Two-sided laser processing method for PCB array micropores

A laser processing method and micro-hole technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency and increasing material costs, and achieve heat dissipation, heat-free processing, and processing high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

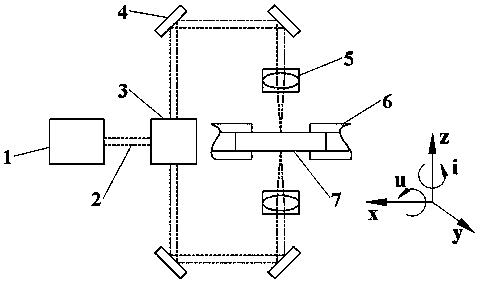

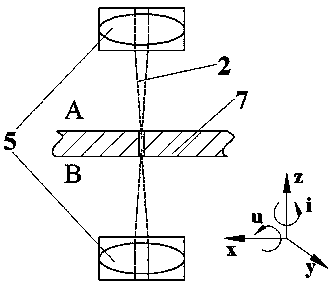

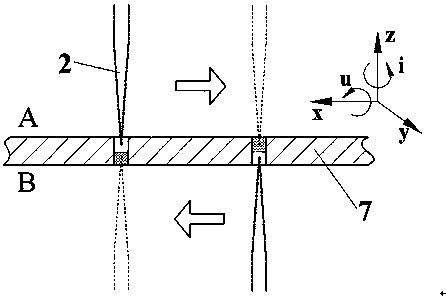

[0029] like figure 1 and 2 As shown, the present embodiment provides a double-sided laser processing method for PCB7 array microholes, and measures the ablation threshold value of the required processing layer material of PCB7; the processed PCB7 is fixed on the ultra-precision platform 6 and the ultra-precision The precision platform 6 rotates along the u direction; the laser 1 outputs the laser beam 2, which is divided into two laser beams 2 by the beam splitting module 3, and the two laser beams 2 respectively pass through the mirror 4 and pass through the focusing module 5, and are installed on the ultra-precision platform The front and back sides of PCB7 of 6 are processed.

[0030] A and B sides are PCB7 with symmetrical structure and through-hole processing with a depth-to-diameter ratio of more than 2:1: the laser system outputs two laser beams 2 as A and B, the output wavelength is 355nm, the pulse width is 80ns, and the power is 8W , a laser beam 2 with a repetitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com