Dehydration and desiccation device and method for sewage sludge

A technology for sludge drying and sewage sludge, which is used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high processing cost, large sludge volume, and large change in moisture content, and reduce the amount of chemicals added. , Simplify the system process and improve the effect of filter press performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

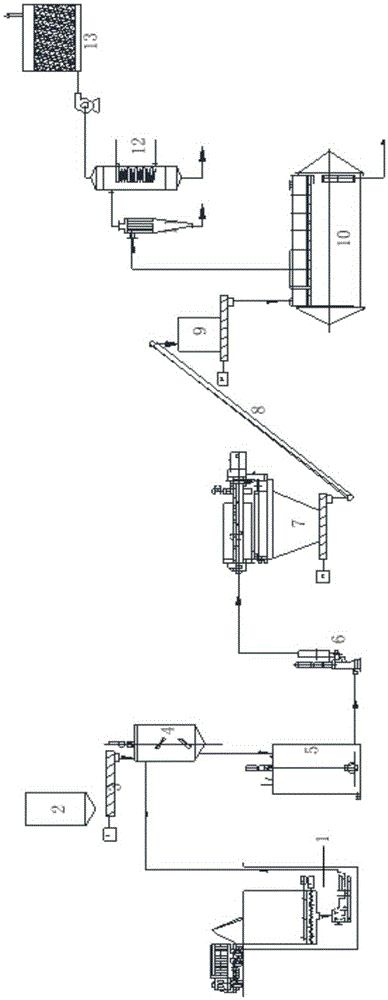

[0063] In order to solve the problems existing in the prior art, the present invention provides a dehydration and drying device for sewage sludge, including: a wet sludge storage and delivery system connected through a closed pipeline, a sludge dewatering system and a sludge drying system. A system for transporting, storing, and modifying the sludge, dehydrating the sludge, and drying and granulating the sludge;

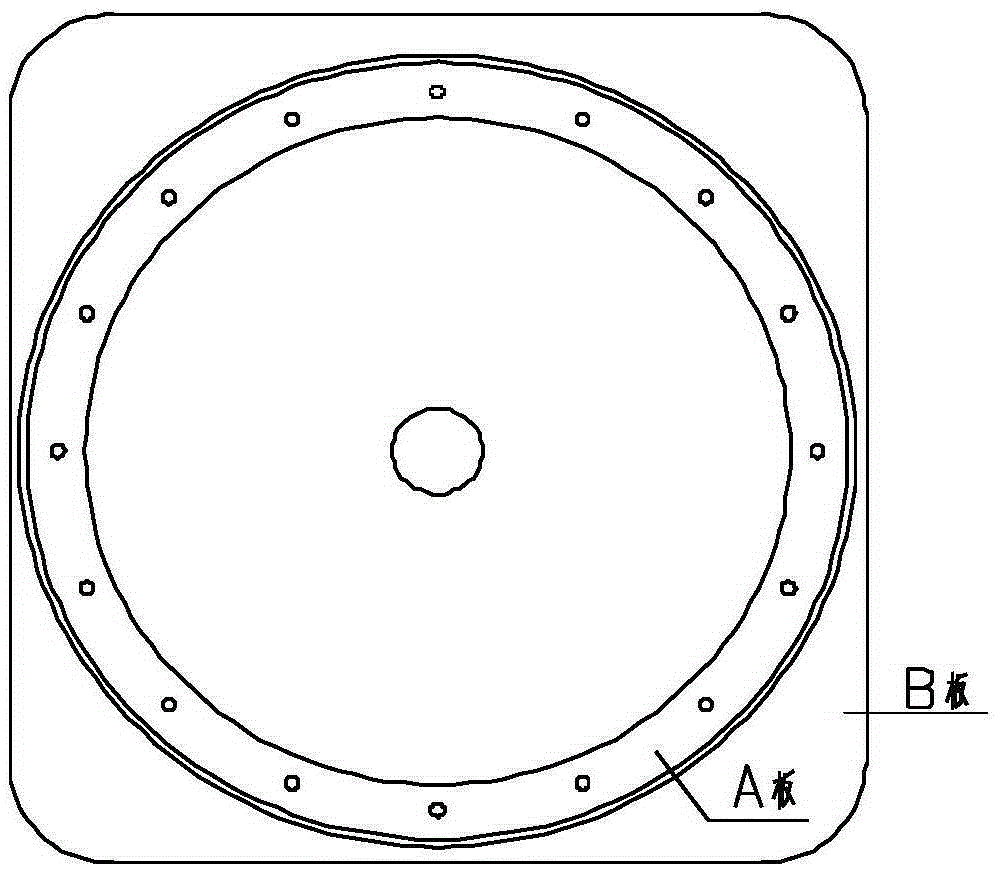

[0064] Wherein, the sludge dewatering system includes at least high-pressure elastic filter press equipment to increase the working pressure of the filter press;

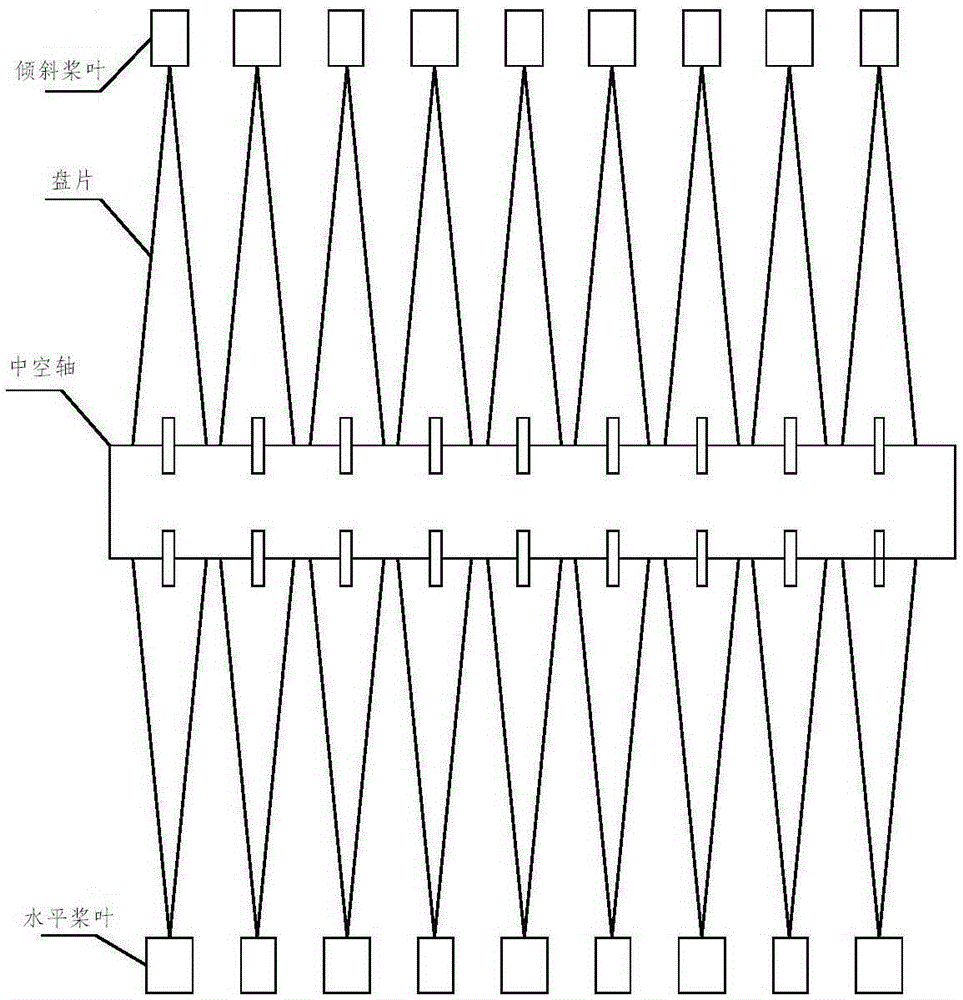

[0065] The sludge drying system at least includes horizontal disc drying equipment to dry the modified and dehydrated sludge.

[0066] Among them, such as figure 1 As shown, the dehydration and drying device for sewage sludge includes sludge storage and conveying equipment 1, modifier silo 2, modifier conveying equipment 3, modified modulation pipe 4, modulated sludge buffer tank 5, sludge Pump 6, high-p...

Embodiment 2

[0110] The present invention also provides a dehydration and drying method based on the above device, comprising:

[0111] Step S1: transporting the sludge to the wet sludge storage and delivery system, so as to transport, store and modify the sludge;

[0112] Step S2: sending the modified sludge to the sludge dewatering system, and removing the water in the sludge through multiple feeding and multiple pressure filtration in the high-pressure elastic filter press equipment;

[0113] Step S3: The sludge filtered by the high-pressure elastic filter press equipment enters the sludge drying system, and the dehydrated sludge is dried into granules in the horizontal disc drying equipment.

[0114] Specifically, the dewatered sludge of the sewage treatment plant is poured into the sludge silo in the plant through vehicle-mounted transportation; the bottom of the sludge silo is equipped with a biaxial screw conveyor, which is sent into the sludge pump through the biaxial screw conveyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com