A Gas Separation System Based on Micro/Nano-Scale Thermal Escape Effect and Macroscopic Eddy Cool-Heat Effect

A technology of gas separation and macroscopic vortex, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of "regeneration" of liquid absorbent and absorbent, high cost of gas membrane separation method, and "regeneration of adsorbent" etc. to achieve the effect of simple equipment, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0051] In this embodiment, the specific process steps are as follows:

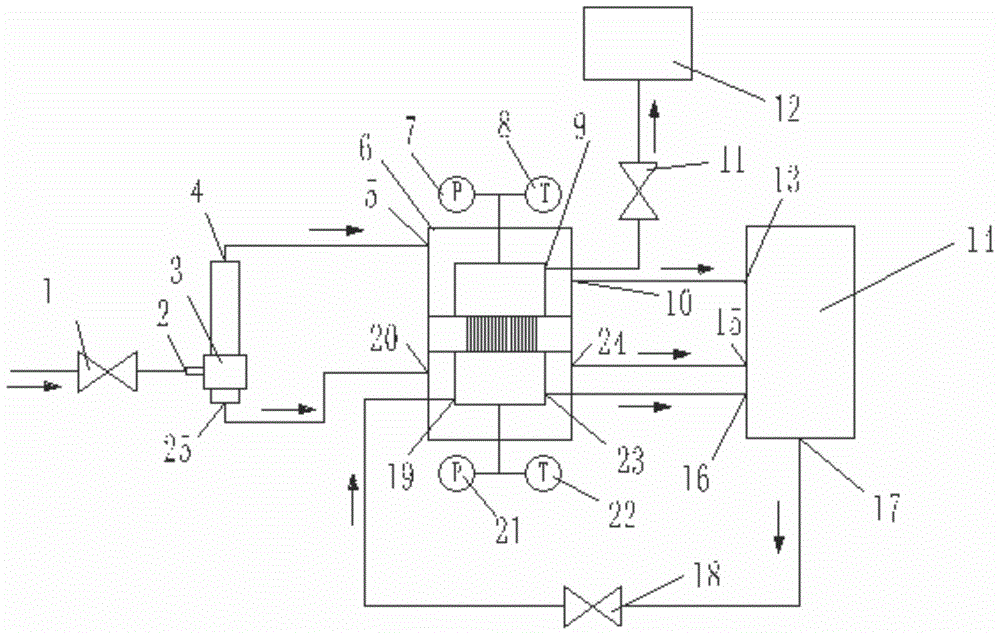

[0052] Such as figure 1 and Figure 4 As shown, the unseparated compressed mixed gas enters the vortex tube nozzle 2 through the flow regulating valve 1, the pressure of the compressed gas in the nozzle 2 decreases and the speed increases, and after the speed of the separated gas increases, it enters the vortex chamber 33 along the tangential direction at a high speed. And a free vortex is formed in the vortex chamber 33, which is separated into two parts with different temperatures through kinetic energy exchange. The kinetic energy of the central part decreases to become low-temperature gas and flows into the vortex tube cold pipe 25 ; the kinetic energy of the edge part increases to become high-temperature gas and flows into the vortex tube heat pipe 4 .

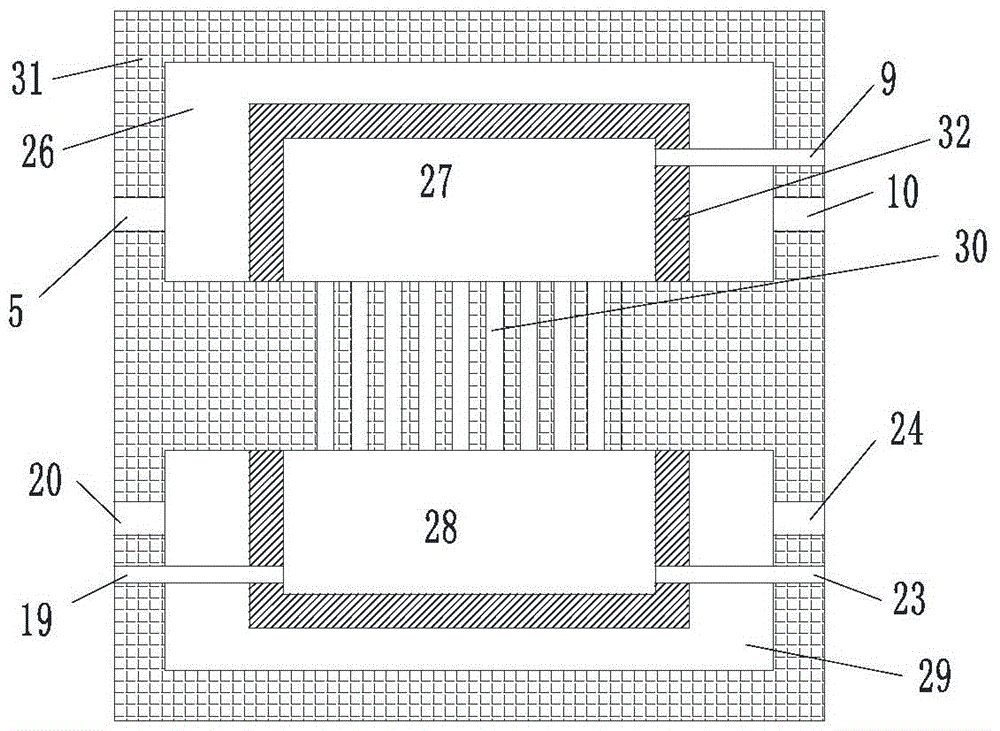

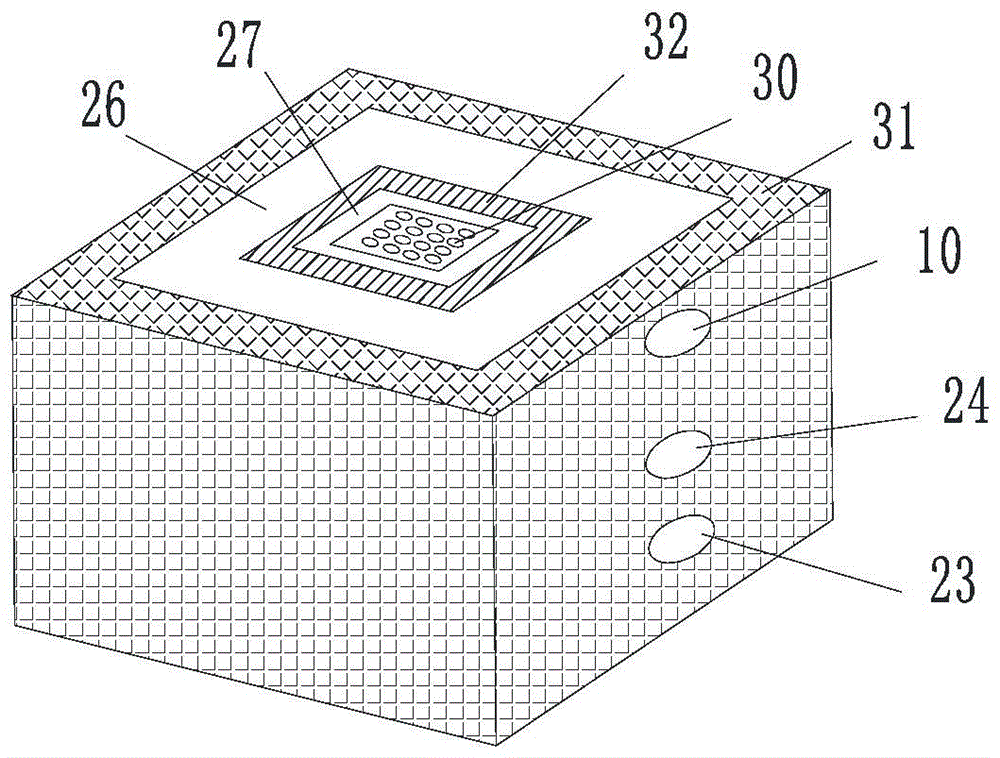

[0053] Such as figure 1 and figure 2 As shown, the high-temperature gas flowing out from the vortex tube heat pipe 4 enters the heat channel 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com