Ship propulsion system

A technology for propulsion systems and ships, applied in ship propulsion, propulsion components, propulsion engines, etc., can solve the problems of many power conversion links, low efficiency, high energy consumption, etc., to improve stealth, reduce noise, and simplify system processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

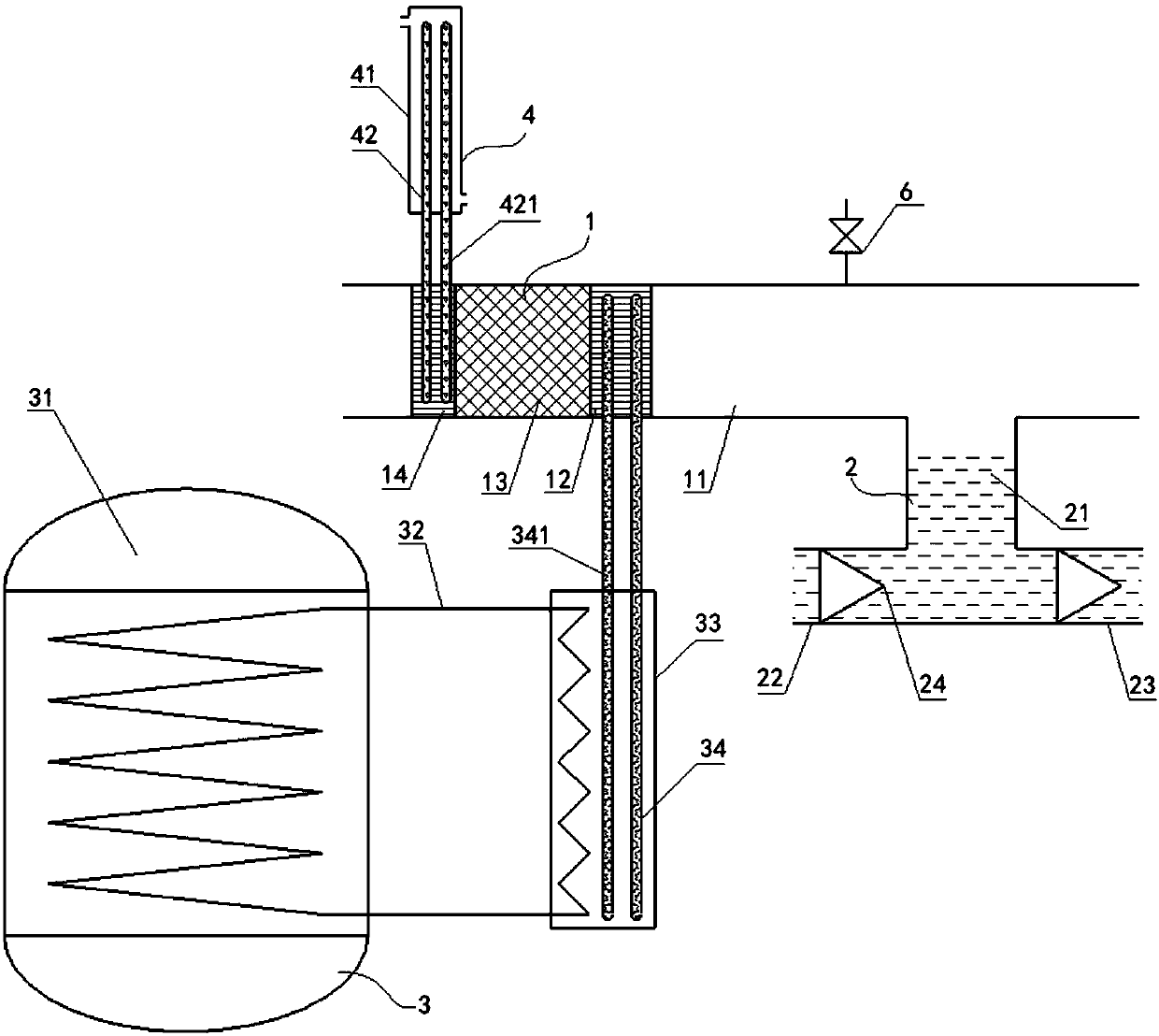

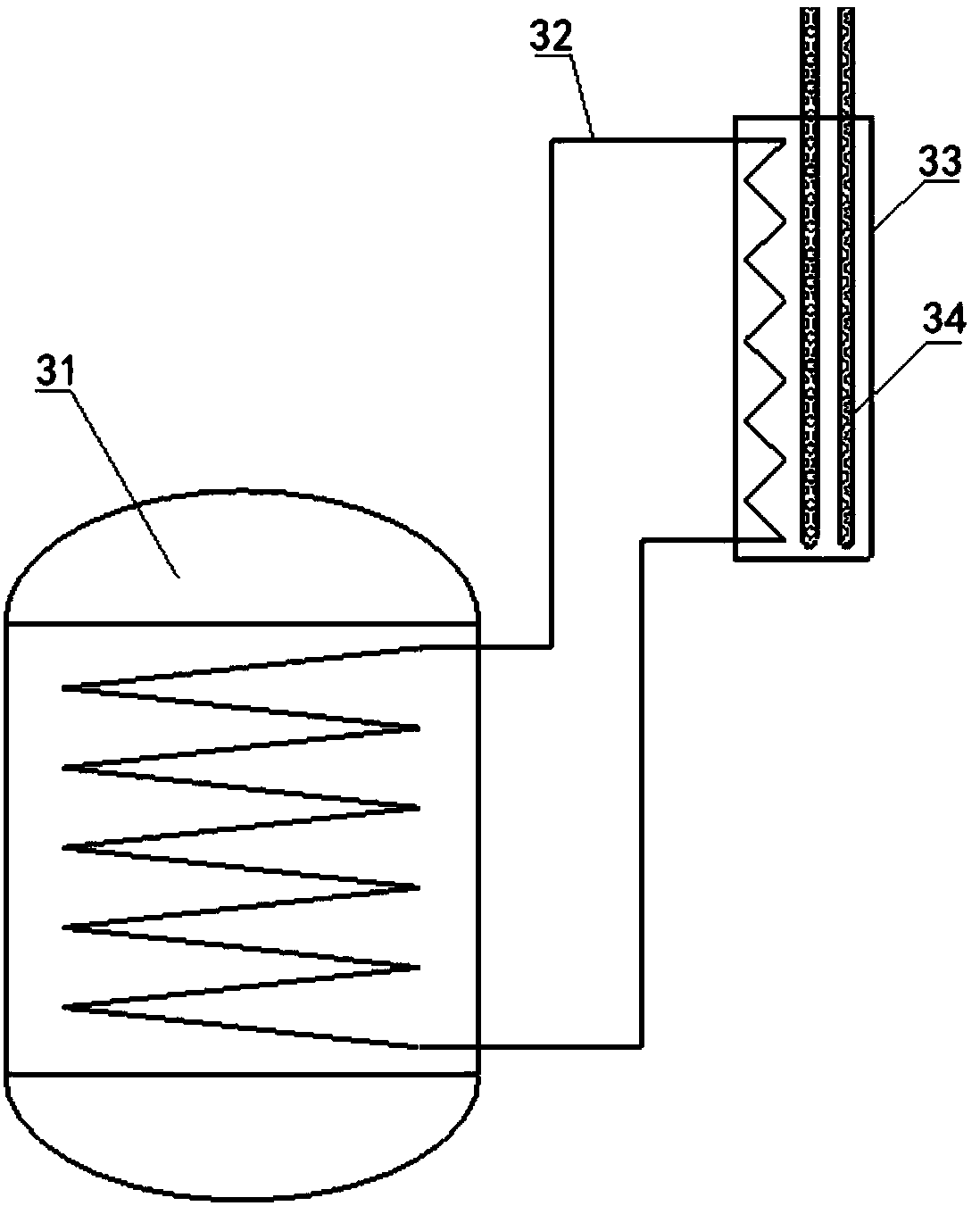

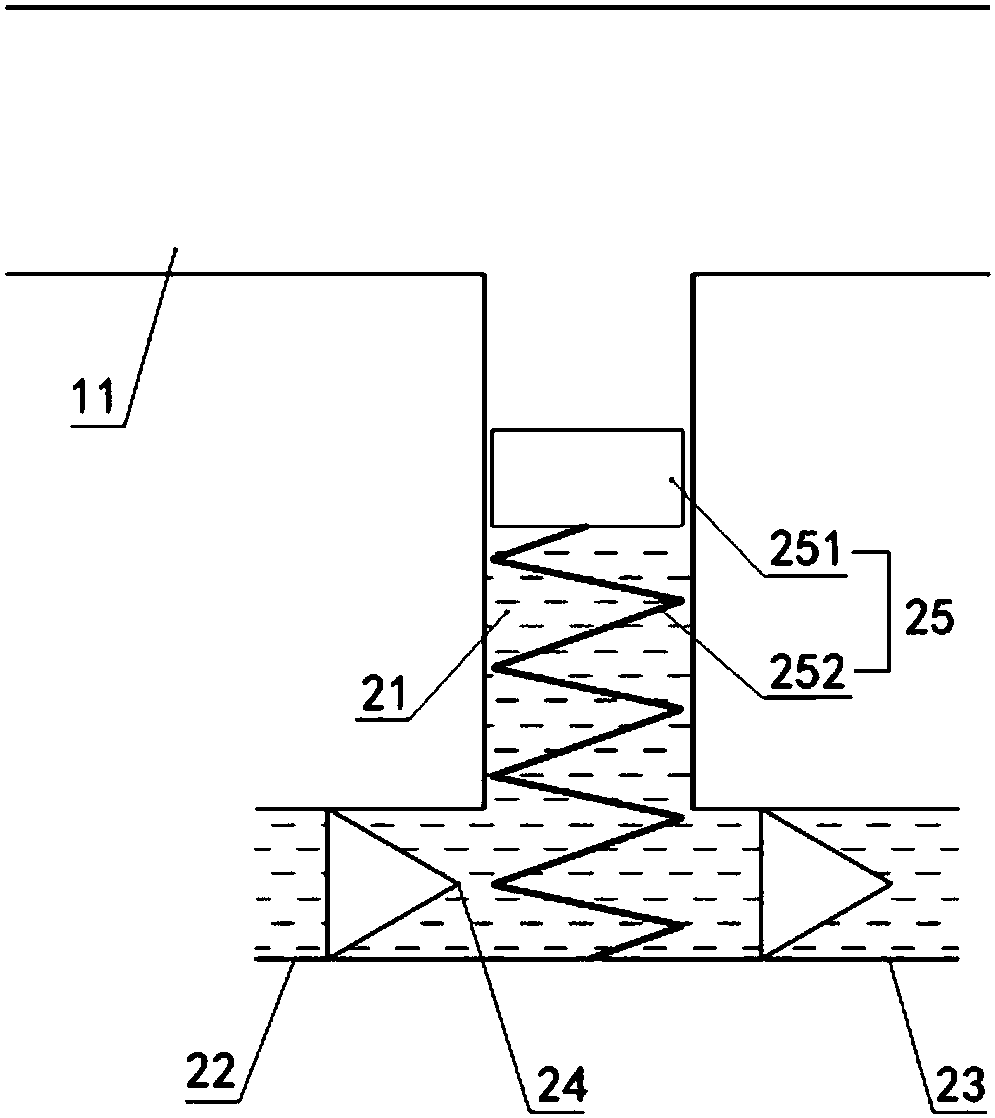

[0030] Such as figure 1 As shown, the ship propulsion system provided by the embodiment of the present invention includes a thermoacoustic engine 1, a propulsion device 2, a heating device 3 and a cooling device 4. The thermoacoustic engine 1 includes an acoustic tube 11 and sequentially connected in the acoustic tube 11. Heater 12, regenerator 13 and heat exchanger 14, heating device 3 is connected with heater 12, cooling device 4 is connected with heat exchanger 14, propulsion device 2 comprises branch pipe 21, and branch pipe 21 comprises the horizontal pipe that communicates with each other and vertical pipe. Straight pipe, the vertical pipe is vertically connected with the acoustic pipe 11, the water surface in the branch pipe 21 is located in the vertical pipe, one end of the horizontal pipe is the water inlet 22, and the other end of the horizontal pipe of the branch pipe 21 is the water outlet 23, and the water inlet 22 faces the ship. At the bow, the water outlet 23 i...

Embodiment 2

[0044] Such as Figure 4 As shown, this embodiment is basically the same as the first embodiment above, except that the first heat conducting element 34 in this embodiment is the second heat exchange circuit 342 , and the pump body 5 is arranged on the second heat exchange circuit 342 . Wherein, the second heat conducting member 42 is a third heat exchange circuit 422 , and the pump body 5 is arranged on the third heat exchange circuit 422 . The second heat exchange circuit between the heat exchanger and the heater can be driven by the pump body, and the third heat exchange circuit between the heat exchanger and the cooler can also be driven by the pump body, especially when the internal heat exchange circuit When the heat exchange medium is a conductive medium, a magnetic fluid pump can be used to promote the circulation of the heat exchange medium. The magnetic fluid pump uses the electromagnetic effect of the current-carrying fluid in the magnetic field to push the fluid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com