Patents

Literature

313results about How to "Solve maintenance difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

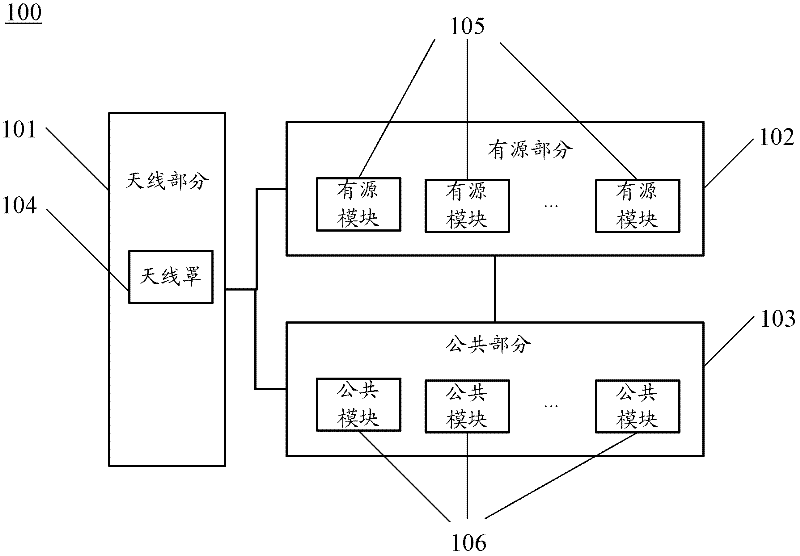

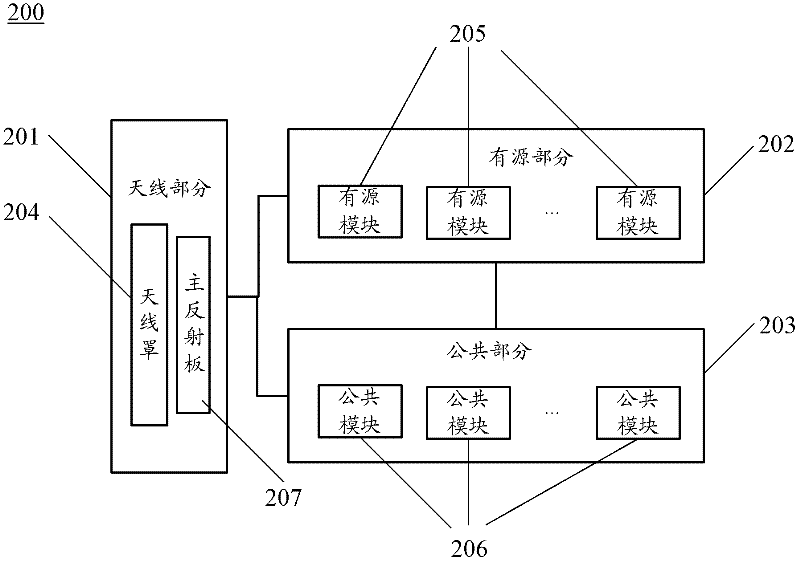

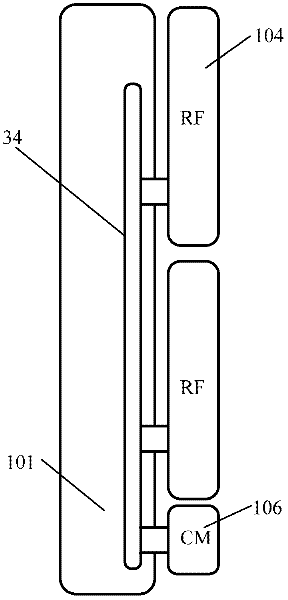

Antenna apparatus, base station and communication system

ActiveCN102522634ASolve the overall replacement and maintenance difficultiesFlexible configurationSimultaneous aerial operationsRadiating element housingsRadio frequencyRadome

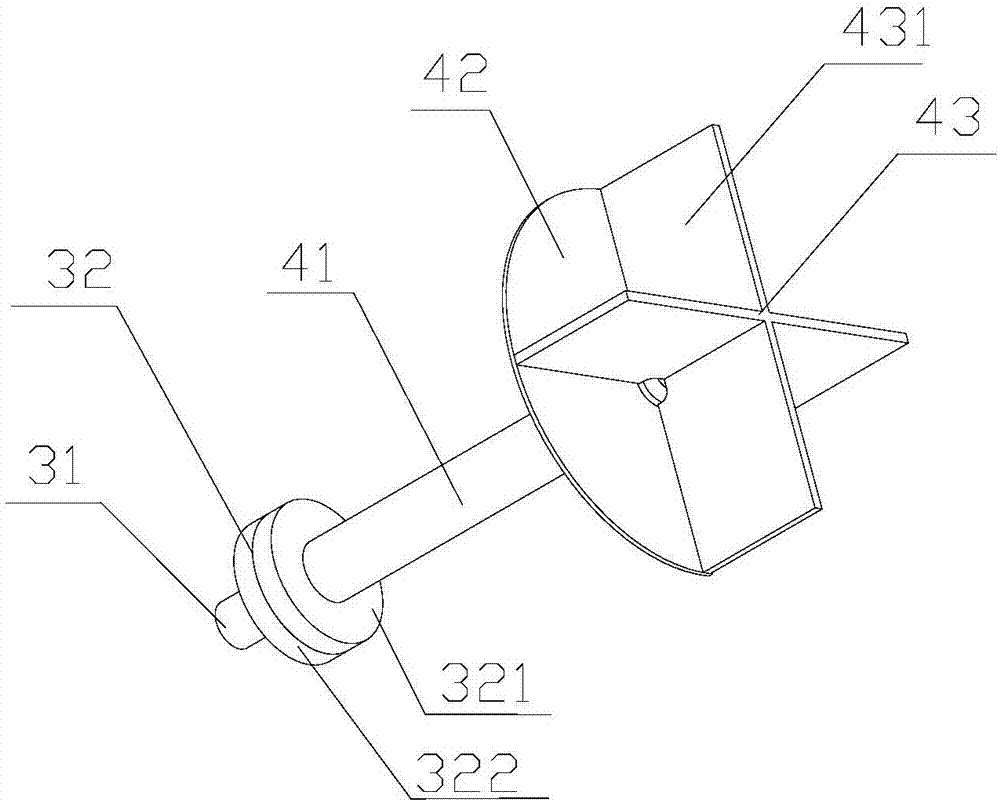

Embodiments of the invention provide an antenna apparatus, a base station and a communication system. The antenna apparatus comprises: an antenna part, an active part and a common part, wherein the antenna part comprises a common radome; the active part is connected with the antenna part and comprises at least one active module; the each active module comprises at least one antenna oscillator, a oscillator reflection plate and a phase shifter; the oscillator reflection plate and a phase shifter correspond with the each antenna oscillator; the oscillator reflection plate of the at least one active module is used for realizing an antenna function; the common part is connected with the active part and the antenna part and is shared by at least one active module in the active part; the common part comprises at least one common module. Through the above antenna apparatus, each radio frequency module can be flexibly configured so as to satisfy combination demands of different products. On-site replacing and maintenance operations can be further simplified.

Owner:HUAWEI TECH CO LTD

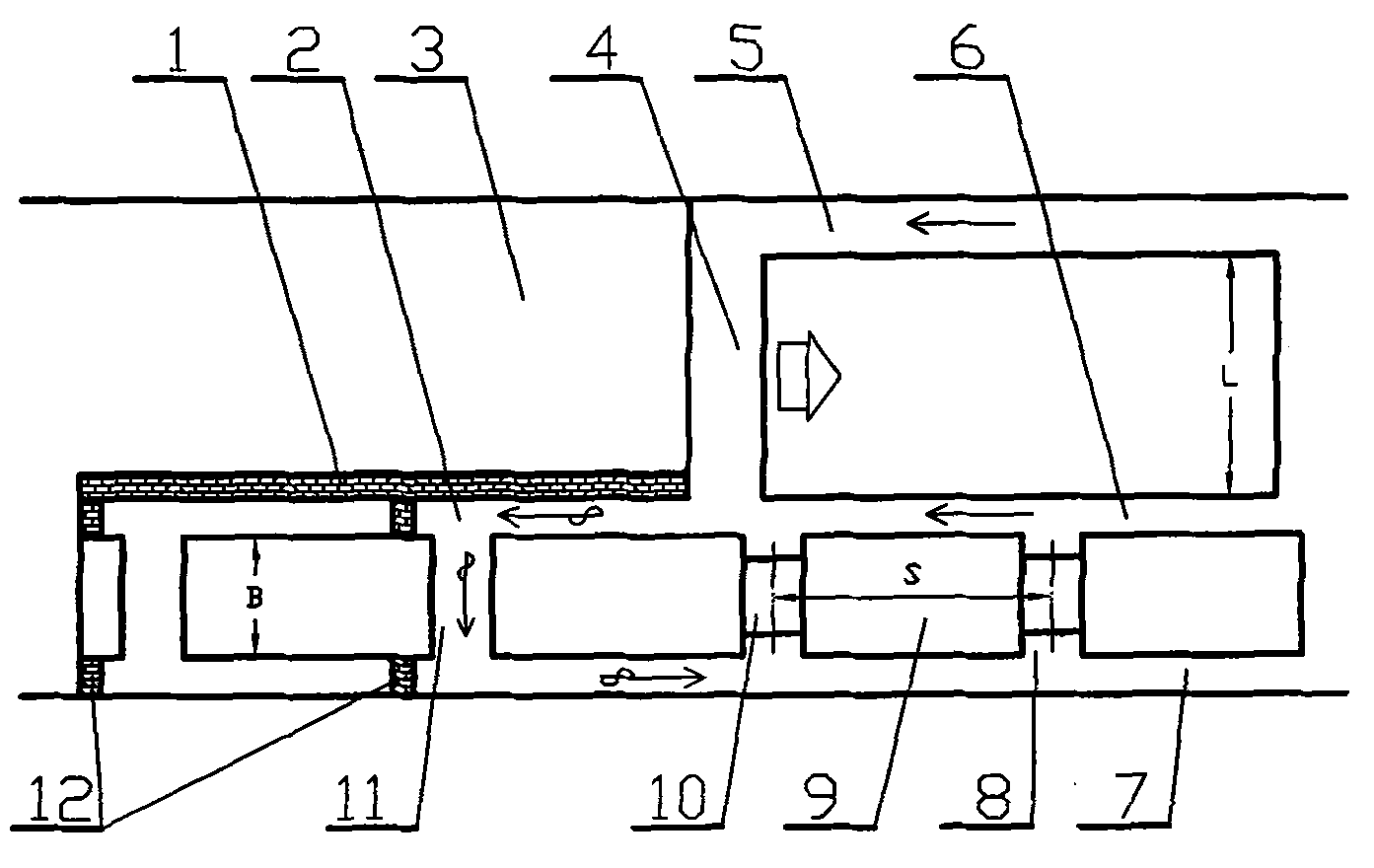

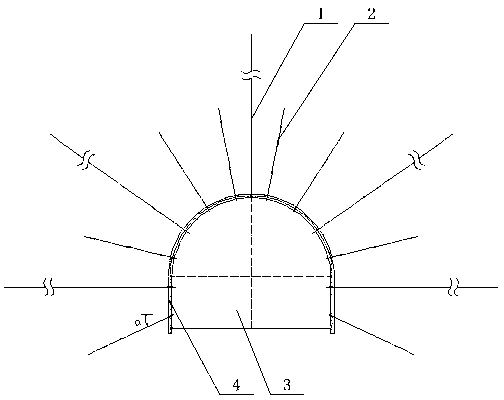

Inverse Y-shaped ventilation method for coal mining working face

InactiveCN102071958ASolve accumulated puzzlesConcentration controllableTunnel/mines ventillationGas removalEconomic benefitsCoal pillar

The invention relates to an inverse Y-shaped ventilation method for a coal mining working face. In the method, a transportation roadway is arranged on one side of the coal mining working face; a railway roadway and a return air roadway are sequentially arranged on the other side of the coal mining working face; coal pillars are positioned between the railway roadway and the return air roadway; contact roadways are formed at certain intervals; sealed partition walls are arranged among the contact roadways; before the working face is actually mined, the contact roadways near the working face are communicated so as to form a return air contact roadway; a beside-roadway wall body is built along the border of a gob, which is close to the back of the working face; a sealing wall is constructed at the position which is 1 to 2m away from the back of the return air contact roadway so as to seal a gob-side entry and the return air roadway; when the working face is actually mined, air flow passes through the railway roadway and the transportation roadway to enter the coal mining work face and returns to the return air roadway through the gob-side entry and the return air contact roadway; and the stroke of the air flow forms an inverse Y shape. The ventilation method is characterized by simple structure and stable air flow, solves the problem of gas accumulation at the upper corner of an actual mining working face and the problem that the god-side entry is difficult to maintain, and has obvious social and economic benefits.

Owner:CHINA UNIV OF MINING & TECH +1

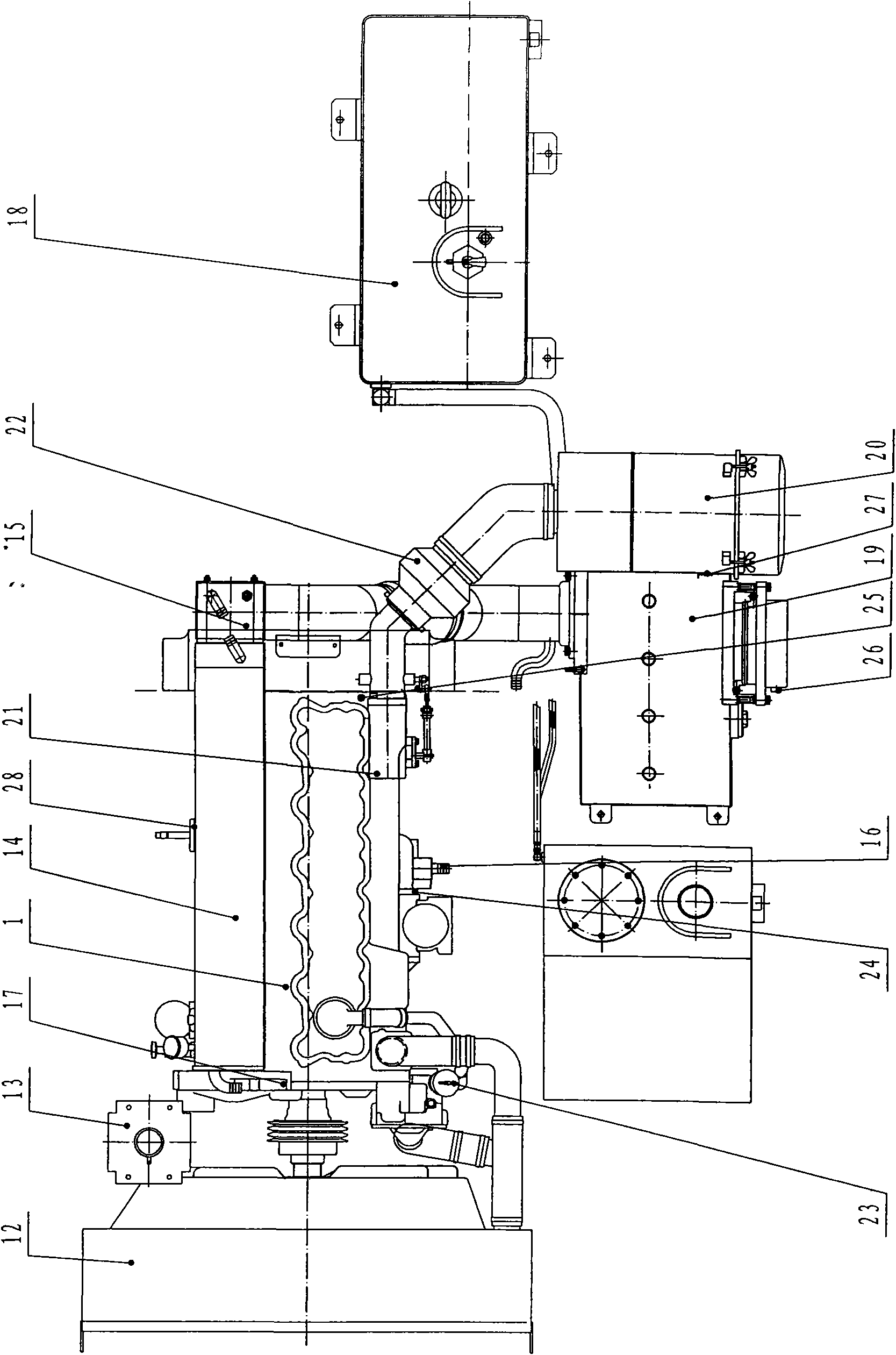

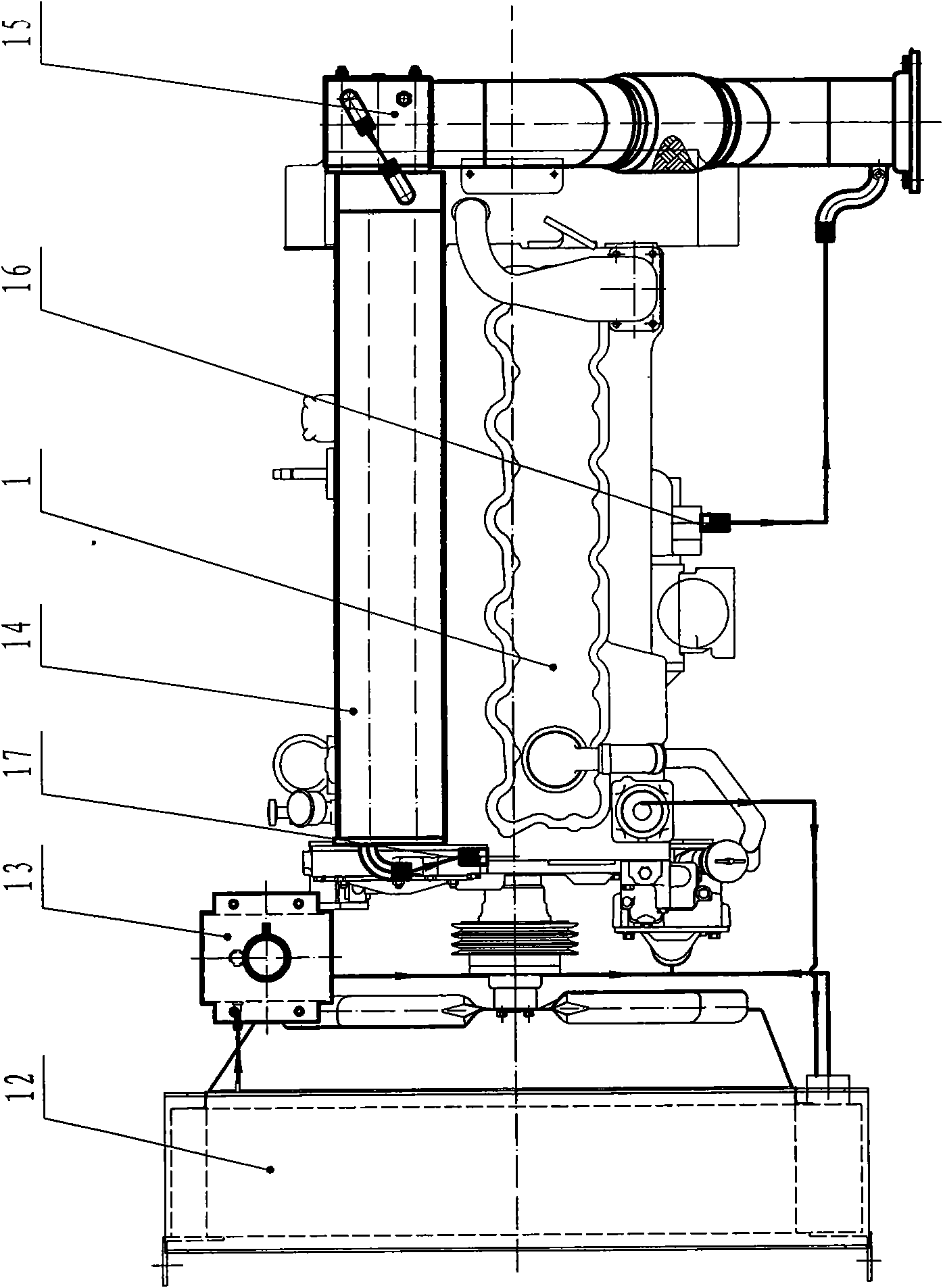

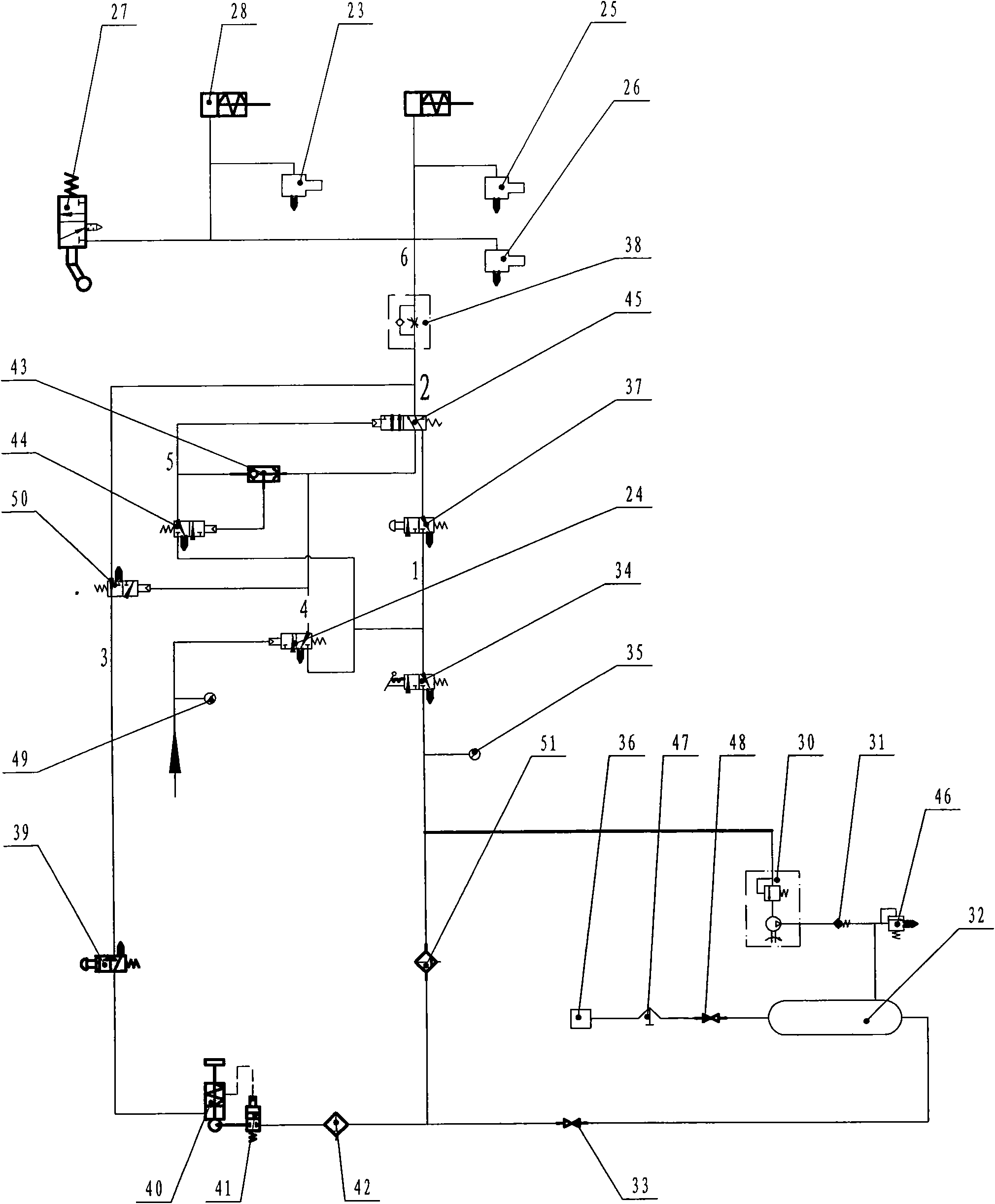

Explosion-proof diesel

ActiveCN101614146AMonitor temperatureMonitor pressureLiquid coolingStarters with fluid-driven auxillary enginesWater jacketProtection system

The invention relates to a diesel, in particular to an explosion-proof diesel, which is applicable to anti-explosion power devices on various fixed and mobile equipment underground coal mine, solving the problems that no explosion-proof diesel product exists in domestic market, while the imported explosion-proof diesel has complicated structure, high price, long lead time of components and parts, untimely service, high maintenance costs and the like. The invention comprises a diesel body, a cooling system, a fuel supply system, an exhaust system and an air intake system, wherein, the cooling system, the fuel supply system, the exhaust system and the air intake system are connected with the diesel body assortatively; an exhaust manifold and an exhaust pipe in the exhaust system are all provided with water jackets; an outlet of the exhaust pipe is connected with a waste gas processing box; the air intake pipeline of the air intake system is provided with an air intake barrier; the invention is further provided with an air starter and protection system. The invention solves the problems of difficult assortment, difficult maintenance and long period of vulnerable components of imported machine types; the air starter and protection system adopts a compressed air starter to start and has the advantages of safety and reliability, convenient maintenance under the mine; the air exhaust is safer and the discharging is effectively reduced.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

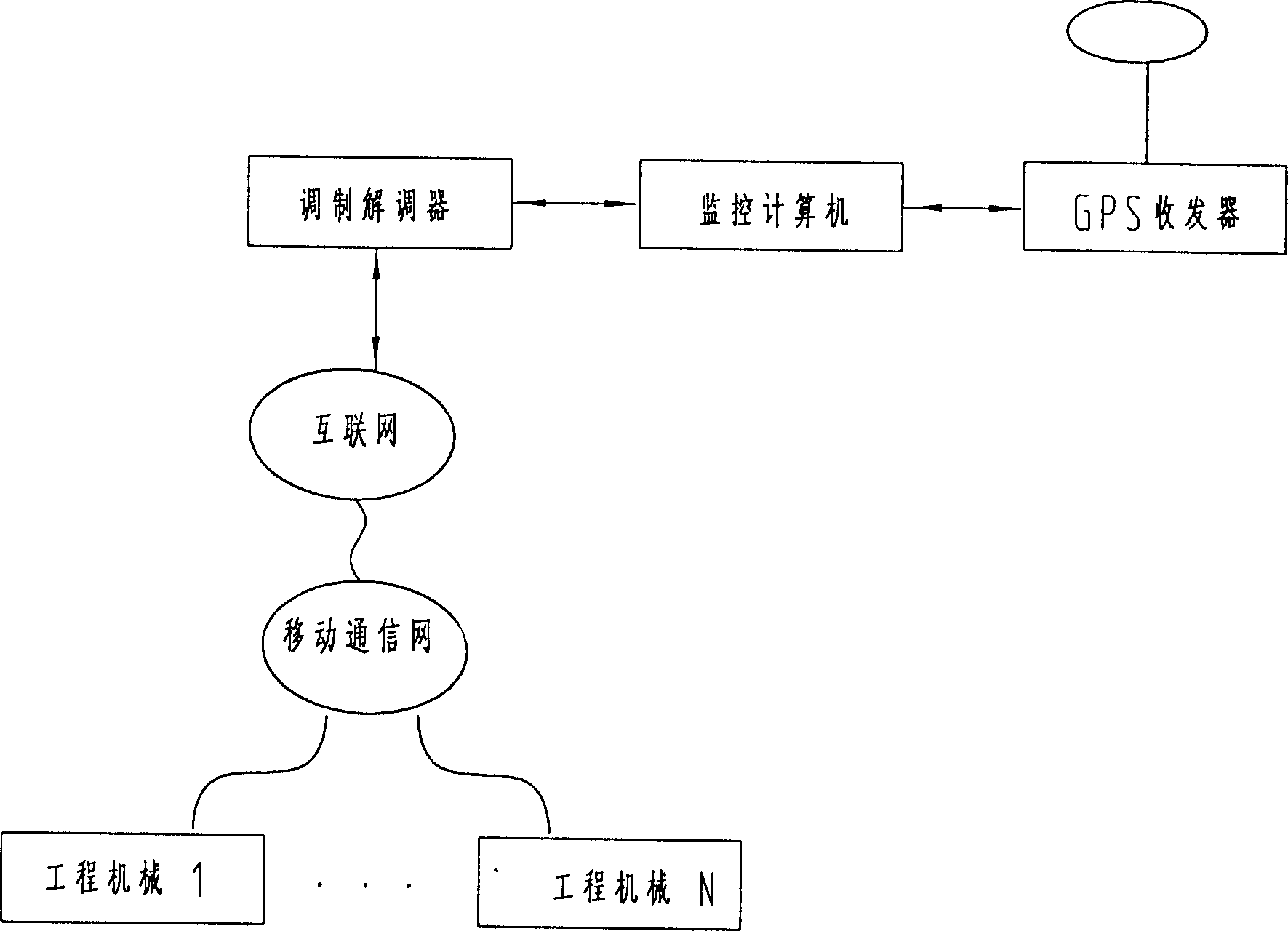

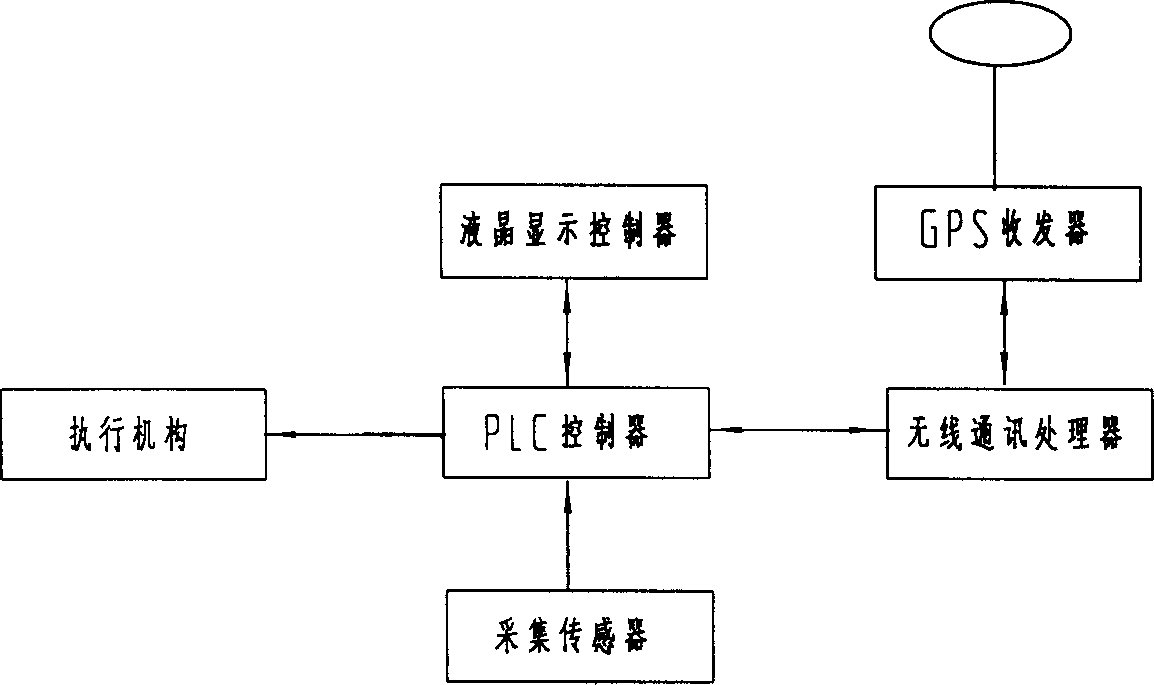

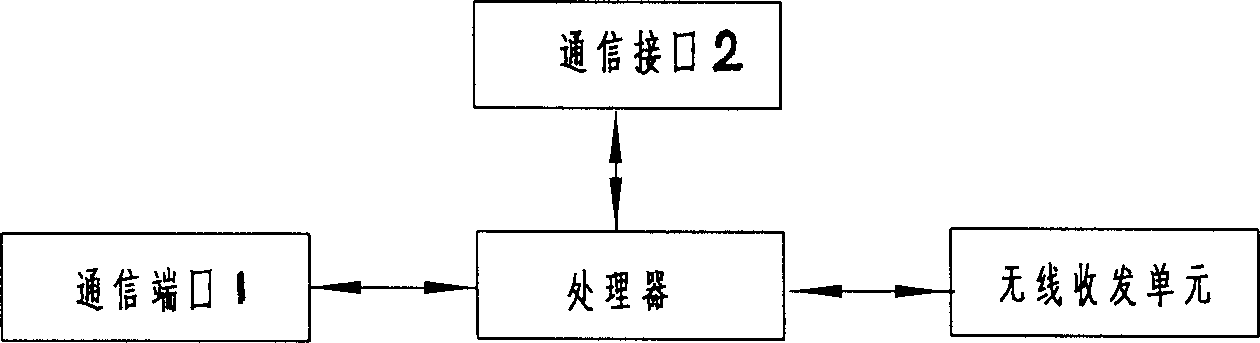

Remote monitoring system for engineering machinery

InactiveCN1409181ASolve maintenance difficultiesResolution cycleComputer controlData switching by path configurationWireless transmissionModem device

A remote monitoring system for engineering equipment includes monitoring computer, modem, internet, mobile communication net and at least one engineering equipment with monitoring computer connected with the internal through the modem. The control part for the engineering equipment consists of signal collecting unit, PLC controller, radio communication processor and executing mechanism. The PLC controller transmits the parameters indicating the operation state of each part of the equipment collected by a collecting unit to the radio communication processor after they are processed by the PLC controller, the processed parameters are sent to the mobile communication net by the radio communication processor, and furthermore are sent to the monitoring computer via internet by mobile communication net.

Owner:SANY HEAVY MACHINERY

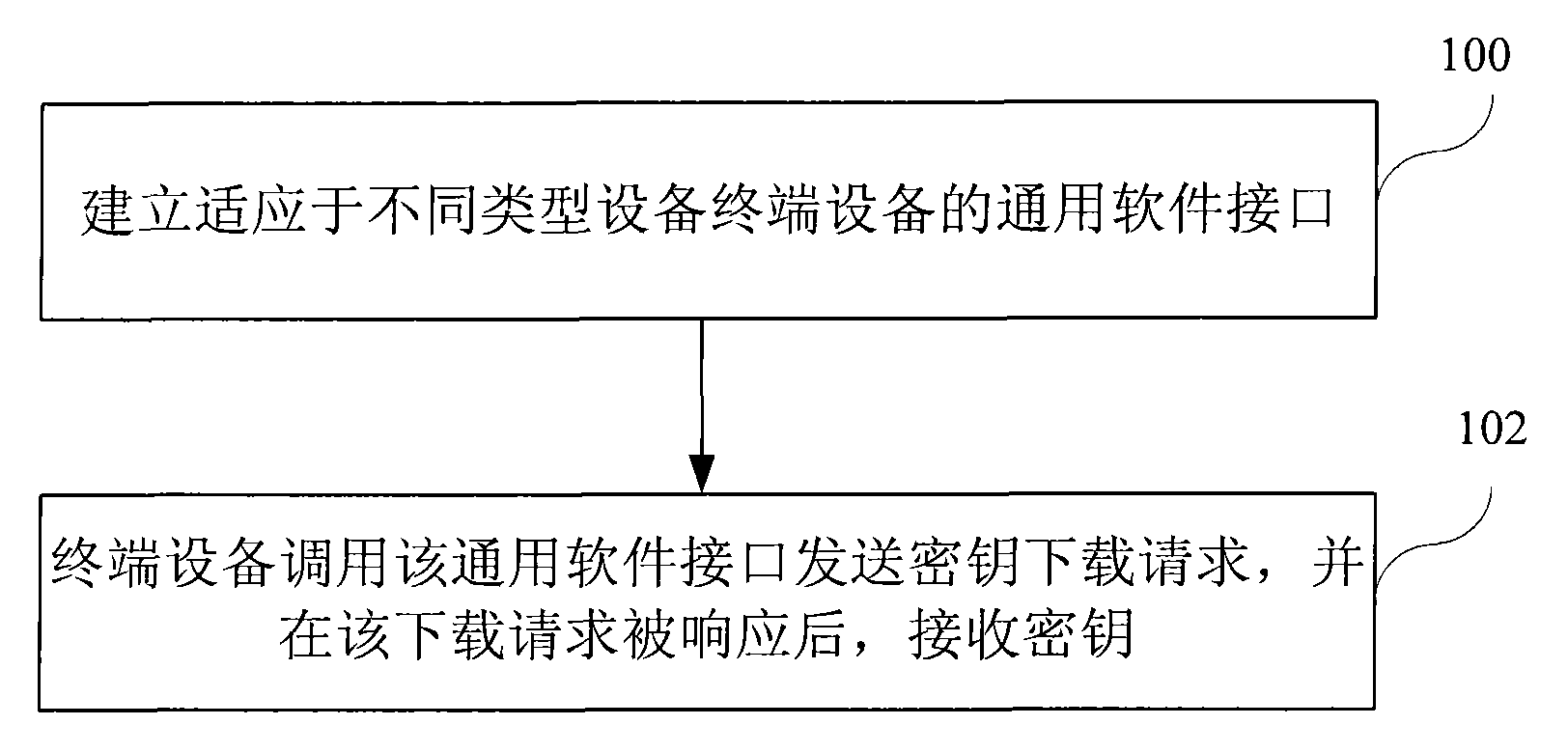

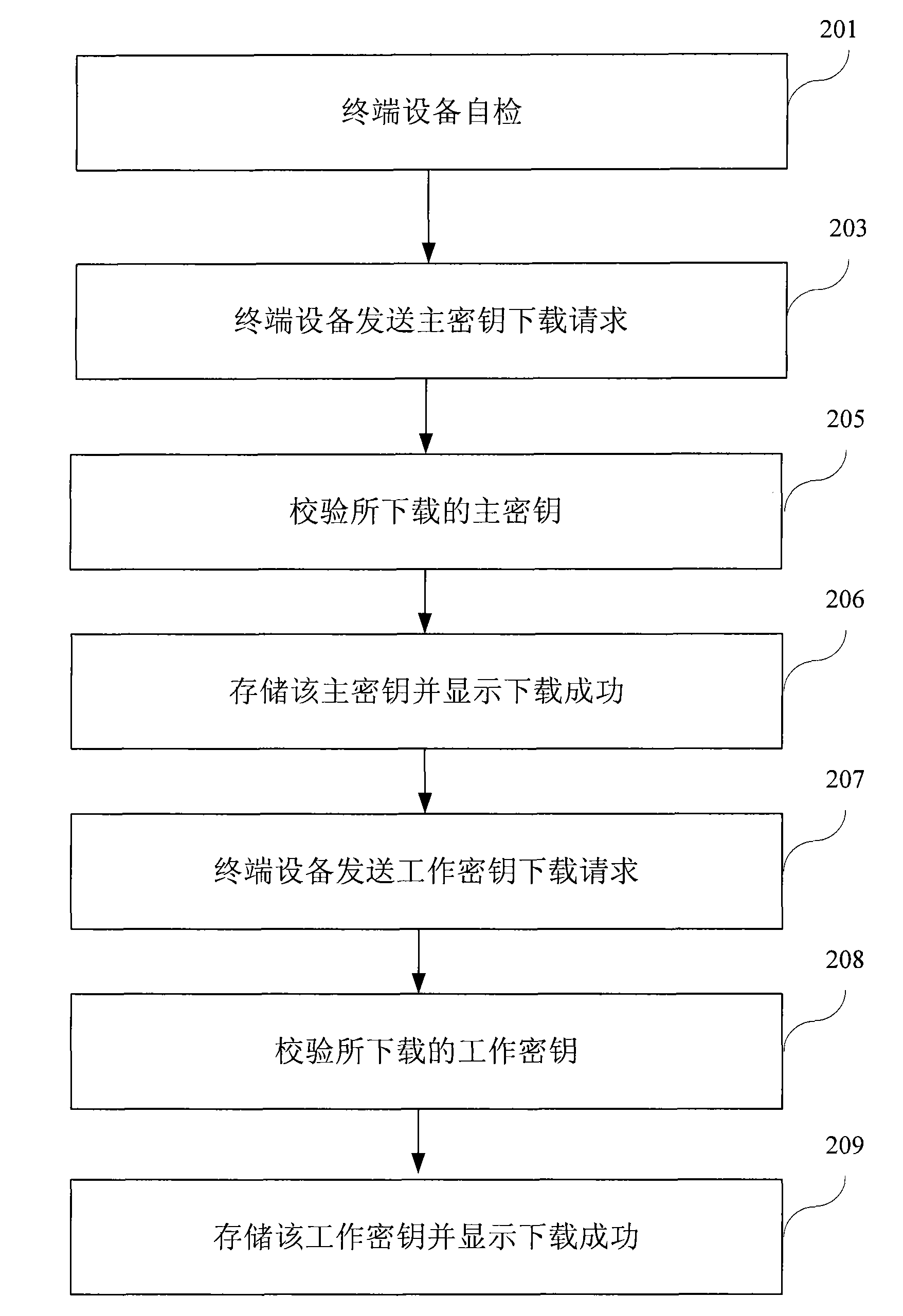

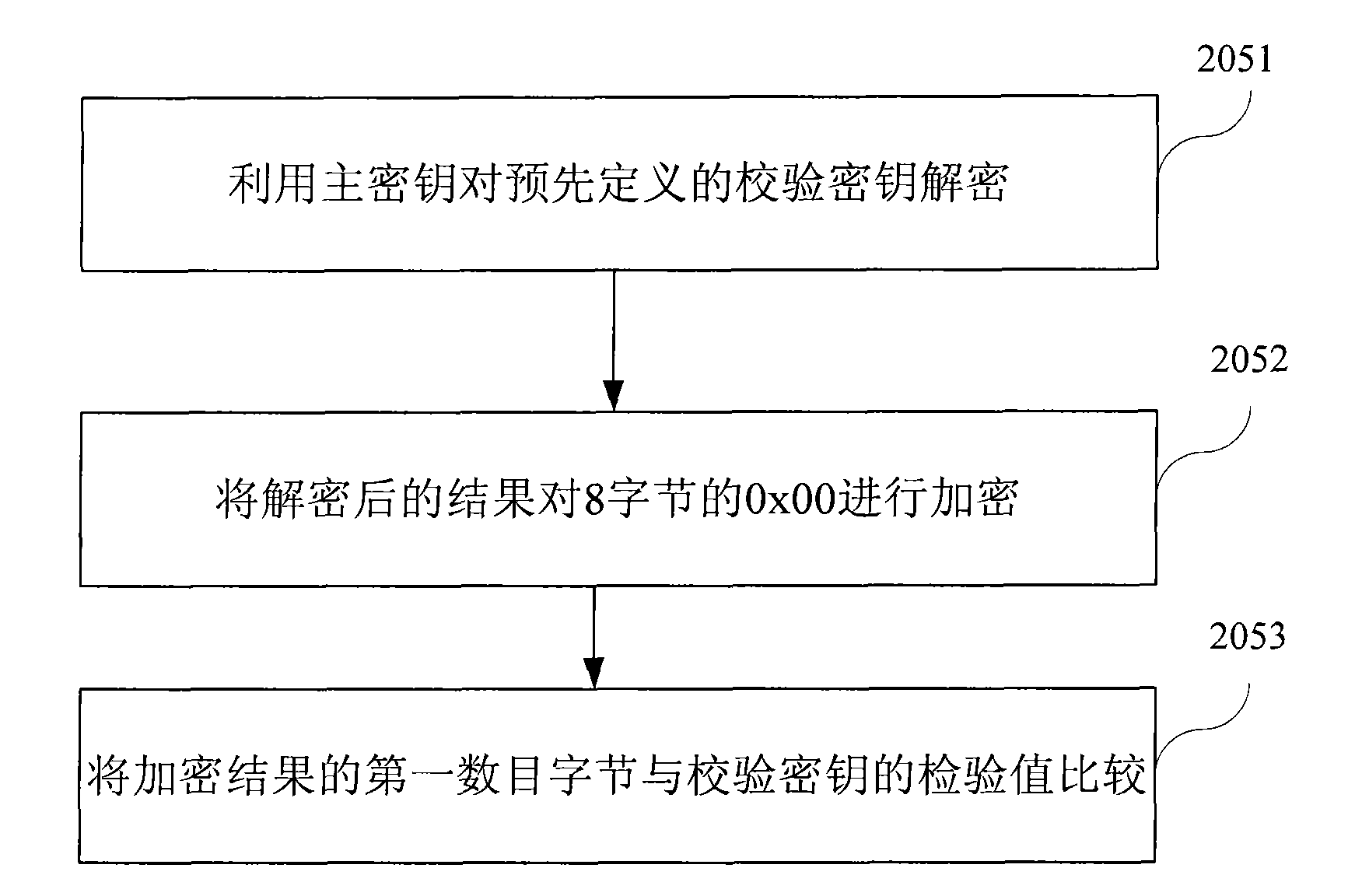

Key downloading method and system

ActiveCN102148799AEasy accessResolve incompatibilitiesPayment architectureTransmissionSoftwareComputer hardware

The invention discloses a key downloading method, which comprises the steps as follows: a universal software interface corresponding to different types of terminal devices is established, wherein a software library comprises library files corresponding to different types of terminal devices; then a terminal device sends a key downloading request to a device providing key downloading through the universal software interface, and receives the key from the universal software interface after the downloading request is responded. The invention also provides a key downloading system, which comprises the universal software interface. The key downloading method and system rely on the compatibility of the universal software interface to enable different types of terminal devices to conveniently download the keys.

Owner:CHINA UNIONPAY

Method for controlling surrounding rock deformation of gateway subjected to repeated overhead mining by using hollow grouting anchor cable

InactiveCN103075170AImprove the support effectSolve the large amount of deformationAnchoring boltsMining engineeringPre stress

The invention relates to a method for controlling surrounding rock deformation of a gateway subjected to repeated overhead mining by using a hollow grouting anchor cable. The method comprises the following implementation steps of: performing repair brushing on the section of the gateway, reinforcing support in a bottom plate gateway to be mined in an advance face which is 280-320 meters in range by adopting high-performance pre-stressed anchor rods, and meanwhile, arranging a metal net on the entire section of the gateway; arranging a novel hollow grouting anchor cable between a top plate of the gateway and the high-performance pre-stressed anchor rods on both sides; grouting on the surface of the surrounding rock of the gateway for enclosing; and injecting a grouting material into the hollow grouting anchor cable. The method has the characteristics of high setting load, sudden increase in resistance and high bearing capability, the problems of high gateway deformation, strong heaving floors and difficulty in maintaining can be well solved, the gateway repair times are reduced, and the gateway support cost is reduced effectively; and the method is particularly suitable for solving the problems of rapid attenuation and loss of anchoring force caused by looseness, breakage and large deformation of surrounding rock due to repeated overhead mining on the gateway.

Owner:CHINA UNIV OF MINING & TECH +1

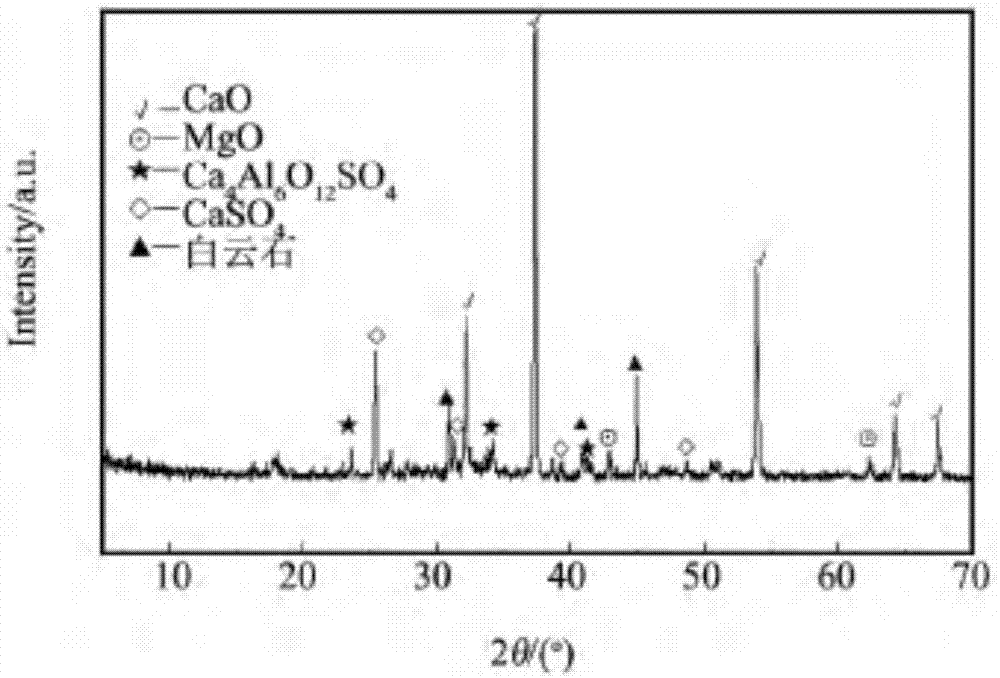

Self-compacting, self-stressing and self-curing high-strength concrete and preparation method thereof

InactiveCN107311567AWith self-maintenance functionSolve voidCeramic shaping apparatusCement mixing apparatusHigh strength concreteChipseal

The invention belongs to the technical field of building materials, and particularly relates to self-compacting, self-stressing and self-curing high-strength concrete and a preparation method thereof. The self-compacting, self-stressing and self-curing high-strength concrete is prepared by mixing cement, fly ash, mineral powder, microbeads, medium sand, gravel, an expanding agent, high molecular absorbent resin SAP, a polycarboxylate superplasticizer and water according to a certain ratio. Through the adoption of the polycarboxylate superplasticizer and addition of a mineral admixture, the concrete is not required to be vibrated and can be compacted through self-leveling; through the addition of the high-efficiency expanding agent, the concrete generates initial self-stress, drying self-shrinkage of the concrete is reduced, and disengagement, a pitted surface and other engineering problems of steel tube concrete are solved; through the addition of the pre-absorbent high molecular resin SAP into the concrete, the problem that the steel tube concrete is difficult to cure is solved. Therefore, the self-compacting, self-stressing and self-curing high-strength concrete has a wide engineering application prospect.

Owner:WUHAN UNIV

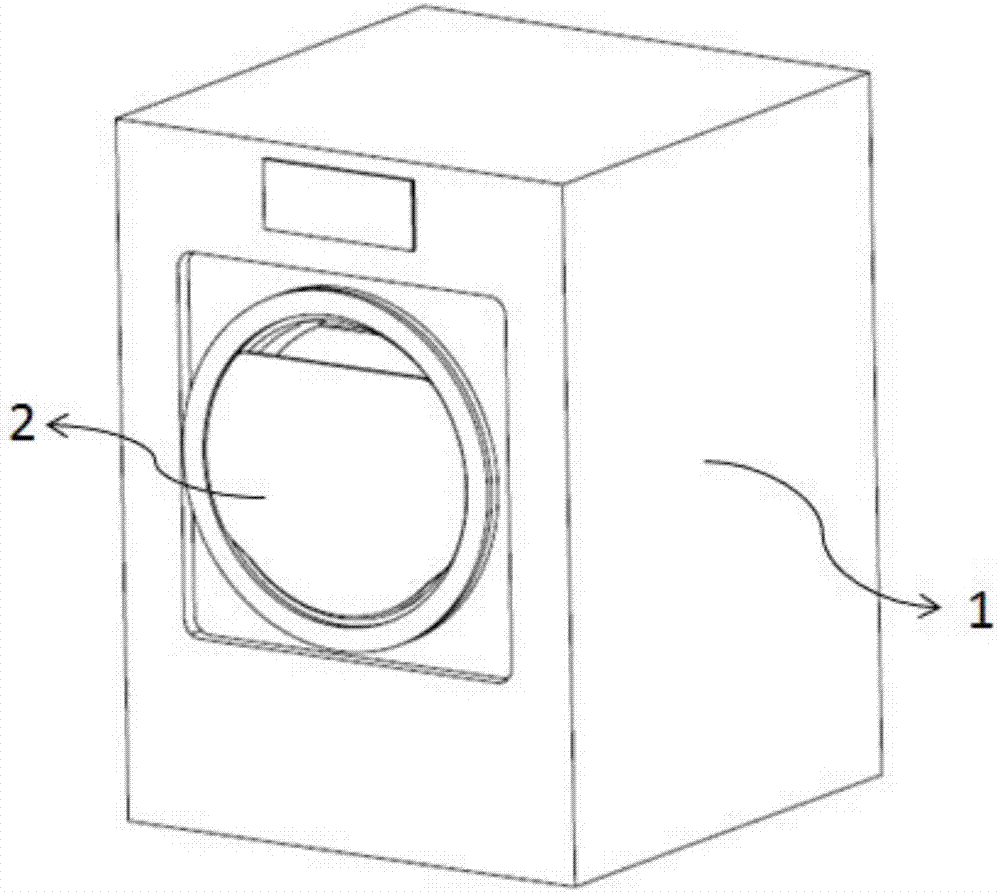

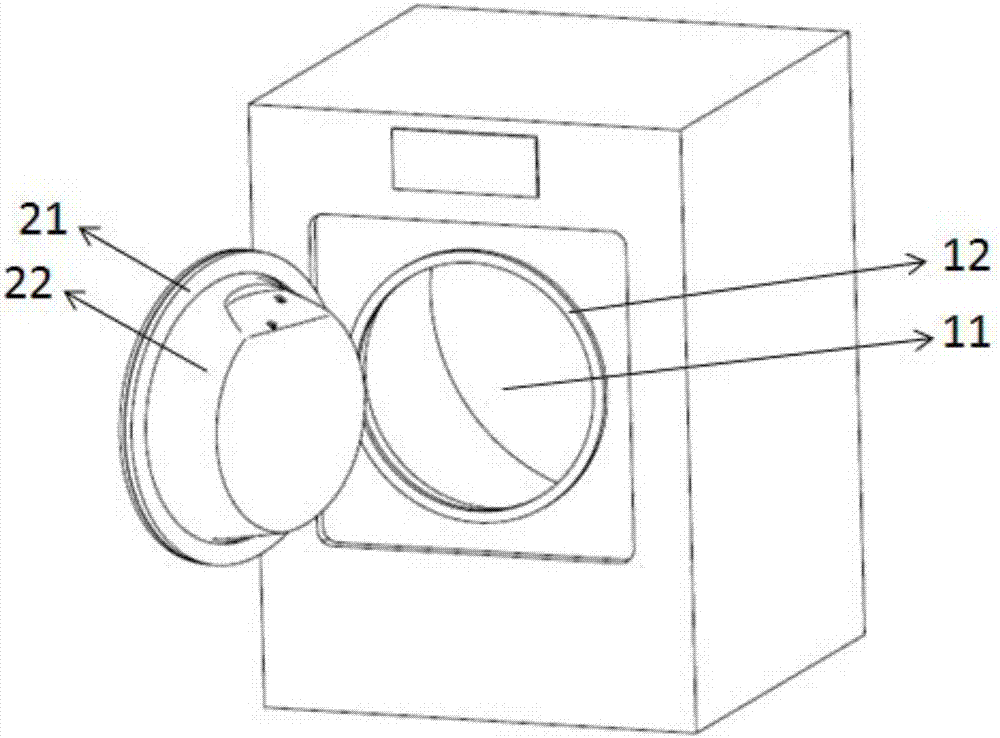

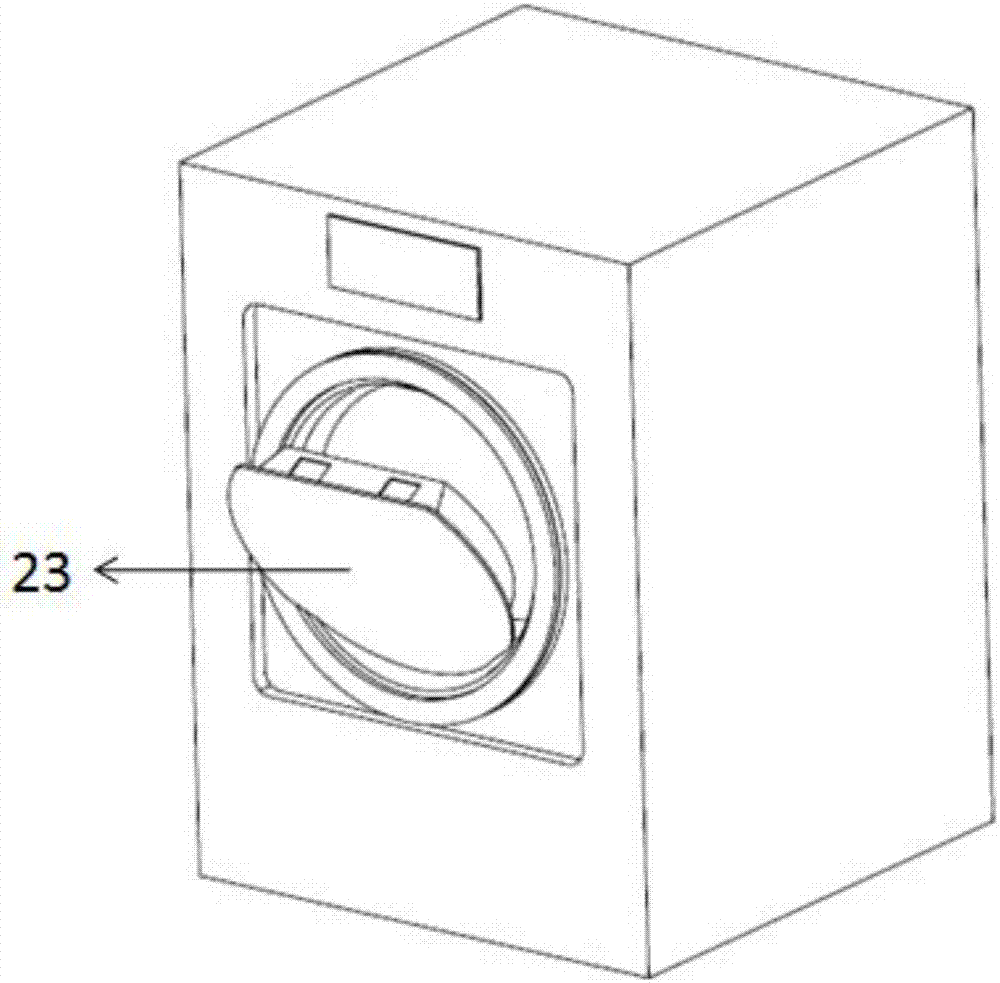

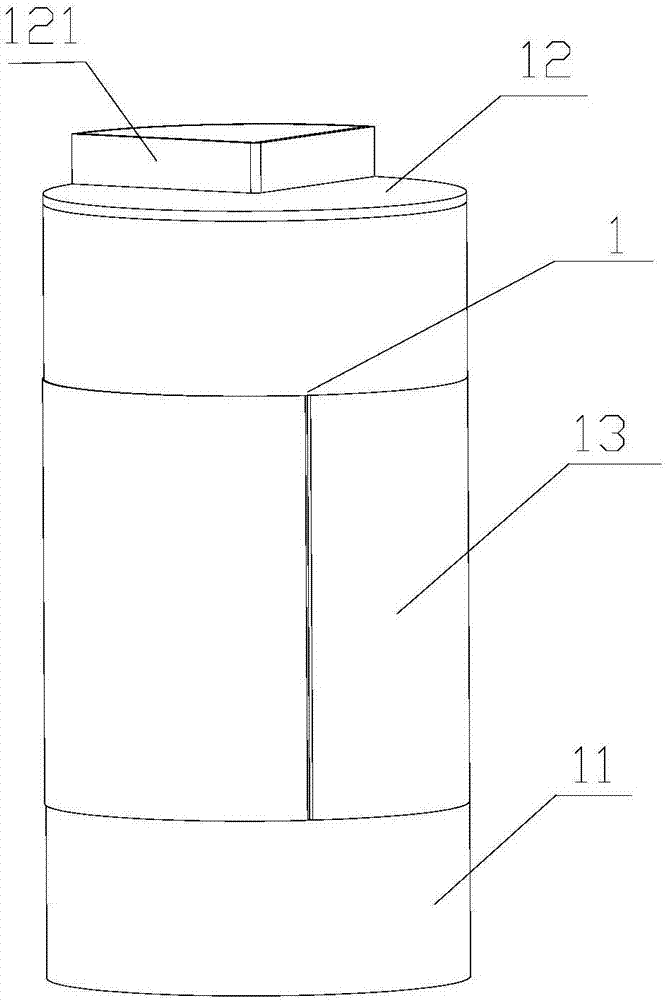

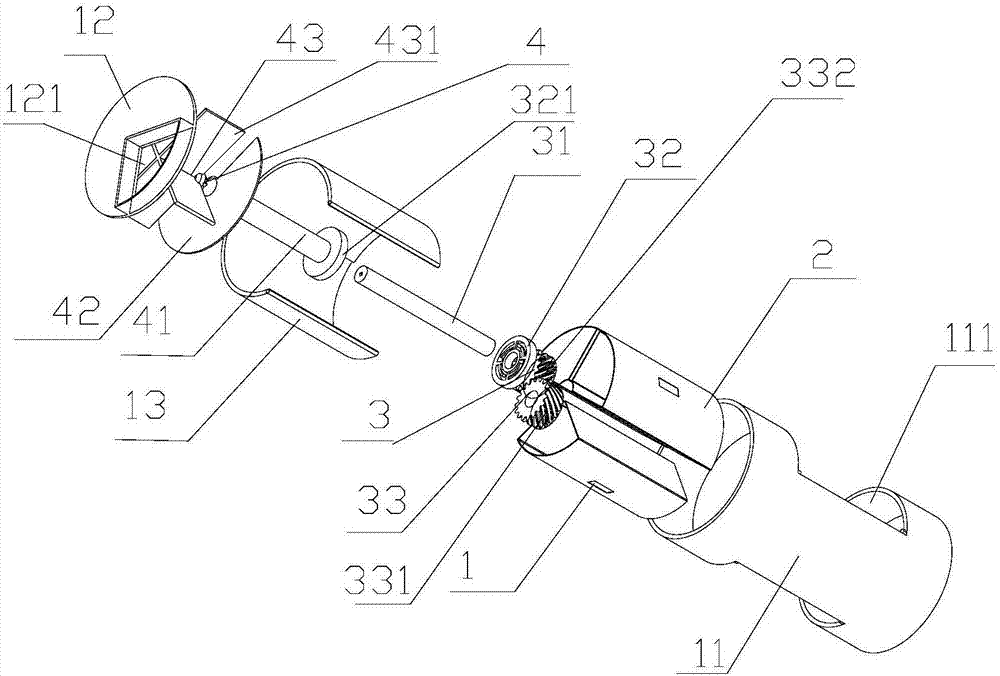

Detergent storage and dropping device and roller washing machine

ActiveCN107541904ASolve underutilized problemsThe installation process is completeOther washing machinesTextiles and paperLaundry washing machinePulp and paper industry

The invention discloses a detergent storage and dropping device and a roller washing machine. The detergent storage and dropping device comprises a first cavity used to store a detergent and having atleast an opening, and a second cavity used to drop the detergent and having at least an opening. The first cavity is communicated with the second cavity. The second cavity is also provided with a stirring device. After the detergent in the first cavity is added into the second cavity, the detergent is stirred by the stirring device and then is discharged. The roller washing machine comprises thedetergent storage and dropping device arranged in a door body. The detergent storage and dropping device drops the detergent into a washing barrel through a glass bowl in the door body. The detergentstorage and dropping device and the roller washing machine improve utilization efficiency of the detergent, and structured holding space which is not used in the glass bowl is fully used, so as to improve space utilization rate of the roller washing machine.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Automatic classification type garbage can

ActiveCN107499775ASolve the costAddressing Structural ComplexityWaste collection and transferRefuse receptaclesScannerControl engineering

An automatic classification type garbage can comprises a garbage outer barrel, a garbage classification scanner, an inner storage barrel, a locating device, a rotating push-conveying mechanism, a controller and a power supply, wherein the inner storage barrel, the locating device, the rotating push-conveying mechanism, the power supply and the controller are arranged in an inner cavity of the garbage outer barrel; the bottom of the locating device is in detachable connection with the inner storage barrel; the power output end of the locating device is connected with the driving end of a rotating pushing mechanism arranged at the top of the inner storage barrel; the signal output end of the garbage classification scanner is electrically connected with the signal input end of the controller, and the control end of the locating device and the control end of the rotating push-conveying mechanism are separately and electrically connected with the signal output end of the controller; and the power transmission end of the garbage classification scanner, the power transmission end of the locating device and the power transmission end of the controller are separately electrically connected with the corresponding power supply ends of the power supply. The automatic classification type garbage can has the beneficial effect that the problems that the classification type garbage can is high in cost, complicated in structure and difficult to repair are solved, manual operation is not needed, and the garbage classification work of a user is reduced.

Owner:ZHEJIANG UNIV OF TECH

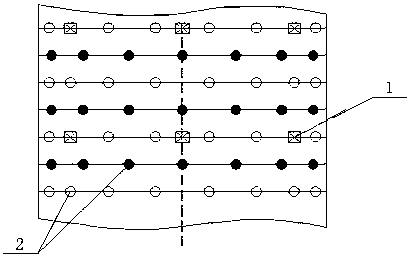

Double-layer anchor net cable supporting structure for controlling mining roadway surrounding rock deformation and method thereof

InactiveCN106321119AImprove support strengthImprove carrying capacityUnderground chambersTunnel liningEngineeringStructural engineering

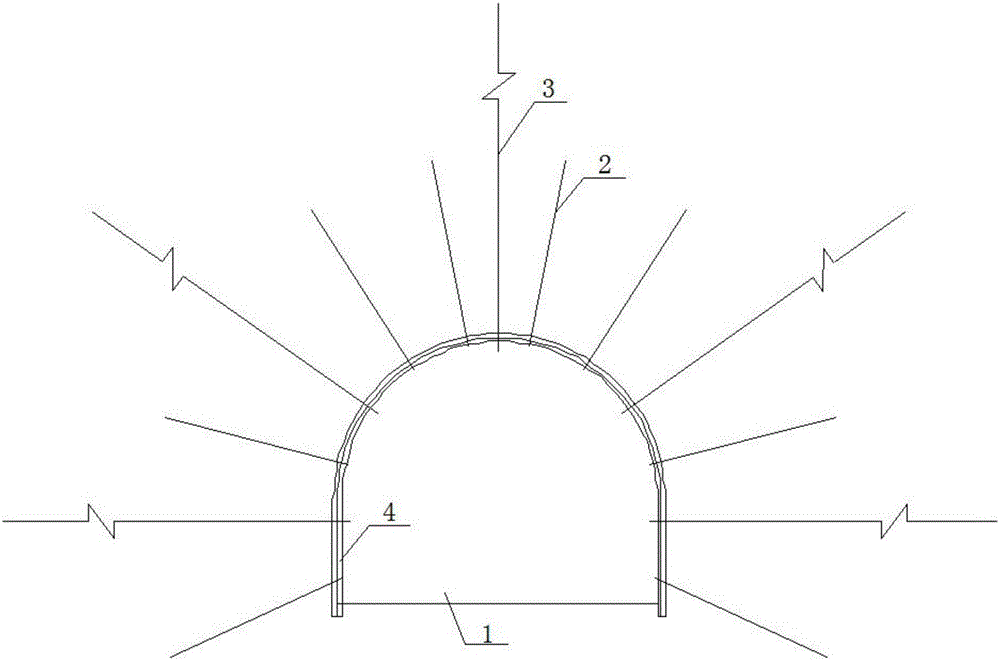

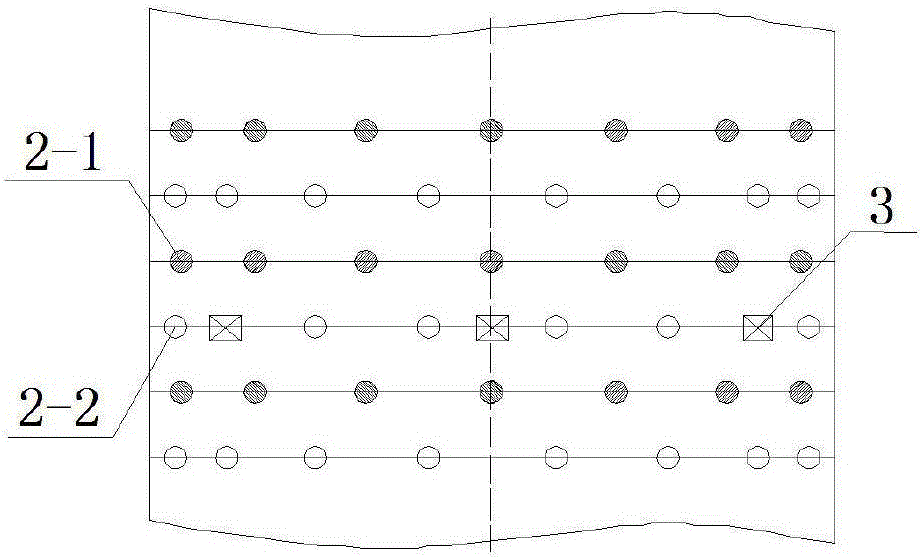

The invention discloses a double-layer anchor net cable supporting structure for controlling mining roadway surrounding rock deformation. The double-layer anchor net cable supporting structure is characterized in that secondary anchor net supporting is performed on the basis of primary anchor net supporting, secondary supporting anchor rods (2-2) and primary supporting anchor rods (2-1) are arranged at intervals, the row spacing between the anchor rods is 700-900 mm, the specifications of the secondary supporting anchor rods (2-2) are the same as those of the primary supporting anchor rods (2-1), hollow grouting anchor cables (3) are arranged between the secondary supporting anchor rods (2-2), the interval between the hollow grouting anchor cables (3) is 1000-1500 mm, and the row spacing is 700-1800 mm. According to the supporting structure, the capability of a double-layer anchor net actively supporting shallow part surrounding rock can be brought into full play, the supporting capability of deep part surrounding rock can be improved through the anchor cables, the roadway supporting safety reliability is improved, severe deformation of a mining roadway can be controlled, it can be guaranteed that the supporting structure is continuously effective during the service life of the roadway, the roadway rework times are reduced, and the roadway maintenance cost is reduced.

Owner:GUIZHOU UNIV

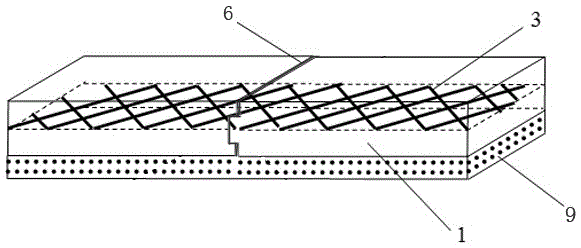

Assembling type inclined slow-adhesion pre-stressed concrete road surface structure

ActiveCN105862538AConstrained two-way deformationOvercome vertical and horizontal cracksSingle unit pavingsClimate change adaptationEnvironment effectPre stress

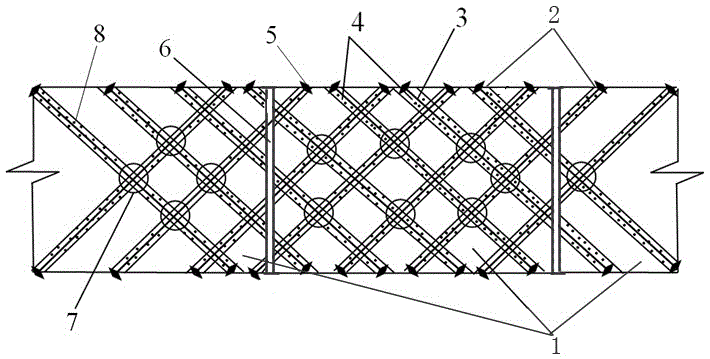

The invention discloses an assembling type inclined slow-adhesion pre-stressed concrete road surface structure. The assembling type inclined slow-adhesion pre-stressed concrete road surface structure comprises a rubber waterstop, a CA mortar connection layer and an anchor head; the structure is formed by the mutual connection of a plurality of prefabricated pre-stressed concrete road surface plates; a plurality of pore channel holes and grouting holes are formed in the adapted positions of each side face and the upper end face of the prefabricated pre-stressed concrete road surface plates; and slow-adhesion pre-stressed steel bars are inserted into a steel bar pore channel through the pore channel holes and cement mortar is filled from the grouting holes. The structure disclosed by the invention is prefabricated in a factory and is positioned and mounted in a construction site; concrete does not need to be cast on site; the structure is convenient and rapid to mount, the influences caused by the environment are slight, the production efficiency is high and the quality is good; and a lot of manpower resources are saved. A road surface does not need to be provided with a transverse seam so that a damage phenomenon caused by the seam on a common cement concrete road surface is solved; the road surface repairing and maintenance cost is reduced; the use performance of the road surface is improved, the noise of the road surface is lowered and the driving comfort is improved; and the service life of the cement concrete road surface is prolonged.

Owner:芽米科技(广州)有限公司

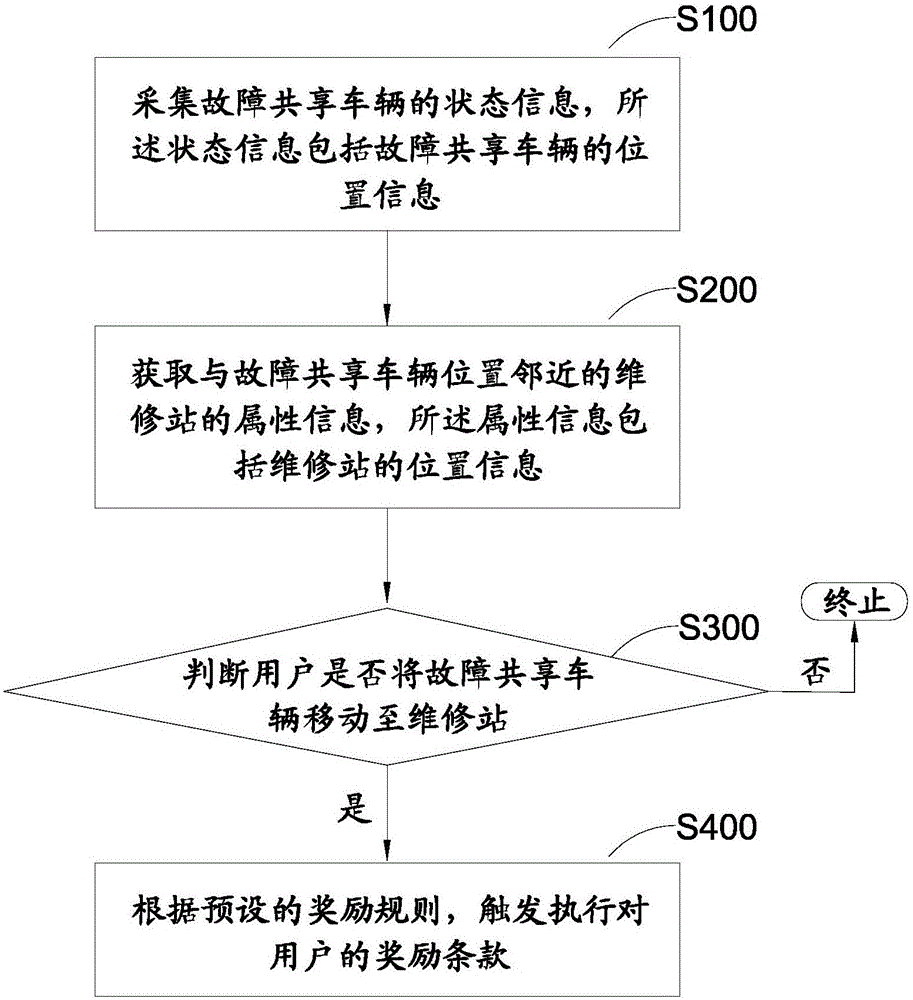

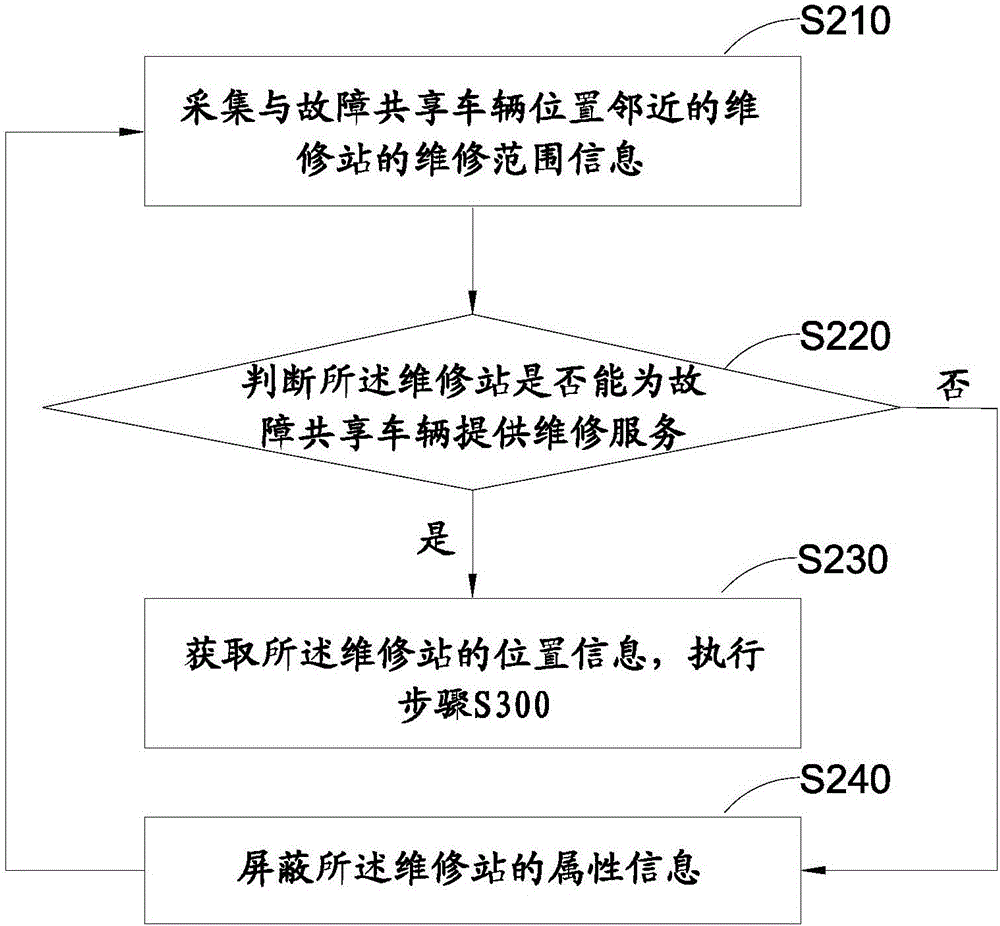

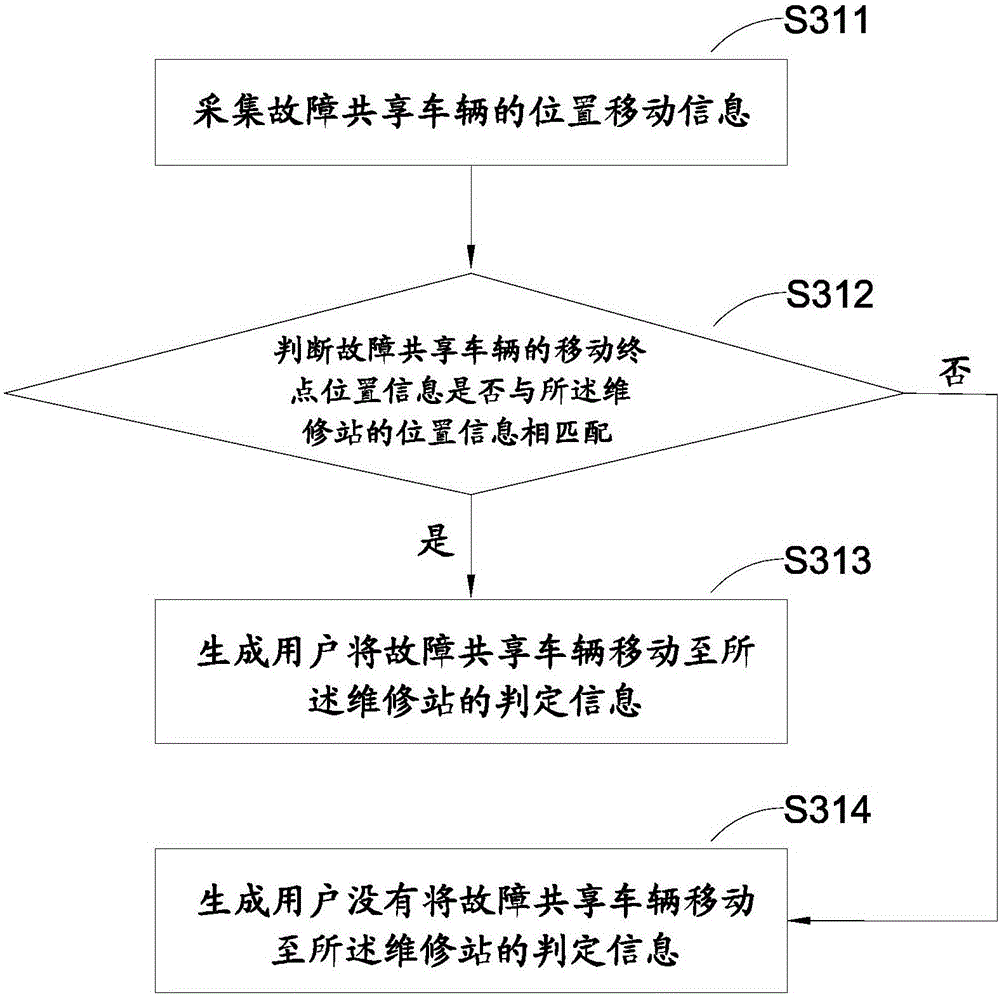

Maintenance implementation method, system and client of shared vehicles

PendingCN106600013ASolve maintenance difficultiesImprove effective utilizationDiscounts/incentivesBuying/selling/leasing transactionsComputer scienceUtilization rate

The invention provides a maintenance implementation method, system and client of shared vehicles, and belongs to the technical field of shared means of transportation. The maintenance implementation client comprises an acquisition circuit used for acquiring state information of fault vehicles; a storage chip used for storing attribute information of each maintenance station; a screening circuit connected with the acquisition circuit and the storage chip for screening maintenance stations nearby fault shared vehicles and outputting position information of the maintenance stations; a determining circuit connected with the acquisition circuit and the screening circuit for determining whether users move the fault shared vehicles to the maintenance stations; and a rewarding circuit connected with the acquisition circuit and the determining circuit for triggering execution of reward items for the users. According to the scheme provided by the invention, the method, system and client have the following advantages: the problems of affecting user application and increasing maintenance difficulty after the shared vehicles are damaged are solved by use of the method, system and client, maintenance of the fault shared vehicles is facilitated, and the effective utilization rate of the shared vehicles is improved.

Owner:SHANGHAI LIANGMING TECH DEV

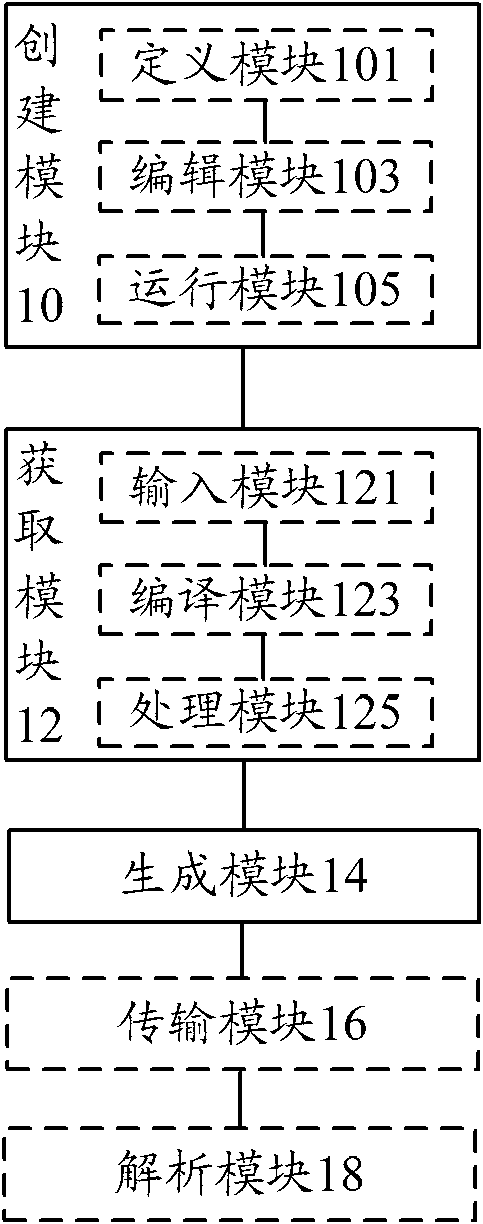

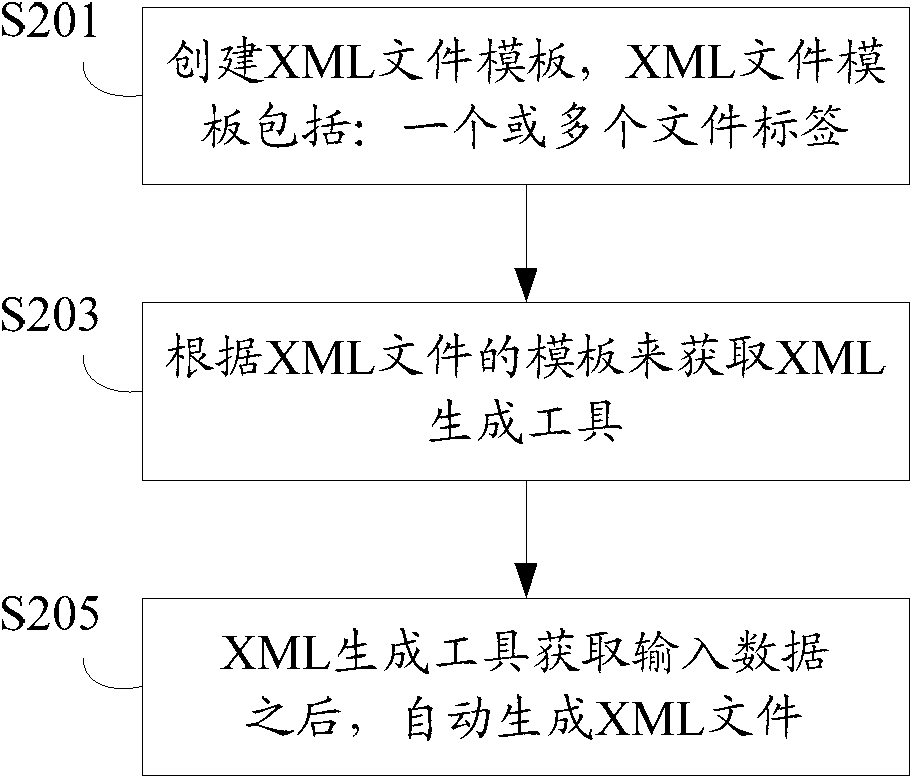

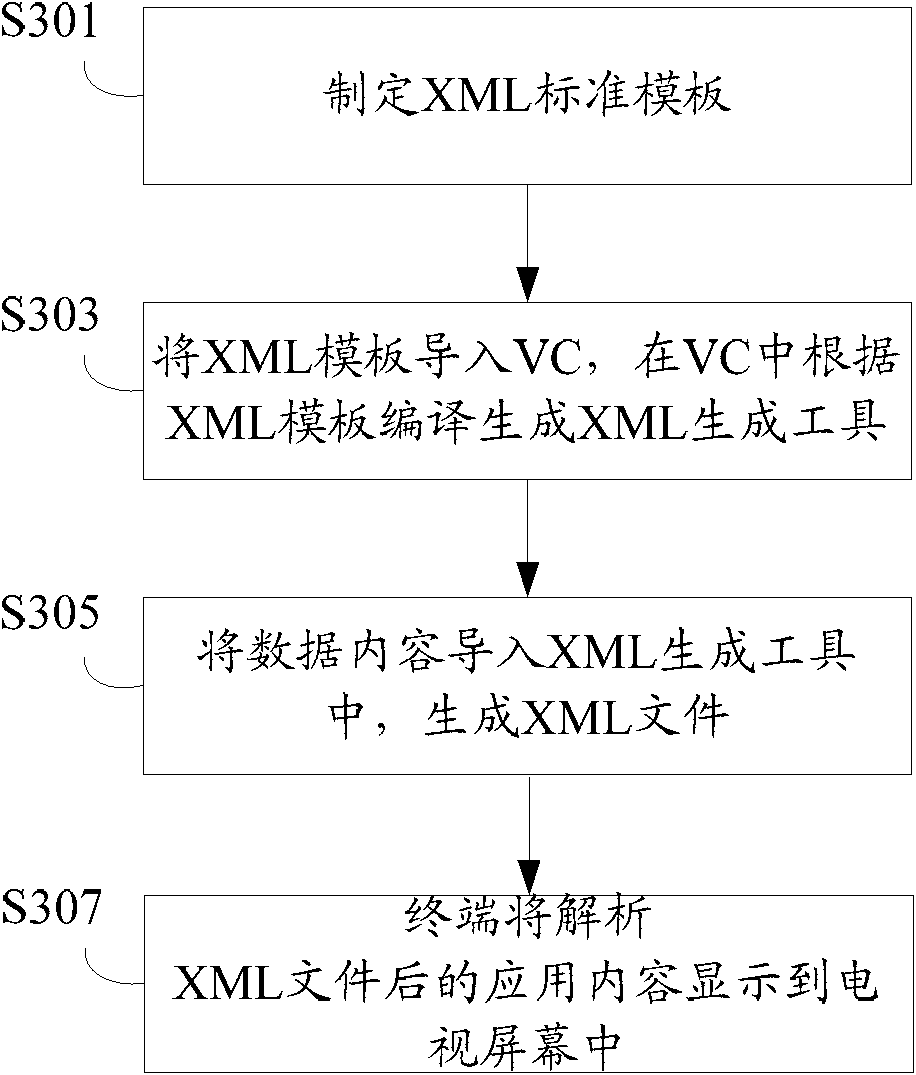

XML (Extensible Markup Language) file generating method and device as well as terminal equipment

InactiveCN102646102ASolve efficiency problemsSolve space problemsSpecial data processing applicationsTerminal equipmentExtensible markup

The invention discloses an XML (Extensible Markup Language) file generating method and device as well as terminal equipment. The XML file generating method comprises a step of: establishing an XML file template, wherein the XML file template comprises one or more than one file label; obtaining an XML generating tool according to the XML file template; and automatically generating an XML file after the XML generating tool obtains input data. With the adoption of the XML file generating method and device provided by the invention, resource content is flexibly controlled according to demands so a storage space of an application is saved, image-text type application development and content maintenance are facilitated, and the working efficiency of research staff is improved.

Owner:HISENSE VISUAL TECH CO LTD

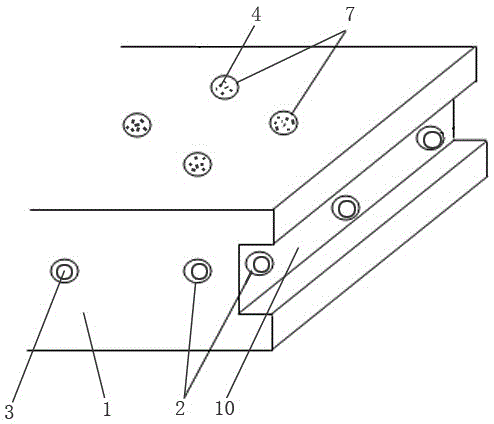

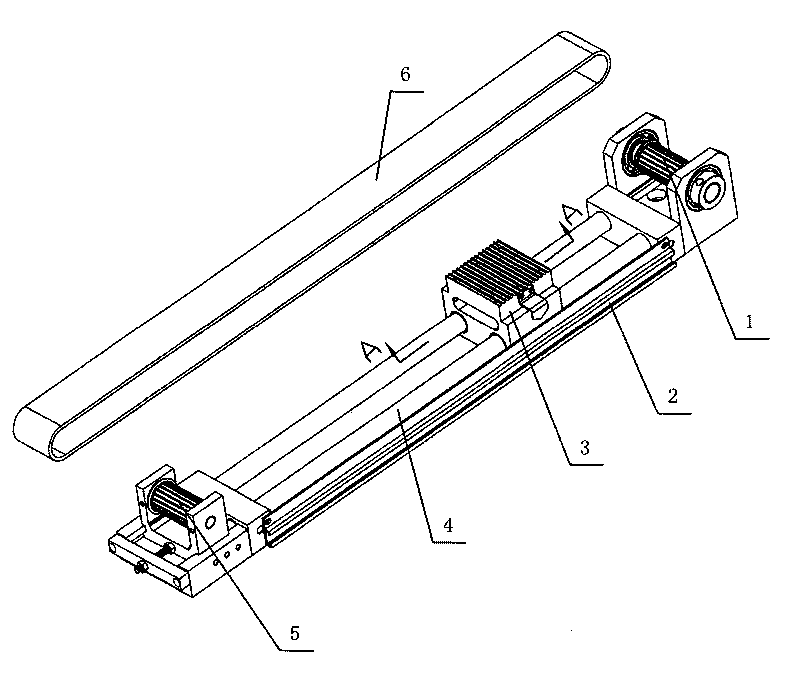

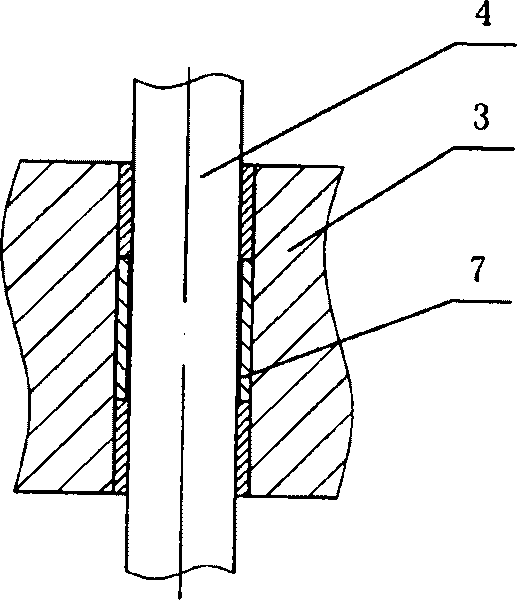

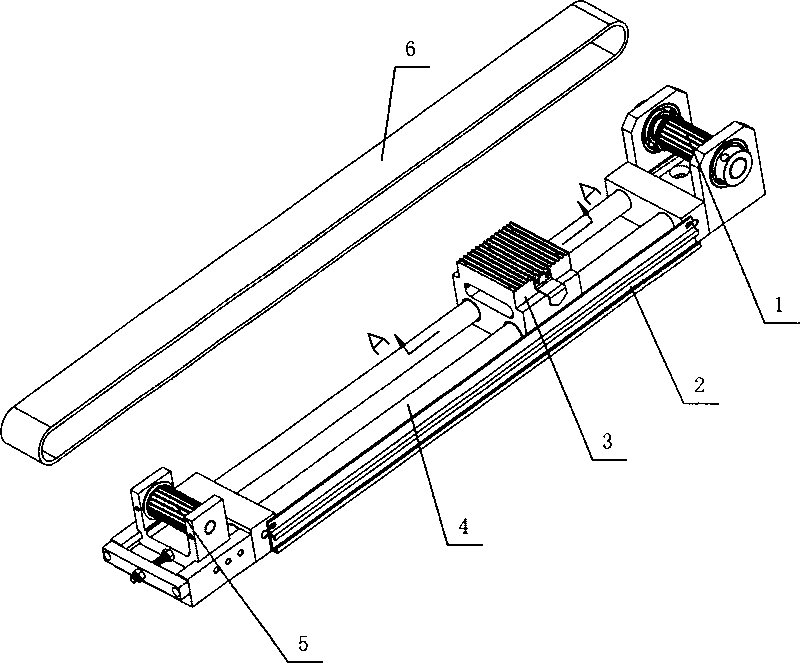

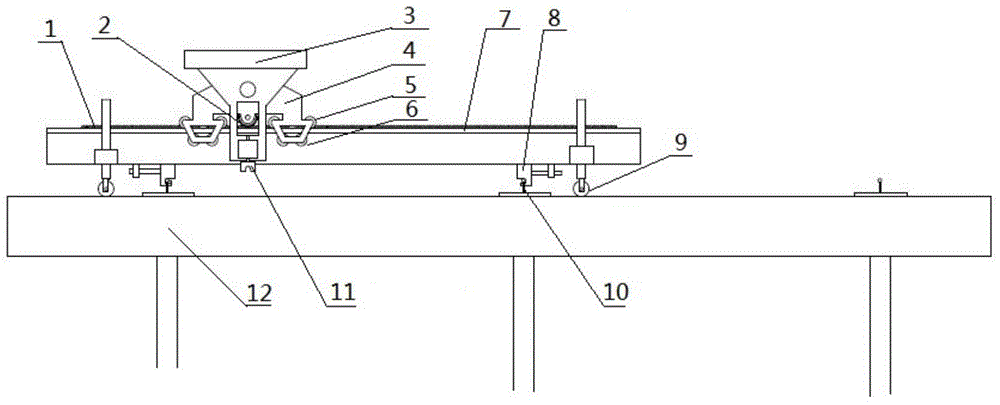

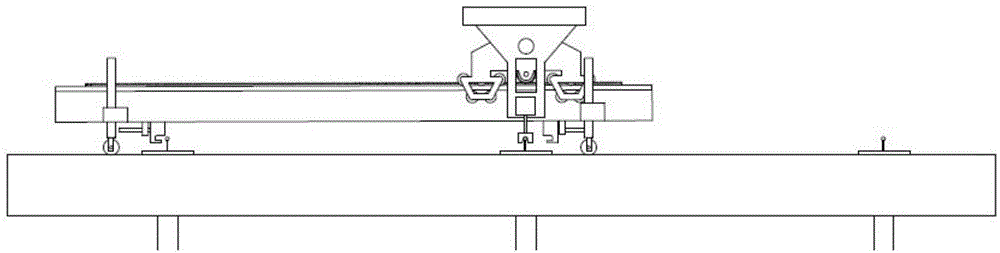

Mechanism for feeding cloth in X and Y directions for computerized embroidery machine

The invention relates to a mechanism for feeding cloth in X and Y directions for a computerized embroidery machine, which comprises a driving wheel, a driven wheel, a synchronous belt and a sliding block, wherein racks are arranged on the upper surfaces of the driving wheel, the driven wheel and the sliding block; the synchronous belt is sleeved on the driving wheel and the driven wheel; the internal teeth of the synchronous belt are meshed with the racks arranged on the upper surface of the sliding block; the driving wheel and the driven wheel are longitudinally installed at two ends of two parallel guide posts; and the two guide posts are sleeved in guide holes in the sliding block. The invention has the advantages of simple integral structure, scientific and reasonable design, high transmission accuracy, fine quality of embroideries and higher innovation and practicability, greatly prolongs the service life of the mechanism for feeding cloth by adopting the two guide posts, and obviously reduces the maintenance frequency.

Owner:上工富怡智能制造(天津)有限公司

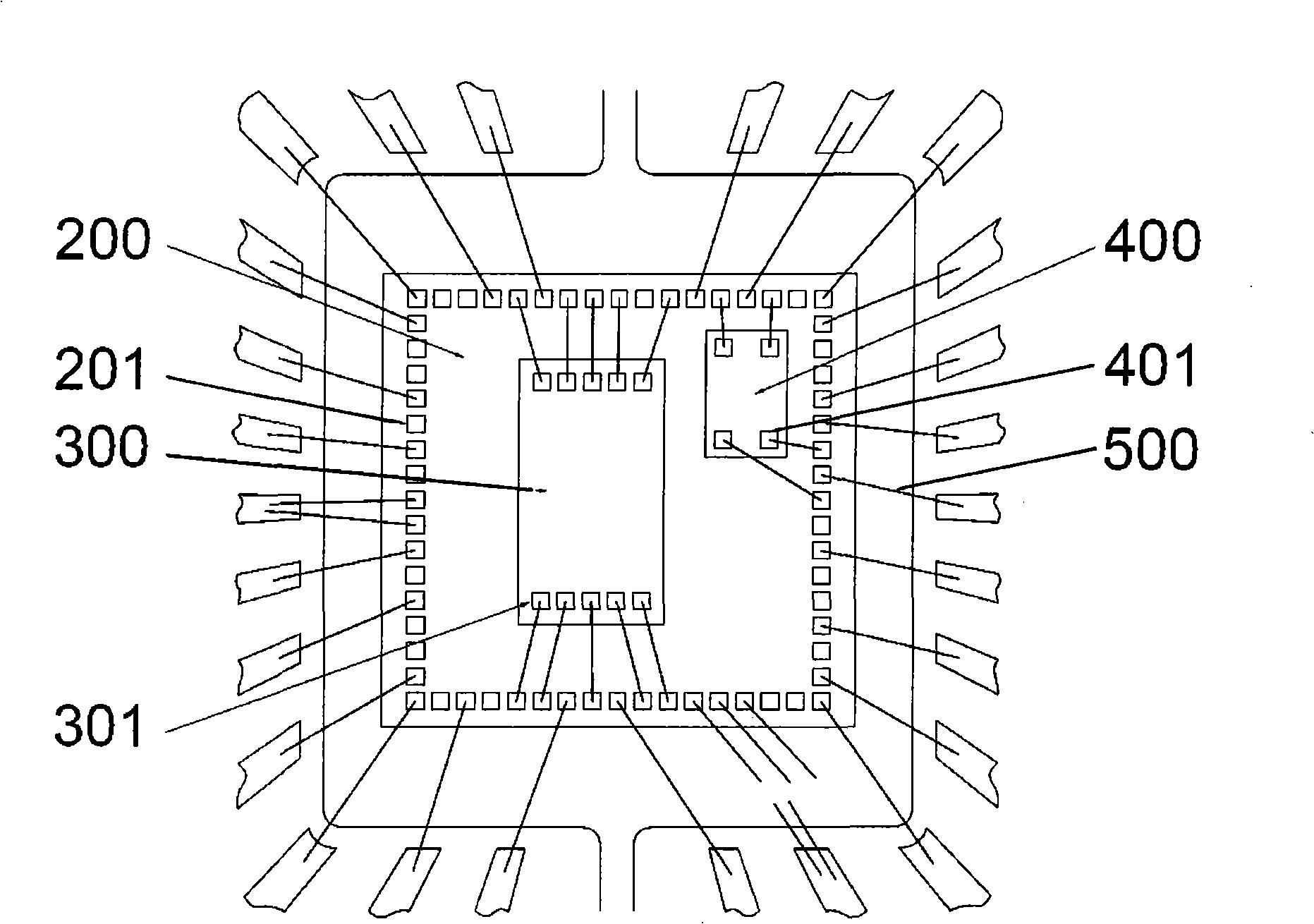

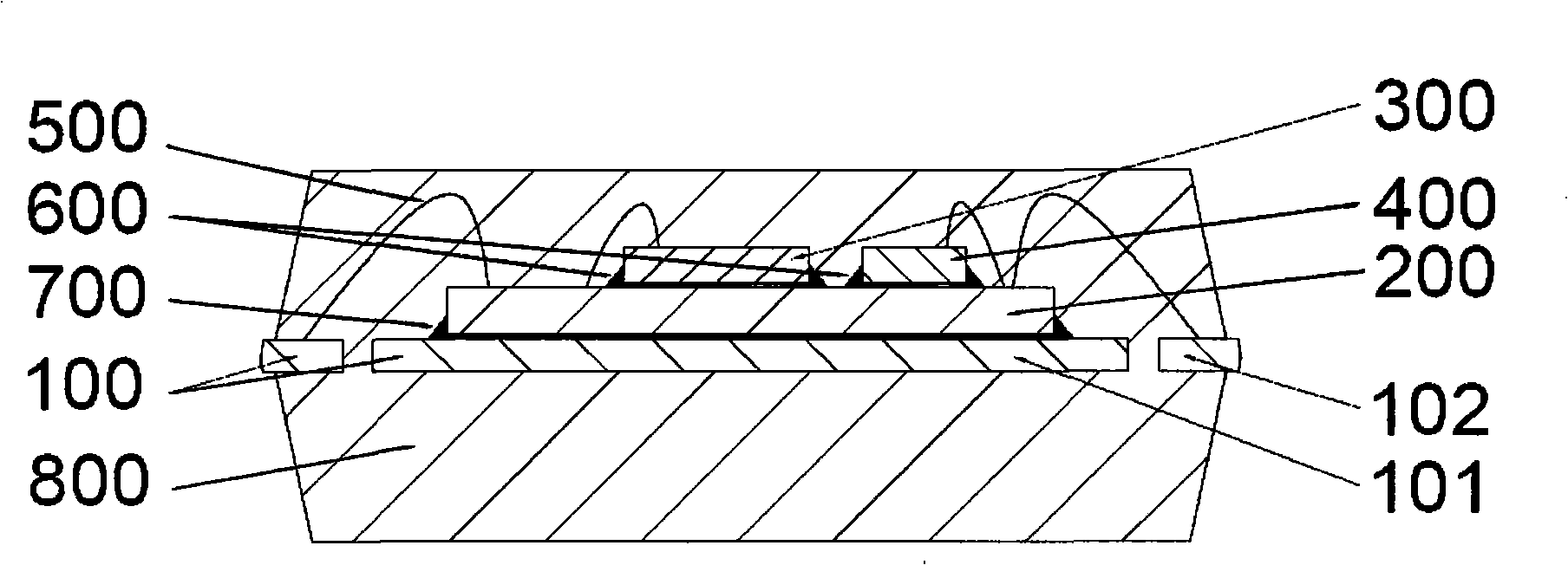

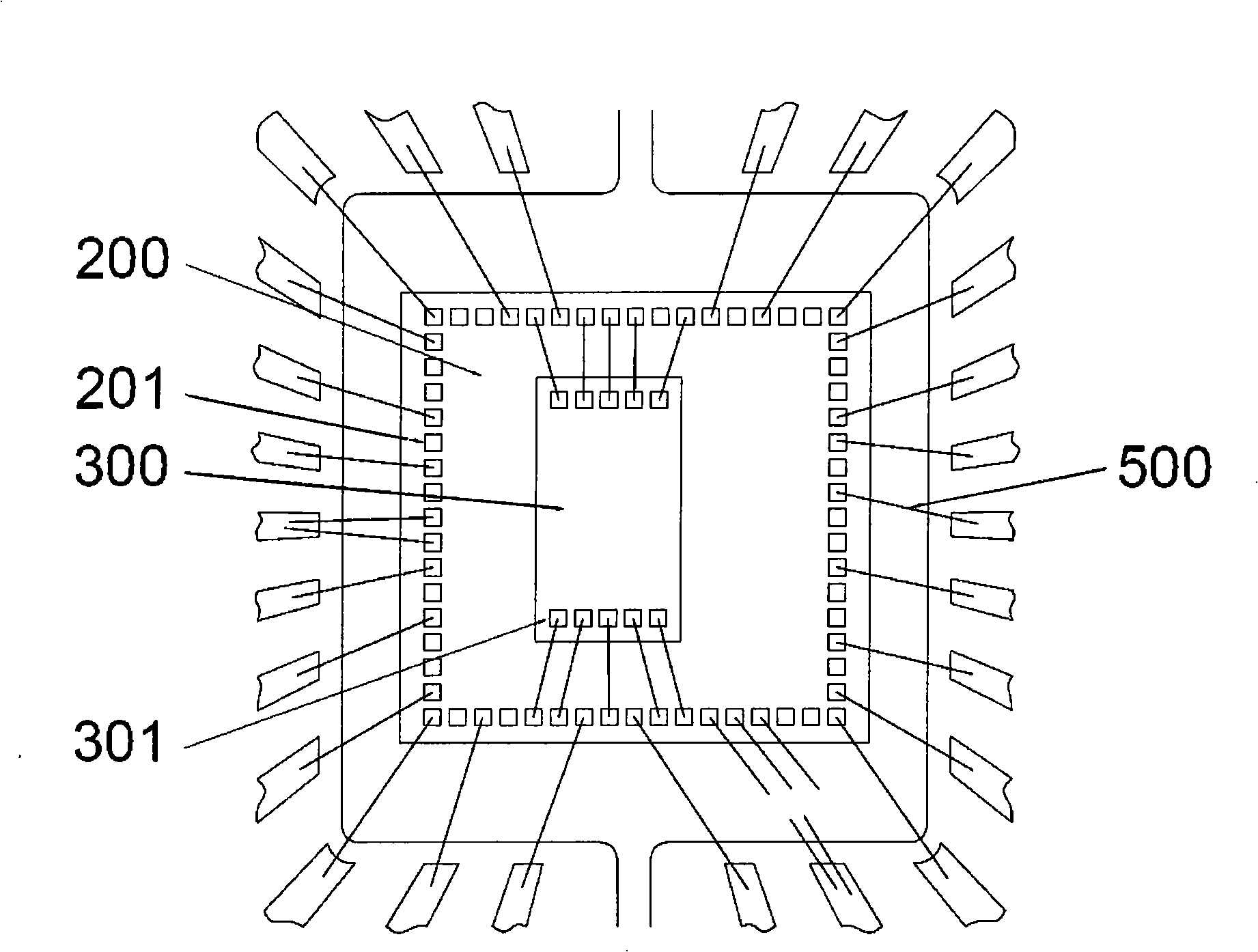

Multi-chip 3D stacking and packaging structure

InactiveCN101404279AReduce areaReduce package sizeSemiconductor/solid-state device detailsSolid-state devicesVideo processingEngineering

The invention relates to a multi-chip 3D stacked packaging structure. The structure comprises a main chip and at least one auxiliary chip. The main chip and the auxiliary chip are respectively provided with a circuit surface and a back surface facing the circuit surface; the auxiliary chip is stacked on the main chip; a main bonding pad is arranged on the circuit surface of the main chip, and an auxiliary bonding pad is arranged on the circuit surface of the auxiliary chip; the auxiliary bonding pad is connected with the main bonding pad by a metal wire. By using the multi-chip 3D stacked packaging structure, the main chip for video processing is designed to connect a plurality of auxiliary chips completely by internal leads in a package, and the functional integration of three chips in a dual in-line package is finished. High formation degree of the chip reduces the area of a circuit board, lowers the production cost of manufacturers, reduces the signal transmission delay and improves the system performance simultaneously. And the system board and the module have the advantages of small packaging size and light weight.

Owner:HUAYA MICROELECTRONICS (SHANGHAI) INC

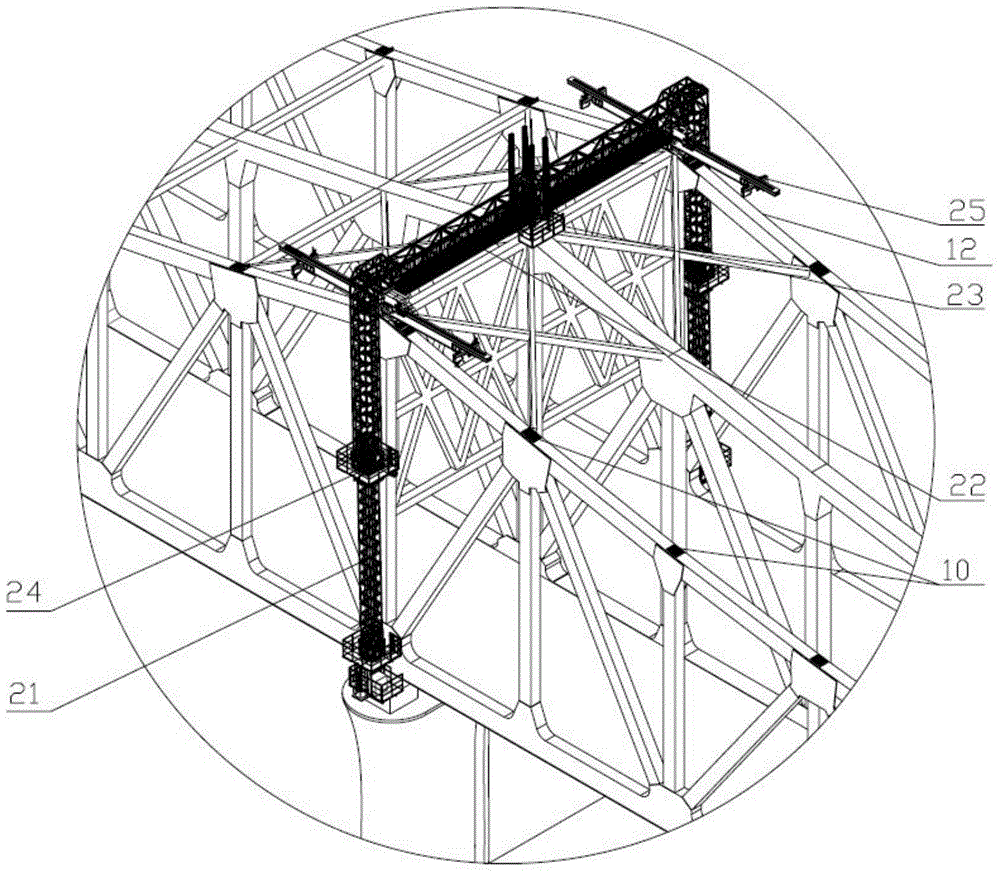

Inspection trolley for bridge upper chord

InactiveCN105317005ASolve maintenance difficultiesLow costBridge structural detailsFull bridgeEngineering

The invention relates to the field of bridge inspection, and discloses an inspection trolley for a bridge upper chord. The inspection trolley for the bridge upper chord comprises a connecting corridor and stand columns, the stand columns are fixed to the connecting corridor, walking mechanisms are symmetrically arranged at the two ends of the connecting corridor respectively, and the connecting corridor is movably installed on a bridge through the walking mechanisms. Each walking mechanism comprises a walking beam and a bearing platform, wherein the bearing platform is movably installed on the walking beam, the walking beam is movably installed on the bridge, jack catches are arranged at the bottom of the walking beam, the top of the bearing platform is fixed to the connecting corridor, and the bottom of the bearing platform is provided with a liftable supporting clamp. Multiple connecting pieces are arranged on the bridge, and the jack catches and the supporting clamps can be connected to the connecting pieces on the bridge in a clamped mode. According to the inspection trolley for the bridge upper chord, due to the fact that the walking mechanisms can climb up a hill, it is unnecessary to lay tracks, materials of track laying are saved, and overall bridge cost is low.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

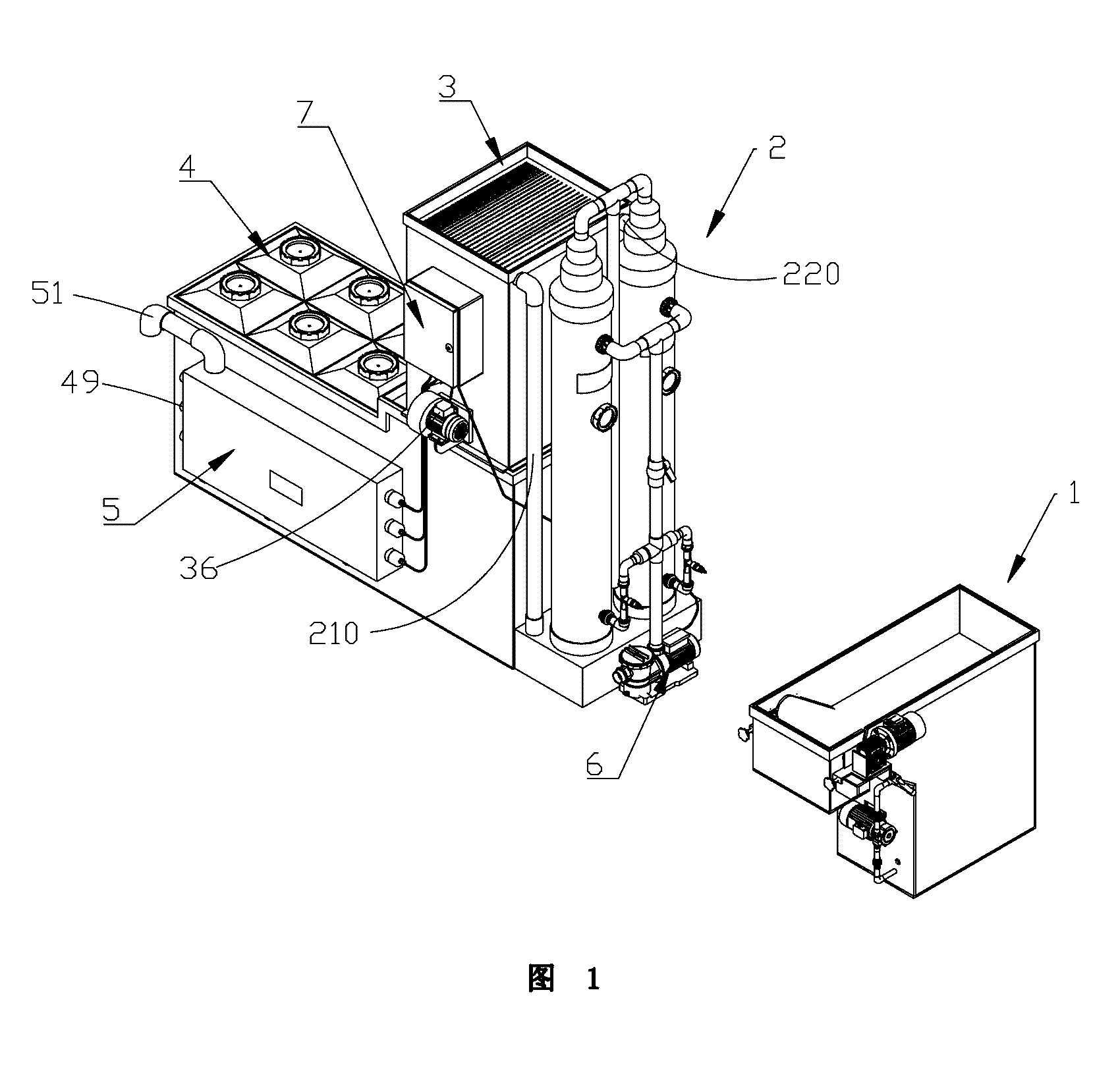

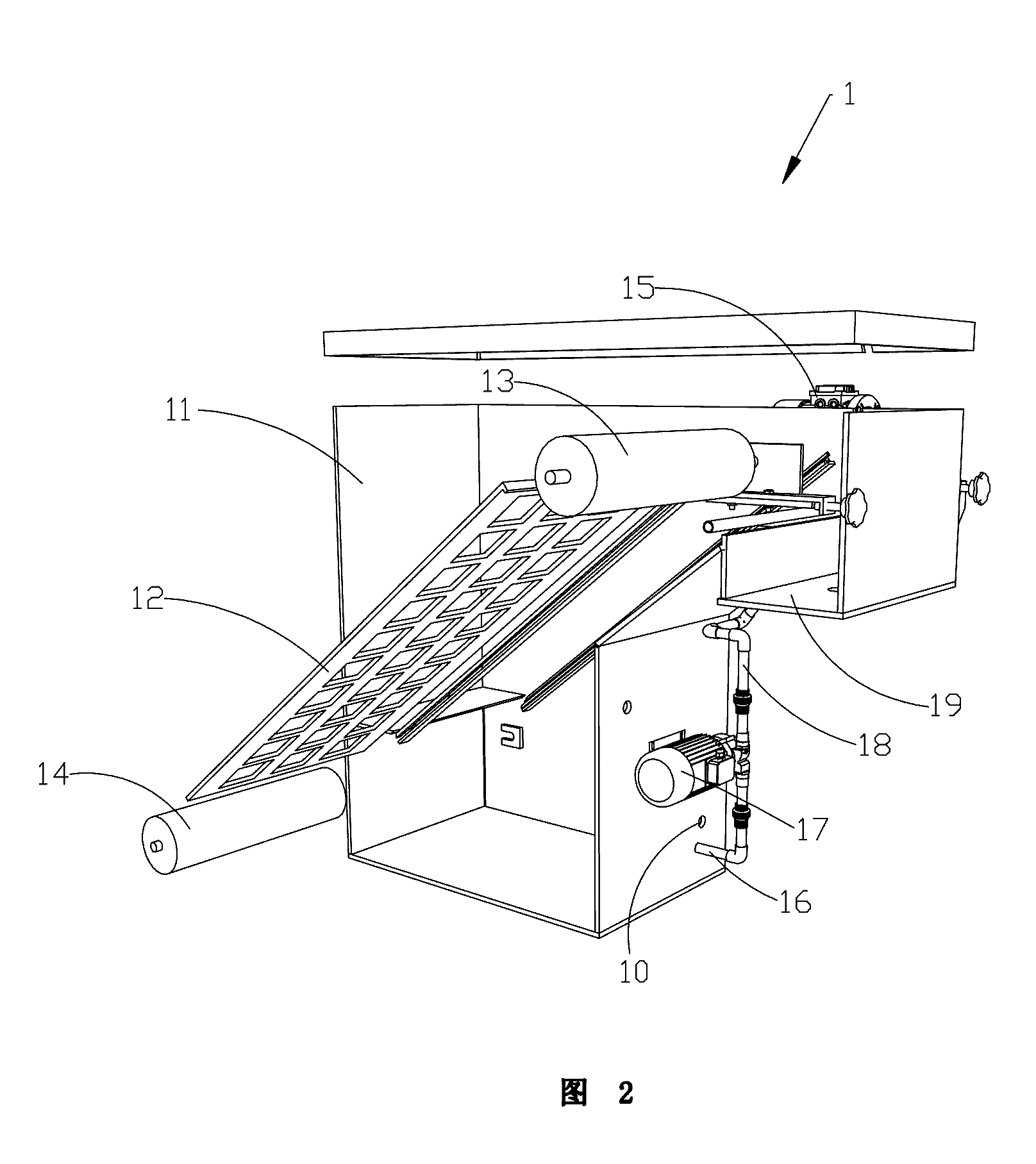

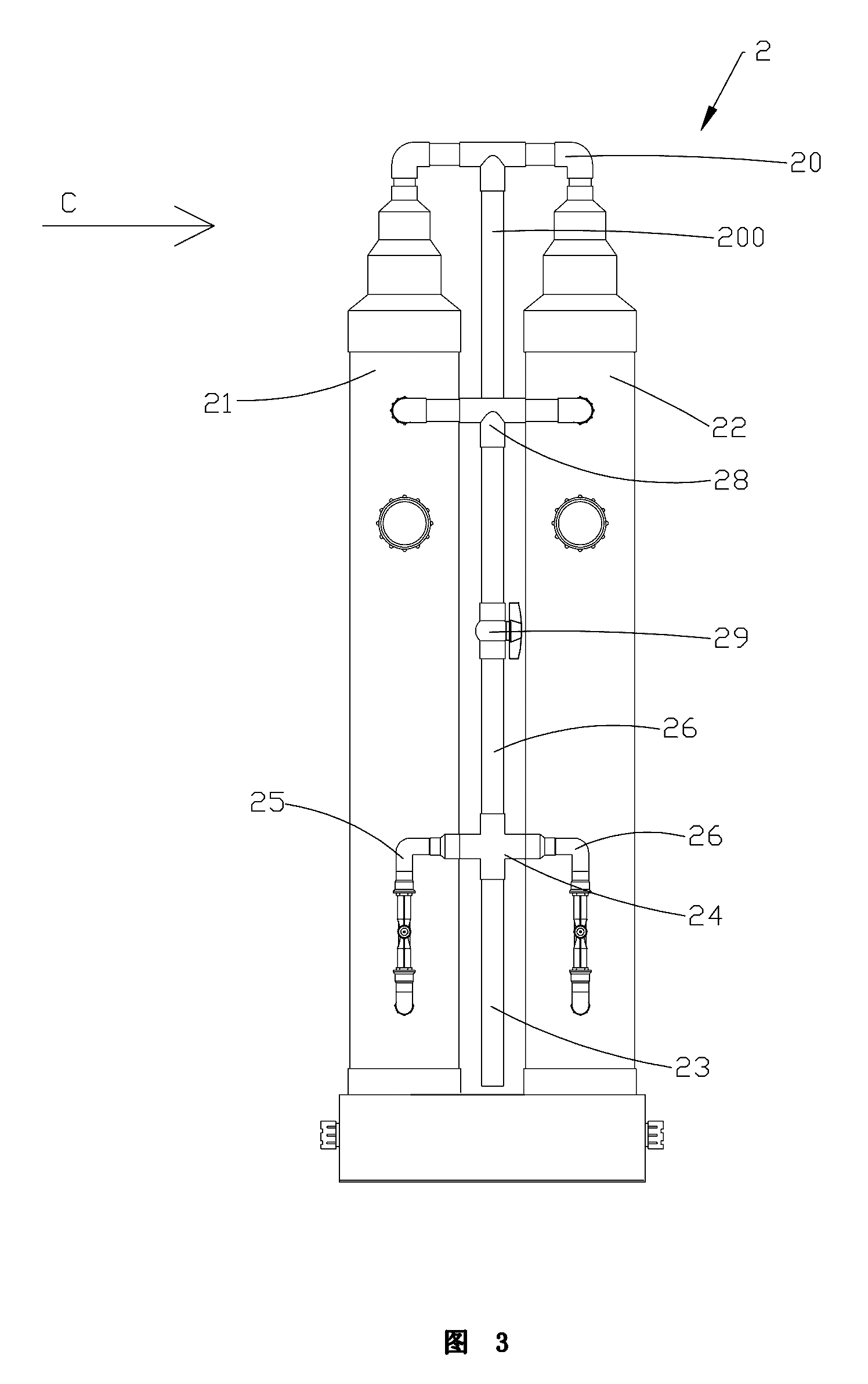

Combined modular circulating water cultivating system

ActiveCN103070127ASolve the cost problemSolve space problemsPisciculture and aquariaSystems designElectronic controller

The invention discloses a combined modular circulating water cultivating system, which comprises a belt type mechanical filter, a protein separator, a dripping box, a bio-filter, an ultraviolet disinfector and a central electronic controller, wherein the protein separator is connected with the belt type mechanical filter; the dripping box is connected with the protein separator; the bio-filter is connected with the dripping box; the ultraviolet disinfector is connected with the bio-filter; the belt type mechanical filter is used for pumping water into the protein separator through a water pump; the dripping box is arranged above the bio-filter; the highest water level of the protein separator is higher than the highest water level of the dripping box; the highest water level of the bio-filter is higher than the highest water level of the ultraviolet disinfector; and both the ultraviolet disinfector and the water pump are connected with the central electronic controller. According to the combined modular circulating water cultivating system, the defects of high manufacturing cost, large occupied space, complex pipeline connection, difficulty in maintaining, high running cost, poor treatment effect and the like caused by the complex and single equipment system design of the conventional circulating water cultivating system are overcome completely; and the combined modular circulating water cultivating system is more convenient and practicable.

Owner:GOLDBILL FUJIAN AQUACULTURE TECH

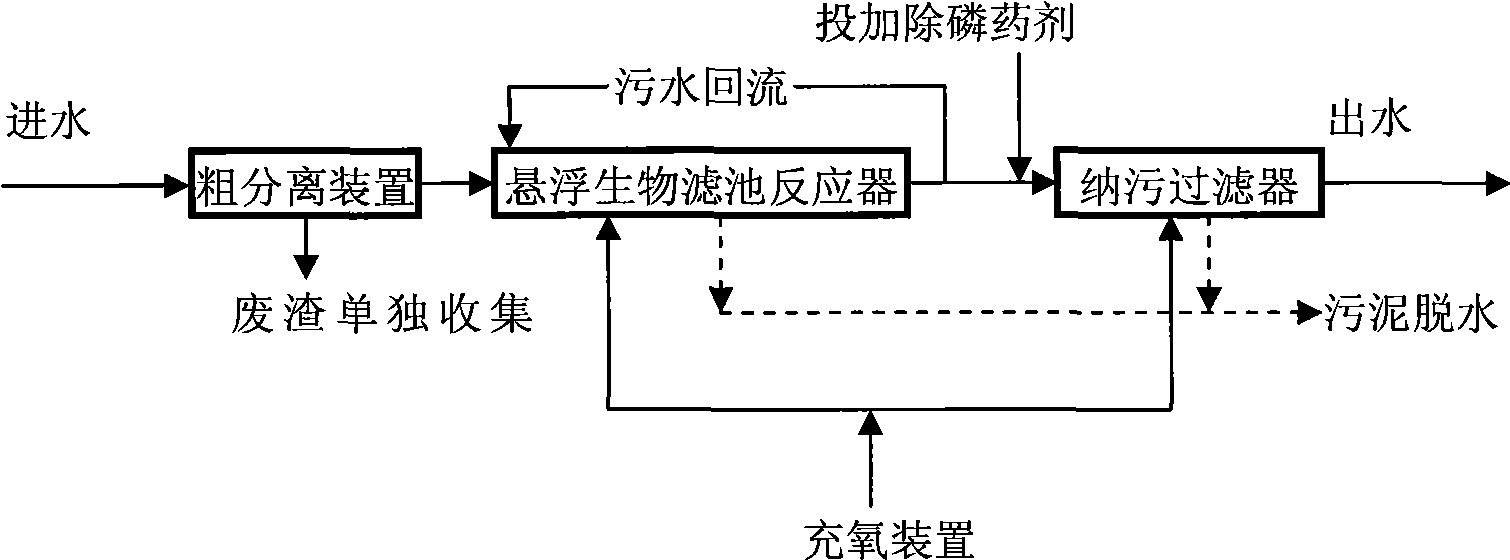

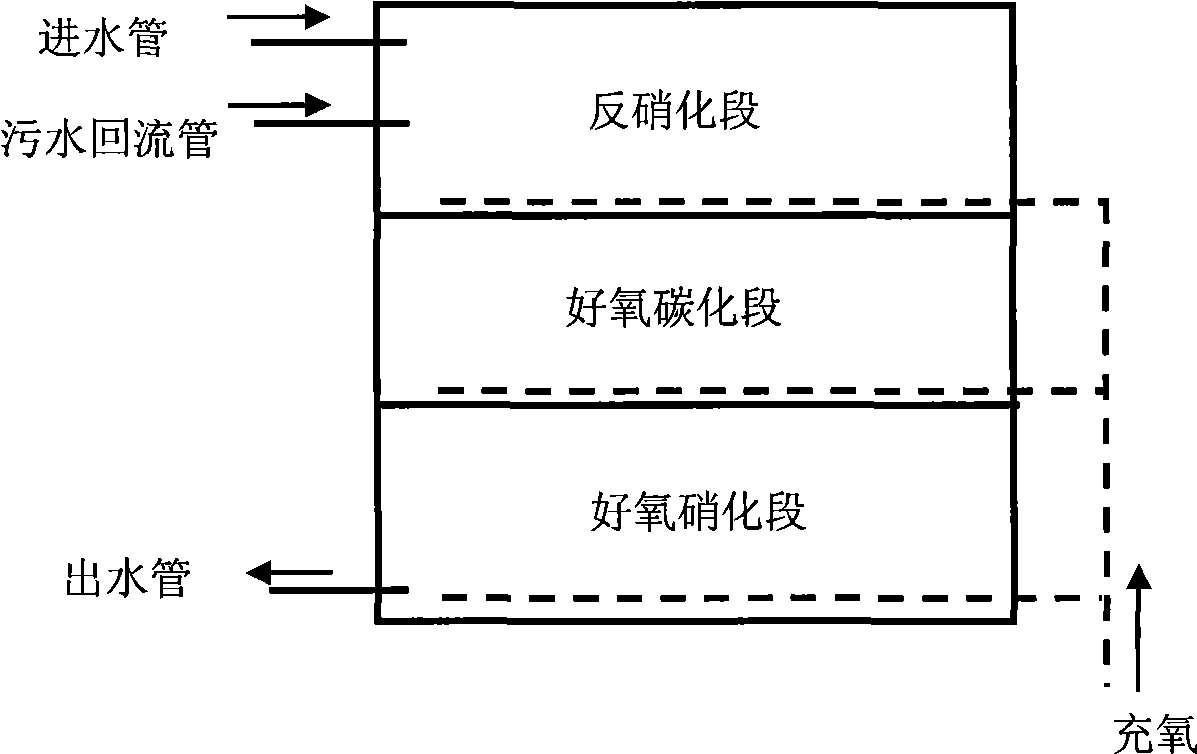

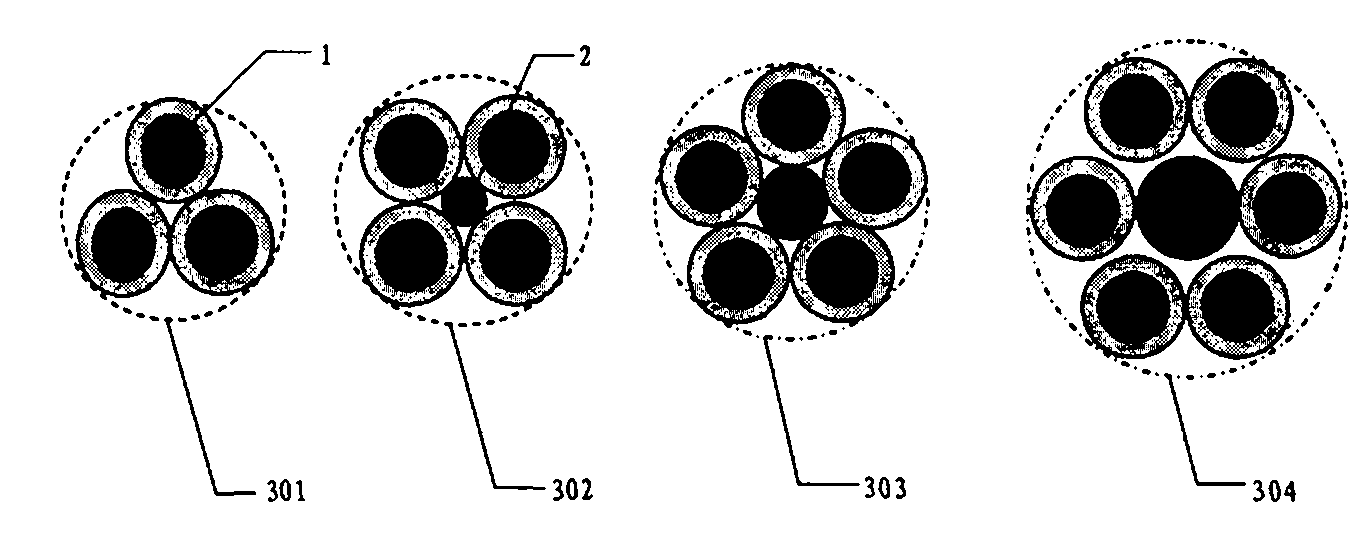

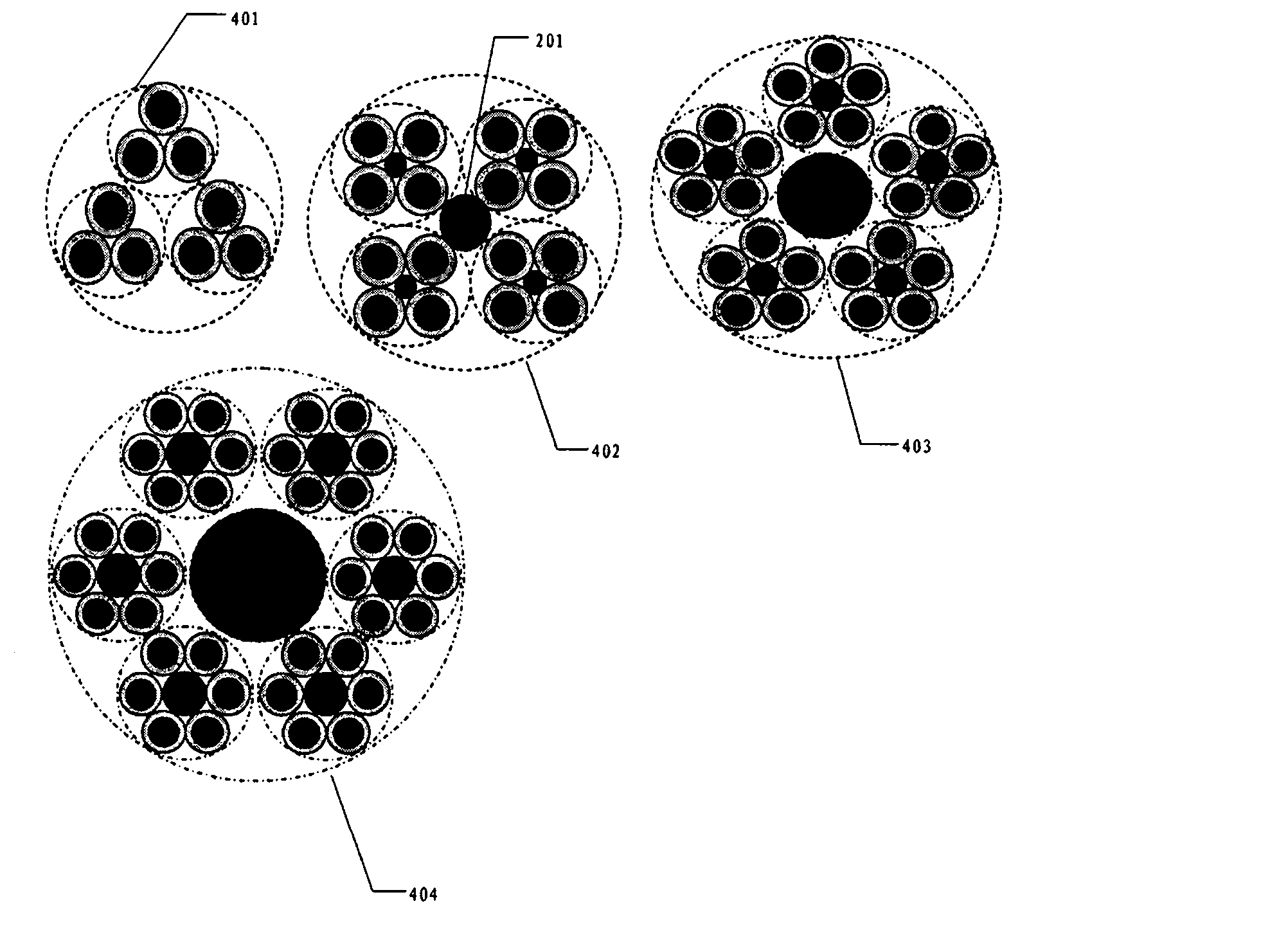

Method for treating town sewage

InactiveCN101544451AEfficient removalEasy to realize complete set of equipmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeCarbonization

The invention discloses a method for treating town sewage. The method comprises that: after large granular impurities in the town sewage are removed by a crude separation device, the town sewage enters a denitrifying section of a suspended biological filter reactor and then is subjected to denitrification and removal of partial organic pollutants by using denitrifying bacteria and facultative aerobe attached to biological carriers; and the denitrifying section yields water to an aerobic carbonization section, most organic pollutants are removed by aerobic heterotrophic bacteria, then the aerobic carbonization section yields water to an aerobic nitration section, ammonia nitrogen in the sewage is removed by the nitrobacteria attached to the biological carriers, the aerobic nitration section yields water to a sludge accommodating filter, the phosphorus-containing sediment generated by coagulating sedimentation is intercepted by the sludge accommodating filter, and finally the town sewage can be discharged after reaching standards and also can be recycled. The method can efficiently remove the organic pollutants, ammonia nitrogen and total nitrogen, and is easily realized by complete equipment. The adopted suspended biological filter needs no filter plate, shortens construction period and reduces investment. The method is suitable for sewage treatment of medium-small towns.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

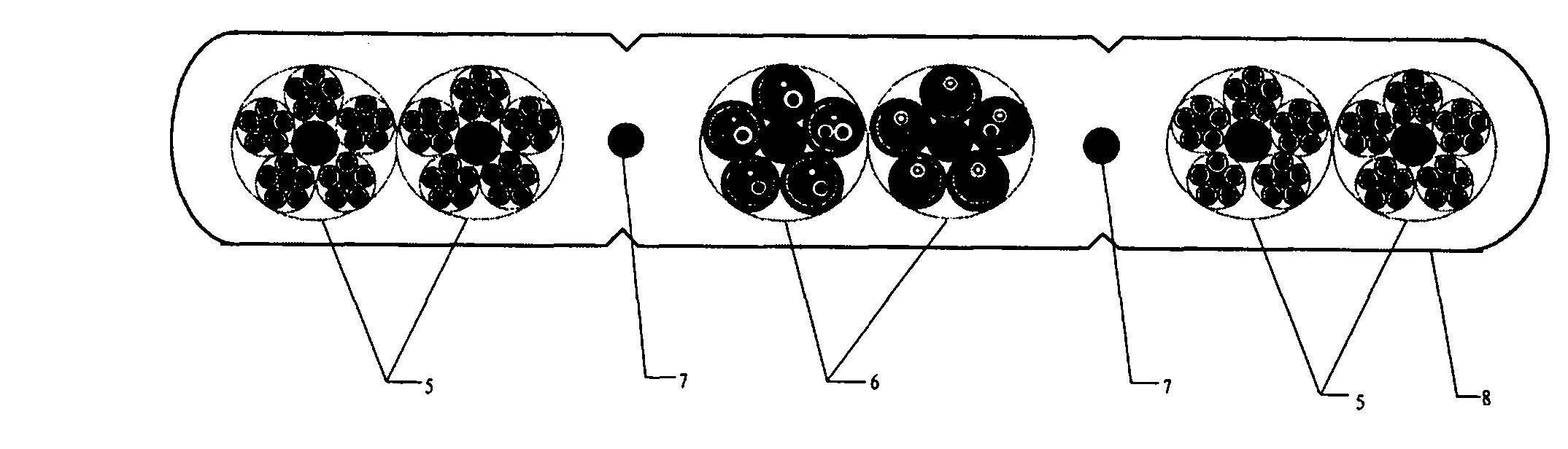

Method for manufacturing super multi-core cable of super high-speed elevator

InactiveCN102110499ASolve the current situation of importSolve maintenance difficultiesCable/conductor manufactureEngineeringWire rope

Owner:SHANGHAI NANYANG FUJIKURA CABLE

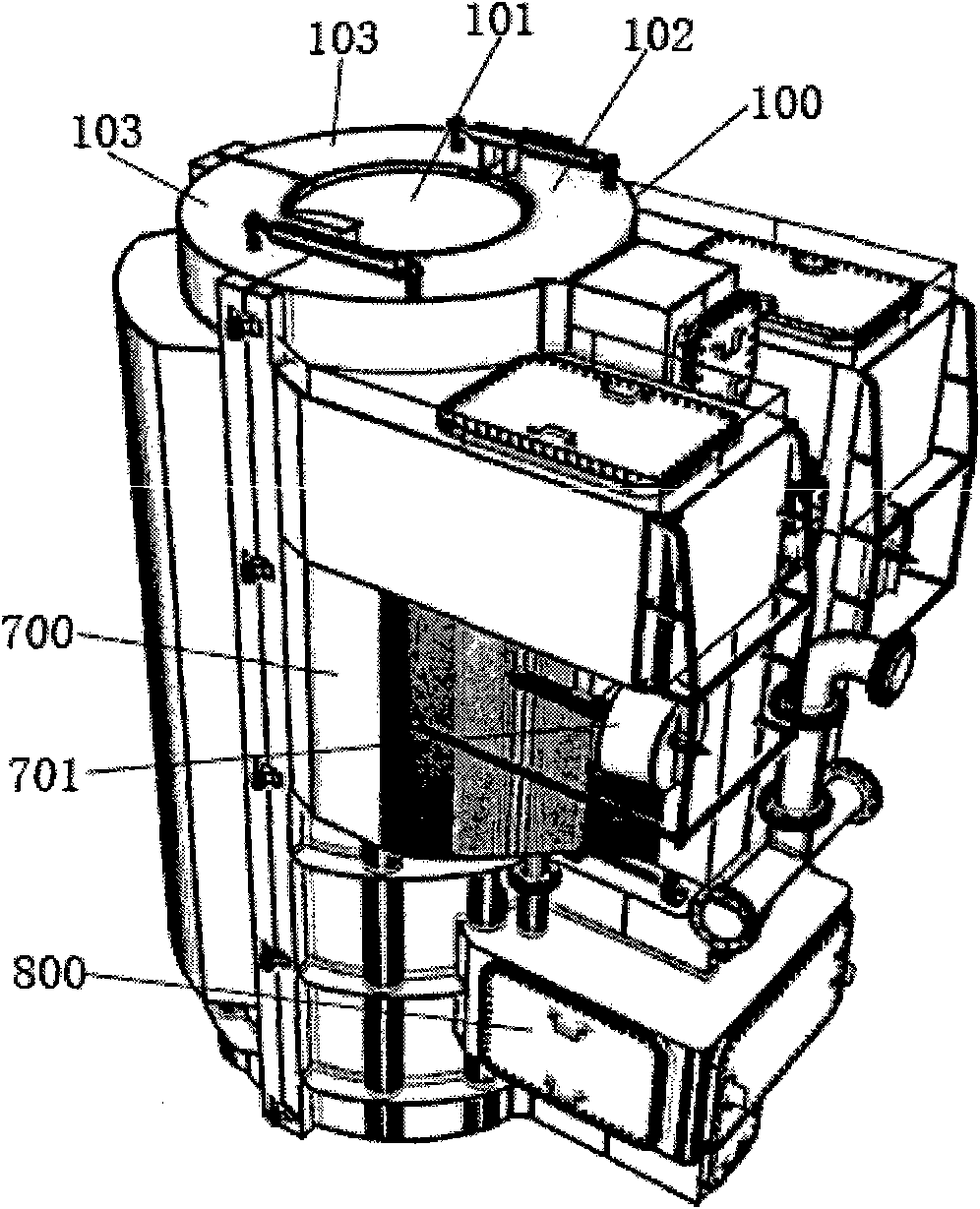

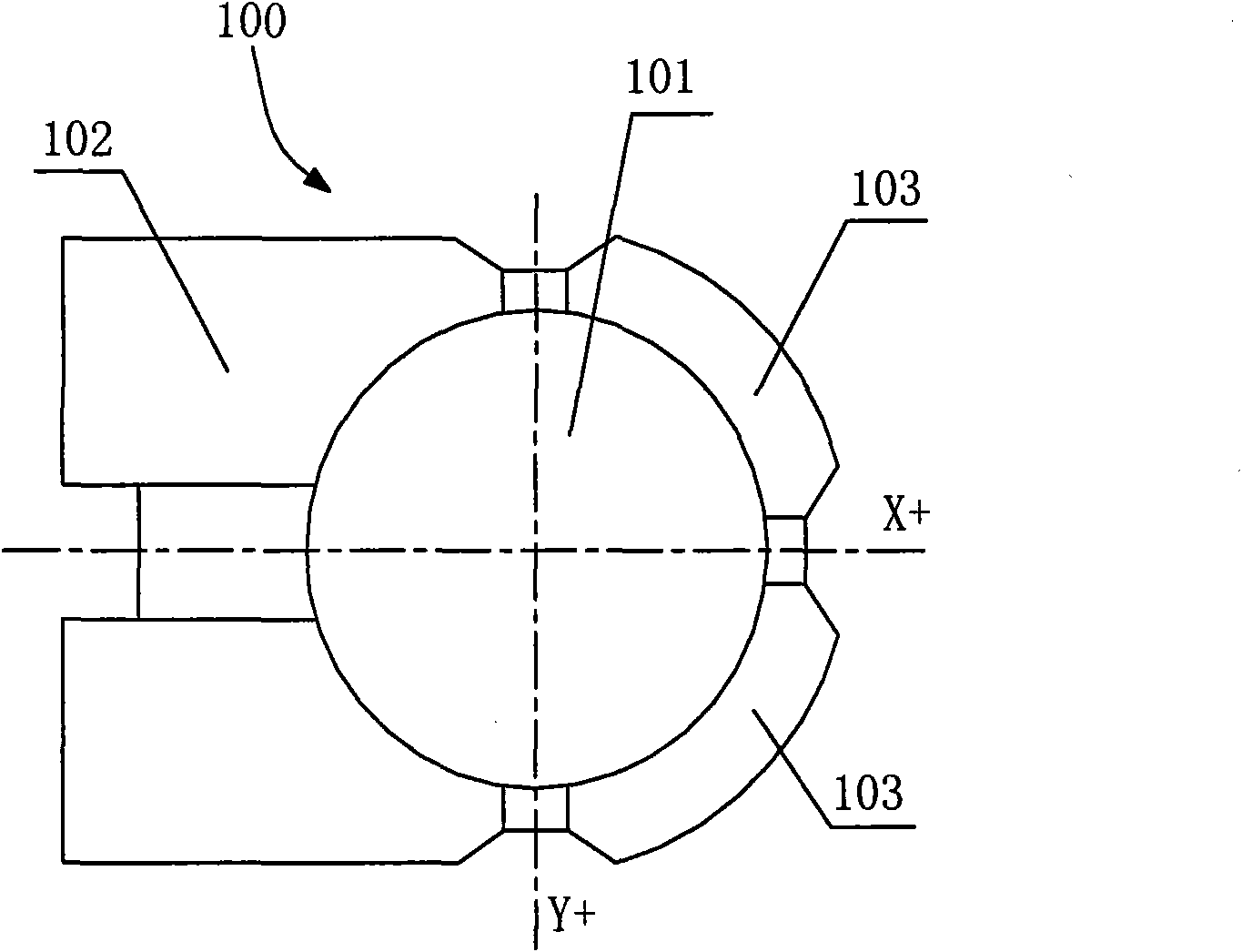

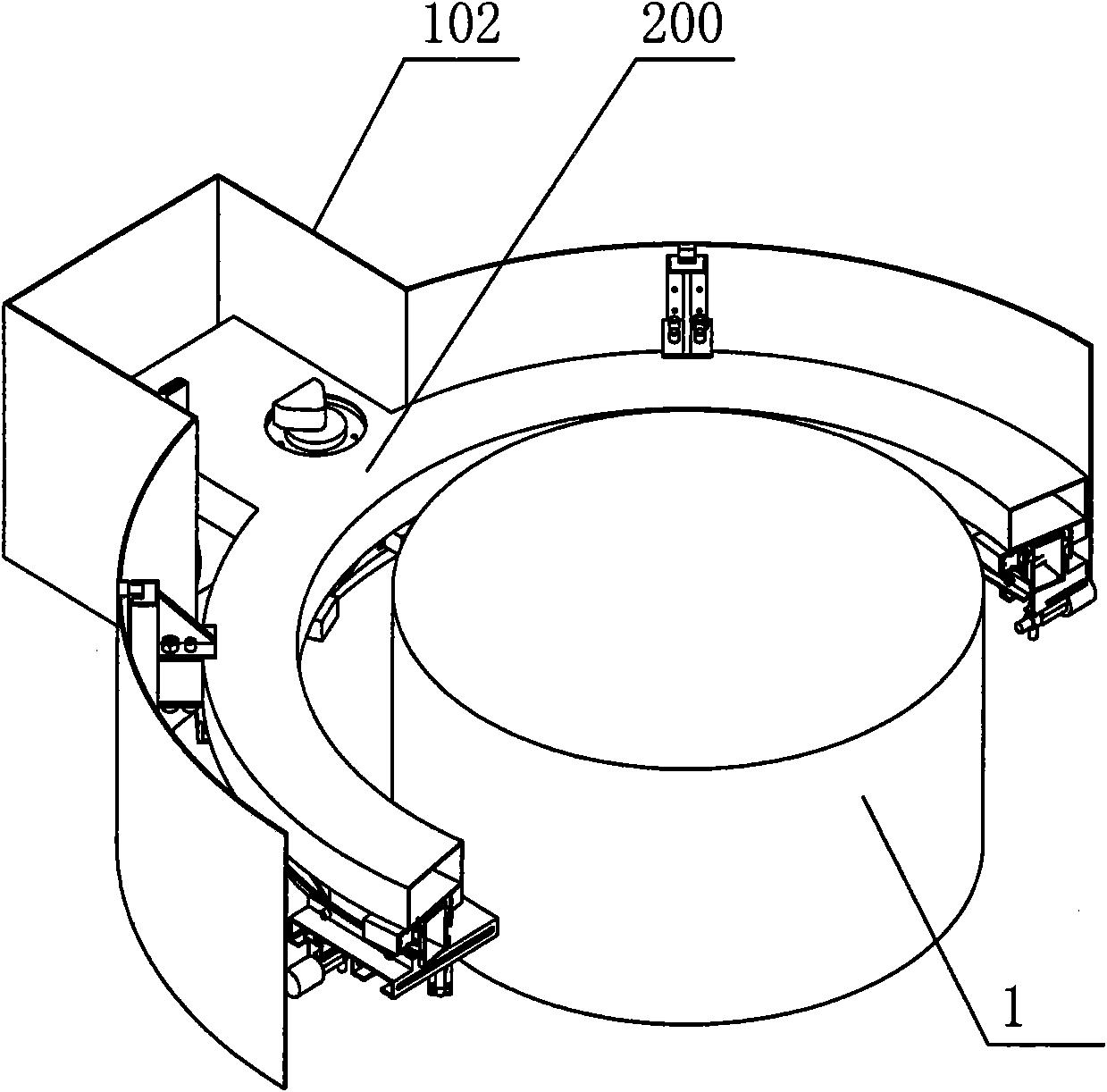

Roller type human body omnidirectional movement platform and speed synthesis method for same

ActiveCN109248415AEliminate the effects of restraintSolve the problem that the movement is limited by the real spaceStiltsMovement coordination devicesHuman bodyVirtual space

The invention discloses a roller type human body omnidirectional movement platform. The roller type human body omnidirectional movement platform comprises a shell, a plurality of groups of spiral rollers which are alternately placed in the shell, and motors used for driving the spiral rollers, wherein the spiral rollers comprise clockwise spiral rollers and anticlockwise spiral rollers, rotatablewheels are slantwise embedded in bodies of the clockwise spiral rollers at a certain angle, gears and bearings playing a supporting role are mounded at two ends of the rollers, and the anticlockwise spiral rollers and the clockwise spiral rollers are in mirror symmetry. The invention provides the active human body omnidirectional movement platform, compared with the passive omnidirectional movement platform, the active human body omnidirectional movement platform has the advantages that the human body is free of the constraint, thus more real movement feeling can be provided, therefore, the problem that the movement of the virtual space is limited by real space is effectively solved, and meanwhile, the roller type human body omnidirectional movement platform has the characteristics of lownoises and light machine body.

Owner:北京云创启航智能科技有限公司

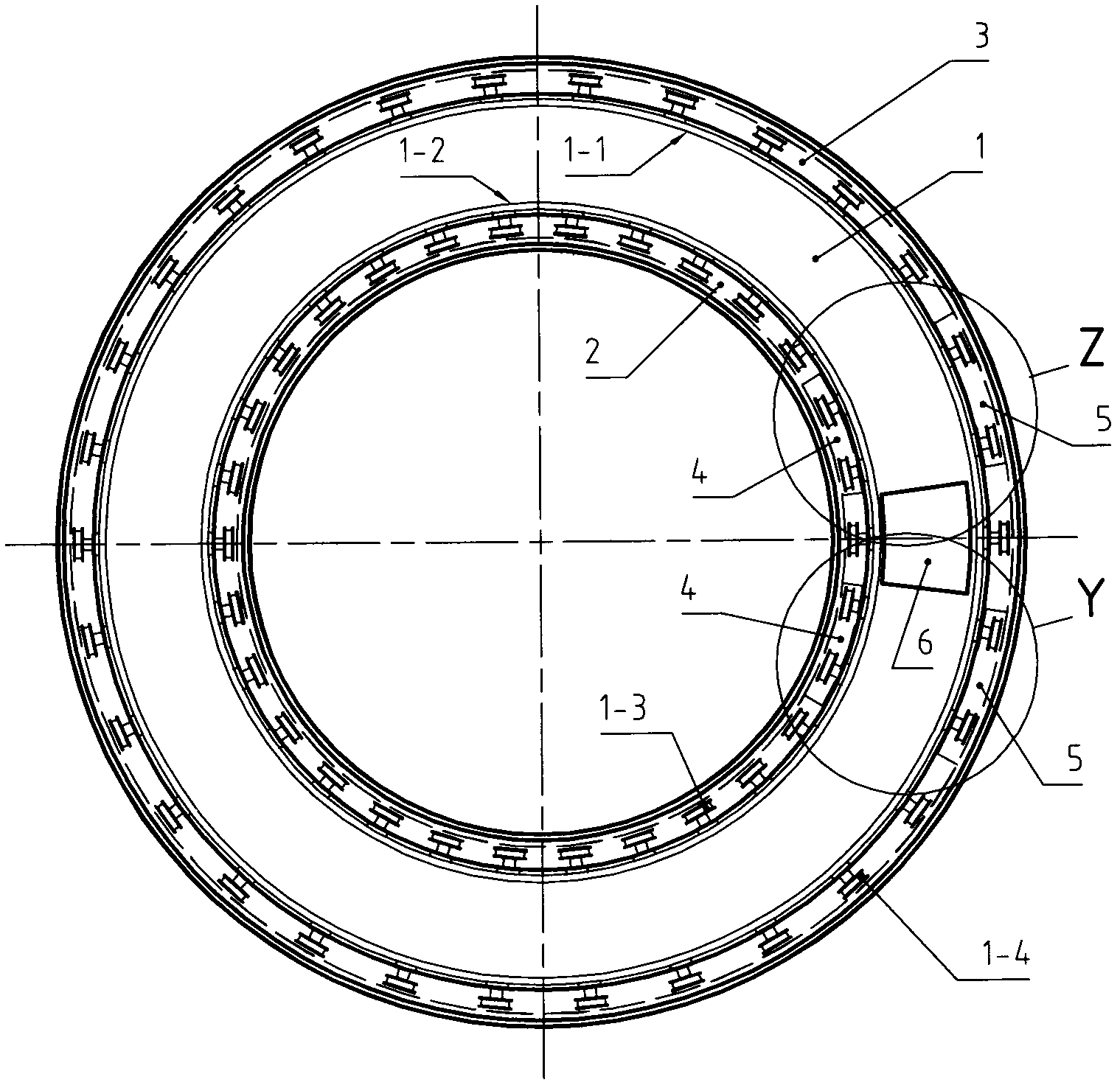

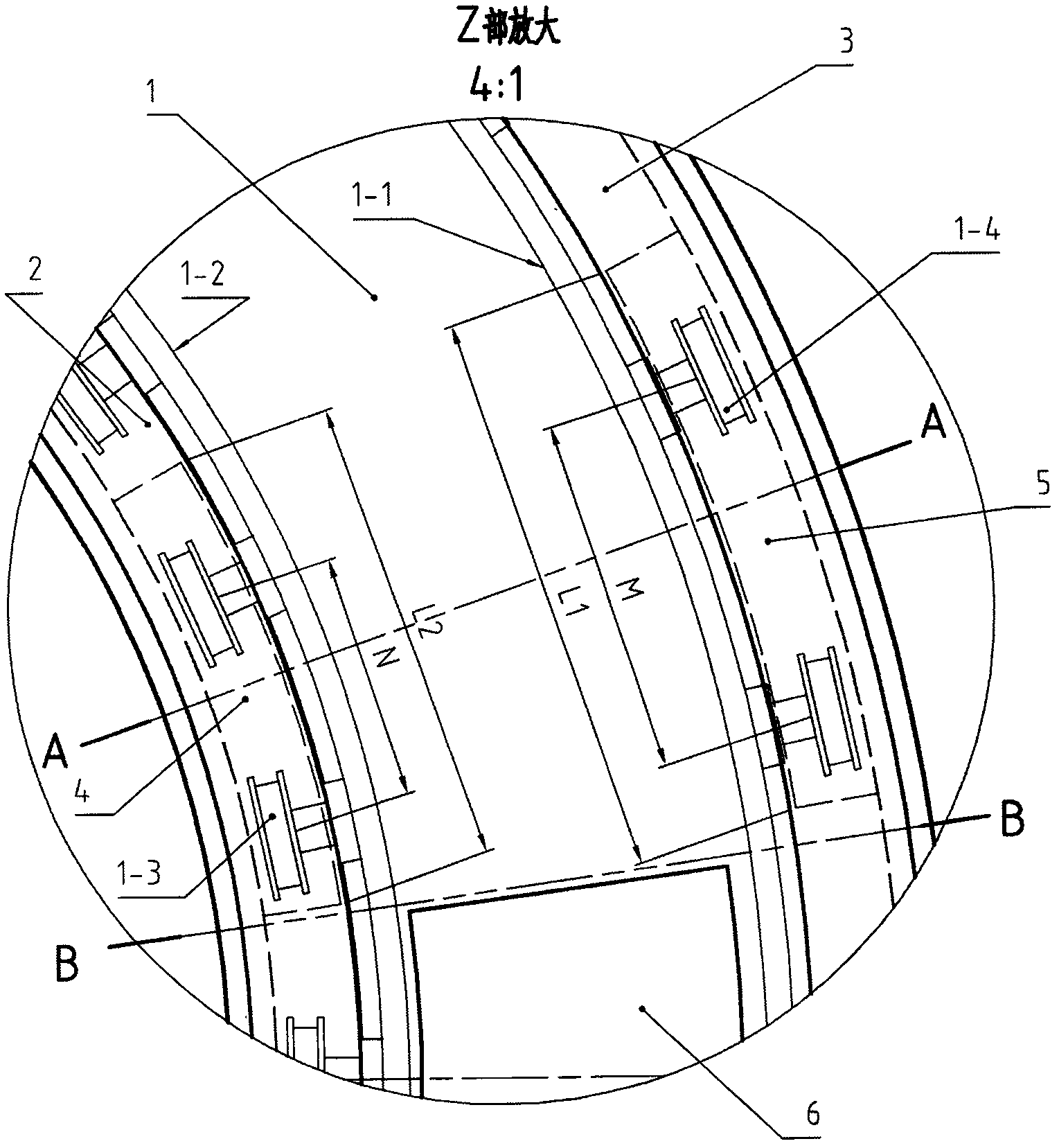

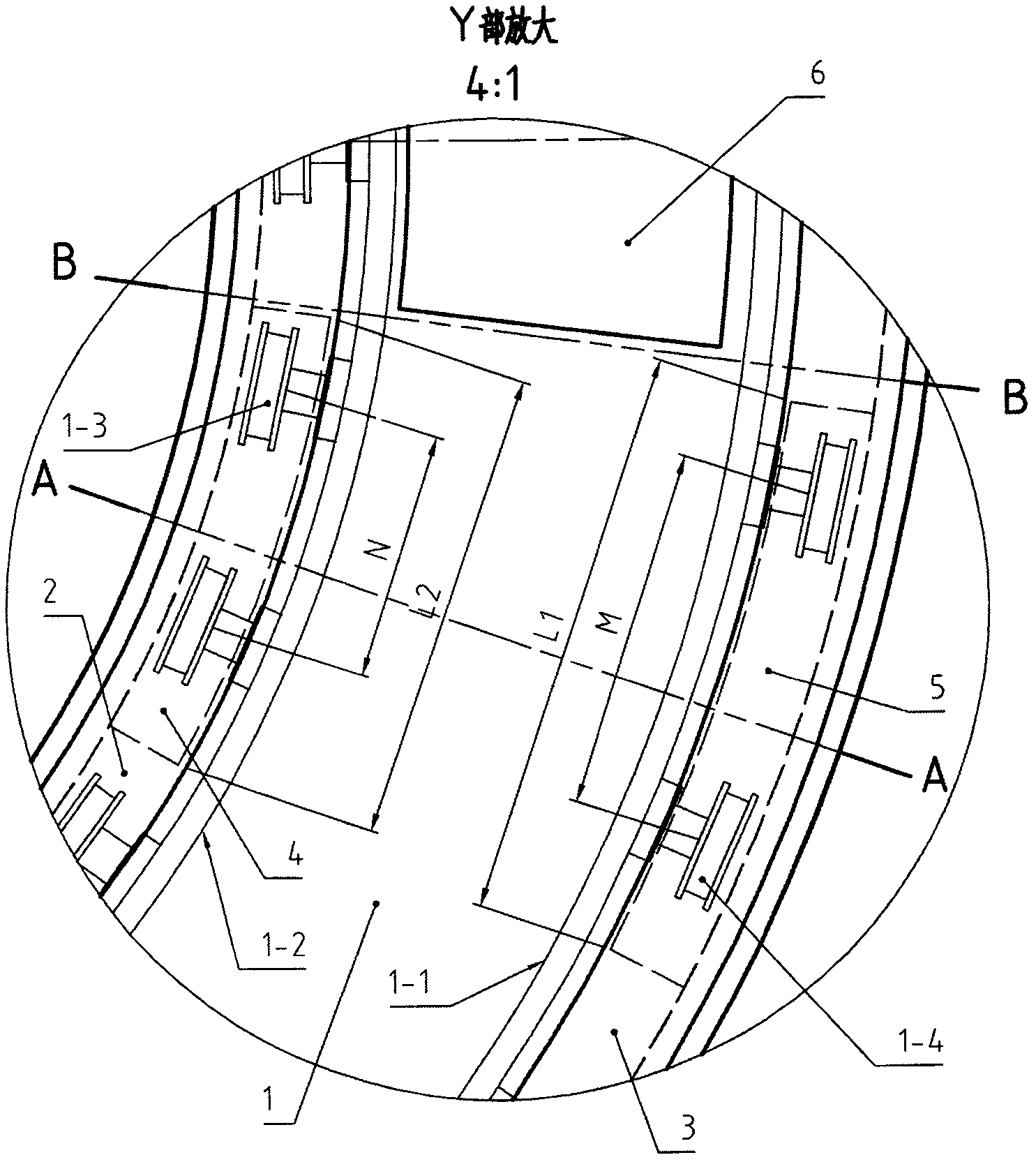

Sealing device of circular cooler

ActiveCN102997690AGuaranteed validityGuaranteed reliabilityHandling discharged materialLife timeMechanical engineering

The invention discloses a sealing device of a circular cooler, which belongs to the technical field of sealing a circular type cooler of a sintering machine and aims at obviously prolonging the service life of the sealing device, increasing the working reliability of the sealing device and solving the problem that the maintenance is difficult. The sealing device is characterized by being provided with a sealed cover type structure which comprises a sealing mechanism and contains an air leakage zone of the circular cooler. The sealing device disclosed by the invention is suitable for the circular type cooler and has the characteristics that the sealing is reliable, durable, sealing effects are good, the maintenance is convenient, and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

High efficient functional composite material and its preparation method and application

InactiveCN101057980AEffective treatmentImprove the quality of lifeOrganic active ingredientsHeavy metal active ingredientsCurative effectSoft solids

The invention belongs to powder product field, and relates to a medical functional complex material with high curative effect. Said complex material comprises following raw materials: 66-96% of tourmaline ultra-micro powder and / or crystal infrared material ultra-micro powder, 0. 01-30% of dielectric strengthened material and 1-5% of embedding material, soft solid and hard solid material. It is used in the field of health-care, treatment and recovery, and can be used to produce medical apparatus.

Owner:杨孟君

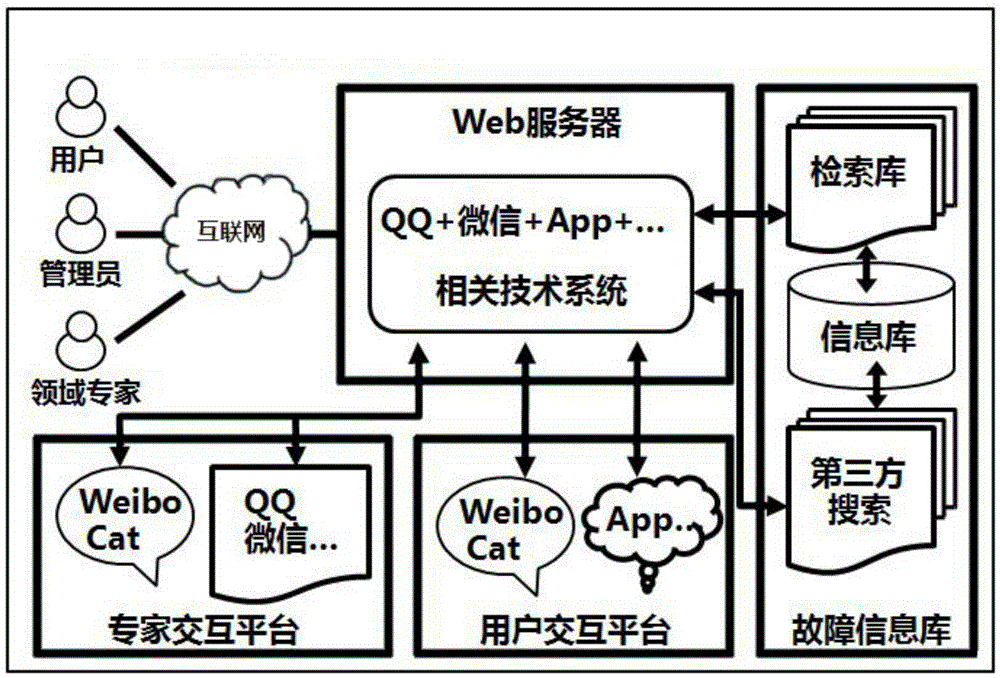

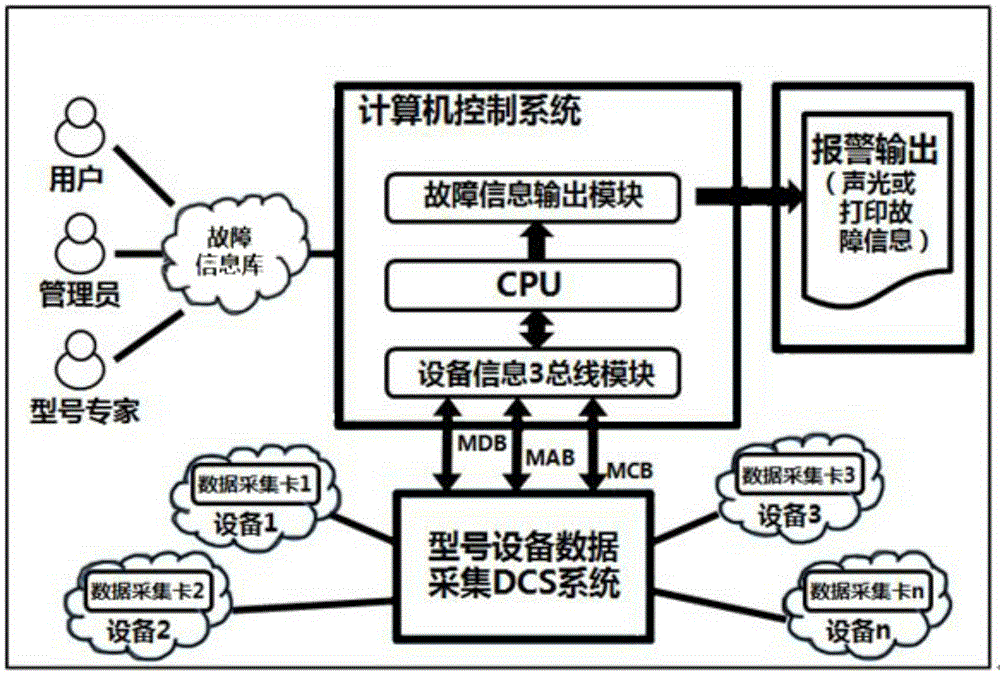

Internet plus-based medical equipment fault self checking and repairing system

ActiveCN105391800ARealize onlineEasy to detectData processing applicationsTransmissionInformatizationResearch Object

The invention discloses an Internet plus-based medical equipment fault self checking and repairing system. The Internet plus-based medical equipment fault self checking and repairing system includes a resource sharing big data base subsystem and a fault detection subsystem which is connected via the Internet; the resource sharing big data base subsystem includes a Web server, a fault information base, a user interaction platform and an expert interaction platform connected with the Web server; and the fault detection subsystem includes a computer control system, an alarm output part connected with the computer control system and a model equipment data acquisition DCS connected with the computer control system. According to the Internet plus-based medical equipment fault self checking and repairing system of the invention, medical equipment maintenance and faults are adopted as research objects, and key technologies such as Internet plus, Internet of things, big data and single-chip microcomputer control are integrated, and therefore, the monopoly of techniques of medical device manufacturers can be crushed, the problems of difficult modern medical equipment maintenance, high cost and scarcity of technicians can be solved, and the informationalized services of hospitals and resources sharing of modern diagnosis technologies can be promoted, and the economic burden of the hospitals and patients can be reduced.

Owner:SICHUAN INFORMATION TECH COLLEGE +1

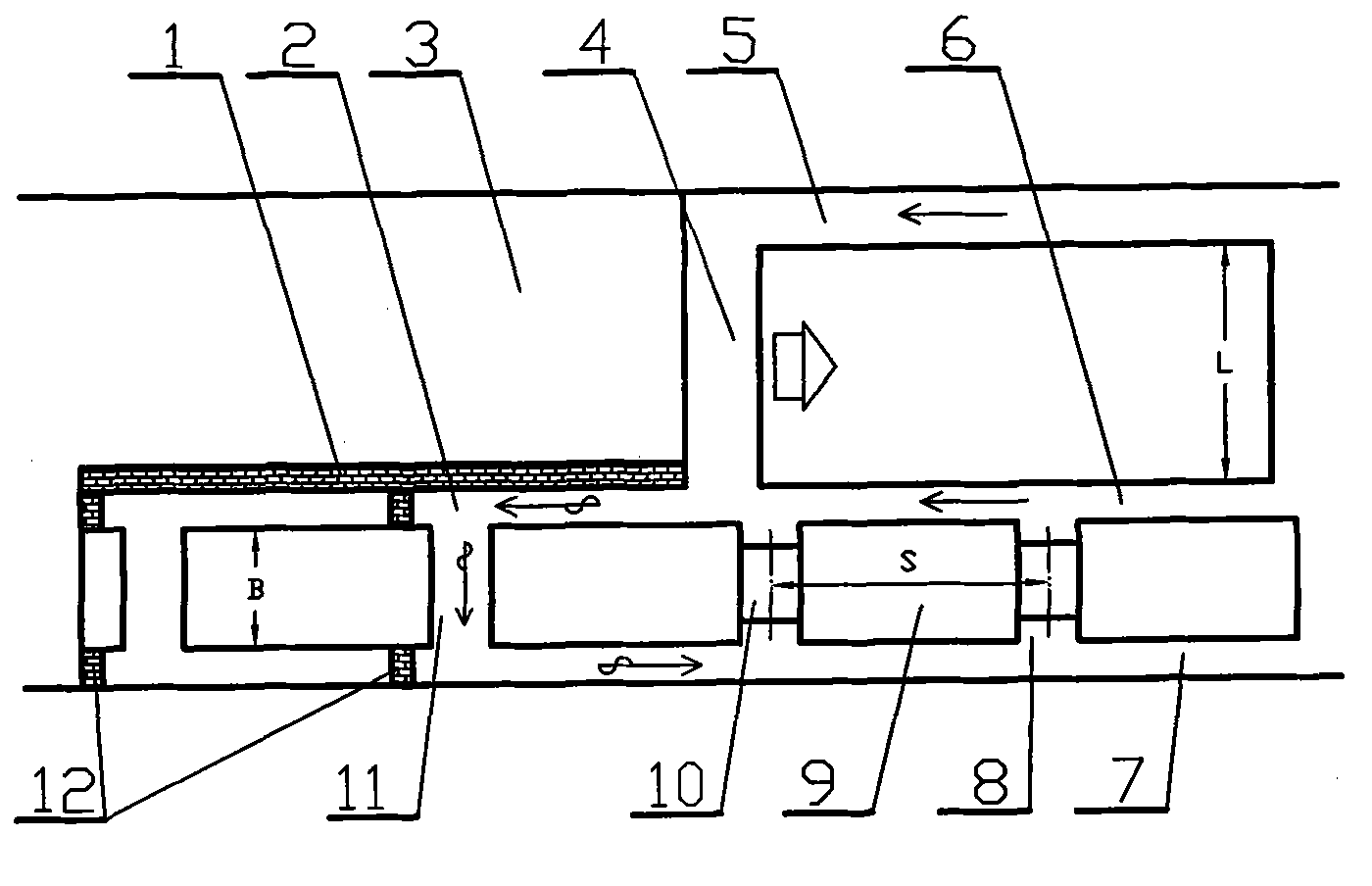

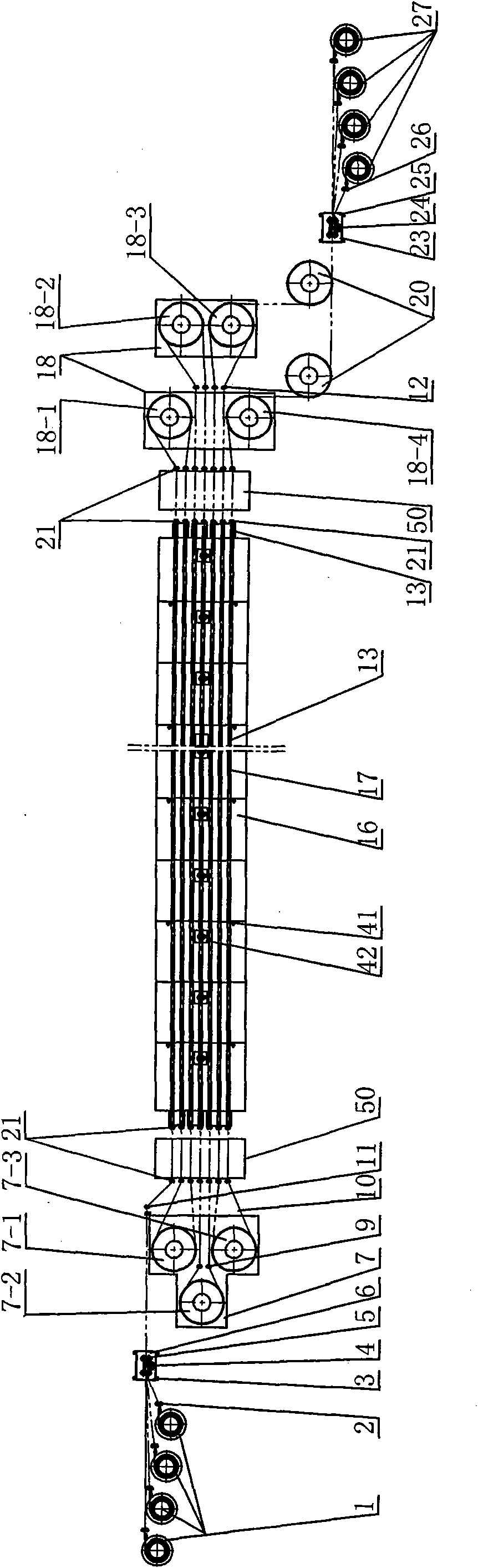

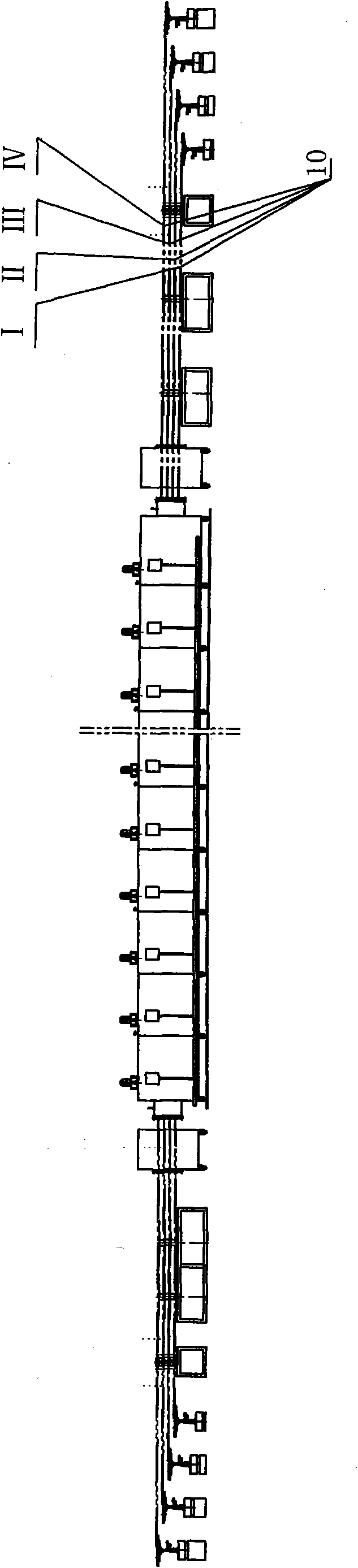

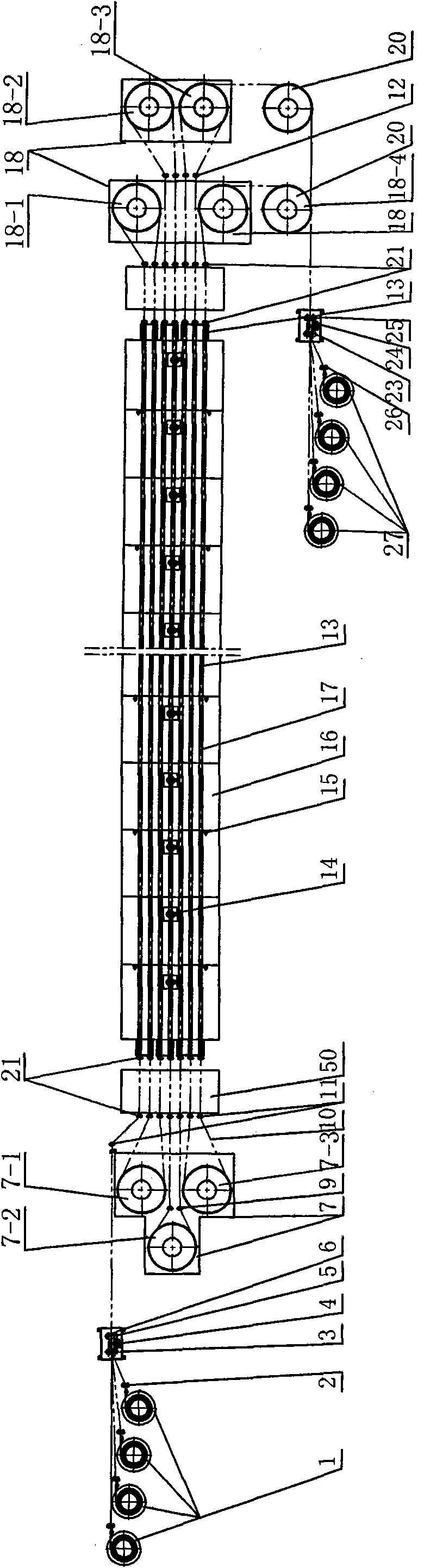

Online full-automatic tempering equipment and technology for same-furnace multi-strip bimetal strip saw

ActiveCN102002574ASolve the accuracy problemIncrease heating speedFurnace typesHeat treatment furnacesProduction lineHigh energy

The invention discloses online full-automatic tempering equipment and technology for a same-furnace multi-strip bimetal strip saw, and relates to tempering equipment and tempering technology. The invention solves the problems that the conventional tempering equipment and technology for the bimetal strip saw cannot finish the tempering technology on one production line at one time, the tempering technology has low production efficiency and high energy consumption and the like. The tempering equipment comprises a front rotating device, a box-type tempering furnace and a rear rotating device. The production efficiency of the saw is improved by 5 to 8 times, the energy consumption is greatly reduced, a great amount of energy is saved, the energy consumption of the box-type tempering furnace is reduced by over 60 percent compared with that of a bell-type tempering furnace or a well-type tempering furnace due to calculation, the occupancy area is reduced by over 90 percent, the problems that the bell-type tempering furnace or the well-type tempering furnace has non-uniform inner and outer temperature field and upper and lower temperature field, the bending stress of the saw is non-uniform, and the saw is easily upwarped are solved, repeated rewinding processes needed by the box-type tempering furnace or the well-type tempering furnace are canceled, and the problem of difficulty in controlling the saw tempering technology and quality and the problem of difficulty in maintaining the equipment are solved.

Owner:曹玉贵

Method and device for generating interface document

ActiveCN104954363ASolve the problem of troublesome acquisition and cumbersome manual inputSolve writingTransmissionDomain nameClient-side

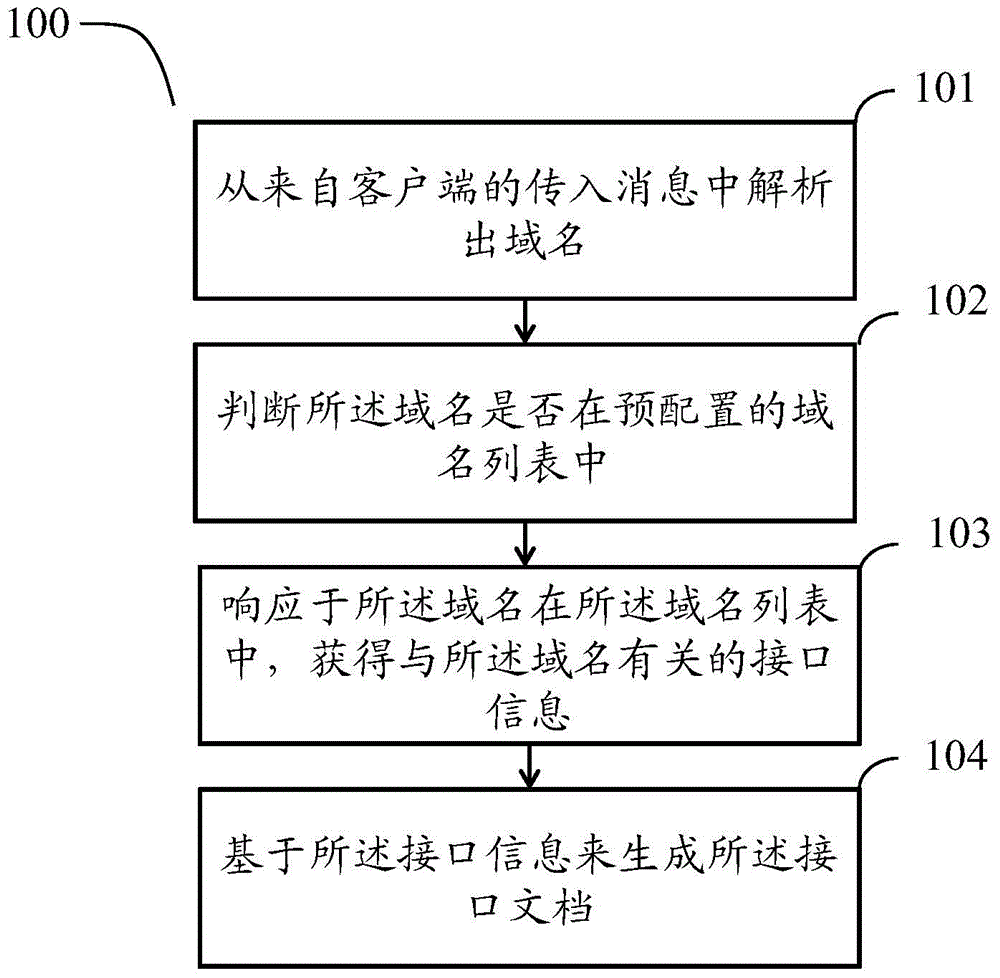

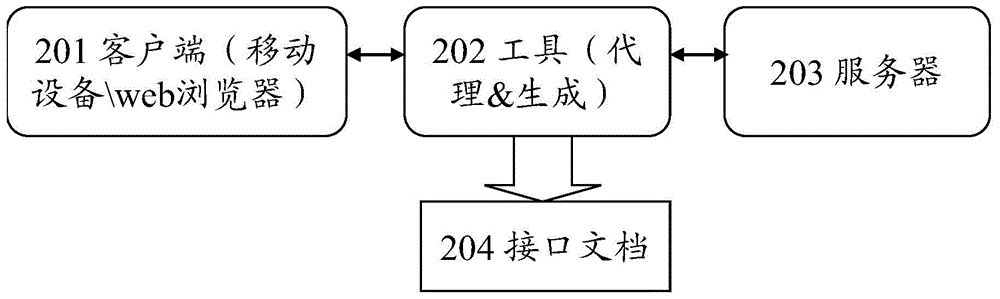

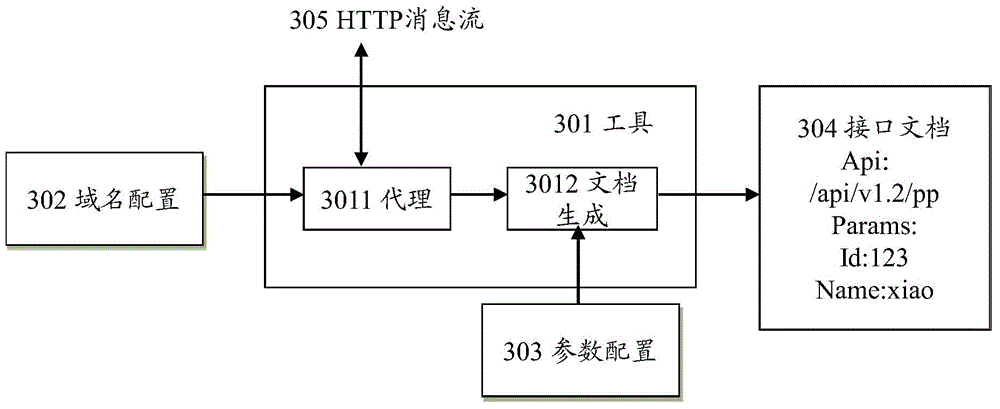

An embodiment of the invention provides a method and a device for generating an interface document. The method includes the steps: analyzing a domain name in an incoming message from a client; judging whether the domain name is placed in a preconfigured domain name list or not; responding to the domain name in the domain name list and acquiring interface information related to the domain name; generating the interface document based on the interface information.

Owner:BEIJING DIDI INFINITY TECH & DEV

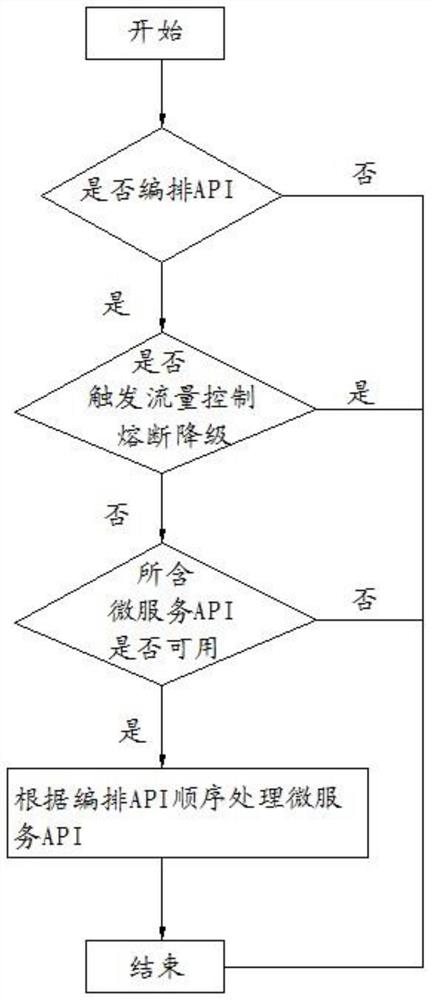

Microservice API arrangement method and system based on gateway

PendingCN113037830ASimplify the process of creating an orchestration APISolve maintenance difficultiesTransmissionSoftware engineeringMicroservices

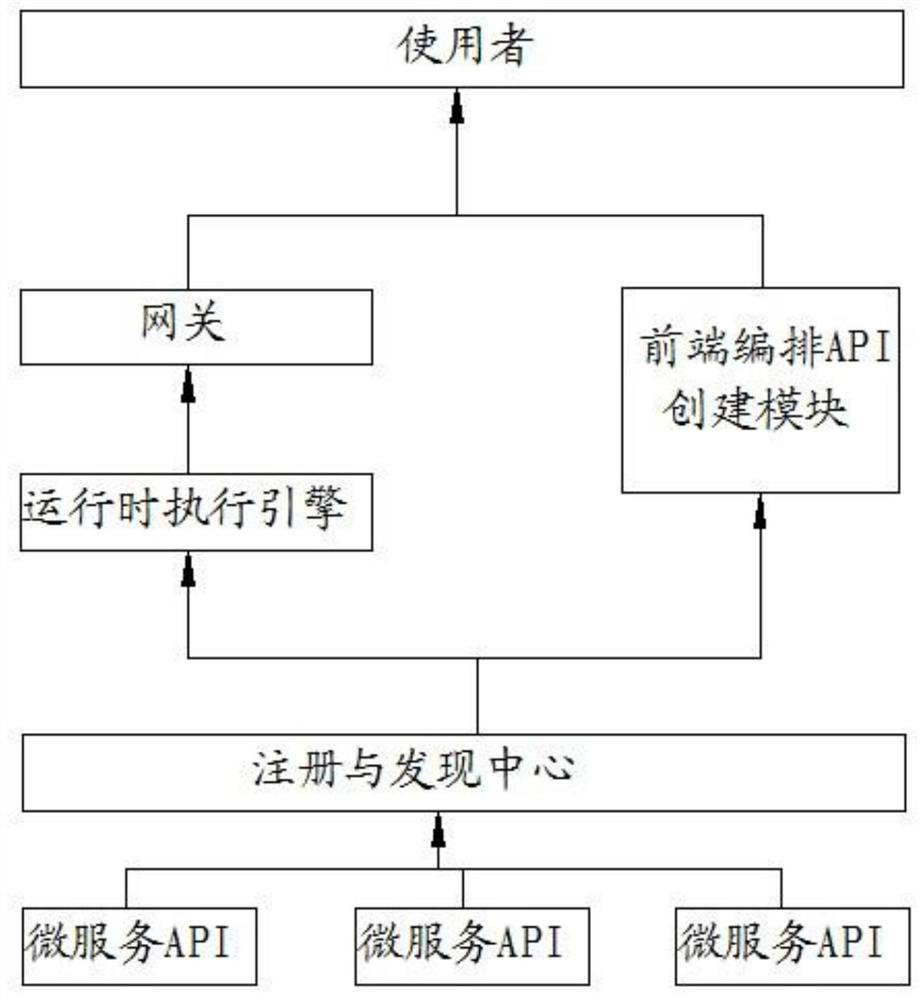

The invention discloses a gateway-based micro-service API arrangement method and system, belongs to the technical field of micro-services, and aims to solve the technical problems of how to reduce the workload of API arrangement and reduce the maintenance difficulty. The system comprises a front-end arrangement API creation module which comprises a management interface and an editor; the editor is used for carrying out calling process arrangement on a micro-service API and creating an arrangement API, and the management interface is used for carrying out editing configuration on the arranged API; the rear end arrangement API execution engine comprises a pre-filter and a runtime execution engine, the pre-filter is used for identifying an arrangement API request and forwarding the arrangement API request to the runtime execution engine, and the runtime execution engine is used for performing flow control and fusing degradation check on the arrangement API, performing availability check on the called micro-service API, and achieving the access to the micro-service API through the RestTemplate.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

Steel pile anticorrosion operation equipment

ActiveCN102039995ASolve maintenance difficultiesReliable working environmentUnderwater equipmentPropellerEngineering

The invention discloses steel pile anticorrosion operation equipment, which comprises an operation well, a drainage device, a vertical walking mechanism, a circumferential scanning mechanism, a surface treatment device, a spraying device and a propelling bin, wherein the operation well can float on the water level, the center of the operation well is provided with a cavity, the operation well consists of at least two valves capable of being switched, the switched operation well can encircle a steel pile, and the top and the bottom of the cavity are provided with sealing devices which can form seal together with the surface of the steel pile; the vertical walking mechanism is positioned in the cavity of the operation well and can move up and down; the circumferential scanning mechanism is arranged on the vertical walking mechanism and can move in the cavity of the operation well along the circumference; the surface treatment device is connected with the circumferential scanning mechanism and can clean the surface of the steel pile; the spraying device is connected with the circumferential scanning mechanism; and two independent driving devices are arranged in the propelling bin and connected with two propellers respectively. The equipment can finish a full secondary anticorrosion process of the steel pile, and provides a reliable operation environment and an effective operation means for anticorrosion maintenance of the marine steel pile.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD

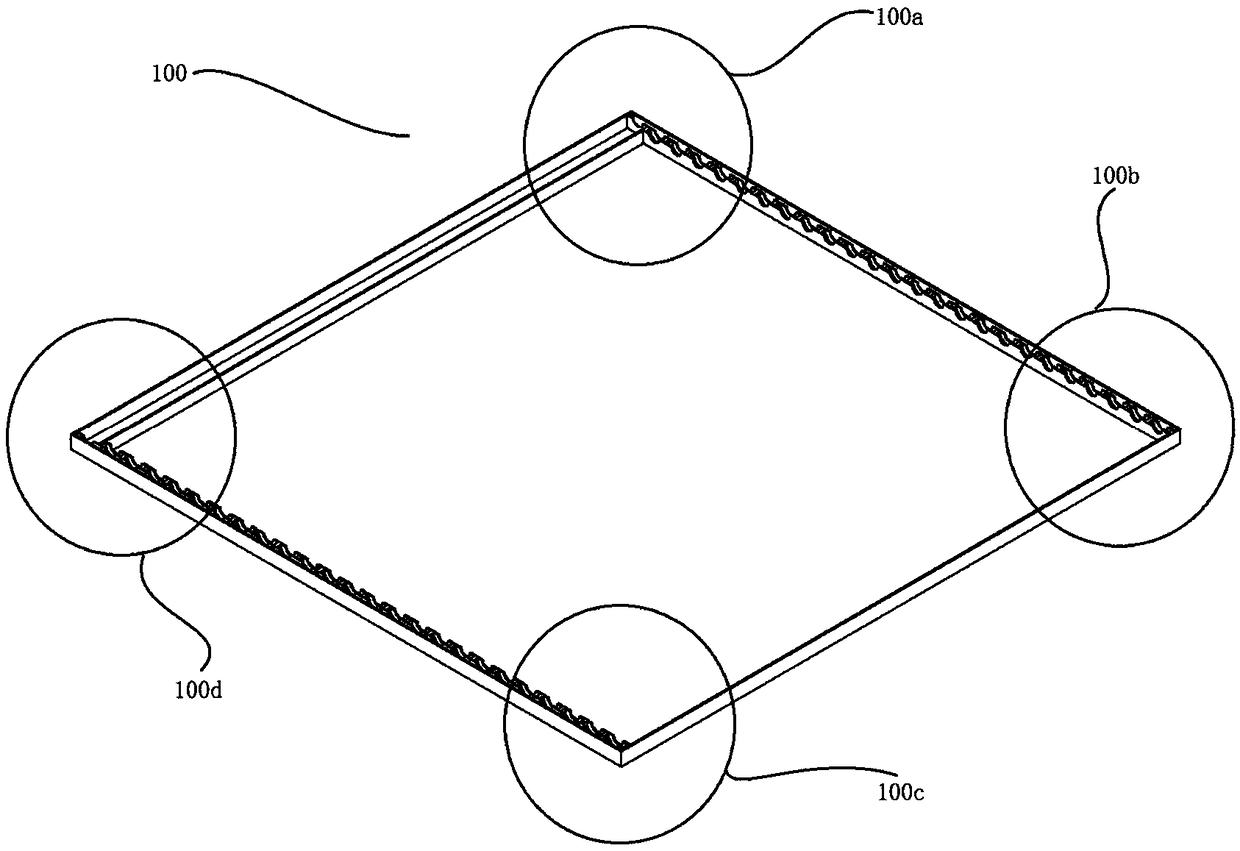

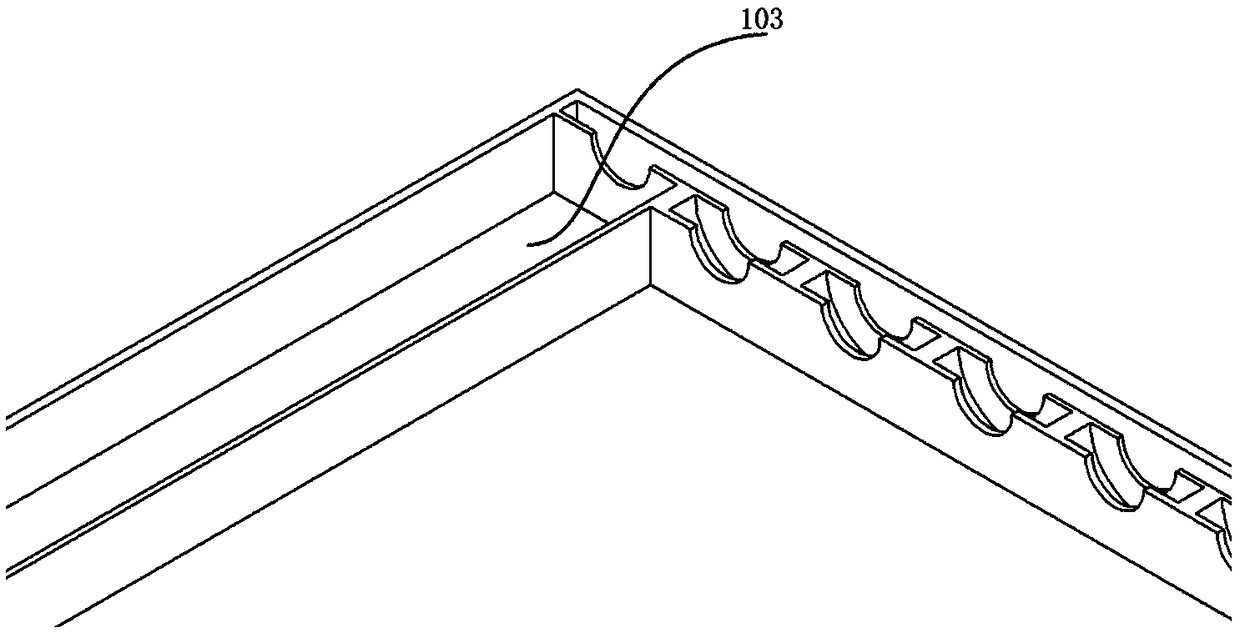

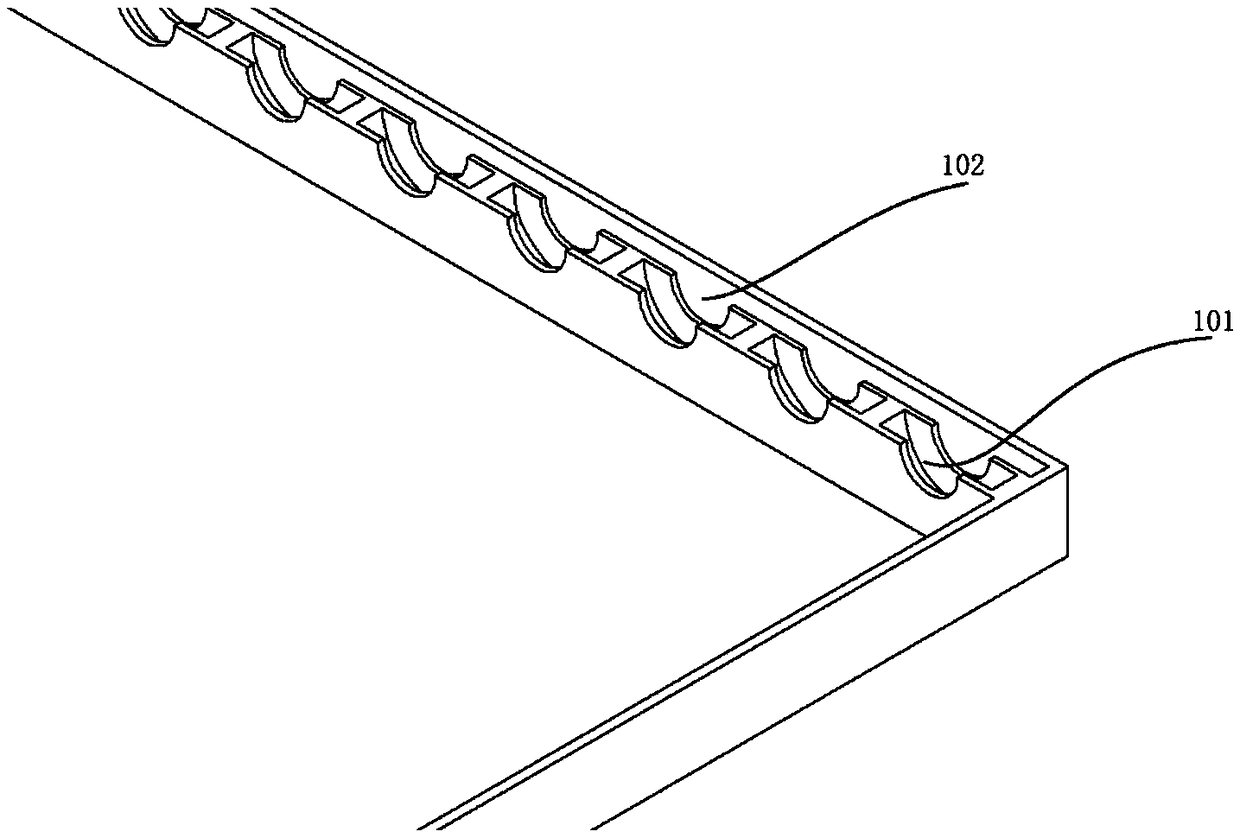

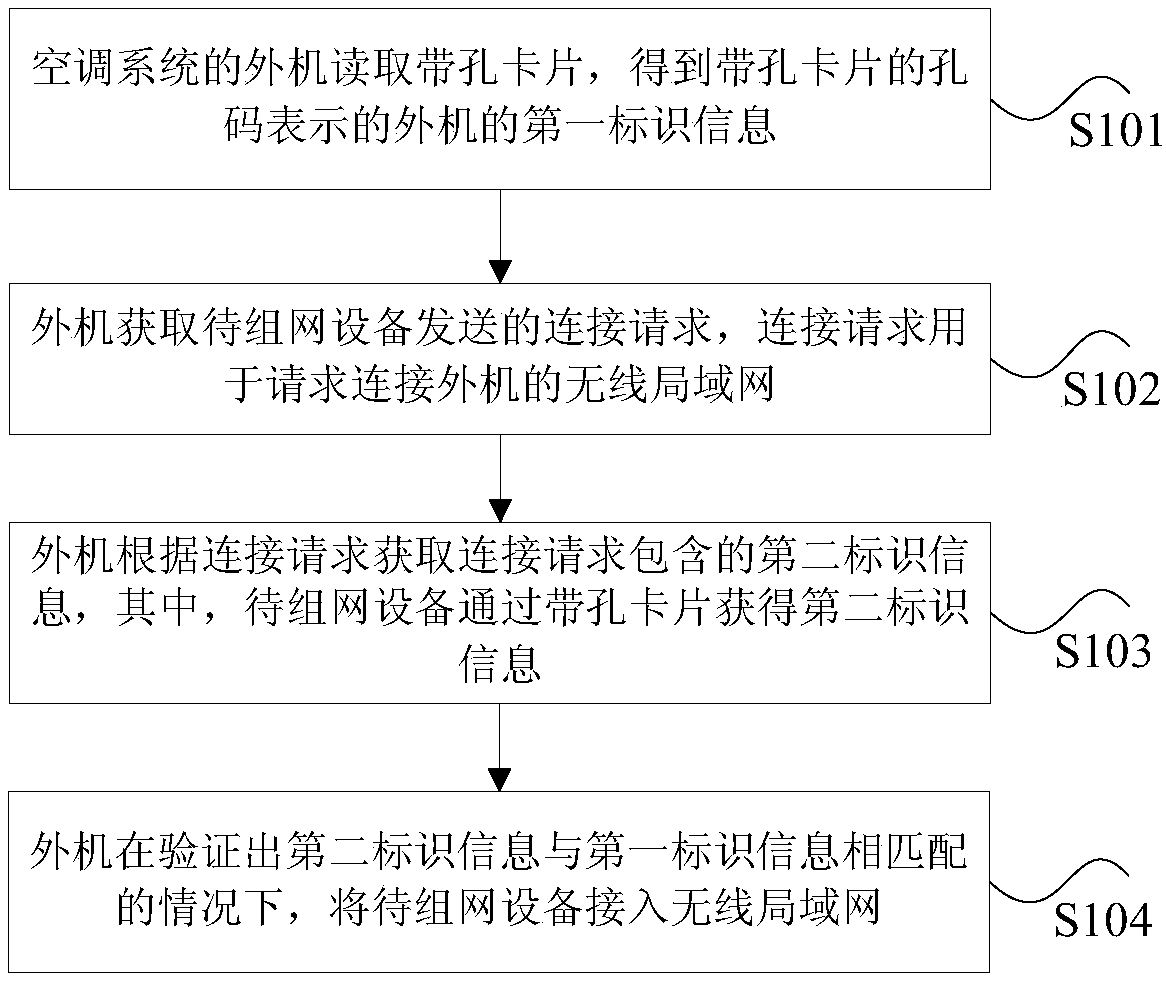

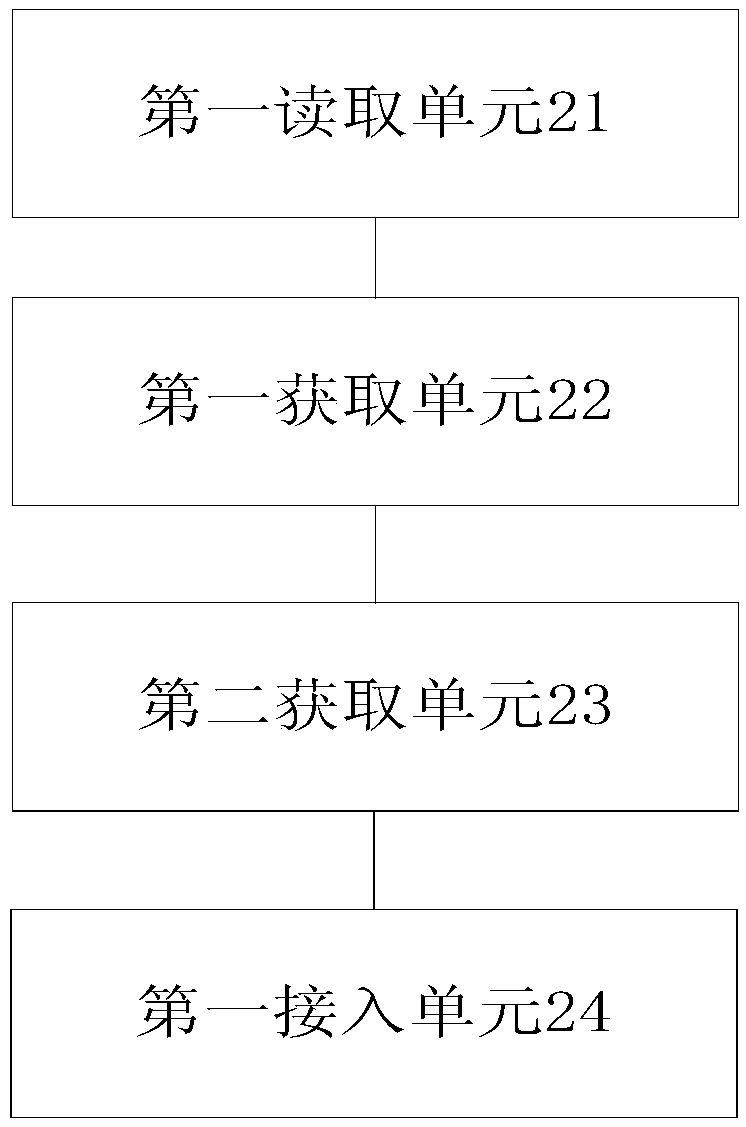

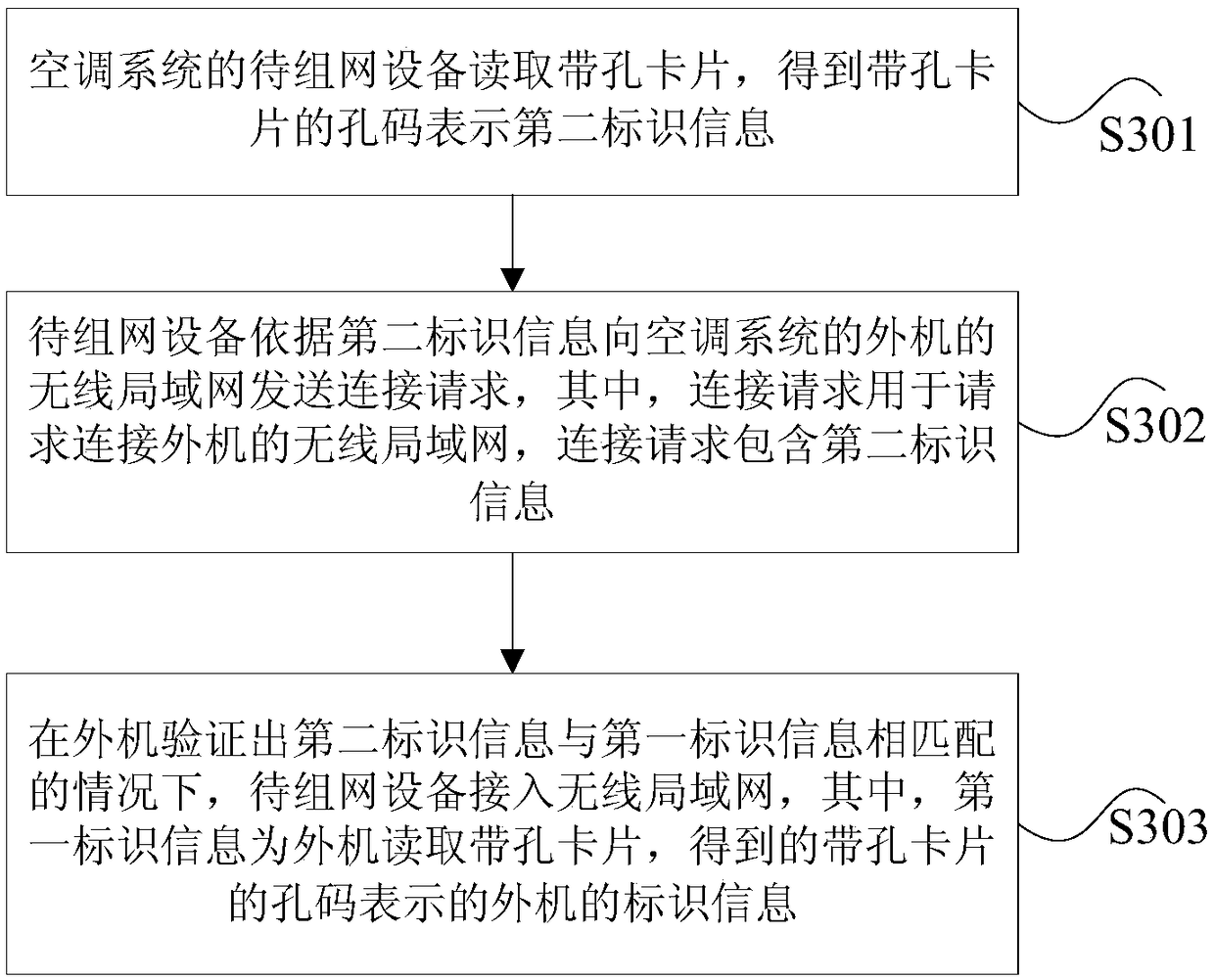

Wireless networking method and device for air conditioning system

ActiveCN108616966AFast and accurate buildSolve maintenance difficultiesMechanical apparatusConveying record carriersWired communicationAir conditioning

The invention discloses a wireless networking method and device for an air conditioning system. The method comprises steps: an external unit of the air conditioning system reads a perforated card, soas to obtain first identity information of the external unit expressed by the pore code of the perforated card; the external unit acquires an access request sent by a to-be-networked device, wherein the access request is used for requesting to be accessed to a wireless local area network of the external unit; the external unit acquires second identity information contained in the access request according to the access request, wherein the to-be-networked device acquires the second identity information through the perforated card; and in a condition in which the second identity information andthe first identity information are verified to be matched, the external unit enables the to-be-networked device to be accessed to the wireless local area network. Thus, the problems of difficult mounting and wiring and difficult process maintenance of multi-couple units in wired communication in a related technology can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

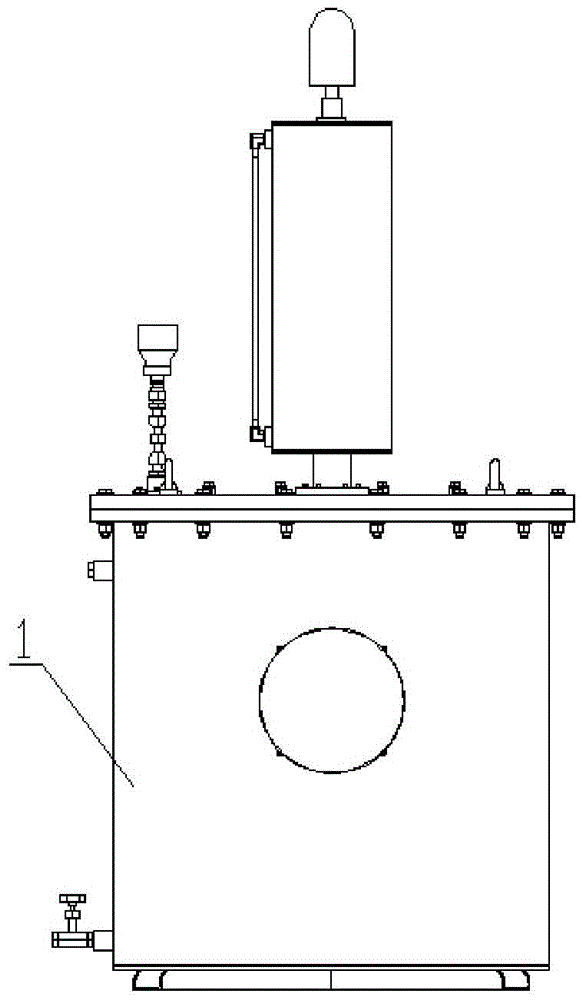

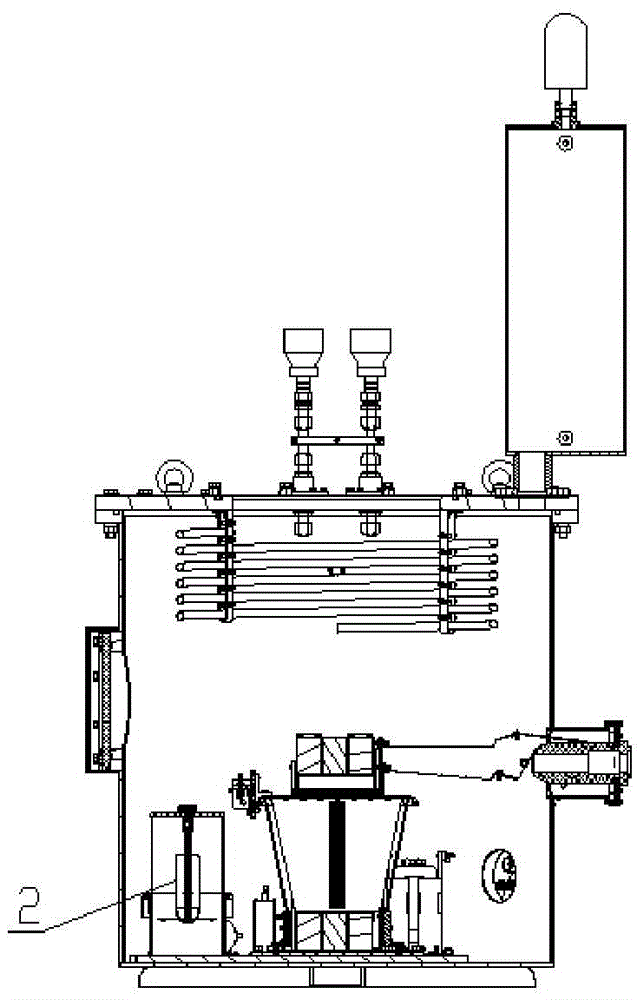

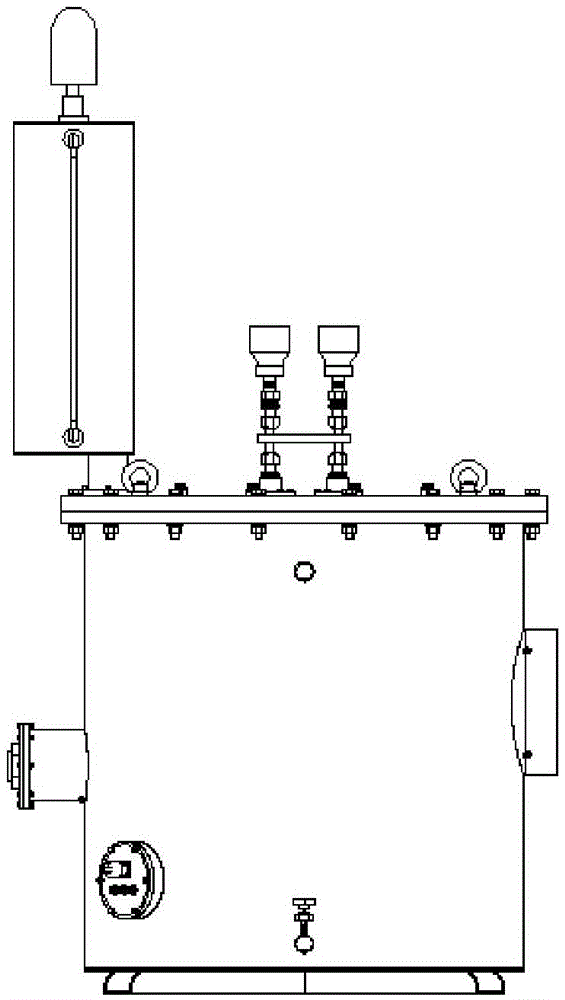

Ultra-high voltage pulse transformer

ActiveCN105489356AFix damageSolve assembly problemsTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCapacitanceUltra high voltage

The invention discloses an ultra-high voltage pulse transformer, which comprises a transformer component and an oil cylinder, wherein the transformer component is connected with the oil cylinder in a rapid connecting manner of a socket and a plug; the transformer component comprises a main transformer, a bias inductor, a capacitive voltage divider, a current transformer and an equipotential capacitor, which all are arranged on a semicircular bottom plate to be conveniently and quickly installed and maintained; the main transformer is formed by combining multiple groups of iron cores which are rectangular cutting iron cores in parallel; and corners of all iron cores are rounded. According to the ultra-high voltage pulse transformer, multiple problems that a traditional ultra-high voltage pulse transformer is huge in volume, heavy, not beautiful in appearance, complicated in structure, difficult to produce, assemble and maintain, too long in pulse rising time and the like, and the problem that surroundings and operators are harmed due to the fact that the radiation dose of dangerous rays exceeds the standard in online charging work are solved; the production cost is reduced; and the production efficiency is improved.

Owner:GLORYMV ELECTRONICS

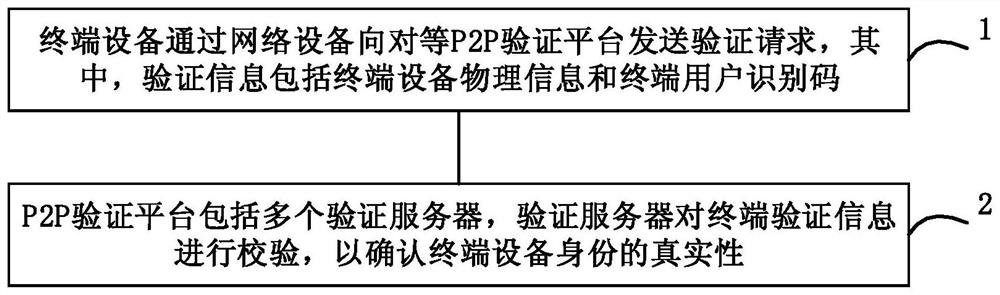

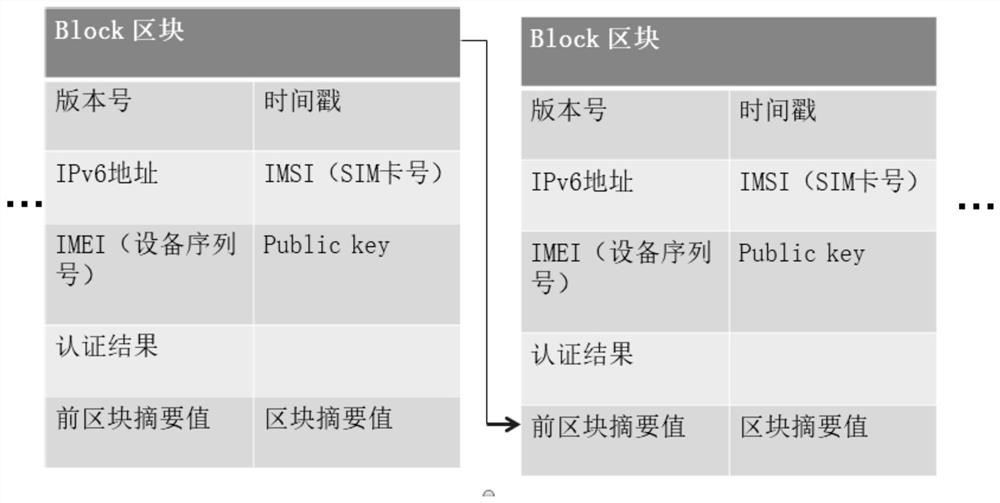

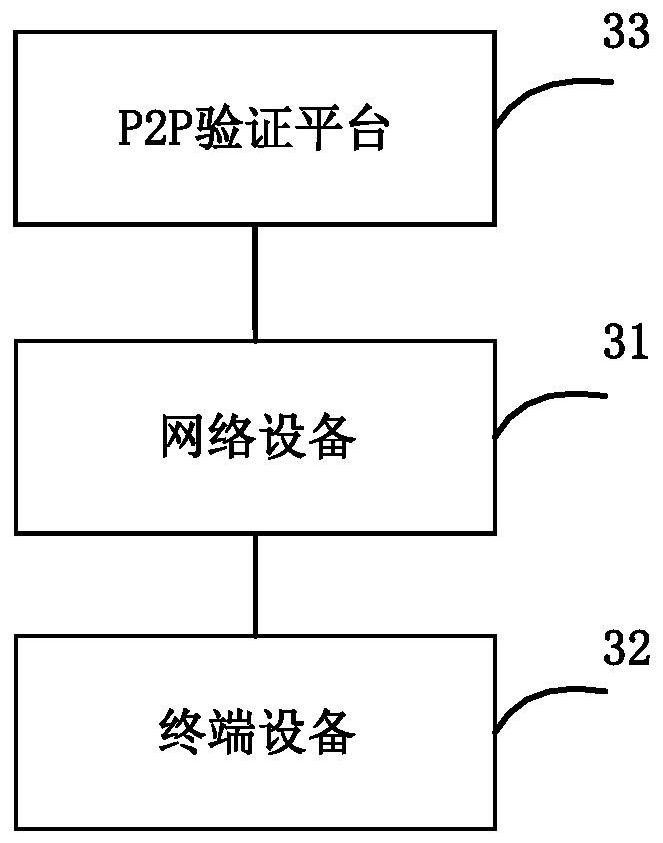

Terminal authentication method and system, terminal equipment, P2P verification platform and medium

ActiveCN113055176AImprove securityImprove the efficiency of access authenticationUser identity/authority verificationTerminal equipmentCentralized management

The invention relates to a terminal authentication method and system, terminal equipment, a P2P verification platform and a medium. The terminal authentication method comprises: the terminal equipment sends a verification request to a peer-to-peer (P2P) verification platform through a network device, the verification request comprising terminal verification information, and the terminal verification information comprising terminal equipment physical information and a terminal user recognition code; and the P2P verification platform comprises a plurality of verification servers, and the verification servers verify the terminal verification information to confirm the authenticity of the identity of the terminal equipment. According to the invention, the IPv6 address of the terminal is generated based on the physical characteristics of the chip, counterfeit equipment is prevented from accessing the network from the chip level, and the safety capability of the network is enhanced. According to the method, the equipment access authentication efficiency is improved by adopting the decentralized infrastructure, and the difficulty of centralized management and maintenance is solved.

Owner:CHINA TELECOM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com