Bridge inspection method

A bridge and automatic inspection technology, applied in three-dimensional position/channel control, optical test flaws/defects, etc., can solve the problems of poor data acquisition stability, low degree of automation, and heavy workload, so as to ensure safe return and improve automation degree, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

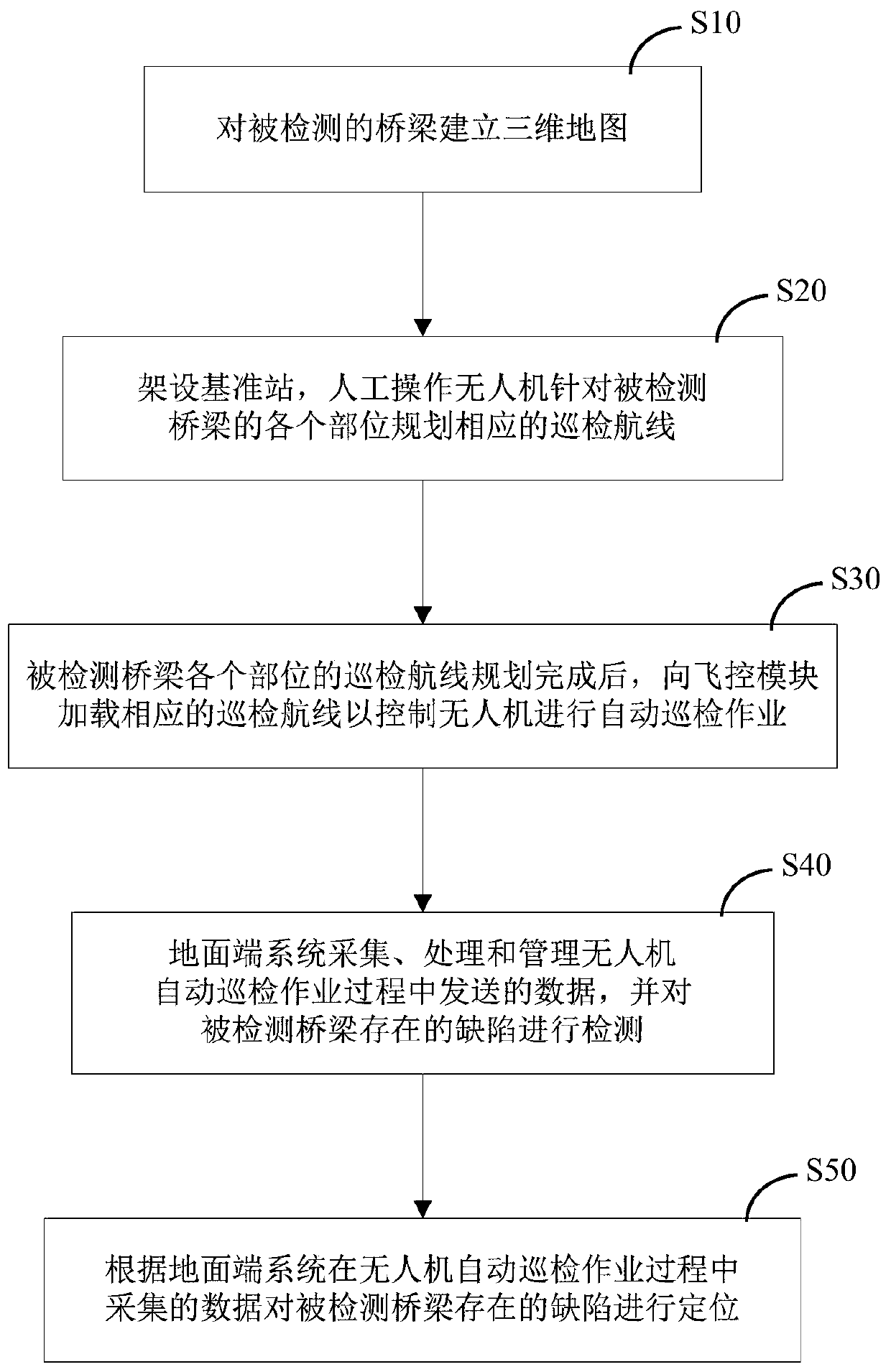

[0094] as attached image 3 As shown, an embodiment of the bridge inspection method of the present invention specifically includes the following steps:

[0095] S10) building a three-dimensional map of the detected bridge;

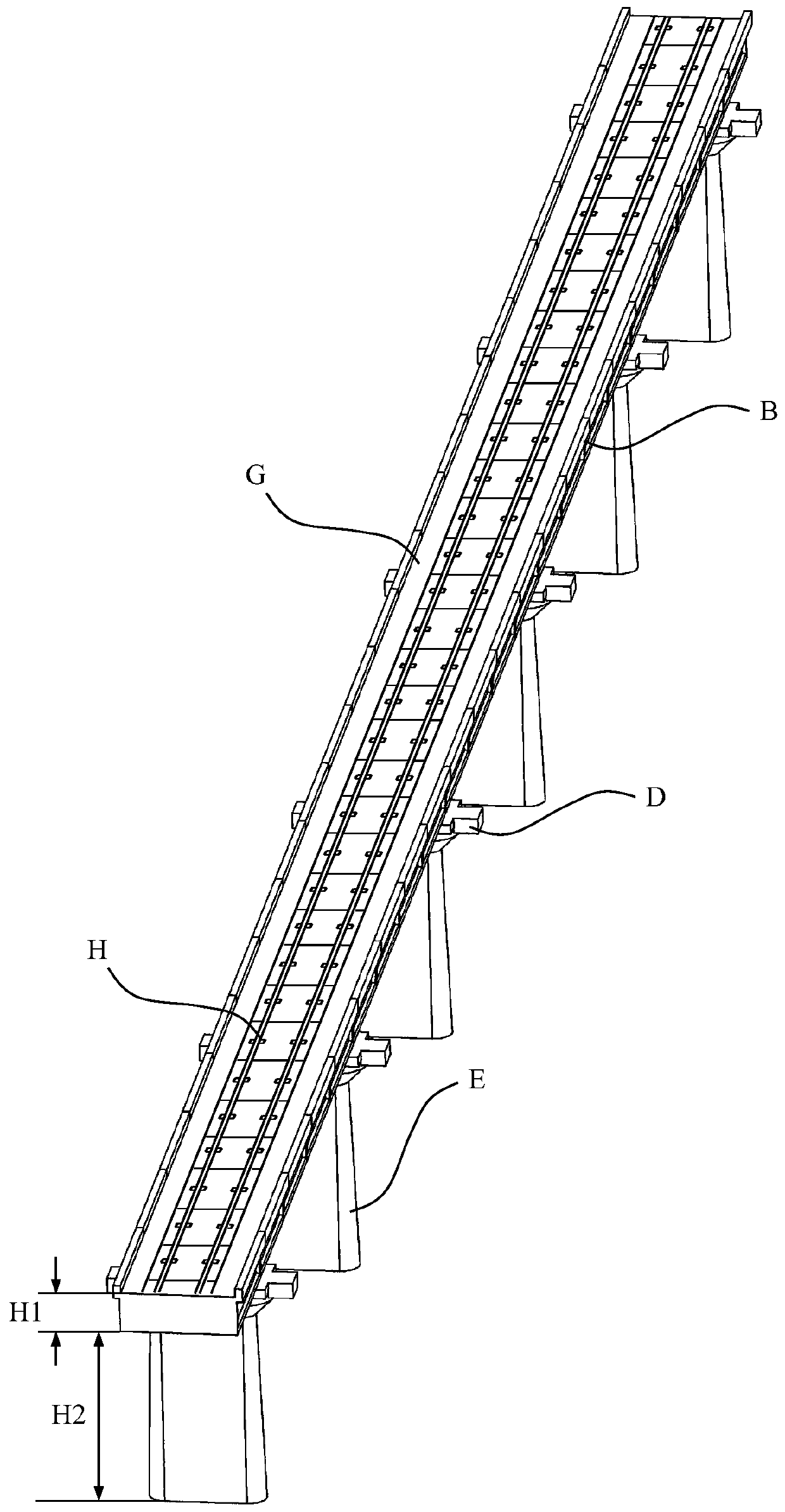

[0096] S20) set up reference station 4 (such as GNSS-RTK reference station can be adopted, GNSS: Global Navigation Satellite System, the abbreviation of Global Navigation Satellite System; RTK: Real Time Kinematic, the abbreviation of real-time dynamic positioning), the artificially operated UAV 10 targets the Detect the various parts of the bridge and plan the corresponding inspection routes. The structure of the reference station 4 is as attached Figure 15 shown;

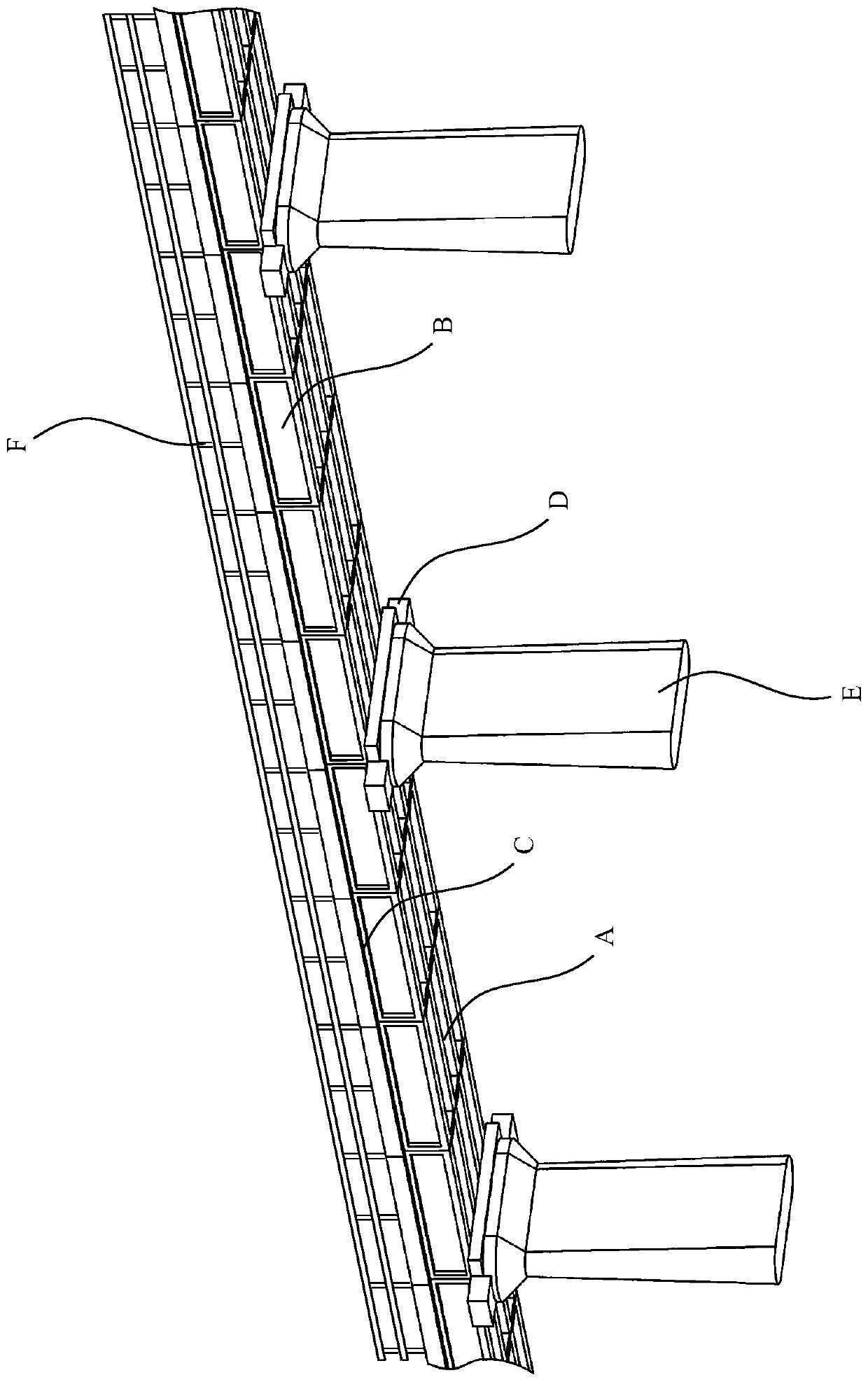

[0097] In the inspection route planning (calibration) process, firstly carry out three-dimensional measurement and modeling for the bridges that need to be inspected, and generate a three-dimensional map of the bridge; then, manually operate the UAV 10 pairs of bridge bottom, outer edge, si...

Embodiment 2

[0171] as attached Figure 5 As shown, an embodiment of a bridge inspection system based on the method described in the embodiment specifically includes: an unmanned aerial vehicle system 1 and a ground terminal system 2 . The unmanned aerial vehicle system 1 further includes an unmanned aerial vehicle 10, and an airborne data processing unit 11, a pan-tilt camera 12, a flight control module 16, an obstacle avoidance module 110 and a positioning module 111 mounted on the unmanned aerial vehicle 10, and the ground terminal system 2 further comprises a ground station 20. The UAV 10 performs the first inspection operation on the bridge to be detected under manual operation, and collects bridge surface data through the pan-tilt camera 12, and according to the positioning signal obtained by the positioning module 111 (such as: using GNSS signals, Global Navigation Satellite System , the abbreviation of global navigation satellite system, such as GPS, Glonass, Galileo, Beidou satel...

Embodiment 3

[0185] An embodiment of a bridge inspection unmanned aerial vehicle system applied to the method described in embodiment 1, specifically comprising: an unmanned aerial vehicle 10, and an airborne data processing unit 11 and a pan-tilt camera 12 mounted on the unmanned aerial vehicle 10 , the first data transmission station 13 and the first image transmission station 14. During the automatic inspection operation, the airborne data processing unit 11 sends bridge surface data acquisition control signals to the pan-tilt camera 12 , and the airborne data processing unit 11 sends flight control signals to the UAV 10 . The PTZ camera 12 acquires high-definition data on the surface of the bridge, and the bridge video data collected by the PTZ camera 12 is sent to the first image transmission station 14 through the on-board data processing unit 11, and the bridge video data is sent to the ground by the first image transmission station 14 The end system 2 performs display monitoring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com