Bridge inspection and maintenance device

A technology for inspection and maintenance of bridges, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of inspection and maintenance vehicles that cannot be installed and used, and achieve the effect of improving connection efficiency and connection reliability, and ensuring automatic connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

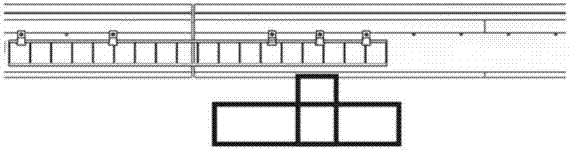

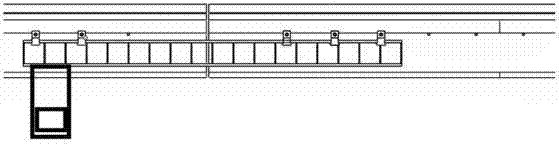

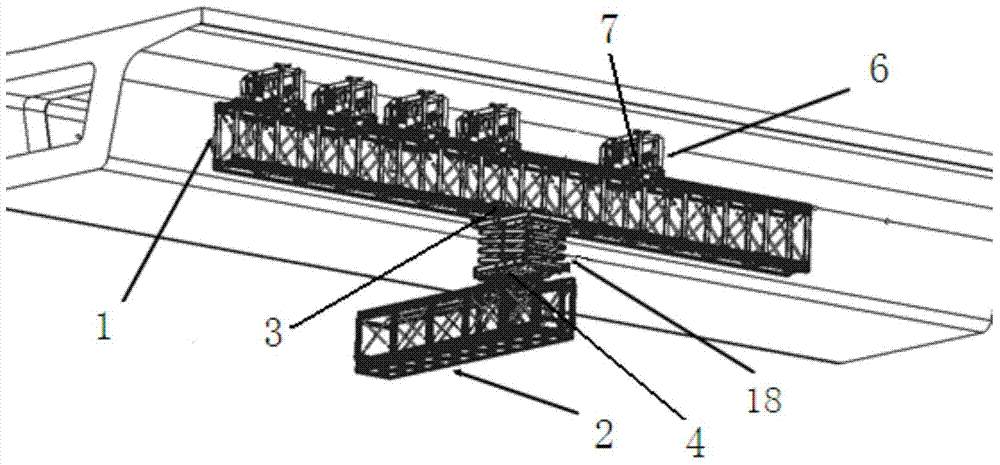

[0042] The specific solutions of the present invention will be explained below in conjunction with the accompanying drawings.

[0043] see figure 1 , a bridge inspection and maintenance device of the present invention, comprising a walking guide beam 1, an inspection channel 2, a channel traveling mechanism 3, a channel turning mechanism 4, a series of discrete ventilation holes 5 as a mounting mechanism, and five supporting walking units 6 and the controller. The longitudinal direction of the walking guide beam 1 is arranged along the extension direction of the high-speed rail bridge, the maintenance channel 2 is used to carry maintenance personnel and equipment, and the channel walking mechanism 3 is used to drive the maintenance channel 2 to move along the walking guide beam 1 , the channel turning mechanism 4 is arranged between the channel traveling mechanism 3 and the maintenance channel 2, and is used to rotate the maintenance channel 2 from a position vertically exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com