Activated carbon/coke-based coke oven flue gas desulfurization and denitration system and activated carbon/coke-based coke oven flue gas desulfurization and denitration method

A technology of desulfurization and denitrification, activated carbon, applied in the direction of chemical instruments and methods, separation methods, alkali metal sulfite/sulfite, etc., can solve the problems of difficult desulfurization by-products, low denitrification efficiency of activated carbon, etc., and reduce operating costs , improve stability and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

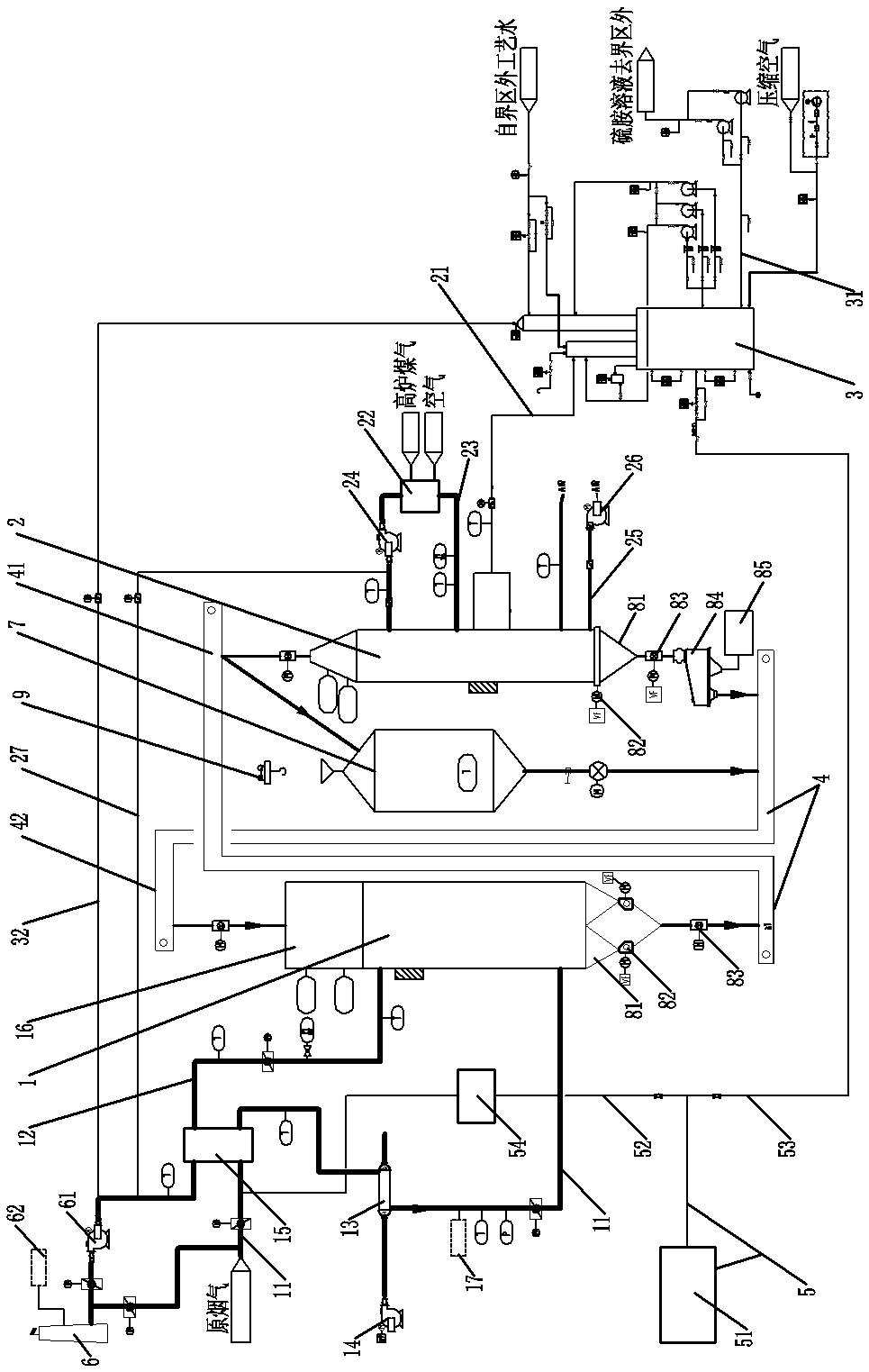

[0029] As shown in Figure 1, the coke oven flue gas desulfurization and denitrification system based on activated carbon / coke in this embodiment includes an activated carbon / coke flue gas purification tower 1 and an activated carbon / coke regeneration tower 2, and the purification tower 1 is connected with a flue gas inlet pipe 11 and the purified gas exhaust pipe 12, the flue gas inlet pipe 11 is located below the purified gas exhaust pipe 12, an activated carbon / coke conveyor 4 is arranged between the purification tower 1 and the regeneration tower 2, and the regeneration tower 2 is connected with High-temperature heating system and regeneration gas pipeline 21, described desulfurization and denitrification system also includes chimney 6, ammonia water injection system 5 and absorption tower 3, and described ammonia water injection system 5 comprises ammonia water storage 51, is connected with parallel arrangement on the ammonia water storage 51 The first ammonia water pipelin...

specific example

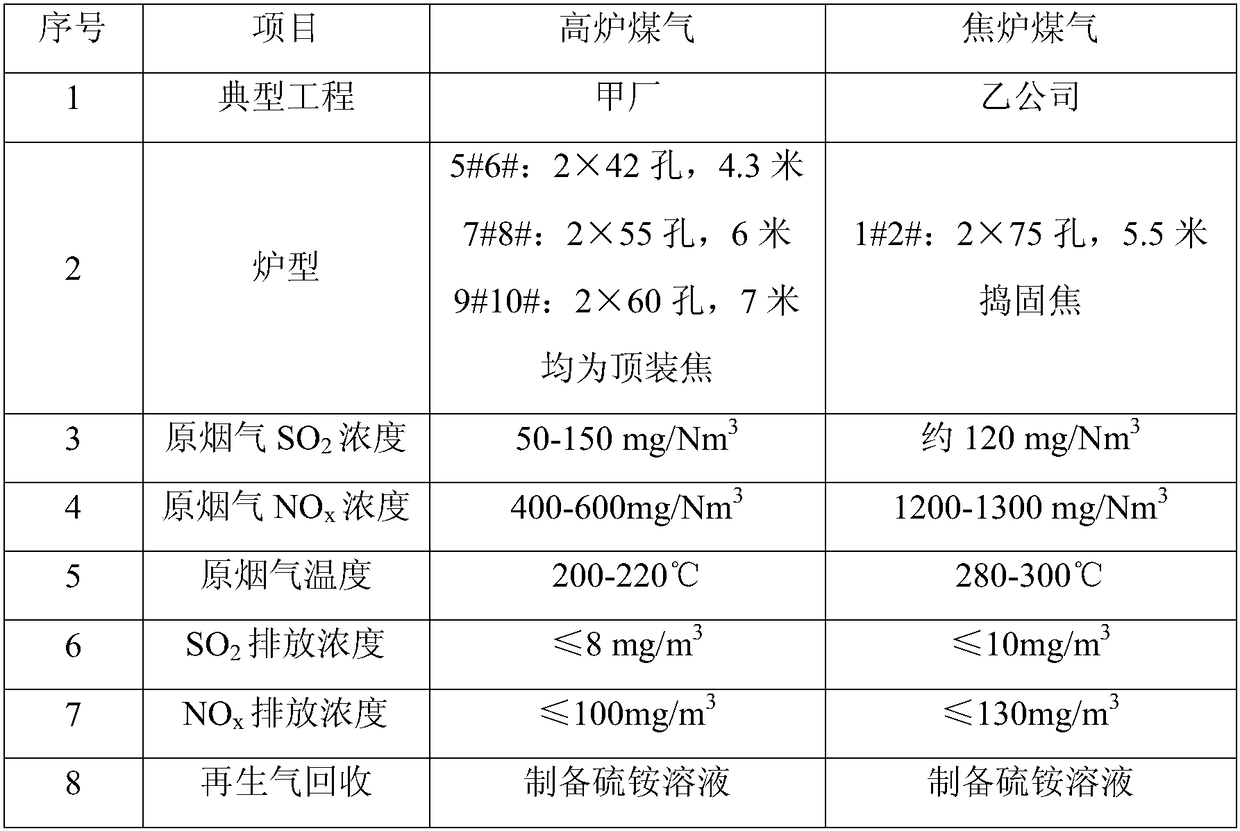

[0063] Factory A is a coking plant of a certain iron and steel co., ltd., which has 5#, 6#, 7#, 8#, 9# and 10# coke ovens. The fuel is blast furnace gas. The activated carbon / coke CCMB technology of the present invention is used to treat coke oven flue gas Medium pollutants, particulate matter after flue gas emission and purification ≤10mg / m 3 , SO 2 ≤8mg / m 3 , NO x ≤100mg / m 3 .

[0064] Company B is a coking gas company with existing 1# and 2# coke ovens, the fuel is coke oven gas, and the activated carbon / coke CCMB technology of the present invention is used to treat pollutants in coke oven flue gas. 10mg / m 3 , SO 2 ≤10 mg / m 3 , NO x ≤130mg / m 3 .

[0065] The flue gas comparison of the two fuels is shown in the table below. Regardless of whether the coke oven uses blast furnace gas or coke oven gas, the emission value is far lower than the design standard, and even lower than the national standard for special emission limits.

[0066]

[0067] It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com