Patents

Literature

244 results about "Bridge inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bridge inspector is a civil engineer construction specialist. Inspectors are familiar with the load rating analysis system required for designing bridges, parking garages, and other transportation-related structures.

Method and System for Remotely Inspecting Bridges and Other Structures

ActiveUS20130216089A1Facilitating spatial integrationFacilitating automated damage detectionImage enhancementImage analysisJet aeroplaneOn board

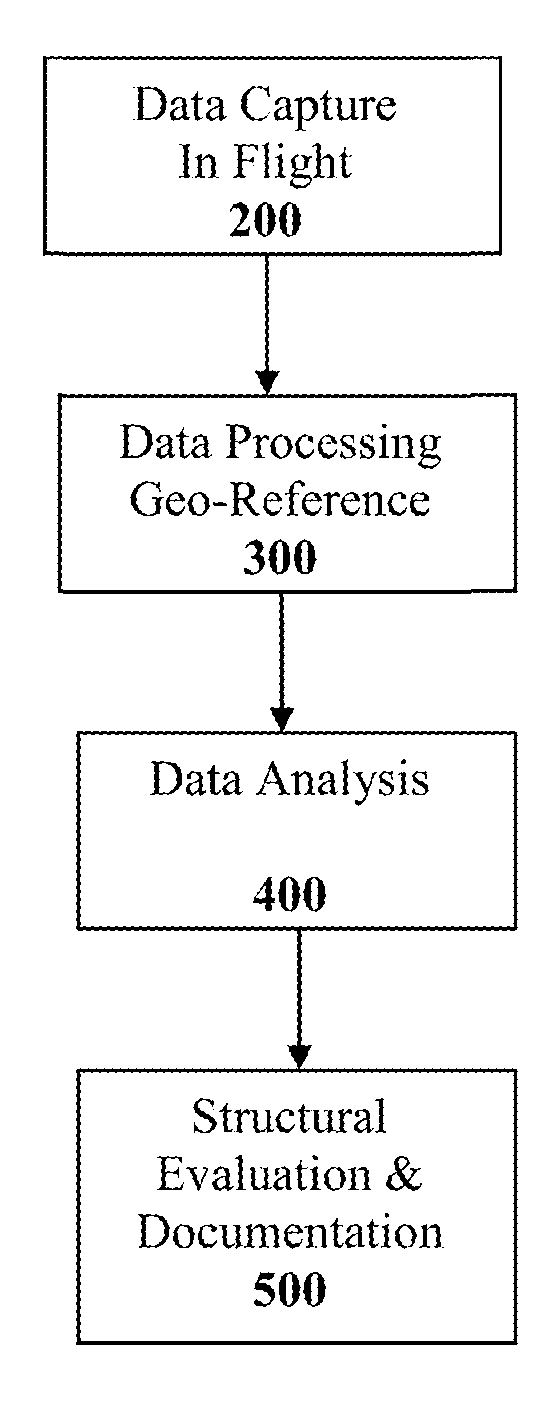

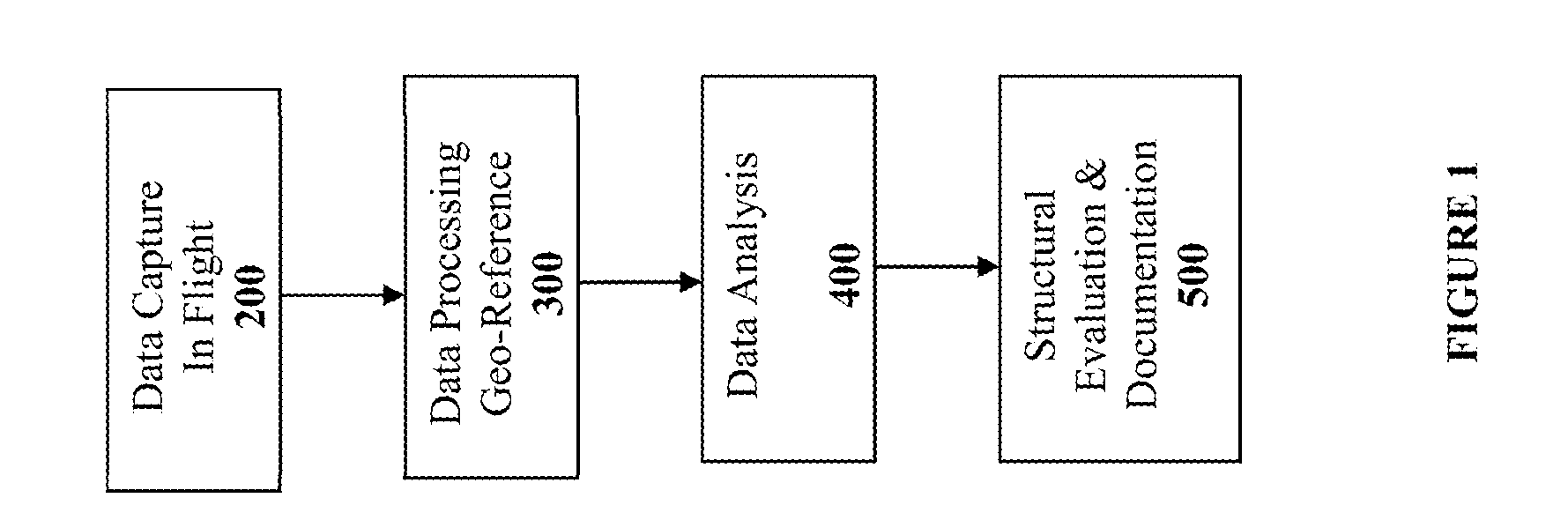

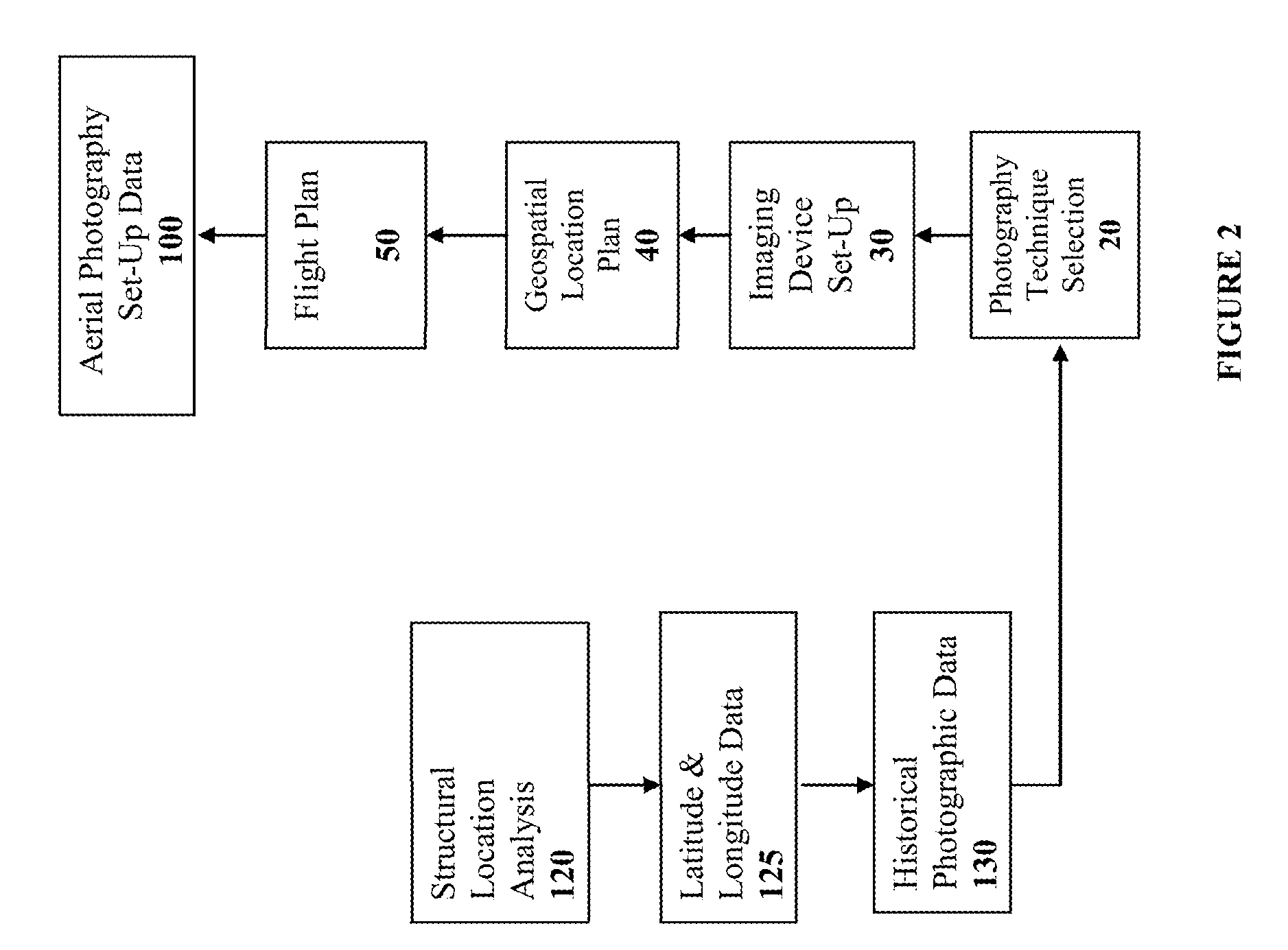

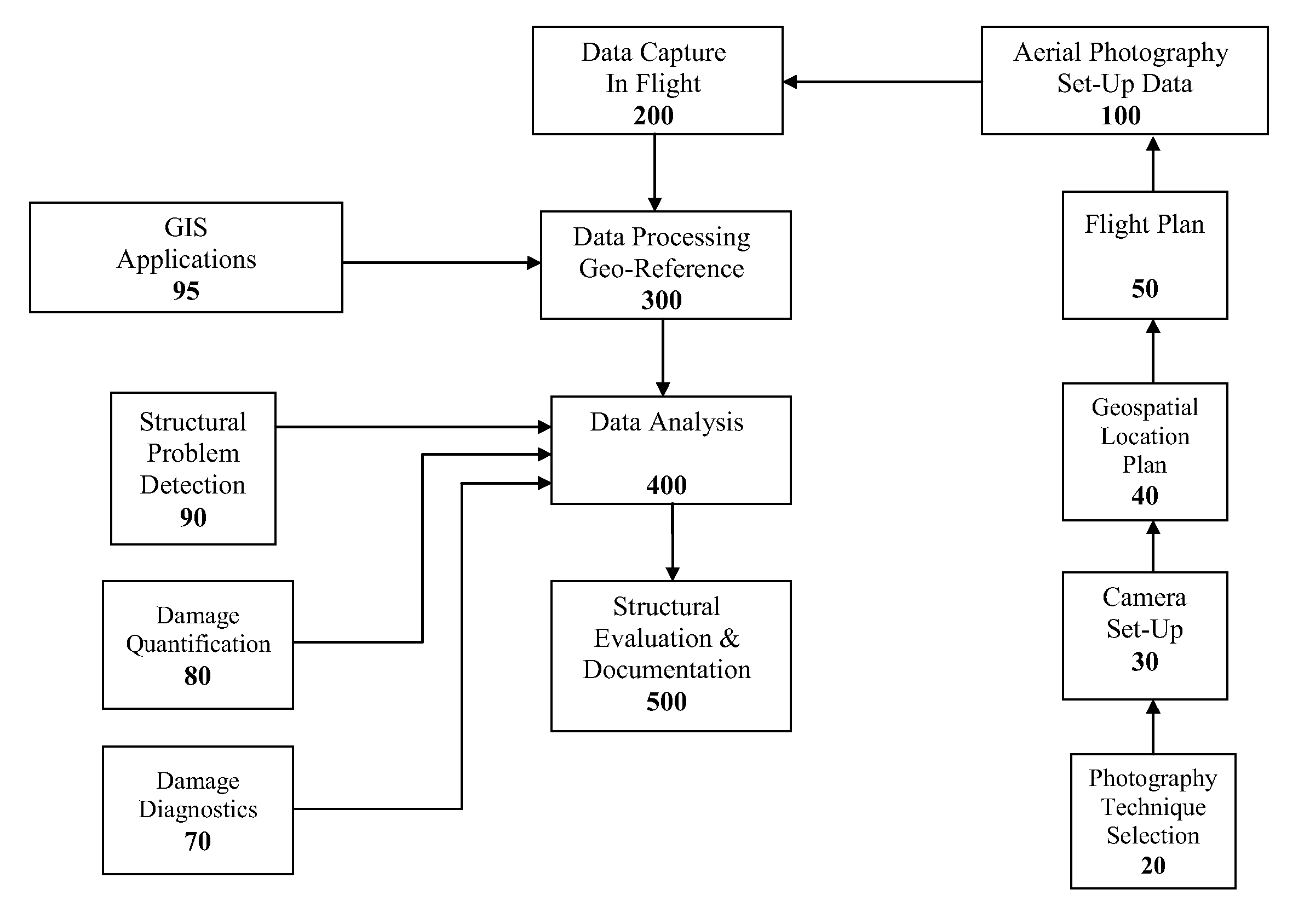

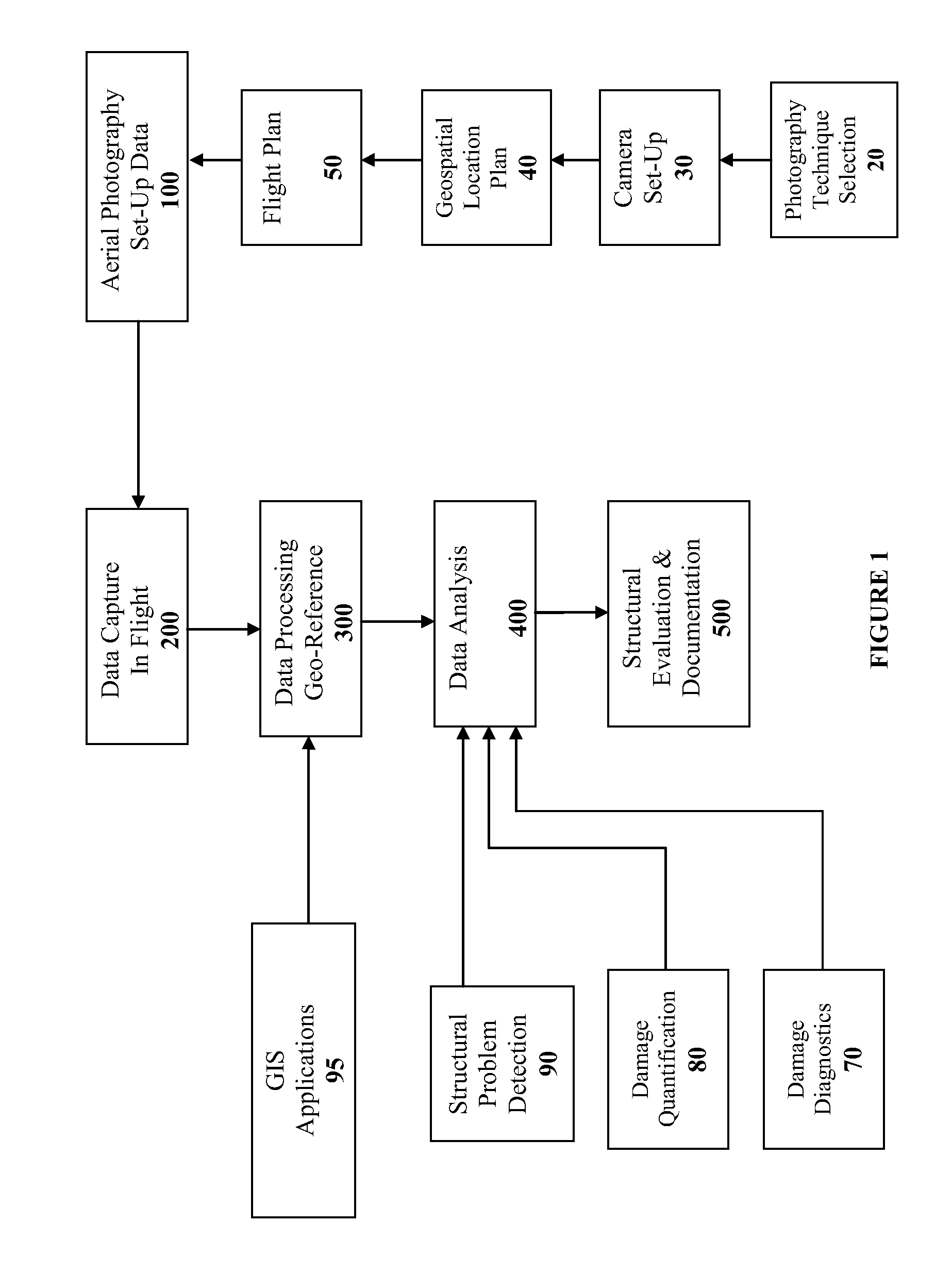

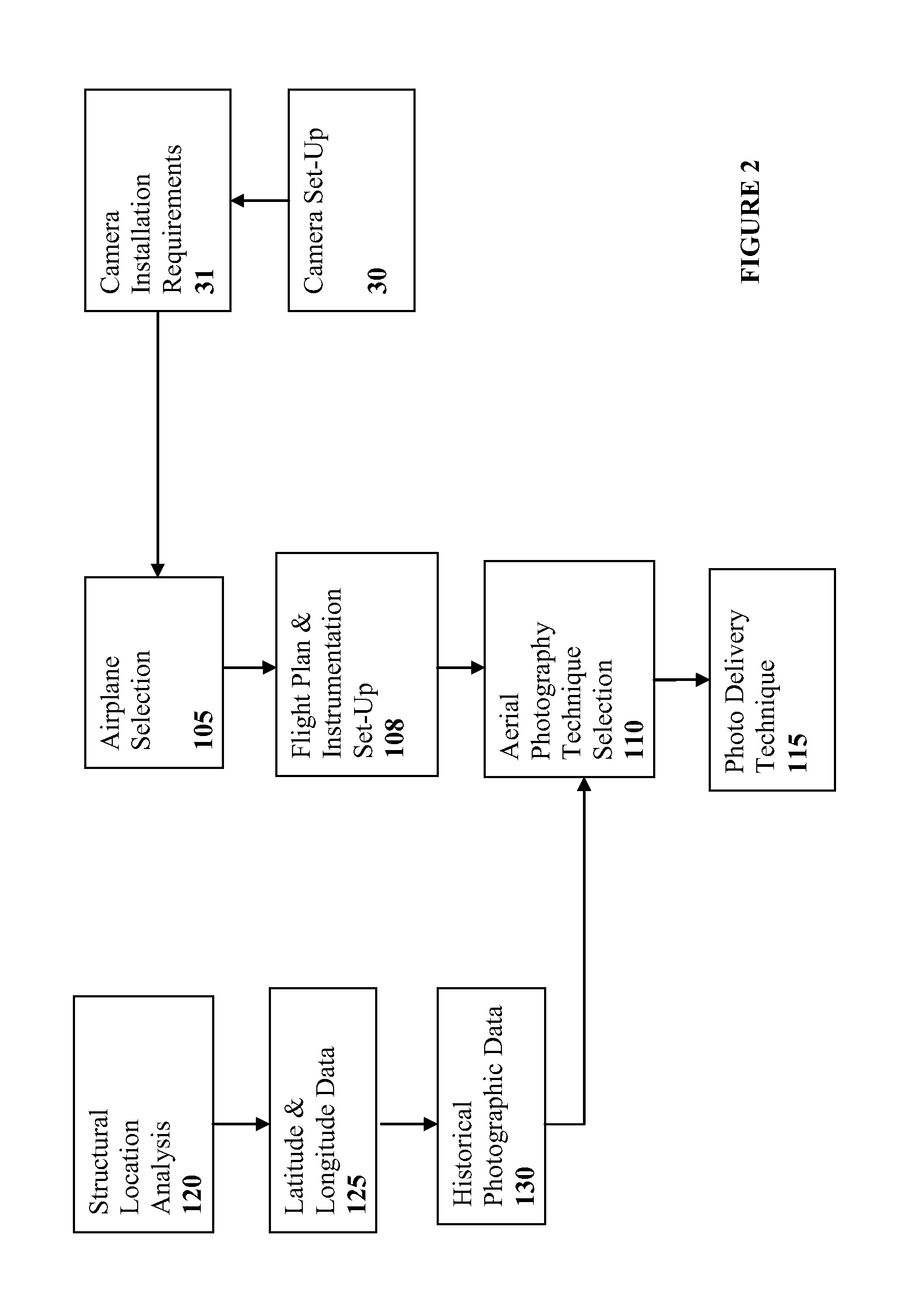

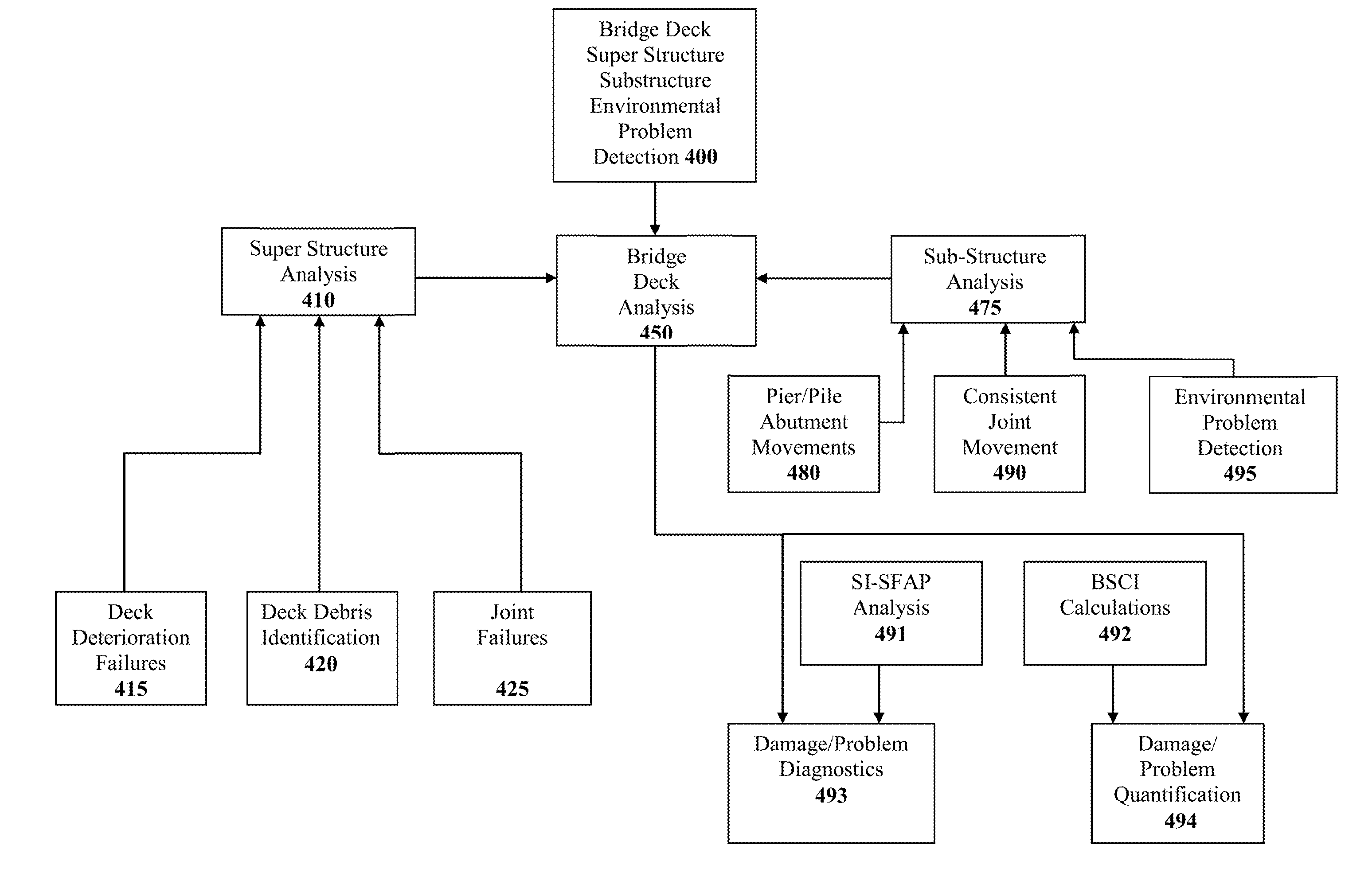

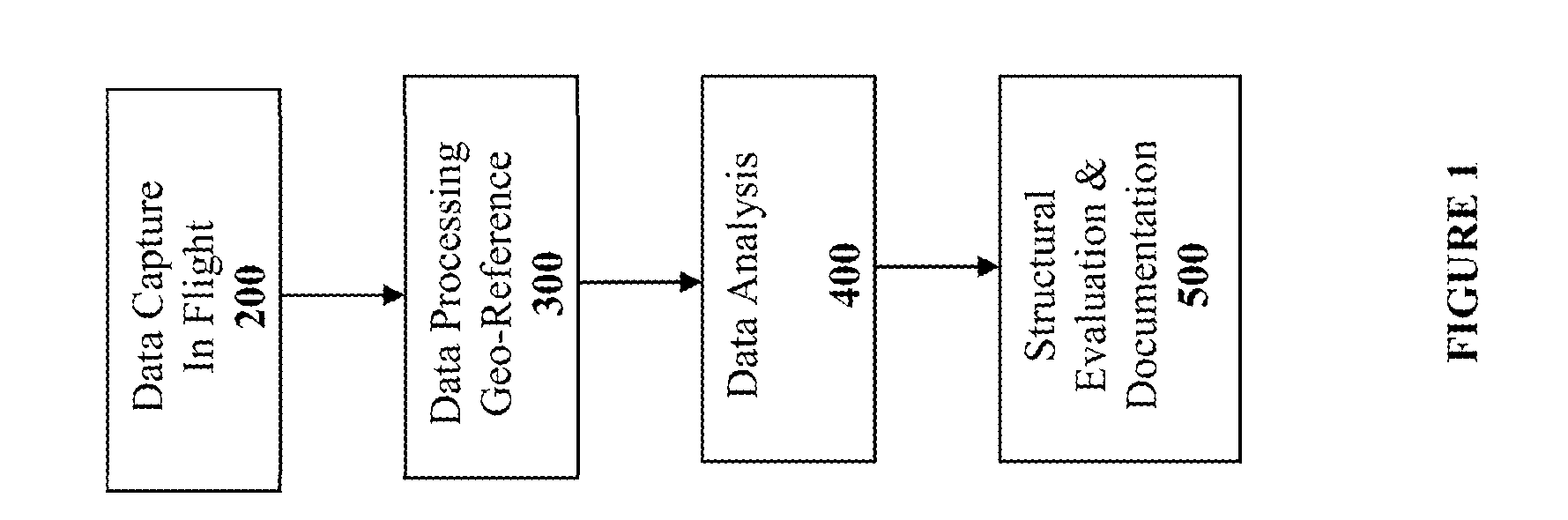

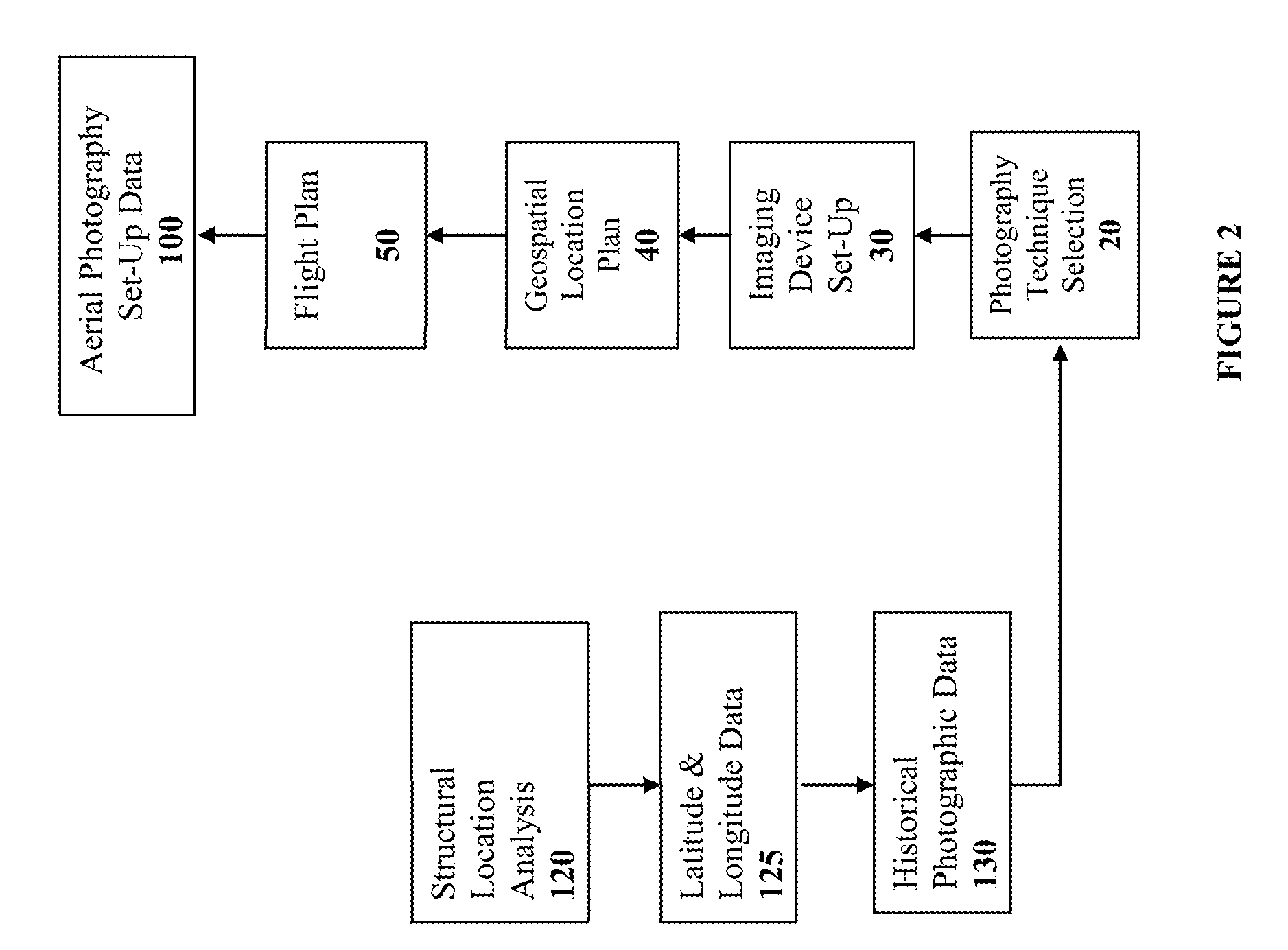

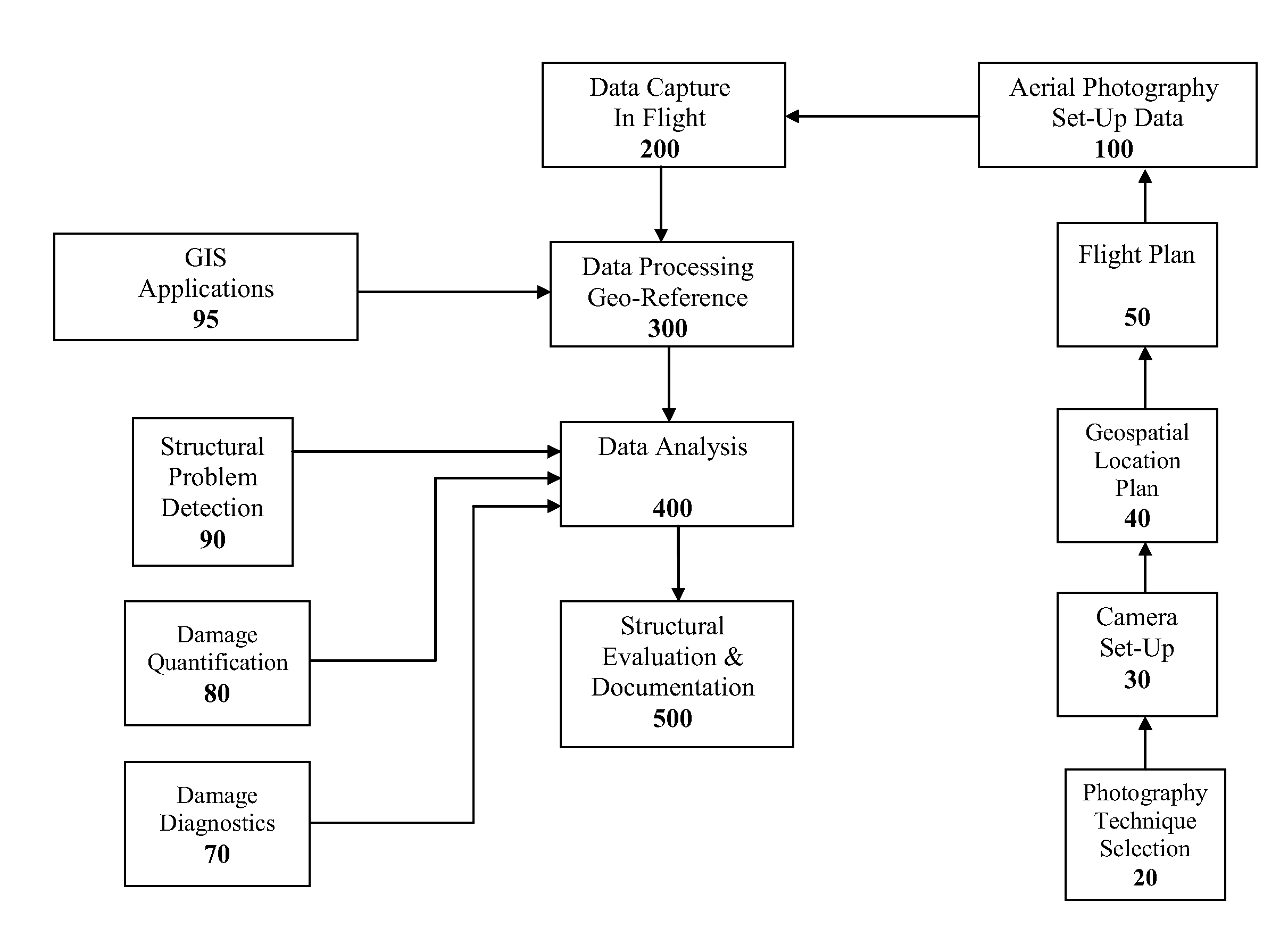

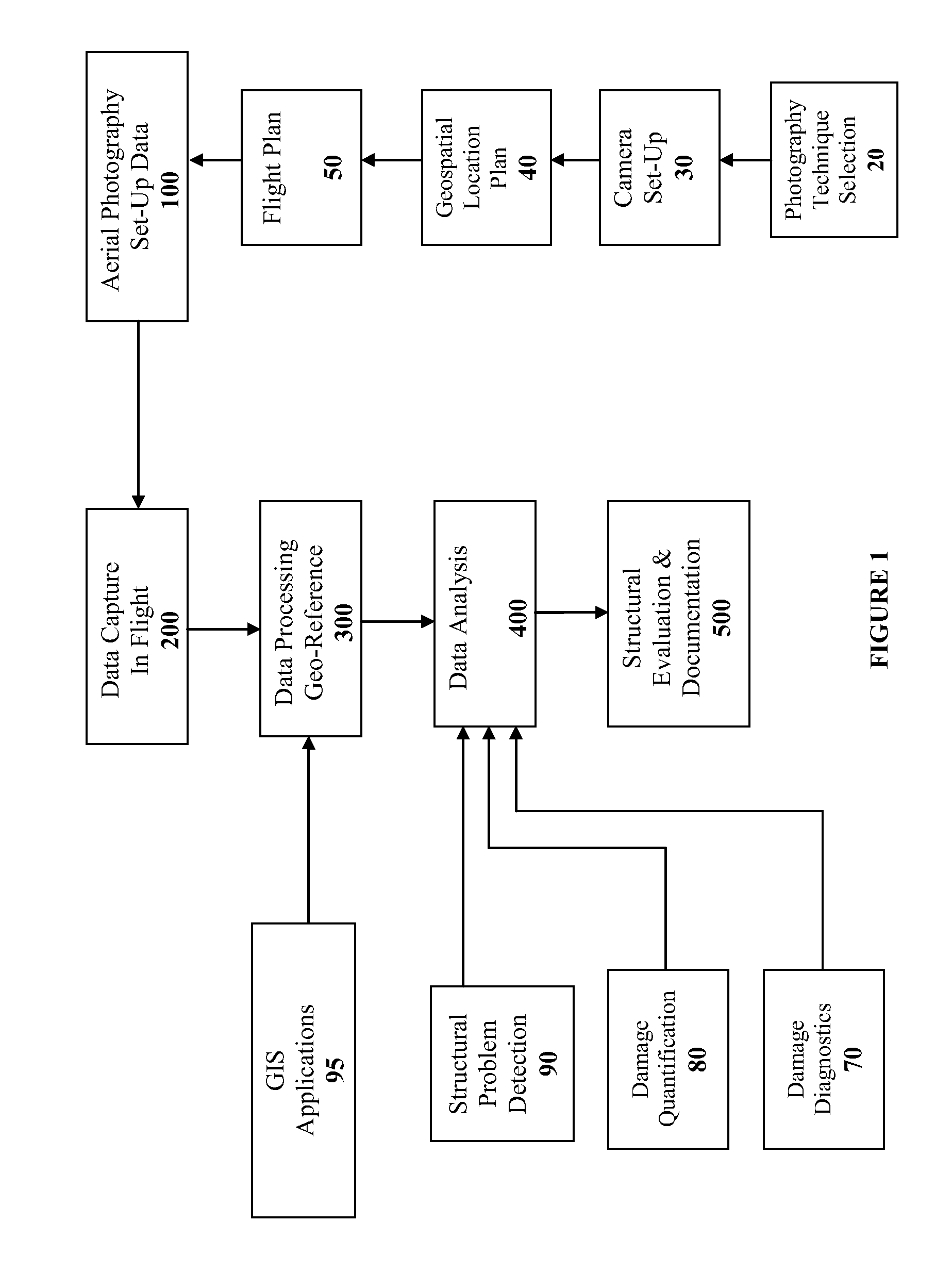

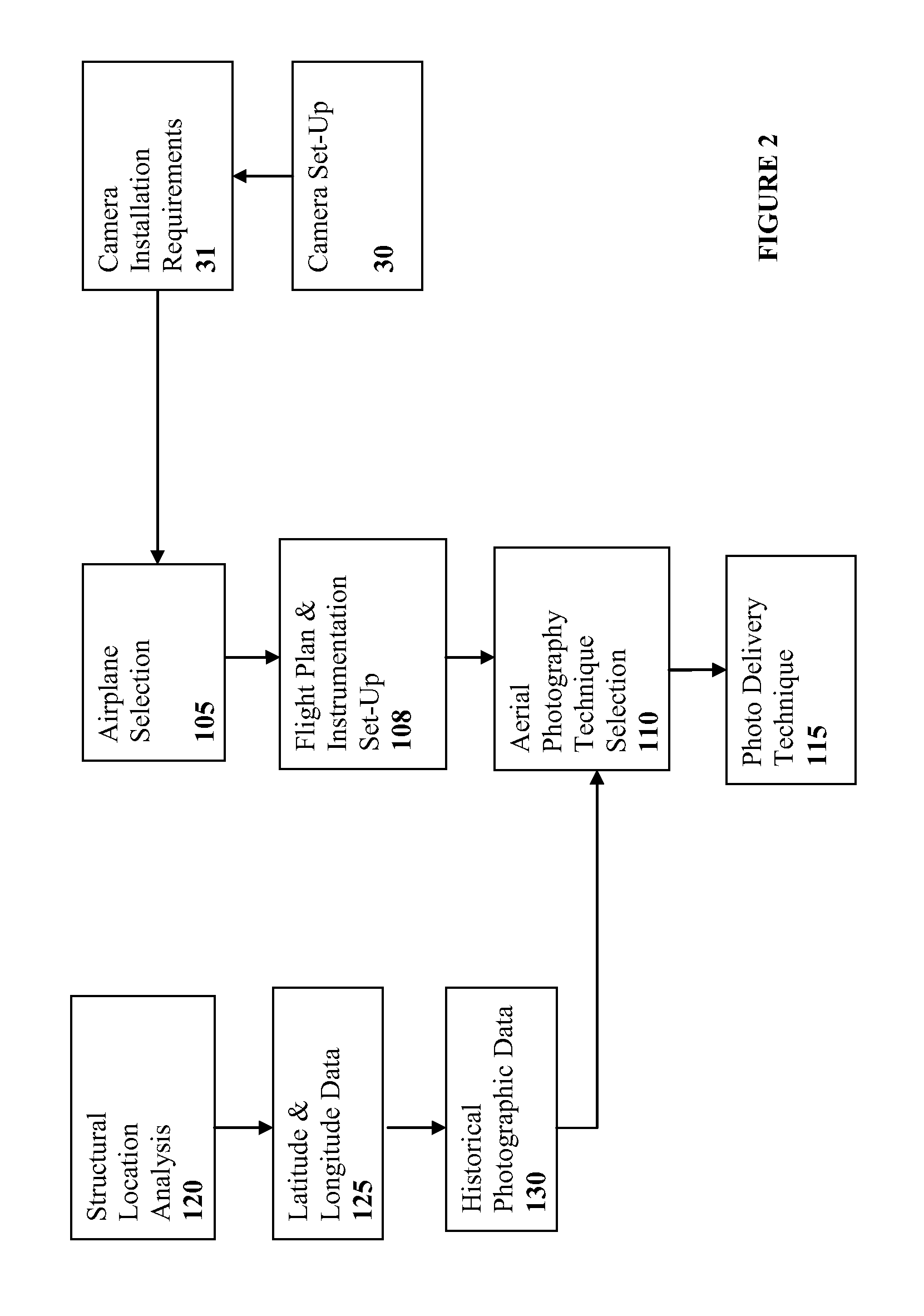

Spatially Integrated Small-Format Aerial Photography (SFAP) is one aspect of the present invention. It is a low-cost solution for bridge surface imaging and is proposed as a remote bridge inspection technique to supplement current bridge visual inspection. Providing top-down views, the airplanes flying at about 1000 feet can allow visualization of sub-inch (large) cracks and joint openings on bridge decks or highway pavements. On board Global Positioning System (GPS) is used to help geo-reference images collected and facilitate damage detection. Image analysis is performed to identify structural defects such as cracking. A deck condition rating technique based on large crack detection is used to quantify the condition of the existing bridge decks.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Spatially integrated aerial photography for bridge, structure, and environmental monitoring

Spatially Integrated Small-Format Aerial Photography (SFAP is one aspect of the present invention. It is a low-cost solution for bridge surface imaging and is proposed as a remote bridge inspection technique to supplement current bridge visual inspection. Providing top-down views, the airplanes flying at about 1000 ft, can allow visualization of sub-inch (large) cracks and joint openings on bridge decks or highway pavements. On board Global Positioning System is used to help geo-reference images collected and allow automated damage detection. A deck condition rating technique based on large crack detection is used to quantify the condition of the existing bridge decks.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Method and system for remotely inspecting bridges and other structures

ActiveUS9036861B2Damage detectionIntegration damageImage enhancementImage analysisJet aeroplaneOn board

Spatially Integrated Small-Format Aerial Photography (SFAP) is one aspect of the present invention. It is a low-cost solution for bridge surface imaging and is proposed as a remote bridge inspection technique to supplement current bridge visual inspection. Providing top-down views, the airplanes flying at about 1000 feet can allow visualization of sub-inch (large) cracks and joint openings on bridge decks or highway pavements. On board Global Positioning System (GPS) is used to help geo-reference images collected and facilitate damage detection. Image analysis is performed to identify structural defects such as cracking. A deck condition rating technique based on large crack detection is used to quantify the condition of the existing bridge decks.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

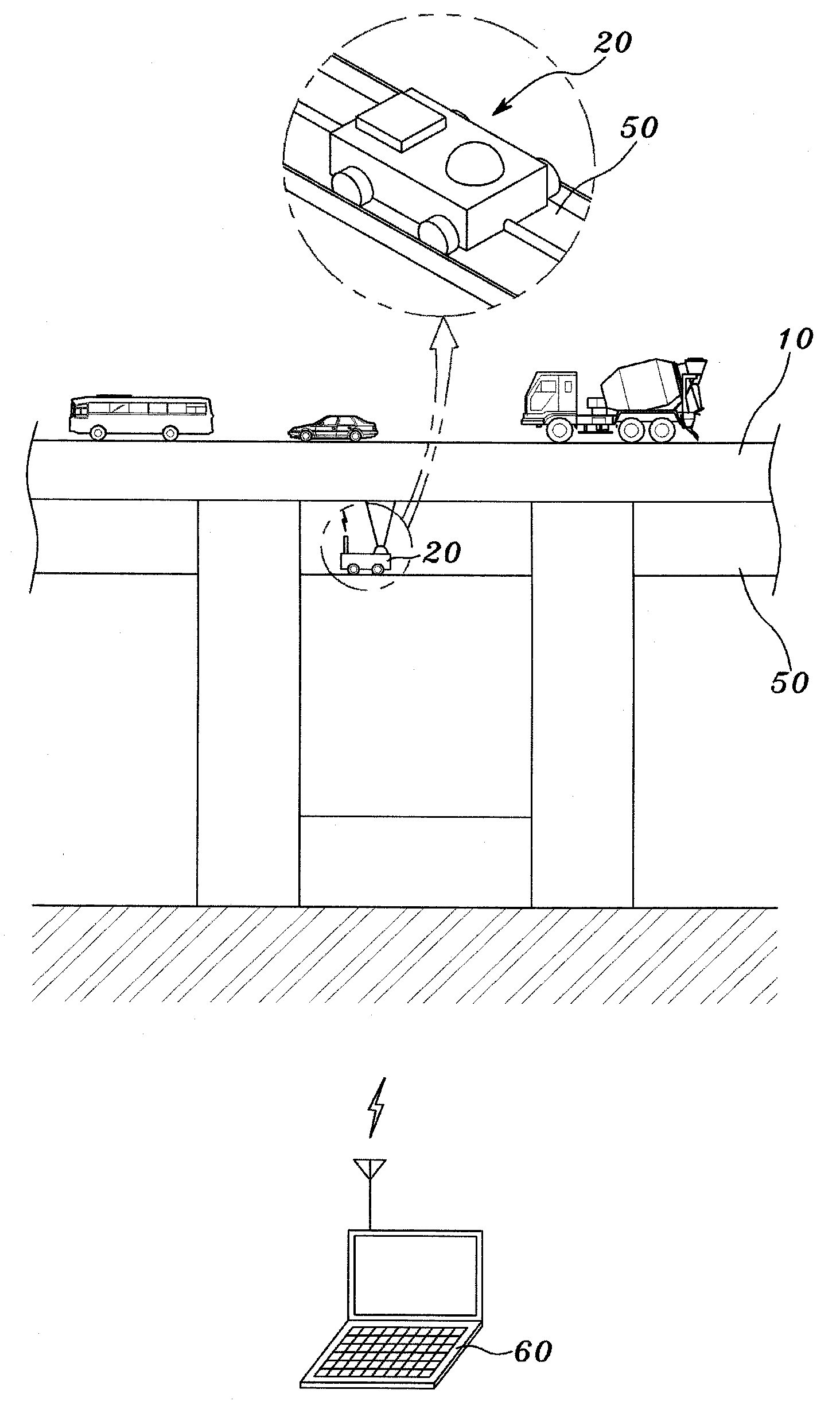

Method of controlling robot for bridge inspection

The present invention relates to a method of controlling a robot for bridge inspection. In the present invention, whether a defect image is being received from a robot device is determined. As a result of the determination, when the defect image is being received, a current location of the robot device is stored. Whether a predetermined period of time has been elapsed after the storage of the current location is determined. When the predetermined period of time has elapsed, a control command for moving the robot device to a prestored location is output. Whether a defect image at a same location as the prestored location is being received is determined. When the defect image at the same location is being received, a defect image at a previous time is compared with a defect image at a current time. A result of the comparison is displayed.

Owner:DEALIM IND & ACAD COOPERATION CENT +1

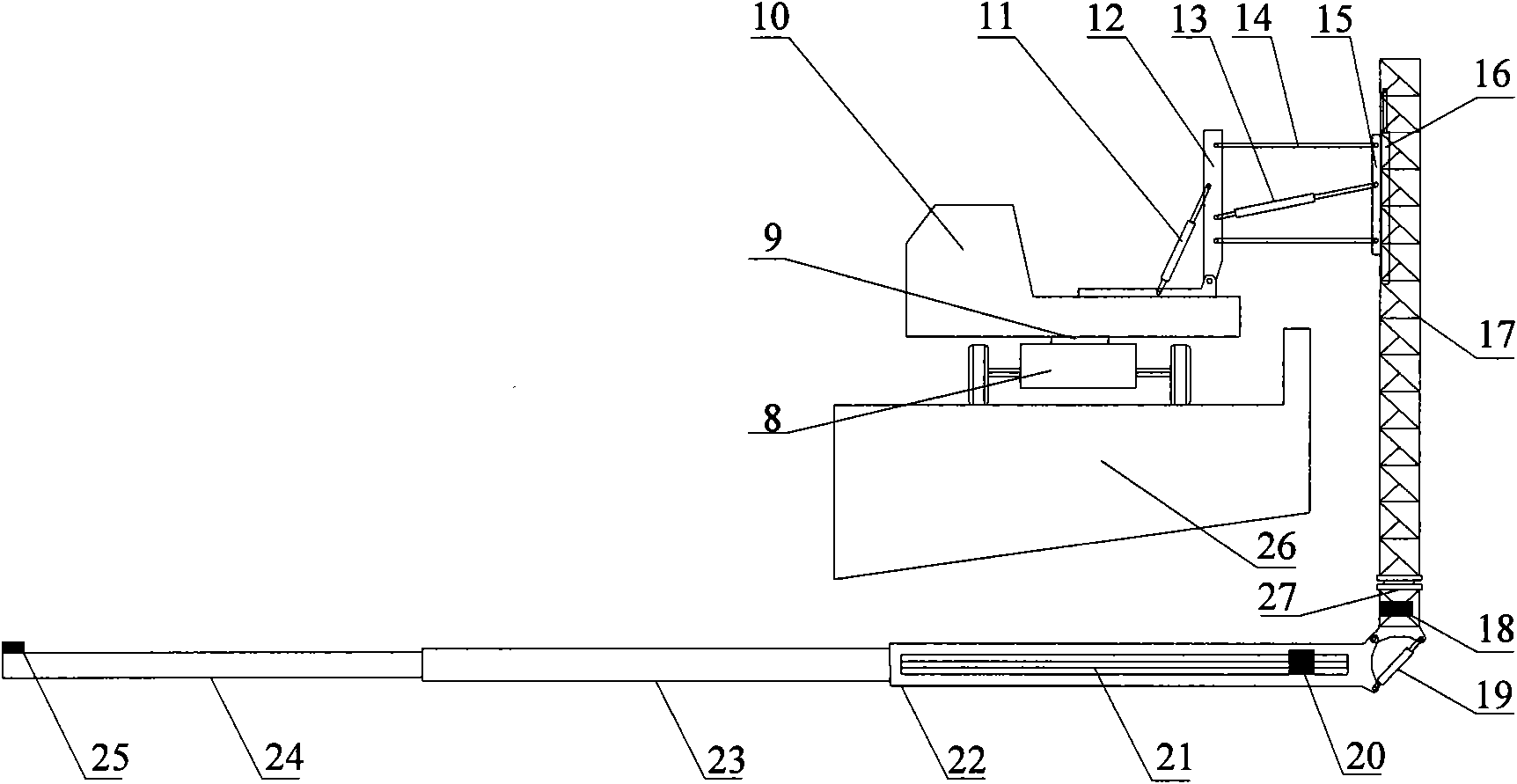

Bridge inspection vehicle

The invention relates to a device for bridge inspection, in particular a novel self-walking intelligent bridge inspection vehicle which comprises a lower carriage (8) and an upper carriage (10) connected with the lower carriage through a pivoting support (9), wherein the upper carriage (10) is connected with a vertical arm oil cylinder (16) at the upper end part of a vertical arm (17) through a quadrangular connecting and lifting mechanism, a rotating device (27) is arranged at the lower end part of the vertical arm (17) and connected with a horizontal working arm that extents to the bottom of a bridge, photographing devices are arranged on the rotating device (27) and the horizontal working arm, a frame oil cylinder (11) is arranged between the upper carriage (10) and the quadrangular connecting and lifting mechanism, and a connecting oil cylinder (19) is arranged between the rotating device (27) and a first telescopic arm (22). As the device is unmanned, the requirements to the structural strength of a cantilever crane are relatively smaller, thereby the volume and the weight of the bridge inspection vehicle are reduced, and the flexibility is enhanced; and meanwhile, an intelligent video device is adopted to store inspection videos, and the more specific analysis can be carried out conveniently, thereby the inspection result is more objective, and the inspection efficiency is higher.

Owner:YANSHAN UNIV

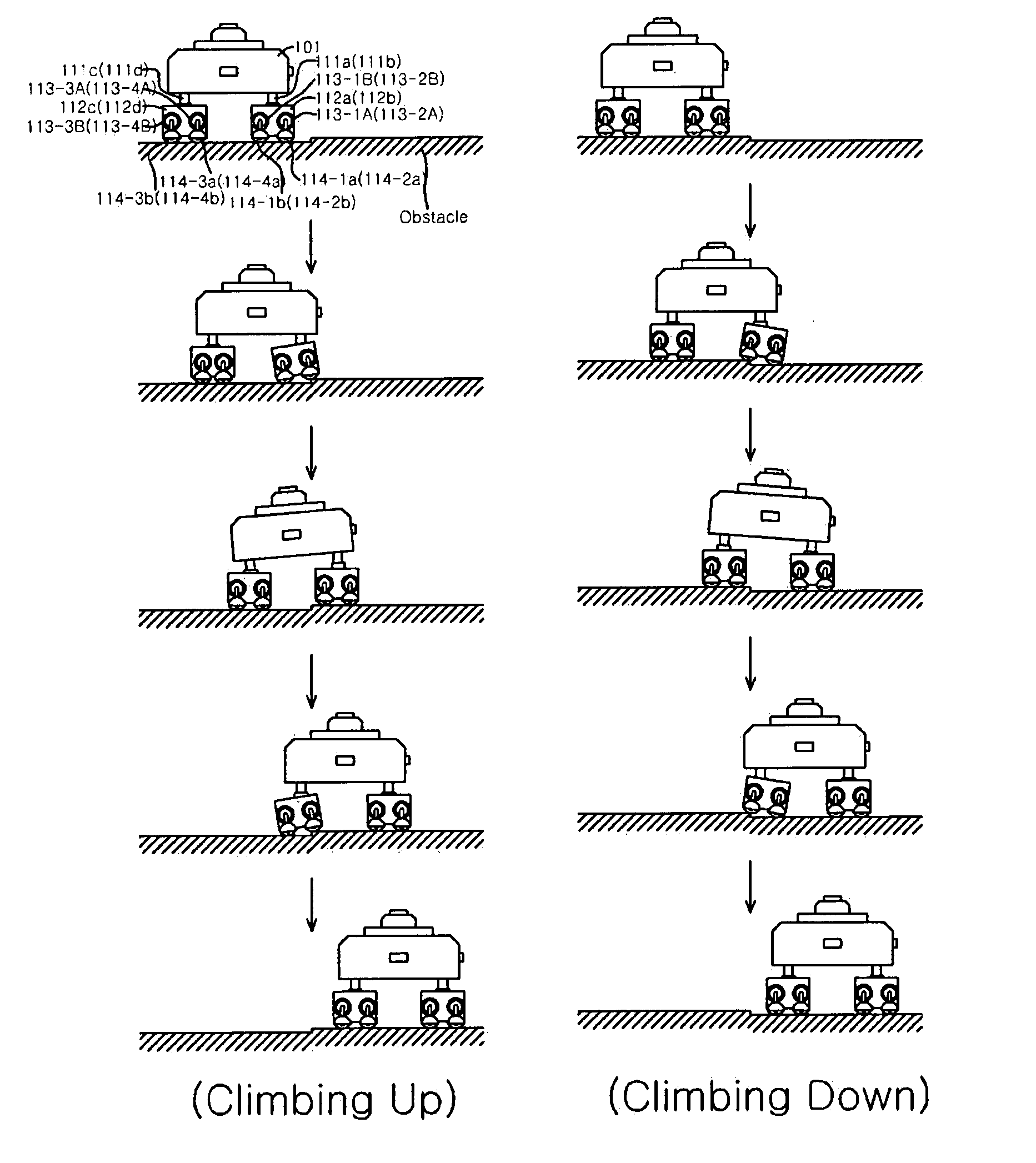

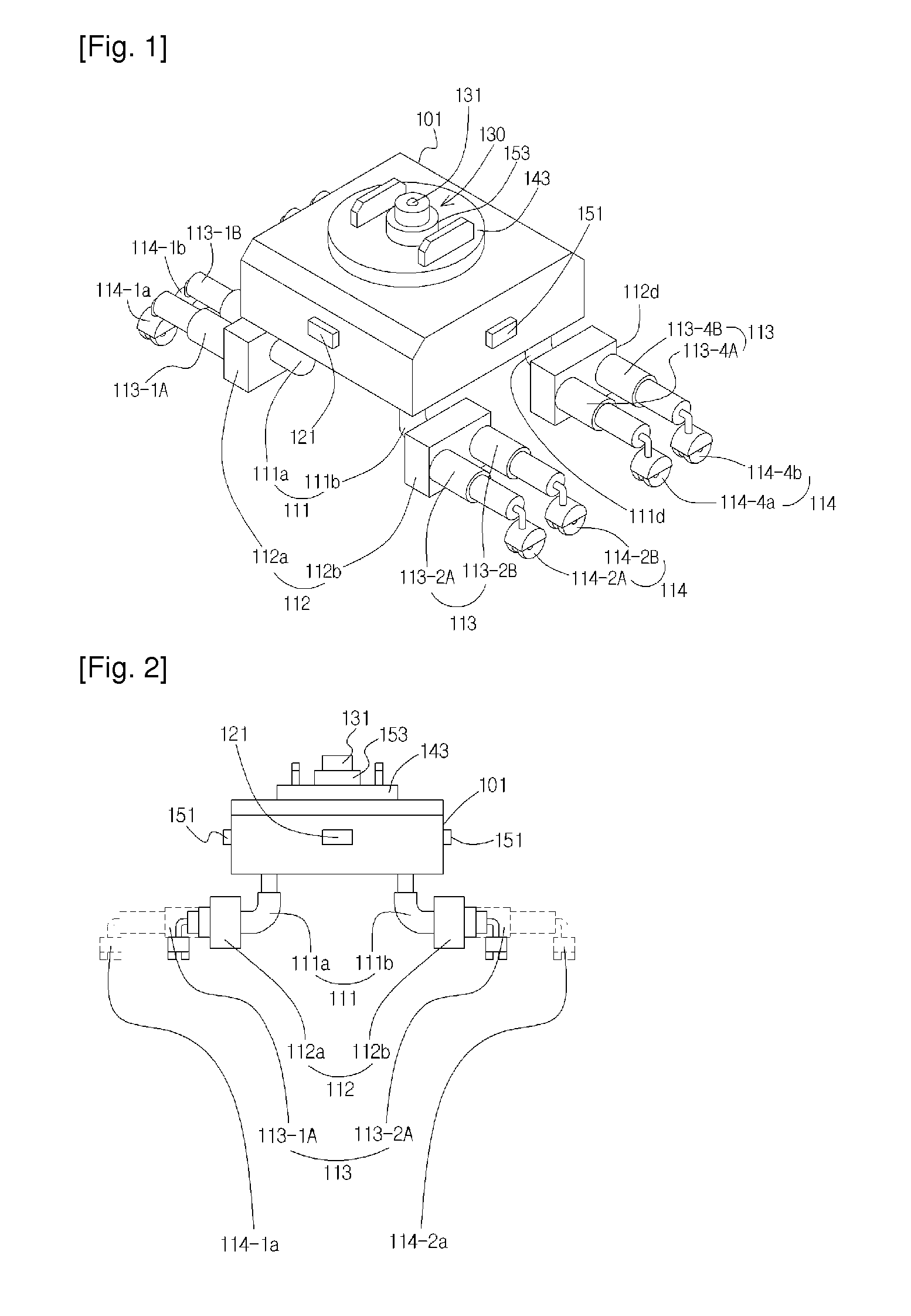

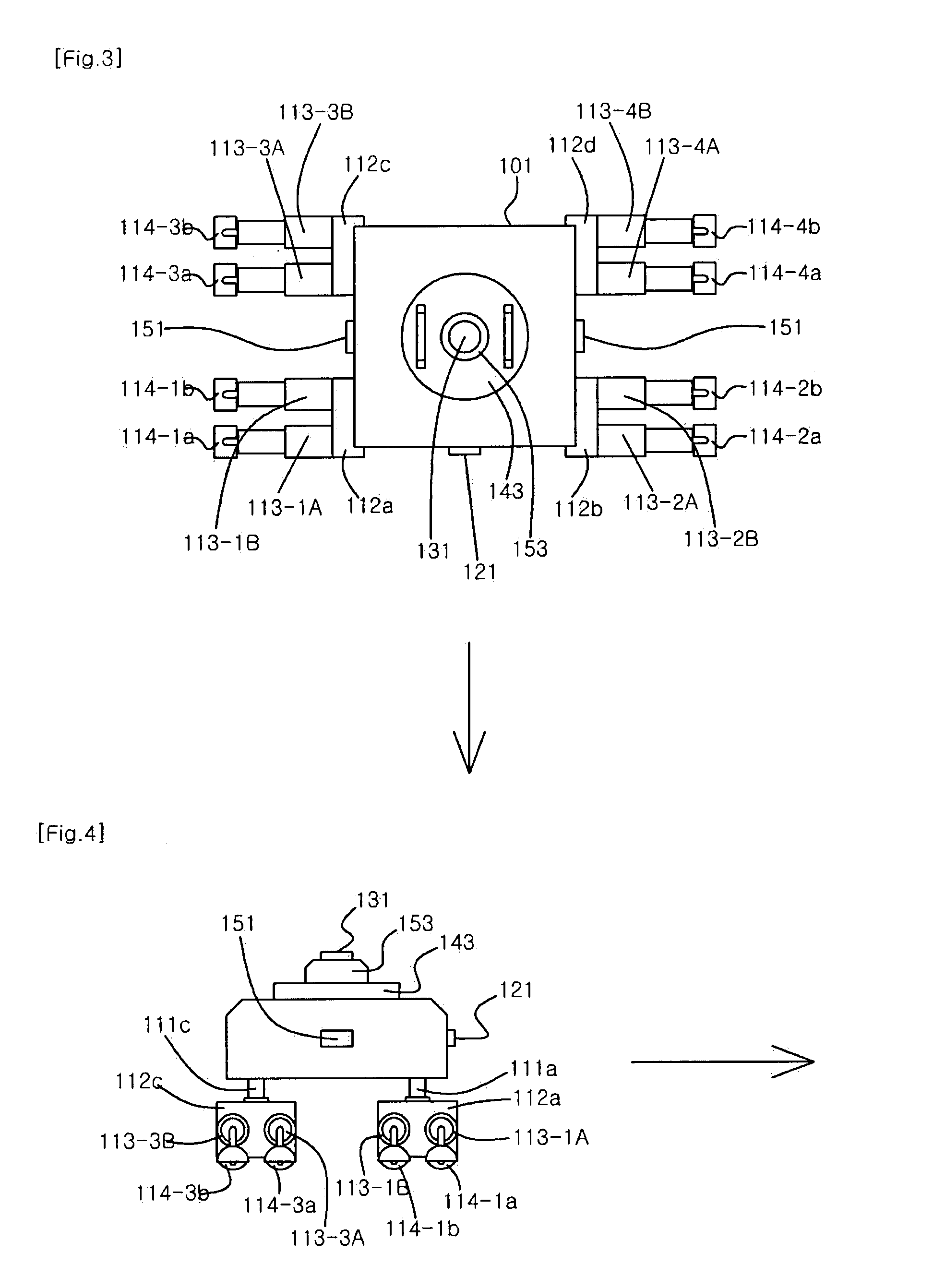

Bridge inspection robot capable of climbing obstacle

Provided is a bridge inspection robot which is capable of climbing over an obstacle, the bridge inspection robot including: a climbing-over portion (110) which is extended to correspond to a gap distance between a flange (1 Ia) of a first girder (11) and a flange (12a) of a first girder (12) which are provided at the upper side of a pier (L) of a bridge (10) in which a robot main body (101) climbs up / down or avoids and climbs over an obstacle, when the robot main body (101) moves on the flange, for example, along a bridge inspection path; an obstacle detection portion (120) which detects the obstacle which exists on the flanges; a photographing altitude control portion (150) which detects an altitude change of an image photographing portion (130) according to height of the obstacle when the robot main body (101) climbs up / down or avoids and climbs over the obstacle, and adjusts a photographing height of the image photographing portion (130) so as to correspond to the altitude change, to thus have a z-axis coordinate of an identical height all the time; a position calculation portion (160) which measures a mobile position of the robot main body (101) which corresponds to a consecutive image

Owner:EXPRESSWAY & TRANSPORTATION RES INST KOREA EXPRESSWAY CORP

Spatially integrated aerial photography for bridge, structure, and environmental monitoring

ActiveUS9014415B2Damage detectionIntegration damageImage enhancementImage analysisAviationJet aeroplane

Spatially Integrated Small-Format Aerial Photography (SFAP) is one aspect of the present invention. It is a low-cost solution for bridge surface imaging and is proposed as a remote bridge inspection technique to supplement current bridge visual inspection. Providing top-down views, the airplanes flying at about 1000 feet can allow visualization of sub-inch (large) cracks and joint openings on bridge decks or highway pavements. On board Global Positioning System (GPS) is used to help geo-reference images collected and allow automated damage detection. A deck condition rating technique based on large crack detection is used to quantify the condition of the existing bridge decks.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Bridge inspection method

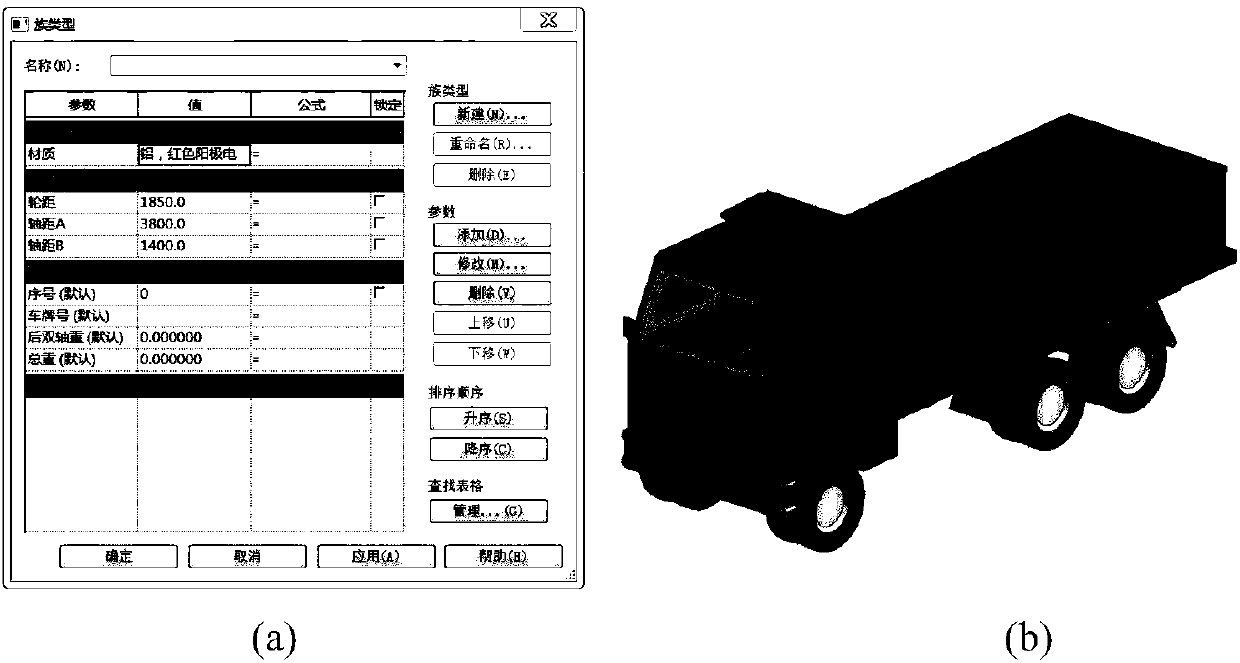

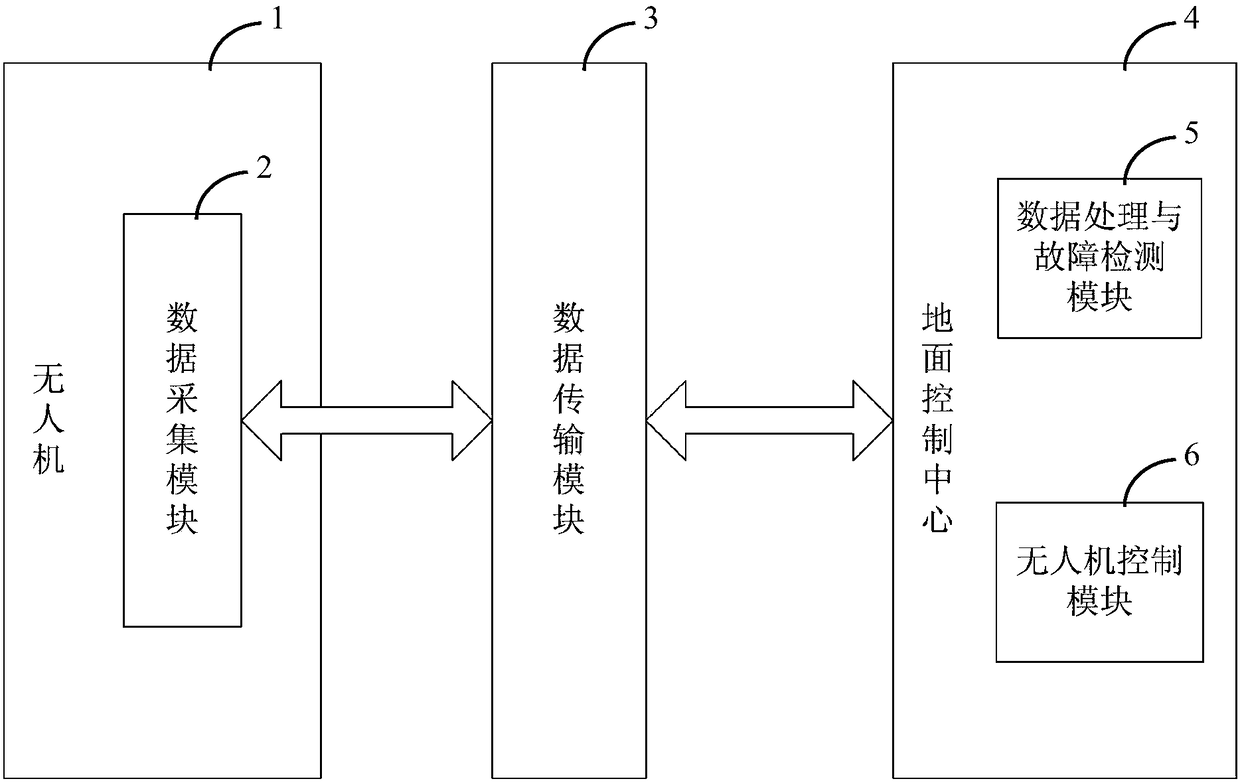

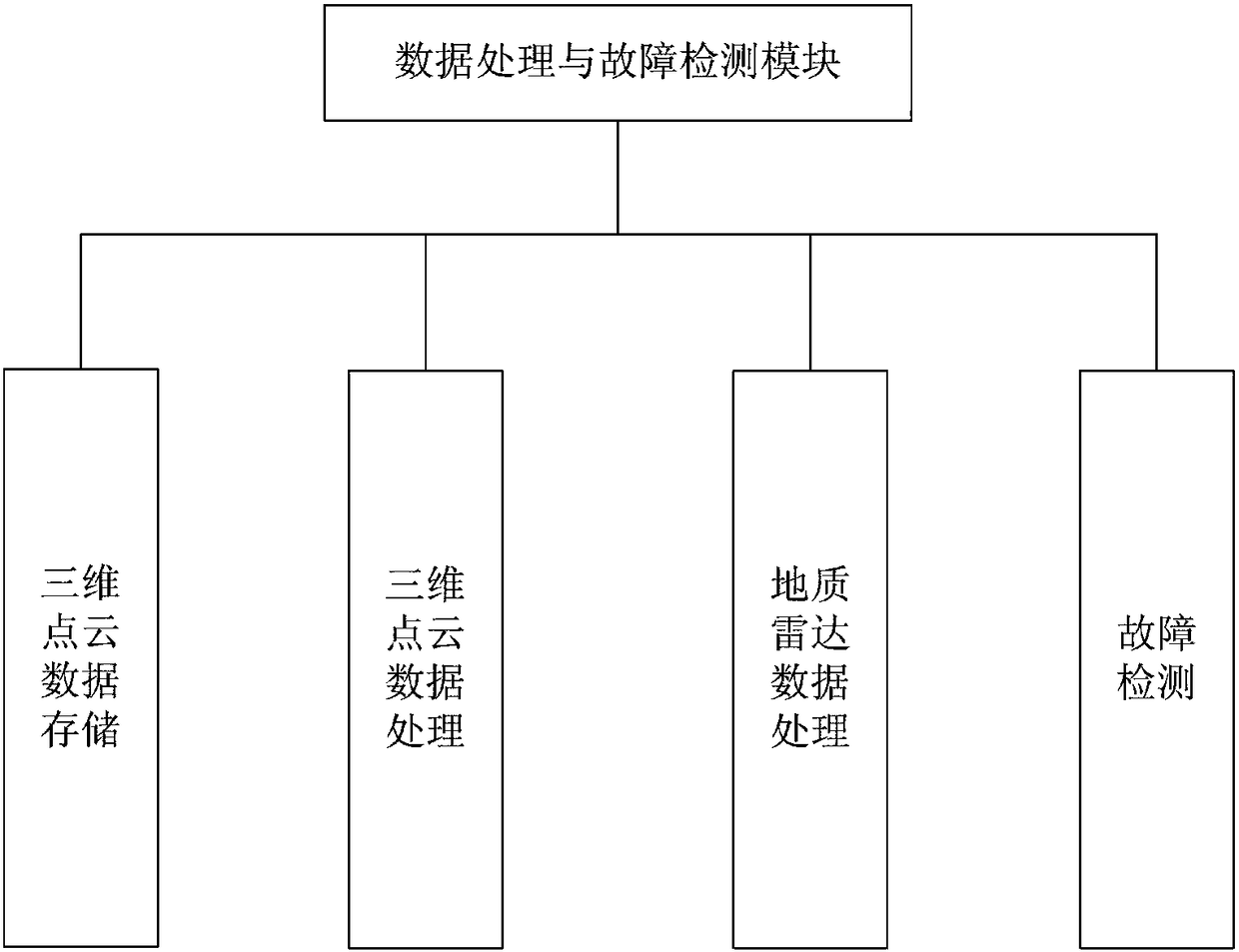

InactiveCN108318499AImprove securityNo need to occupyMaterial analysis using wave/particle radiationOptically investigating flaws/contaminationRadarDimensional modeling

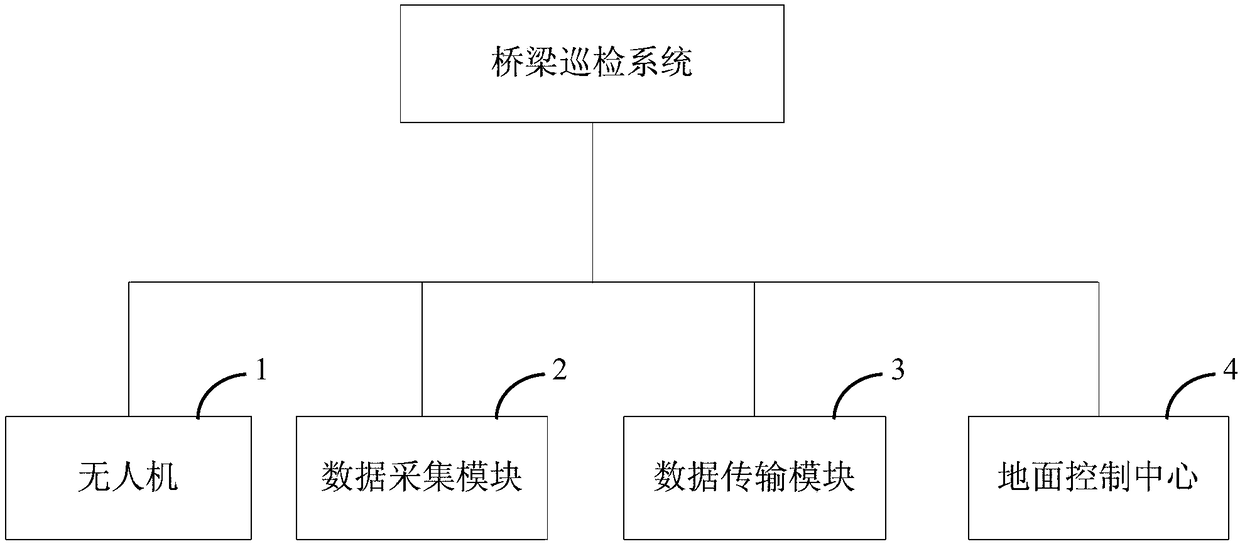

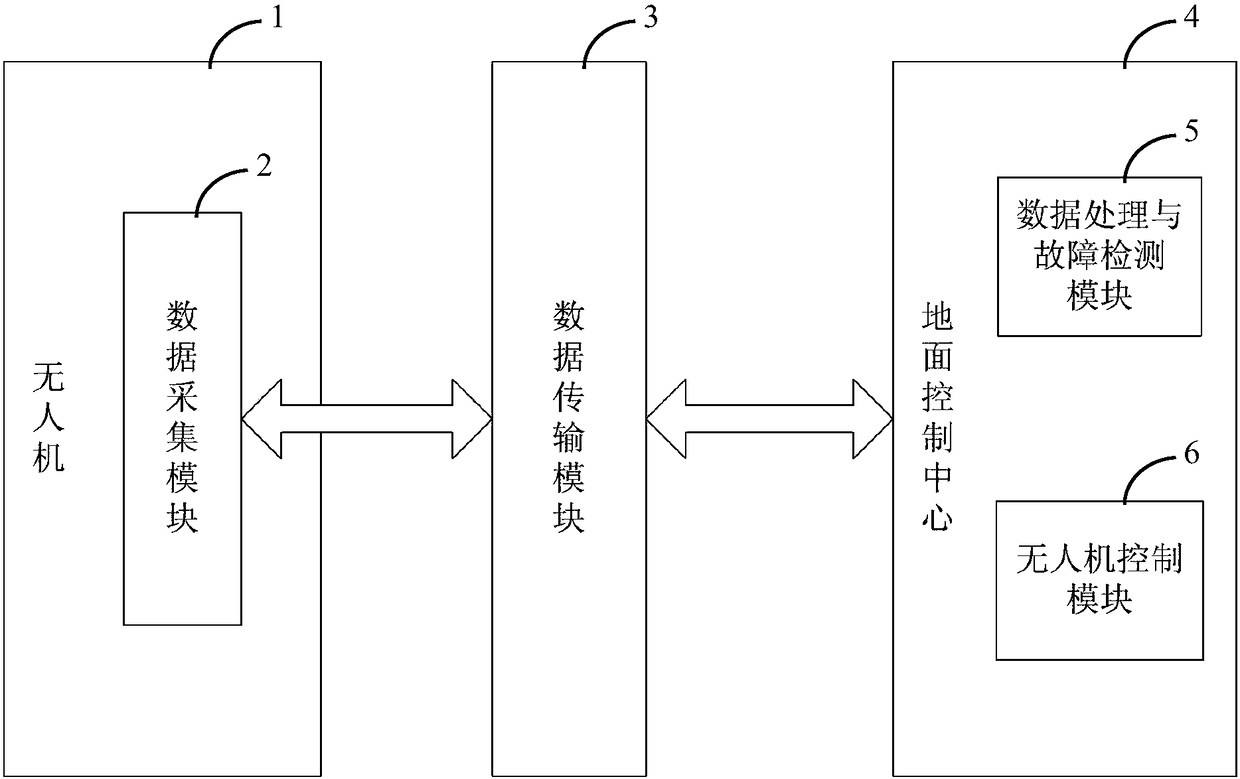

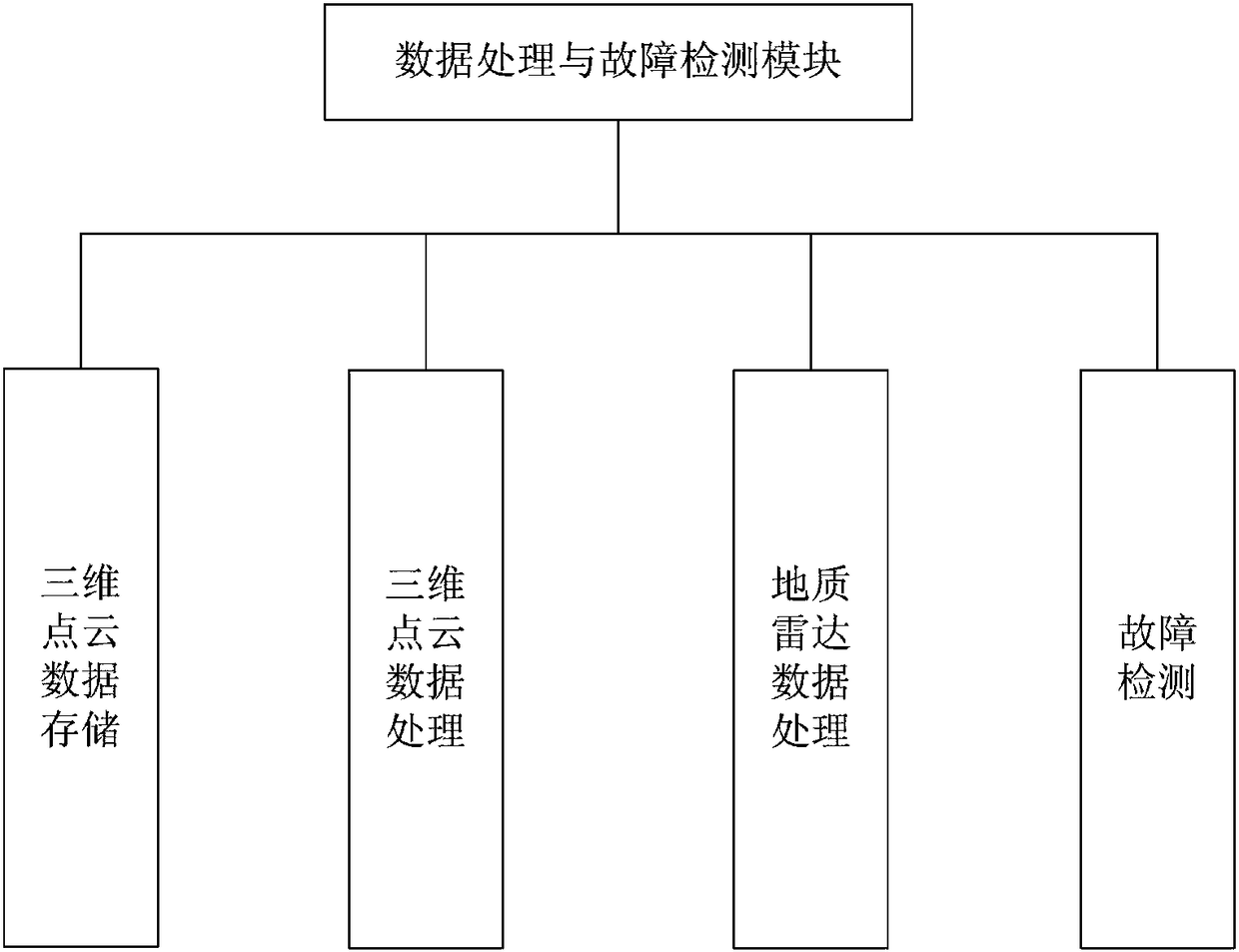

The invention discloses a bridge inspection method. The bridge inspection method comprises the following steps: acquiring field data of a bridge by an unmanned aerial vehicle through a laser three-dimensional scanner and a geological radar which are mounted thereon, sending the field data acquired by the unmanned aerial vehicle to a ground control center through a data transmission module, processing laser three-dimensional scanning data acquired by the laser three-dimensional scanner to complete three-dimensional modeling of a detected area of the bridge and processing radar echo data acquired by the geological radar by a data processing and fault detection module of the ground control center, and analyzing the three-dimensional modeling and the radar echo data to detect defects of the bridge and positions of the defects by the data processing and fault detection module. By the bridge inspection method, the technical problems of high cost, low efficiency, single means and low reliability of the existing bridge inspection method can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

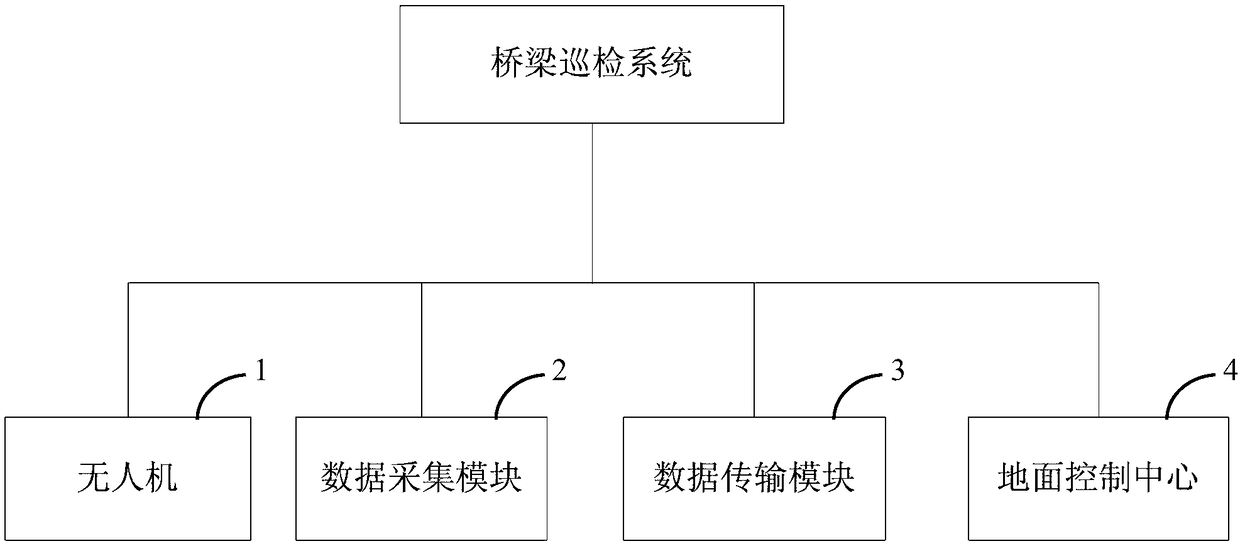

Unmanned aerial vehicle (UAV) bridge inspection tour system and inspection tour method

InactiveCN106054916AWide coverageForecastingPosition/course control in three dimensionsUncrewed vehicleRoute planning

The invention provides an unmanned aerial vehicle (UAV) bridge inspection tour system. An on-site control platform sets an unmanned aerial vehicle (UAV) flight route instruction and sends the UAV flight route instruction to an unmanned aerial vehicle (UAV) aerial platform, the UAV aerial platform flies according to the flight route instruction, the on-site control platform sends an information acquisition instruction to the UAV aerial platform when the UAV aerial platform flies to a specified position, and the UAV aerial platform completes bridge information acquisition through an information acquisition business terminal and saves the bridge information data; and the UAV aerial platform sends the bridge information data to a remote monitoring center, and the remote monitoring center analyzes and releases the bridge information data. The system achieves a function of an on-line implementation of autonomous route planning of a to-be-inspected bridge, has the advantage of a wide cover range, has the advantages of being simple, portable, flexible and so on, and can be widely applied to bridge floor inspection tour and other related industries.

Owner:HEFEI INST FOR PUBLIC SAFETY RES TSINGHUA UNIV +1

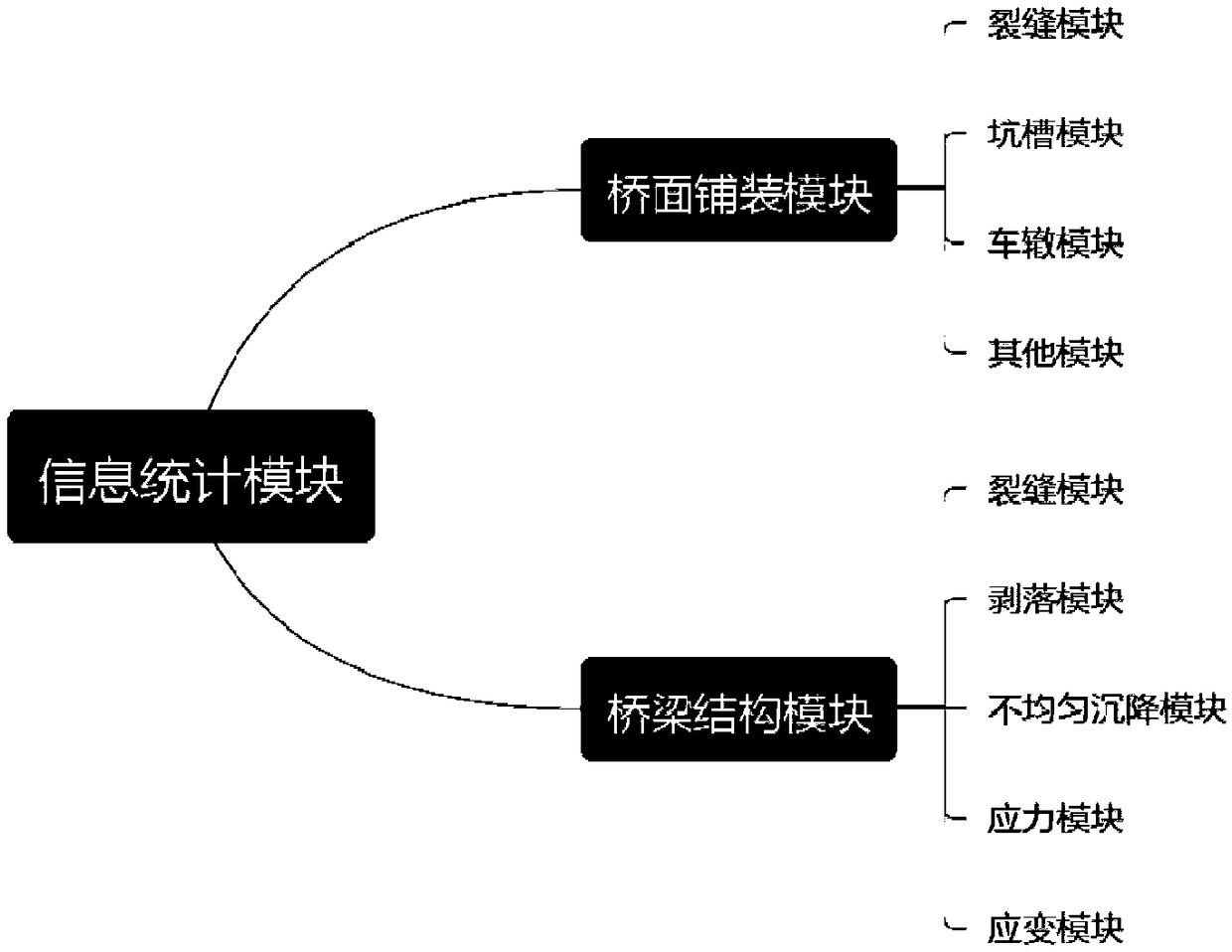

BIM-based bridge inspection information management method and system

ActiveCN107818227AAchieve integrationRealize static displayDesign optimisation/simulationSpecial data processing applicationsNon destructiveComputer module

The invention discloses a BIM-based bridge inspection information management method and system. The system comprises a non-destructive inspection module, a dynamic and static load testing module, a damage information BIM module, a detection vehicle information BIM module, a sensor information BIM module, a model intelligent conversion module, a technical condition evaluation module and a loading capacity state evaluation module. According to the system, the standardized recording and integrated management of various types of inspection information can be realized; the inspection information isconverted into three-dimensional visual information by virtue of a BIM technique, so that the visual expression of the inspection information is realized; and by converting a model, processing actualmeasurement information and calculating a theoretical value, the intelligent evaluation on multiple aspects of the technical condition, the loading capacity and the like of bridges is realized. According to the system, the defects that the information is fragmentized, the recording is nonstandard, the expression is not visual, the evaluation is asynchronous, and the like in traditional bridge inspection information management can be improved, and great convenience is provided for the bridge information management works.

Owner:XIAMEN UNIV

Bridge routing inspection system

The invention discloses a bridge routing inspection system, which comprises an unmanned aerial vehicle, a data transmission module, a ground control center and a data acquisition module carried on theunmanned aerial vehicle. The data acquisition module comprises a laser three-dimensional scanner and a geological radar. The unmanned aerial vehicle collects field data of a bridge through the laserthree-dimensional scanner and the geological radar. Field data collected by the unmanned aerial vehicle are sent to the ground control center through the data transmission module. The data processingand fault detection module of the ground control center processes laser three-dimensional scanning data collected by the laser three-dimensional scanner, so that the three-dimensional modeling of thedetected area of the bridge is completed. Meanwhile, radar echo data collected by the geological radar are processed. The data processing and fault detection module analyzes three-dimensional modelingand radar echo data, detects the defect of the bridge and the position of the defect of the bridge. According to the invention, the technical problem that an existing bridge inspection mode is high in cost, low in efficiency, single in means and low in reliability can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

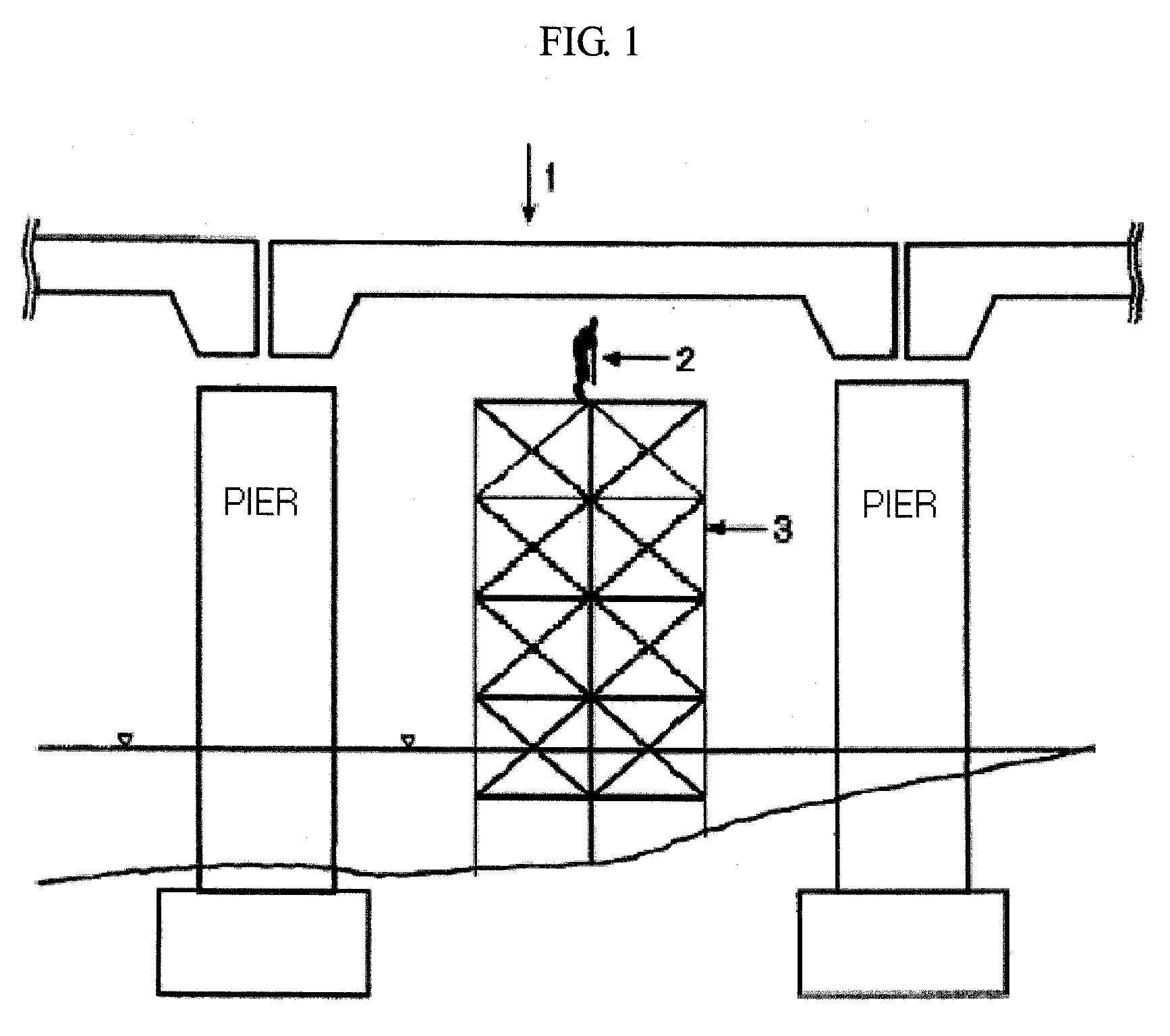

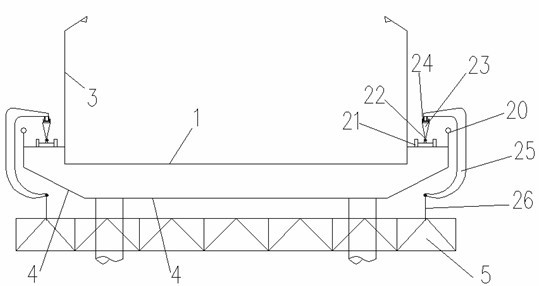

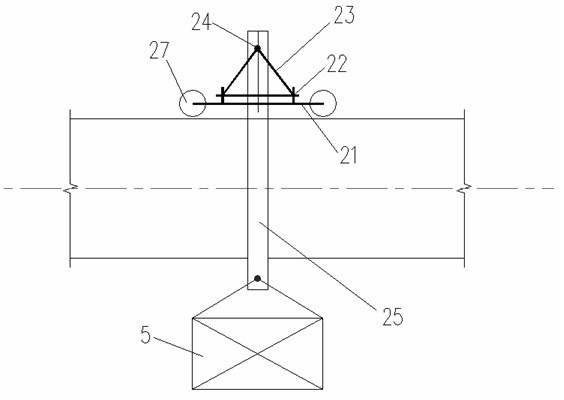

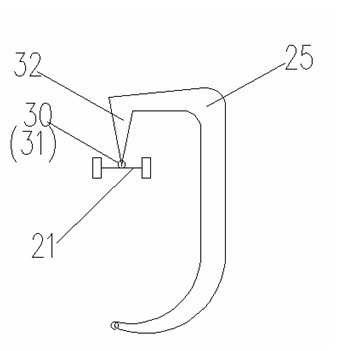

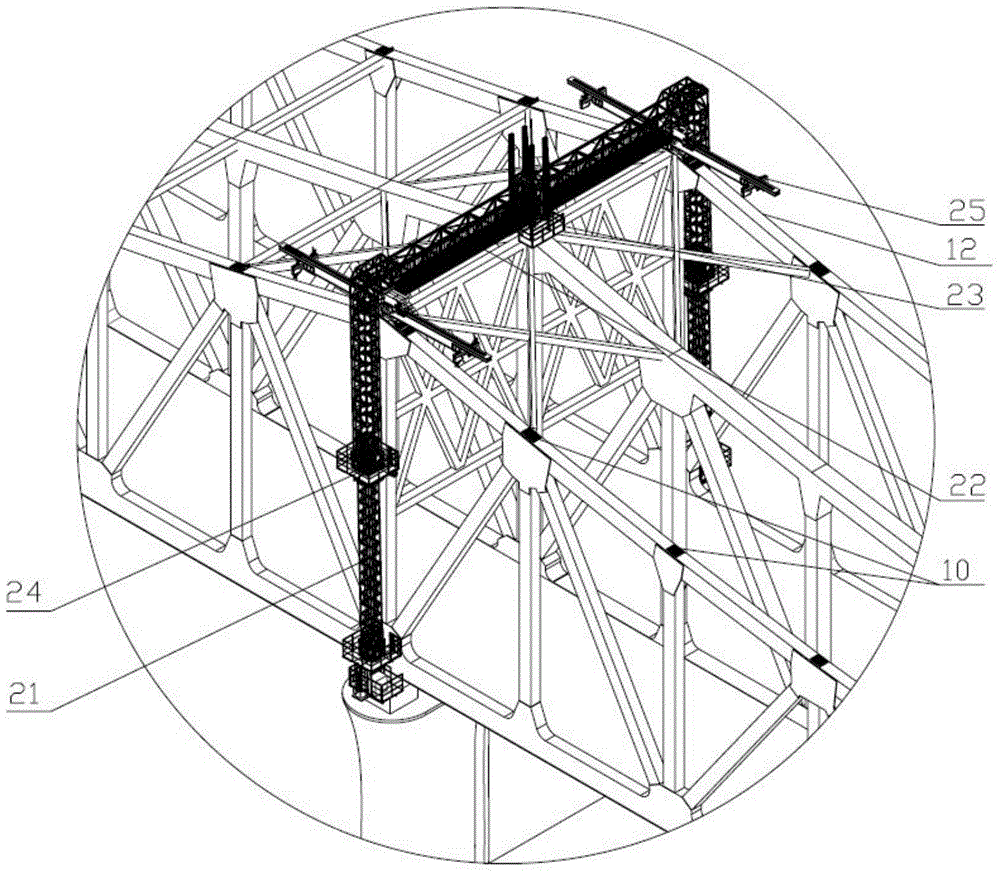

Hanger articulated bridge inspection vehicle

The invention discloses a hanger articulated bridge inspection vehicle, belonging to bridge maintenance and construction equipment. The hanger articulated bridge inspection vehicle comprises a frame chassis (21), a suspension arm is a C-type hanger (25), the frame chassis (21) is articulated with the lower end of a pillar (23) by a longitudinal axis hinge (22) and a longitudinal axis, the upper end of the pillar (23) is articulated with the protruded end of an upper cross beam of the C-type hanger (25) by a transverse axis hinge (24) and a transverse axis, or the frame chassis (21) is articulated with the protruded end of the upper cross beam of the C-type hanger (25) by the longitudinal axis hinge (22) and the longitudinal axis, and the protruded end of a lower cross beam of the C-type hanger (25) is at least provided with a fixed point of a lifting rope (26) or a lifting rope extending-retracting device. According to the invention, the pulling force of the lifting rope (26) on an inspection platform (5) can be directly transferred to a bridge floor (2), therefore, the vehicle disclosed by the invention is small in overturning moment, light in structure and convenient to assemble and use, and can be erected on sidewalks on both sides of a bridge, so that the vehicle is especially suitable to be applied to the bottom detection and maintenance engineering of heavy traffic bridges.

Owner:WUDA JUCHENG STRUCTURE CO LTD

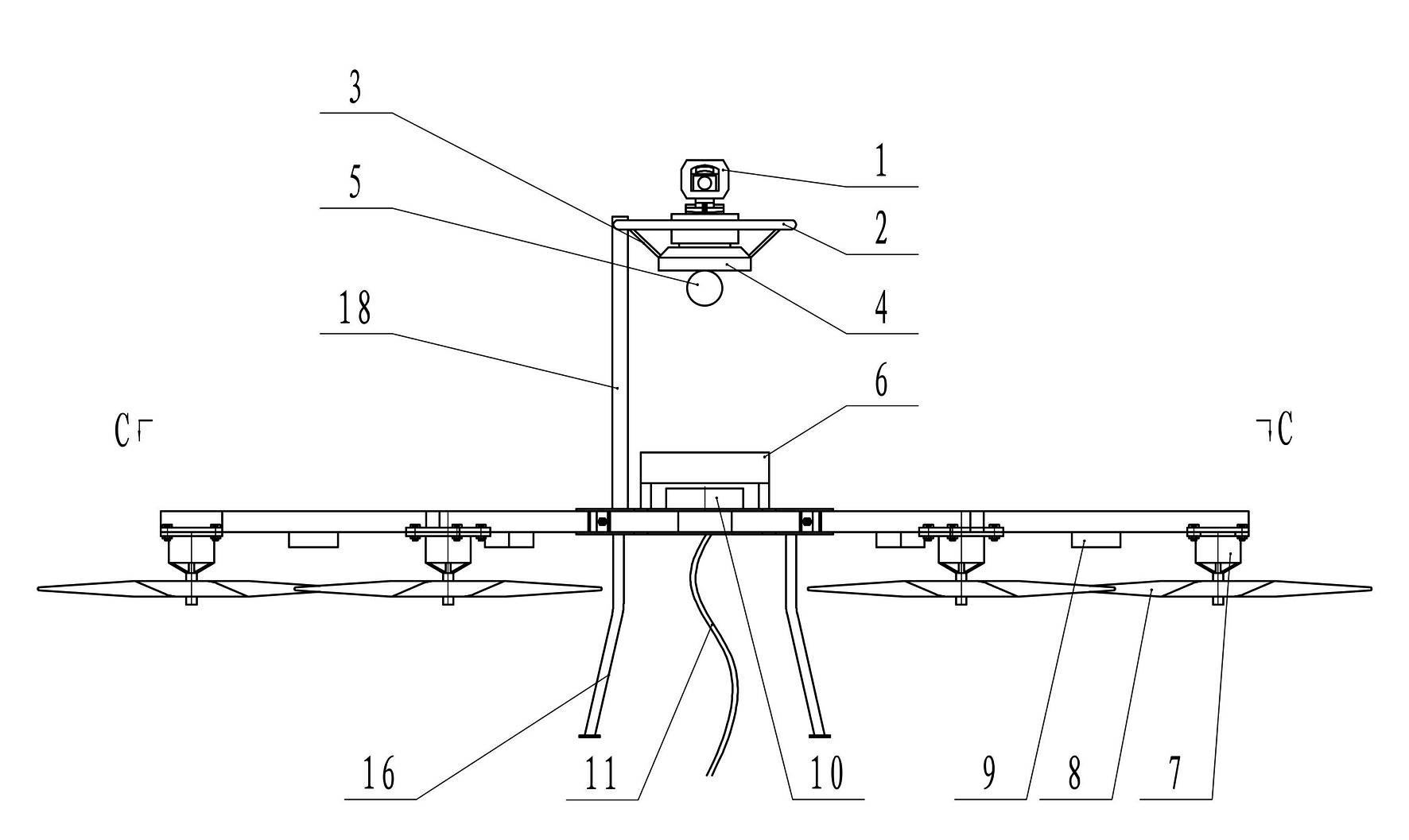

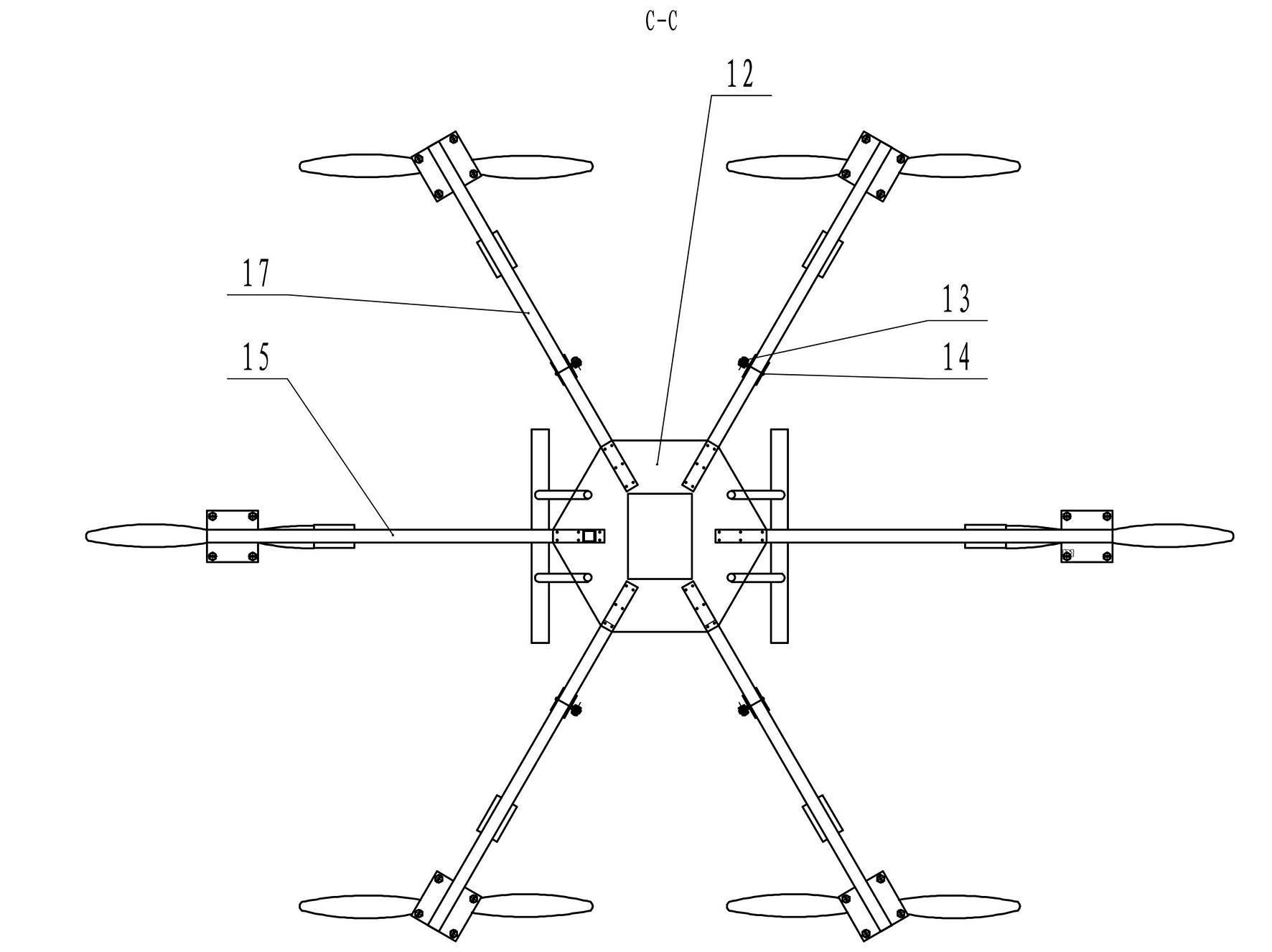

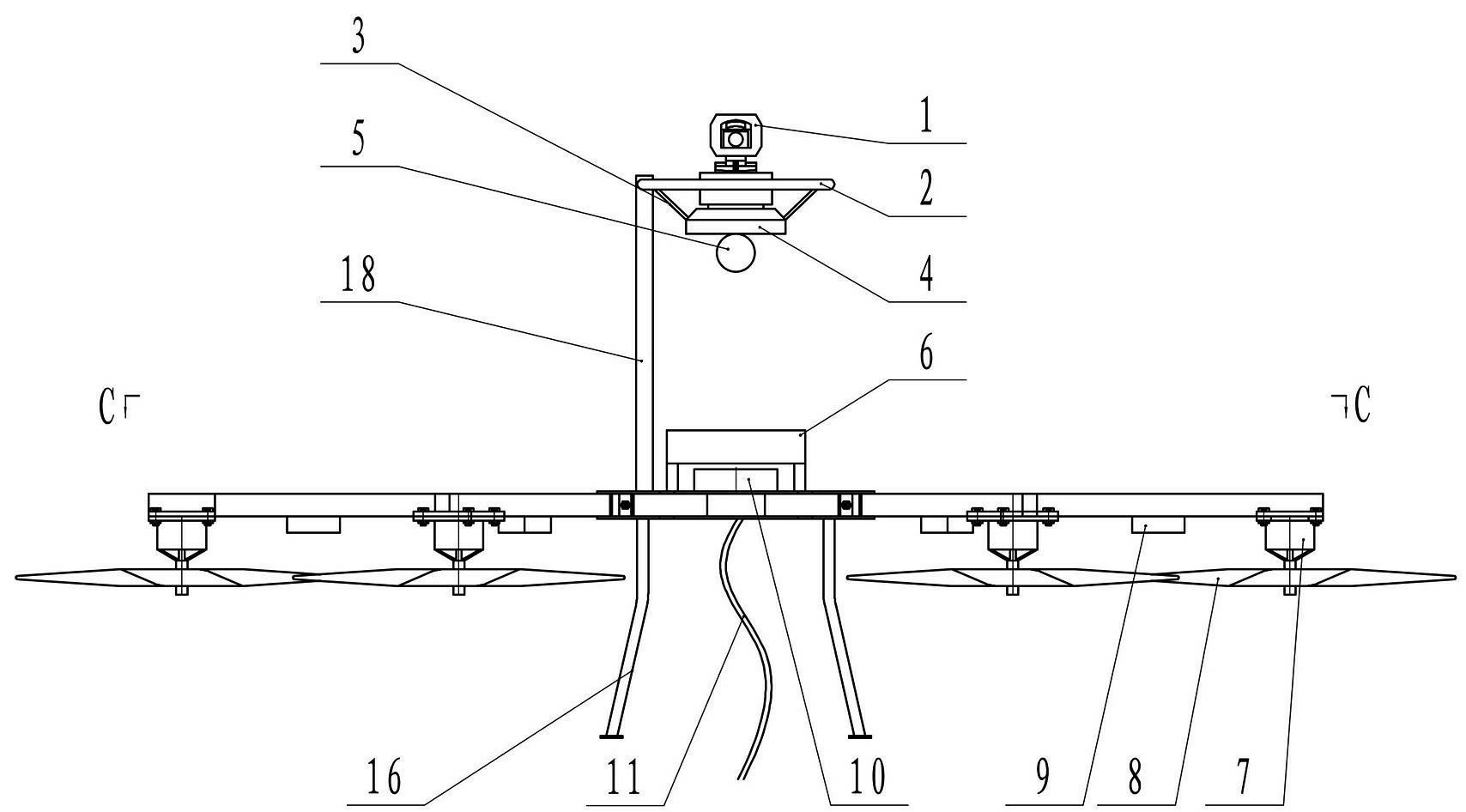

Multi-shaft video electric aerocraft for bridge inspection

InactiveCN102627145AReduce weightReduce noiseEfficient propulsion technologiesPower plant typeElastic componentVideo transmission

The invention relates to a multi-shaft video electric aerocraft for bridge inspection, which comprises an aerocraft and an aerial shooting system, wherein the aerocraft comprises an aerocraft rack, a flight control unit, supporting legs and 4-12 supporting beams; the aerial shooting system comprises a camera, a camera rack, an elastic component, a cradle head, a gyrostabilizer and a video transmission and camera cradle head controller; an upright post is fixed on the aerocraft rack, a camera ring stand is installed on the upright post, the camera, the cradle head and the gyrostabilizer are fixed on the camera ring stand by the elastic component, and the video transmission and camera cradle head controller is installed on the aerocraft rack; and the power line of a motor is connected with a power supply on the ground by a speed governor, a power terminal of the aerocraft and a power lead. According to the invention, the aerial shooting system is installed at the upper part of the aerocraft, and can inspect the beam body and support of the bridge, so that the bridge inspection is more convenient and quicker, and the bridge inspection efficiency and reliability are improved; and the aerocraft is powered by a wired manner, so that the flight load is reduced, ample power is provided for the aerocraft, and the aerocraft can fly in a stagnant manner in a limited airspace for a long time.

Owner:焦建民

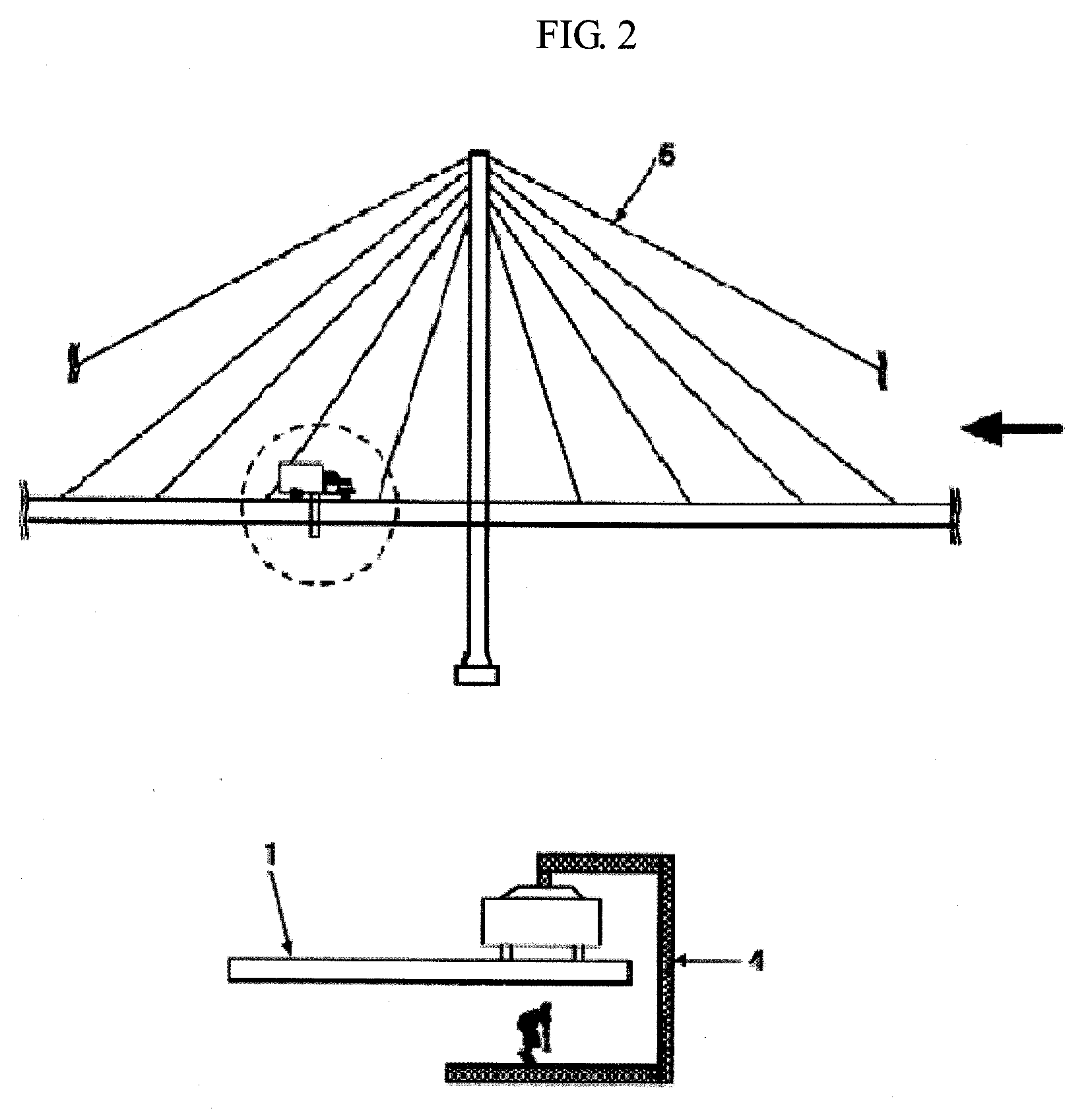

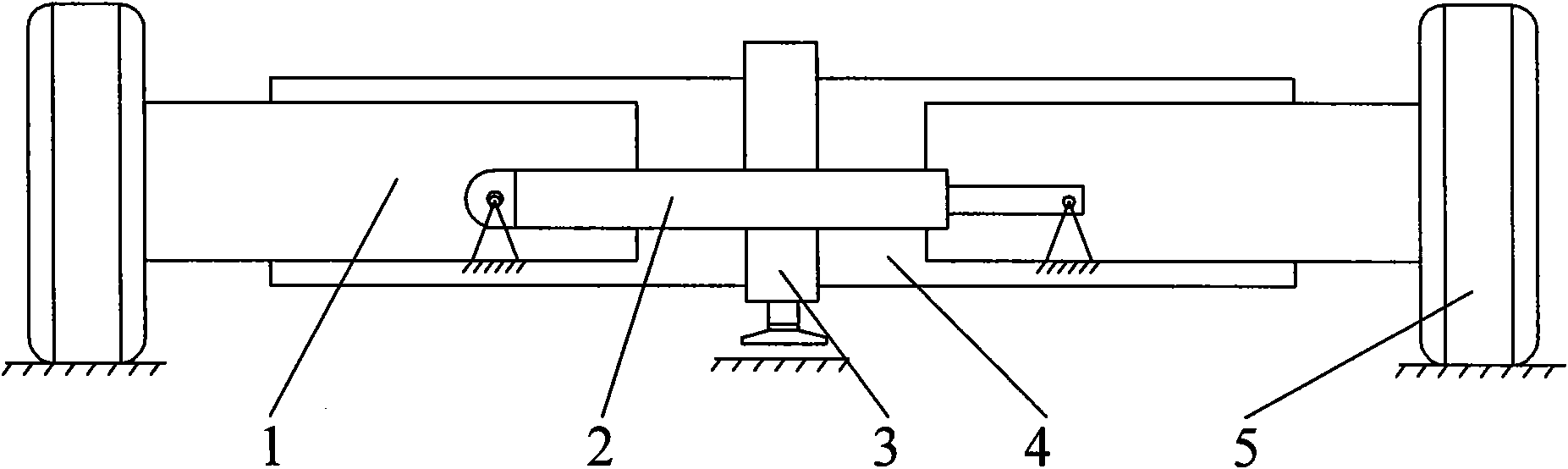

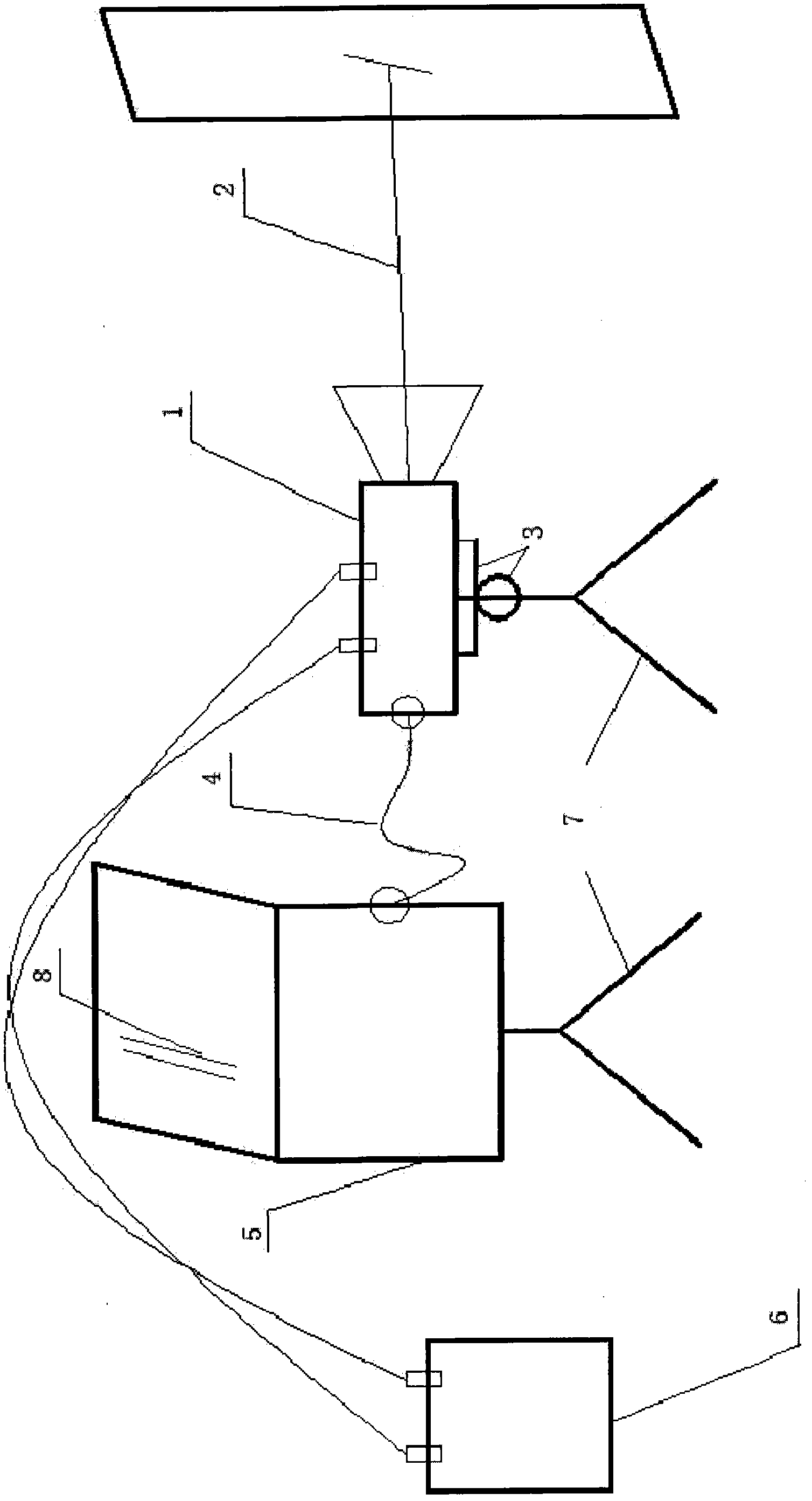

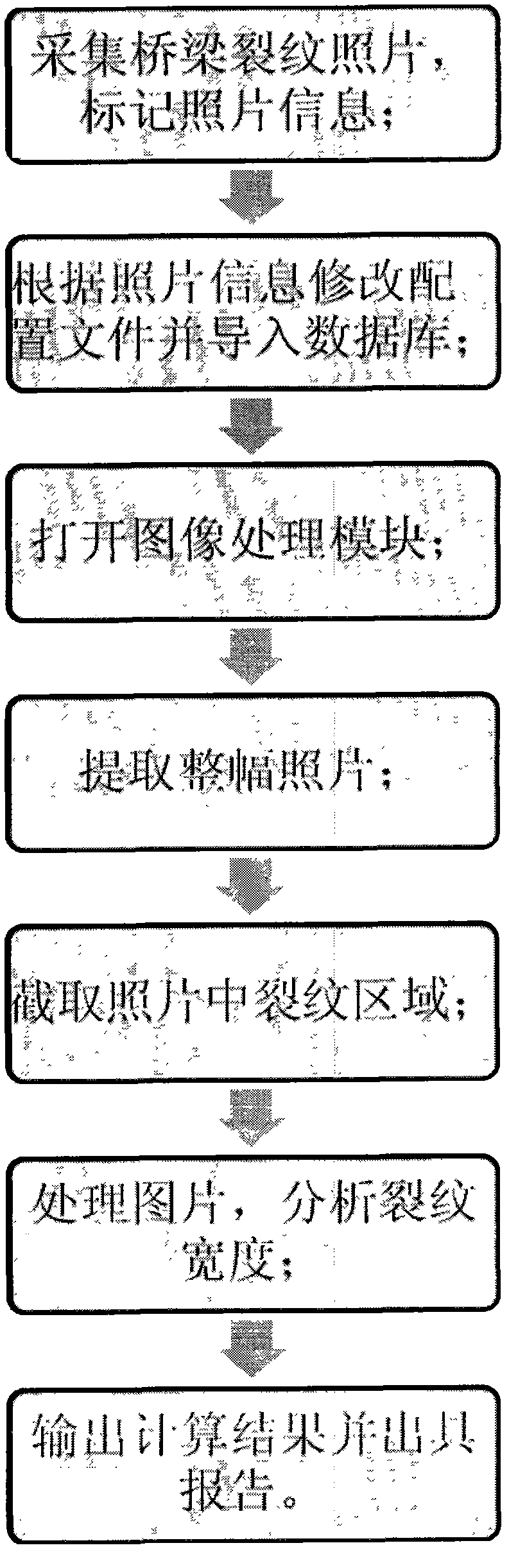

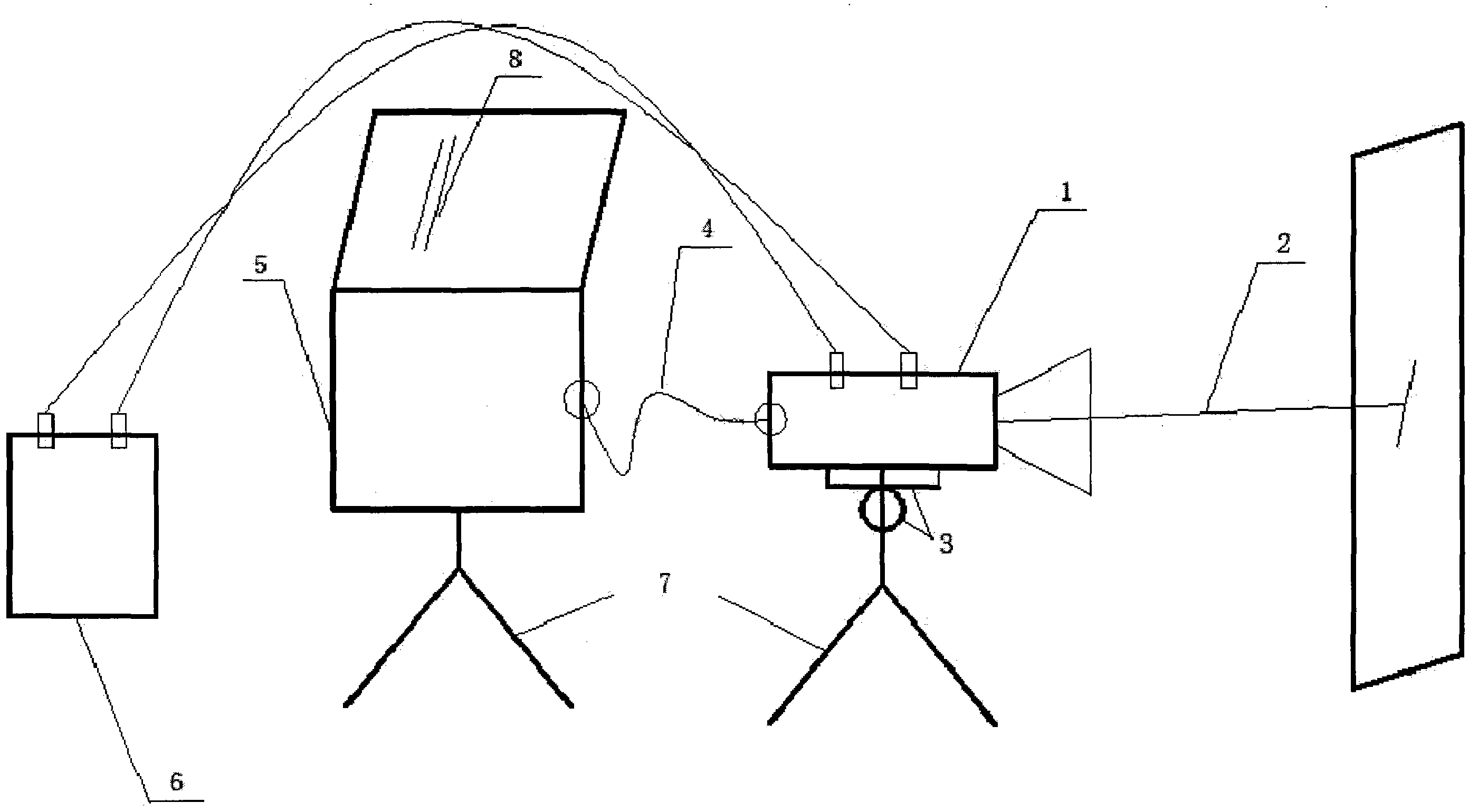

System for carrying out image acquisition and analysis on crack defects of bridge structure

InactiveCN102419331AEliminate hidden dangersSimple structureOptically investigating flaws/contaminationImaging processingHigh energy

The invention discloses a system for carrying out image acquisition and analysis on crack defects of a bridge structure. The system comprises a crack image acquisition subsystem, a crack analysis and database management subsystem and a power-supply and support subsystem, wherein the image acquisition subsystem mainly comprises a crack imaging device (1), a distance sensor (2), an angle sensor (3) and a data transmission device (4); the crack analysis and database management subsystem is composed of a portable computer (5) and a set of self-researched image processing and database management software; and the power-supply and support subsystem is composed of a high-energy battery (6) and a support platform (7). The system disclosed by the invention has the characteristics of high efficiency, rapidness and convenience, and can be widely used in the field of bridge inspection.

Owner:CHANGAN UNIV

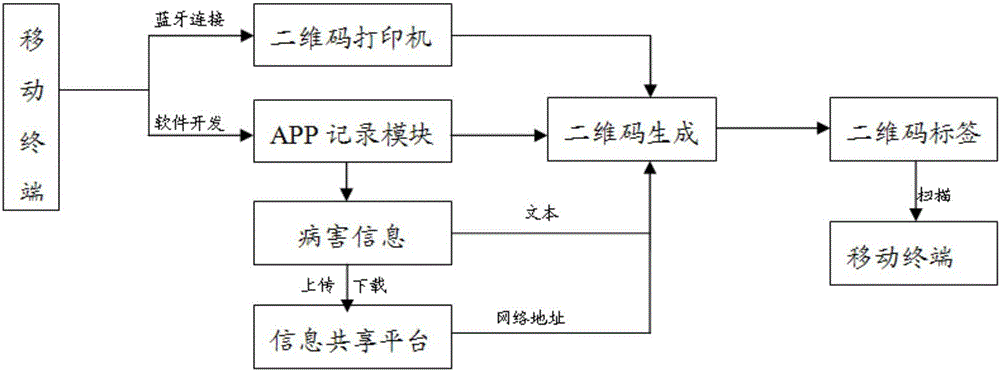

Digital characterization system of bridge onsite detected typical diseases

ActiveCN106556605ARealize digital recordsAchieve storageOptically investigating flaws/contaminationUsing optical meansDiseaseInformation sharing

The invention provides a digital characterization system of bridge onsite detected typical diseases. The system comprises a disease information recording module, a disease information generating module and a disease information sharing module, wherein the disease information recording module comprises a character recording sub-module, a standard table recording sub-module and a standard part unfolding picture recording sub-module. The system has the following advantages: (1) digital recording and storage of bridge onsite detected disease information are realized, long time, paper record sheet sorting, data processing and other tedious works of manual recording are solved, and the efficiency of onsite inspection, recording, data processing and other works is improved; and (2) the standardized recording of the bridge diseases is realized, that is: the standard table recording module uses a pre-established standard table template and the standard part unfolding picture module uses a standard part unfolding picture template to standardize the bridge diseases part number, position determination, the disease type code and the disease size representation technology in order to guarantee the professionality of bridge inspection.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

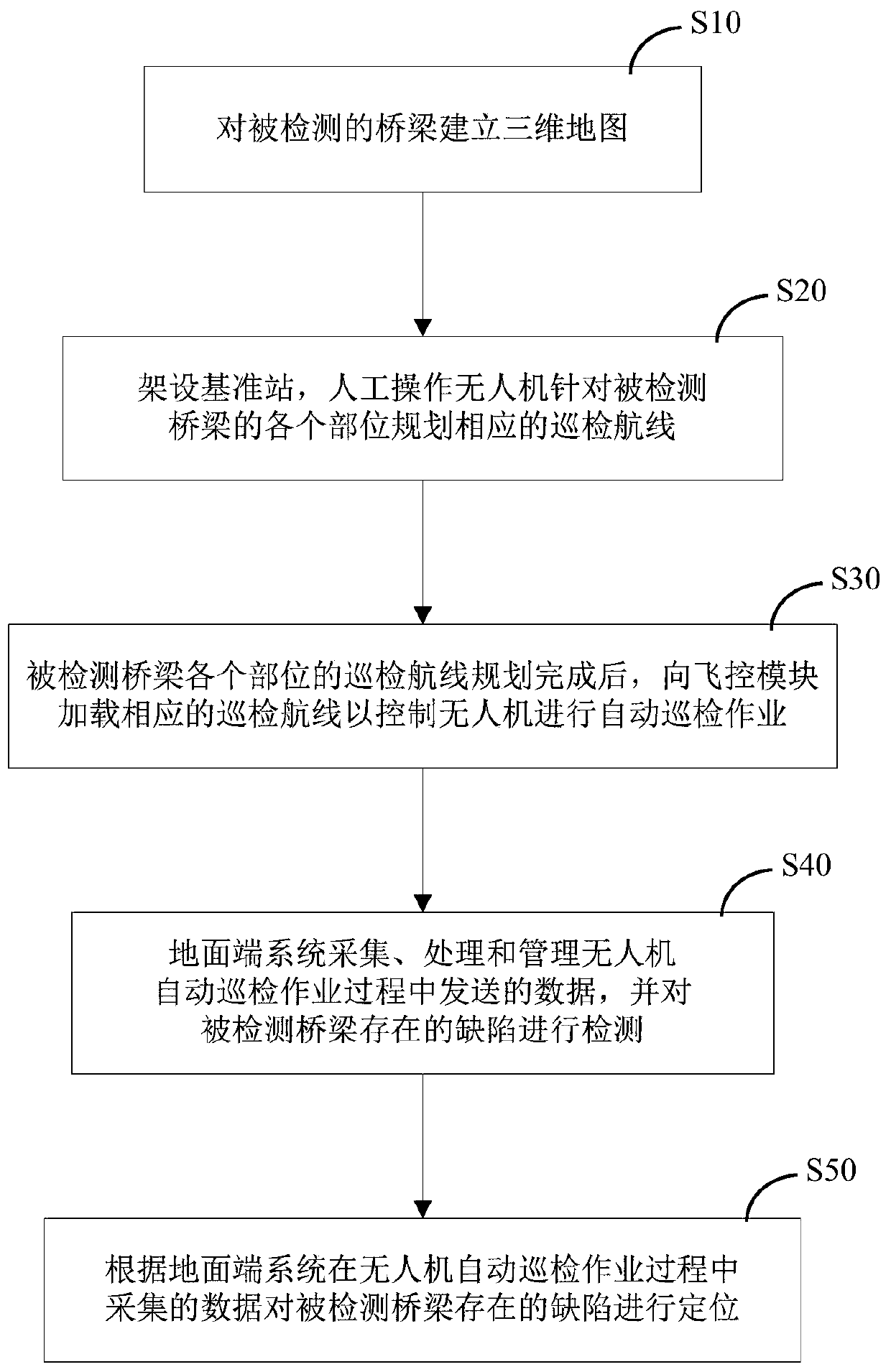

Bridge inspection method

InactiveCN109901624AHigh degree of automationImprove stabilityOptically investigating flaws/contaminationPosition/course control in three dimensionsUncrewed vehicleWorkload

The invention discloses a bridge inspection method comprising the following steps: S10, establishing a three-dimensional map of a detected bridge; S20, erecting a base station and controlling an unmanned aerial vehicle manually to plan corresponding inspection routes for all parts of the detected bridge; S30, after completion of inspection route planning of all parts of the detected bridge, loading a corresponding inspection route for a flight control module to control the unmanned aerial vehicle to carry out automatic inspection; S40, collecting, processing, and managing data sent by the unmanned aerial vehicle in an automatic inspection working process by a ground station and detecting defects existing in the detected bridge; and S50, locating the defects existing in the detected bridgeaccording to the data received by the ground station in the automatic inspection working process of the unmanned aerial vehicle. Therefore, technical problems that the automation degree is low, the workload is large, the stability of the acquired data is poor, and the safety is low because the existing UAV bridge inspection mode mainly relies on the manual operation for bridge surface data collection by the UAV are solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

Novel bridge inspection vehicle

InactiveCN102733300ASimple structureEasy to manufactureBridge structural detailsBridge erection/assemblyCoupling systemCantilever

The invention relates to a novel bridge inspection vehicle, which is a travelling crane applied to inspection of the inner side or bottom of a truss bridge in a manner of a rotary folding vehicle body. The inspection vehicle body is composed of a middle vehicle body and additional vehicle bodies on cantilevers at two sides together, wherein the vehicle body and the additional vehicle bodies are mutually connected through a rotating hinge and a fixing pin, and a wheel mechanism is arranged above the vehicle body. The inspection vehicle walks and works under the track on which the bridge is vertically arranged in an unfolding manner in general; a hand shank is rotationally opened and closed when the inspection vehicle comes across a lateral coupling system member in a truss or a pier support; and the additional vehicle bodies on the cantilevers at two sides horizontally rotate oppositely, and are overlapped on the front and back parts of the vehicle body, and the vehicle body is folded and shortened into 1 / 3 of original length and then traverses an obstacle. According to the invention, an inspection work surface is expanded and the inspection vehicle can extend to the outer side of the truss to work. The distance between the tracks is wide, and the vehicle body and the tracks are directly connected by the wheels, so the inspection vehicle is stable in structure when walking and working. The novel bridge inspection vehicle has the advantages of being simple in structure, convenient to use, economic and practical, and has been successfully applied to engineering practice.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

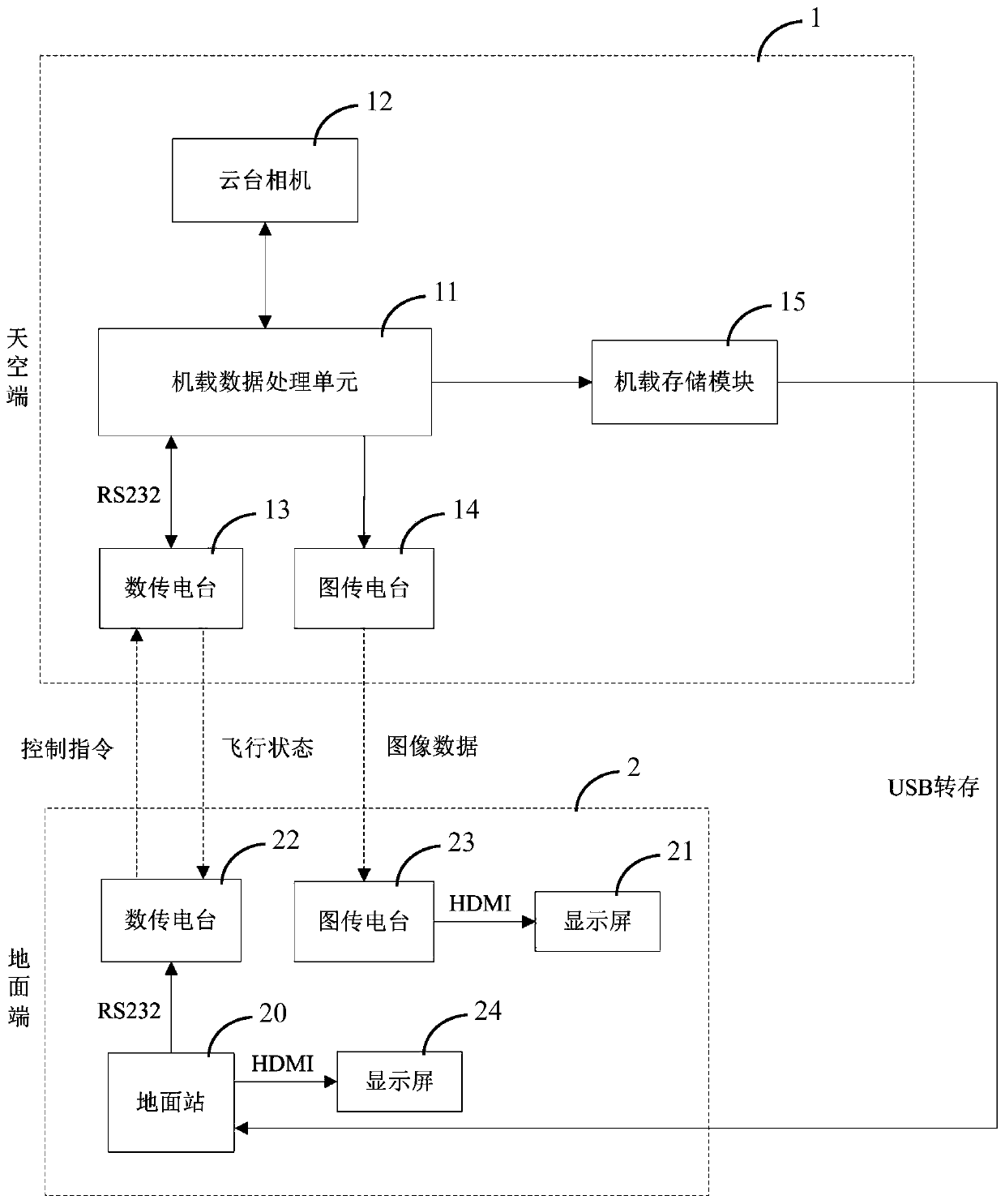

Bridge inspection system

ActiveCN109901625AHigh degree of automationImprove stabilityNavigational calculation instrumentsOptically investigating flaws/contaminationEngineeringGround station

The invention discloses a bridge inspection system. An unmanned aerial vehicle carries out first inspection on a bridge needing detection under the manual operation; a cloud desk camera carried out bridge surface data collection and generates an inspection route based on a positioning signal obtained by a positioning module; an unmanned aerial vehicle carries out inspection automatically based onan inspection route of a writing flight control module; an airborne data processing unit carries out processing based on data sent by an obstacle avoidance module; and the flight control module controls the unmanned aerial vehicle to carry out automatic obstacle avoidance emergency treatment. The cloud desk camera carries out video acquisition and image capturing according to set parameters in theautomatic inspection process; videos collected by the cloud desk camera are sent to a ground terminal system for display; and a ground station performs defect detection and positioning according to the captured images during the automatic inspection process. According to the invention, technical problems that the automation degree is low, the workload is large, the stability of the acquired datais poor, and the safety is low because the existing UAV bridge inspection mode mainly relies on the manual operation for bridge surface data collection by the UAV are solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

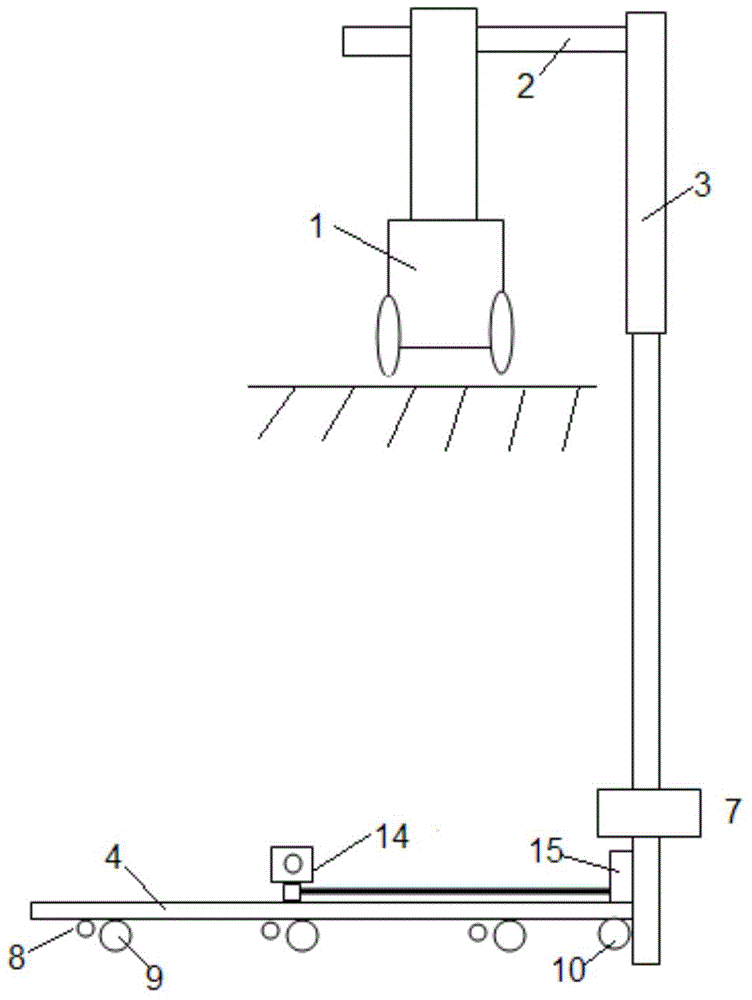

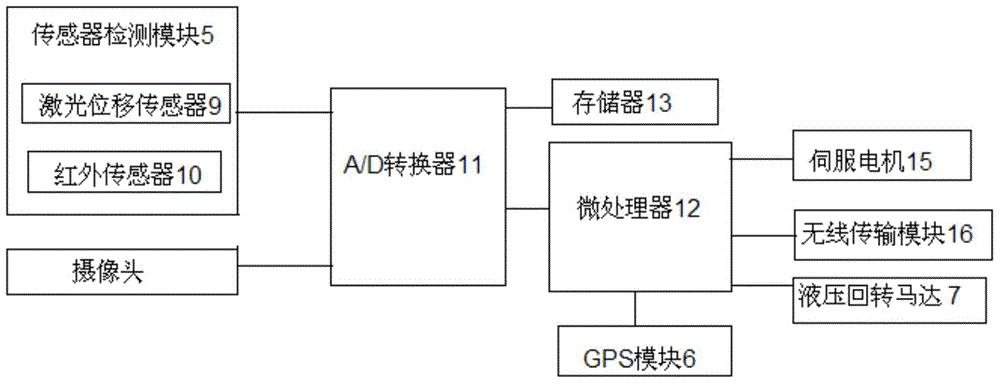

Intelligent bridge detection equipment

InactiveCN104878691AMonitor the situation at any timeImprove securityBridge structural detailsComputer moduleEngineering

The invention discloses intelligent bridge inspection equipment. The inspection equipment comprises a freely-traveling trolley, a first horizontal arm lever, a vertical arm lever, a second horizontal arm lever, a sensor inspection module and a GPS module; one end of the first horizontal arm lever is installed on the freely-traveling trolley, and the other end of the first horizontal arm lever is connected with the upper end of the vertical arm lever; the lower end of the vertical arm lever is connected with the second horizontal arm lever through a hydraulic rotary motor; the sensor inspection module comprises multiple laser displacement sensors which are distributed uniformly on the second horizontal arm lever and infrared sensors installed at the two ends of the second horizontal arm lever, and the output ends of the laser displacement sensors and the output ends of the infrared sensors are sequentially connected with an A / D converter, a microprocessor and a storer; the data transmission end of the microprocessor is connected with the data transmission end of the GPS module, and the output end of the microprocessor is further connected with the control end of the hydraulic rotary motor. According to the intelligent bridge inspection equipment, the structure is simple, useful data can be collected effectively, the data size is reduced, and the good application prospect is achieved.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

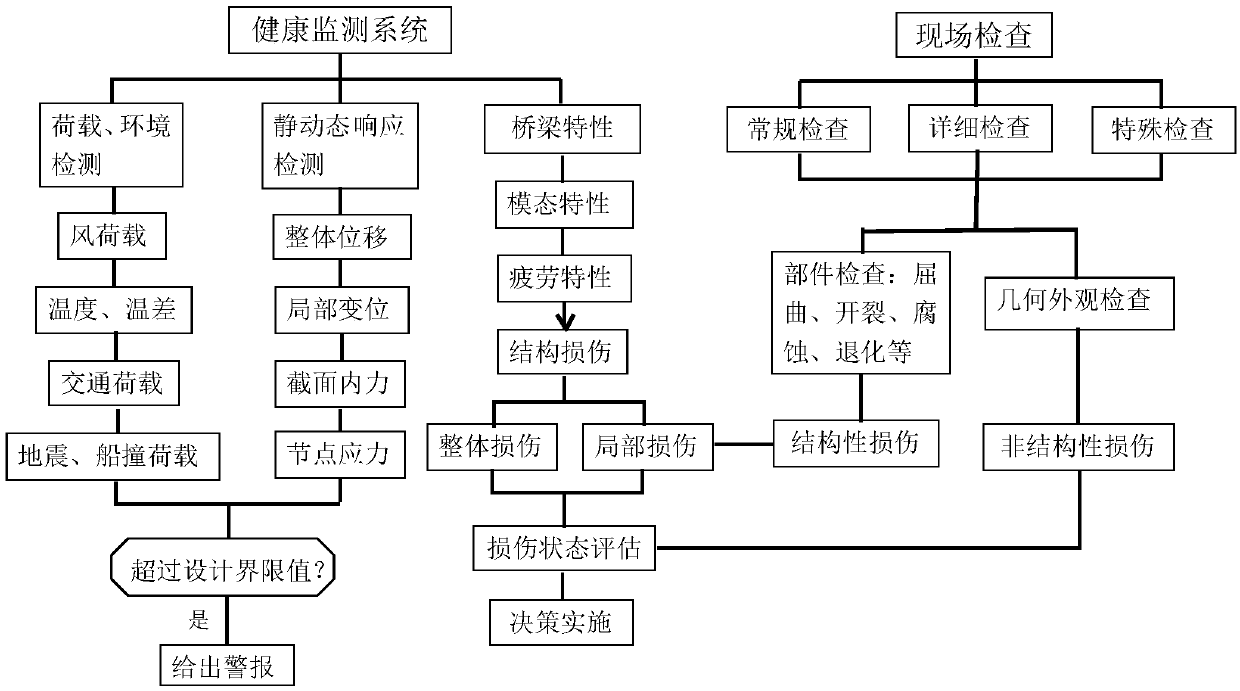

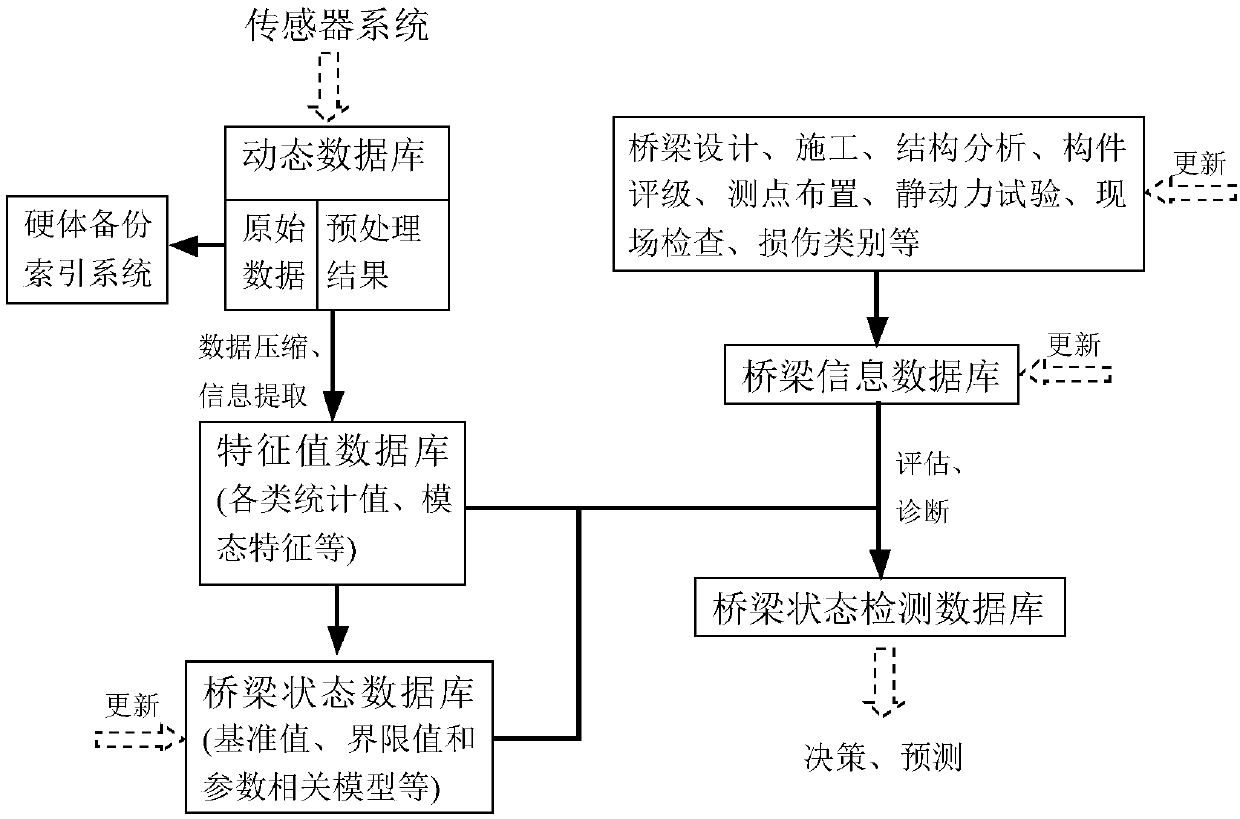

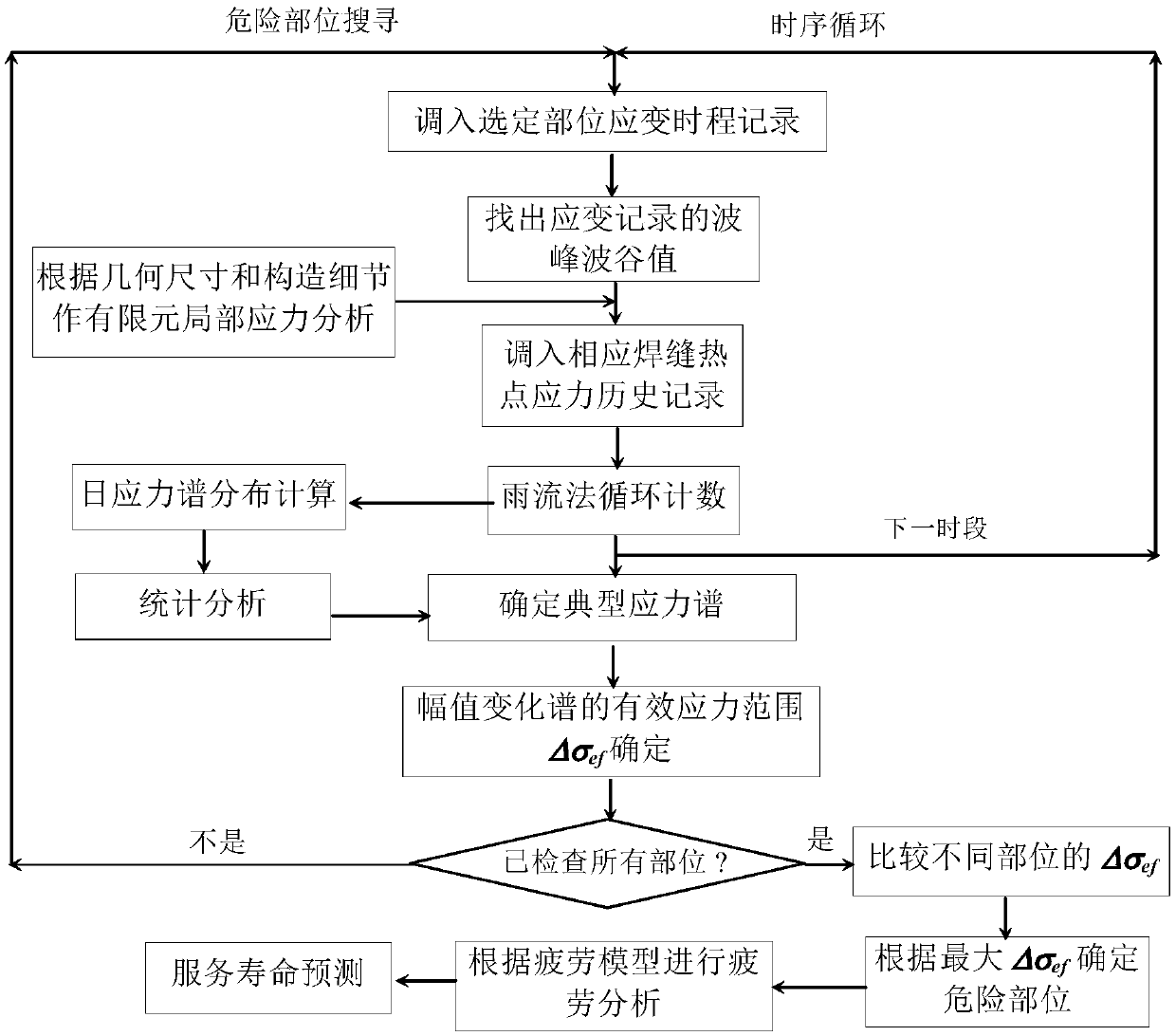

A bridge inspection and monitoring integrated health condition assessment system and a use method thereof

InactiveCN109559025AEffective maintenanceGuaranteed to workDigital data information retrievalDesign optimisation/simulationEngineeringUsability inspection

The invention discloses a bridge inspection and monitoring integrated health condition evaluation system and a use method thereof, belongs to the field of building bridges, and adopts the technical scheme that the bridge inspection and monitoring integrated health condition evaluation system comprises a health monitoring system and an on-site inspection part which are combined for use, and the health monitoring system comprises a data management system, a component rating system and a damage evaluation system; the data management system is used for managing detection data of the sensor systemand a preset database; the component rating system is used for rating importance, danger degree and vulnerability of the bridge components; the damage assessment system is used for assessing the damage assessment state; the on-site inspection portion includes conventional inspection, detailed inspection, and special inspection to evaluate a damage state of the component. The invention also discloses a use method of the system. The system has the advantages that the engineering decisions can be scientifically guided, effective maintenance, repair and reinforcement work can be carried out on thebridge, and the service life of the bridge is prolonged. The method is suitable for the bridge structure detection and monitoring.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

Road and bridge three-dimensional reconstruction method and apparatus based on unmanned aerial vehicle

ActiveCN105513119AShorten inspection cycleWill not affect traffic3D-image rendering3D modellingReconstruction methodUncrewed vehicle

The invention discloses a road and bridge three-dimensional reconstruction method and apparatus based on an unmanned aerial vehicle. An image acquisition system is carried by use of the unmanned aerial vehicle, sequence image data of roads and bridges is acquired through control of flight of the unmanned aerial vehicle, a road and bridge surface grid model is obtained through a subsequent image data processing process, and thus a basis is provided for treatment of road and bridge damage. Since the road and bridge surface grid model is constructed by acquiring the image data of the roads and bridges on the basis of the unmanned aerial vehicle, the road and bridge inspection period is greatly shortened, and traffic passage is not affected.

Owner:恒华数元科技(天津)有限公司

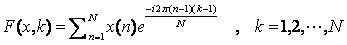

Moving load locating method used for bridge safety inspection

The invention provides a moving load locating method used for bridge safety inspection. A position of a moving load in a time path curve is determined by utilizing the traditional midspan vertical speed response time path signal. The cost of the bridge inspection is lowered without increasing additional special devices and the analysis of bridge kinetic response parameters is simpler, clearer andquicker. The moving load locating method is implemented by comprising the following steps of: carrying out a Fourier transform on a midspan vertical acceleration response time path signal x(t) of a bridge; corresponding a signal x(t) of a time domain to frequency domain space, and writing the signal x(t) as F(x, theta); selecting a weight function H(theta), weighting the F(x, theta), and writing the F(x, theta) as HF(x, theta); carrying out an inverse Fourier transform on the HF(x, theta), returning a signal in a frequency domain to time domain space, and writing the signal as F<-1>HF(x,t); and determining a moment of the moving load of the signal x(t) in the midspan. The moving load locating method used for the bridge safety inspection has an important significance to simplify test equipment for bridge load carrying capacity and lower test costs.

Owner:SUN YAT SEN UNIV

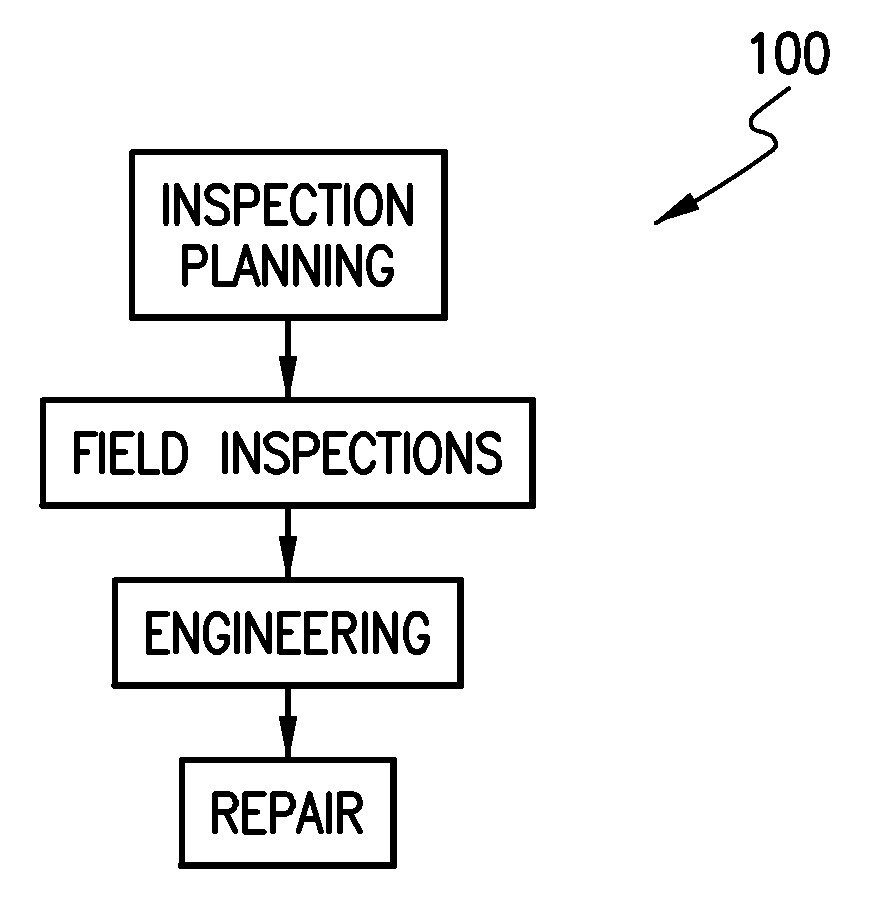

Bridge inspection diagnostic system

InactiveUS8527550B1Improve efficiency and efficacyImprove accuracyDigital data processing detailsSpecial data processing applicationsThe InternetComputer science

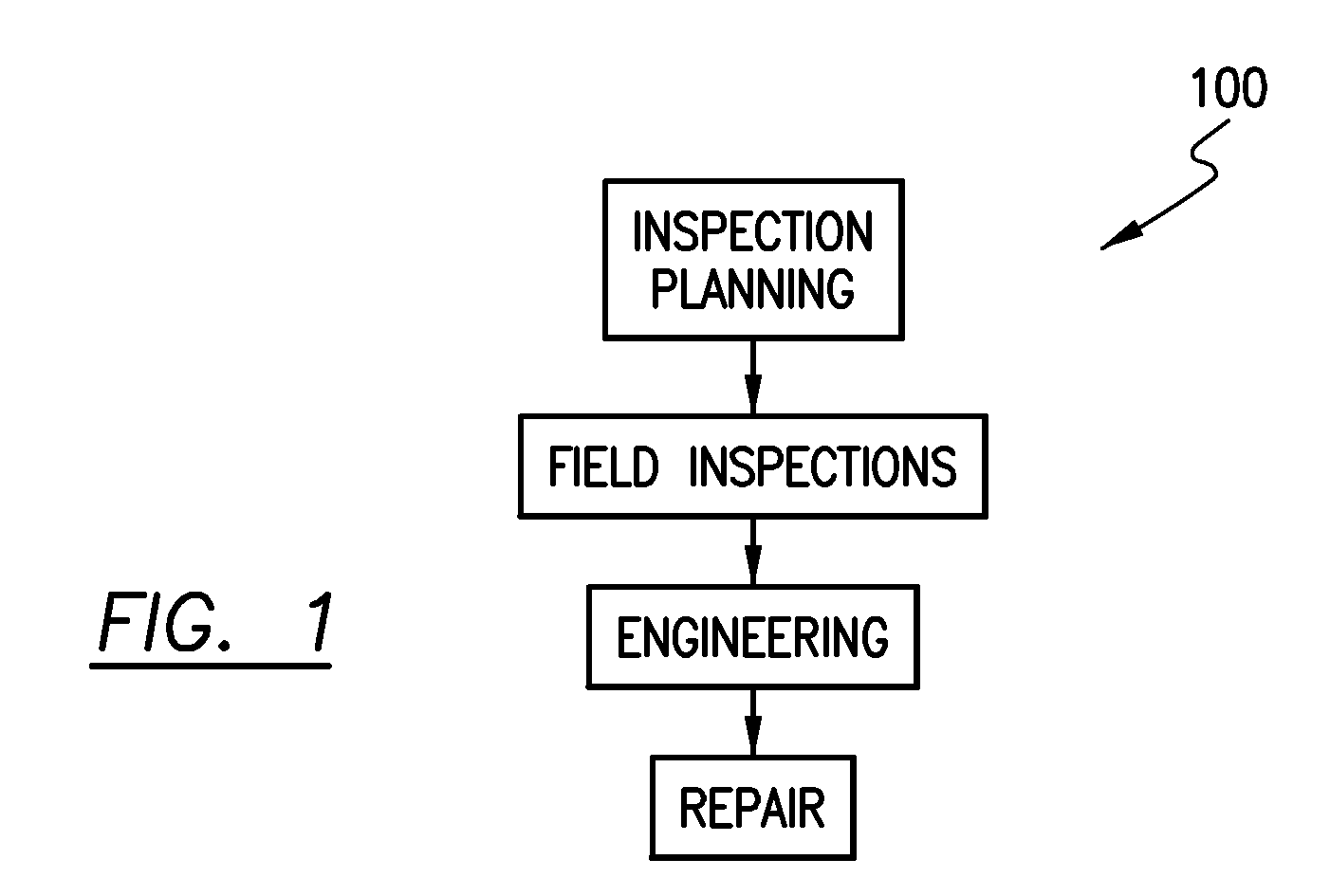

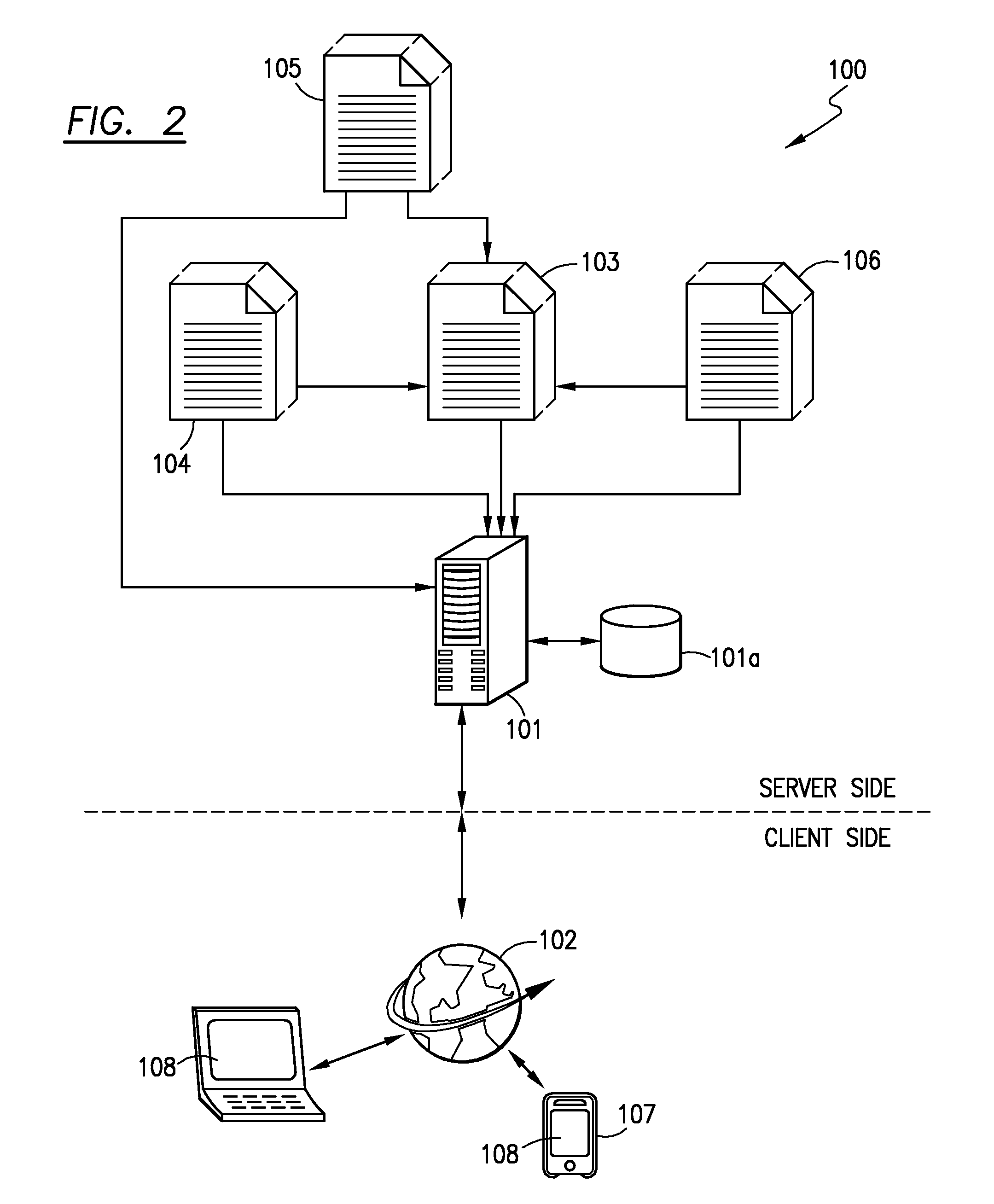

A Bridge Inspection Diagnostic System (“BIDS”) for improving the efficiency and efficacy of the operations of a bridge inspection and management department. BIDS is able to store, automatically index and cross references, and provide access to over the Internet all bridge related data, such as inspection related data, repair related data, and historical background related data that is necessary for the operations of a bridge inspection and maintenance department. This information, which can be uploaded from different locations, including on site at a bridge, and at different times, is automatically sorted by the BIDS engine such that all of such information relating to any bridge is easily accessible when other information for that bridge is accessed.

Owner:QUINTANA OSIRIS

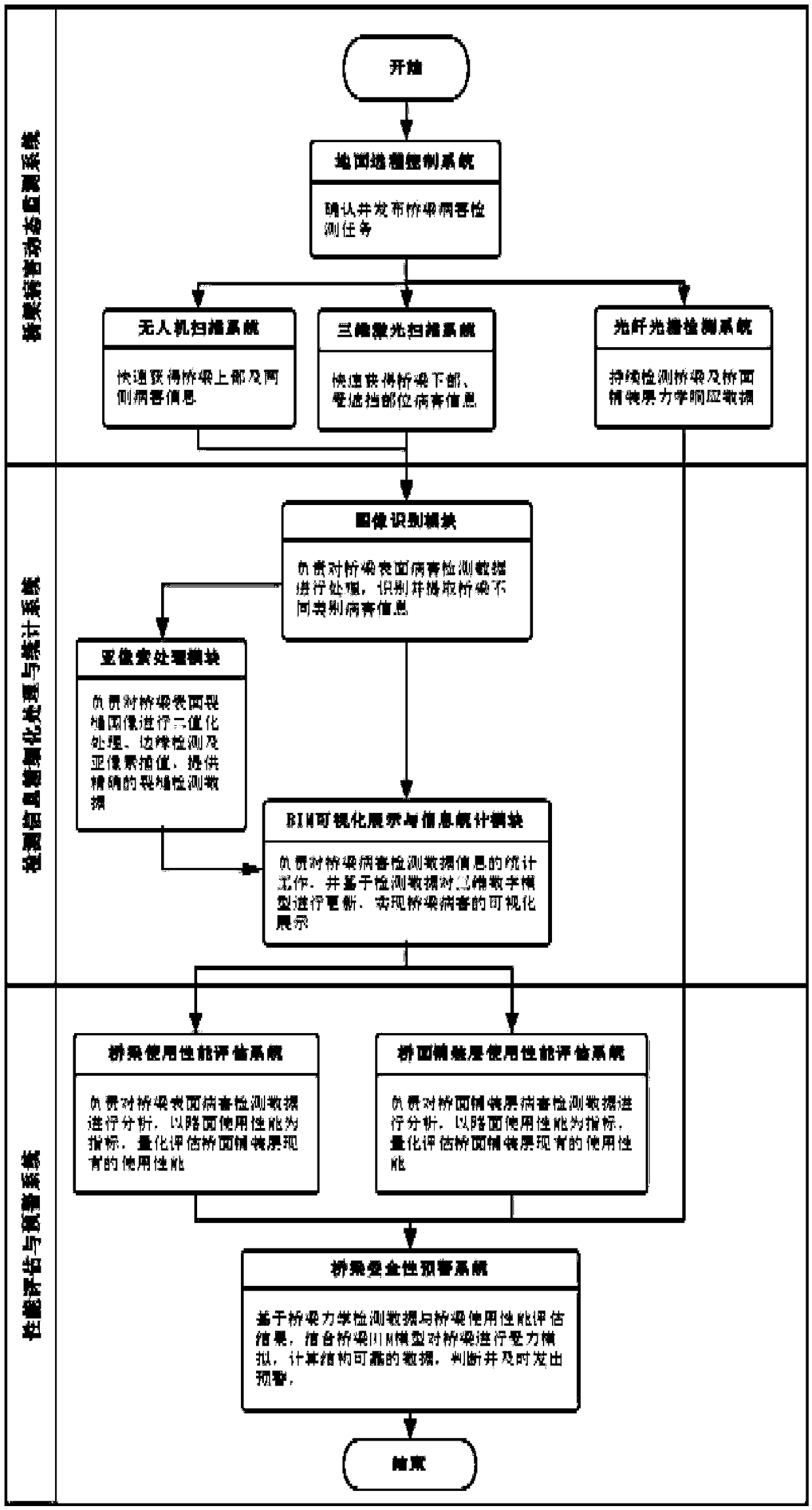

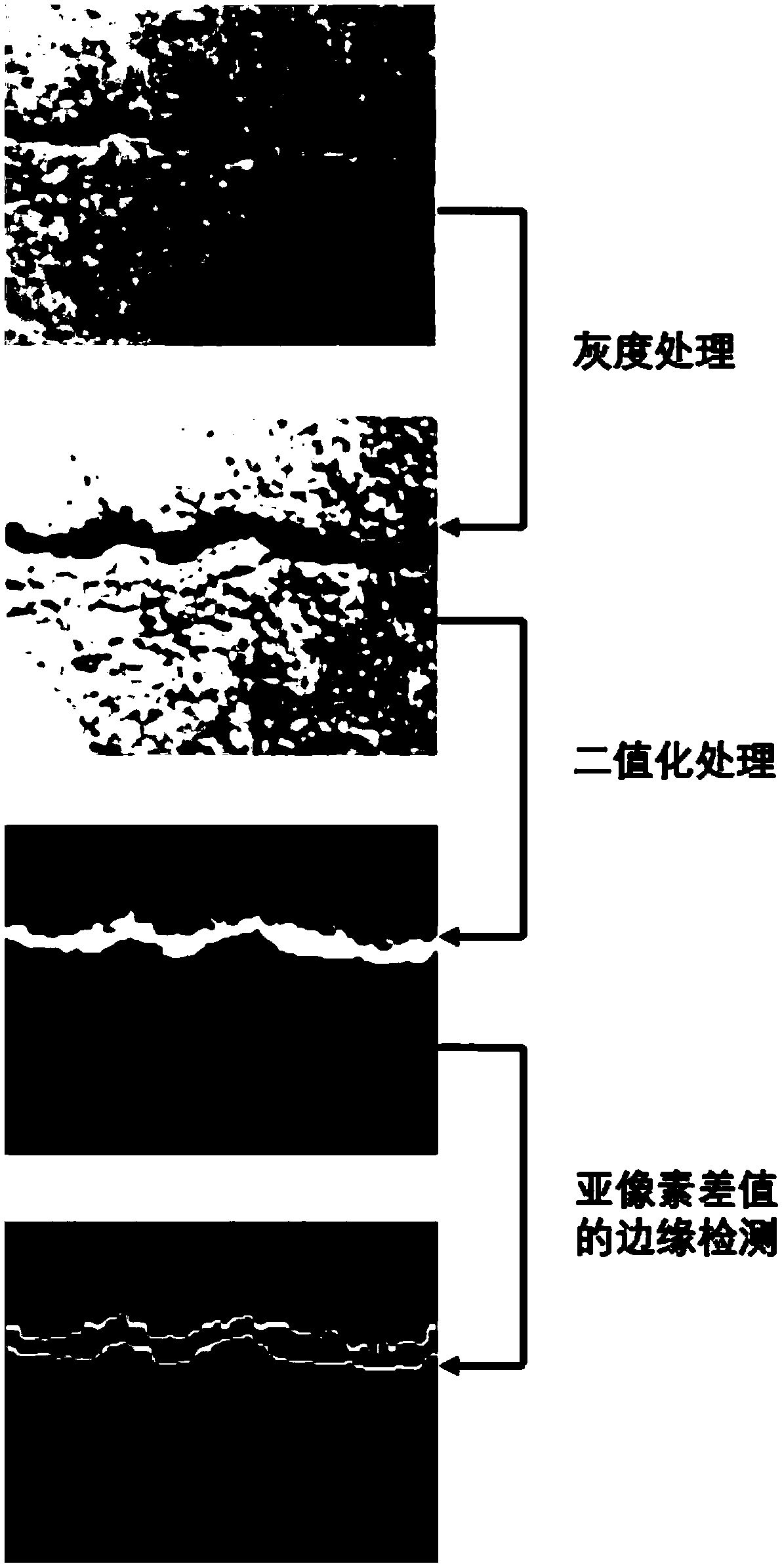

BIM-based multi-source detection system and detection method of operating bridge

ActiveCN109374043AImprove inspection efficiencyHigh precisionMeasurement devicesDesign optimisation/simulationImaging processingDecision system

The invention discloses a BIM-based multi-source detection system and detection method of an operating bridge. On the basis of the BIM technology, the unmanned aerial vehicle and the three-dimensionallaser detection technology are integrated into the bridge disease detection, so that the bridge inspection efficiency and precision are improved greatly. An image processing method based on a sub-pixel difference is proposed, so that a defect of poor precision of the existing hardware equipment is overcome to a certain extent. Therefore, the bridge operation and maintenance inspection efficiencyare improved substantially; the informationization and intelligence degrees of the operation and maintenance decision-making system of the bridge are increased; and thus operation and maintenance decision-making of the bridge becomes scientific.

Owner:常熟市交通工程管理处 +2

Rotary lifting maintenance platform

ActiveCN102817317AEasy to operateEasy to useBridge structural detailsPortal frameReliability engineering

The invention discloses a rotary lifting maintenance platform, which belongs to the technical field of the bridge inspection vehicle. The rotary lifting maintenance platform comprises a maintenance platform, wherein the maintenance platform is hinged to a truss system or a portal frame; an oscillating driving device is connected between the maintenance platform and the truss system; and the oscillating driving device can control the maintenance platform to oscillate in a manner relative to a hinge point. The rotary lifting maintenance platform disclosed by the invention has the advantages of simpleness in operation, convenience in use, high maintenance efficiency and safe and reliable performance and is suitable to popularize and apply.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

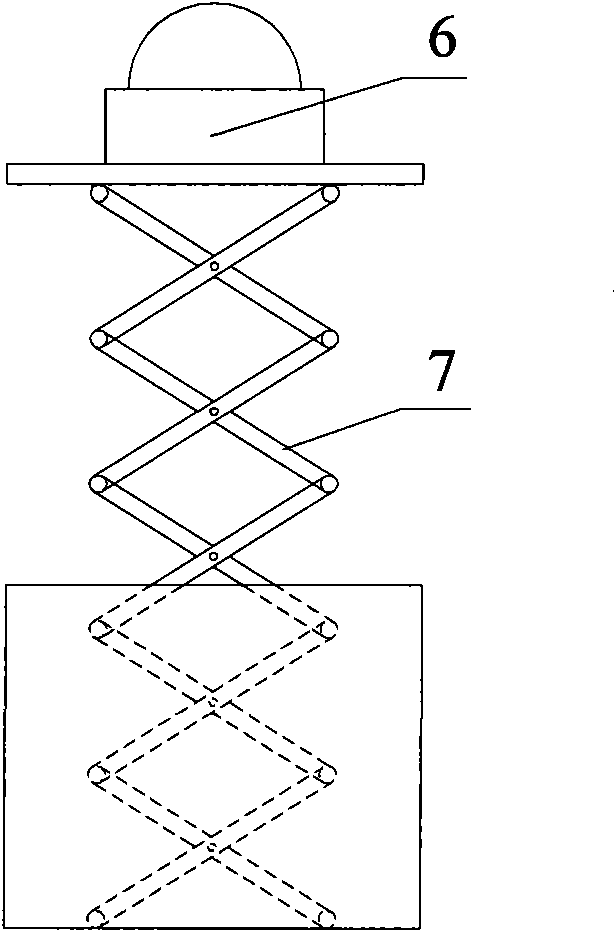

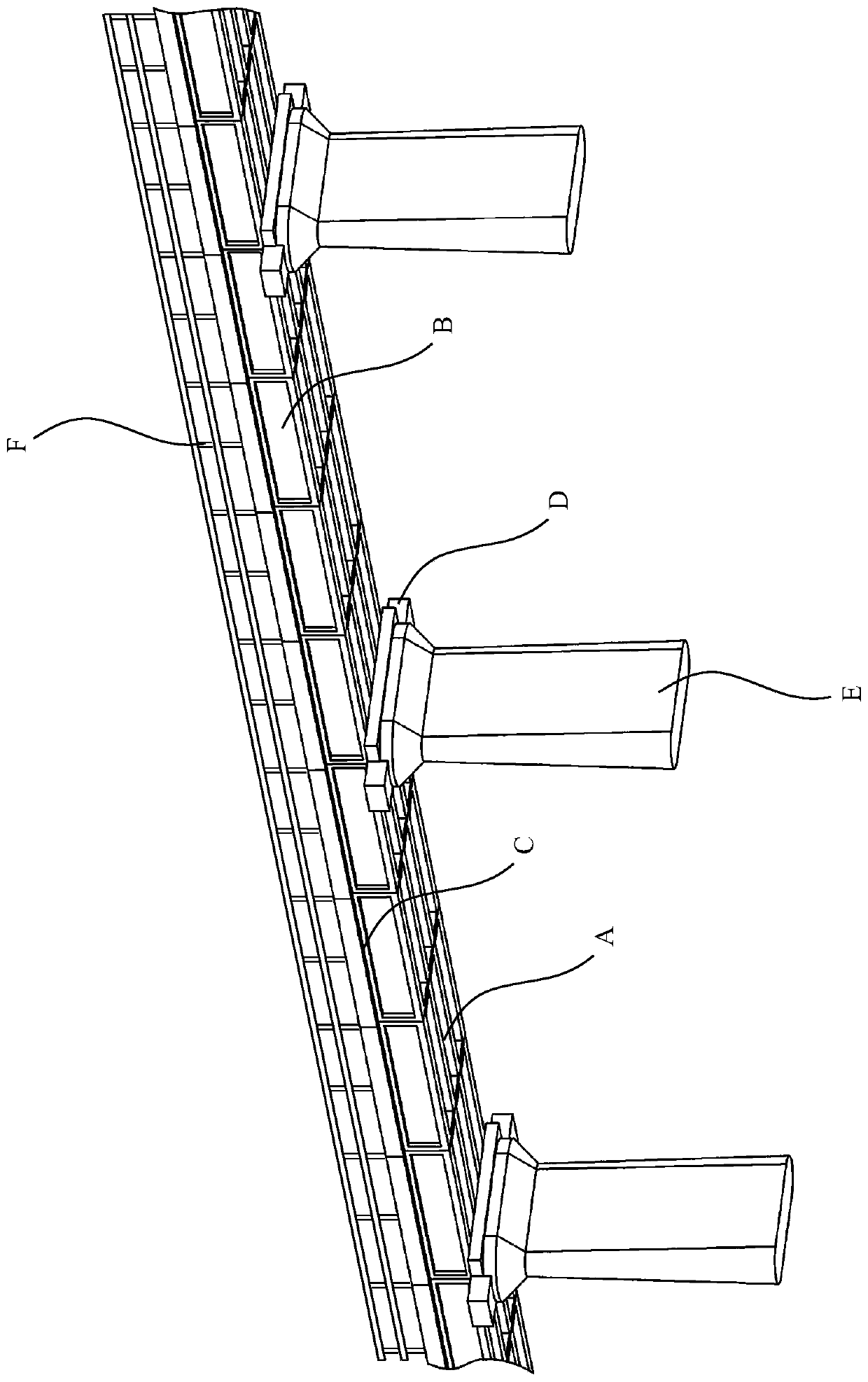

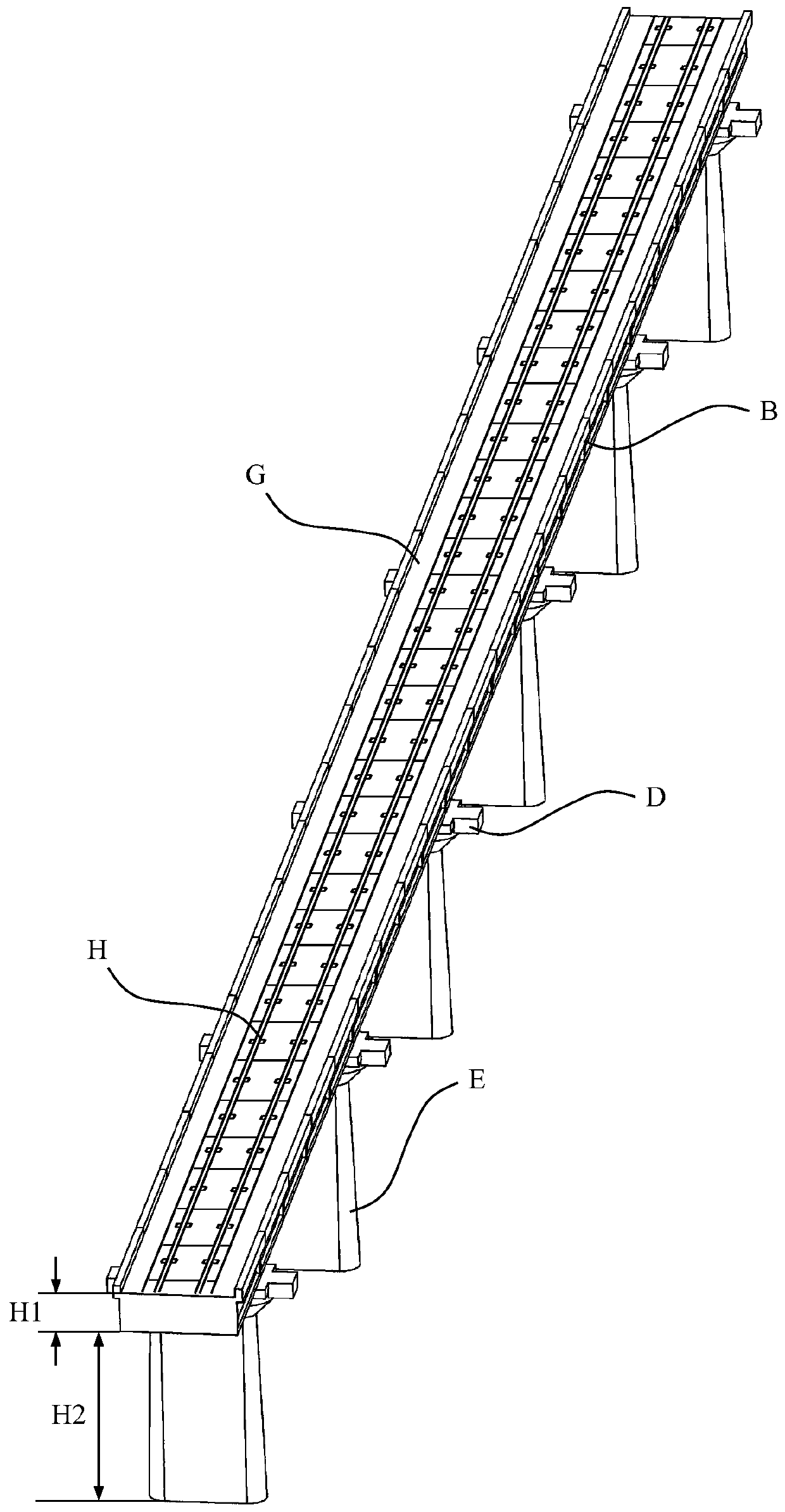

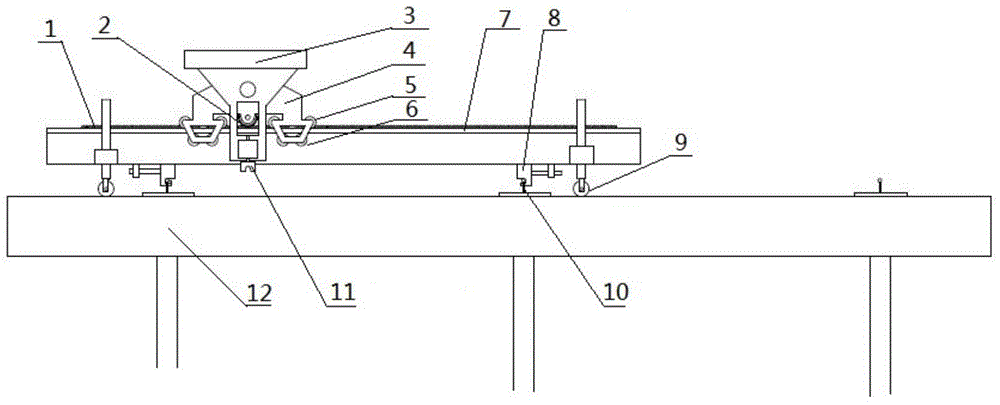

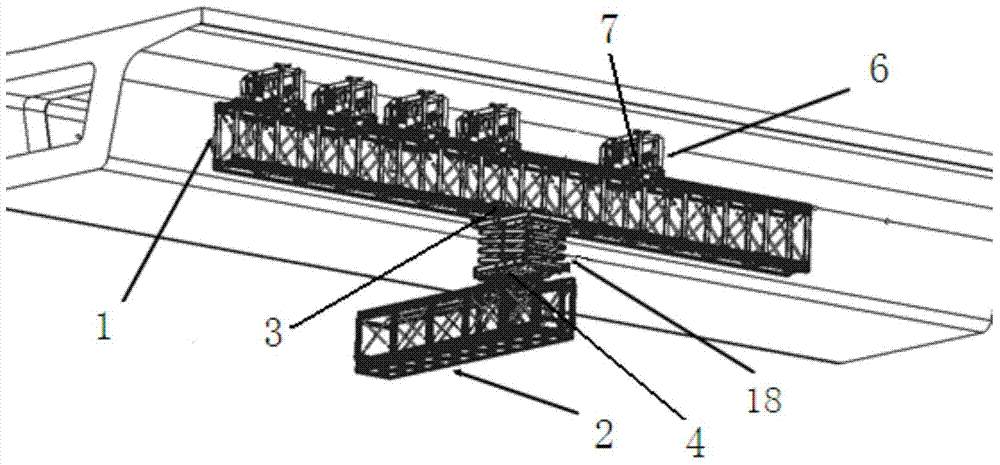

Inspection trolley for bridge upper chord

InactiveCN105317005ASolve maintenance difficultiesLow costBridge structural detailsFull bridgeEngineering

The invention relates to the field of bridge inspection, and discloses an inspection trolley for a bridge upper chord. The inspection trolley for the bridge upper chord comprises a connecting corridor and stand columns, the stand columns are fixed to the connecting corridor, walking mechanisms are symmetrically arranged at the two ends of the connecting corridor respectively, and the connecting corridor is movably installed on a bridge through the walking mechanisms. Each walking mechanism comprises a walking beam and a bearing platform, wherein the bearing platform is movably installed on the walking beam, the walking beam is movably installed on the bridge, jack catches are arranged at the bottom of the walking beam, the top of the bearing platform is fixed to the connecting corridor, and the bottom of the bearing platform is provided with a liftable supporting clamp. Multiple connecting pieces are arranged on the bridge, and the jack catches and the supporting clamps can be connected to the connecting pieces on the bridge in a clamped mode. According to the inspection trolley for the bridge upper chord, due to the fact that the walking mechanisms can climb up a hill, it is unnecessary to lay tracks, materials of track laying are saved, and overall bridge cost is low.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

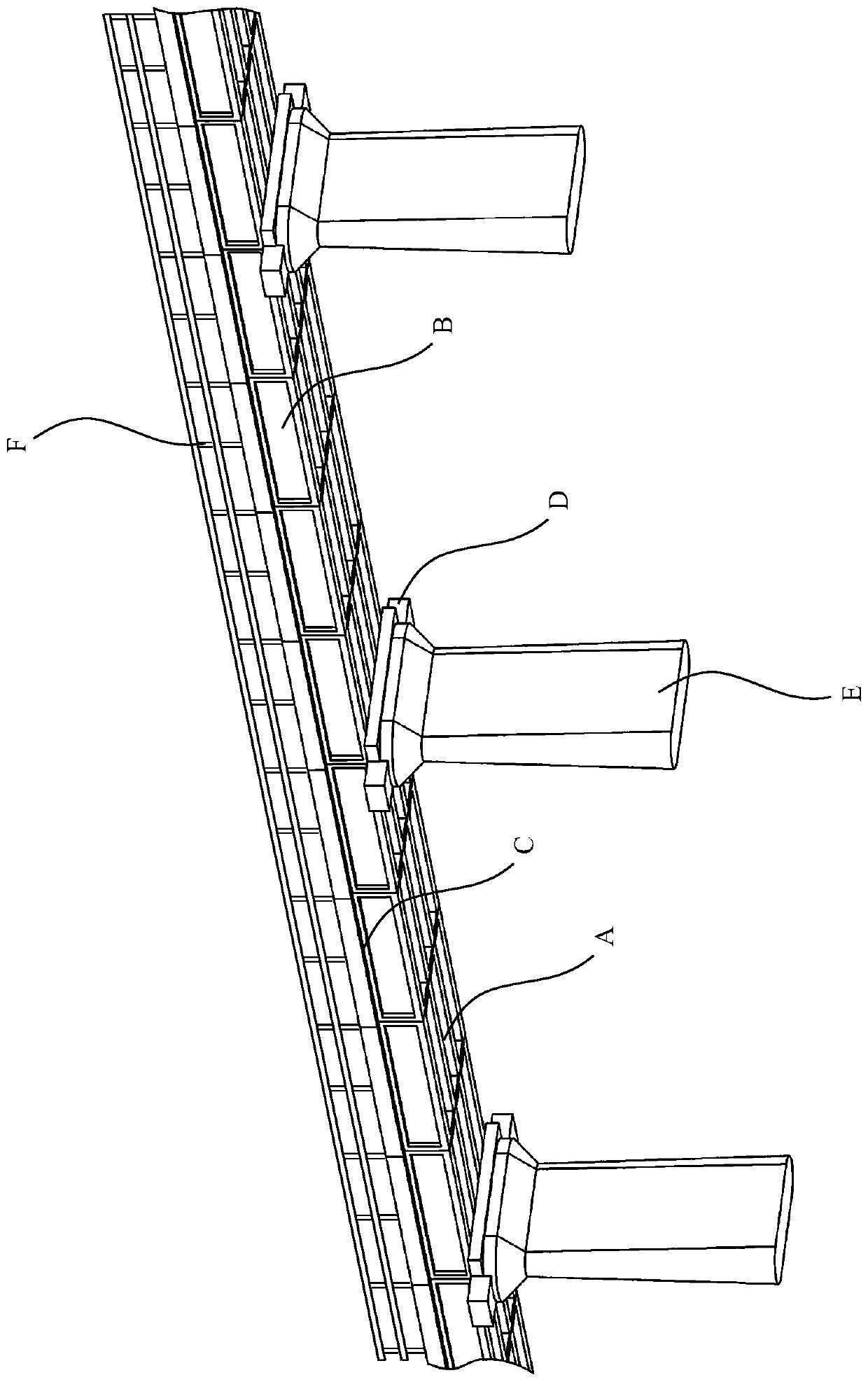

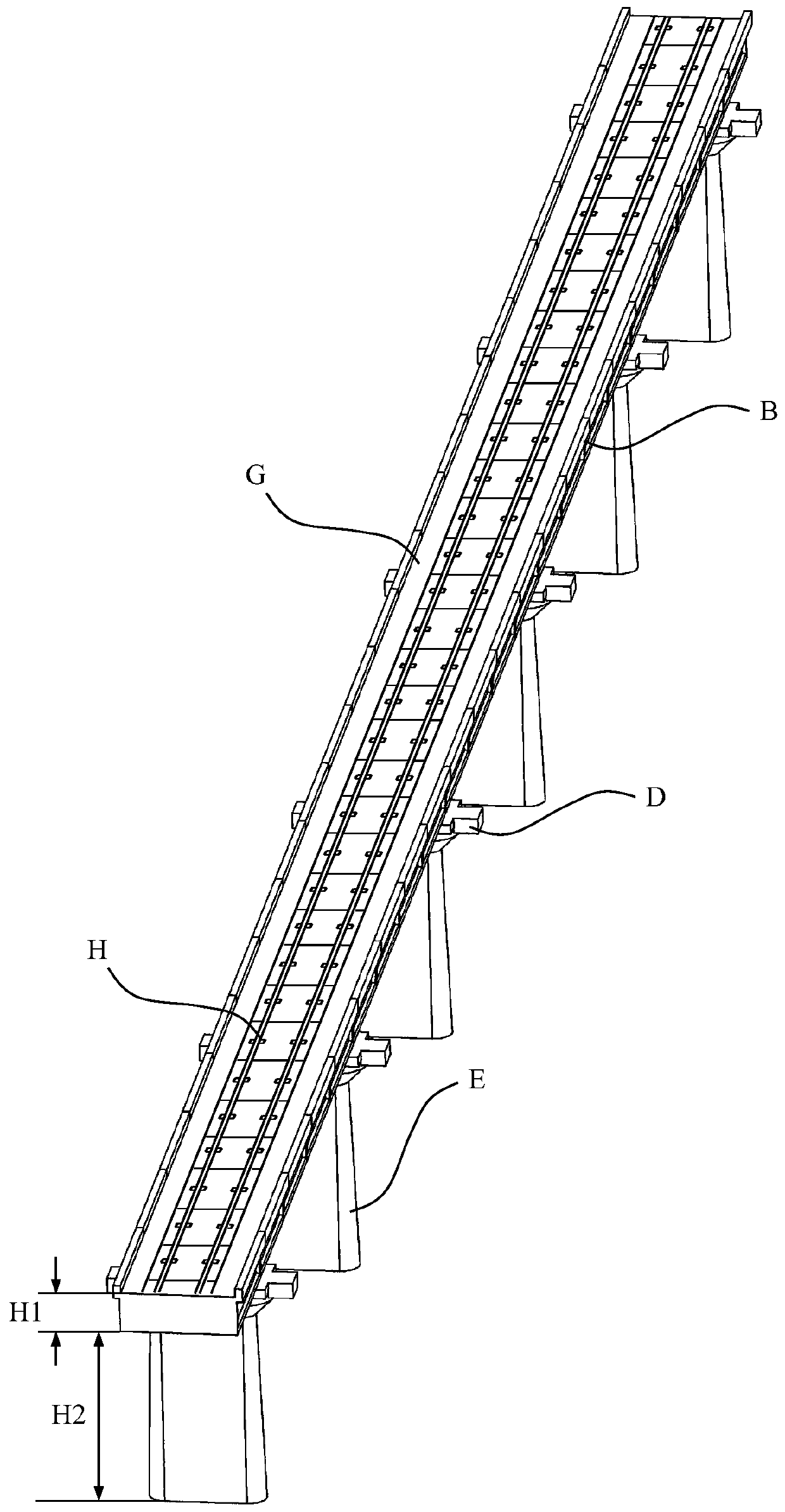

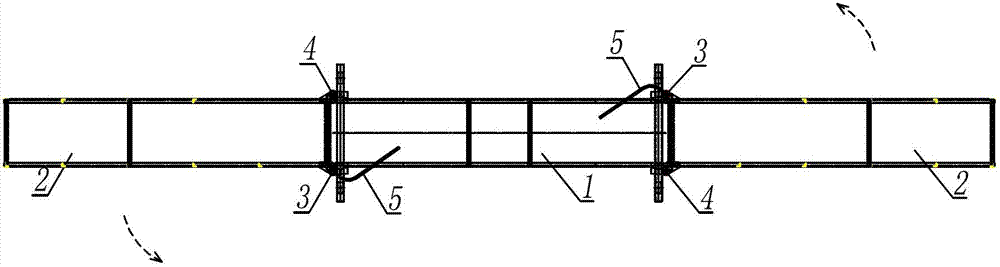

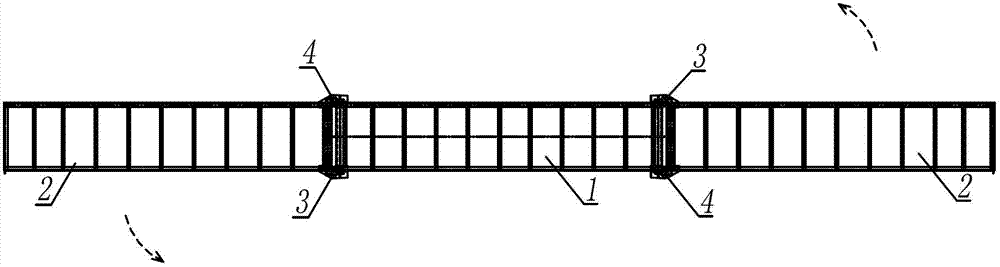

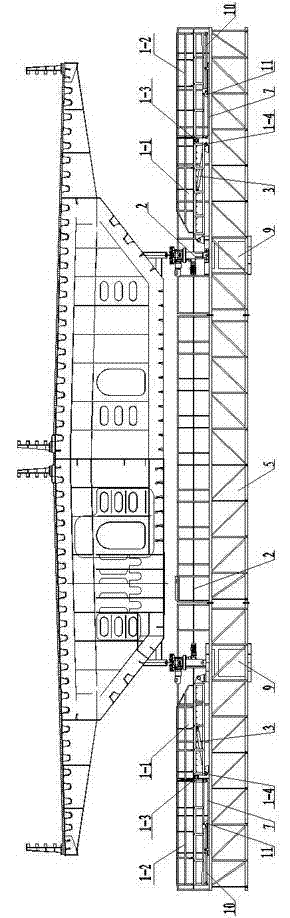

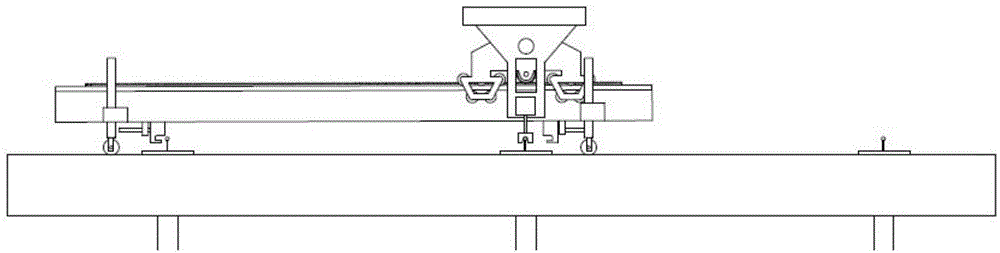

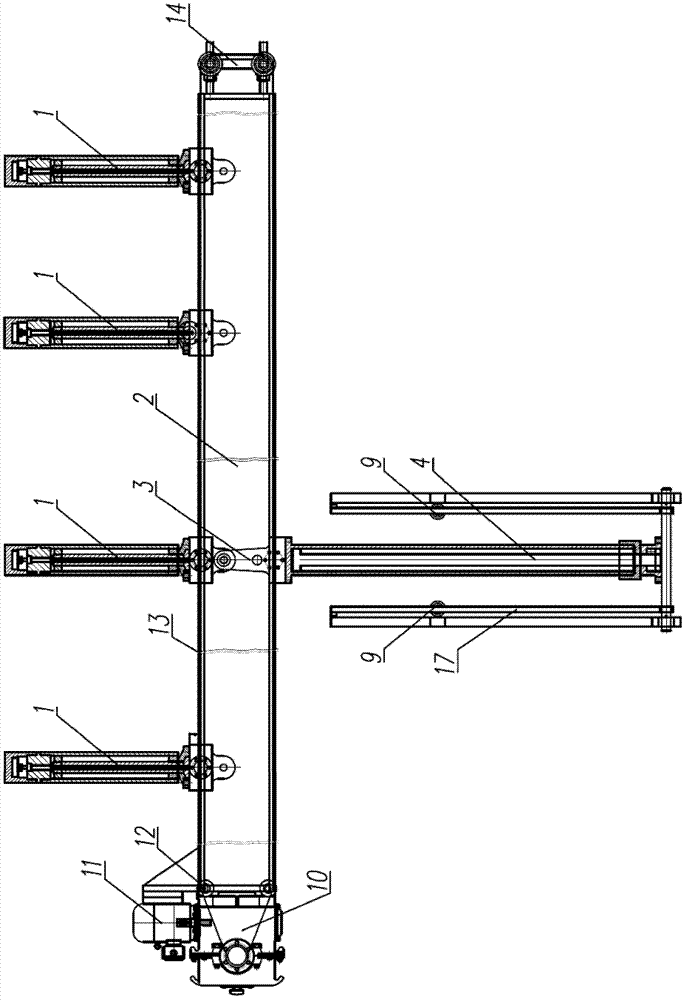

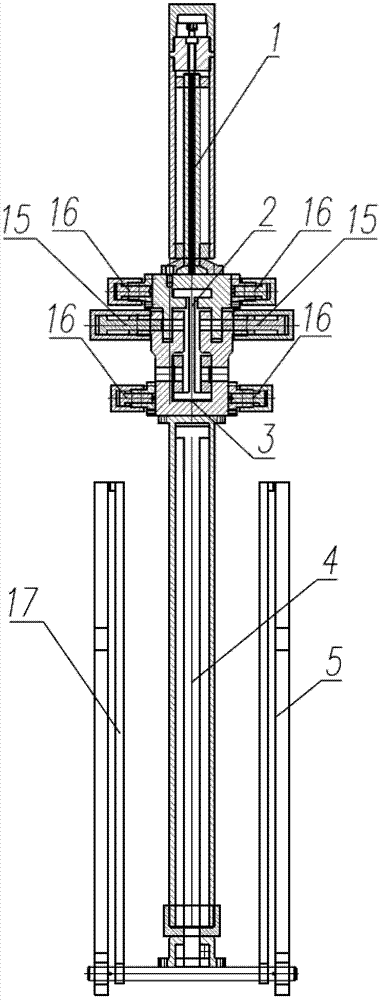

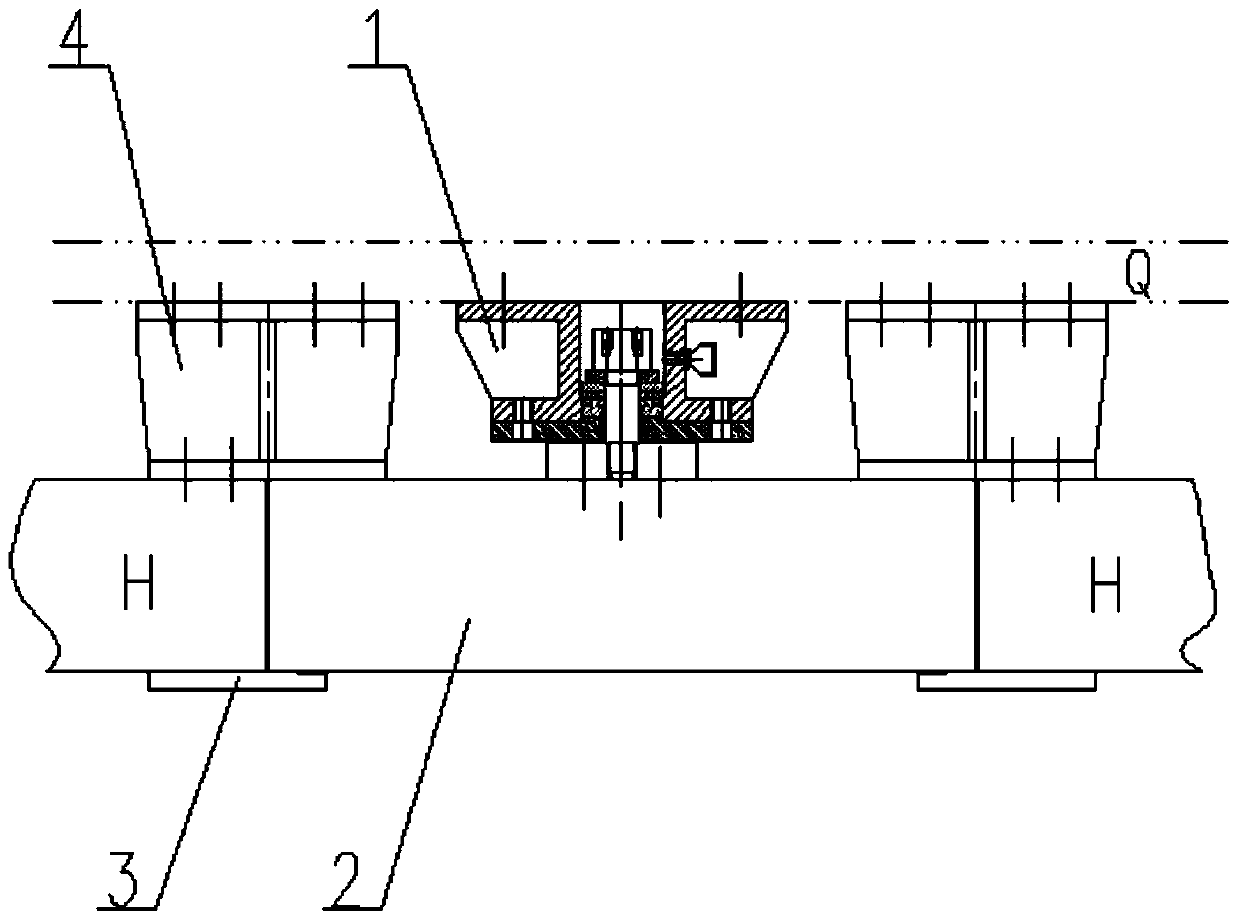

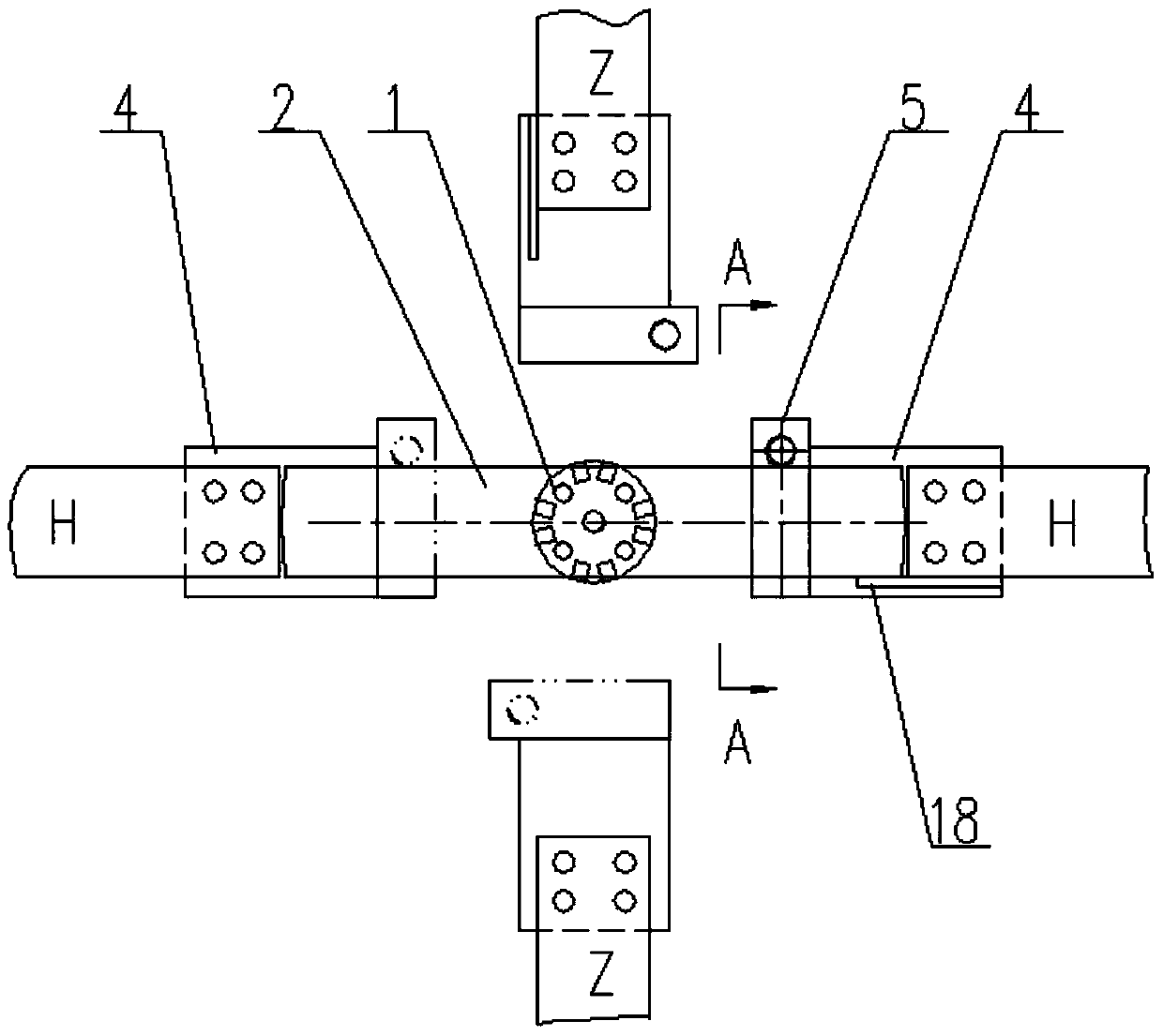

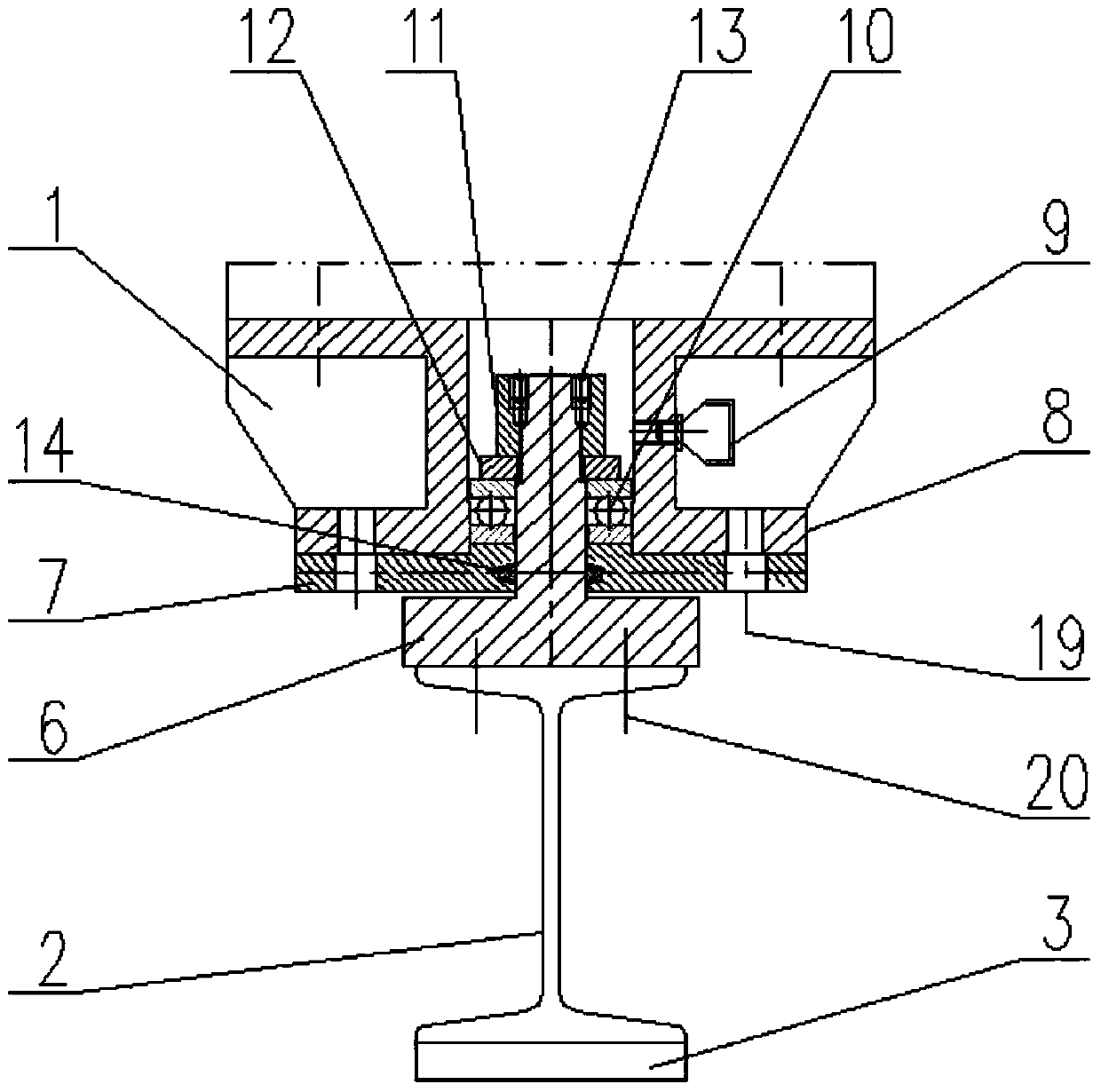

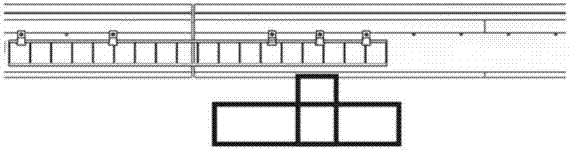

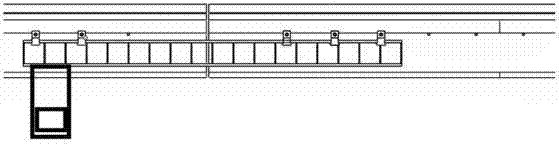

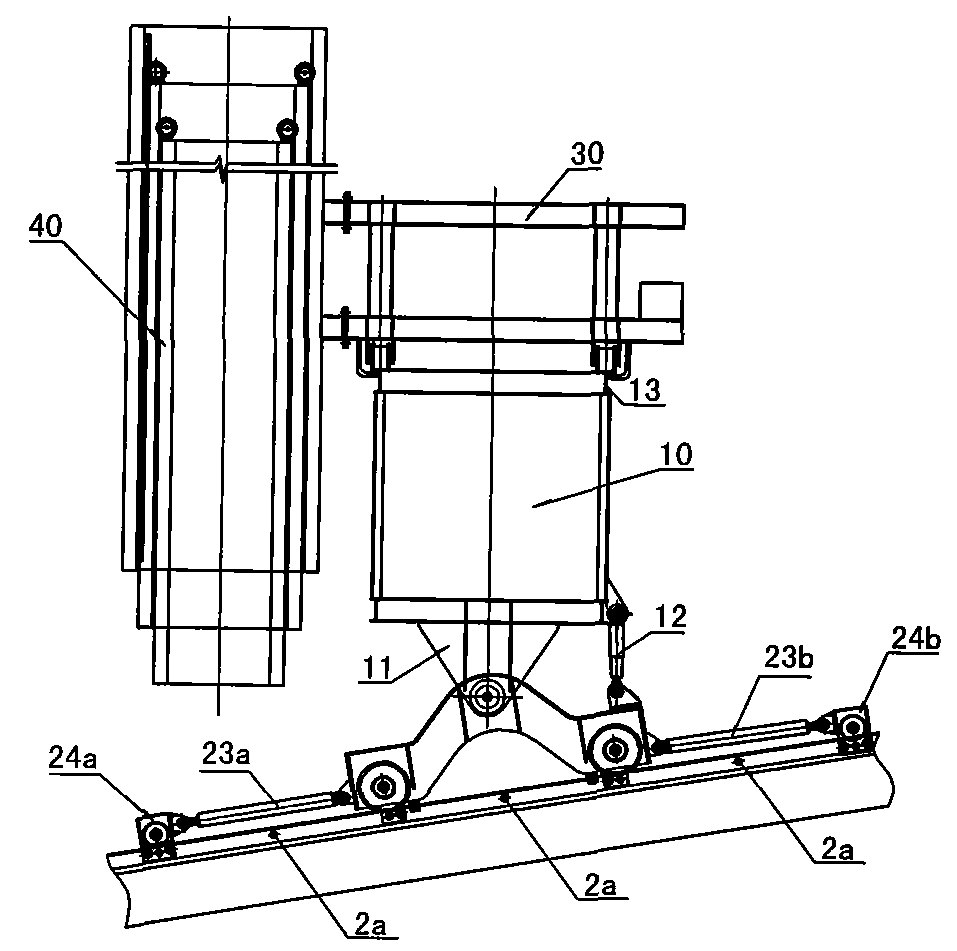

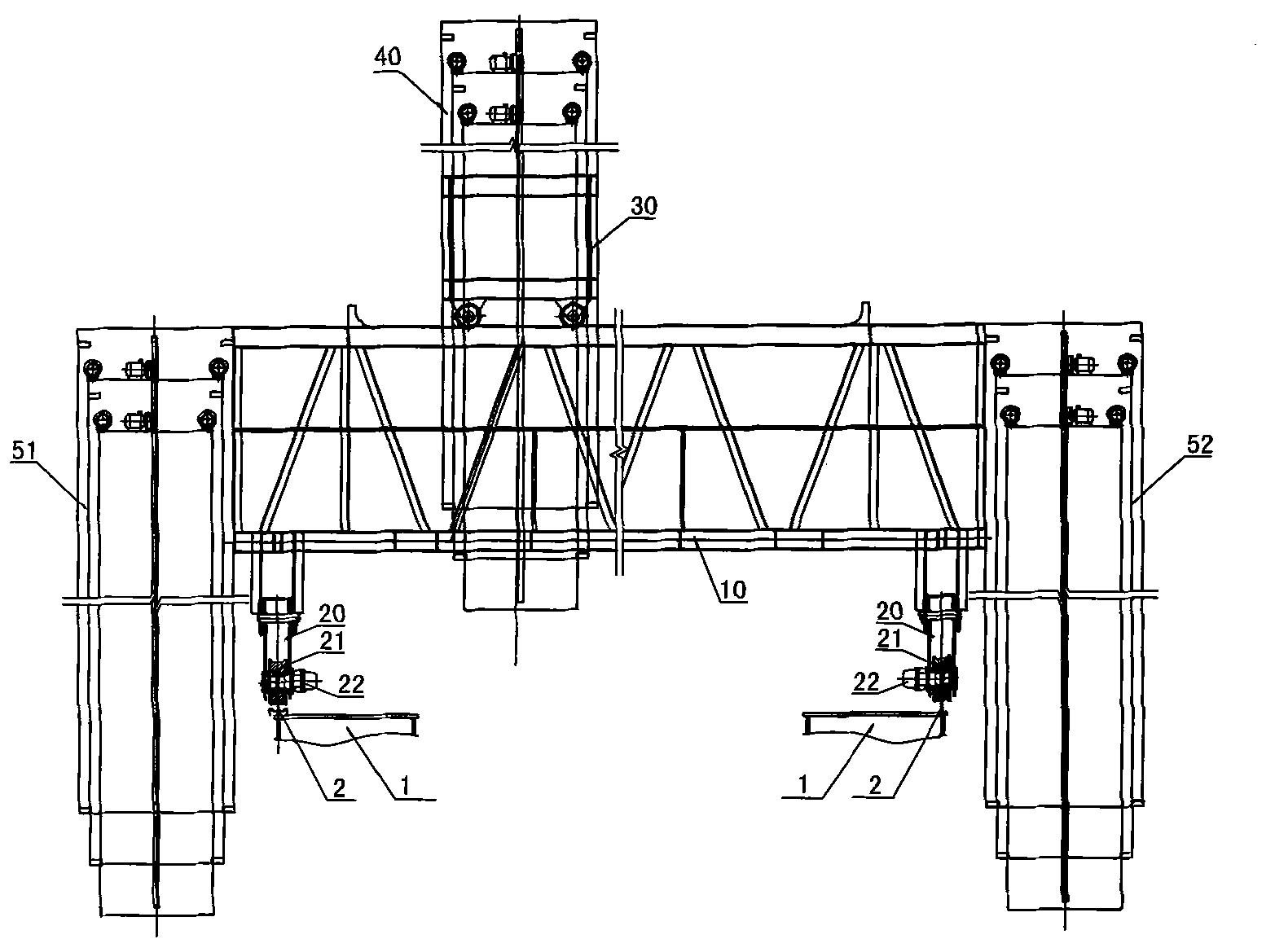

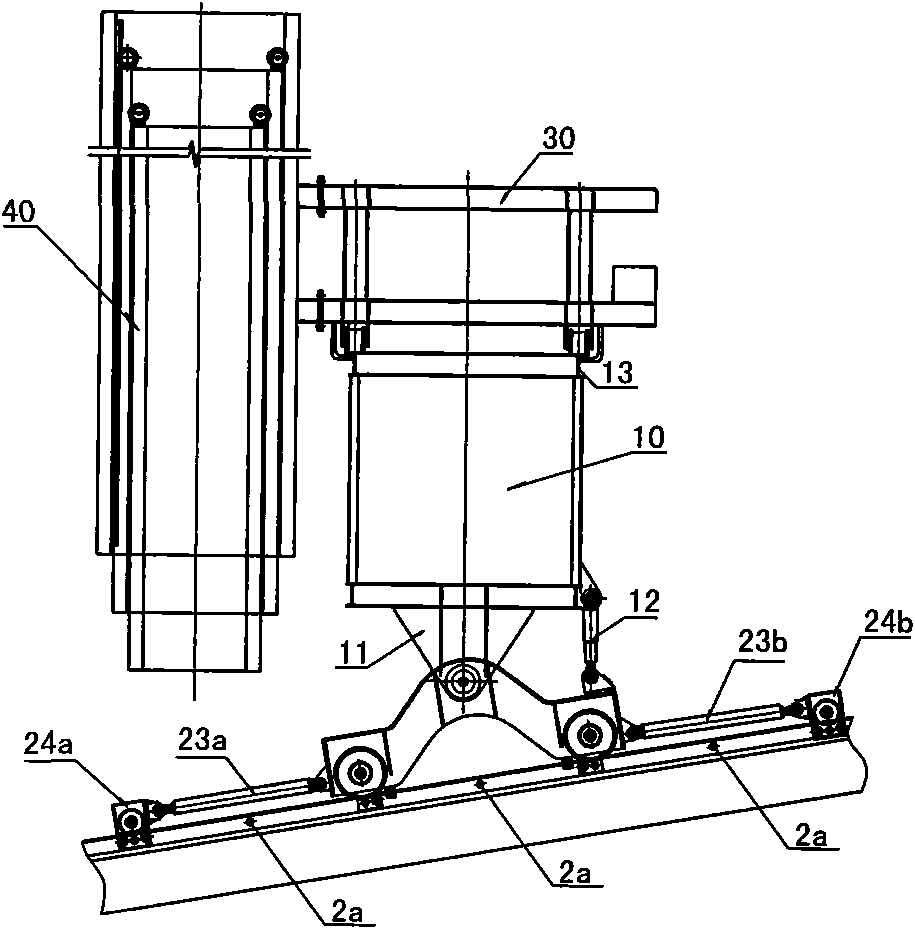

Self-anchorage track laying type bridge inspection vehicle

InactiveCN103194965ARunning does not affectDoes not occupy bridge deck spaceBridge structural detailsHydraulic cylinderControl system

The invention relates to a self-anchorage track laying type bridge inspection vehicle which comprises four groups of anchor hanging systems 1, a detecting running track 2, a detecting arm sliding system 3, a detecting arm lifting system 4, a detecting arm 5, a hydraulic power unit 6, an engine 7, a balance weight 8, a driving system, a detecting arm self-poise control system, a bridge bottom anchoring part 18, a movable detecting platform 19, a hydraulic pipeline, and a drive circuit, wherein the driving system comprises a turbine decelerator 10, a motor 11, a knotless steel cable 13, rope pressing devices 16, a steel cable guide wheel 12 and a steel cable tensioning device 14; and the detecting arm self-poise control system comprises the balance weight 8, balancing hydraulic cylinders 9 and a balance detecting switching circuit 17. The self-anchorage track laying type bridge inspection vehicle can be anchored on the bridge structure, such as drain holes or ventilation holes of the bridge body when in use, and take the bridge as the supporting body of the bridge inspection vehicle; and all the components of the whole vehicle can be matched with alternating anchors of the anchor hanging systems and move forward step-by-step in a track laying manner by relying on the same driving system. The bridge inspection vehicle, provided by the invention, has the advantages that the bridge inspection vehicle is safe and reliable, and is suitable for the running of the bridge detecting equipment in wide-ranging lines; the running of the lines is not influenced; the pre-buried or pre-mounted assistant part is not needed; and the hole-penetrating capability is strong.

Owner:曹新恒

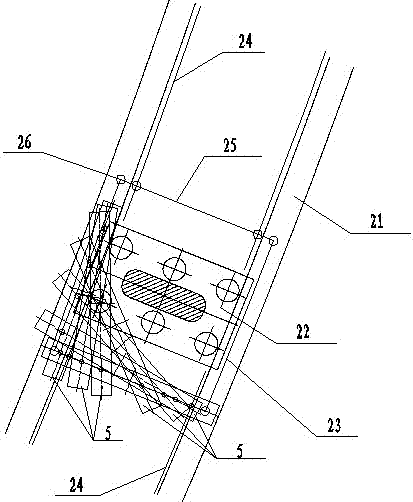

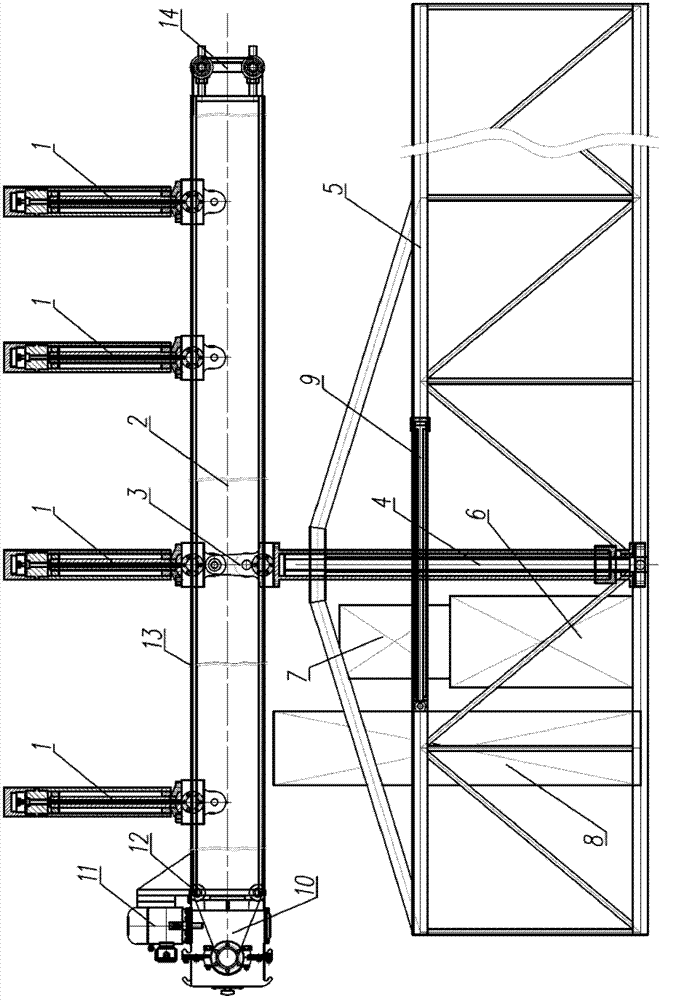

Bridge inspection car running track manual shifter

ActiveCN103422433ARealize track change operationSimple and innovative structureBridge structural detailsButt jointCoupling

The invention provides a bridge inspection car running track manual shifter, and belongs to the field of bridge equipment. The bridge inspection car running track manual shifter comprises a rotary support, a rotary track, an upper rotating and positioning mechanism, a lower rotary supporting block and fixed connection supports; the rotary support is composed of a combination coupling shaft and a bearing pedestal, wherein the rotary support is installed in the bearing pedestal in a matched mode through a bearing outer ring and the lower end of the combination coupling shaft is connected with the rotary track. Two running tracks are located in the same horizontal plane, wherein an included angle is formed between the two running tracks, and the middle portions of the two running tracks are broken and respectively provided with two opposite internal end sockets; the four fixed connection supports are installed at corresponding joints of the internal end sockets of the two running tracks and the two end portions of the rotary track respectively. The combination coupling shaft is pushed manually to drive the rotary track connected to the lower end of the combination coupling shaft to rotate 360 degrees; when the rotary track rotates to a position where the two ends of the rotary track are in butt joint with the internal end sockets of the corresponding running tracks at the fixed connection supports respectively, the rotating and positioning mechanism is used for positioning and locking the rotary track, therefore, track transfer is realized, and the requirement that an inspection car changes running directions to conduct inspection and maintenance operation is met.

Owner:WUHAN WUQIAO TRAFFIC EQUIP TECH CO LTD

Bridge inspection and maintenance device

ActiveCN104846739ASave rail materialAvoid Positioning ErrorsBridge structural detailsEngineeringBridge inspection

The invention relates to a bridge inspection and maintenance device comprising a walking guidance beam (1) which is arranged along the extension direction of a bridge, an inspection channel (2) which is used for supporting maintenance personnel and equipment, a channel walking mechanism (3) which is used for driving the inspection channel (2) to move along the walking guidance beam (1), a channel rotating mechanism (4) which is used for rotating the inspection channel (2) from a position vertically extending with respect to the walking guidance beam (1) to a position being parallel to the walking guidance beam (1), a series of separated hanging mechanisms that are alternately arranged on corresponding beams of the bridge, and at least three supporting walking units (6). The distance between the farthest two hanging mechanisms among any three adjacent hanging mechanisms is less than the length of the walking guidance beam (1); each of the supporting walking units (6) is provided with a unit walking mechanism that is arranged on the walking guidance beam (1) in a walking manner, and is hung on the walking guidance beam (1). Comparing with the prior art, the bridge inspection and maintenance device reduces the building cost of bridges, and the bridge inspection and maintenance device is convenient to be popularized.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

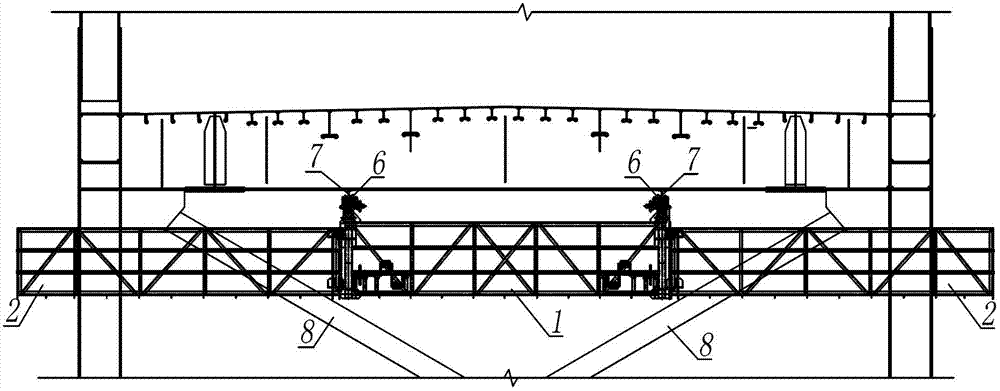

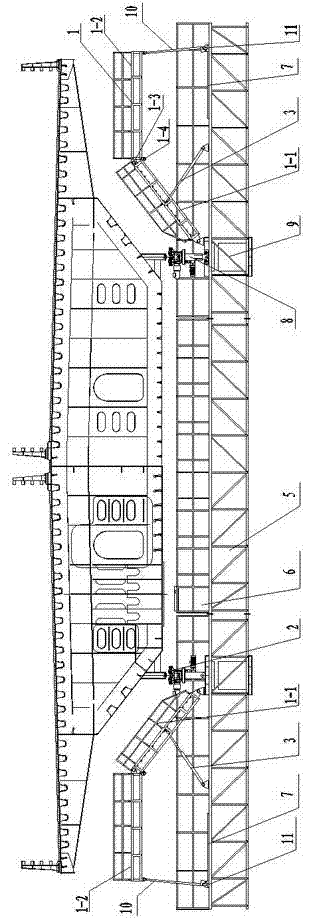

Variable-height continuous steel truss girder railway bridge inspection vehicle

ActiveCN101890963AReduce stepsImprove securityRailway inspection trolleysBridge erection/assemblyMotor driveFull bridge

The invention discloses a variable-height continuous steel truss girder railway bridge inspection vehicle, aiming at realizing arch climbing and straddle walk and conveniently inspecting and repairing each part of a girder. The railway bridge inspection vehicle comprises a repair main truss (10) which steps over a steel truss girder cross the surface of a bridge and a running gear which drives the repair main truss (10) to move along rails (2) which are paved on top booms (1) of the steel truss girder in the direction of the bridge, wherein a repair workbench is arranged on the repair main truss (10), the running gear is formed by combining a motor-driven running gear and a hydraulic-driven walking type running gear, and locking devices are respectively arranged between the motor-driven running gear or the hydraulic-driven walking type running gear and the rails (2). The railway bridge inspection vehicle can realize the arch climbing and straddle walk, and the repair work of the whole bridge can be finished only by one inspection vehicle, thereby providing guarantee for daily inspection and maintenance. The inspection vehicle has simple structure, novel form, safety and reliability and higher automation, prevents operation staffs from operating on the top booms as much as possible, and greatly increases the safety of construction operations.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com