Patents

Literature

52results about How to "The system process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

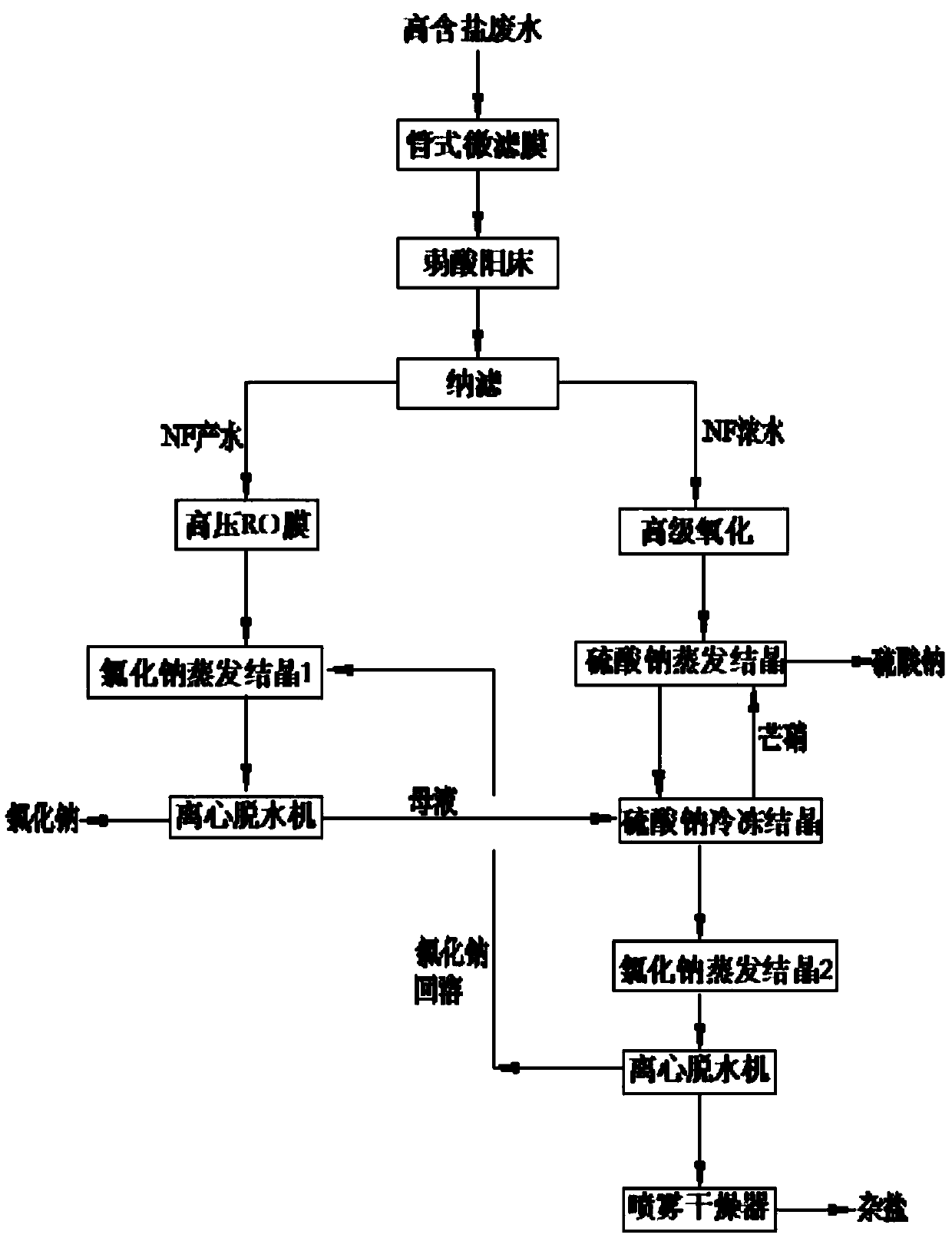

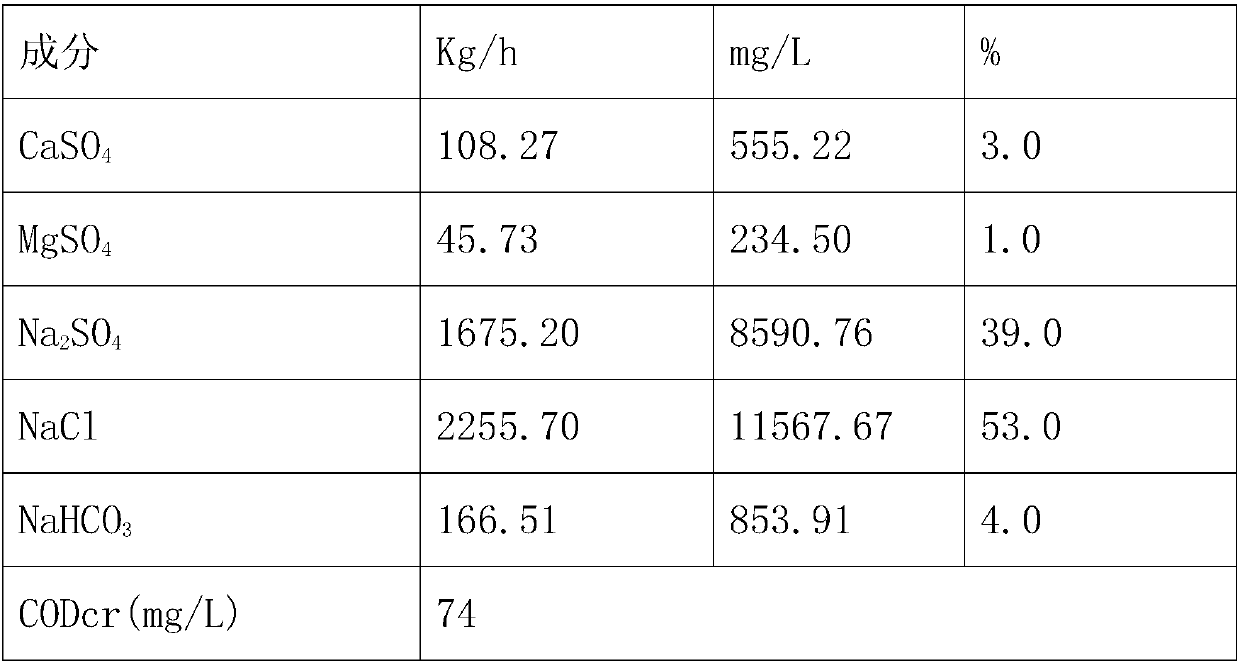

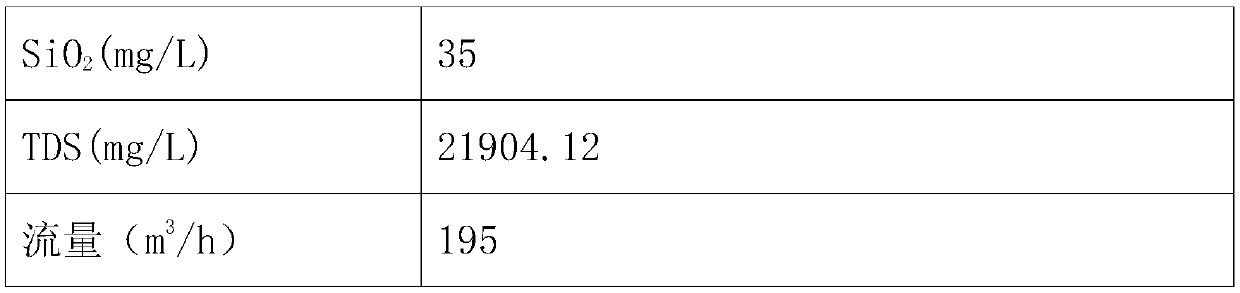

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

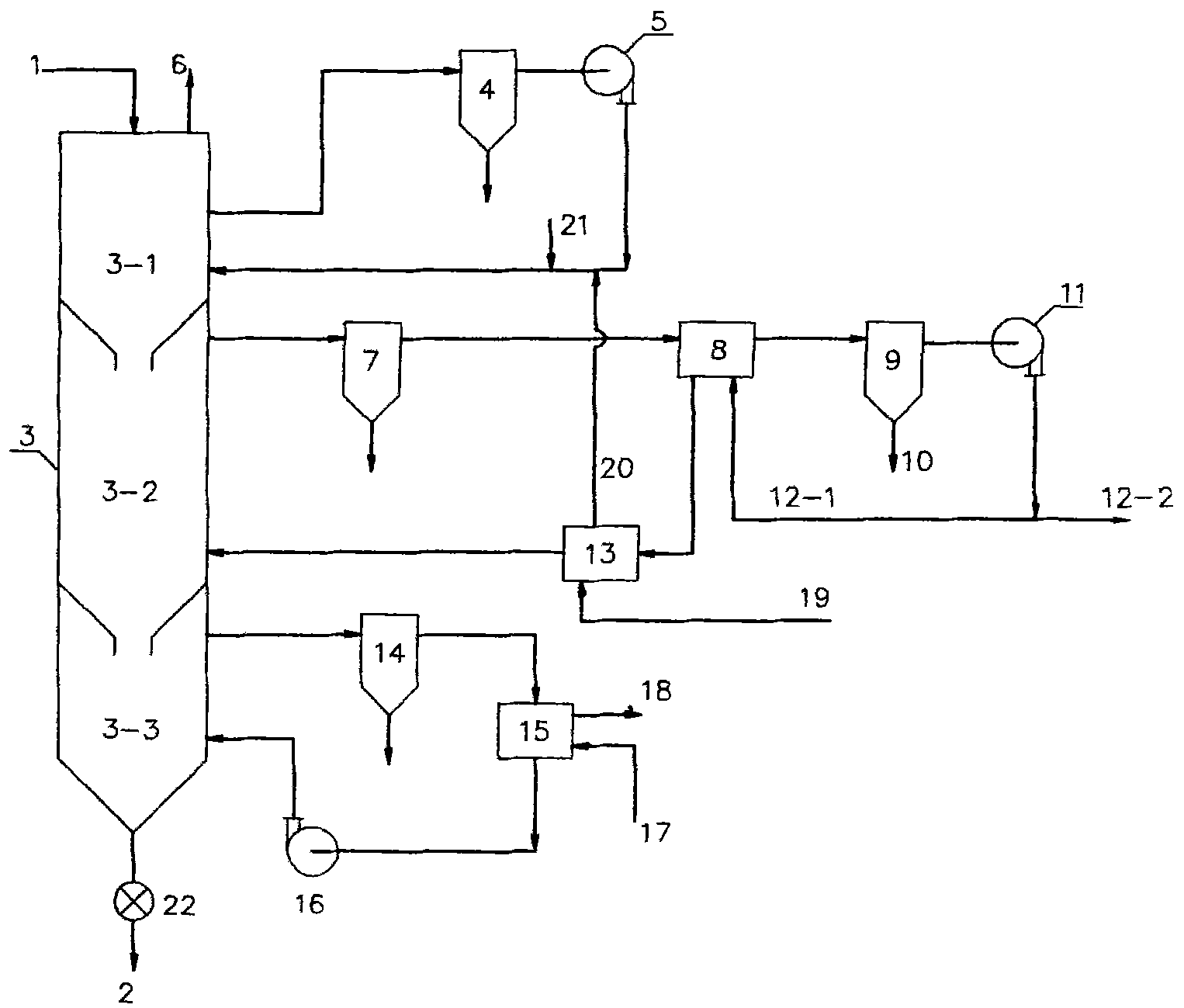

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

Dry distillation production process for lignite or high volatile coal

InactiveCN101885973AReduce the temperatureQuality improvementDirect heating destructive distillationHeat carrierTar

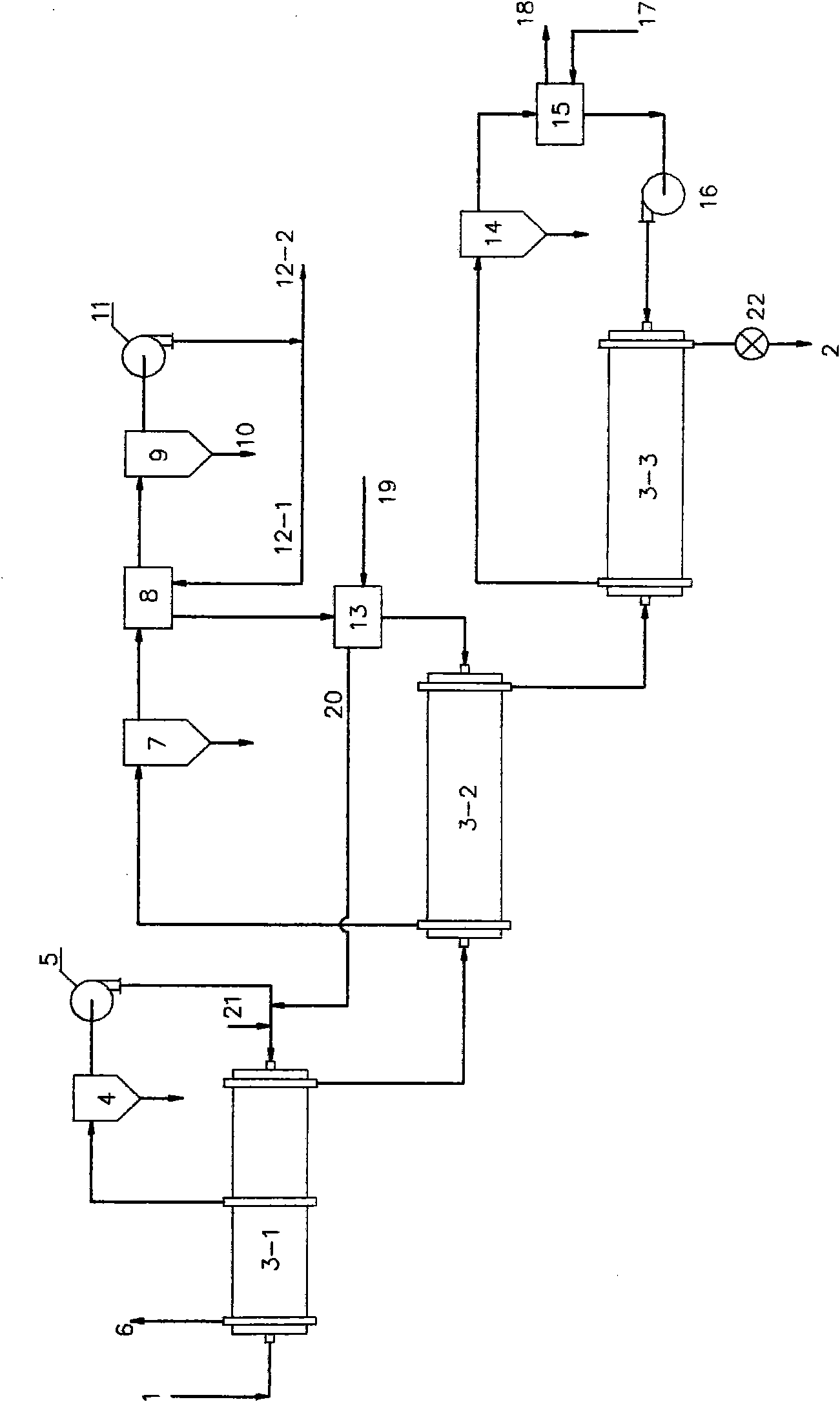

The invention discloses a dry distillation production process for lignite or high volatile coal. A high-temperature dry distillation gas serving as a heat carrier enter a dry distillation furnace to transmit heat with coal inside the furnace by contact to change the coal into semicoke through pyrolysis and dry distillation; the gas overflowing through the dry distillation flows into a heat carrier gas and then out of the furnace together; after the gas from the furnace is cooled and purified, which is equivalent to that a part of the original heat carrier gas is heated through a partition to a high temperature to serve as a heat carrier to return to the dry distillation furnace for recycling; and the balance of gas serves as an external supply. The dry distillation production process has the advantages of both internal and external heat dry distillation and obtains the approximately same gas purity as that of the external heat dry distillation process, so that the gas for the externalsupply has a high quality, heat value and application value and is an ideal chemical raw material or high-quality fuel; moreover, all the dry distillation gas can be used for the external supply; thecoal is slightly affected by a temperature and uniformly heated; tar has a high yield; the system has a wide heat source and can use low-quality fuel smoke, such as powdered coal, the gas and the like; and the system has a simple flow, is easy to operate and control in production and operation and has less industrialization construction investment.

Owner:NANTONG JINGHUAN ENERGY TECH CO LTD

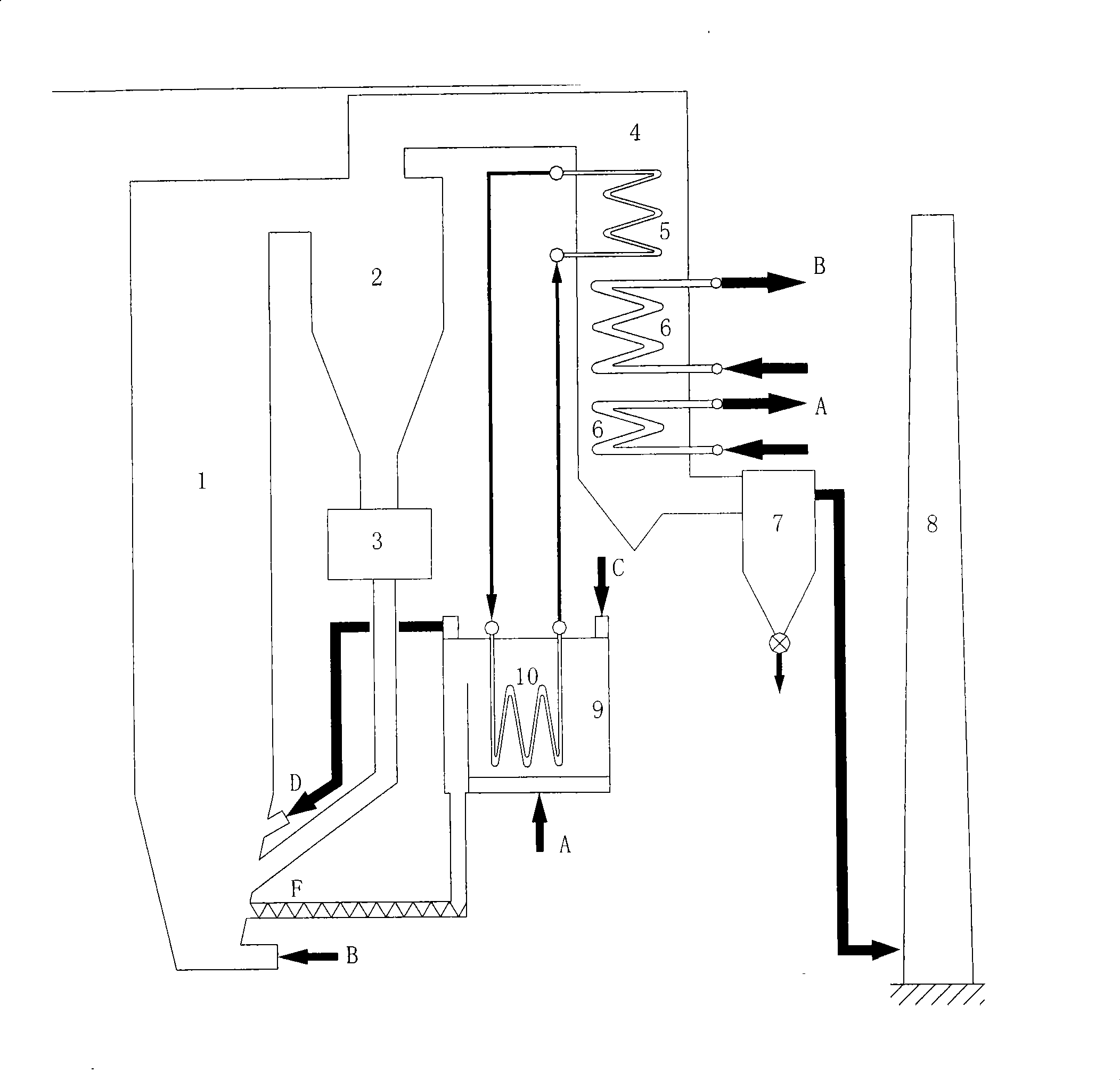

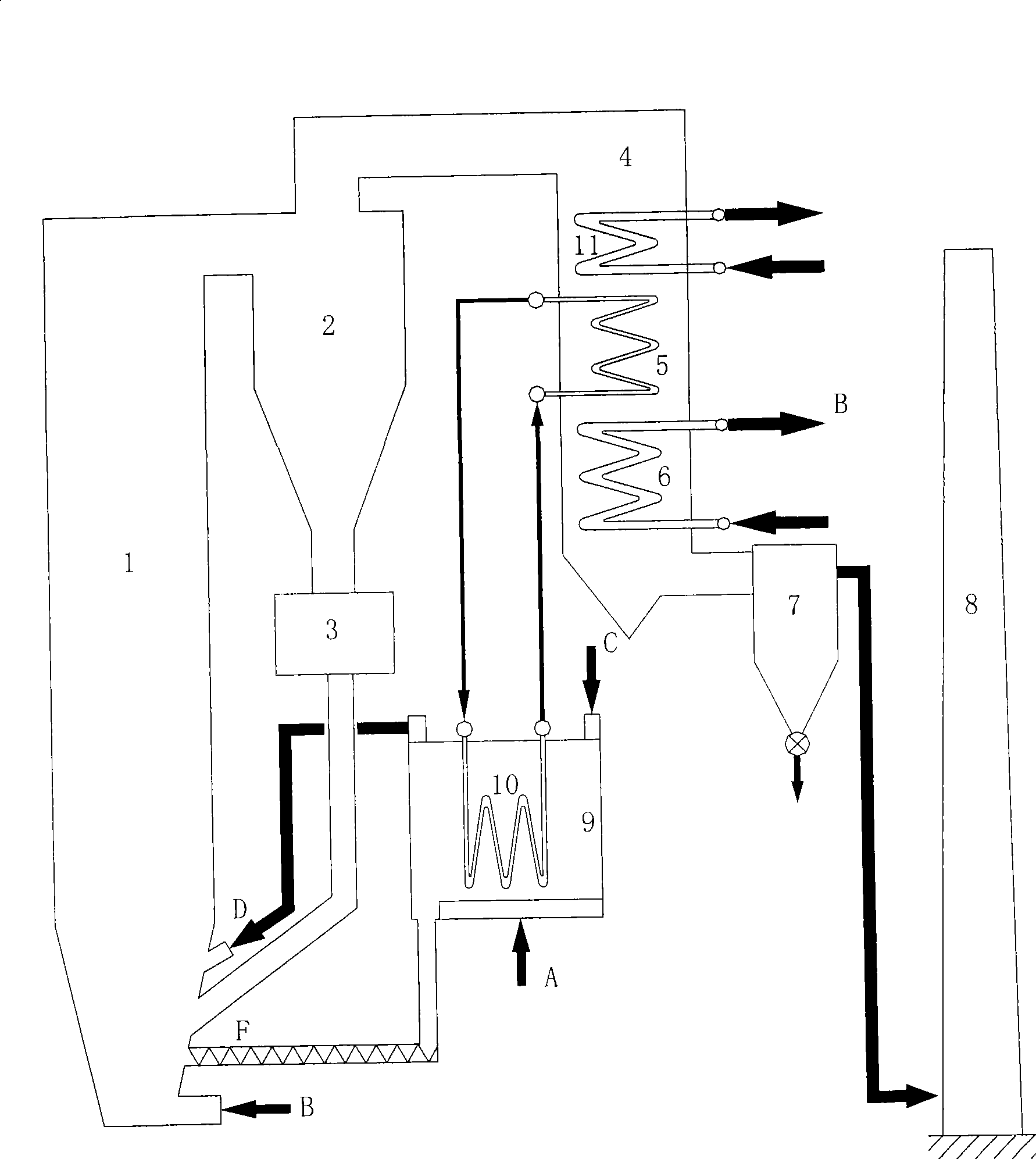

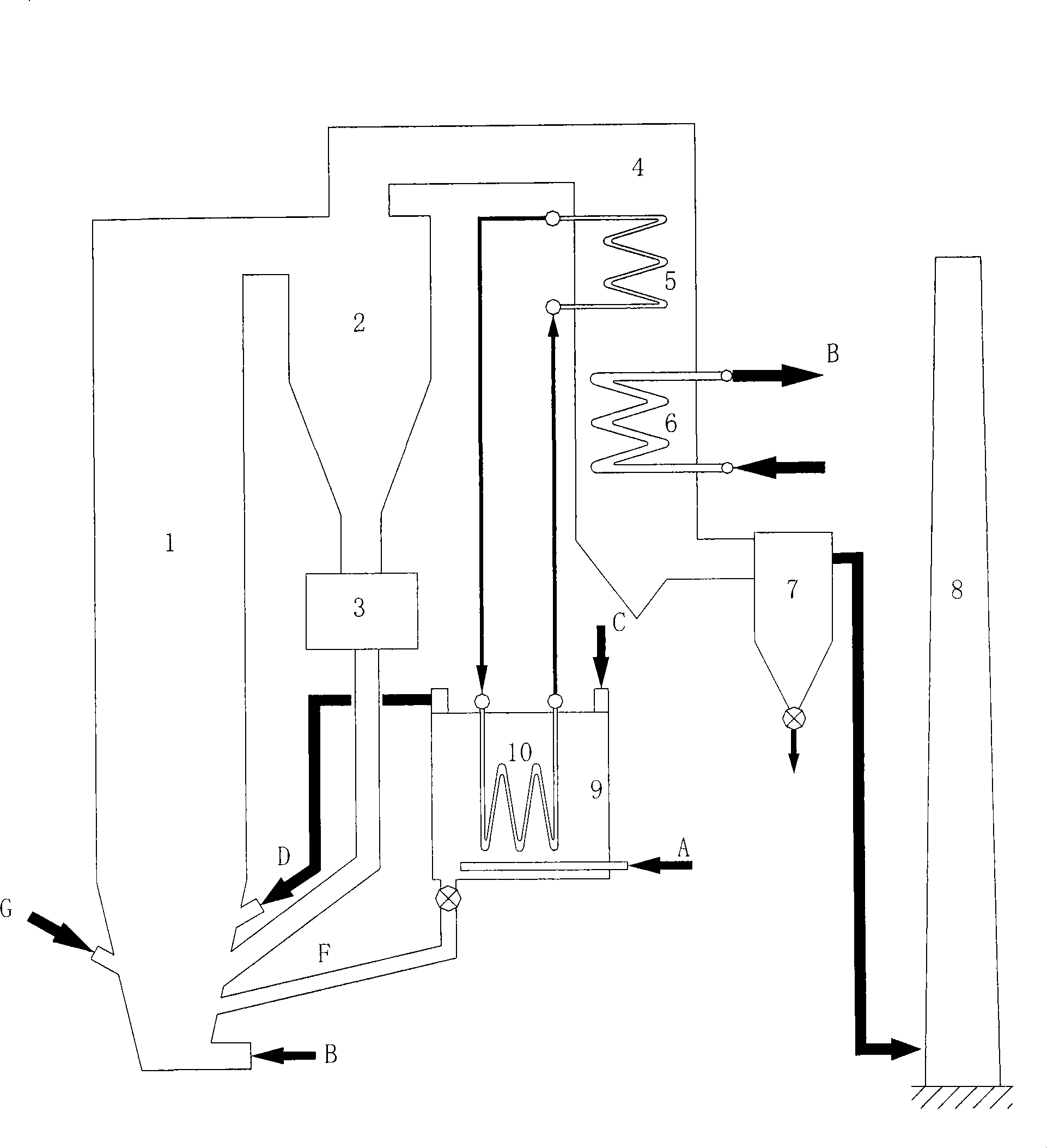

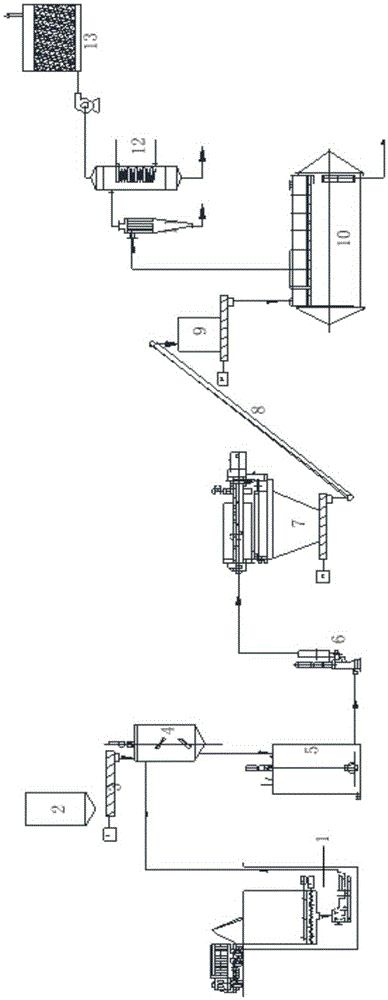

Anhydration and incineration processing method for wet sludge

InactiveCN101386464ARealize deodorization and harmlessnessReduce consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeFlue gas

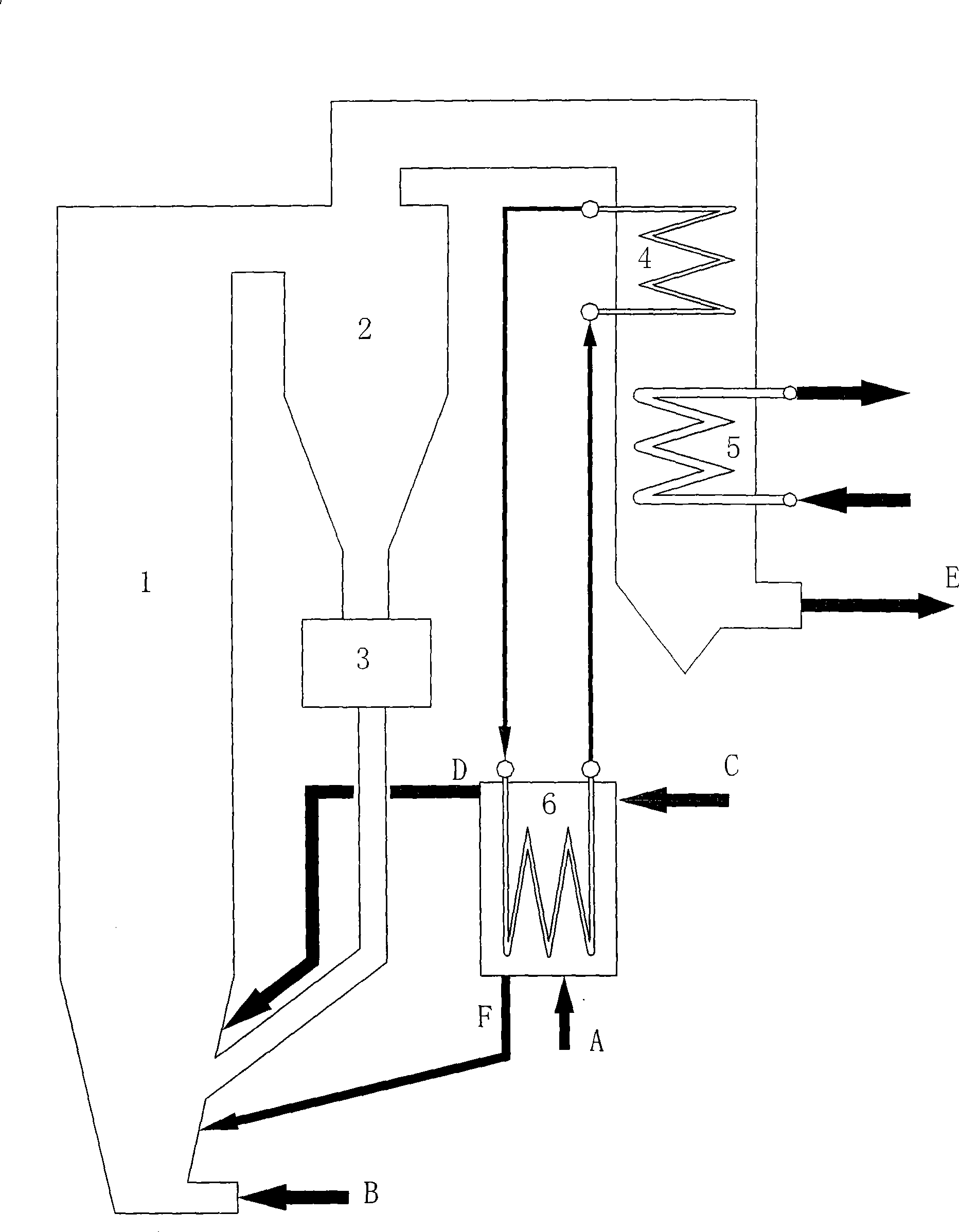

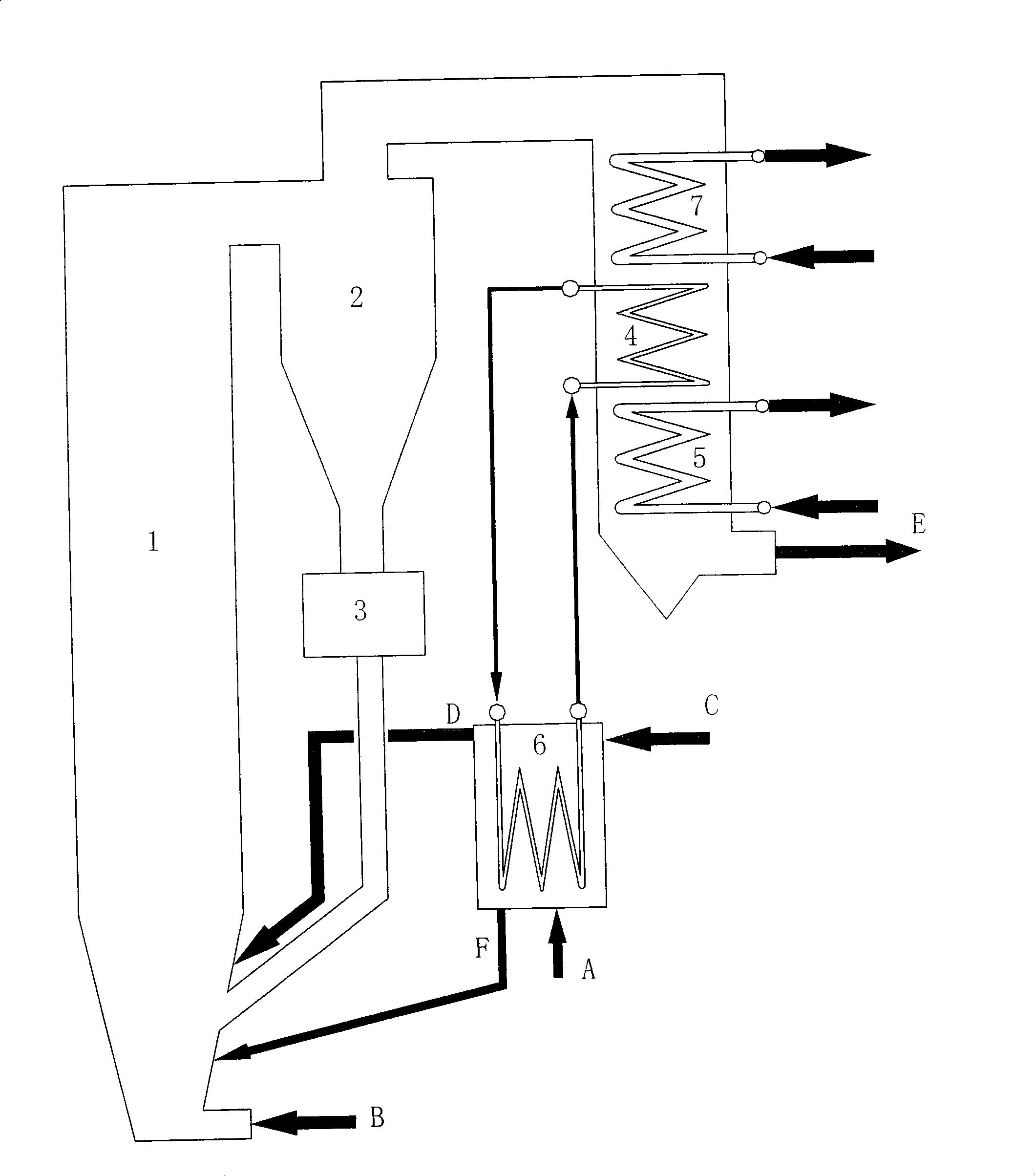

The invention discloses a wet sludge drying and incineration processing method, relating to the technology of waste disposal. Wet sludge with the water content of 60 percent to 90 percent is incinerated in an incinerator of a circulating fluidized bed and a heat exchanger is arranged in a tail flue and is communicated with a heat release coiled pipe arranged in a fluidized bed type sludge drier. Heat exchange media in the heat exchanger and the heat release coiled pipe absorb heat from flue gases of the tail flue and release heat in the sludge drier; the wet sludge to be incinerated is firstly put into the sludge drier and dried to form the dry sludge with a water content of 5 percent to 25 percent, and then the dry sludge is sent into a firing space for incinerating at a temperature of 850 DEG C to 900 DEG C; exhaust gas discharged from the sludge drier is led into the lower part of the firing space as secondary air. The method of the invention has possibly simple technology and reclaims heat generated by the incineration of the sludge as far as possible, thereby incinerating and processing the wet sludge with low energy consumption and low costs.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

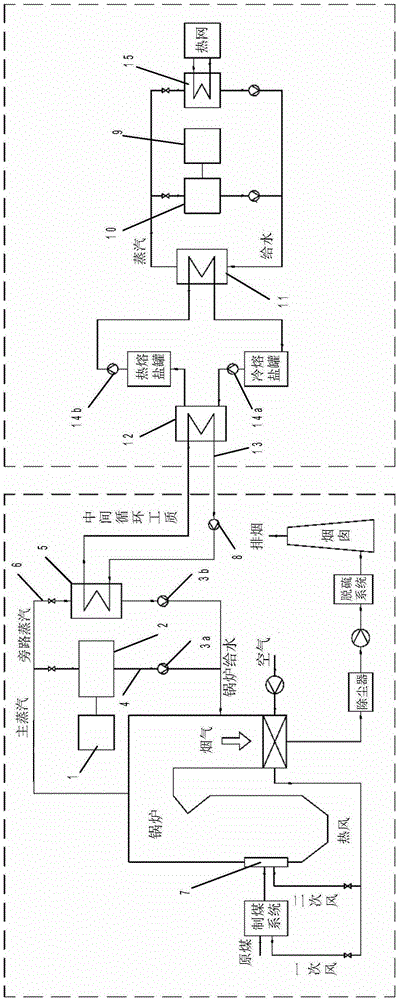

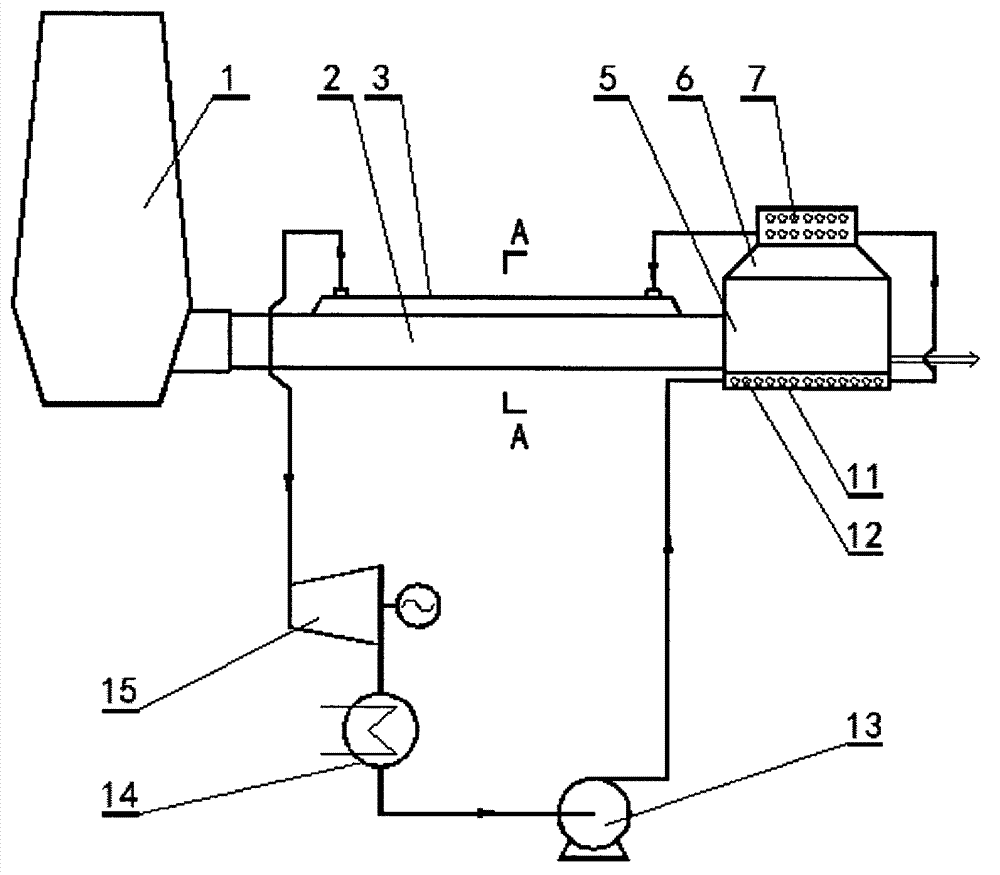

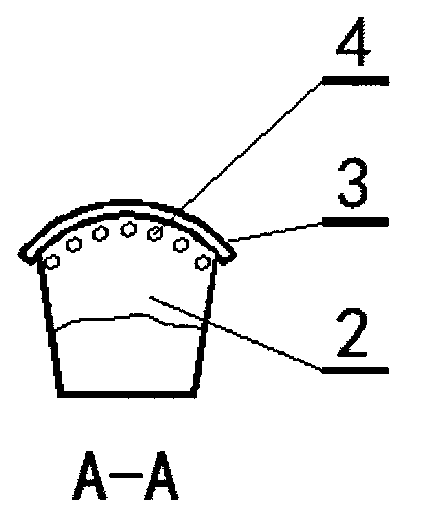

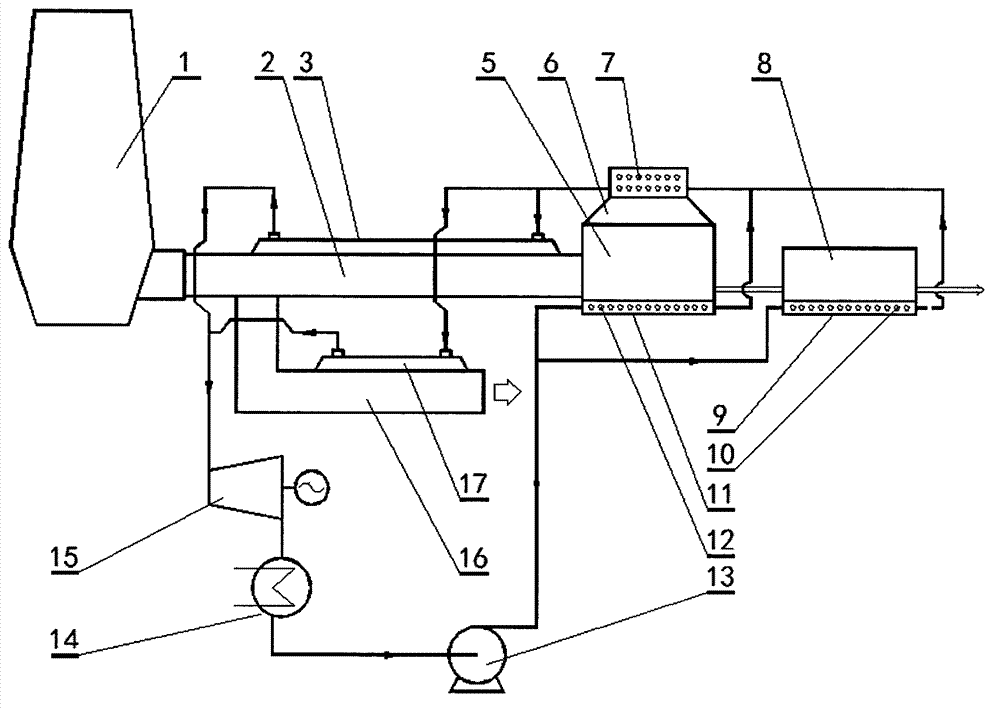

Thermal power generation system and method with fused salt energy storage, power supply and heat supply functions

InactiveCN105351018AThe system process is simpleLess process equipmentHeat storage plantsSteam engine plantsThermal energyThermal energy storage

The invention discloses a thermal power generation system and method with fused salt energy storage, power supply and heat supply functions. By arranging a bypass steam pipeline, a high-pressure condenser and a molten salt heater, excess steam heat energy generated by the load change of a power grid can be stored though molten salt. When the peak load of the power grid is reached, a molten salt energy storage power generation subsystem can participate in peak regulation of power supply of the power grid. In this way, the problems of peak regulation of the power grid, low utilization rate of power equipment and the like are solved, it is guaranteed that the power generation efficiency of the power generation system is equal to that of an existing thermal power generating unit, and the thermal power generation system and method have the outstanding advantages that energy storage and variable-load power supply are achieved, and high-efficiency power generation is guaranteed.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

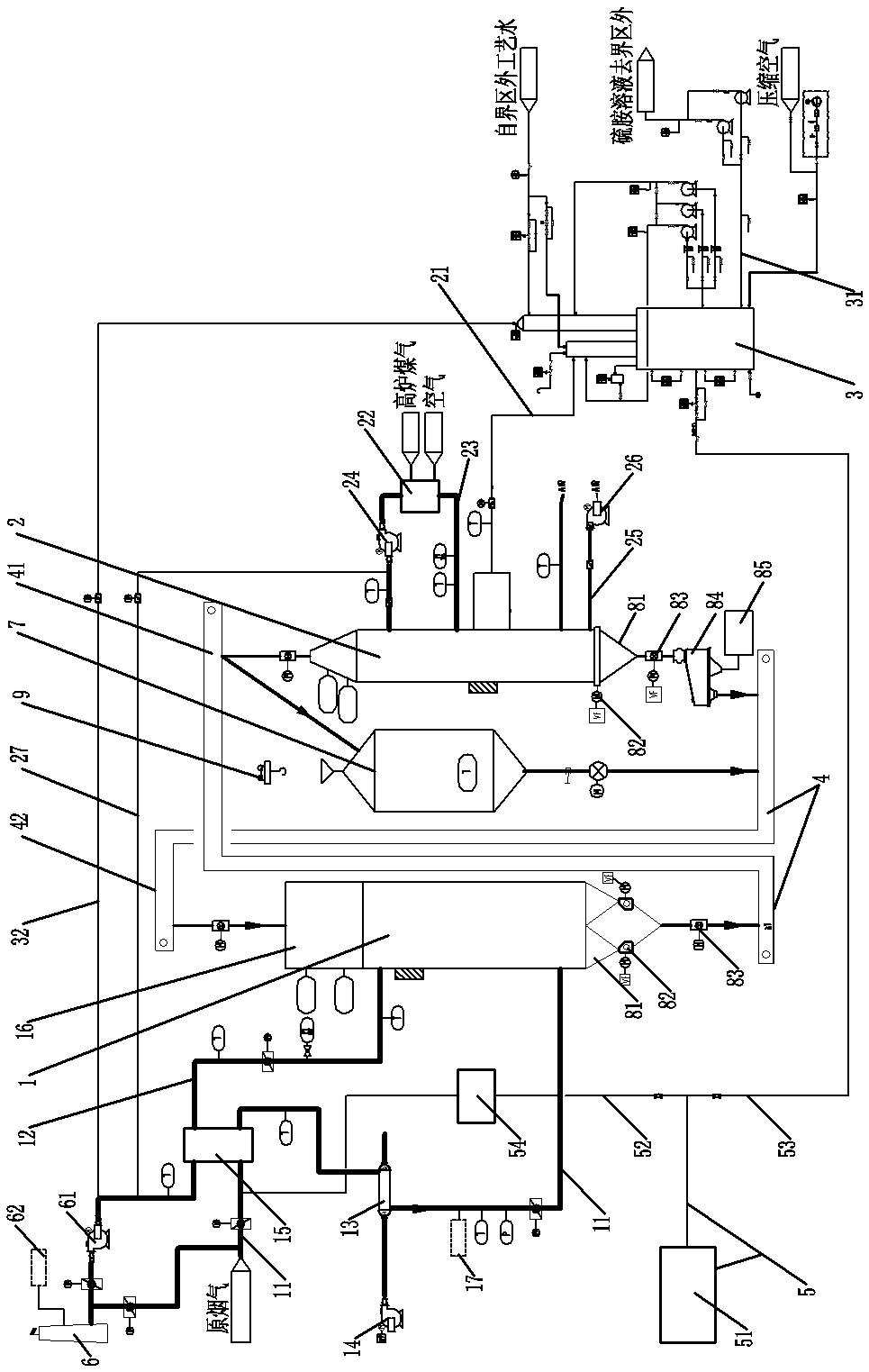

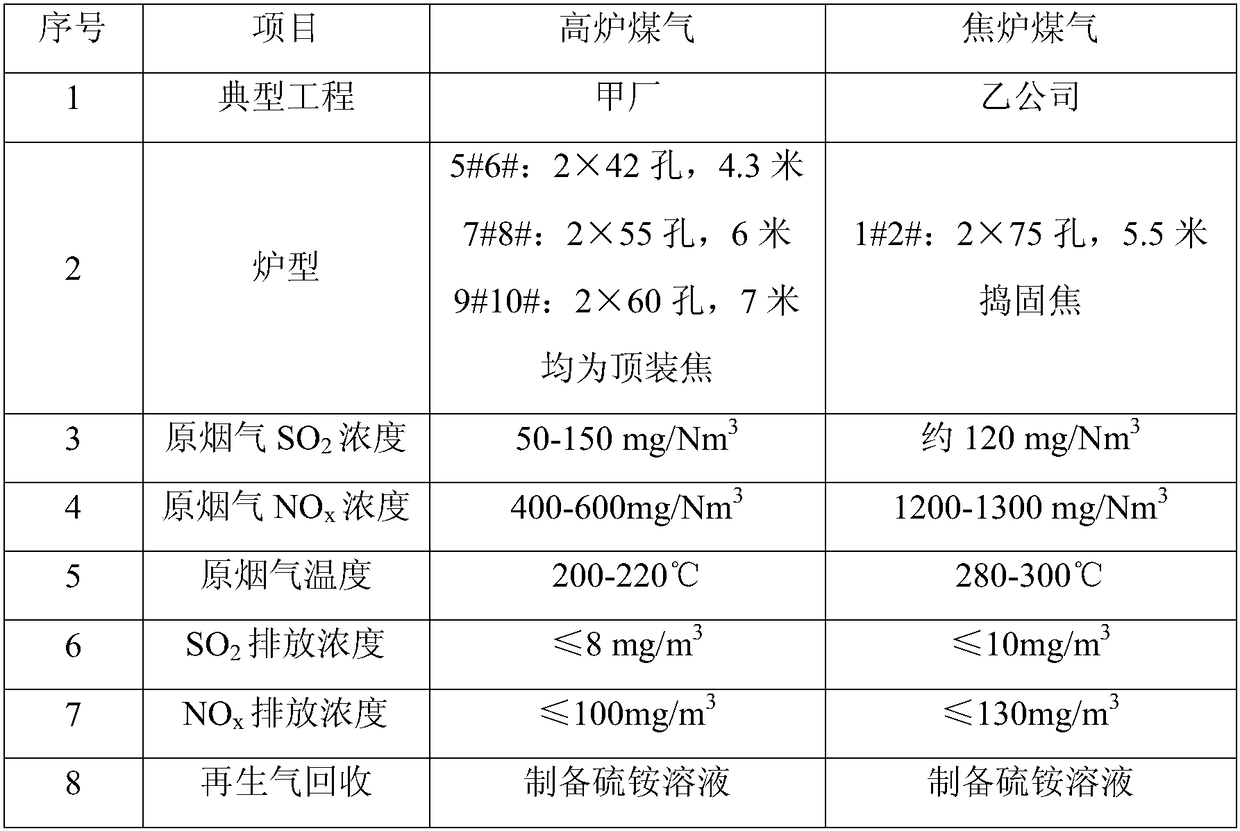

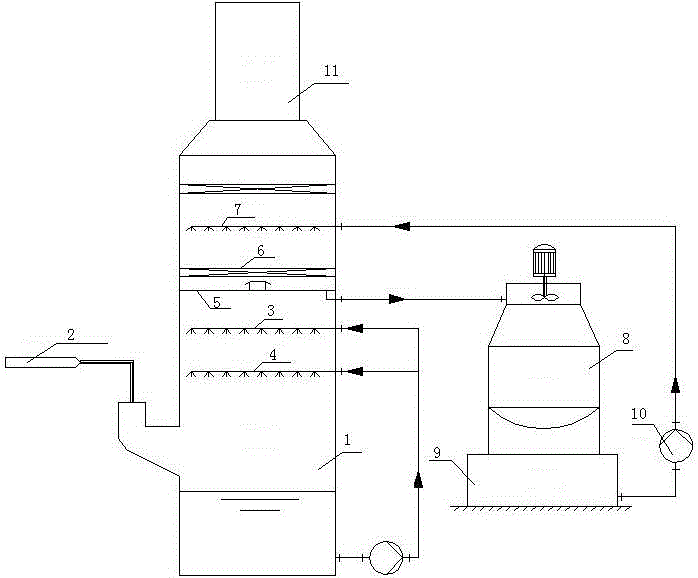

Activated carbon/coke-based coke oven flue gas desulfurization and denitration system and activated carbon/coke-based coke oven flue gas desulfurization and denitration method

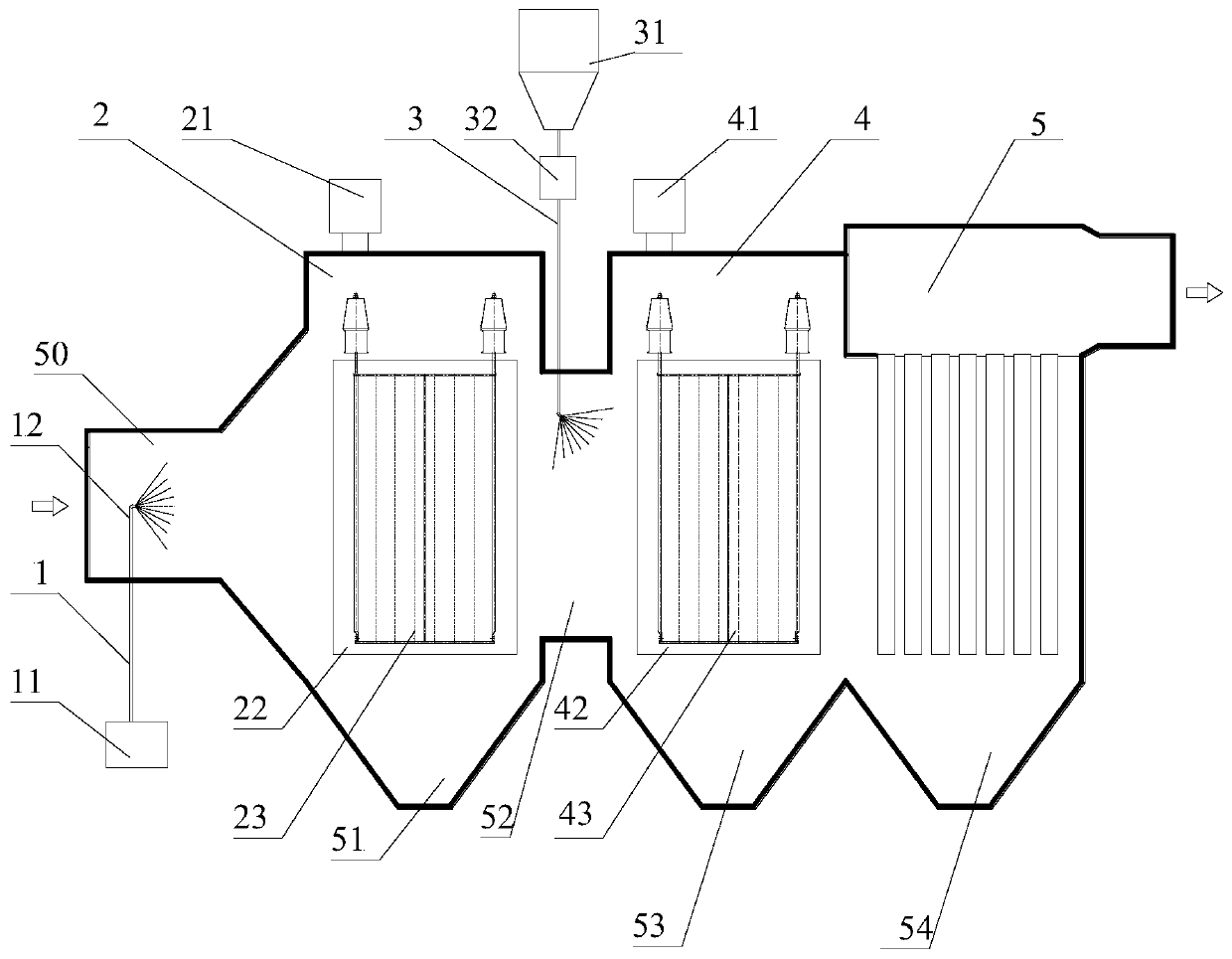

PendingCN108380041AReduce escapeWell mixedGas treatmentDispersed particle separationEngineeringAmmonium sulfate

The invention discloses an activated carbon / coke-based coke oven flue gas desulfurization and denitration system and an activated carbon / coke-based coke oven flue gas desulfurization and denitration method. The flue gas desulfurization and denitration system comprises an activated carbon / coke flue gas purification tower, an activated carbon / coke regeneration tower, a chimney, an ammonia water injection system and an absorption tower, wherein an activated carbon / coke conveyor is arranged between the purification tower and the regeneration tower; the regeneration tower is connected with a high temperature heating system and a regenerated gas pipeline; the ammonia water injection system comprises an ammonia water container; the ammonia water container is connected with a first ammonia water pipeline and a second ammonia water pipeline which are arranged in parallel; the first ammonia water pipeline and the second ammonia water pipeline are respectively communicated with the interiors of aflue gas inlet pipeline and the absorption tower; the bottom of the absorption tower is connected with an ammonium sulfate solution pipeline, and the top of the absorption tower is connected with a waste gas exhaust pipeline; the regenerated gas pipeline is communicated with the interior of the absorption tower; a purified gas exhaust pipeline and the waste gas exhaust pipeline are communicated with the chimney; the activated carbon / coke conveyor comprises an old material conveyor used for conveying activated carbon / coke at the bottom of the purification tower onto the top of the regenerationtower, and a new material conveyor used for conveying activated carbon / coke at the bottom of the regeneration tower onto the top of the purification tower.

Owner:南京泽众环保科技有限公司

Technology of saving water and controlling aerosol phenomenon in ammonia desulphurization technology

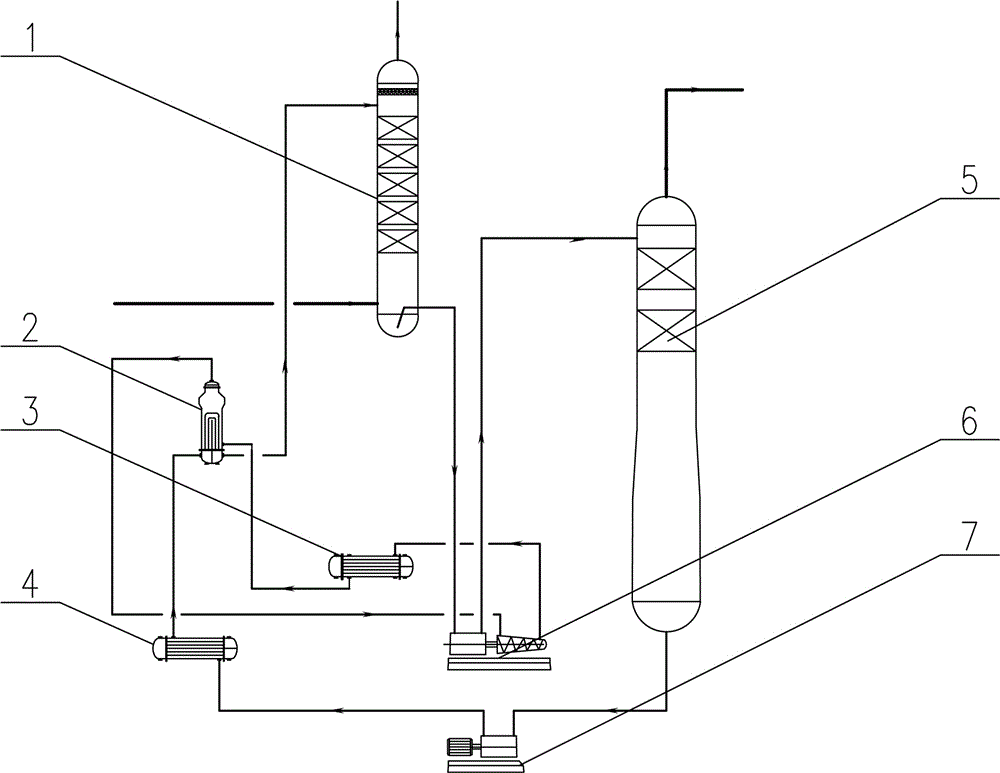

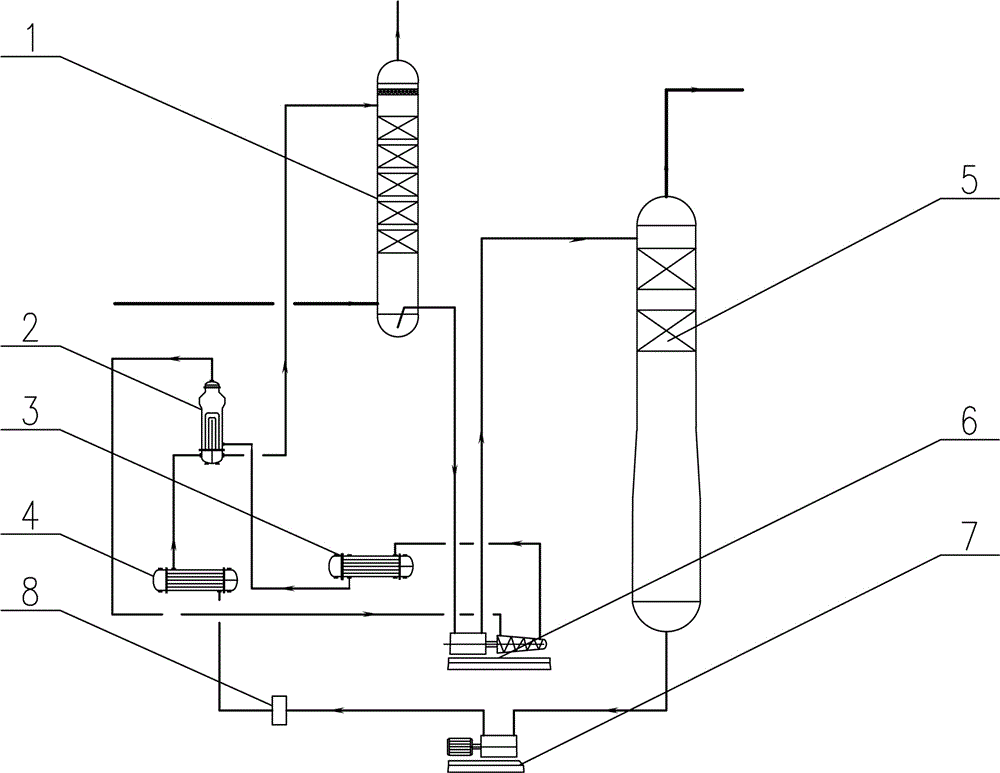

InactiveCN106731630AThe system process is simpleImprove cooling effectUsing liquid separation agentFlue gasCooling effect

The invention discloses a technology of saving water and controlling an aerosol phenomenon in an ammonia desulphurization technology. Boiler flue gas enters a desulphurization tower, spraying liquid and the flue gas which enters the desulphurization tower and contains SO2 are sprayed, are in contact with cooling water on a filler layer through the filler layer and then are in contact with a washing and spraying layer, and the cooling water at the bottom of the filler layer falls onto a washing hydrops disc, flows back to a water cooling tower, then enters a washing pool and is pumped to the washing and spraying layer through a washing water conveying pump to carry out circulation utilization. The technology has the advantages of simpleness in system flow, good cooling effect, low running cost and the like. According to the technology, the cooling water is sprayed to absorb (NH4)2SO4 particles, SO2 and NH3 substances in the boiler flue gas, saturated steam in the boiler flue gas carries out dew formation to form water drops by taking the (NH4)2SO4 particles as cores, and the (NH4)2SO4 particles in the boiler flue gas are captured to inhibit formation of aerosol, so that the concentration of particulate matters in the boiler flue gas discharged by the ammonia desulphurization technology is lower than 30mg / m<3>.

Owner:JIANGSU HEYICHANG ENVIRONMENTAL PROTECTION ENG & TECH

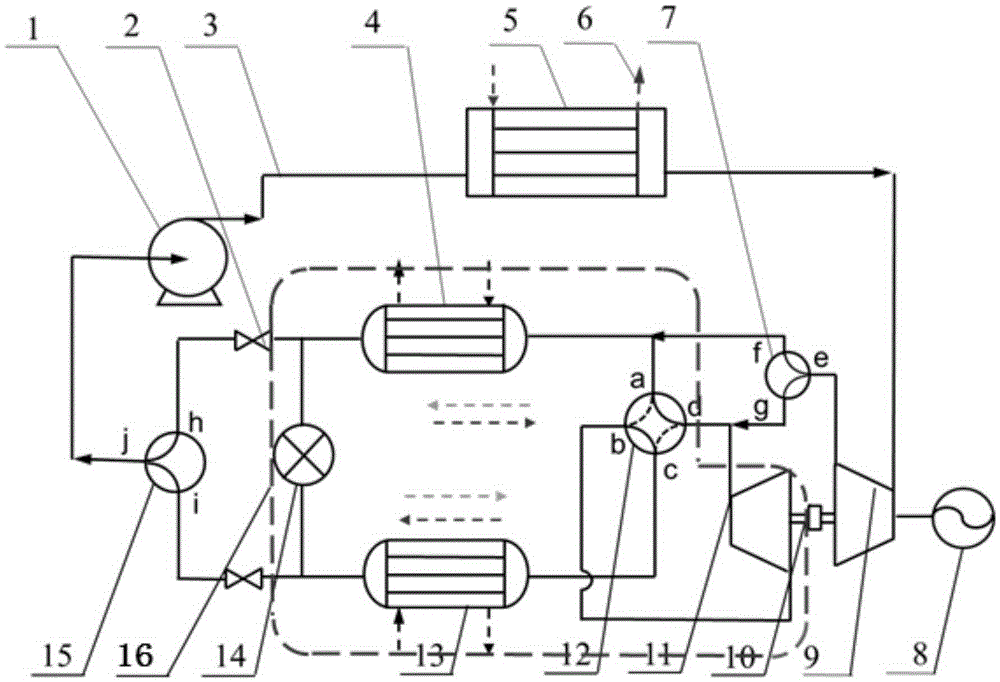

Combined cooling heating and power system driven by low-grade waste heat

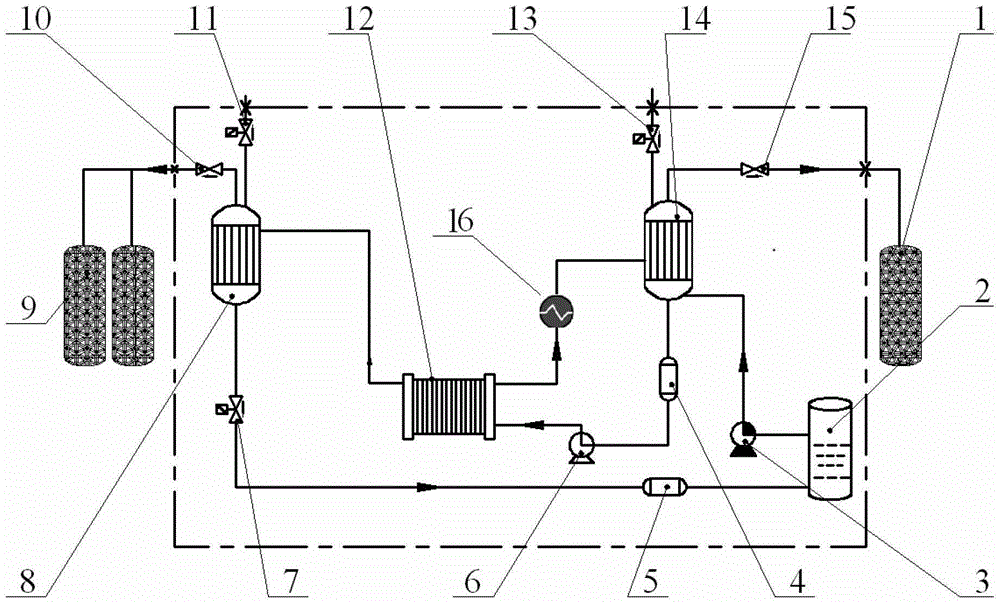

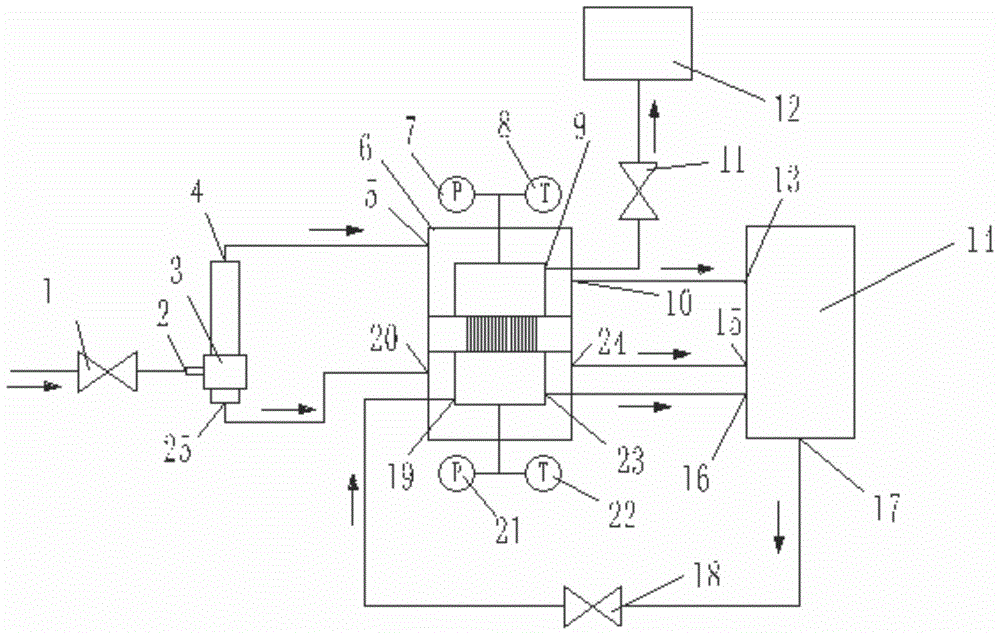

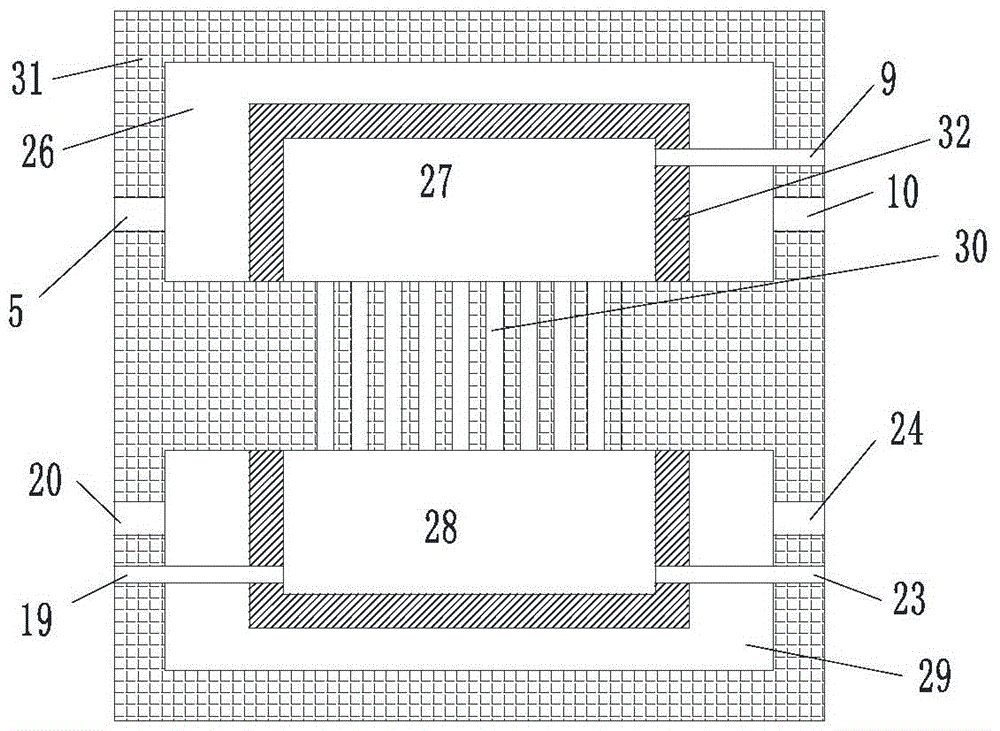

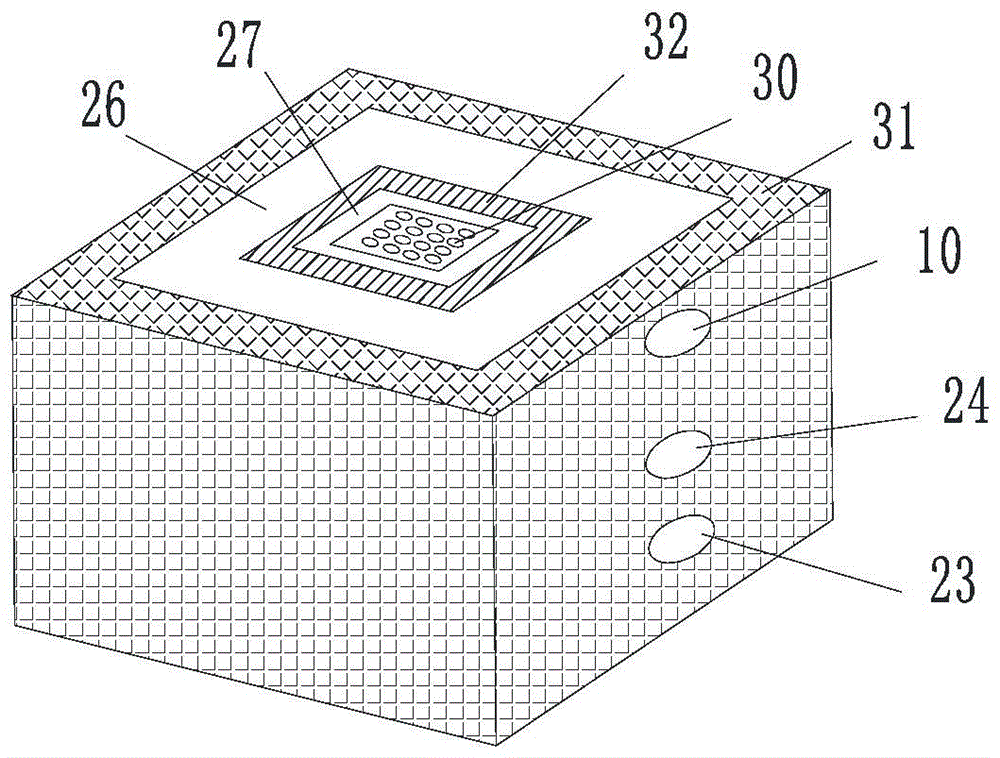

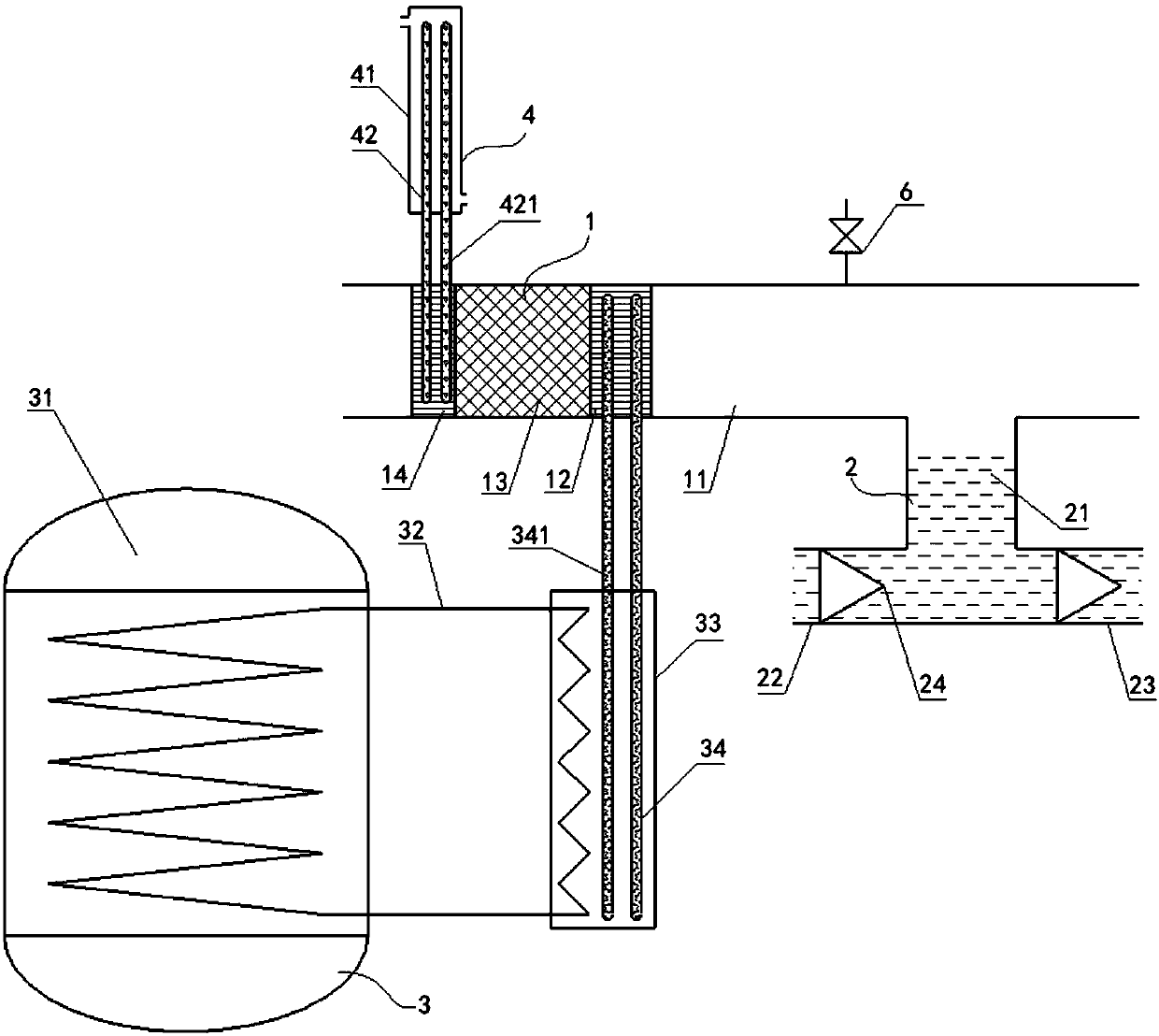

ActiveCN105258386AAvoid lossThe system process is simpleMechanical apparatusClimate change adaptationThermal energyOrganic Rankine cycle

The invention relates to a combined cooling heating and power system driven by low-grade waste heat. The combined cooling heating and power system comprises an organic Rankin cycle (ORC) unit. The ORC unit is composed of a working medium pump, an evaporator, an expander and a built-in heat pump cycle unit which are sequentially connected and form circulation. The built-in heat pump cycle unit comprises a first heat exchanger, a throttle valve, a second heat exchanger, a compressor and a four-way reversing valve. Heat exchange is conducted between the evaporator and the first heat exchanger in the built-in heat pump cycle unit. Heat exchange is conducted between the second heat exchanger and waste heat flow and between the second heat exchanger and externally-connected heat exchange flow. The output work end of the expander is connected with the compressor and the electric generator. When the combined cooling heating and power system is operated, work acted by the expander preferentially drives the compressor coaxially connected with the expander, so that output of cold energy or heat energy of the built-in heat pump cycle unit is achieved; the remaining work drives the electric generator to generate electricity; therefore combined cooling heating and power of the combined cooling heating and power system is achieved. Compared with the prior art, the combined cooling heating and power system has the advantages that the process is simple; the equipment parts are small in number; the use ratio of the waste heat energy is high; the cost of the devices of the combined cooling heating and power system is low, etc.

Owner:TONGJI UNIV

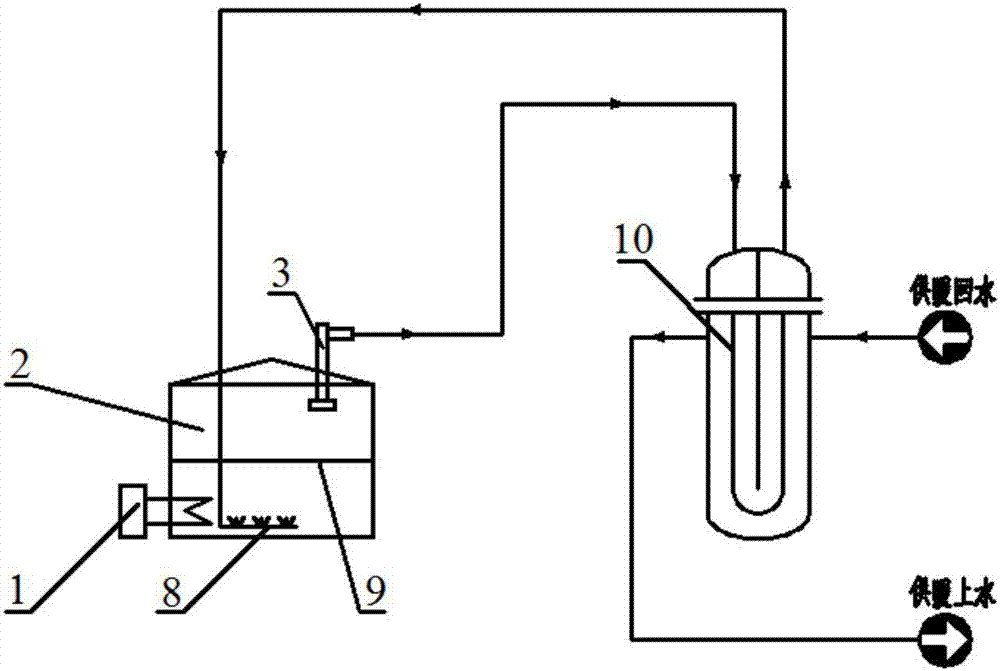

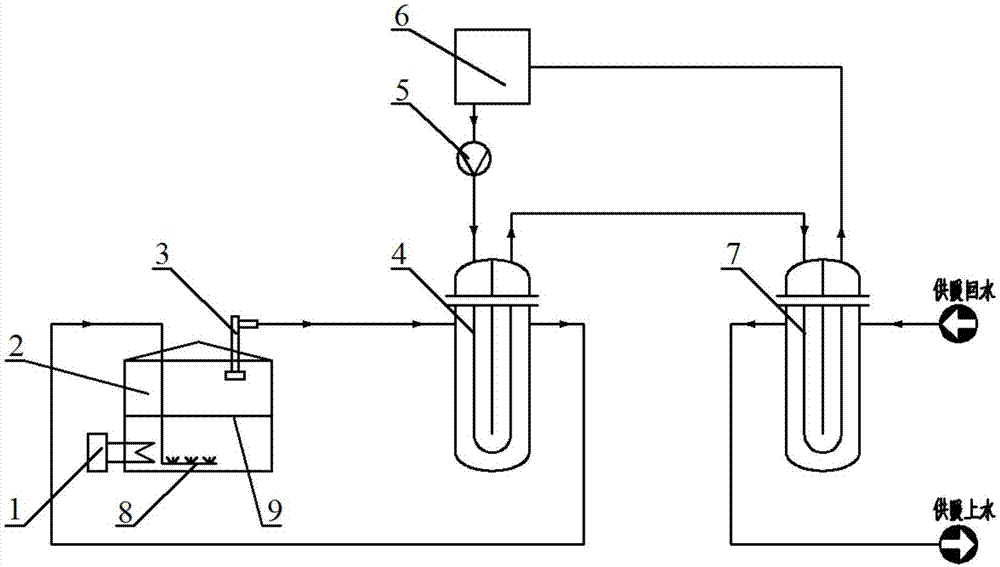

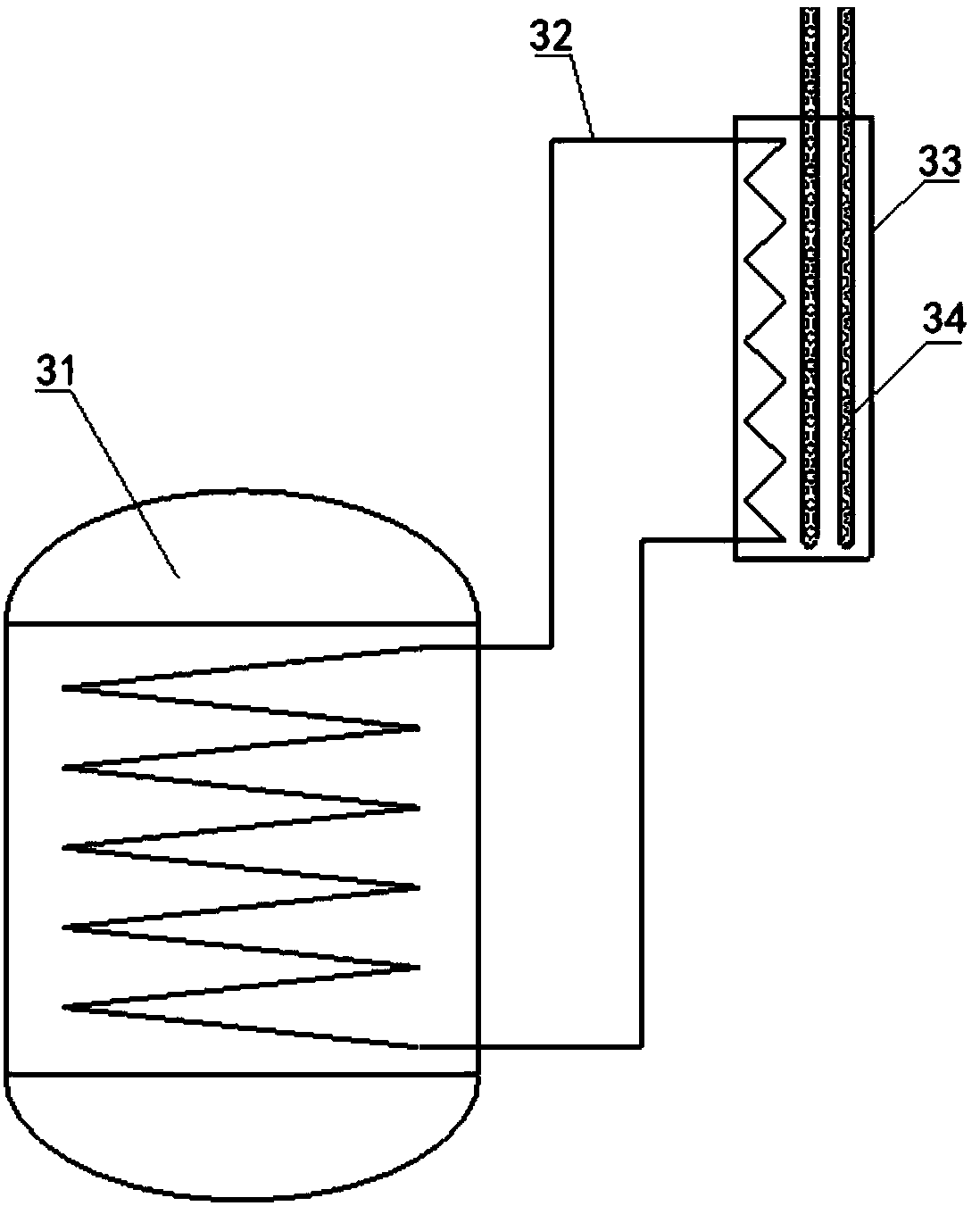

Fused salt heat storage heating system

InactiveCN107062371AStable temperatureSmall footprintLighting and heating apparatusCentral heating systemMolten saltEngineering

The invention provides a fused salt heat storage heating system. The fused salt heat storage heating system comprises a single fused salt tank. A pore plate used for separating low-temperature fused salt and high-temperature fused salt is arranged in the fused salt tank. The backflow low-temperature fused salt subjected to heat exchange is contained in the lower zone of the pore plate. By arranging the single fused salt tank and the pore plate, and through the characteristic that the density of fused salt is lowered with increase of the temperature, heat storage and heating are achieved; and compared with traditional fused salt heat storage heating systems, the investment cost is lowered, the system technological process is simplified, the equipment occupied size is reduced, and the fused salt outlet temperature is stable.

Owner:北京万机汇机电工程技术有限公司

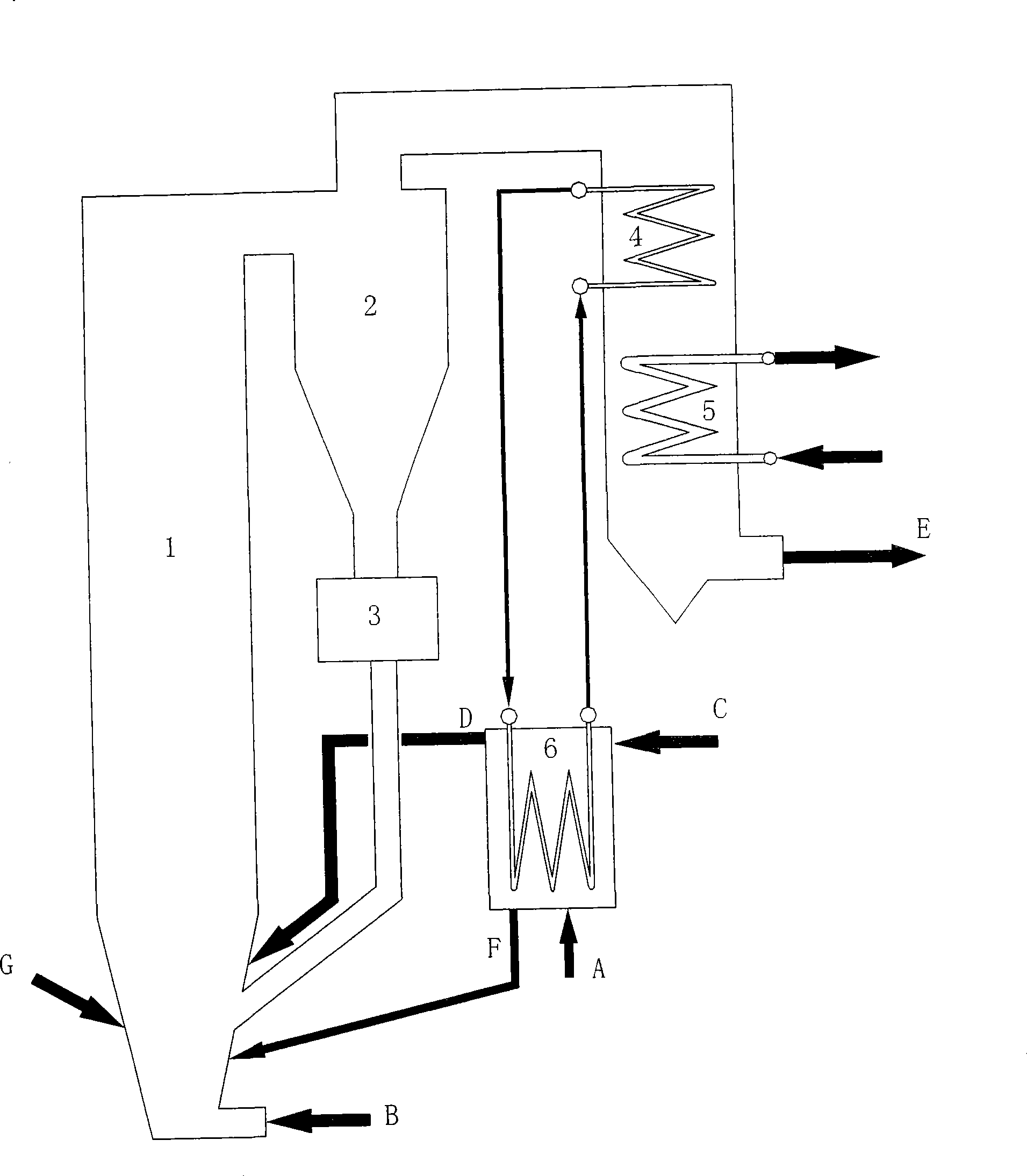

Wet sludge drying, incinerating and treating device

InactiveCN101387404ARealize deodorization and harmlessnessSuppress generationIncinerator apparatusAir preheaterFluidized bed

The invention discloses an incineration treatment device for wet sludge and relates to a technology for treating waste. The device comprises a circulating fluidized bed hearth, a separator, a feed returning device, a tail flue, a dust catcher and a chimney and also comprises a fluidized bed type sludge drier; the top of the sludge drier is provided with an exhaust gas outlet and a wet sludge inlet; the bottom of the sludge drier is provided with a wind distribution device and a dry sludge outlet; the inside of the sludge drier is provided with an exothermic pipe coil filled with a heat exchange medium; the tail flue is provided with an air preheater and a heat exchanger; the heat exchanger is communicated with the exothermic pipe coil in the sludge drier; the lower part of the sidewall of the circulating fluidized bed hearth is provided with a secondary wind port, a feed returning port and a dry sludge inlet; the dry sludge inlet is communicated with the dry sludge outlet of the sludge drier; and the secondary wind port is communicated with the exhaust gas outlet of the sludge drier. The device recycles heat of sludge incineration with a process as simple as possible, carries out incineration treatment to the wet sludge with low energy consumption and simultaneously has no harmlessness to gas deodorization.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

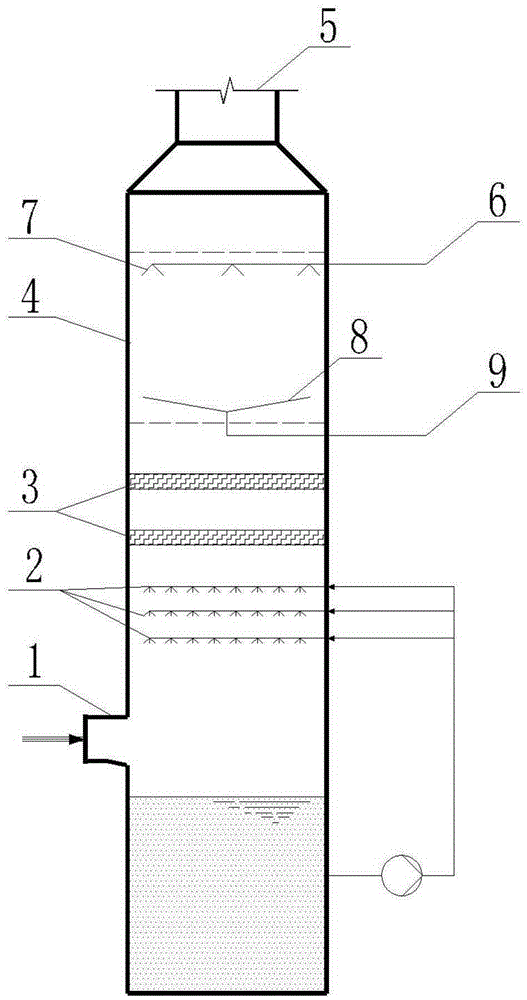

Wet flue gas desulfurization tower with deep dehumidification function and dehumidification process

ActiveCN105413430AIncrease superheatThe system process is simpleLighting and heating apparatusUsing liquid separation agentCorrosion preventionProcess engineering

The invention discloses a wet flue gas desulfurization tower with a deep dehumidification function and a dehumidification process. Desulfurization spraying layers, demisters and a dehumidifier are sequentially arranged in the desulfurization tower from the middle part to the upper part, wherein the dehumidifier comprises dehumidification nozzles and a liquid receiving device arranged below the dehumidification nozzles. The wet flue gas desulfurization tower has the benefits as follows: the wet flue gas desulfurization tower integrates functions of desulfurization, demisting and dehumidification, and flue gas discharged from the desulfurization tower is not saturated wet flue gas with 100% relative humidity, but unsaturated and wet flue gas with adjustable and controllable relative humidity; the dew point temperature of the flue gas is reduced, the temperature is increased, the superheat degree is improved, the phenomena of white smoke and stack rain formed due to flue gas condensation are fundamentally avoided, and expensive materials used for corrosion prevention of a chimney are not required; the system flow is simplified, the equipment function integration degree is high, and the device occupies little land.

Owner:SHANDONG UNIV

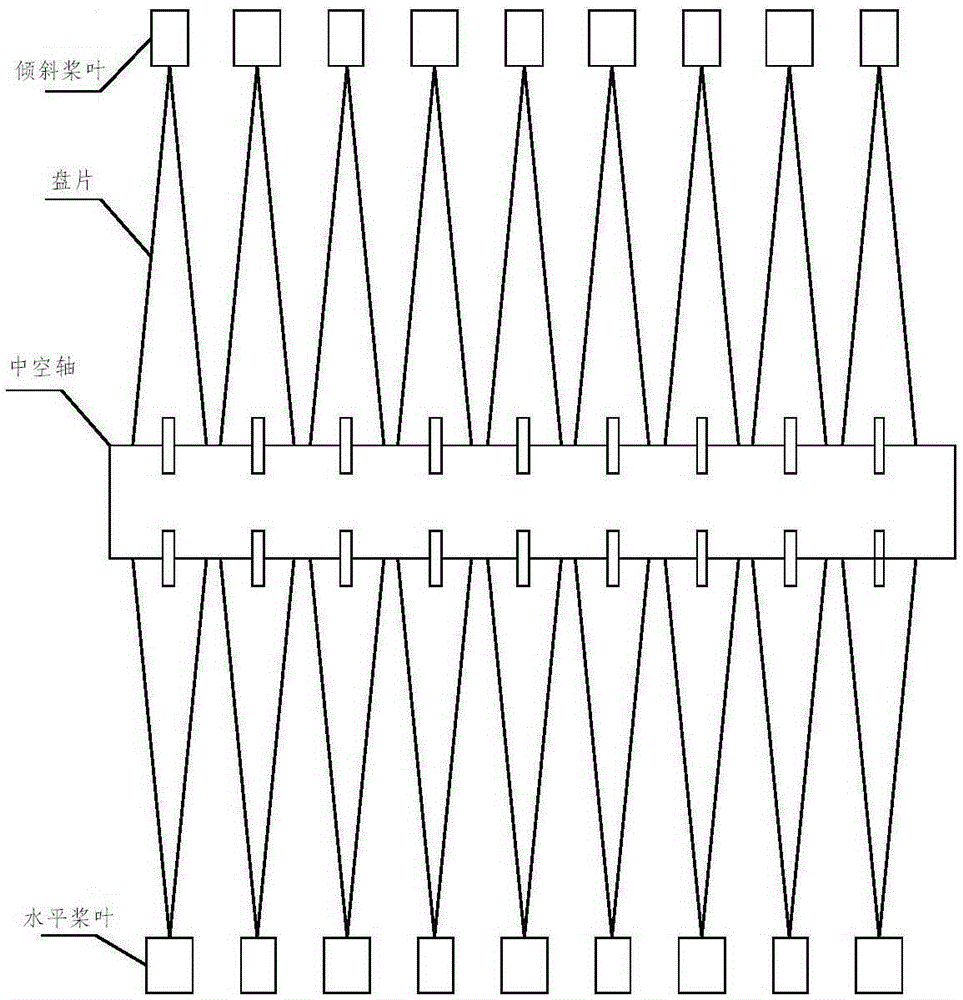

Dehydration and desiccation device and method for sewage sludge

InactiveCN105271629AKeep the environment hygienicHigh work pressureSludge treatment by de-watering/drying/thickeningSewageHigh pressure

The invention relates to a dehydration and desiccation device and method for sewage sludge. The device comprises a wet sewage sludge storage and delivery system, a sludge dehydration system and a sludge desiccation system which are communicated through closed type pipelines and used for delivering, storing and modifying sludge, dehydrating the sludge and desiccating the sludge into grains respectively, wherein the sludge dehydration system comprises high pressure elastic press filtering equipment at a minimum so that working pressure of a filter press can be raised; the sludge desiccation system comprises horizontal type disc desiccation equipment at a minimum so that the sludge obtained after modification and dehydration can be desiccated. The dehydration and desiccation device is applicable to treatment and disposal of sludge of different water contents, and the sludge from different sewage treatment plants can all be treatment through the process. The sludge is sent into a sludge bin in the mode of vehicle carrying and transportation and then delivered through a pump and the pipelines, environmental pollution caused by delivery of the sludge is not caused, and environmental sanitation is good.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +1

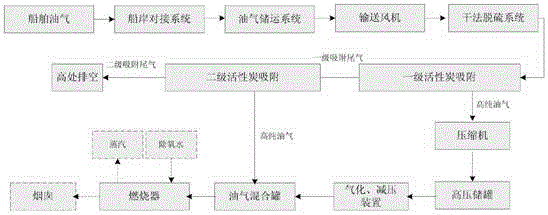

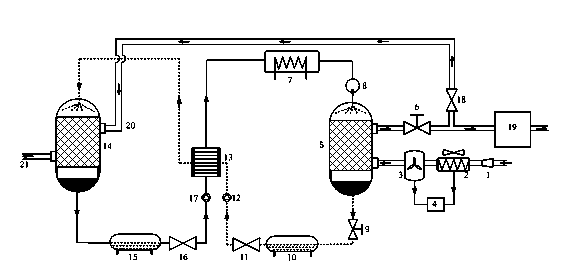

Crude oil shipping oil and gas recycling method

InactiveCN105289194ASolve processing problemsTo achieve the treatment effectCargo handling apparatusDispersed particle filtrationRecovery methodEconomic benefits

The invention aims at providing a crude oil shipping oil and gas recycling method which is applicable to crude oil shipping oil and gas recycling of large-size port wharfs so as to effectively treat environmental pollution caused by oil and gas emission of cabins during shipping to realize zero emission in wharf work, and is used for recycling and reutilizing original exhausted oil and gas to generate certain economic benefits. The crude oil shipping oil and gas recycling method comprises the following steps: connecting a gas conveying arm or a gas conveying hose of a ship and bank abutting joint system to a special oil and gas connector of an oil tanker, so as to lead out oil-and-gas-containing gas in the cabin of the oil tanker, wherein led-out oil and gas pass through an online monitoring system while being conveyed to an oil and gas recycling device; carrying out condensate removing treatment on the led-out oil-and-gas-containing gas in the cabin; and introducing the led-out oil-and-gas-containing gas to a desulfurization active carbon tank filled with desulfurization active carbon and carrying out desulfurization treatment on the oil and gas by virtue of the desulfurization active carbon.

Owner:SINOCHEM XINGZHONG OIL STAGING ZHOUSHAN

Dehumidification device and dehumidification method for normal-temperature regeneration pressurizing solution

InactiveCN103406002AReduce energy consumptionThe system process is simpleDispersed particle separationCorrosion preventionProcess engineering

The invention discloses a dehumidification device for a normal-temperature regeneration pressurizing solution. The dehumidification device comprises a compressed air dehumidification assembly and a pressurizing solution dehumidification and regeneration cycle assembly, wherein the compressed air dehumidification assembly comprises an air compressor, an air cooler, an air-water separator, an automatic water drainer, a dehumidifier and a first throttling valve; the pressurizing solution dehumidification and regeneration cycle assembly comprises the dehumidifier, a cooler, a pressurizing solution pump, a second throttling valve, a first liquid storage unit, a first regulating valve, a first anti-corrosion solution pump, a heat exchanger, a regenerator, a second liquid storage unit, a second regulating valve, a second anti-corrosion solution pump and a third regulating valve; the dehumidifier in the compressed air dehumidification assembly and the dehumidifier in the pressurizing solution dehumidification and regeneration cycle assembly are the same part. The dehumidification device is high in dehumidification efficiency and good in energy-saving effect. The invention also provides a dehumidification method corresponding to the dehumidification device. Compressed air is deeply dehumidified, the solution is regenerated by using part of deep dry air which is dehumidified and throttled to a normal pressure state, and the energy consumption is low.

Owner:SOUTHEAST UNIV

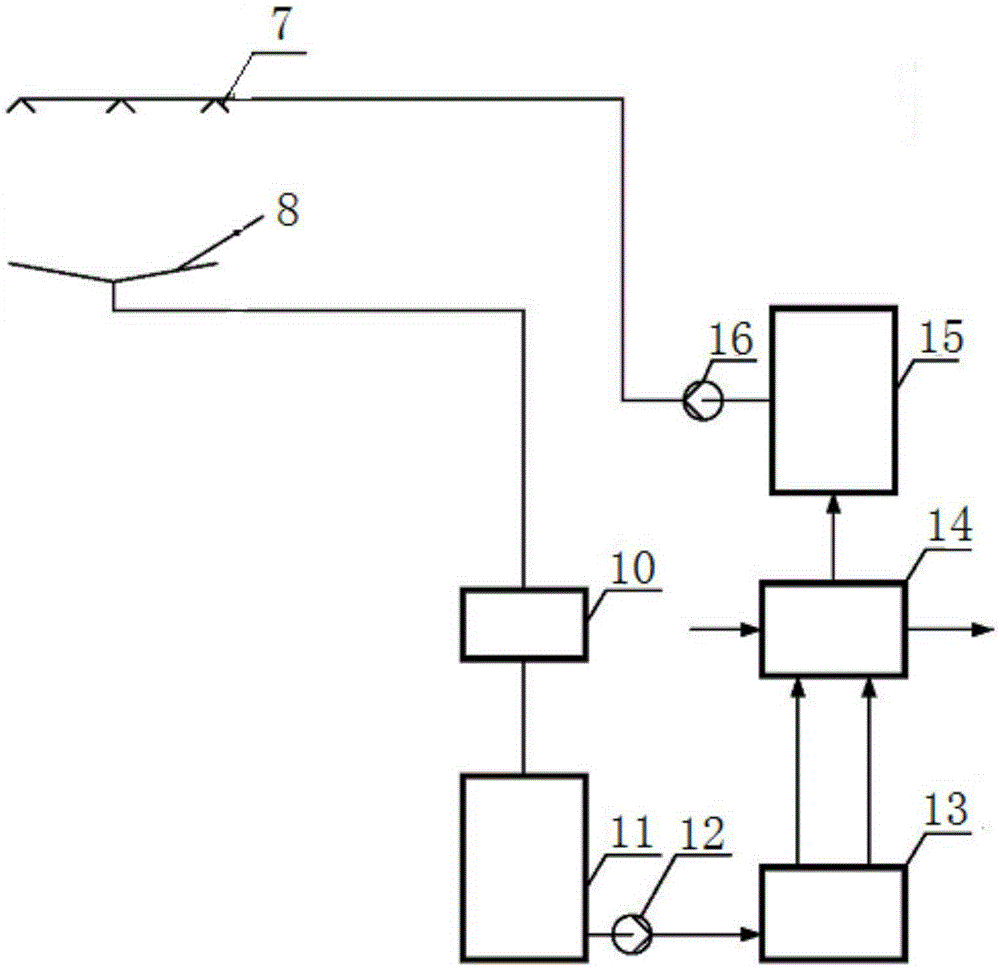

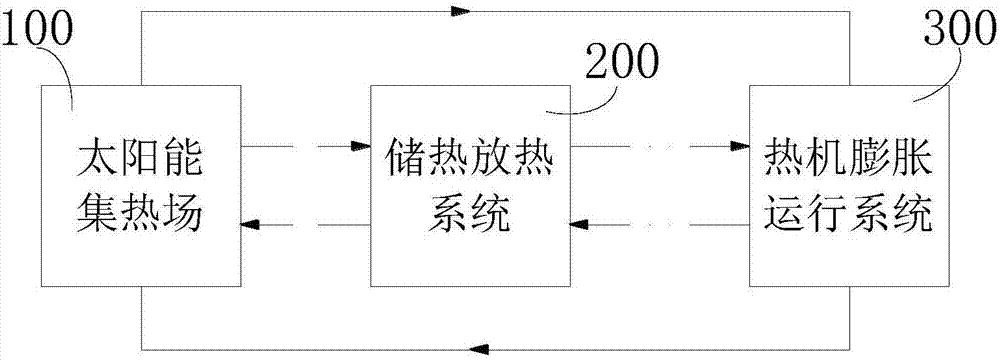

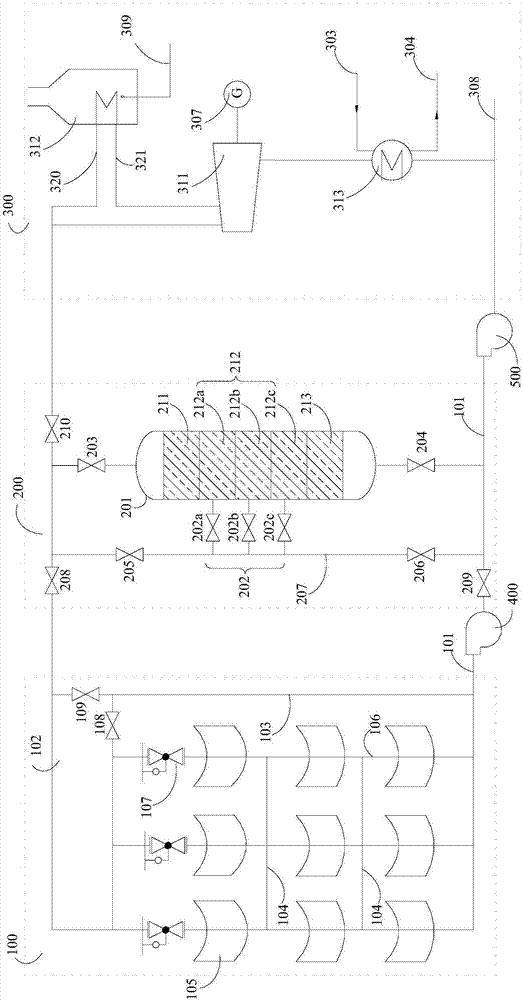

All-weather solar power generation method and system doing work based on heat engine expansion

InactiveCN107191342AImprove abilitiesImprove heat transfer efficiencyFrom solar energySolar heat devicesThermal energyEngineering

The invention discloses an all-weather solar power generation method and system doing work based on heat engine expansion. The system comprises a solar heat collecting yard, a heat storing and releasing system and a heat engine expansion running system; the solar heat collecting yard comprises a solar heat collector, a low temperature heat transfer medium mother pipe and a high temperature heat transfer medium mother pipe; the heat storing and releasing system and the heat engine expansion running system are connected between the low temperature heat transfer medium mother pipe and the high temperature heat transfer medium mother pipe in parallel; a top filler area, a middle filler area and a bottom filler area are arranged in a heat storing tank of the heat storing and releasing system; and the heat engine expansion running system comprises a heat expansion machine, a power generator and the like. The dual-loop system with heat transfer and heat storage separated is adopted for the method, heat transfer media are circulated in the solar heat collecting yard to absorb solar energy, exchange heat with energy storing media in the heat storing and releasing system to store or acquire heat energy, and do work through expansion to generate power in the heat engine expansion running system, meanwhile, gas media under pressure are adopted as the heat transfer media, and the heat storing and releasing effect and the power generating efficiency are improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

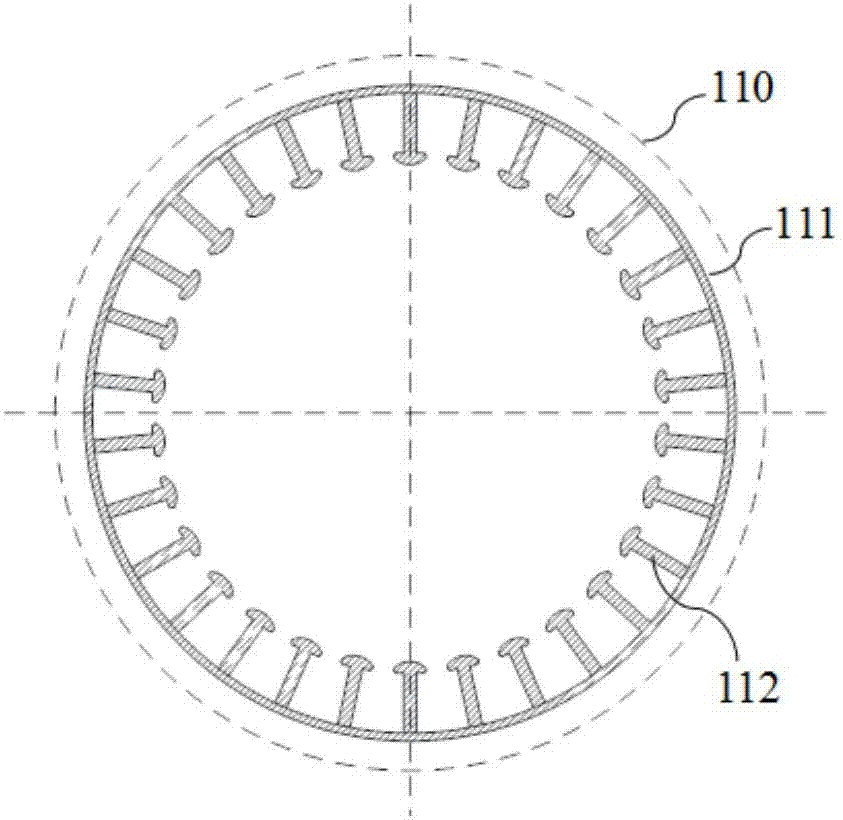

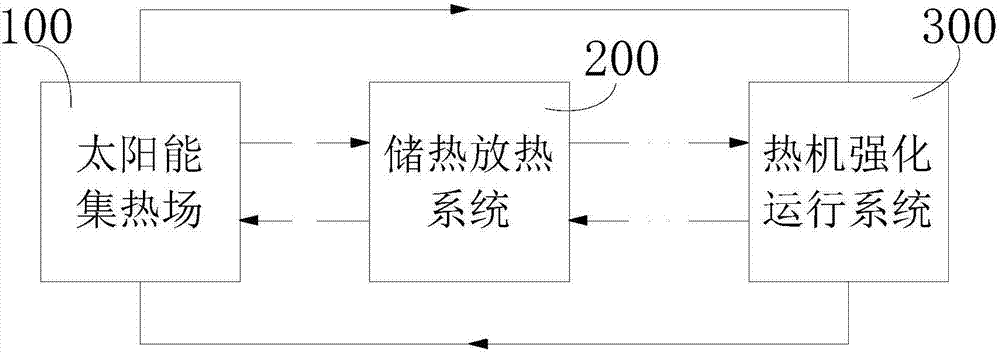

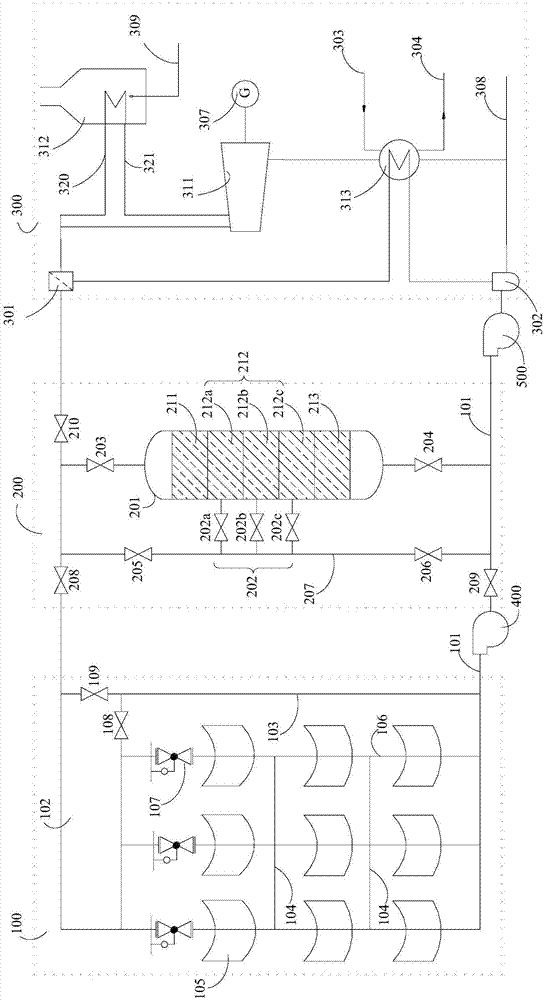

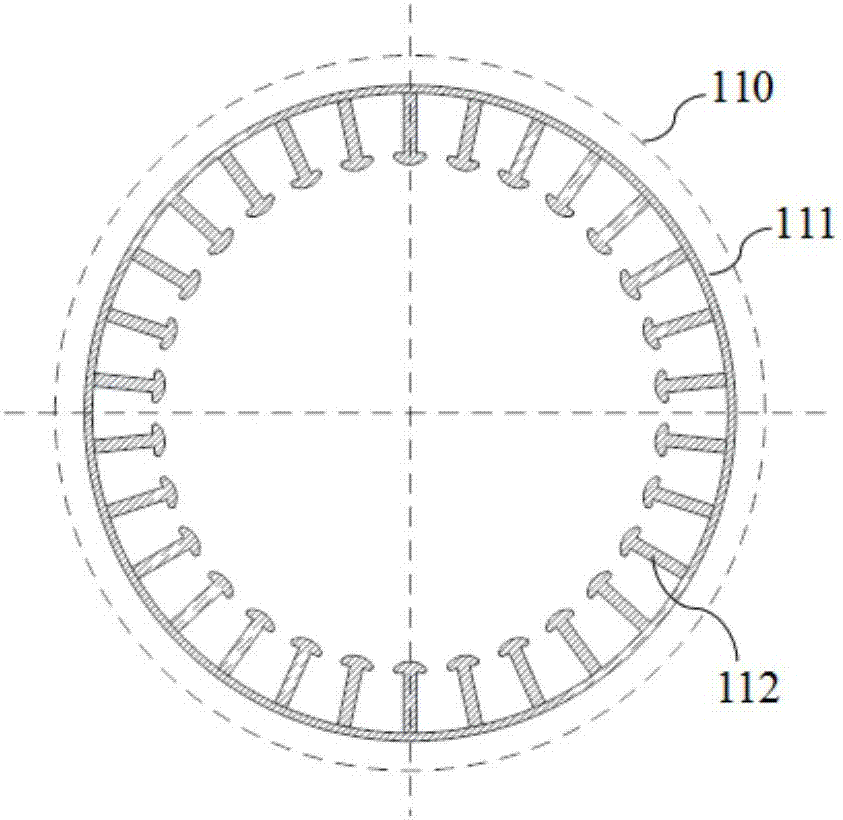

All-weather solar power generation method and system based on gas enhanced heat transfer

InactiveCN107191341AAchieve separationAchieve hybridFrom solar energySolar heat devicesThermal energyEnhanced heat transfer

The invention discloses an all-weather solar power generation method and system based on gas enhanced heat transfer. The system comprises a solar heat collecting field, a heat storage and release system and a heat engine enhanced operation system; the solar heat collecting field comprises a solar heat collector, a main low-temperature heat-transfer medium pipe, and a main high-temperature heat-transfer medium pipe; the heat storage and release system and the heat engine enhanced operation system are connected between the main low-temperature heat-transfer medium pipe and the main high-temperature heat-transfer medium pipe in parallel; a heat storage tank of the heat storage and release system is internally provided with a top packing area, a middle packing area and a bottom packing area; and the heat engine enhanced operation system comprises a heat expansion machine, a power generator and the like. According to the method, the double-loop system with heat transfer separated from heat storage is adopted, heat-transfer media absorb solar energy circularly in the solar heat collecting field and exchange heat with energy storage media in the heat storage and release system so that heat energy can be stored or obtained, meanwhile, gas mixed with solid particles is used as the heat-transfer media, does work through expansion in the heat engine enhanced operation system after being filtered so that power can be generated, and the heat transfer efficiency is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

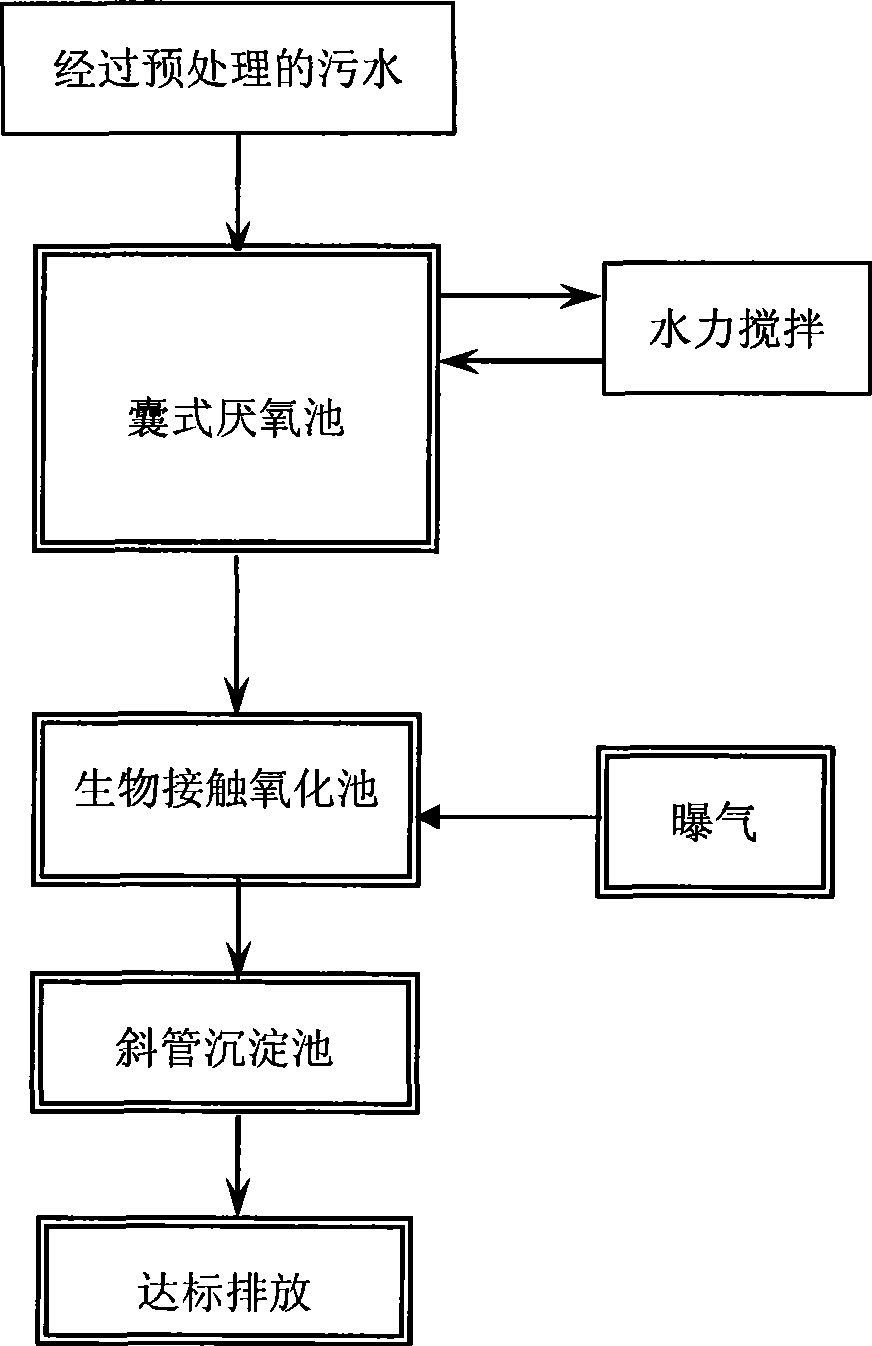

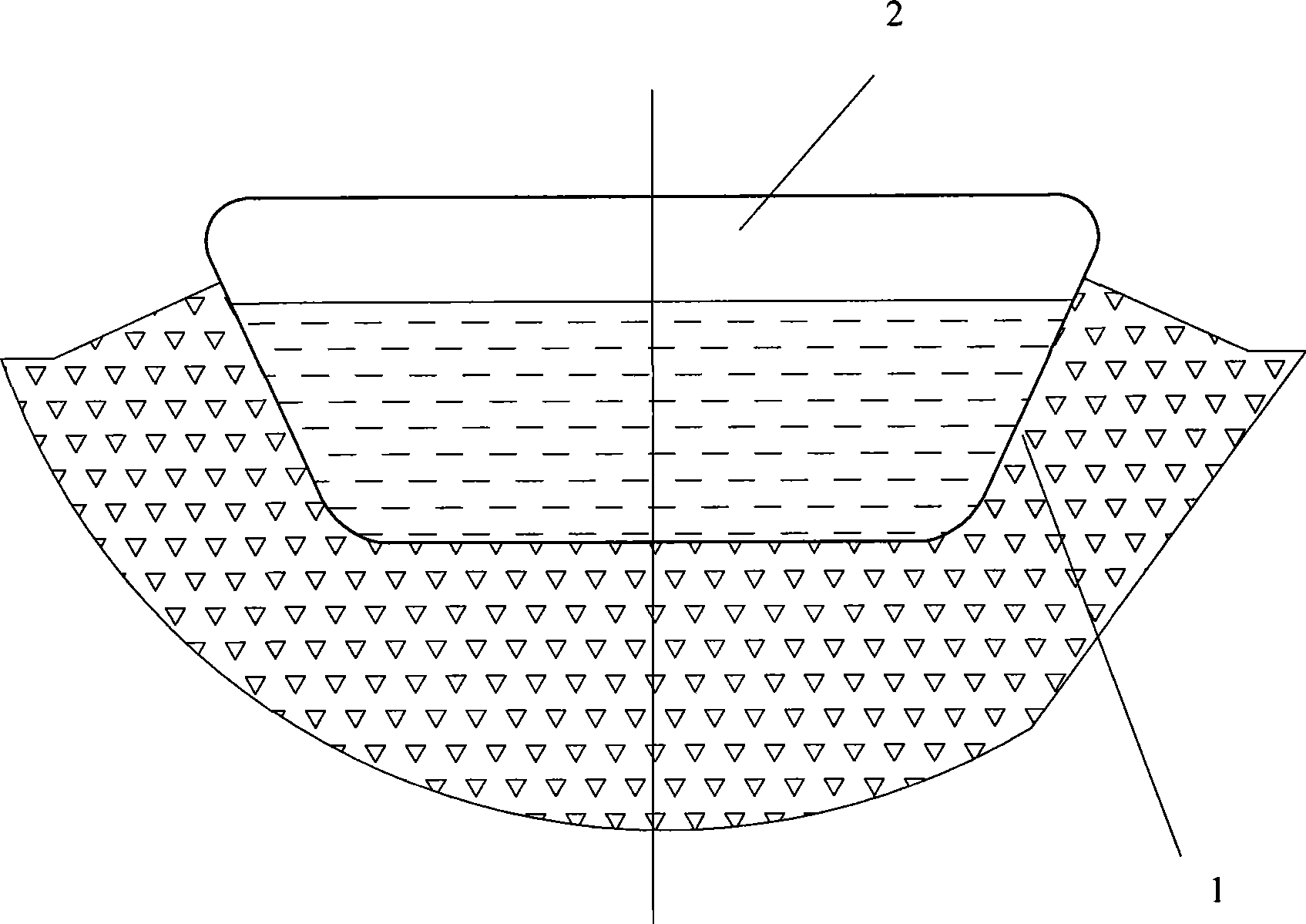

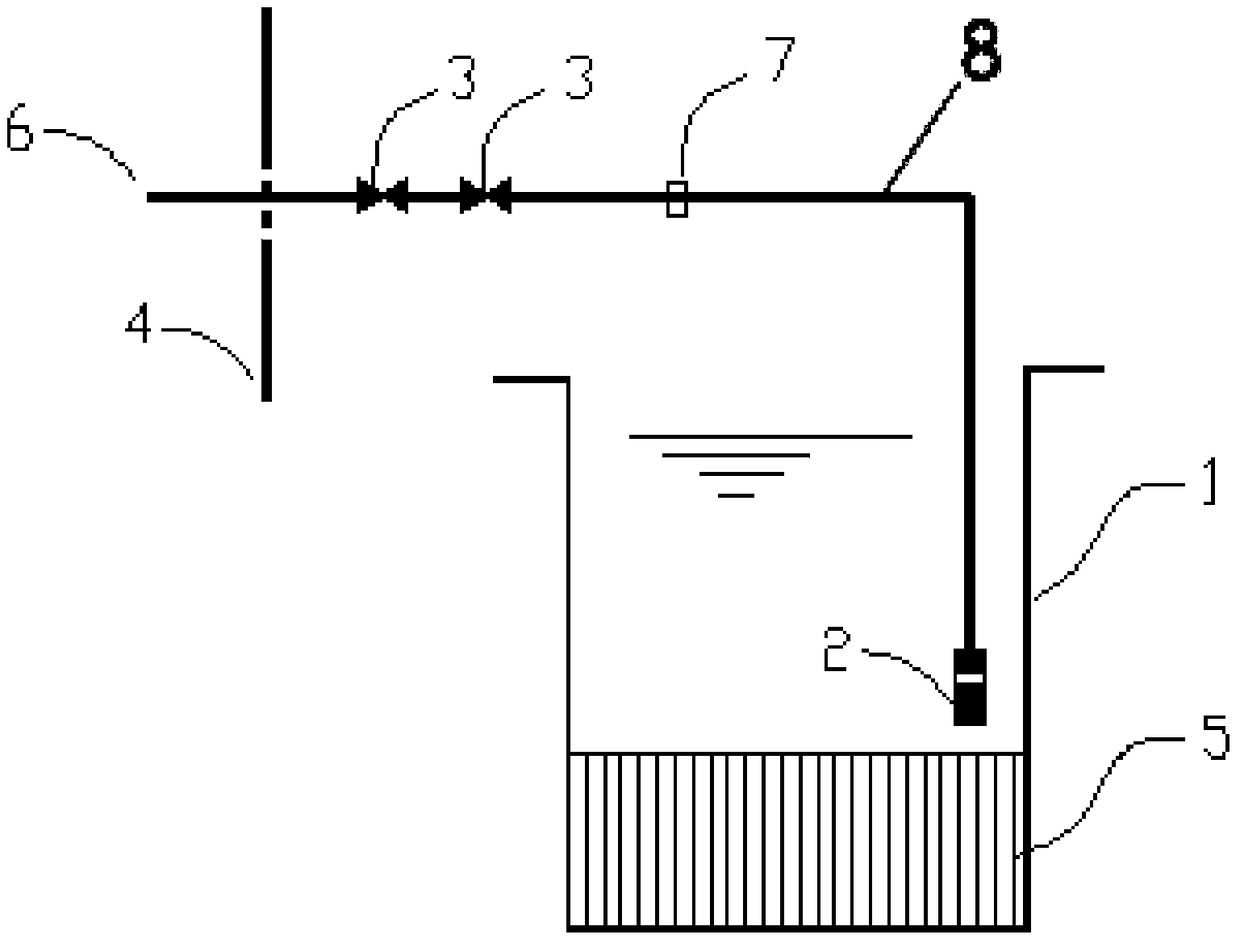

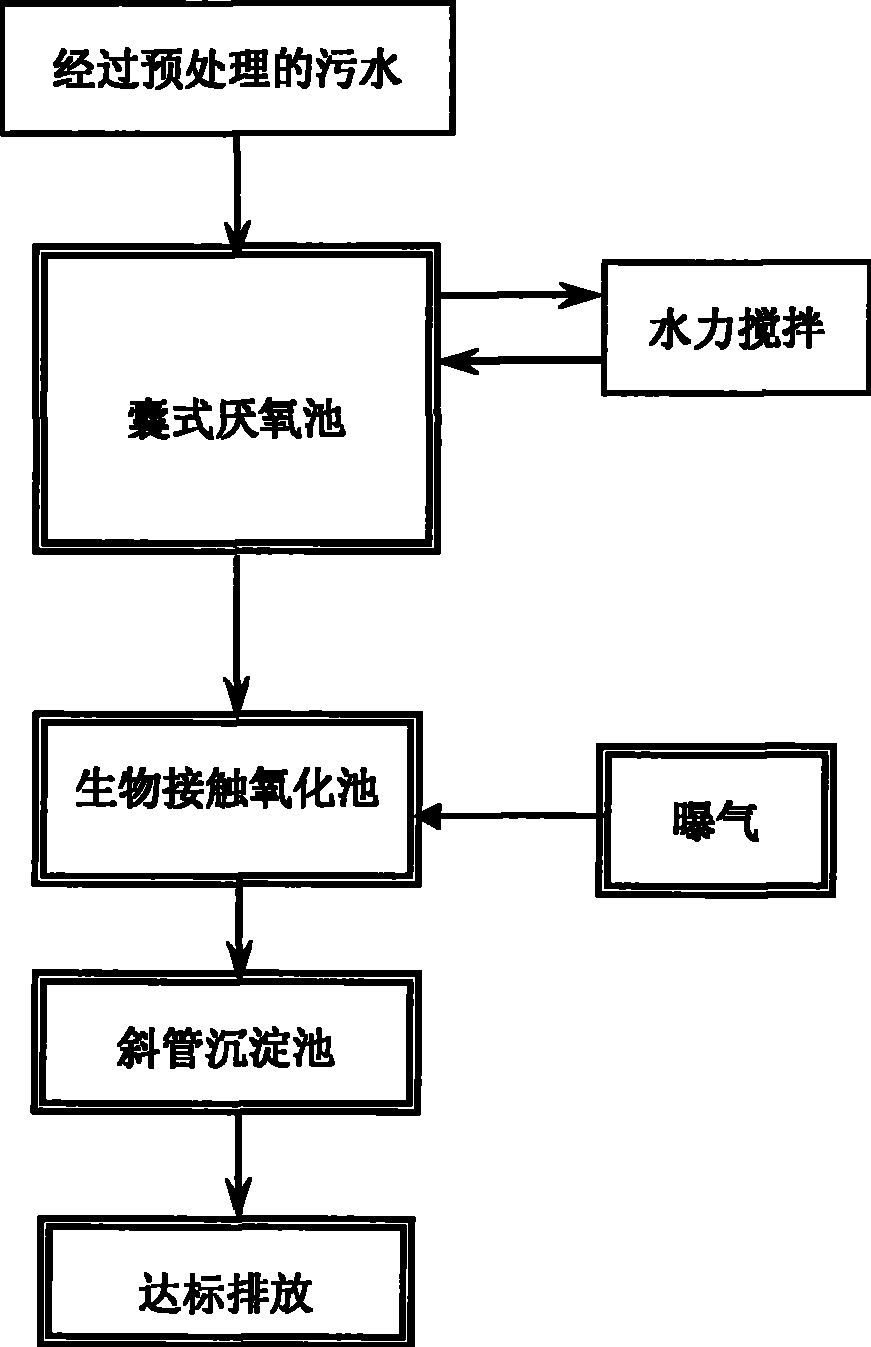

Industrial wastewater treatment method using bladder-type anaerobic pond

ActiveCN101381160ASingle pool volume is largeThe system process is simpleTreatment with aerobic and anaerobic processesHigh intensityPlastic film

The present invention discloses a method for disposing industrial sewage in a bag type anaerobic pool, and relates to a method for disposing industrial sewage. The method overcomes the drawback that the anaerobic pool used in the prior method costs a lot of labor and constructional material and is small in single pool volume by changing the structure of the anaerobic pool. The method comprises the following steps of a. pretreated sewage is discharged into the bag type anaerobic pool; after jet mixing, the sewage contacts and absorbs a returned sludge at an end of the bag type anaerobic pool for anaerobic reaction; the bag type anaerobic pool is a water bag made from a high strength HDPE plastic film, and acidogenic bacterium and methanogenic bacterium are accreted inside the water bag; b. an aerobic reaction of the sewage treated by the step a is carried out to further remove the surplus organic substance in the water, and gas is aerated into a biological contact oxidation pond by a blower; c. the sewage processed by the step b enters an inclined tube settling pond so as to separate sludge and water; d. the sewage processed by the step c is discharged.

Owner:哈尔滨北方环保工程有限公司

Containment filtration and exhaust system of nuclear power plant

PendingCN109147981AThe system process is simpleFlexible arrangementNuclear energy generationEmergency protection arrangementsIsolation valveFiltration

The invention provides a containment filtration and exhaust system of a nuclear power plant. The containment filtration and exhaust system comprises a spent fuel tank, a containment isolation valve, apipeline and an exhaust bubbler; a gas inlet of the pipeline penetrates into the containment of the nuclear power plant; an exhaust port of the pipeline is inserted into the spent fuel tank; the exhaust bubbler is arranged at the exhaust port of the pipeline; and the containment isolation valve is arranged on the pipeline and is used for opening or closing the pipeline. The system is simple in process and flexible in arrangement, and the existing spent fuel tank of the pressurized water reactor nuclear power plant is utilized, arrangement of a complicated special system or equipment is not needed, manufacturing cost is low, and operation is simple.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

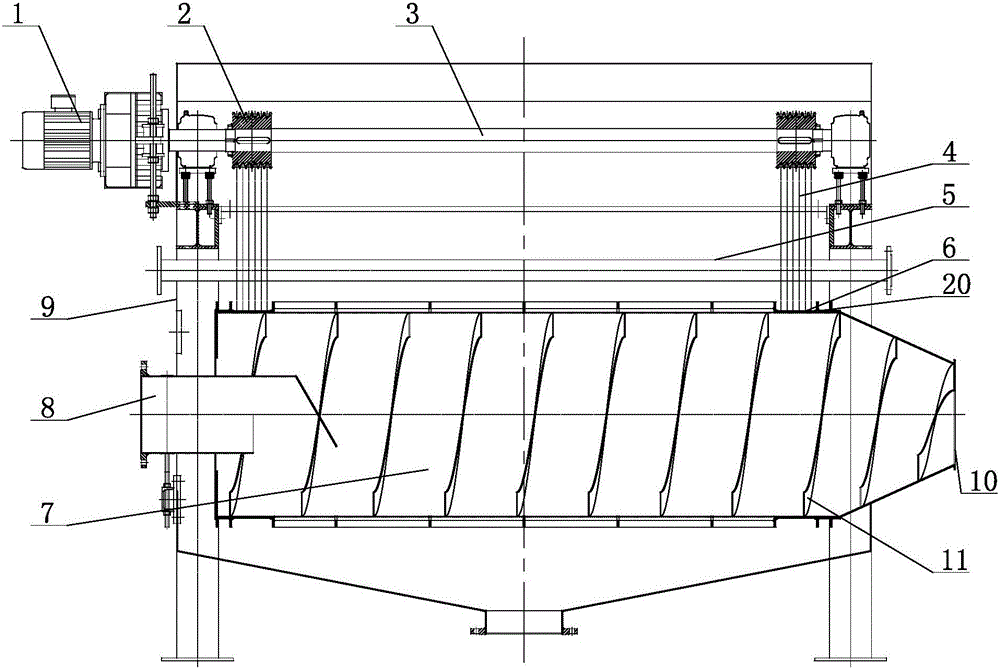

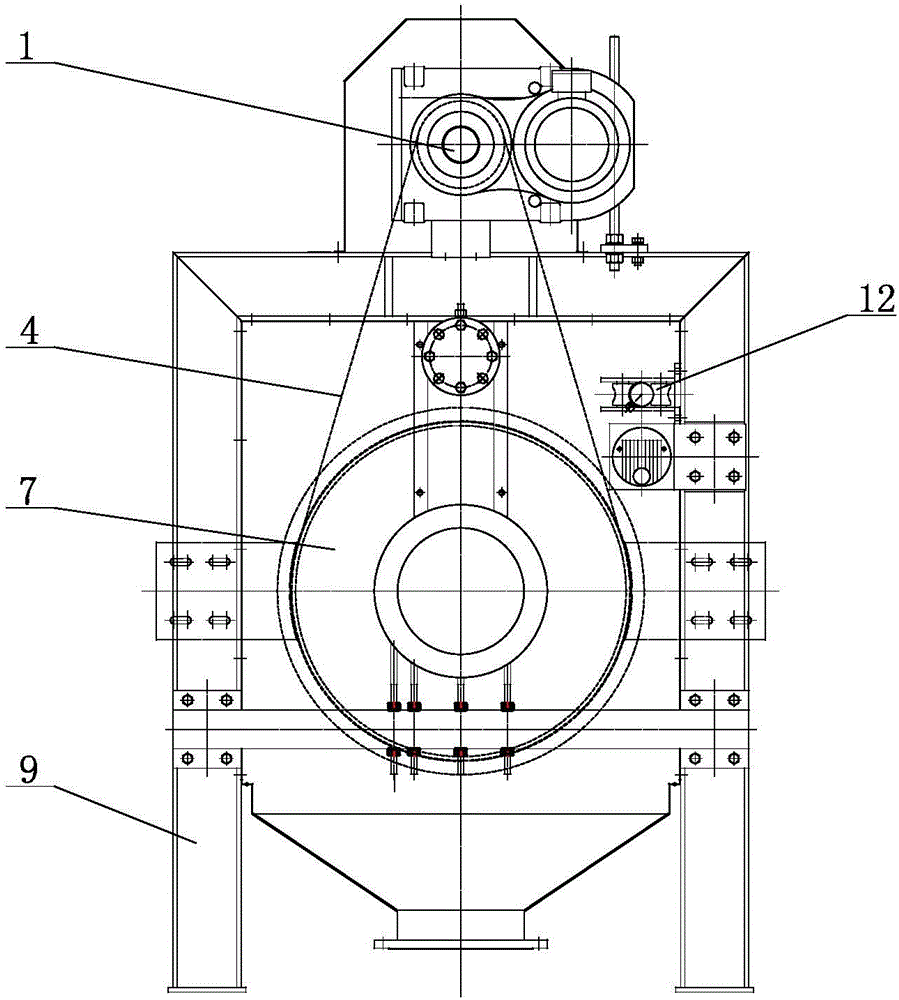

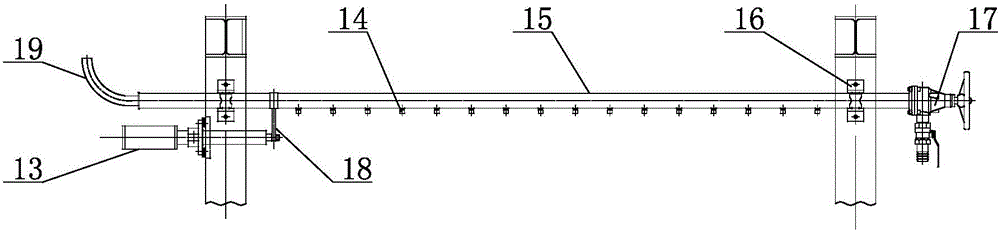

Drum-type pulp washer

ActiveCN106731153AHigh recovery rateSimple structurePaper material treatmentMoving filtering element filtersIndustrial waste waterDrive motor

The invention relates to a drum-type pulp washer. The drum-type pulp washer is used for earlier stage slagging separation of pulping equipment, the interception and transportation of the municipal industrial waste water garbage, or other general suspension-containing water treatment and purification. The drum-type pulp washer comprises a screen cylinder, the screen cylinder is installed on a frame, a dilution water pipe is arranged above the screen cylinder, a main shaft transmission device is arranged above the dilution water pipe, the main shaft transmission device comprises a driving motor and a main shaft, the output end of the driving motor is connected to the main shaft, two ends of the main shaft are provided with driving belt wheels, driving belt installation grooves are arranged at the outer side of the screen cylinder corresponding to the driving belt wheels, the driving belt wheels are connected to the driving belt installation grooves through driving belts, the dilution water pipe and the main shaft transmission device are installed on the frame, and one side above the screen cylinder is provided with a mobile cleaning device. Compared with the existing advanced tailings treatment device such as a pressure-type tailings sieve, the drum-type pulp washer greatly simplifies a system process and reduces power consumption. Compared with the vibrating frame flat screen, the drum-type pulp washer can greatly improve the sorting efficiency and optimize the operating environment.

Owner:SHANDONG CHENZHONG MACHINERY

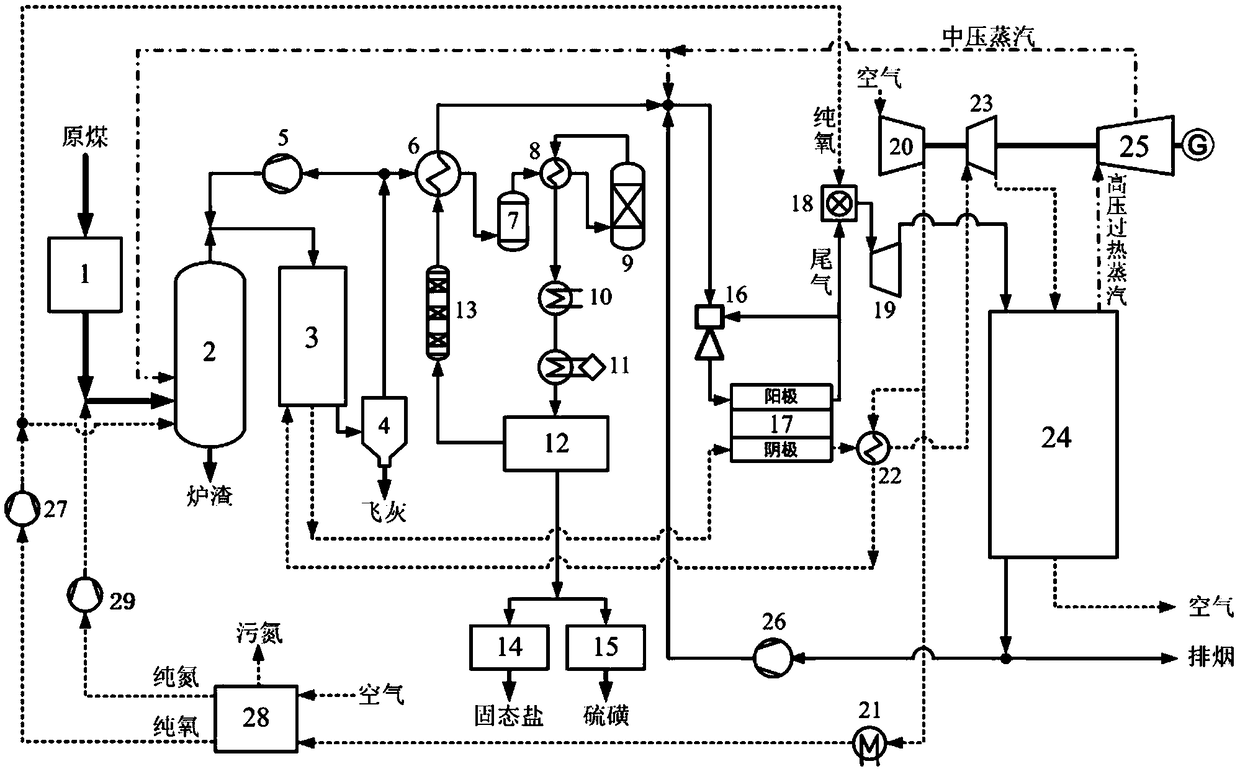

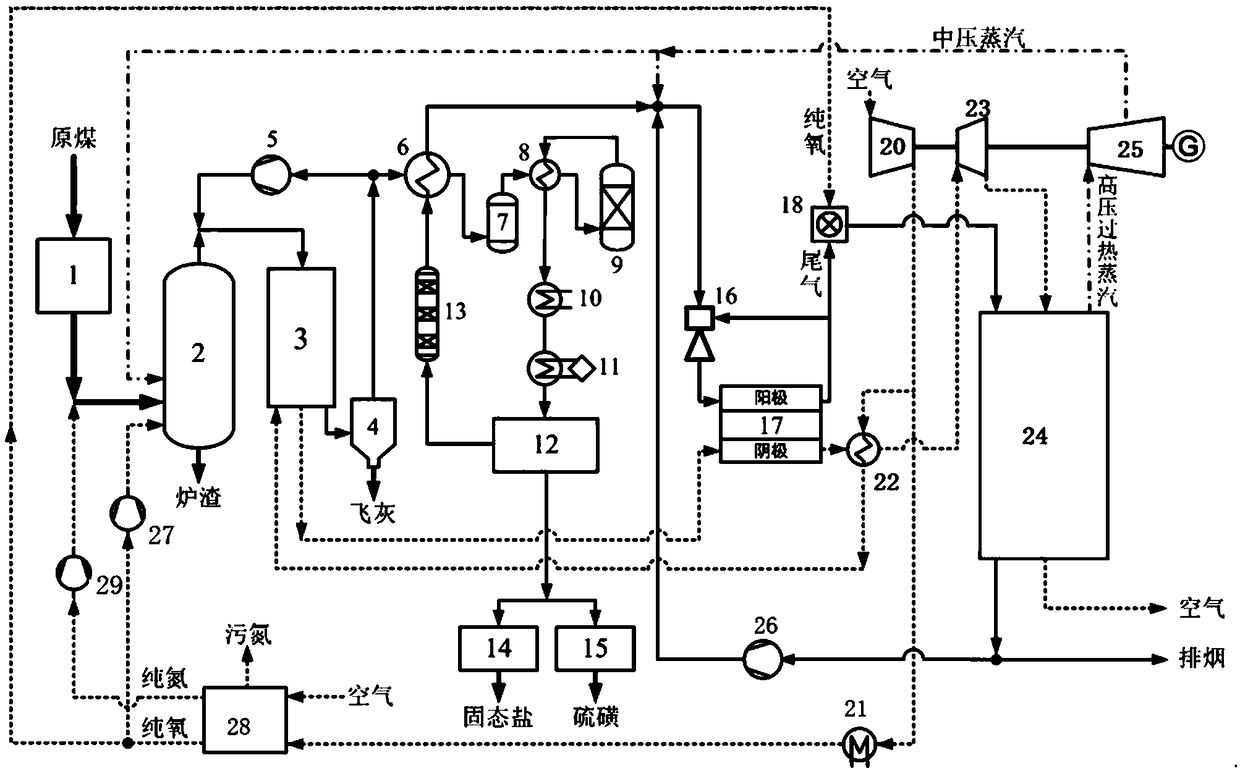

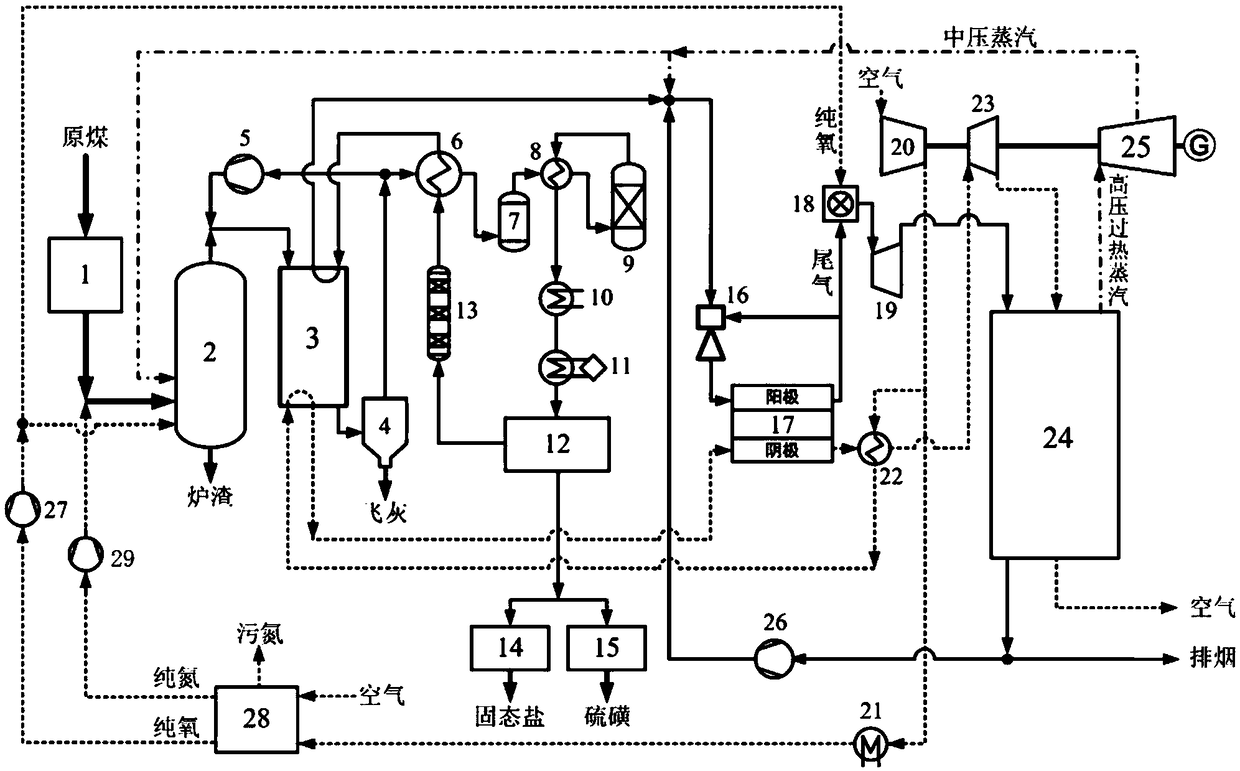

An integrated coal gasification fuel cell power generation system and method utilizing high temperature sensible heat of coal gas

ActiveCN109148919AAvoid high temperature sensible heat conversionImprove net power generation efficiencyFuel cell heat exchangeSteam useEngineeringStart up

The invention discloses an integrated coal gasification fuel cell power generation system and method utilizing high-temperature sensible heat of coal gas, which comprises a waste heat boiler, an ejector, a fuel cell and a cathode regenerator. As that high temperature sensible heat of the gas is utilize to directly heat the cathode air, the fuel gas needed for maintain the operating temperature inthe fuel cell is saved, the high temperature sensible heat of the gas is avoided to be converted into steam, the steam turbine generate electricity, and the net power generation efficiency of the system is improved; Cathode air is directly heated by high temperature sensible heat of coal gas, which reduces the volume of cathode regenerator, avoids the correlation between gas cooling process and steam power generation process, simplifies the system flow, and is easy to realize the sequential start-up of the system. The invention effectively improves the net power generation efficiency of the IGFC under the premise of ensuring the reasonable cost of the equipment, and solves the problems existing in the prior art.

Owner:HUANENG CLEAN ENERGY RES INST

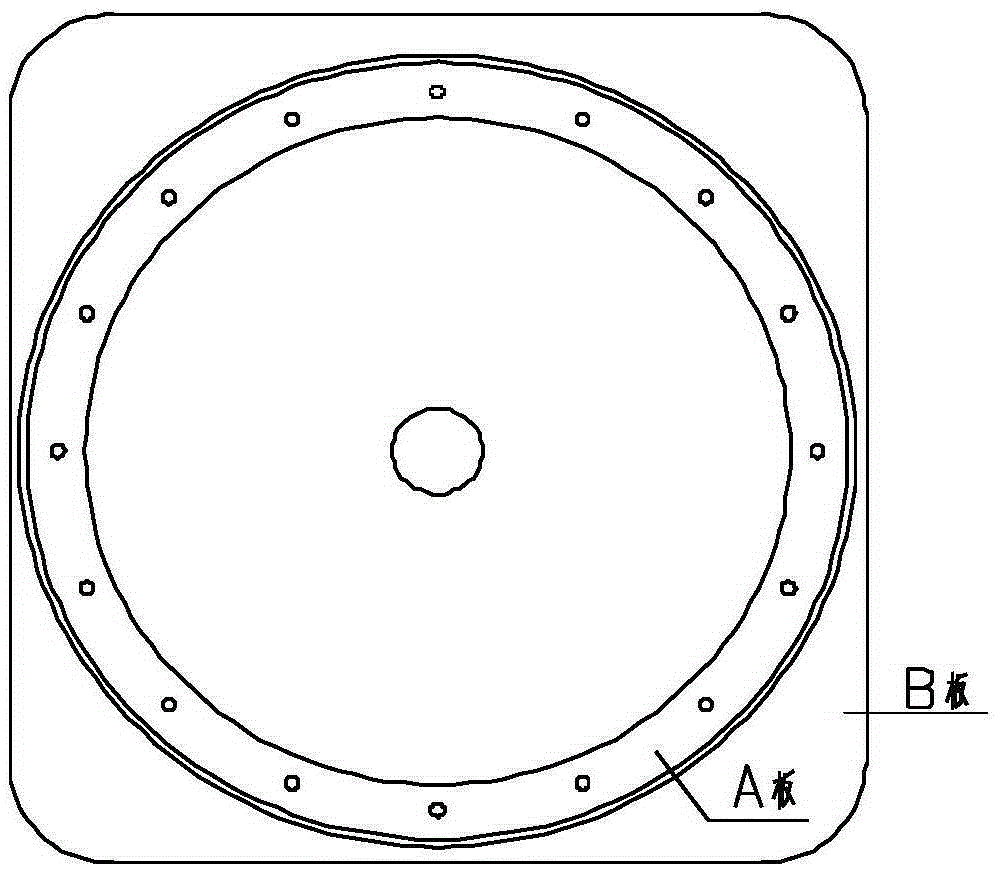

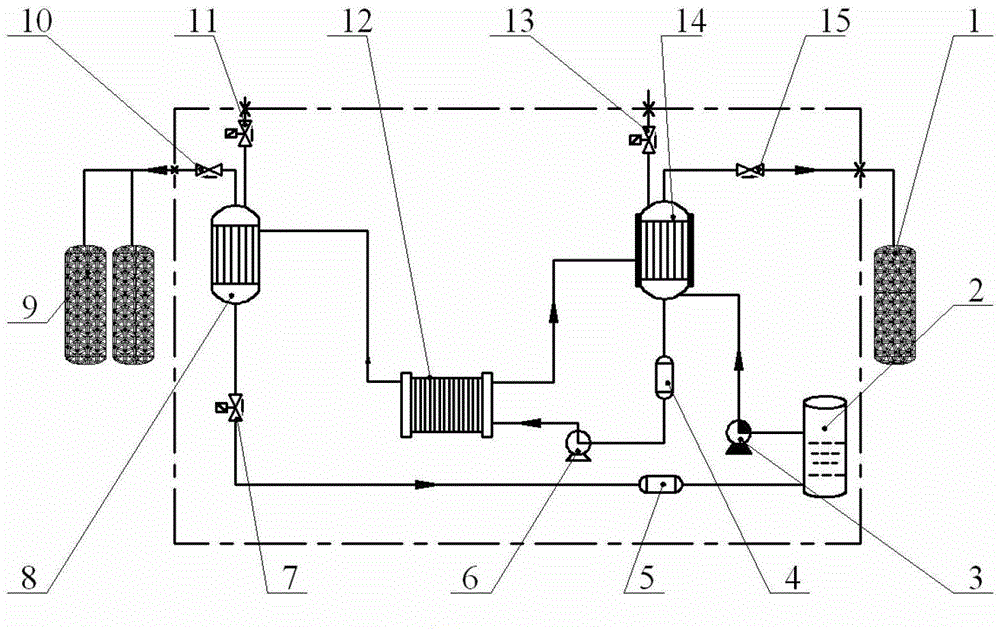

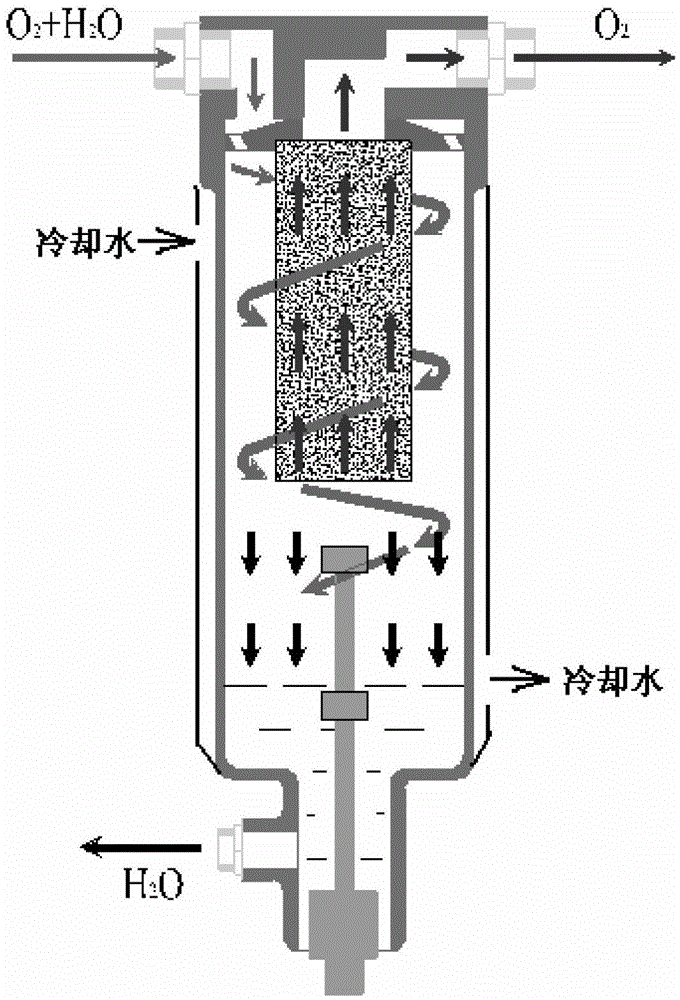

A medium and high pressure solid polymer water electrolysis device

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A Gas Separation System Based on Micro/Nano-Scale Thermal Escape Effect and Macroscopic Eddy Cool-Heat Effect

ActiveCN104587790BEasy to adjustReduce energy consumptionDispersed particle separationThermal transpirationThermodynamics

The invention discloses a gas separating system based on a micro / nanoscale thermal transpiration effect and a macroscopic eddy current cold and hot effect. The system comprises a flow rate regulating valve, an eddy current pipe, a thermal transpiration type gas separating device, a gas collecting tank, a first pressure regulating valve, a gas mixing tank, a second pressure regulating valve and the like. Compared with the prior art, the gas separating system has the advantages that firstly, a liquid absorbent regeneration system is not required, a solid absorbent regeneration system is also not required, and the gas separating system is low in energy consumption, is simple in system process, and can run continuously; secondly, multiple gas products can be obtained by adjusting the running condition; the gas separating system is low in cost, is rapid to start, and is easy to operate and regulate.

Owner:GUANGXI UNIV

PC decarbonization process PC liquid pressure energy recovery method and device

InactiveCN106016854AEfficient recyclingCooling balanceMechanical apparatusDomestic cooling apparatusRecovery methodRefrigeration compressor

The invention provides a PC decarbonization process PC liquid pressure energy recovery method and device. The method comprises the steps of depressurization and cooling. The device comprises a decarbonization tower, a flashing tower and a turbine driven refrigeration compressor. The turbine driven refrigeration compressor comprises a turbine and a refrigeration compressor body driven by the turbine. The decarbonization tower communicates with the flashing tower through the turbine driven refrigeration compressor. The flashing tower communicates with a water cooler through a decarbonization pump. The water cooler communicates with an evaporator. The evaporator communicates with the decarbonization tower. The refrigeration compressor body of the turbine driven refrigeration compressor communicates with the decarbonization pump. The decarbonization pump communicates with the flashing tower. The decarbonization pump communicates with the flashing tower. The turbine driven refrigeration compressor, a condenser and the evaporator communicate in sequence to form a cooling loop. The PC decarbonization process PC liquid pressure energy recovery method and device have the advantages that the temperature of PC working fluid is lowered, so that gasification loss is reduced in the washing and regeneration process of PC; and no external energy supplements are needed.

Owner:HUBEI SANNING CHEM

Gas boiler smoke discharge device and process

PendingCN110115916AIncrease humidityEasy to controlCombination devicesGas treatmentEngineeringSmall footprint

The invention discloses a gas boiler smoke discharge device and process. The process includes the following steps of spraying ammonium hydroxide for denitration, redoxing pollutants through low-temperature plasma reaction, spraying dry powder for deacidification, conducting dry-type electrostatic dust removal to remove dust particles and solid salt type particles in smoke, conducting cloth bag dust removal to obtain super-clean smoke, and discharging the super-clean smoke through a chimney. The synergistic, efficient and deep removal of various pollutants (NOX, SOX and dust) in gas boiler smoke of a steel plant can be realized, the discharge of the dust, NOX and SOX can be well controlled, and the super-low discharge of the gas boiler smoke of the steel plant is realized, wherein NOX is smaller than 50 mg / Nm3, SOX is smaller than 35 mg / Nm3, and dust is smaller than 5 mg / Nm3. Meanwhile, the integrated device with the combined optimization design of channel processing, ammonia spraying,plasma reacting, dry powder spraying, electrostatic dust removing and cloth bag dust removing has the advantages of being compact in structure, simple in system process, low in operation cost, small in occupied area and the like.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

Ship propulsion system

ActiveCN110341924AReduce noiseImprove stealth performancePropulsion power plantsMachines/enginesThermal energyWater flow

The invention relates to the technical field of ship power, in particular to a ship propulsion system. The ship propulsion system comprises a thermoacoustic engine, a propulsion device, a heating device and a cooling device; the thermoacoustic engine comprises an acoustic pipe and a heater, a heat regenerator and a heat exchanger, wherein the heater, the heat regenerator and the heat exchanger areconnected and arranged in the acoustic pipe in sequence; the heating device is connected with the heater; the cooling device is connected with the heat exchanger; the propulsion device comprises a branch pipe; the branch pipe comprises a horizontal pipe and a vertical pipe communicating with each other; the vertical pipe and the acoustic pipe vertically communicate with each other; the water surface in the branch pipe is positioned in the vertical pipe; one end of the horizontal pipe is a water inlet; the other end of the horizontal pipe of the branch pipe is a water outlet; the water inlet faces towards a bow of a ship; and the water outlet faces towards a stern. According to the ship propulsion system, by using a heat source to drive the thermoacoustic engine, the thermoacoustic engineconverts heat energy into mechanical energy in the form of acoustic waves; through the propulsion device, the acoustic waves suck water flow from the bow direction of the ship and spray the water flowfrom the stern direction so as to push the ship to advance; and therefore, problems of multiple power conversion links and low efficiency on the current ship are solved; and noises are reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

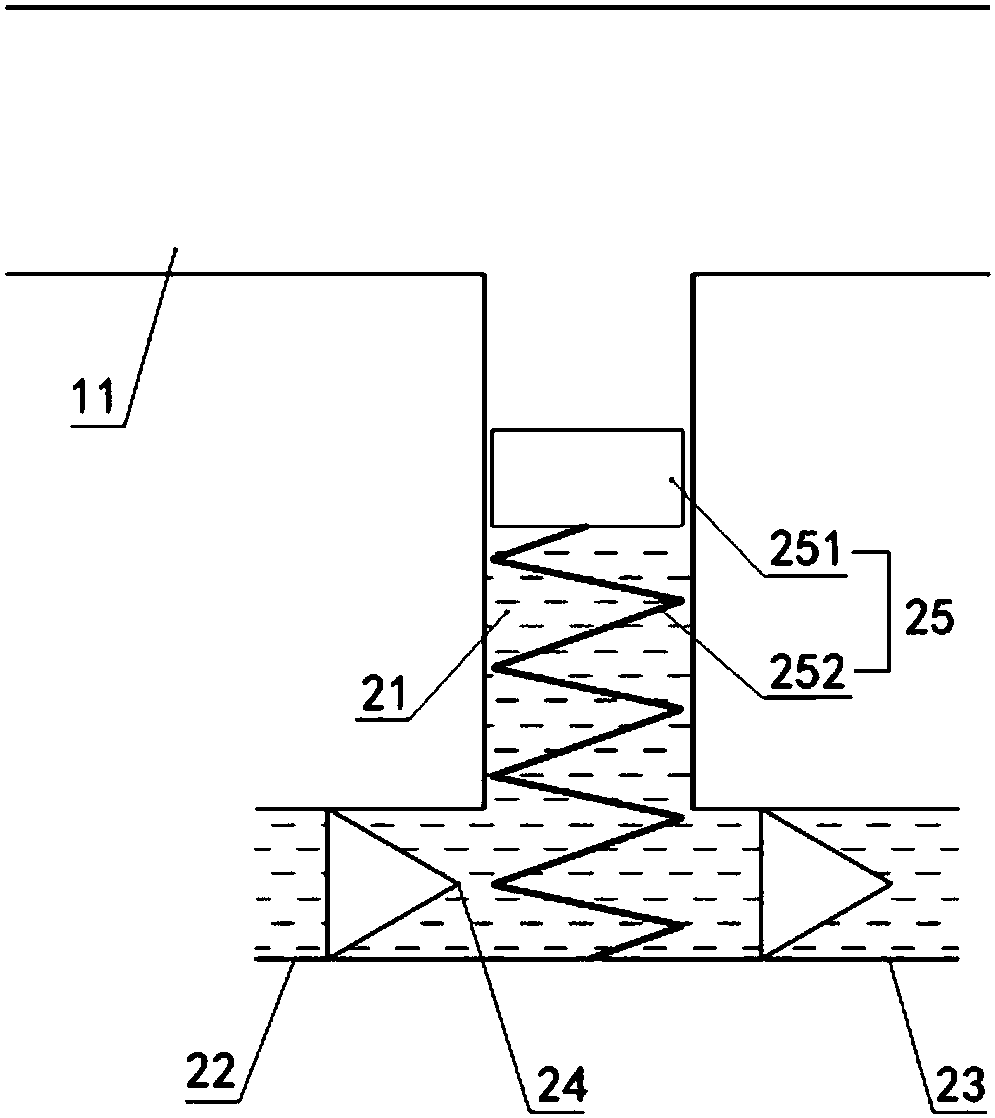

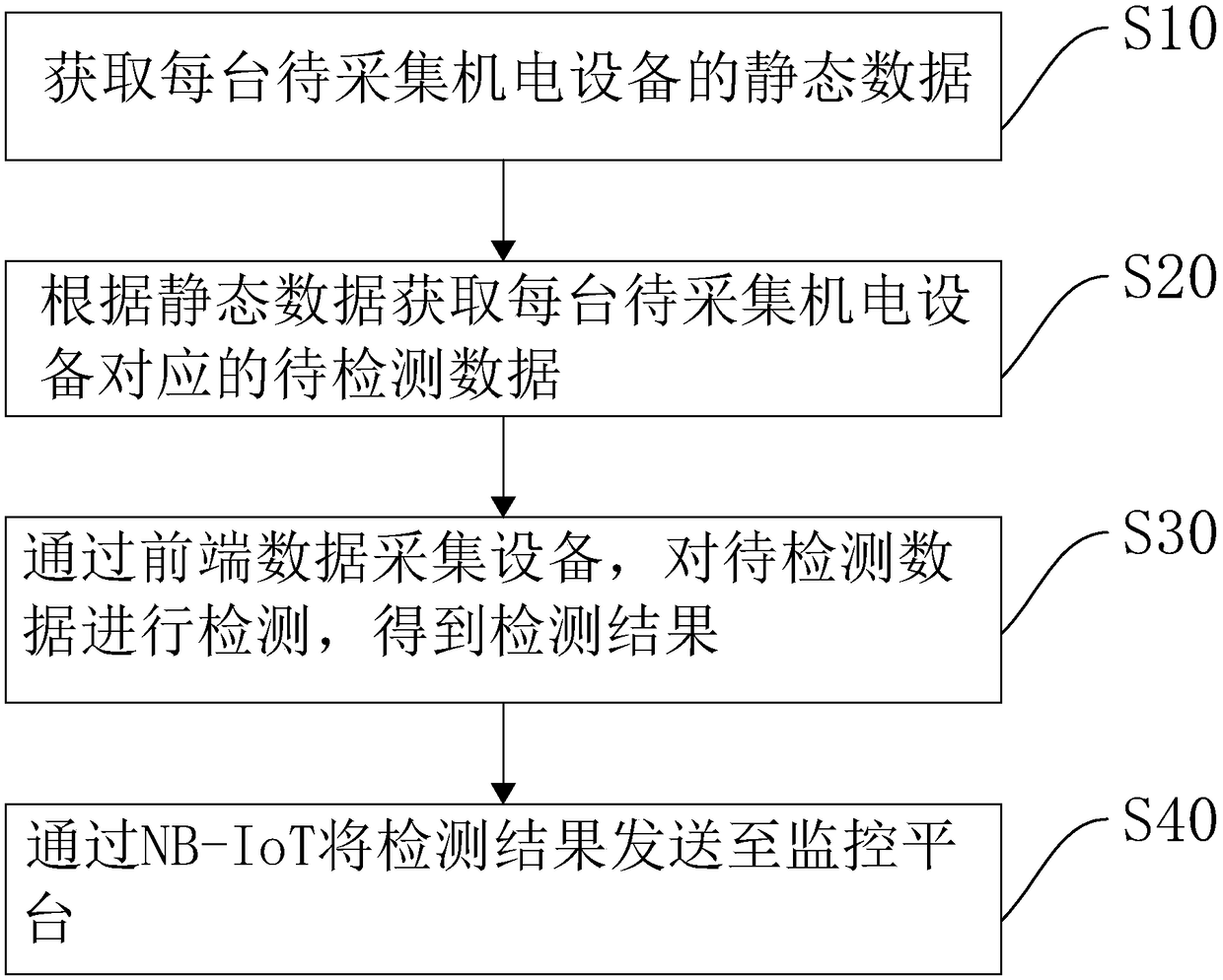

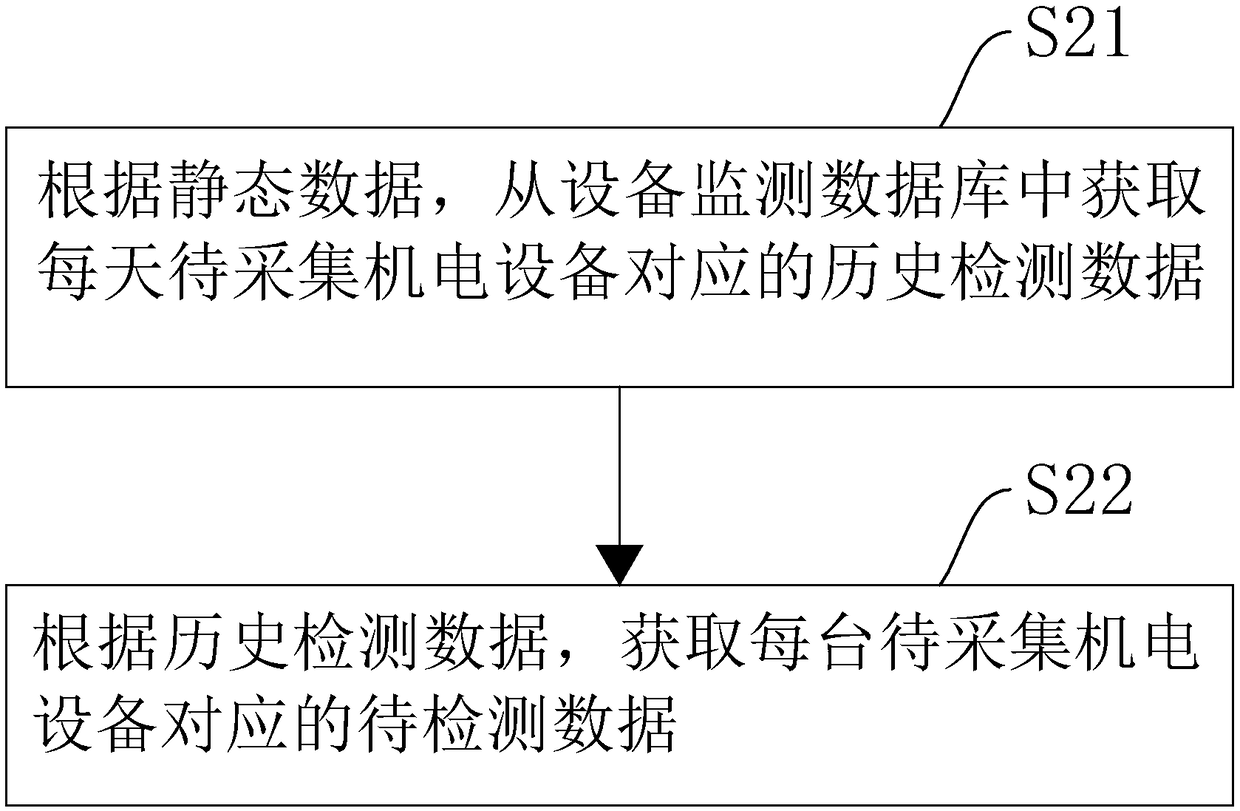

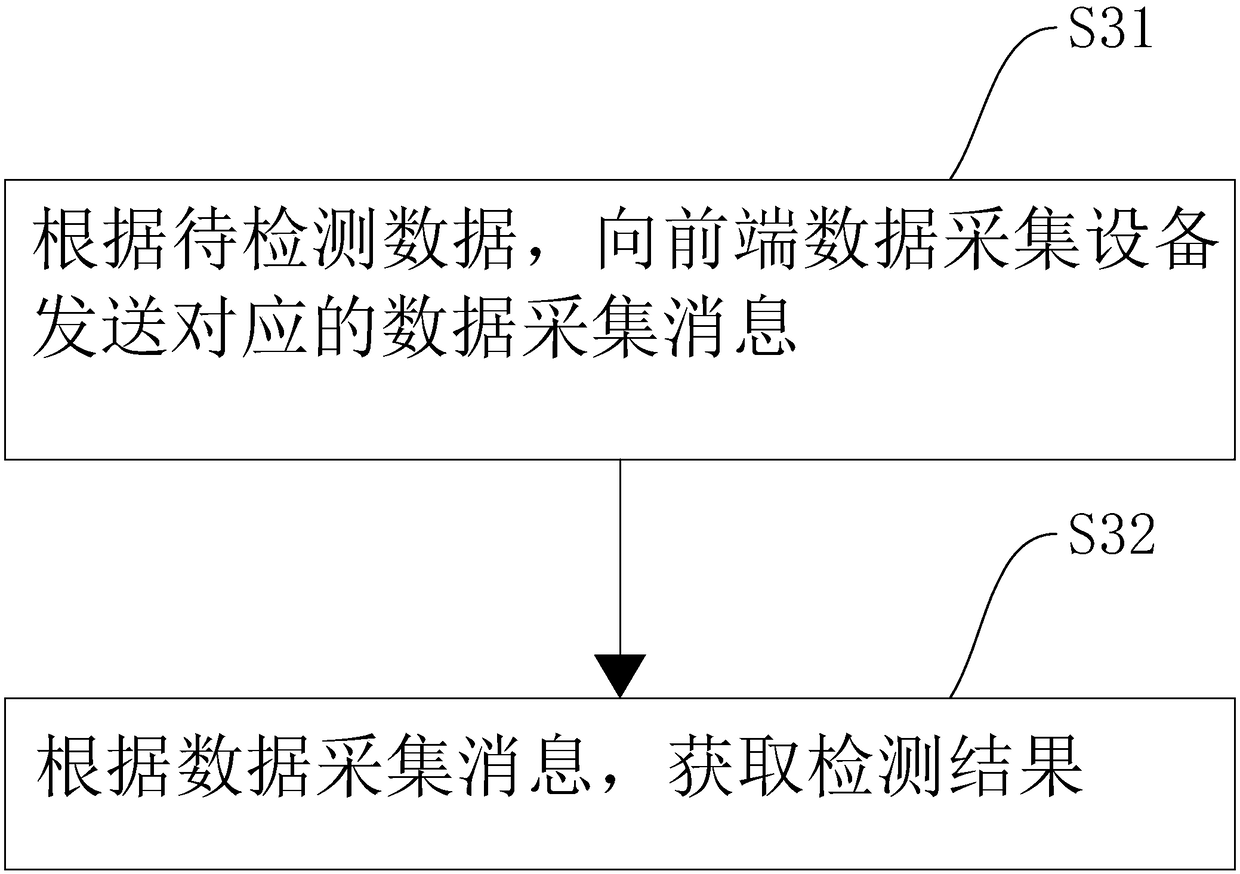

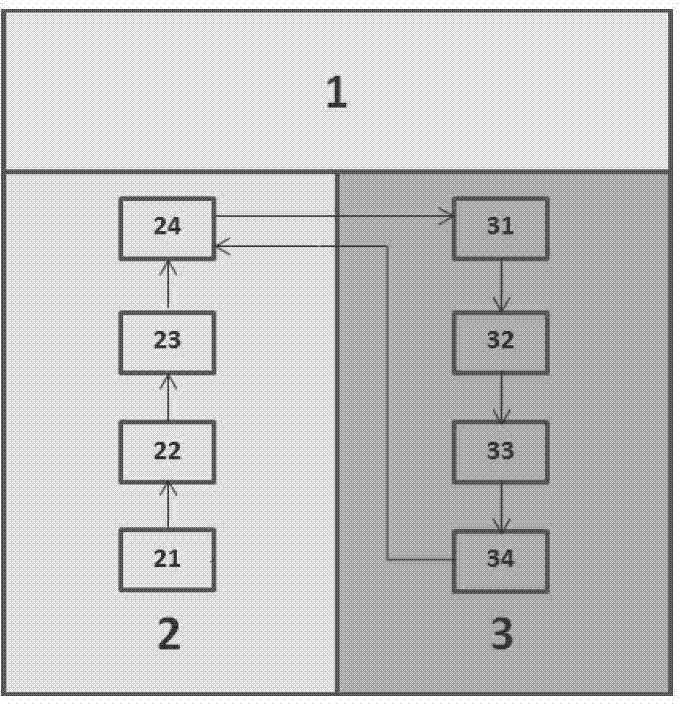

Narrowband technology-based electromechanical equipment operation and maintenance data collection method and system

InactiveCN109451460AMeet the needs of long battery lifeReduce power consumptionPower managementParticular environment based servicesData acquisitionReliability engineering

The invention relates to the technical field of information technology, and particularly relates to a narrowband technology-based electromechanical equipment operation and maintenance data collectionmethod and system. The narrowband technology-based electromechanical equipment operation and maintenance data collection method comprises steps of acquiring static data of each to-be-collected electromechanical equipment; acquiring to-be-detected data corresponding to each to-be-collected electromechanical equipment according to the static data; detecting the to-be0detected data through front-enddata collection equipment, so as to obtain a detection result; and sending the detection result to a monitor platform through NB-IoT. The method based on the narrowband technology facilitates transmission of detection data of the electromechanical equipment.

Owner:GUANGZHOU SPACEFLIGHT HAITE SYST ENG

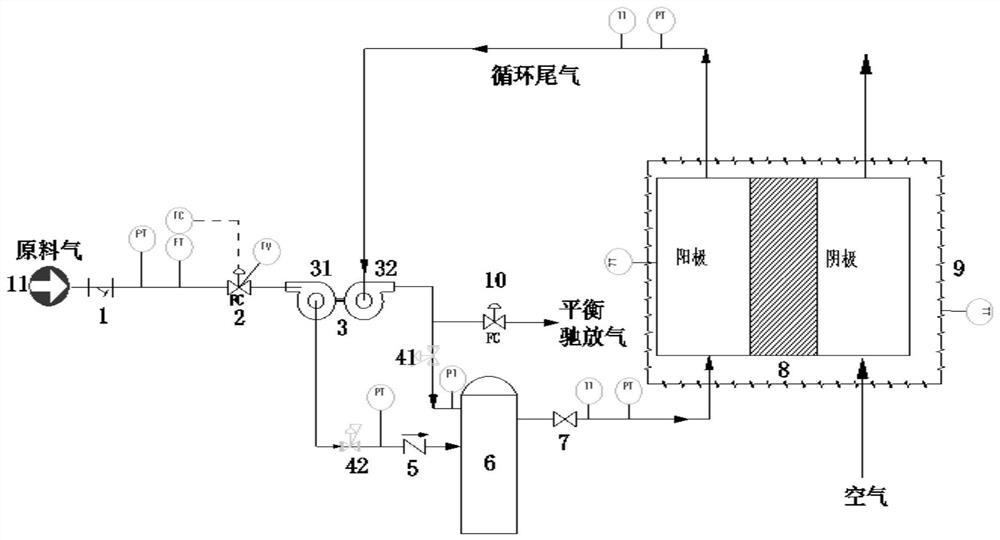

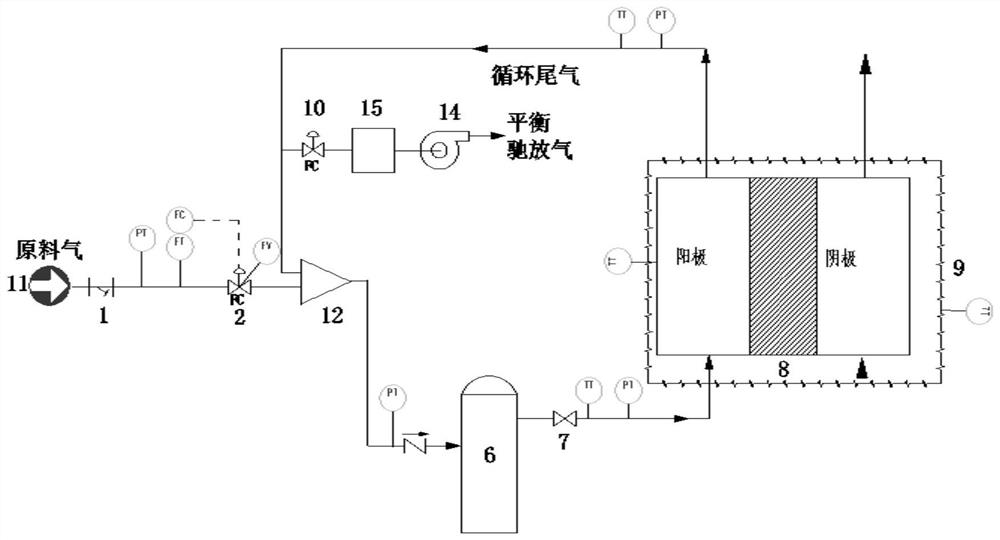

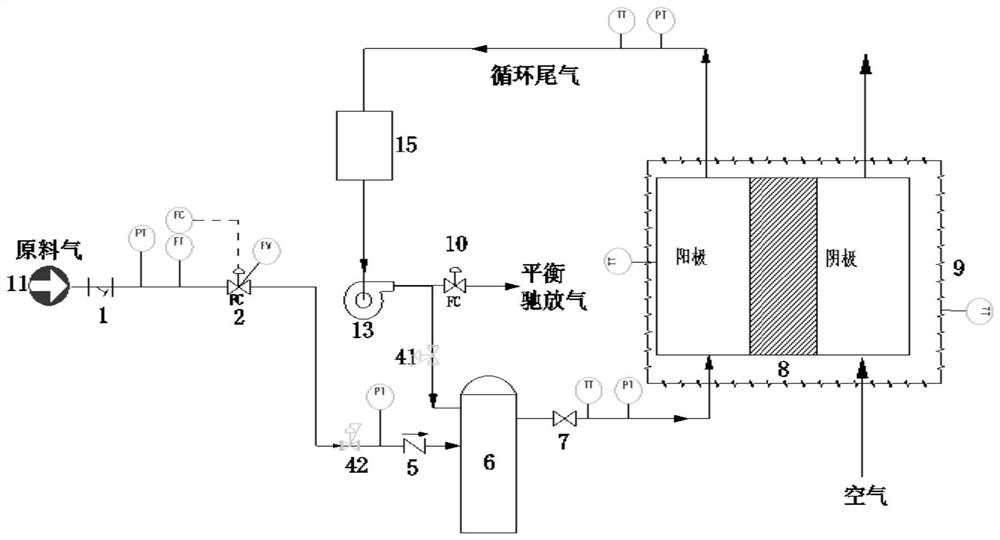

Solid oxide fuel cell system and solid oxide fuel cell power generation method

InactiveCN112310437AAchieve cycleWide range of pressure adjustmentFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsElectrical battery

The invention relates to the field of solid oxide fuel cells, in particular to a solid oxide fuel cell system and a solid oxide fuel cell power generation method. The system comprises a raw material gas source (11), a mixing tank (6), an electric pile (8) and a turbocharging device (3), wherein the turbocharging device (3) is communicated with the raw material gas source (11) and the mixing tank (6) and is communicated with the electric pile (8) and the mixing tank (6). According to the system and the method, the power generation efficiency of a battery can be remarkably improved, and the content of pollution gas in exhaust gas is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

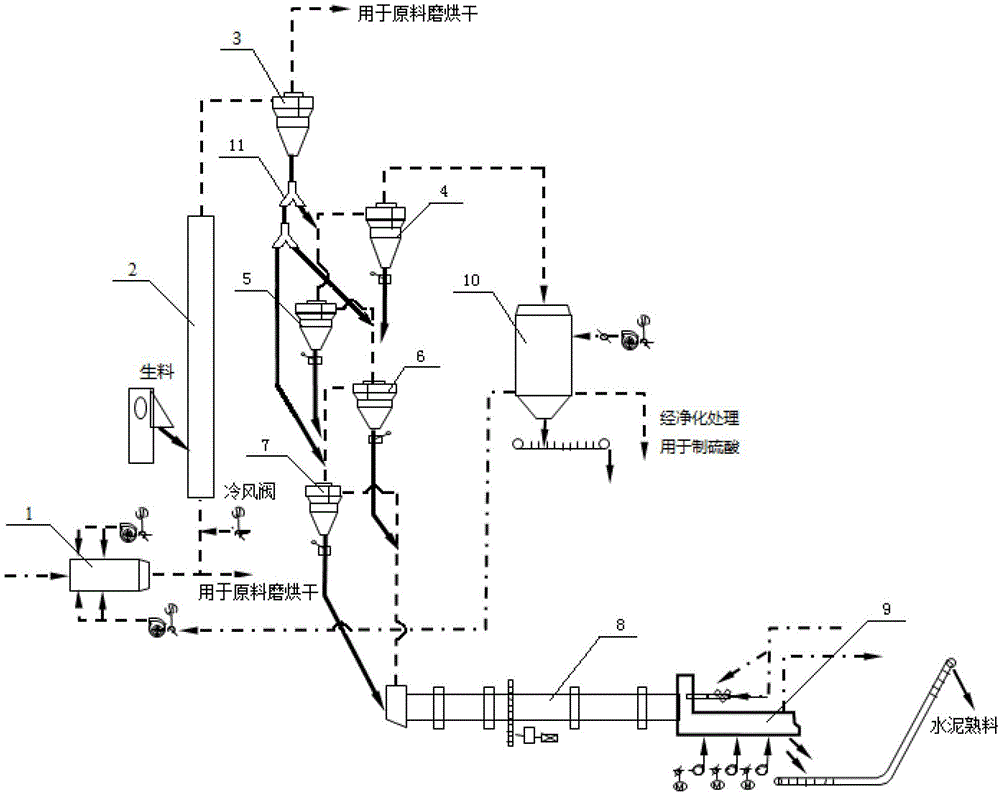

Drying and calcining process and device for coproduction of sulfuric acid and cement from gypsum

ActiveCN103241717BReduce heat consumptionLower dew point temperatureSulfur compoundsClinker productionWater vaporReducing agent

The invention discloses a drying and calcining process for coproduction of sulfuric acid and cement from gypsum. The process comprises the following steps of: before feeding raw materials containing the gypsum, a reducing agent and auxiliary materials into a firing system, completely removing physical water and crystal water from the raw materials; and obtaining acid-making smoke containing SO2 and cement clinker by using the firing system. The invention also discloses a drying and calcining device for coproduction of the sulfuric acid and the cement from the gypsum, which applies the process. The drying and dehydrating process of the gypsum is transferred from a preheater system or a rotary kiln in the past to a drying and dehydrating device, so that heat consumed by dehydration of the gypsum is separated from heat consumption of the firing system, and the amount of waste gas generated by combustion of fuel required by heat generation in the firing system is reduced; and water vapor formed by dehydration cannot be mixed with smoke for preparing the sulfuric acid, so the SO2 concentration of the smoke can be increased and the favorable condition is created for the subsequent preparation process of the sulfuric acid.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Low boiling point working fluid circulation system for recovering blast furnace slag heat

InactiveCN102899428ATechno-economically feasibleThe system process is simpleIncreasing energy efficiencyDischarge devicesThermal energyWorking fluid

The invention relates to a low boiling point working fluid circulation system for recovering blast furnace slag heat, and belongs to mechanical equipment. According to the low boiling point working fluid circulation system, a low boiling point working fluid heat conduction device, a low boiling point working fluid heat convection device and a low boiling point working fluid heat radiation device are arranged on a slag ditch, a punching box and other facilities in the existing water quenching treatment system for the blast furnace slag, heat exchanges between the low boiling point working fluid and hot water on the bottom of the punching box, between the low boiling point working fluid and water steam on the top of the punching box, and between the low boiling point working fluid and slag ditch high temperature slag are performed respectively in three manners such as heat conduction, heat convection and heat radiation to form the low boiling point working fluid steam so as to drive a low boiling point working fluid generating unit to generate electricity, heat generated in various links of the high temperature slag water quenching process is systematically recovered in an organized manner through the system, efficient waste heat resource utilization is achieved, and energy consumption of iron and steel enterprises is saved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Industrial wastewater treatment method using bladder-type anaerobic pond

ActiveCN101381160BSingle pool volume is largeLess investment in infrastructureTreatment with aerobic and anaerobic processesEngineeringHigh intensity

The present invention discloses a method for disposing industrial sewage in a bag type anaerobic pool, and relates to a method for disposing industrial sewage. The method overcomes the drawback that the anaerobic pool used in the prior method costs a lot of labor and constructional material and is small in single pool volume by changing the structure of the anaerobic pool. The method comprises the following steps of a. pretreated sewage is discharged into the bag type anaerobic pool; after jet mixing, the sewage contacts and absorbs a returned sludge at an end of the bag type anaerobic pool for anaerobic reaction; the bag type anaerobic pool is a water bag made from a high strength HDPE plastic film, and acidogenic bacterium and methanogenic bacterium are accreted inside the water bag; b.an aerobic reaction of the sewage treated by the step a is carried out to further remove the surplus organic substance in the water, and gas is aerated into a biological contact oxidation pond by a blower; c. the sewage processed by the step b enters an inclined tube settling pond so as to separate sludge and water; d. the sewage processed by the step c is discharged.

Owner:哈尔滨北方环保工程有限公司

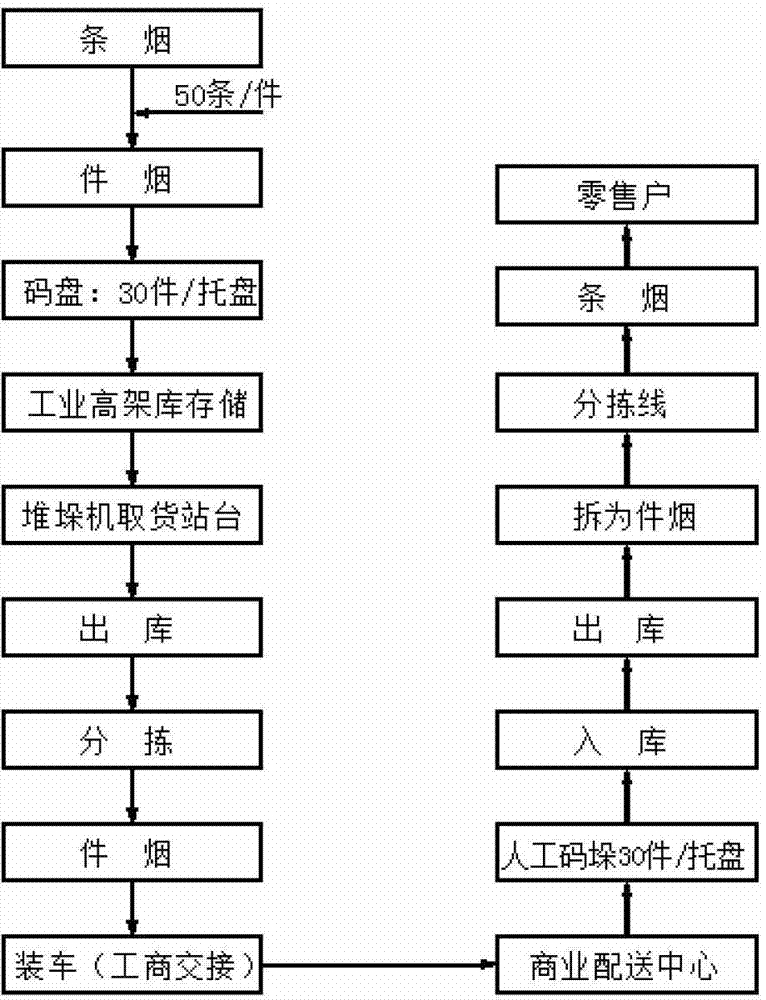

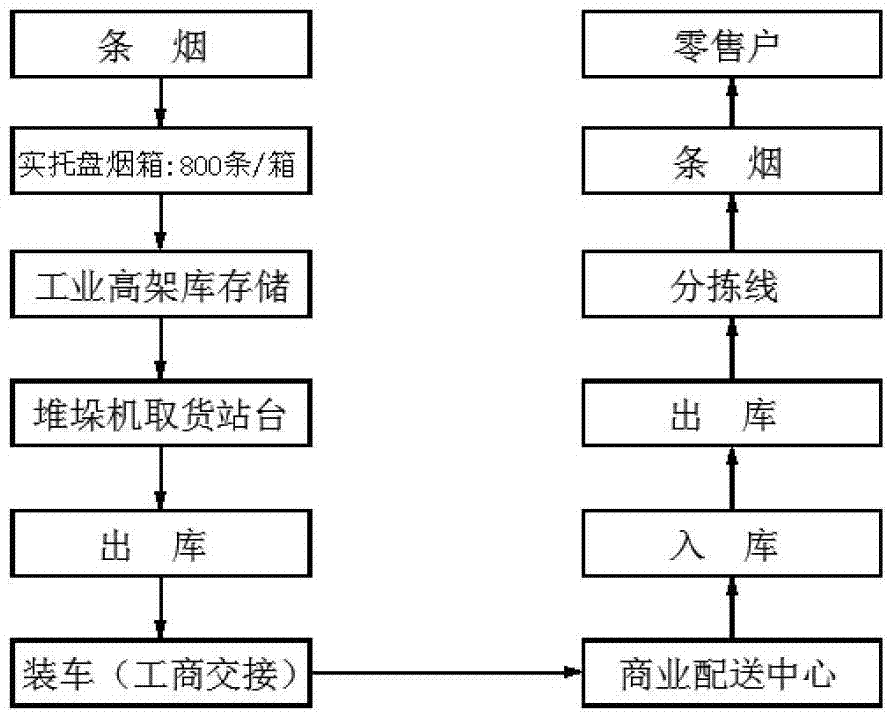

A logistics method for cigarette packaging, storage and transportation in collaboration with industry and commerce

InactiveCN103318653BAvoid wastingReduce wasteStorage devicesComputer control systemLogistics management

The invention relates to a cigarette logistics system, in particular to an industrial and commercial cooperation cigarette packaging, storage and transportation logistics system. The logistics system comprises a computer control system, an industrial cigarette plant area and a commercial distribution center area. The industrial cigarette plant area comprises an encasement area, a warehouse inlet area, an elevated warehouse area and a warehouse outlet area. The commercial distribution center area comprises a warehouse inlet area, an elevated warehouse area, a warehouse outlet area and a sorting area. A packaging and transportation mode between industrial finished product cigarettes and commercial distribution is converted from an original industrial and commercial separation mode to an industrial and commercial cooperation mode, and a system operation process is simplified; mechanical hands and conveyors replace encasement sealing machine sets, turnover cigarette boxes are changed from cartons to wood cigarette boxes, resource waste caused by carton abandonment is avoided, and production cost is reduced; a cigarette barcode recognition mode is changed into a tray radio frequency identification (RFID) recognition mode, the problem of system errors caused by barcode pollution and the like is solved, and working efficiency is improved.

Owner:北京达特集成技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com