Self-guided beam type bridge monitoring and overhauling device

A technology for overhauling machines and bridges, which is applied in bridges, bridge parts, bridge construction, etc. It can solve the problems of high-speed railway bridges that cannot run, maintenance vehicles that cannot walk, etc., and achieve the effects of simplifying construction work procedures, saving work sites, and advanced design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

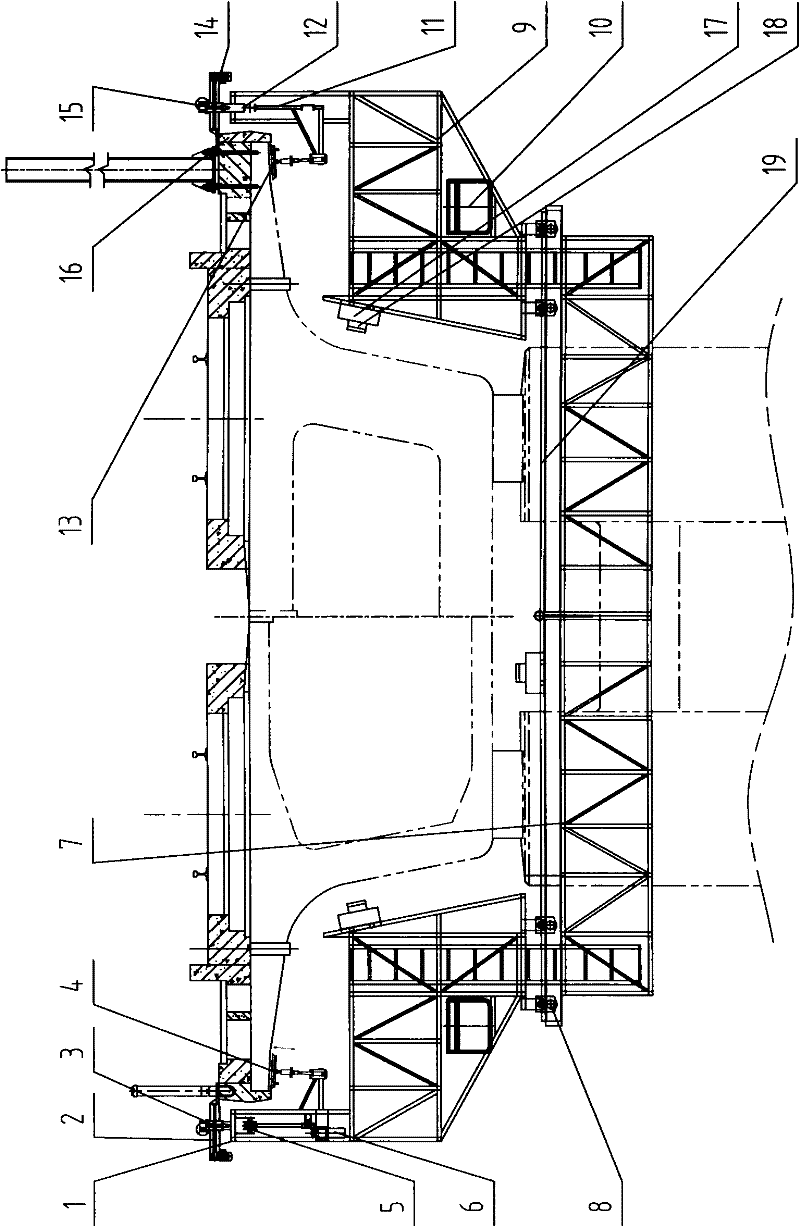

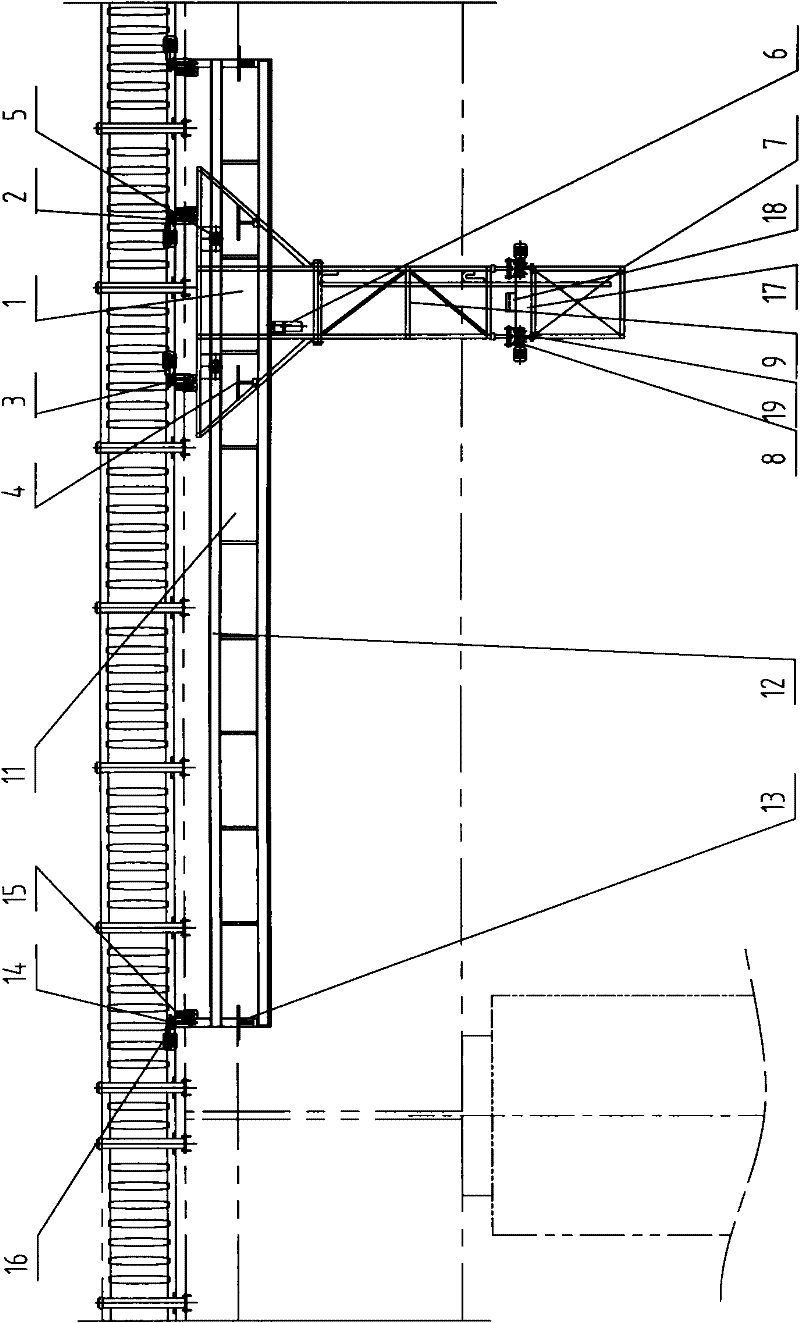

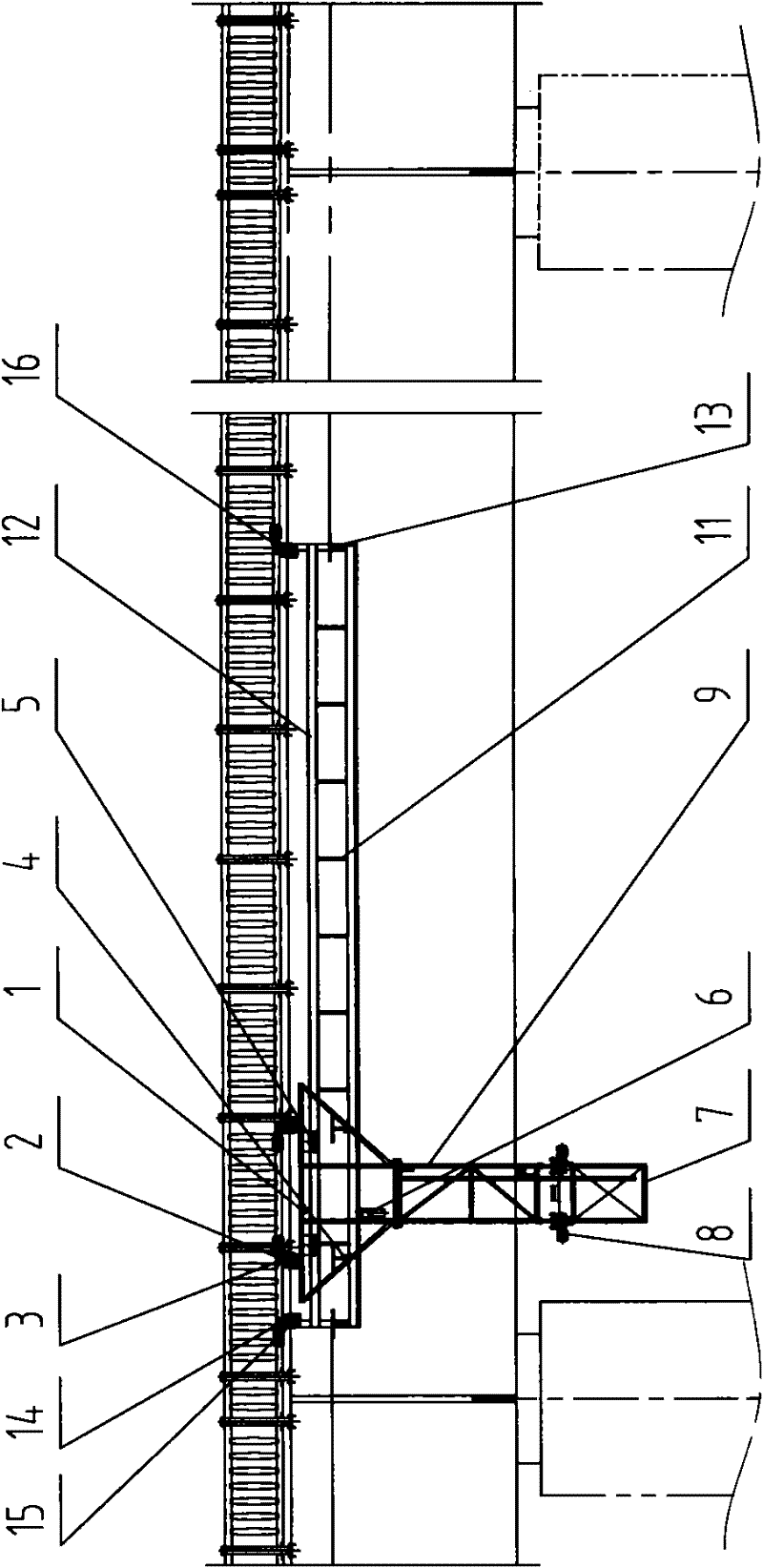

[0024] like figure 1 , figure 2 As shown, the self-guiding beam type bridge monitoring and maintenance machine of the present invention includes: a main beam 11 and a driving guide beam 1, wherein the main beam 11 is composed of a main beam horizontal expansion device 12 and a shutter 16, a main beam vertical lifting device 15, a truss type The track 12 and the main girder vacuum suction cup system 13 are composed. The shutters 16 fixed on the main girder horizontal telescopic device 12 of the main girder 11 are suspended on the upper surfaces of both sides of the bridge, and are adsorbed under the bridge through the main girder vacuum suction cup system 13. The surface is fixed; the drive guide beam 1 is composed of a drive guide beam horizontal expansion device 2 and a shutter 16, a drive guide beam vertical lifting device 3, a drive guide beam vacuum suction cup system 4, a sprocket drive device 6, a generator set 10, and a guide wheel Group 5, side maintenance platform 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com