A kind of particle board molding processing method

A technology for forming and processing particle boards, applied in forming/shaping machines, wood processing appliances, special forming/shaping machines, etc., can solve the problems of reducing the production efficiency of sheets, the specifications of the sheets do not meet the requirements, and the position of the sheets is offset. To achieve the effect of reducing the cleaning workload, good fixing effect, and free cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

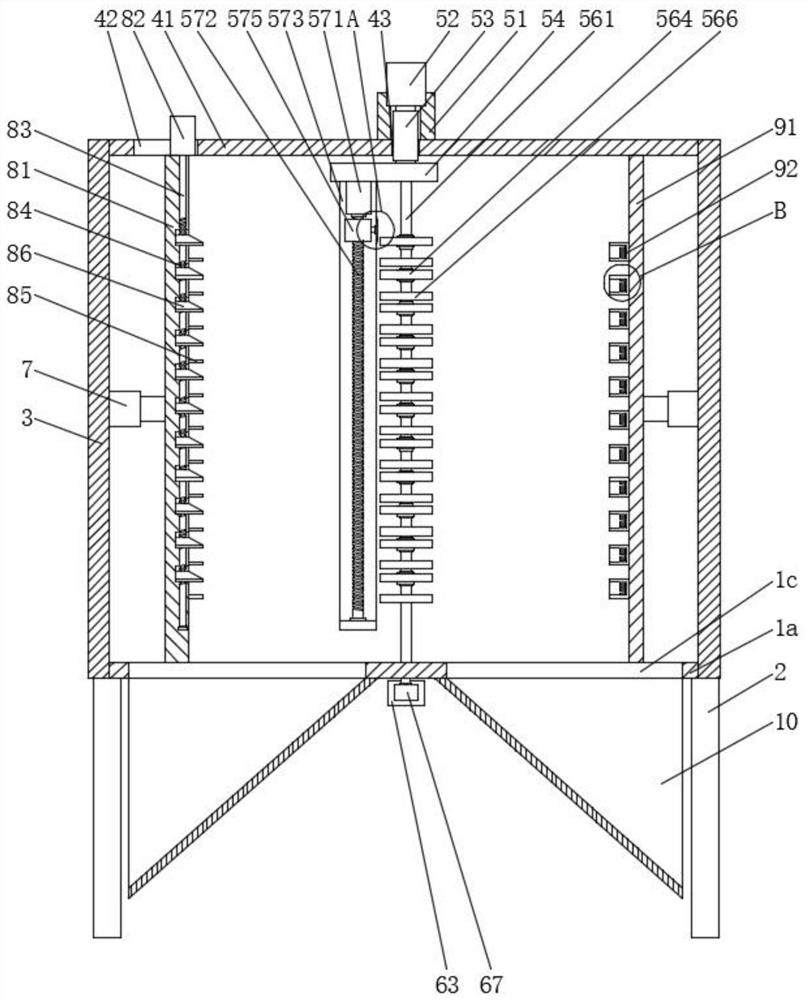

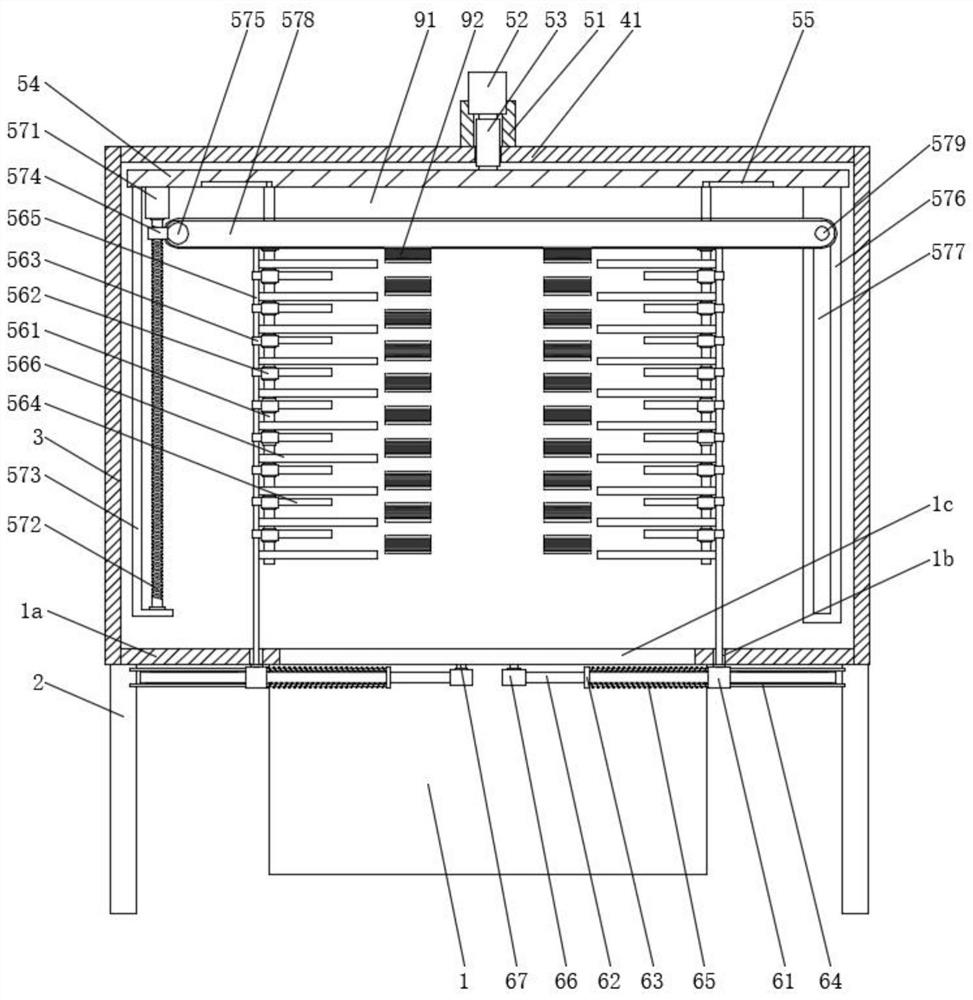

[0033] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

[0034] like Figure 1 to Figure 8 As shown, a particle board forming and processing method, the particle board forming and processing method adopts the following equipment. There is a ring wall 3, a top cover plate 4 is fixedly installed in the upper part of the ring wall 3, the middle part of the top cover plate 4 is located in the ring wall 3, and a movable clamping and cutting device 5 is fixedly installed through the ring wall 3, and the bottom of the mobile clamping and cutting device 5 is movable. An elastic clamping structure 6 is connected, the middle parts of the left and right sides of the inner wall of the ring wall 3 are respectively fixedly installed with a second hydraulic rod 7, and a left clamping device 8 is fixedly installed on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com