Monorail crane transportation system pulled by steel wire rope of hydraulic winch

A hydraulic winch and transportation system technology, which is applied in underground transportation, transportation and packaging, and heavy-duty pulleys. It can solve problems such as unfavorable installation and removal, single speed change mode, and large floor space, so as to reduce transportation links and post work. Personnel, improved safety factor, less maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

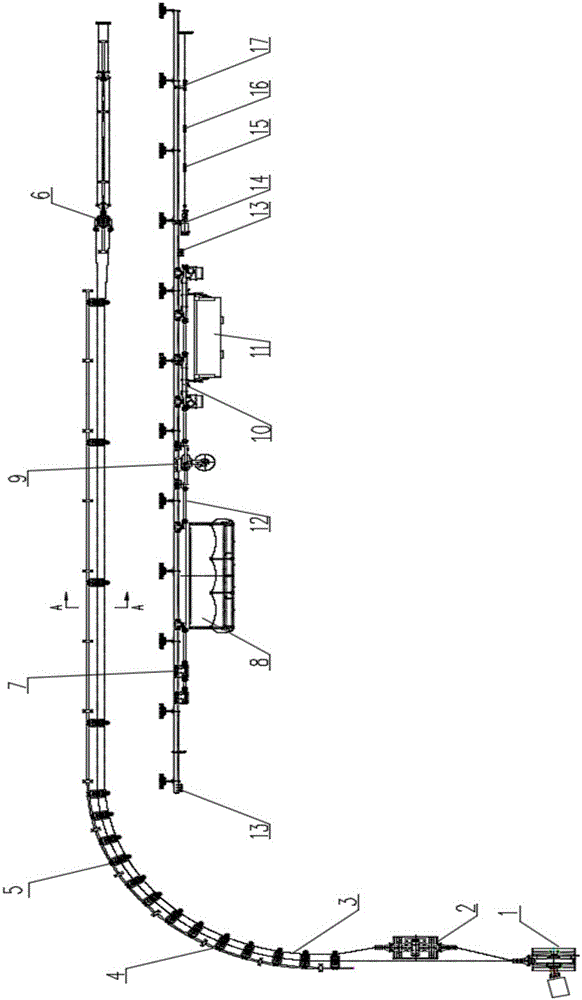

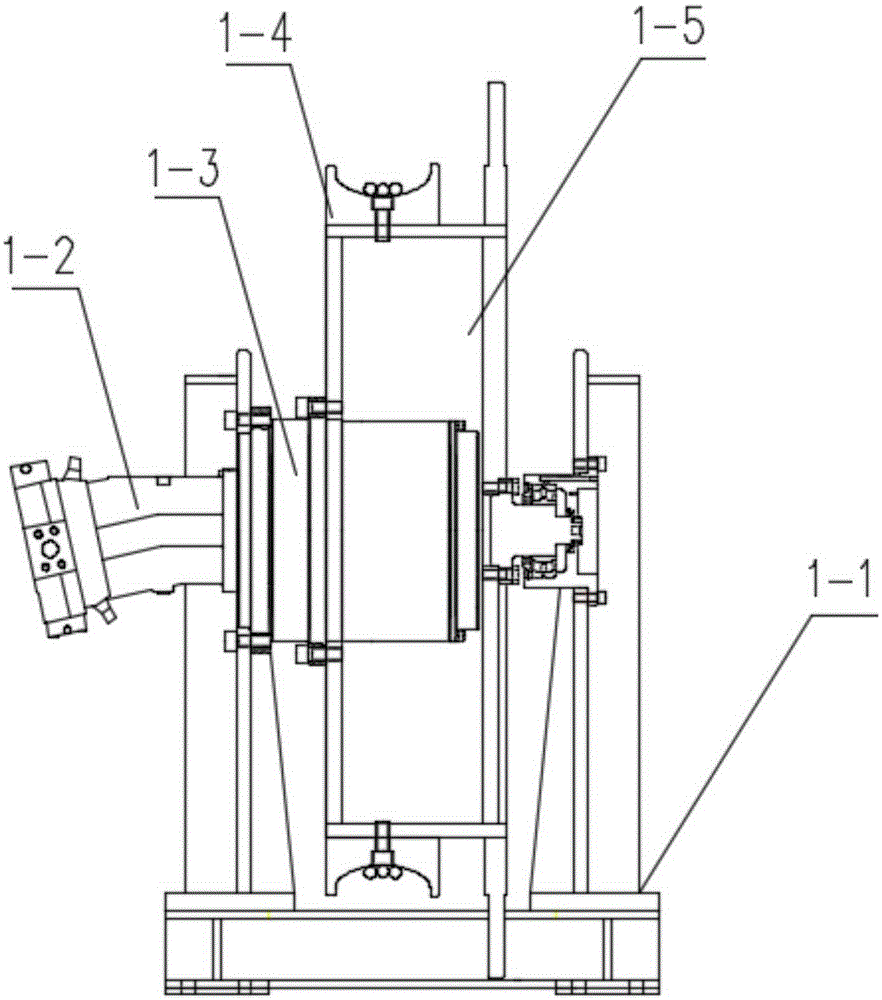

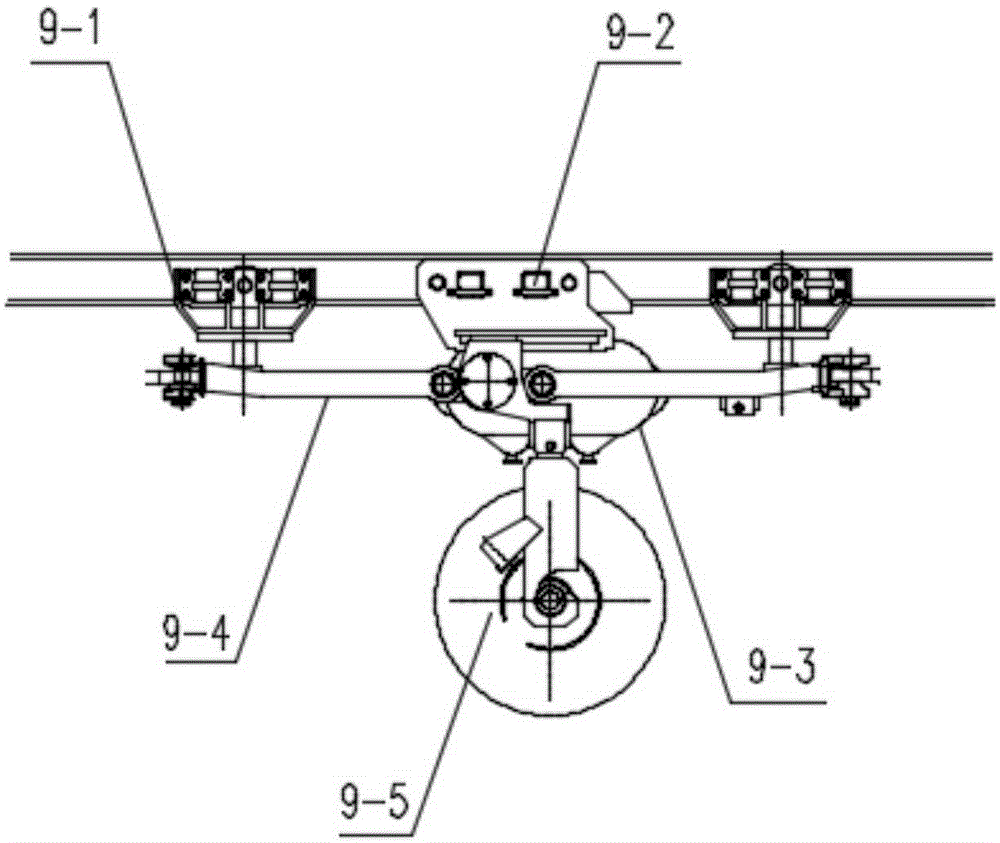

[0023] Such as figure 1 As shown, the hydraulic winch steel wire rope traction monorail crane transportation system of the present invention includes a suspension track 4 and a steel wire rope 3, the suspension track 4 is fixed on the top surface of the roadway, and a plurality of guide wheel frames 6 are installed on the suspension track 4. Winch 1, tensioning tower 2, slewing station 5, tractor 9, lifting beam 10, man-vehicle 8 and brake car 7, the hydraulic winch 1 and tensioning tower 2 are arranged at the front end of the suspension track 4, the slewing station 5 It is installed at the end of the suspension track 4 and fixed on the wall through a fixed rod. The slewing station 5 is easy to install and quick to disassemble. Even if it is used on the excavation surface, it can also be adjusted forward with the extension of the road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com