Self-compacting, self-stressing and self-curing high-strength concrete and preparation method thereof

A high-strength concrete, self-stressing technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of hollowing out of steel pipe and concrete, difficult maintenance, and pitted surface, so as to improve bearing capacity and solve maintenance difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In combination with the invention, the preparation method of self-compacting, self-stressing and self-curing high-strength concrete is described in detail below. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0042] The present invention prepares a self-compacting, self-stressing and self-curing high-strength concrete, and its raw material mixing ratio (according to 1m 3 The amount of concrete material calculated) and performance are as follows:

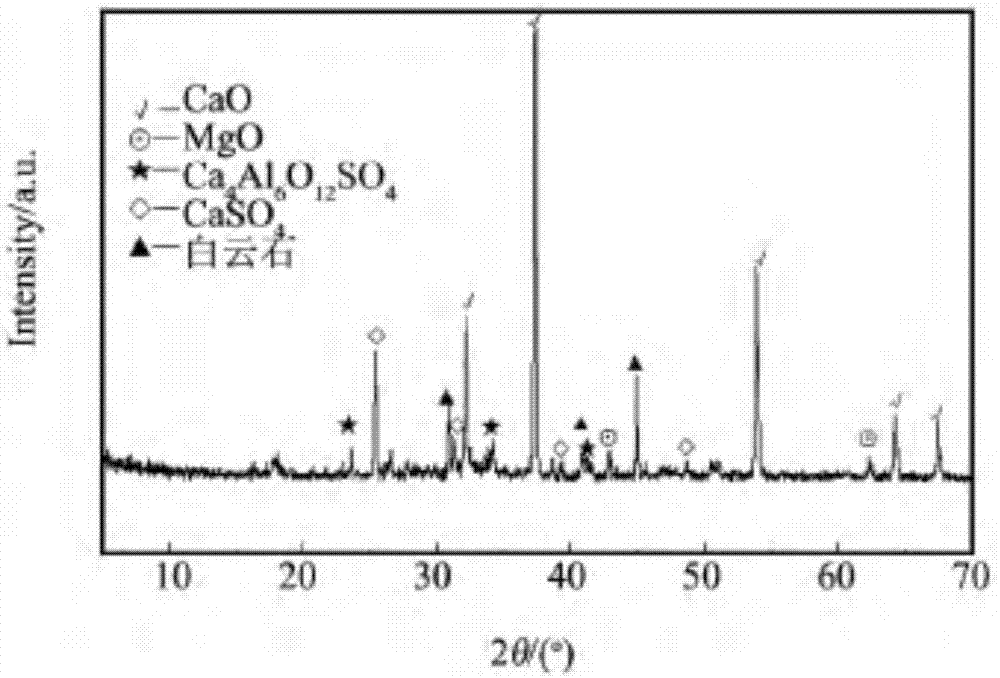

[0043] The cement adopts 42.5 ordinary Portland cement, the 28d compressive strength is controlled at 52±2MPa, the strength variation coefficient is small, it is suitable for configuring high-strength concrete, and its performance indicators meet the relevant regulations of "General Portland Cement" GB175-2007, apparent density 3010kg / m 3 ; Grade I fly ash: Macheng Grade I fly ash, apparent density is 2090kg / m 3 , Water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com