Loader capable of feeding through multiple feeding hoppers

A loader and hopper technology, applied in loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of low loading efficiency and large space, and achieve the effect of preventing excessive loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

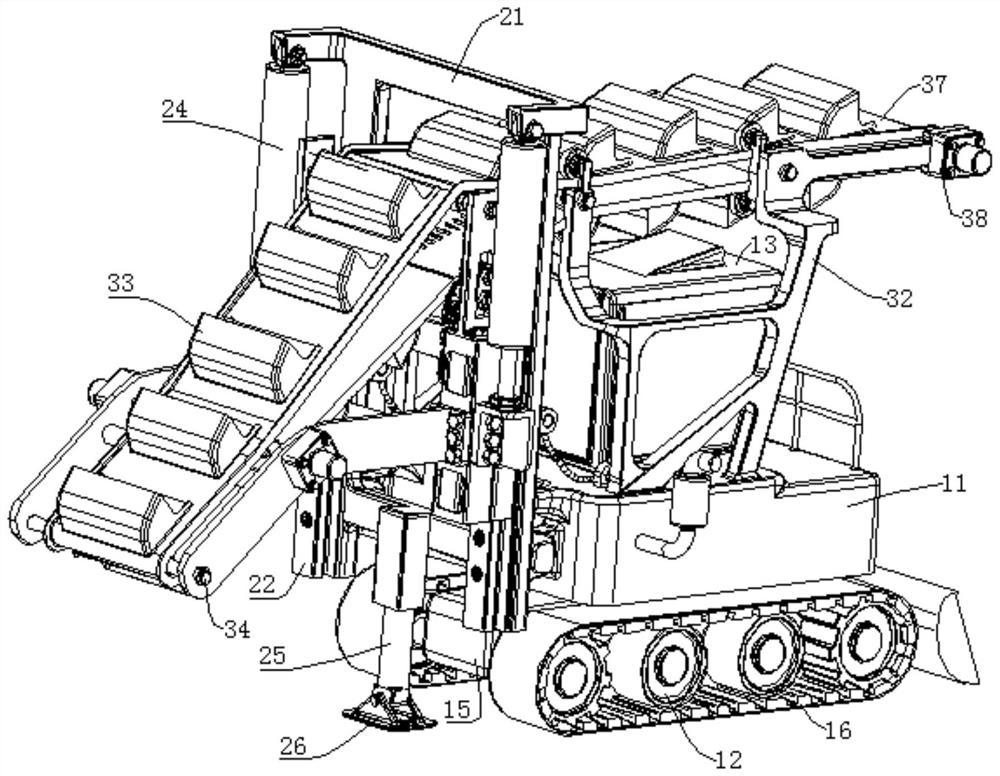

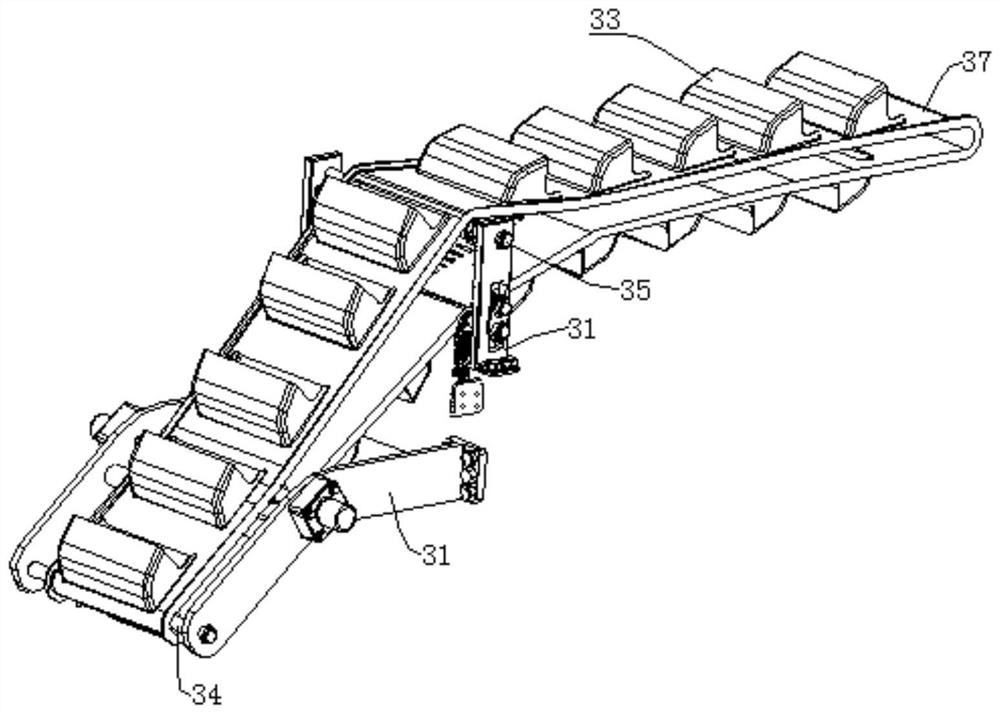

[0025] like figure 1 , figure 2 as well as Image 6 As shown, a loader that feeds materials through multiple hoppers includes a traveling device, a connecting device and a feeding device. The running gear is preferably a crawler-type running gear, and the running gear is made up of a crawler-type running gear and a steering system, etc. 12 and speed changer, etc., the engine of the running gear drives the wheels 12 and crawler belts 16 through the hydraulic system and the speed changer, and the steering system is used to control the steering of the running gear. The main function of the walking device is to enable the feeding device and the belt conveying device to move and walk, so the walking device can also be replaced by other mechanical devices with walking functions.

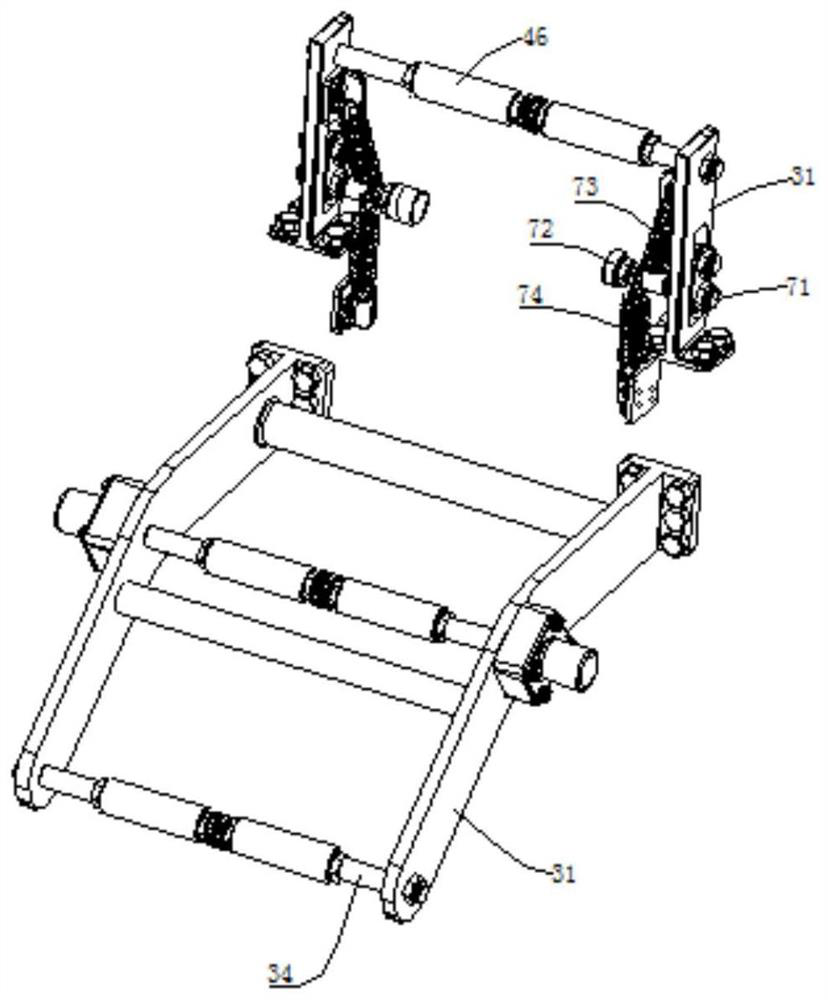

[0026] like figure 1 as well as Figure 3-5 As shown, a connecting device is installed between the feeding device and the traveling device. The connecting device includes a connecting frame 21, a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com