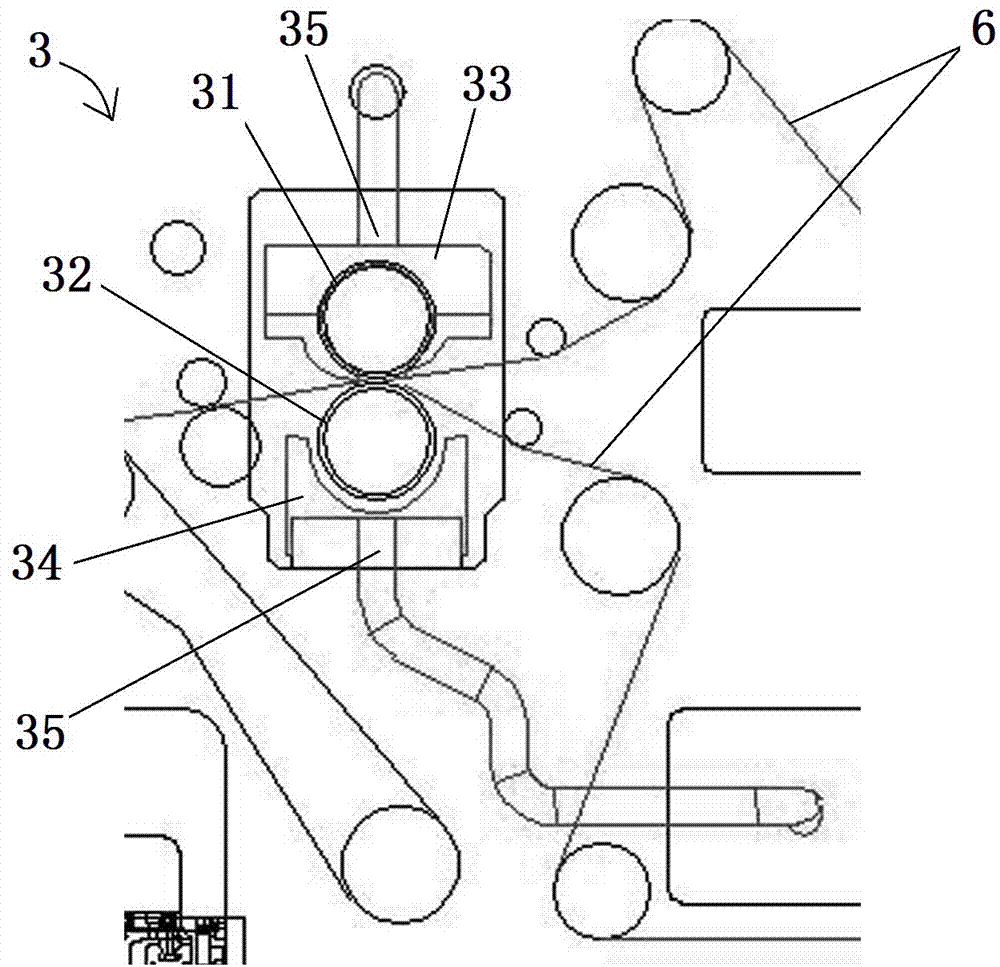

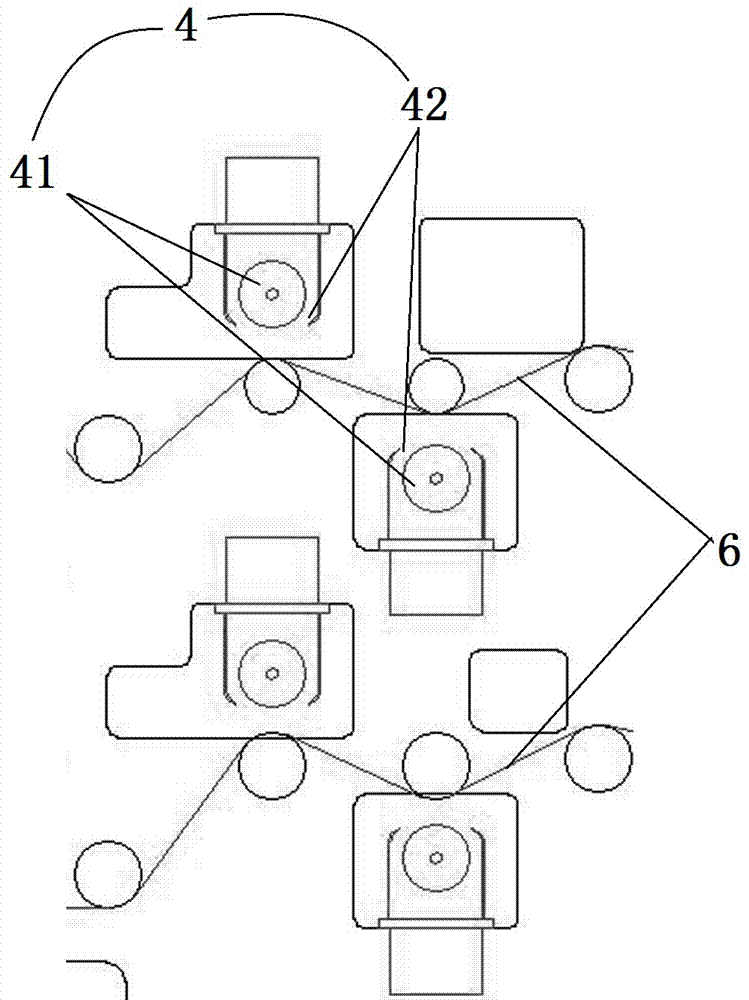

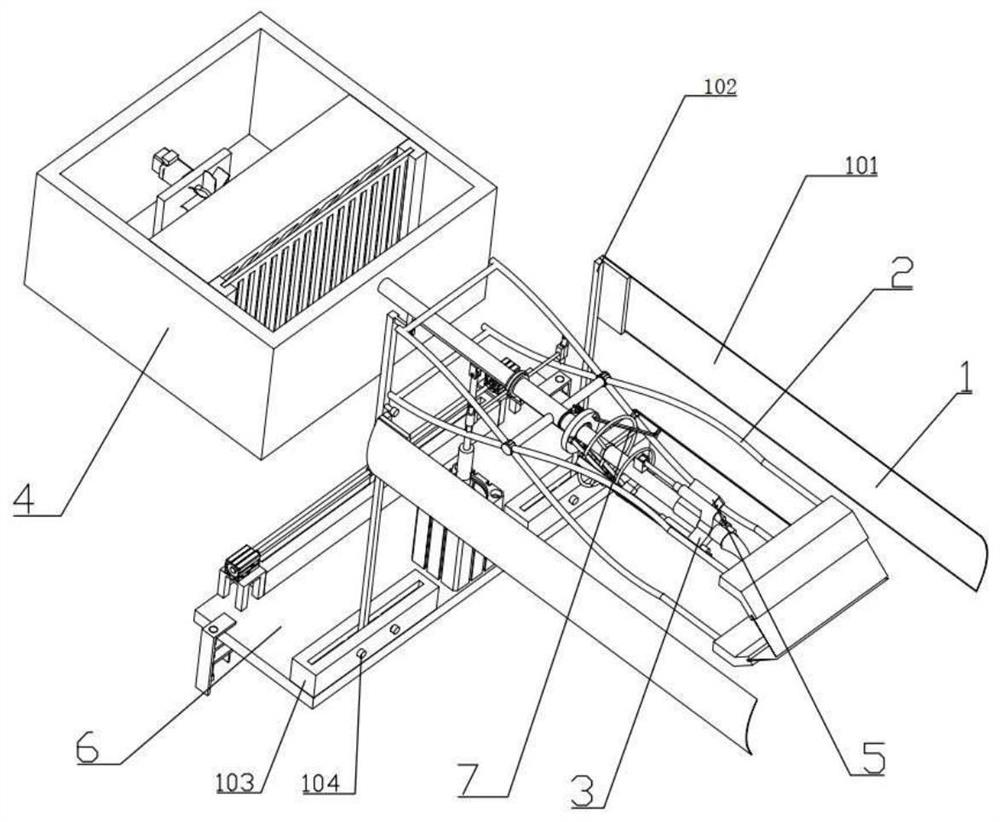

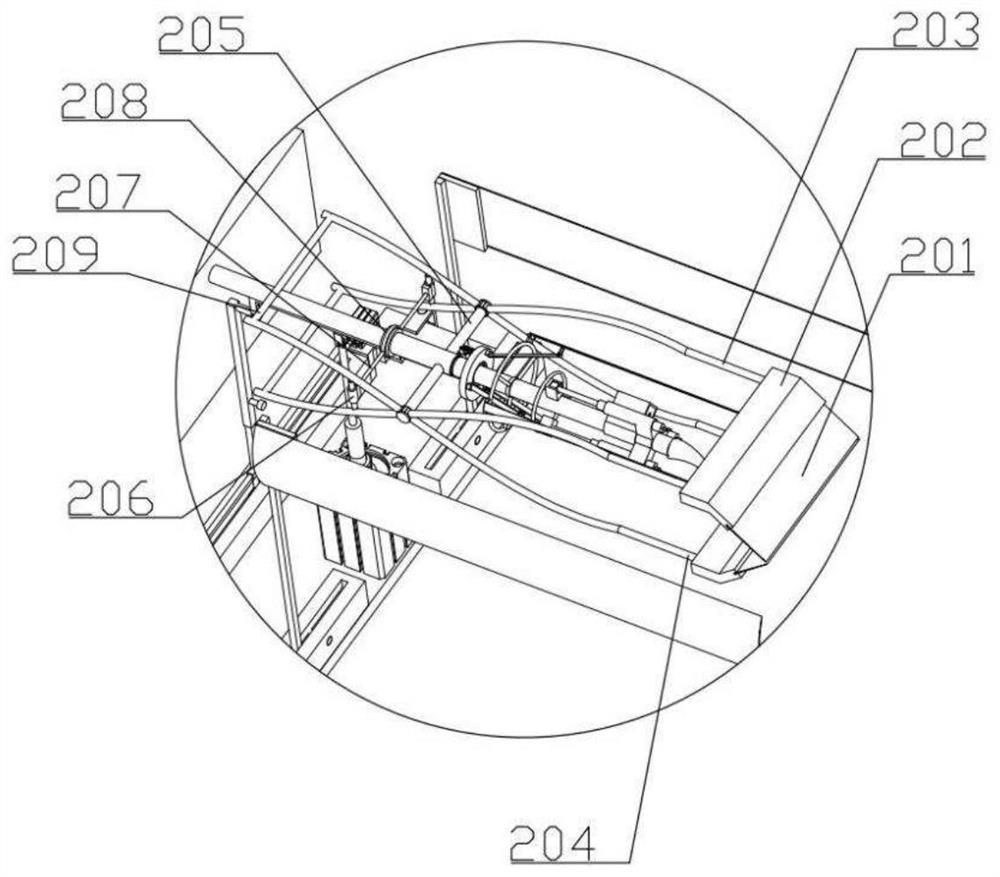

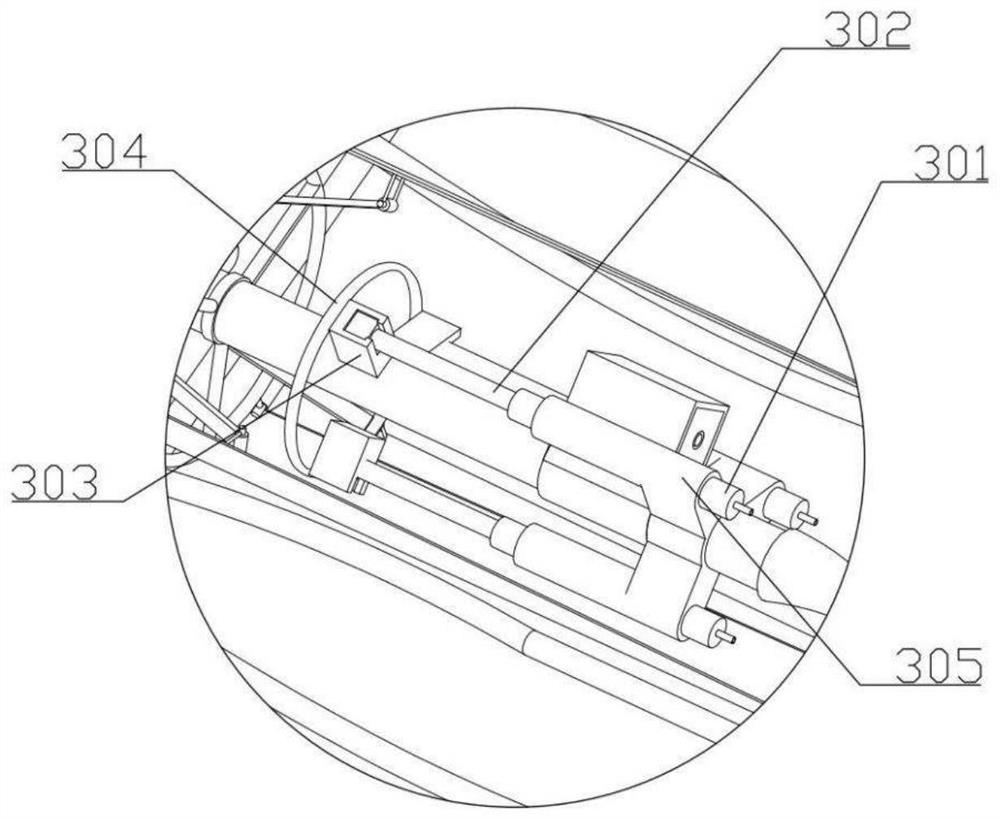

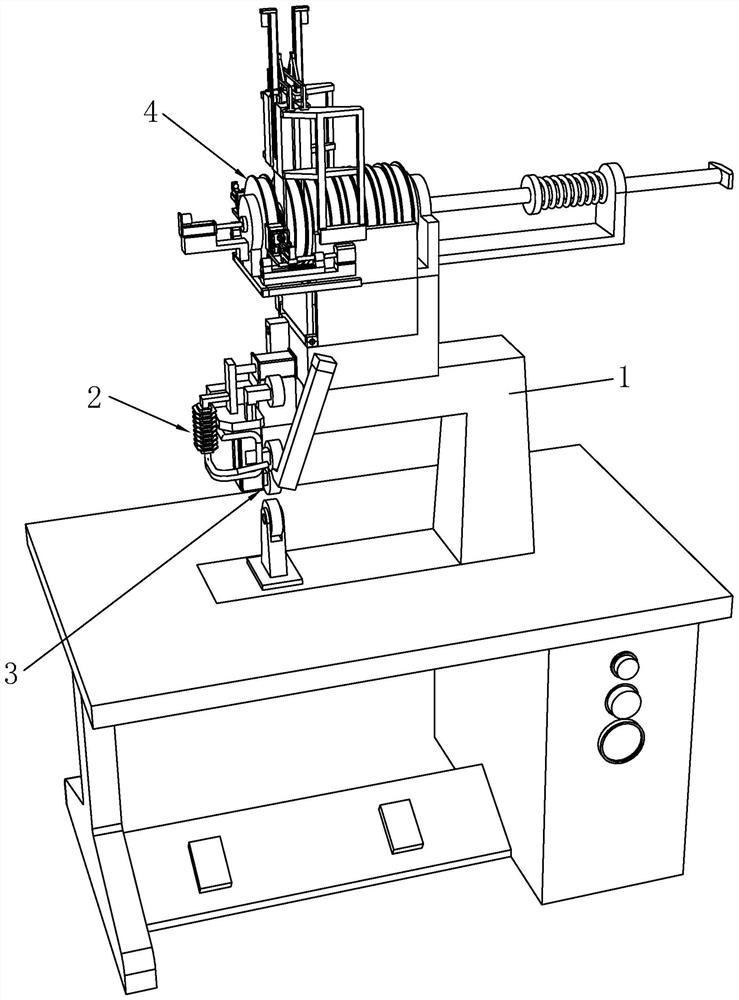

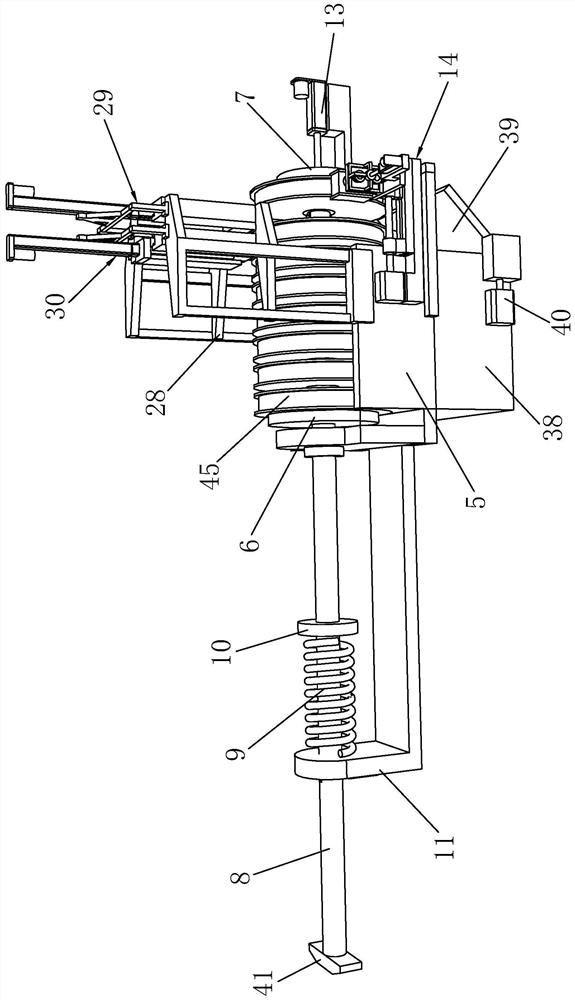

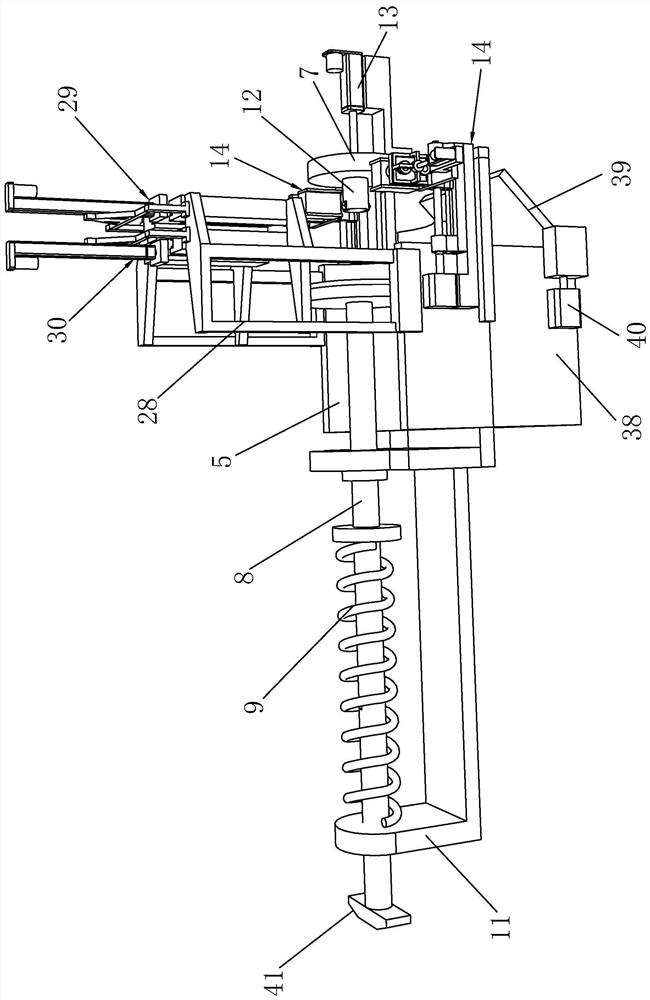

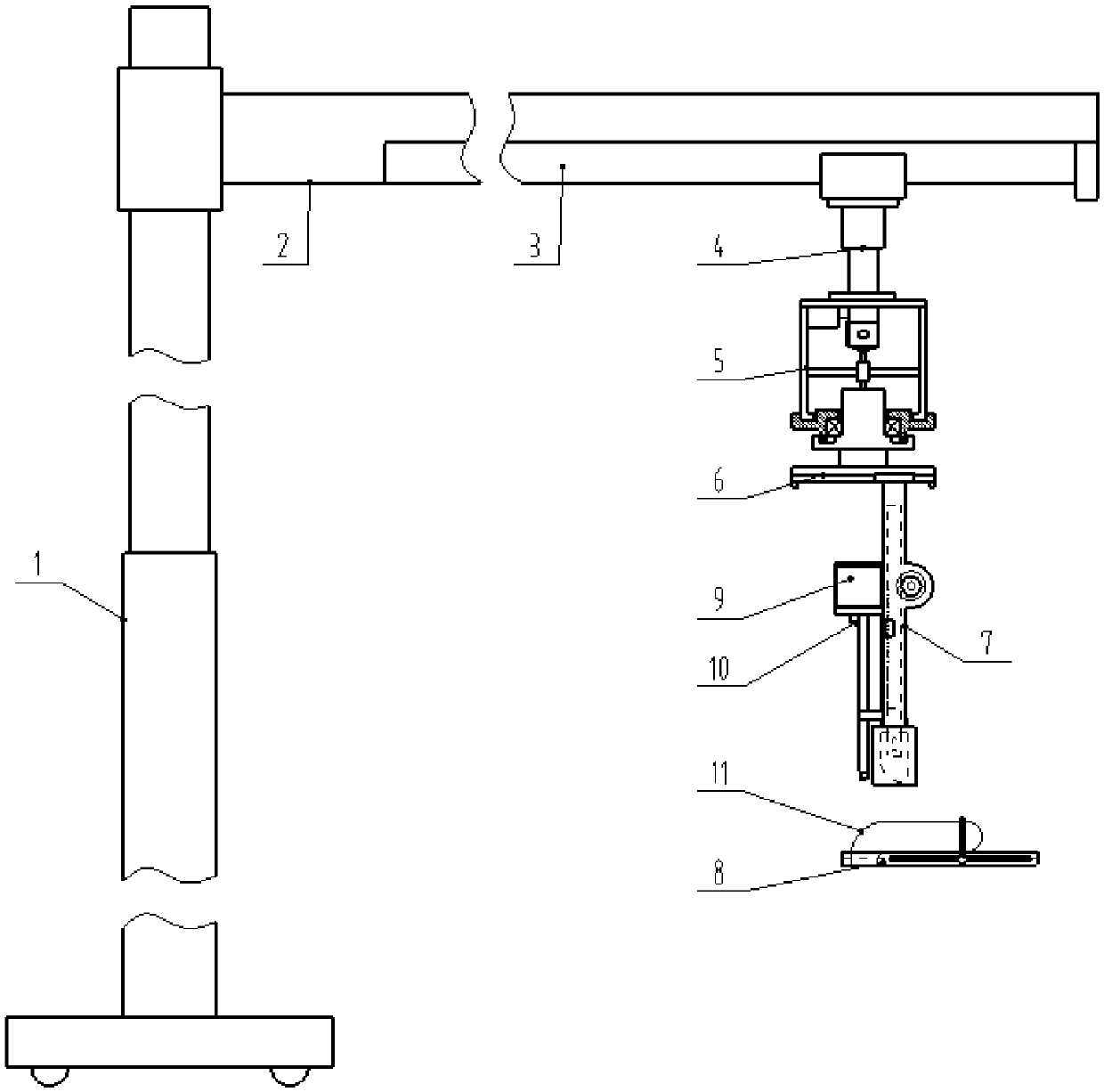

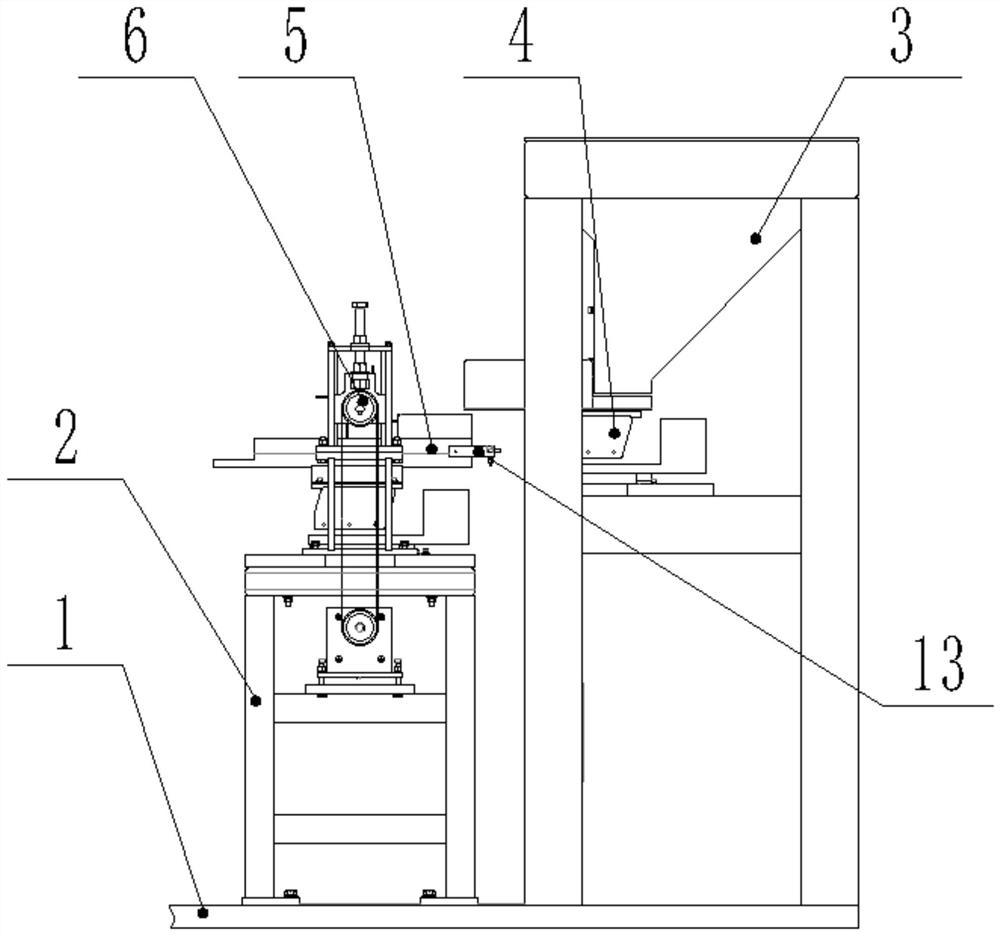

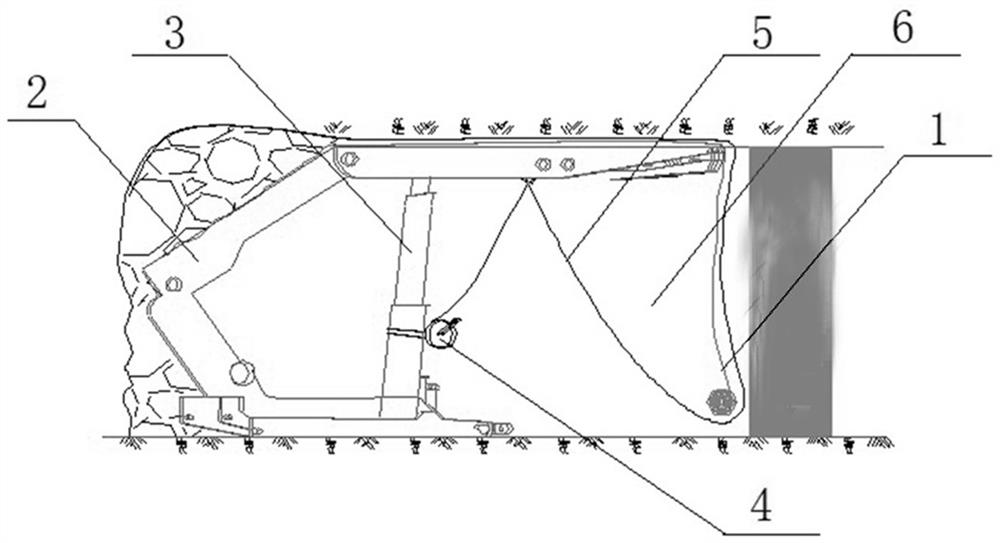

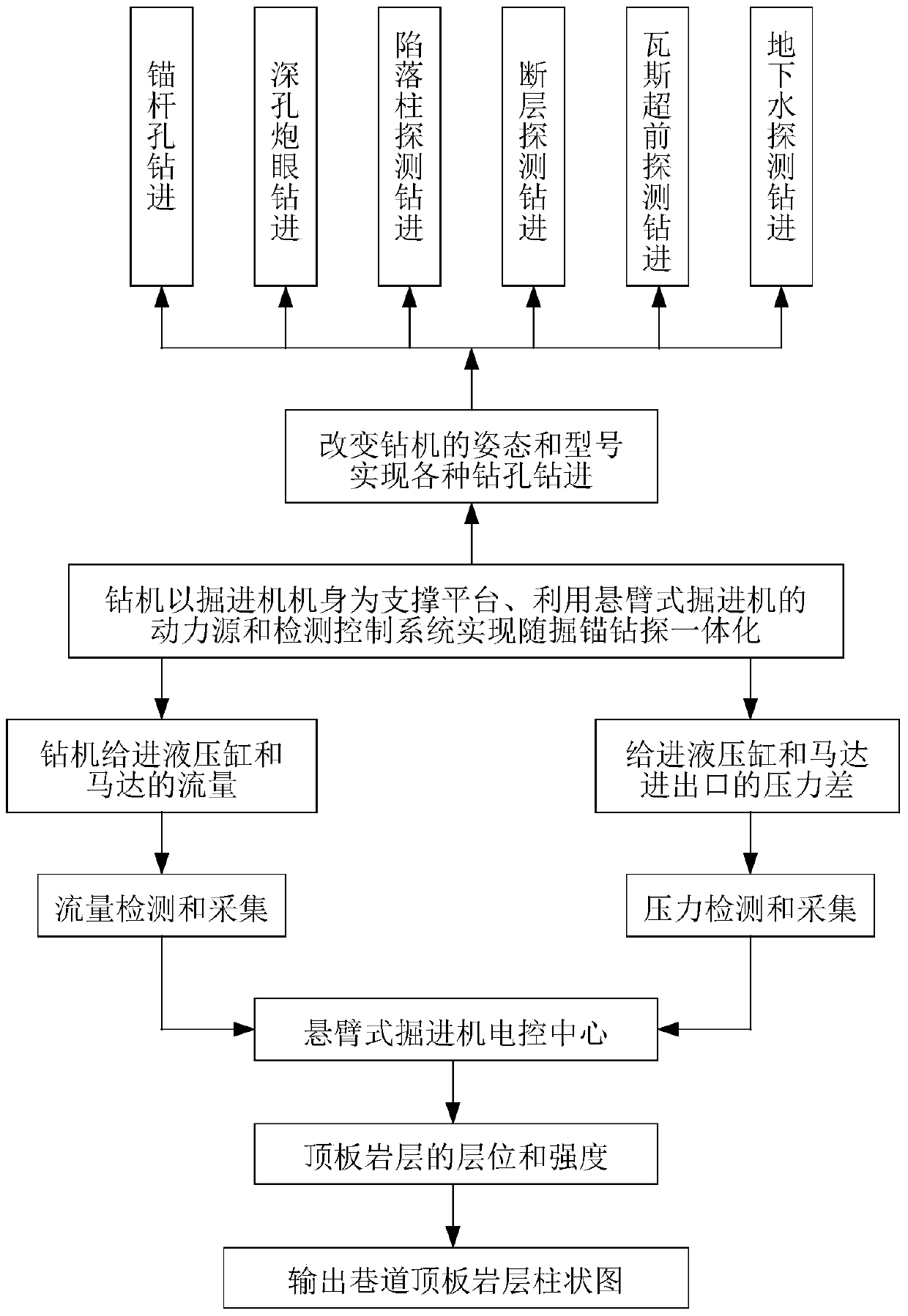

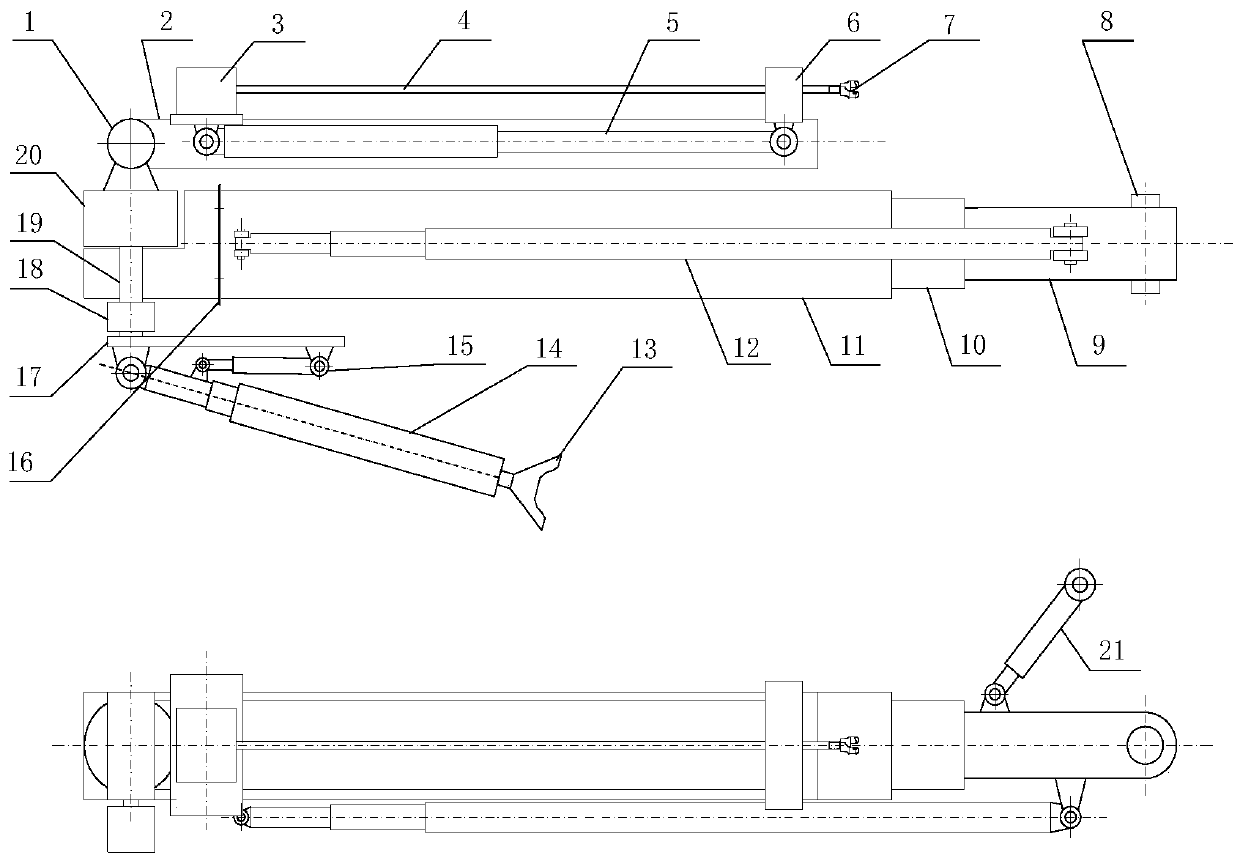

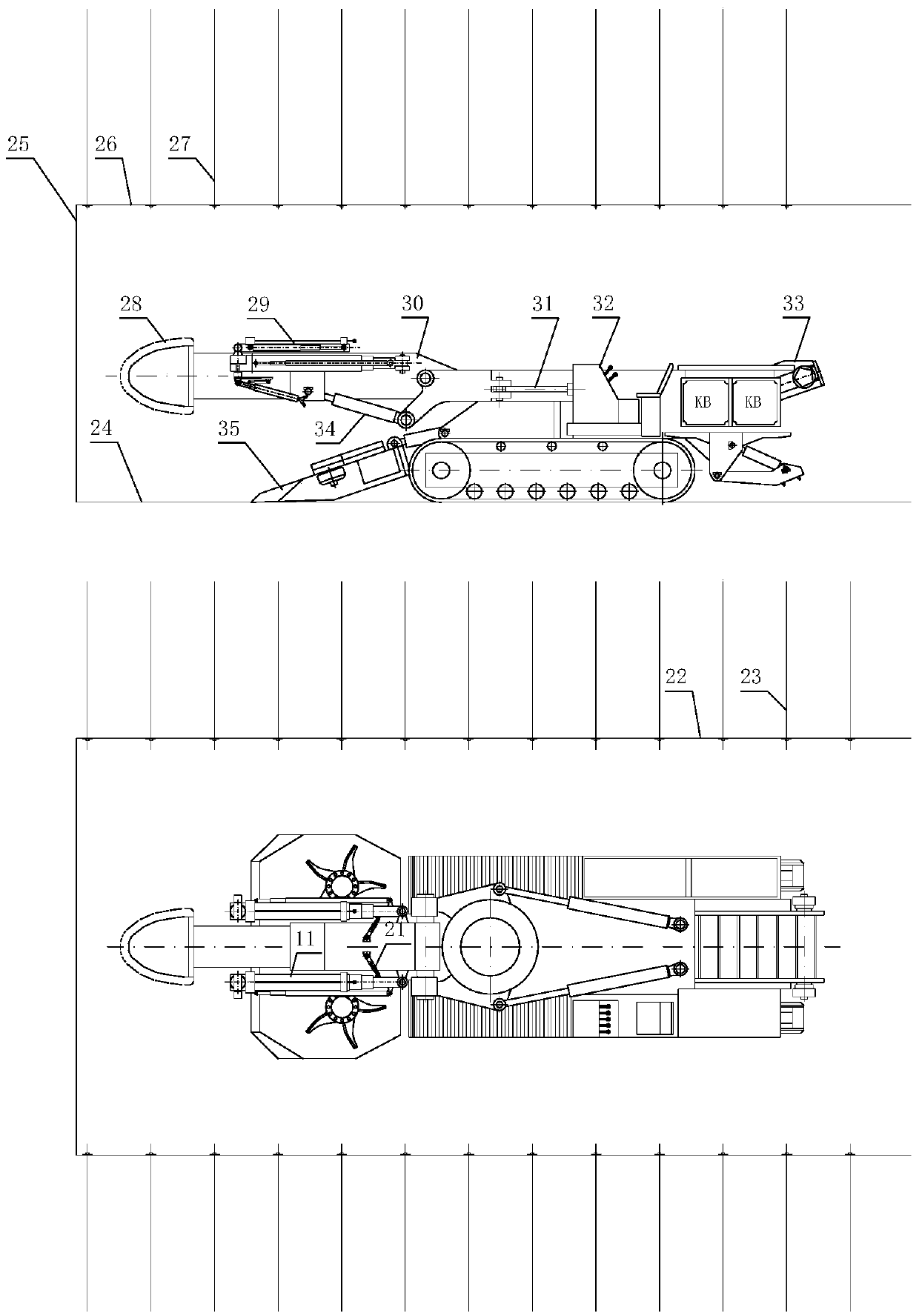

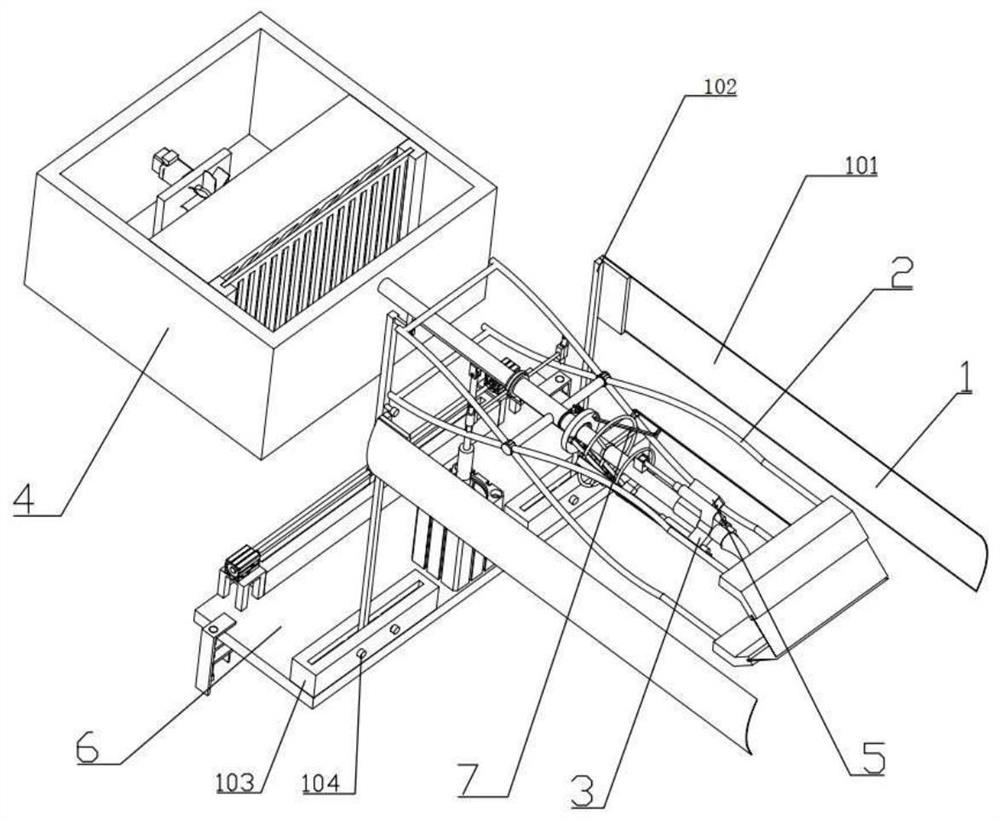

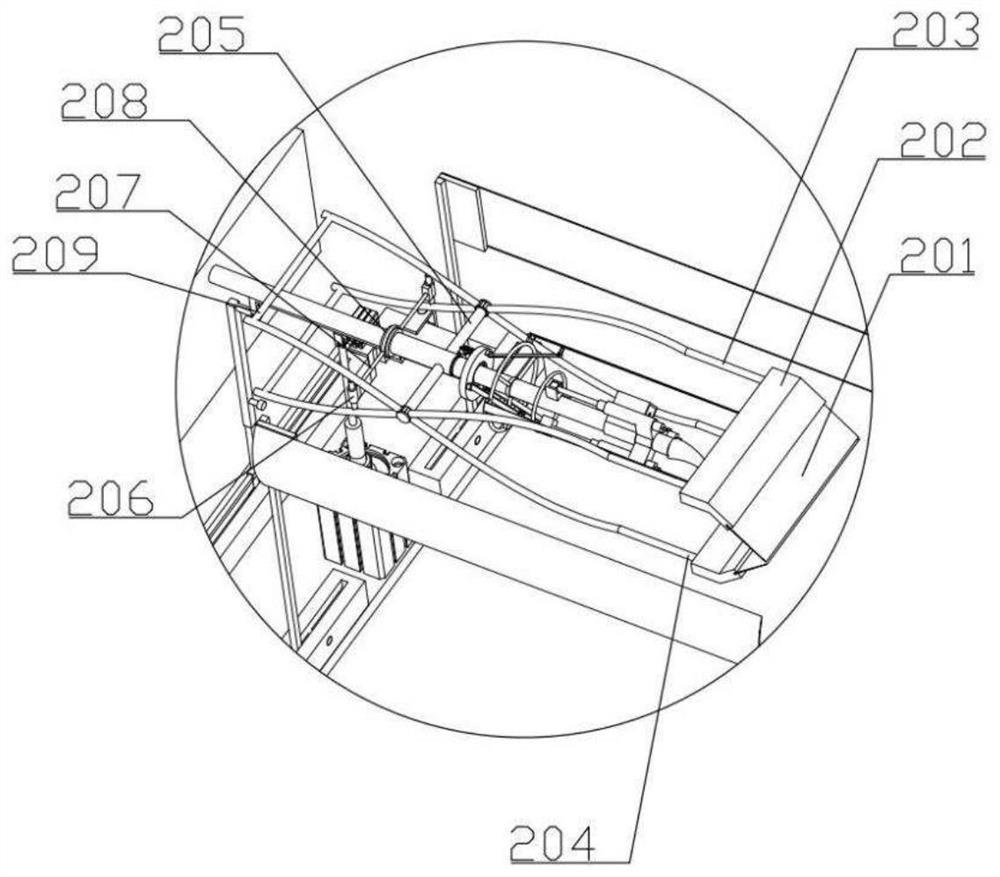

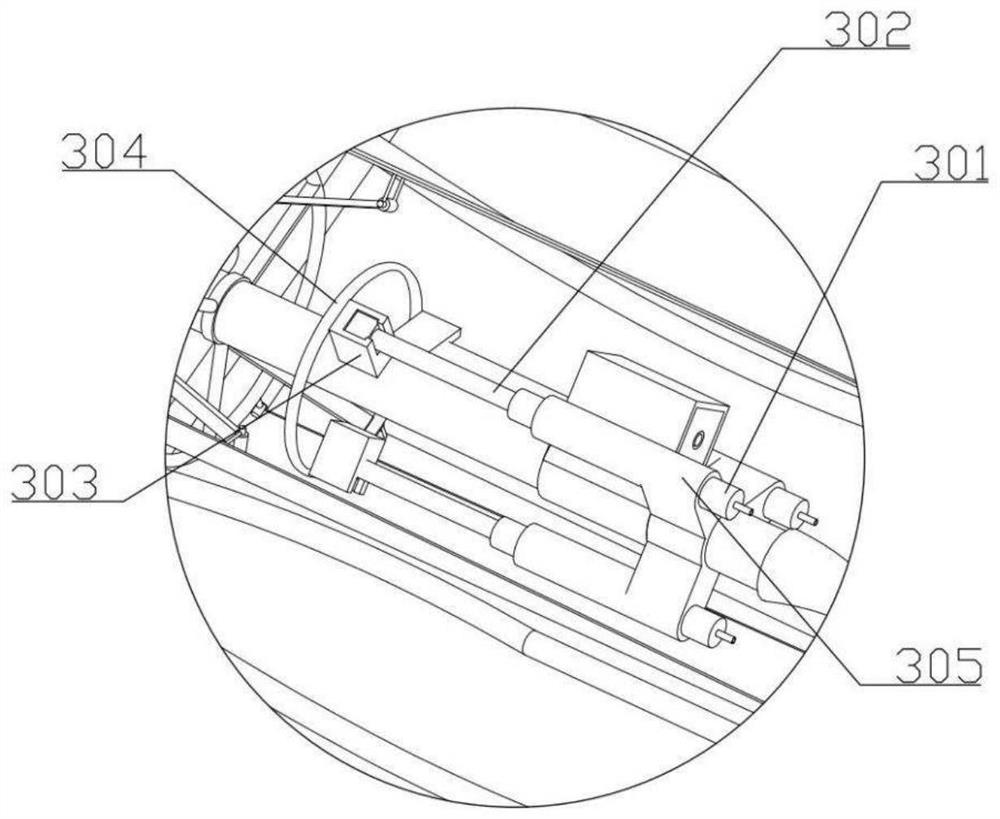

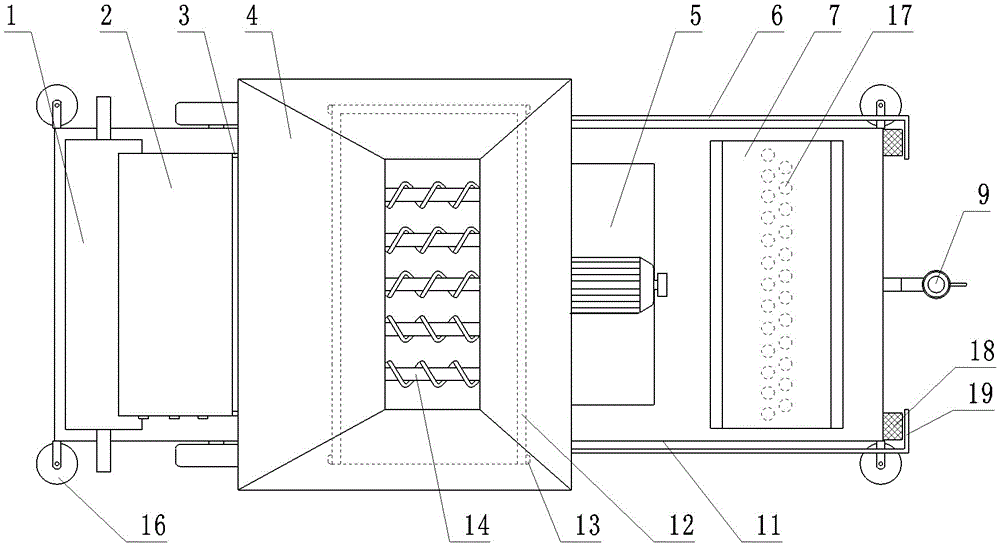

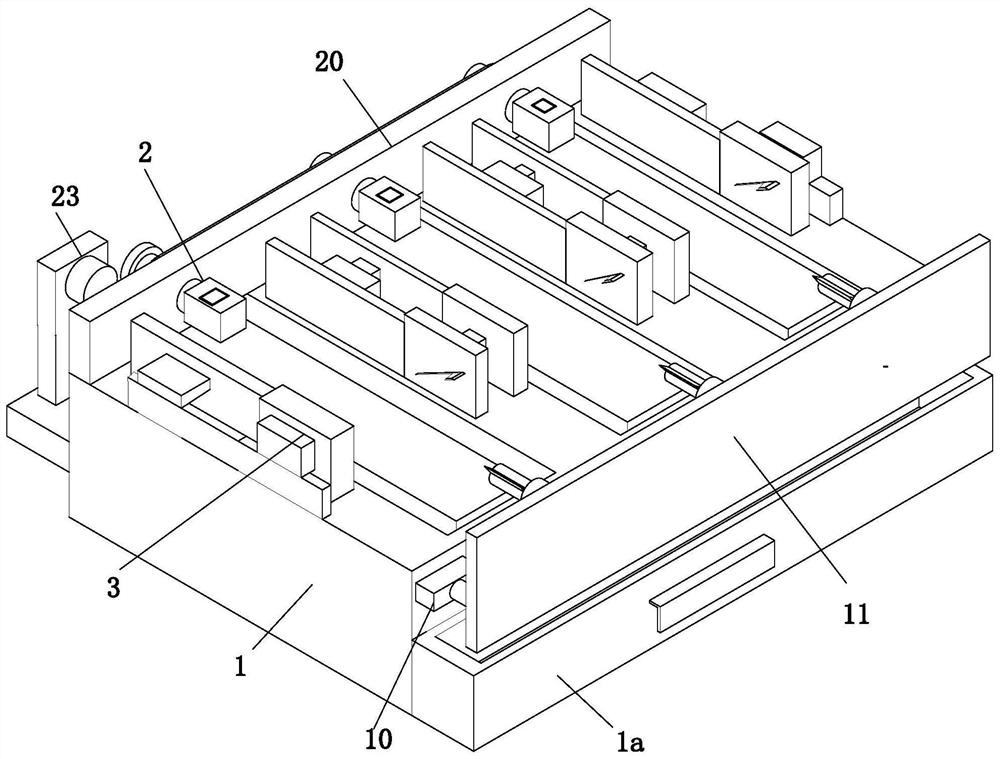

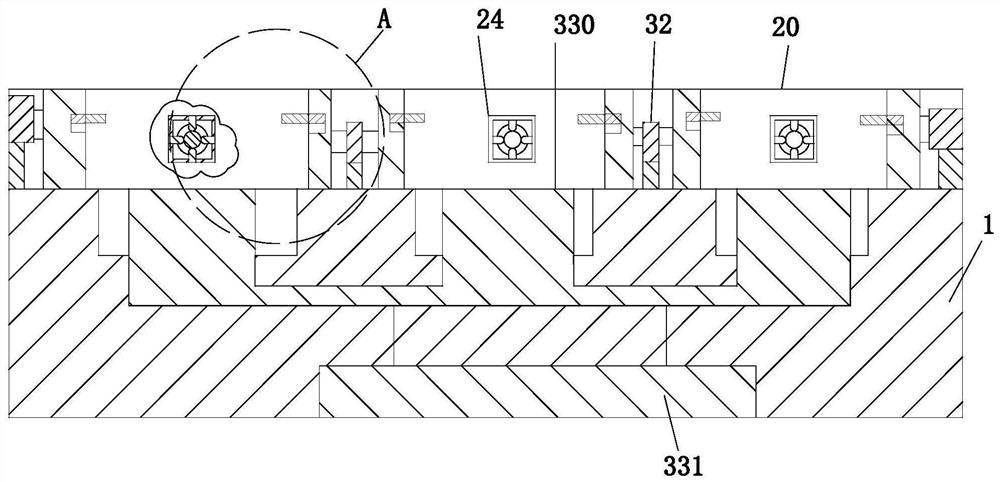

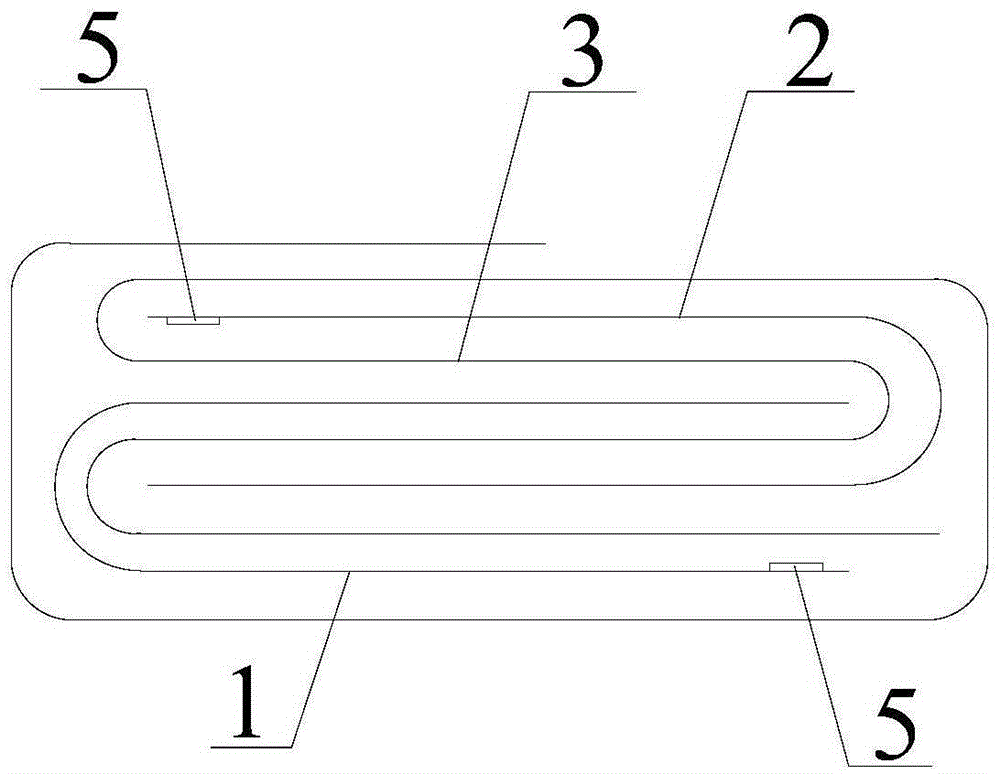

Boom-type roadheader mounted tunneling anchor-along drilling integrated drilling machine

ActiveCN103993879AEasy to operateFlexible and labor-saving operationCutting machinesSteel platesTransmission system

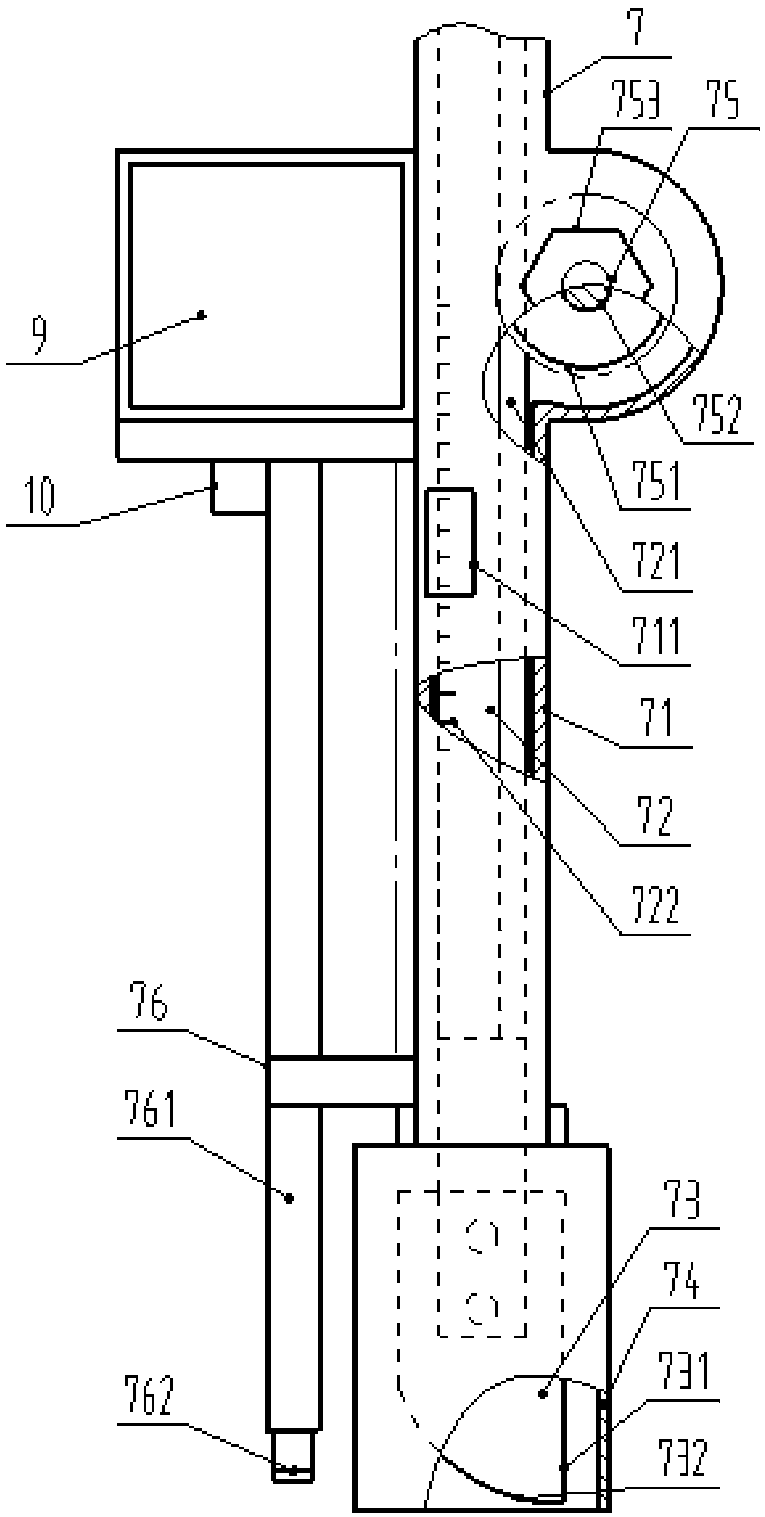

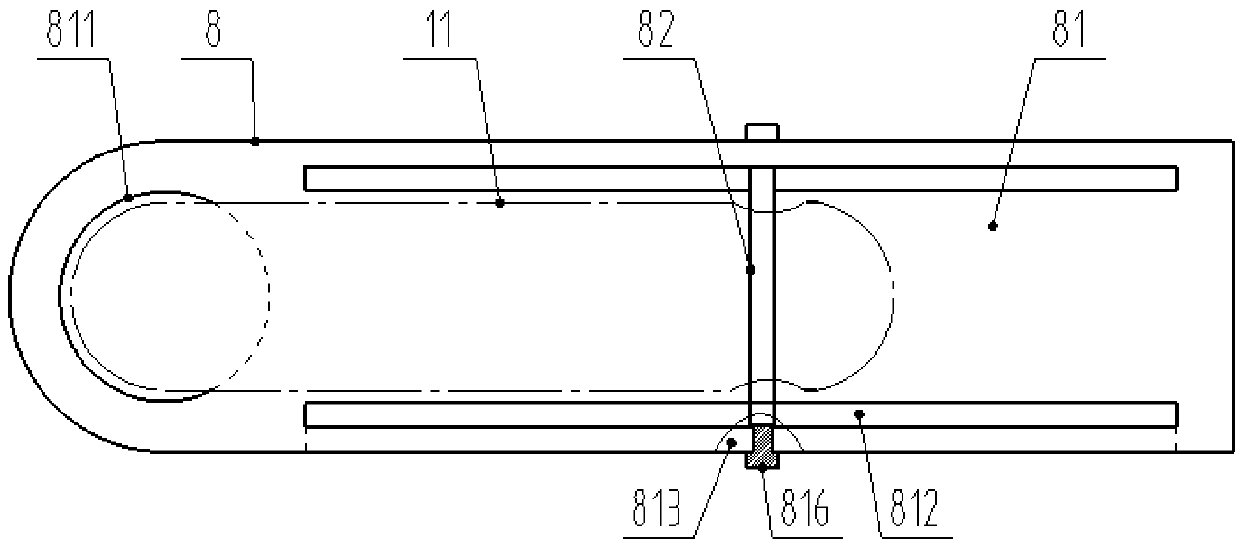

The invention discloses a boom-type roadheader mounted tunneling anchor-along drilling integrated drilling machine which mainly consists of a steel plate structural piece and a hydraulic system, wherein the steel plate structural piece of the drilling machine comprises a main withdrawing and release arm, a drilling machine rack, a vertical rotary mechanism and a horizontal rotary mechanism; the hydraulic transmission system of the drilling machine comprises a drilling hole hydraulic motor, a drilling machine horizontal rotary hydraulic motor, a drilling machine vertical rotary hydraulic motor, a telescopic leg hydraulic cylinder, a drilling machine thrust hydraulic cylinder, a hydraulic control element and a hydraulic auxiliary element. The drilling machine is characterized in that the drilling machine and a tunneling machine are integrally combined and are distributed on two sides of a tunneling machine cantilever, and the walking of the drilling machine is achieved through a walking mechanism of the tunneling machine. Holes can be drilled in an all-direction and multifunction manner in a tunneled roadway, both anchor bolt support and top plate lithology detection can be achieved, and drilling of shotholes, drilling of gas sucking and discharge holes, geologic drilling and the like can be achieved, and facilities and methods are provided for safe, rapid and efficient roadway tunneling.

Owner:ANHUI UNIV OF SCI & TECH

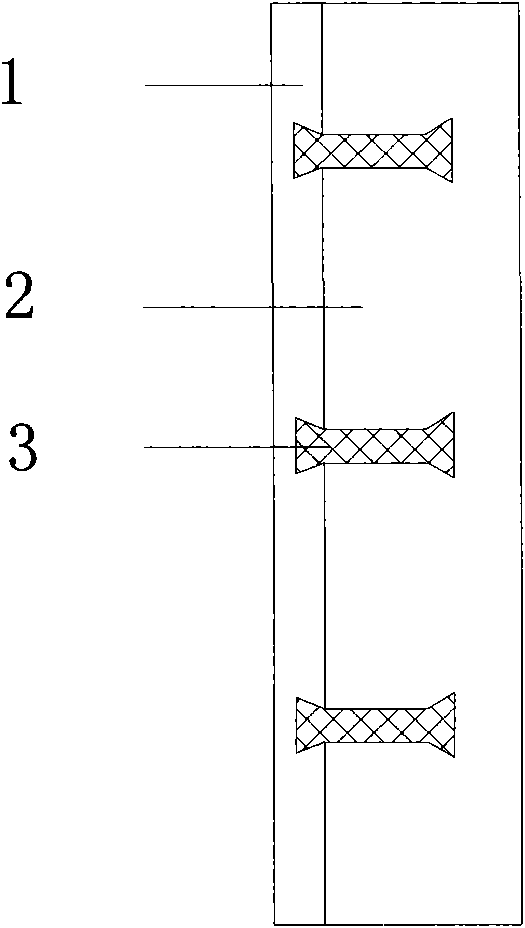

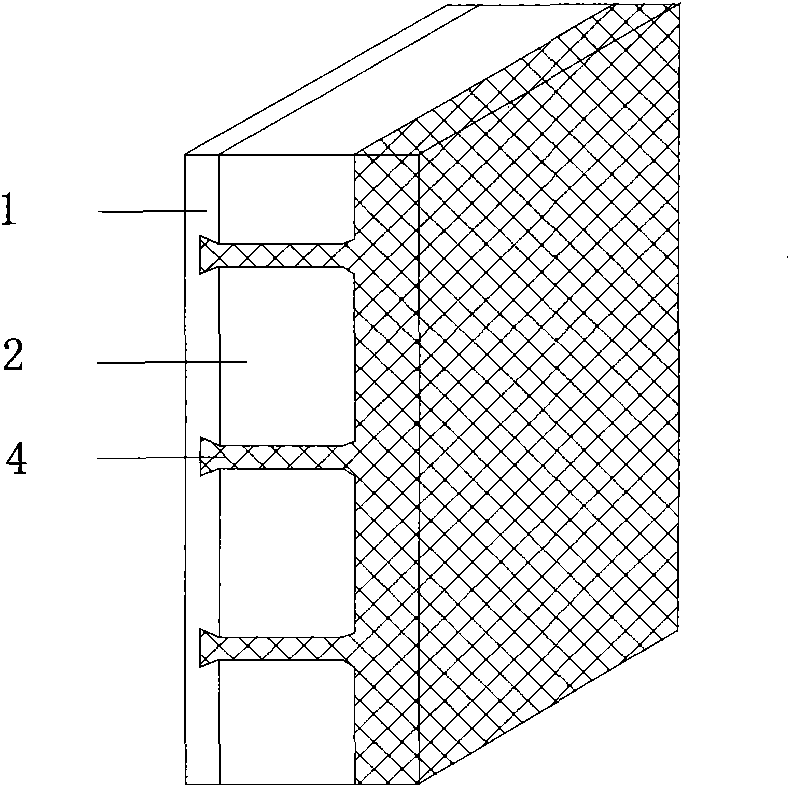

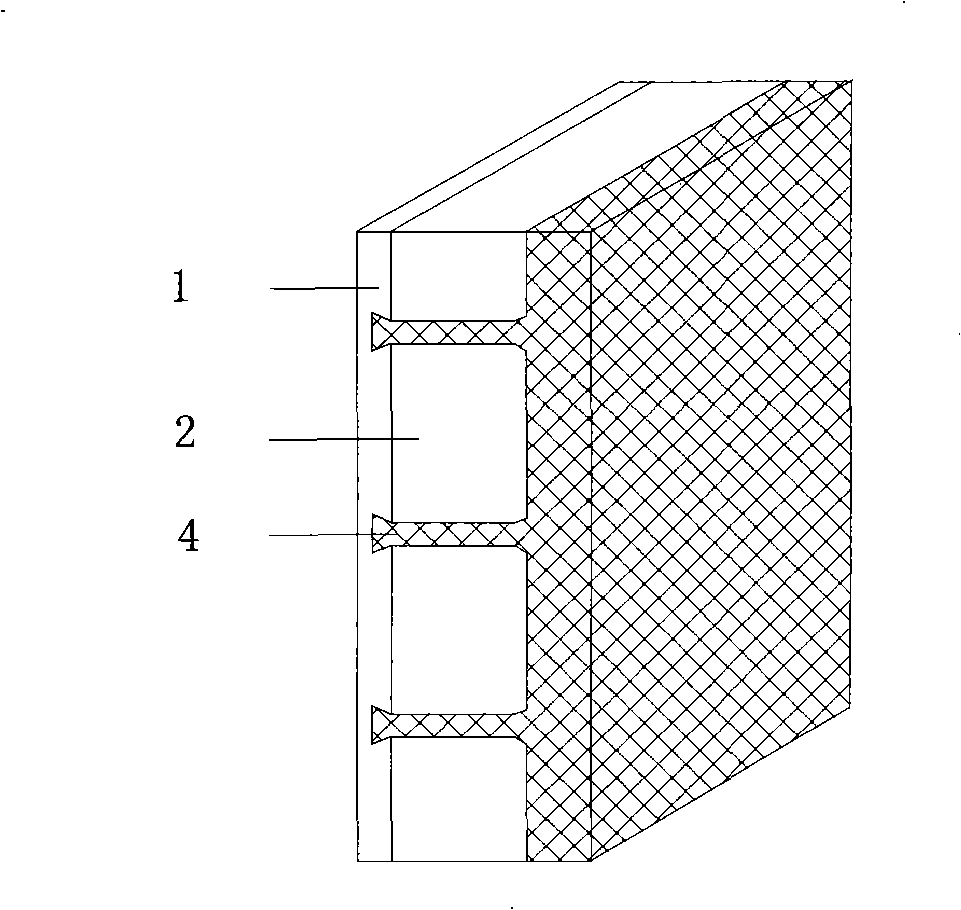

Molded composite board with improved firmness and preparation method thereof

ActiveCN101775874ASolve the deformationSolve insulation problemsCovering/liningsBuilding componentsEngineeringUltimate tensile strength

The invention provides a molded composite board with improved firmness, which comprises a lining layer and a heat insulating layer; a plurality of grooves or holes are correspondingly arranged on the opposite sides of the lining layer and the heat insulating layer; stuff enabling the lining layer and the heat insulating layer to be tightly bonded with each other is arranged in the grooves or holes or wedge-shaped buckles connecting and buckling the lining layer with the heat insulating layer are arranged in the grooves or holes; and the lining layer and the heat insulating layer are connected through the stuff which is tightly bonded or through the wedge-shaped buckles. The invention enables the bonding between the layers of the composite board to be firm, ensures that the layers do not disengage with each other and enhances the deformation resistance of the board. The invention solves the problems of easy deformation, the hidden trouble that the heat insulating layer disengages with the lining layer and poor strength in the prior art. The molded composite board does not need to be notched during site construction and is simple to construct and easy to operate, and the molded composite board is lower in price as compared with the prior art (aluminum sandwich composite panel) and has more obvious technological advantage, therefore, the molded composite board has higher application value and market popularization value.

Owner:ASIA CUANON TECH SHANGHAI

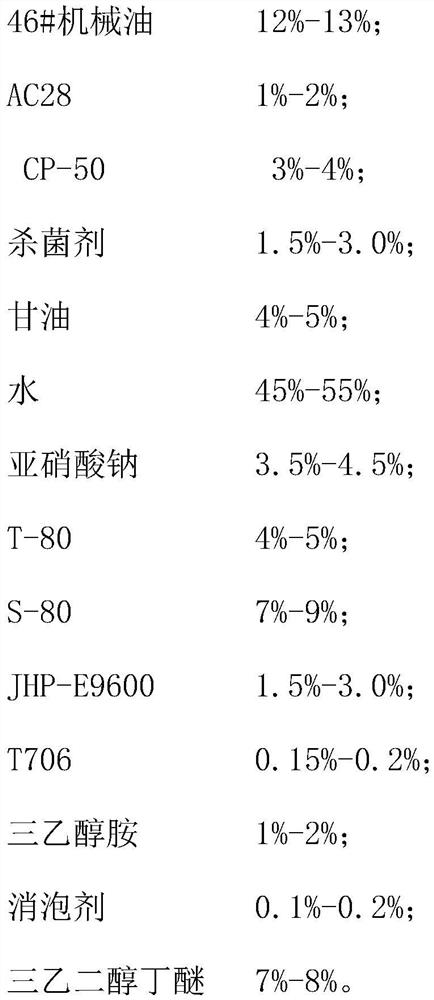

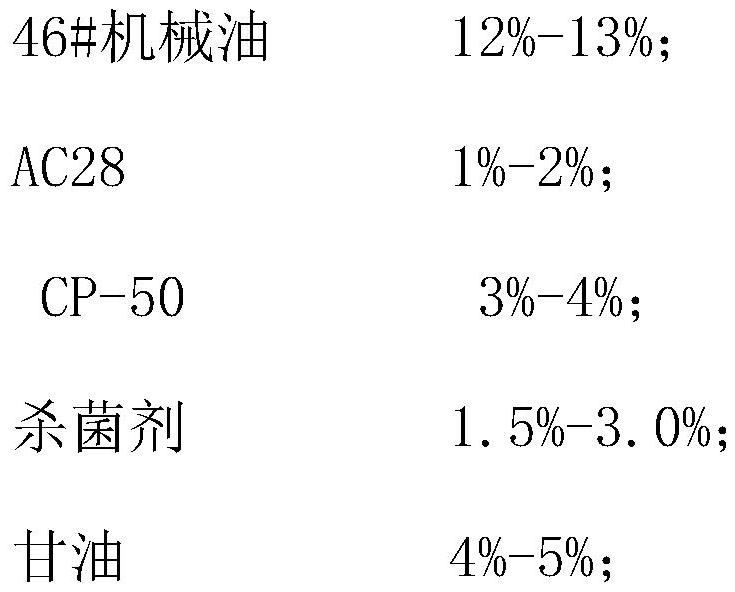

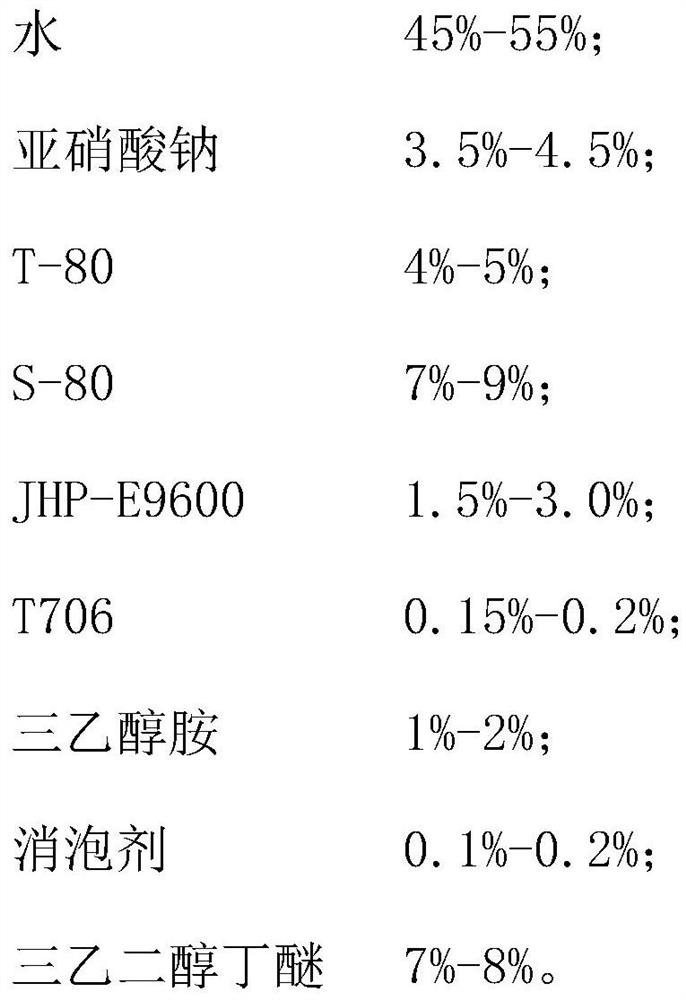

Special long-acting cutting fluid for aluminum alloy

ActiveCN111607457ALow maintenanceExtended cleaning cycleLubricant compositionSodium nitriteDefoaming Agents

The invention discloses a special long-acting cutting fluid for aluminum alloy, and mainly relates to the technical field of metal cutting fluids, the special long-acting cutting fluid comprises the following components by mass percentage: 46 # machine oil 12%-13%; AC28, 1%-2%; CP-50, 3%-4%; 1.5%-3.0% of a bactericide; 4%-5% of glycerol; 45%-55% of water; 3.5%-4.5% of sodium nitrite; T-80, 4%-5%;S-80, 7%-9%; JHP-E9600, 1.5% 3.0%; T706, 0.15%-0.2%; 1%-2% of triethanolamine; 0.1%-0.2% of a defoaming agent; 7%-8% of triethylene glycol butyl ether; microemulsions are more stable, better hard water resistace is achieved through anion-free design, a prepared diluent is effective for a long time, the diluent is still effective after mechanical oil is separated out, cutting is not affected, cleaning is not needed, the second set of wonderful lubricating scheme enables a user to use the machine all the time, the purpose that the cost of the user is reduced is achieved, energy is saved, the maintenance cost is low, the cleaning period is long, and a large number of raw materials are saved.

Owner:山东三晶润滑科技有限公司

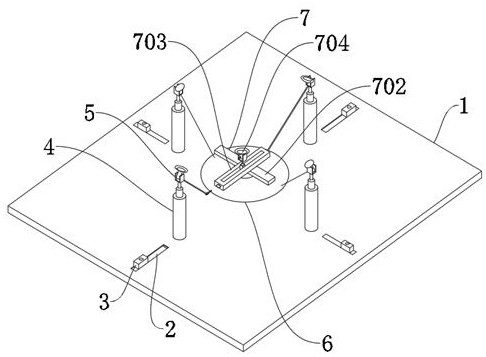

Plant protection unmanned aerial vehicle with fertilization function

InactiveCN108791888AWith fertilization functionEasy to sprayAircraft componentsLaunching weaponsAgricultural engineeringFertilizer

The invention discloses a plant protection unmanned aerial vehicle with a fertilization function. The plant protection unmanned aerial vehicle comprises an unmanned aerial vehicle body, and the left and right sides of the lower surface of the unmanned aerial vehicle body are separately and fixedly connected to upper parts of the left and right side faces of a shell through fixing devices. A firstbearing is connected to the upper surface of the shell in a clamped mode, and a first rotating shaft is connected into the first bearing in a sleeved mode. According to the plant protection unmanned aerial vehicle with the fertilization function, by arranging a first motor, an output shaft of the first motor rotates left and right to drive a first rotating shaft and a connecting rod to rotate leftand right before the unmanned aerial vehicle body takes off, and stirring blades are rotated left and right under the action of solid fertilizer resistance, so that the stirring blades and first through holes can rotate up and down, a solid fertilizer can be more fully stirred in the shell, the process that the solid fertilizer is first stirred in an agitator by people and then put into the shellis avoided, and it is convenient for people to use the unmanned aerial vehicle body for the spraying operation.

Owner:张强

Pole roll slitting machine

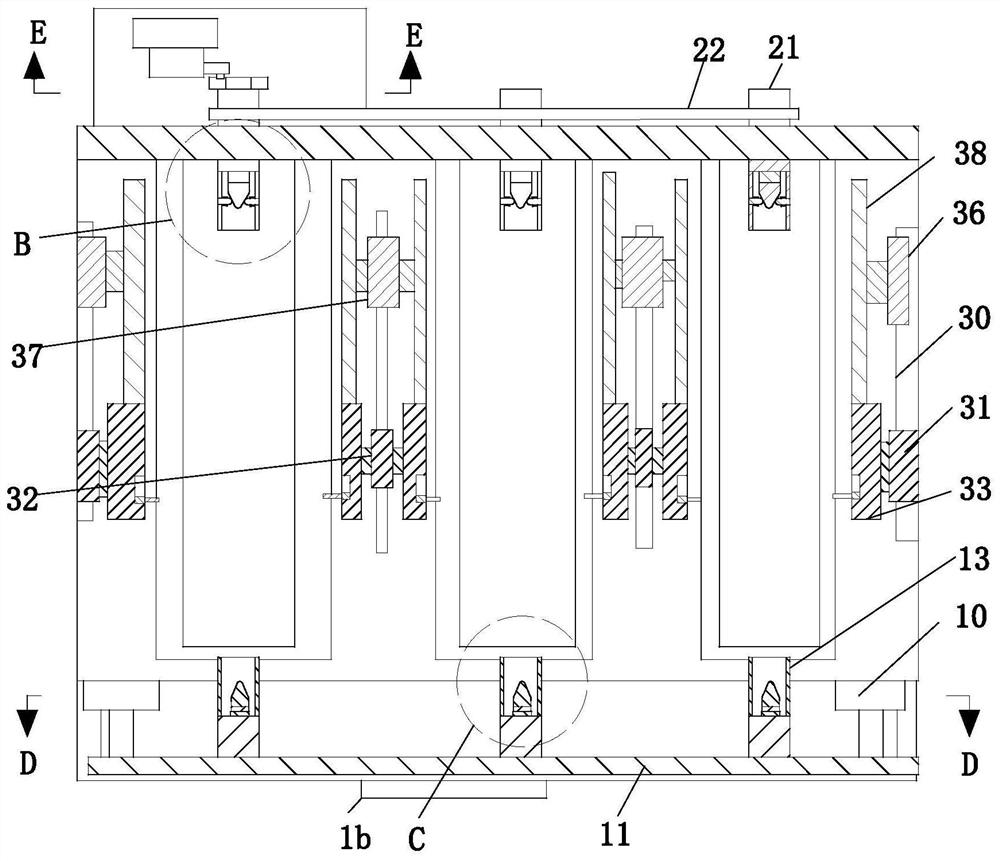

InactiveCN107138791AImprove cut qualityAvoid vicious circleShearing machinesMaintainance and safety accessoriesRoll slittingEngineering

The invention relates to a pole roll slitting machine. The pole roll slitting machine includes the body and the upper and lower slitting knives arranged on the body. The body is also equipped with a first dust suction device. The first dust suction device includes a slitting air outlet, which is aligned with the Slitting position setting of upper and lower slitting knives. Using the pole roll slitting machine of the present invention, the slitting position air outlet is set at the position of the slitting knife in the pole roll slitting process, and the root position where the most dust and metal scraps are generated during the slitting process is sucked and dedusted, It can not only significantly reduce the dust and metal filings content inside the slitting machine and on the coil, reduce the influence of dust and metal filings on the coil, but also remove the metal filings on the slitting knife to avoid sticking of the slitting knife. Attached metal shavings lead to a decrease in slitting quality due to the existence of metal shavings in the subsequent slitting process, resulting in a vicious circle of more metal shavings and improving the slitting quality of the slitting knife.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

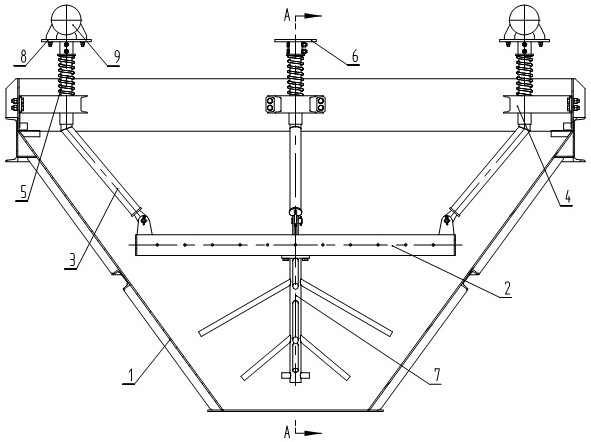

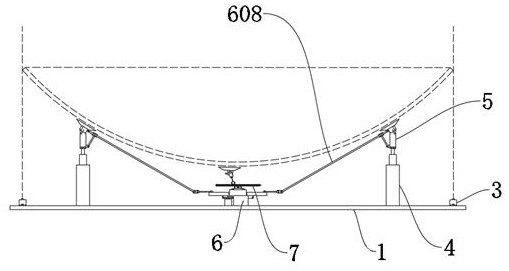

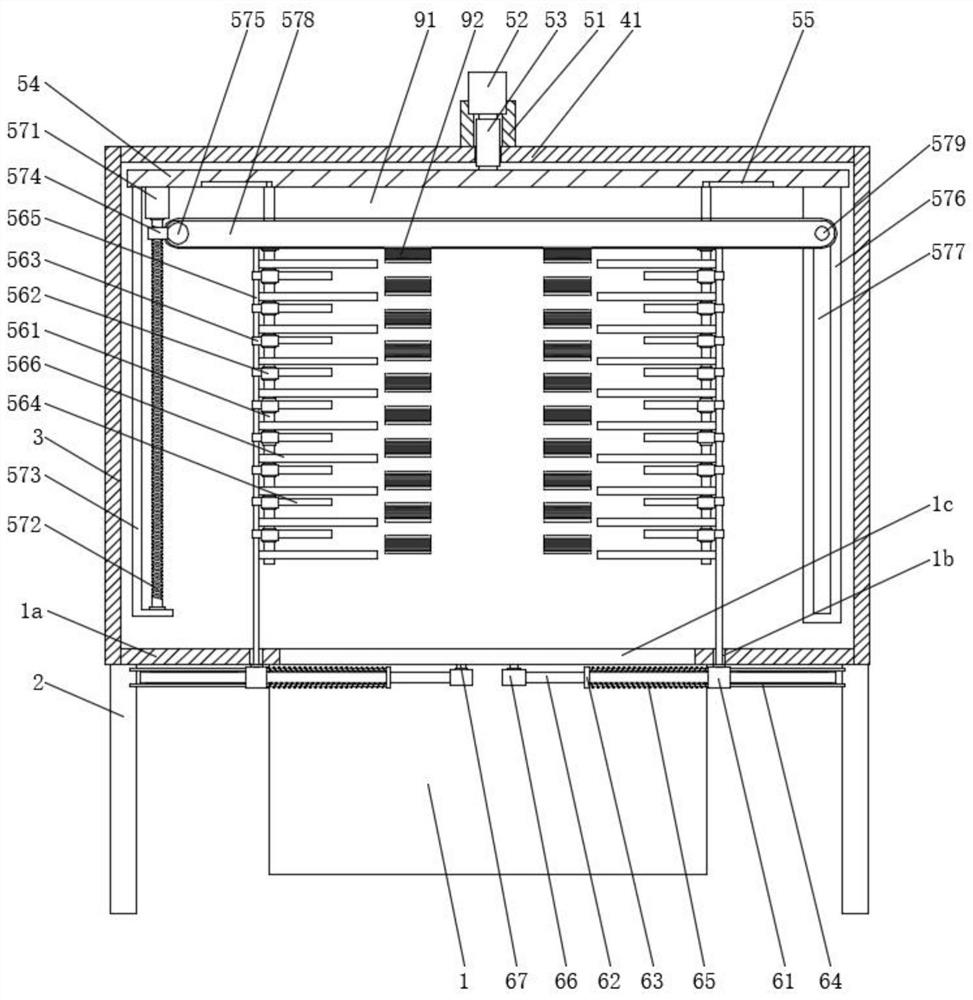

Aeolian sand and loess hopper vibration type discharging device

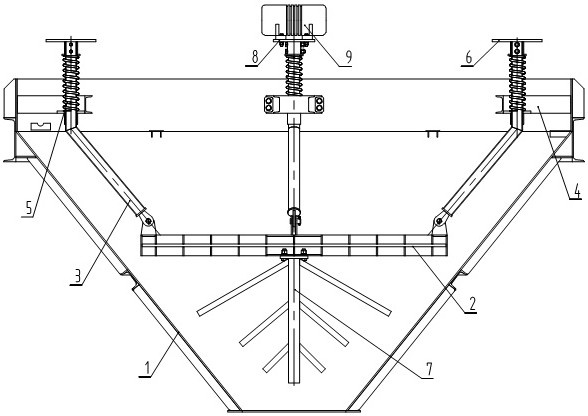

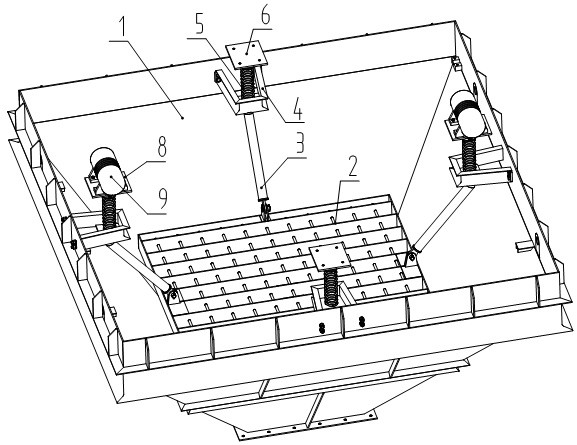

PendingCN111806906AOutflow smoothlyPlay a filtering roleSievingScreeningMotor vibrationElectric machinery

The utility model discloses an aeolian sand and loess hopper vibration type discharging device, and belongs to hopper vibration type discharging devices. The vibration type discharging device comprises a receiving hopper, a vibration grate net, a vibration pull rod, a spring bracket, a spring, a mounting plate, a vibrating device, a vibration motor base and a vibration motor; the mounting plate orthe vibration motor base is connected to the upper end of the vibration pull rod, the vibration motor is connected to the vibration motor base, and the mounting plate is used for fixing the vibrationtype discharging device; the lower end of the vibration pull rod is connected with the vibration grate net, and the middle position of the bottom surface of the vibration grate net is connected withthe vibrating device; the inner wall of the upper end of the receiving hopper is connected with the spring bracket; and the vibration pull rod below the mounting plate is sleeved with the spring, thelower end of the spring is located on the spring support, and the vibration pull rod can slide in the spring. The utility model has the advantages of simple structure, less parts, greatly reduced failure rate and convenience in disassembly and maintenance. And real-time start and stop and frequency adjustment can be controlled on site and remotely. The vibration grate net is used for filtering impurities in the materials; and the vibrating device is used for treating the corners of the discharging opening.

Owner:XUZHOU CUMT BACKFILL TECH

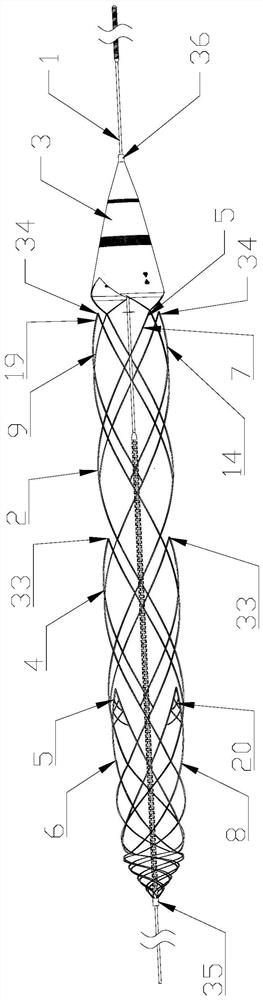

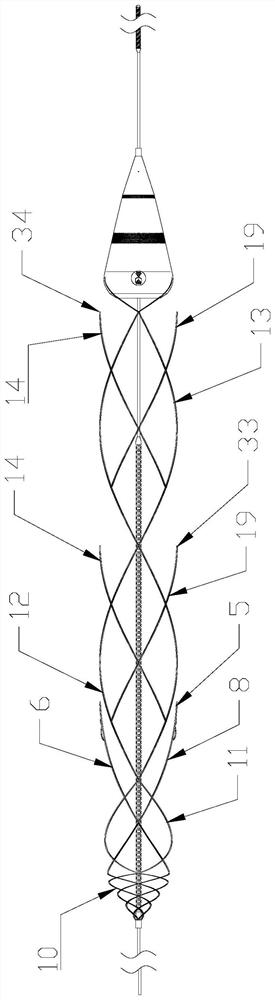

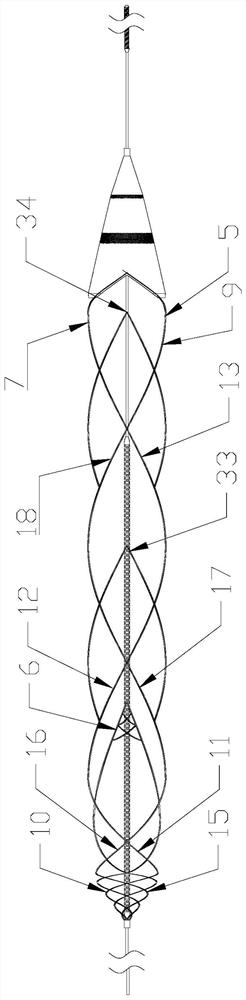

Thrombus withdrawing support

ActiveCN112690872AEffectively cut thrombusThrombectomy process went wellSurgeryThrombusApparatus instruments

The invention discloses a thrombus withdrawing support and belongs to the technical field of medical appliances. The thrombus withdrawing support provided by the invention comprises a guide wire, a reticular support main body and a protective umbrella, wherein the reticular support main body and the protective umbrella sleeve the guide wire; and the reticular support main body is formed through spirally stretching a plurality of first metallic wires along the circumferential direction of the guide wire, proximal ends of the first metallic wires are of semi-fusiform retracting, distal ends of the first metallic wires are openings, and the distal ends of the first metallic wires are connected to form a wing. By arranging the first metallic wires, the reticular support main body can be used for effectively cutting a thrombus during self-dilation, and a thrombus withdrawing process can be more successful.

Owner:上海璞慧医疗器械有限公司

Hysteromyoma resection instrument

InactiveCN111821004AQuick washRapid DisinfectionSuture equipmentsInternal osteosythesisVaginal dilationEngineering

The invention discloses a hysteromyoma resection instrument. The hysteromyoma resection instrument comprises a vaginal dilation device, a resection device, a cleaning device, a suction device, an observation device, a fixing device and a clamping device. The vaginal dilation device can dilate the vaginal orifice of a patient and keep the state to guarantee subsequent operation; the resection device can resect hysteromyoma; the cleaning device can disinfect wounds and clean residues from the inner wall of the uterus after resection, so that the safety of an operation process is guaranteed and infection is avoided; the suction device can suck away the cleaned residues and waste liquid used for cleaning; the observation device can observe the myoma position after the instrument enters the vaginal orifice; the resection device and the overall structure are fixed to the resection position through the fixing device; and the clamping device can clamp the myoma and is stretched backwards. Thecutting position of a cutter is reserved, so that subsequent cutting is facilitated; the myoma is taken out of the uterus through cooperation of the clamping device, the suction device and the vaginaldilation device; and disinfection is completed through the cleaning device, so that it is guaranteed that medical pollution is avoided.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Adhesive pressing device for producing high-barrier spunlace medical protective clothing

PendingCN112477161AImprove stabilityImprove feeding effectGarmentsDomestic articlesAdhesive beltMechanical engineering

The invention discloses an adhesive pressing device for producing high-barrier spunlace medical protective clothing. The device comprises a machine frame, a heating mechanism for heating an adhesive tape and an adhesive pressing mechanism for pressing the adhesive tape on cloth; the heating mechanism and the adhesive pressing mechanism are both arranged on the machine frame; the machine frame is provided with a continuous adhesive feeding mechanism for uninterrupted continuous adhesive feeding; the continuous adhesive feeding mechanism comprises an adhesive feeding frame, an adhesive ejectingplate and a fixing disc; the adhesive ejecting plate is provided with a sliding rod; the sliding rod is arranged on the adhesive feeding frame and slidably connected with the adhesive feeding frame; the sliding rod is sleeved with an adhesive ejecting spring, and is provided with a limiting block, the adhesive feeding frame is provided with a top plate, and the adhesive ejecting spring is arrangedbetween the top plate and the limiting block; and the fixing disc is provided with a fixing shaft which is slidably connected with the fixing disc, and is further provided with a first electric pushrod which drives the fixing shaft to stretch in the fixing disc. Replacement of the adhesive tape and adhesive feeding can be facilitated, the production quality of the protective clothing is improved, and the production efficiency is improved.

Owner:浙江乐芙医疗用品有限公司

Production device and preparation process of low-temperature curing color coated steel plate

ActiveCN113997079ANo reboundNo archingOther manufacturing equipments/toolsShearing machine accessoriesElectron bunchesMachining

The invention discloses a production device and a preparation process of a low-temperature curing color coated steel plate. The production device comprises a workbench, an electron beam device, an extrusion coating device, a front storage rack and a rear storage rack, the rear storage rack is fixed to the upper surface of the workbench through bolts, a first inlet loop is fixed to the upper surface of the rear storage rack through bolts, a first deviation rectifying machine is fixed to the left side surface of the rear storage frame through bolts, a first tension machine is fixed to the upper surface of the workbench through bolts, and a transition roller is fixedly connected to the upper surface of the workbench. According to the production device and the preparation process of the low-temperature curing color coated steel plate, a friction block is arranged, through deformation recovery of a spring, the friction block can rub the fit opening of a steel plate body, and then burrs on the steel plate body are removed, so that after the steel plate body is machined, and the steel plate body does not need to be transferred for deburring machining, therefore, the use limitation of the whole device is reduced, and the applicability of the whole device is improved.

Owner:江苏卡欧彩涂钢板有限公司

Environment-friendly waterborne antirust agent and preparation method thereof

InactiveCN109666407ANo pollutionDoes not affect cuttingRosin coatingsAnti-corrosive paintsPEG 400Organic solvent

The invention discloses an environment-friendly waterborne antirust agent. The environment-friendly waterborne antirust agent is prepared by proportioning the following components in parts by weight:7 parts of rosin polymer, 5 parts of heterocyclic antirust agent, 20 parts of triethanolamine borate, 12 parts of ethanolamine (MEA), 0.3 part of ethylenediamine tetraacetic acid disodium (EDTA disodium), 0.2 part of polyethylene glycol 400 and 55.5 parts of pure water. The antirust agent made of the rosin polymer has good post-cleaning performance and better antirust capability than conventionalwaterborne antirust agent, has very high absorptivity and spreadability on the surface of steel and iron, and has performance similar to that of oily products, and the raw materials for preparing theantirust agent are easily available and low in price; and meanwhile, the environment-friendly waterborne antirust agent does not contain organic solvents such as benzene, toluene, xylene, formaldehydeand the like and heavy metals, is incombustible and non-explosive, does not pollute the environment, and belongs to an environment-friendly product.

Owner:扬州新东方金属材料制造有限公司

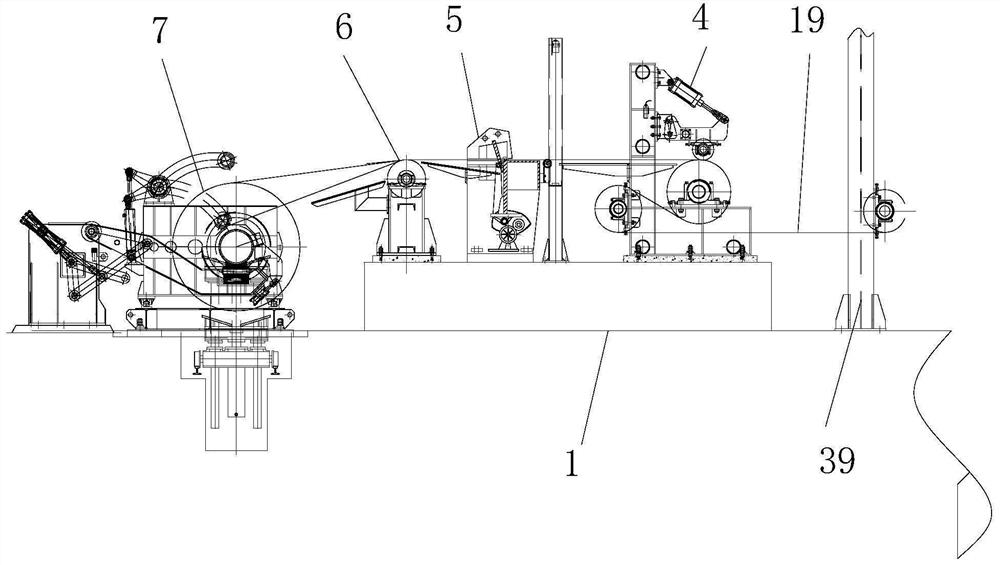

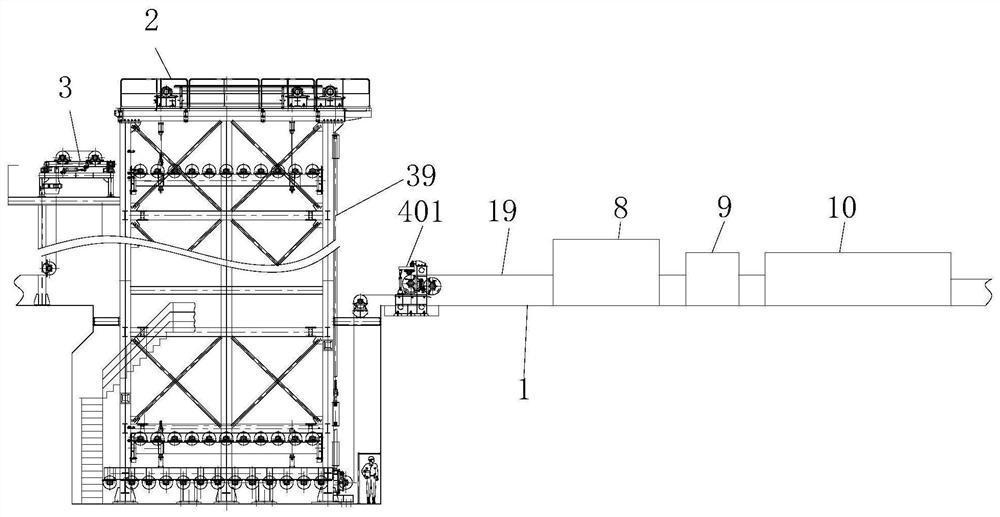

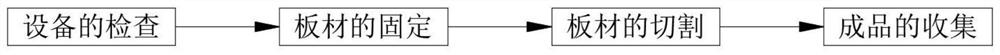

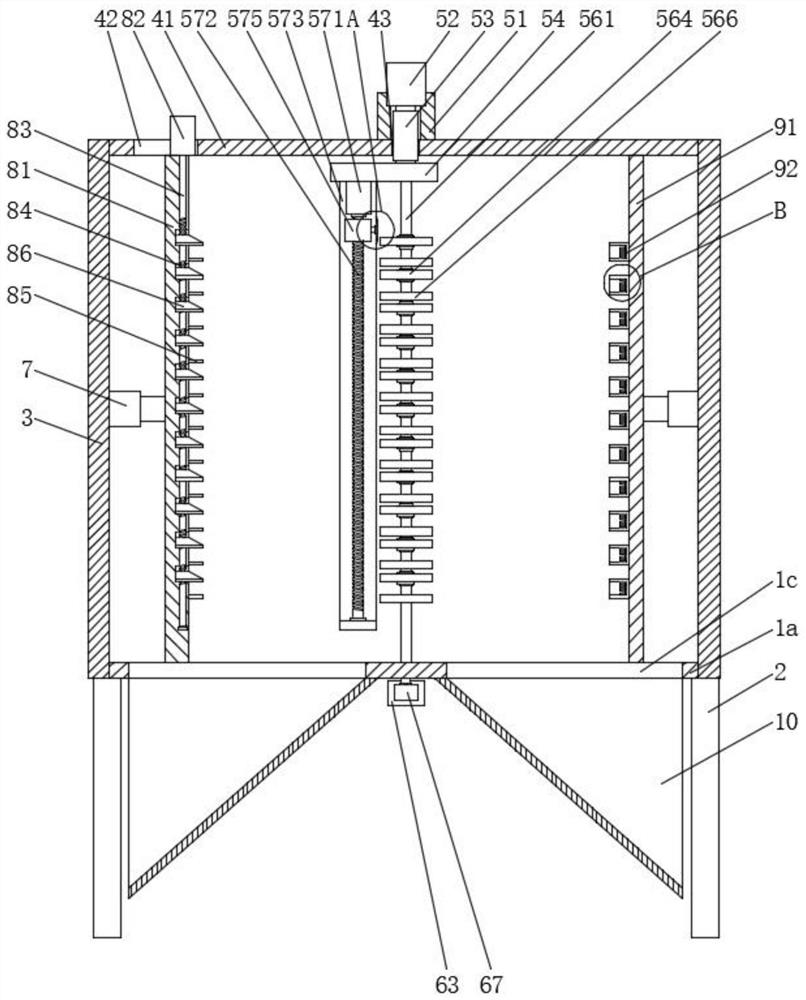

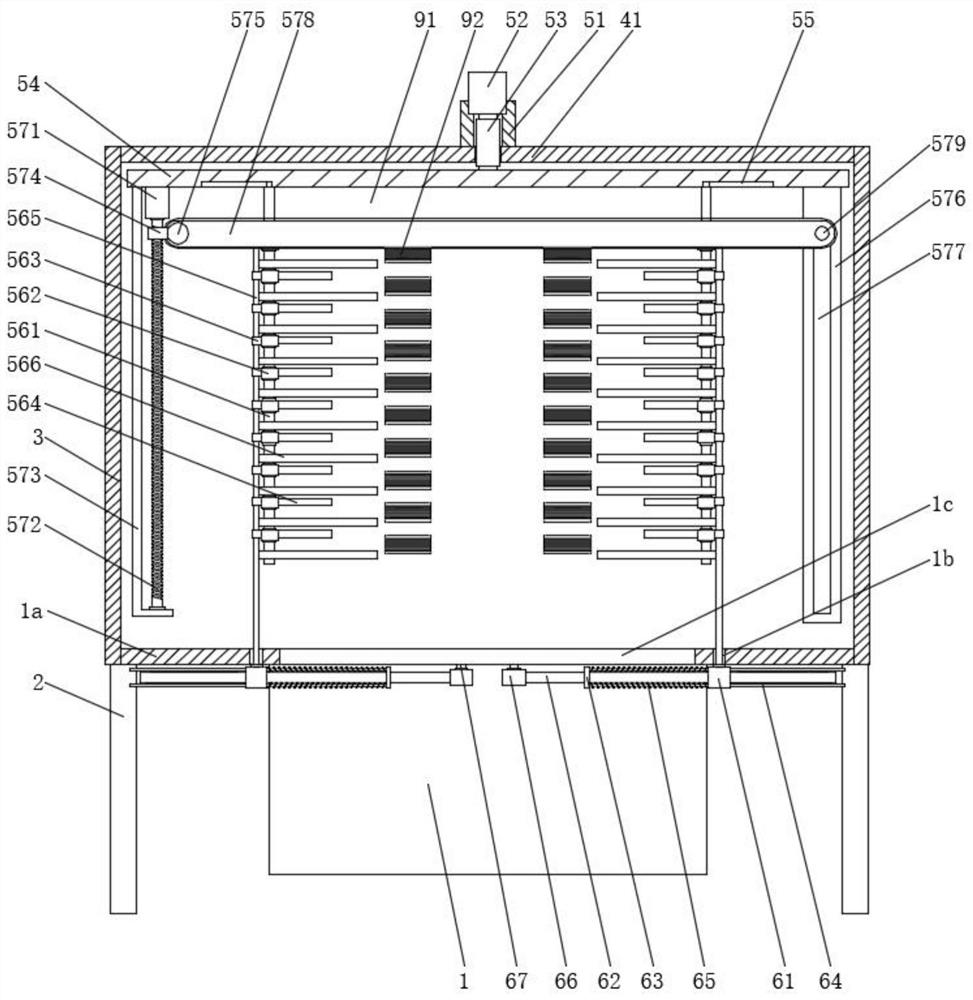

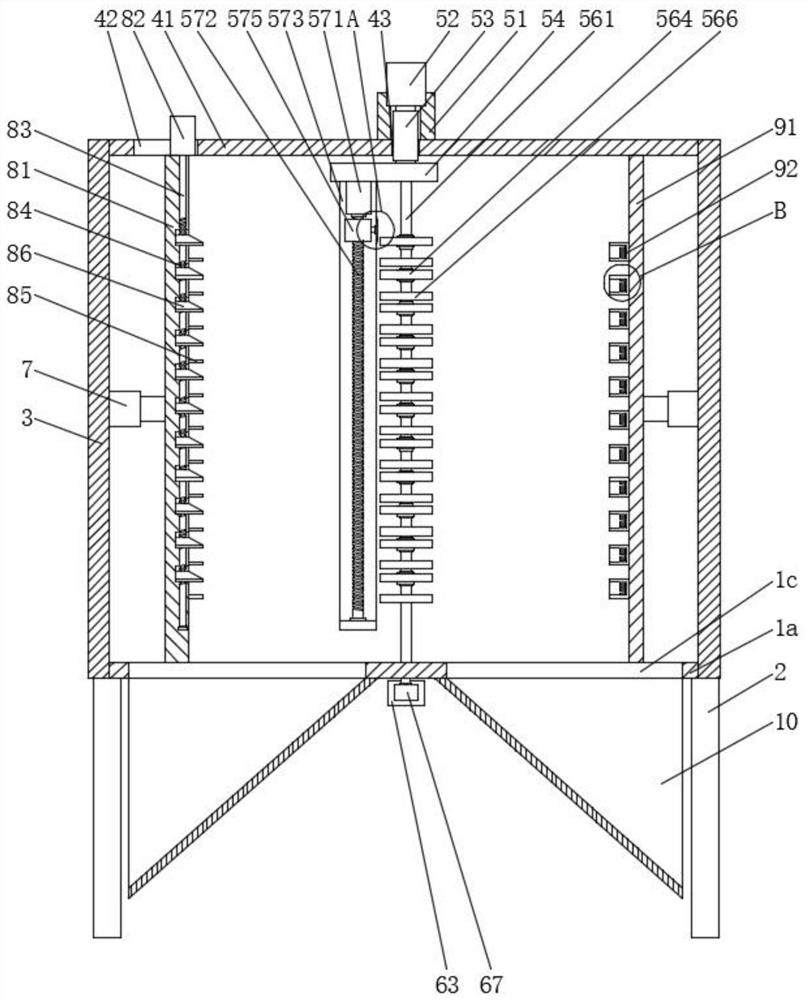

Particle board forming machining method

ActiveCN112223443AKeep the environment hygienicReduce cleaning workloadProfiling/shaping machinesEngineeringParticle board

The invention relates to a particle board forming machining method. Following equipment is adopted for the particle board forming machining method. The equipment comprises a bearing plate, wherein supporting legs are fixedly mounted on the lower surface of the bearing plate, an annular wall is fixedly mounted on the upper surface of the bearing plate, and a top cover plate is fixedly mounted in the upper portion of the annular wall; and a movable clamping and cutting-off device is fixedly mounted at the position, located in the annular wall, of the middle of the top cover plate in a penetrating mode. Traditional open type cutting is changed into cutting in a closed type box body, the closed type box body composed of the bearing plate, the annular wall and the top cover plate is utilized, cutting equipment is arranged in the closed type box body, thus, flying chips generated in the board cutting process can be basically blocked by the box body and finally penetrate through the bearing plate to be collected from the bottom in a centralized mode, the environmental sanitation of a whole machining workshop is guaranteed, the sanitation and health of workers are protected, and meanwhilethe sweeping workload of the workshop is reduced.

Owner:蒙山县大正科技有限公司

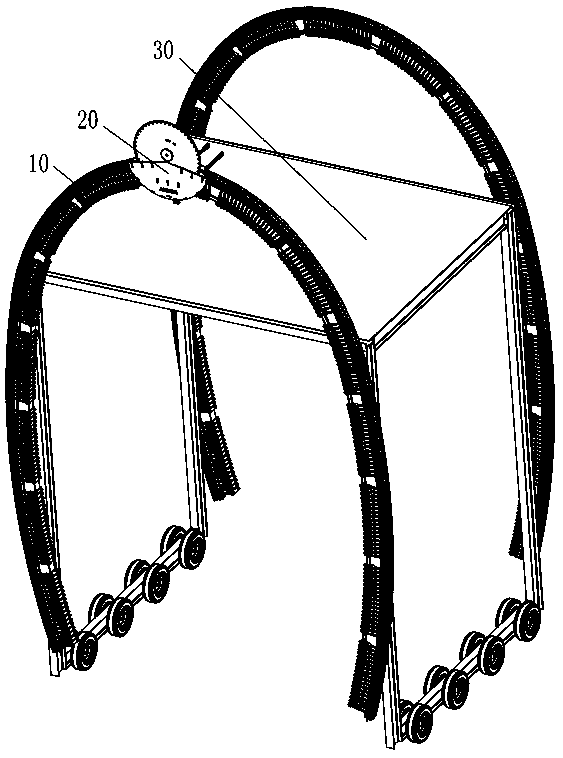

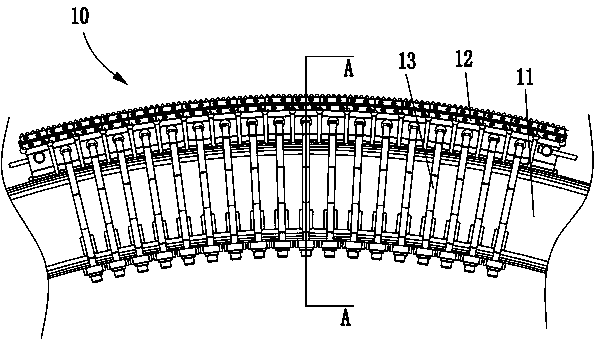

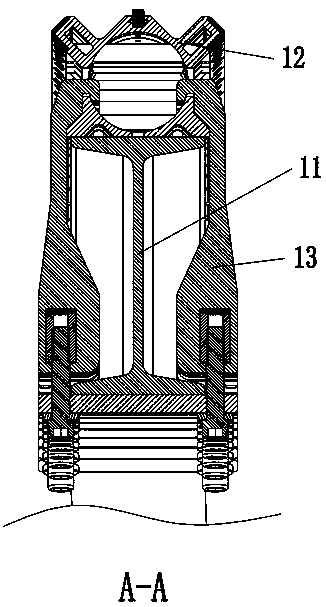

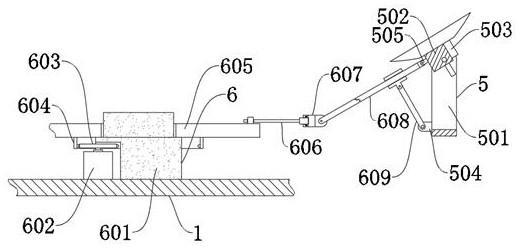

Arc-shaped track wall-sawing machine

PendingCN108789859ANo change in support strengthDoes not affect cuttingWorking accessoriesStone-like material working toolsKeelRadian

The invention provides an arc-shaped track wall-sawing machine. Through machining a track into a keel shape, the track is curved to a radian attached to an arc-shaped track bed, the supporting intensity of the track does not changed, and the track is reusable. The track bed is segmented and convenient to install and disassemble. A wall-sawing machine head can be disassembled and installed rapidly,a suitable gap is formed between the outer cambered surface of an arc-shaped track and the inner wall of a tunnel, and the arc-shaped track and a trolley moving in the tunnel is convenient. A motor in-out oil pipe is vertically arranged in the section direction of the arc-shaped track, cutting of the wall-sawing machine does not be affected, and the thickness of the wall-sawing machine head is compressed to enable the wall-sawing machine head to have the maximum passing ability. A meshing center of a feeding gear and a rack is on the center section of left and right wheels to avoid the feeding gear breaking away from the rack or getting stuck caused by changing of the track radian. The arrangement of an elastic adjustment device enables rollers to mesh with multi-radian arc-shaped tracks,the feeding gear on the center of the two rollers is ensured, and the problem of shield protection is further solved.

Owner:VOPEN ENG EQUIP CO LTD

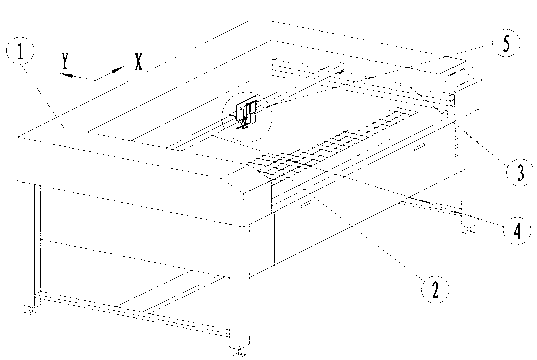

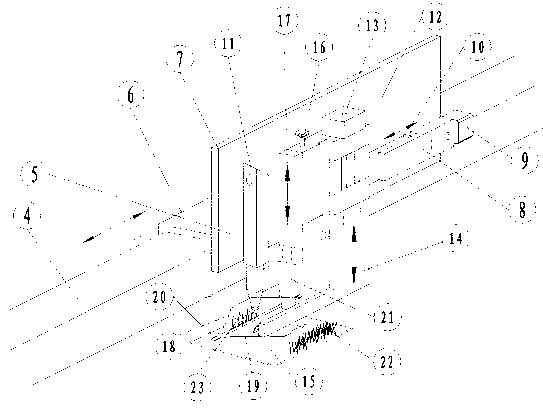

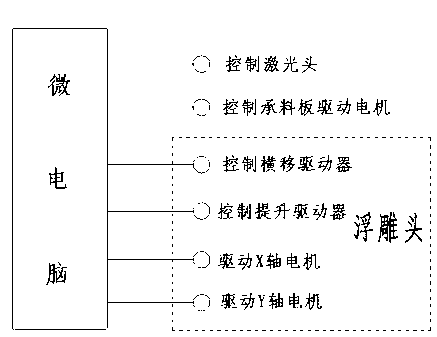

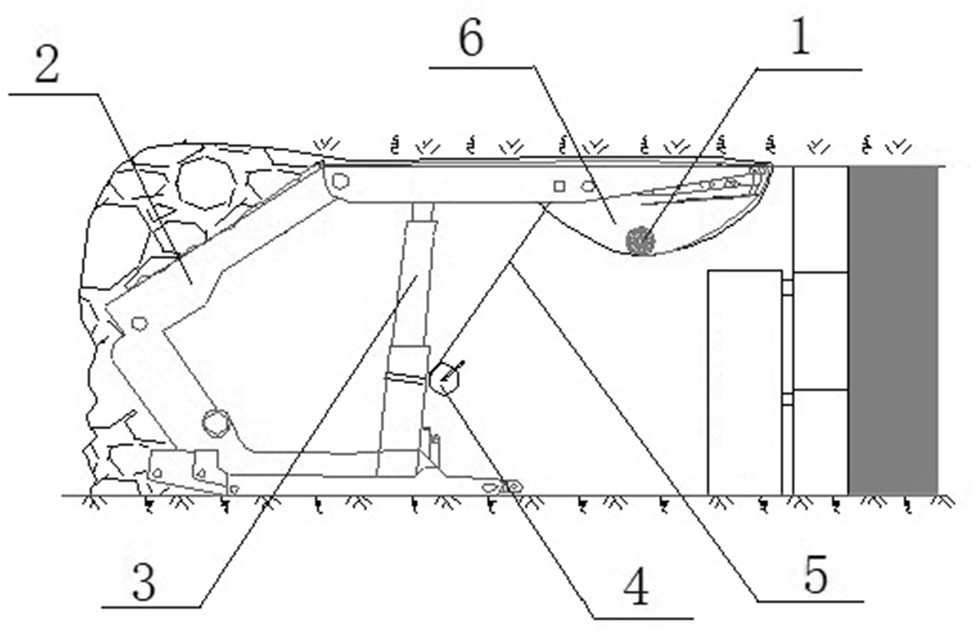

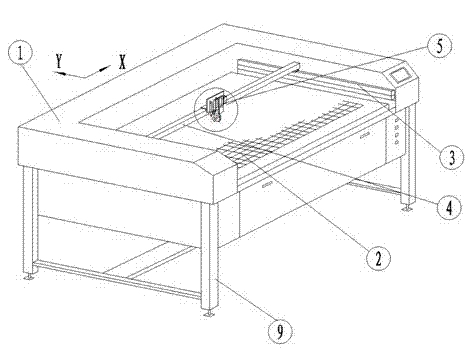

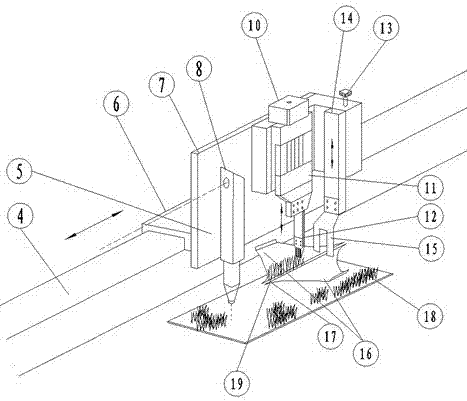

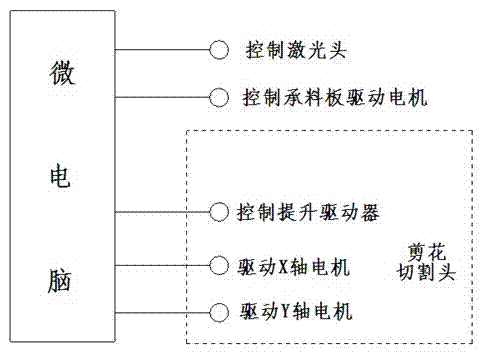

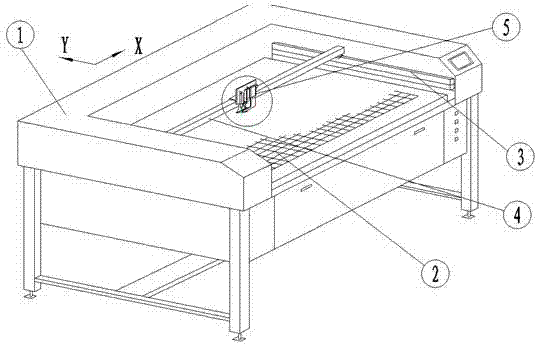

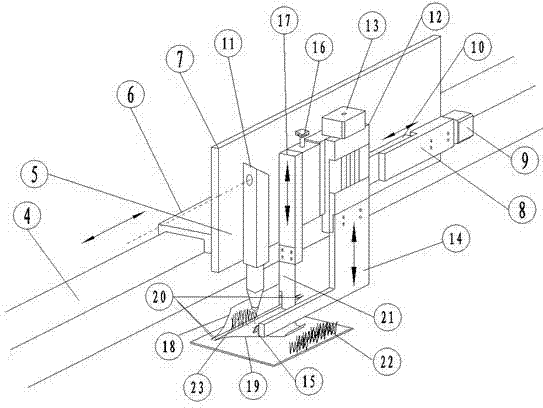

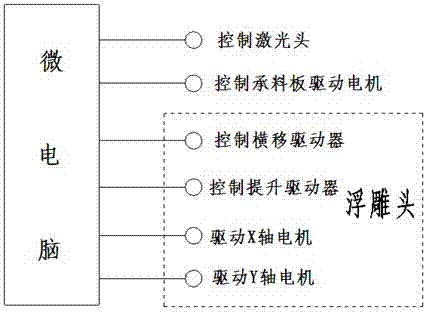

Plush laser embossing machine

The invention discloses a plush laser embossing machine which comprises a working platform, a microcomputer and an embossing head, wherein the embossing head is arranged on the working platform in a sliding way; the microcomputer is connected with the embossing head; the embossing head comprises an embossing head bottom plate, a laser head, a reflecting mirror and a plush divider; one side of the embossing head bottom plate is arranged on the working platform in the sliding way, and the other side of the embossing head bottom plate is provided with the laser head, the reflecting mirror and the plush divider; the reflecting mirror is arranged on the embossing head bottom plate in a way of being capable of sliding up and down; the plush divider is arranged on the embossing head bottom plate in the sliding way. According to the plush laser embossing machine, the embossing head is controlled to move along the X axis and the Y axis of the working platform by the microcomputer, and a lifting driver and a transverse movement driver are controlled to process plushy fabric by the microcomputer; multiple embossed patterns can be preset, so that the plush laser embossing machine has multiple types of patterns; the plush laser embossing machine is convenient to operate, thus being suitable for embossment processing of the plushy fabric in small batches.

Owner:CHUZHOU SEEK ELECTRONICS

Penile dorsal nerve isolation cutting operation device under microscope

InactiveCN107582141AMeet the needs of safe use functionsImprove cutting accuracyIncision instrumentsLocking mechanismSurgical site

The invention discloses a penile dorsal nerve isolation operation cutting device under a microscope. The structural principle of combining a cutting assembly and a solid locking mechanism is adopted,the cutting assembly can be adjusted to an appropriate operation position through a bracket and a manual sliding guide rail, automatic cutting of a compound trajectory on an operation site is carriedout through an arranged tool combination driven by a lifting mechanism, a rotating mechanism and an automatic sliding guide rail, cuttings of linear, arc-shaped, and various types of wound can also becarried out, and the arranged solid locking mechanism can carry out good auxiliary fixing for a penis to cooperate with the cutting of the cutting tool combination; compared with conventional surgical tools, the penile dorsal nerve isolation cutting device is high in cutting precision, safe and reliable, easy to operate, and convenient to use, functional needs of the safe use of a penile dorsal nerve isolation operation under the microscope are met, meanwhile the cutting assembly is also applicable to other surgical cuttings, the cutting device is high in practicability, and suitable for popularization and application.

Owner:重庆爱德华医院有限公司

Novel automatic intelligent food slicing machine

ActiveCN113843845AHigh quality cuttingImprove pass rateMetal working apparatusControl engineeringProcess engineering

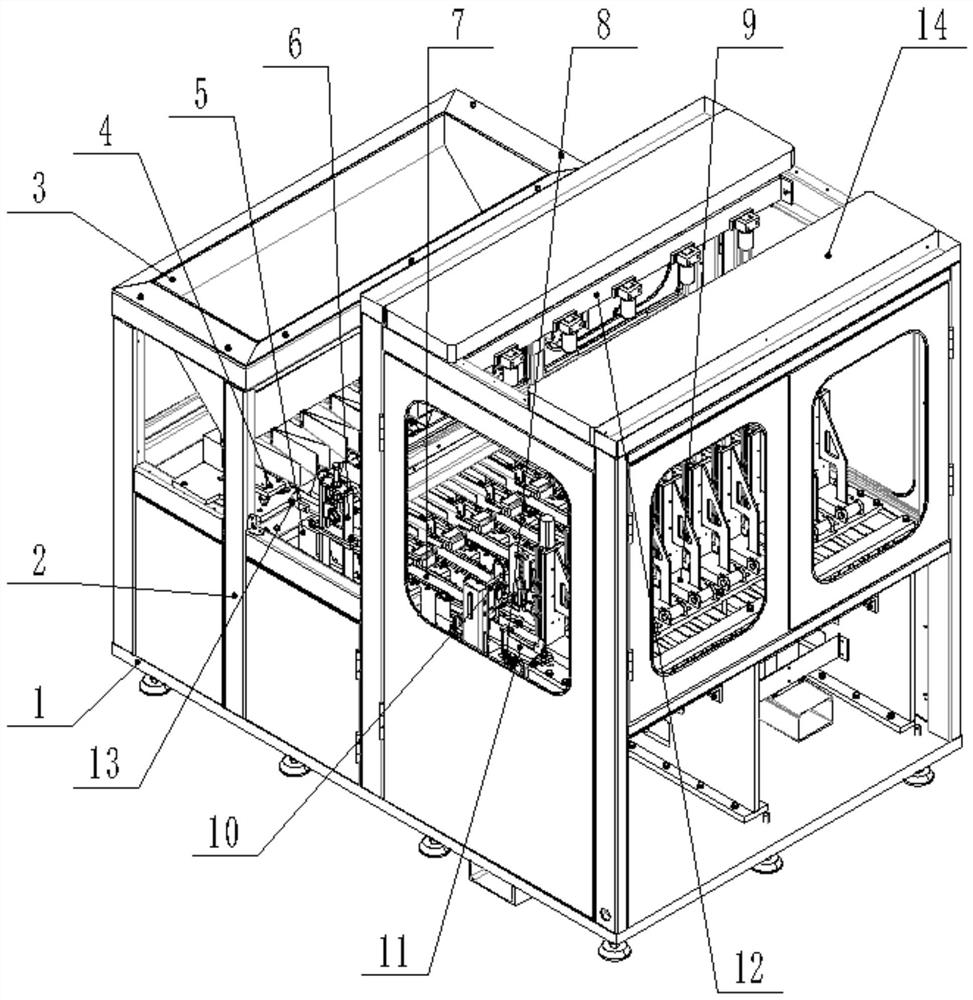

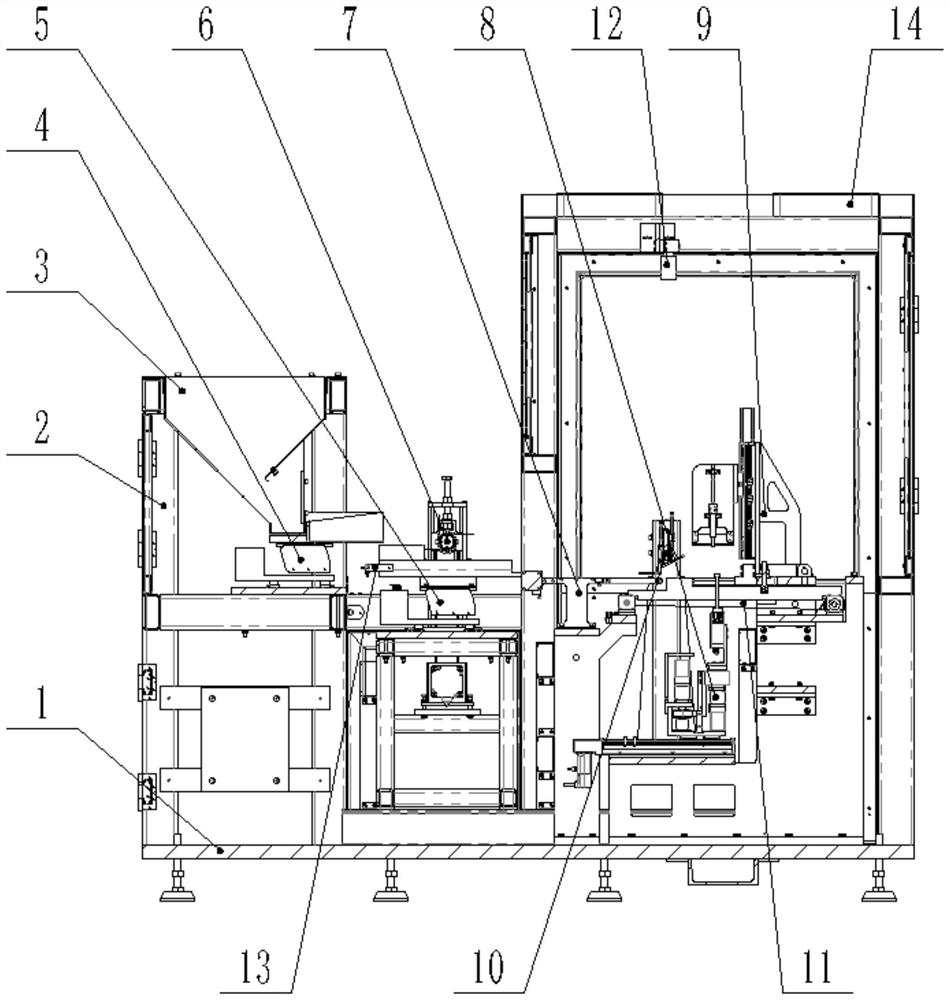

The invention discloses a novel automatic intelligent food slicing machine which comprises a machine base, a machine frame arranged on the machine base and at least one feeding unit arranged on the machine frame. Each feeding unit comprises a storage bin mechanism, a first-stage feeding mechanism, a second-stage feeding mechanism and an anti-overlapping mechanism. The novel automatic intelligent food slicing machine further comprises feeding mechanisms, a clamping translation and rotation mechanism, a slicing mechanism, a posture adjustment and discharging mechanism and a discharging belt conveyor, and the feeding mechanisms correspond to the feeding units respectively. Food to be cut in storage bins enter the feeding mechanisms after sequentially passing through the first-stage feeding mechanisms, the second-stage feeding mechanisms and the anti-overlapping mechanisms, the food is subjected to position adjustment by the clamping translation and rotation mechanism after posture adjustment, and the food is sliced by the slicing mechanism and then is conveyed out by the discharging belt conveyor. According to the novel automatic intelligent food slicing machine, the clamped food is subjected to proper translation and rotation, so that the ideal cutting joint position is overlapped with a cutter, high-quality cutting of the food is realized, and the qualification rate and grade of food slicing, especially cutting of areca nuts, are improved.

Owner:湖南会当智能科技有限公司

A kind of bevel cutting equipment for rectangular square tube of electric tower

ActiveCN112091316BSolve the rotation problemSame cutting positionShearing machinesMaintainance and safety accessoriesStructural engineeringOblique angle

The invention relates to a bevel cutting equipment for a rectangular square tube of a power iron tower, which includes a working table, a clamping and rotating mechanism and a fixed cutting mechanism. The working table is installed on the working ground, and the rear end of the working table is equipped with a clamping and rotating mechanism , the upper end surface of the workbench is equipped with a fixed cutting mechanism, the clamping and rotating mechanism adopted in the present invention can solve the rotation problem of the rectangular square tube, the rectangular square tube is fixed in the clamping and rotating mechanism, and then the required angle Adjust and rotate, so that the cutting position of the rectangular square tube is the same, fix the left and right sides of the rectangular square tube through a fixed cutting mechanism, and cut the rectangular square tube through a cutting blade installed obliquely, so that the cutting position of the rectangular square tube is the same, said The No. 2 electric cylinder pushes the inclined clamping plate to clamp the front end of the rectangular square tube, so that the rectangular square tube is easy to rotate when rotating, and the inclined clamping plate does not affect the cutting of the rectangular square tube by the cutting blade.

Owner:安徽宝光特钢集团万里电力铁塔有限公司

Roof reinforcing protection method for equipment withdrawing channel of fully mechanized coal mining face

PendingCN114790906AFast layingDoes not affect cuttingMine roof supportsMine roof capsPulleyWire rope

The invention provides a top plate reinforced protection method for a fully mechanized coal mining face equipment withdrawing channel, which comprises the following steps: fixing a plurality of steel wire ropes at the bottom of a whole fiber net along the long edge direction, rolling up and dragging to a working face, fixing the end parts of the fiber net and the steel wire ropes on a top plate, and positioning the rest parts on a hydraulic support; a rope coiling device and a pulley are fixed on the hydraulic support, a steel strand passes through the pulley, and a containing cavity is formed at the pulley and the top plate and used for containing a fiber net and a steel wire rope which are not spread; the fiber net and the steel wire ropes are laid along with pushing of the hydraulic support, all the rope coiling devices are tightened at intervals, and the steel wire ropes on the two sides of the laid fiber net are tensioned and fixed to a top plate through anchor cables; and the hydraulic support is pushed to be close to a mining stopping line of the retracement roadway, the front end of the hydraulic support extends the remaining fiber net and the steel wire rope to the top plate and the side of the retracement channel, and the fiber net and the steel wire rope in the channel area are fixed. The labor intensity of workers is reduced, and the supporting efficiency is improved.

Owner:SHANXI FENXI MINING GRP

Plush flower-shearing cutting machine

The invention discloses a plush flower-shearing cutting machine which comprises a working platform, a microcomputer and a flower-shearing cutting head, wherein the flower-shearing cutting head is arranged on the working platform in a sliding way; the microcomputer is connected with the flower-shearing cutting head; the flower-shearing cutting head comprises a flower-shearing cutting head bottom plate, a laser head, a pair of electric shears and a plush divider; one side of the flower-shearing cutting head bottom plate is arranged on the working platform in the sliding way, and the other side of the flower-shearing cutting head bottom plate is provided with the laser head, the electric shears and the plush divider; the electric shears and the plush divider are arranged on the flower-shearing cutting head bottom plate in a way of being capable of sliding up and down. According to the plush flower-shearing cutting machine, the flower-shearing cutting head is controlled to move along the X axis and the Y axis of the working platform by the microcomputer, and a lifting driver and a plush dividing height adjuster are controlled to process plushy fabric by the microcomputer; multiple embossed patterns can be preset, so that the plush laser embossing machine has multiple types of patterns; the plush flower-shearing cutting machine is convenient to operate, thus being suitable for embossment processing of the plushy fabric in small batches.

Owner:CHUZHOU SEEK ELECTRONICS

Integrated Drilling Rig for Bolt-while-Driving Drilling

The invention discloses a boom-type roadheader mounted tunneling anchor-along drilling integrated drilling machine which mainly consists of a steel plate structural piece and a hydraulic system, wherein the steel plate structural piece of the drilling machine comprises a main withdrawing and release arm, a drilling machine rack, a vertical rotary mechanism and a horizontal rotary mechanism; the hydraulic transmission system of the drilling machine comprises a drilling hole hydraulic motor, a drilling machine horizontal rotary hydraulic motor, a drilling machine vertical rotary hydraulic motor, a telescopic leg hydraulic cylinder, a drilling machine thrust hydraulic cylinder, a hydraulic control element and a hydraulic auxiliary element. The drilling machine is characterized in that the drilling machine and a tunneling machine are integrally combined and are distributed on two sides of a tunneling machine cantilever, and the walking of the drilling machine is achieved through a walking mechanism of the tunneling machine. Holes can be drilled in an all-direction and multifunction manner in a tunneled roadway, both anchor bolt support and top plate lithology detection can be achieved, and drilling of shotholes, drilling of gas sucking and discharge holes, geologic drilling and the like can be achieved, and facilities and methods are provided for safe, rapid and efficient roadway tunneling.

Owner:ANHUI UNIV OF SCI & TECH

A myomectomy device

InactiveCN111821004BQuick washRapid DisinfectionSuture equipmentsInternal osteosythesisEngineeringMechanical engineering

The invention discloses a hysteromyomectomy device, which comprises a vaginal expansion device, a resection device, a cleaning device, a suction device, an observation device, a fixing device and a clamping device. The vaginal expansion device can stretch the patient's vaginal opening and maintain the state to ensure subsequent progress. The resection device can remove uterine fibroids, and the cleaning device can disinfect the wound after resection and clean the residue from the inner wall of the uterus to ensure The operation process is safe and will not cause infection. The suction device can absorb the cleaning residue and the waste liquid used for cleaning. The observation device can observe the position of the fibroids after the instrument enters the vaginal opening. Fixed at the resection position, the clamping device can clamp the fibroids and stretch them backwards, leaving a position for cutting by the cutter, which is convenient for subsequent cutting. Take it out, and complete the disinfection through the cleaning device to ensure that there will be no medical pollution.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

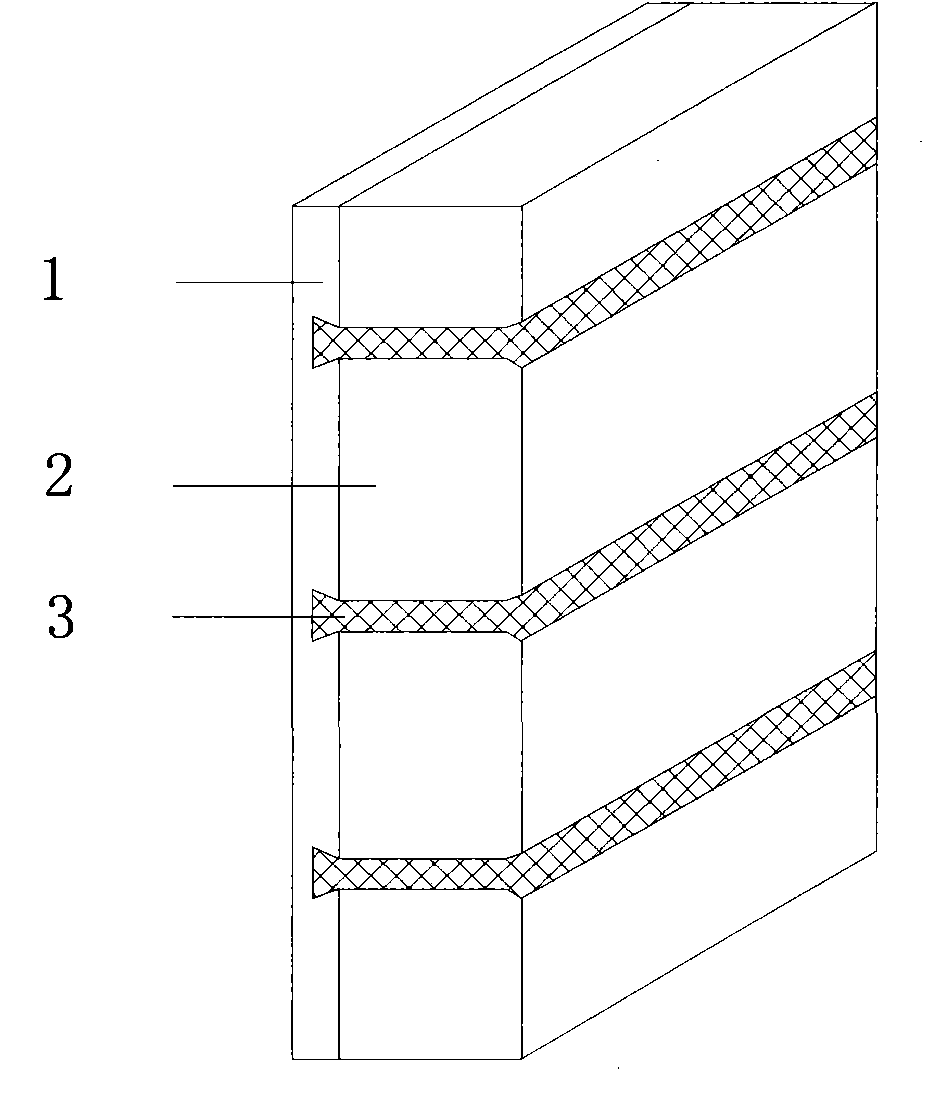

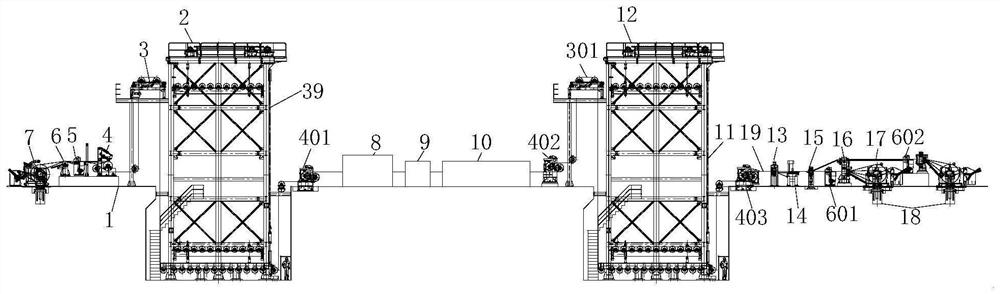

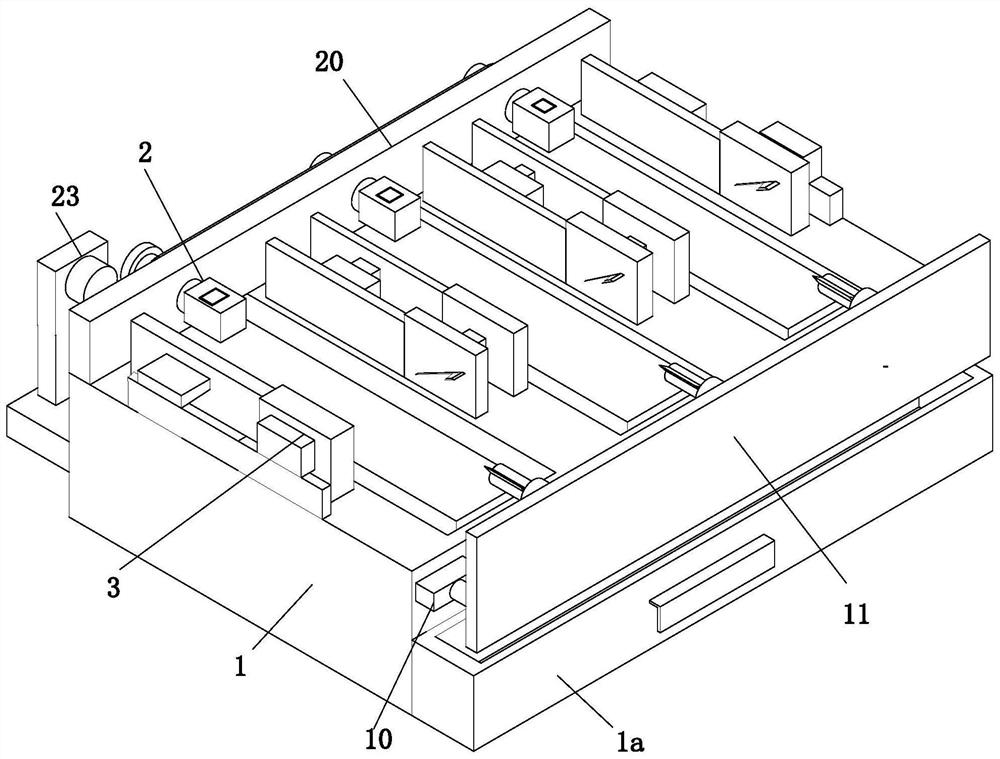

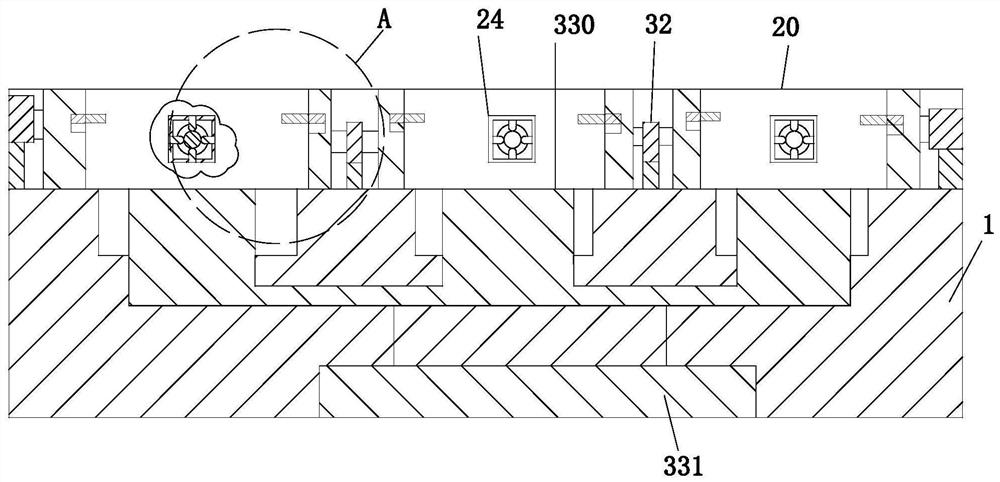

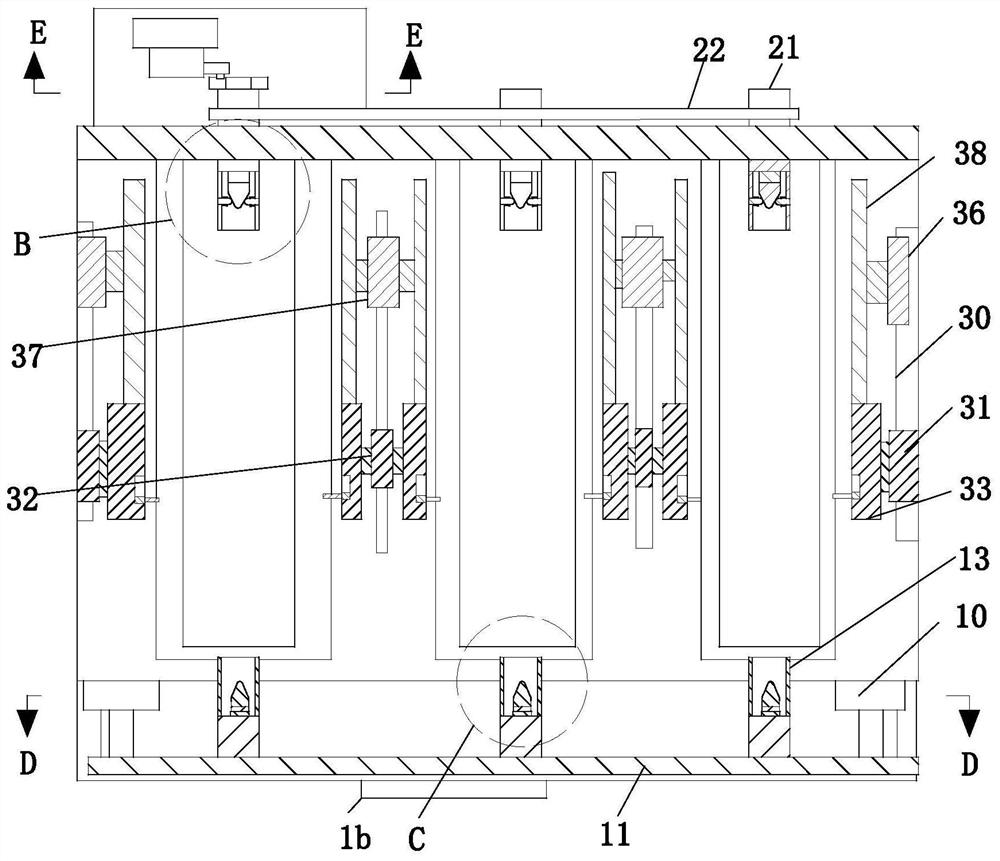

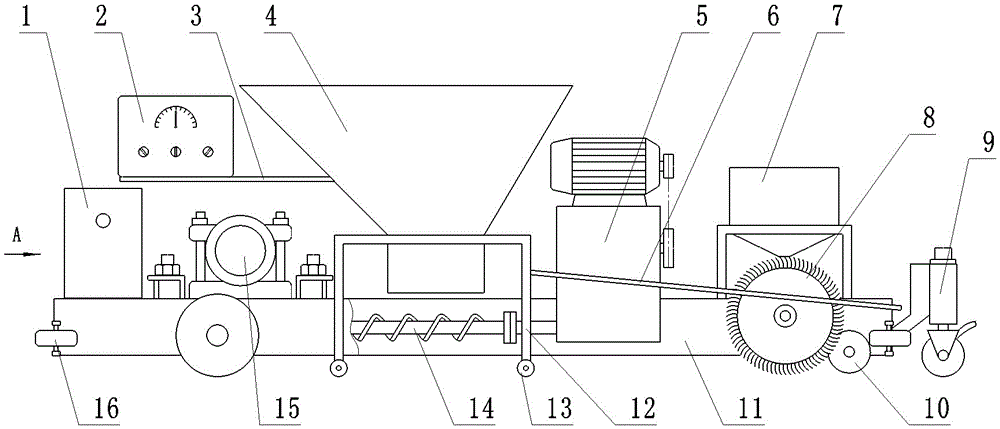

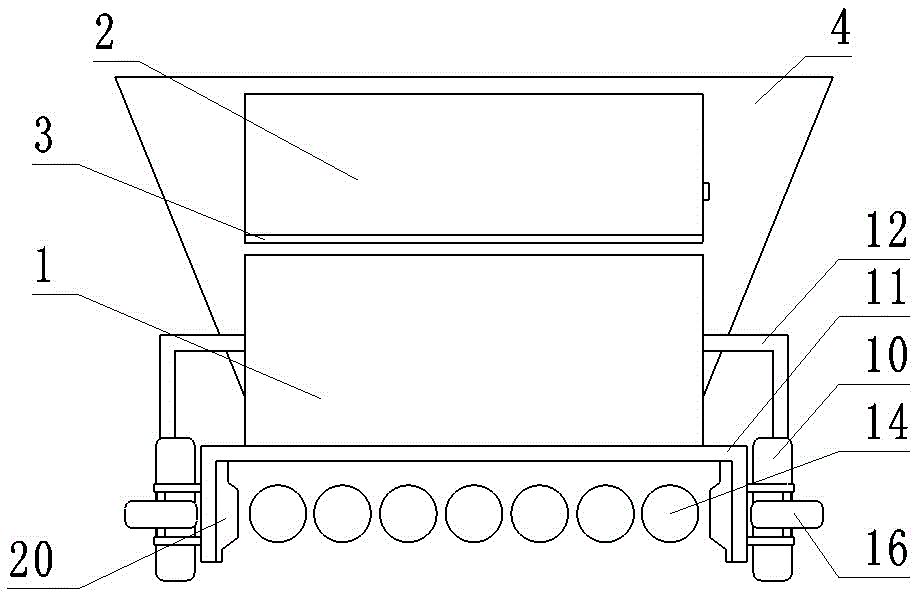

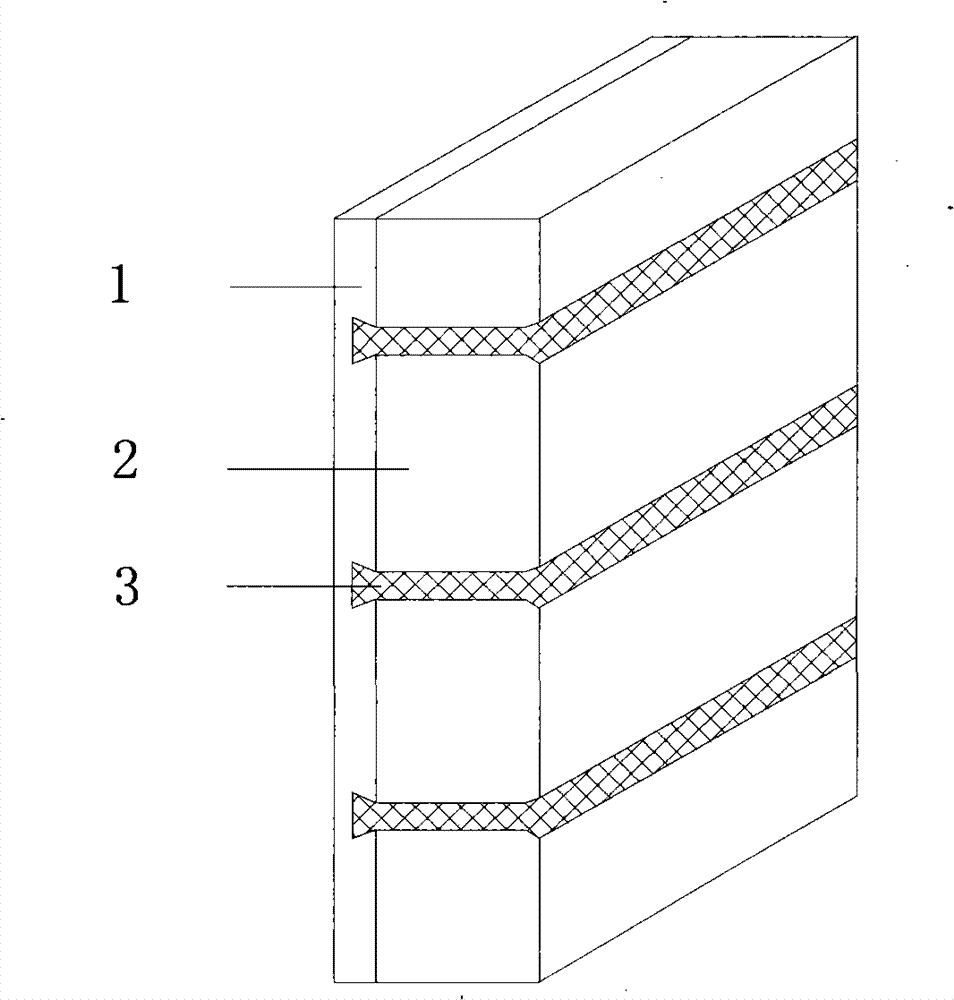

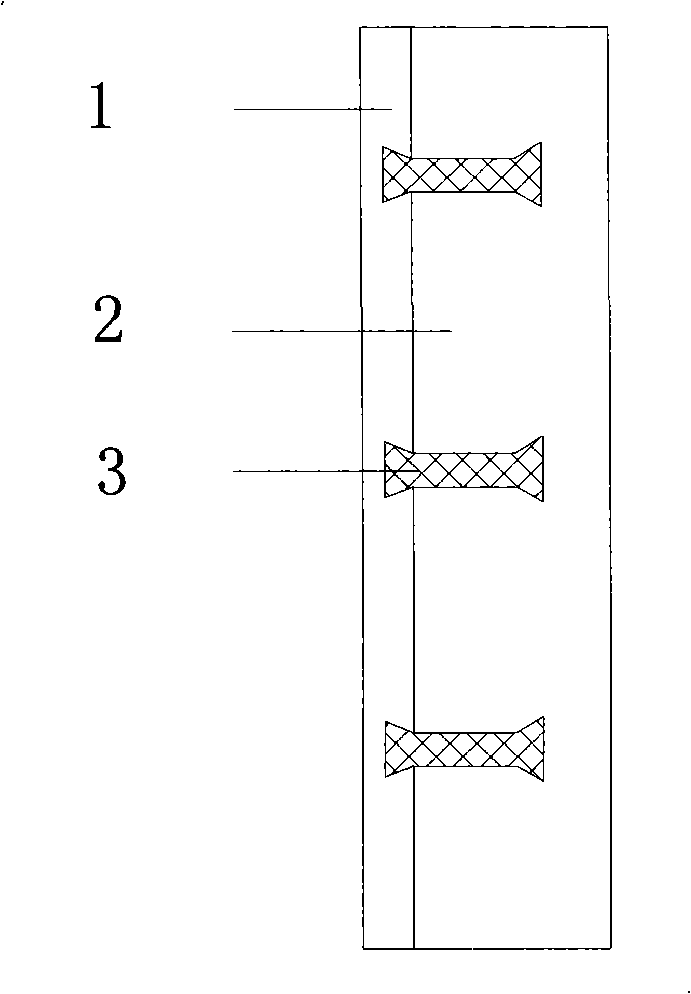

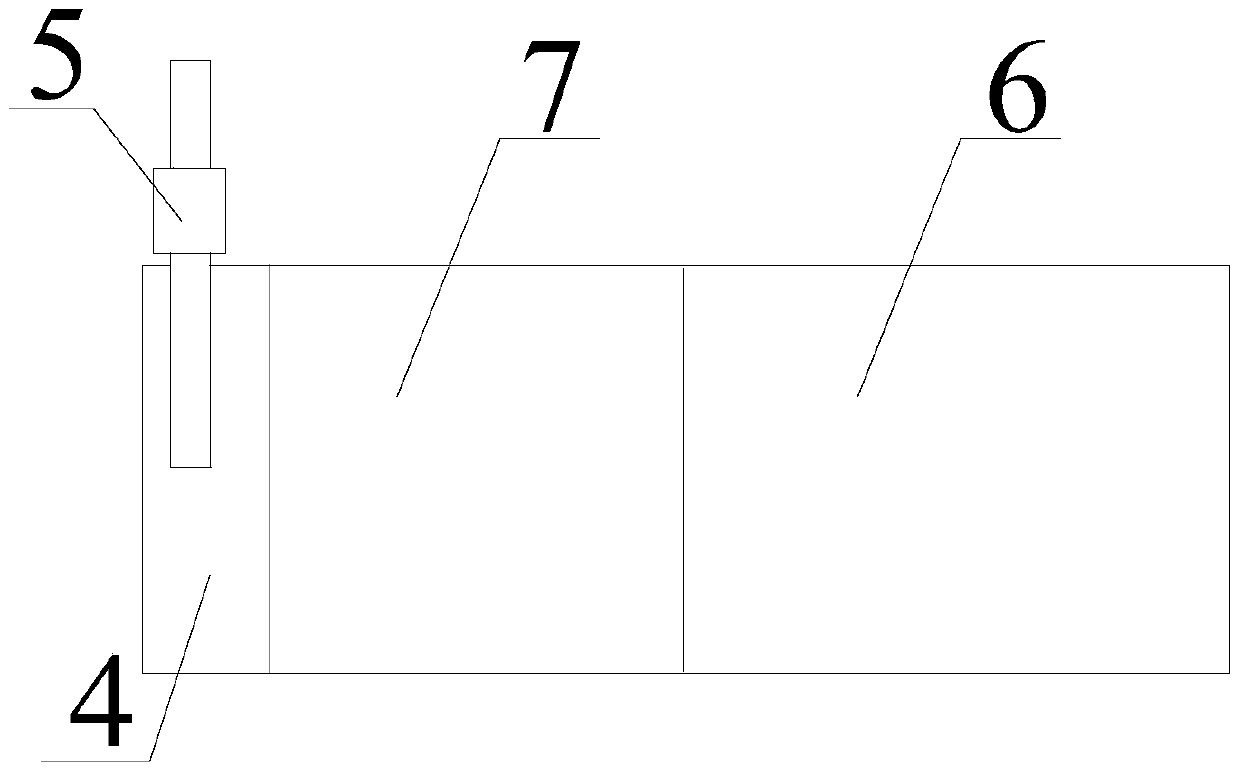

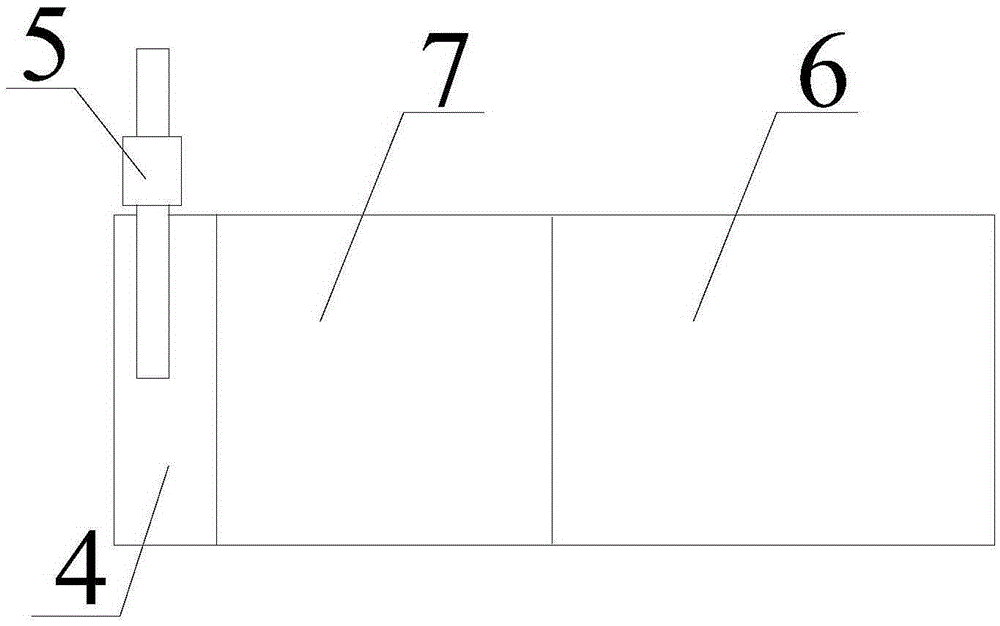

Lightweight partition wall block forming machine, partition wall block and connection method of the partition wall block

InactiveCN103802195BDoes not affect cuttingAvoid cloggingConstruction materialWallsBrickMolding machine

The invention discloses a lightweight partition wall block forming machine, a partition wall block and a connection method of the partition wall block. By separating the hopper from the unit, the vibration of the unit does not affect the feeding of the hopper when producing the partition wall block. , can prevent the material in the hopper from being vibrated and cause blockage, so it can be vibrated for a long time to produce thicker outer wall blocks, which are denser and stronger, and do not need to be placed inside the wall blocks The required strength can also be achieved by setting the steel bars. There are track positioning wheels on both sides of the front and rear ends of the frame, which can walk in the track. The partition wall blocks produced are straighter. There is a spacer box at the front end of the frame. The bottom of the release agent box is also provided with a brush roller, which can automatically smear the release agent on the ground when the partition wall block is produced to prevent the partition wall block from sticking to the ground. Compared with the prior art, the present invention not only It saves resources, saves time and labor, and can also be used as exterior wall bricks.

Owner:汤凯全

Molded composite board with improved firmness and preparation method thereof

ActiveCN101775874BAct as a firm connectionBalanced thermal expansion and contraction coefficientsCovering/liningsBuilding componentsComposite plateUltimate tensile strength

The invention provides a molded composite board with improved firmness, which comprises a lining layer and a heat insulating layer; a plurality of grooves or holes are correspondingly arranged on the opposite sides of the lining layer and the heat insulating layer; stuff enabling the lining layer and the heat insulating layer to be tightly bonded with each other is arranged in the grooves or holes or wedge-shaped buckles connecting and buckling the lining layer with the heat insulating layer are arranged in the grooves or holes; and the lining layer and the heat insulating layer are connectedthrough the stuff which is tightly bonded or through the wedge-shaped buckles. The invention enables the bonding between the layers of the composite board to be firm, ensures that the layers do not disengage with each other and enhances the deformation resistance of the board. The invention solves the problems of easy deformation, the hidden trouble that the heat insulating layer disengages with the lining layer and poor strength in the prior art. The molded composite board does not need to be notched during site construction and is simple to construct and easy to operate, and the molded composite board is lower in price as compared with the prior art (aluminum sandwich composite panel) and has more obvious technological advantage, therefore, the molded composite board has higher application value and market popularization value.

Owner:ASIA CUANON TECH SHANGHAI

Satellite Antenna Panel Positioning Fixture

ActiveCN113275913BPrecise positioningImprove machining accuracyWork holdersPositioning apparatusSatellite antennasControl theory

The invention relates to the technical field of satellite parts processing, in particular to a positioning fixture for a satellite antenna panel, including a base and a laser detector. The upper surface of the base is uniformly provided with a chute, and a laser detector is slidably connected to the chute. An angle adjustment mechanism is fixed on the upper surface of the base, and a cylinder is uniformly fixed around the angle adjustment mechanism, and a first adsorption assembly is movably connected to the top of the cylinder, and the angle adjustment mechanism is linked with the first adsorption assembly. The top of the angle adjustment mechanism is fixed with a positioning correction assembly, the positioning correction assembly includes a positioning seat, an X-axis linear slide and a Y-axis linear slide, and the Y-axis linear slide is slidingly connected with the X-axis linear slide. A universal pulling mechanism is fixedly connected to the Y-axis linear slide table. The invention facilitates the positioning of the satellite antenna panel in a non-destructive and non-shielding way, and improves the machining accuracy.

Owner:烟台海上航天科技有限公司

Plush laser embossing machine

The invention discloses a plush laser embossing machine which comprises a working platform, a microcomputer and an embossing head, wherein the embossing head is arranged on the working platform in a sliding way; the microcomputer is connected with the embossing head; the embossing head comprises an embossing head bottom plate, a laser head, a reflecting mirror and a plush divider; one side of the embossing head bottom plate is arranged on the working platform in the sliding way, and the other side of the embossing head bottom plate is provided with the laser head, the reflecting mirror and the plush divider; the reflecting mirror is arranged on the embossing head bottom plate in a way of being capable of sliding up and down; the plush divider is arranged on the embossing head bottom plate in the sliding way. According to the plush laser embossing machine, the embossing head is controlled to move along the X axis and the Y axis of the working platform by the microcomputer, and a lifting driver and a transverse movement driver are controlled to process plushy fabric by the microcomputer; multiple embossed patterns can be preset, so that the plush laser embossing machine has multiple types of patterns; the plush laser embossing machine is convenient to operate, thus being suitable for embossment processing of the plushy fabric in small batches.

Owner:CHUZHOU SEEK ELECTRONICS

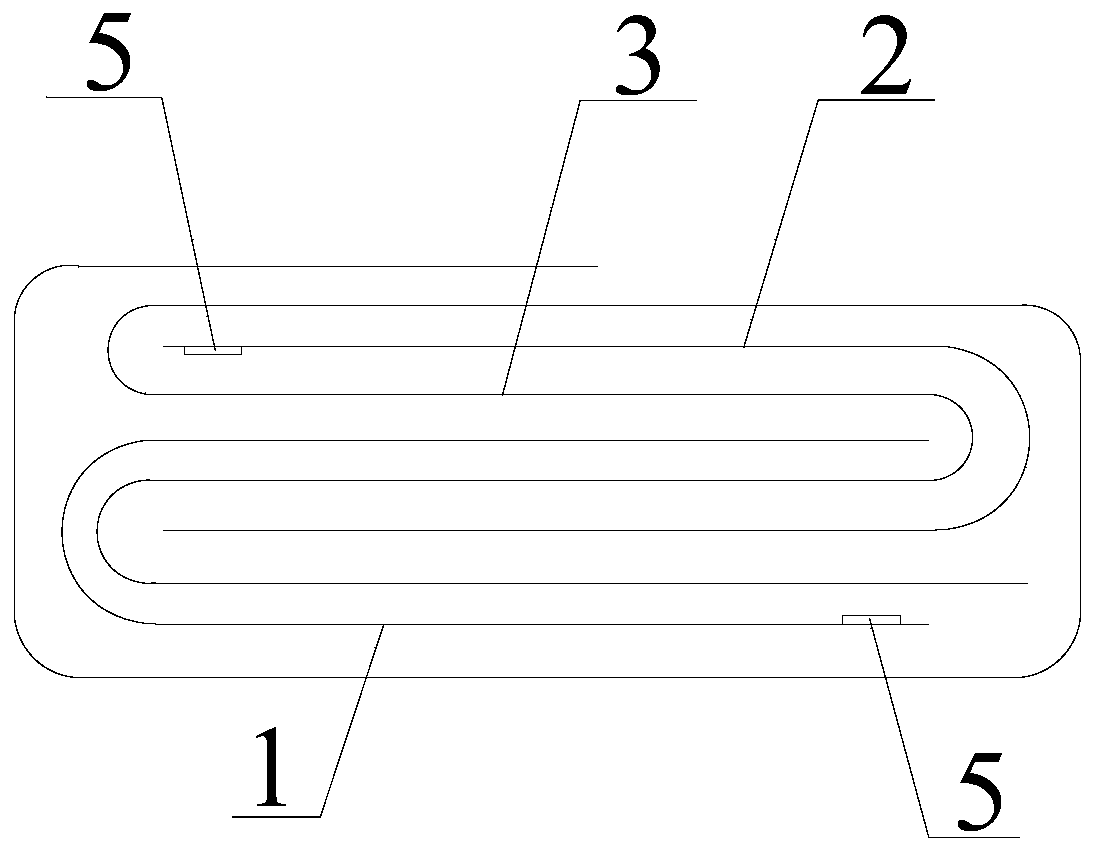

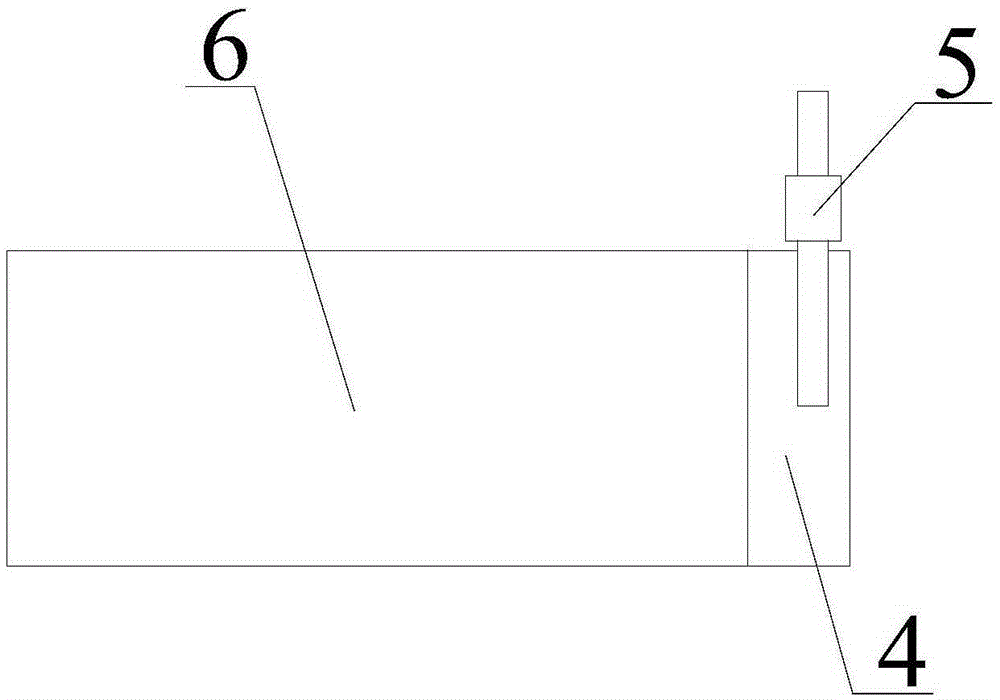

A kind of lithium battery and preparation method thereof

ActiveCN105261797BAvoid Rolling and RollingThe overall thickness is thinFinal product manufactureElectrode carriers/collectorsEngineeringSpot welding

The invention discloses a lithium battery and a preparation method thereof, comprising a flat winding battery core, the non-powder area on the back of the pole plate is located between the spot-welded empty foil area and the powder area, and the area of the non-powder area is Not larger than the area of the powder area; the ends of the two pole plates face opposite, and the two tabs are arranged at both ends of the width direction of the wound battery core, and are respectively located on the wound battery core top and bottom of . The lithium battery and the preparation method thereof provided by the present invention avoid the roll-up of the pole plate caused by the excessive area of the non-powder area, and therefore, will not affect the cutting of the pole plate, spot welding of tabs and production of winding cores. At the same time, by staggering the tabs and the powder area, the thickness of the overall wound battery is reduced, which can be applied to the production of thinner lithium-ion batteries, especially for ultra-thin polymers with a thickness of less than 1.0mm. Mass production of batteries.

Owner:EVE ENERGY CO LTD

Oblique angle cutting equipment for rectangular square pipe of electric power iron tower

ActiveCN112091316ASolve the rotation problemSame cutting positionShearing machinesMaintainance and safety accessoriesEngineeringOblique angle

The invention relates to oblique angle cutting equipment for a rectangular square pipe of an electric power iron tower. The oblique angle cutting equipment comprises a workbench, a clamping and rotating mechanism and a fixing and cutting mechanism, wherein the workbench is arranged on the working ground; and the clamping and rotating mechanism is arranged at the rear end of the workbench, and thefixing and cutting mechanism is arranged on the upper end face of the workbench. According to the oblique angle cutting equipment for the rectangular square pipe of the electric power iron tower, theadopted clamping and rotating mechanism can solve the rotating problem of the rectangular square pipe, the rectangular square pipe is fixed in the clamping and rotating mechanism, and then the required angle is adjusted and rotated, so that the cutting positions of the rectangular square pipe are the same; the left side and the right side of the rectangular square pipe are fixed through the fixingand cutting mechanism, and the rectangular square pipe is cut through obliquely-arranged cutting blades, so that the cutting positions of the rectangular square pipe are the same; and electric air cylinders two push oblique clamping plates to clamp the front end of the rectangular square pipe, so that the rectangular square pipe is prone to rotate in the rotating process, and meanwhile the oblique clamping plates do not influence cutting of the rectangular square pipe by the cutting blades.

Owner:安徽宝光特钢集团万里电力铁塔有限公司

Lithium battery and preparation method therefor

ActiveCN105261797AReduce thicknessAvoid Rolling and RollingFinal product manufactureElectrode carriers/collectorsEngineeringPole piece

The invention discloses a lithium battery and a preparation method therefor. The lithium battery comprises a tabular winding type electric core; a non-powder region on the back surface of a polar plate is positioned between a point-welding empty foil region and a powder region; the area of the non-powder region is not larger than that of the powder region; the tail ends of the two polar plates are opposite in directions; two tabs are arranged at the two ends of the winding type electric core in the width direction, and the two tabs are positioned on the top and at the bottom of the winding type electric core respectively. According to the lithium battery and the preparation method therefor provided by the invention, the situation that the pole pieces are rolled and wound caused by the over-large area of the non-powder region, so that the slitting of the pole pieces, the point welding of the tabs and the manufacturing of the coiled cores are not affected; and meanwhile, by adoption of the staggered manner of the tabs and the non-powder region, the thickness of the overall winding type electric core is reduced, so that the preparation method is suitable for the production of thinner lithium batteries, in particular suitable for mass production of polymer ultra-thin batteries with thicknesses of less than 1.0 mm.

Owner:EVE ENERGY CO LTD

A kind of particle board molding processing method

ActiveCN112223443BKeep the environment hygienicReduce cleaning workloadProfiling/shaping machinesEnvironmental hygieneParticle board

The present invention relates to a particle board forming and processing method. The particle board forming and processing method adopts the following equipment. The device includes a supporting plate, the lower surface of the supporting plate is fixedly equipped with supporting legs, and the upper surface of the supporting plate is fixed A ring wall is installed, and a top cover plate is fixedly installed in the upper part of the ring wall. The middle part of the top cover plate is located in the ring wall and is fixedly installed with a mobile clamping and cutting device. The present invention can change the traditional open cutting For the cutting in the closed box, the closed box composed of the support plate, the ring wall and the top cover is used to set the cutting equipment in it, so that the flying chips generated during the cutting process of the plate will be basically blocked by the box Down, and finally pass through the support plate and collect from the bottom, which not only ensures the environmental sanitation of the entire processing workshop, protects the health of the staff, but also reduces the cleaning workload of the workshop.

Owner:蒙山县大正科技有限公司

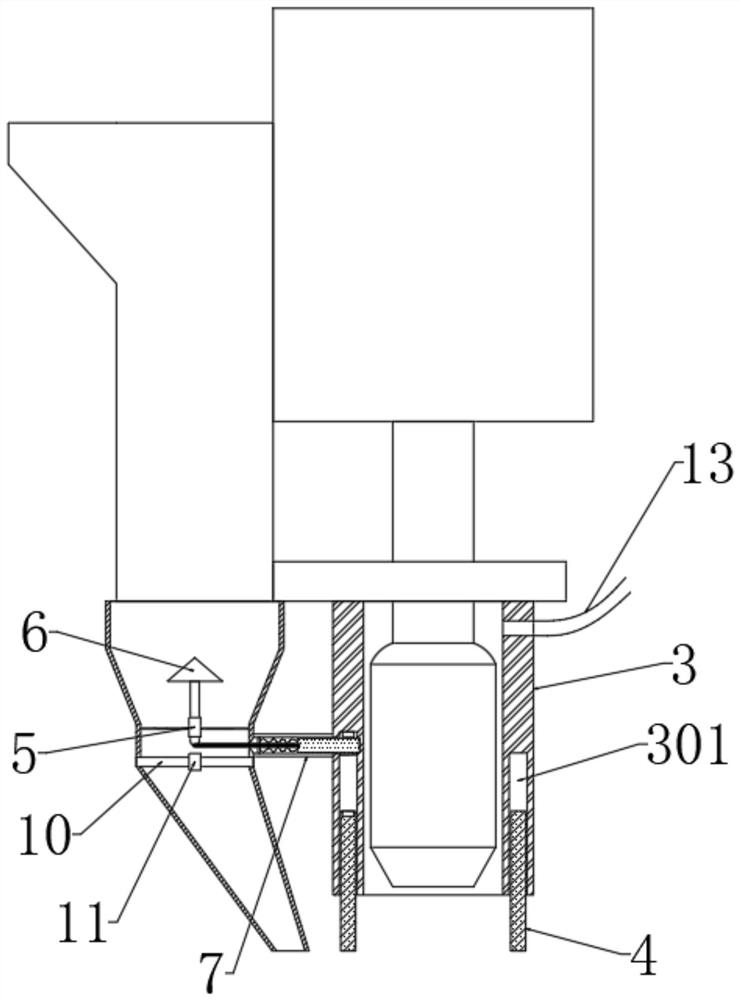

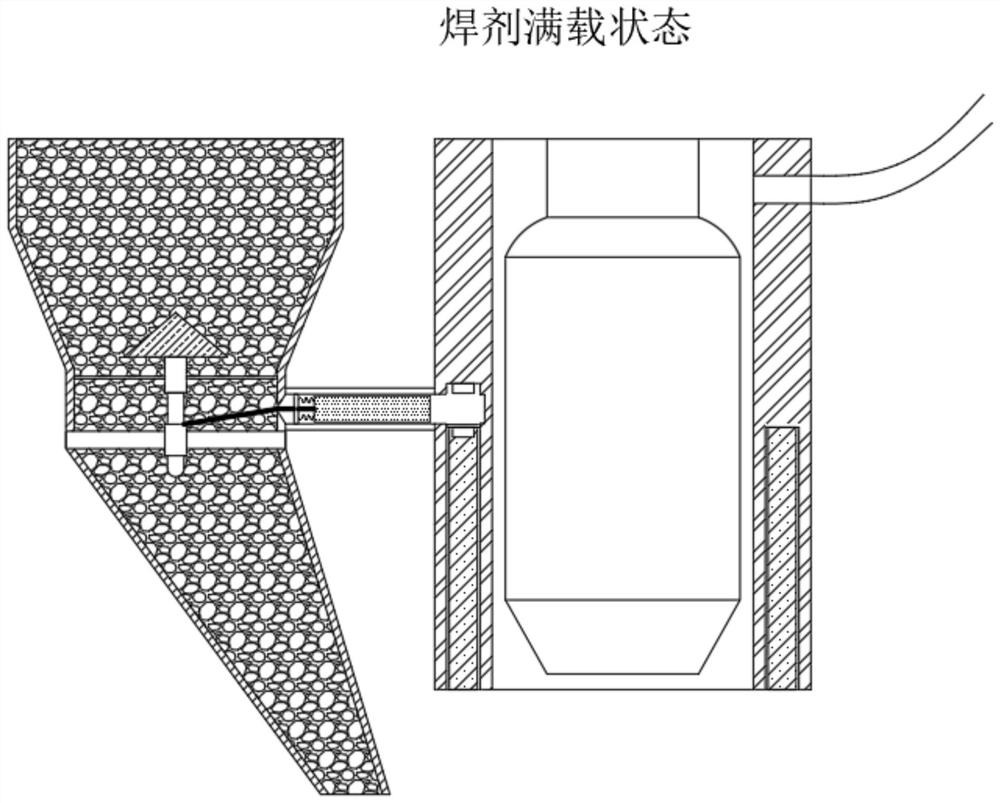

Excess material early warning type submerged arc welding machine and using method thereof

PendingCN114260548AAvoid burnsDoes not affect cuttingWelding accessoriesStructural engineeringMechanical engineering

The invention discloses an excess material early-warning type submerged arc welding machine and a using method thereof, and belongs to the field of electric arc welding. An excess material reflecting part is additionally arranged in an existing welding flux box, the excess material reflecting part descends under the pressing effect of welding flux, at the moment, a magnetism isolating plate retracts into a communicating pipe under the pulling effect of the excess material reflecting part, and therefore the welding flux box is protected; therefore, the light blocking cover is adsorbed into the protection cover, the accident that eyes are burnt by arc light is effectively avoided, meanwhile, the excess material reflecting part adsorbs the prompting part into the storage pipe, and when welding flux is consumed and descends to be lower than the excess material reflecting part, the excess material reflecting part restores to the original position under the action of elastic force. At the moment, the magnetism isolating plate is bounced back to cut off the magnetic adsorption force of the light blocking cover, so that the light blocking cover falls onto the surface of the workpiece, the situation that eyes are burnt by strong arc light due to stop of supply of the welding flux is effectively avoided, and meanwhile the prompting piece is bounced out to send an early warning signal to a worker to remind the worker to add the welding flux in time.

Owner:徐州市富昌制药机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com