Railway solidified and closed ballast bed and solidification and closing method

A ballast bed and railway technology, applied to roads, tracks, ballast layers, etc., can solve problems affecting production and transportation order, high construction technical requirements, waste of transportation speed, etc., and achieve simple construction, good sealing and waterproof performance, and convenient filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

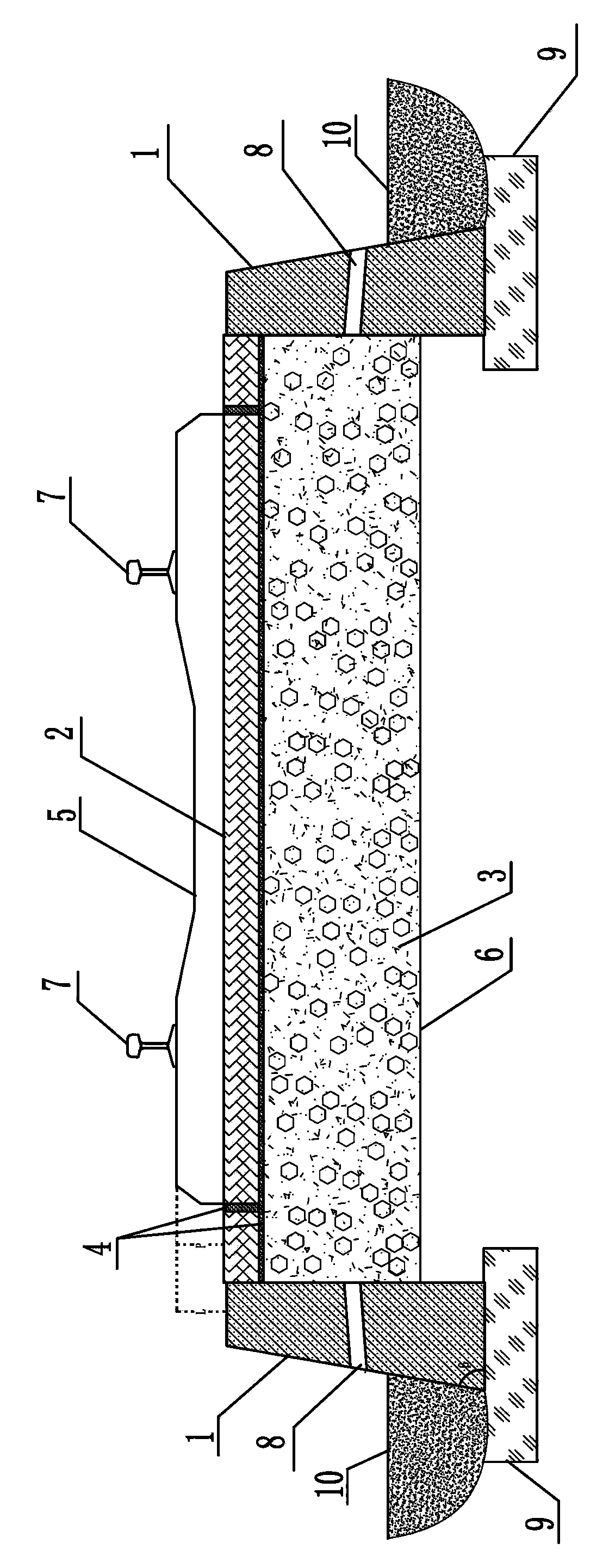

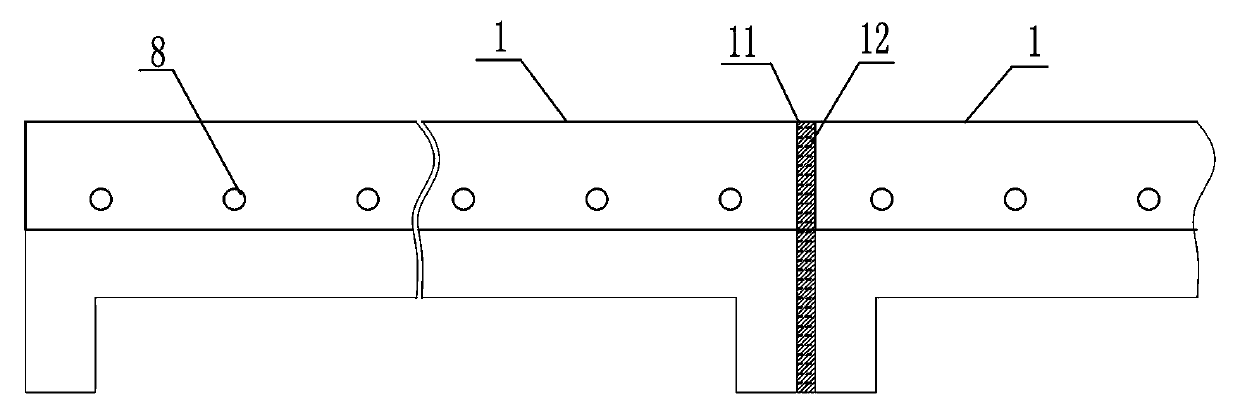

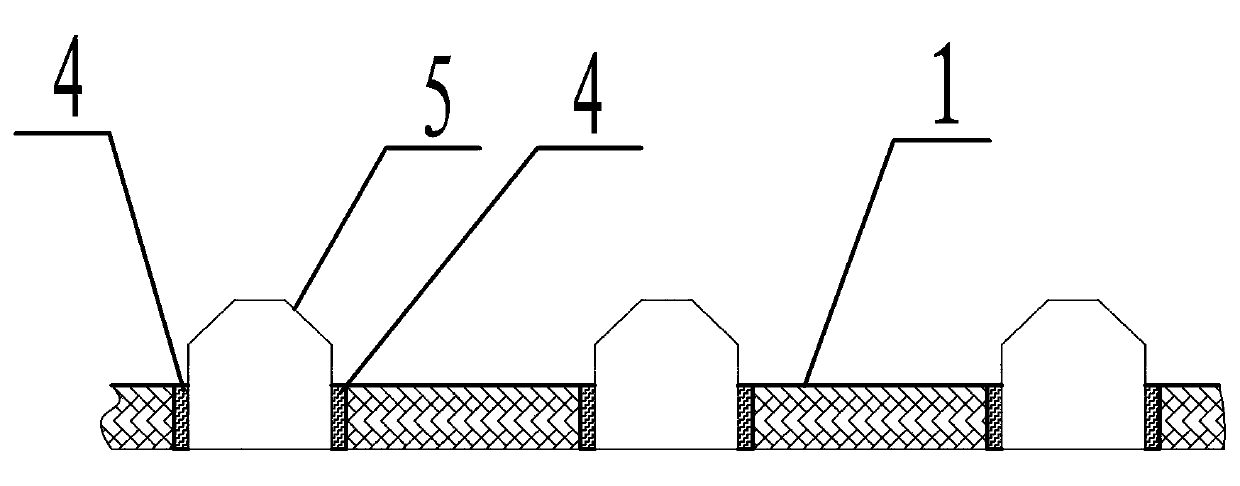

[0025] as attached figure 1 , 2 , 3, the railway solidified closed track bed of the present invention comprises ballast retaining walls 1 respectively arranged on both sides of the railway track bed 6, filling material 3 arranged in the track bed 6 and being arranged on the top of the track bed 6 by mixing steel fibers and ordinary concrete The anti-crack concrete layer 2, the anti-crack concrete layer 2 made of steel fiber and ordinary concrete can significantly improve the tensile strength, flexural strength and fatigue resistance of the anti-crack concrete, and can significantly reduce the thickness when used in pavement engineering , to improve road performance; an elastic sealing material 4 is arranged on the top of the ballast bed 6 and between the top of the ballast bed 6 and the sides of the sleeper 5, and the elastic sealing material 4 is a SBS modified bitumen waterproof coiled material, which has good durability High temperature performance, can be used in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com