Patents

Literature

769results about How to "Save work space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

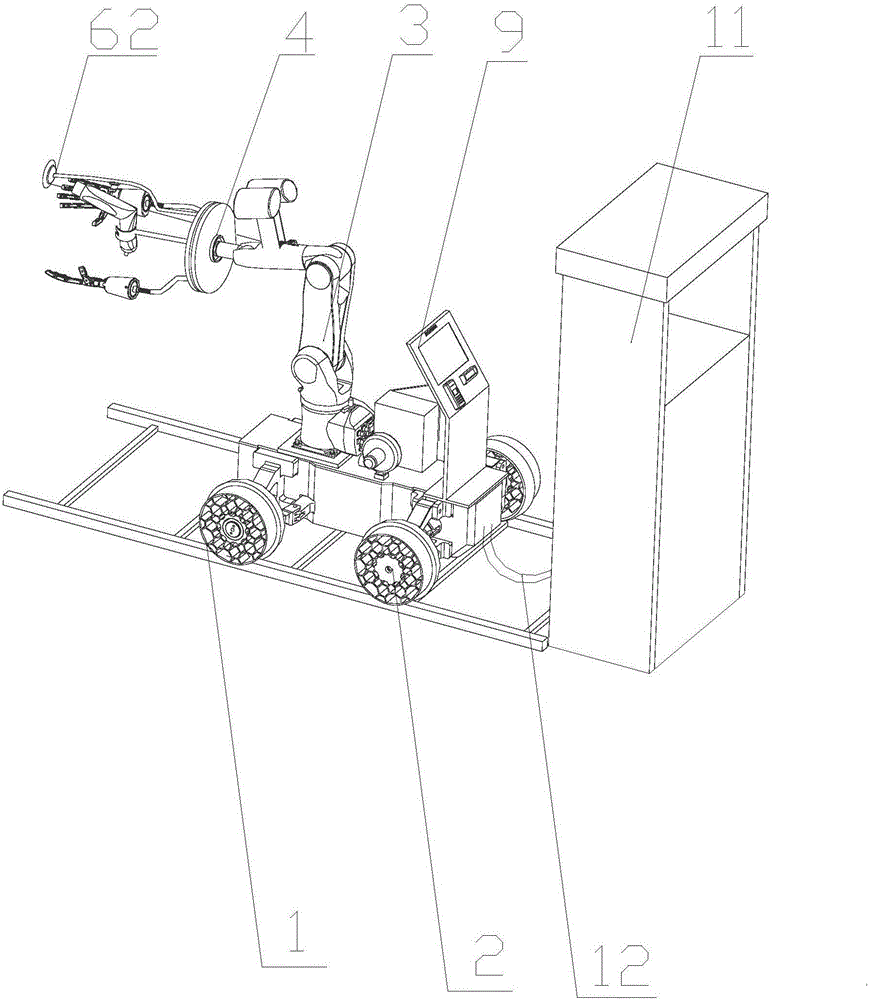

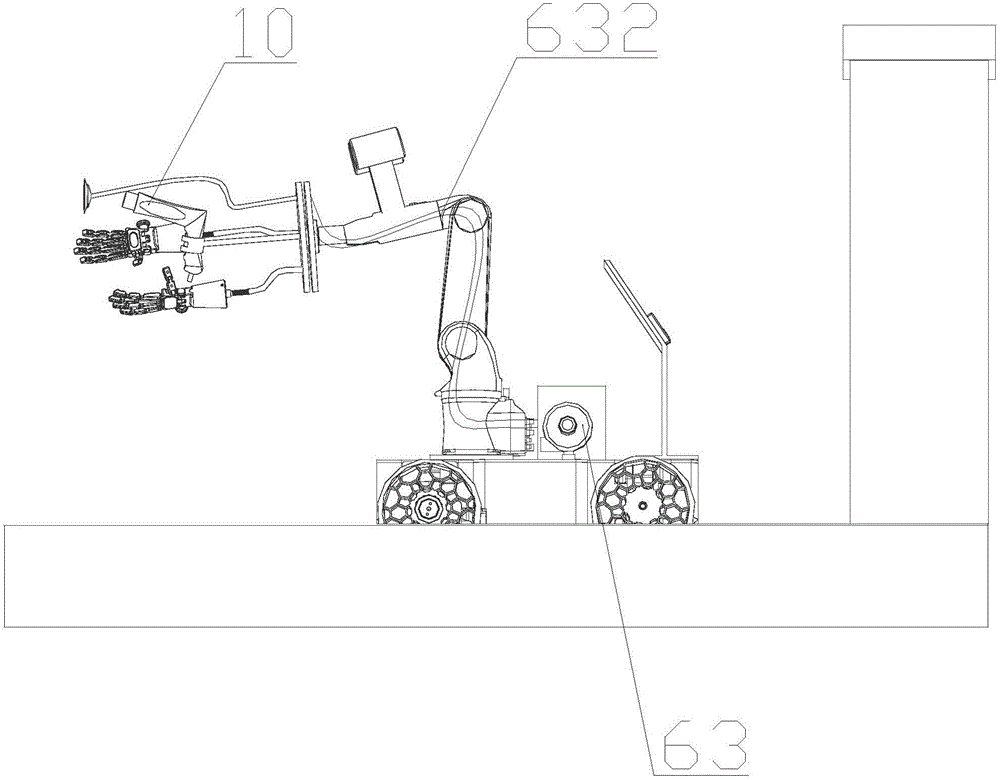

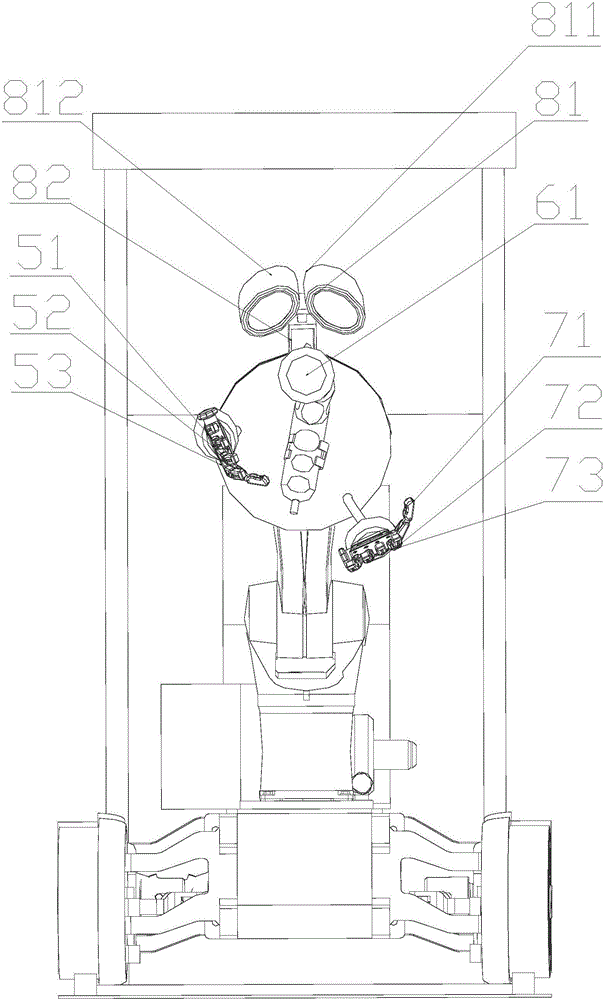

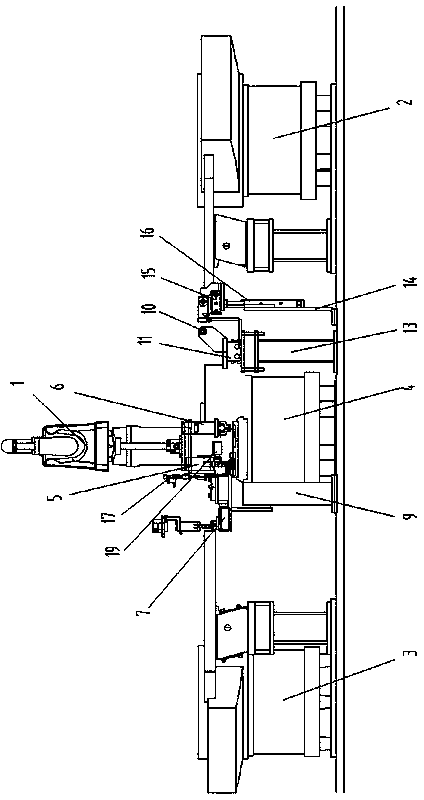

Full-automatic oiling serving robot for unmanned oiling station and oiling serving method

ActiveCN105666502ASolve the problem of unmanned implementationFully automatedGripping headsInteraction systemsFuel tank

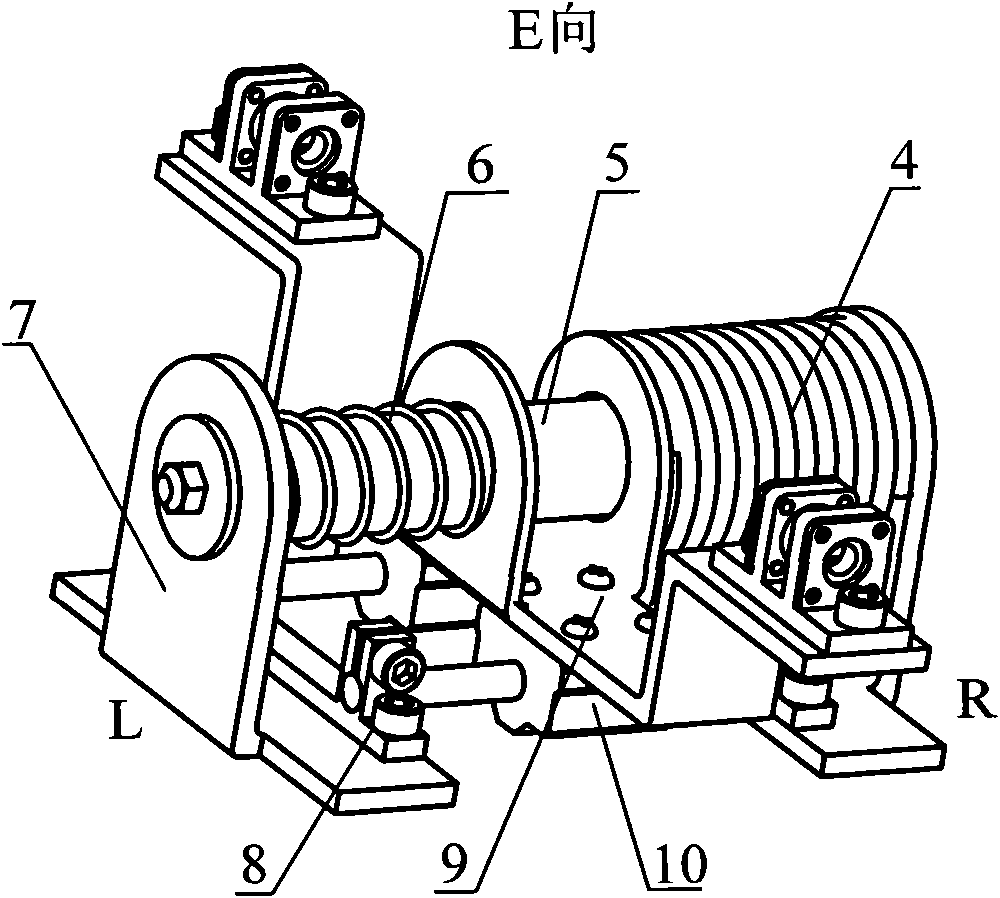

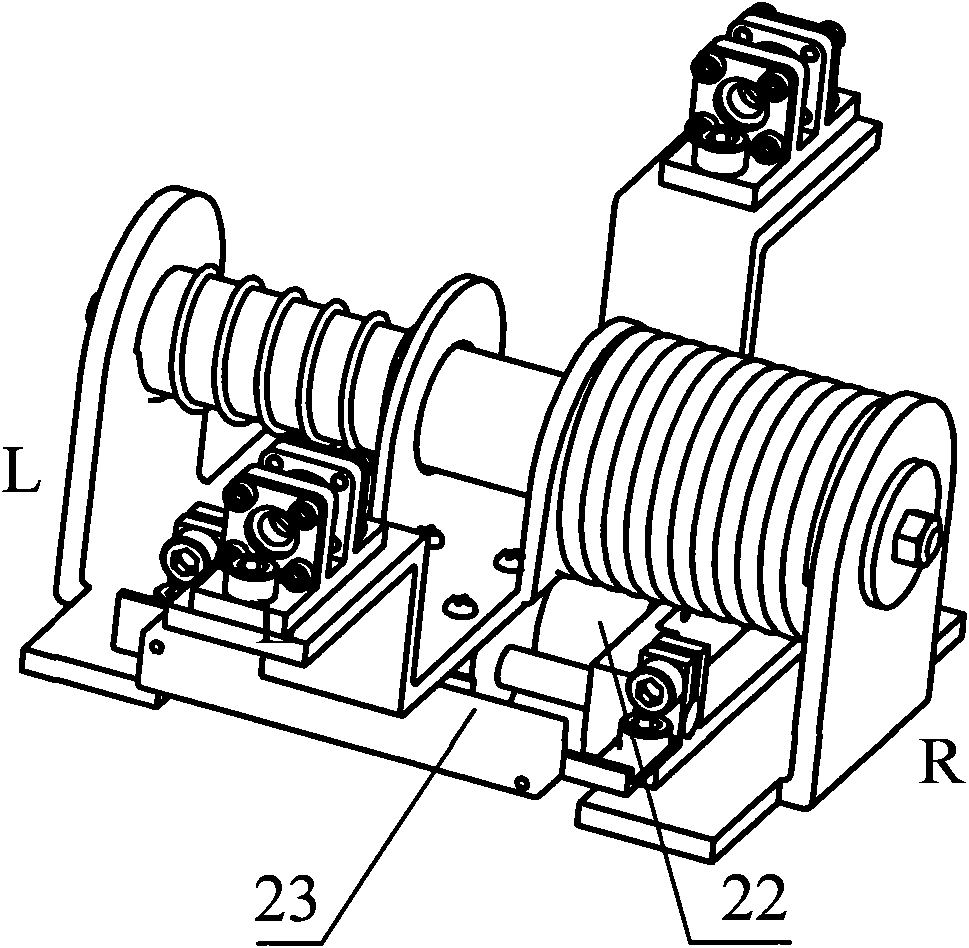

The invention relates to a full-automatic oiling serving robot for an unmanned oiling station.The full-automatic oiling serving robot comprises an external-expansion type rail, a movable intelligent platform, an industrial mechanical arm, a function switching rotating disc, a humanoid mechanical gripper, an electric suction cup, a touch mechanical gripper, a machine vision system, a man-computer interaction system, an oiling gun, an oiling machine, an oil pipe and a control cabinet.Automatic station switching of different kinds of devices is achieved through the function switching rotating disc in cooperation with supports with different functions and the like, and switching efficiency is improved; full-automatic oiling operation of different vehicles is achieved by using the humanoid mechanical gripper, the electric suction cup and the touch gripper in a matched mode, and the serving range of the robot is expanded; shape and position identification of outer cover plates and oil tank covers of automobiles is achieved in combination with the machine vision system, and the functions of monitoring and identifying the running condition, automobile license plates, owner identity and the like are further achieved; due to the cooperation of the human-computer interaction system, the types of the automobile oiling services of the full-automatic oiling serving robot are richer, and the application range is wider.

Owner:SHANDONG GUOXING SMARTECH CO LTD

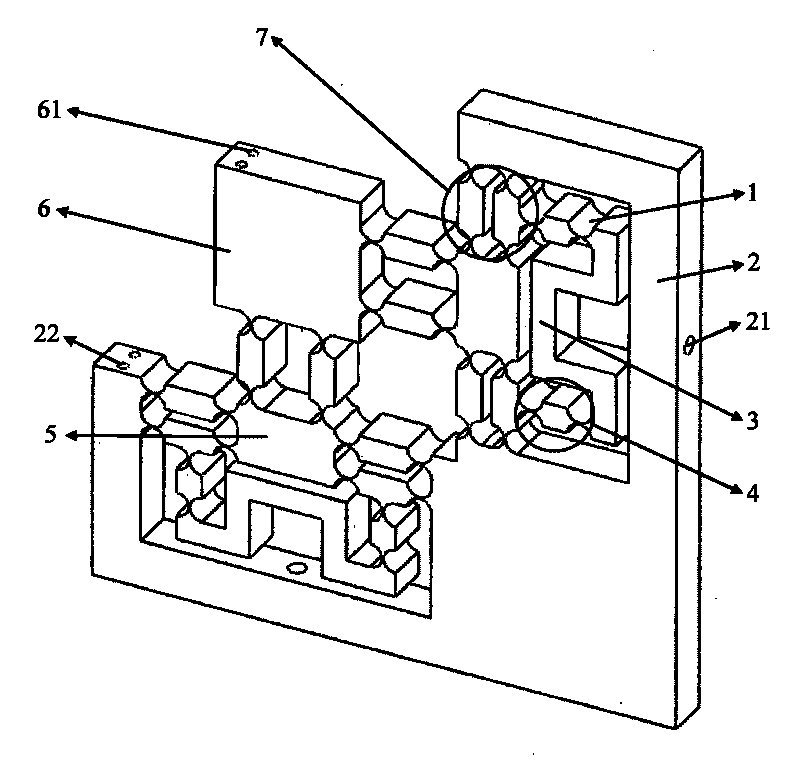

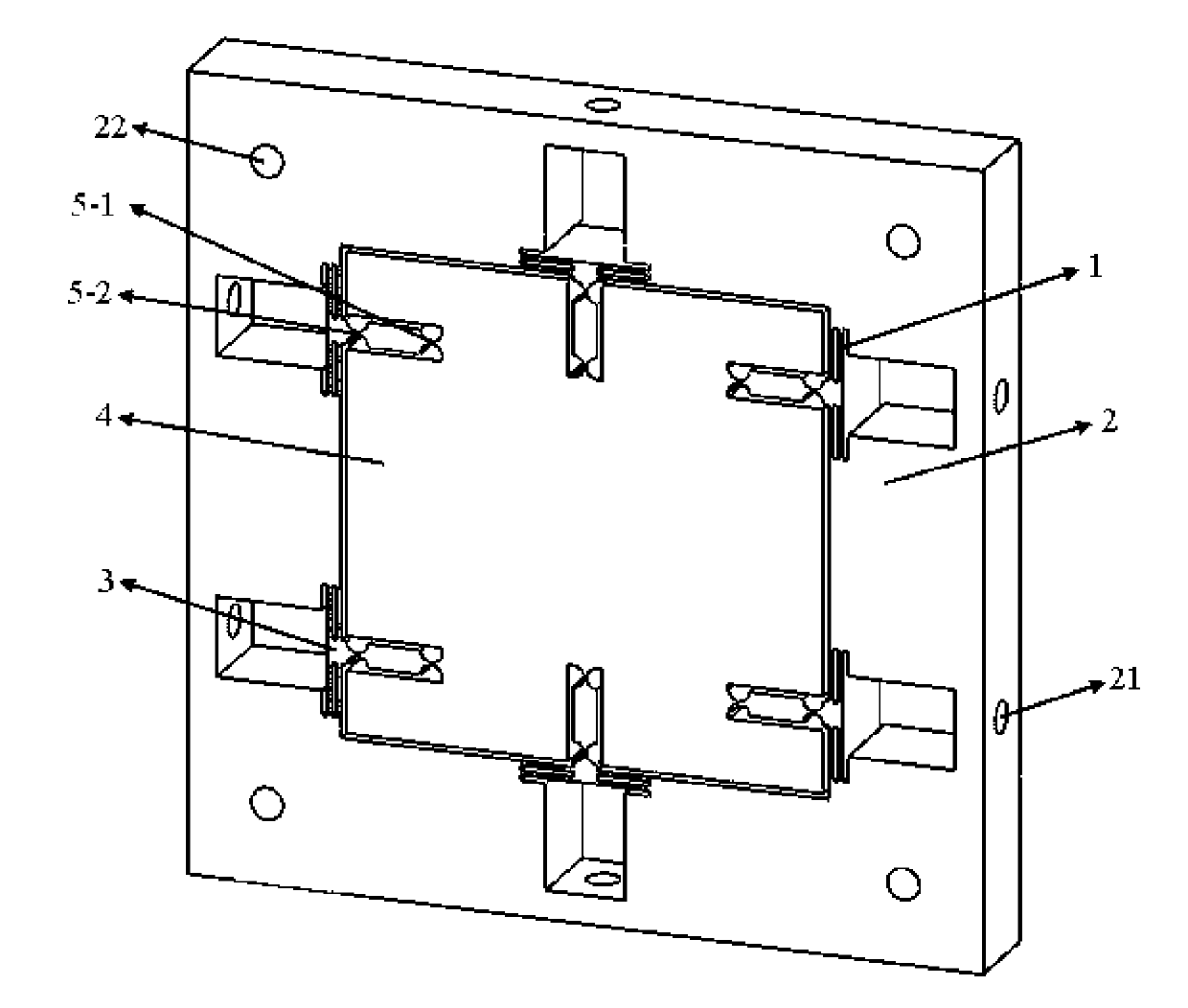

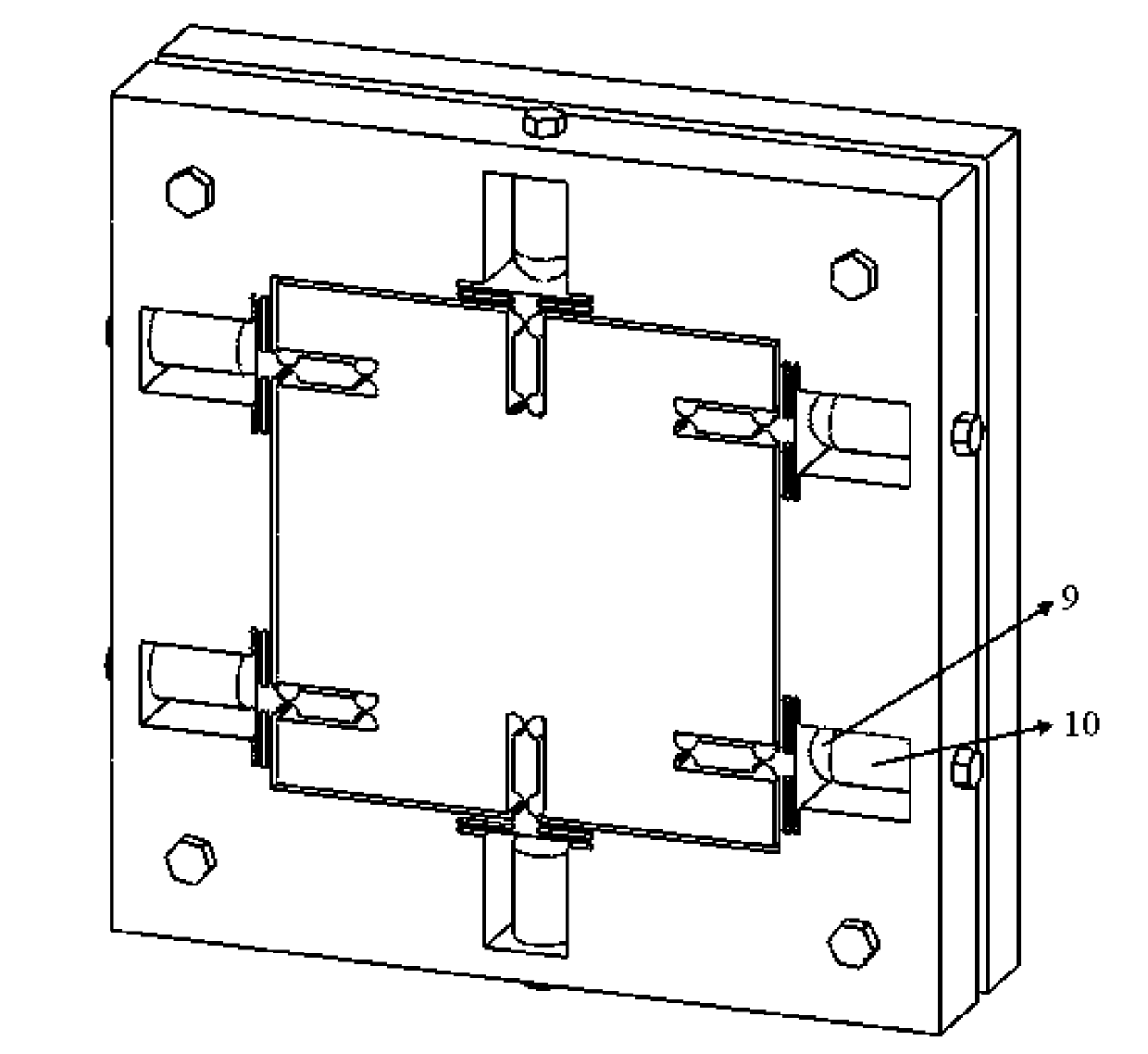

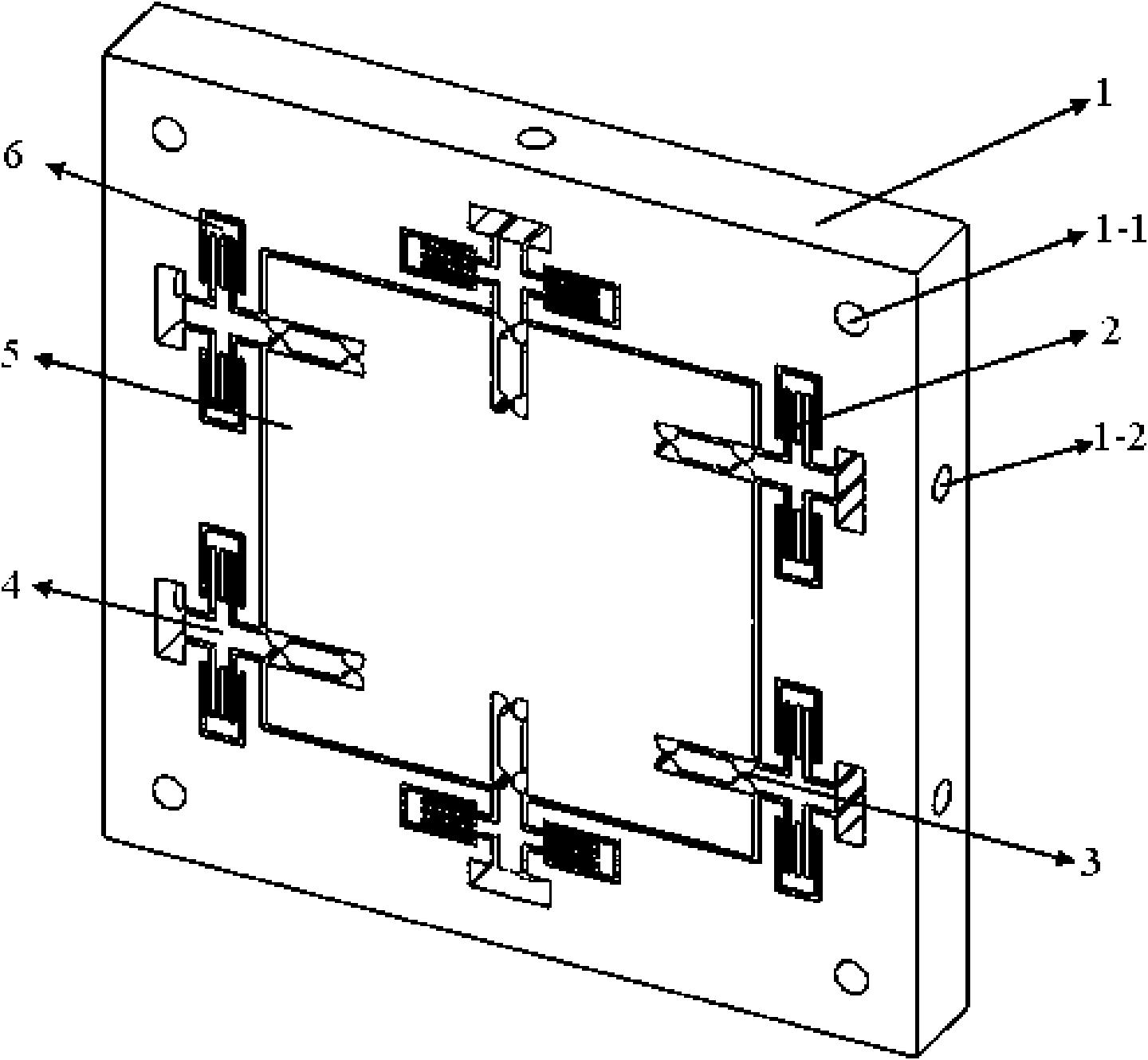

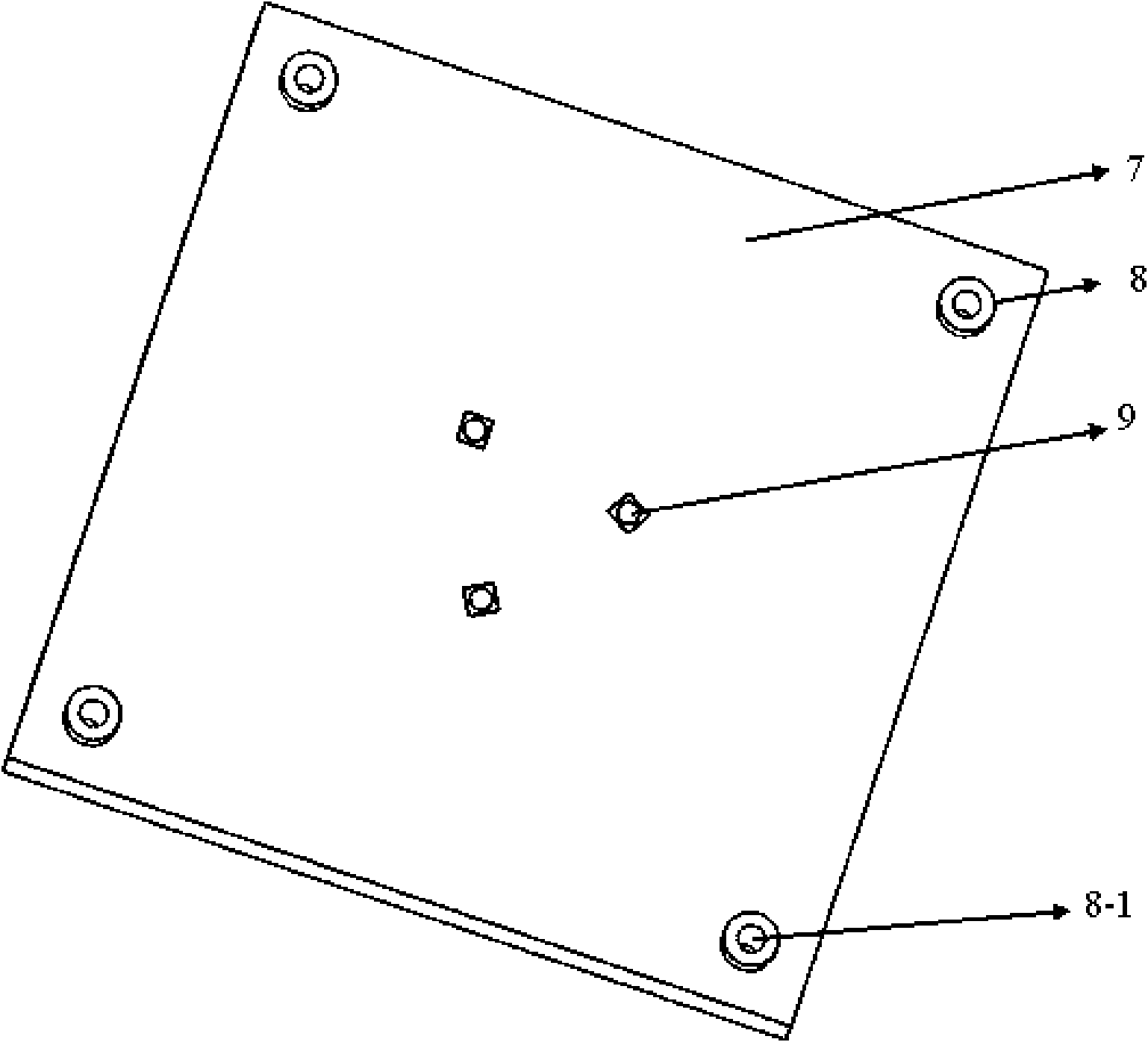

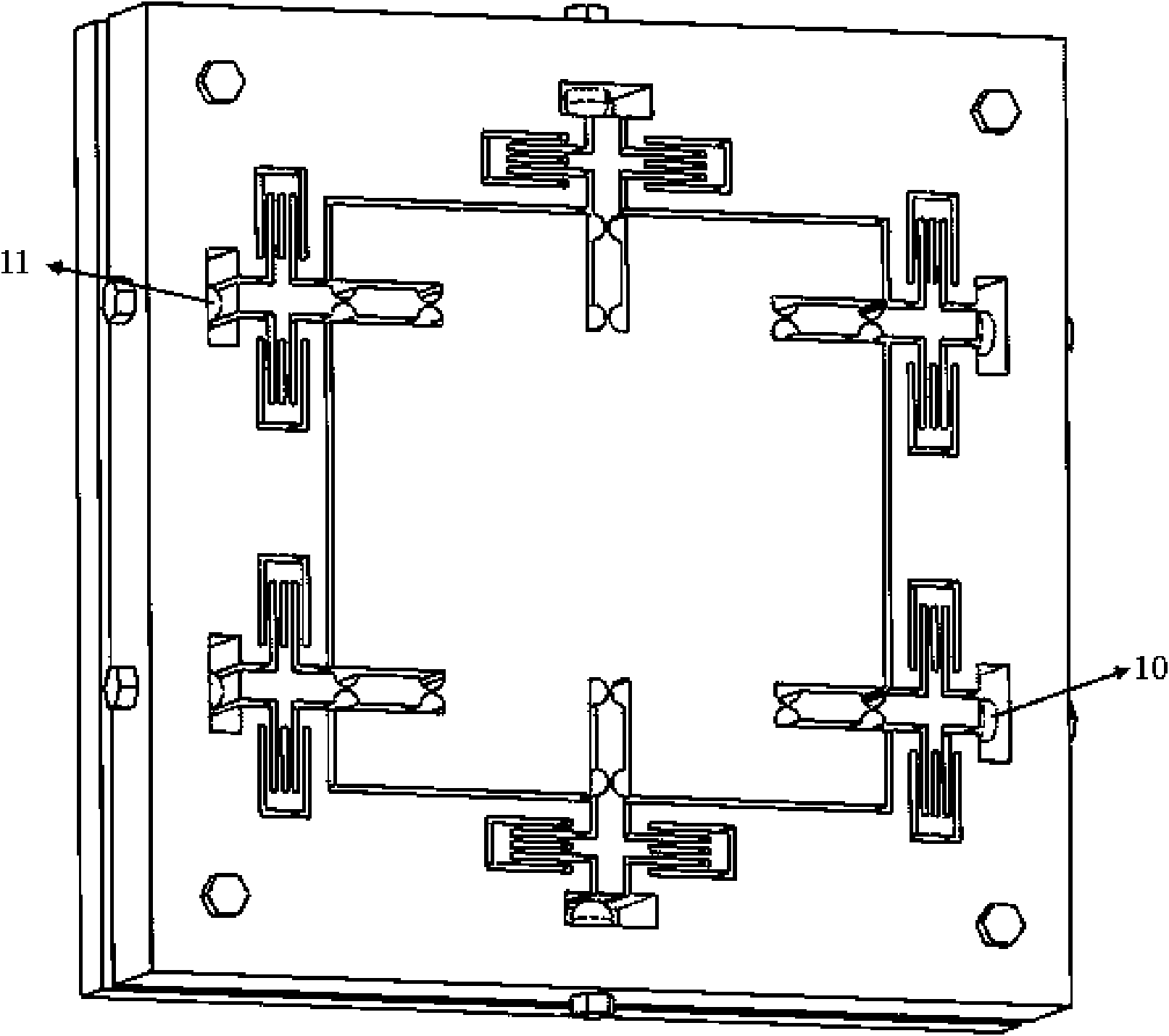

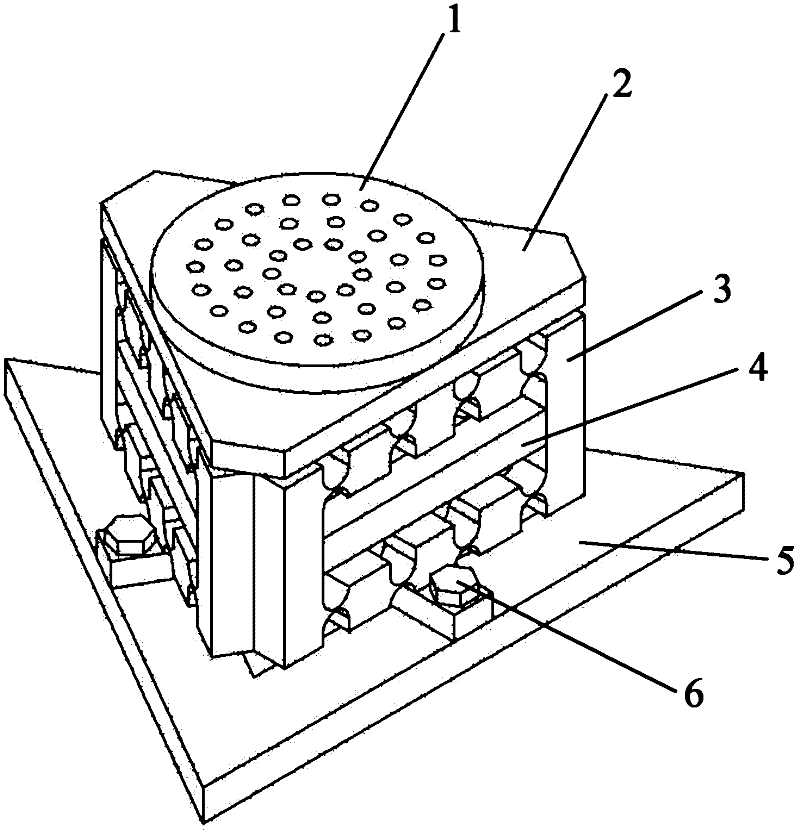

Flexible micro-positioning stage with two degrees of freedom

ActiveCN101738855AAvoid assemblyNo gapPhotomechanical apparatusFlexible MechanismsLithographic artist

The invention discloses a flexible micro-positioning stage with two degrees of freedom, the design of the flexible micro-positioning stage with two degrees of freedom comprises a flexible mechanism and an integral structure, two piezoelectric ceramic drivers are adopted in the structure, the tail part of each driver is connected with a base through a bolt, and the top end of each driver is connected with a spherical joint through a thread, thereby realizing Hertz contact. The flexible mechanism of the positioning stage mainly comprises three parts of the base, flexible branched chains with entirely consistent structures and a supporting movable platform thereof. Two displacement sensors are used for measuring actual output of the movable platform and respectively fixed between the base and the movable platform through an L-shaped support and a Z-shaped support. The flexible micro-positioning stage is characterized by high resolution and fast dynamic response speed, and can be taken as an auxiliary positioning platform of a nano-imprint lithography positioning system for realizing micro-feeding and precise positioning.

Owner:南通致远船舶设计有限公司

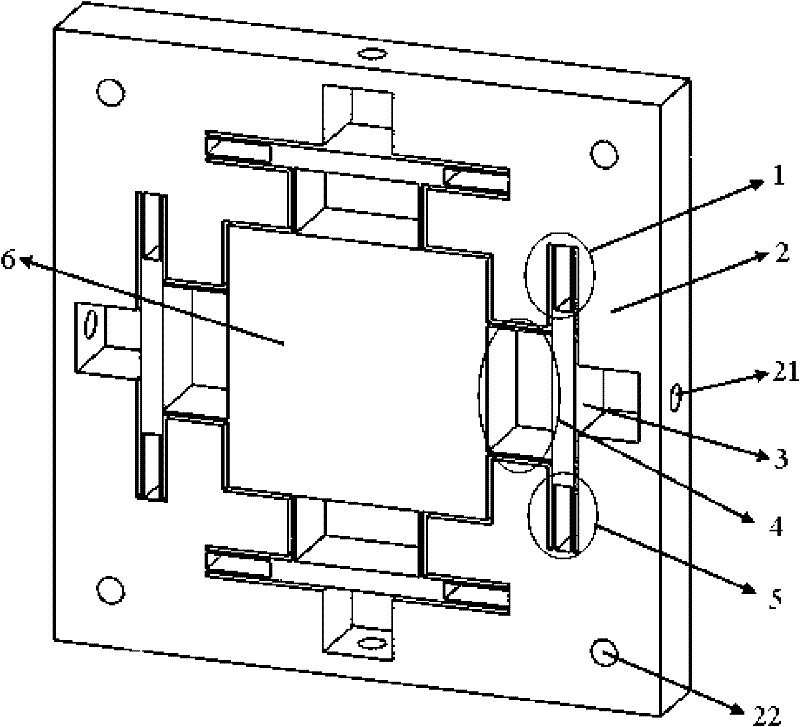

Three-degree of freedom flexible precision positioning workbench

InactiveCN101770182AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistThree degrees of freedom

The invention discloses a three-degree of freedom flexible precision positioning workbench. In a structure of the workbench, six piezoelectric ceramic drivers are adopted, the tail of each driver is connected with a substrate through bolts, and the top end is in threaded connection with a ball joint to realize hertz contact; a flexible structure of the positioning workbench mainly comprises the substrate, six flexible branched chains with identical structures and a movable platform supported by the flexible branched chains; and three position sensors are used for measuring the actual output of the movable platform and are respectively fixed between a rigid support and the movable platform. The precision positioning workbench has the characteristics of high resolution ratio and high speed of dynamic response, and can be used as an assisted positioning platform of a nano-imprint lithography positioning system to realize microscale feeding and precision positioning.

Owner:TIANJIN UNIV

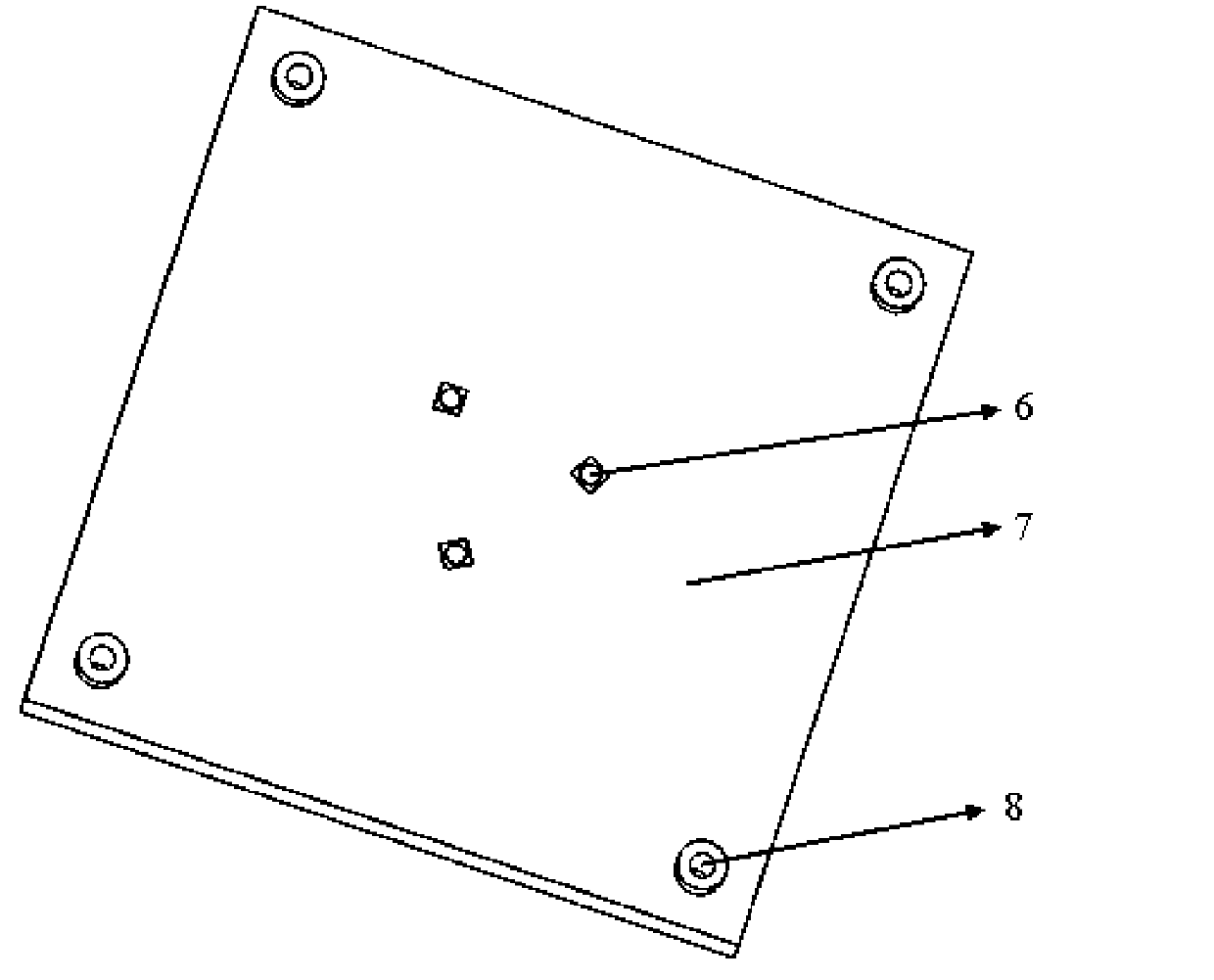

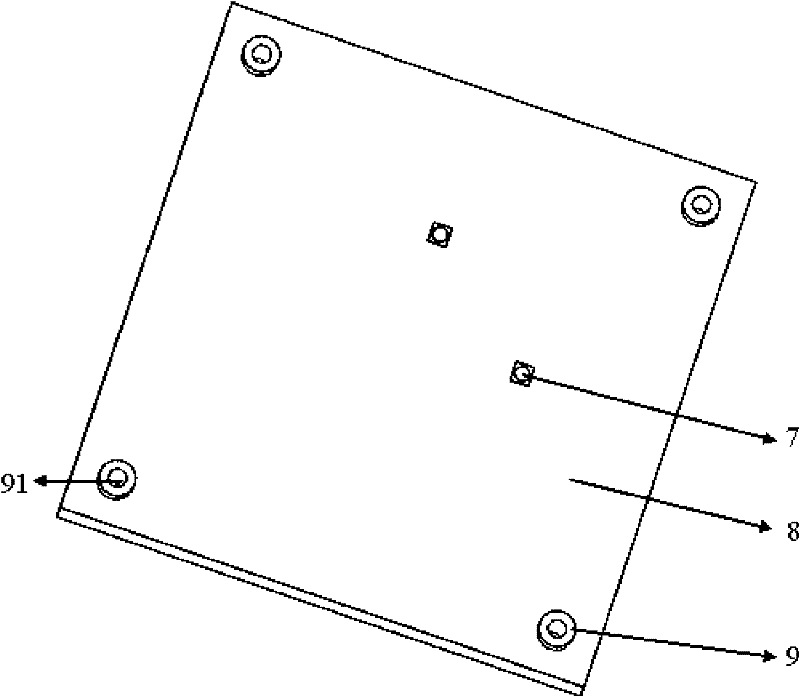

Two-degree of freedom precise positioning work table

The invention discloses a two-degree of freedom precise positioning work table, which comprises a base, a moving platform, a rigid support which is connected with the bottom of the base, and four flexible branched chains which are connected between the moving platform and the base, wherein each flexible branched chain comprises a moving block and three groups of flexible plate spring structures; each flexible plate spring structure consists of two '-'-shaped flexible plate springs; a first group and a second group of the flexible plate spring structures are respectively positioned at the left side and the right side of the moving block; the lower ends of the two '-'-shaped flexible plate springs of a third group of the flexible plate spring structures are connected with the side wall of the upper end of the moving block, and the upper ends thereof are connected with the side wall of the moving platform; four piezoelectric ceramics driving devices are respectively horizontally arranged; a ball-shaped joint of each driving device is supported on the side wall of the lower end of the moving block; and conducting strips of two position sensors are respectively connected with the upper plane of the rigid support and the lower plane of the moving platform. The positioning work table can be taken as an auxiliary positioning platform of a nanometer embossing photoetching positioning system to realize the microscale feeding and the precise positioning.

Owner:TIANJIN UNIV

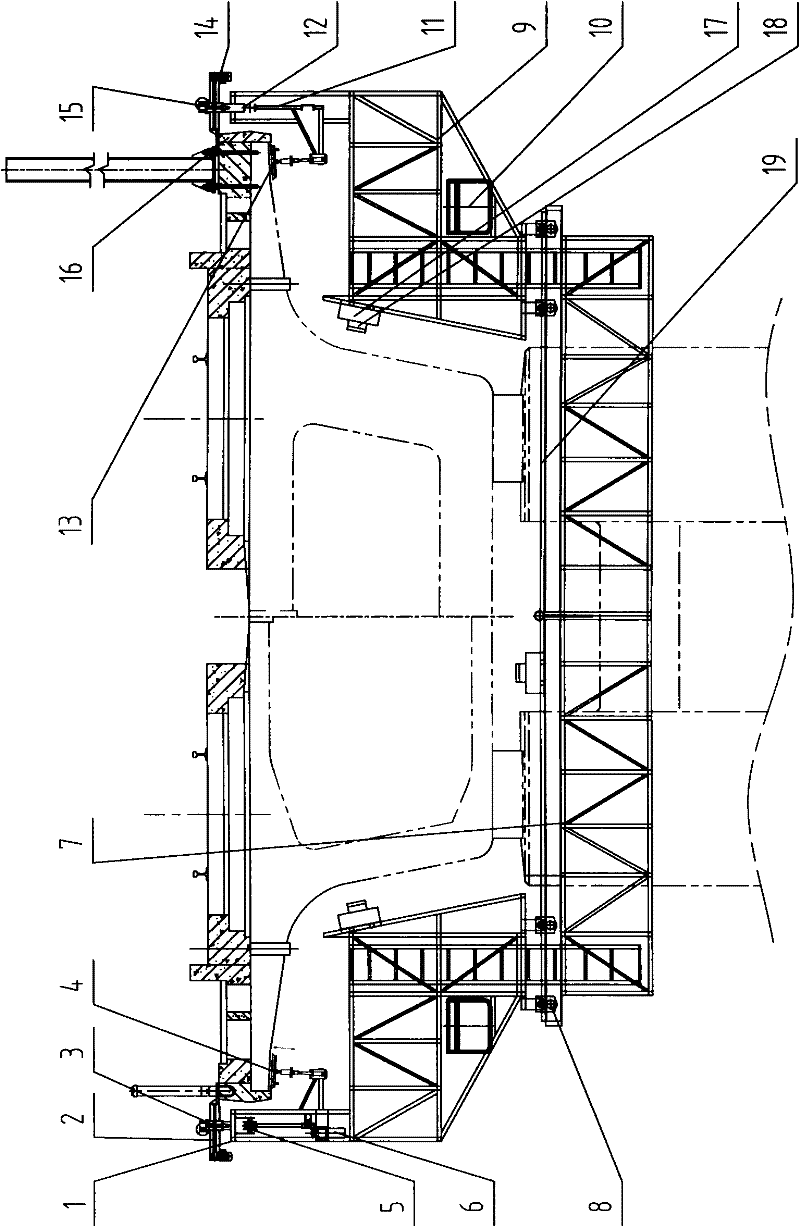

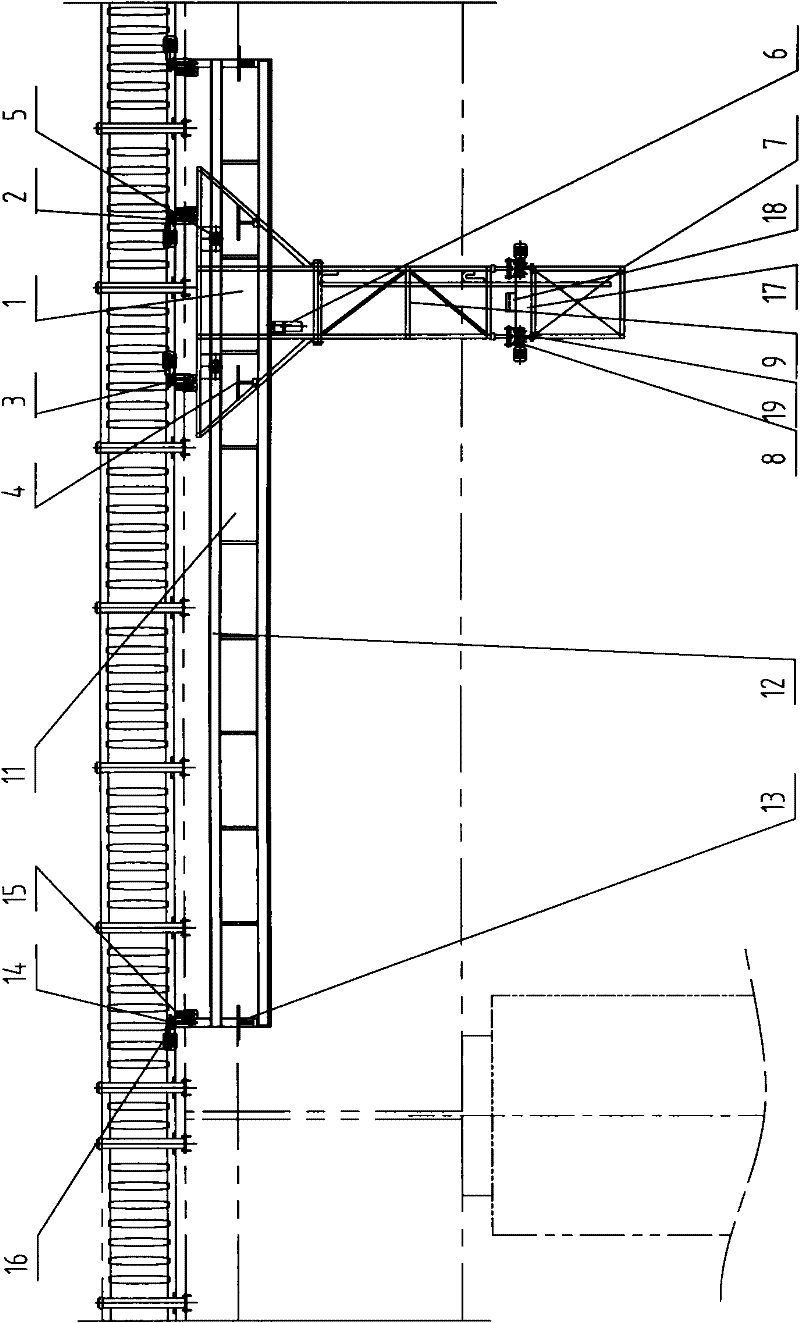

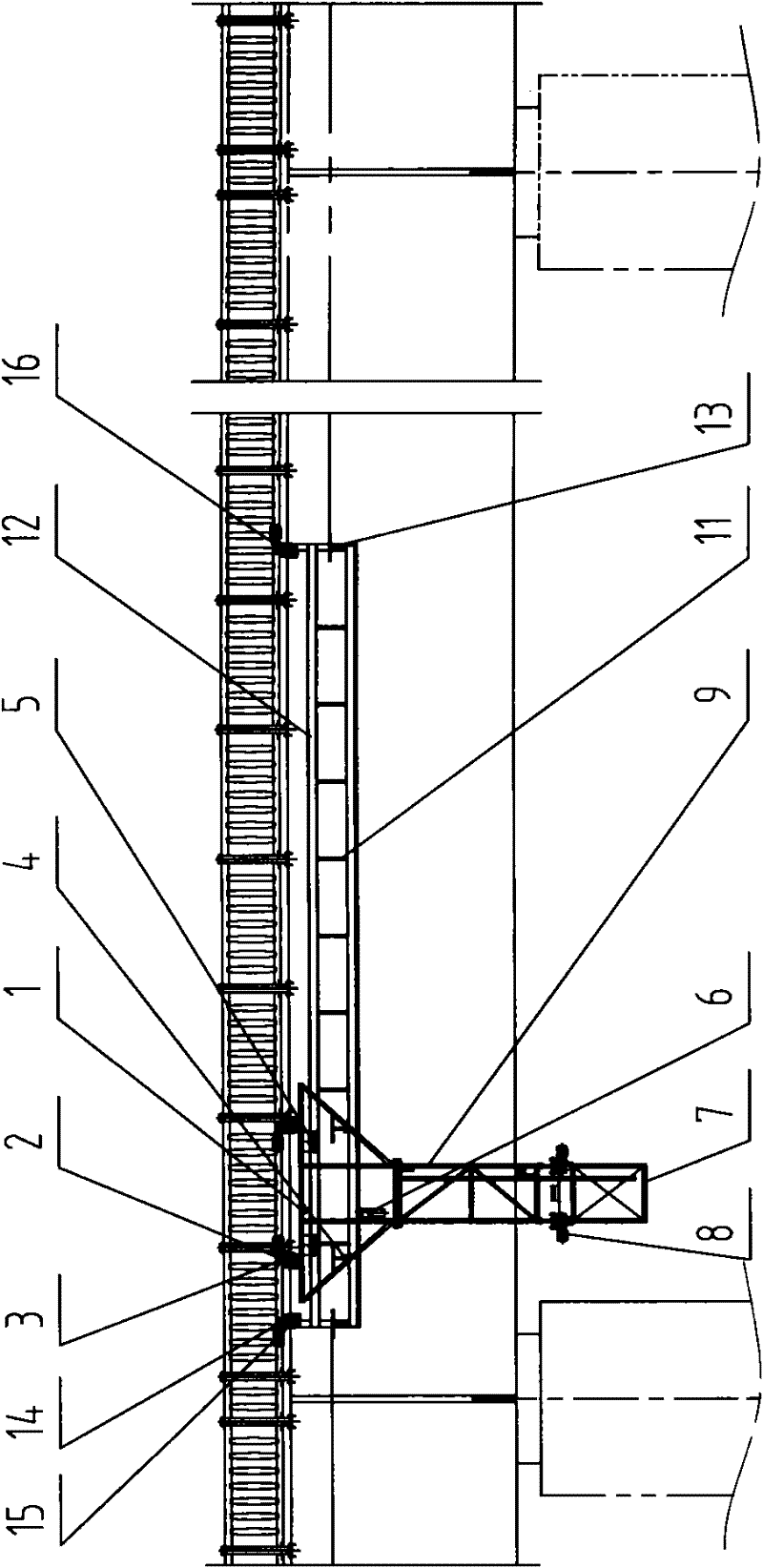

Self-guided beam type bridge monitoring and overhauling device

The invention discloses a self-guided beam type bridge monitoring and overhauling device and relates to a device for performing constructions operations such as bridge detection, maintaining, repairing and the like, aiming to provide a self-guided beam type bridge monitoring and overhauling device which performs construction operations such as high-speed rail bridge detection, maintaining and the like. The self-guided beam type bridge monitoring and maintaining device comprises a main guide beam and a driving guide beam, the main guide beam comprises a truss-type rail, a bridge fixing device and the like, the driving guide beam comprises a guide wheel set, a chain wheel driving device, a side surface overhauling platform, a bottom part overhauling platform, an electric generating set, a pier-passing expansion device, a beam fixing device and the like, when the self-guided beam type bridge monitoring and overhauling device is used, the main guide beam and the driving guide beam are respectively fixed on a bridge, the self-guided beam type bridge monitoring and overhauling device can move longitudinally along the bridge by combination with the guide wheel set and the chain wheel driving device, meanwhile, a detection dolly can perform repeated detection automatically on a detection dolly rail and transmit the detection records, when a problem is detected, a staff can perform overhauling on the side surface overhauling platform and a construction operation passageway platform formed by a steel ladder and the bottom part overhauling platform.

Owner:北京万桥兴运工程技术有限公司

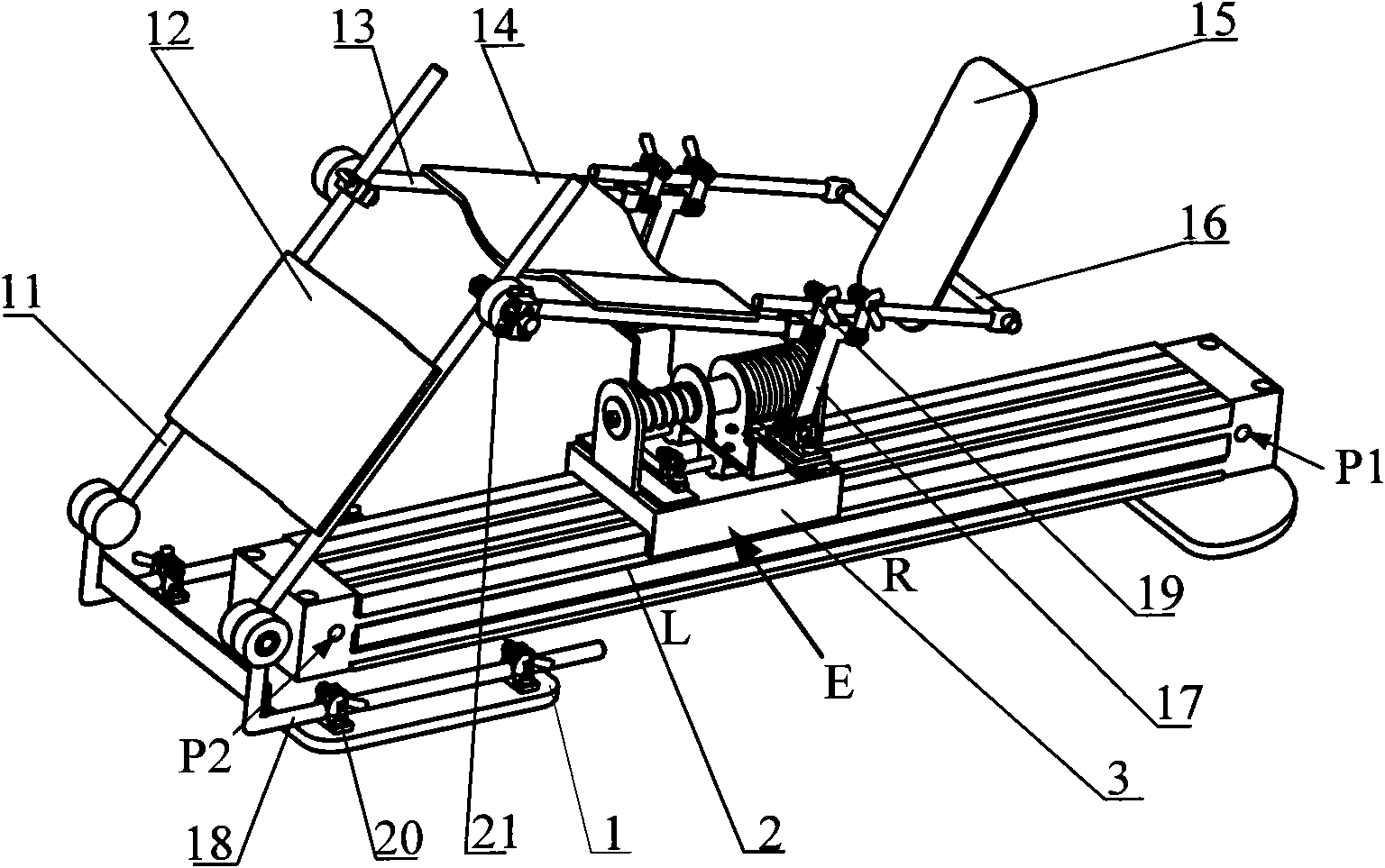

Flexible active and passive knee-joint rehabilitation training device

ActiveCN101836930AAvoid secondary damageImprove flexibilityGymnastic exercisingChiropractic devicesThighBaseboard

The invention discloses a flexible active and passive knee-joint rehabilitation training device, comprising a linear drive unit, a leg bracket unit and a control unit, wherein, the linear drive unit comprises a baseboard, a rodless cylinder, a sliding table for the rodless cylinder, an inflatable extendible flexible driver, a guide rod, a spring, a fixed support, a connecting piece, a removable bracket and a sliding pair; the leg bracket unit comprises a thigh rod, a thigh supporting board, a shank rod, a shank supporting board, a feet bracket, a connecting rod, a T-type connecting piece, a L-type rod, a first regulating device and a second regulating device; and the control unit comprises an angular displacement sensor, a force sensor, a displacement sensor and a controller. The training device can conveniently achieve a plurality of rehabilitation training modes such as knee-joint passive training, active training and the like according to the rehabilitation degree of a patient, and an applying force (including a driving force in the passive training and a damping force in the active training) is regulated in a stepless manner.

Owner:TECH TRANSFER CENT CO LTD NANJING UNIV OF SCI & TECH

Method for regenerating alkali liquor containing sodium thioalcohol

InactiveCN101077981AIncrease the speed of oxidation reactionSave working spaceHydrocarbon oils refiningSulfideAqueous sodium hydroxide

The method of regenerating alkali solution containing sodium mercaptide is to oxidize sodium mercaptide in alkali solution with oxygen-rich air with oxygen concentration of 26-99.99 vol% intelligent presence of catalyst, such as cobalt phthalcyanide sulfonate, into disulfide. Sodium mercaptide including sodium methyl mercaptide, sodium ethyl mercaptide, etc in alkali solution, such as water solution of sodium hydroxide, is mixed with oxygen-rich air and reacted under the action of catalyst, such as cobalt phthalcyanide sulfonate, to produce sodium hydroxide and disulfide, such as dimethyl disulfide, diethyl disulfide, etc., so that the alkali solution has lowered sodium mercaptide concentration and raised sodium hydroxide concentration. The regenerated alkali solution after eliminating the disulfide may be reused in the mercaptide eluting process of liquefied alkali.

Owner:NINGBO ZHONGYI PETROCHEM TECH

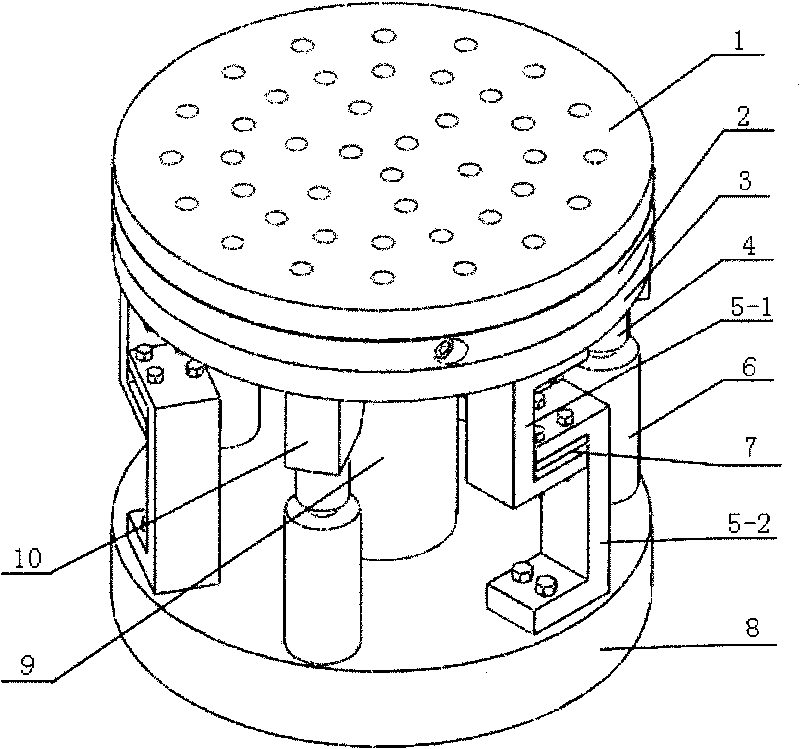

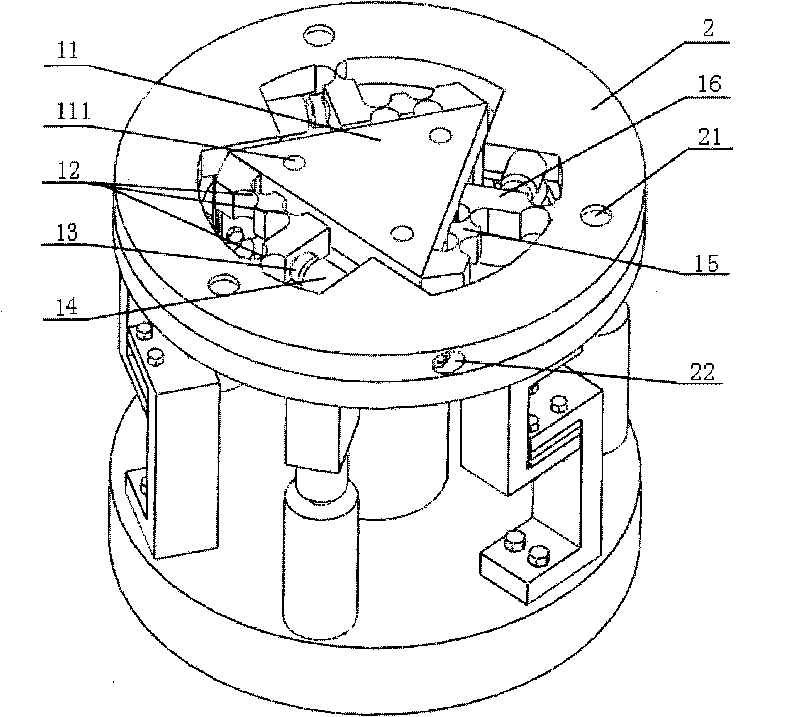

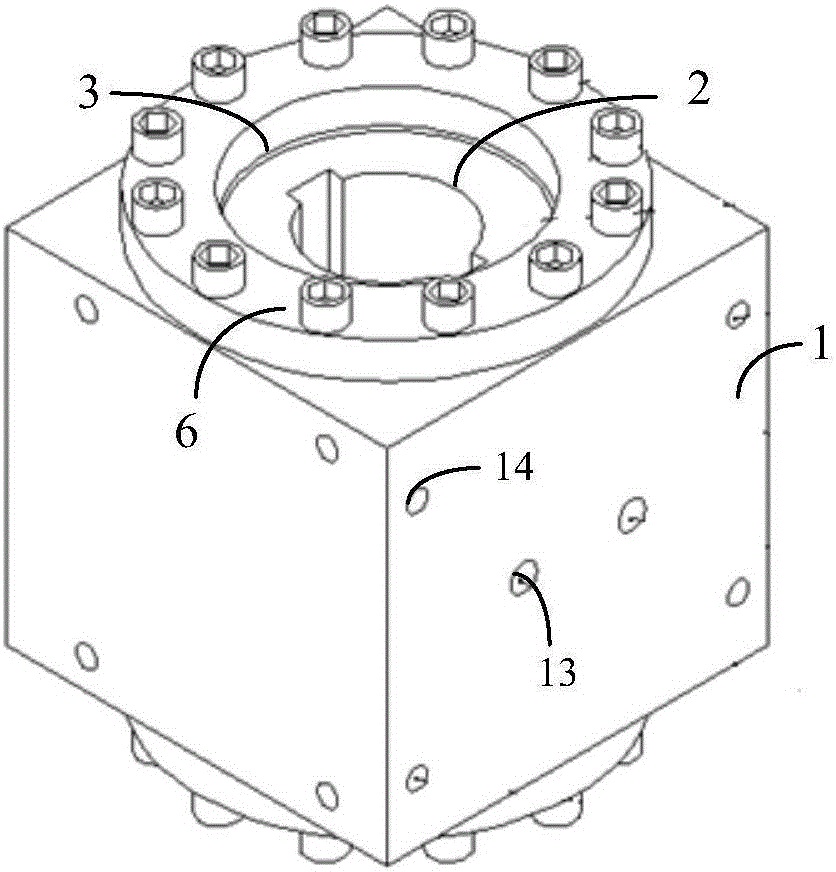

Six-freedom-degree precision positioning table for nano-imprint lithography system

ActiveCN101726997ACompact structureIncrease stiffnessPhotomechanical apparatusWork benchesElectricityImage resolution

The invention discloses a six-freedom-degree precision positioning table for a nano-imprint lithography system, wherein a spatial flexibility mechanism comprises a pre-tightening mechanism, three first displacement sensor and three first piezoelectric ceramic drivers, the pre-tightening mechanism comprises an elastic pre-tightening ring connected with a rigid ring, a base, a vertical column, three bottom elastic hinges and a first displacement sensor, the piezoelectric ceramic drivers are pushed on the elastic hinges; a plane flexibility mechanism comprises a rigid ring, a rigid supporting table, three flexible branched chains and three second piezoelectric ceramic drivers, each flexible branched chain comprises three top part elastic gemels, three second elastic gemels are connected by a driving connecting rod and a middle connecting rod, two second elastic gemels are respectively connected with the rigid ring and the rigid supporting table, the second piezoelectric ceramic drivers are pushed against on the driving connecting rod, three pairs of the supports are arranged, and each pair of the supports are connected with a second displacement sensor, and the rigid supporting table is connected with a movable platform; the working table has high resolution ratio and rapid dynamic response speed.

Owner:南通致远船舶设计有限公司

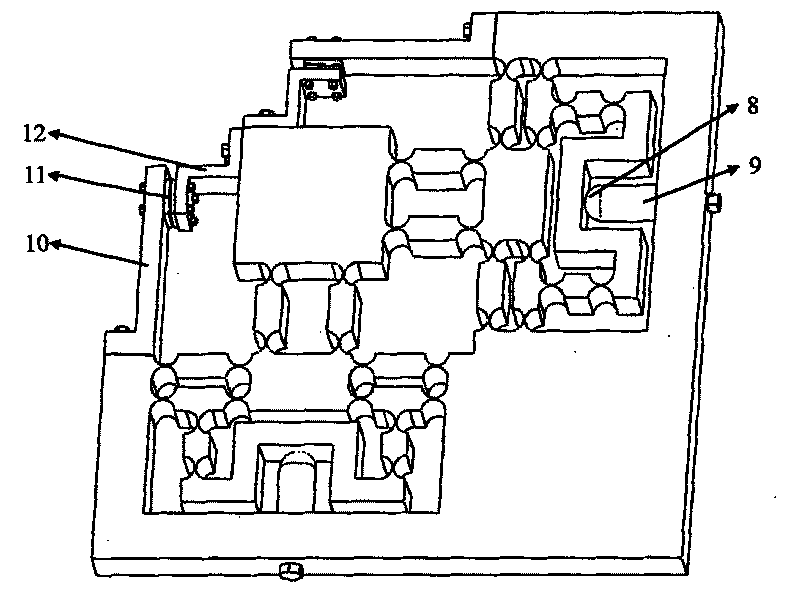

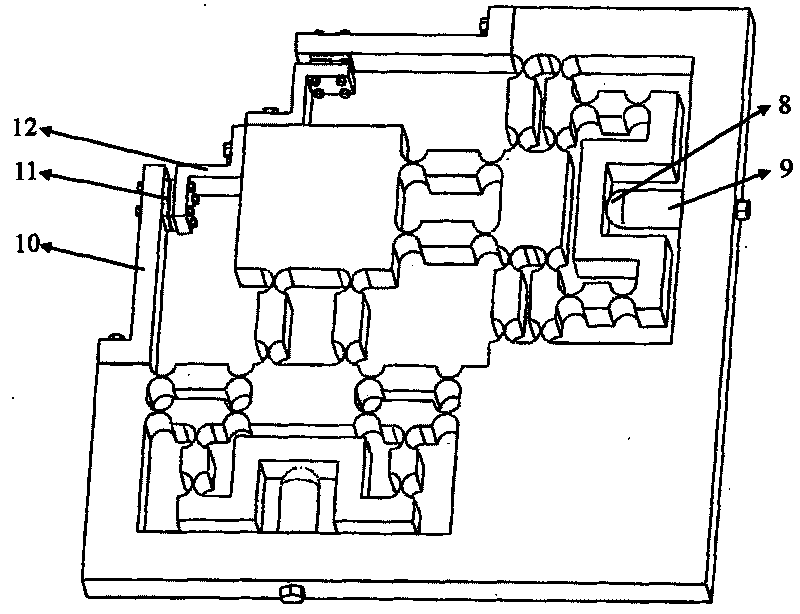

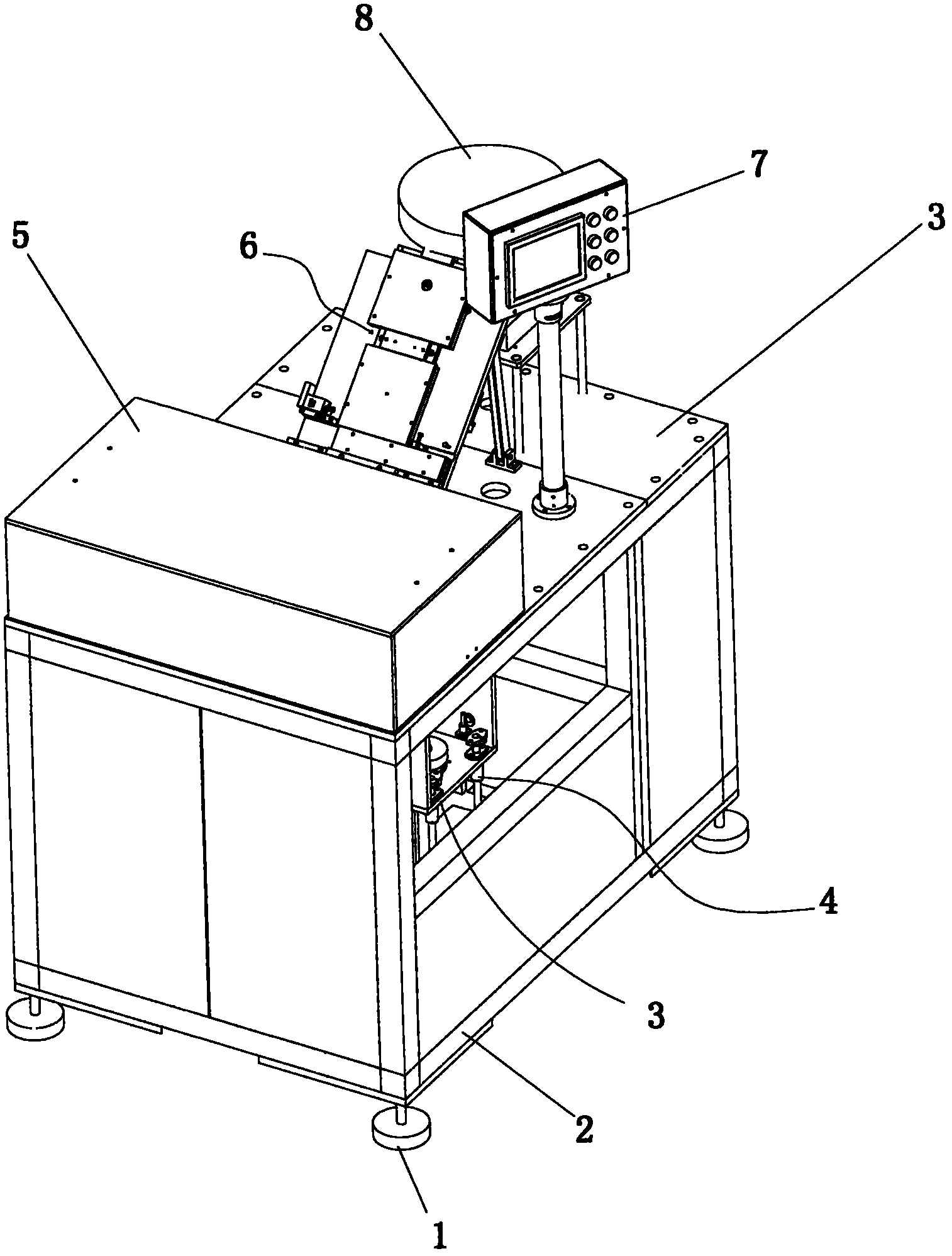

Full automatic packing machine for button cells

The invention discloses a full automatic packing machine for button cells, which comprises a machine frame, a bottom board and a vibrating disk, wherein the bottom board is arranged on the machine frame; and a blanking mechanism for automatically putting the button cells and uniformly placing the button cells in a packing box, a displacement mechanism for pushing a product tool for placing the packing box to carry out fore-and-aft movement, a box transferring mechanism for transferring an empty packing box and a packing box filled with cells, a loading mechanism for automatically filling up the empty packing box and a finished product discharging mechanism for automatically discharging the packing box filled with cells are further arranged on the machine frame. The full automatic packing machine for the button cells has the advantages of being full automatic in work, high in production efficiency and low in cost, and the market competitive power is improved.

Owner:DONGGUAN CITY TIANXIANG AUTOMATION EQUIP

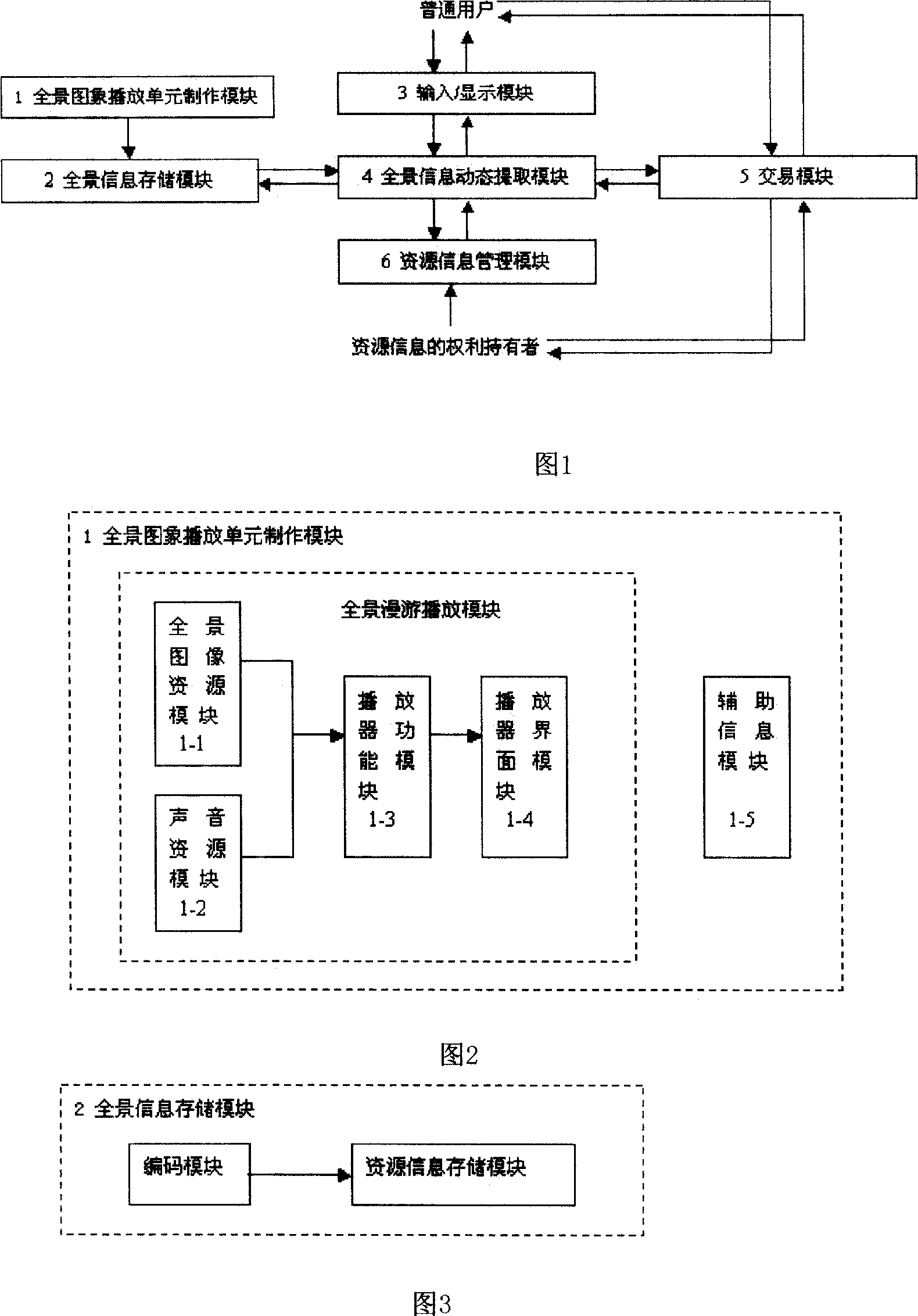

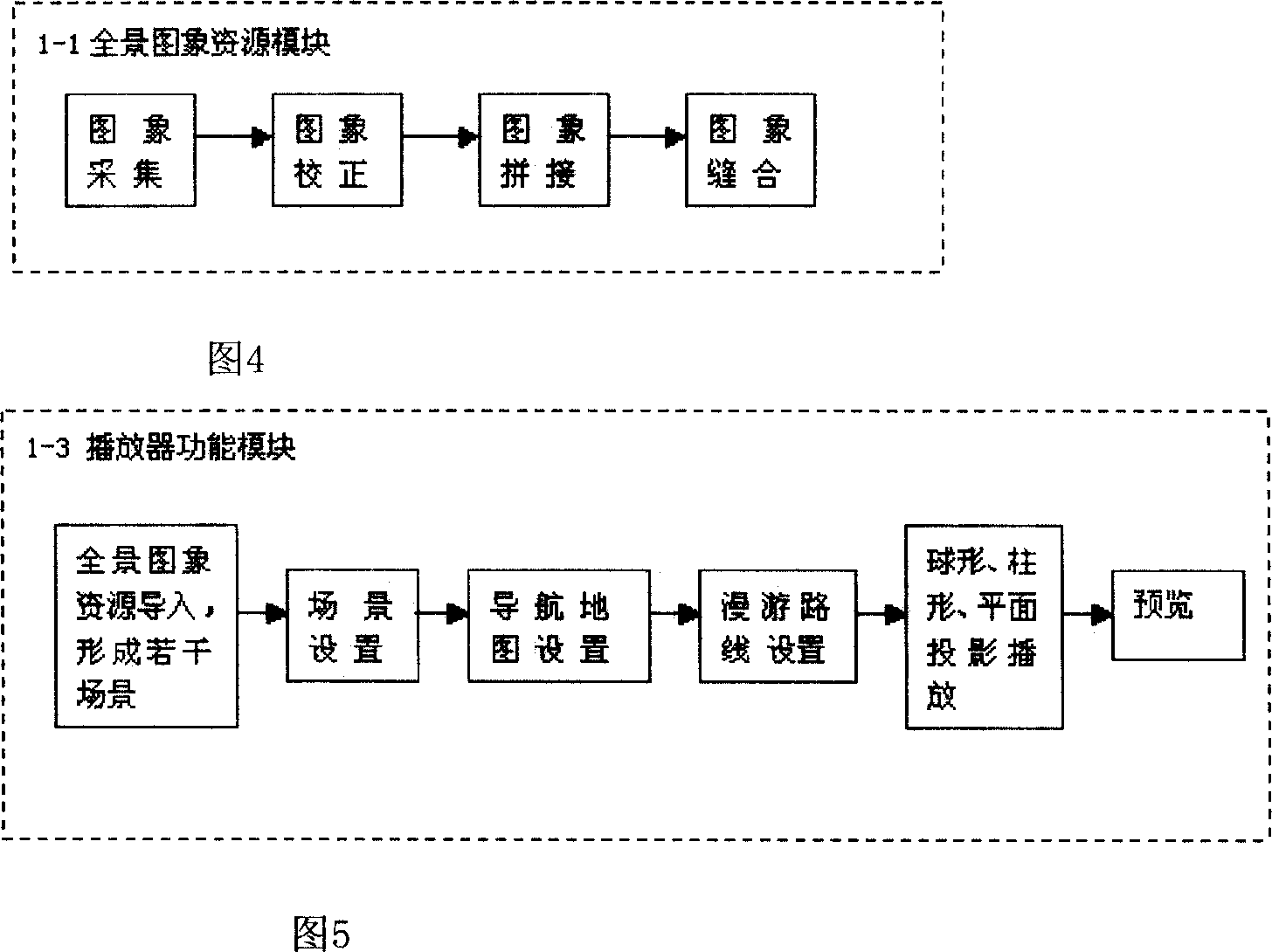

Panorama manufacturing and displaying system of resource information

InactiveCN101136022AEasy to manufactureEasy to manageImage data processing detailsSpecial data processing applicationsUser inputResource information

The system comprises: a panorama image of resource information play unit making module used for making encode for the panorama image play unit; a panorama information storage module for storing the panorama information; a display module for providing input operation for user and displaying its corresponding content; a panorama information dynamically extracting module; a transaction module used for providing the interaction information for the user and resource information owner; a resource information management module used for modifying the content of resource information.

Owner:李筑

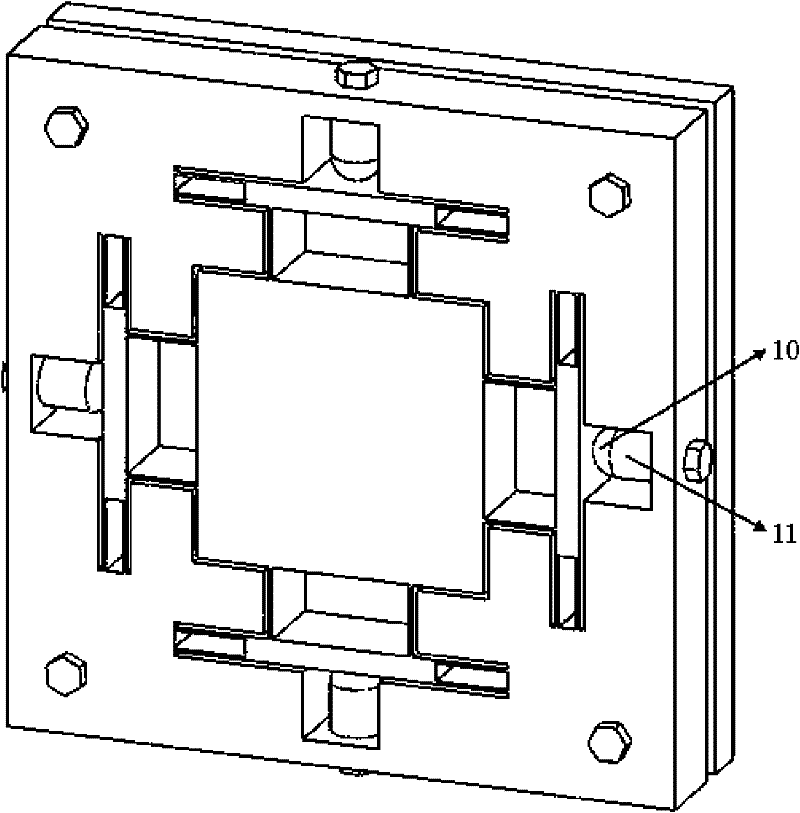

Three DOF micro-positioning workbench for nano-imprint lithography system

InactiveCN101776851AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusFlexible MechanismsLithographic artist

The invention discloses a three DOF micro-positioning workbench for a nano-imprint lithography system, which comprises six piezoelectric ceramic drives; and each drive is connected with a base, and the top end is connected with a spherical connector by thread. The workbench also comprises six flexible fork chains of a flexible mechanism with totally consistent structure and a moving platform which is supported by the flexible fork chains; and three position sensors are used to measure the actual output of the moving platform, and are respectively fixed between a rigid support and the moving platform. The micro-positioning workbench is characterized by high resolution and high dynamic response speed, can serves as an auxiliary positioning platform of a nano-imprint lithography positioning system, and realize micro feeding and precise positioning.

Owner:TIANJIN UNIV

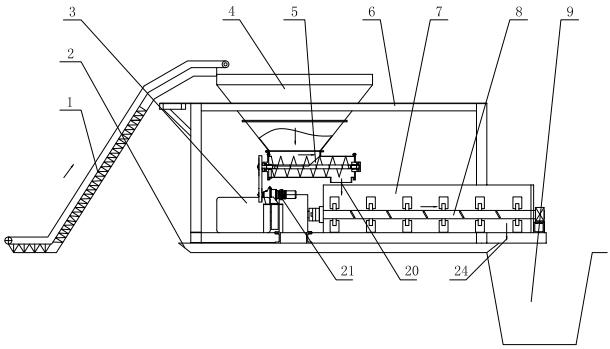

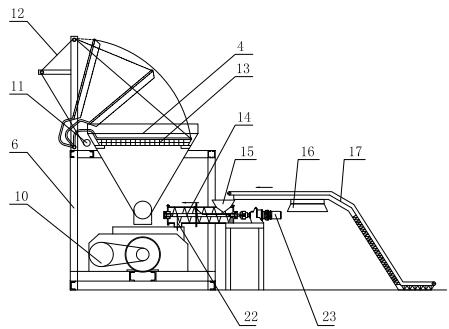

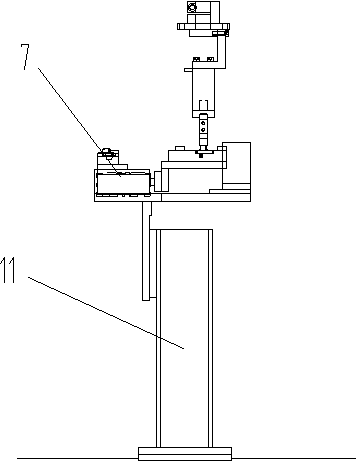

Silt solidification processor

InactiveCN102040328APrecise quantitative feedingTimely and effective filter removalSludge treatment by de-watering/drying/thickeningFailure rateSmall footprint

The invention relates to a silt solidification processor which is characterized in that a stirring chamber is arranged at the lower part of a frame, two spiral stirring shafts which rotate relatively are arranged in the stirring chamber, the stirring shafts are driven by a main motor to rotate, two feed ports are arranged above the initial segment of the stirring chamber, one feed port is a silt feed port used for carrying out series connection and transportation through a silt conveyor belt, a silt hopper and a silt conveying spiral shaft, and the other feed port is a solidifying agent feed port used for carrying out the series connection and the transportation through a solidifying agent conveyor belt, a solidifying agent hopper and a solidifying agent conveying spiral shaft; and a discharge port at the tail end of the stirring chamber is arranged above a silt solidifying pond. The silt solidification processor has the advantages that the structure is compact and reasonable, the occupied area is small, and the problem that the silt solidification processor in the prior art is in a large structure requiring a lifting mechanism for conveying a solidifying agent can be improved. A flap filtering device is arranged at the inlet of the silt hopper, thereby effectively filtering and removing large solid impurities in silt in time, preventing blockage and damages to equipment and realizing low failure rate.

Owner:无锡中科建设工程有限公司

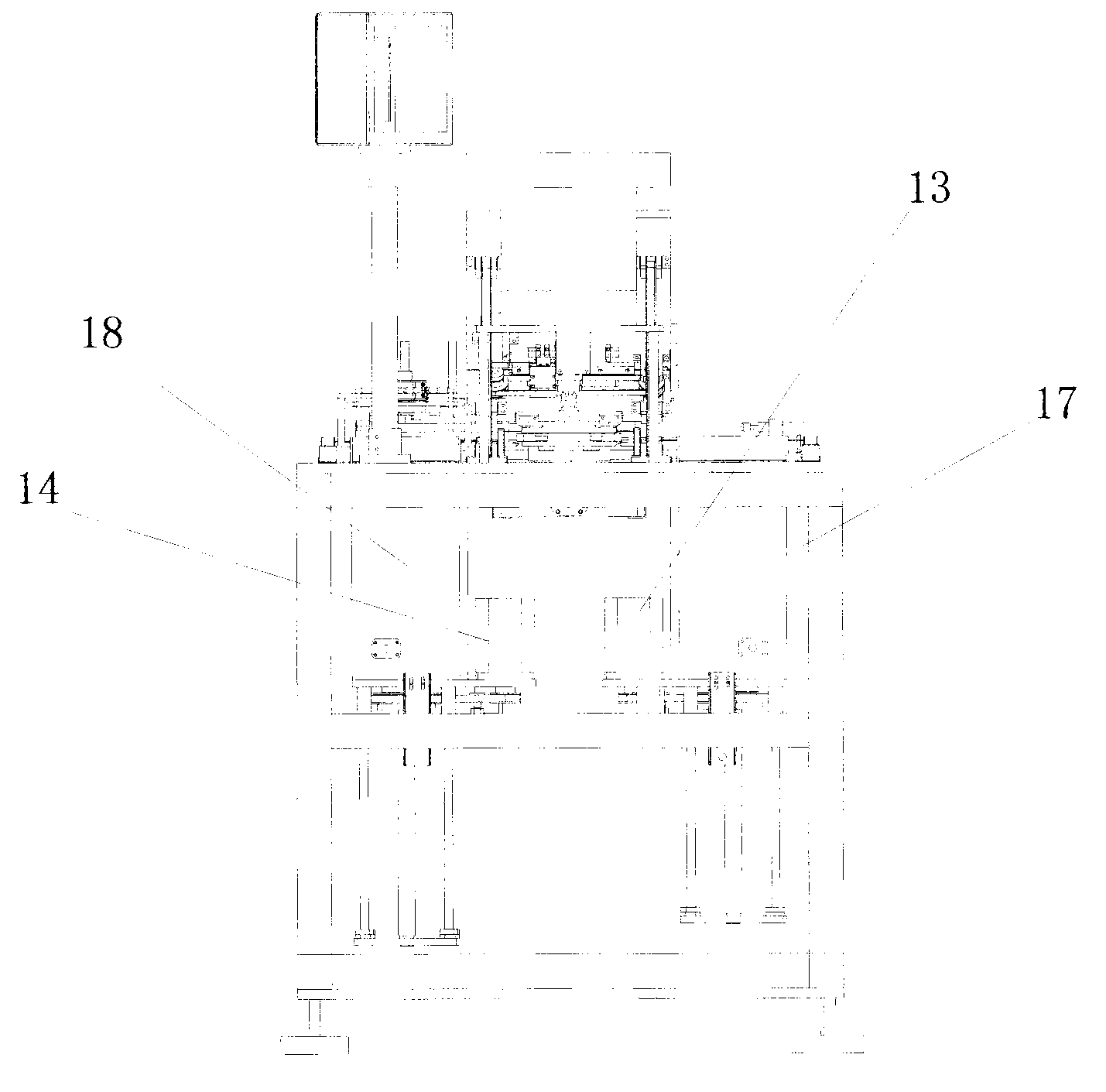

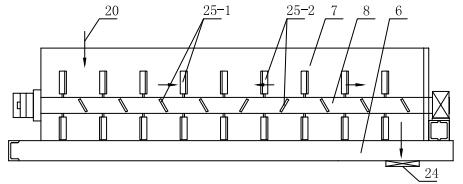

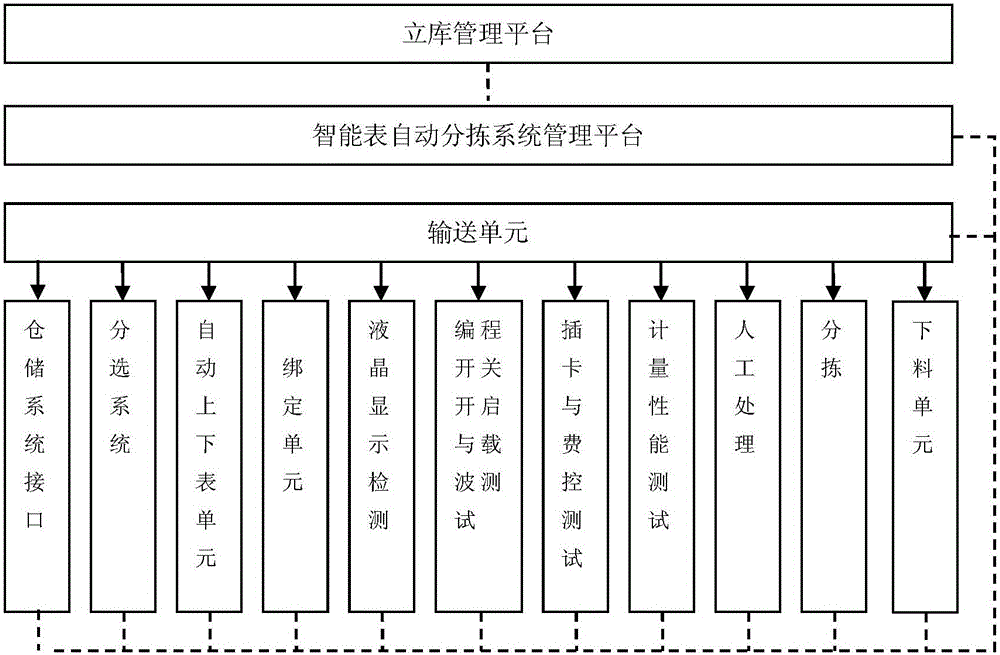

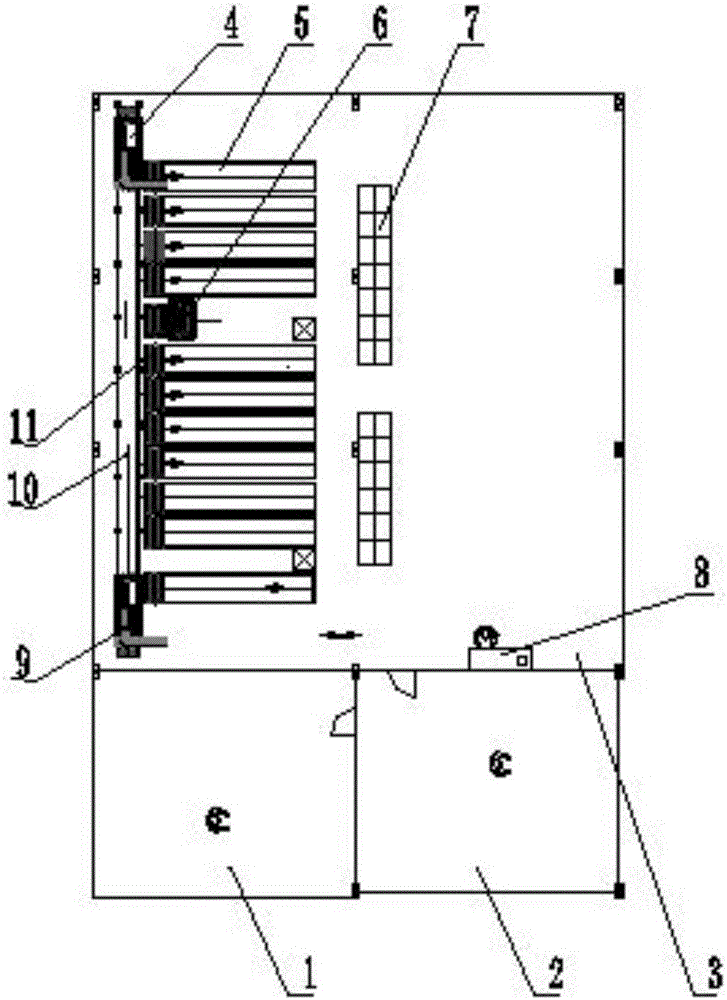

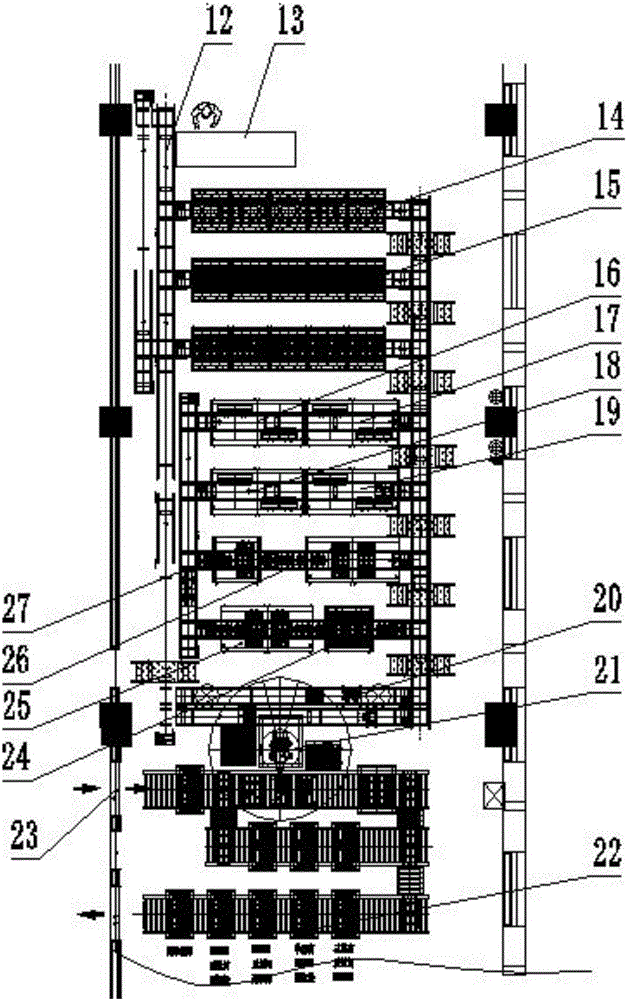

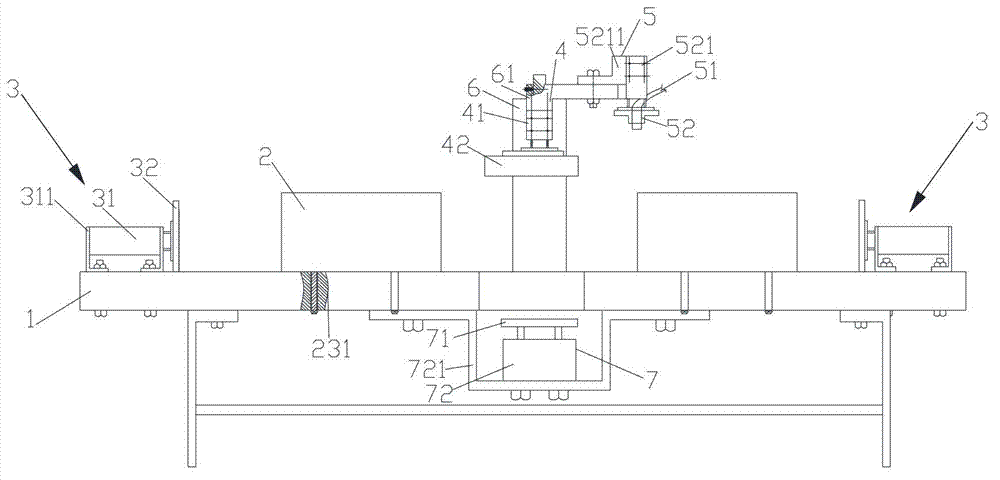

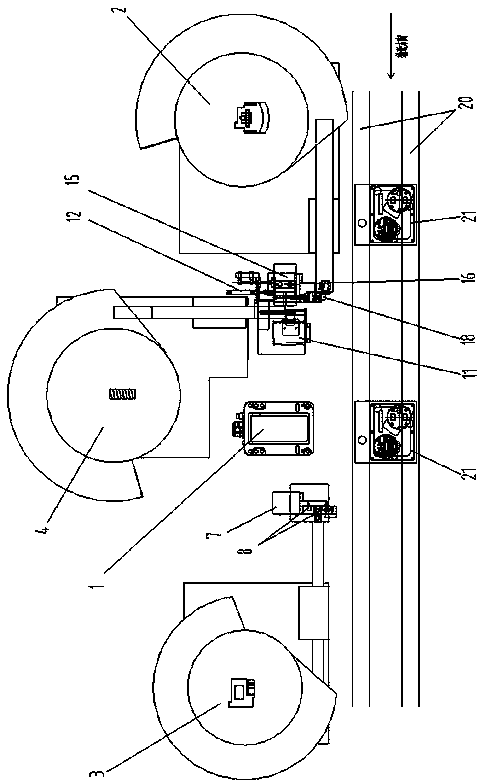

Automatic detection streamline compatible with single-phase and three-phase electric energy meters

InactiveCN106093829ASave work spaceImprove detection accuracyElectrical measurementsEngineeringThree-phase

The invention relates to an automatic detection streamline compatible with single-phase and three-phase electric energy meters. The automatic detection streamline is divided into two parts of a sorting system and a selecting and detecting system. The sorting system performs a labor preliminary sorting flow and an automatic sorting flow. The selecting and detecting system performs a selecting detecting flow which comprises concrete work flows of 1, a labor preliminary selecting flow, 2, an automatic selecting flow and 3, a selecting and detecting flow. The processing system provided by the invention can support single-phase and three-phase electric energy meter detection at the same time, and achieves full-process automation and intelligentization, and thus the operation space is greatly saved, the detection accuracy is improved, and the reliability is improved.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

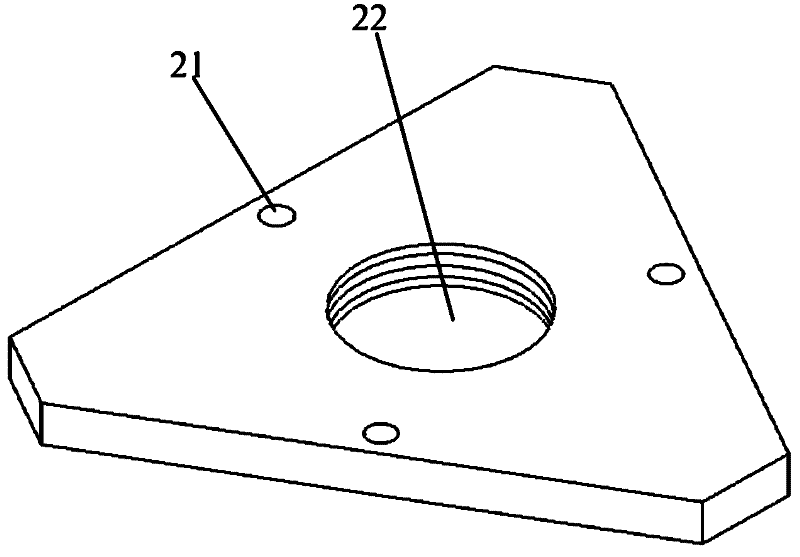

2R1T three degree of freedom space flexible precision positioning platform

InactiveCN102360160AIncrease stiffnessHigh precisionPhotomechanical apparatusWork benchesIsoetes triquetraThree degrees of freedom

The invention discloses a 2R1T three degree of freedom space flexible precision positioning platform, which is characterized by comprising, from up to bottom, a moving platform, a rigid end bracing frame, three rectangular branched chains, three piezoelectric ceramic driver and a rigid pedestal. The moving platform is in an inverted boss shape; the rigid end bracing frame is in an equilateral triangle shape; the three rectangular branched chains are in a same shape and structure, which comprises eight single degree of freedom flexible hinges arranged on an upper beam and a lower beam; the three rectangular branched chains are arranged along three edges of the triangle rigid pedestal; the three piezoelectric ceramic drivers are arranged horizontally between two vertical beams of each rectangular branched chain to form an H-shape structure; the rigid pedestal is in a hollow equilateral triangle structure; and the three rectangular branched chains are rigidly fixed on the rigid pedestal.

Owner:HEBEI UNIV OF TECH

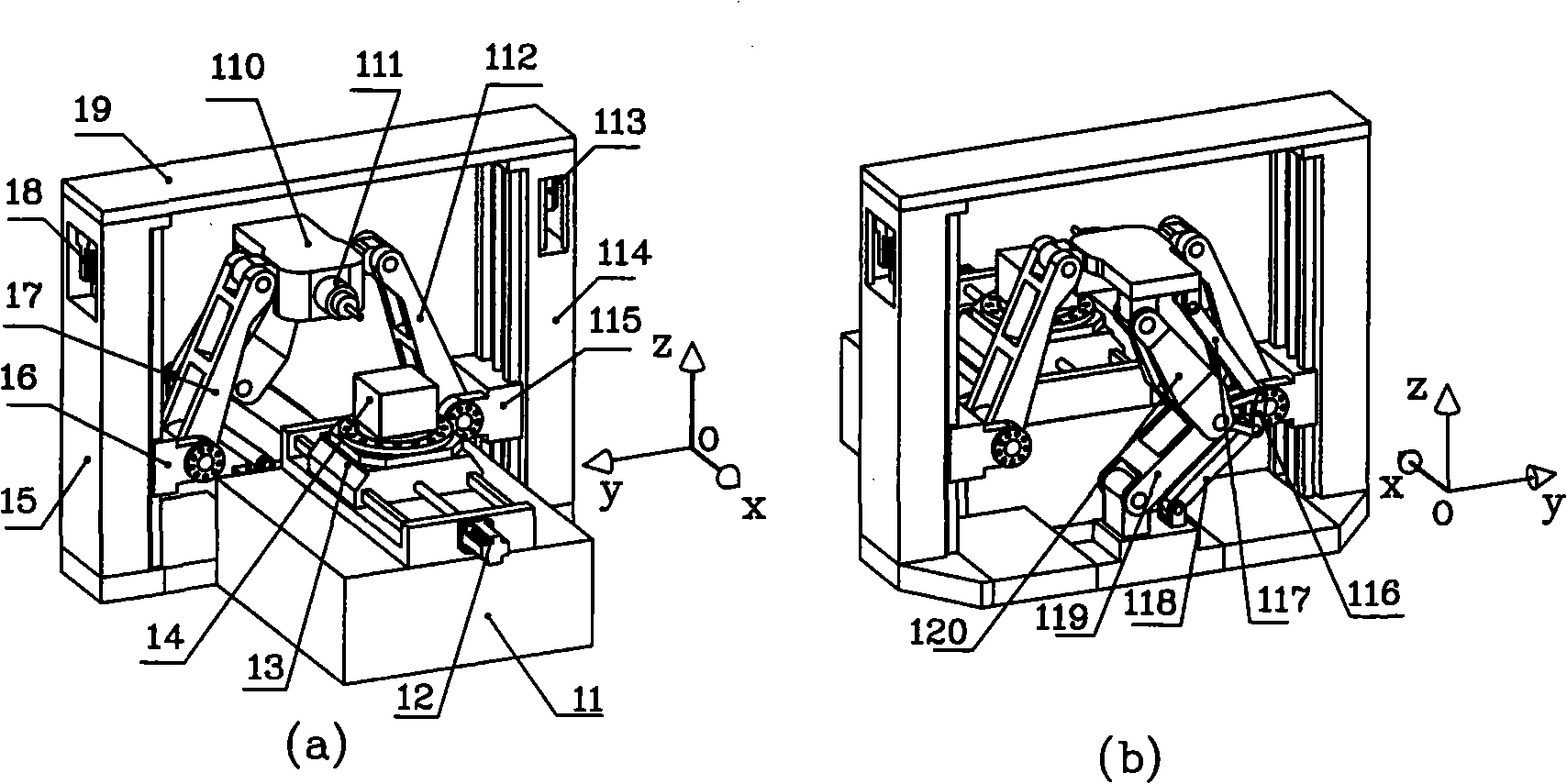

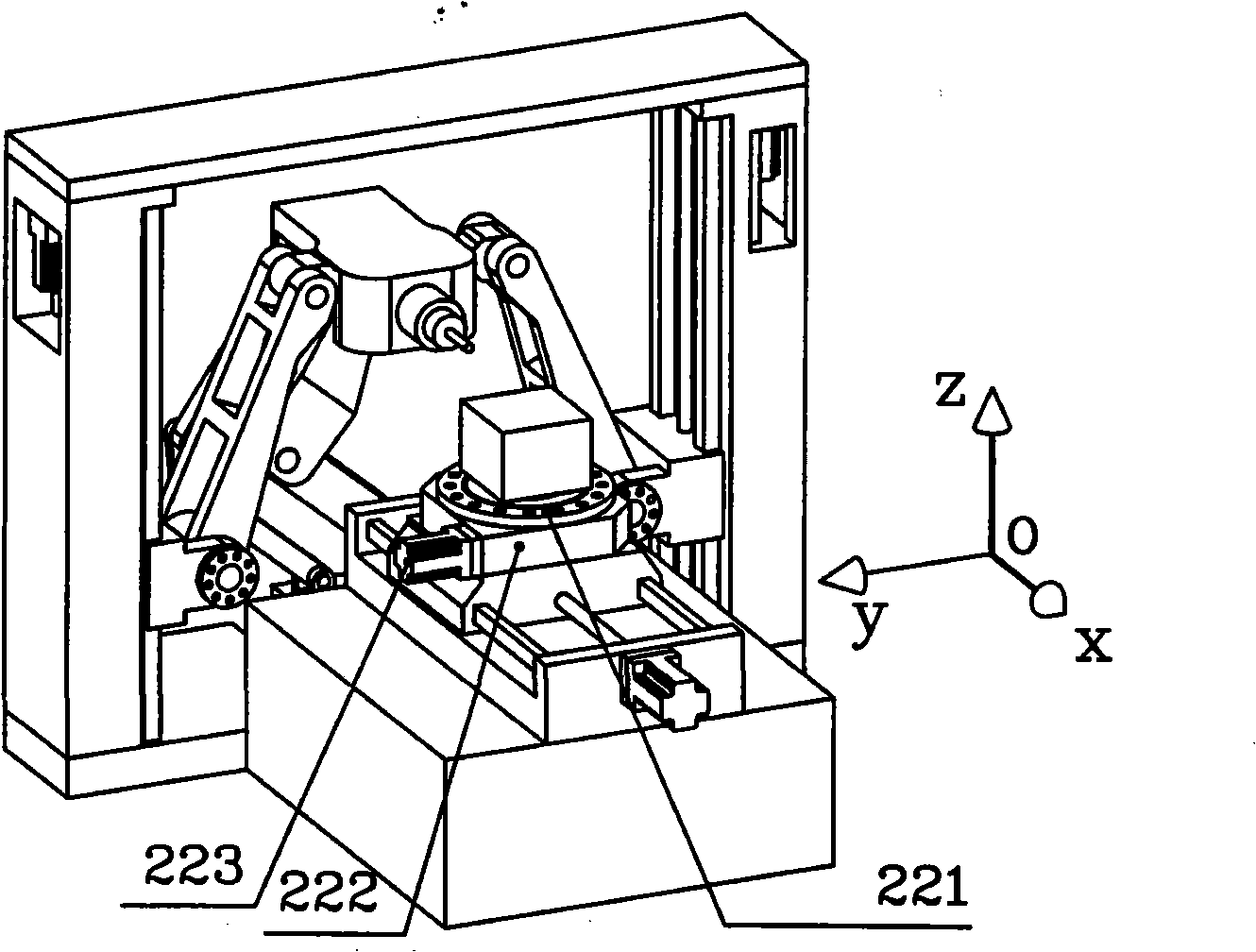

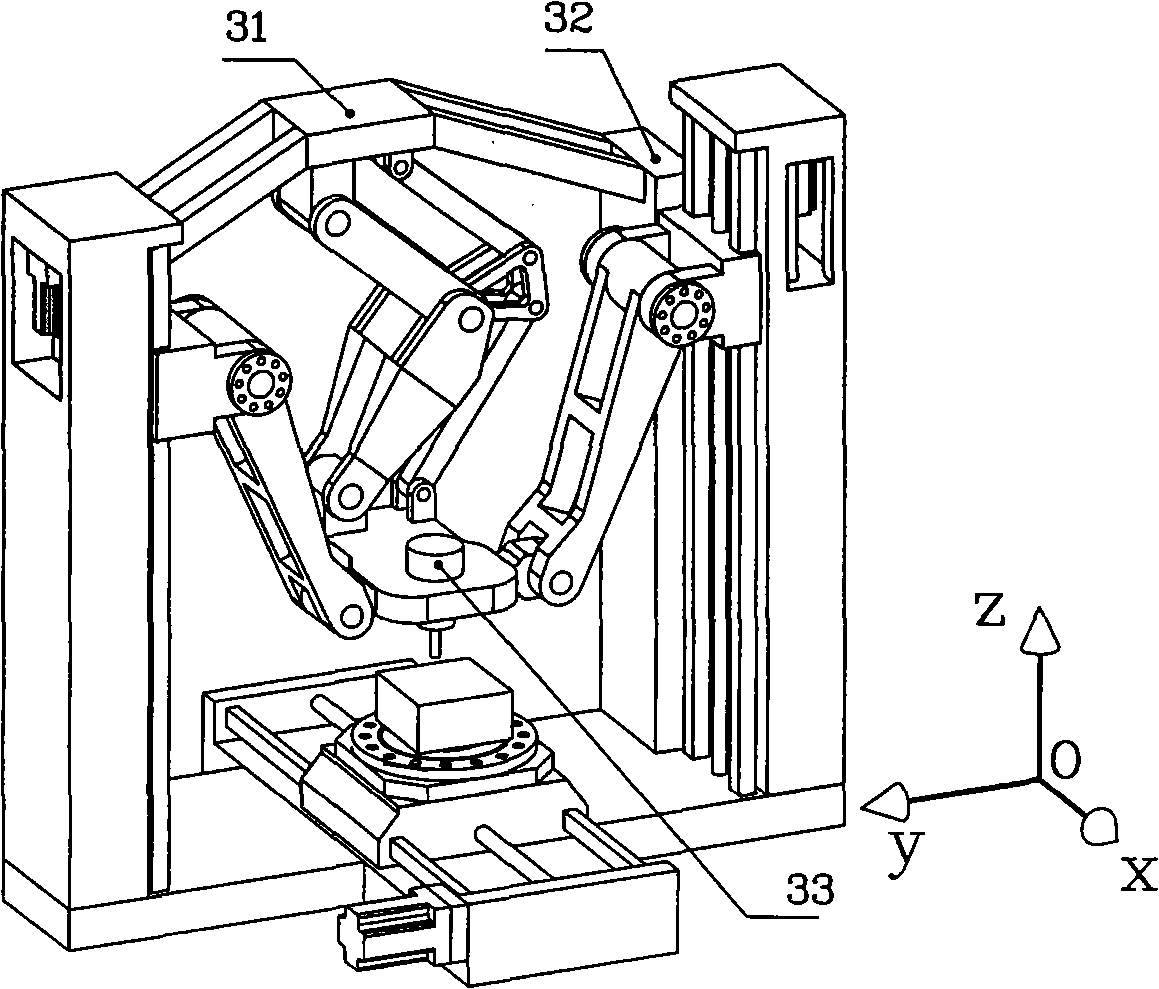

Multi-axes synchronous hybrid device

InactiveCN101279425AMovement restrictionIncrease stiffnessLarge fixed membersNumerical controlHigh stiffness

The invention belongs to the manufacturing field of a numerical control device and relates to a multiaxial linkage series-parallel, which comprises a bed body, a moving platform, a joint type swinging head on which a spindle is arranged, three branched chains and a worktable on which a cut workpiece is arranged; wherein, a prismatic pair connection is achieved between the bed body and the worktable, the joint type swinging head on which the spindle is arranged is fixedly connected with the moving platform, the three branched chains are respectively connected between the bed body and the moving platform so as to form a spatial parallel closed-chain mechanism with the bed body and the moving platform and the spatial parallel closed-chain mechanism is used for realizing a freedom of two-dimensional movement, the worktable is used for realizing a freedom of one to two dimension, the joint type swinging head is used for realizing a freedom of zero to two dimension, and the compound motion of the worktable, the spatial parallel closed-chain mechanism and the joint type swinging head can realize at least a triaxial linkage control. The device has simple structure, reasonable layout, high stiffness, easy control, large work space and high machining accuracy, and can work with being placed vertically or horizontally, thus satisfying the requirements for multiaxial linkage numerical control machining of parts with complex curved surfaces.

Owner:TSINGHUA UNIV

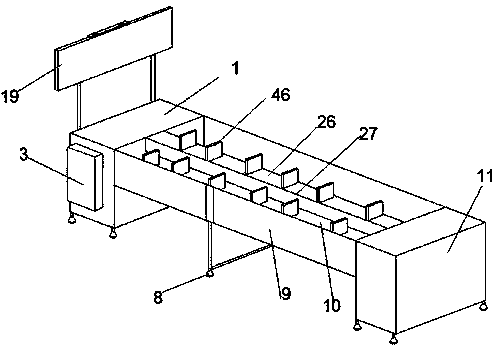

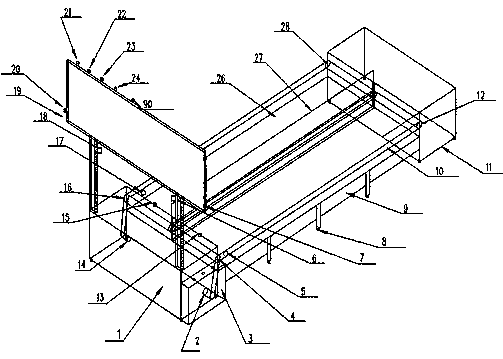

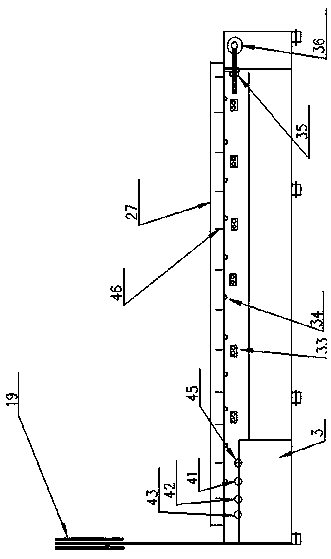

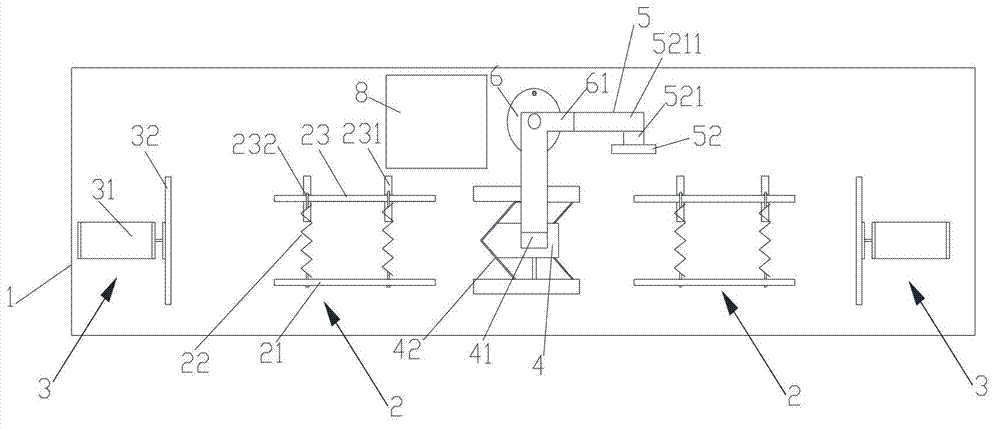

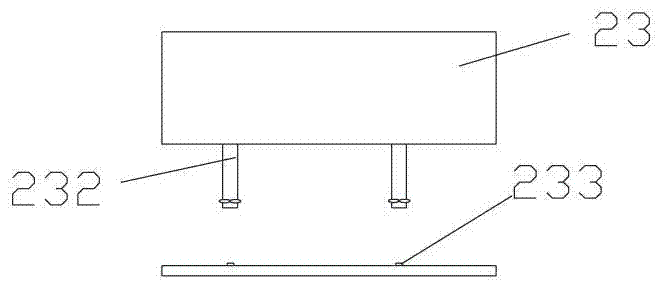

A single-line and double-line interchangeable intelligent beat assembly line system

ActiveCN107814133BIncrease or decrease quantityMeet production requirementsConveyorsControl devices for conveyorsProduction lineDisplay device

The invention discloses an intelligent pace production line system realizing single-line and double-line switching. The system comprises an equipment front part power main frame, a distribution box, an equipment middle part connecting frame, an equipment rear part frame, a front displayer and a rear displayer; the equipment front part power main frame, together with the equipment middle part connecting frame and the equipment rear part frame, forms whole equipment; an equipment levelness adjusting foot margin is installed at the bottom of the equipment; a supporting leg levelness adjusting nutis installed on the equipment levelness adjusting foot margin; the distribution box is installed on the equipment front part power main frame through a bolt; and the front displayer and the rear displayer are installed on the equipment front part power main frame through connecting rods. The system disclosed by the invention can realize single-line / double-line switching; when products of two styles are to be produced, two single lines run, production workers are divided into two groups for operation and processing; one wide line runs when the two lines run synchronously so as to complete moreworking procedures and manufacture a style requiring complicated technology, and moreover product quantity can be recorded intelligently, and the work efficiency can be reflected.

Owner:利胜智能装备(湖北)有限公司

Seedling grafting machine and grafting method of seedling grafting machine

The invention belongs to the field of planting machinery and provides a grafting machine, which consists of a work table, a cutting engagement device and a seedling positioning device. The invention also provides a grafting method adopting the grafting machine. The seedling grafting machine has the beneficial effects that 1, the grafting mechanization is realized, and the problems of high work intensity and low work efficiency of artificial grafting are solved; 2, when the grafting machine provided by the invention is adopted, the cutting surfaces of stocks and cions are precisely aligned, at least one side of the forming layer is aligned, and the grafting survival rate is high; and 3, a wax coating mode is adopted for fixing the cutting surface combining part of the stocks and the cions, the wound infection is avoided, in addition, the seedling thickness increase is not influenced, and the binding rope unlocking treatment after the traditional grafting is omitted.

Owner:CHINA AGRI UNIV

Atomic force microscope-based multifunctional combined probe system

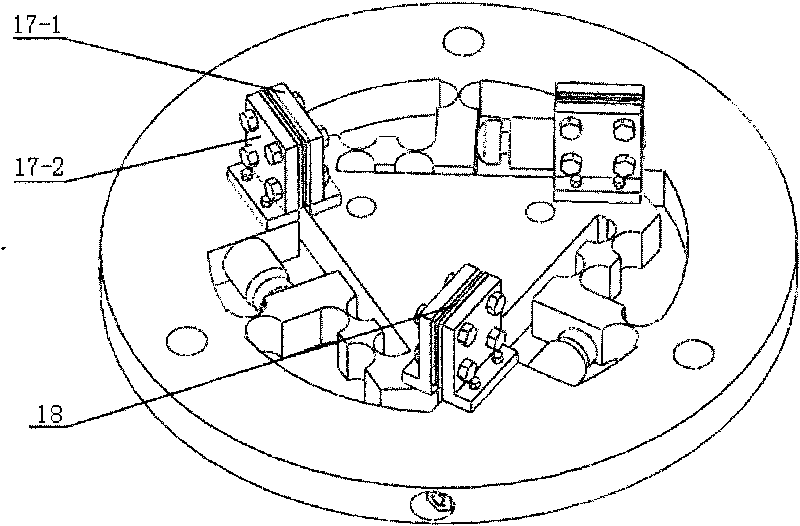

InactiveCN105891549AFlexible and convenient switchingHigh positioning accuracyScanning probe microscopyAtomic force microscopyWorking environment

The present invention discloses an atomic force microscope-based multifunctional combined probe system. The system can switch the probes having different functions in various set working environments by the program control and in an in situ switching manner, thereby in situ realizing the functions, such as the microscopic friction and wear experiments, the surface topography scanning, the crystal structure evolution and detection, the friction energy dissipation measurement, etc., in a same experiment area. When the system switches the probes in the in situ switching manner, the working environment does not need to be destroyed, thereby avoiding the pollution of the external environment to the sample surfaces effectively.

Owner:SOUTHWEST JIAOTONG UNIV

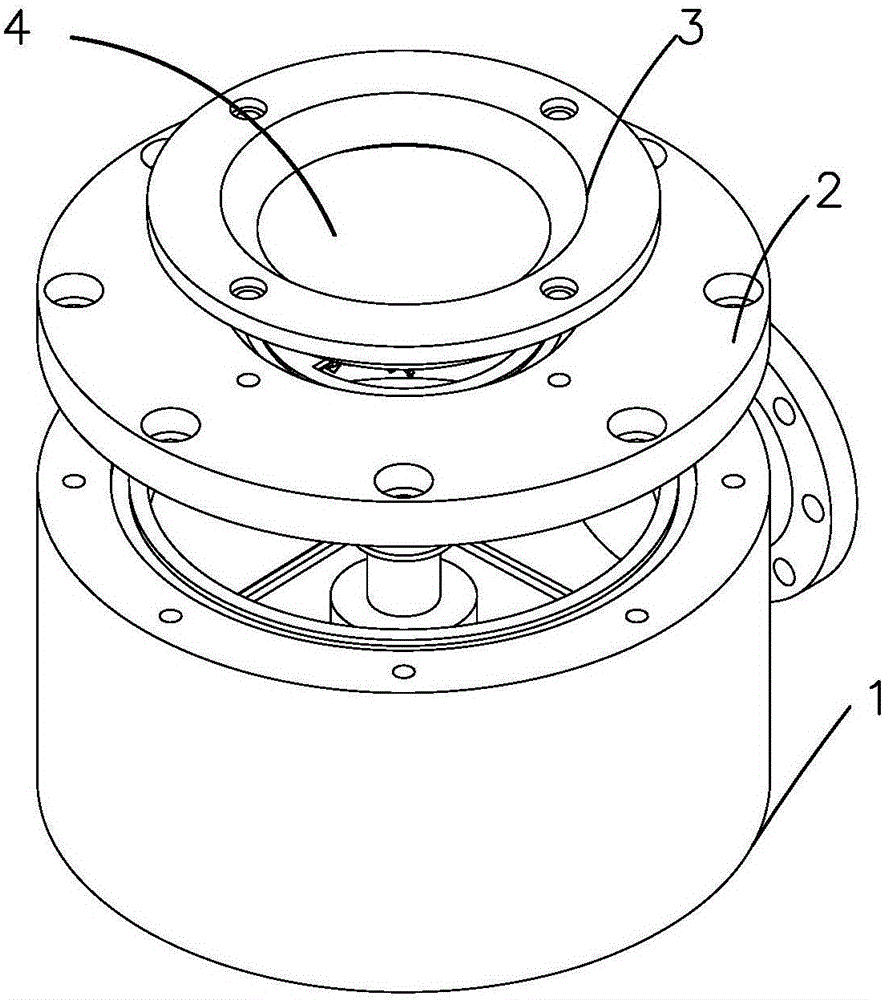

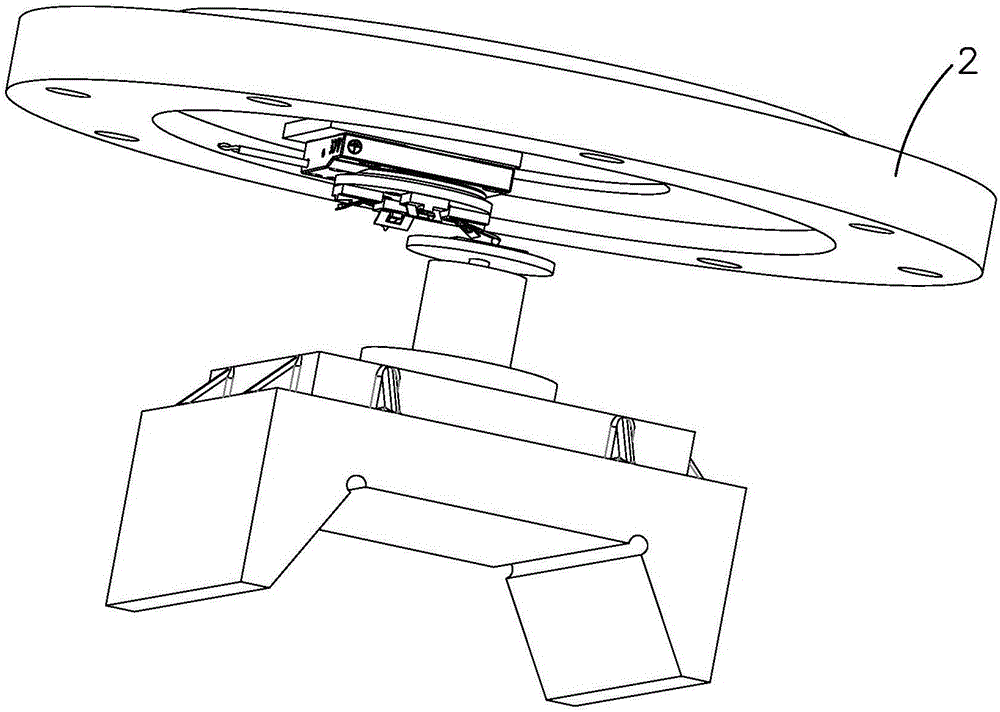

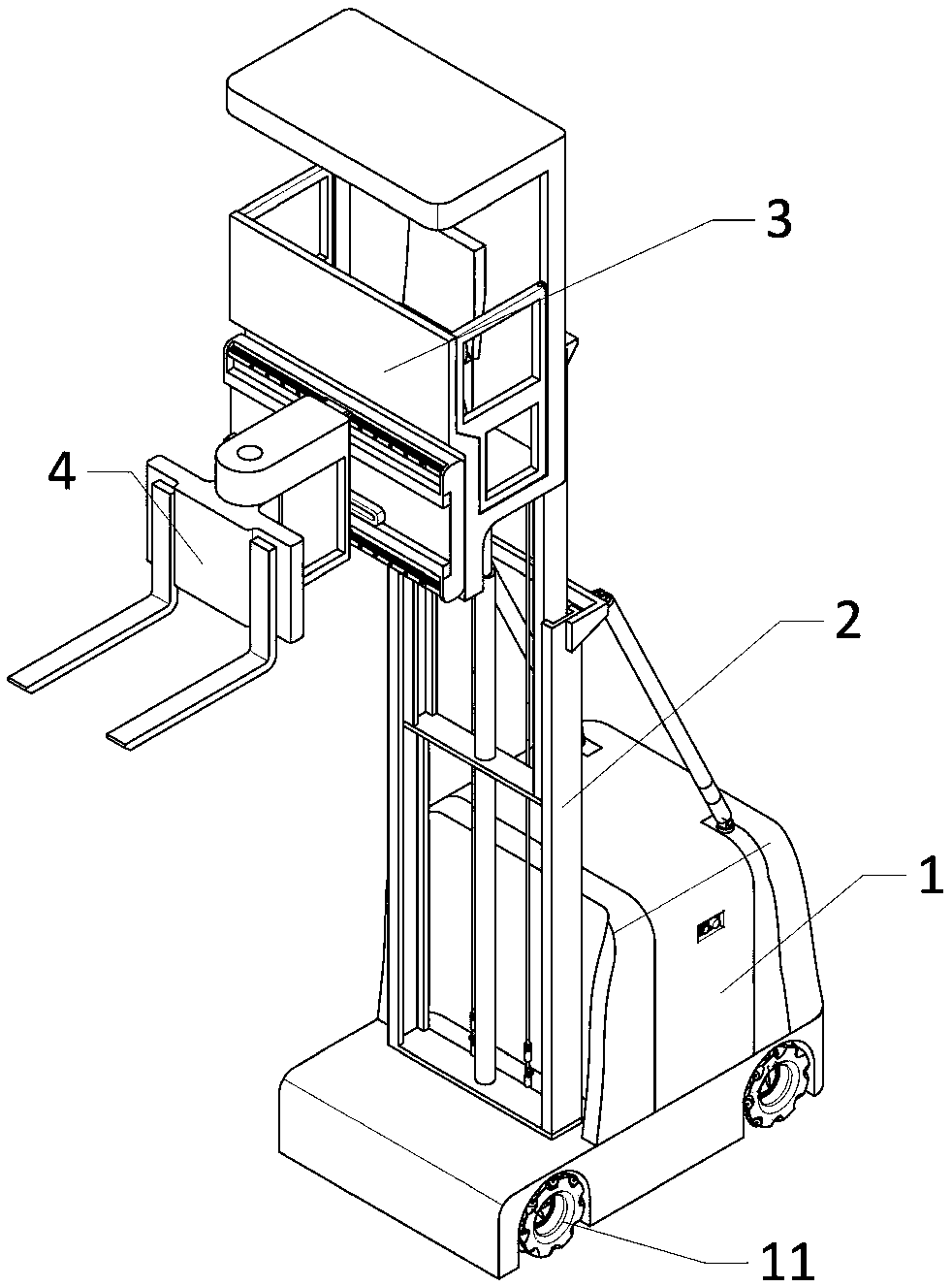

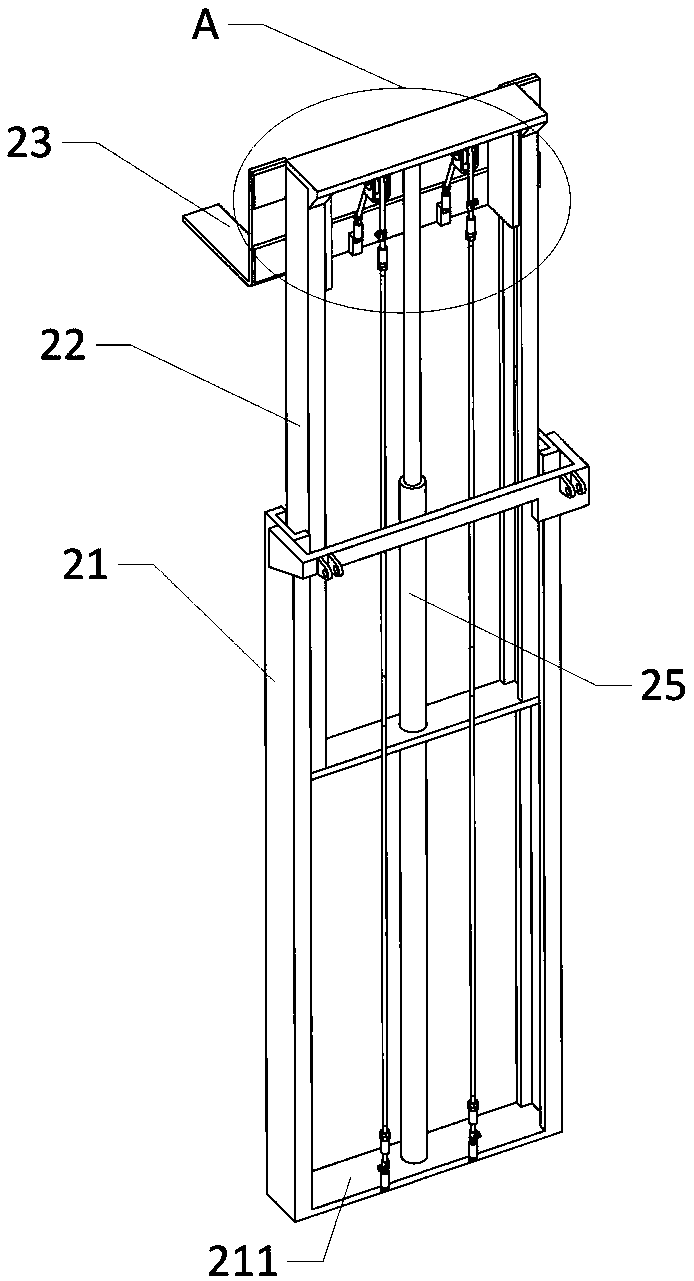

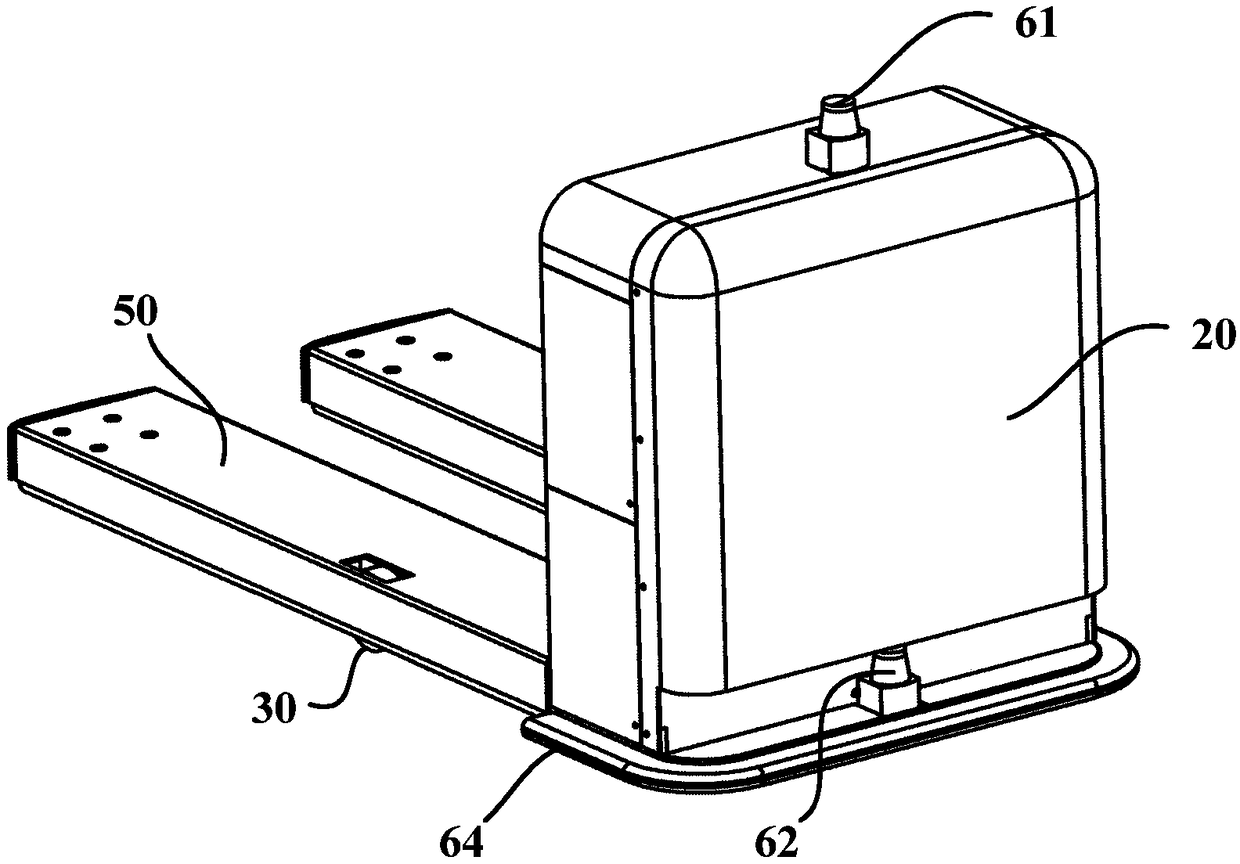

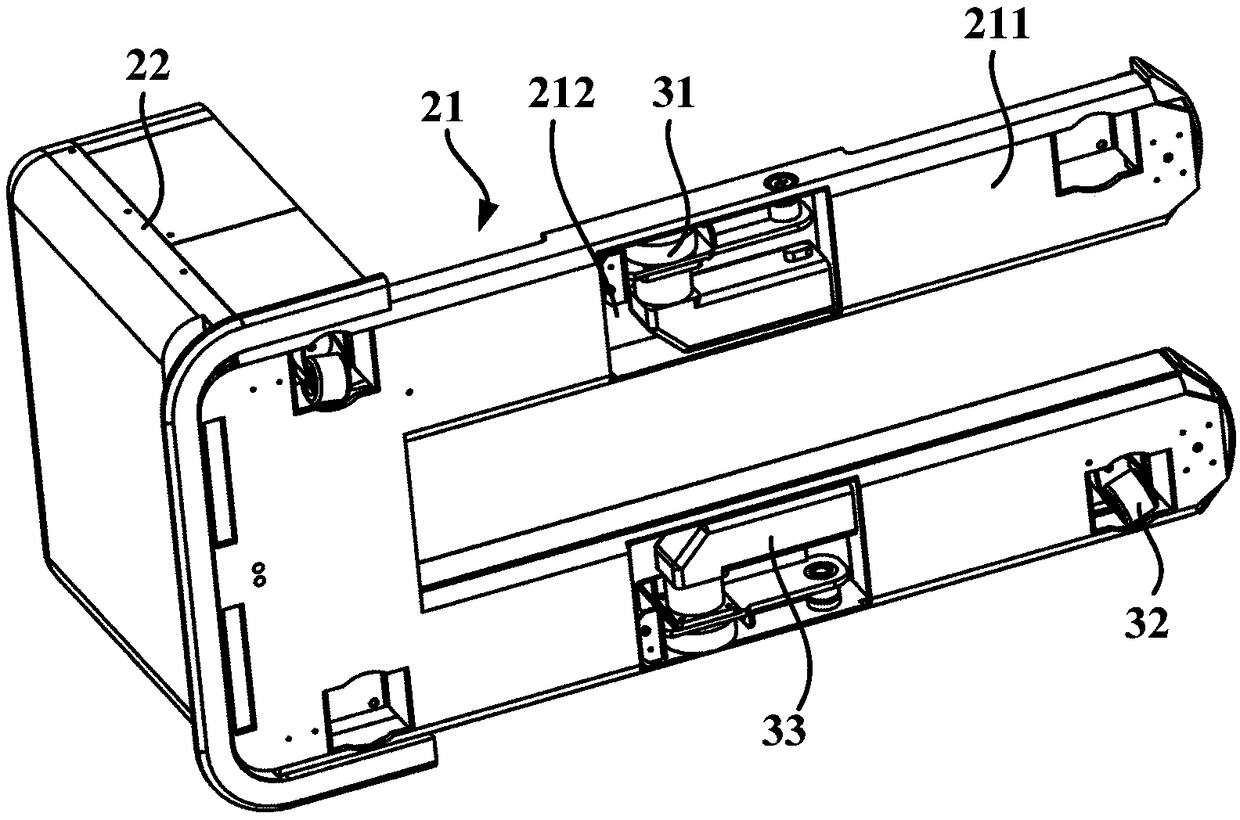

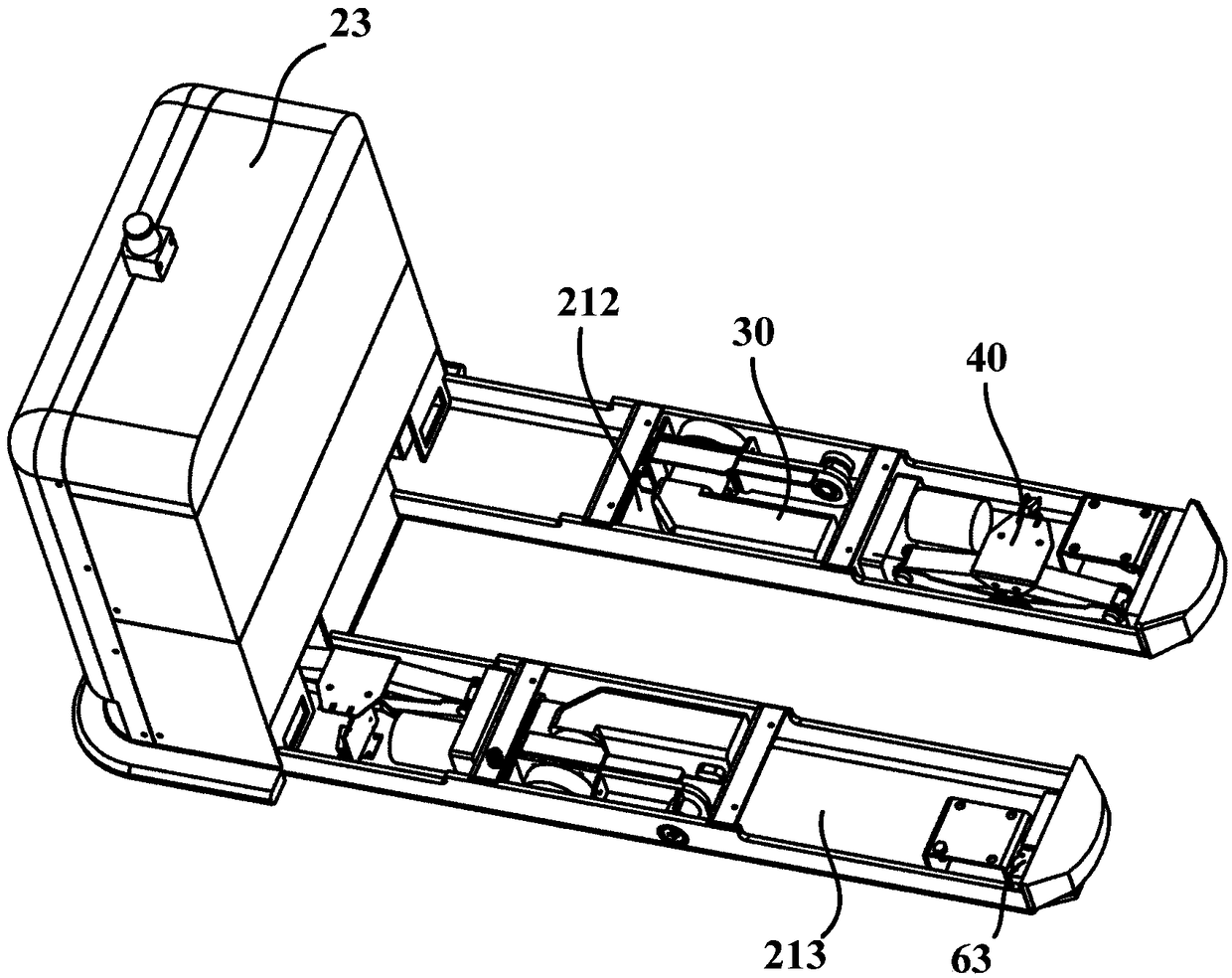

Omni-directional stacking order picker

The invention relates to an omni-directional stacking order picker, and relates to the technical field of storage operation. The omni-directional stacking order picker can freely move in a warehouse,a pallet fork has three work directions, in the process of taking and pacing goods, the required working space is small, the rate of utilizing the warehouse can be effectively increased, and the workefficiency is greatly improved.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

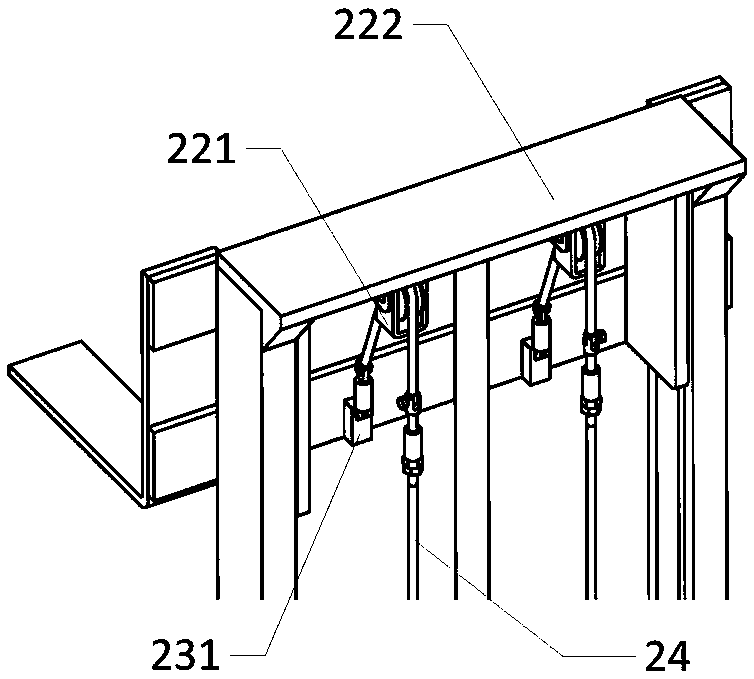

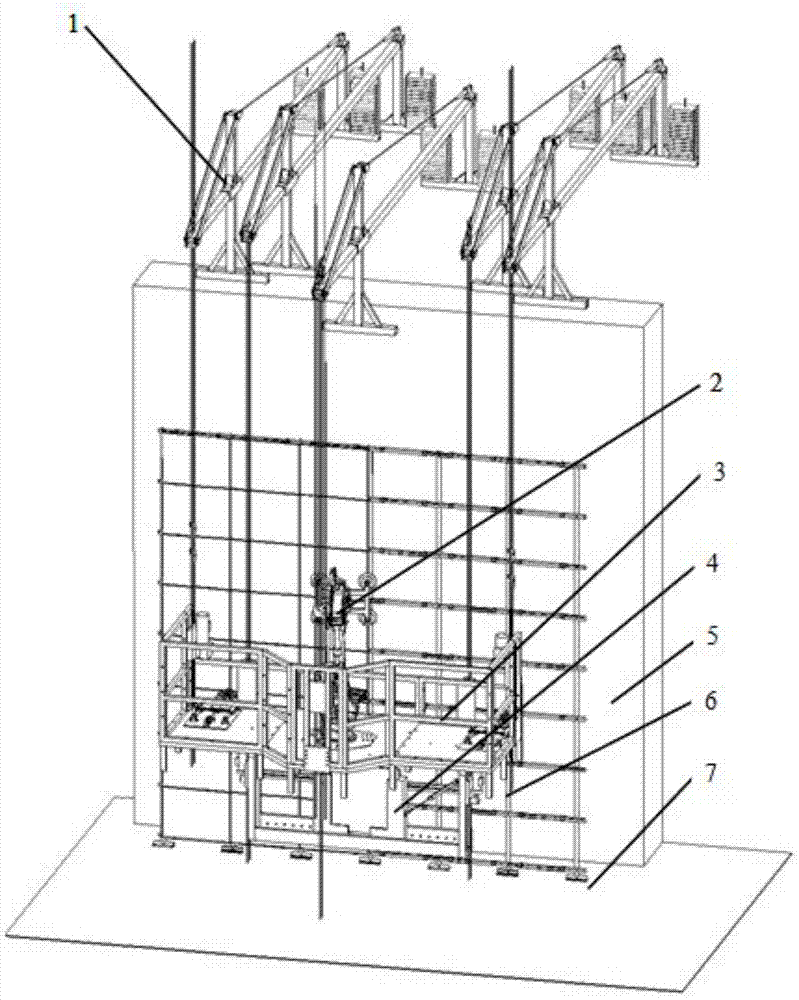

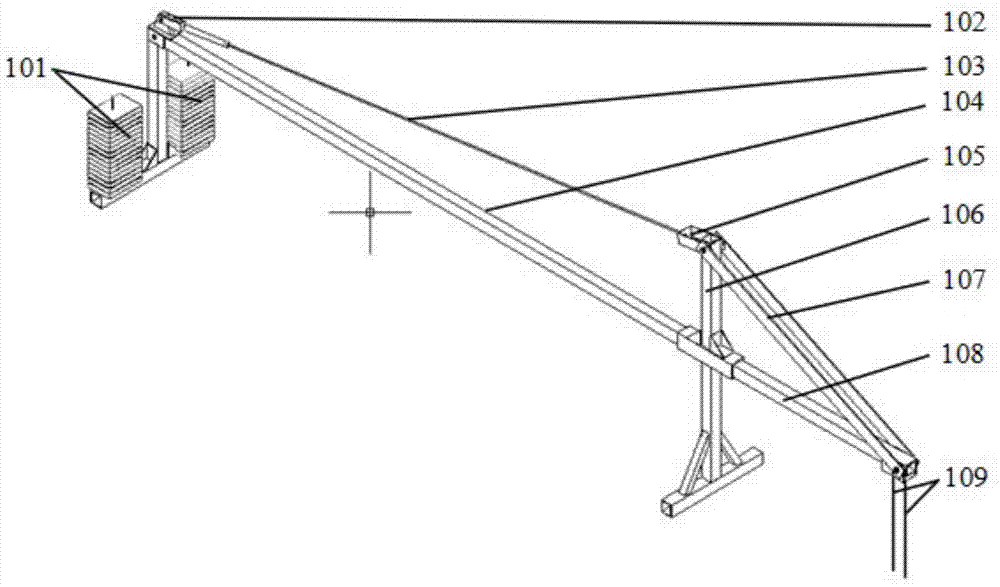

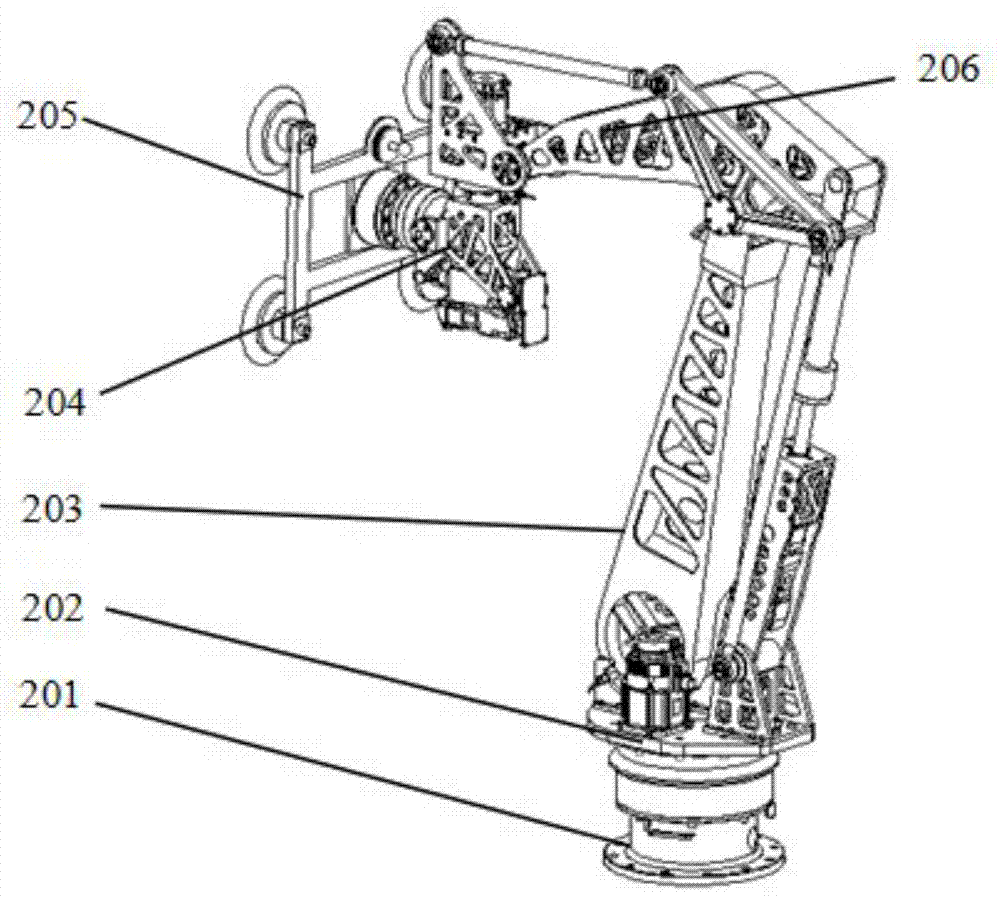

High-altitude board installation mechanical system

The invention relates to a high-altitude board installation mechanical system. The high-altitude board installation mechanical system comprises a suspension mechanism, a manipulator, a high-altitude operation platform and an automatic feeding mechanism, wherein the suspension mechanism is installed on a roof of a building in the working process and bears the suspension work of the high-altitude operation platform; the suspension mechanism is provided with a sling; elevators are arranged on the high-altitude operation platform and the automatic feeding mechanism; the high-altitude operation platform and the automatic feeding mechanism move through mutual cooperation of the corresponding sling and the corresponding elevators; the automatic feeding mechanism is arranged between the high-altitude operation platform and the operation stand surface; the manipulator is installed on the high-altitude operation platform. The high-altitude board installation mechanical system is characterized in that the manipulator has six degrees of freedom and comprises a base, a rotary machine frame, a big arm parallelogram mechanism, a tail end gesture adjusting device, a tail end actuator and a small arm parallelogram mechanism; the base, the rotary machine frame, the big arm parallelogram mechanism, the small arm parallelogram mechanism, the tail end gesture adjusting device and the tail end actuator are sequentially connected.

Owner:HEBEI UNIV OF TECH

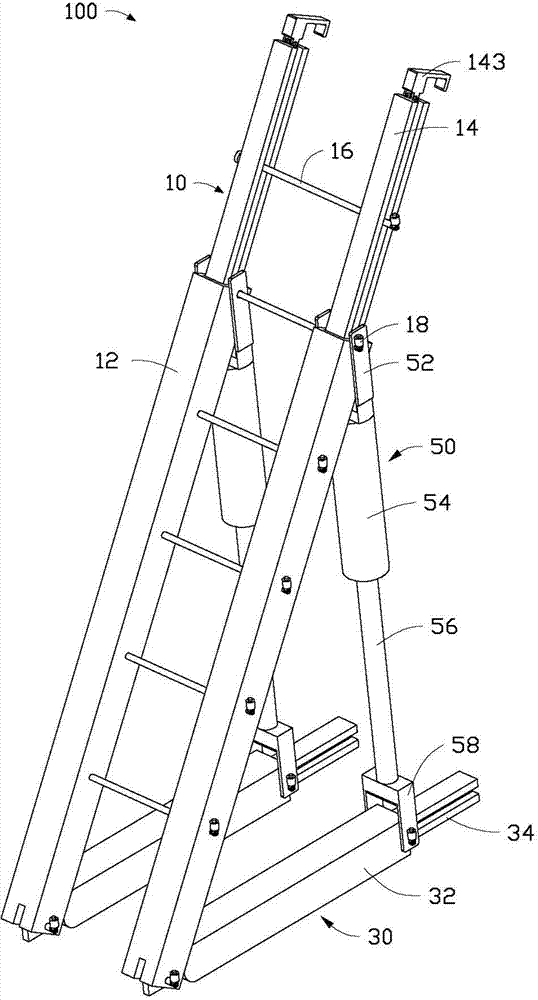

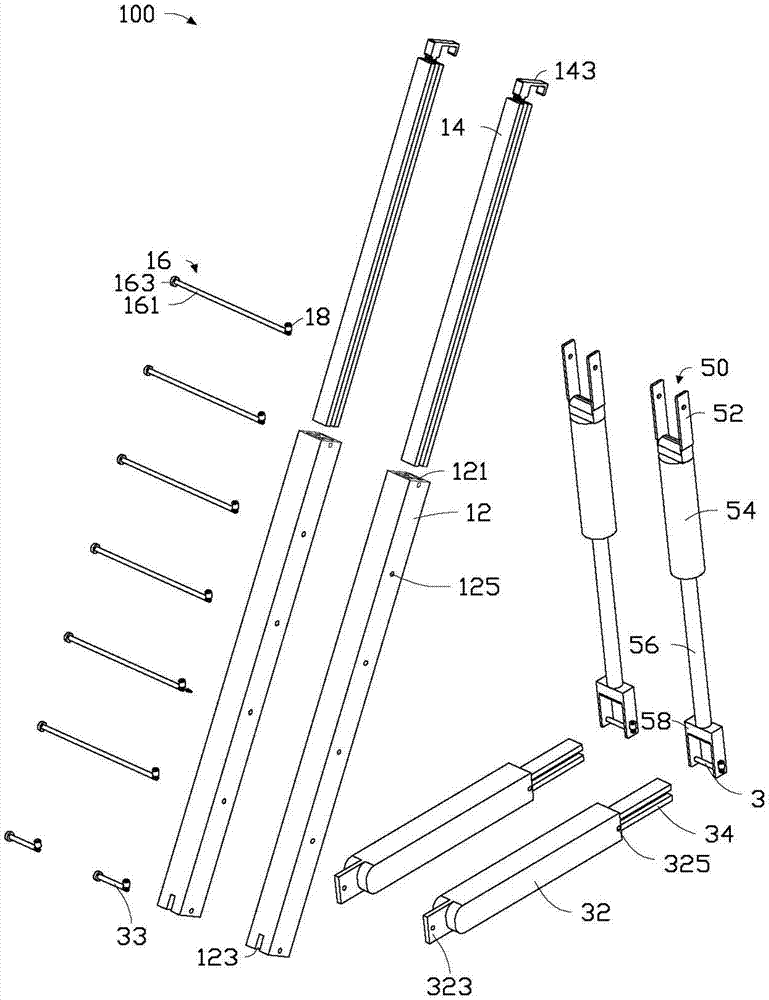

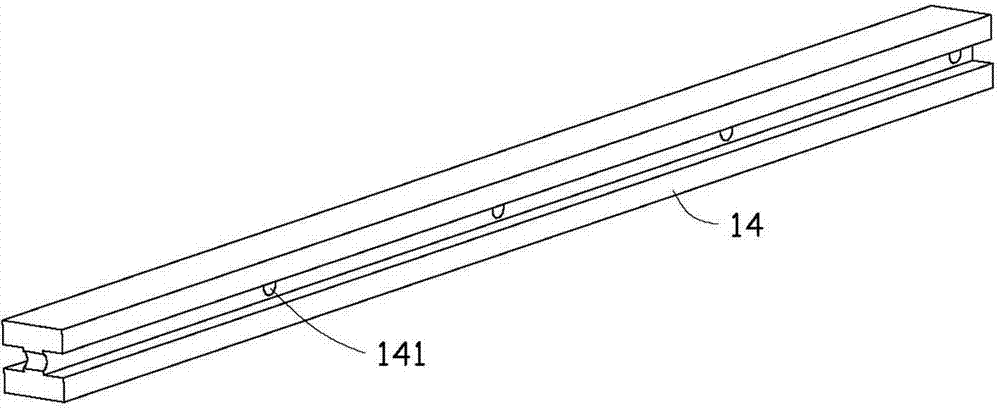

Telescopic ladder

ActiveCN104712246AImprove use security and stabilitySave work spaceLaddersTelescopic cylinderEngineering

Owner:HONG FU JIN PRECISION IND TAIYUAN CO LTD

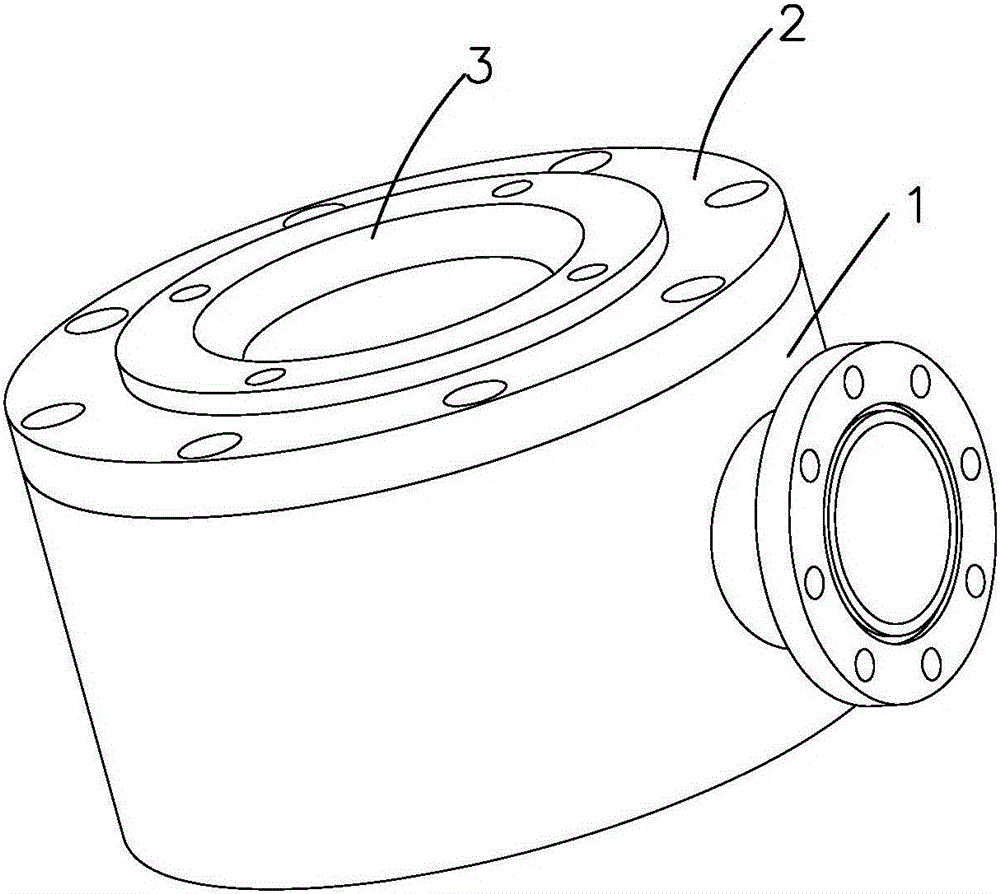

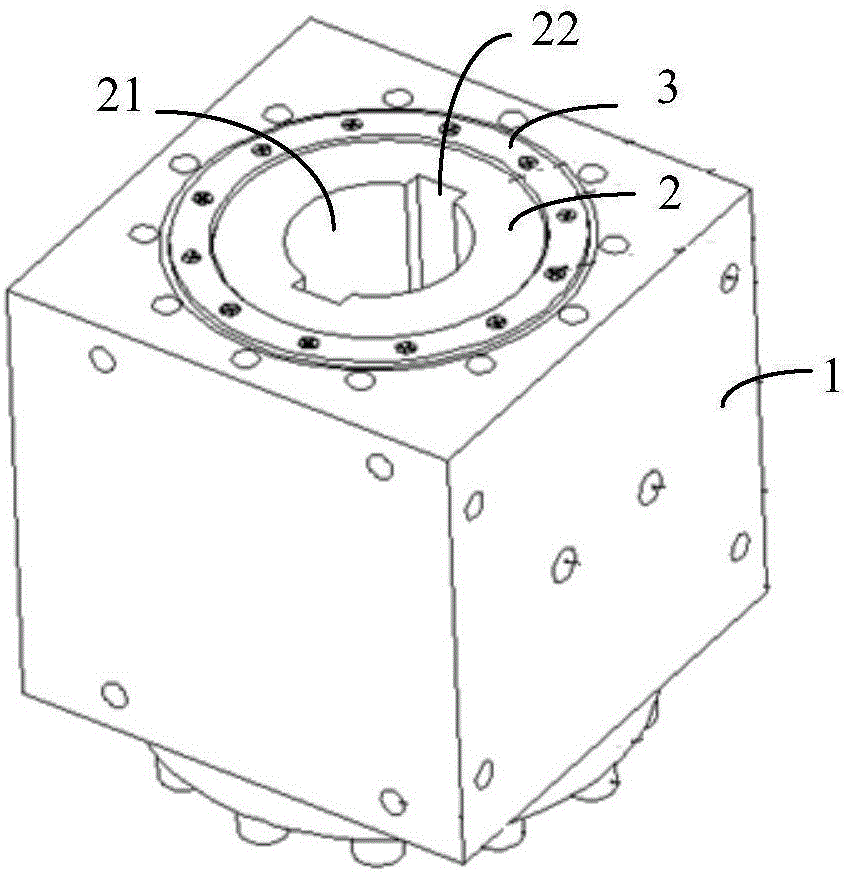

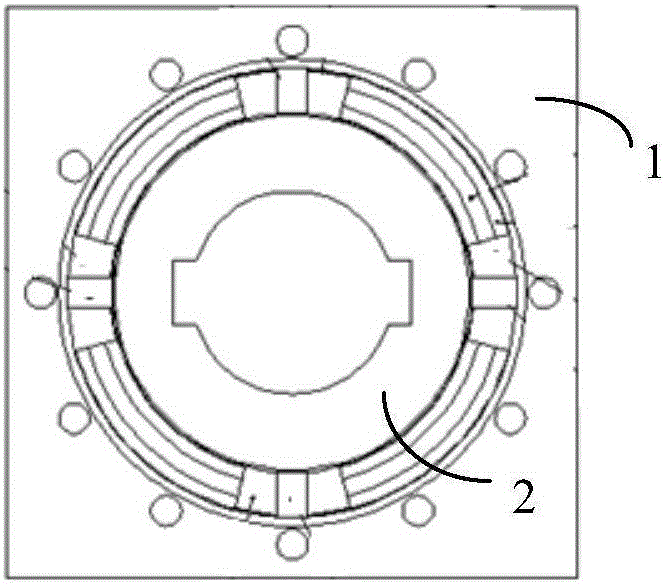

Through type hydraulic swing oil cylinder

InactiveCN106837914AEasy to installClear directionFluid-pressure actuatorsCylinder blockHydraulic pressure

The invention discloses a through type hydraulic swing oil cylinder. The through type hydraulic swing oil cylinder comprises a cylinder body stator, a cylinder body rotor, an end surface sealing part, rotor blades and stator blades, wherein the cylinder body stator adopts a hollow structure, first support parts are fixed on the inner wall of the cylinder body stator, a first support groove is formed between each pair of first support parts, and the stator blades are clamped in the first support grooves; oil delivery holes are formed in the cylinder body stator; the cylinder body rotator adopts a cylindrical structure, second support parts are fixed on the peripheral surface of the cylindrical structure, a second support groove is formed between each pair of second support parts, and the rotor blades are clamped in the second support grooves; during mounting, the cylinder body rotor penetrates through the hollow structure, the end surface sealing part is pressed on end surfaces of the stator blades, and a closed space is formed among outer walls of the end surface sealing part, the stator blades and the cylinder body rotor and communicated with the oil delivery holes.

Owner:WUHAN UNIV OF SCI & TECH

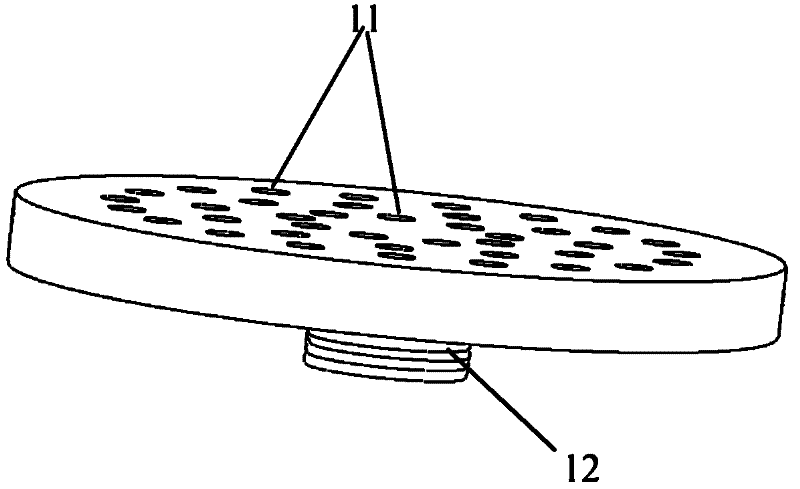

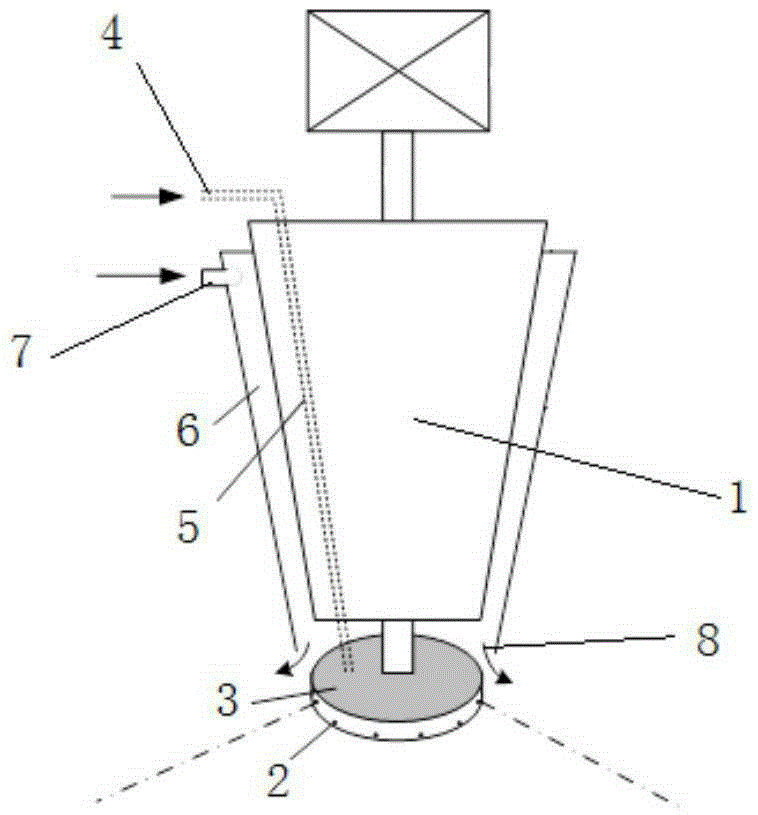

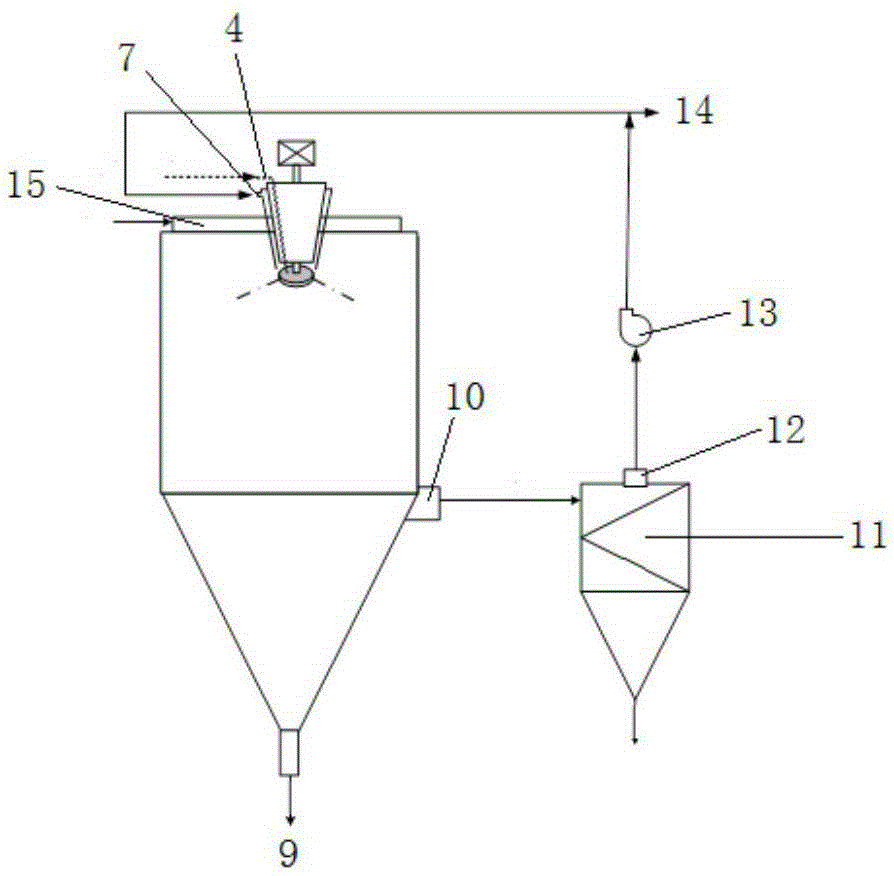

Centrifugal atomizing nozzle and spray dryer

InactiveCN106607197AReduce the chance of breakageAvoid direct contactSpray nozzlesEvaporation by sprayingNebulizerMicrosphere

The invention relates to the field of spray dryers and discloses a centrifugal atomizing nozzle and a spray dryer comprising the same. The centrifugal atomizing nozzle comprises a centrifugal atomizer and a protection wind guide pipe, wherein the centrifugal atomizer is internally provided with an atomizing disc which is used for spraying materials into fog drips and provided with atomizing holes, and a material guide pipe connected with the atomizing disc and a material inlet; and the protection wind guide pipe is provided with a protection wind inlet and a protection wind spraying opening. The protection wind guide pipe is arranged around the centrifugal atomizer, so that protection wind sprayed by the protection wind spraying opening surrounds the fog-drip-shaped materials sprayed by the atomizing holes. When spray drying is conducted by adopting the dryer comprising the centrifugal atomizing nozzle, the problems that microspheres are burst, abnormal shapes and fine powder are produced in the drying process can be solved, and the sphericity of obtained dried particles can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

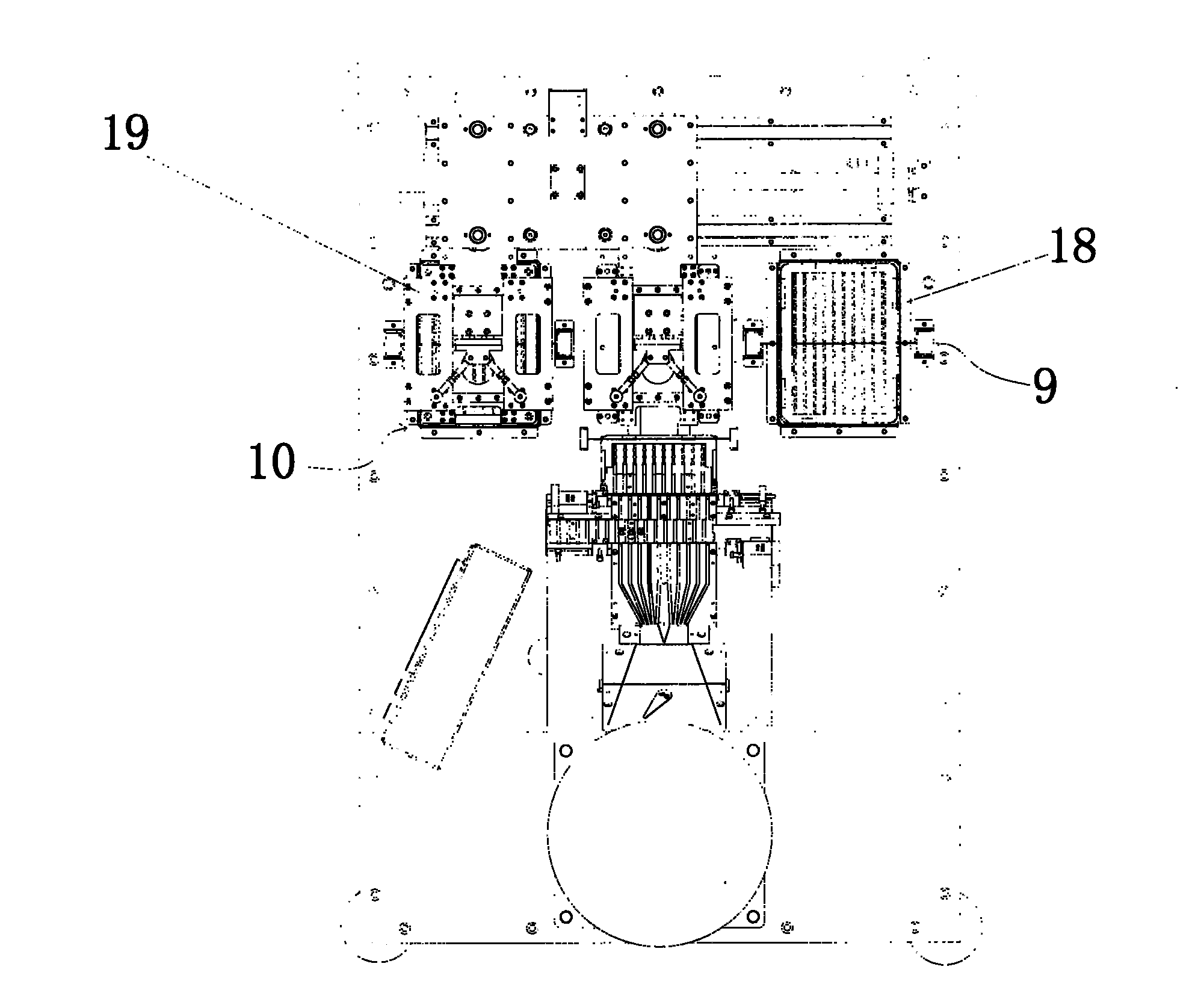

Automatic assembling machine of LED (light emitting diode) socket adapter robot and working method thereof

The invention relates to an automatic assembling machine of an LED (light emitting diode) socket adapter robot and a working method thereof, which belongs to the technical field of the automatic assembling of the robot. The automatic assembling machine of the LED socket adapter robot is characterized in that: on an IV large green-piece / large spring (two) / small green-piece station, a robot is fixed in the center, a green-piece vibrating disc is arranged on the right side, a small green-piece vibrating disc is arranged on the left side, a large spring vibrating disc is arranged on the rear side, a two-row conveyor belt is arranged on the front side, a plurality of tray jigs are arranged on the two-row conveyor belt, a large green-piece spring claw and a small green-piece claw are installed on the front end of the robot, the assembling is carried out by the virtue of cooperation of different detection switches and air cylinders, and all assembling work including material reclaiming, positioning, detection and compression of a large green piece, a small green piece and a large spring on the IV large green-piece / large spring / small green-piece station can be automatically completed. The assembling machine is simple, practical in structure, high in application reliability, capable of liberating hands of an operator, greatly saving the labor, substituting the repeated mechanical and physical labor, capable of reducing the operation space, guaranteeing the product quality and improving the production efficiency.

Owner:DALIAN HAOSEN EQUIP MFG

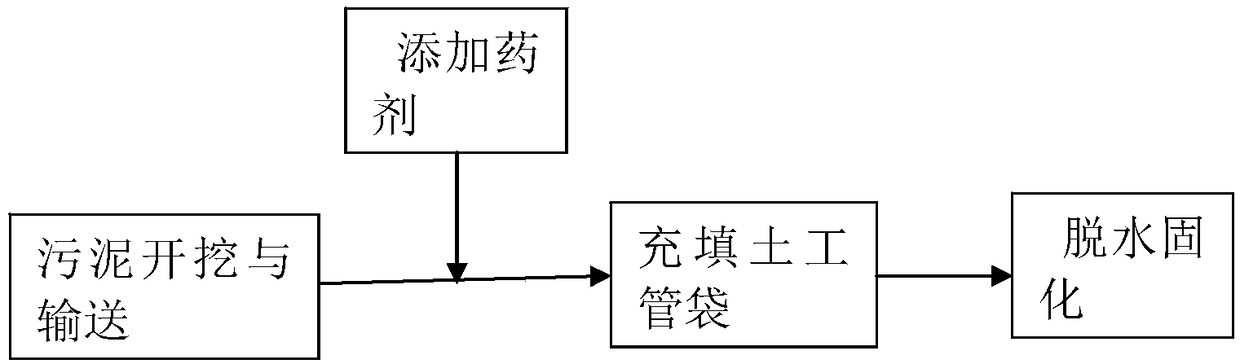

Construction method for dredging ditch sediment based on hydraulic punching and filling geotechnical pipe bag

InactiveCN108978577AContinuityClosedSludge treatment by de-watering/drying/thickeningClimate change adaptationSurface cleaningCut and fill

The invention relates to a construction method for dredging ditch sediments based on a hydraulic punching and filling geotechnical pipe bag and belongs to the technical field of dredging constructionof sediments in stinky water body ditches. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag includes the following steps of temporary storage yard construction, surface cleaning, sectional construction of cofferdam, construction drainage, assembly of a mud conveying pipeline, hydraulic punching and dredging of the sediments,adding medicament, geotechnical pipe bag filling, sludge dewatering and solidification and transportation or reuse of solidified soil. For the construction method, earth excavation is completed withthe help of hydraulic cutting; soil is then filled by a mud pump through the mud conveying pipeline to a large geotechnical pipe bag; in the dredging pipes, dredging mud and the medicament are fully stirred to produce a flocculation group to be precipitated in a geotechnical pipe belt, and then dehydration and solidification treatment of the sediments is achieved. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag has the advantages of continuity, integrated operation of dredging, conveying and filling, low cost, high construction efficiency, sealing property, no secondary pollution during transportation, good environmental protection performance, high construction precision, good effect, convenient operation and savedworking space.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

Photocureable coating for pianos

The invention discloses a photocureable coating for pianos. A method for preparing the photocureable coating comprises the following steps: mixing 5 to 20 portions of active diluting agent, 55 to 70 portions of oligomer, 4 to 6 portions of powder, 3 to 4 portions of photoinitiator, and 0.4 to 0.6 portion of additive by weight, then stirring the mixture, grinding the mixture, and then adding a solvent which accounts for 10 to 12 percent of the total weight of the materials into the mixture to be stirred evenly to obtain photocureable coating for the pianos. The photocureable coating for the pianos has quick curing speed, can perform quick and continuous operation, and greatly improve production efficiency; the coating does not need to be heated and dried, so the coating can save 75 to 90 percent of energy sources than the prior heat dry coating during the construction; coating equipment for an UV coating is compact, does not need a drying tunnel, has simple and convenient operation, is easy to realize production automation, saves floor area, and reduces operation space; and the UV coating has no the volatilization of VOCs during the film formation, does not cause the pollution to the environment, and improves surface performances such as paint film hardness, flexibility, wear and scratch resistance, chemical resistance, high gloss, durability and the like.

Owner:浜二(宜昌)涂料有限公司

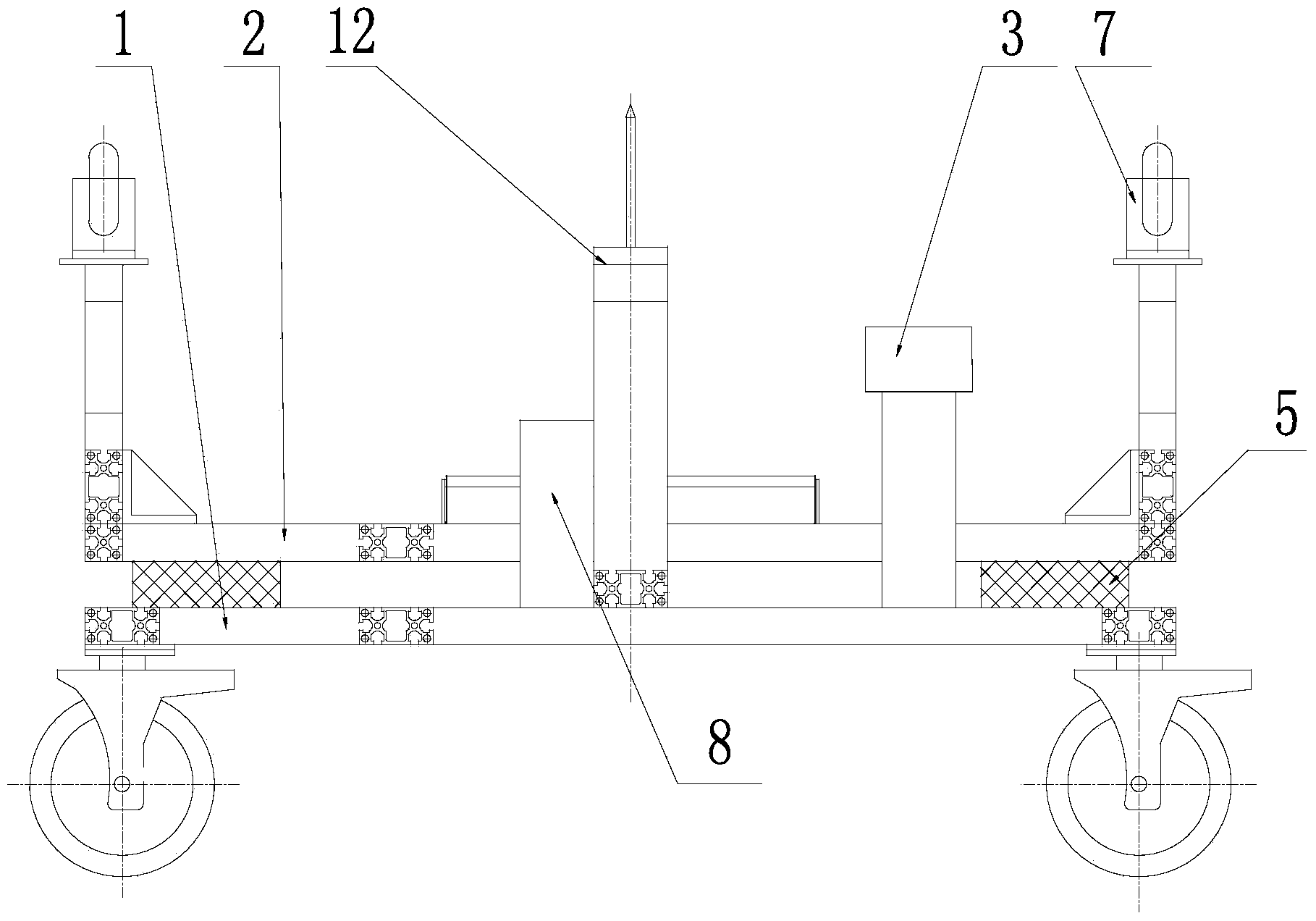

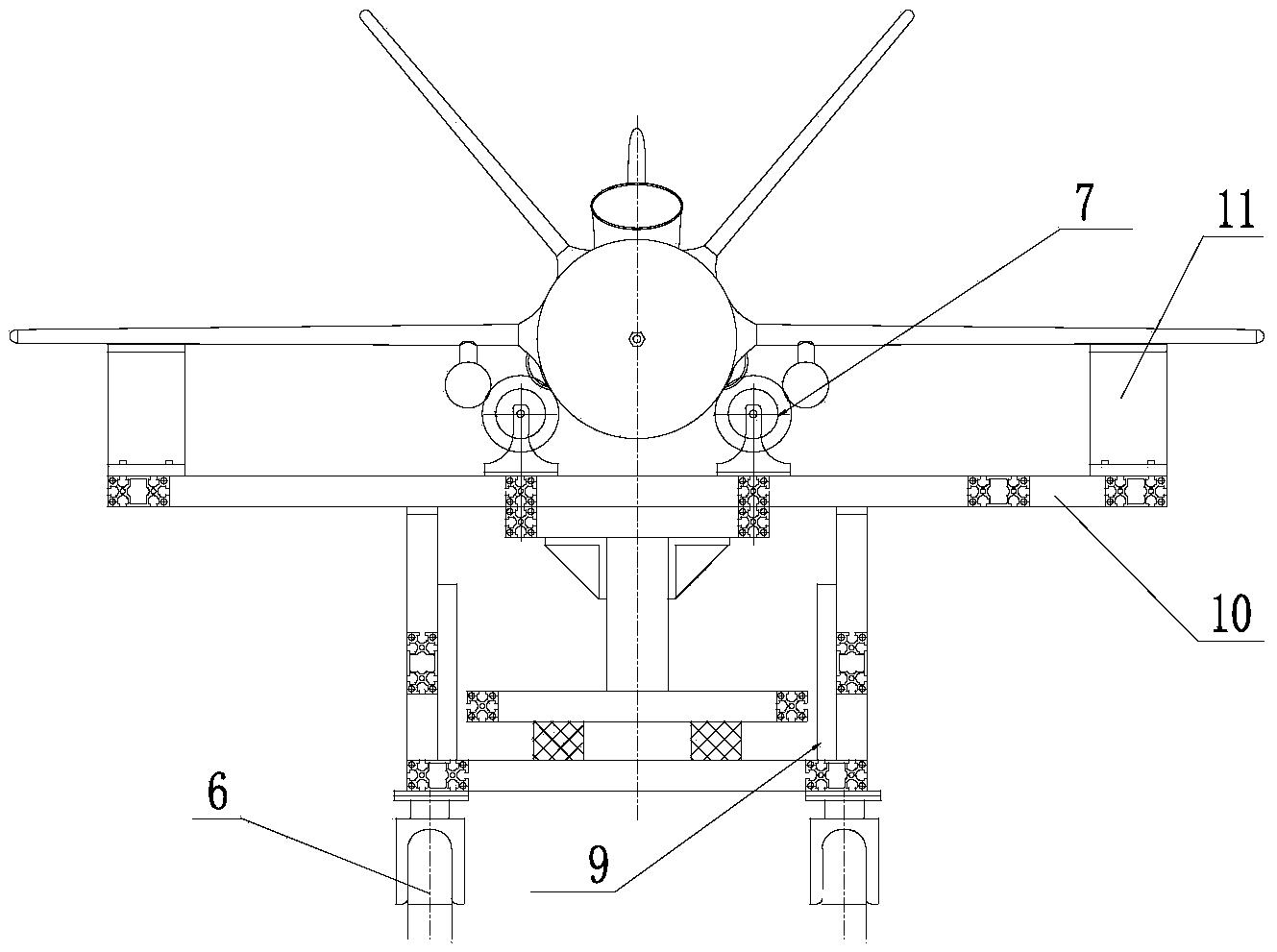

UAV (Unmanned Aerial Vehicle) assembling and debugging vehicle

ActiveCN103770951AEasy to operateImprove performanceAircraft assemblyAircraft components testingEngineeringPressure sensor

The invention relates to a UAV (Unmanned Aerial Vehicle) assembling and debugging vehicle which mainly comprises a chassis, a weighing disk, a balancing device, a display mechanism, support frames and lifting mechanisms. The weighing disk is arranged on the chassis; at least two pressure sensors are arranged between the chassis and the weighing disk; the T-shaped support frames are respectively arranged at the front and rear ends of the weighing disk; both sides of the upper parts of the support frames are provided with roller wheels; the chassis at both sides of the weighing disk is fixedly provided with the lifting mechanisms; each lifting mechanism is mainly formed by a motor, an electric push rod and a linear guide rail; the support frames arranged on the linear guide rails are pushed to ascend and descended by the electric push rods driven by the motors; the balancing device consists of balancing knife edges at both sides and a balancing cross bar; the balancing cross bar is fixedly arranged on supporting rods at both sides; and the balancing knife edges are symmetrically fixed at both sides of the balancing cross bar. The UAV assembling and debugging vehicle integrates each set of tool in each link of debugging, weighing, balancing and turnover of a UAV; the equipment is simple to operate, has reliable performance and is convenient to move; a work place is saved; and the UAV assembling and debugging vehicle can be suitable for the requirements for assembling and debugging of various types of UAVs.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

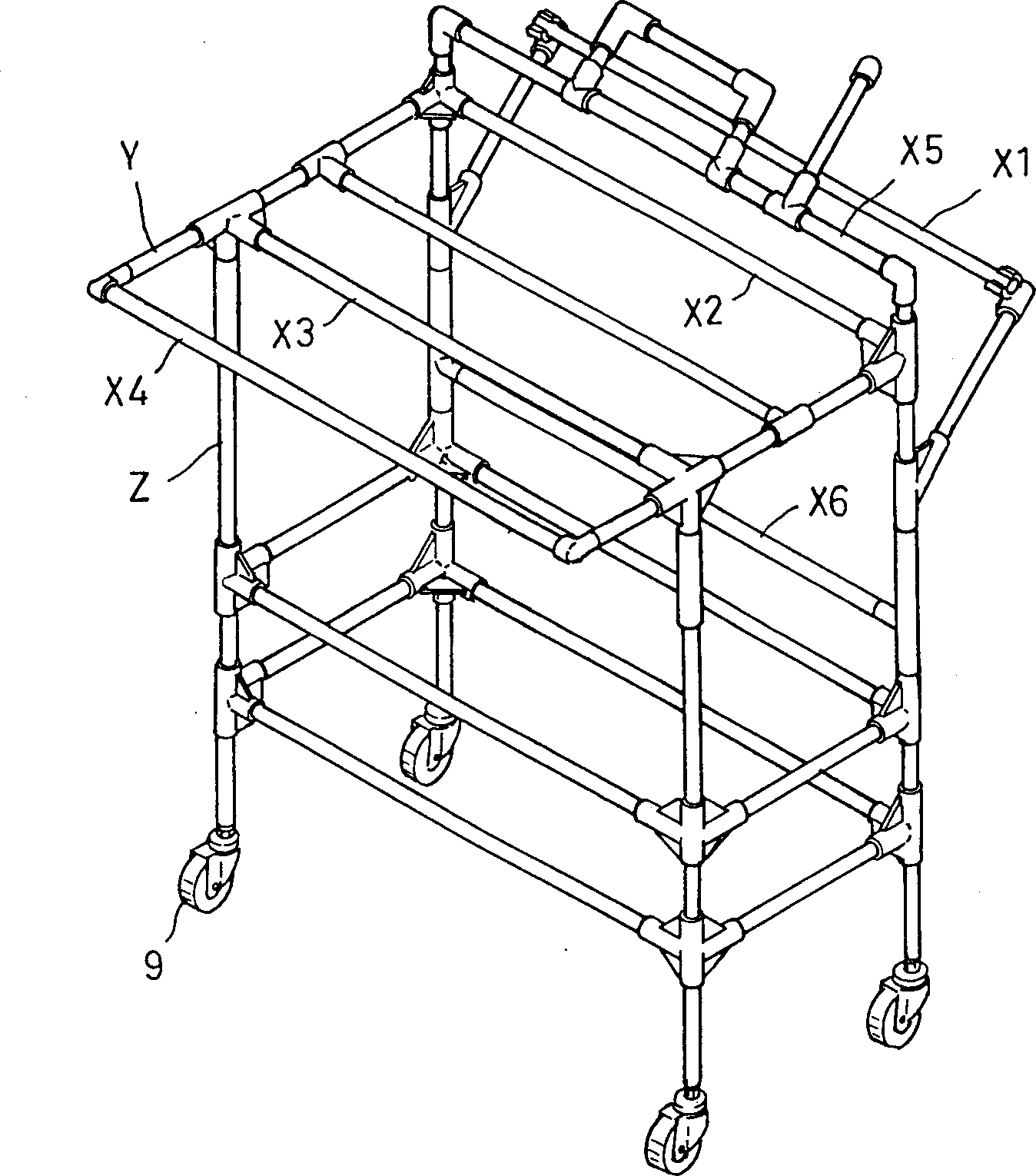

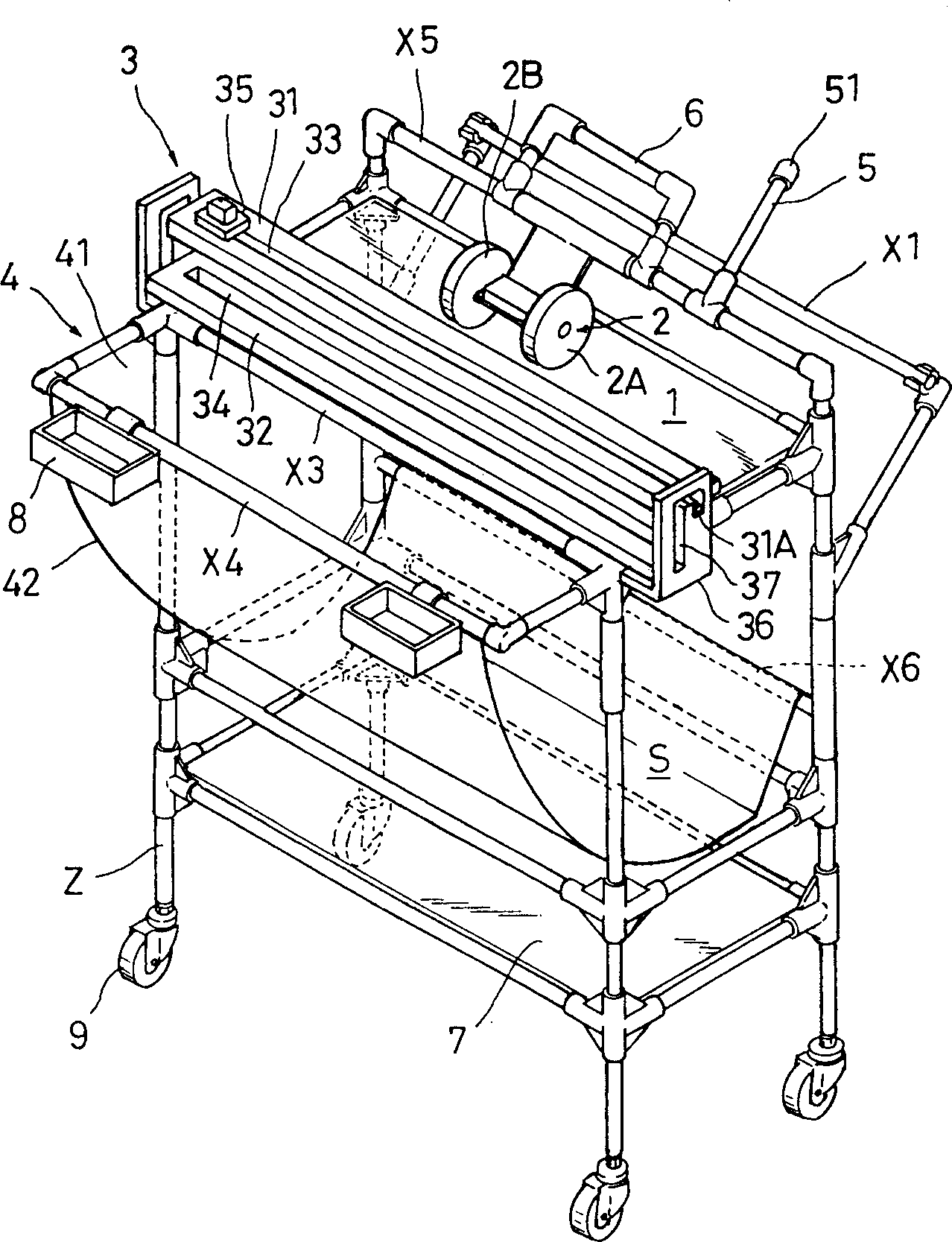

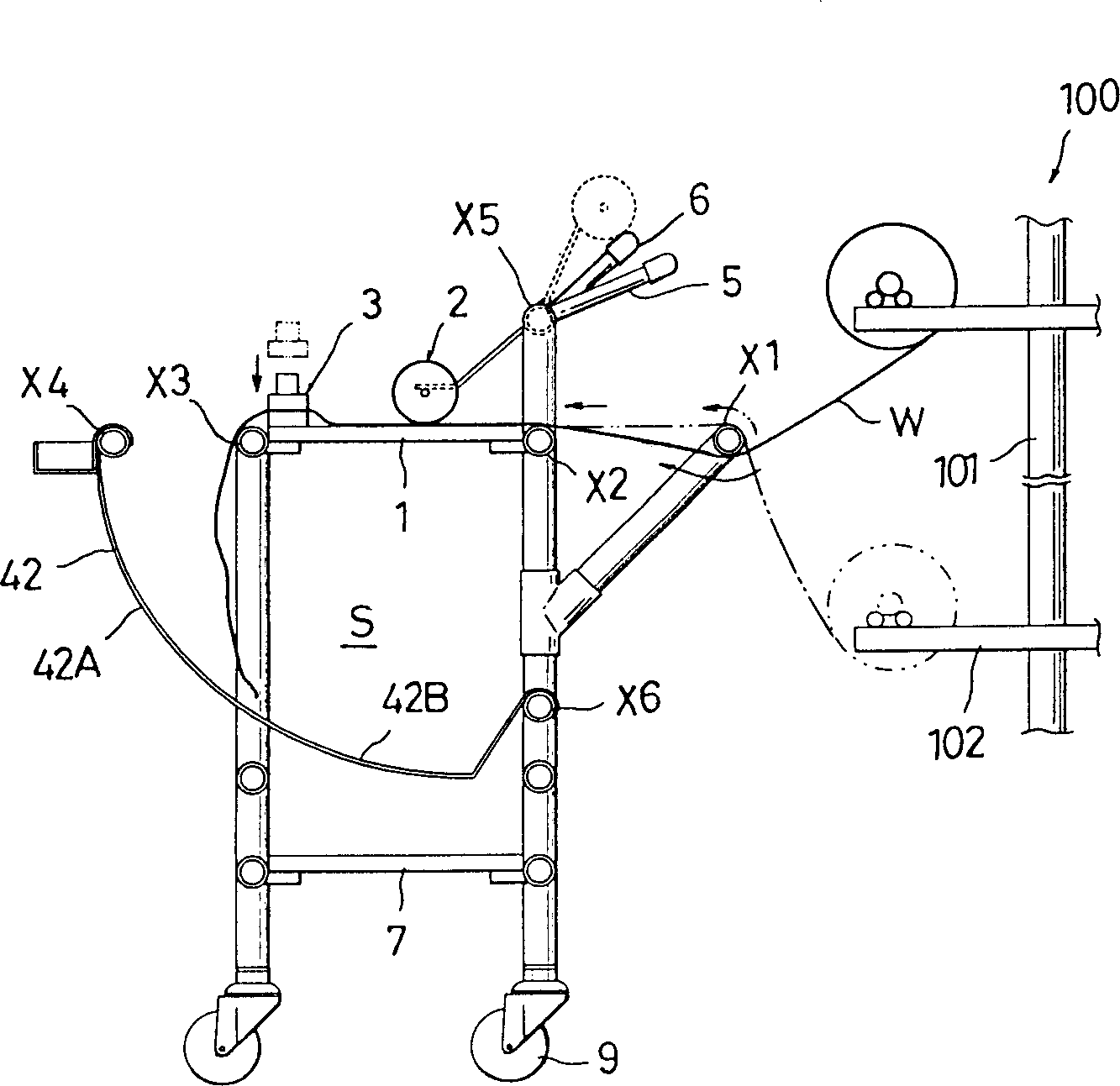

Simple cutter

InactiveCN1351210ACutting is simple and accurateSave work spaceSevering textilesMetal working apparatusEngineeringCaster

The invention provides a simplified cutting apparatus, which is without requiring a level of skill and simply and accurately cuttable. This simplified cutting apparatus has a frame body and cuts woven material W in a prescribed length and is equipped with a supporting table 1 attached to the frame body and supporting the woven material W, a measuring device 2 attached to the frame body and freely groundable to the woven material on the supporting table 1, a cutting machine attached to the frame body and arranged behind the supporting table, a housing part 4 for receiving cut woven material W, attached to the frame body, and a caster 9 installed at the lower end of the frame body. The apparatus makes a space for installing large cutting apparatus unnecessary and makes operation for moving a woven material to a cutting table by human hands unnecessary and efficient and is readily handleable without requiring a level of skill and simply and accurately cuttable by only traveling a blade in sandwiched state.

Owner:センチュリーテクノコア

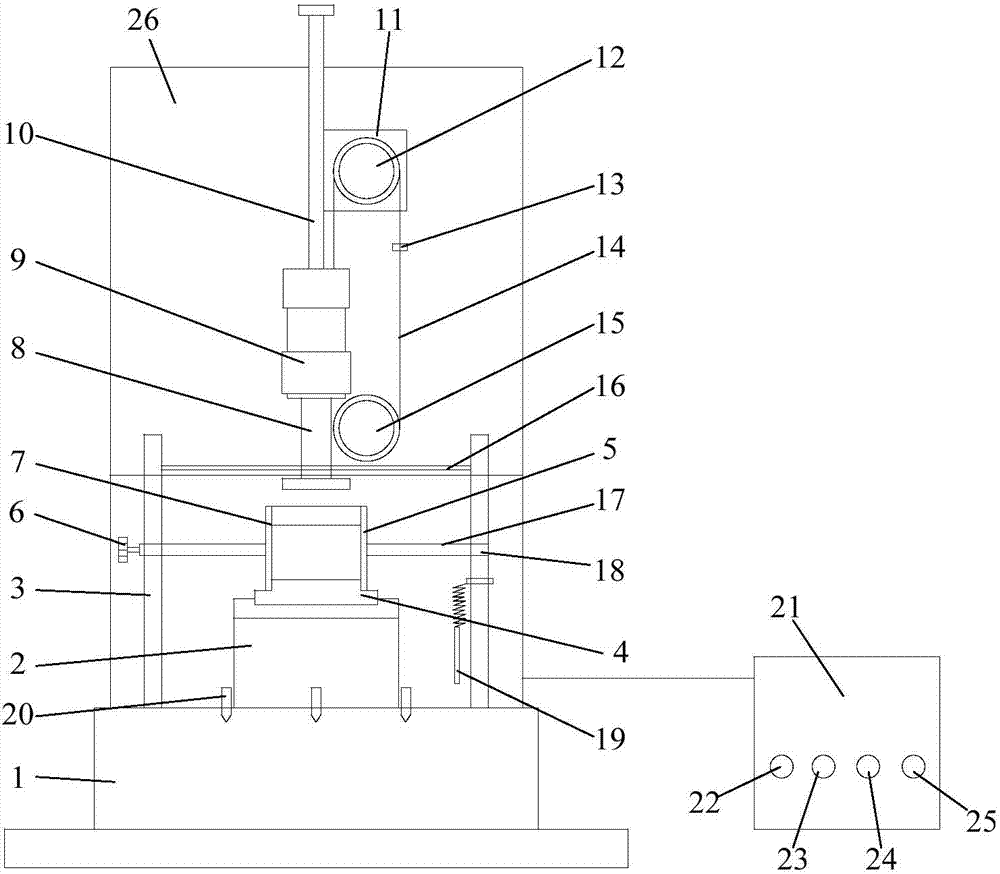

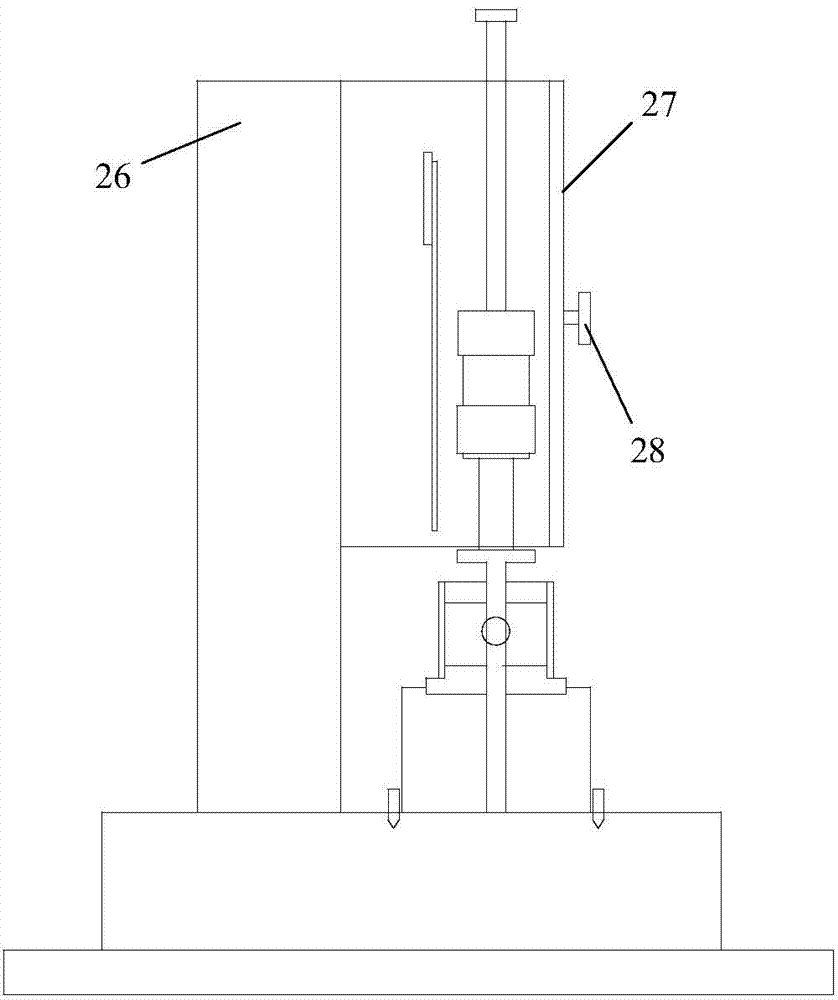

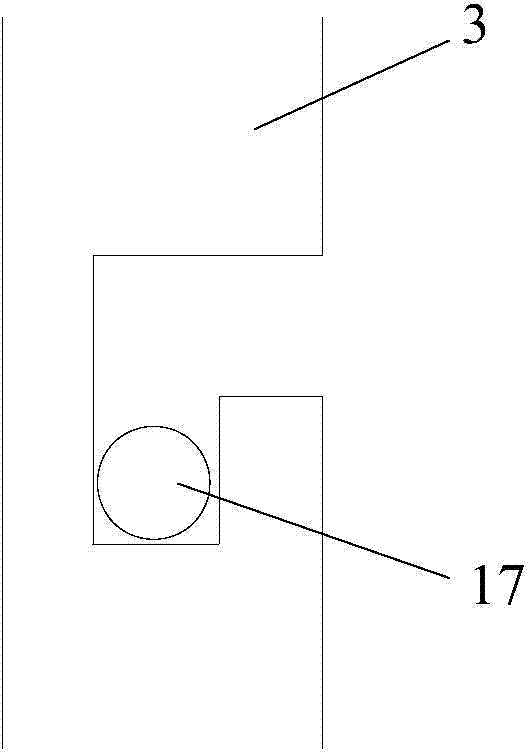

Automatic Marshall compaction device and test method

InactiveCN103698180ASmooth rotationSimple designPreparing sample for investigationPresent methodEngineering

The invention discloses an automatic Marshall compaction device and a test method. The automatic Marshall compaction device comprises a controller and a supporting part, wherein the supporting part is used for adding an asphalt mixture; a safety protection part and an inserting and tamping rod are arranged on the supporting part; the inserting and tamping rod is used for uniformly inserting and tamping the asphalt mixture; a compaction part which is used for compacting the asphalt mixture is arranged above the safety protection part; a power part which is used for driving the compaction part to operate is connected to the compaction part. According to the automatic Marshall compaction device, the supporting part which is used for adding the asphalt mixture and the compaction part which is used for compacting the asphalt mixture are controlled through the controller, and the compaction part is driven by the power part to repeatedly compact the asphalt mixture. The automatic Marshall compaction device is simple in design and convenient to use, a rotary shaft can be conveniently rotated, the inserting-tamping compaction time is shortened, and the compaction efficiency is improved.

Owner:CHANGAN UNIV

Multifunctional automatic guide transport vehicle

The invention relates to a multifunctional automatic guide transport vehicle. The multifunctional automatic guide transport vehicle comprises a vehicle body, a vehicle driving system, a multi-point jacking device, two supporting plates, a bus system and a safety guide device, wherein the vehicle body is provided with a chassis, and the chassis is provided with two fork foot base frames which are arranged in parallel; the vehicle driving system is provided with two driving wheels, a plurality of universal wheels and two first driving devices used for correspondingly driving the two driving wheels to rotate; the two driving wheels are arranged on the lower portions of the two sides of the middle of the chassis in the front-back direction correspondingly; the multi-point jacking device is provided with a plurality of lifting devices and second driving devices used for correspondingly driving the plurality of lifting devices to perform lifting motion; each supporting plate is provided withat least two lifting devices; the bus system synchronously controls the plurality of second driving devices; and the safety guide device is provided with a solid state laser radar, a laser obstacle avoidance sensor, a contact type sensor, a mechanical anti-collision strip arranged in the vehicle body, a sound-light alarm and an emergency stop button. According to the multifunctional automatic guide transport vehicle, the height of a cargo fork can be reduced to the largest extent, and turning can be realized at the minimum radius.

Owner:ZHEJIANG FIELD INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com