Patents

Literature

35results about How to "Realize continuous transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

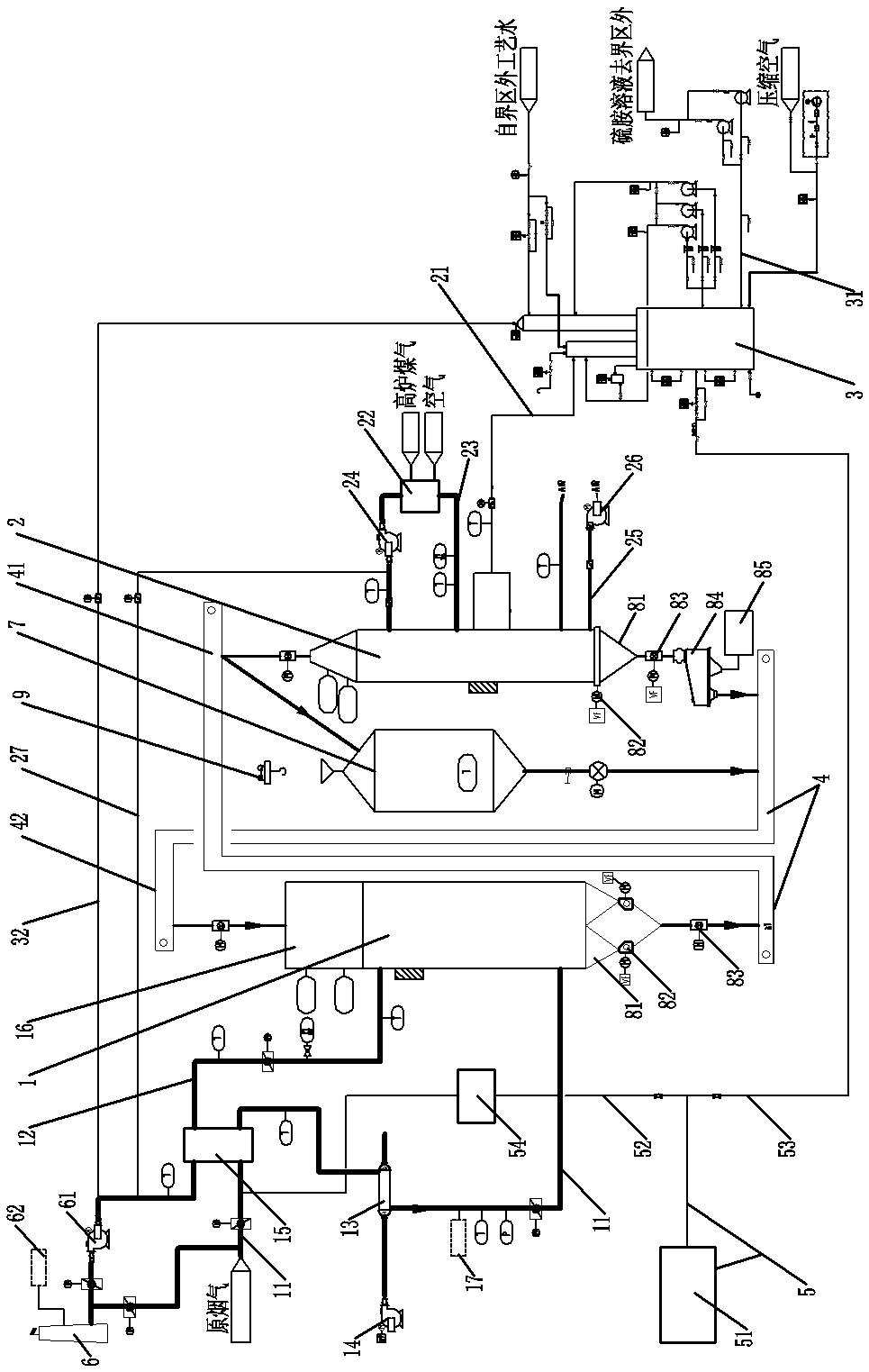

Activated carbon/coke-based coke oven flue gas desulfurization and denitration system and activated carbon/coke-based coke oven flue gas desulfurization and denitration method

PendingCN108380041AReduce escapeWell mixedGas treatmentDispersed particle separationEngineeringAmmonium sulfate

The invention discloses an activated carbon / coke-based coke oven flue gas desulfurization and denitration system and an activated carbon / coke-based coke oven flue gas desulfurization and denitration method. The flue gas desulfurization and denitration system comprises an activated carbon / coke flue gas purification tower, an activated carbon / coke regeneration tower, a chimney, an ammonia water injection system and an absorption tower, wherein an activated carbon / coke conveyor is arranged between the purification tower and the regeneration tower; the regeneration tower is connected with a high temperature heating system and a regenerated gas pipeline; the ammonia water injection system comprises an ammonia water container; the ammonia water container is connected with a first ammonia water pipeline and a second ammonia water pipeline which are arranged in parallel; the first ammonia water pipeline and the second ammonia water pipeline are respectively communicated with the interiors of aflue gas inlet pipeline and the absorption tower; the bottom of the absorption tower is connected with an ammonium sulfate solution pipeline, and the top of the absorption tower is connected with a waste gas exhaust pipeline; the regenerated gas pipeline is communicated with the interior of the absorption tower; a purified gas exhaust pipeline and the waste gas exhaust pipeline are communicated with the chimney; the activated carbon / coke conveyor comprises an old material conveyor used for conveying activated carbon / coke at the bottom of the purification tower onto the top of the regenerationtower, and a new material conveyor used for conveying activated carbon / coke at the bottom of the regeneration tower onto the top of the purification tower.

Owner:南京泽众环保科技有限公司

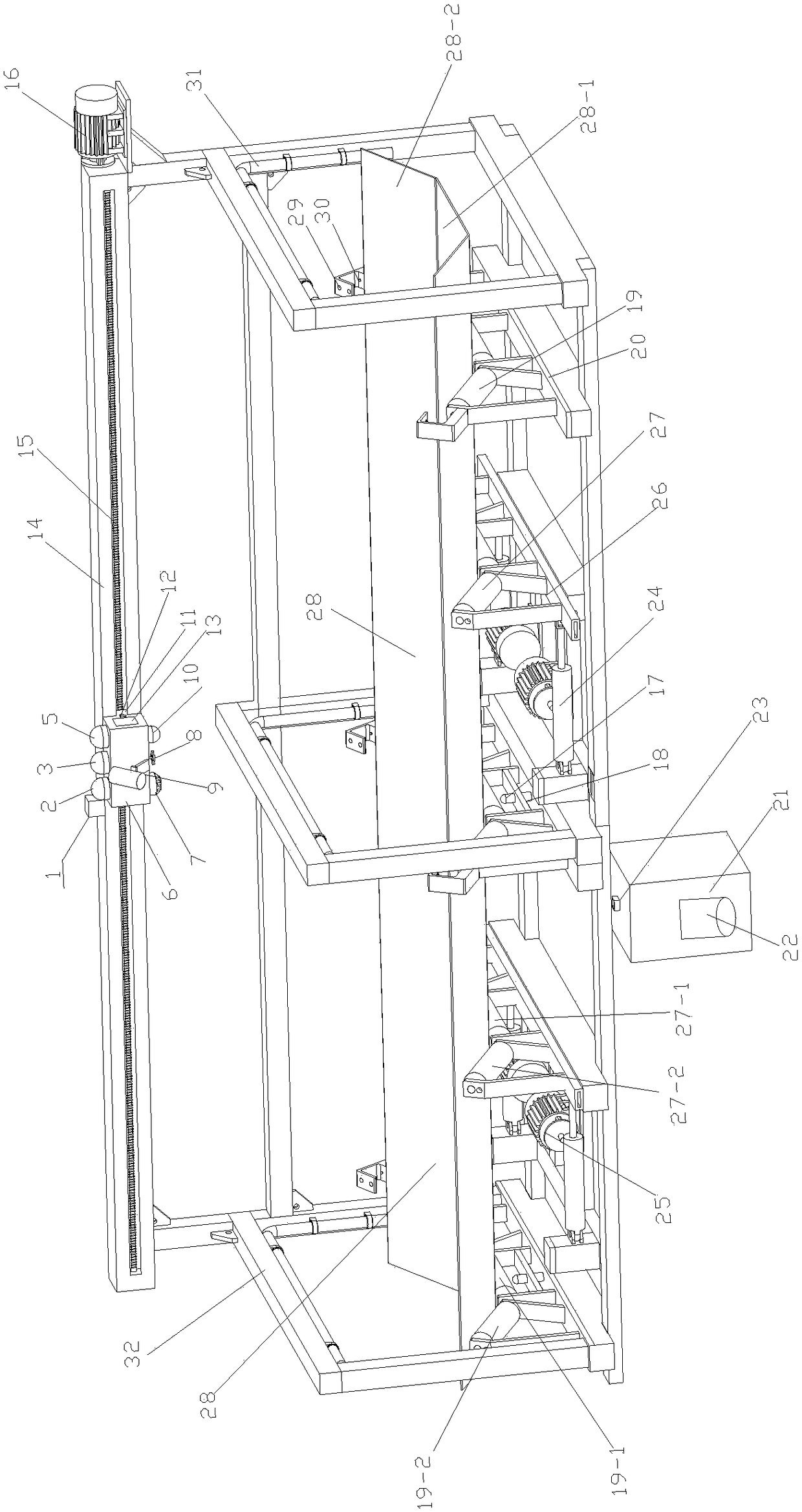

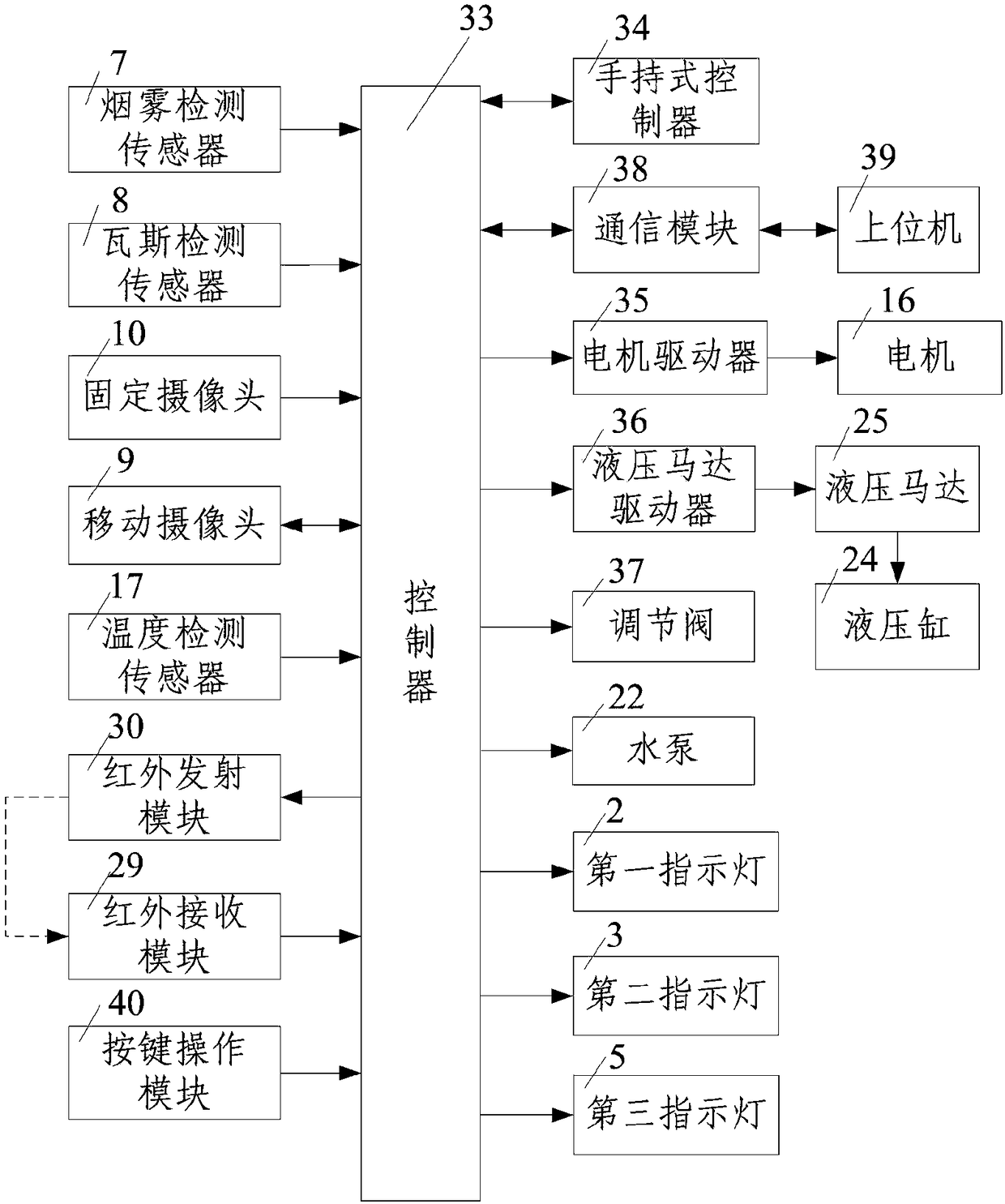

Belt transportation system

InactiveCN106219193ASimple structureReasonable designConveyorsControl devices for conveyorsEngineeringLeather belt

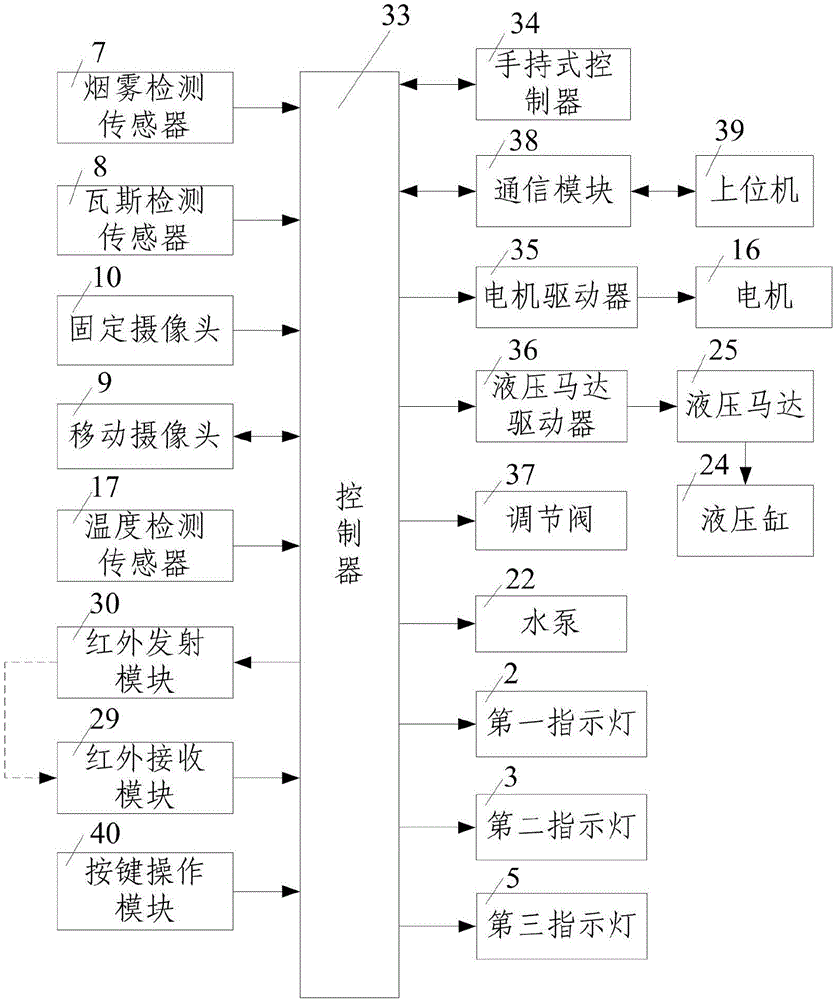

The invention discloses a belt transportation system which comprises a belt transportation mechanism, a belt detection device, a monitor device, belt deviation adjusting mechanisms and a belt cooling mechanism. The belt transportation mechanism comprises a belt and belt supporting components. The belt detection device comprises a routing inspection mechanism, temperature detection sensors and belt deviation detection modules. A routing inspection sliding mechanism and a sliding drive mechanism are arranged on a rack. The routing inspection mechanism comprises a routing inspection box, a smoke detection sensor, a gas detection sensor and a fixed camera. The monitor device comprises a control device, a wireless power supply module, a cooling control mechanism and a deviation adjusting drive mechanism. The belt transportation system is simple in structure and convenient to implement; the belt transportation work condition is detected in real time; the belt is adjusted and cooled; belt deviation or high-temperature work is prevented from bringing potential safety hazards to workers and coal mine transportation; continuous transportation of the belt is achieved; and the coal production efficiency is improved, and labor intensity is relieved.

Owner:XIAN UNIV OF SCI & TECH

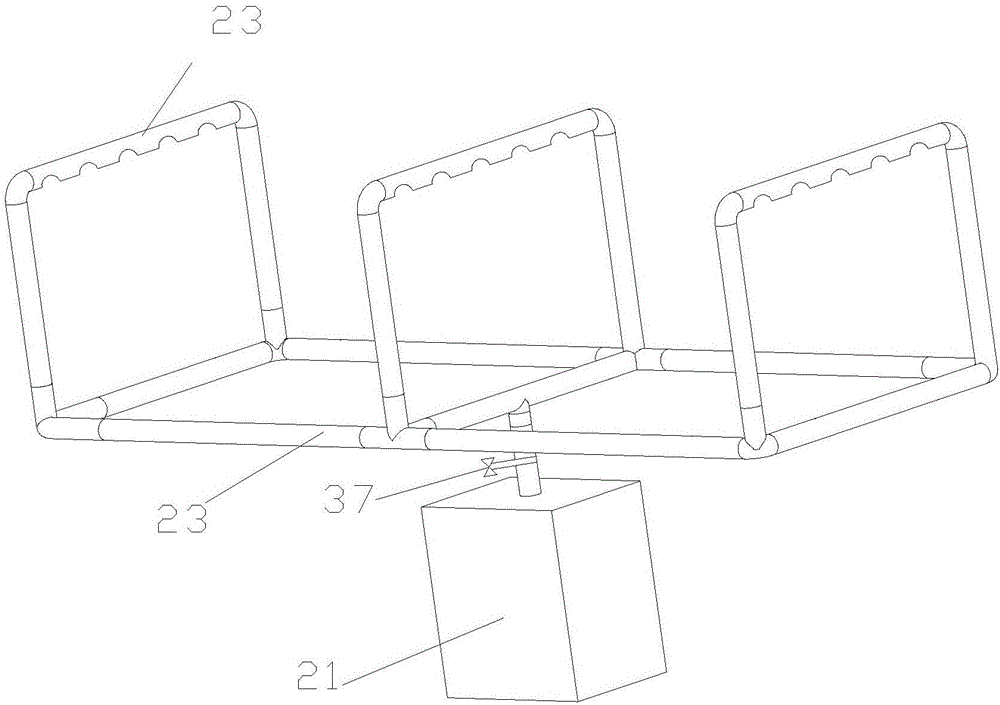

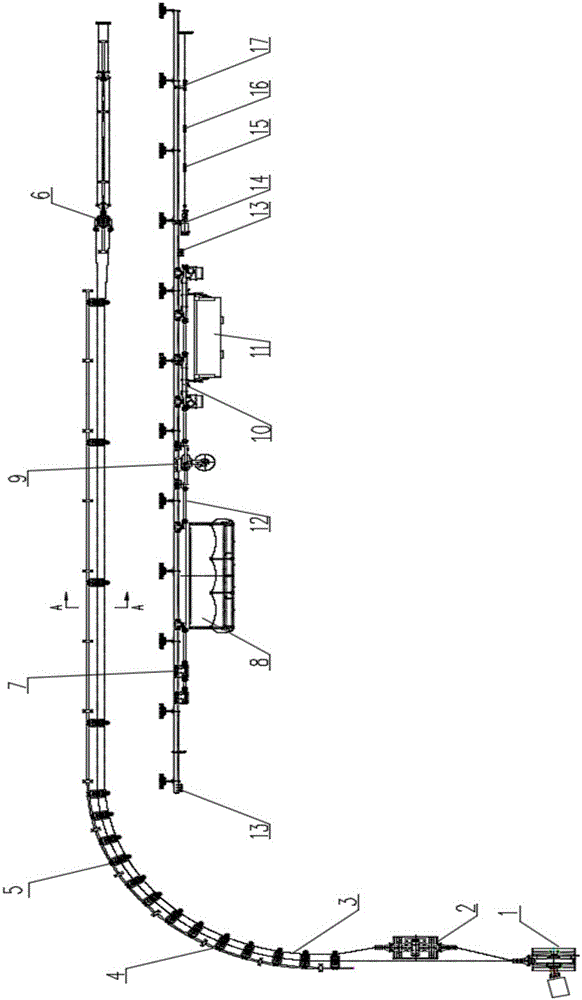

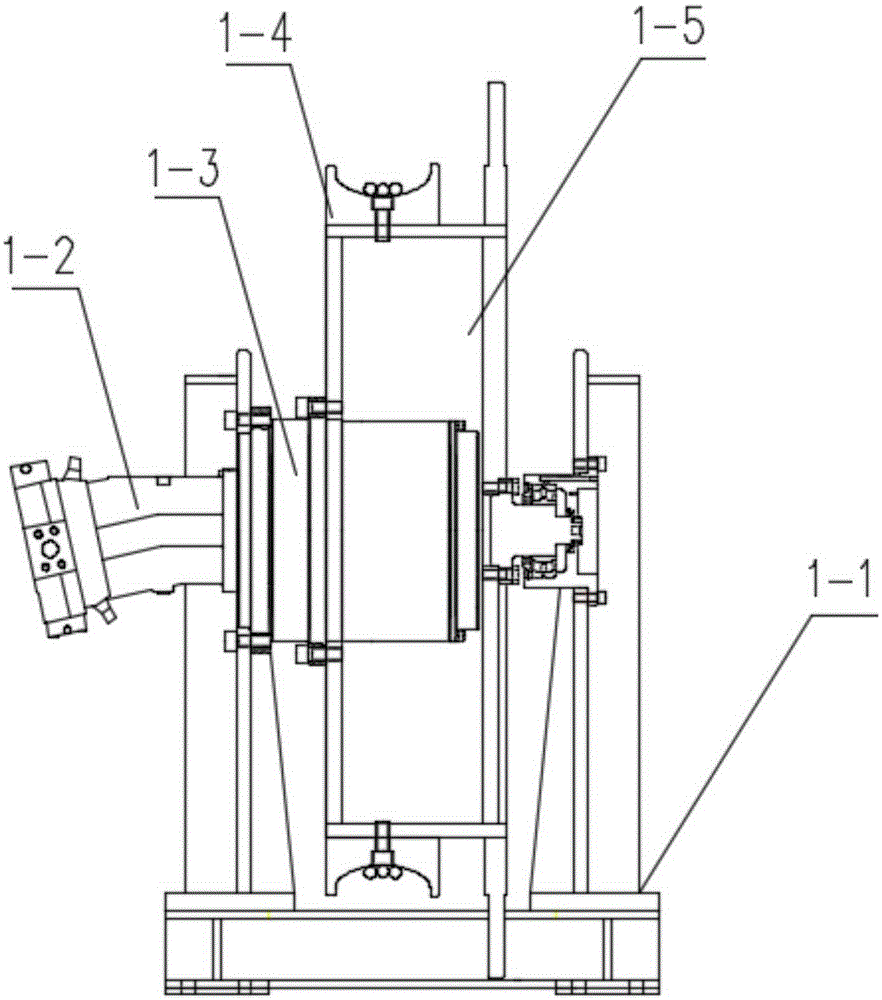

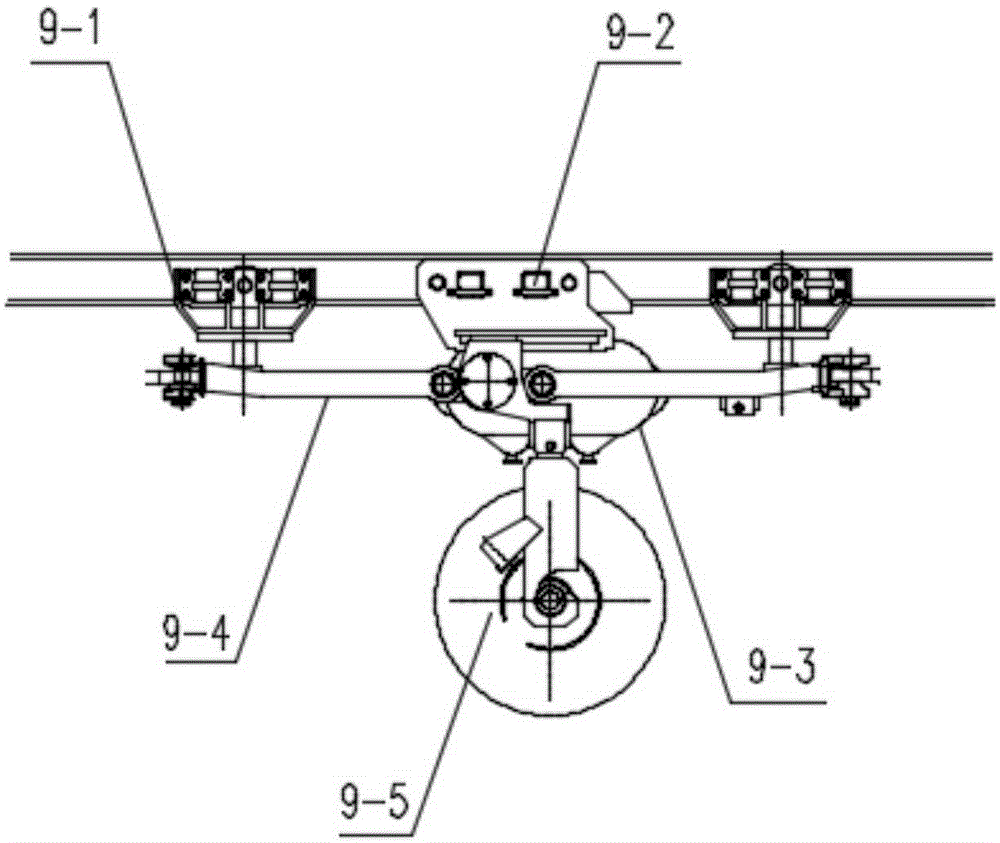

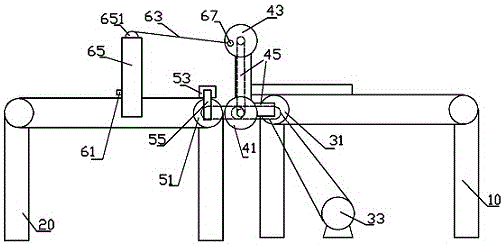

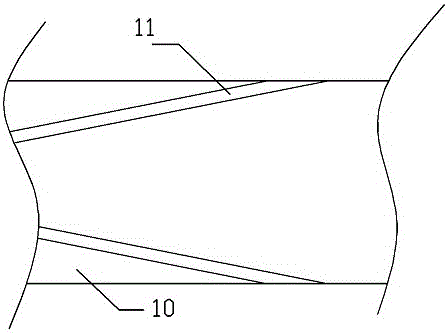

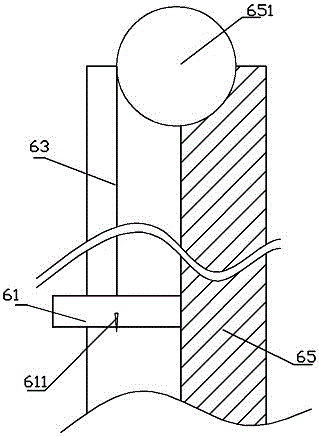

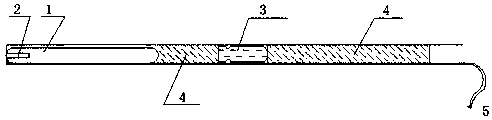

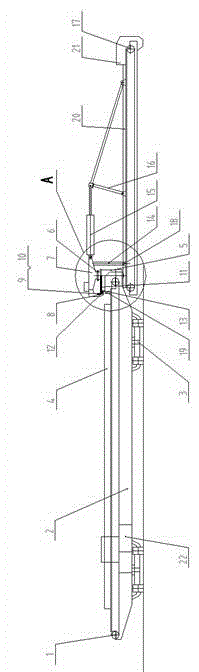

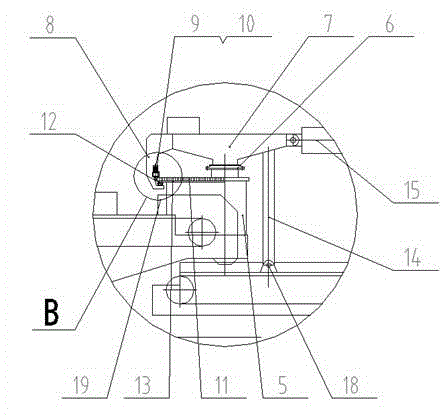

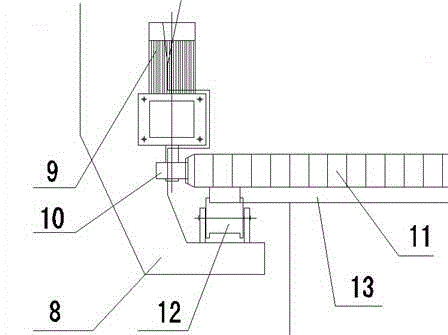

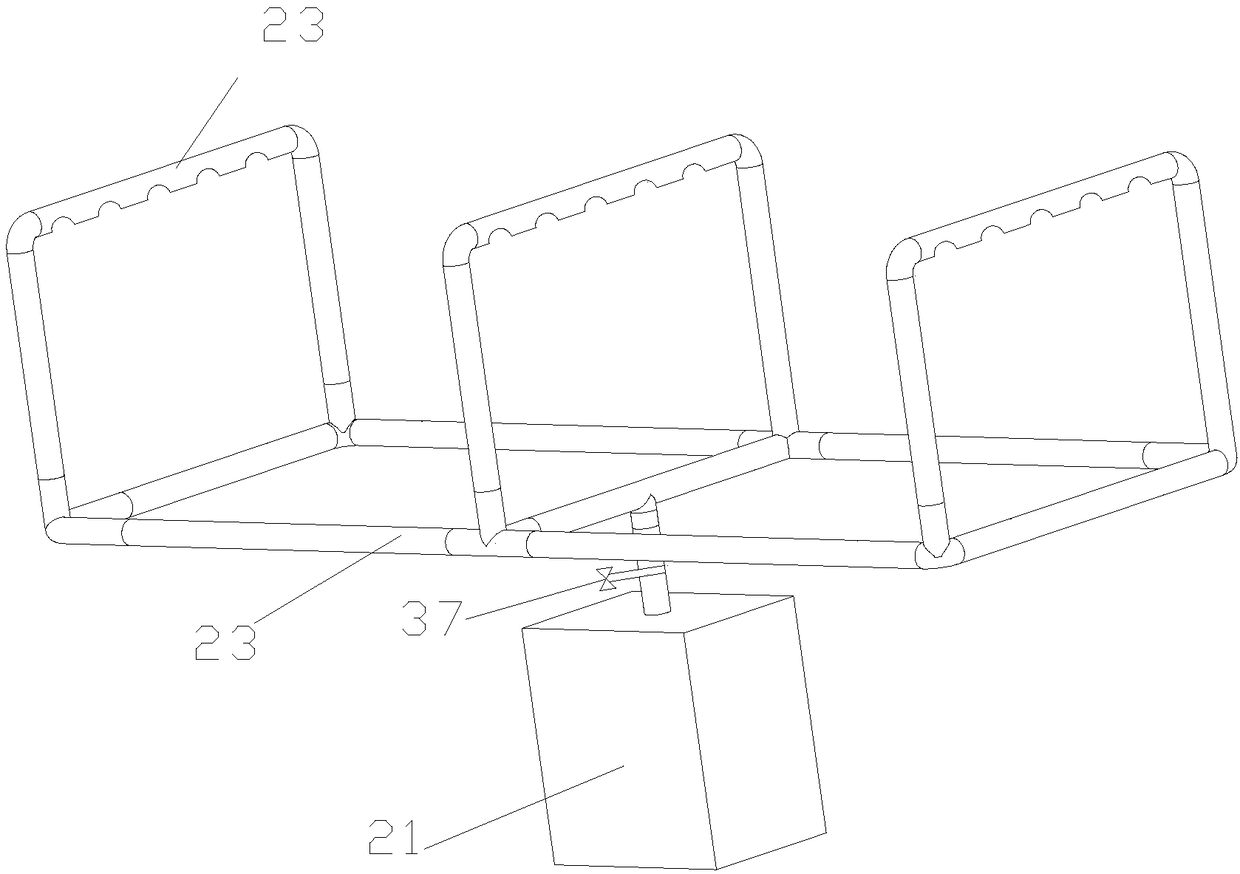

Monorail crane transportation system pulled by steel wire rope of hydraulic winch

InactiveCN105174053ARealize continuous transportationEasy constructionEarth drilling and miningUnderground transportTowerWinch

The invention discloses a monorail crane transportation system pulled by a steel wire rope of a hydraulic winch. The monorail crane transportation system comprises a suspended rail, a steel wire rope, the hydraulic winch, a tensioning tower, a rotary station, a tractor, a braking vehicle, a manual vehicle and a hoisting beam, wherein the steel wire rope penetrates through the hydraulic winch and the tensioning tower and penetrates through wheel guide frames and the rotary station to form a closed endless rope; the head and tail parts of the steel wire rope are fixedly connected with the tractor; in a transportation process, a monorail crane is pulled and controlled by the steel wire rope to operate; the braking vehicle, the manual vehicle, the tractor and the hoisting beam are suspended on the suspended rail and are in sliding connection with the suspended rail; the tractor is connected with the manual vehicle and the hoisting beam respectively through pull rods; and the manual vehicle is connected with the braking vehicle through a pull rod. The monorail crane transportation system is driven by the hydraulic winch, has a compact structure and a reasonable layout and is simple to operate, and the speed is convenient to regulate; endless speed regulation is realized, and transportation links and post workers are reduced; and security coefficients in the transportation process are improved.

Owner:徐州华东机械有限公司

Strip mining machine for mine

InactiveCN102691503AImprove stabilityImprove compactnessSlitting machinesOpen-pit miningIntegrated operationsMechanical engineering

A strip mining machine for a mine belongs to technical field of mining equipment, and is applied to integral strip mining of surrounding rock and mineral of an open-pit mine. The technical scheme is that the strip mining machine comprises a cutting, slotting and scraper type loading part, a raking down part, a scratch board transporting device, a crushing device, a rubber belt transporting device, a rotating and elevating system, a walking part and a rotating part, wherein the cutting, slotting and scraper type loading part is arranged at the front end of the strip mining machine; the scratch board transporting device is mounted at the lower part of the cutting, slotting and scraper type loading part; the back end of the scratch board transporting board device is connected to the crushing device; the crushing device is connected to the rubber belt transporting device; the rotating and elevating system is mounted at the lower part of the rubber-belt transporting device; the transporting belt of the rubber belt transporting device is mounted in the middle of the track of the walking part; the raking down part is arranged above the cutting, slotting and scraper type loading part; and the rotating part is mounted above the walking part. The strip mining machine can realize the integrated operation of continuous strip mining, crushing, transshipping and transporting for the open-pit mine, thereby greatly improving the strip mining efficiency and the productivity of the mine.

Owner:TIANDI TANGSHAN MINING TECH

Stone dumper for pile foundation filling

InactiveCN110667787ARealize throwing and fillingReal-time monitoring of throwing and filling effectsCargo handling apparatusPassenger handling apparatusArchitectural engineeringHull

The invention discloses a stone dumper for pile foundation filling. The stone dumper comprises a hull, a drum, a feed hopper and a material conveying mechanism, wherein the drum is arranged at the side part of the hull, and is used for pile foundation filling; the feed hopper is arranged at the upper part of the drum for feeding the drum; the material conveying mechanism is fixed on the deck of the hull, and is used for feeding the materials to the drum when filling and realizes continuous feeding of the materials; and an opening of the feed hopper faces upward, the end of the material conveying mechanism faces downward, and the feeding opening of the feed hopper and the end of the material conveying mechanism are opposite to each other. The stone dumper realizes continuous and long-distance feeding by adopting the separate material conveying mechanism to feed the drum, improves the efficiency, and expands the application range.

Owner:CCCC THIRD HARBOR ENG

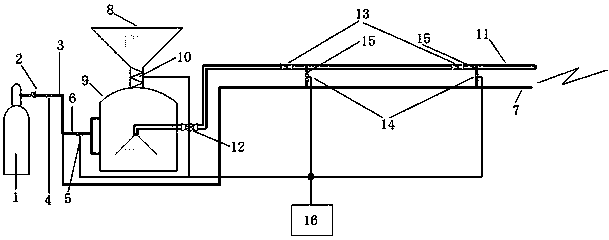

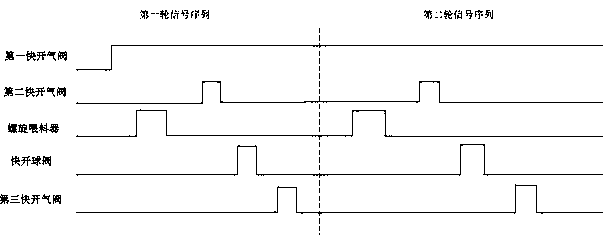

Extended-range long-distance dry powder fire extinguishing system and operation method thereof

The invention relates to an extended-range long-distance dry powder fire extinguishing system and an operation method thereof. The extended-range long-distance dry powder fire extinguishing system comprises a pressure-resistant powder tank and an inert gas source, wherein one end of a partial pressure pipeline communicates with the inert gas source, and the other end of the partial pressure pipeline is divided into two branches, one branch is a connecting pipeline, and the connecting pipeline simultaneously communicates with the pressure-resistant powder tank; one end of a conveying pipeline communicates with the pressure-resistant powder tank, and the other end of the conveying pipeline communicates with a conveying terminal; a hopper for conveying dry powder extinguishing agent is arranged at the top of the pressure-resistant powder tank; the other branch of the partial pressure pipeline is a pressurizing pipeline, the pressurizing pipeline and the conveying pipeline communicate witheach other through at least one communicating pipeline, and one communicating pipeline corresponds to a one-way valve. According to the system, the dry powder extinguishing agent can be used as a fire extinguishing medium on a high-altitude fire-fighting platform, the characteristic that the dry powder medium and gas powder two-phase mixed flow is light in self weight is fully utilized, the fireextinguishing medium can reach higher height easily, and the problem of high-altitude fire fighting is solved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Wooden floorboard conveying device

InactiveCN108946029AEasy to transportNo falling phenomenonBuilding material handlingMechanical conveyorsEngineeringMechanical engineering

The invention provides a wooden floorboard conveying device and relates to the technical field of floorboard conveying machines. The wooden floorboard conveying device comprises a fixing mechanism. The fixing mechanism comprises a retractable bottom plate, auxiliary plates arranged on two sides of the retractable bottom plate and used for limiting floorboards, and an area-variable bearing part used for holding the floorboards, and the bearing part is fixedly connected with an elastic part fixedly arranged on the retractable bottom plate. A retractable mechanism used for pushing the floorboardsis further included and comprises a retractable frame and an elastic block which is fixedly arranged at the end of the retractable frame. The floorboards can be rapidly conveyed to a machining region, the safety of the whole conveying process is high, the phenomenon that the floorboards fall off cannot occur, and continuous conveying of the floorboards is achieved. The retractable bottom plate and the area-variable bearing part can broaden the using range of the conveying device, the conveying device is suitable for the floorboards in different sizes, and the elastic part and the retractablemechanism can achieve successive conveying of the floorboards.

Owner:ZHEJIANG NEW INSIGHT MATERIAL TECH CO LTD

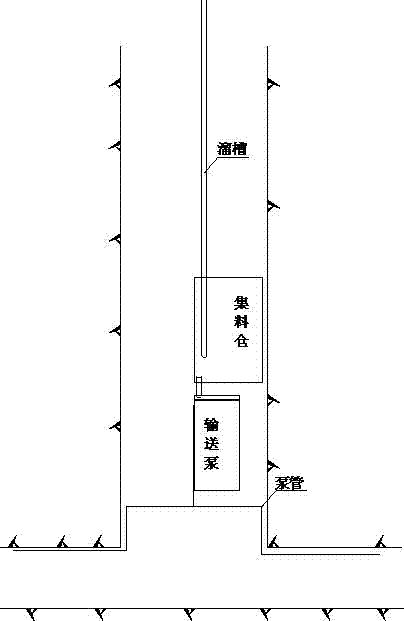

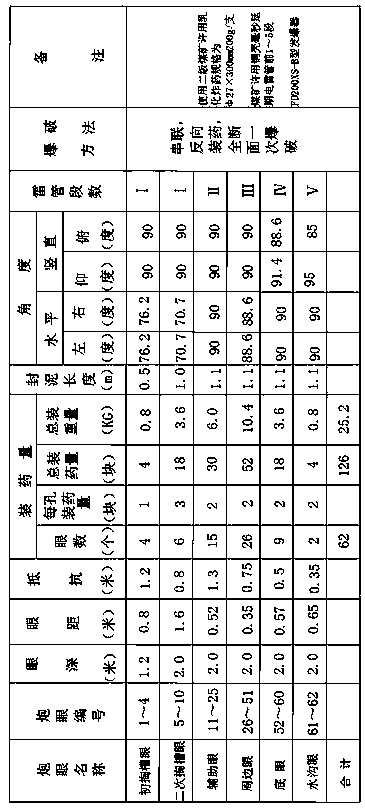

Method for concrete conveying and lining construction in large-slope long inclined-shaft small-section tunnel

InactiveCN107288662ASpeed up dismantlingImprove efficiencyUnderground chambersTunnel liningSlagSteep slope

The invention discloses a concrete transportation and lining construction method for a small-section tunnel with a long inclined shaft with a large slope: the inclined shaft penetrates into the main tunnel from the side of the tunnel, and the mixed concrete enters the aggregate bin at the bottom of the inclined shaft through a chute installed on the inclined shaft , and then transported to the pouring areas on both sides by the delivery pump, and each pouring area uses four sets of bottom formwork and two sets of side arch formwork for partition pouring. The invention solves the problem of rail slag transportation and concrete hole pouring transportation through the inclined shaft chute The interference of parallel operations, through the pumping relay in the front tunnel, overcomes the difficulties of trackless transportation, concrete transportation and bottom sorting equipment in the tunnel. The difficulty of large and narrow passages for bottom picking equipment is increased through the formwork configuration of 4 sets of bottom formwork and 2 sets of side and top arches combined with partitioned pouring. The working surface is optimized, the space is optimized, and the construction progress is accelerated under the premise of ensuring the construction quality and safety.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Tea packaging machine

InactiveCN106347762ARealize continuous transportationRealize reciprocating motionWrapper twisting/gatheringEngineeringConductor Coil

The invention discloses a tea packaging machine, relates to the mechanical field of packaging parts or materials and aims at solving the problem that packaging belt is manually put in a clamping unit and the packaging efficiency is low during packaging bag heal-sealing in the prior art and providing a packaging machine for pipeline operation. The tea packaging machine comprises a support and a second support. A clamping framework of the first support comprises a first winding drum and a second winding drum which are wound with packaging bag films, the first heat-sealing unit of the second support comprises a heat-sealing block, a second heat-sealing unit of the second support comprises a heat-sealing strip, a connecting piece, a supporting rod and a driving rod, the end, close to the first support, of the second support is in rotary connection with the supporting rod, the supporting rod is fixedly connected to the end, close to the first support, of the second support and is provided with a sliding groove, a heat-sealing strip is connected in the sliding groove in a sliding mode, one end of the connecting piece is connected with the heat-sealing strip, the other end of the connecting piece bypasses the upper end of the supporting to be connected with the driving rod, and the driving rod is connected to the side wall of one end of the second winding drum and is away from the center of the second winding drum.

Owner:GUIZHOU PROVINCE ZHENGAN COUNTY YIREN TEA IND CO LTD

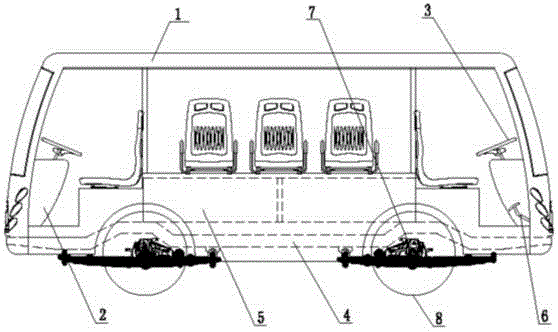

Mining flame-proof two-way electric rubber-tyred mancar

InactiveCN105291867AIncrease driving spaceReal-time monitoring of operationVehicular energy storageElectric/fluid circuitLithiumSteering wheel

The invention discloses a mining flame-proof two-way electric rubber-tyred mancar which comprises an electric rubber-tyred mancar body. The mining flame-proof two-way electric rubber-tyred mancar is characterized in that a vehicle control system and a steering wheel are arranged at each of the front end and the rear end of the electric rubber-tyred mancar; a flame-proof lithium ion storage battery power supply and a braking system are arranged at a chassis of the electric rubber-tyred mancar; two steering axles are arranged on the front side and the rear side of the electric rubber-tyred mancar. The mining flame-proof two-way electric rubber-tyred mancar effectively solves the problem of severe environmental pollution of the conventional trackless rubber-tyred car; the electric rubber-tyred mancar runs in two directions, so that the demand of the turning radius on an underground roadway is reduced, the roadway construction investment is reduced, the vehicle running space is increased, the continuous transport is realized, and the working efficiency is improved; the running condition of vehicle can be monitored in real time in the running process, the visual operation is improved, and the safety production of mines is improved.

Owner:济宁高科股份有限公司

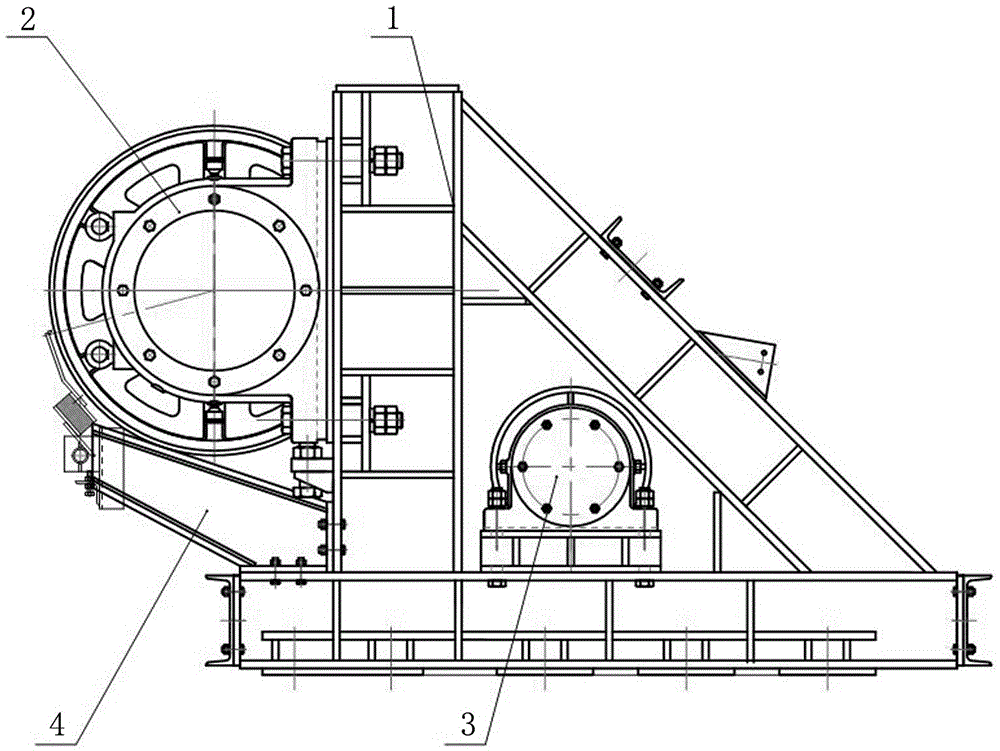

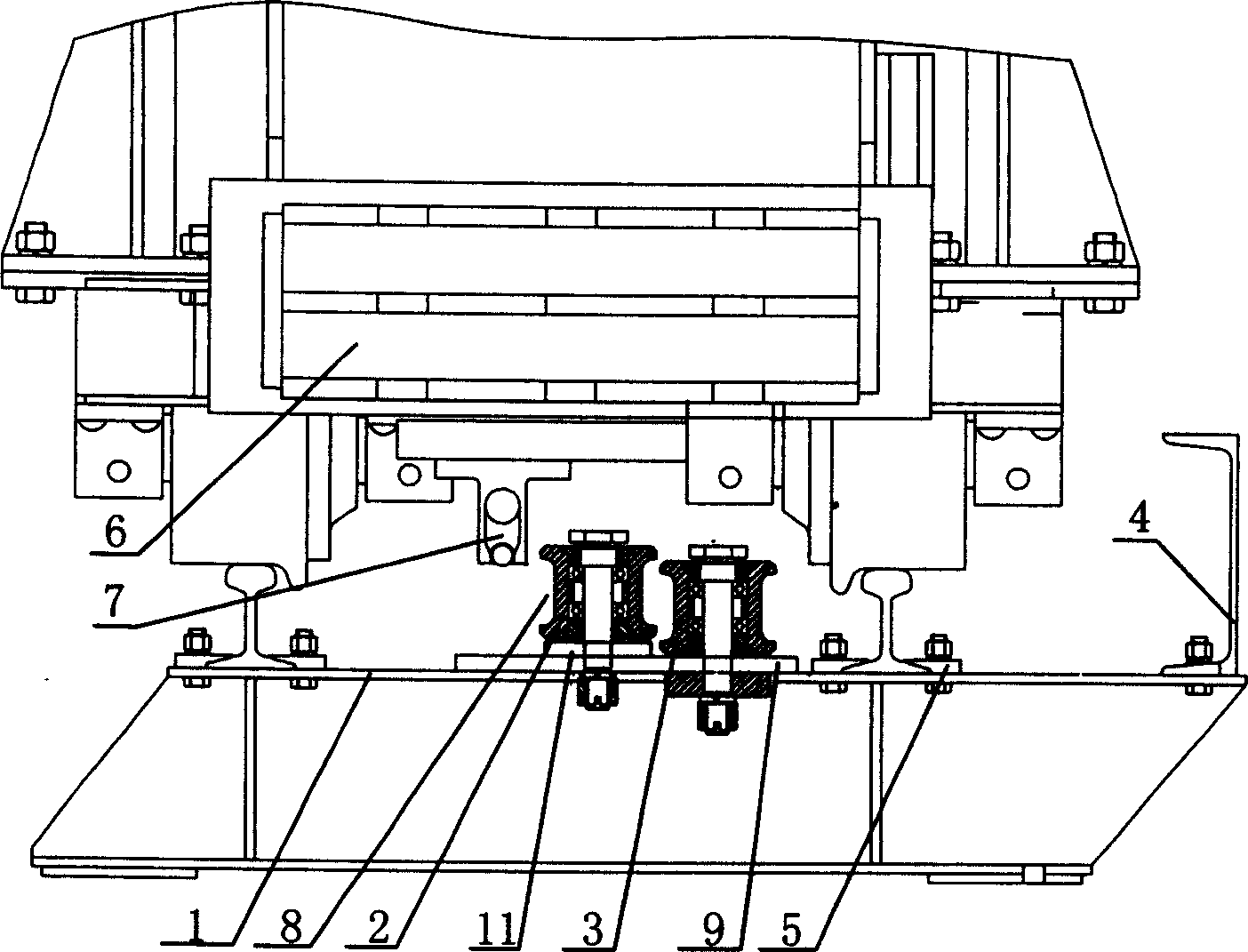

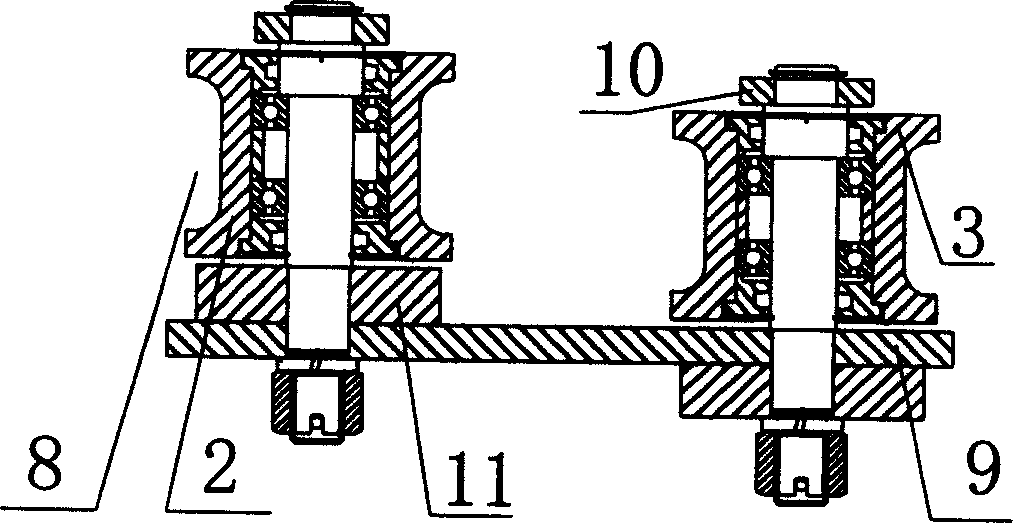

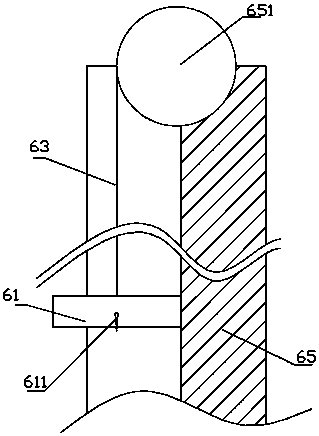

Coal unloading device for high-power belt conveyor

InactiveCN105460583AReasonable designIncrease stiffnessConveyorsCleaningEconomic benefitsEngineering

The invention relates to underground coal mine conveying arrangement, in particular to a coal unloading device suitable for an underground coal mine high-power belt conveyor. The coal unloading device comprises an unloading triangular rack (1), and a towing drum (3) is mounted on the unloading triangular rack (1). The coal unloading device for the high-power belt conveyor is characterized in that a connecting seat (8) is fixedly mounted on the upper part of the unloading triangular rack (1); a drum support (10) is mounted on the connecting seat (8); an unloading drum (2) is mounted in the drum support (10); a cleaner support (4) is mounted on the drum support (10); and an inclined strut (5) is arranged between the drum support (10) and the unloading triangular rack (1). The coal unloading device suitable for the underground coal mine high-power belt conveyor is reasonable in design, requirements of coal unloading of a coal house can be met or the head and the tail of a belt can overlap each other. The coal unloading device is reasonable in design, simple in structure, good in using effect, obvious in economic benefit and worthy of being popularized and used.

Owner:XISHAN COAL ELECTRICITY GRP

Turning mechanism of consecutive mining tractor

Owner:SHANXI COKING COAL GROUP

Time-sharing transporting and filling system for underground coal and waste rock

InactiveCN101871363BRealize continuous transportationImprove dynamic transmission capacityMaterial fill-upUnderground transportTime-sharingCrusher

Owner:新汶矿业集团有限责任公司孙村煤矿

Zero-leakage alkali discharging device

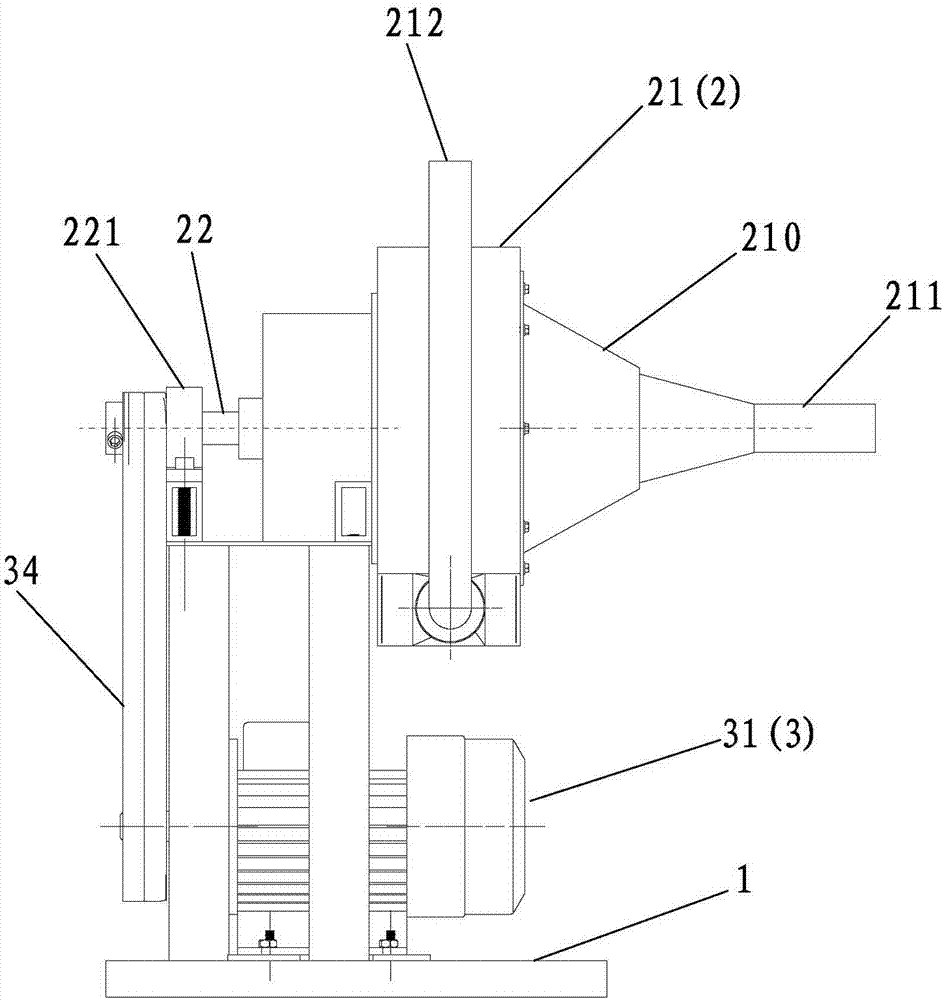

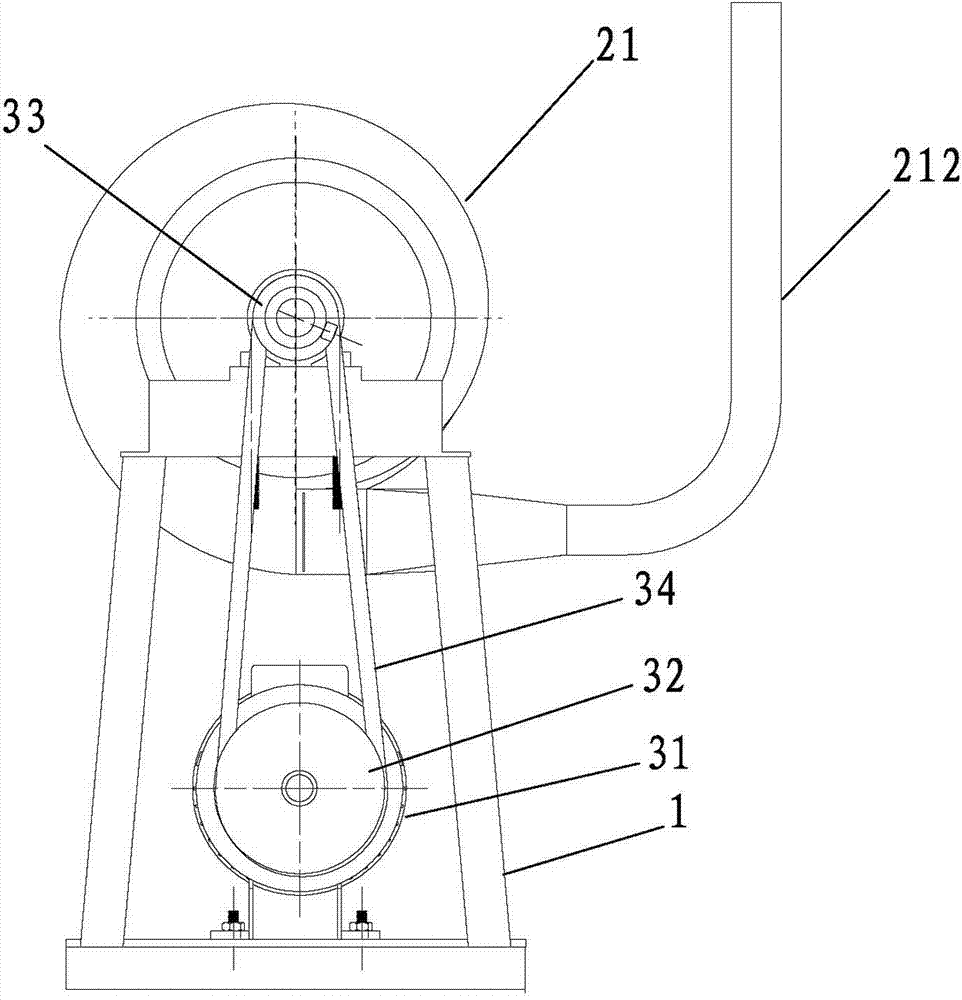

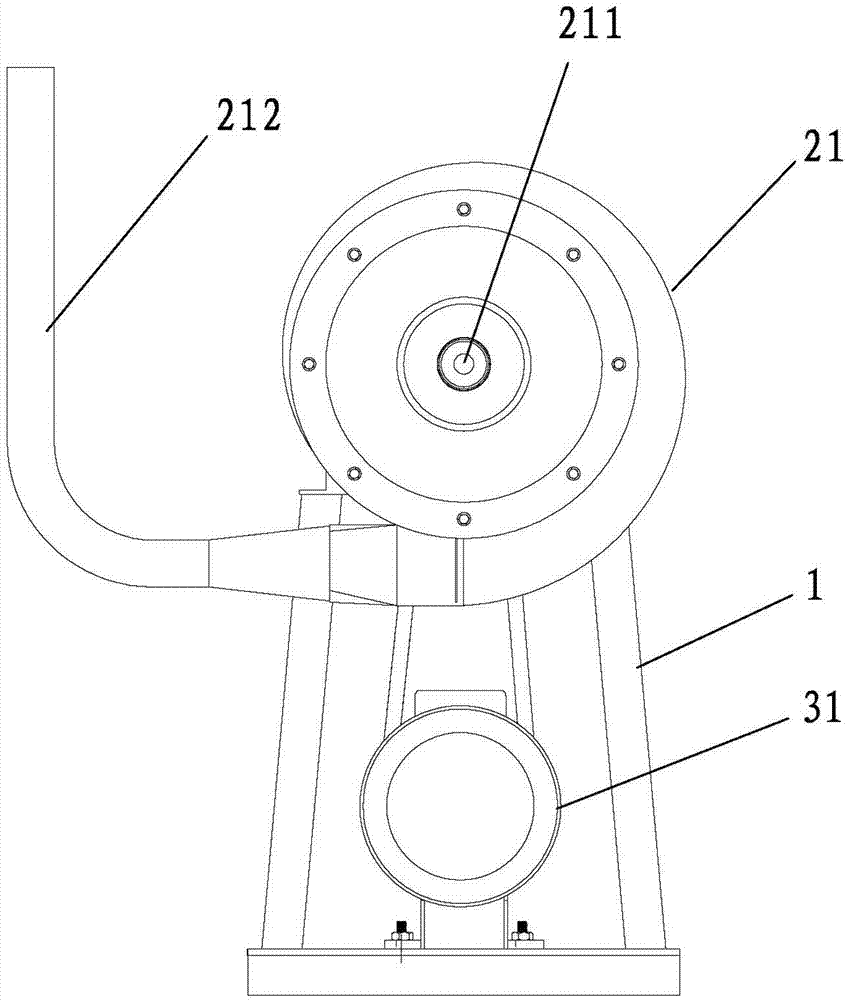

InactiveCN104847669ARealize continuous transportationReduce pollutionSpecific fluid pumpsPump componentsImpellerChemical solution

The invention discloses a zero-leakage alkali discharging device, which comprises a rack, a device body arranged on the rack and a driving mechanism, wherein the device body comprises a housing, an impeller and a main shaft; the housing is volute-shaped, and the side surface and the spiral tail end are provided with an alkali inlet pipeline and an alkali outlet pipeline; one end of the main shaft is in transmission connection with the driving mechanism, the other end of the main shaft extends into the housing along the axial direction of the housing, the impeller is arranged in the housing and axially arranged at the other end of the main shaft, and the impeller is driven to rotate by the driving mechanism through the main shaft. Compared with the prior art, the alkali discharging device disclosed by the invention has the advantages of zero leakage, high efficiency, environment protection, no residual solution, ability of reducing resource waste and environmental pollution and the like, has great economic values and application values and is wide in application prospect, thereby being an optimal choice for transporting chemical solutions in each industry.

Owner:XIAMEN UNIV OF TECH

Tunnel deslagging device and system and deslagging method

InactiveCN110905824ARealize continuous transportationHigh degree of automationPump installationsTunnelsStructural engineeringShield tunneling

The invention provides a tunnel deslagging device and system and a deslagging method. The tunnel deslagging device comprises a continuous belt conveyor, a shield tunneling machine arranged in a tunneland a turn-back belt conveyor arranged in a launching shaft, wherein the shield tunneling machine is used for digging out muck in the tunnel and outputting the dug muck to the continuous belt conveyor; the continuous belt conveyor is provided with a horizontal conveying part and an inclined conveying part, the horizontal conveying part is horizontally arranged in the tunnel, the inclined conveying part is obliquely arranged in the launching shaft, and the horizontal conveying part is used for conveying muck excavated by the shield tunneling machine to the inclined conveying part; the inclinedconveying part is used for transferring muck from the horizontal conveying part to the turn-back belt conveyor; the turn-back belt conveyor is obliquely arranged, the inclination direction of the turn-back belt conveyor is opposite to that of the oblique conveying part, and the turn-back belt conveyor is used for conveying muck from the oblique conveying part to the tail end to be unloaded so asto complete deslagging. The tunnel deslagging device can be used in a tunnel with a small section, and has the advantages of safety, reliability, high transportation efficiency and the like.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

Metal mask cutting protection equipment

ActiveCN113024098AIncreased continuous transportImprove practicalityFouling preventionGlass severing apparatusRatchetManufacturing engineering

The invention discloses metal mask cutting protection equipment, and relates to the technical field of mask cutting protection equipment, in particular to metal mask cutting protection equipment. The equipment comprises a first servo motor, an output shaft of the first servo motor is fixedly sleeved with a driving disc, the edge of the front face of the driving disc is fixedly connected with a driving column, and the outer surface of the driving column is movably sleeved with one end of a driving sleeve rod. According to the metal mask cutting protection equipment, the upper surface of a clamping jaw is a flat rectangle, a fixing notch is formed in the inward side of the upper surface of the clamping jaw, and the fixing notch is matched with a second hydraulic telescopic rod, a bearing table, a lifting sleeve and a ratchet wheel, so that a mask conveyed by a poke rod can be conveyed to the clamping jaw by the bearing table, the mask can be cut in the inner cavity of a protective case and taken on the outer side of the protective case, and the hidden danger caused by splashing of crushed materials when the mask is cut can be effectively solved.

Owner:常州高光半导体材料有限公司

Paper feeding device for three-dimensional paper box forming machine

ActiveCN106003819ARealize continuous transportationAvoid replacementBox making operationsPaper-makingData controlDrive shaft

A paper feeding device for a three-dimensional paper box forming machine is characterized in that an induction control mechanism comprises a data disk, a photoelectric induction switch and a driven shaft, the driven shaft and a drive main shaft are in synchronous transmission fit, and the data disk is arranged on the driven shaft; and the photoelectric induction switch corresponds to the data disk and is used for recording the rotation angle of the data disk and controlling a drive assembly to drive a paper outlet bottom plate. The paper feeding device has the beneficial effects that a touch screen or a data control center can be directly arranged, assigned signal data are set to the photoelectric control switch, when the photoelectric induction switch records that the data disk rotates by a certain angle, the drive assembly is controlled to drive the paper outlet bottom plate to be located at the first position or the second position, and continuous conveying of various kinds of paper different in size and length can be achieved. Compared with the prior art, the structure is simpler, a cam does not need to be replaced, and operation is more convenient.

Owner:温州科迈机械有限公司

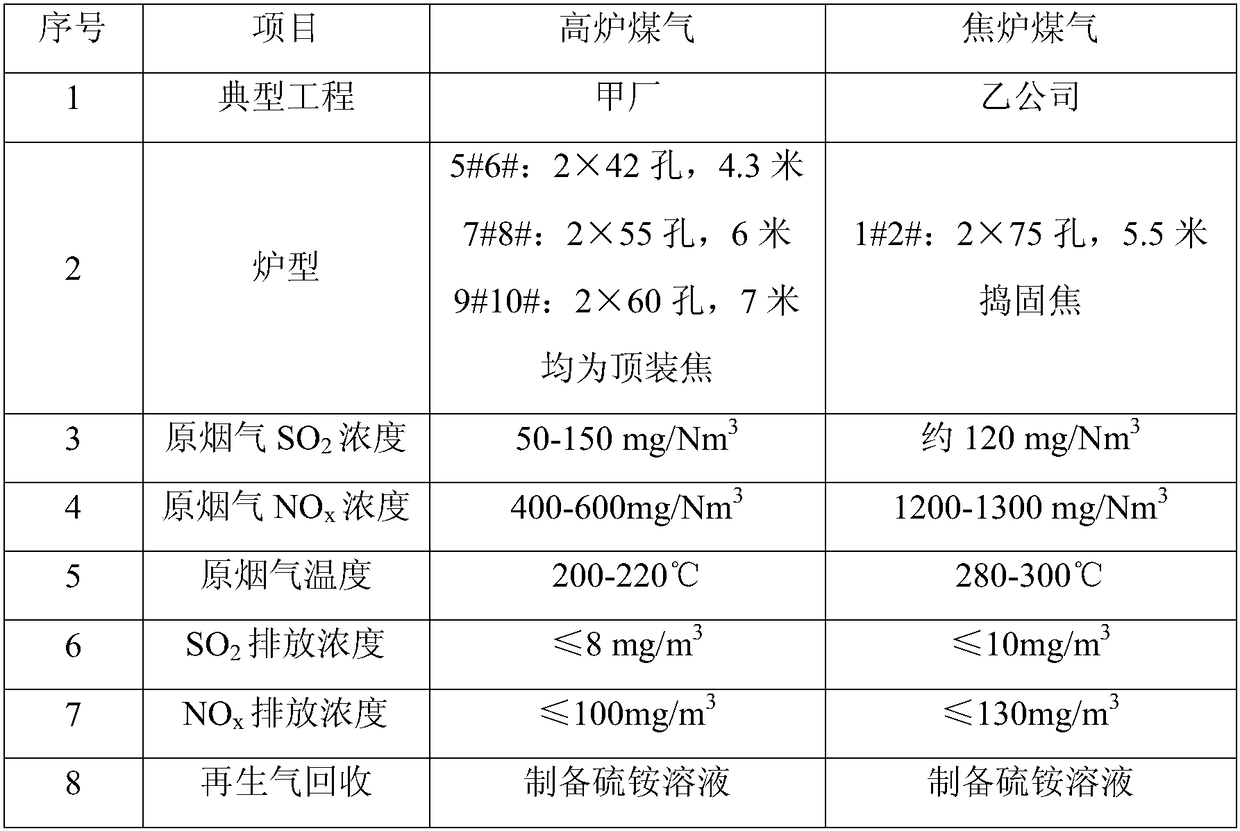

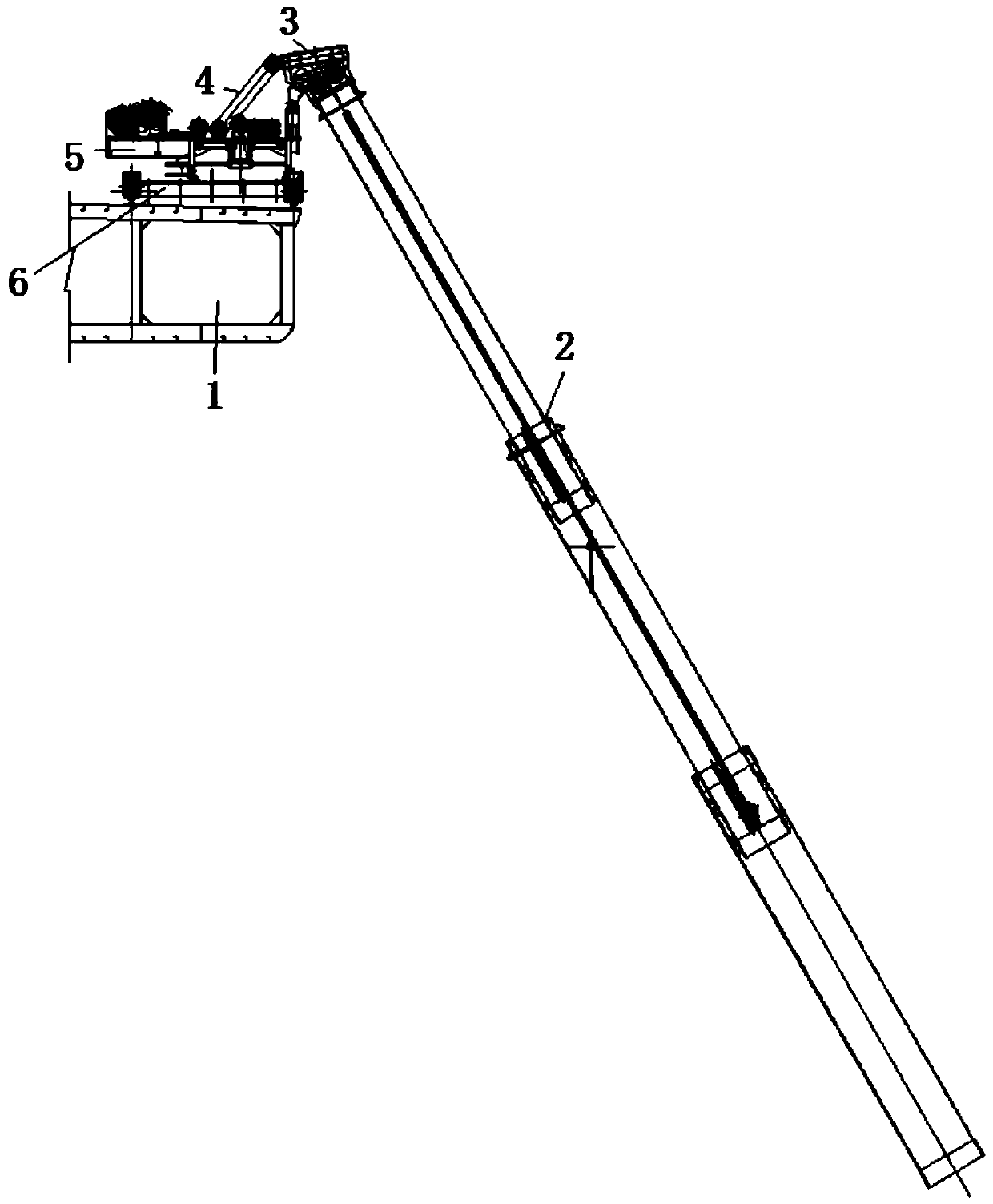

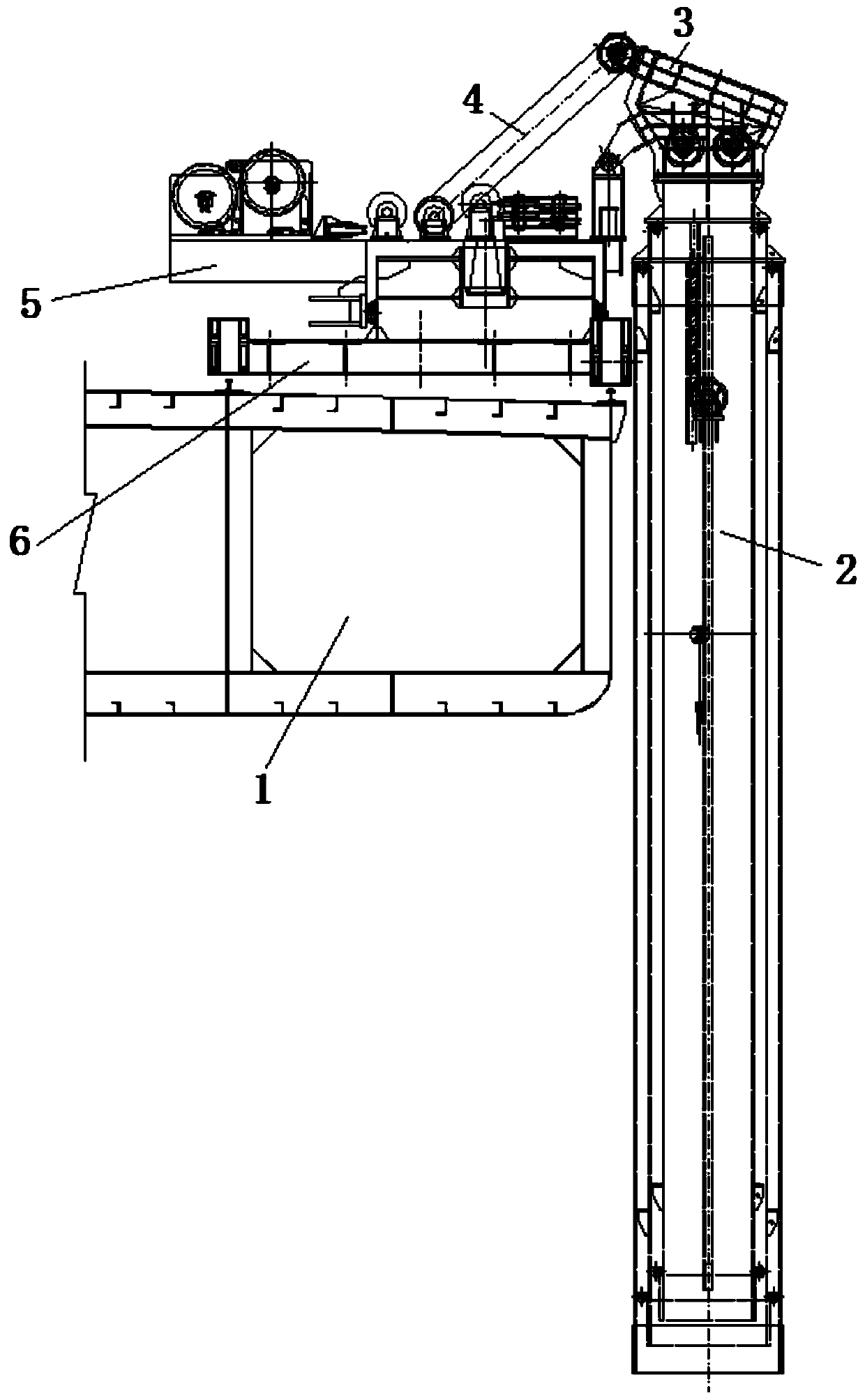

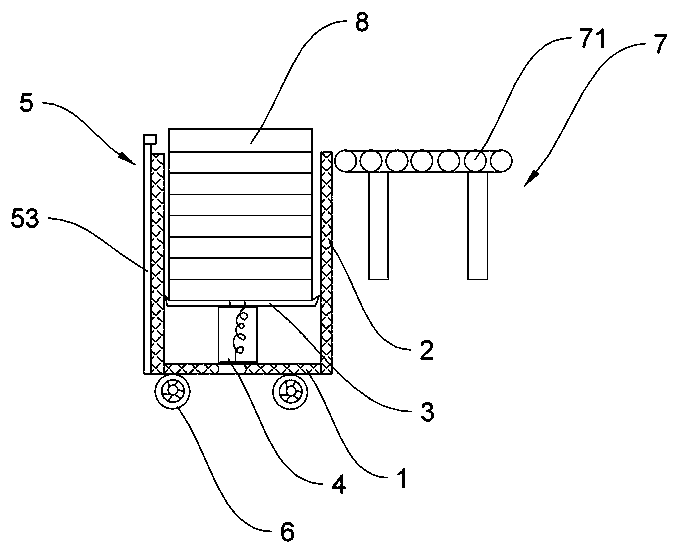

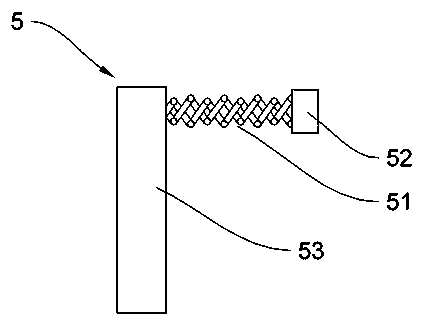

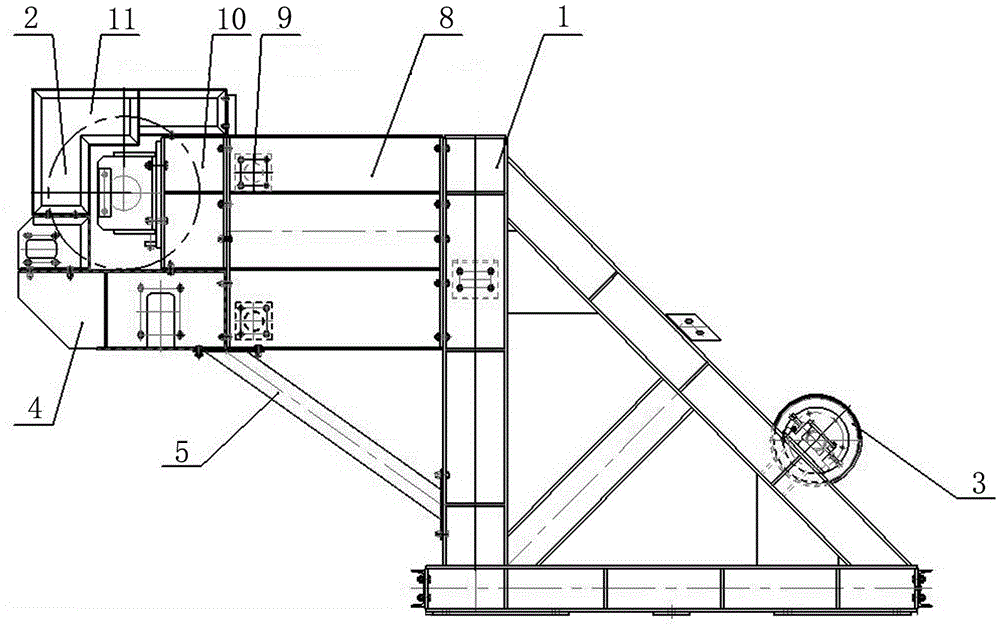

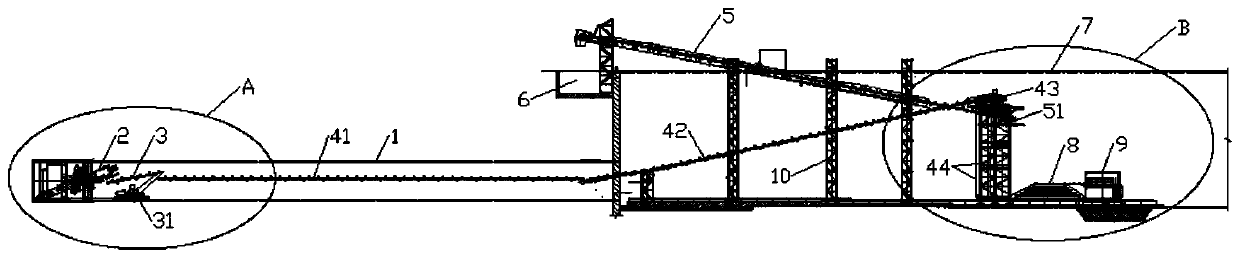

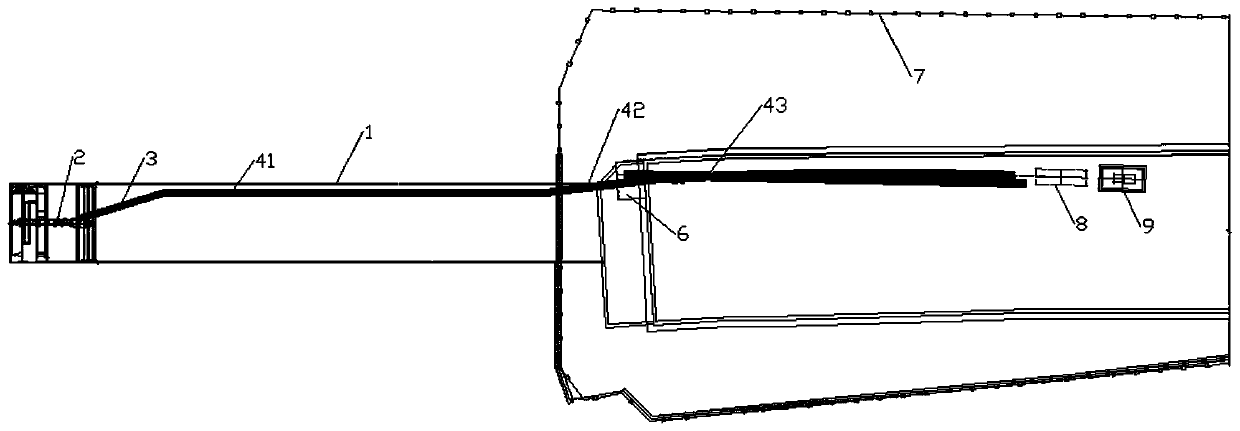

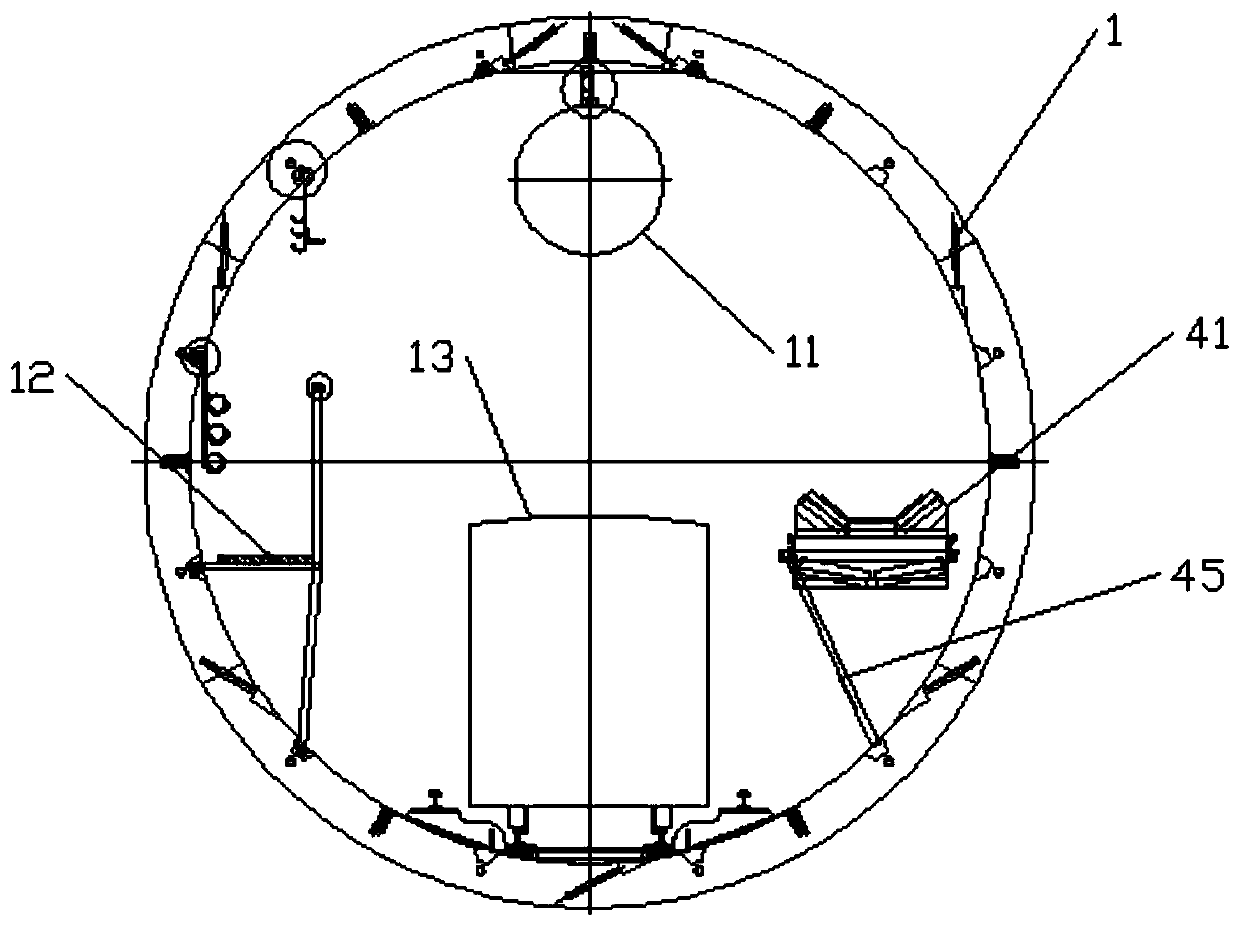

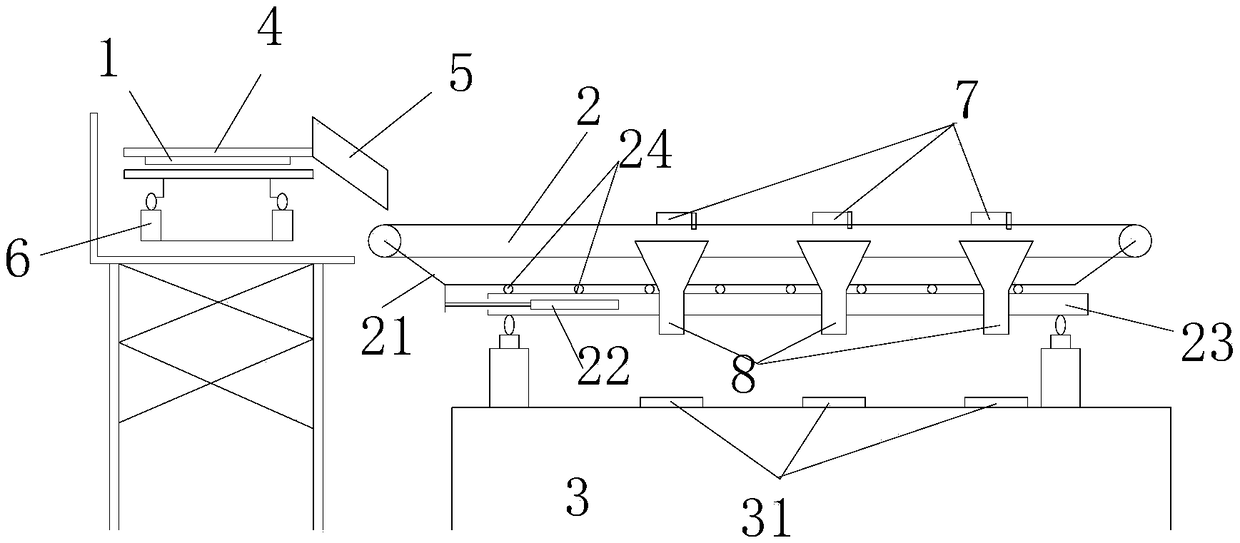

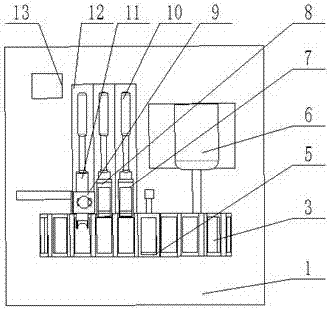

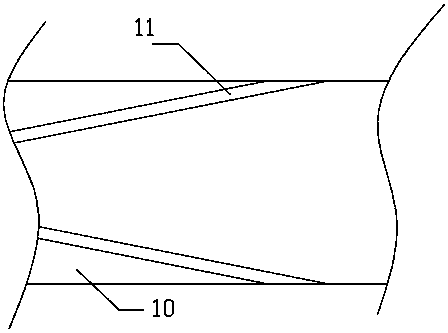

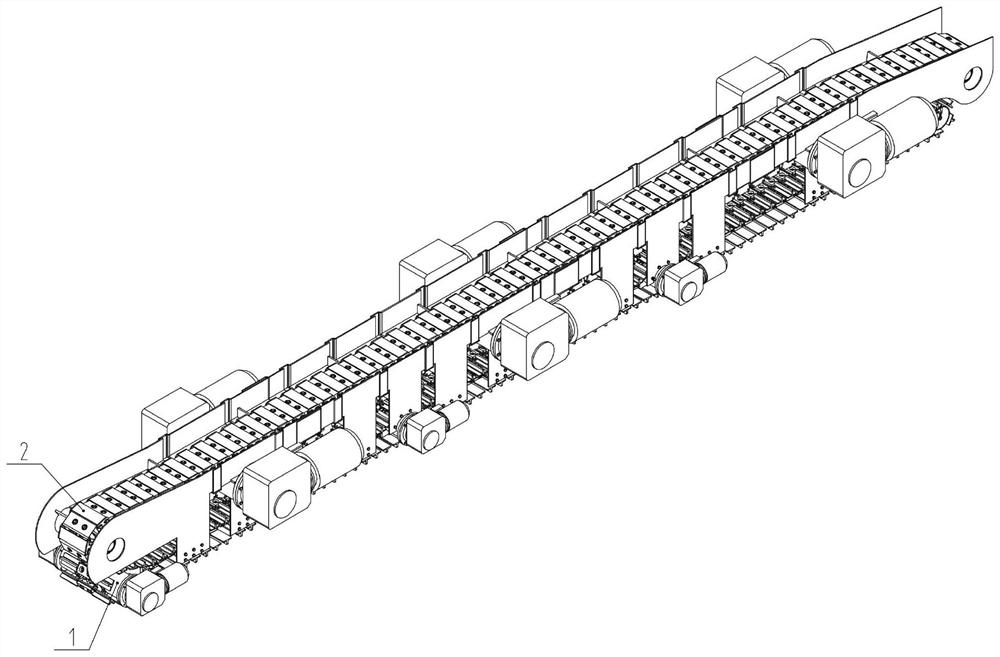

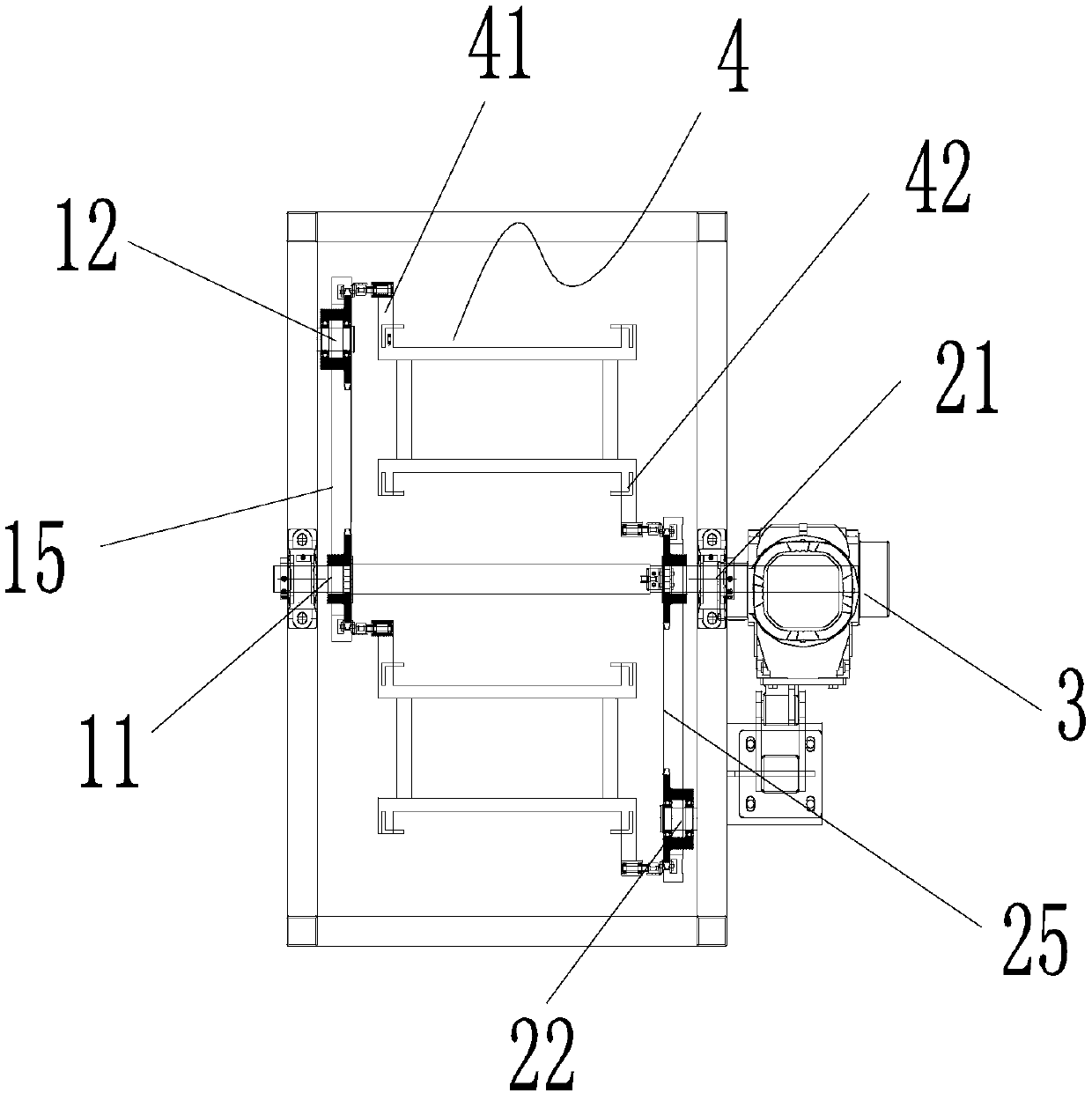

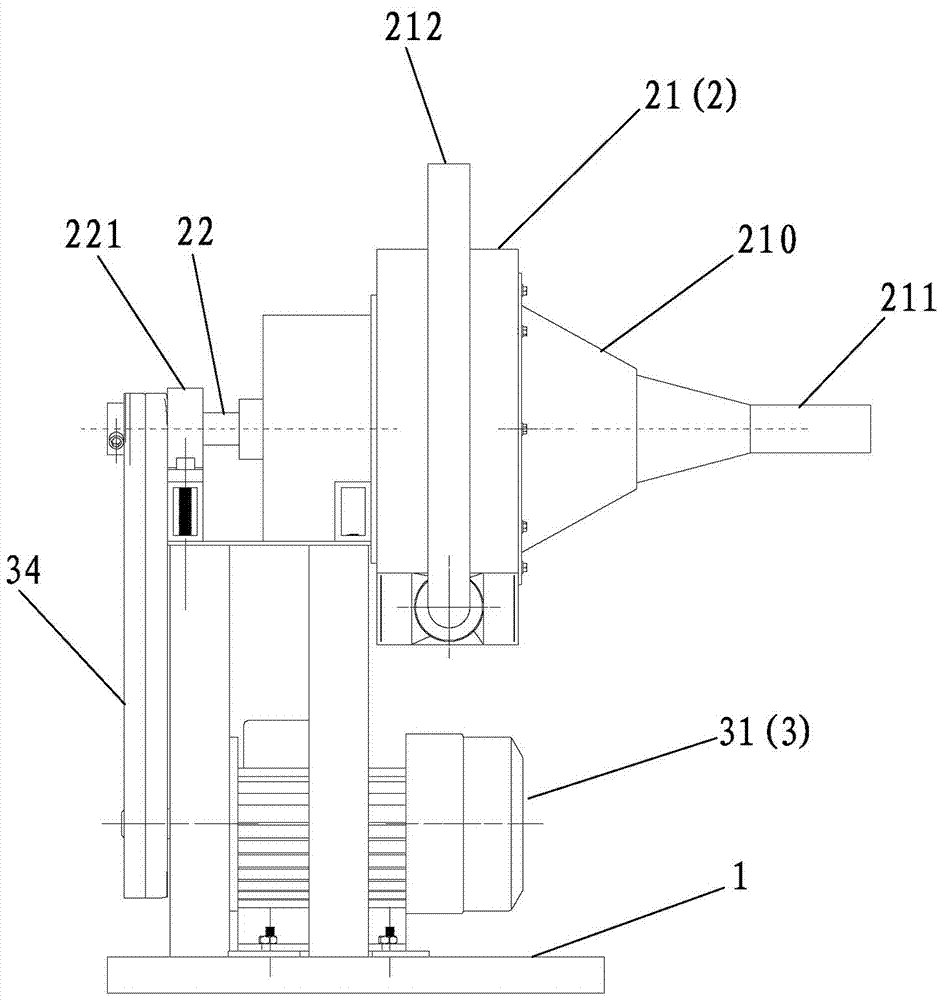

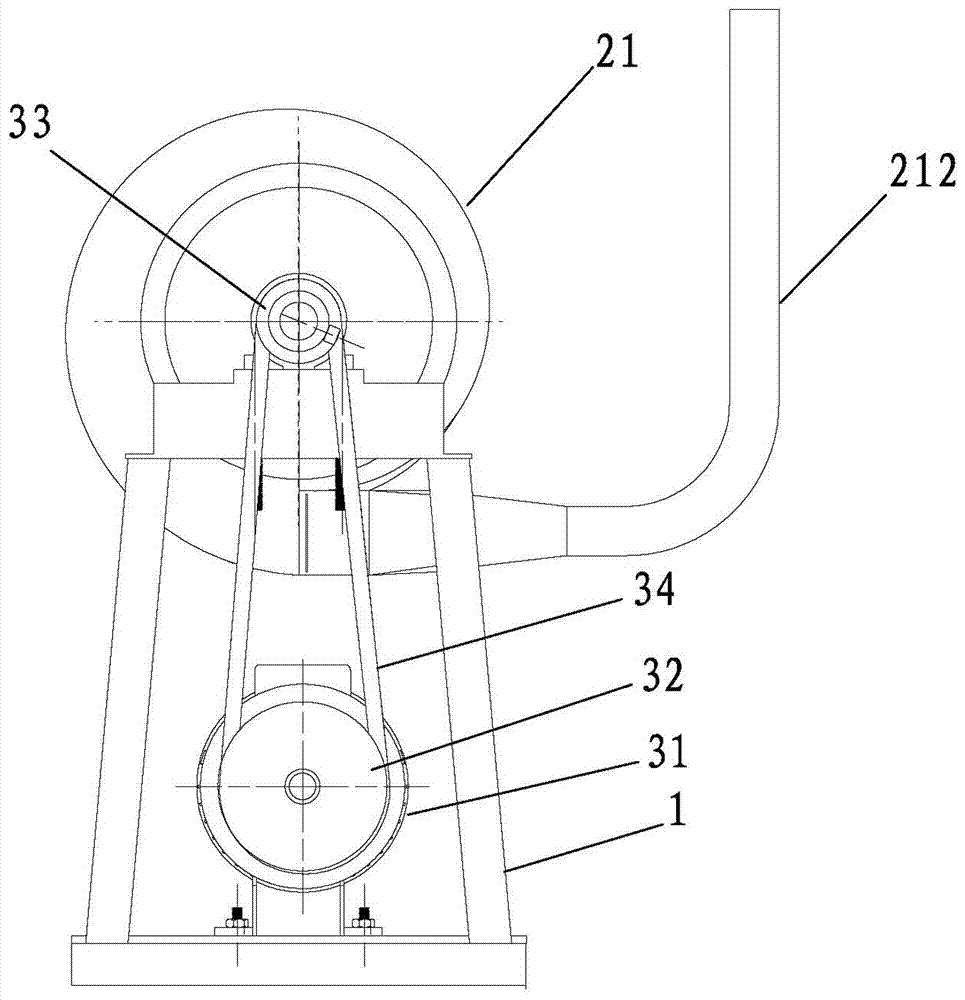

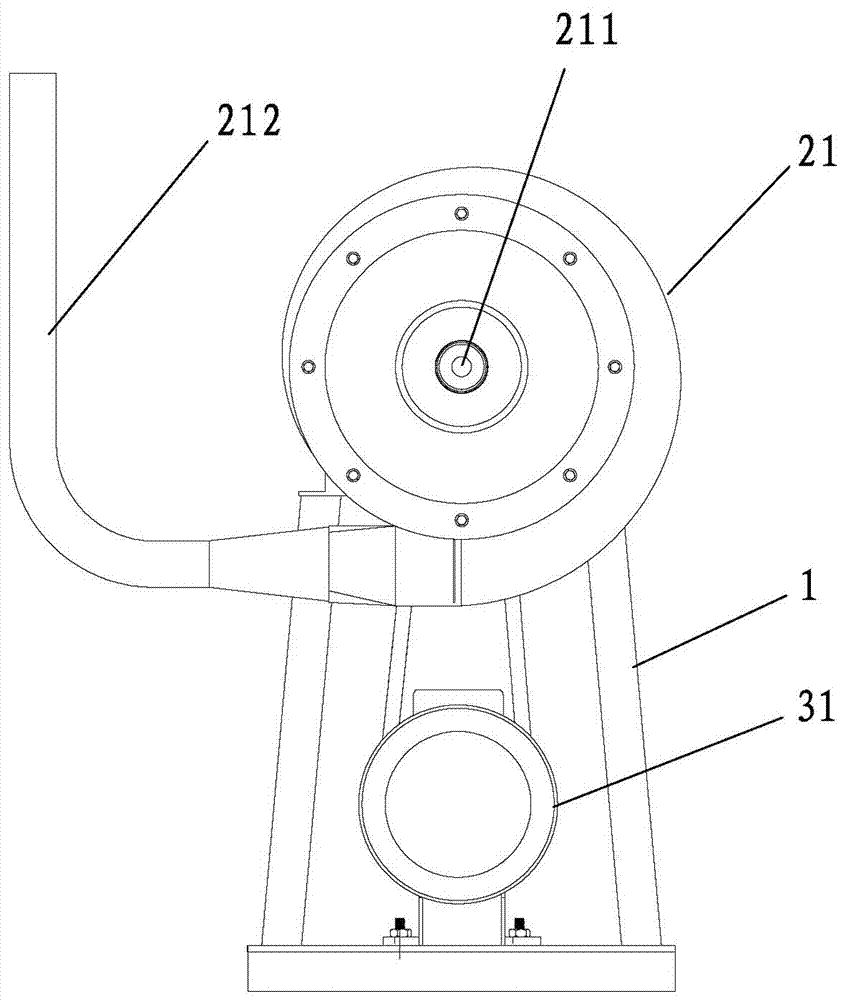

Top coal loading system for coke oven

PendingCN109368224ARealize continuous transportationEasy to operateConveyorsLoading/unloadingCoke ovenEngineering

The invention relates to the technical field of top coal loading for coke ovens, in particular to a top coal loading system for a coke oven. The top coal loading system comprises a coal receiving beltconveyer (1), a first unloading device, a coal unloading belt conveyer (2) and a second unloading device; the coal receiving belt conveyer (1) is used for receiving and conveying coal; the first unloading device is connected with the coal receiving belt conveyer (1) and arranged to be capable of transferring the coal on the coal receiving belt conveyer (1) to the coal unloading belt conveyer (2);the coal unloading belt conveyer (2) is arranged to be capable of being connected to the top of the coke oven (3); and the second unloading device is connected with the coal unloading belt conveyer (2) and arranged to be capable of transferring the coal on the coal unloading belt conveyer (2) to a top inlet (31) of the coke oven (3). According to the top coal loading system, cooperative operationof the coal receiving belt conveyer and the coal unloading belt conveyer is adopted, therefore, continuous belt conveying is achieved for top coal loading operation, operation is easy, fast and efficient, and an oven body of the coke oven is protected.

Owner:山西沁新能源集团股份有限公司

Paper feeding device of three-dimensional carton forming machine

ActiveCN106003819BRealize continuous transportationAvoid replacementPaper-makingBox making operationsNumerical controlDrive shaft

A paper feeding device of a three-dimensional carton forming machine. It is characterized in that: the induction control mechanism includes a data disk, a photoelectric sensor switch, and a driven shaft, and the driven shaft cooperates with the drive shaft in synchronous transmission, the data disk is installed on the driven shaft, and the photoelectric sensor switch corresponds to the data disk Set, used to record the rotation angle of the data disk and control the drive assembly to drive the output bottom plate. Its advantage is that it can be directly equipped with a touch screen or CNC control center. By setting the specified signal data for the photoelectric control switch, when the photoelectric sensor switch records the data disc and rotates through the specified angle, the control drive component drives the paper output bottom plate to the first position or the second position. position, it can realize the continuous transportation of papers of various sizes and lengths. Compared with the prior art, not only the structure is simpler, but also there is no need to replace the cam, and the operation is more convenient.

Owner:温州科迈机械有限公司

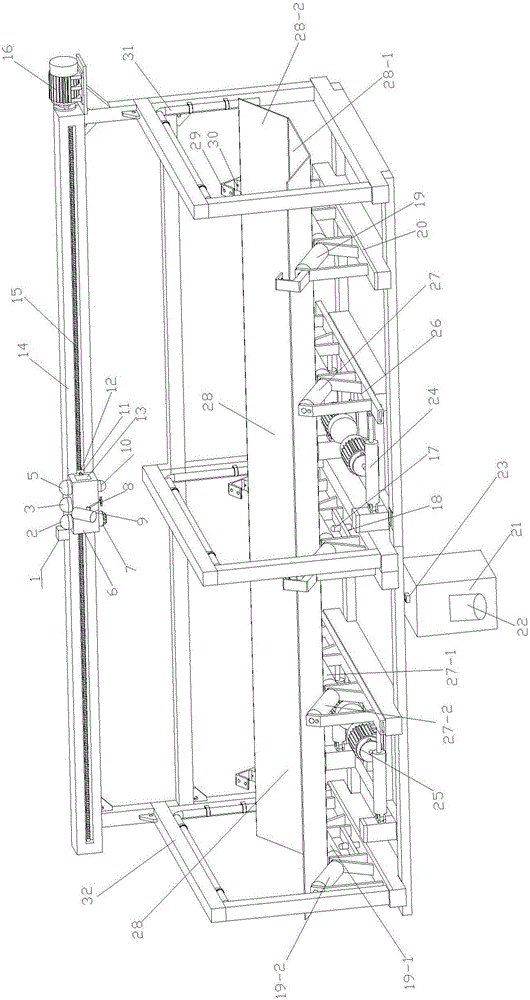

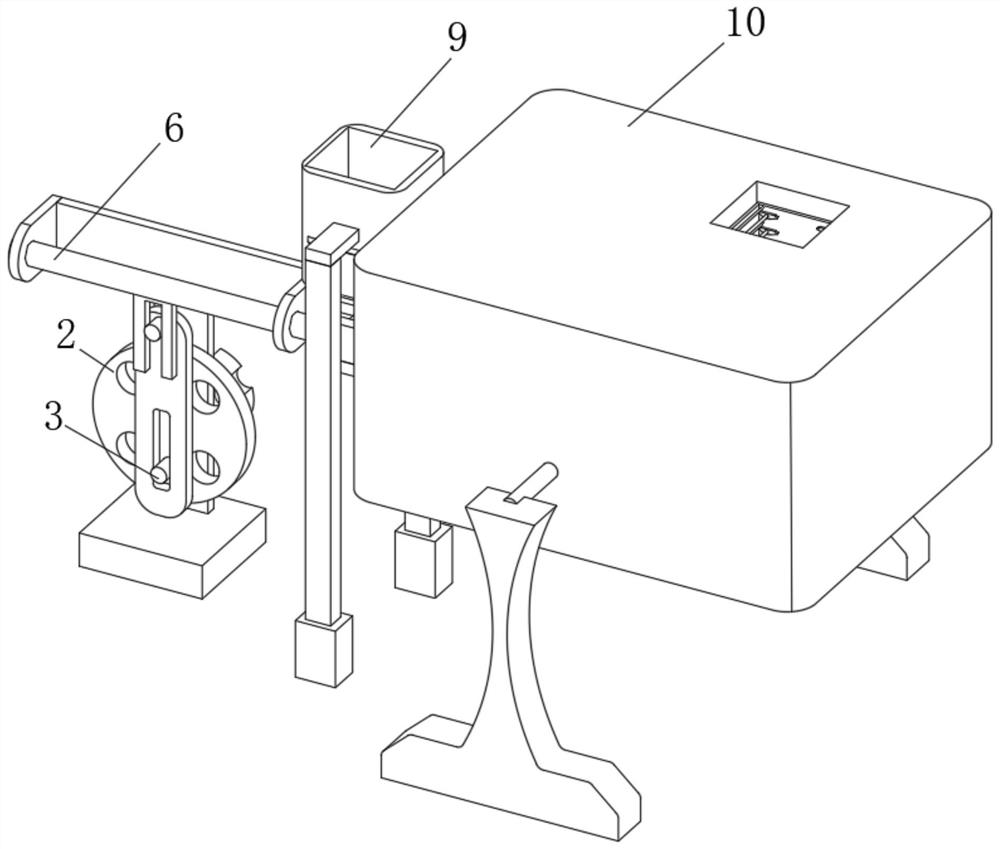

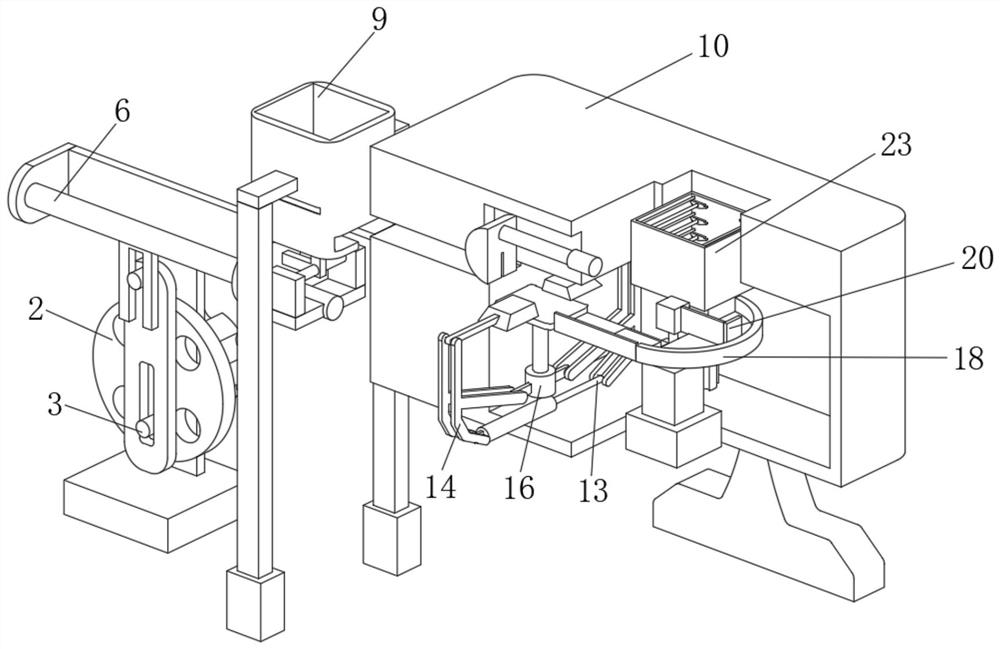

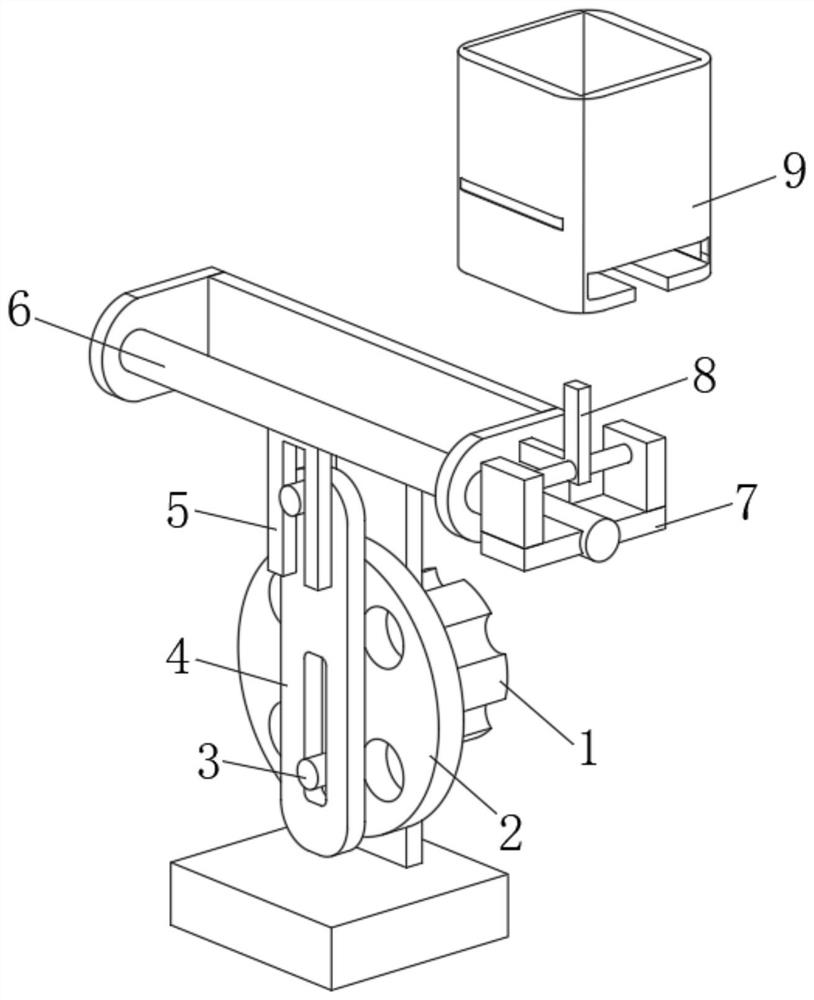

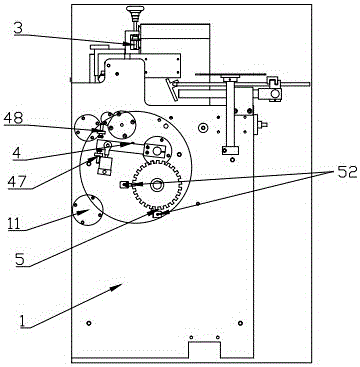

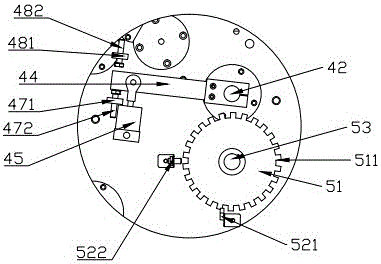

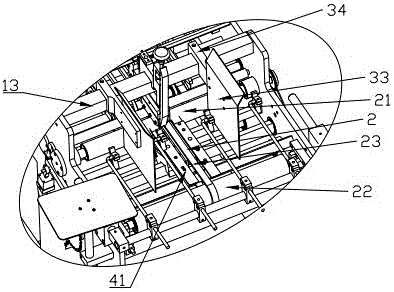

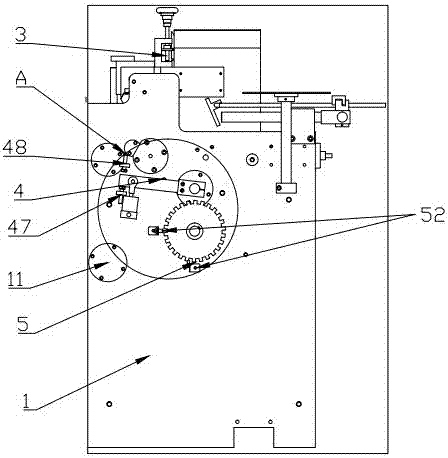

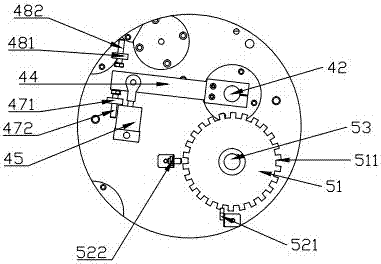

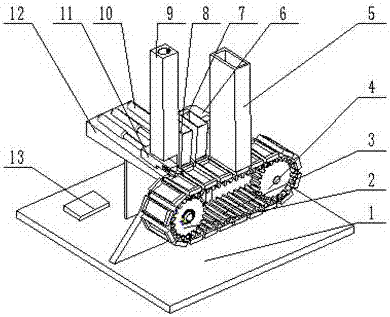

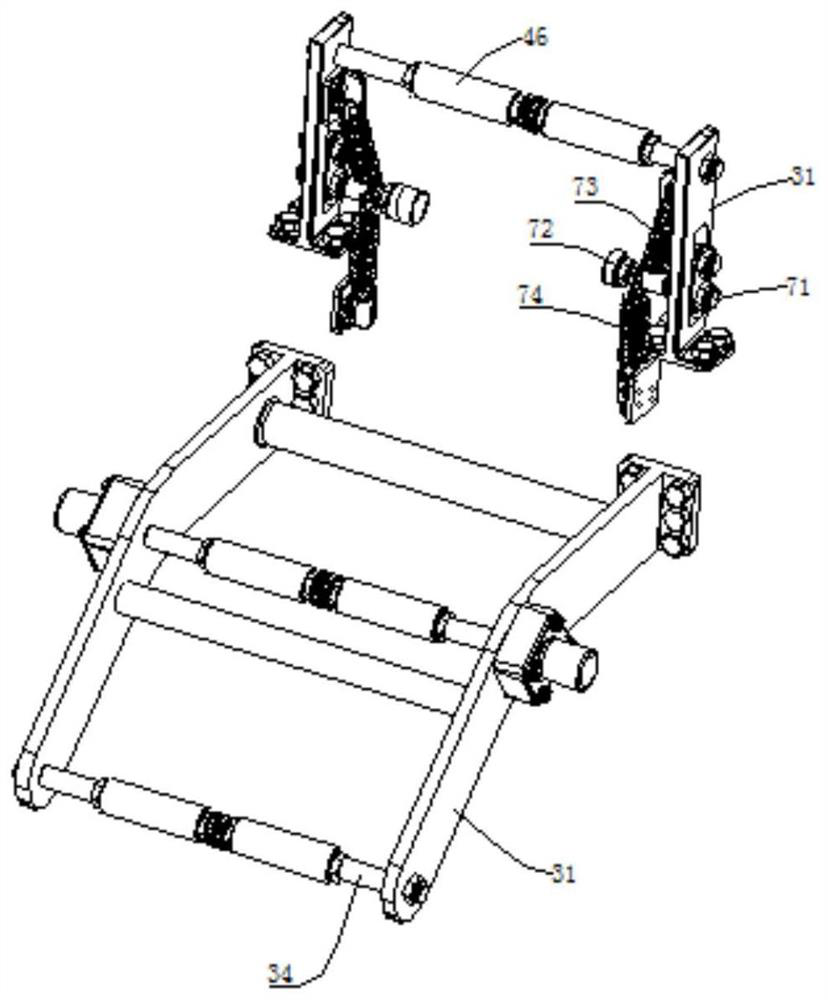

Medical thinprep clamp automatic assembly robot

InactiveCN107186692ARealize continuous transportationAssembly machinesManipulatorHydraulic cylinderEngineering

The invention relates to a medical thinprep clamp automatic assembly robot, and belongs to the field of medicinal machines. The medical thinprep clamp automatic assembly robot is composed of a rack, a gear set, a crawler set, gears, a base channel, a stepping motor, sheet grooves, a barrel channel, hydraulic cylinders, a push head, a hydraulic cylinder base and a controller; the hydraulic cylinder base, the base channel, the controller and the gear set are installed on the rack, the gears are installed on the stepping motor, the crawler set is installed on the gear set and the gears, the sheet grooves are fixed to the hydraulic cylinder base, a rectangular hole in the lower end of the sheet groove is close to a base groove of the crawler set, the push head is placed on the hydraulic cylinder base, the hydraulic cylinders are installed on the hydraulic cylinder base and are connected with the sheet grooves and the push head correspondingly, and the barrel channel is installed on the hydraulic cylinder base and is located above the push head; and the medical thinprep clamp automatic assembly robot is characterized in that the crawler set is composed of the base groove and crawlers, and the base groove is installed on the outer sides of the crawlers. The medical thinprep clamp automatic assembly robot has the beneficial effects that the base groove is installed on the crawlers, and continuous supply of a thinprep clamp base can be achieved; and a fixing column is arranged below the base groove, and a base can be fixed to the crawlers.

Owner:柴传程

tea packaging machine

InactiveCN106347762BRealize continuous transportationRealize reciprocating motionWrapper twisting/gatheringEngineeringConductor Coil

The invention discloses a tea packaging machine, relates to the mechanical field of packaging parts or materials and aims at solving the problem that packaging belt is manually put in a clamping unit and the packaging efficiency is low during packaging bag heal-sealing in the prior art and providing a packaging machine for pipeline operation. The tea packaging machine comprises a support and a second support. A clamping framework of the first support comprises a first winding drum and a second winding drum which are wound with packaging bag films, the first heat-sealing unit of the second support comprises a heat-sealing block, a second heat-sealing unit of the second support comprises a heat-sealing strip, a connecting piece, a supporting rod and a driving rod, the end, close to the first support, of the second support is in rotary connection with the supporting rod, the supporting rod is fixedly connected to the end, close to the first support, of the second support and is provided with a sliding groove, a heat-sealing strip is connected in the sliding groove in a sliding mode, one end of the connecting piece is connected with the heat-sealing strip, the other end of the connecting piece bypasses the upper end of the supporting to be connected with the driving rod, and the driving rod is connected to the side wall of one end of the second winding drum and is away from the center of the second winding drum.

Owner:GUIZHOU PROVINCE ZHENGAN COUNTY YIREN TEA IND CO LTD

Mine rock work technology

The invention discloses a mine rock work technology which comprises the following steps of 1) drilling in which a hydraulic driving drill carriage carries out drilling; 2) explosion in which medium-length holes are used for explosion and a double slotting plus reverse charging explosion method is implemented; 3) rock shipment in which an excavation type loader is used to remove waste rocks, airborne hydraulic forepoling temporary support is used, the temporary support efficiency is improved, shipment of waste rock removal is continuous, waste rock removing time is shortened, a hydraulic forepoling system is installed in an upper platform of the excavation type loader, and the forepoling temporary support can move forwards, elevate and back off automatically; and 4) ditching in which a tunnel restorer digs rough ditches, and artificial excavation is replaced. According to the mine rock work technology, the drilling manner is improved by taking high efficiency and rapid excavation as a target, and the construction speed is improved; and the explosion technology is optimized, the explosion efficiency is improved, the rock shipping system is improved, continuous transport is realized,and the working efficiency is improved.

Owner:枣庄矿业(集团)有限责任公司蒋庄煤矿

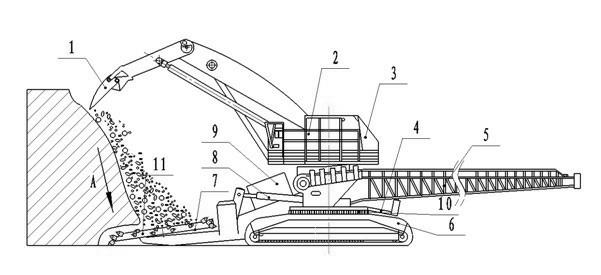

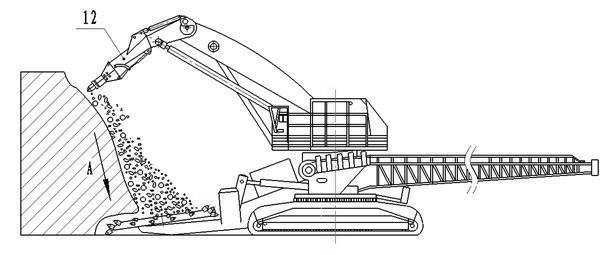

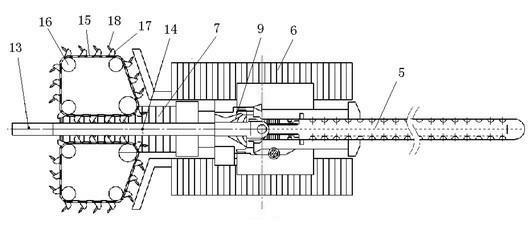

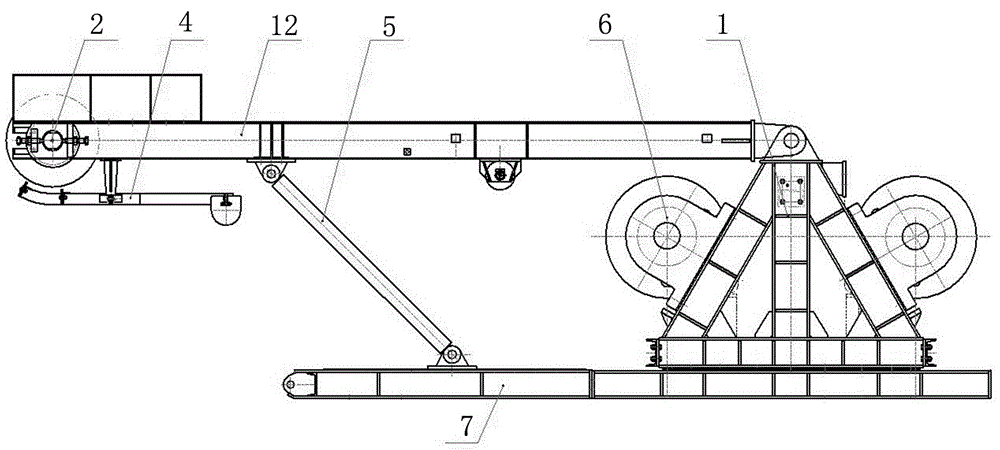

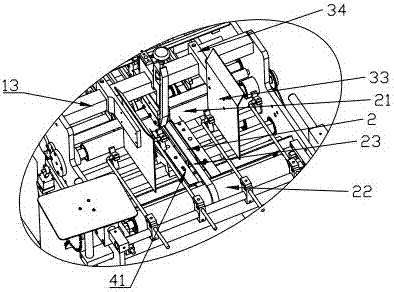

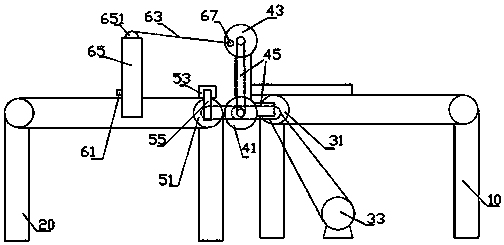

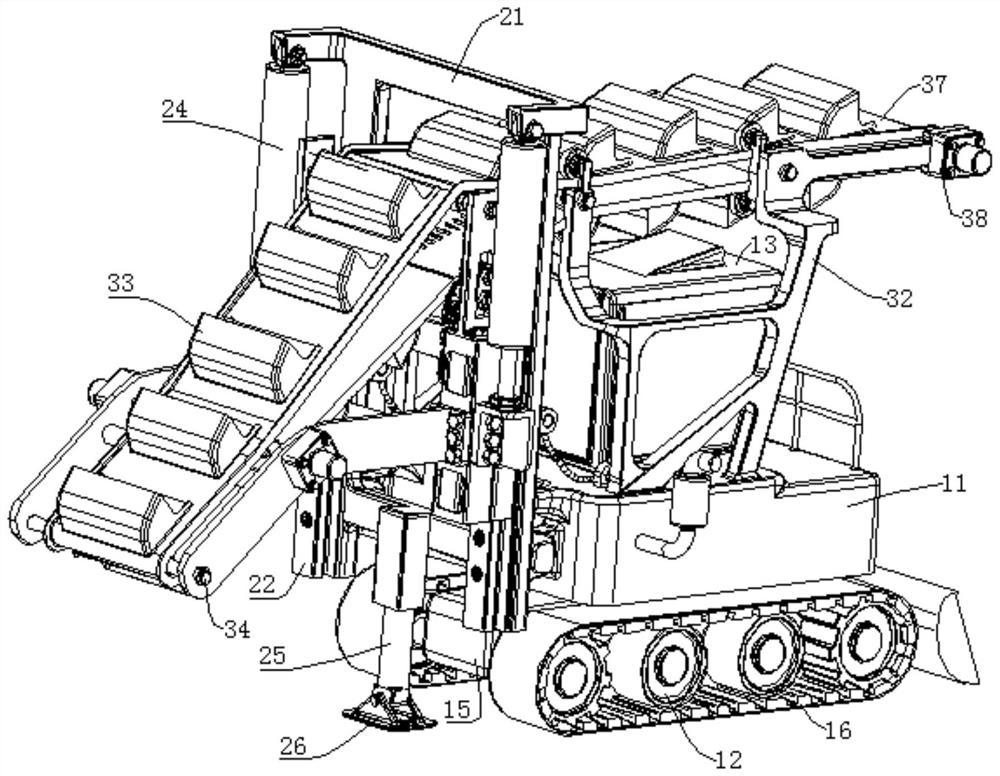

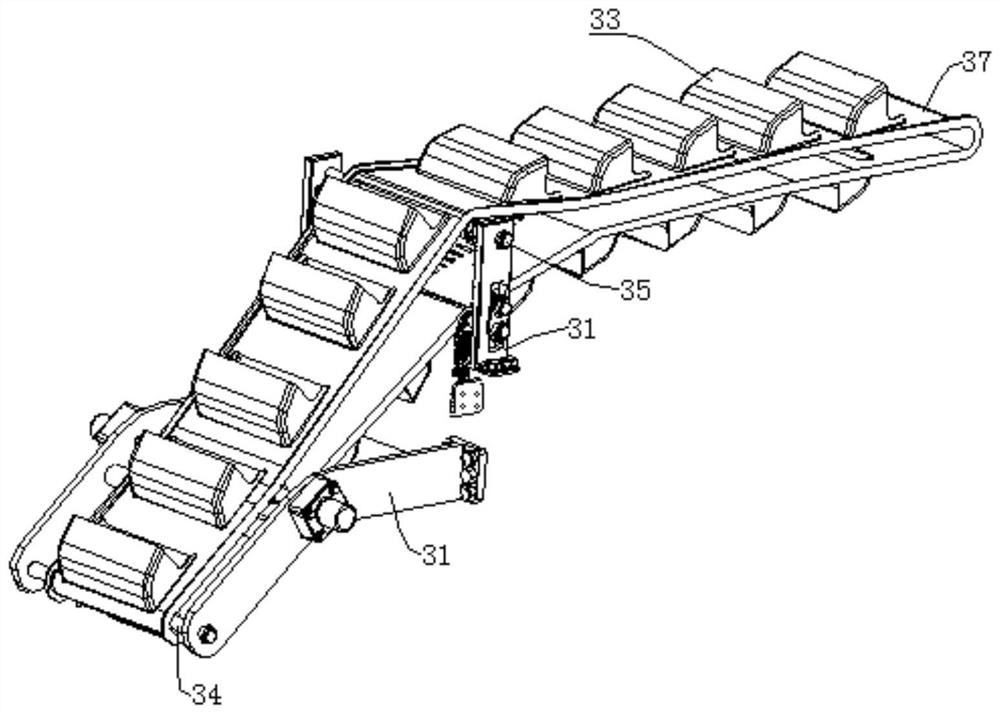

Self-moving loader for open-pit mining face

ActiveCN103485787BRealize continuous transportationImprove work efficiencyOpen-pit miningHydraulic cylinderOpen-pit mining

The invention provides a self-moving reversed loader for a mining working surface of an open-pit mine, and aims to solve the problem that when the open-pit mine is mined by a crawler loader, overburden materials or valuable minerals are transported by a car, so that the operation efficiency is low. The self-moving reversed loader adopts the key points that a material receiving end of a discharging belt conveyor is placed below a discharging end of a material receiving belt conveyor; a steel structure platform is arranged at the head of a support frame; a slewing bearing is arranged between the steel structure platform and a T-shaped frame; the two ends of a horizontal rod of the T-shaped frame are respectively connected with one end of a C-shaped arm rest and one end of a hydraulic cylinder; the other end of the hydraulic cylinder is hinged to one end of a V-shaped frame; the upper end and the lower end of a drag link arm are respectively connected onto the right end of the horizontal rod of the T-shaped frame and the discharging belt conveyor; an electric motor and a drive gear are mounted on the C-shaped arm rest; the drive gear is meshed with a gear ring; the gear ring is fixed on the steel structure platform; a ring-shaped rail is fixed on the lower surface of the gear ring; a pulley is mounted at the lower end of the C-shaped arm rest, and walks on the ring-shaped rail.

Owner:中煤科工集团沈阳设计研究院有限公司

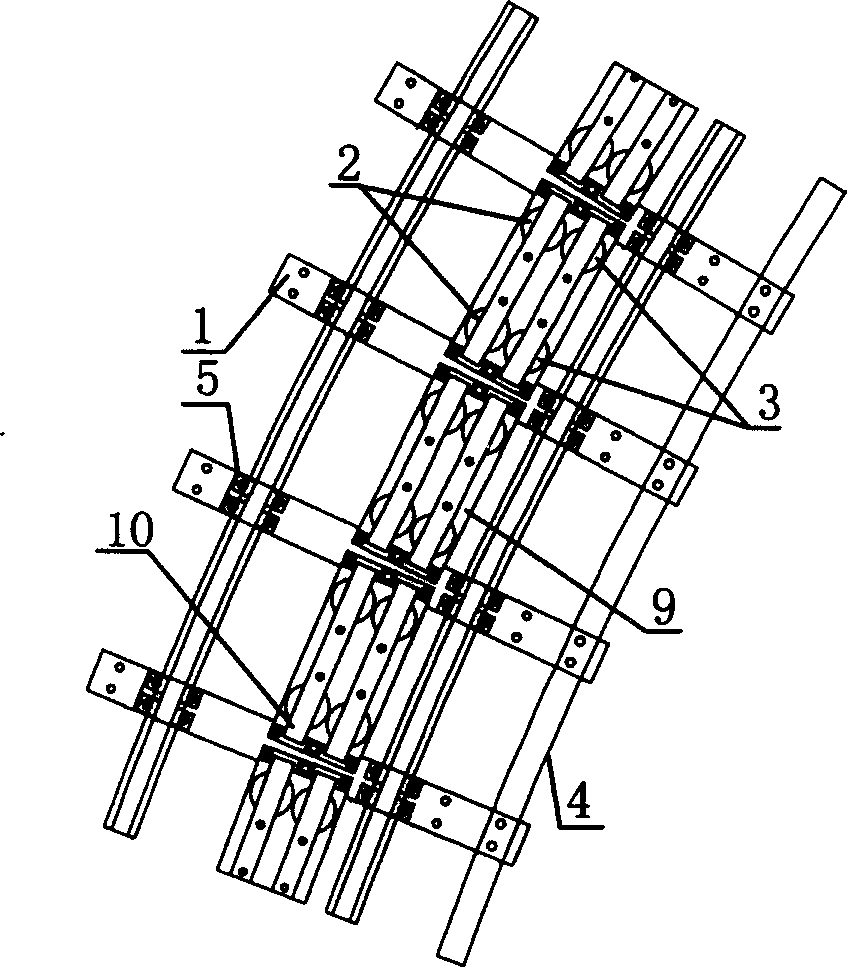

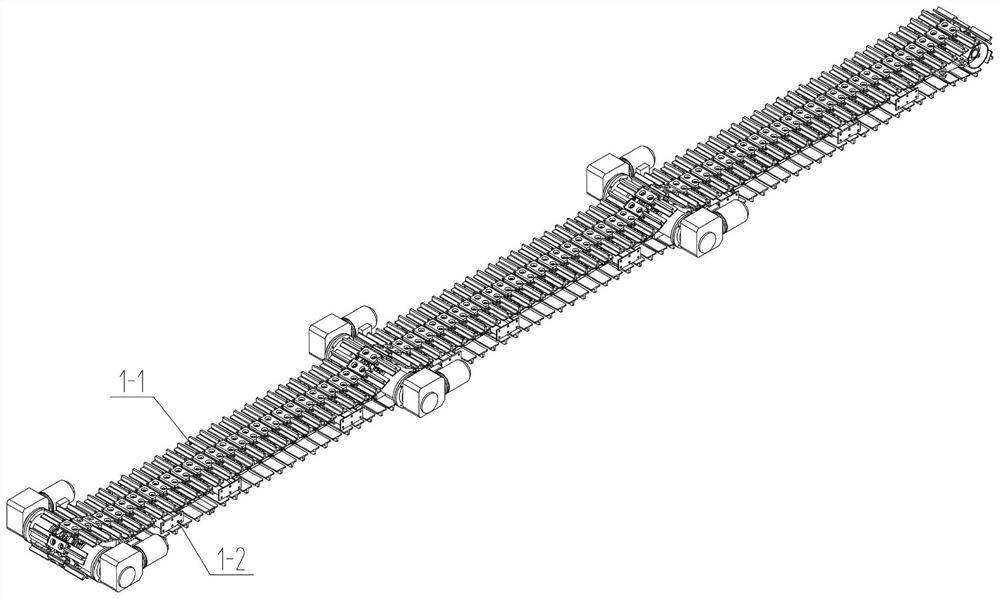

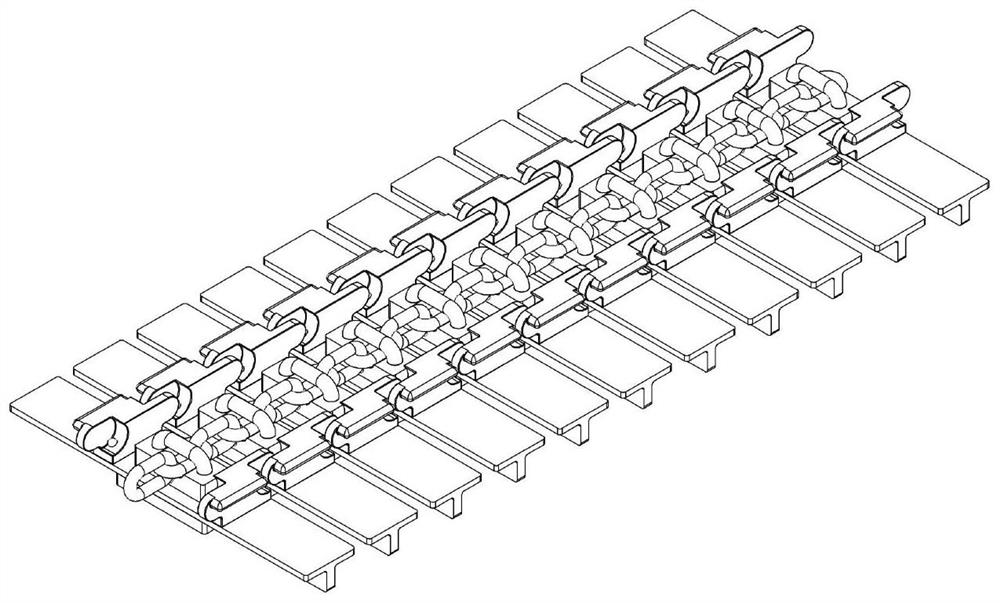

Crawler belt self-moving type bendable scraper conveyor

PendingCN114516515ARealize continuous transportationImprove continuous mining efficiencyConveyorsChain linkIndustrial engineering

The invention relates to a bendable scraper conveyor with a self-moving crawler belt, which belongs to the technical field of underground coal mine transportation, solves the technical problems of low production efficiency and low automation degree of a continuous mining and continuous filling process, and comprises a crawler belt walking mechanism and a scraper conveying mechanism, and the scraper conveying mechanism is arranged above the crawler belt walking mechanism. The crawler walking mechanism comprises a crawler assembly and a walking crawler frame, and the crawler assembly and the walking crawler frame bend or move synchronously; the scraper conveying mechanism comprises a scraper mechanism and a conveying device, the conveying device drives the scraper mechanism through a circular ring chain to convey materials from the tail to the head, and the scraper mechanism and the conveying device bend or move synchronously. The device can freely walk in a roadway, 90-degree moving and bending continuous transportation in the horizontal direction is achieved, coal mined by a heading machine or a continuous miner of a coal mine continuous mining and continuous filling working face is continuously conveyed to transportation crossheading equipment, matched continuous transportation behind coal mining equipment of the continuous mining and continuous filling working face is achieved, and the continuous mining efficiency is greatly improved.

Owner:鄂尔多斯市绿矿技术服务有限公司

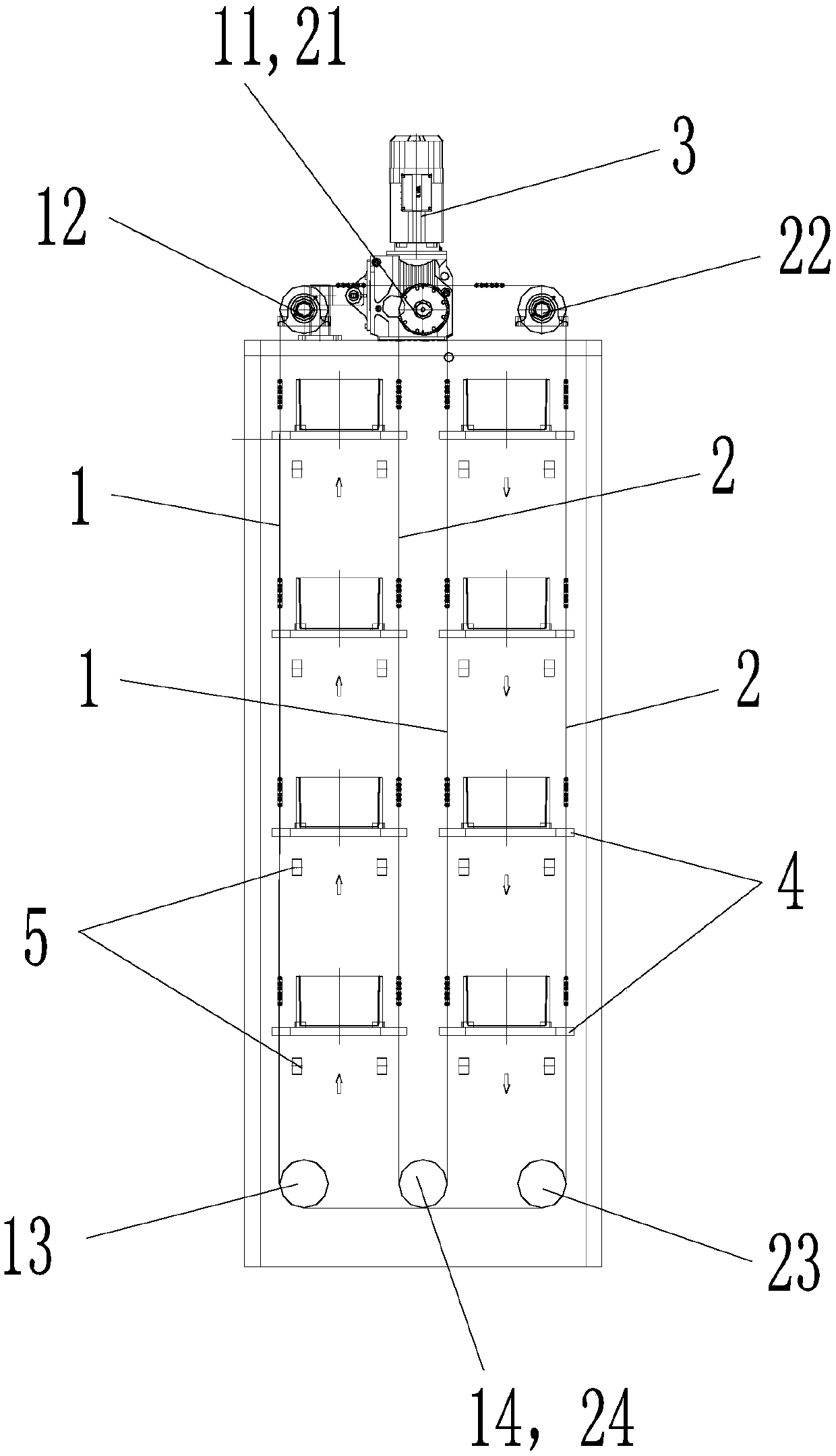

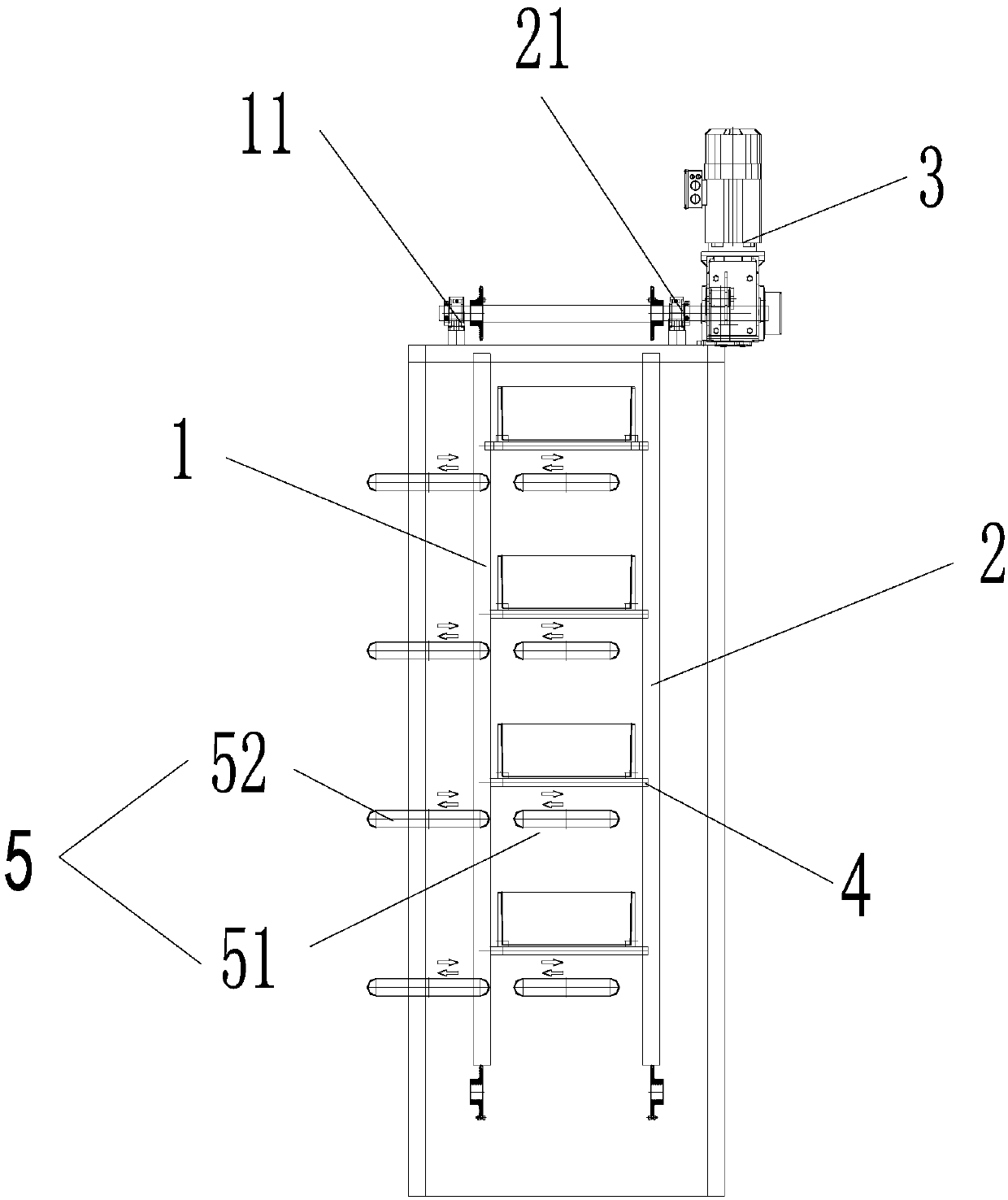

Medical box type material circulating elevator

ActiveCN109516346ARealize continuous transportationAvoid interferenceBuilding liftsConveyor partsContinuous/uninterruptedEngineering

The invention provides a medical box type material circulating elevator and belongs to the technical field of medical elevators. The medical box type material circulating elevator can realize continuous uninterrupted transportation between different floors and comprises a first transmission mechanism and a second transmission mechanism, wherein the first transmission mechanism and the second transmission mechanism are vertically arranged in parallel. The medical box type material circulating elevator further comprises a hollow shaft speed reducing motor, a plurality of goods carrying tables and transverse conveying mechanisms, wherein a hollow shaft of the hollow shaft speed reducing motor is connected to the first transmission mechanism and the second transmission mechanism and is used for driving the first transmission mechanism and the second transmission mechanism to synchronously rotate; the goods carrying tables are equidistantly arranged between the first transmission mechanismand the second transmission mechanism and are used for carrying goods; and the transverse conveying mechanisms are arranged on all floors correspondingly and comprise inner-section conveyors and outer-section conveyors, and the inner-section conveyors can be turned over within a certain angle.

Owner:江苏达实久信智慧物流系统有限公司

A zero-leakage unloading device

InactiveCN104847669BRealize continuous transportationReduce pollutionSpecific fluid pumpsPump componentsImpellerChemical solution

The invention discloses a zero-leakage alkali discharging device, which comprises a rack, a device body arranged on the rack and a driving mechanism, wherein the device body comprises a housing, an impeller and a main shaft; the housing is volute-shaped, and the side surface and the spiral tail end are provided with an alkali inlet pipeline and an alkali outlet pipeline; one end of the main shaft is in transmission connection with the driving mechanism, the other end of the main shaft extends into the housing along the axial direction of the housing, the impeller is arranged in the housing and axially arranged at the other end of the main shaft, and the impeller is driven to rotate by the driving mechanism through the main shaft. Compared with the prior art, the alkali discharging device disclosed by the invention has the advantages of zero leakage, high efficiency, environment protection, no residual solution, ability of reducing resource waste and environmental pollution and the like, has great economic values and application values and is wide in application prospect, thereby being an optimal choice for transporting chemical solutions in each industry.

Owner:XIAMEN UNIV OF TECH

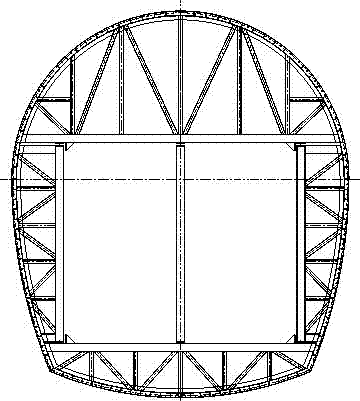

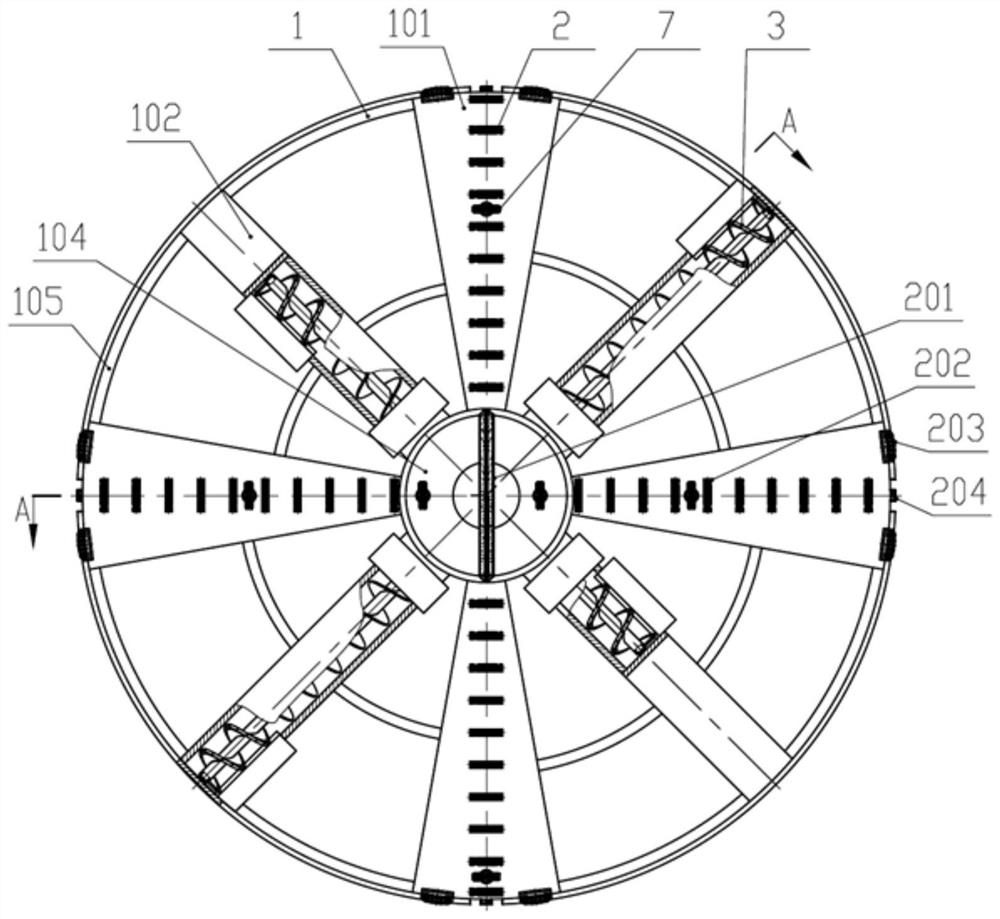

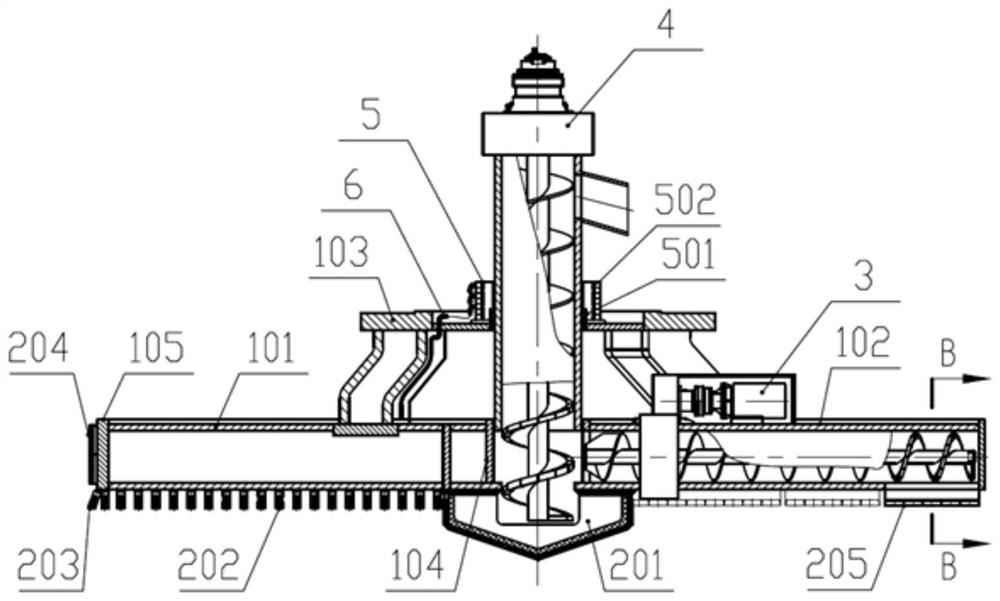

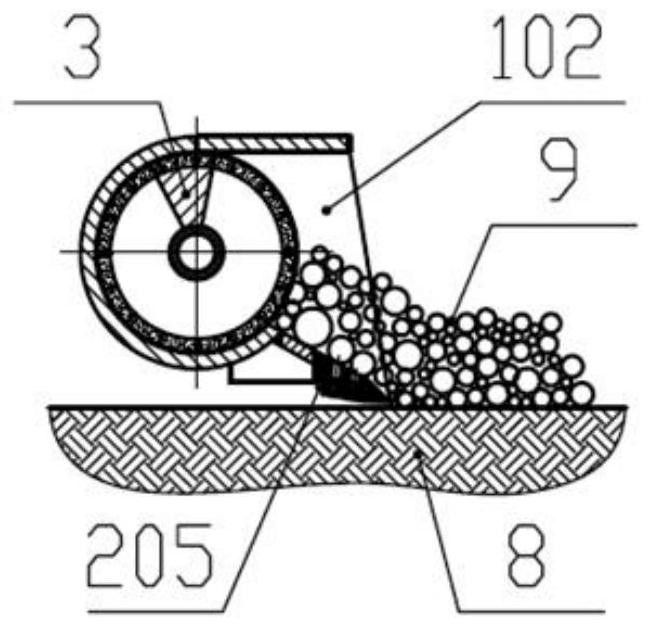

A shaft cutter head, a shaft boring machine and a shaft drilling rig

ActiveCN110206546BImprove discharge efficiencyPrevent leakageShaft sinkingIndustrial engineeringSpoke

The invention discloses a shaft cutterhead, which comprises a cutterhead body, a spoke screw machine for gathering the dregs in the non-central area of the face of the shaft to the central area, and a central auger for outputting the dregs in the central area The central screw machine is arranged at the center of the cutter body, and the spoke screw machines are arranged radially on the outer periphery of the central screw machine; and both the central screw machine and the spoke screw machines are connected with the cutter body. Since the muck is transported by the center screw machine and the spoke screw machine in this application, the problem of the muck leaking from both sides of the scraper is avoided during the transportation process, and the continuous transportation of the muck can be realized, making the muck The transportation efficiency and cleaning quality are improved, which can effectively improve the slag cleaning effect. In addition, the present invention also discloses a shaft boring machine including the above-mentioned shaft cutter head and a shaft drilling machine including the above-mentioned shaft cutter head.

Owner:CHINA RAILWAY CONSTR HEAVY IND

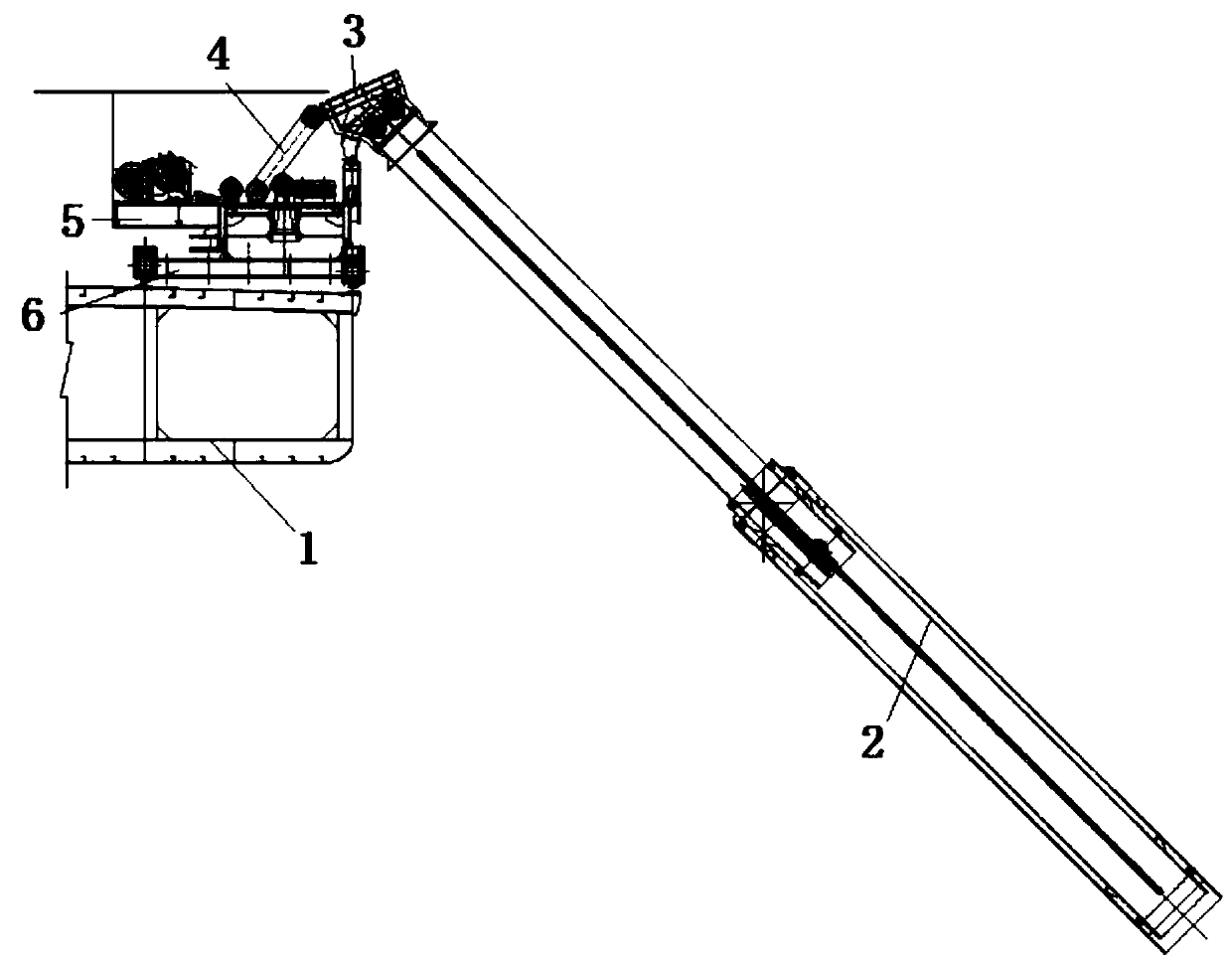

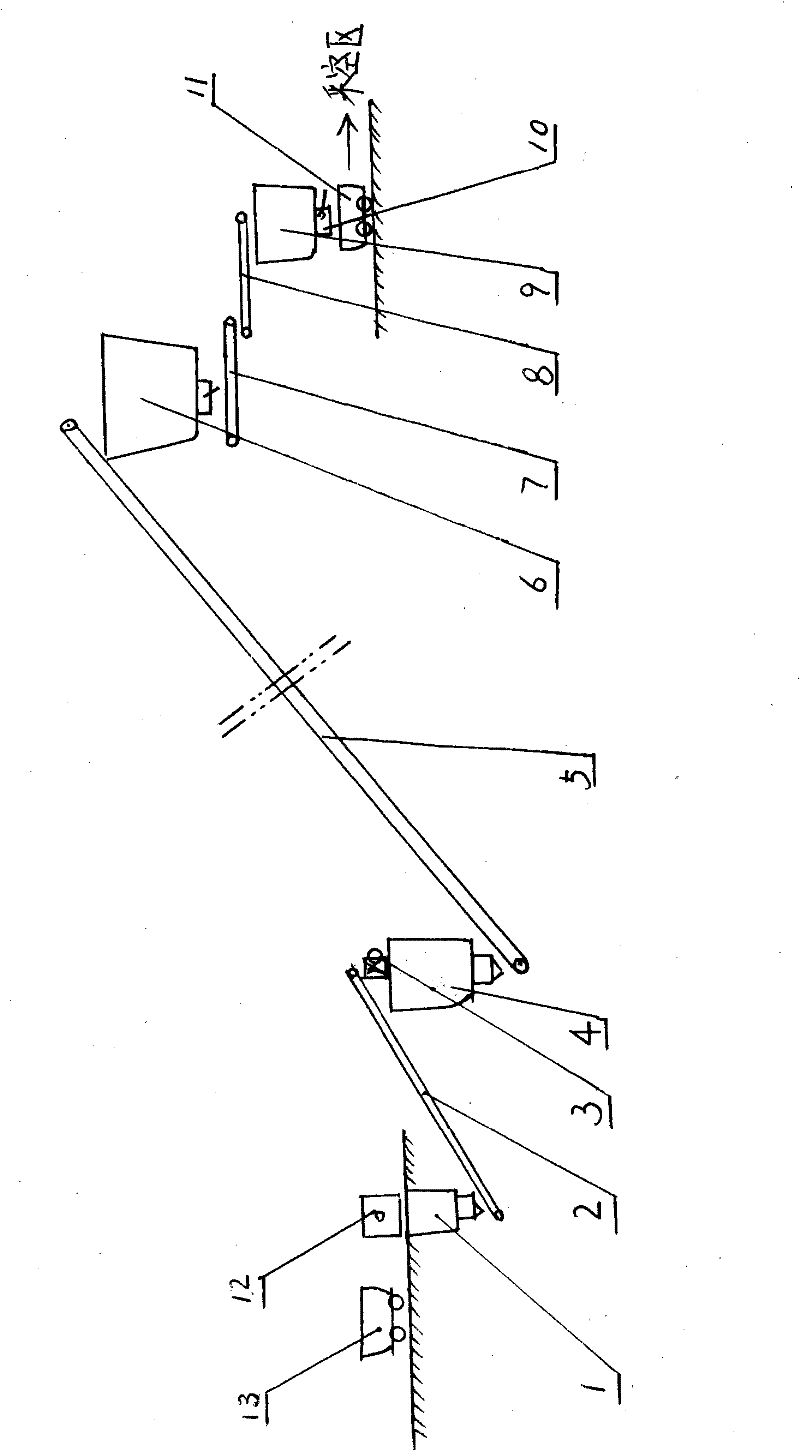

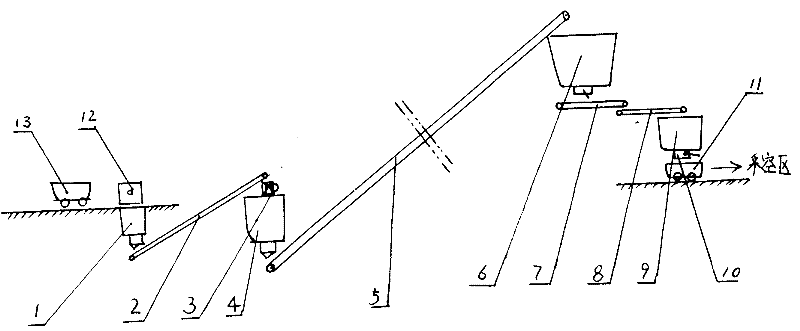

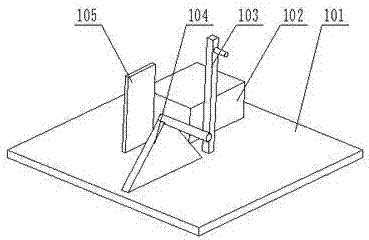

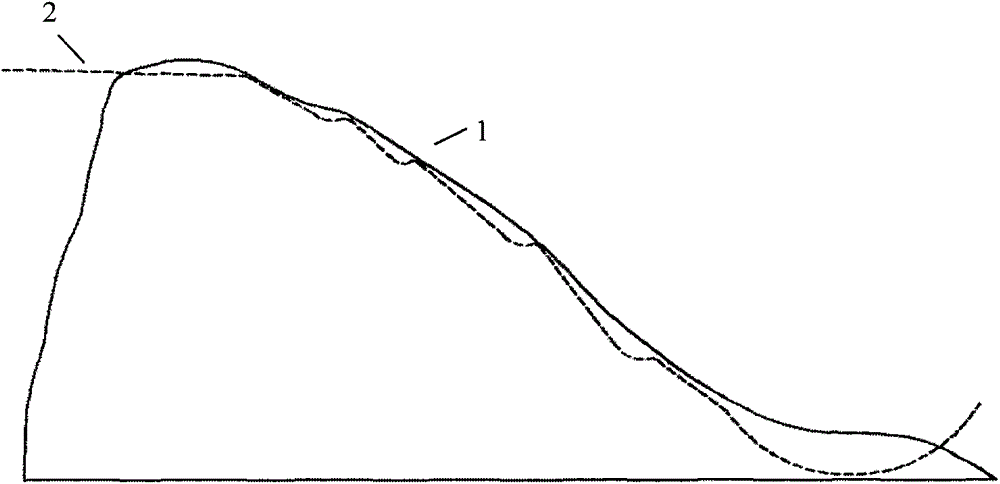

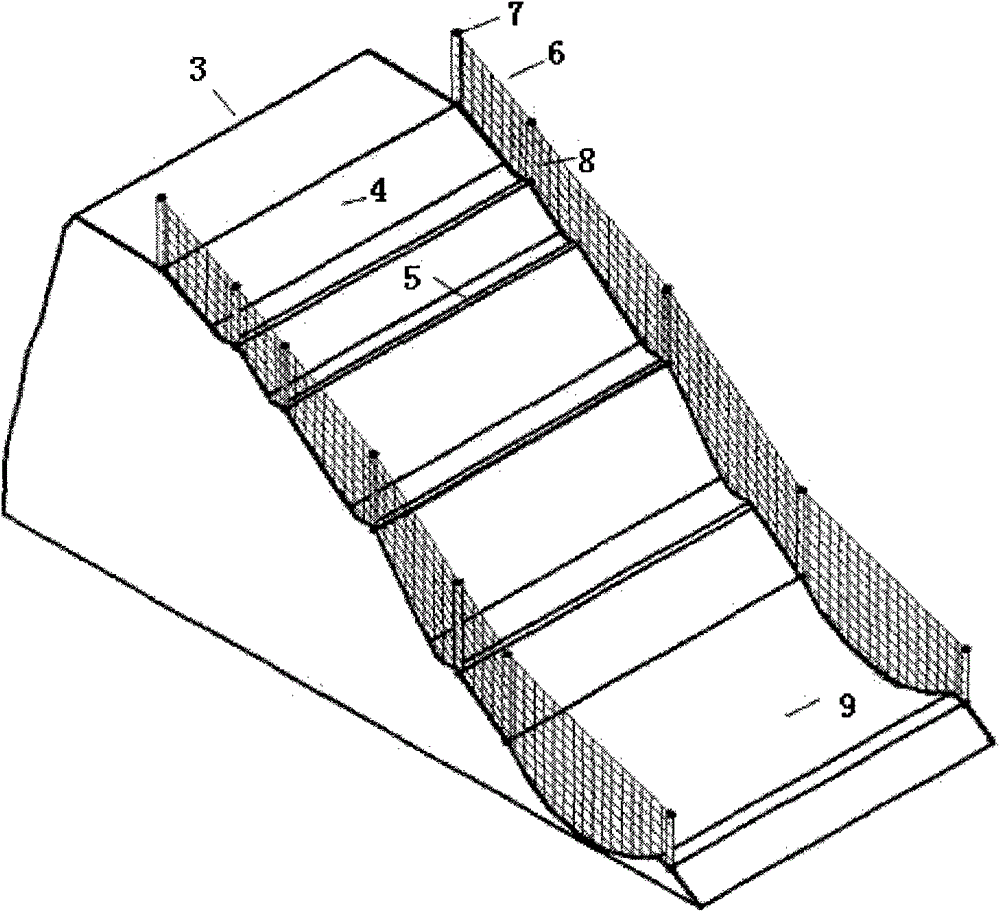

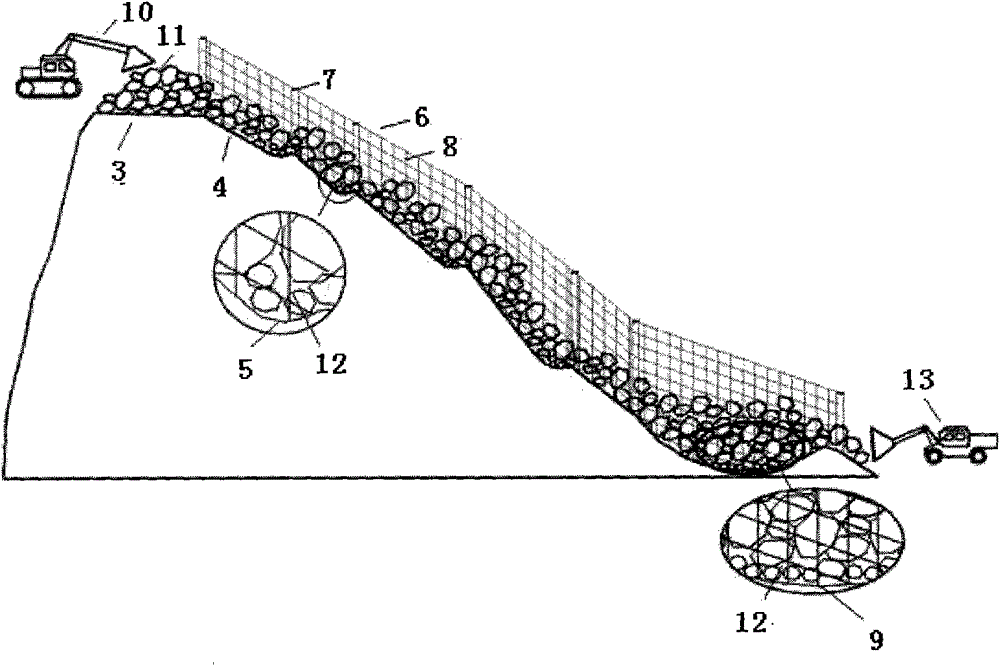

A kind of vertical transportation system and transportation method for mountain stone materials

InactiveCN103397636BEasy constructionSmall amount of workFoundation engineeringBuilding material handlingTerrainTransport system

The invention discloses a vertical transportation system for mountain stone and a transportation method of the vertical transportation system. The vertical transportation system comprises at least one step surface (5) based on a mountain slope (1), a transfer bin (9) and a stone piling platform (3), wherein the mountain slope (1) is divided into at least two step inclined planes (4) by the step surfaces (5), and the transfer bin (9) and the stone piling platform (3) are located at the bottom and the top of the mountain slope (1) respectively. The vertical transportation system and the transportation method are applicable to vertical transportation of the large stone in a steep terrain; the vertical transportation system is free from limitation of a terrain condition, has a small influence on a surrounding environment, and is simple to construct, small in engineering workload, convenient to maintain and large in conveying capacity; the transportation cost of the stone is lowered; and the transportation efficiency is improved.

Owner:北京华石纳固科技有限公司

Loader capable of feeding through multiple feeding hoppers

PendingCN111924564ARealize continuous transportationAffect normal workConveyorsLoading/unloadingHydraulic cylinderControl engineering

The invention provides a loader capable of feeding through multiple feeding hoppers. The loader comprises a walking device, a connecting device and a feeding device, wherein the connecting device comprises a connecting frame, sliding rails, sliding blocks and first hydraulic cylinders, the sliding rails are vertically fixed to the front side of the connecting frame, the upper ends of the first hydraulic cylinders are hinged to the top of the connecting frame, the lower ends of the first hydraulic cylinders are fixedly connected with the sliding blocks, the connecting frame is mounted at the front of the walking device, the feeding device includes a supporting frame and a conveyor belt mechanism, the supporting frame comprises a front supporting frame and a rear supporting frame, the frontpart of the conveyor belt mechanism is located in front of the walking device and obliquely arranged downwards, the front part of the conveyor belt mechanism is supported on the sliding blocks throughthe front supporting frame, the rear part of a conveyor belt is supported by the rear supporting frame and extends to the rear of the walking device, and the multiple feeding hoppers arranged at equal intervals are fixedly arranged on the outer side wall of the conveyor belt. The technical problems that the space is large and the loading efficiency is low when a traditional loading machine or a transferring machine carries out loading or transfer operation can be solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

a belt conveyor system

InactiveCN106219193BSimple structureReasonable designConveyorsControl devices for conveyorsTransport systemEngineering

The invention discloses a belt transportation system which comprises a belt transportation mechanism, a belt detection device, a monitor device, belt deviation adjusting mechanisms and a belt cooling mechanism. The belt transportation mechanism comprises a belt and belt supporting components. The belt detection device comprises a routing inspection mechanism, temperature detection sensors and belt deviation detection modules. A routing inspection sliding mechanism and a sliding drive mechanism are arranged on a rack. The routing inspection mechanism comprises a routing inspection box, a smoke detection sensor, a gas detection sensor and a fixed camera. The monitor device comprises a control device, a wireless power supply module, a cooling control mechanism and a deviation adjusting drive mechanism. The belt transportation system is simple in structure and convenient to implement; the belt transportation work condition is detected in real time; the belt is adjusted and cooled; belt deviation or high-temperature work is prevented from bringing potential safety hazards to workers and coal mine transportation; continuous transportation of the belt is achieved; and the coal production efficiency is improved, and labor intensity is relieved.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com