Lightweight partition wall block forming machine, partition wall block and connection method of the partition wall block

A molding machine and partition wall technology, which is applied to ceramic molding machines, walls, building components, etc., to achieve the effect of saving resources and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

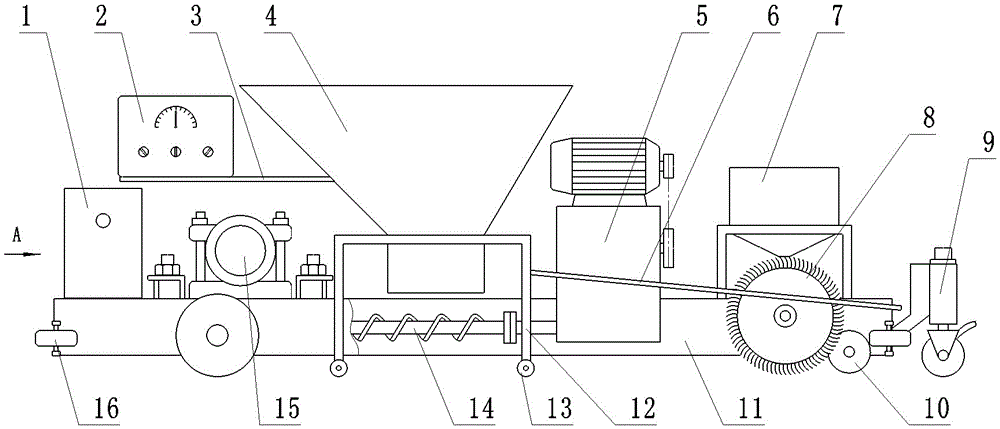

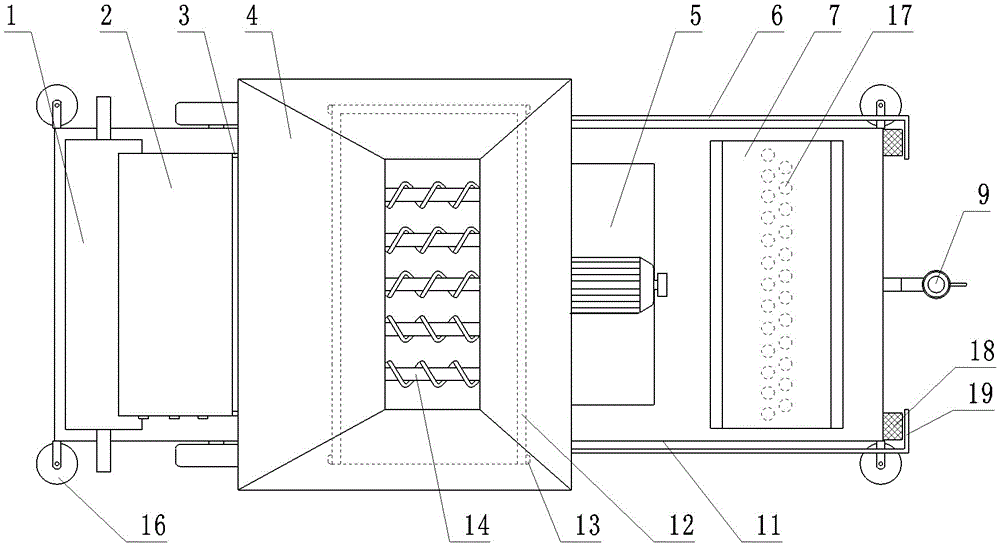

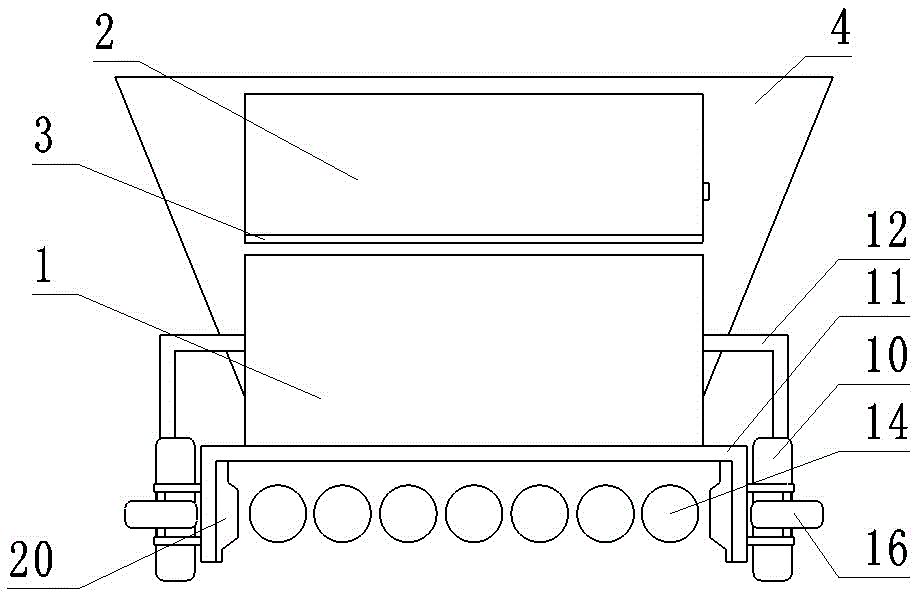

[0036] Example 1: refer to Figure 1 ~ Figure 4, is a structural schematic diagram of Embodiment 1 of the present invention, including a frame (11), a gearbox assembly (5), a distribution box (2), a counterweight (1), a hopper (4), a vibration assembly (15 ), a pushing mechanism (14), a walking wheel (10) and a moving guide wheel (9), characterized in that: the hopper (4) is provided with a separation bracket (12) separated from the frame (11) ), a hopper separation support wheel (13) is provided at the bottom of the hopper separation support (12), a hopper tow hook (6) is provided at the front end of the hopper separation support (12), and a hopper tow hook (6) is provided at the front end of the hopper separation support (6). There is a hook (19), and a pushing mechanism 14 is arranged in the middle part of the frame 11. The pushing mechanism 14 in the present embodiment is a screw squeezing mechanism, which is made of parallel screw augers. The frame 11 is provided with ...

Embodiment 2

[0040] Example 2: refer to Figure 8 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the pushing mechanism 14 in Embodiment 2 is a pushing mechanism, and the pushing mechanism is a piston mechanism. Since the hopper 4 is separated from the whole unit, it can also make the produced partition wall block more dense, even if the unit vibrates for a long time, it will not affect the feeding of the hopper, so it can also be used to make thicker exterior wall blocks. The produced wall blocks have good compactness, high strength, good finish and formability, and the required strength can be achieved without setting steel bars in the wall blocks.

Embodiment 3

[0041] Example 3: refer to Figure 9 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the difference of this embodiment is that the forming core tube in the pushing mechanism 14 is oval, and the inner hole in the formed partition block is also It is elliptical. When the partition wall blocks produced are relatively thick, the use of elliptical inner holes not only saves material, but also the partition wall blocks are lighter, and the impact resistance is stronger and stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com