Belt transportation system

A kind of belt transportation and belt technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of friction and heating between belts and coal conveying machinery and equipment, can not be detected in real time, and reduce transportation efficiency, etc., to achieve processing and installation Convenient layout, high adjustment and cooling efficiency, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

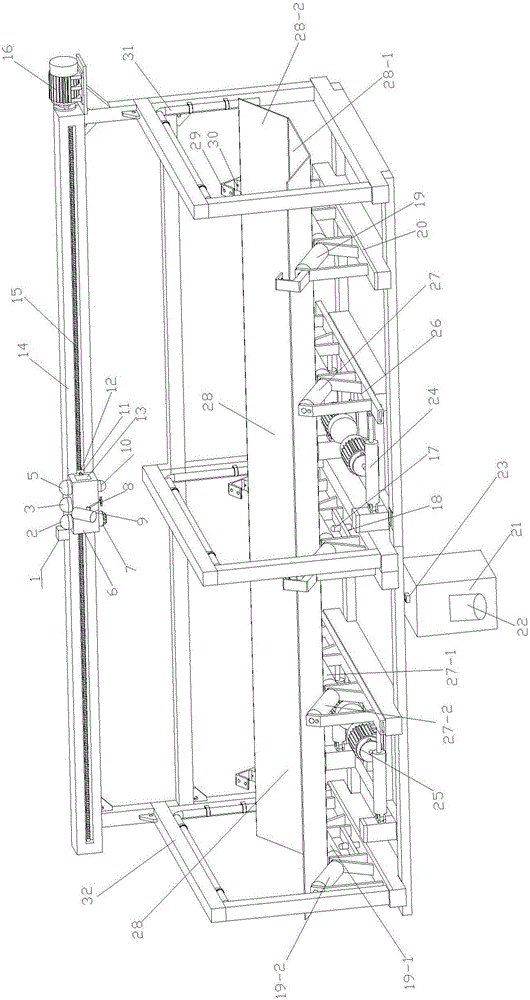

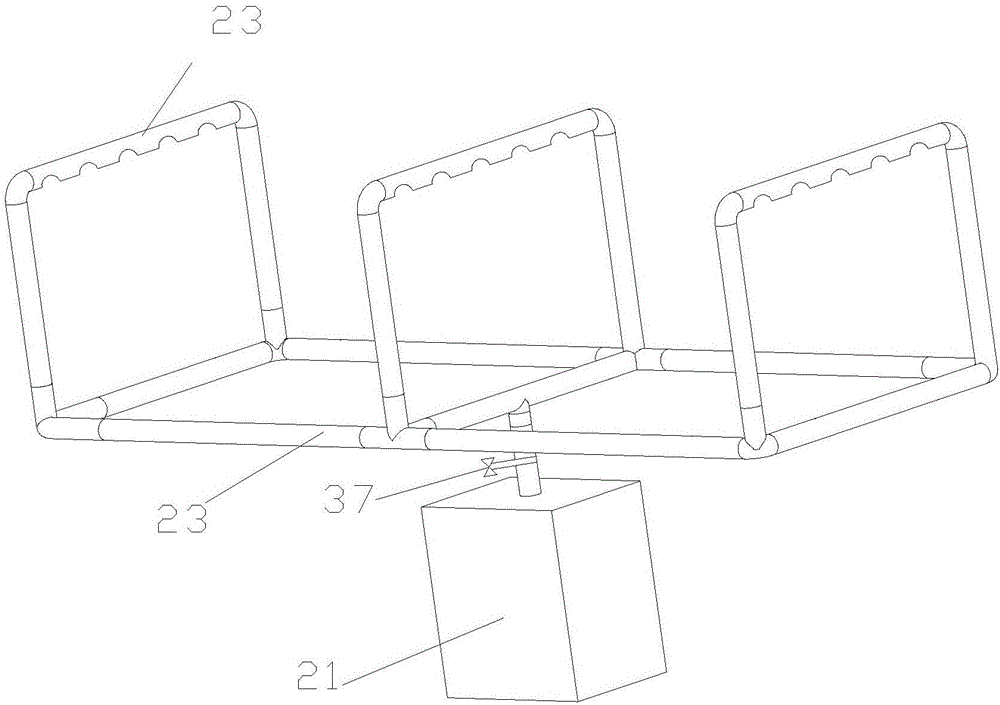

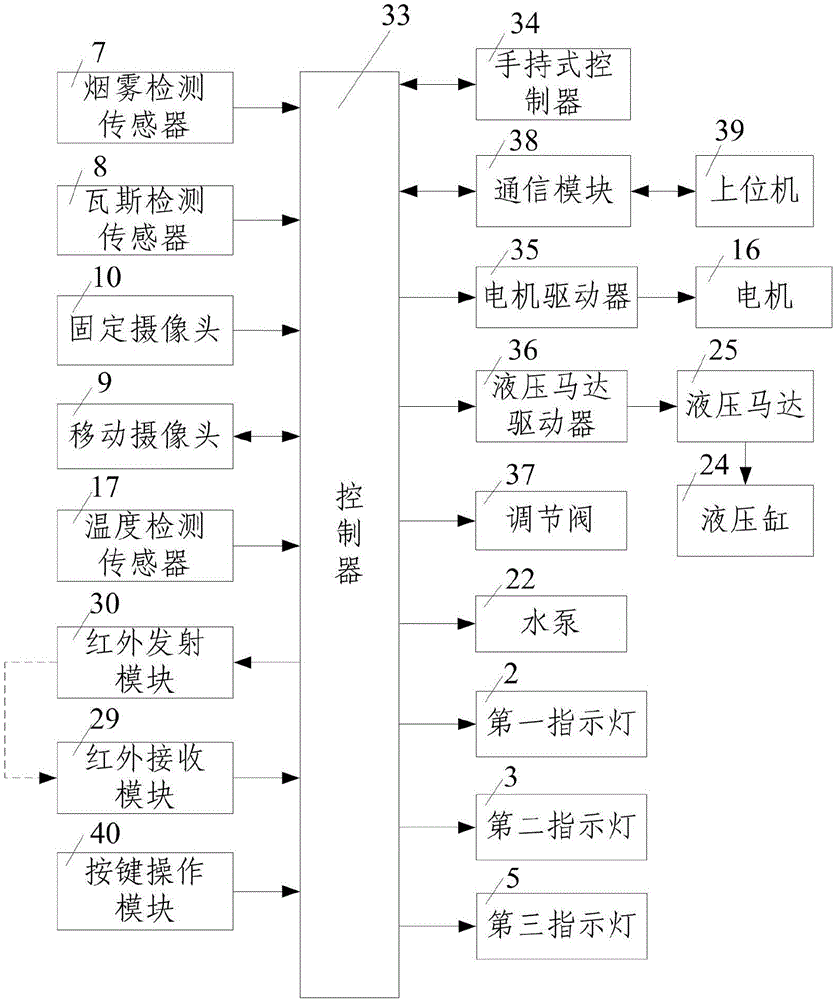

[0056] like figure 1 , figure 2 and image 3 As shown, the present invention includes a belt transport mechanism, a belt detection device for real-time detection of the working conditions of the belt transport mechanism, a monitoring device for monitoring the belt detection device, and a belt conveyor for adjusting the belt transport mechanism. an offset adjustment mechanism and a belt cooling mechanism for cooling the belt transport mechanism;

[0057] The belt transport mechanism includes a belt 28 and a belt support member 19 installed at the bottom of the belt 28 and supporting the belt;

[0058] The belt detection device includes an inspection mechanism installed on the frame 32, a temperature detection sensor 17 for real-time detection of the working temperature of the belt 28, and a belt deviation detection module for real-time detection of the belt 28. An inspection slip mechanism for the inspection mechanism to move back and forth and a slip drive mechanism drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com