Patents

Literature

627 results about "Chipseal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chipseal (also chip seal) is a pavement surface treatment that combines one or more layer(s) of asphalt with one or more layer(s) of fine aggregate. In the United States, chipseals are typically used on rural roads carrying lower traffic volumes, and the process is often referred to as asphaltic surface treatment. In Australia and New Zealand chipsealing is used on a larger percentage of roads, both rural and urban. This type of surface has a variety of other names including tar-seal or tarseal, tar and chip, sprayed seal or surface dressing.

Self-cleaning water permeable brick and preparation method thereof

InactiveCN101445340AWide variety of sourcesImprove pollutionSolid waste managementEcological environmentBrick

The invention discloses a self-cleaning water permeable brick comprising a surface material and a base material. The base material is weighed according to weight percentage, comprising 68.4 percent to 77.5 percent of rubble or building rubbish granule or slag, 10 percent to 25 percent of cement, and 5.3 percent to 12 percent of water. The surface material is weighed according to weight percentage, comprising 66.7 percent to 71.8 percent of high-intensity sand, 10.8 percent to 26.5 percent of cement, 3.4 percent to 10.4 percent of water, and 0.1 percent to 1.0 percent of nanometer titanium dioxide. The surface material and the base material are compacted together to form an integrated water permeable brick. The invention further discloses a preparation method of the self-cleaning water permeable brick. The method comprises the following steps: 1) the base material and the surface material are weighed, respectively premixed and then stirred as raw materials for standby application; 2) molding is carried out; 3) steam curing is carried out; and 4) liquid titanium dioxide is sprayed. Road surfacing of the self-cleaning water permeable brick in the invention can reduce water permeable hole plugging and surface pollution, thereby having the effects of road surface temperature decrease and high-efficient sterilization, regaining circulatory system of natural soil air and water, preventing soil pollution and improving ecological environment.

Owner:程卫国

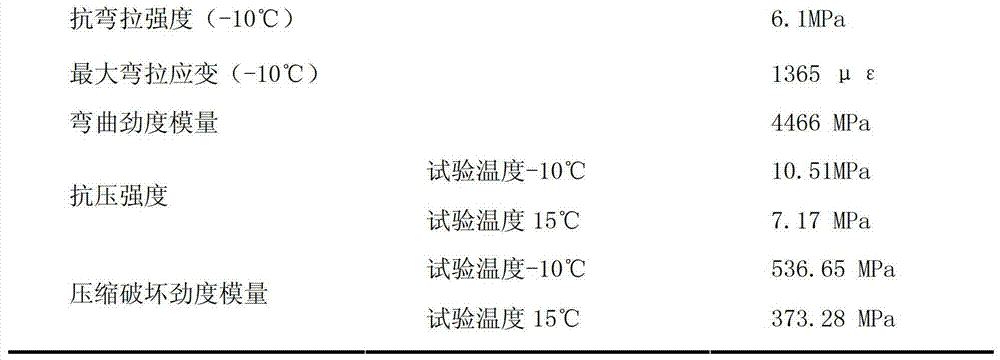

Asphalt macadam stress absorption layer and construction method thereof

InactiveCN101148856AStress Absorption and ReductionEasy to useIn situ pavingsPolymer modifiedChipseal

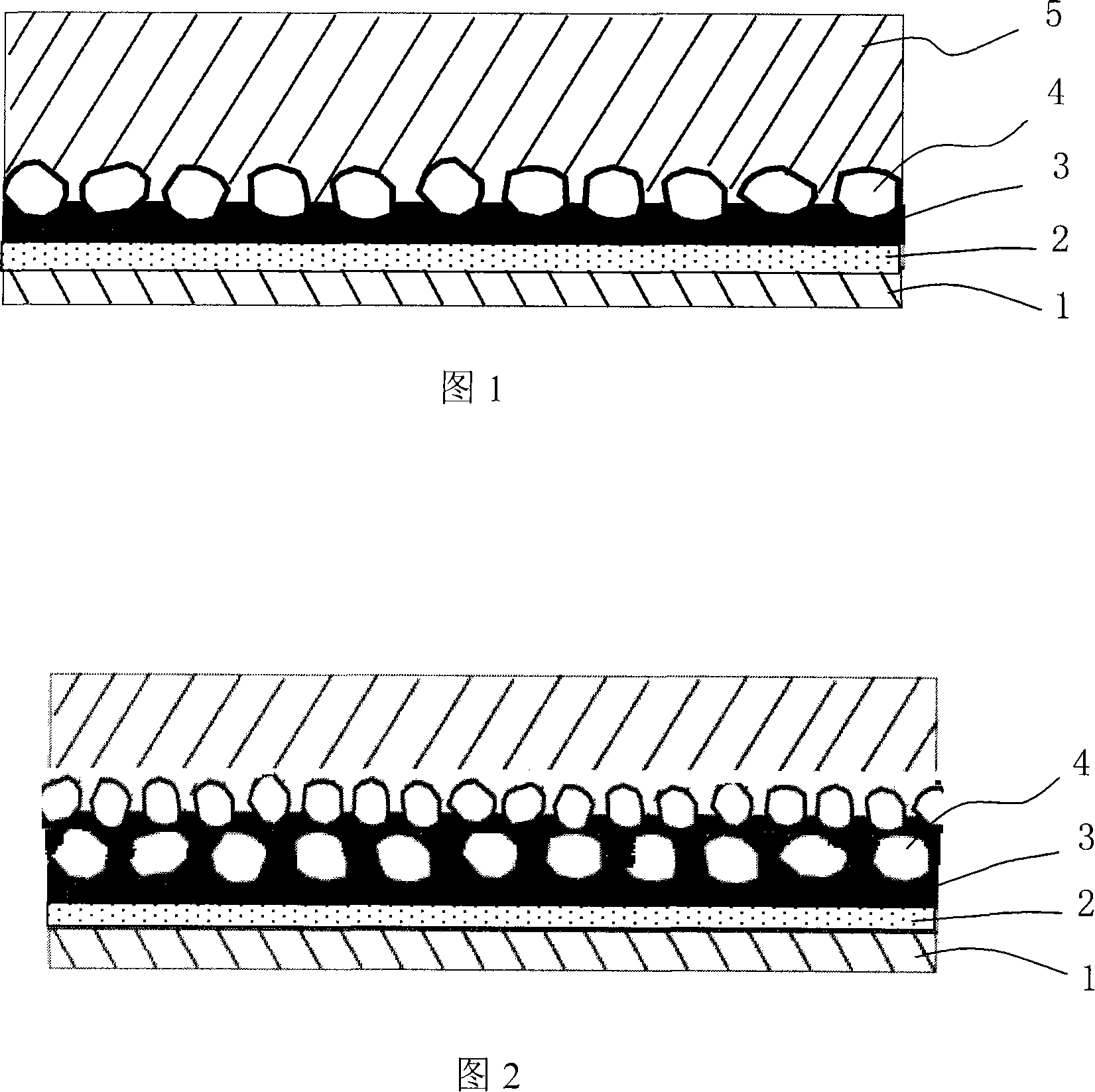

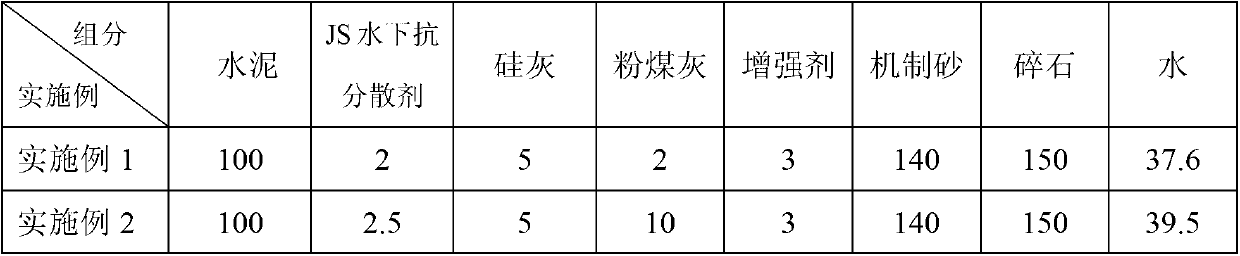

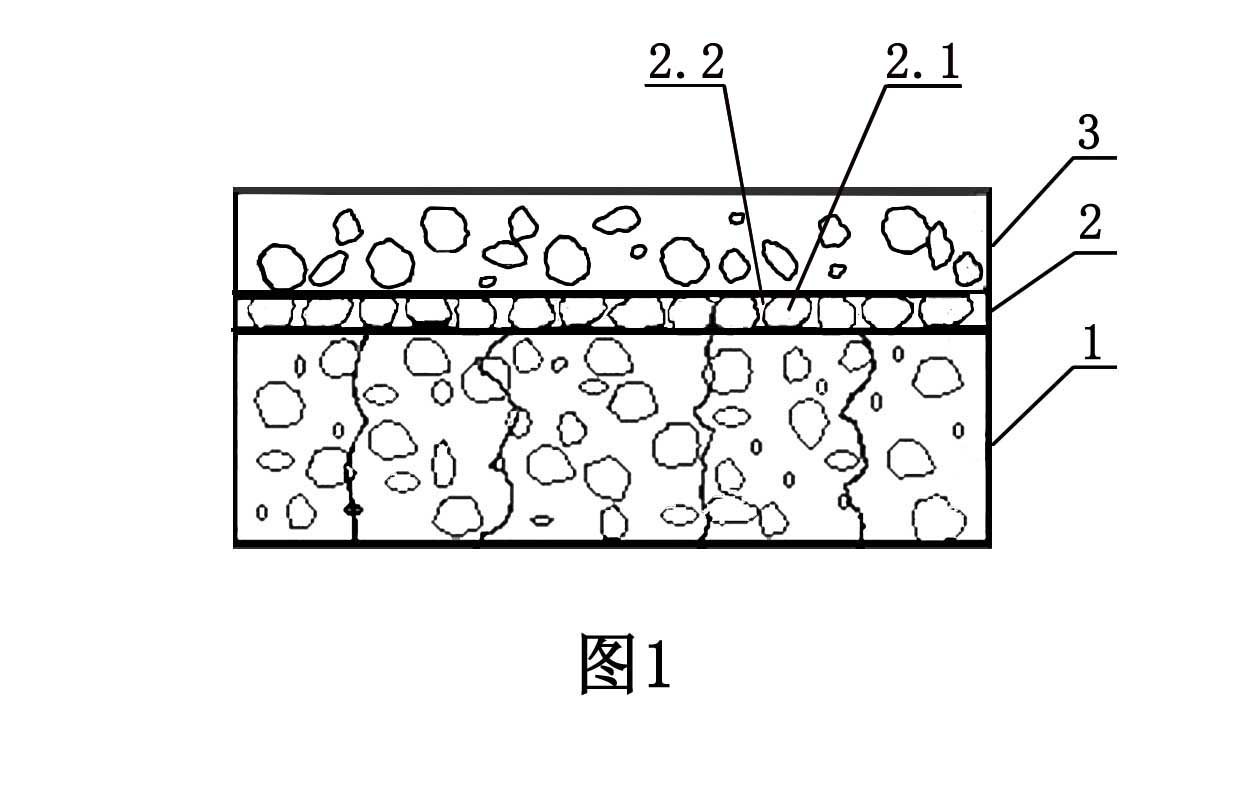

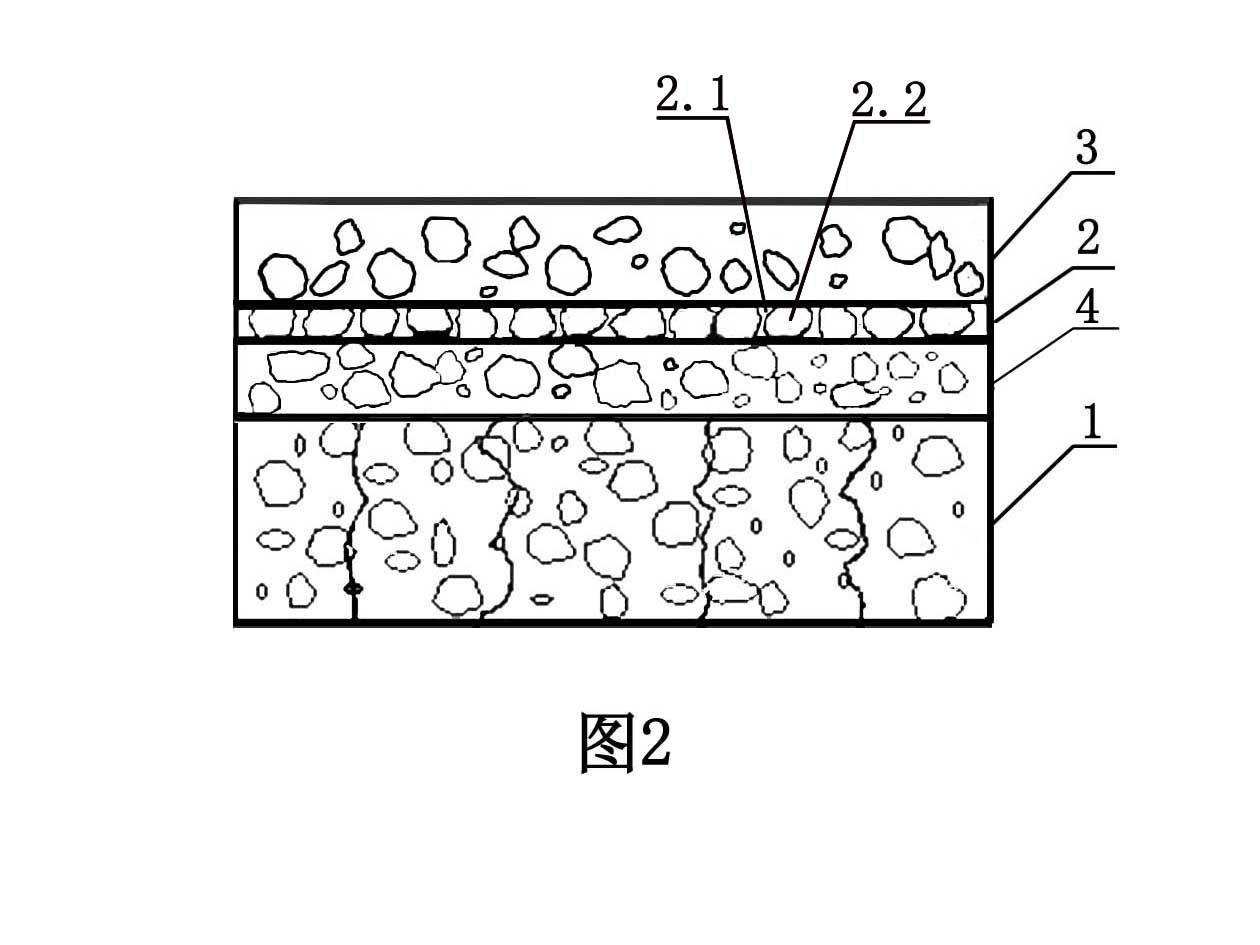

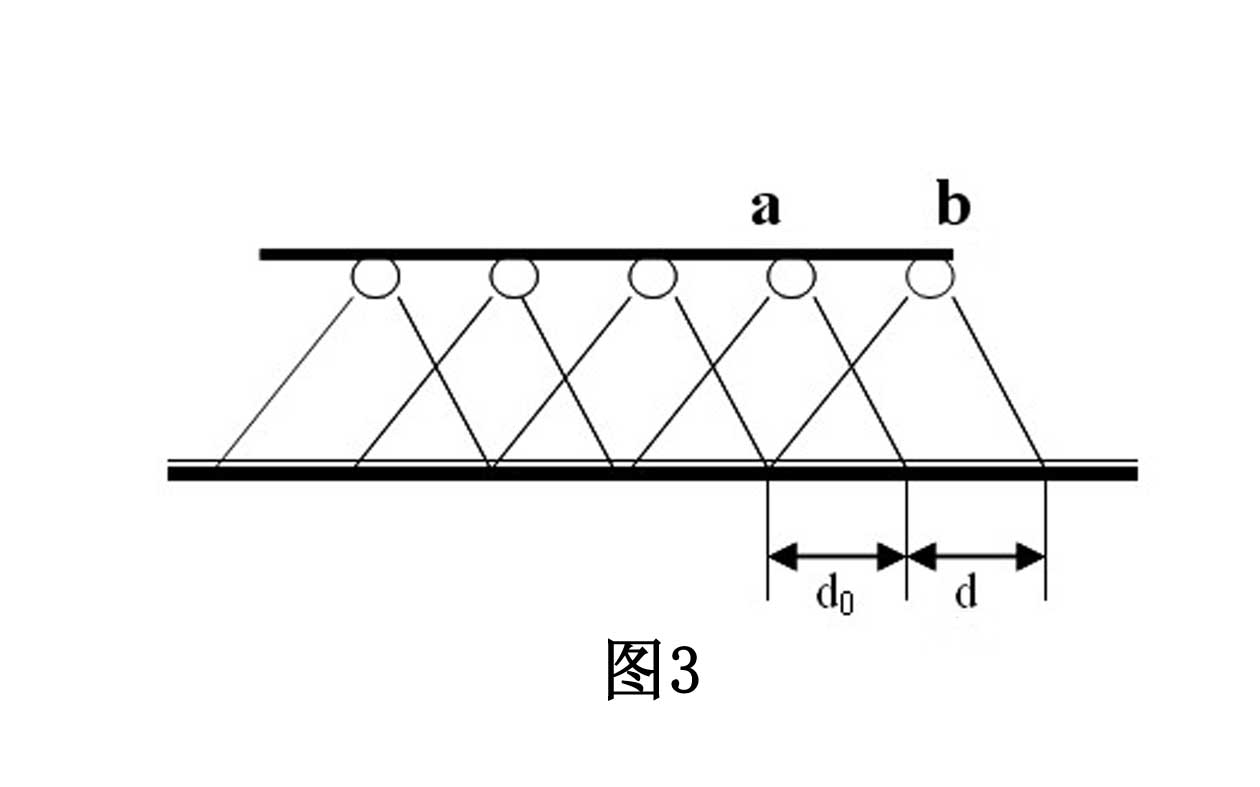

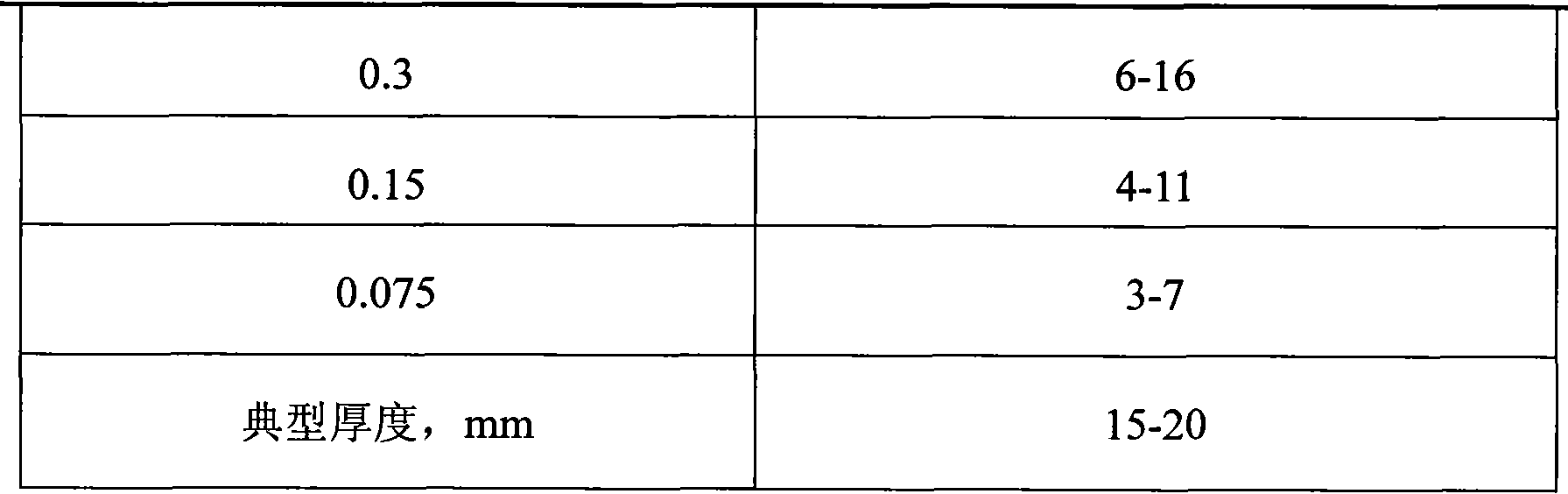

The present invention relates to asphalt road engineering, and is especially one stress absorbing asphalt macadam layer and its construction process. The stress absorbing asphalt macadam layer can absorb and reduce the stress of asphalt road surface or composite road surface and weaken the transmission of cracks to the surface asphalt layer. It consists of one macadam layer, one stress absorbing and binding layer and one connecting layer from top to bottom. Its construction process includes the steps of spreading connecting layer material onto the base layer, spreading the stress absorbing and binding layer and spreading the macadam layer. The stress absorbing and binding layer has material of polymer modified emulsified asphalt, high viscosity emulsified asphalt, hot SBS modified asphalt or rubber modified asphalt; and the connecting layer has material of kerosene diluted asphalt, high permeability emulsified asphalt, concrete interface adhesive, polymer modified emulsified asphalt or hot modified asphalt.

Owner:徐培华

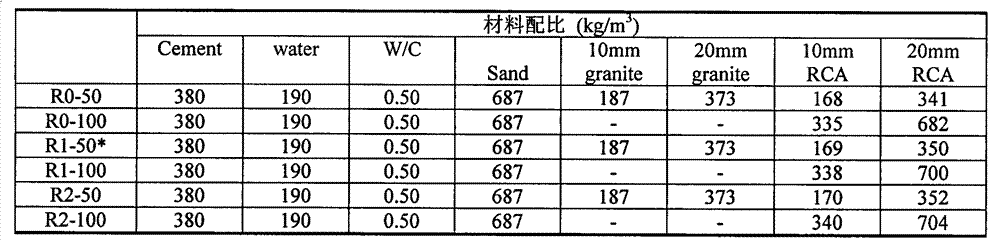

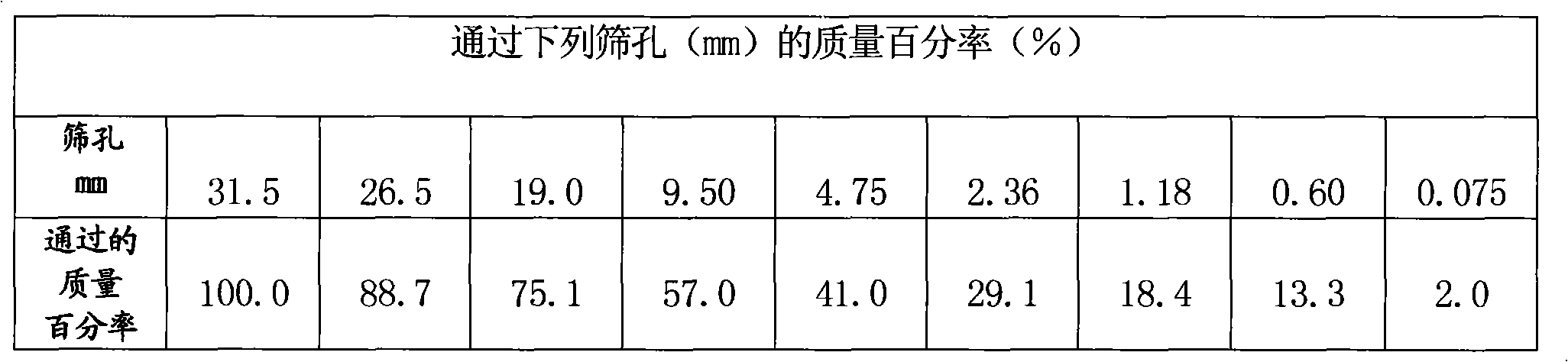

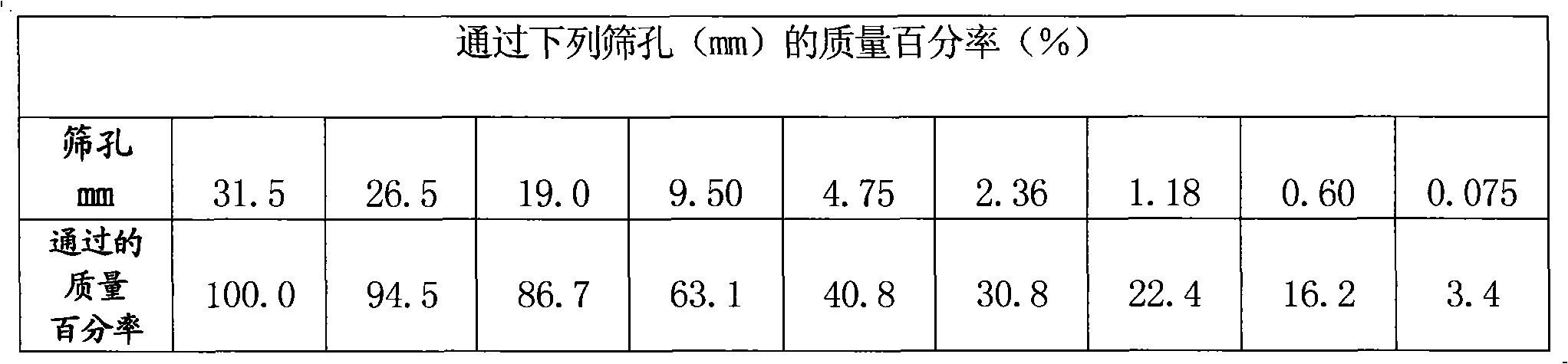

Manufactured sand underwater dispersion resistant concrete and preparation method thereof

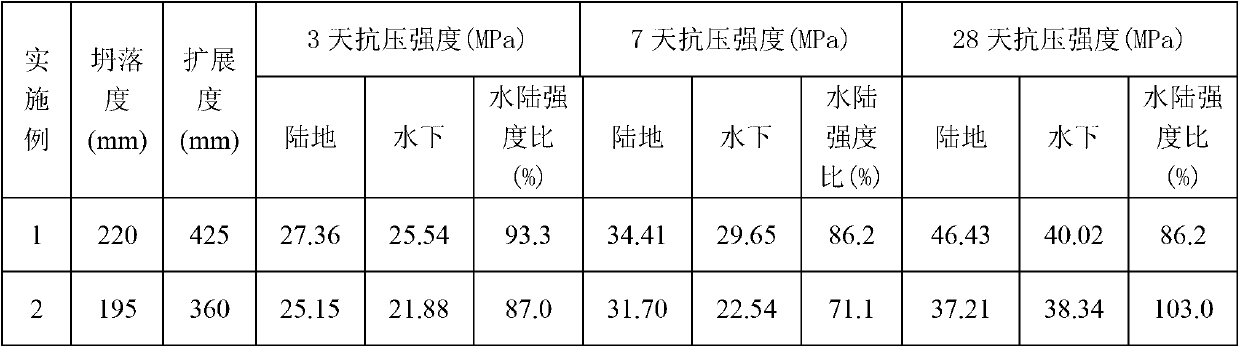

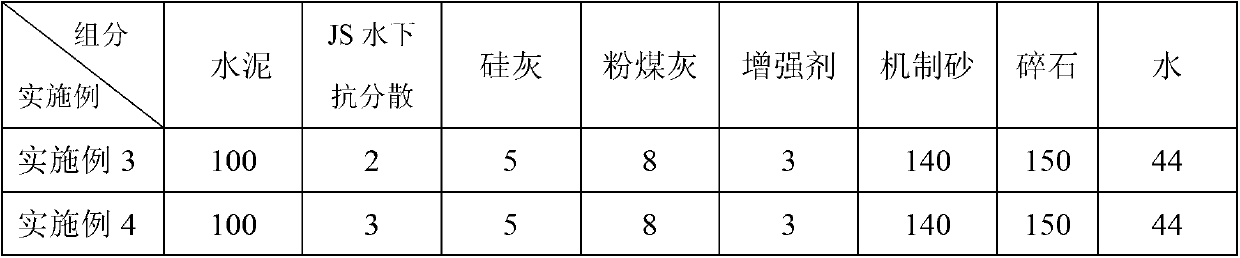

The invention relates to a manufactured sand underwater dispersion resistant concrete, which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of underwater dispersion resistant additive, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of an enhancer, 140-200 parts of manufactured sand, 140-200 parts of macadam, and 30-50 parts of water. The preparation method comprises the following steps of firstly putting the manufactured sand, the macadam aggregate, the cement, the enhancer, the coal ash and the silica fume into an agitator, blending through dry mixing, then adding the underwater dispersion resistant additive to further blend through dry mixing, adding water into the material blended through dry mixing previously, stirring for 5-8 minutes, then preparing the manufactured sand underwater dispersion resistant concrete. The manufactured sand underwater dispersion resistant concrete has strong construction mobility, so that the problem of contradiction of mobility and dispersion resistance of the underwater dispersion resistant concrete is better solved, and therefore, the manufactured sand underwater dispersion resistant concrete not only has good dispersion resistance, but also has self-leveling and self-compaction construction mobility.

Owner:江西万年青水泥股份有限公司

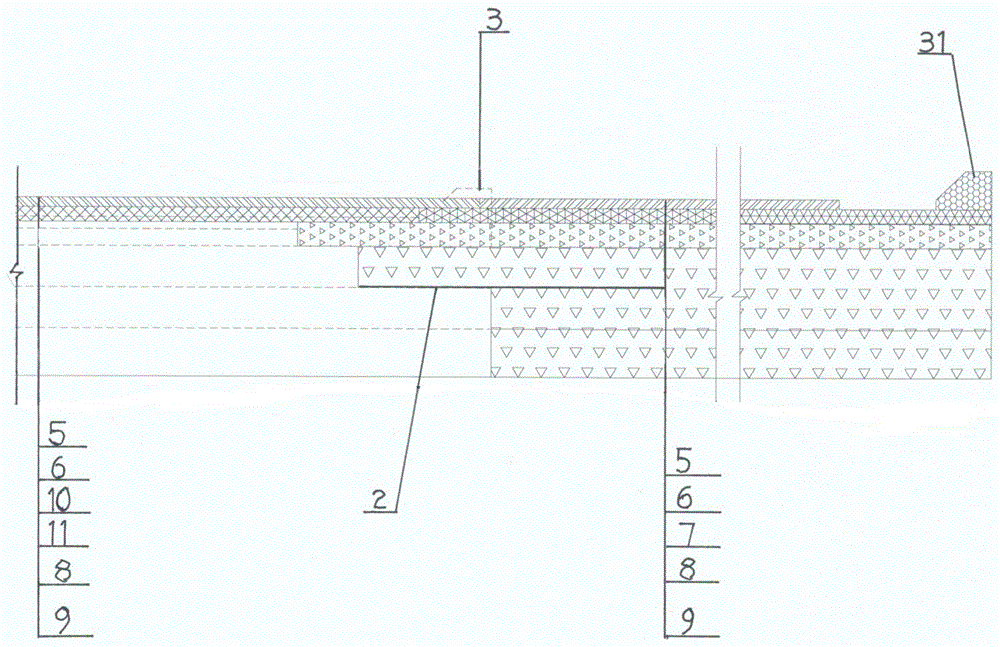

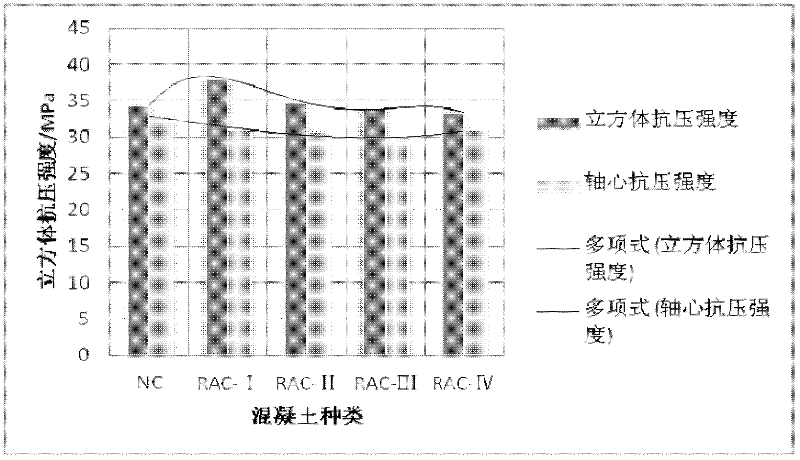

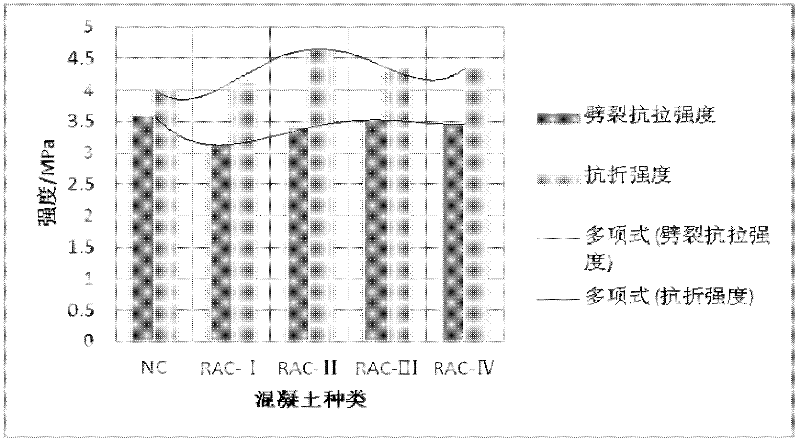

Colorful regeneration permeable concrete for road and preparation method thereof

InactiveCN103011735ALow resolutionSolving Recycling ProblemsSolid waste managementAcid waterChipseal

The invention discloses a colorful regeneration permeable concrete for road and a preparation method thereof. The colorful regeneration permeable concrete consists of aggregate, a cementing material, polypropylene fiber, a water reducing agent, pigment and water; the cementing material consists of silicate cement and mineral waste residue; the ratio of water to glue is 0.27-0.33; the mass ratio of the aggregate to the cementing material is 2.82-3.80; the aggregate consists of coarse aggregate and fine aggregate; the coarse aggregate consists of natural broken stone and regeneration broken stone prepared from waste concrete; the fine aggregate is common water-washing medium sand; the mass of the fine aggregate is 5-20% of the mass of coarse aggregate; the mass of the polypropylene fiber is 0.1-0.3% of the mass of the cementing material; the mass of the polycarboxylic acid water reducing agent is 0.5-1.5% of the mass of the cementing material; and the mass of the pigment is 2.5-7.5% of the mass of the cementing material. Through the combination of recycled aggregate and common aggregate, the invention can recycle the waste resources and solve the problem of low strength.

Owner:CHANGZHOU UNIV

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

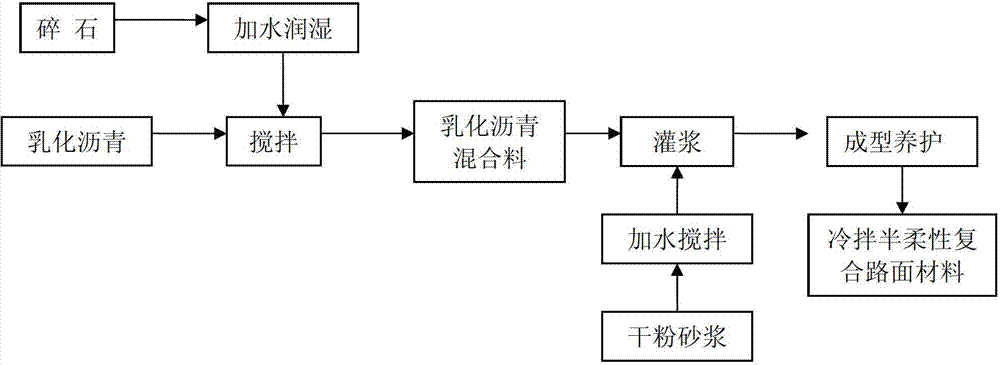

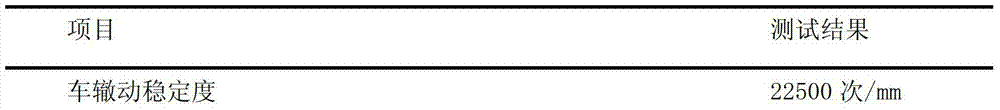

Cold-mix semi-flexible composite pavement material and preparation method thereof

The invention discloses a semi-flexible composite pavement material and belongs to the technical field of modern pavements. The semi-flexible composite pavement material comprises the following components in percentage by weight: 65%-75% of gravels or gravel mixtures, 15%-20% of self-made dry powder cement mortar, 3%-8% of emulsified asphalt, 2%-5% of mineral powder and 5%-10% of water. The cold-mix semi-flexible composite pavement material disclosed by the invention is simple and convenient in construction process without using construction machine and equipment used for large-scale production, is mixed and formed at normal temperature without being heated; the subsequent grouting procedure also can be carried out at the normal temperature, thereby saving the energy; and the cold-mix semi-flexible composite pavement material disclosed by the invention has the advantages of energy conservation and environment friendliness. The invention also discloses a preparation method of the semi-flexible composite pavement material. According to the preparation method, the cement mortar is grouted into large-gap open-graded emulsified asphalt mixtures.

Owner:浙江固路交通科技有限公司

Rubber powder modified asphalt macadam bridge surface waterproof layer and construction method

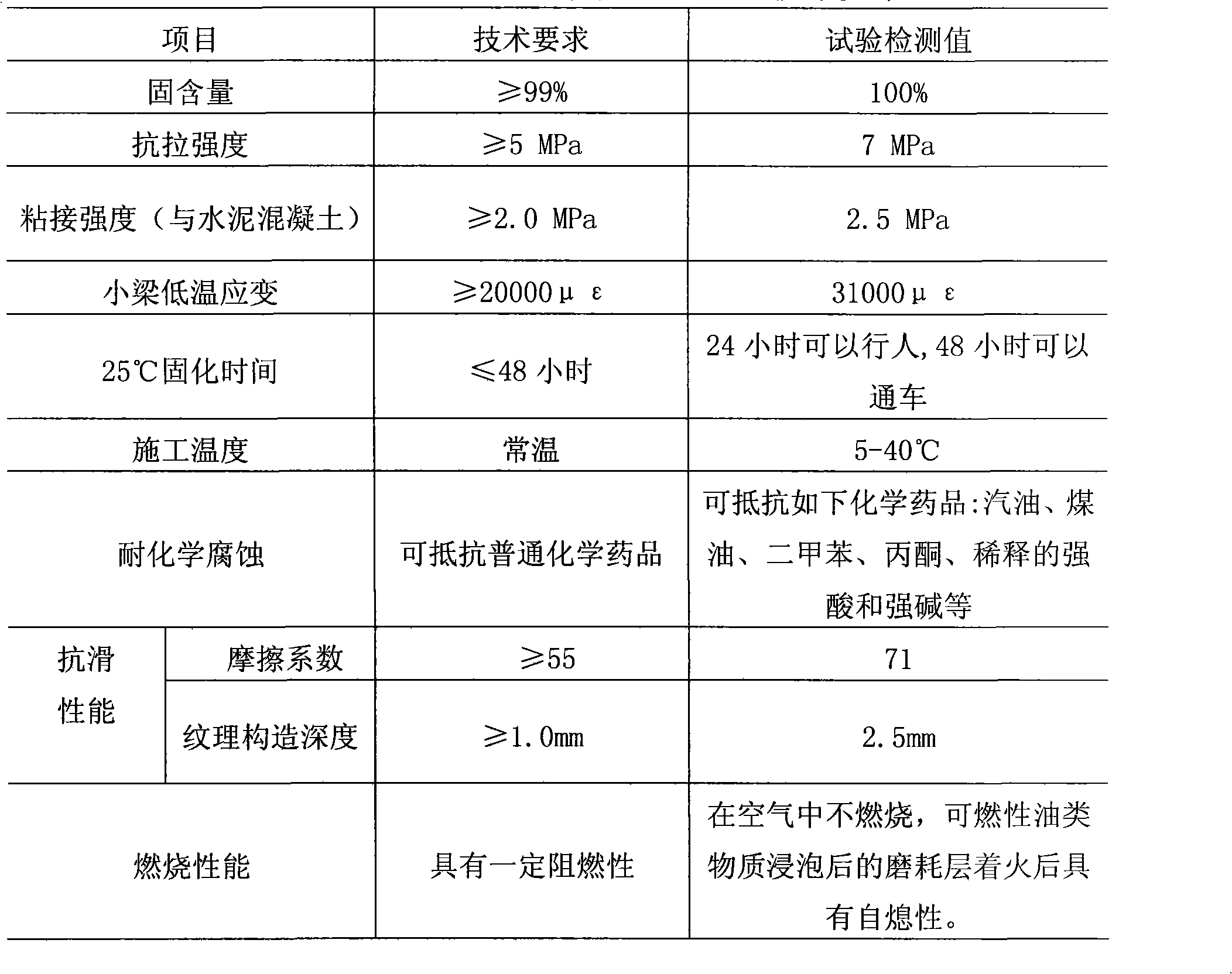

InactiveCN101220579AImprove adhesionImprove waterproof performanceIn situ pavingsBridge structural detailsChipsealCrack resistance

The invention relates to a rubber powder modified asphalt gravel bridge deck waterproof layer and a construction method thereof. The bridge deck waterproof layer of the invention is arranged between a bridge cement concrete paving layer and a bridge deck asphalt paving layer, and the bridge deck waterproof layer consists of a signal particle diameter gravel layer, a rubber powder modified asphalt layer, and an interlayer interface connection layer from top to bottom. The cement concrete paving layer is gigged and cleaned clearly during the period of construction, and then the interlayer interface connection material, the rubber powder modified asphalt and the signal particle diameter gravel are sprayed sequentially. After the rubber-tyre rolling and health preservation, the traffic can be open to the construction vehicles or the construction of the bridge deck asphalt paving layer starts. The bridge deck waterproof layer of the invention has the advantages of good waterproof effect, high interlayer cohesive performance, good high-temperature stability, good low-temperature crack resistance and excellent fatigue resistance, and efficient property of absorbing and reducing the interlayer stress.

Owner:徐培华

Anti-disturbance concrete and preparation method thereof

InactiveCN102060488AUnique performanceUnique advantagesSolid waste managementCrack resistanceMixing ratio

The invention provides an anti-disturbance concrete and a preparation method thereof. The raw material of the anti-disturbance concrete comprises the following components in part by weight: 100 parts of cement, 10 to 100 parts of fly ash, 1 to 40 parts of other mineral admixture, 1 to 10 parts of anti-disturbance additive, 1 to 6 parts of polycarboxylic acid water reducer, 190 to 480 parts of fine aggregate, 200 to 480 parts of broken stone and 30 to 80 parts of water. In the invention, the drawbacks of common concrete, such as low early strength and long initial setting and final setting time interval, can be overcome by optimizing a mixing ratio and using the polycarboxylic acid water reducer with high water reduction rate, high water holding performance and early strength as well as the mineral admixture and the anti-disturbance additive in combination; and the early disturbance resistance, cracking resistance and durability of concrete are improved greatly.

Owner:TONGJI UNIV

Asphalt stabilized macadam overlay reforming method for old road and structure thereof

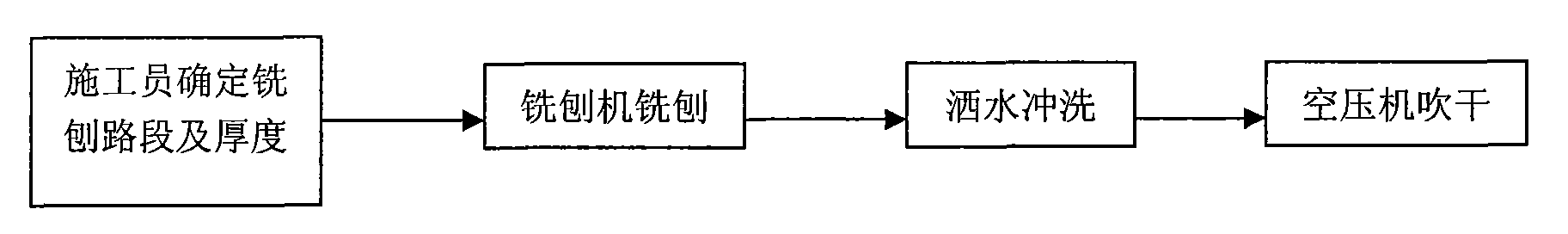

An asphalt stabilized macadam overlay reforming method for old road comprises determining equivalent resilient modulus of original road surface, performing construction by using one of the following three treating schemes or combination, aiming at different damage conditions of road surface, wherein scheme A is to overlay asphalt concrete layer on original road surface which is not seriously damaged; scheme B is to excavate partly a layer of original road surface which is locally damaged, such as spongy surface, track, looseness, crack and the like, back patch asphalt stabilized macadam, overlay an asphalt concrete layer thereon; scheme C is to excavate fully an oil surface layer of the original road surface which is seriously damaged, has a track depth larger than 3cm, local net-shaped cracking, depression and deformation, not scratch the base layer, overlay an asphalt concrete layer thereon after performing priming oil treatment and back patching two layers of asphalt stabilized macadam.

Owner:JIANGXI GANYUE EXPRESSWAY

Recycled aggregate structural concrete and manufacture method

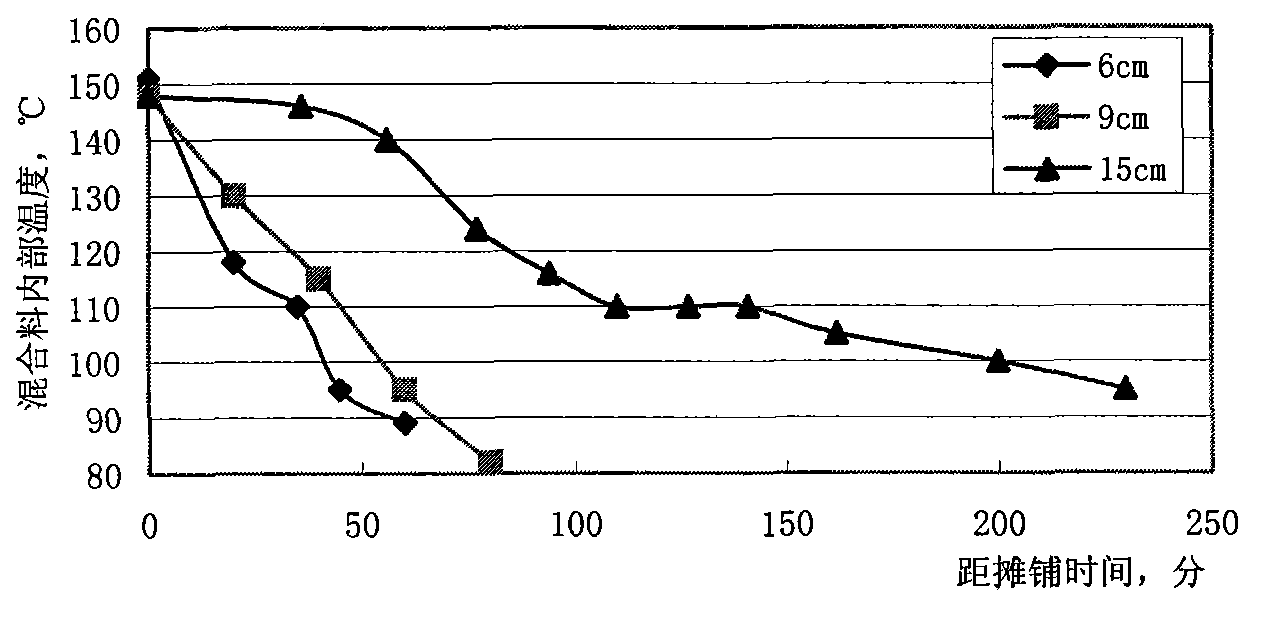

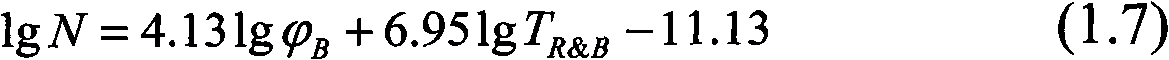

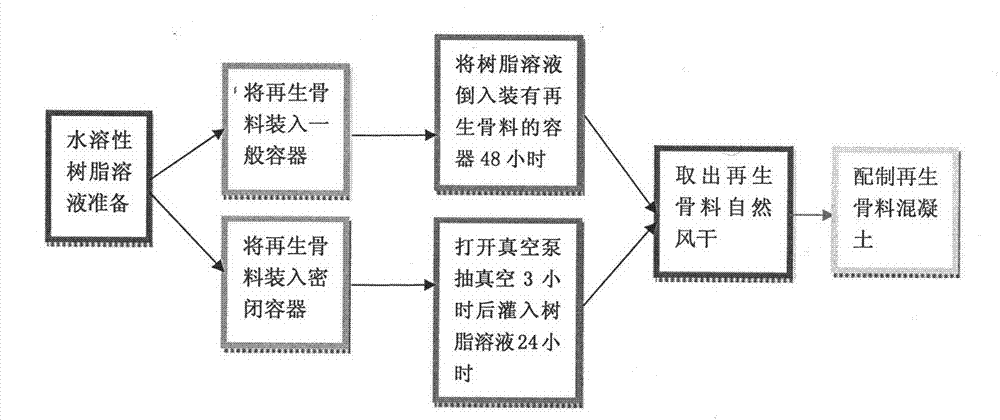

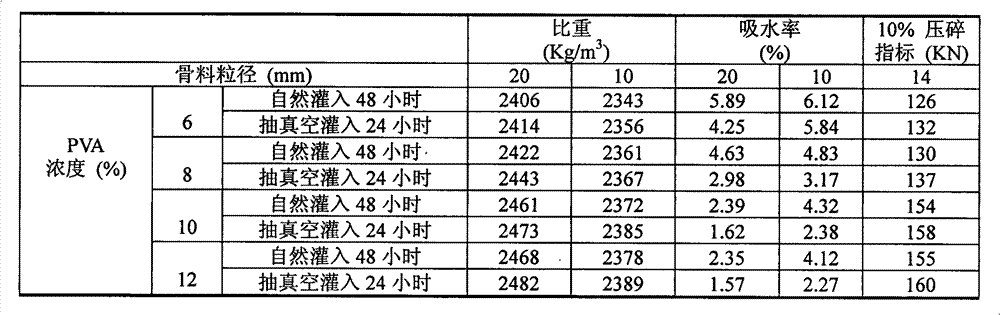

The invention first provides a concept of improving the physical performance and mechanical performance of a recycled aggregate by utilizing water-soluble resin, and the concrete is applicable to a structural concrete and a high-performance recycled aggregate concrete. The invention also provides a manufacture method of the recycled aggregate structural concrete, wherein the cement can be any of the cements which are commonly used in the concrete technology; and the admixture includes the water-soluble resin such as polyving akohol (PVA) and white emulsion. The manufacture method of the concrete comprises the following steps in sequence: mixing the water-soluble resin with the water based on a certain ratio; pouring the mixture into the recycled aggregate through a dipping or a vacuuming way; drying the aggregate by air so as to reduce the water absorption of the recycled aggregate as well as improving the crush index; uniformly stirring the cement, the processed recycled aggregate, the sand or gravel or the fine recycled aggregate and other mineral substances based on a certain mixing ratio; and conveying or pumping the mixture to a construction site to pour, so as to obtain the recycled aggregate structural concrete provided by the invention.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Strong-viscosity emulsified modified asphalt and preparation method thereof

ActiveCN102061099AImprove road performanceImprove adhesionBuilding insulationsPolymer scienceChipseal

The invention discloses strong-viscosity emulsified modified asphalt and a preparation method thereof. The emulsified modified asphalt comprises the following components in percent by mass: 62-70 percent of SBS (Styrene Butadiene Styrene block copolymer) modified asphalt, 0.5-1.5 percent of blender, 0.8-1.5 percent of emulsifying agent, 1-2 percent of stabilizing agent, 0.3-0.5 percent of thickening agent and the balance of water. The preparation method comprises the steps of: preparing the SBS modified asphalt, adding the blender; adding the emulsifying agent, the stabilizing agent and the thickening agent into water to prepare liquid soap; and uniformly dispersing the modified asphalt and the liquid soap by using a colloid mill to obtain the emulsified modified asphalt. The method disclosed by the invention has the advantages of easy obtaining of the raw materials and simple preparation process; and the strong-viscosity emulsified modified asphalt has excellent road service performance, solves the technical problems of poor caking effect of tack coat oil for the common ultrathin wear layer, easiness of bleeding and low strength of a stone-chip seal coat, can remarkably improve the interlayer caking capacity when used as the tack coat oil, and can remarkably improve the strength and the deformation-resisting capacity of the seal coat when used as the stone-chip seal coat.

Owner:辽宁省交通科学研究院有限责任公司

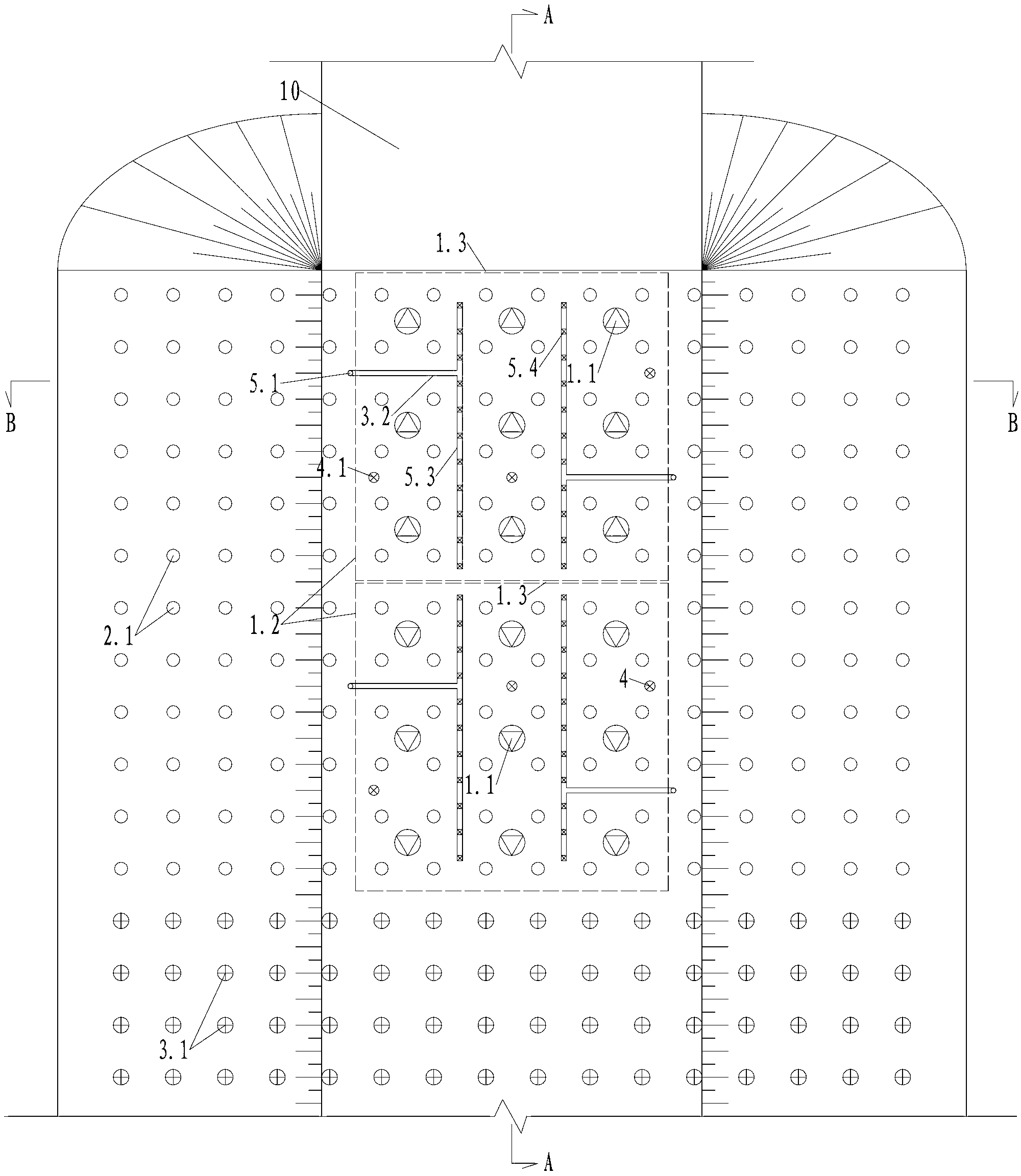

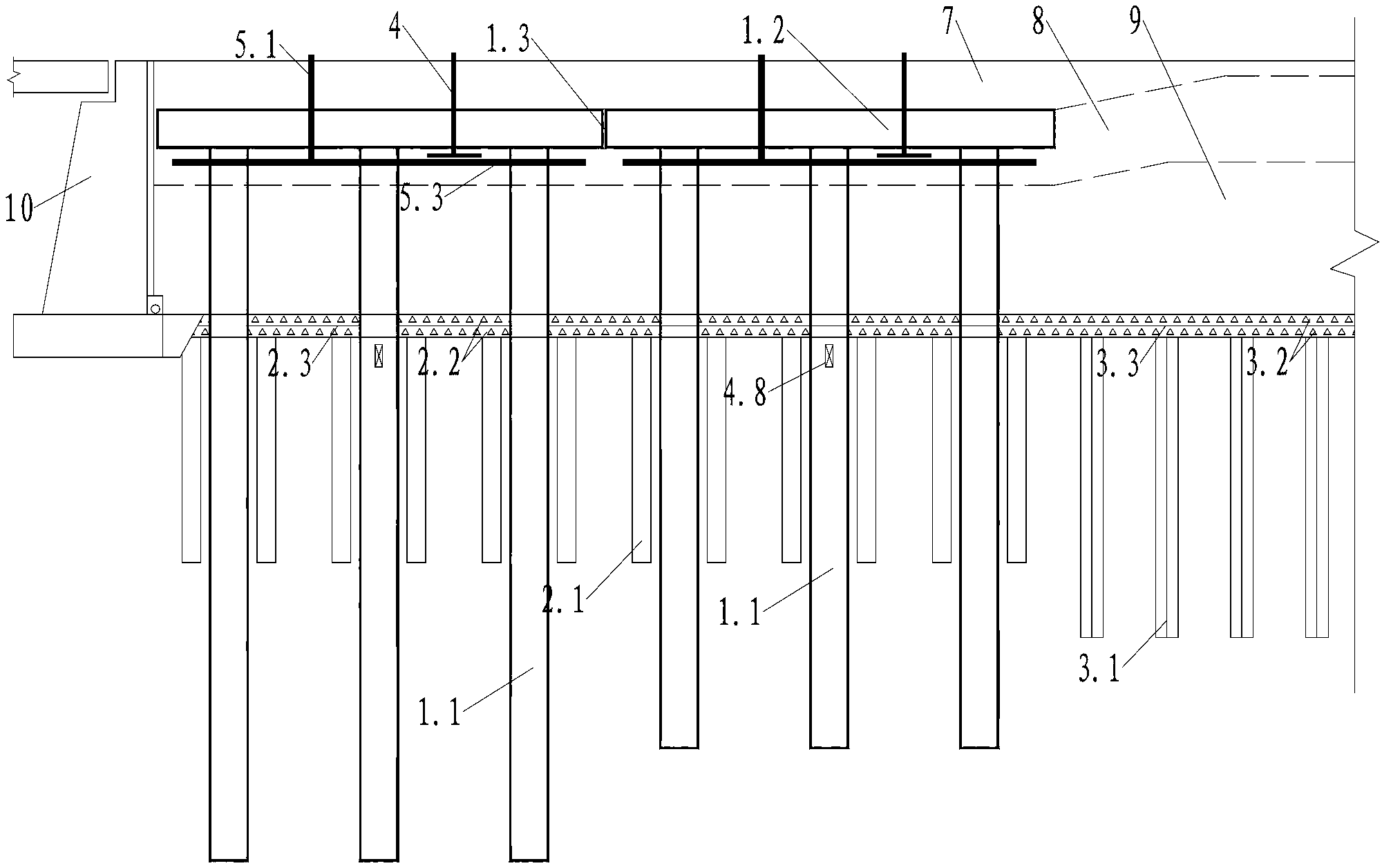

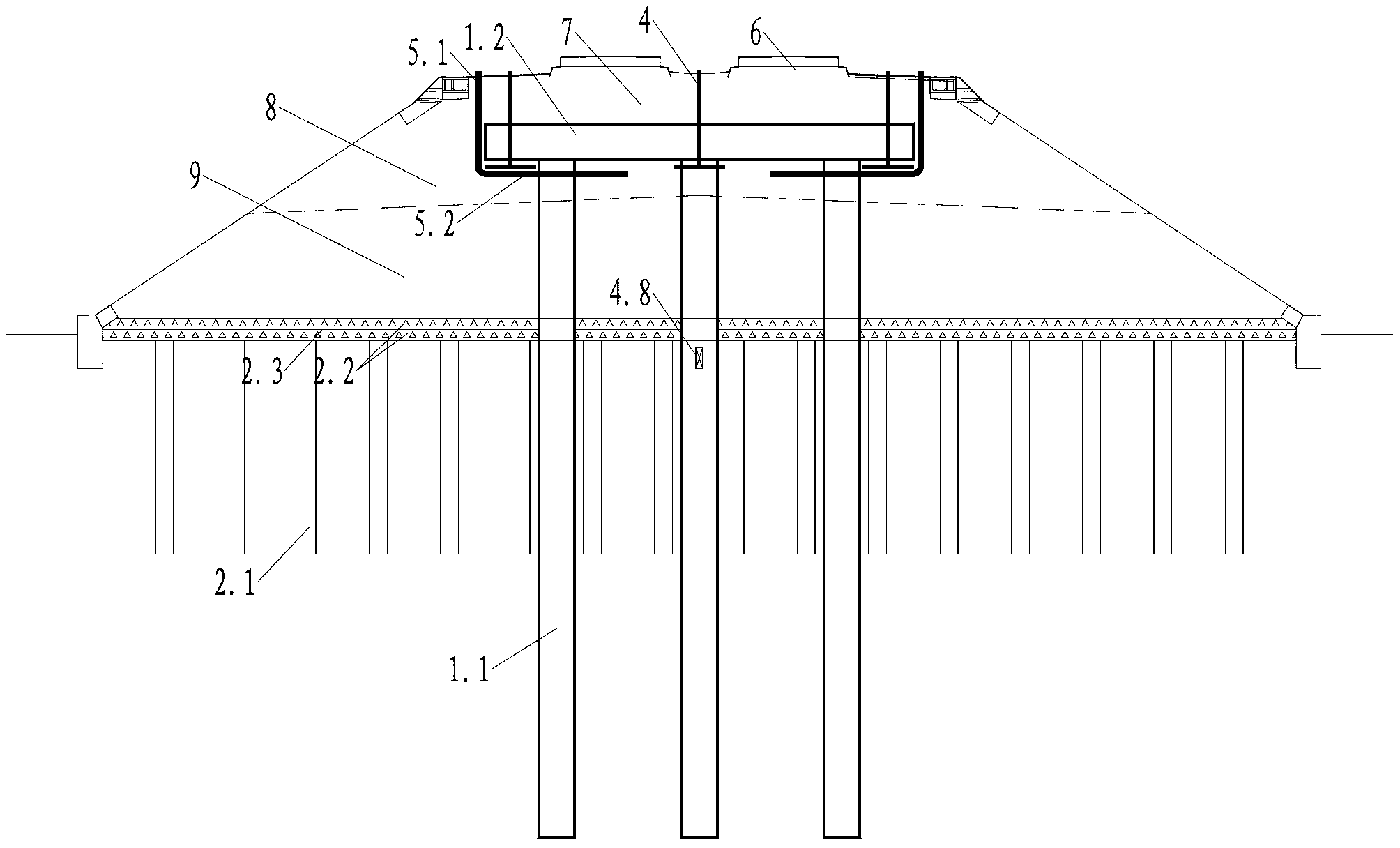

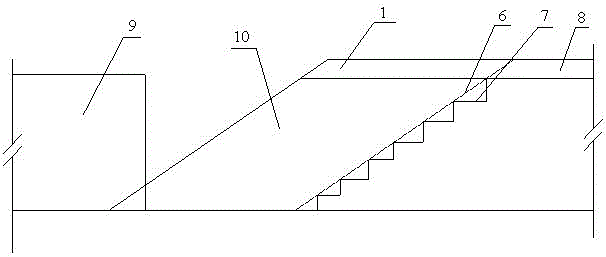

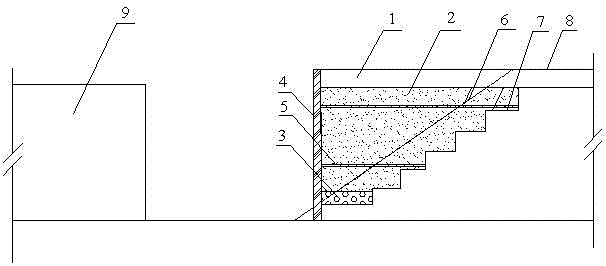

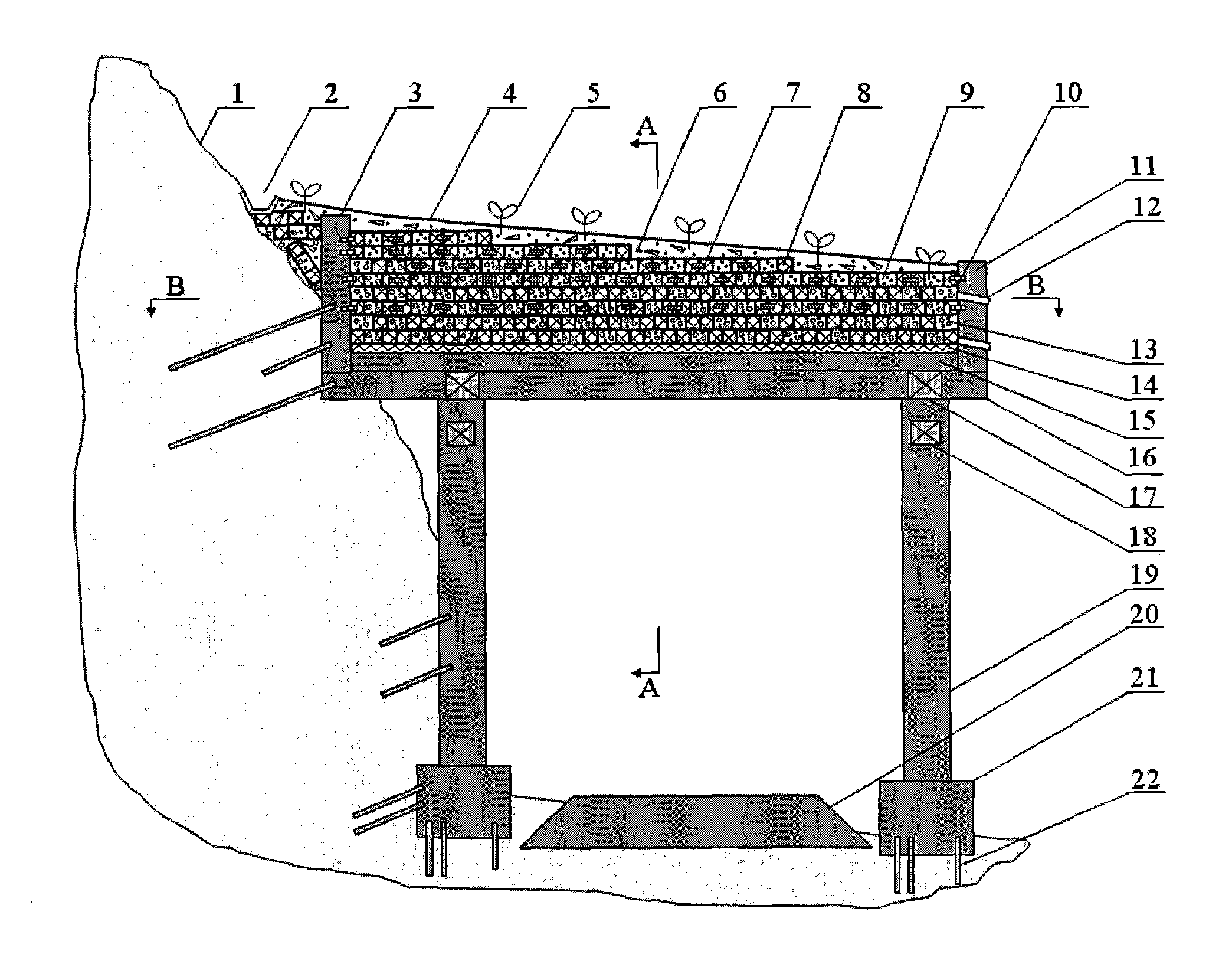

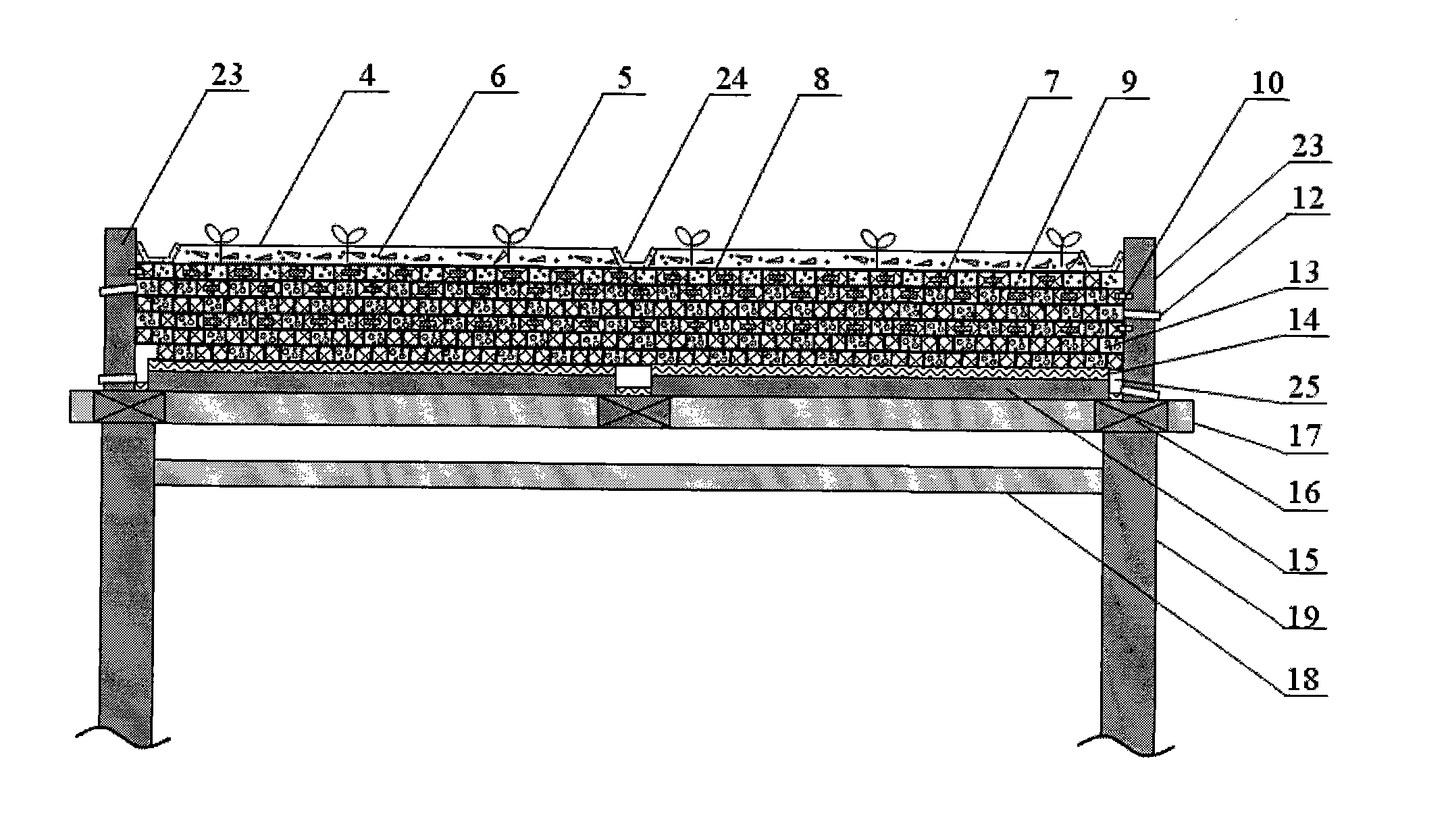

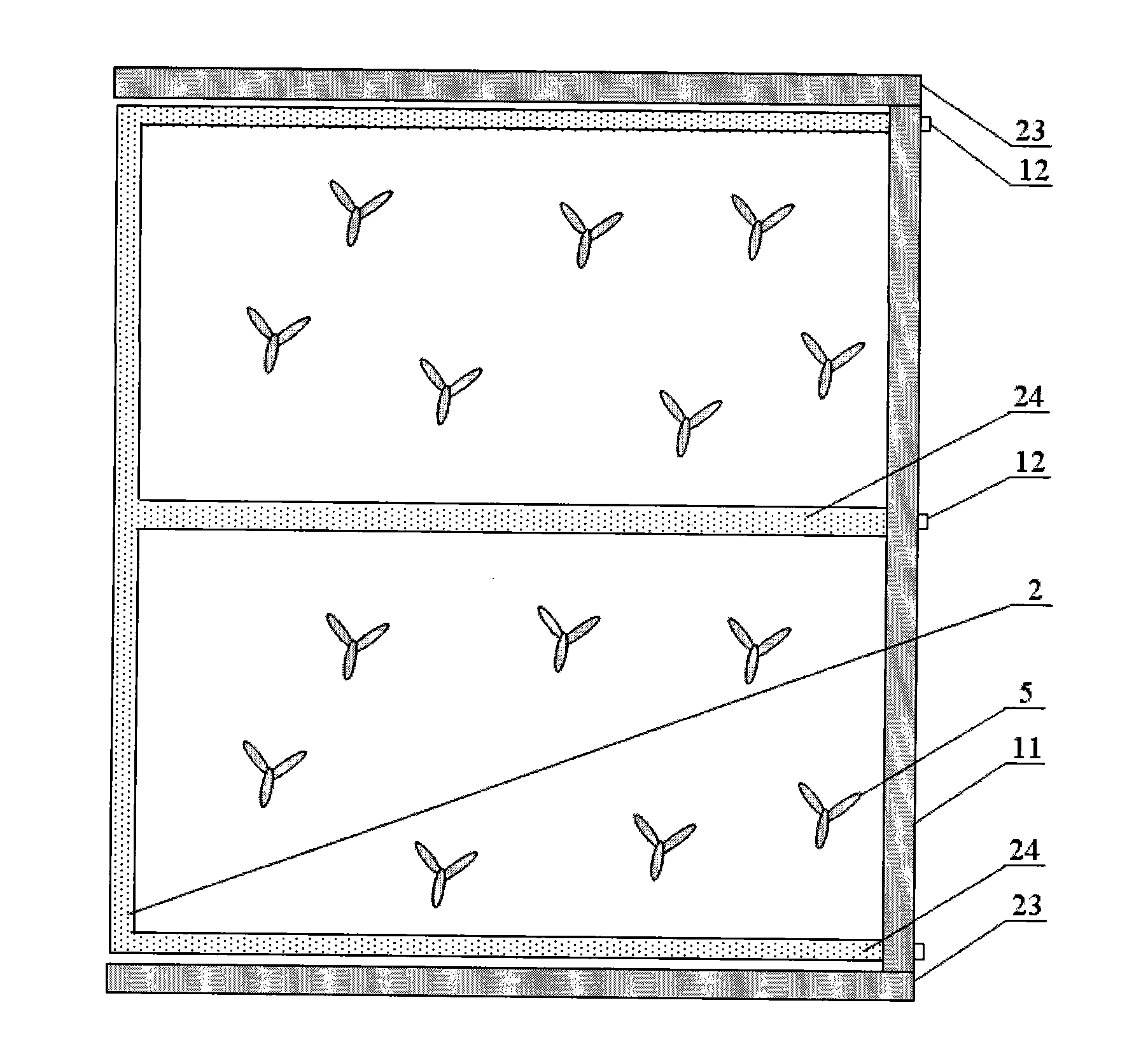

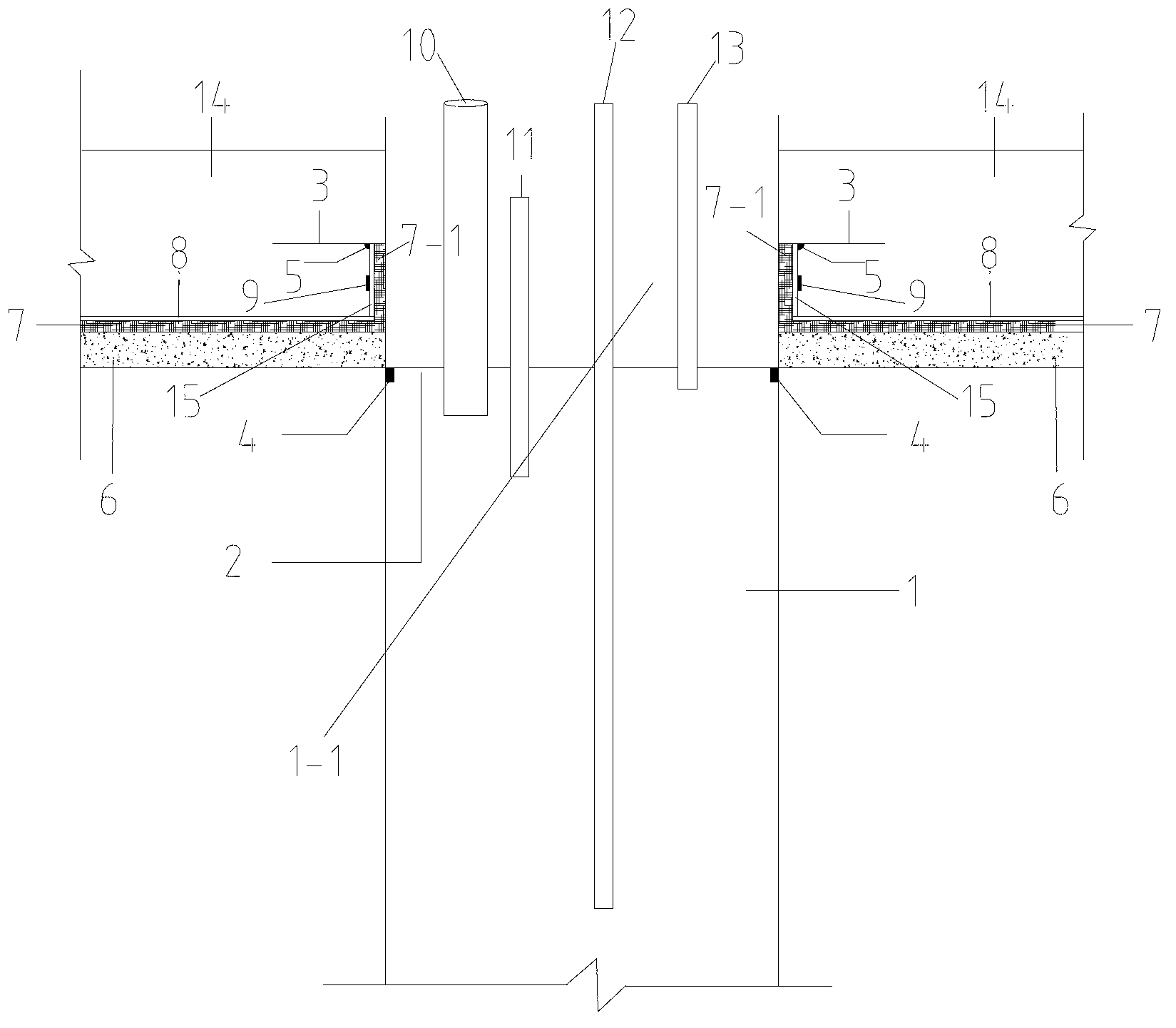

Bridge road transition section roadbed structure of deep layer yielding ground regions

The invention discloses a bridge road transition section roadbed structure of deep layer yielding ground regions. The bridge road transition section roadbed structure of deep layer yielding ground regions comprises a settlement and rigidity smooth transition system, a bearing force control system and a conventional foundation stabilizing system; the conventional foundation stabilizing system is positioned at one side of a roadbed body; the settlement and rigidity smooth transition system and the bearing force control system are positioned between the conventional foundation stabilizing system and a bridge abutment; the settlement and rigidity smooth transition system comprises a raft below a track and a plurality of long piles entering the roadbed; the long piles lengthen gradually from the pavement to the bridge abutment direction; the pile top parts of the long piles enter the raft, and the long piles and the raft are in rigid connection into an integral structure; the bearing force control system comprises a plurality of short piles arranged below the roadbed; the pile top parts of the short piles are provided with first broken stone hardcores for bearing the roadbed, and the long piles penetrate through the first broken stone hardcores.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Hot-distribution rubber bituminous pavement and construction method thereof

InactiveCN101982610AImprove adhesionAvoid enteringIn situ pavingsSolid waste managementInter layerChipseal

The invention discloses hot-distribution rubber bituminous pavement and a construction method thereof. The construction method comprises the following steps: 1, cleaning a lower bearing layer; 2, preparing rubber asphalt; 3, distributing the rubber asphalt, namely, uniformly distributing a rubber asphalt layer on the lower bearing layer, wherein the distribution amount of the rubber asphalt is 2.2 to 2.6 kg / m<2>, and the distribution temperature is 180 to 190 DEG C; 4, distributing broken stone with an amount which is 60 to 70 percent based on the distribution area of the rubber asphalt, wherein the distribution temperature of the broken stone is not lower than 80 DEG C; and 5, rolling and forming, namely, rolling and forming a rubber asphalt waterproof adhesive layer by a rubber-tire pavement roller following a broken stone distribution vehicle, wherein the rubber-wire pavement roller rolls the pavement once to twice back and forth. The construction method of the invention can enhance the inter-layer adhesive performance, prevent water penetration, effectively absorb and eliminate inter-layer stress and reduce reflection cracks caused by the conventional bituminous pavement, and can be applied to the projects of building and rebuilding bituminous pavement, pavement of bituminous concrete bridge floor, bituminous overlaying of cement concrete pavement and the like.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP +2

Black light concrete for paving layer of bridge

InactiveCN1453237ALight weightImprove coordinationSolid waste managementBridge structural detailsCarbon fibersRoad surface

The present invention relates to building material and is especially one kind of black light concrete for paving layer of bridge. The black light concrete features its ingredients including cement; steel fiber, polypropylene fiber, acrylic fiber, carbon fiber or the mixture of steel fiber and polypropylene fiber; fine aggregate; light aggregate; UEA expanding agent; polymer; block coloring agentand water.All the ingredients are mixed homogeneously and the mixture is spread onto the bridge floor. The present invention has cement as basic material; light aggregate to replace partial or even all broken stone and river sand for reduced dead weight; fiber, polymer and expanding ingredient to form interpenetrating network structure resulting in raised wear resisting, crack resisting and penetration resisting performance; and black coloring agent to match the color of the other bridge parts.

Owner:WUHAN UNIV OF TECH

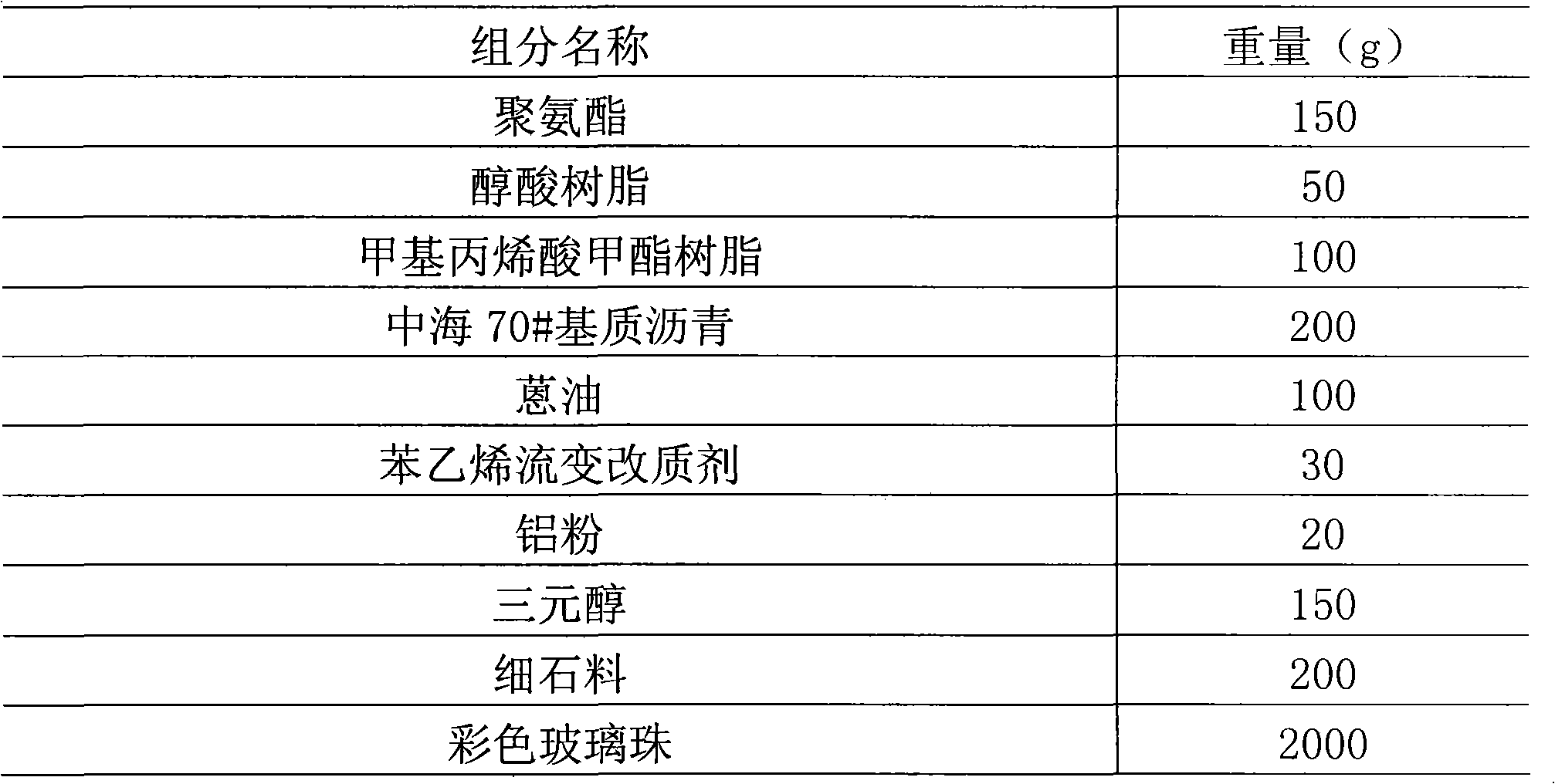

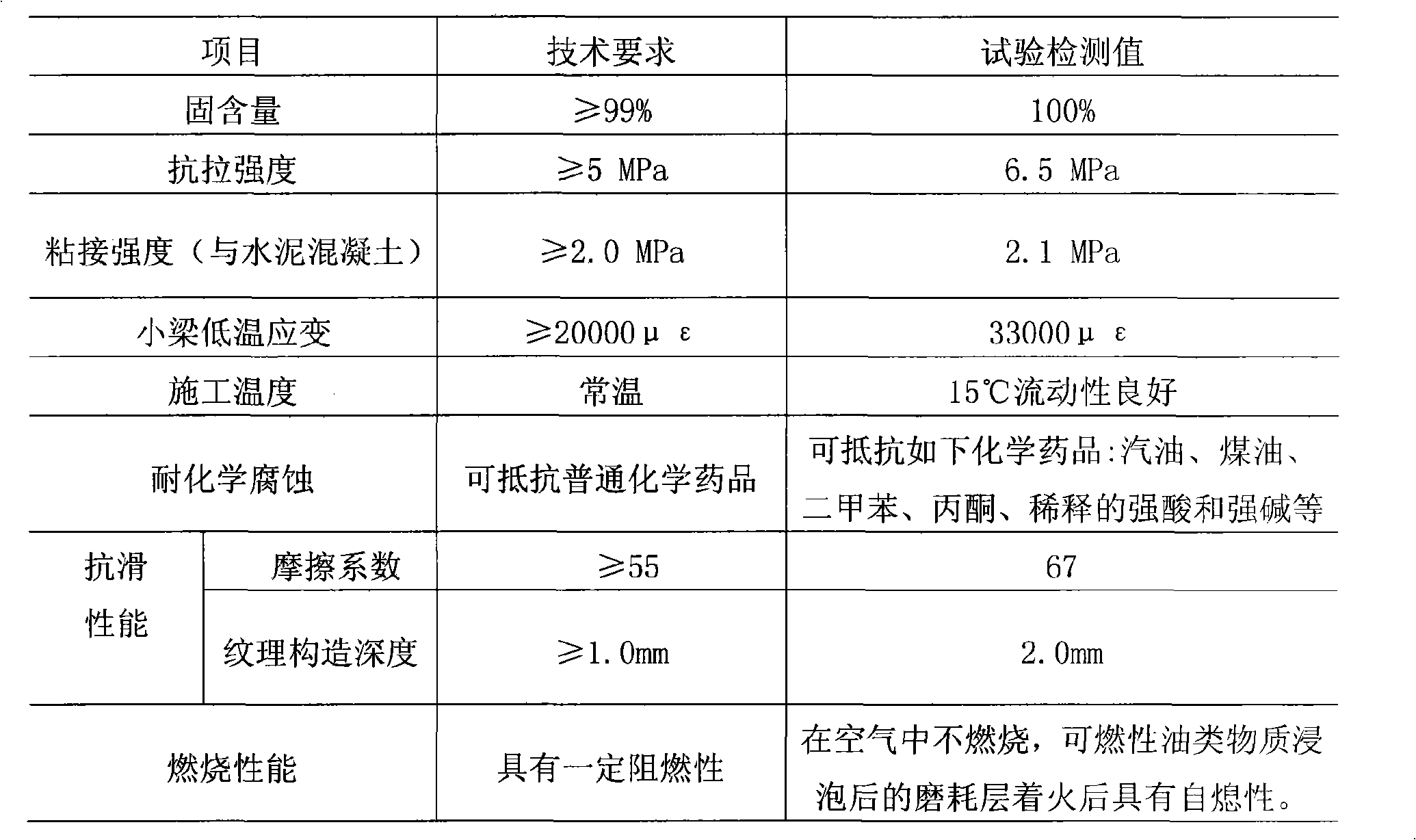

High-elasticity color antiskid wearing layer

The invention relates to a road surface structure of a road project. The mass composition of the invention is that: 0-20 parts of polyurethane,0-20 parts of alkyd, 0-20 parts of methyl-methacrylate resin, 20-50 parts of substrate pitch,10-20 parts of compatiblizing agent, 2-5 parts of rheological agent, 1-5 parts of ultraviolet aging resisting agent, 10-30 parts of curing agent, 10-20 parts of gravel and 50-200 parts of colorful wear-resistant rubble. The invention is characterized by simple formula, easy manufacture, strong adhesive capacity, good antiskid capacity, and good low-temperature property and does not crack in cold areas of the northern. The structure can be applied to laying the surface of the tunnel (especially the tunnel surface 200-300m away from the entrance and exit of the tunnel), bridge, airport pavement, bending section of the senior road and the repair of the used cement concrete pavement.

Owner:重庆市智翔铺道技术工程有限公司

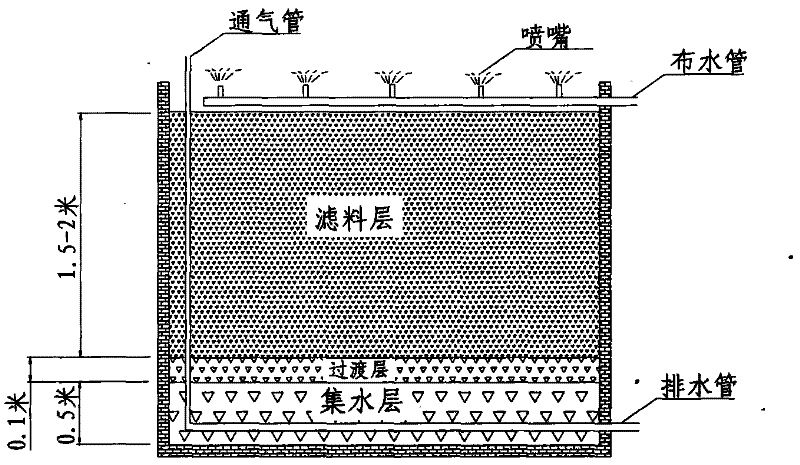

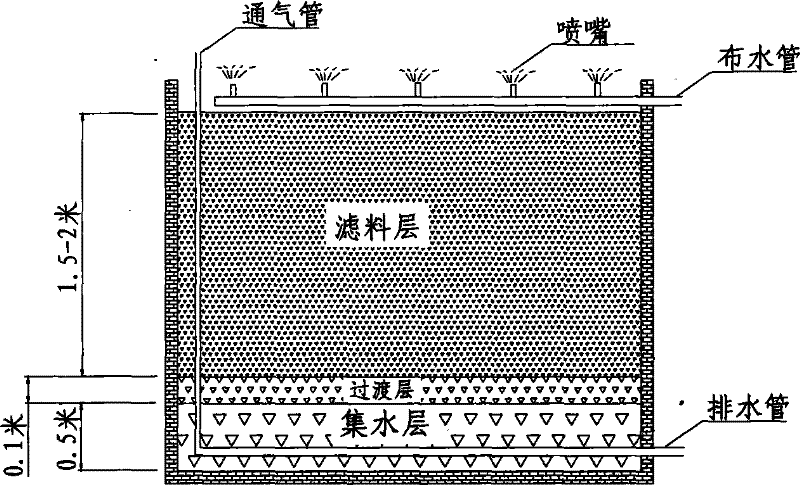

Intermittent water supply biological filter

InactiveCN102674535AAvoid easy cloggingImprove water qualityTreatment using aerobic processesSustainable biological treatmentWater qualityBiological filter

The invention discloses a wastewater treatment system for a novel intermittent water supply biological filter. The novel biological filter is improved from an ordinary biological filter, employs a mixed filter material with relatively small particle sizes to improve an effect of water treatment, and adopts a method of frequently alternating waterflooding states and air-drying states of a filter material layer and installing bottom vent pipe, to replace a natural ventilation for oxygenating and to avoid a blockage of the filter material layer. The intermittent water supply biological filter adopts broken stones (gravels) with particle sizes of 1-2 centimeters mixedly incorporated in particles, with the same size, of magnetite, graphite (or nut shell activated carbon), volcanic, limestone and activated zeolite, as filter materials for water treatment, and can adopt filter materials with diameters of 0.5-1 centimeters if pollutant concentrations of inlet water are relatively low. A height of the filter layer is 1.5- 2 meters; an intermittent quick water distribution is adopted; usually, a water distribution time for every water distribution is 20 minutes; an air-drying state lasts for 60-120 minutes; and a hydraulic load is designed for 2-4 m3 / m2d. The biological filter has the advantages of good water quality for outlet water, high hydraulic load, low investment, low energy consumption, low operation cost and simple management, and is particularly suitable for treating domestic wastewater of small cities.

Owner:钟瑛 +1

Roadbed structure applied to road widening and construction method

The invention relates to a road building structure and a construction method field. A roadbed structure applied to road widening comprises a new road layer, a filling material layer, a broken stone cushion layer, a concrete retaining wall and an original roadbed slope, wherein the original roadbed slope is finished as a step shape; the concrete retaining wall is arranged on the reciprocal nth step of the step-shaped roadbed slope; the surface of the reciprocal n-1th step of the step-shaped roadbed slope is an inclined surface; the broken stone cushion layer is laid on the surface of the bottom layer of the step-shaped roadbed slope; the filling material layer and the new road layer are arranged at the upper part of the broken stone cushion layer in sequence; and the filling material layer is prepared by cement, silicon fume powder, kieselguhr, expanded perlite, water, a water reducing agent, rubber powder, planet fibers, a foaming agent and a micro foam agent. The roadbed structure can be applied to the road widening, can perform the vertical filling to save the land and to reduce the demolition, can largely reduce the filling load to reduce the differential settlement of new and old roadbeds in soft-foundation road sections, and is short in construction period.

Owner:河南华泰新材科技股份有限公司

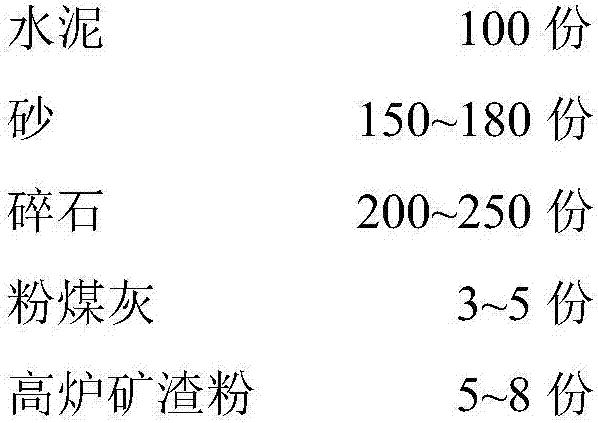

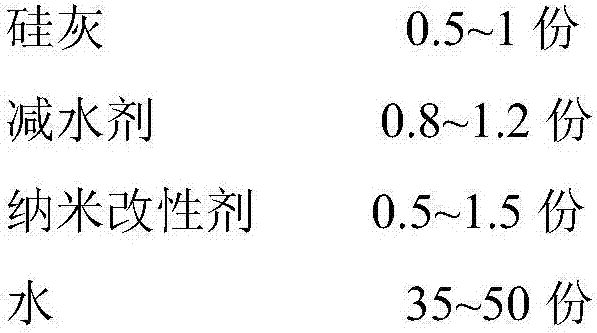

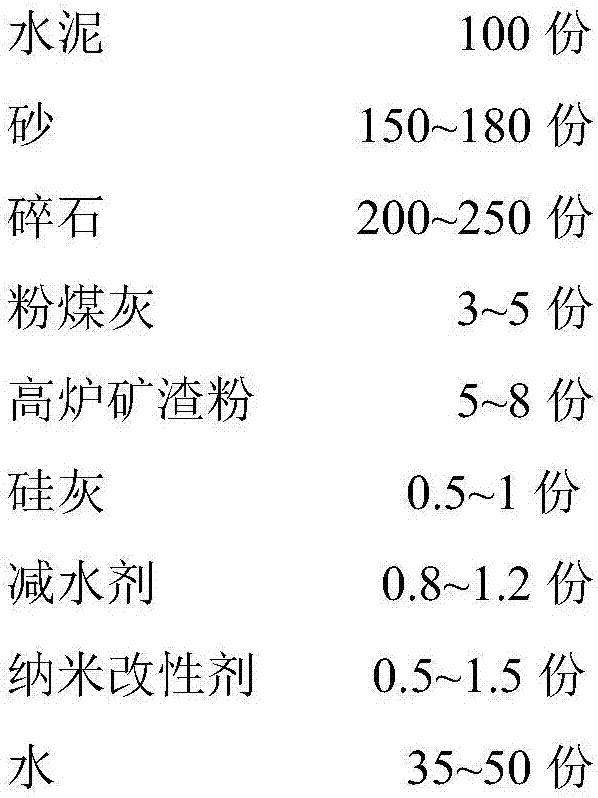

Preparing method of nano-modified high permeability resistant concrete

InactiveCN107032734ATake full advantage of stackingGive full play to the synergistic effectSolid waste managementChipsealSlag

The invention relates to building material engineering, and aims at providing a preparing method of nano-modified high permeability resistant concrete. The preparing method comprises the steps of conducting dry stirring on cement, sand, gravel, fly ash, blast-furnace slag powder and silica fume, and mixing the mixture evenly; mixing a nanometer additive, a water reducing agent and water which accounts for half the weight evenly, and adding the nanometer additive, the water reducing agent and the water which accounts for half the weight into the mixture for stirring; then adding the water which accounts for the other half the weight and continuing to conducting mixing; conducting discharging, and putting the new mixture into molds; conducting maintenance according to a conventional maintenance mode after removing the molds to obtain the nano-modified high permeability resistant concrete. According to the preparing method of the nano-modified high permeability resistant concrete, the limitation of the influence of a single mineral component on the performance of the concrete is solved, through the combination of the multifunctional composition, the effect of function superposition and synergy is achieved, the composite multifunctional composition can effectively optimize the concrete structure grain composition, and by optimizing the internal pore structure of the concrete, the aim of improving the permeability resistance is achieved. The grain composition optimization is conducted on the concrete structure by utilizing the nanometer additive, the high activity and the microcrystal nuclear effect of nano-particles are given full play to at the same time, and the permeability resistance of the concrete structure is improved.

Owner:ZHEJIANG UNIV

Method for manufacturing cushion pad layer of rock protective shed by utilizing waste tyres

InactiveCN101982612ATo achieve the purpose of disaster prevention and mitigationImprove water and soil conservation effectProtective constructionChipsealWaste rubber

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

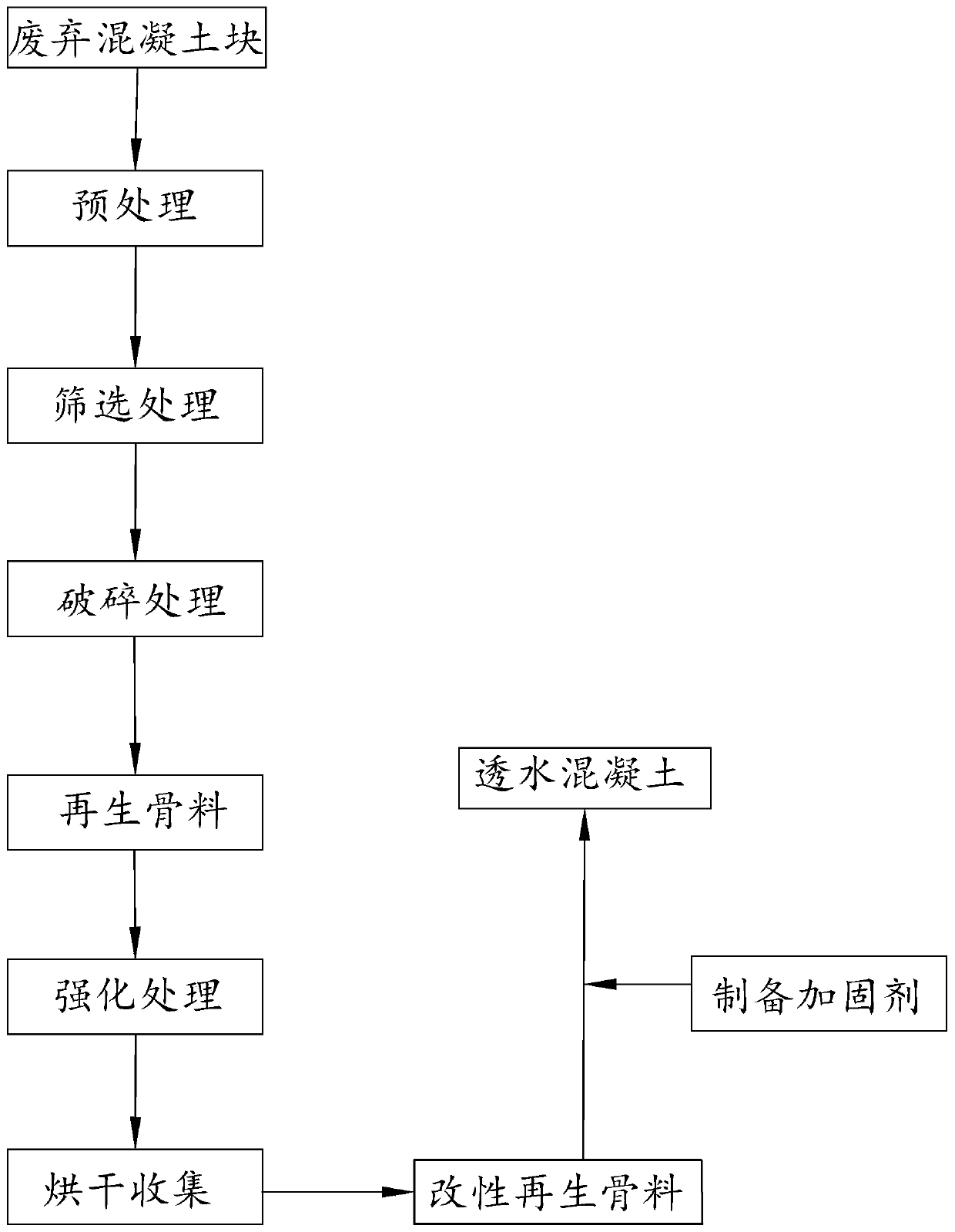

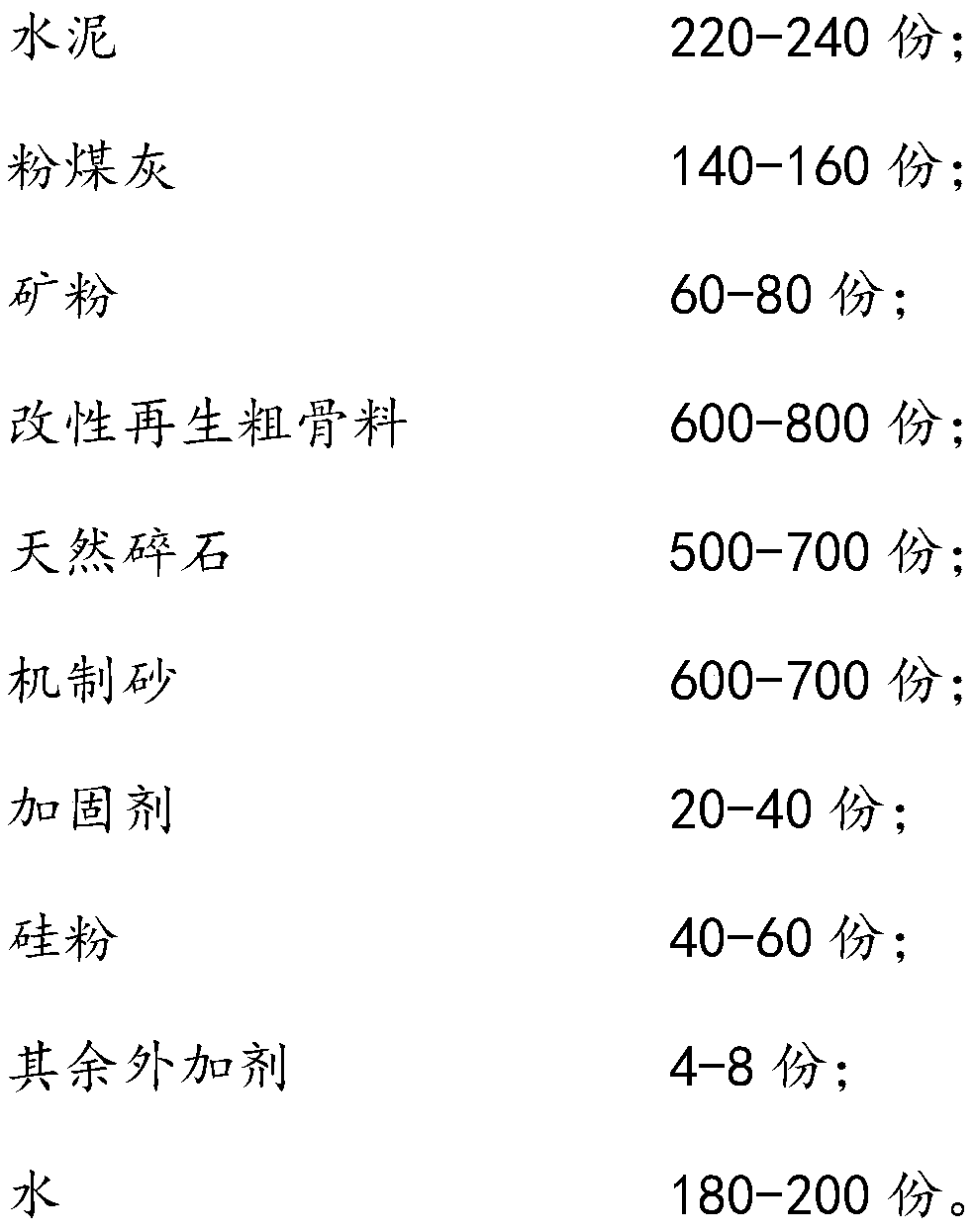

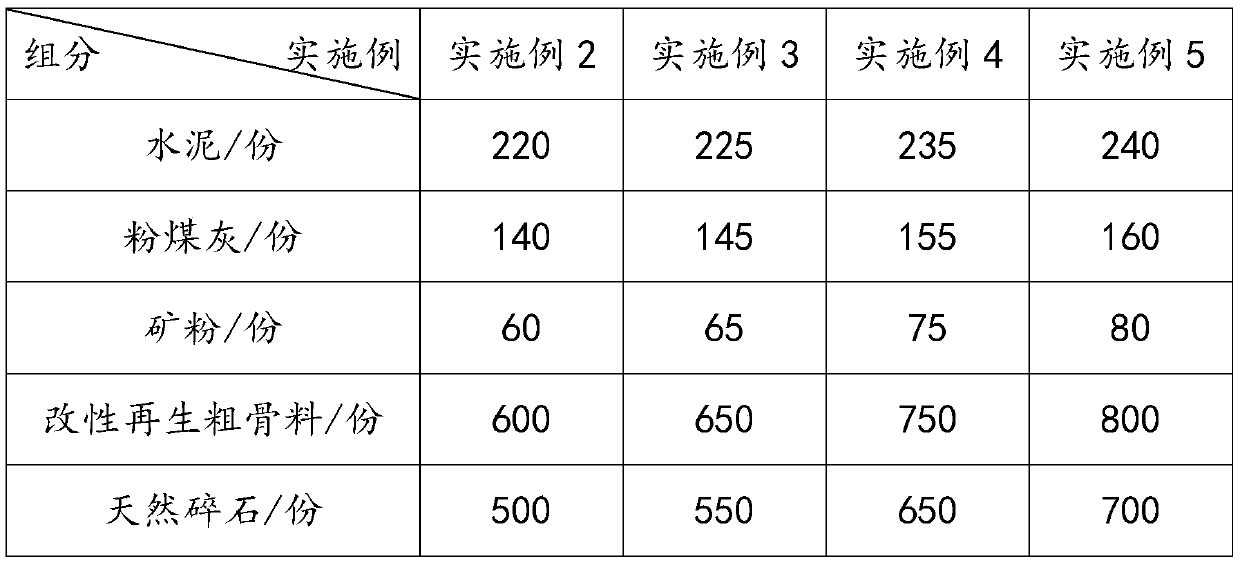

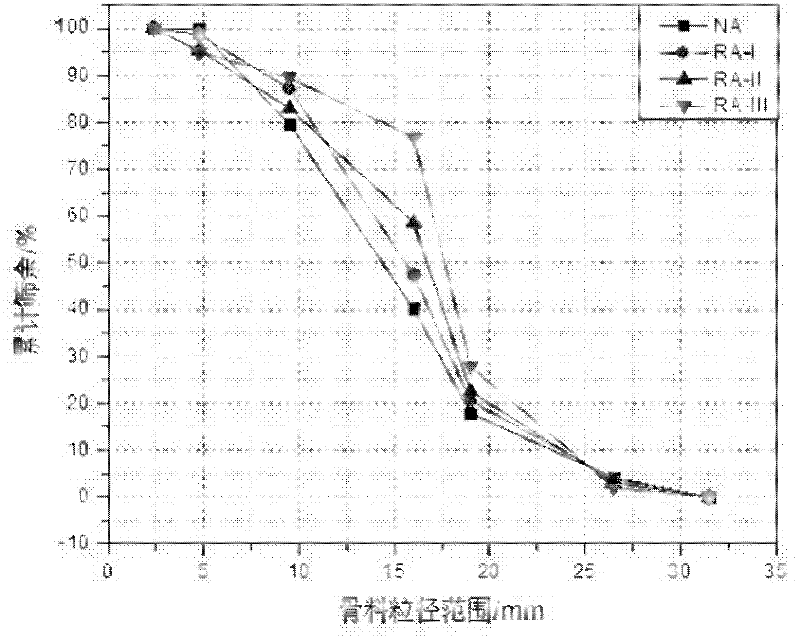

High-performance recycled concrete and preparation process thereof

ActiveCN110540389AImprove work performanceImprove compactnessBuilding material handlingWork performanceChipseal

The invention discloses high-performance recycled concrete and a preparation process thereof, and relates to the technical field of concrete preparation. The concrete includes the following raw materials in parts by weight: 220-240 parts of cement; 140-160 parts of fly ash; 60-80 parts of mineral powder; 600-800 parts of modified recycled coarse aggregate; 500-700 parts of natural gravel; 600-700parts of machined sand; 20-40 parts of a reinforcing agent; 40-60 parts of silicon powder; 4-8 parts of other additives; and 180-200 parts of water. By adjusting the ratio of the various raw materialsof the concrete, adding the reinforcing agent and modifying the recycled aggregate, the working performance of the concrete can be effectively improved, and the compactness and overall strength of the concrete can be improved.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

Artificial compound board prepared by granite stone powder waste material

The invention relates to a novel artificial composite board which is prepared by granite waste materials. The formula comprises a resin, a curing agent, a promoter, granite stone powder and broken stone particles, etc. The artificial composite board has more styles, and the length can be made to be large enough, thereby being applied on various possible occasions. At the same time, the technology utilizes the broken stone waste materials and stone powder as raw materials, thereby benefiting for the protection and the conservation of natural resources.

Owner:FUJIAN QIDALI GROUP

Artificial pavement manufacturing method for improving global warming

The invention relates to an artificial pavement manufacturing method for improving global warming; an artificially paved water-permeable pavement is arranged; a rapid water guide layer which can be broken stones or a sand layer is arranged below the water-permeable pavement; after a separation layer is arranged below the rapid water guide layer, a compacted ecological matched layer is paved; therefore, besides the support function, the lower ecological matched layer can be used for putting a disaster-prevention and water-storage hollow body or a soil improvement hollow body or a micro-organism culture hollow body or a water holding hollow body because a hollow body is arranged in the ecological matched layer, thus, rainwater reaching the ground can be rapidly penetrated to the underground, and the ecological matched layer can be used for greatly holding water and increasing microbial proliferation; when the atmospheric temperature is high, the underground moisture can be evaporated through a pipe body of the water-permeable pavement; and the most effective method for improving the global warming is achieved.

Owner:陈瑞文 +1

Method for regenerating waste solid for use in road foundation

InactiveCN101265685ASolve problems that help protect the environmentImprove protectionRoadwaysBrickSlag

A method of recycling the solid waste in road base engineering belongs to the technology field of waste recycling, and solves the problem of the solid waste recycling. The method includes: using waste concrete blocks, waste bricks, waste tiles and waste stones of the solid waste as the major material, crushing into pieces by a crusher, separating the metal substances by a magnetic separator, obtaining two major categories of recycling gradation solid material with granule diameters of 0-30mm and 0-70mm respectively conform to the granule continuous gradation. The recycling gradation solid material with the granule diameter of 0-30mm can be directly used as the base of a road pavement water permeable pavior brick, the packing of a subgrade bedding layer and the filling / exchanging reinforcing material of a soft soil subgrade; the recycling gradation solid material with the granule diameter of 0-70mm can be directly used as the packing of road engineering subgrade stone column replacement. The recycling gradation solid material can be blended with flyash, lime, carbide slag and cement to form different subgrade materials. The advanced method makes full use of the resources, and is applicable to recycling all solid waste into recycling gradation solid material and further to the road construction, which offers a promising prospect of popularization.

Owner:沧州市市政工程公司

Water-absorbent concrete and preparation method thereof

The invention discloses water-absorbent concrete and a preparation method thereof. The water-absorbent concrete comprises cement-kind gelling materials and aggregate, and the aggregate is water-absorbent resin expansion parts which replace aggregate such as broken stone or pebble in components of common concrete. The preparation method for the water-absorbent concrete includes: firstly permeating water into water-absorbent resin powder to enable the water-absorbent resin powder to be quickly expanded by at least 20 times, then adding water in quantity needed for hydration reaction into the cement-king gelling materials for blending to form cement paste, stirring the water-absorbent resin expansion parts with the paste to enable the water-absorbent resin expansion parts to be coated by the cement paste, and finally forming the water-absorbent resin concrete after setting and hardening. The water-absorbent resin concrete prepared by the method is high in strength, light in dead weight, convenient for long-distance and high-drop pumping construction of low-power centrifugal pumps, capable of being mixed and transported on shipboard, free of setting of special material sites, simple in preparation process and capable of effectively solving the problem of a great quantity of conventional raw material supply and inconvenience in transport in high-sea island and reef and the like.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

High-strength highly-permeable concrete and method for making the same

InactiveCN101182172AReduce Waterlogging ProblemsSolid waste managementClimate change adaptationChipsealRoad surface

The invention aims at providing a concrete high strength and permeability and a preparation method thereof. The invention adopts the following technical scheme: cement with high strength, a special building material additive and special forming method are used; Aeolian sands in desert or fly ashes produced during the power generation of power plants are used as raw materials to prepare the concrete with high permeability. The used raw materials of the invention respectively are: 40-50 grade of ordinary porland cement; gravels, Aeolian sands in desert and fly ashes with respective particle diameter of 10.0-13.0mm, 5.0-10.0mm and 2.5-5.0mm, the adding ratio of which is selected freely; NNO type water reducing agent and JM-SCA type strengthening agent. The concrete made through the method is provided with good permeability, and the compressive strength can reach to 35MPa above. Passage tiles made through the method can be used to pave roads to greatly reduce hydrops on the surface of the roads. In local areas, sewer pipes even can be reduced or do not have to be paved. For even a heavy rainstorm encountered in 100 years happens, rains can rapidly permeate in soils through the tiles successfully in five minutes, which can be changed into renewable underground water.

Owner:SHENGHONG GRP CO LTD

Well sealing waterproof construction method for dewatering well

The invention discloses a well sealing waterproof construction method for a dewatering well. The method comprises the following steps of: (1) constructing a foundation bed on the surrounding of the dewatering well; (2) embedding a steel sleeve for sealing the dewatering well in a foundation pit; (3) laying a waterproof roll material on the foundation bed, and then pouring a fine aggregate concrete protective layer on the waterproof roll material; (4) clamping a waterproof plate on the outer wall of the waterproof roll material on the outer wall of the steel sleeve in an abutted way; (5) clamping the waterproof plate by using a copper strip; (6) injecting a sealing adhesive to the waterproof plate; (7) pouring bottom plate concrete to the fine aggregate concrete protective layer; (8) pumping water; (9) embedding a sealing plate in the steel sleeve; (10) after filling gravels into a filling pipe, injecting a cement paste into a cement paste injection pipe, and stopping the injection of the cement paste until the paste in an overflow pipe flows out; and (11) pouring concrete into the steel sleeve above the sealing plate. Through the adoption of the well sealing waterproof construction method disclosed by the invention, a waterproof treatment problem at the connection of the dewatering well in the foundation pit and the foundation bottom plate in the whole dewatering well sealing waterproof system is solved.

Owner:天津住宅集团建设工程总承包有限公司

Method for preparing pavement base material by stabilizing iron tailings by novel soil stabilizer

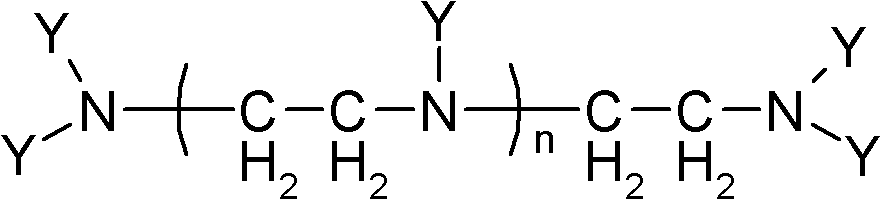

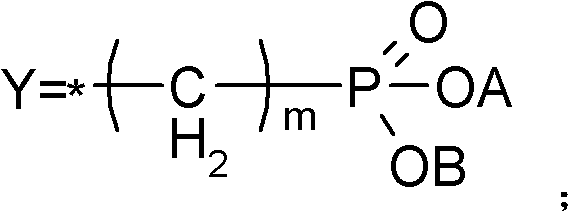

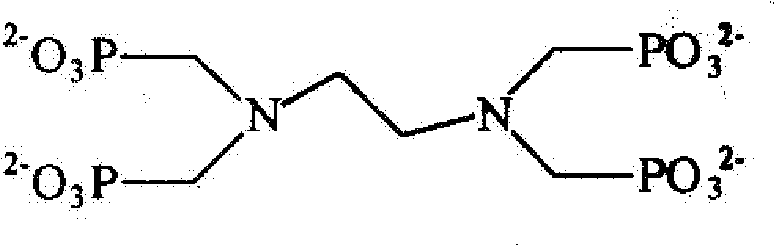

ActiveCN104152148AStrong oxidationImprove solubilitySolid waste managementOrganic fertilisersMicrowaveChipseal

The invention discloses a method for preparing a pavement base material by stabilizing iron tailings by a novel soil stabilizer. The preparation method of the novel soil stabilizer comprises the following steps: diluting a TerranZyme bio-enzyme soil stabilizer with water by 10-100 times, adding solid CaCl2 with mass being 5%-10% that of diluting liquid and acidified water glass with mass being 5%-10% that of the diluting liquid, heating to 30-50 DEG C by microwaves, reacting for 20-60 minutes, and performing mixed modification to obtain the novel soil stabilizer. The novel soil stabilizer can be used for stabilizing the iron tailings to prepare the pavement base material. The method for preparing the pavement base material comprises the following steps: uniformly mixing cement, gravel and the iron tailings with the novel soil stabilizer according to a mass ratio of 5: 30: 68: 2 to obtain an inorganic mixture, adding 1.5kg / m<3> of polypropylene fibers, and uniformly mixing to obtain the pavement base material. All technical indexes of the pavement base material meet the national standard requirements, the utilization rate of the iron tailings is high, the environmental problem caused by piling of a large quantity of the iron tailings and mining of pavement gravel materials is solved, and economic benefits are obtained.

Owner:CENT SOUTH UNIV

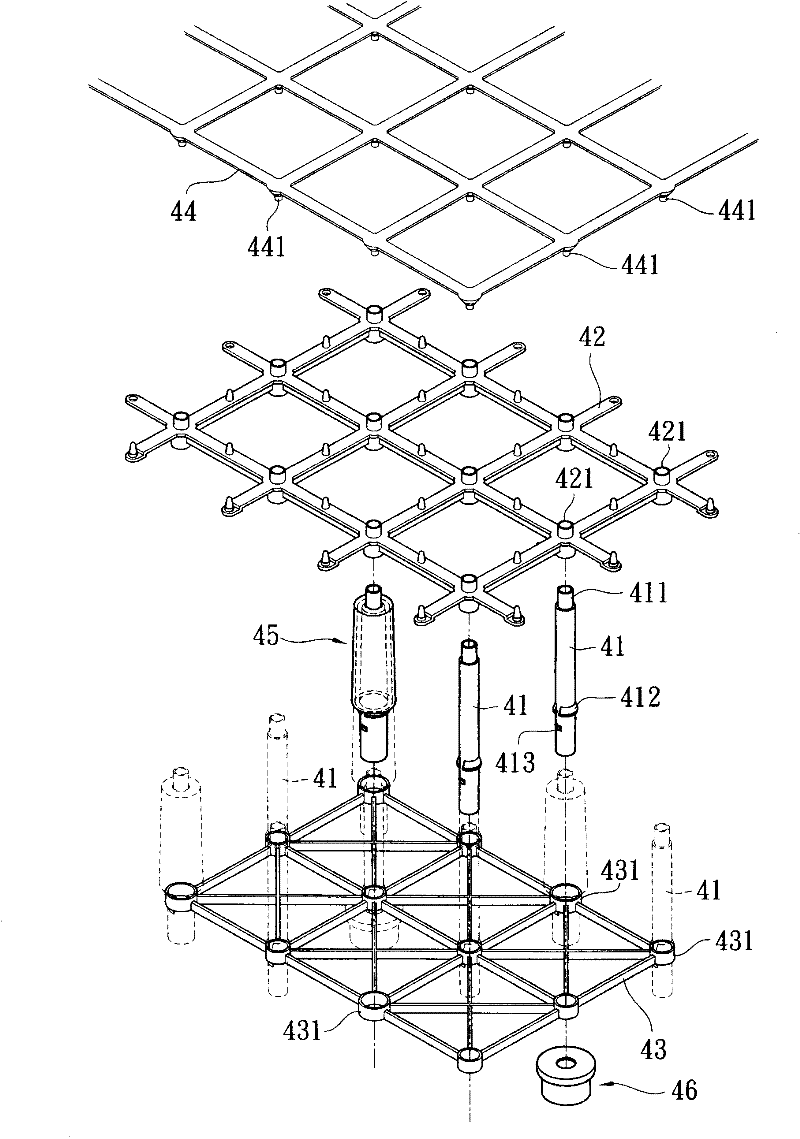

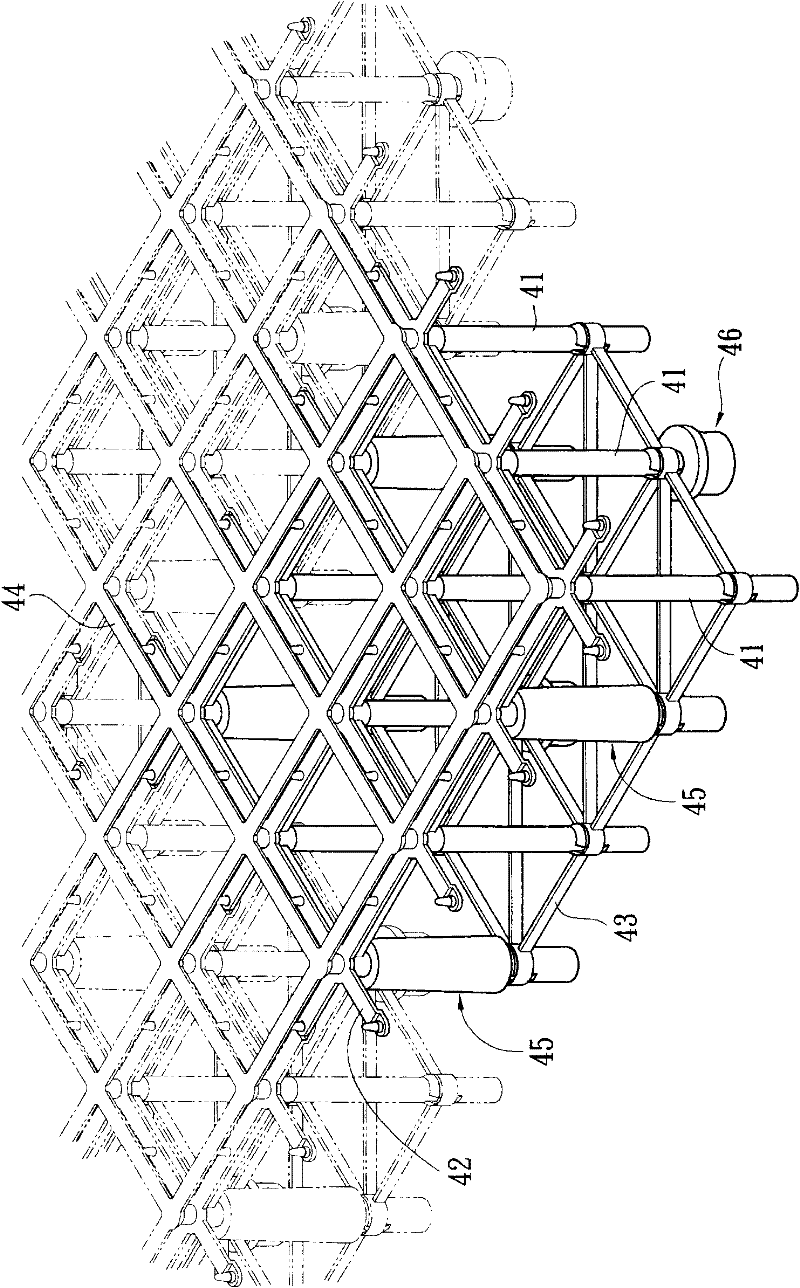

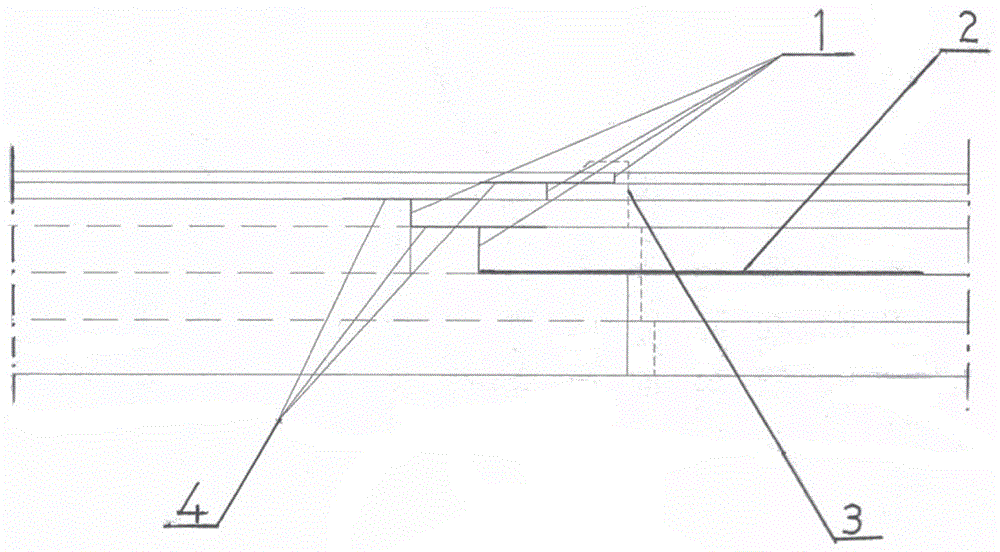

Splicing method and structure for new and old roads in reconstruction and extension of pavement

ActiveCN105926406AImprove stitching qualityStrong shear resistanceIn situ pavingsPaving detailsCarrying capacityChipseal

The invention relates to a splicing method and structure for new and old roads in reconstruction and extension of a pavement. The splicing parts of new and old roads and loading positions of vehicle wheels are staggerly arranged. The base layers and subbase layers of new and old roads are connected in a step manner, so a contact area of the roadbeds of the new and old roads is increased and frictional force at bonding sites is improved. Construction of pavement layers of the new and old roads is carried out in an inverse step manner, and the splicing parts of the pavement layers can be flexibly adjusted to favorable stress states through adjusting the width of step so as to be kept away from wheelmark zones. The thickness of a water-stop belt depends on the height of a longitudinal joint surface where the belt is located, so the functions of sealing and water stopping of the water-stop belt are realized. Ribbed reinforcement nets are laid at the splicing parts on the top of the subbase layers of cement stabilized macadam of the new road to improve the anti-shearing and anti-bending performance of the parts. The splicing method and structure provided by the invention can improve the splicing quality of new and old roads of a pavement reconstruction and extension project and carrying capacity and endurance of an integral pavement project; and the method and structure are simple, practicable, fast in construction speed, labor-saving, time-saving and good in construction quality and allows the pavement to have good anti-shearing and anti-bending performance.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Preparation method of composite reinforced regenerated concrete with regenerated fiber and active minerals

InactiveCN102584134AImprove mechanical propertiesSimple methodSolid waste managementFiberEnvironmental resistance

The invention relates to a preparation method of composite reinforced regenerated concrete with regenerated fiber and active minerals. Broken waste concrete is adopted as partial regenerated coarse aggregate of the regenerated concrete; meridian steel fiber extracted from waste tyres, fly ash, silicon powder and efficient water reducing agents are added to the waste concrete, so as to improve themechanical performance of the regenerated concrete; the regenerated concrete comprises following substances in part by weight: 13 to 15 parts of 32.5R ordinary portland cement, 20 parts of fine aggregates (medium coarse sand), 36 parts of natural gravel, 15 parts of regenerated coarse aggregates, 1 to 2 parts of silicon powder, 4 to 5 parts of class II fly ash, 0.3 part of efficient water reducing agents, 0.01 part to 0.04 part of meridian steel fiber and 9 parts of water. The preparation method is simple, and the mechanical performance of the regenerated concrete is steady; a novel preparation method is provided for the greenness and environmental friendliness advocated in the field of civil engineering and the application of concrete materials to sustainable circular economy; and the preparation method has a wide future and wide commercial prospect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

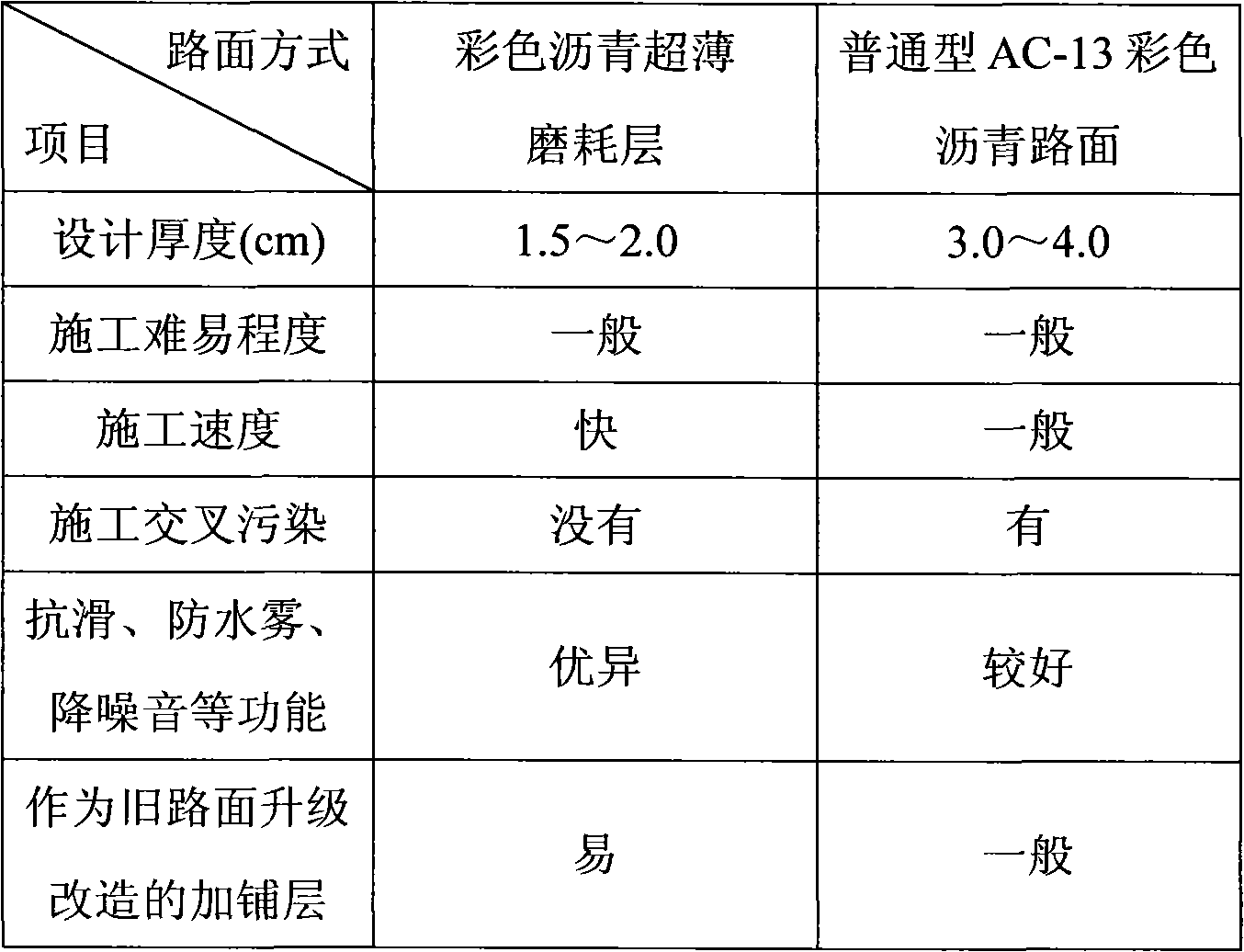

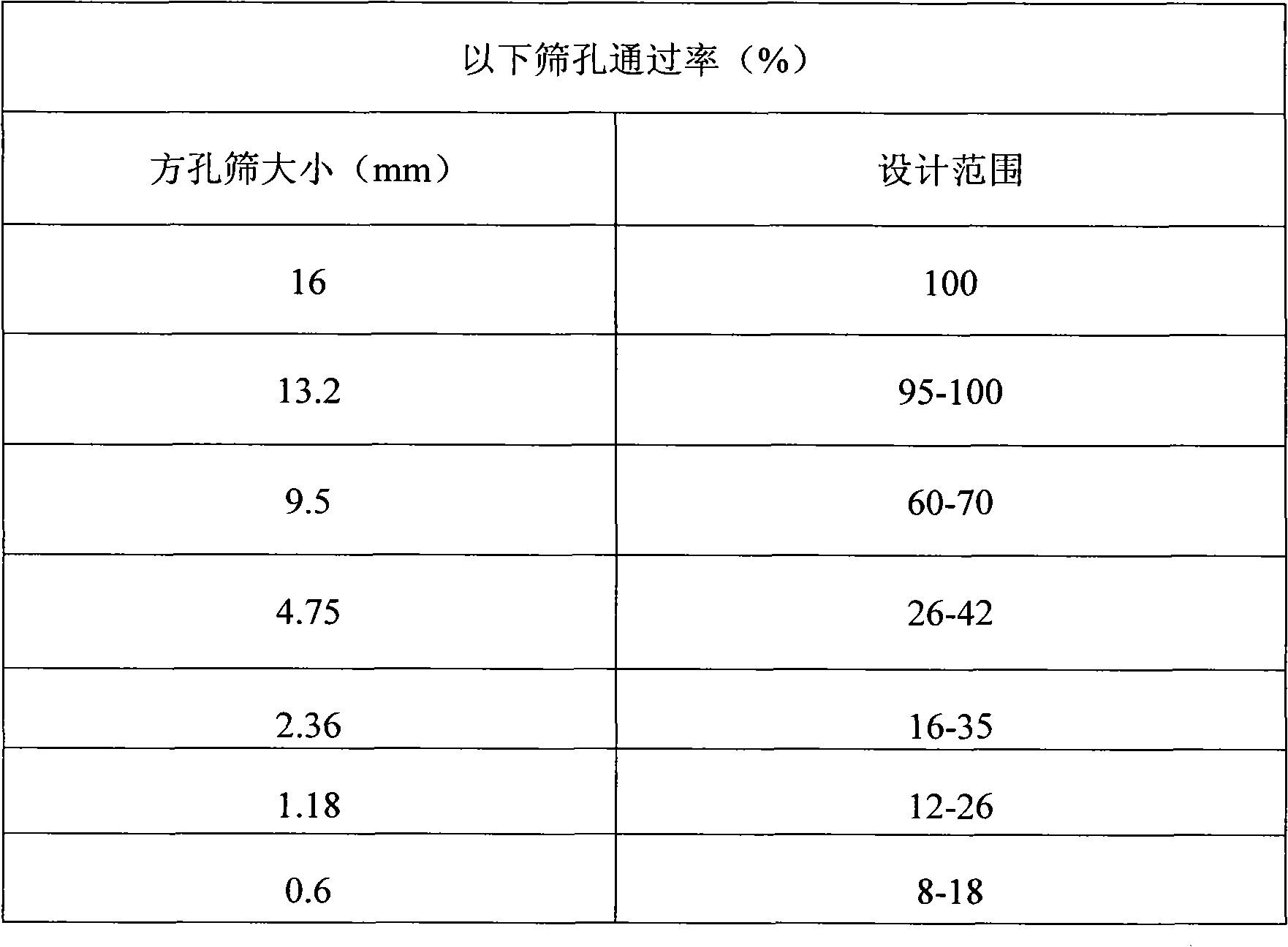

Color asphalt ultrathin wearing layer and preparation method thereof

ActiveCN101929119AImprove skid resistanceExcellent waterproof fogIn situ pavingsChipsealRoad surface

The invention discloses a color asphalt ultrathin wearing layer and a preparation method thereof. The preparation method mainly comprises the following steps of: producing a mixed material: mixing 34-36 parts of 5-10 mm macadam, 11-13 parts of stone chips with a grain size less than 3 mm and 0.8-1.2 parts of mineral powder or cement, then adding 2-3 parts of color asphalt and mixing to obtain a color asphalt mixed material; paving: firstly spraying a layer of polymerized, modified and emulsified asphalt on the lower bearing layer of a road surface by the spraying system of an asphalt paver and then uniformly paving the color asphalt mixed material on a road by the spiral distributor of the asphalt paver; and statically rolling by using a double-steel wheel road roller and forming the road surface. The color asphalt ultrathin wearing layer obtained by using the method has relatively high use value, simple construction method, easy maintenance and low manufacturing cost and can meet the requirements of the color road surface.

Owner:广州新粤交通技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com