Patents

Literature

554results about How to "Reduce the number of settings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

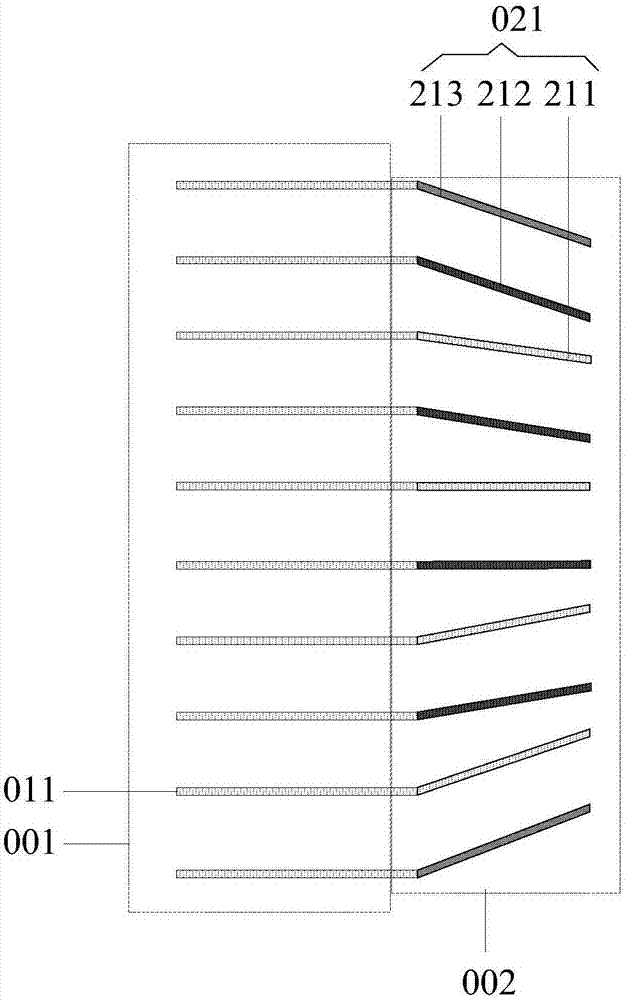

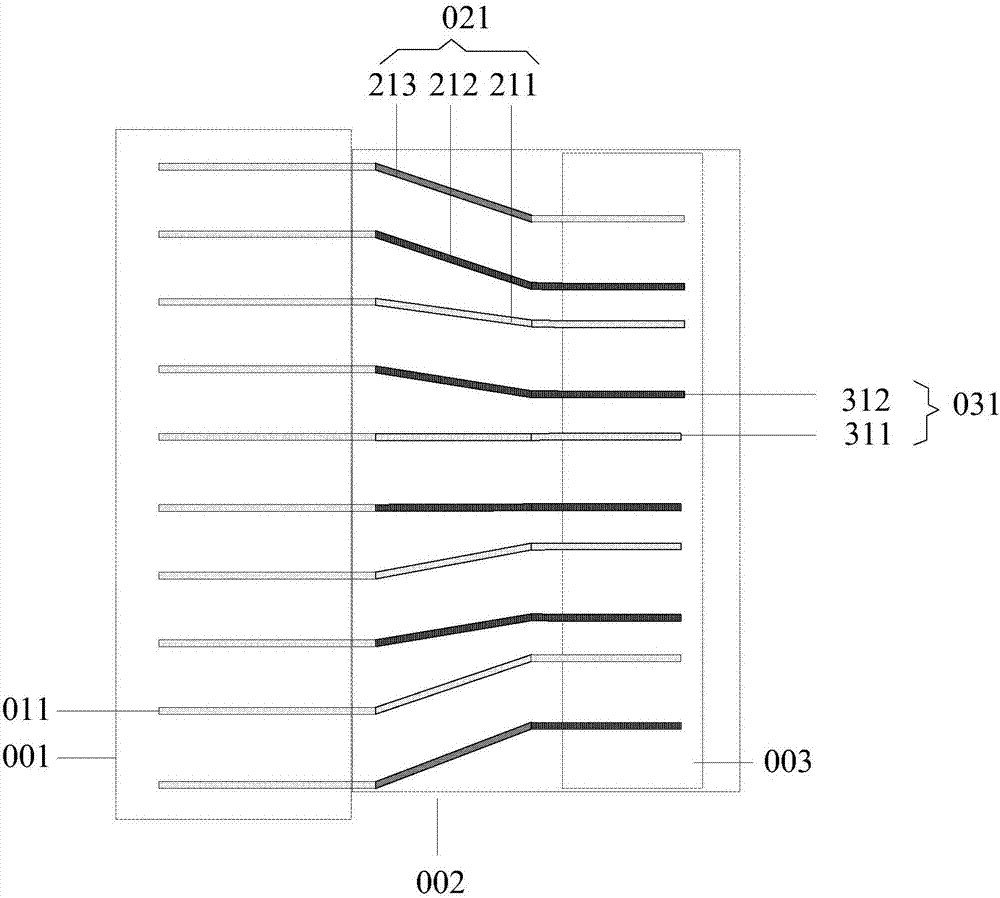

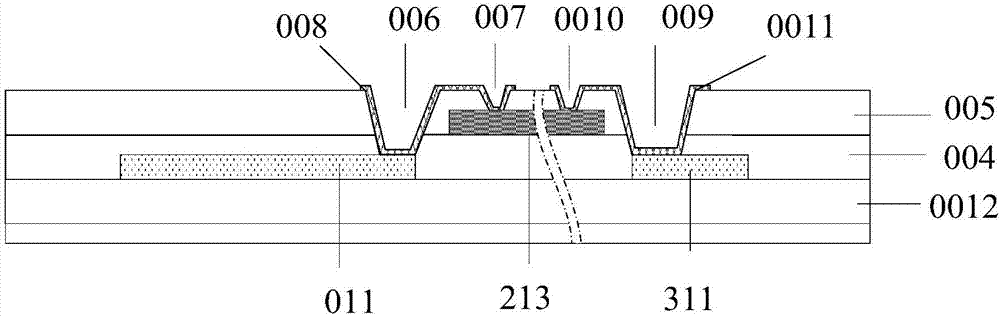

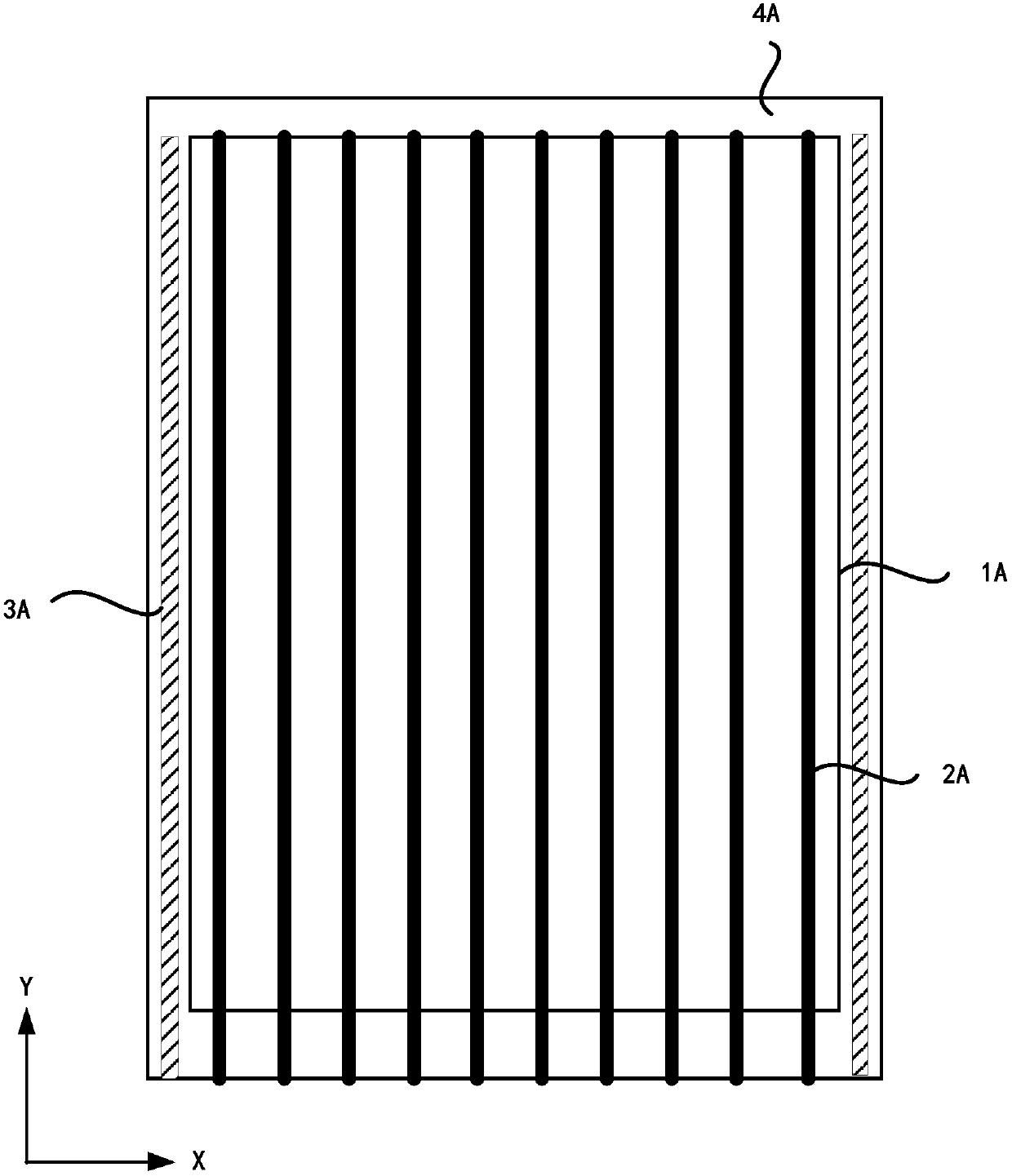

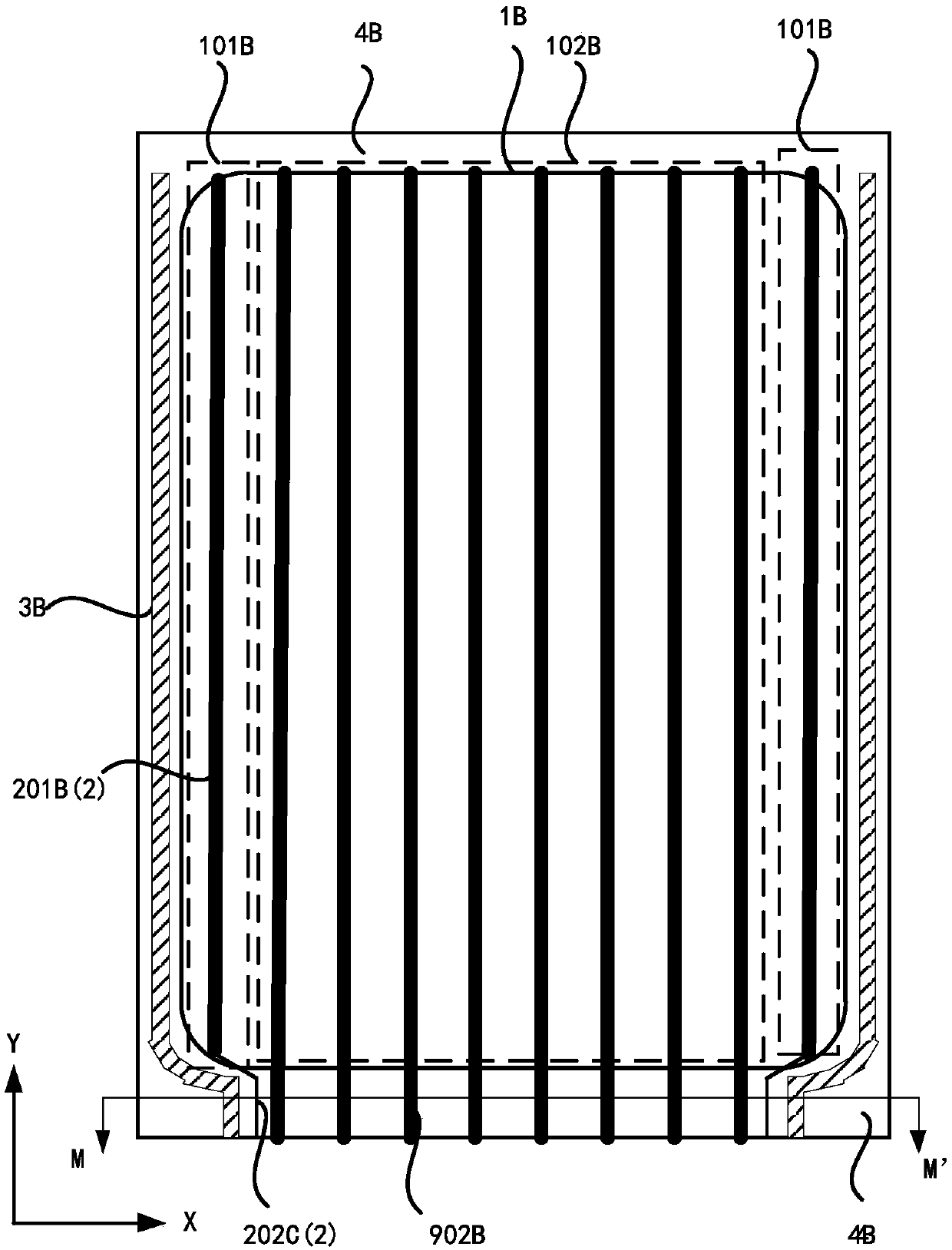

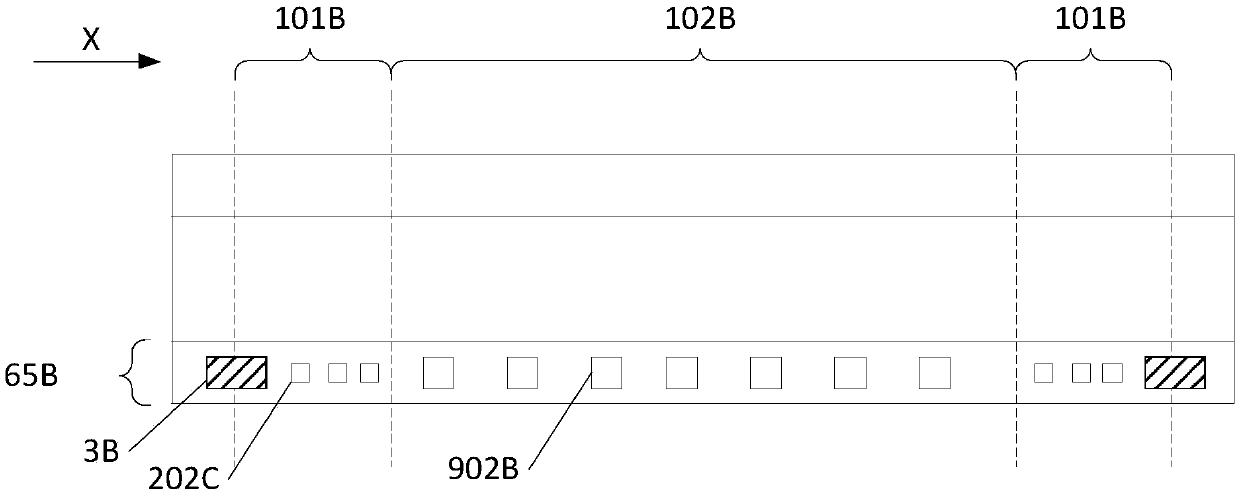

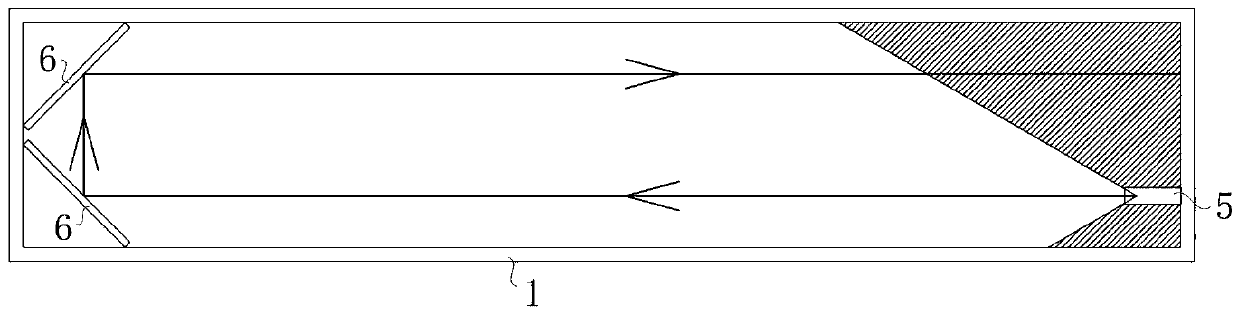

Display substrate and display device

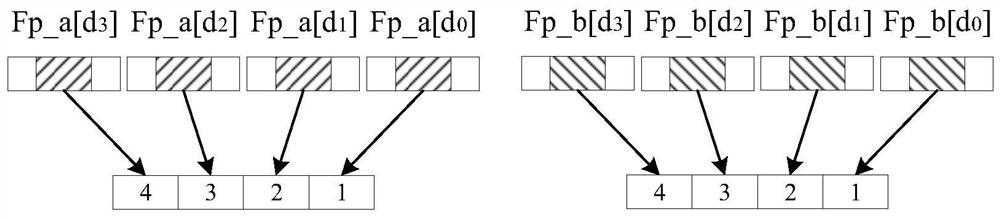

PendingCN107037646AReduce the number of settingsReduce the setting densitySolid-state devicesNon-linear opticsDisplay deviceData signal

The embodiment of the invention discloses a display substrate and a display device. According to the technical scheme, data signal fan-out lines are arranged on a touch electrode layer, a grid layer and a source drain electrode layer, compared with the prior art that data signal fan-out lines are arranged on the grid layer and the source drain electrode layer, the number of the arranged data signal fan-out lines on the grid layer and the source drain electrode layer can be reduced, and thus the setting density of the data signal fan-out lines of the grid layer and / or the source drain electrode layer can be lowered; when a data signal is led out of a display area, the distance between the lines which are aslant arranged is increased, and a short-circuited risk between respective data signal fan-out lines of the grid layer and / or the source drain electrode layer is lowered.

Owner:BOE TECH GRP CO LTD +1

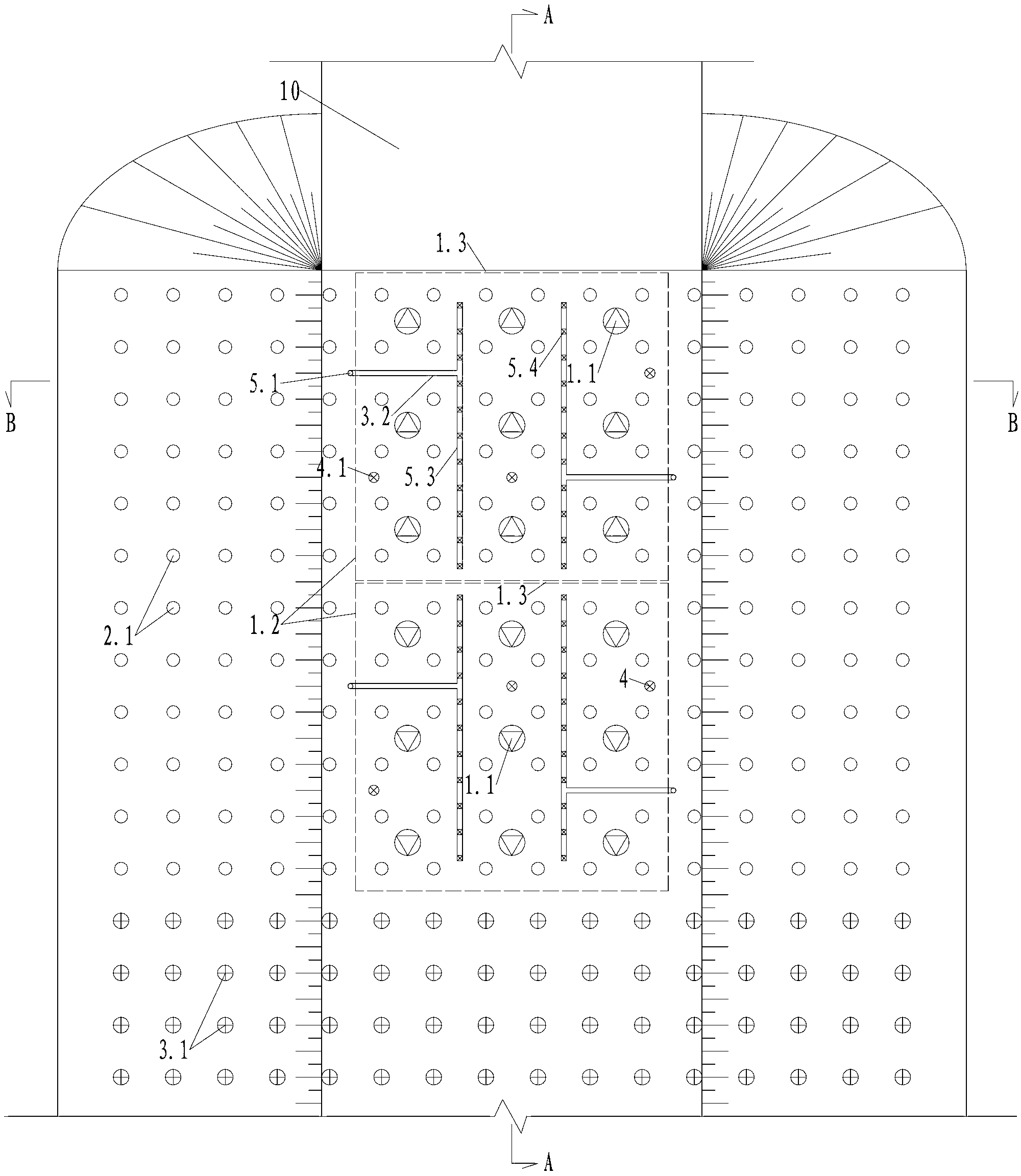

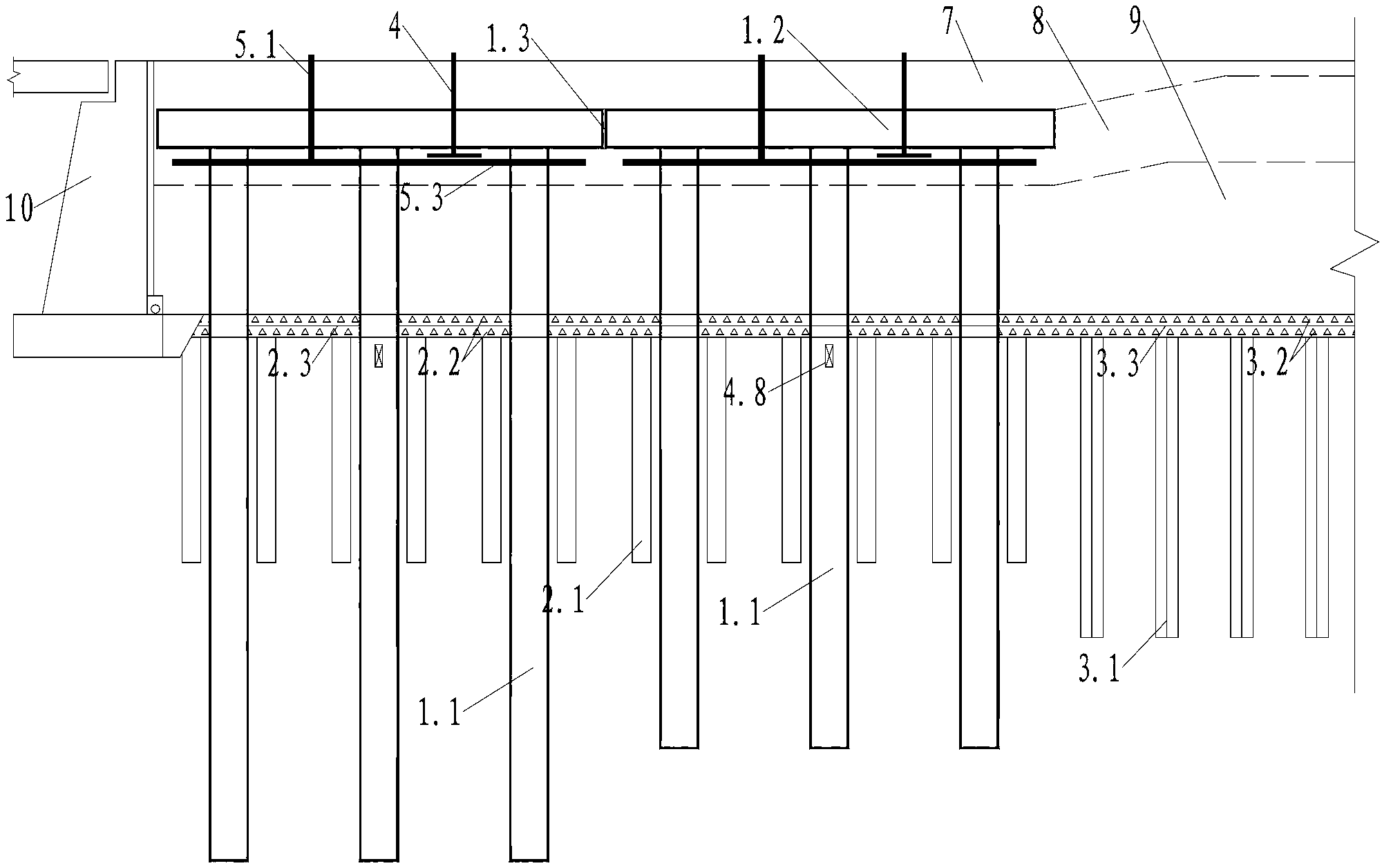

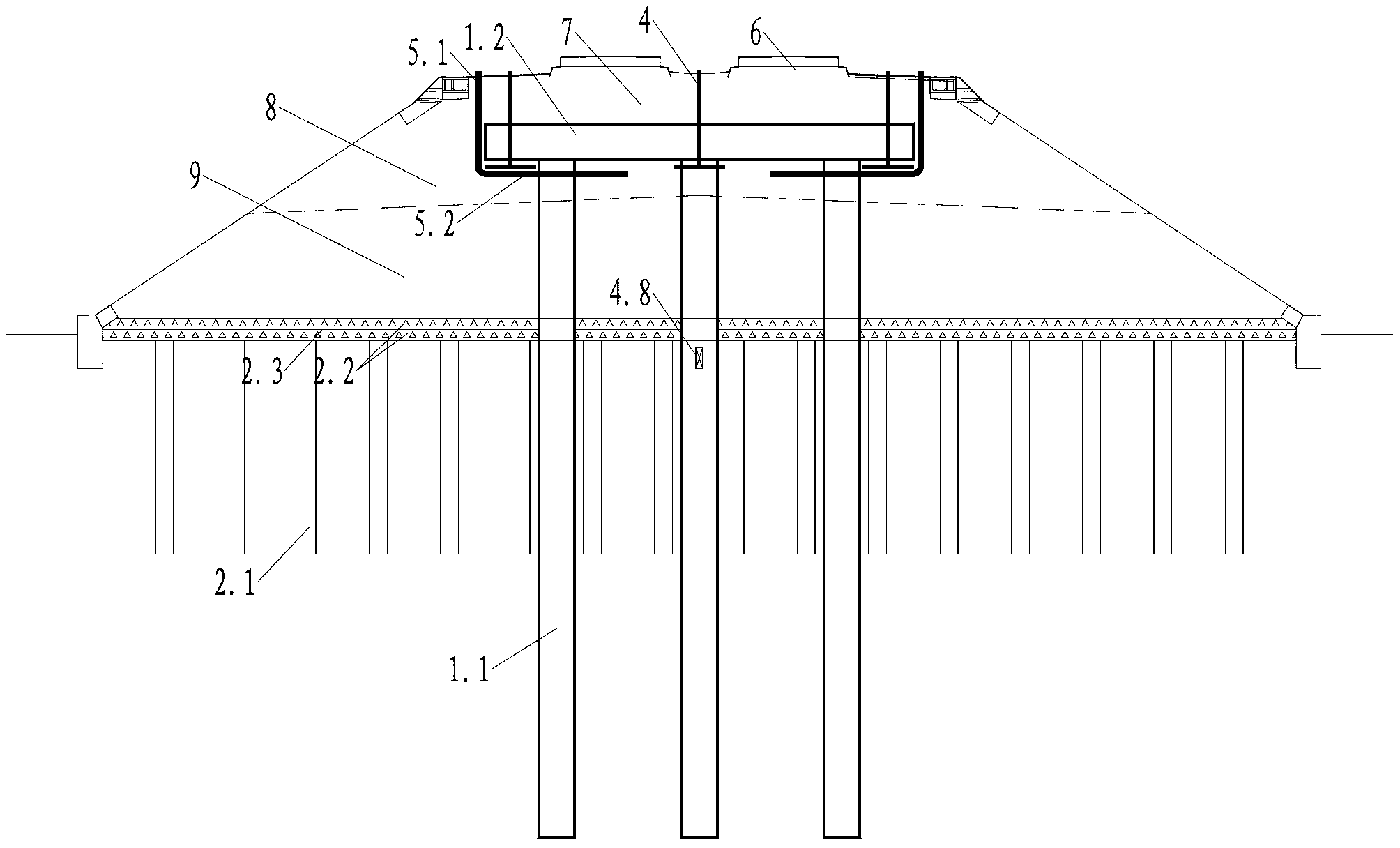

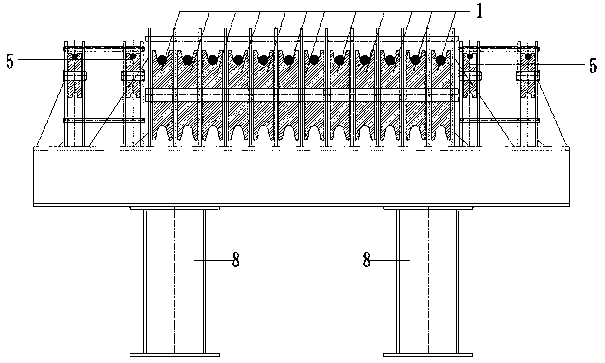

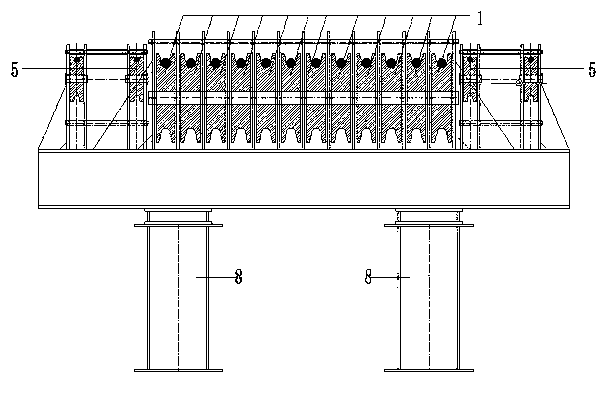

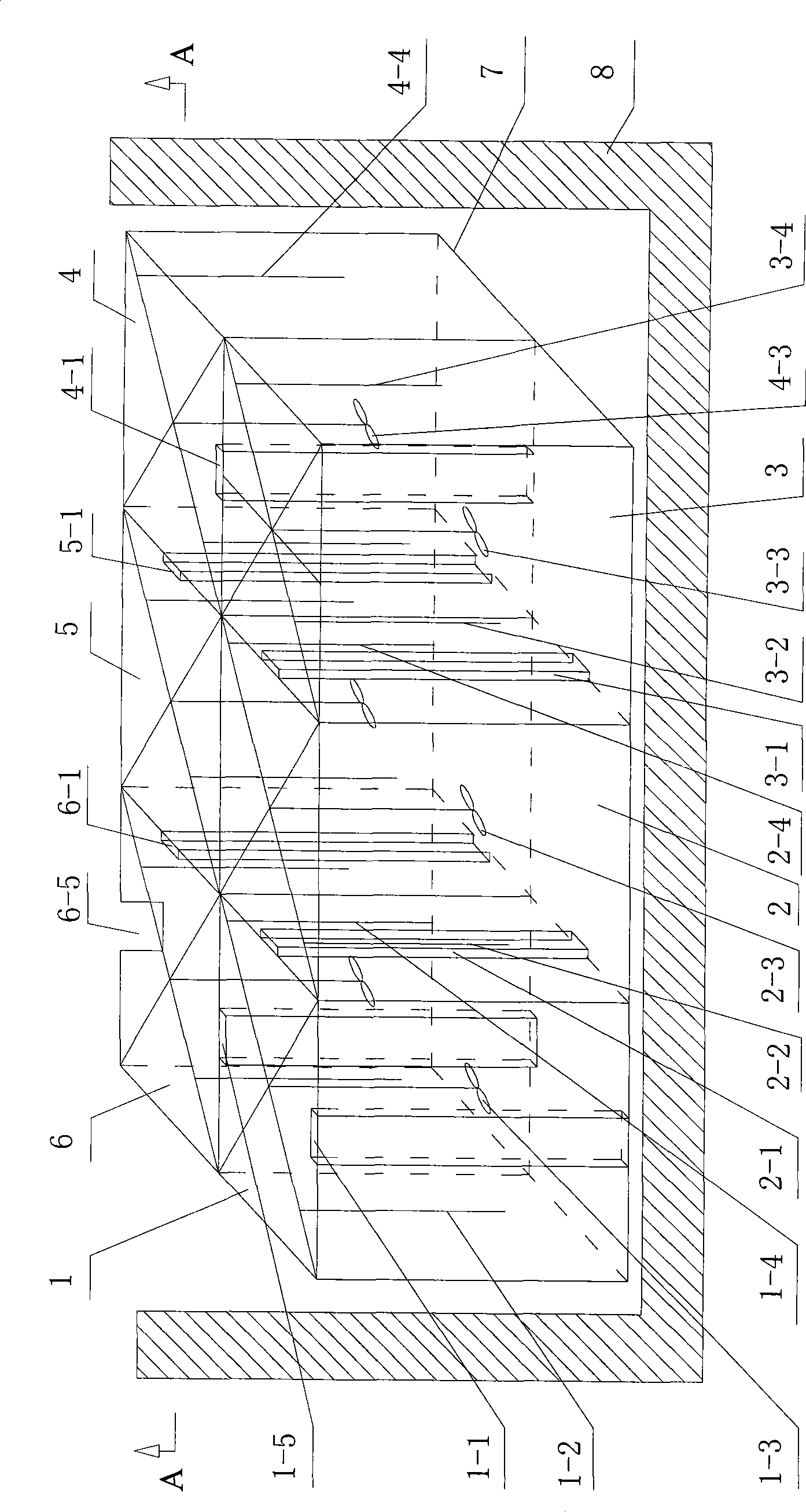

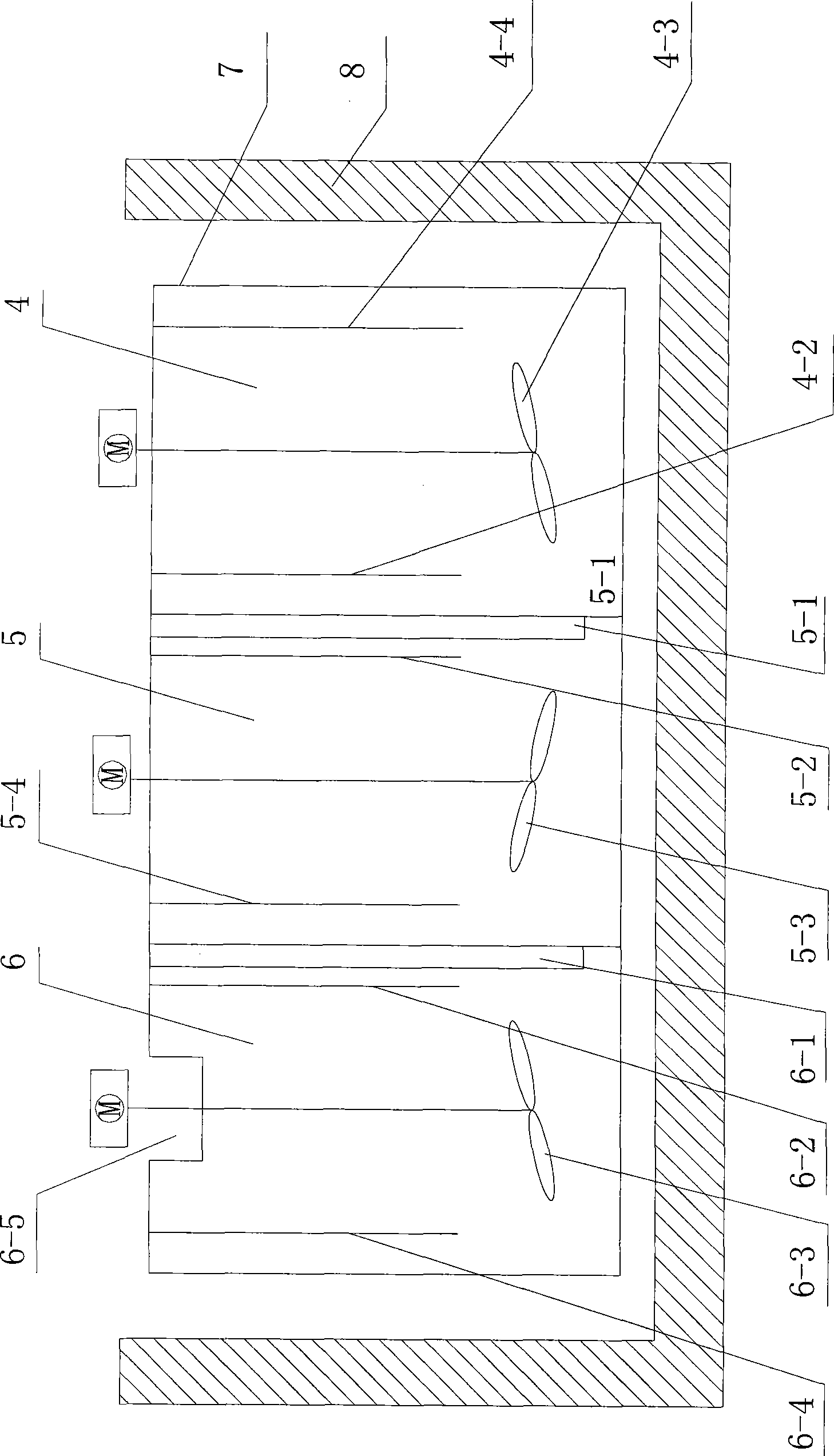

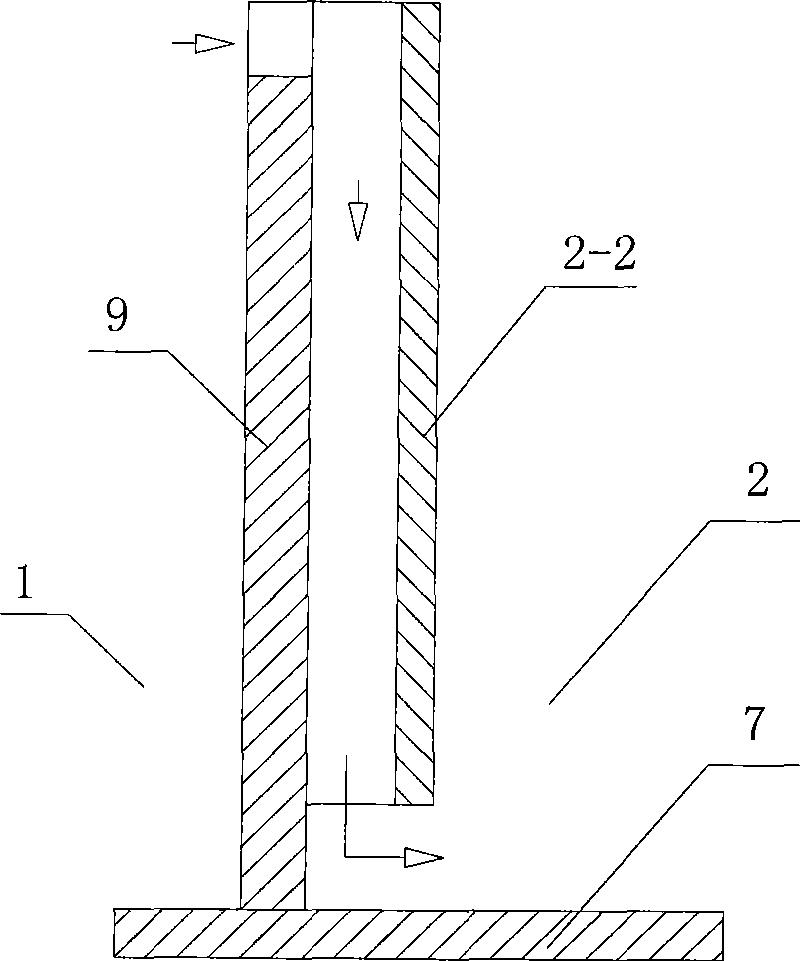

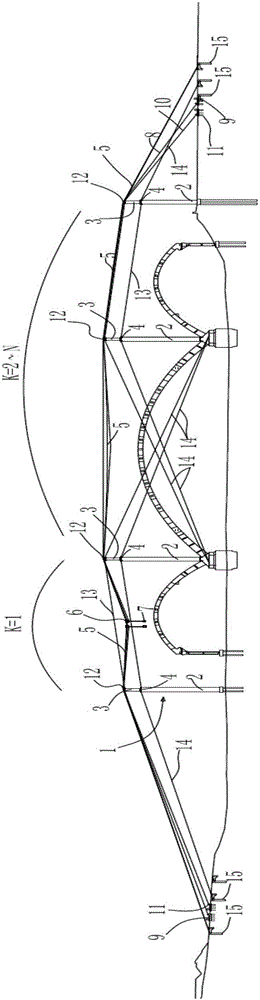

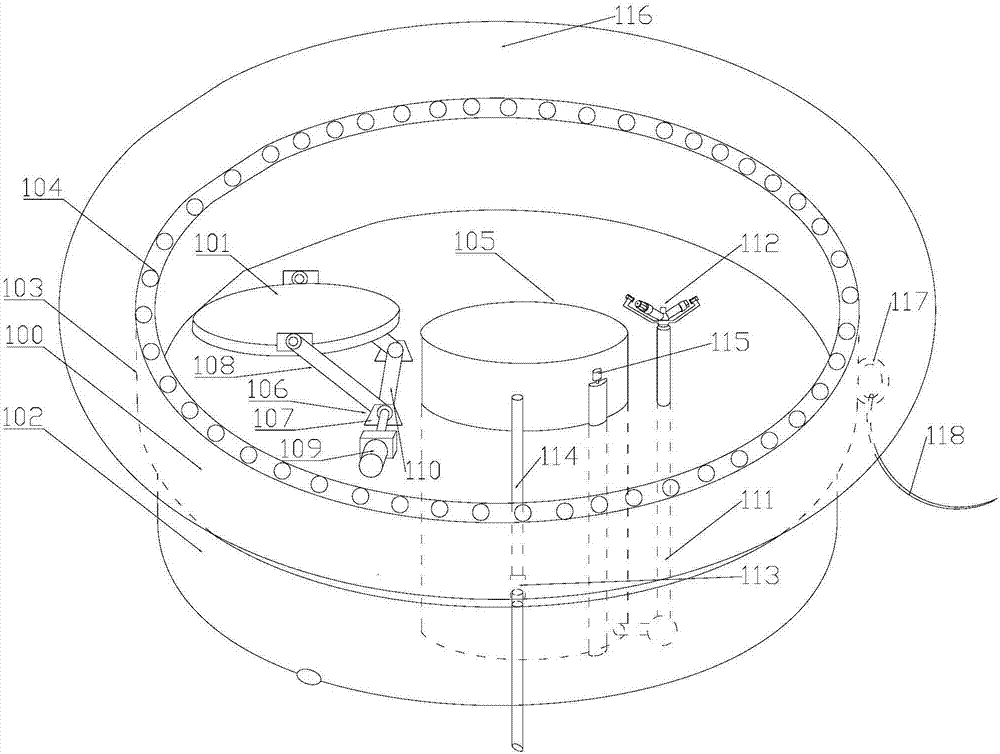

Bridge road transition section roadbed structure of deep layer yielding ground regions

The invention discloses a bridge road transition section roadbed structure of deep layer yielding ground regions. The bridge road transition section roadbed structure of deep layer yielding ground regions comprises a settlement and rigidity smooth transition system, a bearing force control system and a conventional foundation stabilizing system; the conventional foundation stabilizing system is positioned at one side of a roadbed body; the settlement and rigidity smooth transition system and the bearing force control system are positioned between the conventional foundation stabilizing system and a bridge abutment; the settlement and rigidity smooth transition system comprises a raft below a track and a plurality of long piles entering the roadbed; the long piles lengthen gradually from the pavement to the bridge abutment direction; the pile top parts of the long piles enter the raft, and the long piles and the raft are in rigid connection into an integral structure; the bearing force control system comprises a plurality of short piles arranged below the roadbed; the pile top parts of the short piles are provided with first broken stone hardcores for bearing the roadbed, and the long piles penetrate through the first broken stone hardcores.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

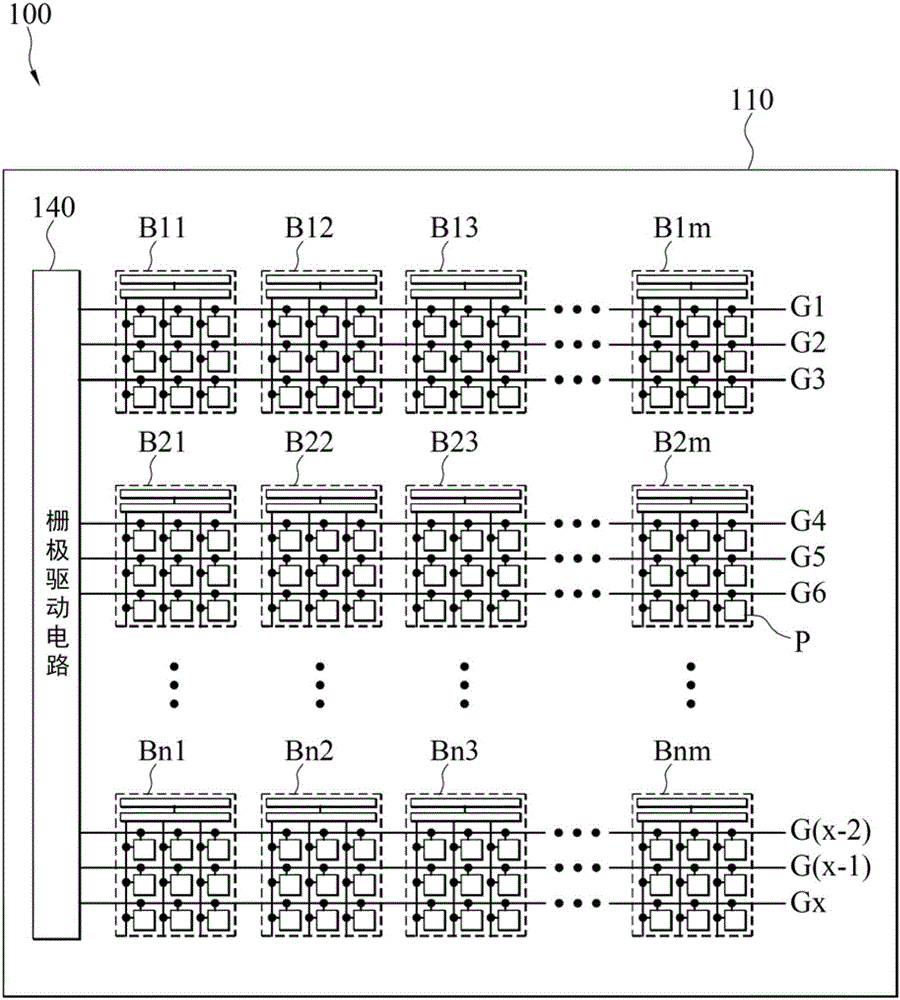

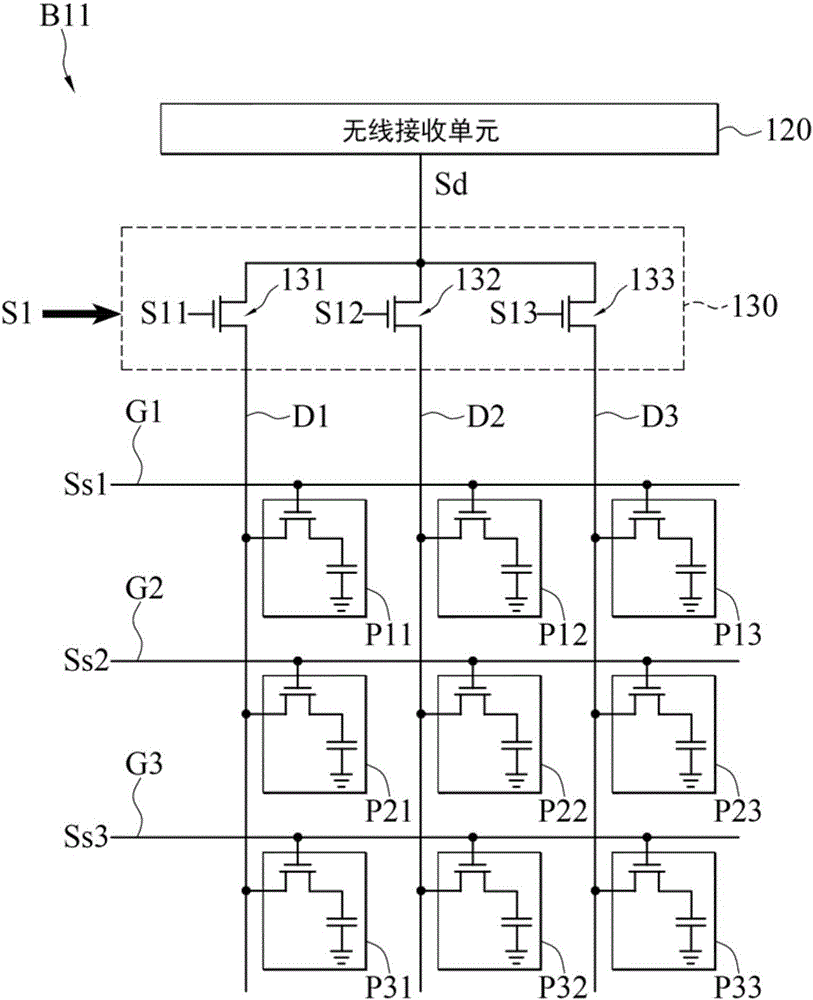

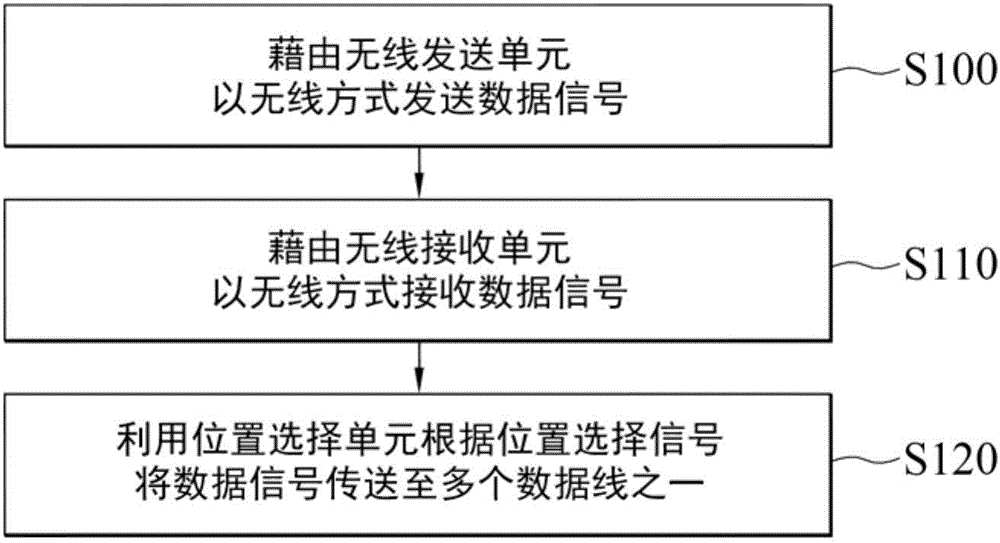

Pixel array structure

ActiveCN106710509AImprove reliabilityImprove the problem of insufficient display spaceStatic indicating devicesData signalComputer science

The invention discloses a pixel array structure comprises a plurality of scanning lines and a plurality of pixel blocks. Each pixel block comprises a plurality of data cables, a plurality of pixel units, a wireless receiving unit and a location selection unit. The plurality of pixel units are arranged in an array manner, each pixel unit is coupled to one of the plurality of scanning lines and one of the plurality of data cables. The wireless receiving unit receives data signals in a wireless manner. The location selection unit transmits the data signals to one of the plurality of data cables according to location selection signals.

Owner:AU OPTRONICS CORP

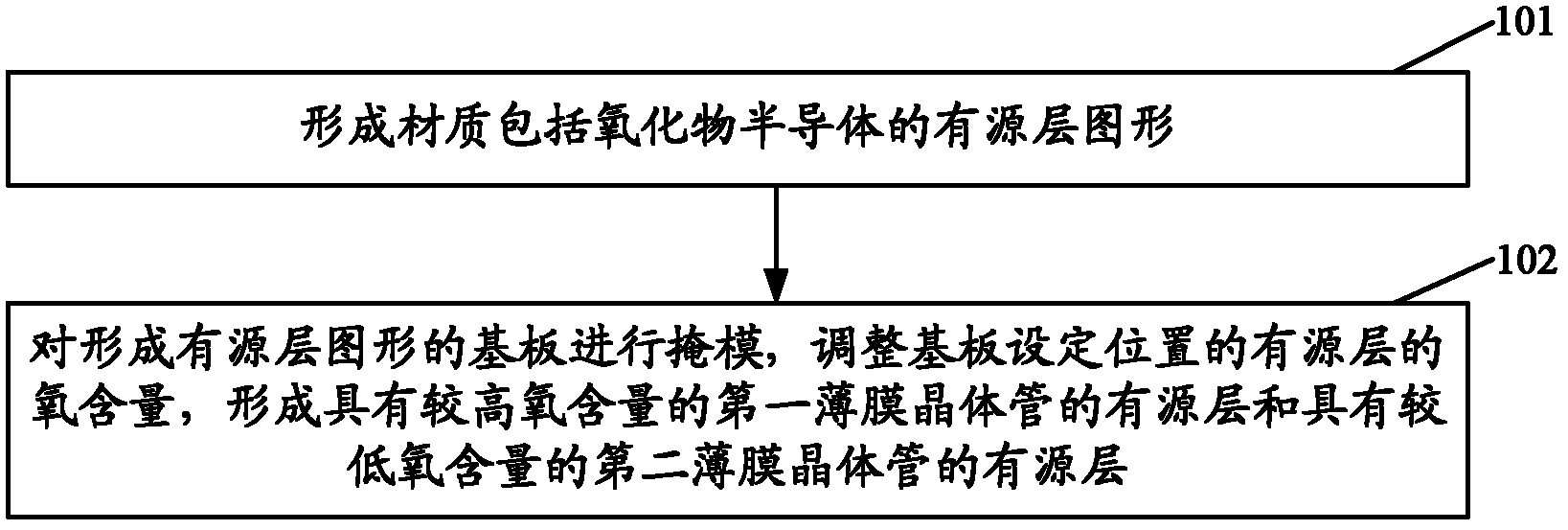

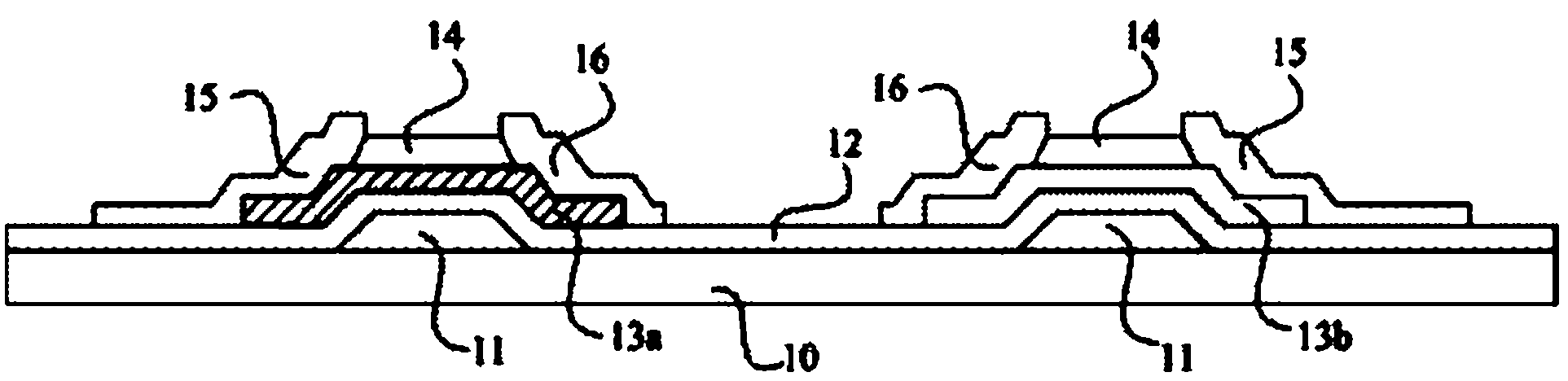

Array substrate and manufacturing method thereof

ActiveCN102646683ASimple structureImprove structural stabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringStructural stability

The invention discloses an array substrate and a manufacturing method of the array substrate. The array substrate comprises a substrate plate, a first TFT (thin film transistor) and a second TFT, wherein the first TFT and the second TFT are respectively arranged on the substrate plate, the first TFT is an enhancement type, and the second TFT is a depletion type. The array substrate plate is provided with the enhancement-type first TFT and the depletion-type second TFT at the same time at preset positions so as to exert the functional characteristics; and compared with a single depletion-type TFT or a single enhancement-type TFT of an array substrate in the prior art, the array substrate disclosed by the invention has the advantages of being capable of reducing the set number of TFTs and simplifying circuit wires so as to largely simplify a structure of the whole array substrate, largely improve the stability of the structure and further increase the effective pixel area of the array substrate.

Owner:BOE TECH GRP CO LTD

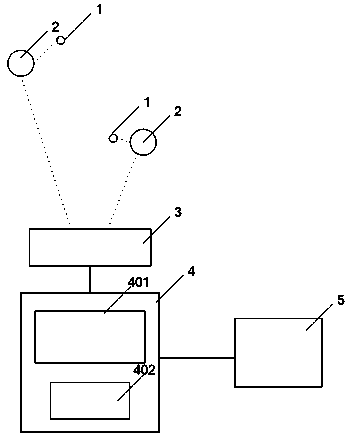

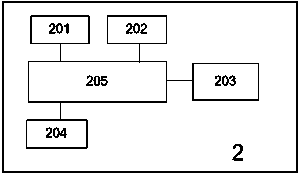

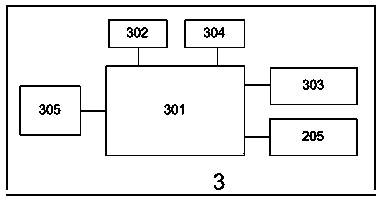

Signal base station three-dimensional positioning system and method based on RSSI and AOA

ActiveCN103458503AReduce the number of settingsReduce energy consumptionPosition fixationWireless communicationWireless gatewayWireless sensor network

The invention discloses a signal base station three-dimensional positioning system and method based on RSSI and AOA. The signal base station three-dimensional positioning system comprises an electronic tag arranged on a person to be positioned or a device to be positioned and further comprises a wireless base station capable of being arranged at a base station positioning position. Wireless communication can be conducted between the electronic tag and the wireless base station, the wireless base station is in wireless connection with a wireless gateway which is connected with a server, and the server is connected with a PDA or a PC. The signal base station three-dimensional positioning system and method based on RSSI and AOA can effectively overcome the defects that an wireless sensor network is poor in penetrability, and inconvenient to install, arrange and maintain, and effectively reduce the number of arranged base stations.

Owner:西安嵌牛电子科技有限公司

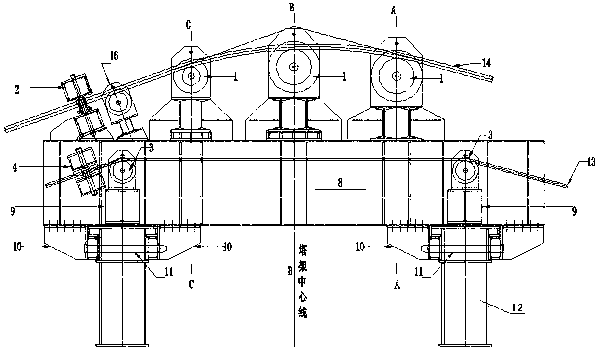

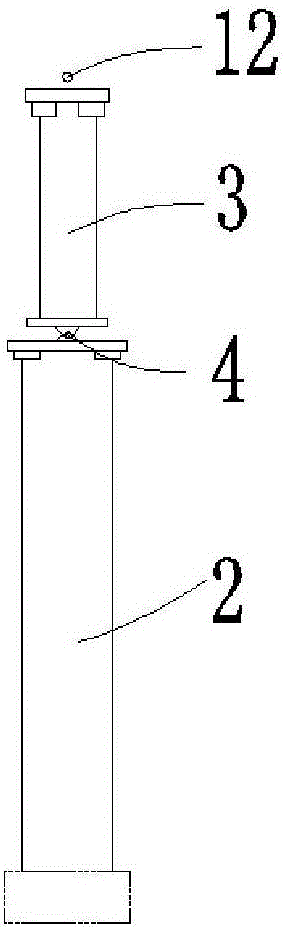

Steering cable saddle for large-tonnage cable crane

InactiveCN103276671AAvoid damageExtended service lifeBridge erection/assemblyCable carsMovable typeEngineering

The invention discloses a steering cable saddle for a large-tonnage cable crane. The steering cable saddle aims at solving the problems that existing movable type cable saddle towers are equipped with a plurality of front and back wind cables along bridge directions and high in cost, and service lives of bearing cable axle assemblies, hoisting cable axle assemblies, traction cable axle assemblies, bearing cables, hoisting cables and traction cables are short. The steering cable saddle comprises cable saddle base distribution beams and a cable saddle base connecting cross beam, wherein each cable saddle base distribution beam is provided with a bearing cable axle assembly, a bearing cable steering device, a hoisting cable steering device, a traction cable axle assembly, a traction cable steering device and a sliding axle assembly; the cable saddle base connecting cross beam is provided with a hoisting cable axle assembly; and the cable saddle base distribution beams are positioned on left and right sides of the cable saddle base connecting cross beam. By means of the steering cable saddle for the large-tonnage cable crane, service lives of the bearing cable axle assemblies, the hoisting cable axle assembly, the traction cable axle assemblies, bearing cables, hoisting cables and traction cables are prolonged.

Owner:HUNAN CONSTR ENG GRP COR +1

Process and device for continuous ultrasound desulfurization of scrapped lead paste

InactiveCN101518711AReduce the number of settingsSmall footprintDispersed particle separationIonSodium carbonate

The invention relates to a process and a device for continuous ultrasound desulfurization of scrapped lead paste. The process for continuous ultrasound desulfurization of scrapped lead paste comprises the following steps: (1) sodium carbonate or ammonium carbonate is selected as desulfurizing agent, and the desulfurizing agent and the scrapped lead paste are taken according to the mole ratio (1.2 to 2.2:1) of the Na iron or the (NH4)2 iron in the desulfurizing agent to the S iron in the scrapped lead paste; (2) the scrapped lead paste, the desulfurizing agent and water are prepared into flowing pulp with solid-liquid (S / L) weight ratio being equal to 3 / 5 to 4 / 5 in a pulping tank; (3) under the condition of ultrasonic wave, the flowing pulp enters a first reaction chamber for heating and stirring from the lower end part in the first reaction chamber, is discharged out from an overflow opening at the upper end of the first reaction chamber, then enters a second reaction chamber for heating and stirring from the lower end part of the second reaction chamber and finally, and is discharged out from a discharging opening at the upper end of an nth (ranging from 3 to 12) reaction chamber after sequent flow for reaction and discharge. The process has the advantages of low cost, small occupied area, continuous production and high efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

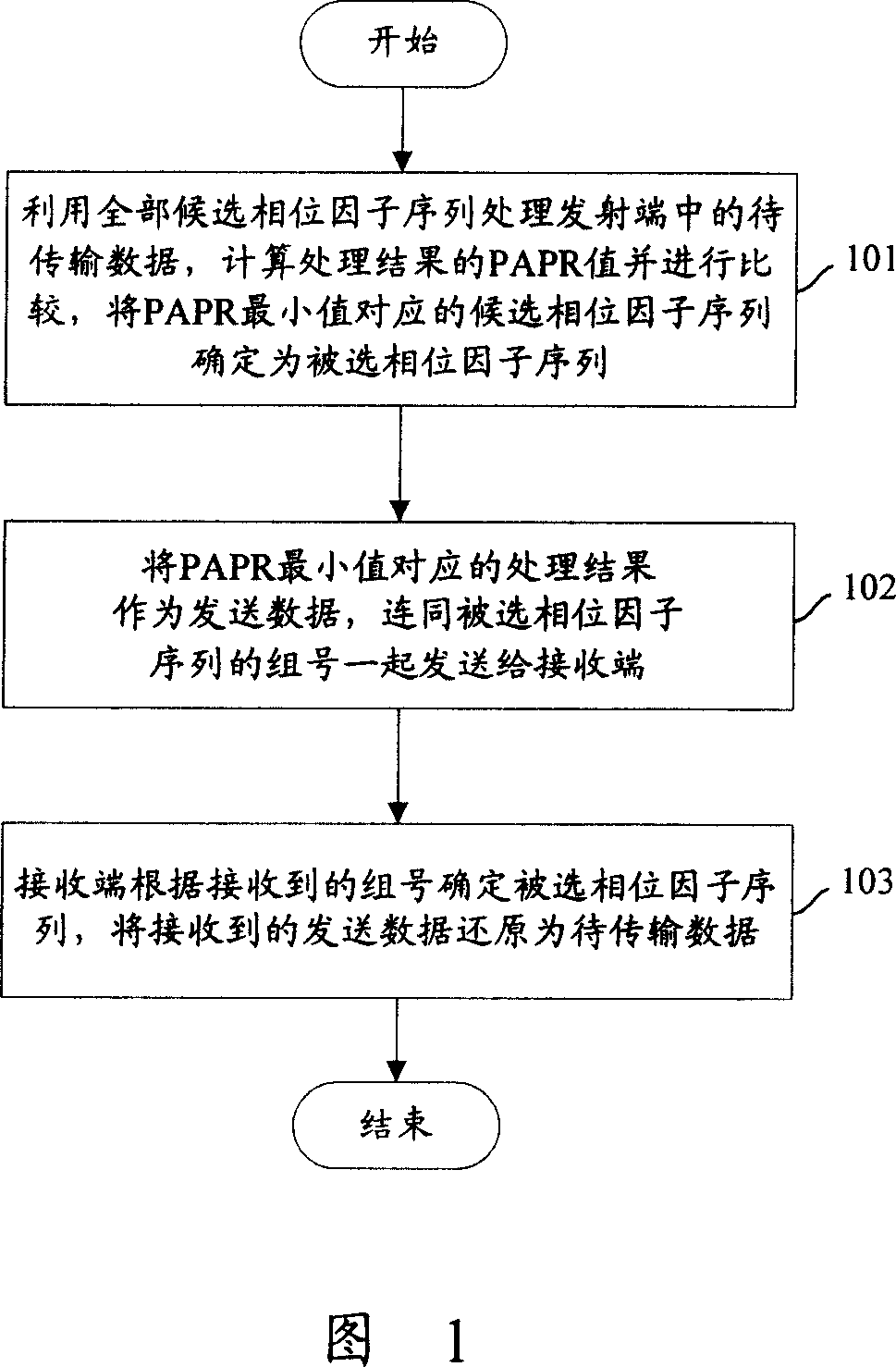

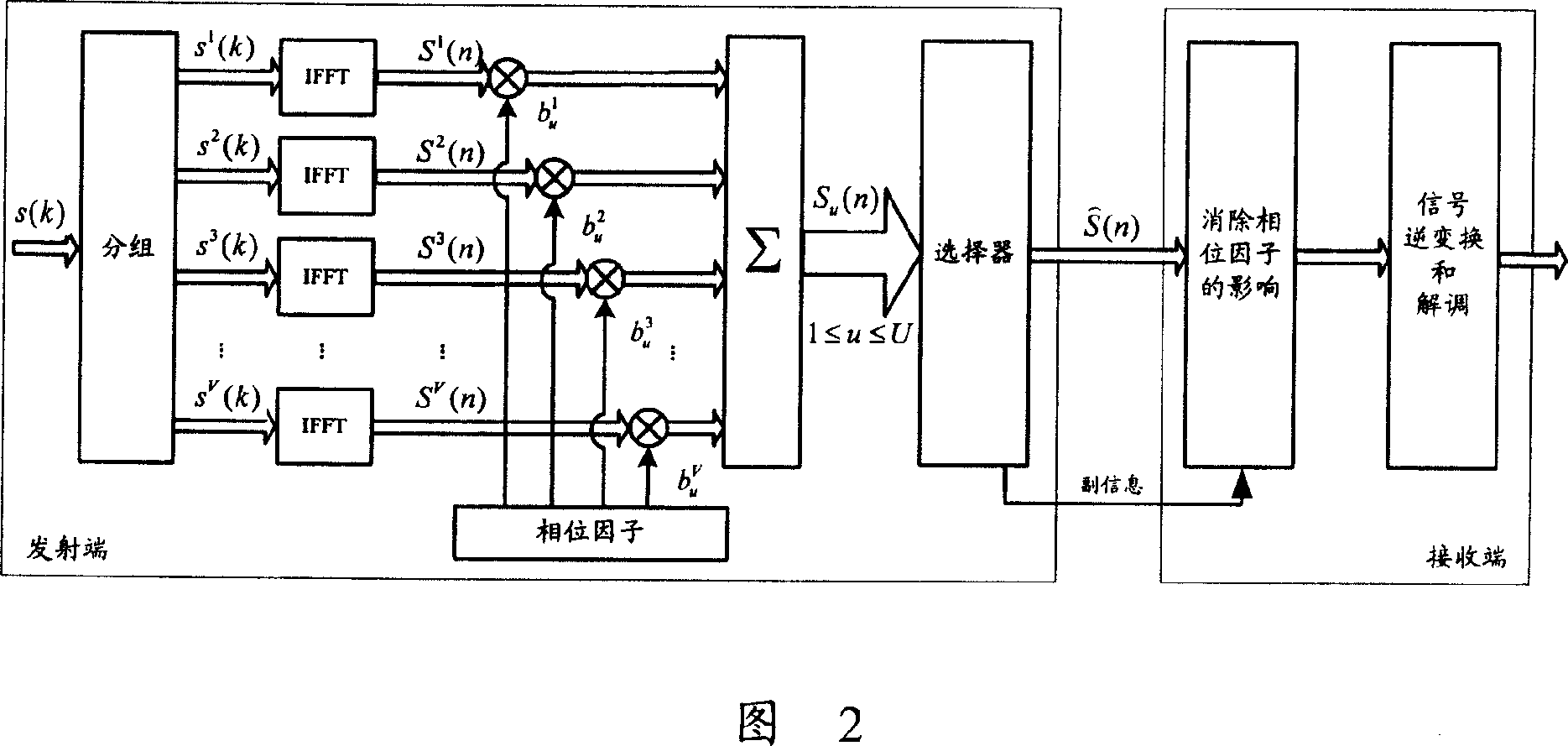

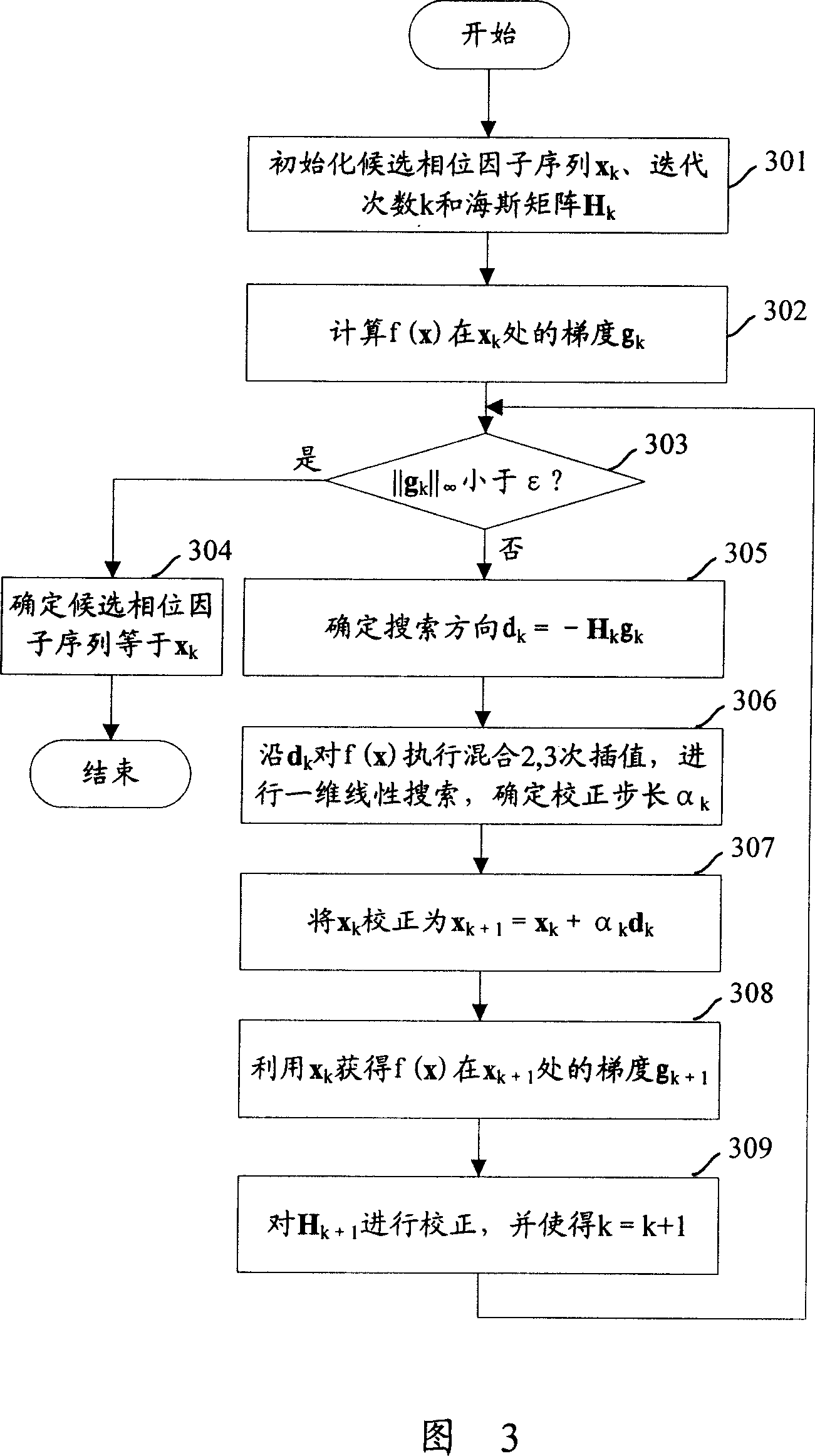

Method for transmitting data of multiple carrier wave

InactiveCN101110809AReduce the number of settingsReduce processing timeMultiple carrier systemsSignal channelsComputation complexityInformation quantity

The present invention discloses a multicarrier data transmission method. A candidate phase factor sequence with small cross correlation is chosen from the unit circle of a coordinate space in advance. The method comprises that, A. the data waiting for transmitting in the transmitting end are processed by using all candidate phase factor sequences, the PAPR values of processing results are computed and compared, the candidate phase factor sequence corresponding to the PAPR minimum value is determined for the phase factor sequence selected; B. the processing result corresponding to the PAPR minimum value is considered as the main information, and the master information and the group numbers of the phase factor sequence selected are transmitted to the receiving end together; C. the receiving end determines the phase factor sequence selected according to the group numbers received, and makes the main information received be restored to the data waiting for transmitting.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

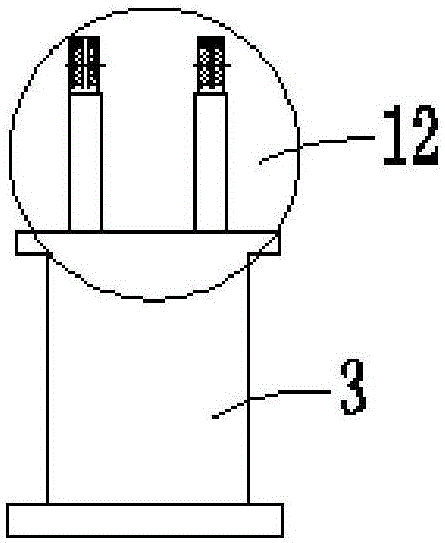

Multi-pylon multi-span lifting cable crane

ActiveCN106276627ALower the altitudeControl altitudeBridge erection/assemblyCable carsTraction systemOverhead crane

The invention discloses a multi-pylon multi-span lifting cable crane. The crane comprises M pylons, N lifting spans connected to the M pylons sequentially, bearing cables, an overhead crane and lifting appliance assembly, traction systems, lifting systems and anchorage systems, wherein each pylon comprises a cable tower and a main tower arranged at the top of the cable tower, and a cable saddle structure for supporting the corresponding bearing cable is arranged at the top of the main tower; two ends of single bearing cable are used for being connected with the anchorage systems located on both banks; one lifting span is formed between every two adjacent pylons, and at least two lifting spans are connected to form a multi-pylon multi-span structure; the traction systems are used for pulling the single overhead crane and lifting appliance assembly to move between the adjacent lifting spans, and the lifting systems are used for lifting materials through the overhead crane and lifting appliance assembly; N and M are both natural numbers, M is larger than or equal to 3, and N is equal to the difference between M and 1. Therefore, multiple lifting spans are formed by arranging multiple pylons, and compared with the conventional double-pylon single-span lifting cable crane, the height of each pylon is reduced substantially and controlled effectively.

Owner:HUNAN ZHONGNAN BRIDGE INSTALLATION ENG +1

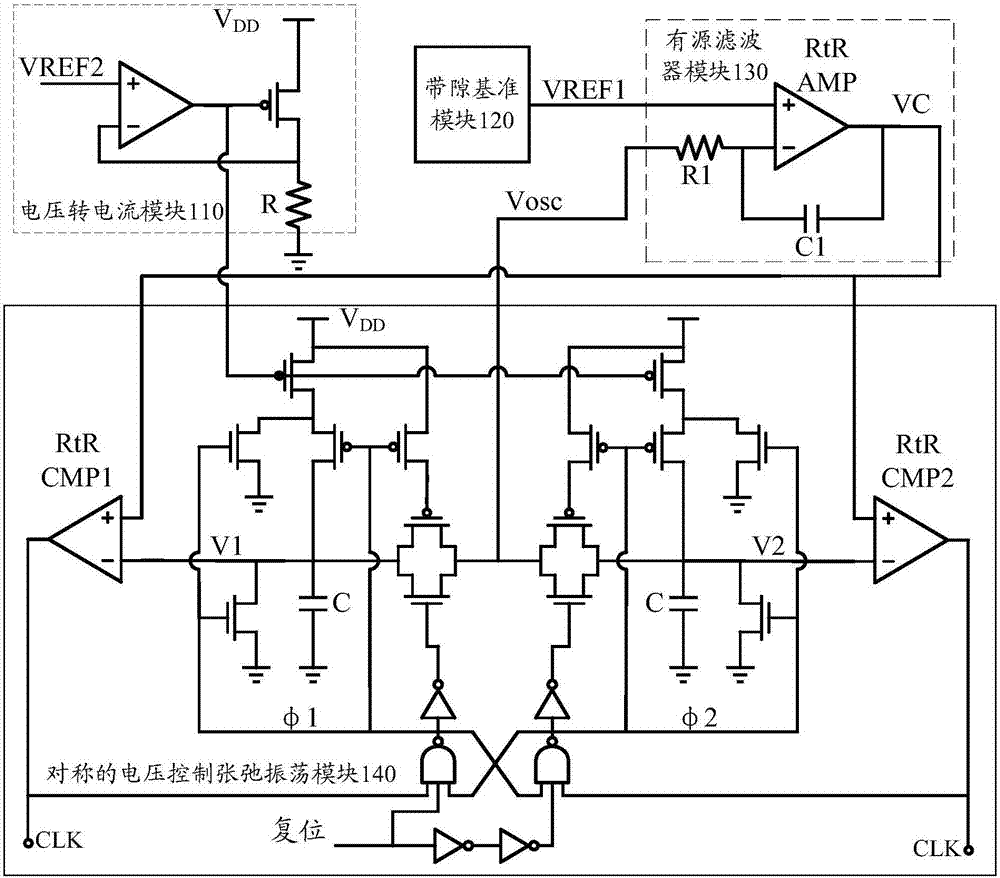

RC vibrator

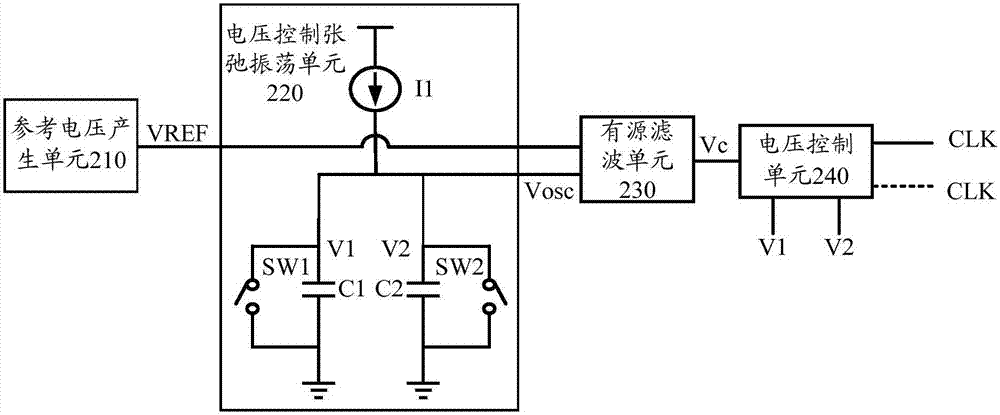

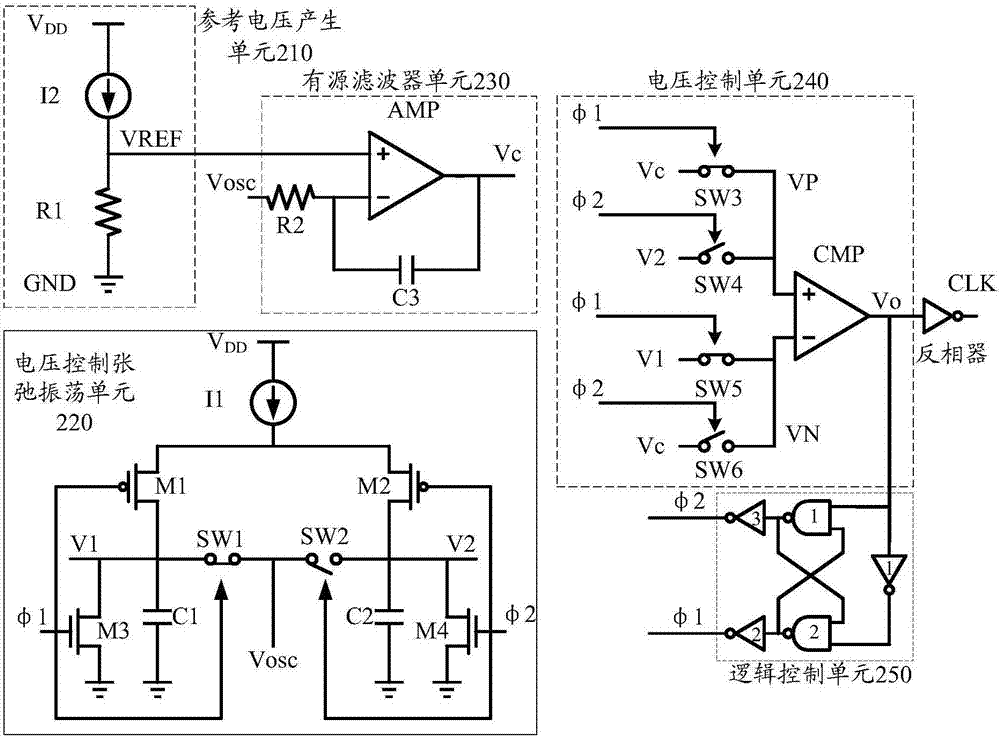

InactiveCN107112947AReduce power consumptionHigh frequency accuracyOscillations generatorsEngineeringVoltage reference

The application provides an RC oscillator, including a reference voltage generation unit used for generating a reference voltage; a voltage control relaxation oscillation unit including a first constant current source and a first charge-discharge loop and a second charge-discharge loop, wherein the first constant current source is used for alternately charging the first charge-discharge loop to generate a first oscillation signal or a second oscillation signal, the first oscillation signal and the second oscillation signal are superposed to obtain a third oscillation signal, and the first charge-discharge loop and the second charge-discharge loop are symmetrical in structure; an active filter unit used for integrating the reference voltage and the third oscillation signal to obtain a fourth signal; and a voltage control unit used for comparing the fourth signal and the first oscillation signal to generate a fifth signal, or comparing the fourth signal and the second oscillation signal to generate a sixth signal.

Owner:SHENZHEN GOODIX TECH CO LTD

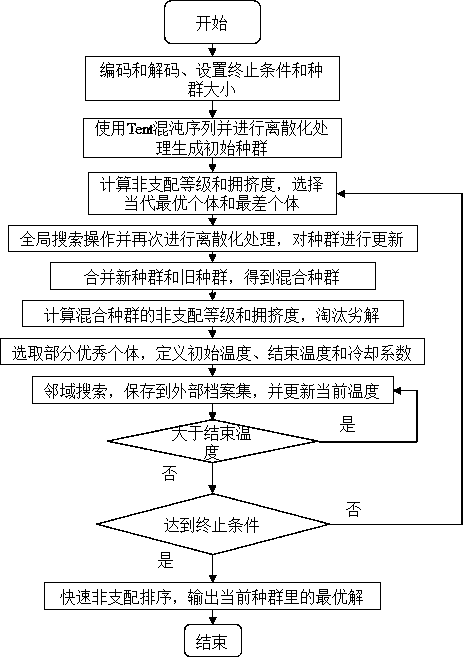

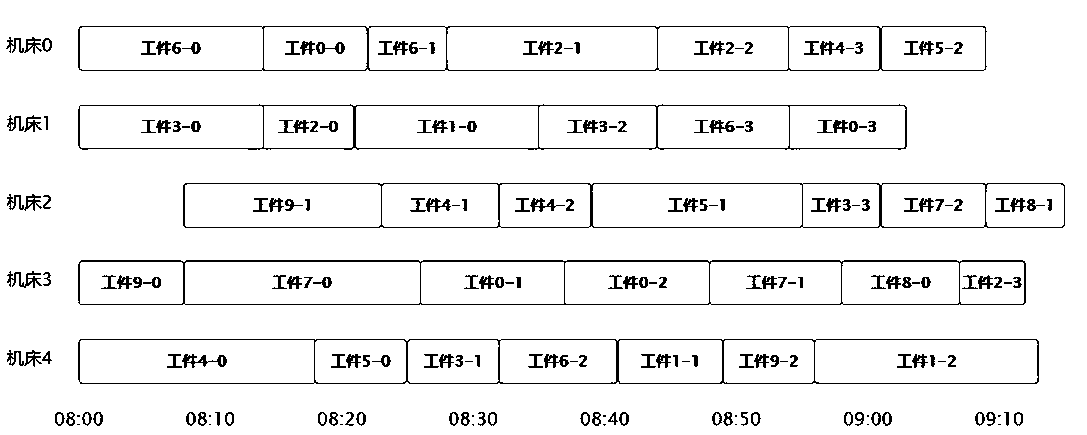

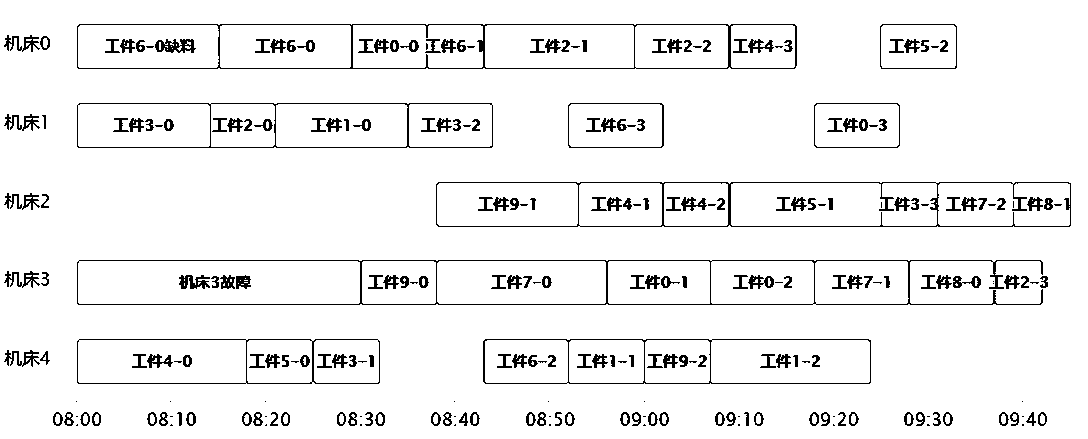

Improved multi-target Jaya algorithm based discrete manufacture workshop production arranging method

ActiveCN109946965AEmissions can be controlledAdapt to changing working conditions in timeAdaptive controlProduction planningInternet of Things

The invention provides an improved multi-target Jaya algorithm based discrete manufacture workshop production arranging method. The method comprises the following steps that real-time state of the discrete manufacture workshops is monitored via the IoT (Internet of Things) system, data is processed, influence of abnormal condition on workpiece processing time is analyzed and determined, if the abnormal condition has influence on the workpiece processing time, information of the abnormal condition is input to the production arranging system, the production arranging system aims at maximizing the completion time and minimizing the workshop carbon emission, a statistical mathematical optimization model taking the machine tool as unit and the improved multi-target Jaya algorithm are used to optimize calculation, and an optimal production arranging scheme is obtained. The method has the advantages that the accuracy is high, production planning is more reasonable and efficiency, and the energy saving and emission reducing effect is good.

Owner:无锡思睿特智能科技有限公司

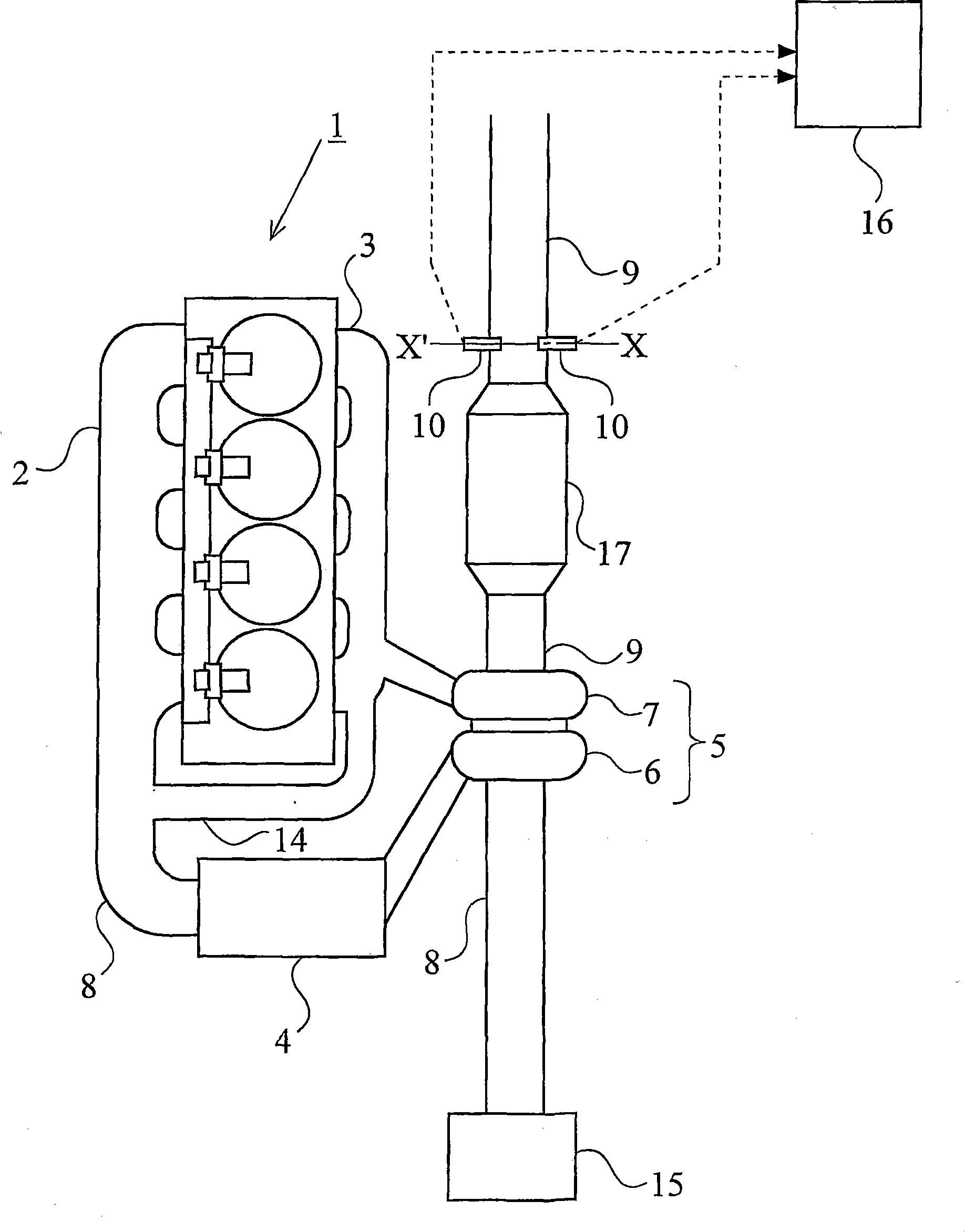

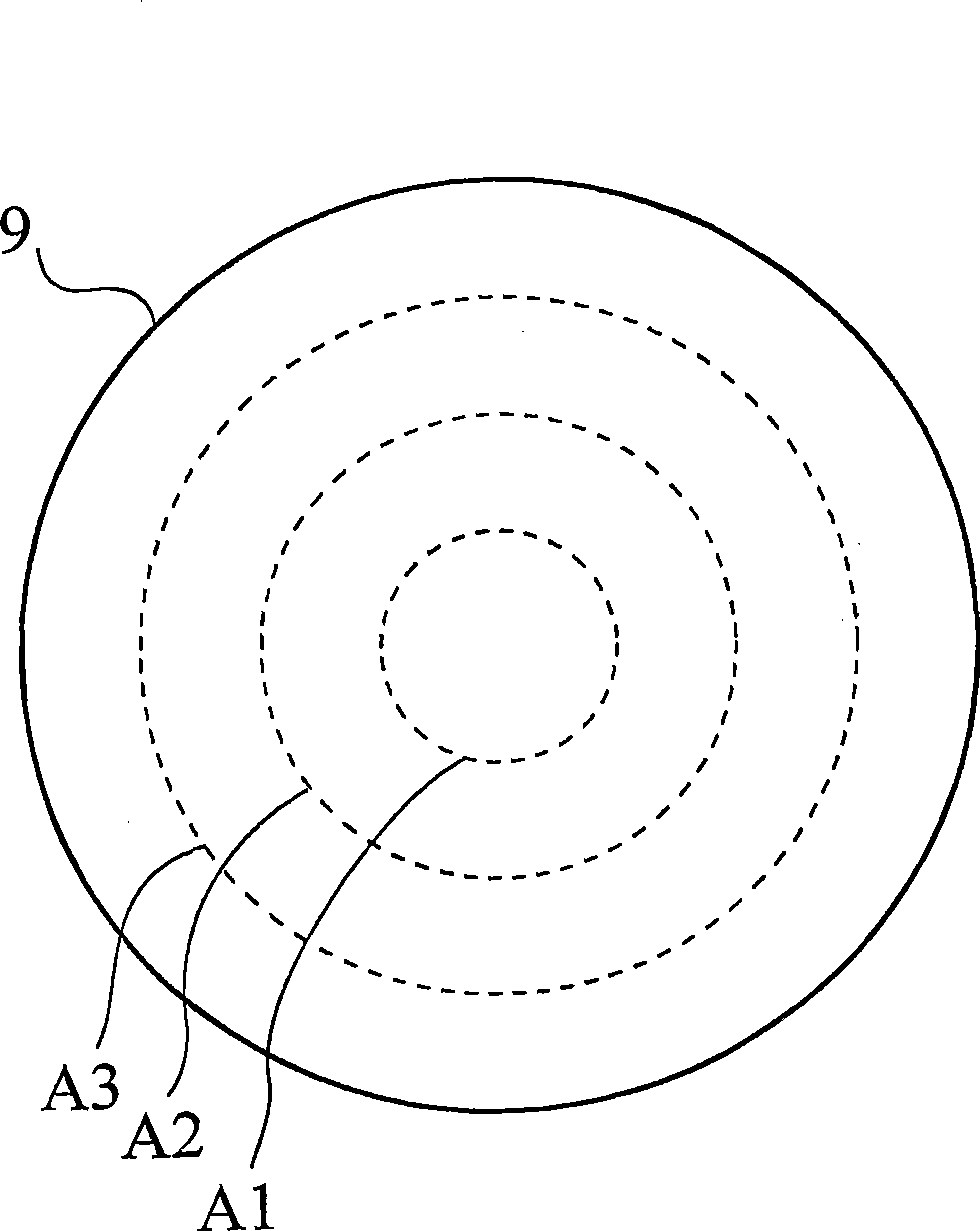

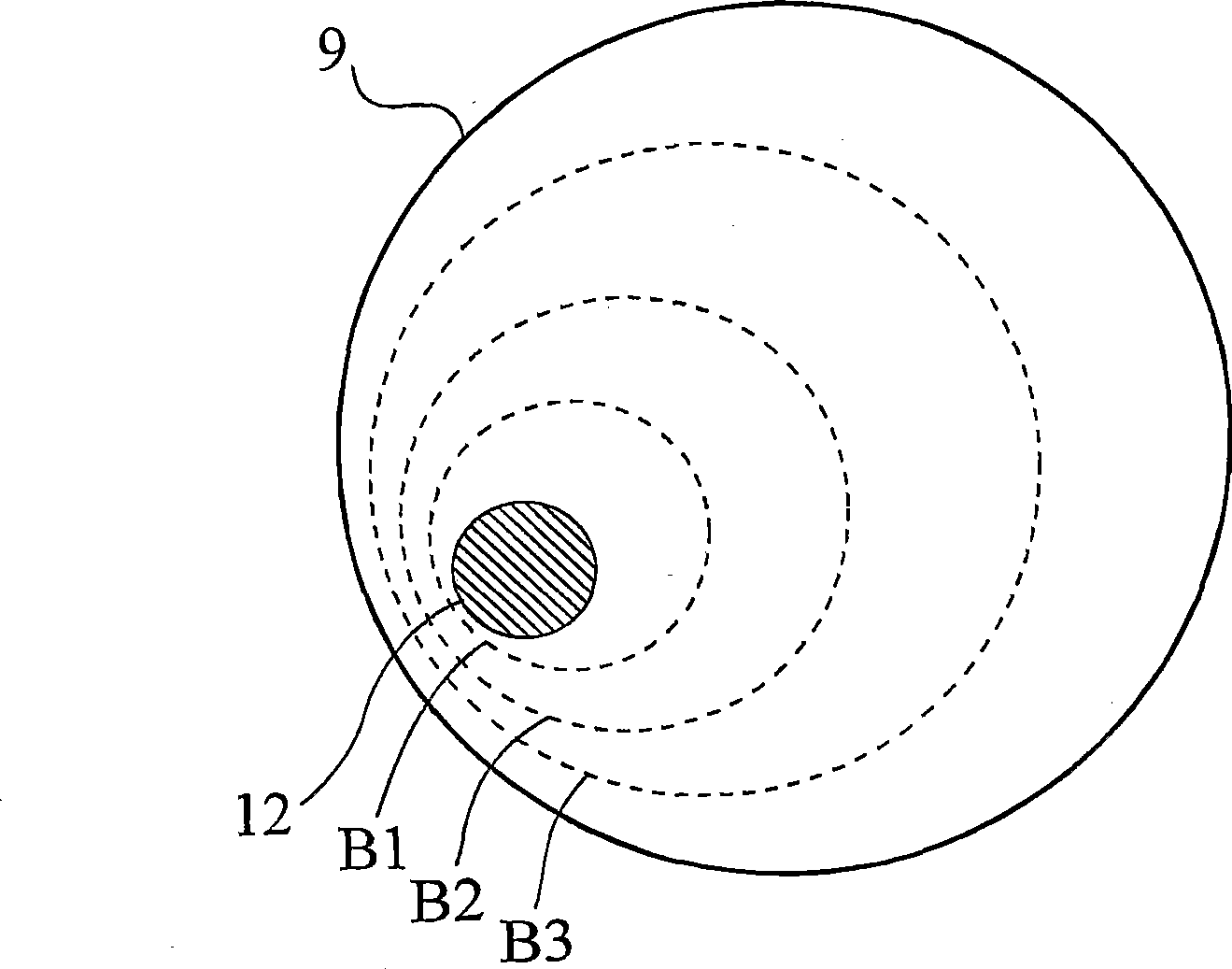

PM trapper failure detection system

InactiveCN101466922AReduce the number of settingsFault Detection System SimplifiedGas treatmentInternal combustion piston enginesReliability engineeringExhaust gas

An object of the present invention is to provide a technology that enables to detect a fault of a PM trapper with improved accuracy. According to the present invention, a plurality of temperature sensors 10 are provided in an exhaust passage 9 just downstream of a PM trapper 17 in such a way that their temperature detection elements are positioned on a plane that is perpendicular to an imaginary center axis of the exhaust passage 9. A change in the radial direction temperature distribution of the exhaust gas flowing out of the PM trapper 17 upon occurrence of a fault in the PM trapper 17 is detected from measurement values of the temperature sensors 10, and a fault of the PM trapper 17 is detected based on this radial direction temperature distribution. Since the measurement values of the temperature sensors 10 are unlikely to be affected by the amount of PM deposited on the PM trapper 17, detection of a fault of the PM trapper 17 can be achieved with improved accuracy.

Owner:TOYOTA JIDOSHA KK

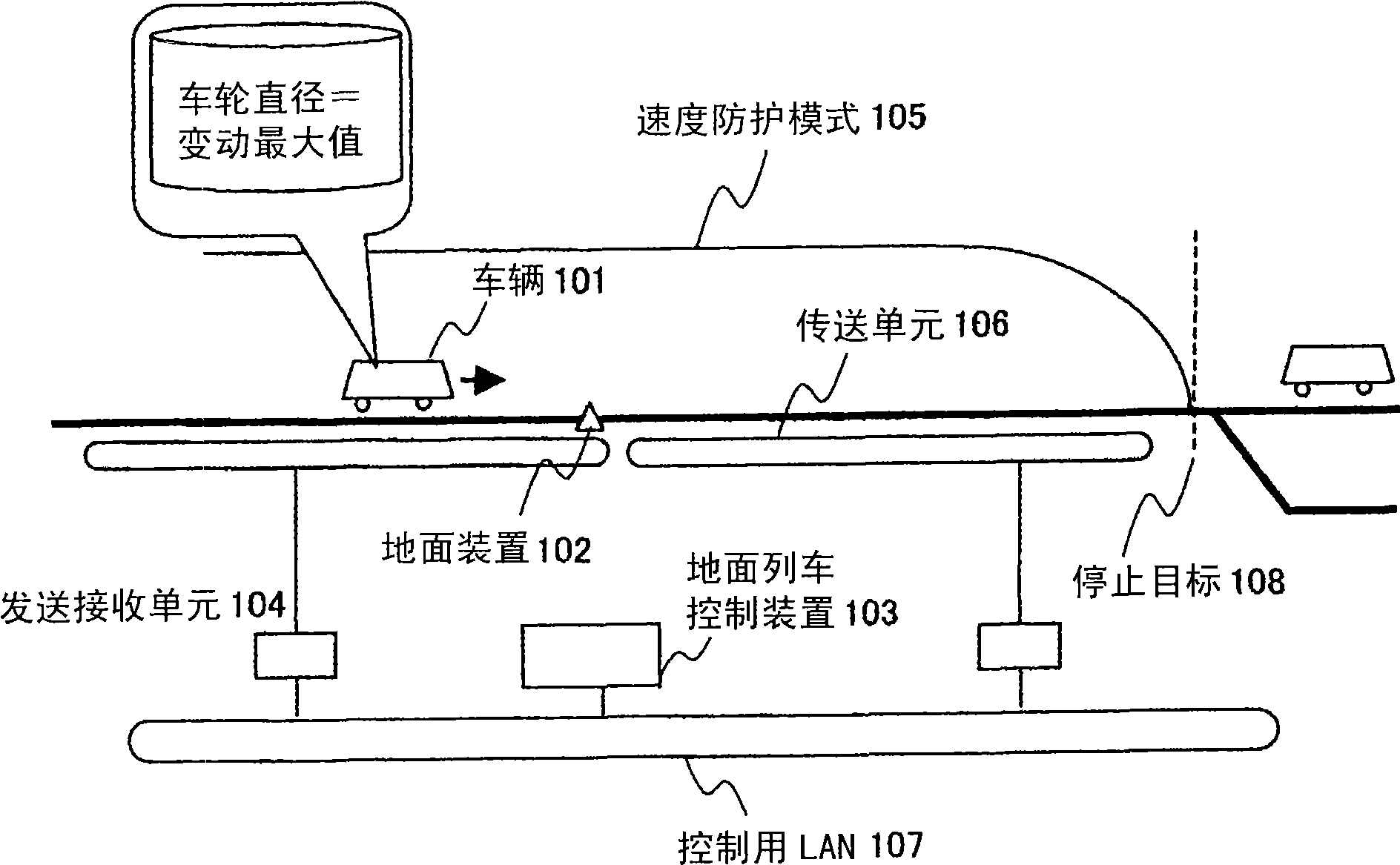

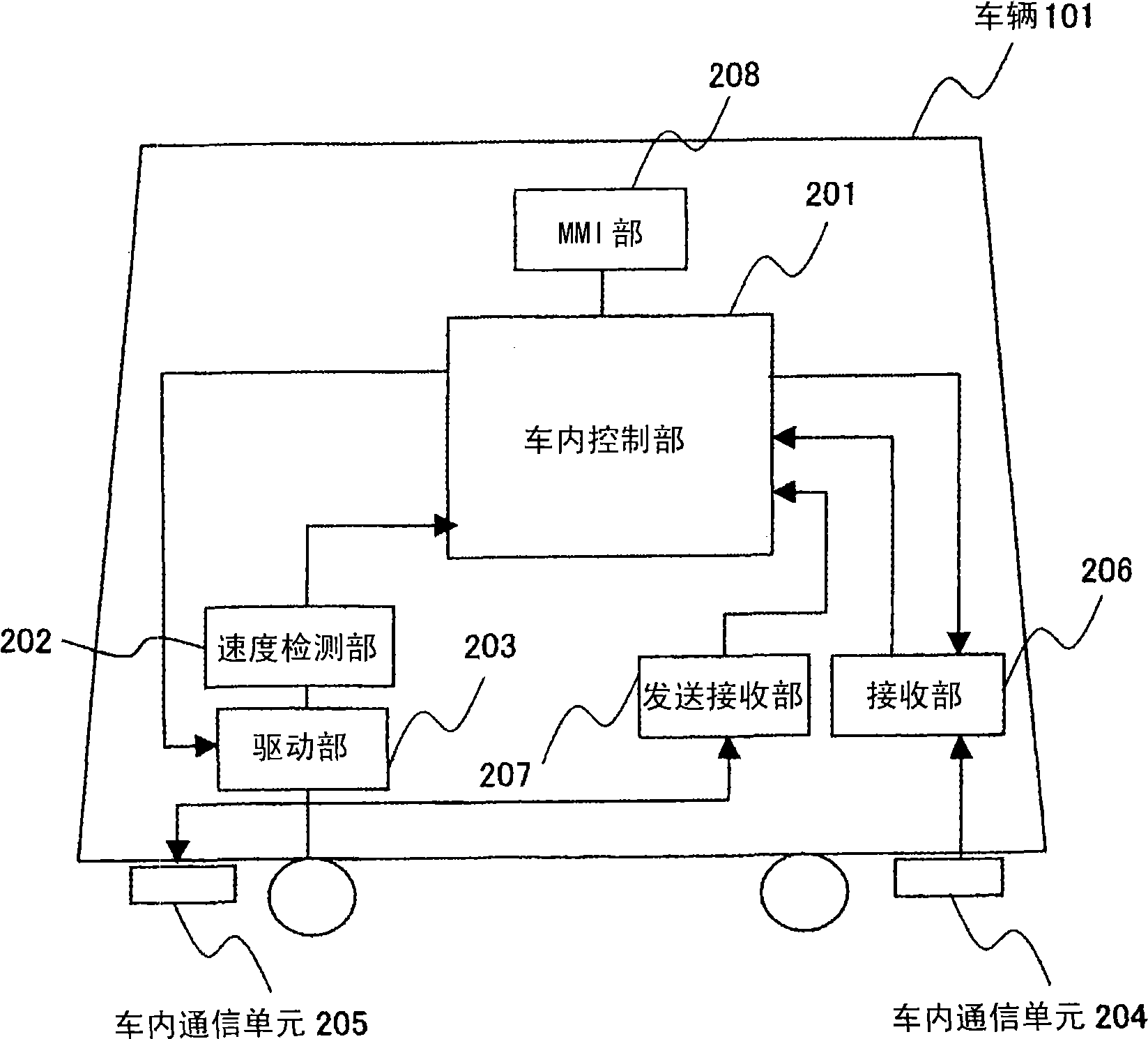

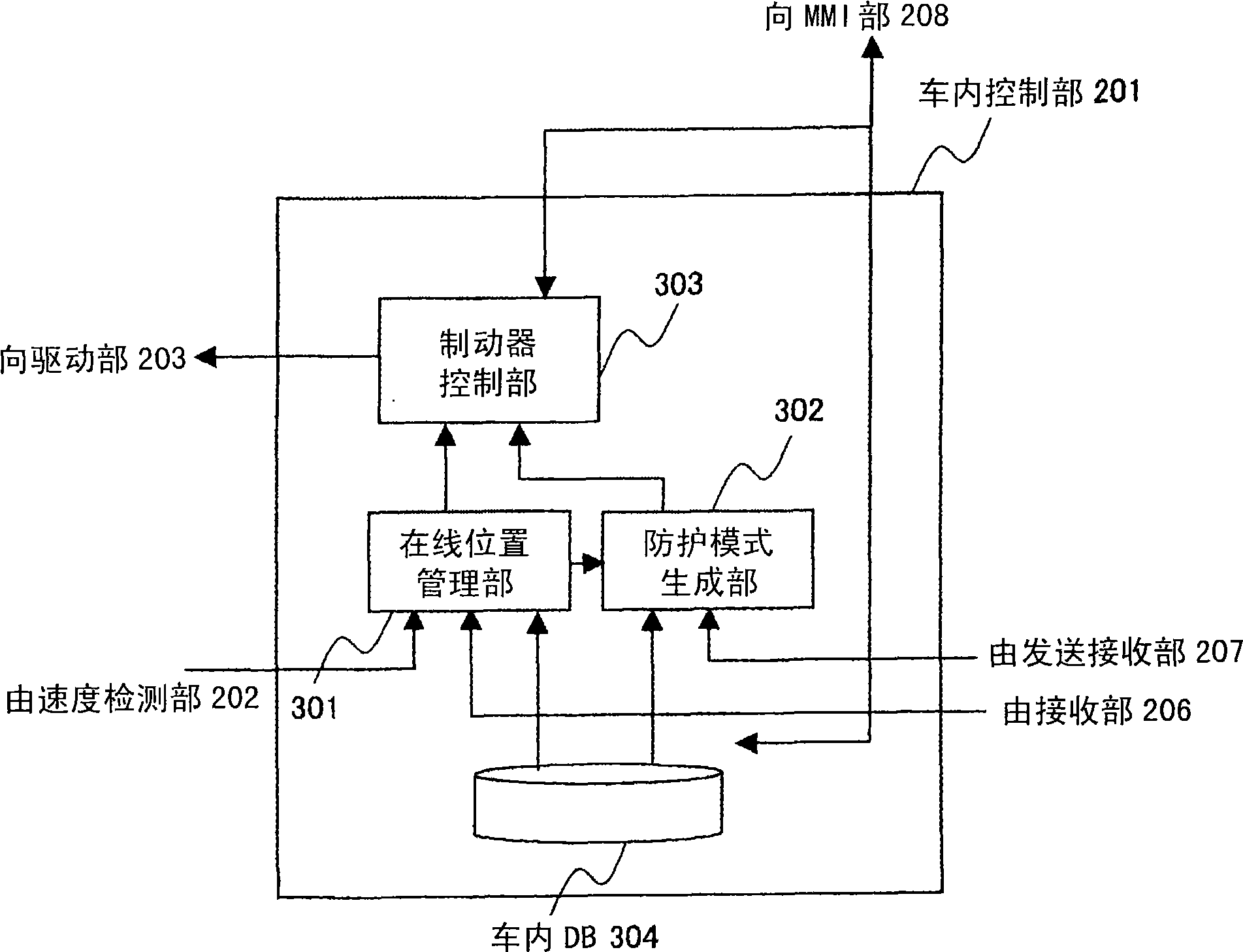

Train controller

ActiveCN101544237AReduce the number of settingsEasy rideRoute devices for controlling vehiclesWheel axle self-adjustmentsAutomotive engineering

The present invention provides a train control method which has the advantages of no requirement of adding the safe clearance distance, capability of reducing the number of ground devices and excellent seating effect. The train controller which controls the train through transmitting information to a ground train control part comprises an in-train control part which is provided with an in-train storing part that pre-stores the likely-changing maximum wheel diameter and the least wheel diameter of the wheel diameter and a speed protection mode. The current position information and speed information of the vehicle are generated based on the maximum wheel diameter, the detected rotating number of wheel and the position information of vehicle received from the ground devices. A corresponding speed protection mode is extracted from the in-train storing part based on the current position information and the stop position target information received from the ground train control part. The brake output is outputted based on the extracted speed protection mode and the generated current position information and speed information.

Owner:HITACHI LTD

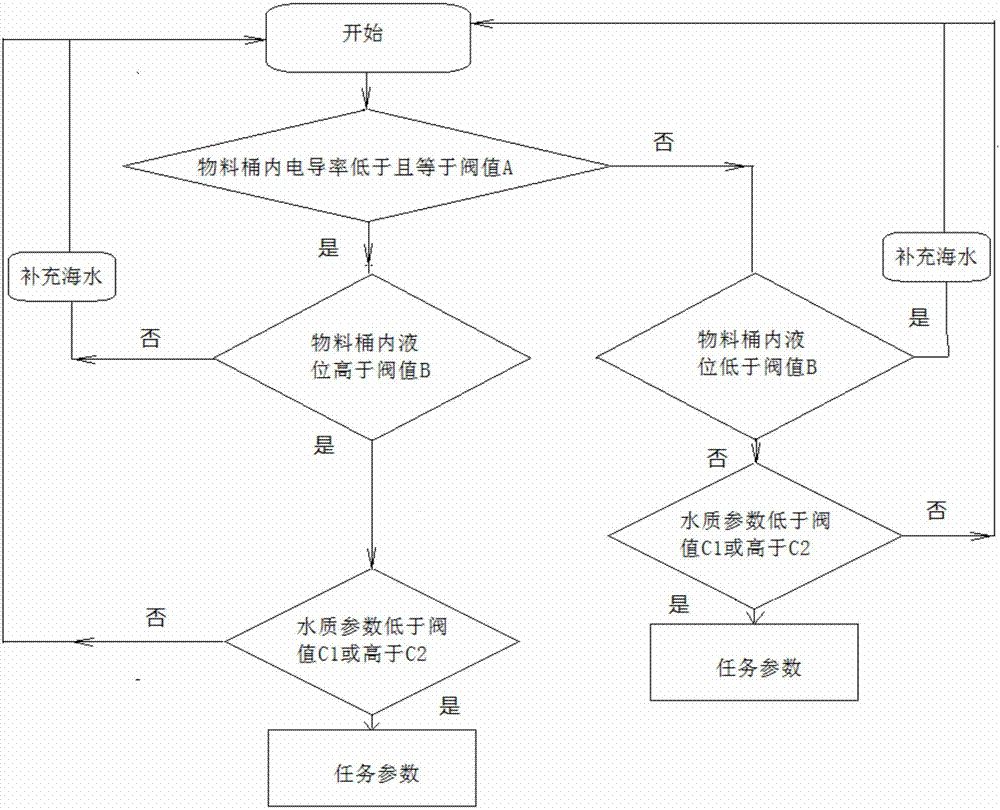

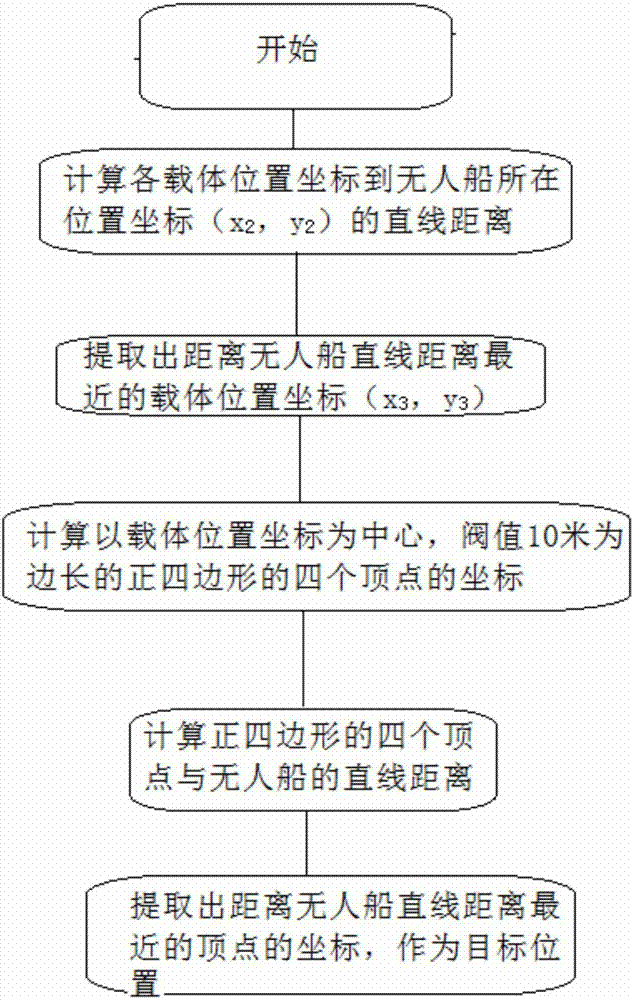

Device and method used for offshore fertilization and pesticide application through unmanned ship and drone

ActiveCN107168318AExtend the effective time of deliveryPrevent eutrophicationFertiliser distributersPosition/course control in two dimensionsMarine engineeringPesticide application

The invention relates to a device and method used for offshore fertilization and pesticide application through an unmanned ship and a drone, and relates to the field of cultivation in water areas through assistance of an unmanned ship. The device consists of a cultivation carrier, an unmanned ship and a drone. A material filling device and a drone recycling device are arranged on an unmanned ship body. Through the cultivation carrier, materials are applied to a cultivation region, the drone detects condition information of the cultivation carrier and the unmanned ship helps the drone to supply materials for the cultivation carrier. Thus, improvement of efficiency for applying materials to the cultivation region is achieved; by applying the unmanned ship technology to the offshore cultivation industry, risks in offshore operation of fishermen are reduced; and efficiency of offshore operation is improved.

Owner:DAPENG GAOKE WUHAN INTELLIGENT EQUIP CO LTD

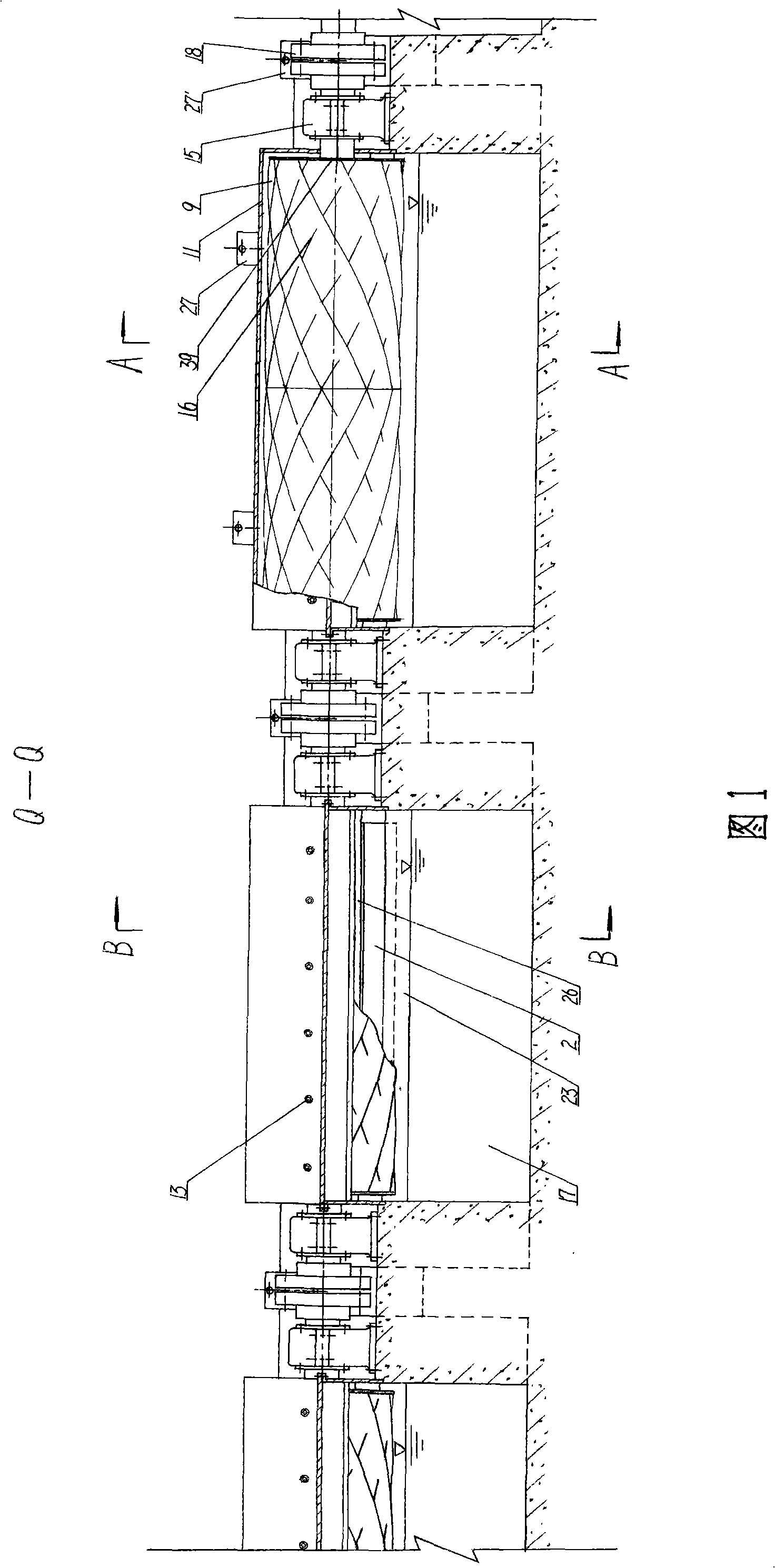

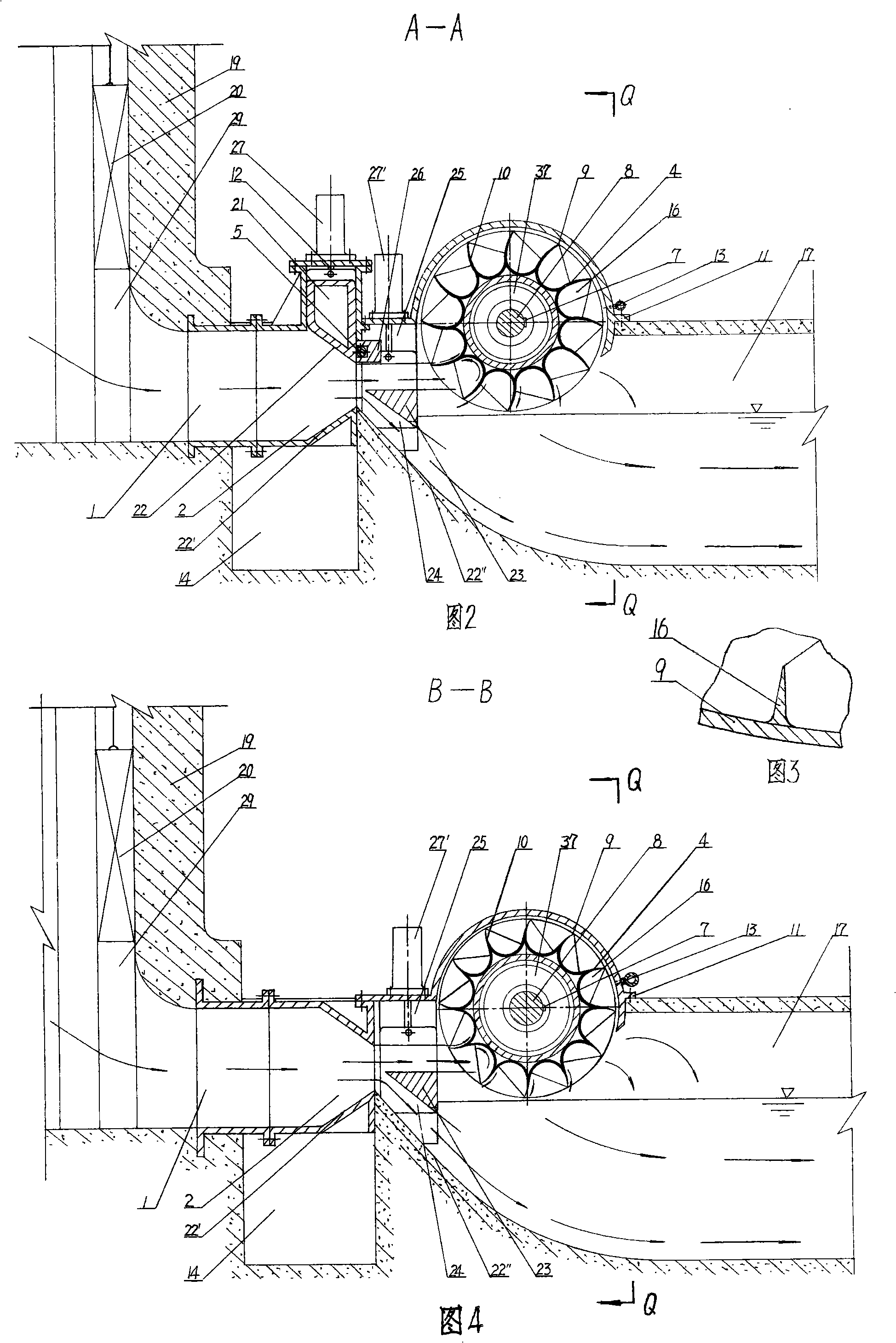

All-purpose hydroturbine

InactiveCN101354004ASmall lossSelf lossHydro energy generationEngine componentsHydro energyWater turbine

A universal water-turbine engine pertains to an impact water-turbine engine which converts pressure energy of current to kinetic energy and converts the kinetic energy to rotating mechanical energy in the hydraulic machinery; the water-turbine engine consists of a or a plurality of jet orifices, a device corresponding to the jet orifices, a or a plurality of turning wheels arranged on a main axis for the universal water-turbine engine, a tailrace arranged under the turning wheel, a speed governor, a driving device and other parts. The water-turbine engine can develop and exploit all waterpower resources and has high efficiency, large capacity, safe and reliable performance, simple and reasonable structure as well as low manufacturing cost; the application of the water-turbine engine significantly promotes the current development and exploitation of the waterpower resource, thus being capable of marking a new epoch of rapid development of the hydroelectric power industry.

Owner:黄国宏

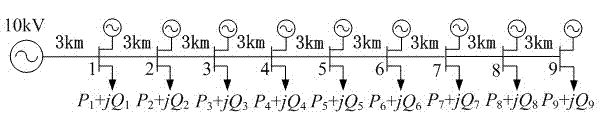

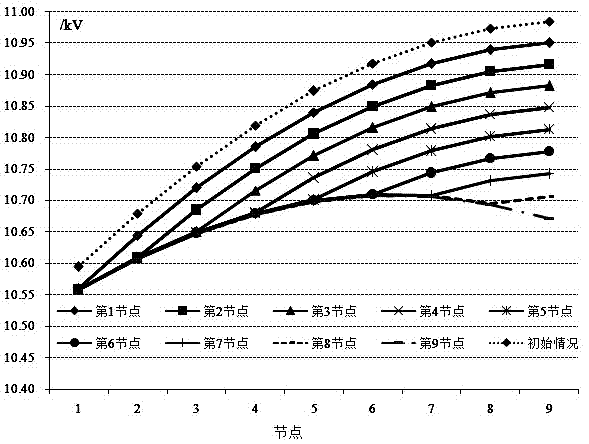

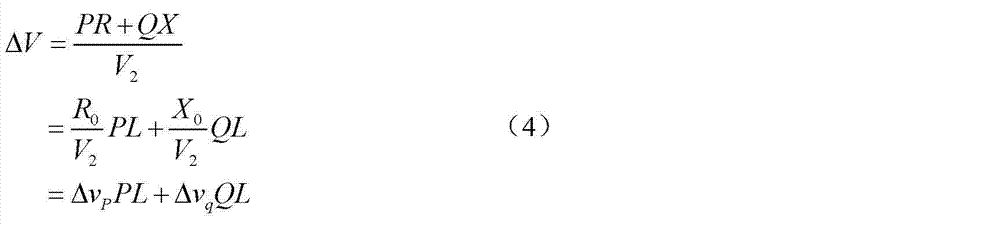

Optimal configuration of 10 kV power distribution network parallel reactor and compensation method of 10 kV power distribution network parallel reactor

InactiveCN103094913AReduce the number of settingsEnsure safetyReactive power adjustment/elimination/compensationReactive power compensationTransformerVoltage reference

The invention provides an optimal configuration of a 10 kV power distribution network parallel reactor and a compensation method of the 10 kV power distribution network parallel reactor. The optimal configuration of the 10 kV power distribution network parallel reactor and the compensation method of the 10 kV power distribution network parallel reactor are used for solving the problem that inductive reactive power optimal allocation of resources of insertion of small hydro to power distribution network and controlling switching of the reactive power compensation. The compensation method of the 10 kV power distribution network parallel reactor comprises the following steps: obtaining a voltage drop reactive decoupling formula by means of a decoupling deduction of the voltage drop formula; ensuring reactive decoupling coefficient according to the line reactance per kilometer and the line voltage reference; ensuring an optimal configured compensation point of the 10 kV parallel reactor according to the voltage drop reactive decoupling formula; ensuring and avoiding the capacity of the 10 kV parallel reactor configuration of the upper limit of the node voltage of a trunk line, and ensuring the capacity of a single unit and the number of configured groups of the 10 kV parallel reactor by a reference of a rule that a voltage regulating effect of reactive compensation equipment of a single group of a transformer substation does not exceed 2.5% of the rated voltage; and monitoring the node voltage of the trunk line including the small hydro in real time, and controlling the switching of the 10 kV parallel reactor according to the voltage drop reactive decoupling formula.

Owner:SOUTH CHINA UNIV OF TECH

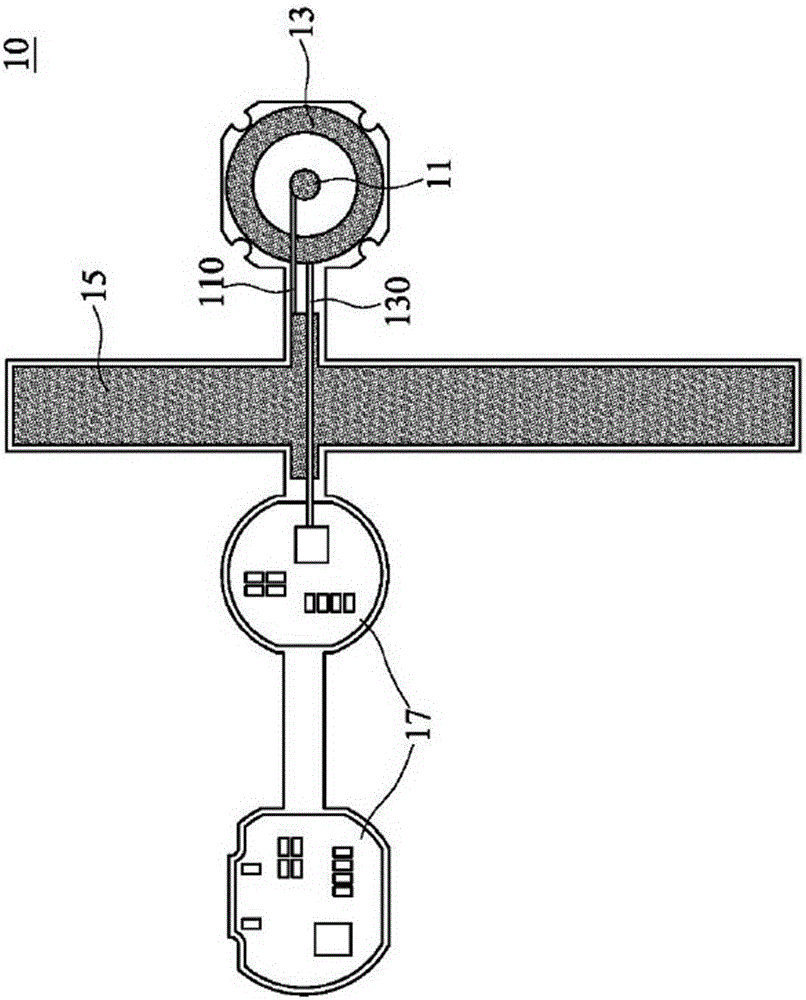

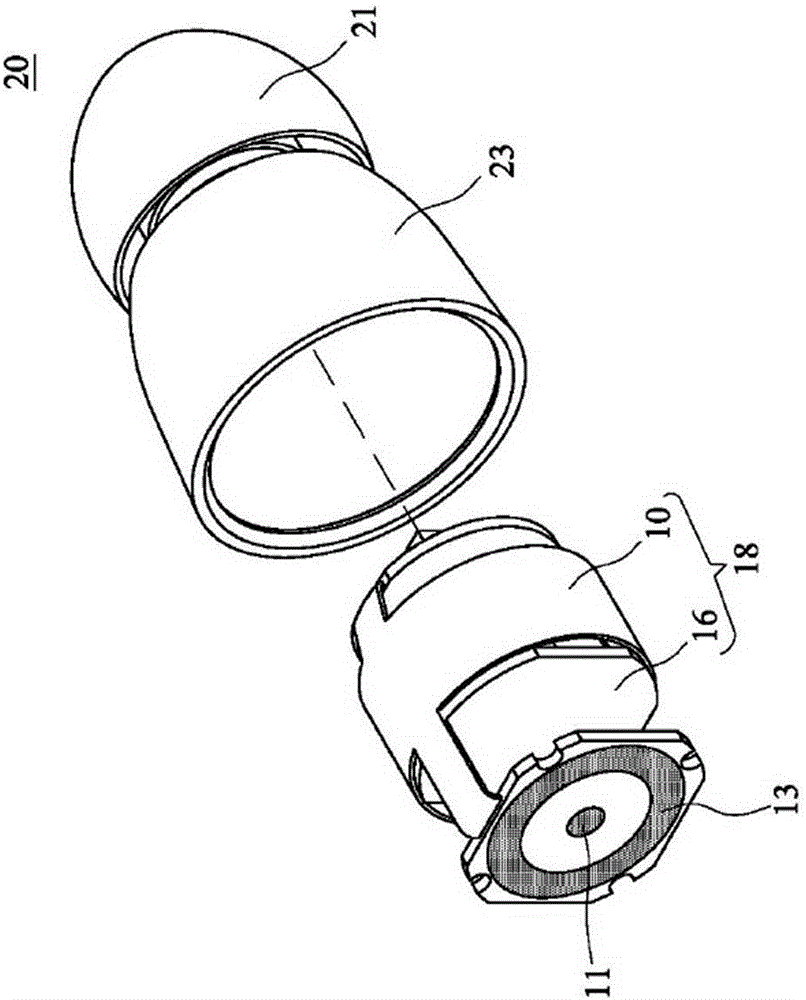

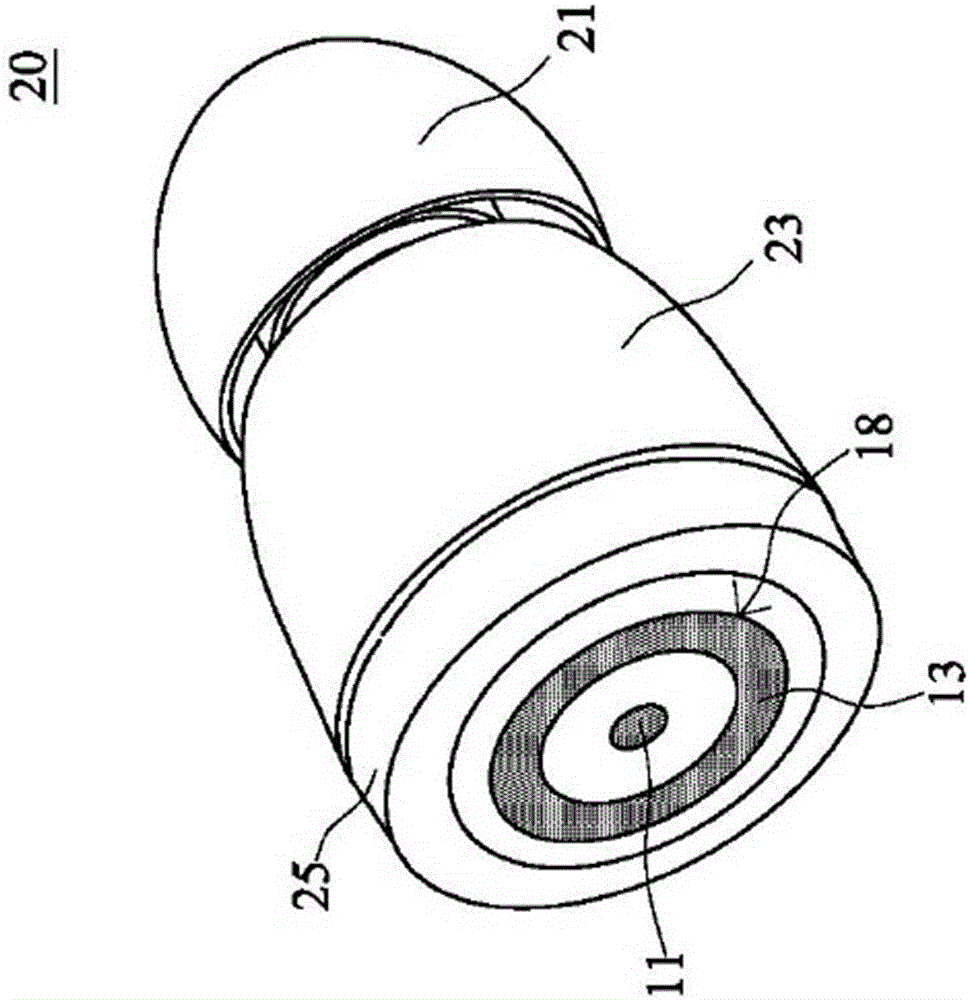

Headphone, headphone charging device and headphone charging circuit

InactiveCN106131725ASmall sizeReduce the number of settingsBatteries circuit arrangementsElectric powerCharge currentHeadphones

The present invention relates to a charging device for an earphone. The earphone is a wireless in-ear type earphone which comprises an ear plug part and a body part.A first terminal and a second terminal surrounding theperiphery of the first terminal are arranged on thecenter of the bottom end of the body part. The charging device comprising a charging seat provided with at least one seat body, the seat part including a plurality of power supply pins; when the body part of the earphone is placed in the seat part of the charging base, the first terminal and the second terminal are in directionless electric contact with the power supply pins. The charging device then outputs charging current to the earphone via the power supply pins.The earphone receives the charging current via the first terminal and the second terminal so as to charge an internal charging battery.

Owner:MAVIN TECH INC

Display panel and display device

ActiveCN107863359AImprove the display effectReduce the number of settingsSolid-state devicesSemiconductor devicesLine widthDisplay device

The embodiment of the invention provides a display panel and a display device. The display panel comprises a display area, a non-display area, a power source signal line and multiple positive pole blocks, wherein the display area is a rectangle provided with at least a fillet; the power source signal line is arranged along a row direction, stretches along a column direction, is electrically connected with a pixel unit on a corresponding column, and comprises the first part of alignment line in the display area and the second part of alignment line in the non-display area, and the first part ofalignment line and the source drain metal layer of a thin film transistor in the pixel unit are arranged on the same layer; the positive pole blocks are arranged on one side, which is far away from asubstrate base plate, of the thin film transistor; the second part of alignment line of a power source signal line in at least a fillet area and the positive pole block are arranged on the same layer, by the design, the line width of the second part of alignment line corresponding to the fillet area becomes large, and then the load gap of the power source signal line corresponding to the fillet area and the power source signal line corresponding to a non-fillet area is reduced, so that the display effect of the display panel is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

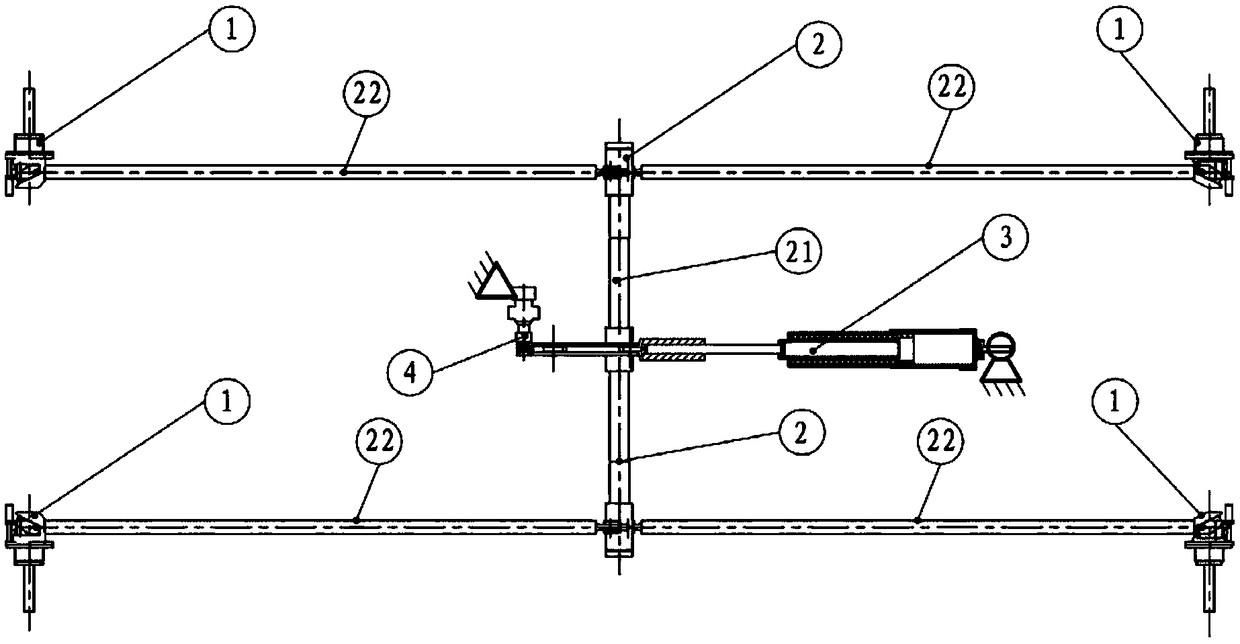

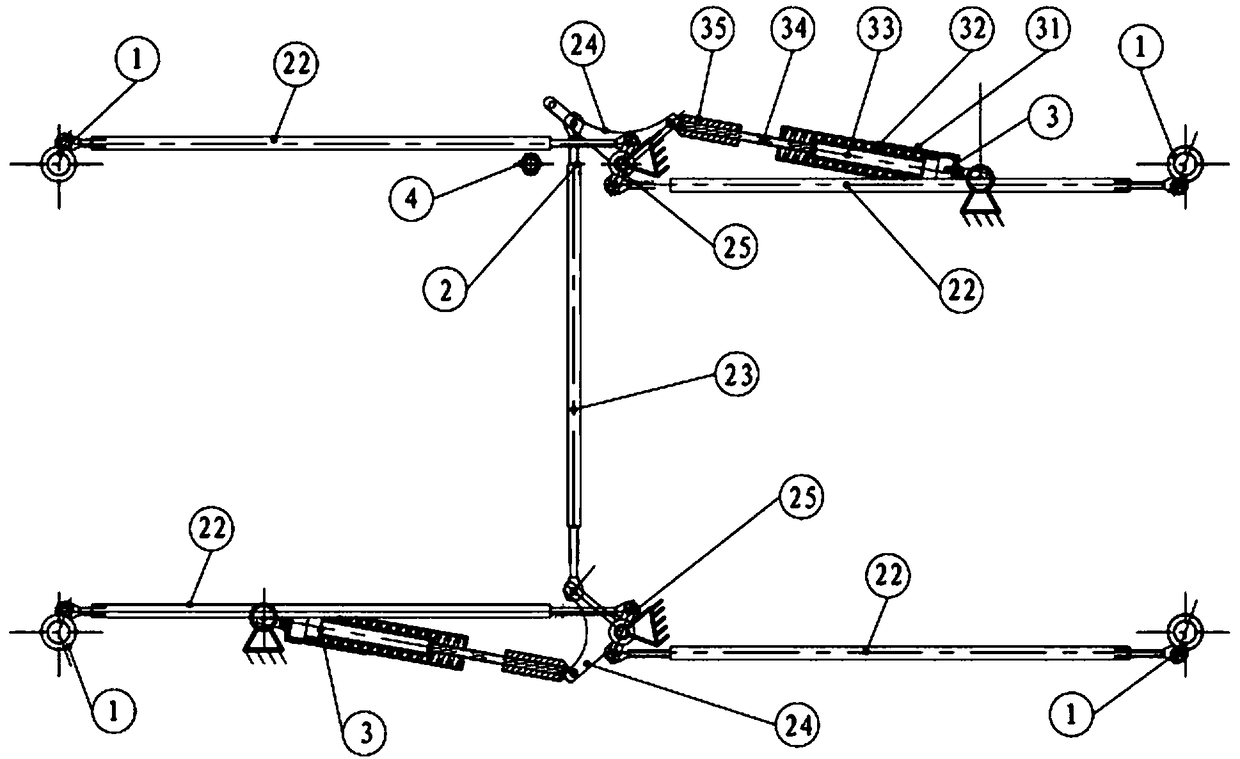

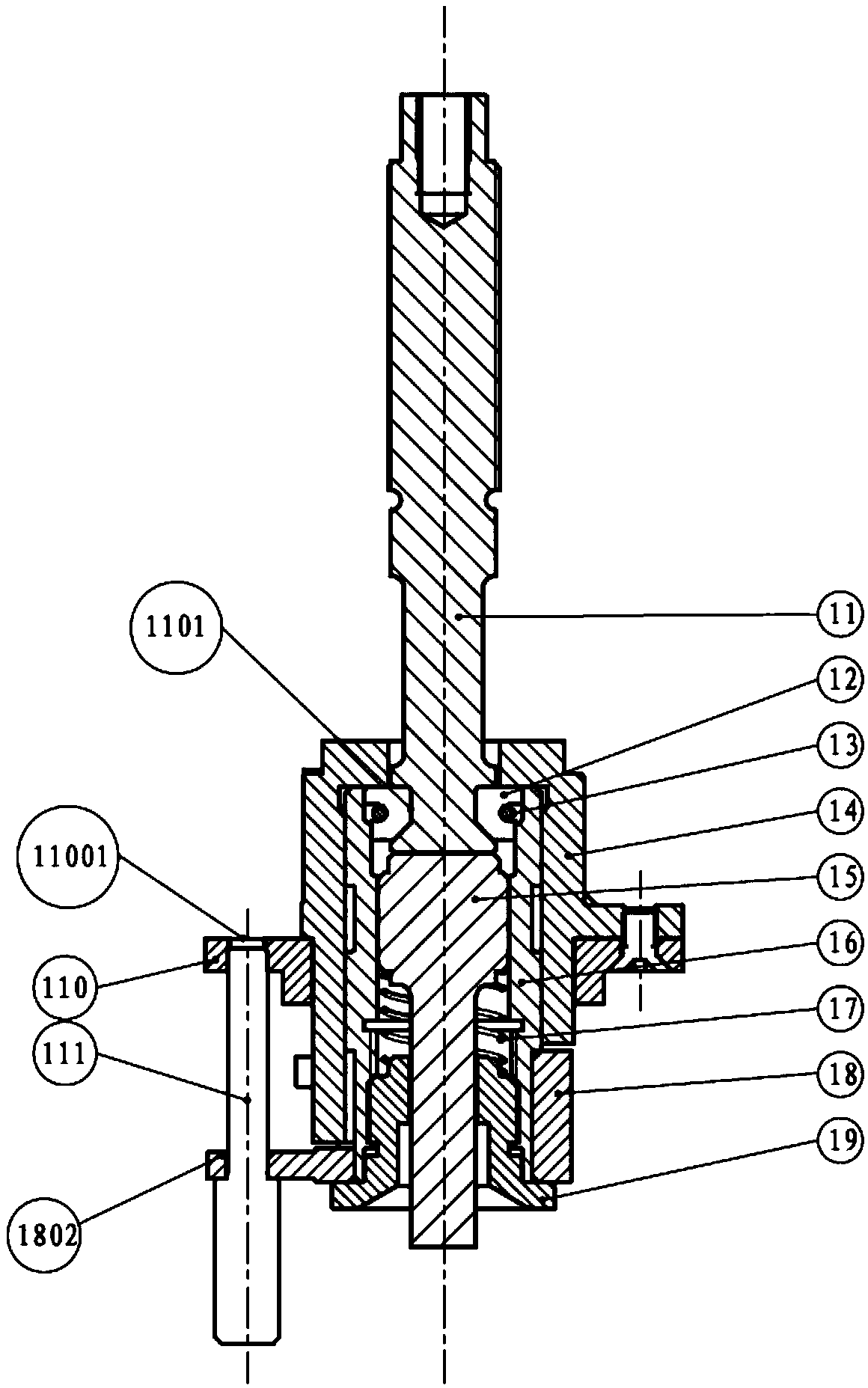

Mechanism-type separation nut and joint unlocking mechanism of satellite and launch vehicle composed of mechanism-type separation nut

ActiveCN109229430AUnlocking shock is smallUnlock power is smallCosmonautic vehiclesCosmonautic component separationMulti linkLaunch vehicle

The invention discloses a mechanism-type separation nut and a joint unlocking mechanism of a satellite and a launch vehicle composed of the mechanism-type separation nut. The joint unlocking mechanismof the satellite and the launch vehicle further comprises a multi-link transmission mechanism, Spring power and lock release, A mechanism-type separation nut is use for connecting satellite, and thatunlocking power source of the plurality of mechanism-type separation nut is provided by a remotely positioned spring power device, and the power is remotely transmitted by a multi-link transmission mechanism, and the locking release device locks the satellite-arrow connection unlocking mechanism before unlocking, and reliably releases the locking power at the unlocking time. The satellite-arrow connection unlocking mechanism of the invention has the functions of connection and unlocking, simultaneously has the characteristics of low impact, multi-point synchronous unlocking, main device can be detected and non-destructively and quickly installed and reset, small power supply demand and high reliability.

Owner:SHANGHAI AEROSPACE SYST ENG INST

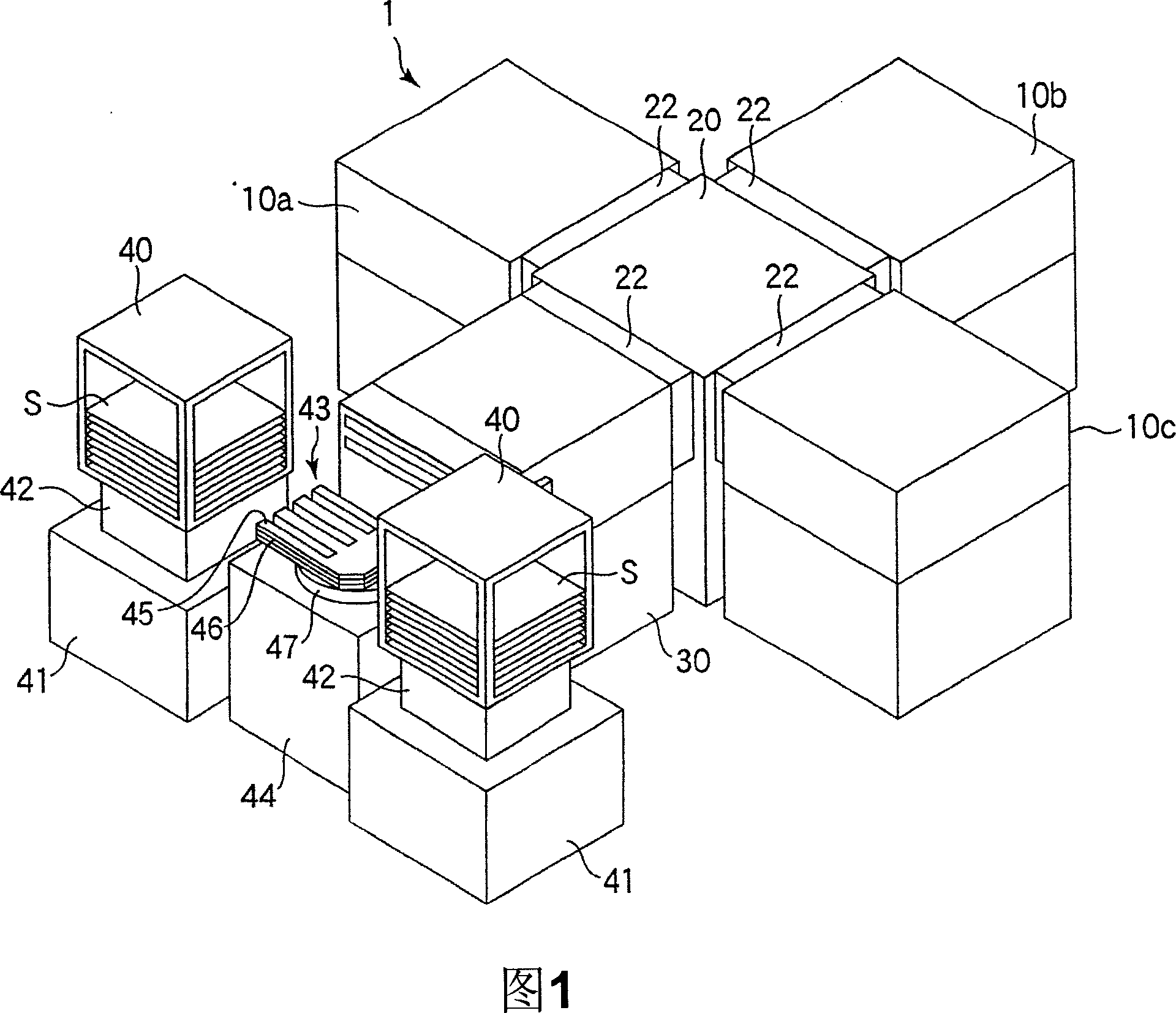

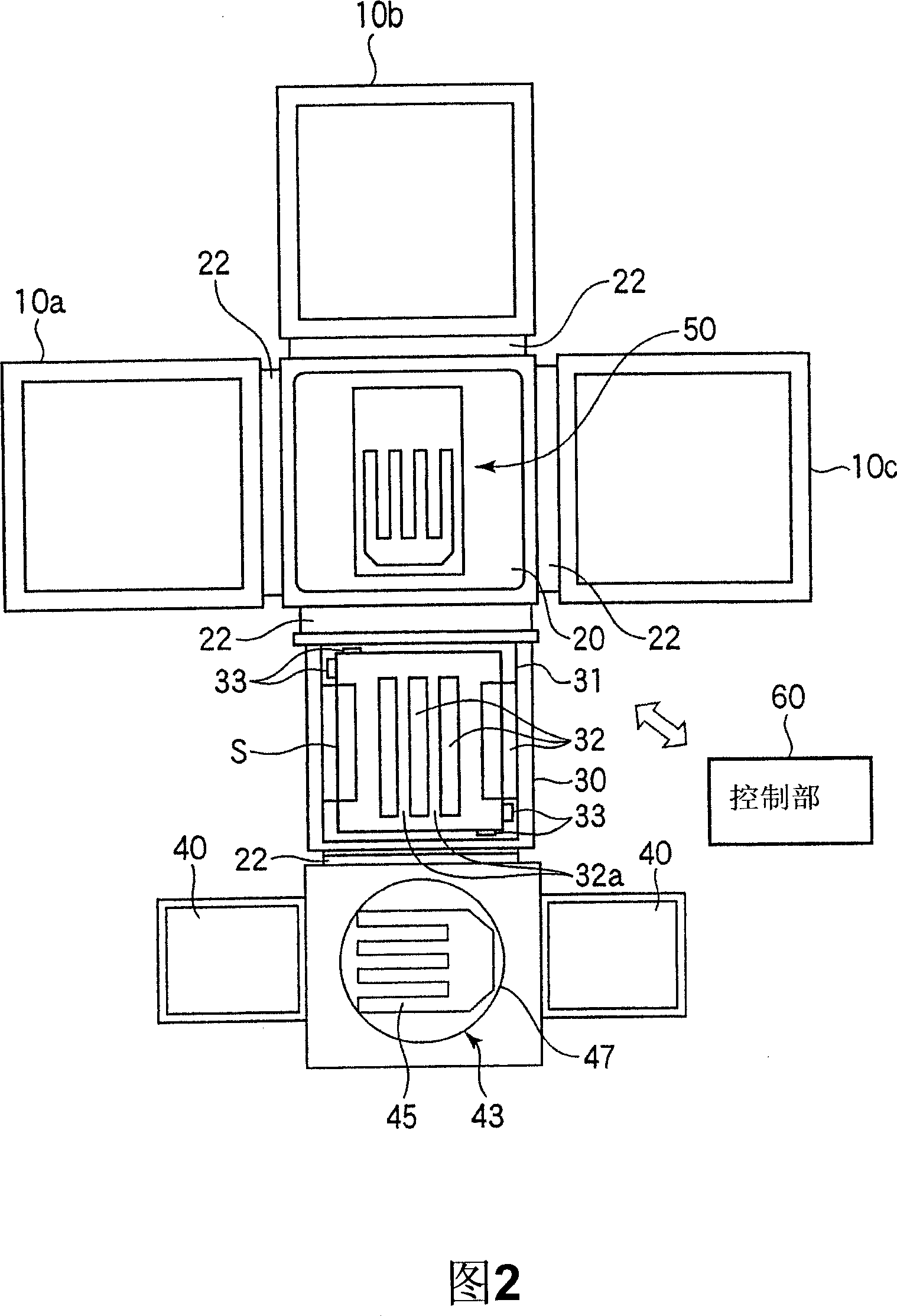

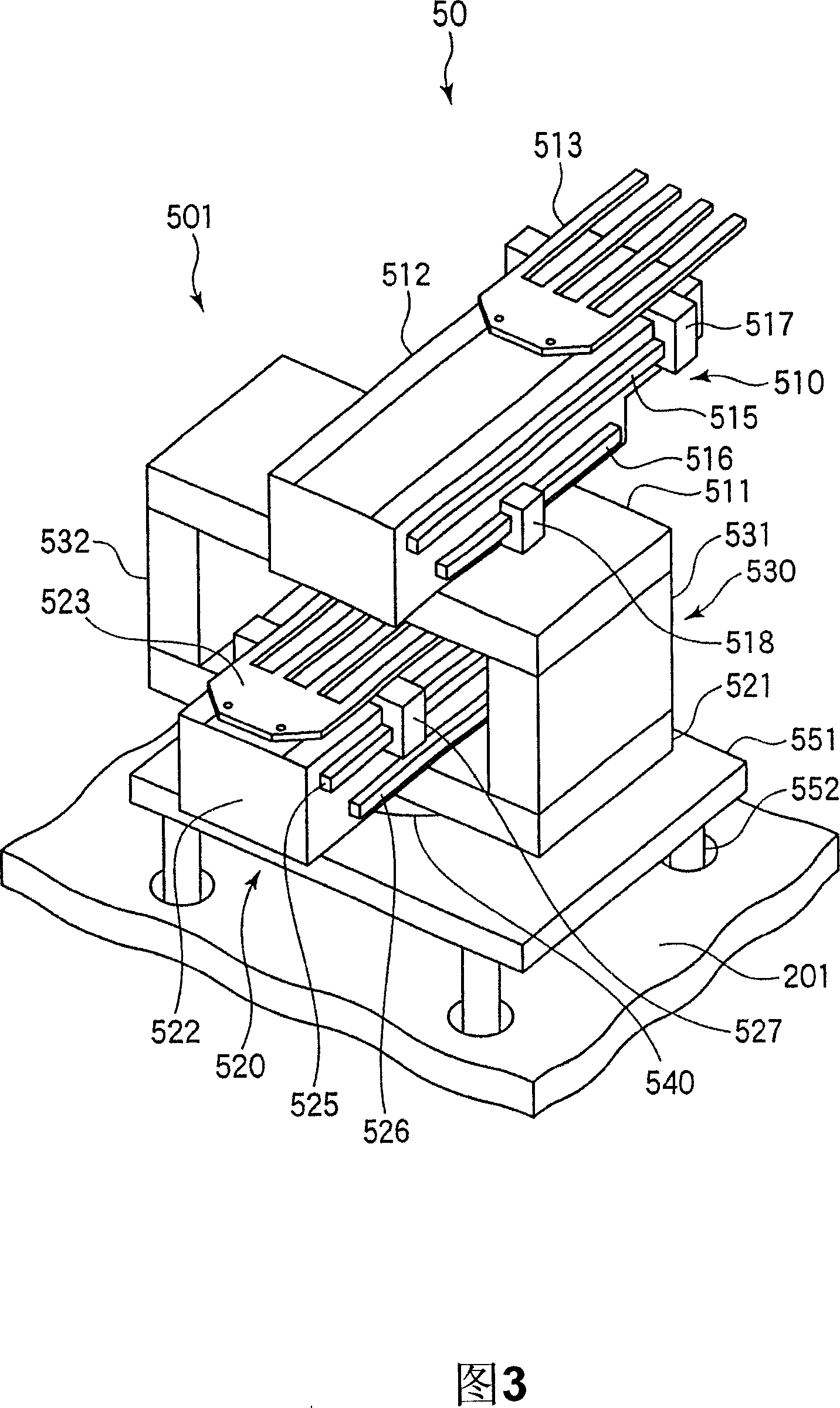

Conveying chamber, substrate processing device, and substrate disorder detection method

InactiveCN1929108ADetect position shiftDetect breakageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingReflectivityElectrical and Electronics engineering

The invention provides a substrate processing apparatus in which such a fault as misregistration or chipping of a large FPD substrate in a conveyance chamber can be detected certainly, and to provide a method for detecting the fault of the substrate. When a substrate (S) is mounted on the slide pick (513) of a conveying device and carried into a process chamber from the interior of a conveyance chamber (20) through a gate opening (22d), the substrate (S) is irradiated with light beams at the parts in the vicinity of the opposite ends shown by dashed lines (A, B) by means of a pair of sensors (70, 70) arranged on the right and left, and misregistration or defect of the substrate S is detected by its reflectivity or transmissivity.

Owner:TOKYO ELECTRON LTD

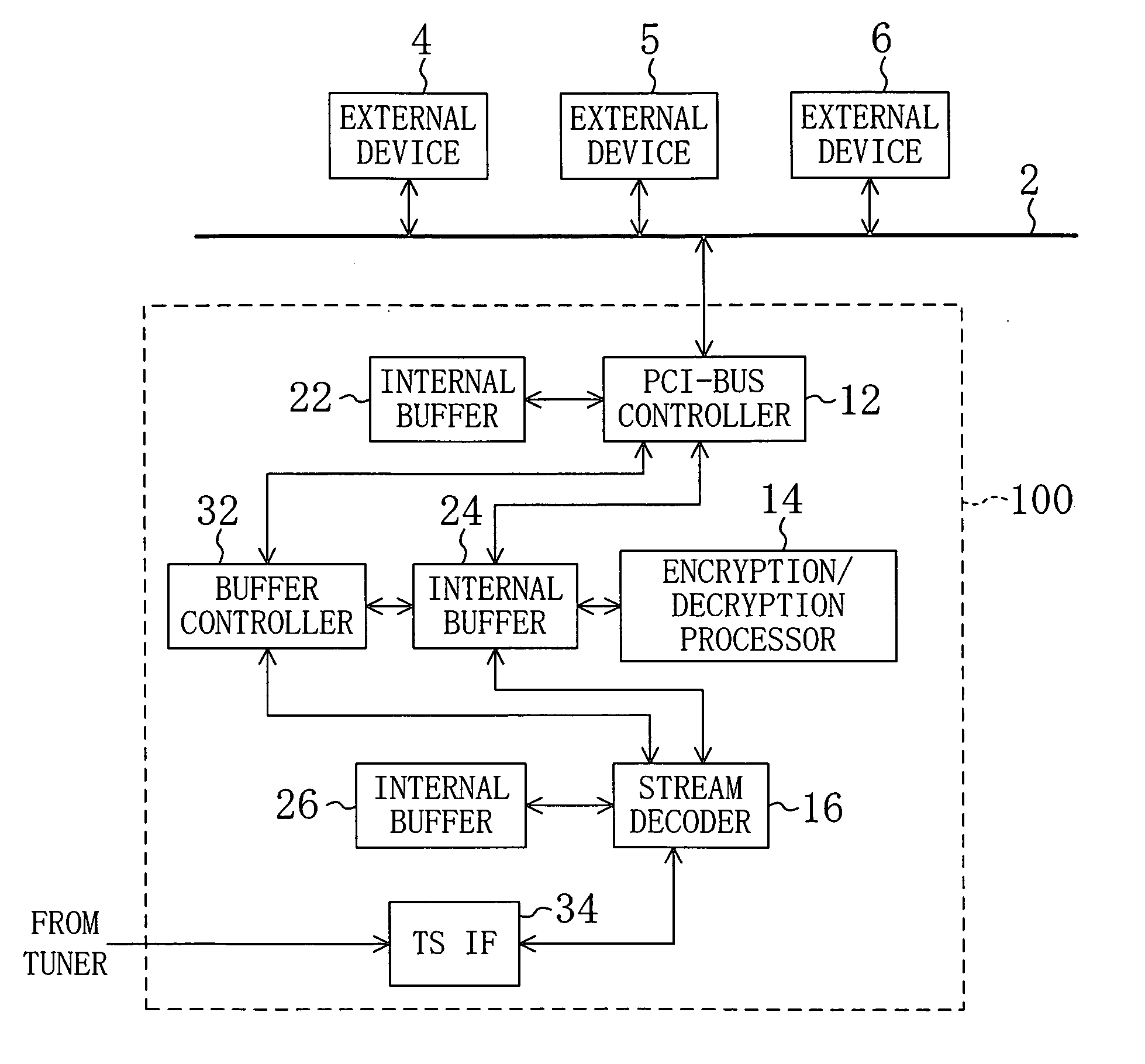

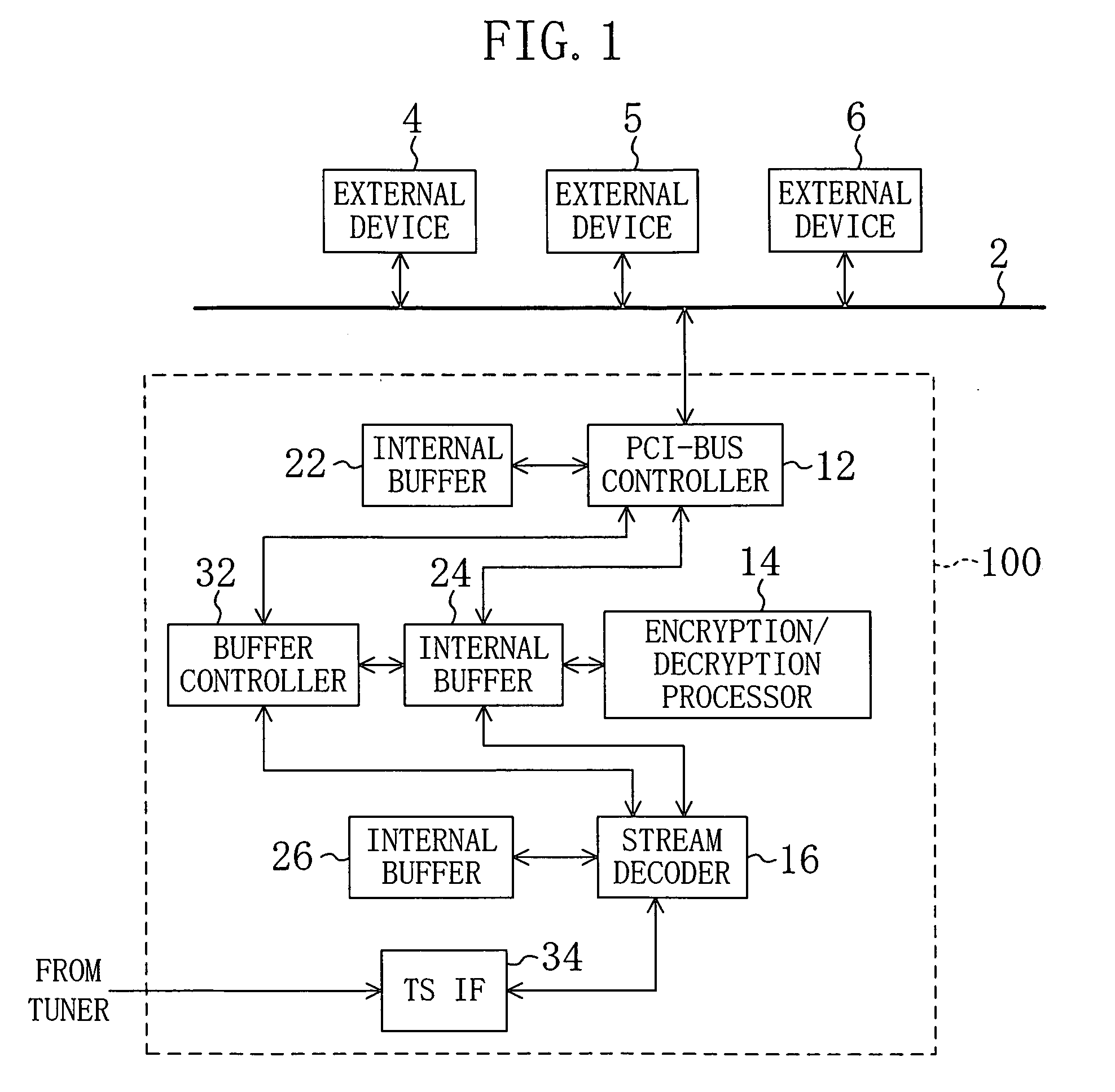

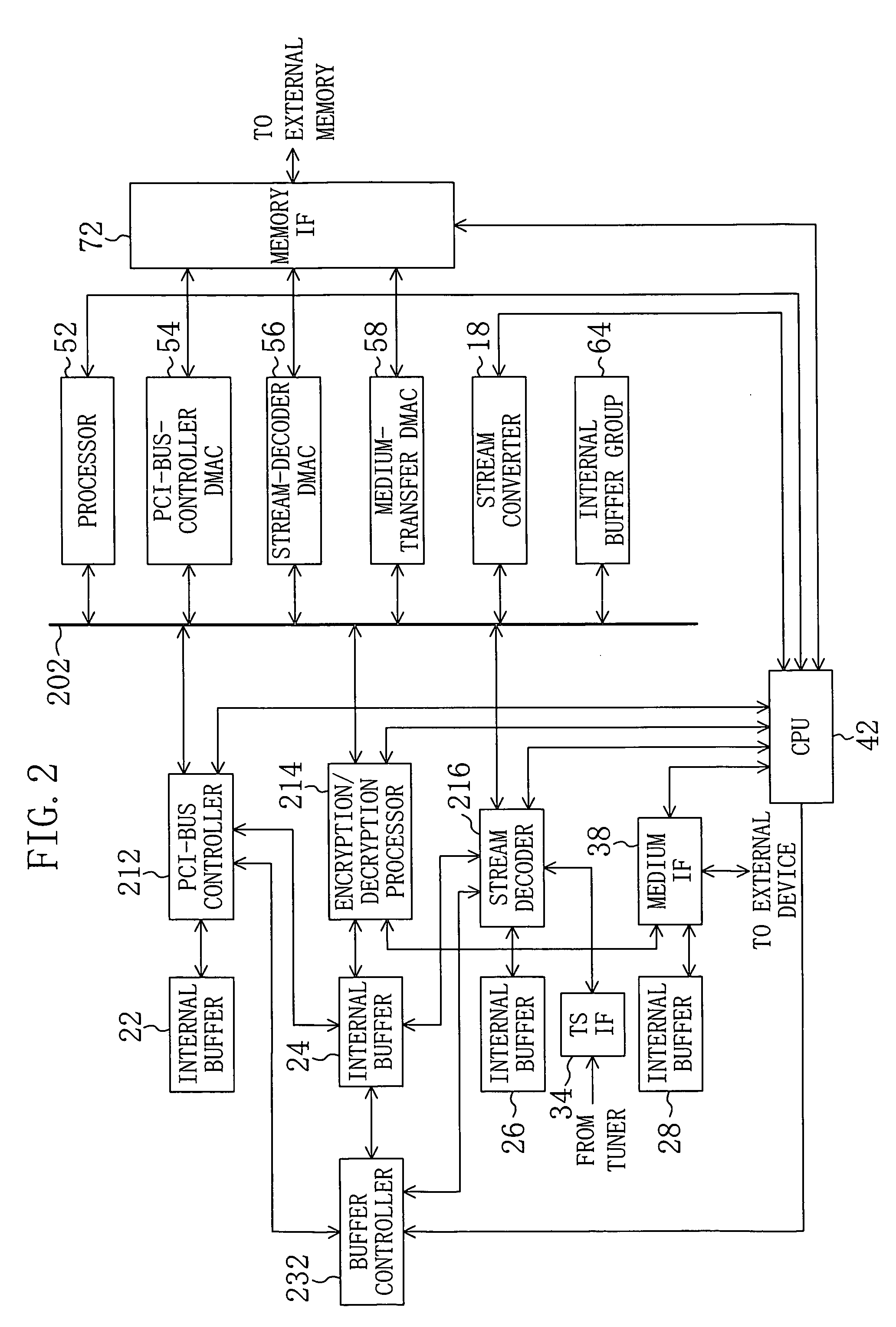

Data processing system and method

InactiveUS20060227967A1Increase speedAmount of data transferTelevision system detailsSynchronising transmission/receiving encryption devicesData processing systemEncryption decryption

A data processing system includes: a stream decoder for decrypting a stream encrypted by broadcast encryption to obtain a first decrypted stream; an internal buffer for storing the first decrypted stream; and an encryption / decryption processor. The encryption / decryption processor decrypts a stream encrypted by content encryption to obtain a second decrypted stream and storing the second decrypted stream in the internal buffer, and reads one of the first and second decrypted streams from the internal buffer and encrypts the read-out stream by content encryption.

Owner:SOCIONEXT INC

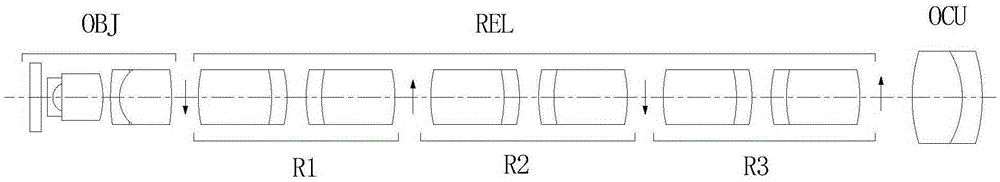

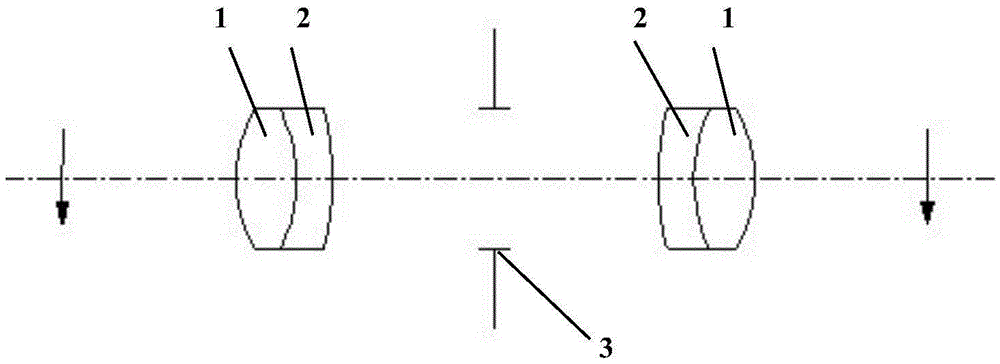

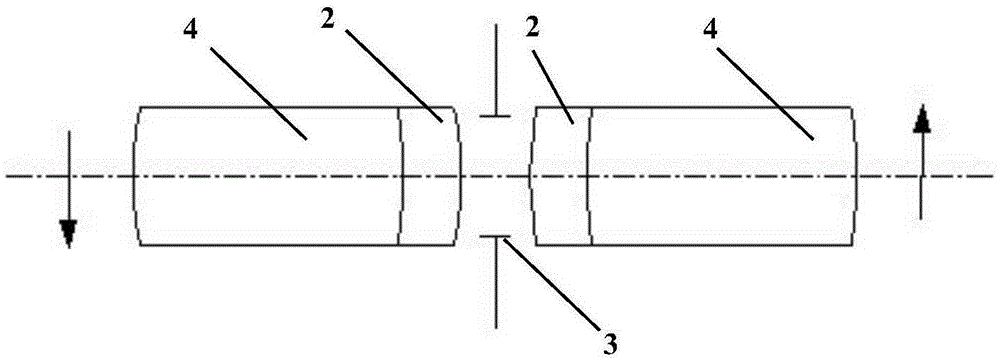

Stereoscopic endoscope electronic imaging optical system

The invention discloses a stereoscopic endoscope electronic imaging optical system. Hopkins rod lenses, more than one of image transferring doublet lenses, rhombic prisms, imaging doublet lenses, single lenses and protective windows are sequentially arranged behind an objective lens and a 1:1 image transferring system composed of three groups of rod lenses which are in structural symmetry along a light ray transmitting direction; the stereoscopic endoscope electronic imaging optical system directly magnifies an image of the image transferring system to a CCD or CMOS pixel surface, and the axial magnification ranges from 1.1 to 2; the Hopkins rod lenses are used for increasing the working length of the system, and effectively reduce the number of lenses; the rhombic prisms are used for increasing the distance between the optical axes of lens groups behind two optical channels of a stereoscopic endoscope, and satisfy spatial layout requirements of two CCD or CMOS devices; and the imaging doublet lenses and the single lenses are used for magnifying images, and participate in system distortion correction so as to reduce the distortion of the system.

Owner:TIANJIN UNIV

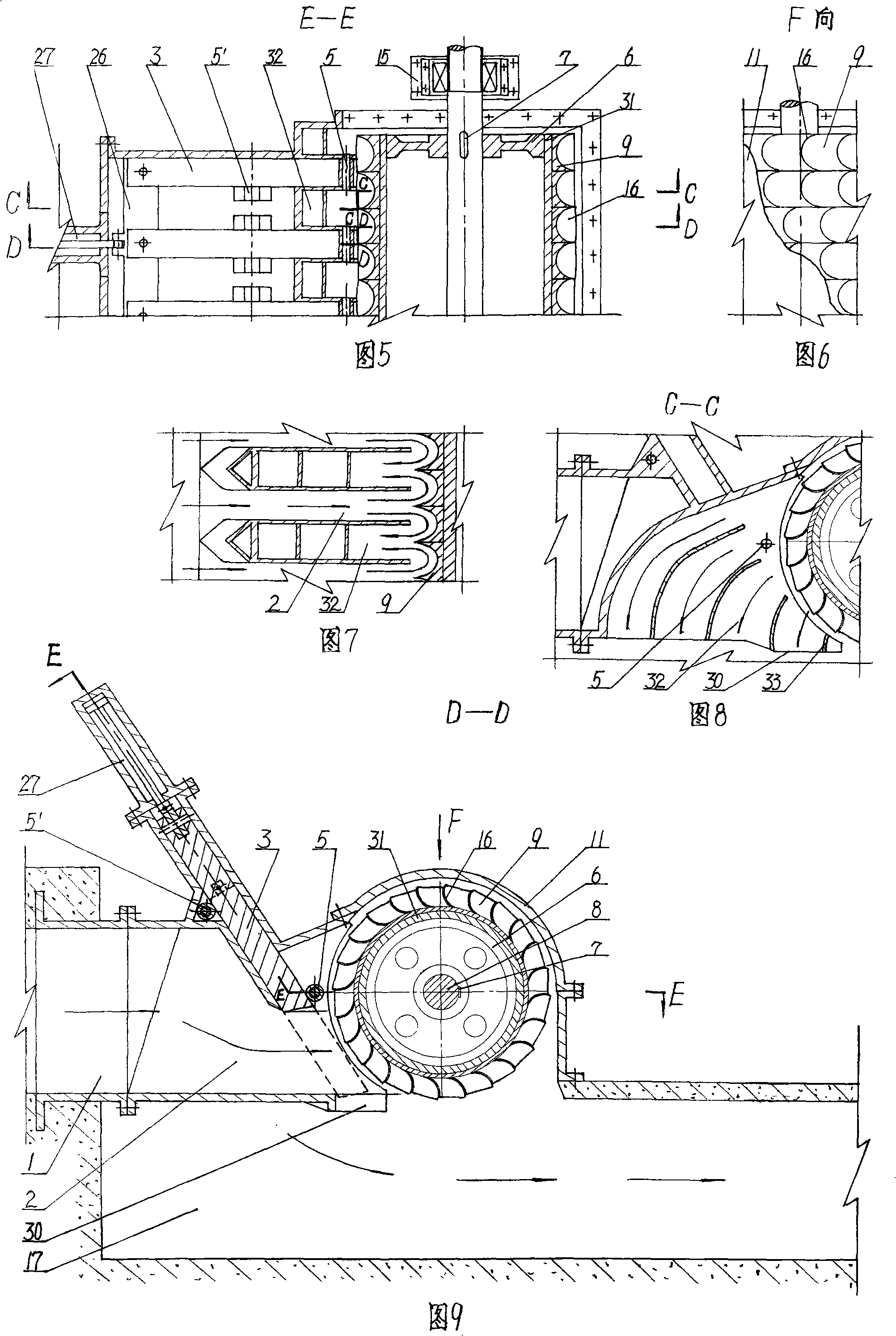

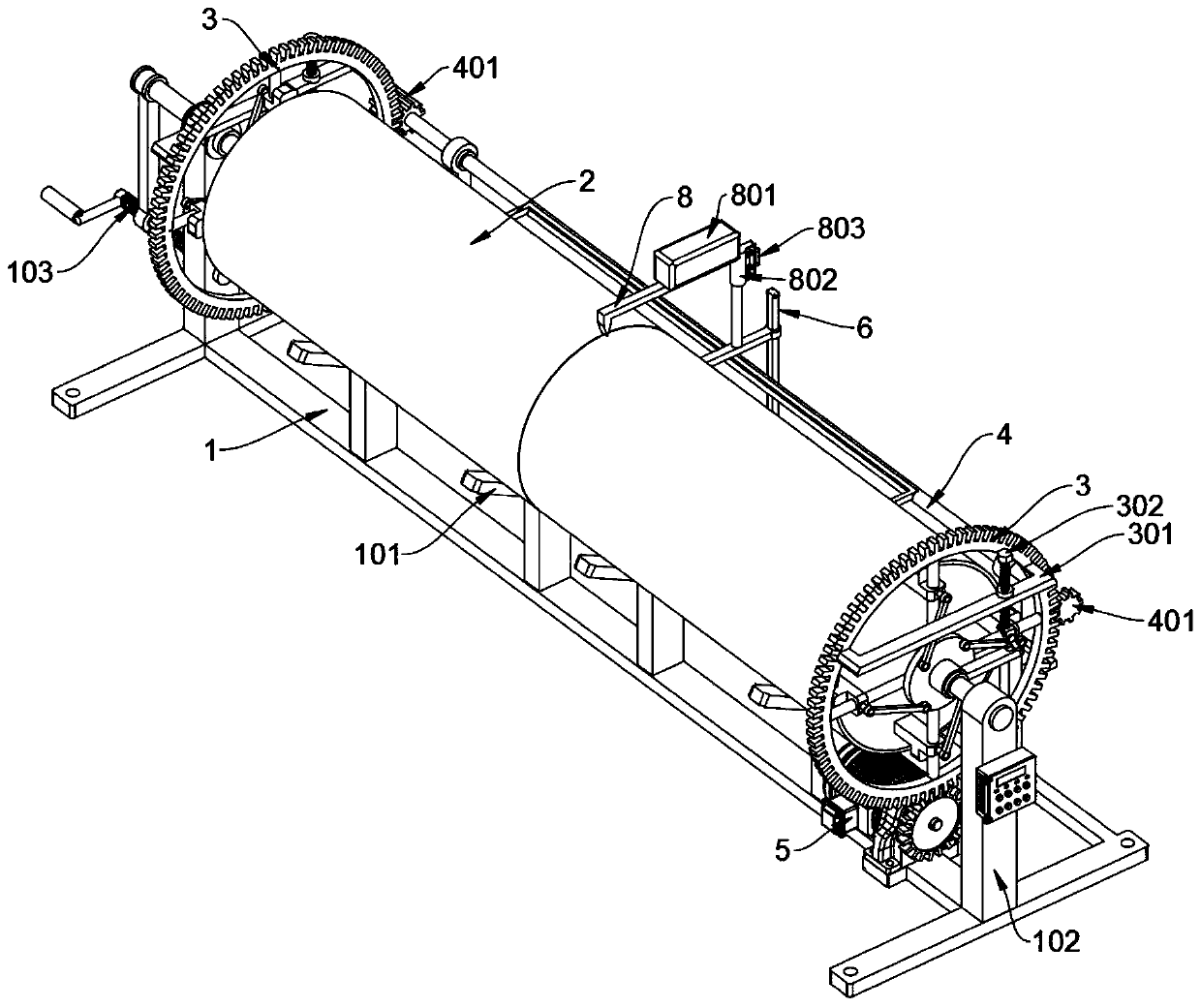

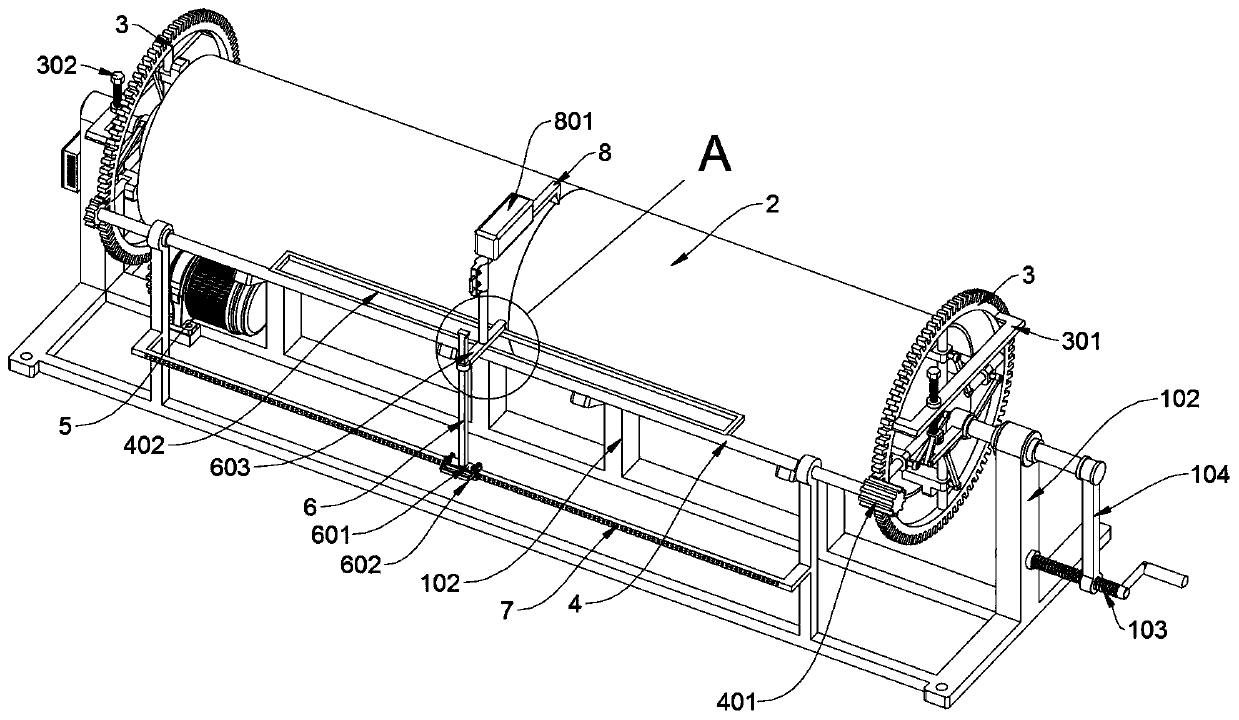

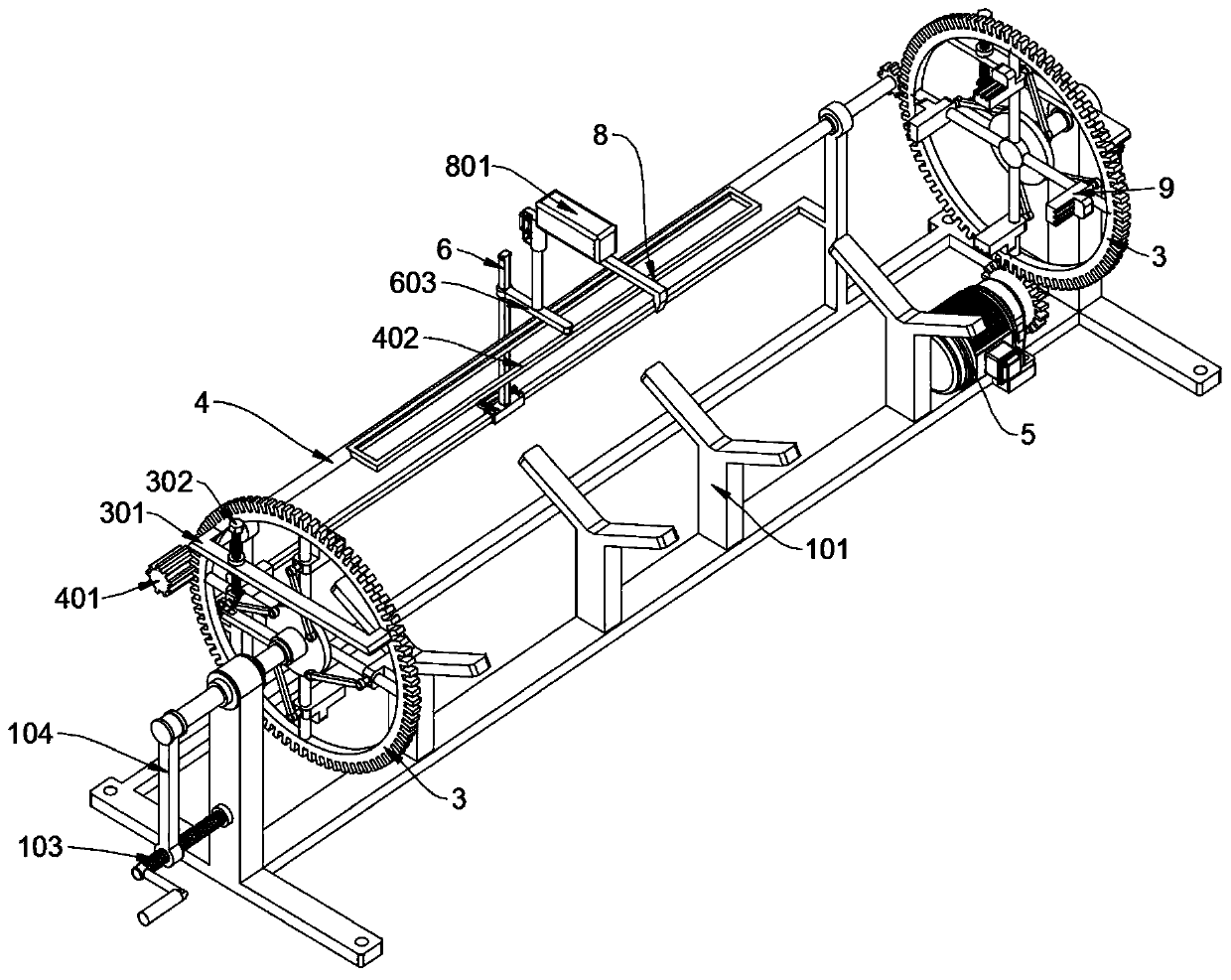

Multi-angle overturning welding device for long-distance large-diameter jacking pipe

InactiveCN111360479AEasy to assemble and disassembleAvoid obstaclesWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Butt welding

The invention discloses a multi-angle overturning welding device for a long-distance large-diameter jacking pipe, relates to the technical field of jacking pipe welding equipment, and solves the problems that according to an existing welding device, a welder needs to manually knock a welding slag coating after welding, the efficiency is low, manpower is wasted, and hand fatigue of the welder is likely to be caused by frequent knocking actions. The multi-angle overturning welding device for the long-distance large-diameter jacking pipe comprises a base and a positioning square rod, wherein thebase comprises a V-shaped supporting plate, vertical supporting rods, a lead screw and a connecting top plate, the base is integrally of an I-shaped structure, and the two vertical supporting rods aresymmetrically welded to the middles of the front side and the rear side of the base; and two gear rings are rotationally inserted and supported at the top ends of the two vertical supporting rods, and the front end side gear ring is movably mounted. According to the multi-angle overturning welding device, a knocking rod can slide left and right along a rail square rod through a square sliding sleeve to be adjusted and is inserted and positioned through the rail square rod, and the device is suitable for knocking welding slag on butt welds at different positions, is flexible to use and wide inapplication.

Owner:王伟

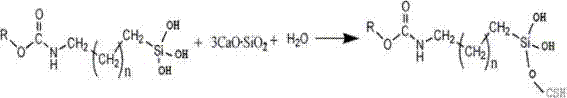

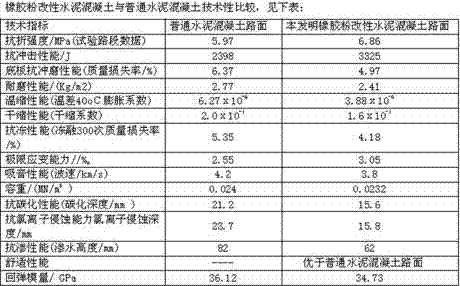

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

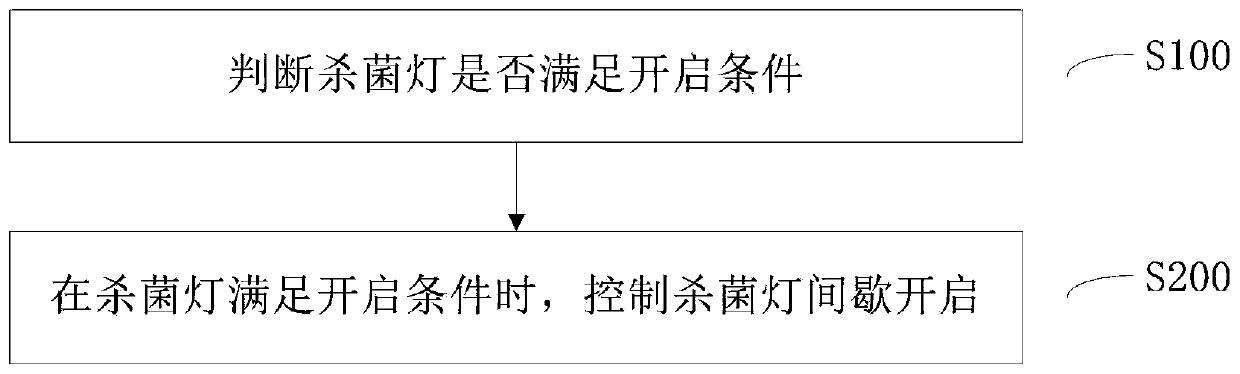

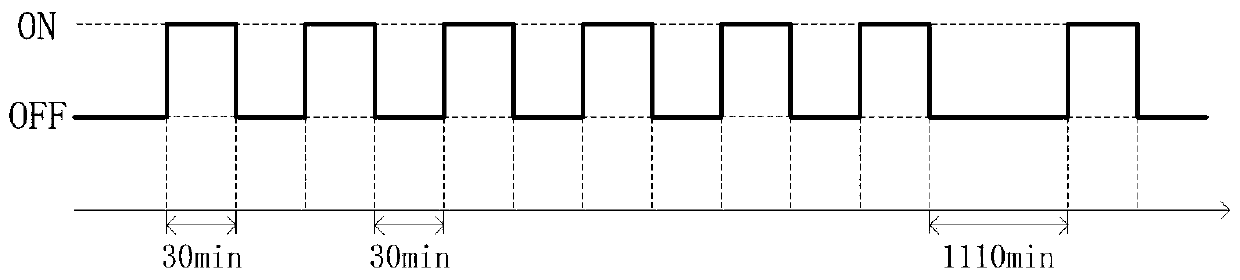

Control method of sterilization air conditioner

PendingCN111426027ALife maximizationImprove accuracyMechanical apparatusSpace heating and ventilation safety systemsMedicineControl manner

The invention relates to the technical field of sterilization air conditioners, and particularly relates to a control method of a sterilization air conditioner. The control method aims at solving theproblem that in the prior art, the cost is high due to the technical scheme that a lamp body is replaced with a light-emitting body with the longer service life or a standby light-emitting body is arranged. In order to achieve the purpose, the control method comprises the steps that whether the sterilization air conditioner meets the starting condition or not is judged; when the starting conditionis met, a sterilization lamp is controlled to be started intermittently; and the starting condition comprises the steps that the automatic sterilization function is in a starting state, the particleconcentration of the operation environment is larger than a high-order threshold value, and a draught fan is in an operation state. According to the control manner, on the premise that the air conditioner hardware cost is not increased, the balance between the sterilization effect and the service life of the lamp body is achieved, and the maximum service life of the lamp body with the sterilization effect is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

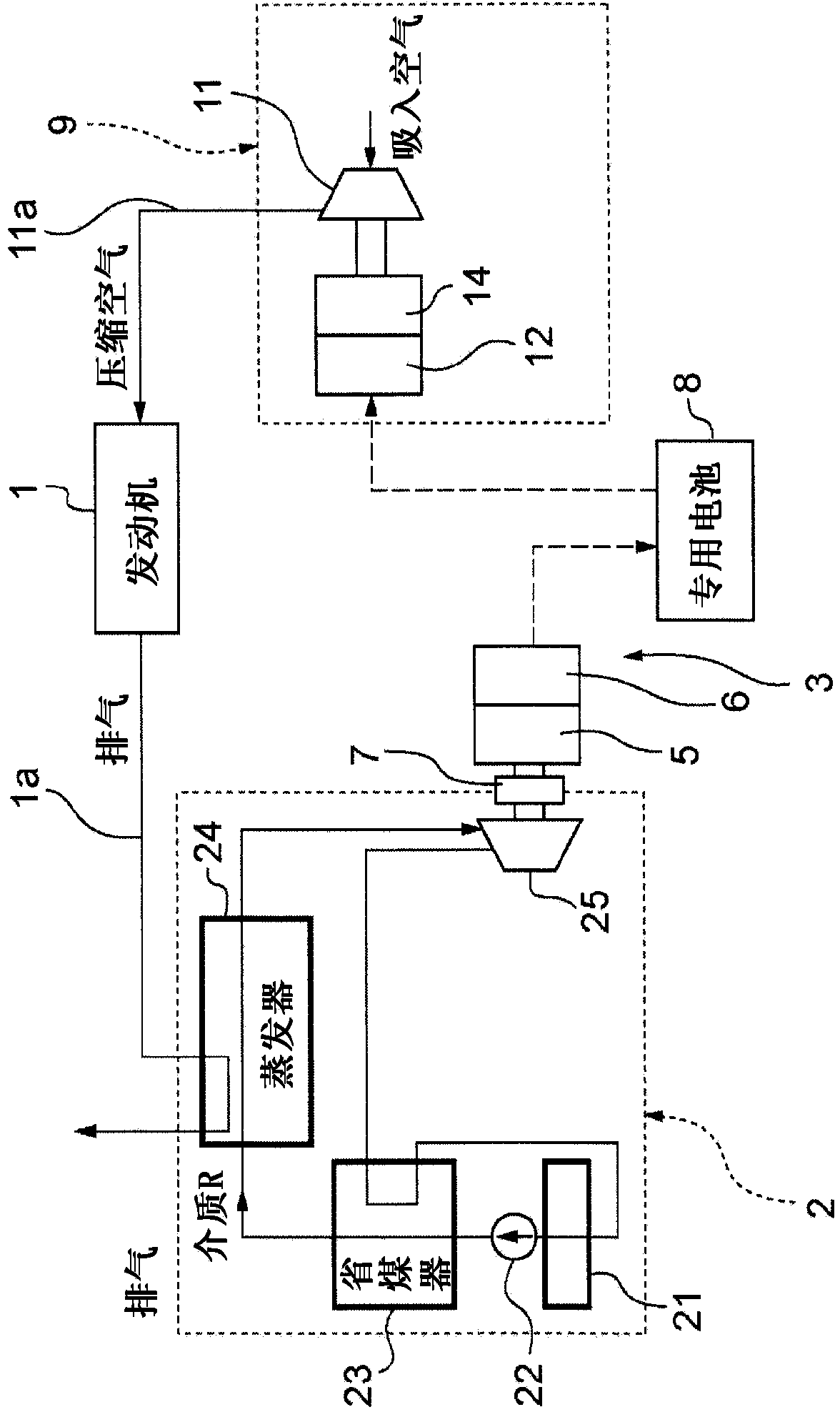

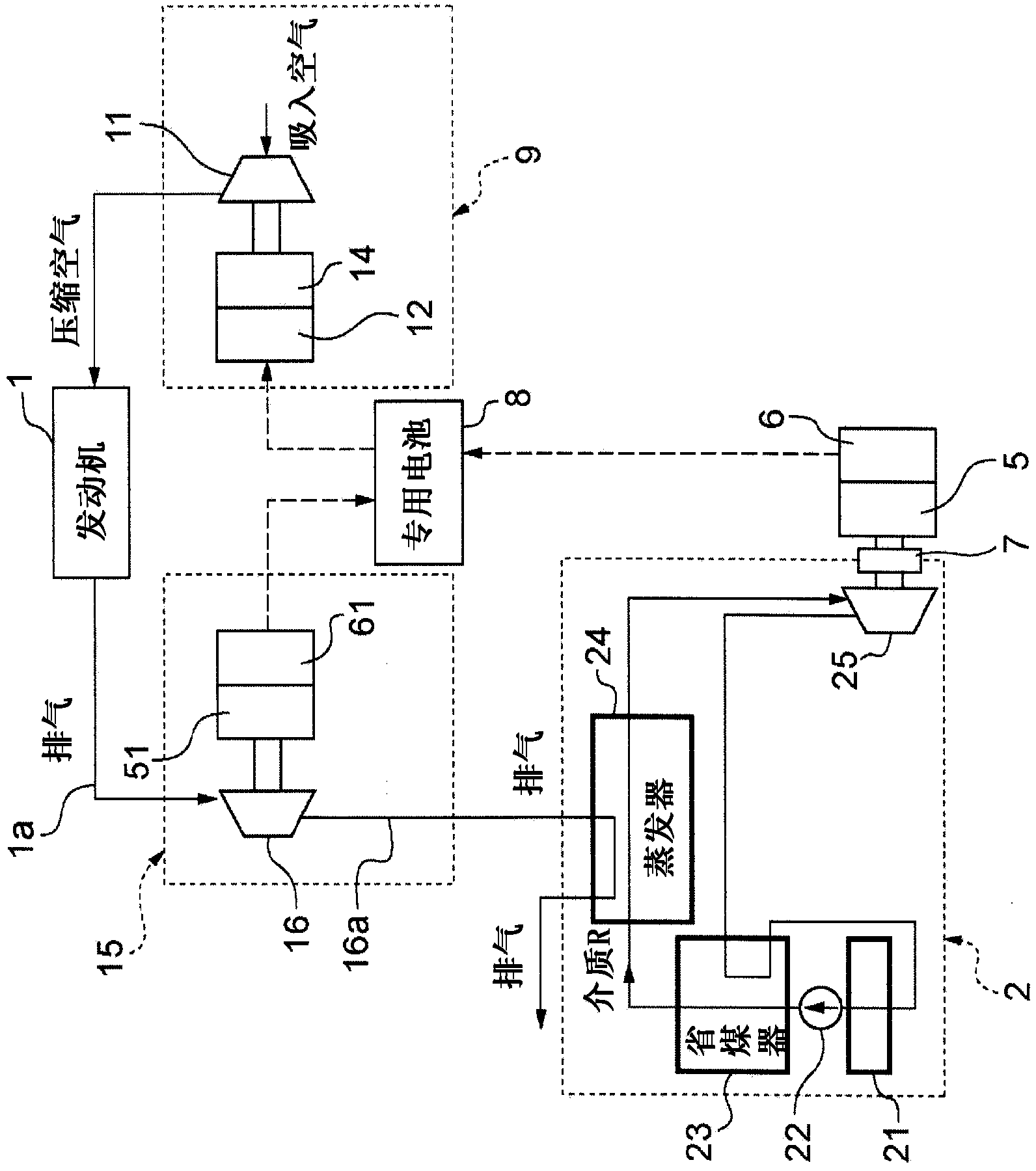

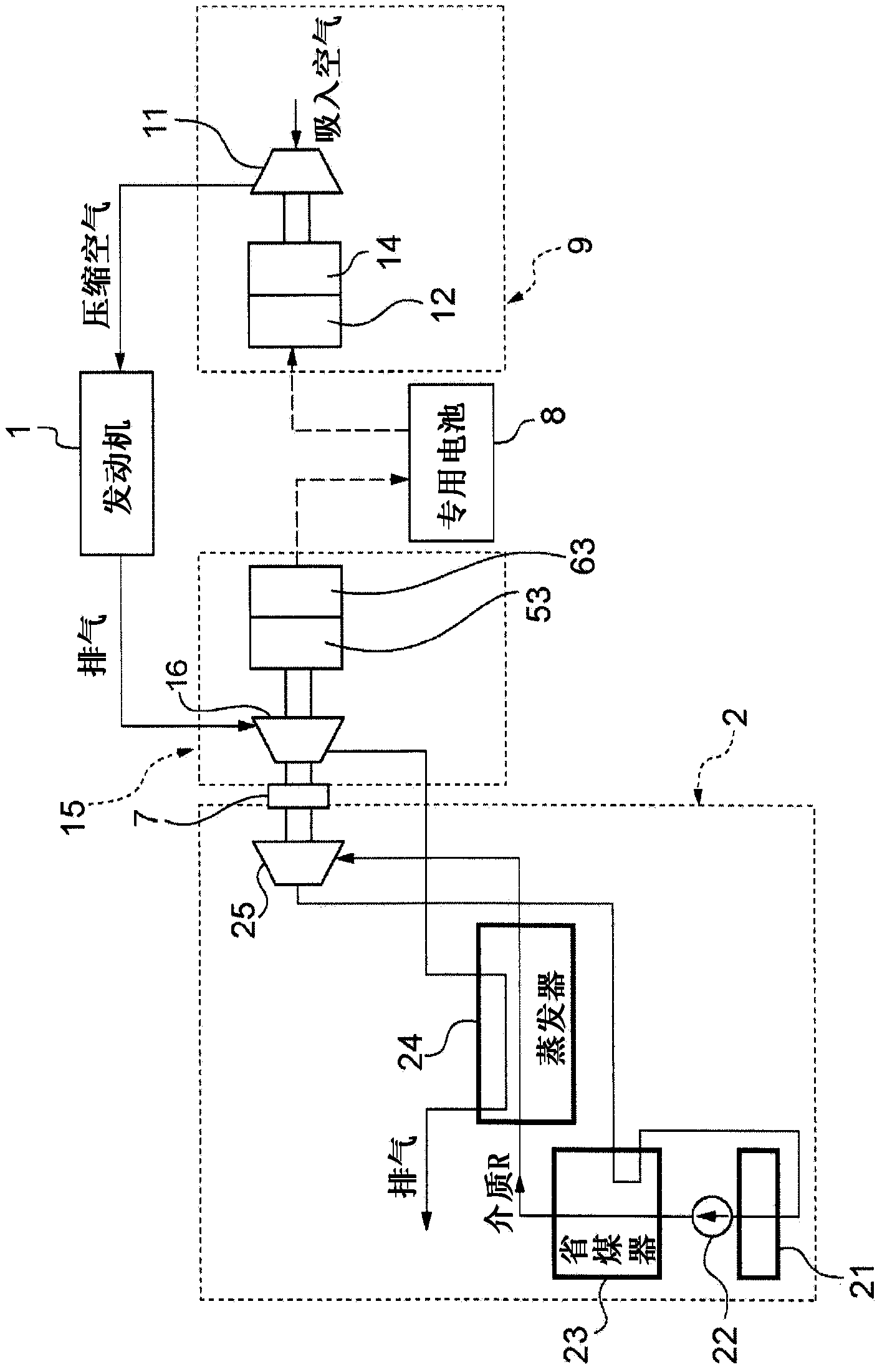

Electric supercharger using waste heat from internal combustion engine and power supply method thereof

InactiveCN103987937AExhaust pressure riseEquivalent fuel efficiencyInternal combustion piston enginesExhaust apparatusExternal combustion engineFuel efficiency

Waste heat from an engine is effectively converted into power and the power is stored in a dedicated power storage device to freely output boost pressure from an electric air compressor so as to improve fuel efficiency, drivability, and exhaust gas purification. The present invention comprises: a steam cycle device (2) which rotates an expander (25) by expanding steam generated by waste heat from an engine (1); a first power generator (5) which is connected to the expander (25) and generates power using torque from the expander (25); a dedicated battery (8) which stores the power that is generated by the first power generator (5); and an electric supercharger (9) which drives a first compressor (11) using a motor (14) driven by the power in the dedicated battery(8) and generates compressed air.

Owner:MITSUBISHI HEAVY IND LTD

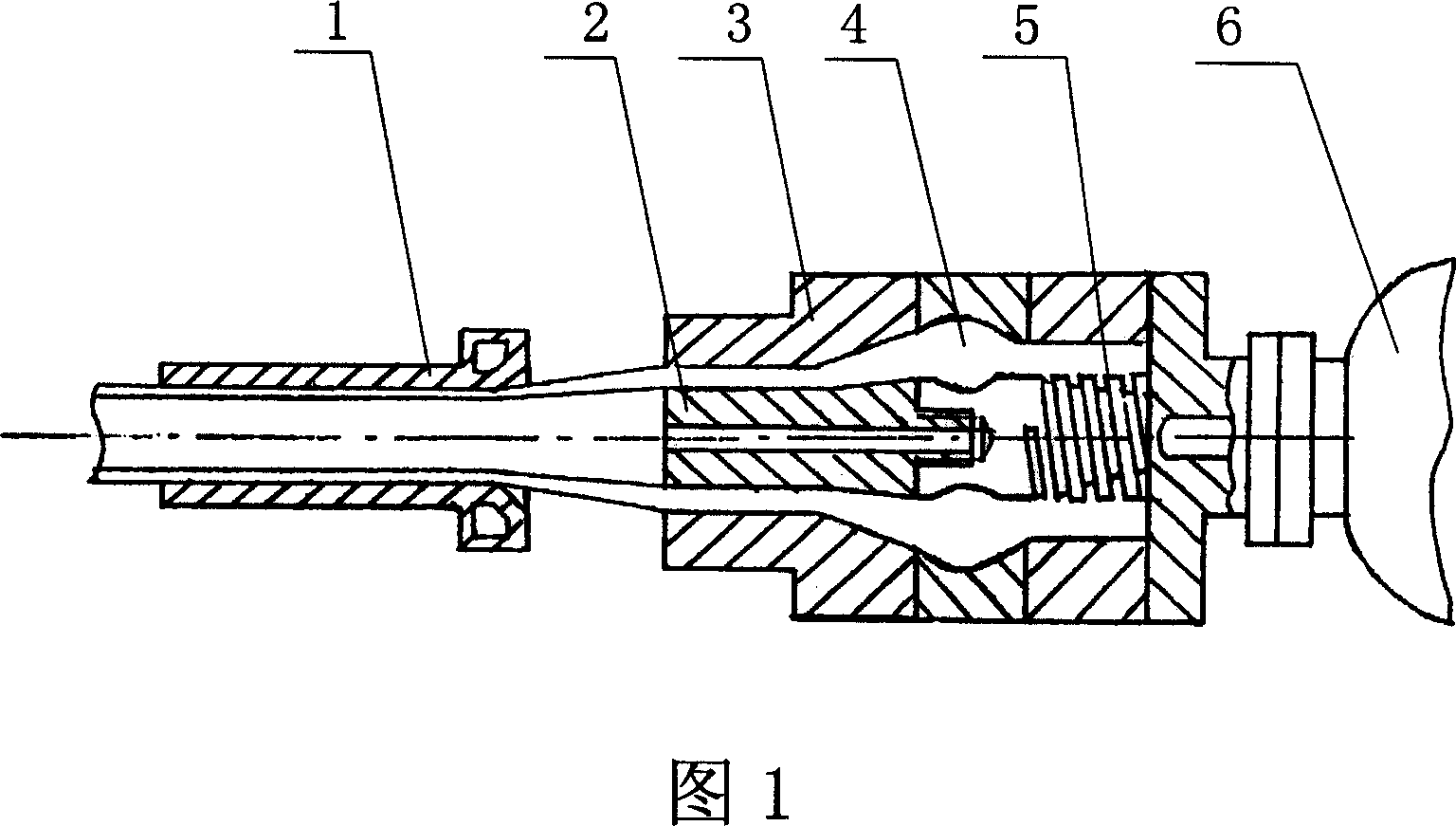

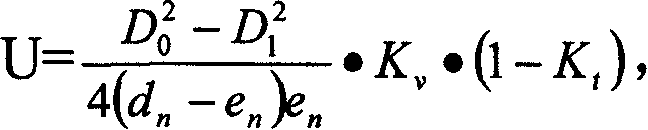

Method for producing multi-specification plastic pipe material by fixed diameter-opening mould and its ram-head mould

The invention is concerned with the method and the bolt head mould for using the sizing opening-module to produce multi-standard plastic pipe, the method is: puts in the material, heats to melt, extrudes, sizing cooling, tows, cutting to length, the heating melted material extrudes from the opening module, then tows in the sizing mould, the inside diameter of the opening mould is bigger that the inside diameter of the sizing mould, the linear velocity ratio of the heating melted material extrusion and the sizing cooling produce is U<=1, the inside cavity diameter of the opening mould is bigger than the inside cavity diameter of the sizing mould, between the opening mould and the sizing mould is a gap. The features of the invention are: can produce multi-standard pipe, save material, improve efficiency, high output.

Owner:烟台东邦塑料建材有限公司

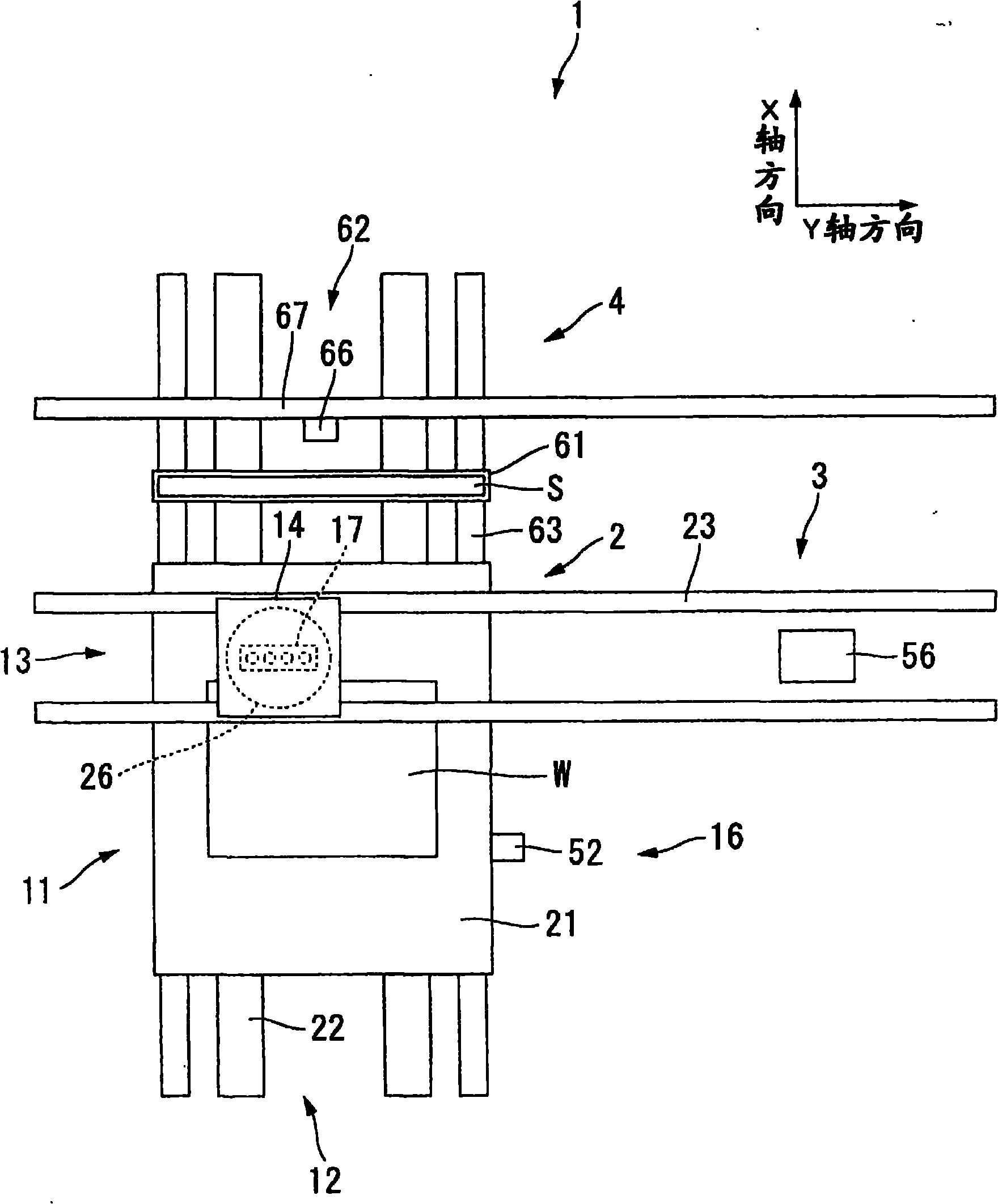

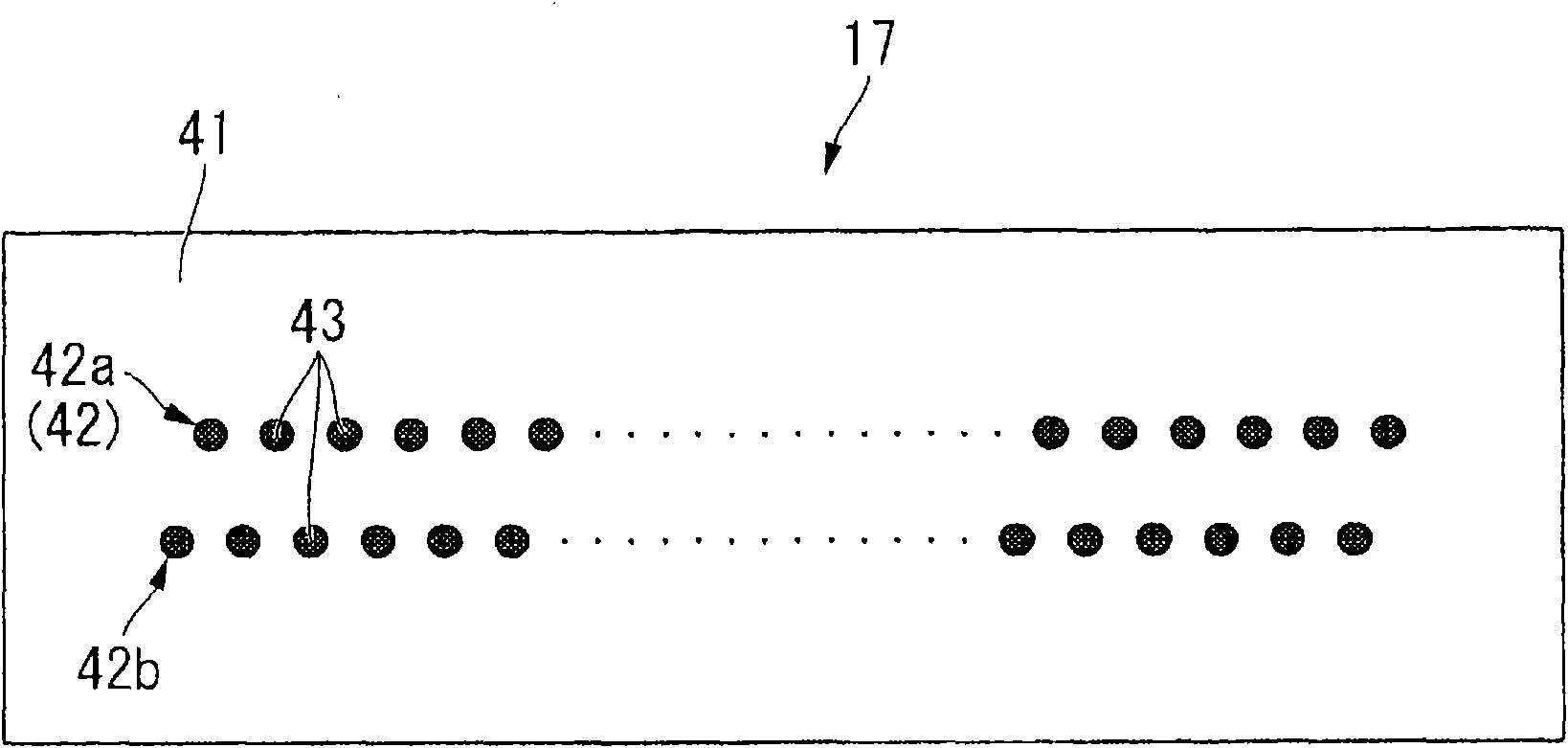

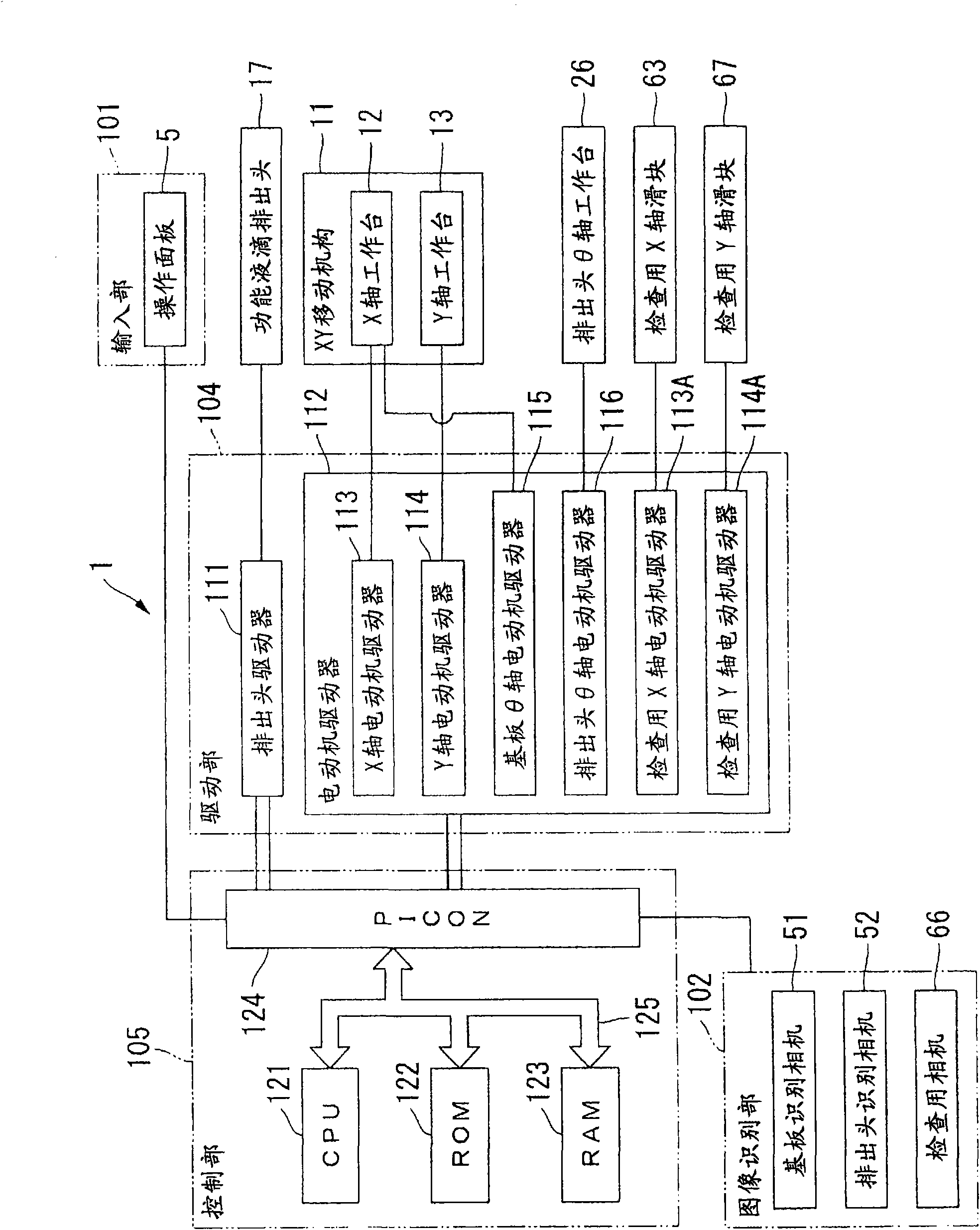

Method for inspecting droplet discharge head, device for inspecting droplet discharge head, and droplet discharge device

InactiveCN101837683AReduce the number of settingsLow costOther printing apparatusImaging processingLuminosity

The present invention provides a method for inspecting a droplet discharge head, a device for inspecting a droplet discharge head, and a droplet discharge device whereby dot patterns having a predetermined color tone can be appropriately inspected using image processing. A discharge inspection unit 4 includes an inspection camera 66 for performing filming to dot patterns P having a predetermined color tone function droplet discharged from the function droplet discharge head; and an illumination device 65, projecting illumination light to the examination region R; and adopting the image processing to perform examination to the dot patterns P obtained by filming. The illumination device 65 has a red LED (Light Emitting Diode) 68R, a green LED 68G, and a blue LED 68B having a plurality of lighting sources with different tones with each other. The illumination device 65 has a configuration in which the controller 105 can adjust the luminosity of the illuminating light generated by selecting at least one of the lighting source based on the tone of the dot patterns P and performing light modulation to the light of the selected lighting source.

Owner:SEIKO EPSON CORP

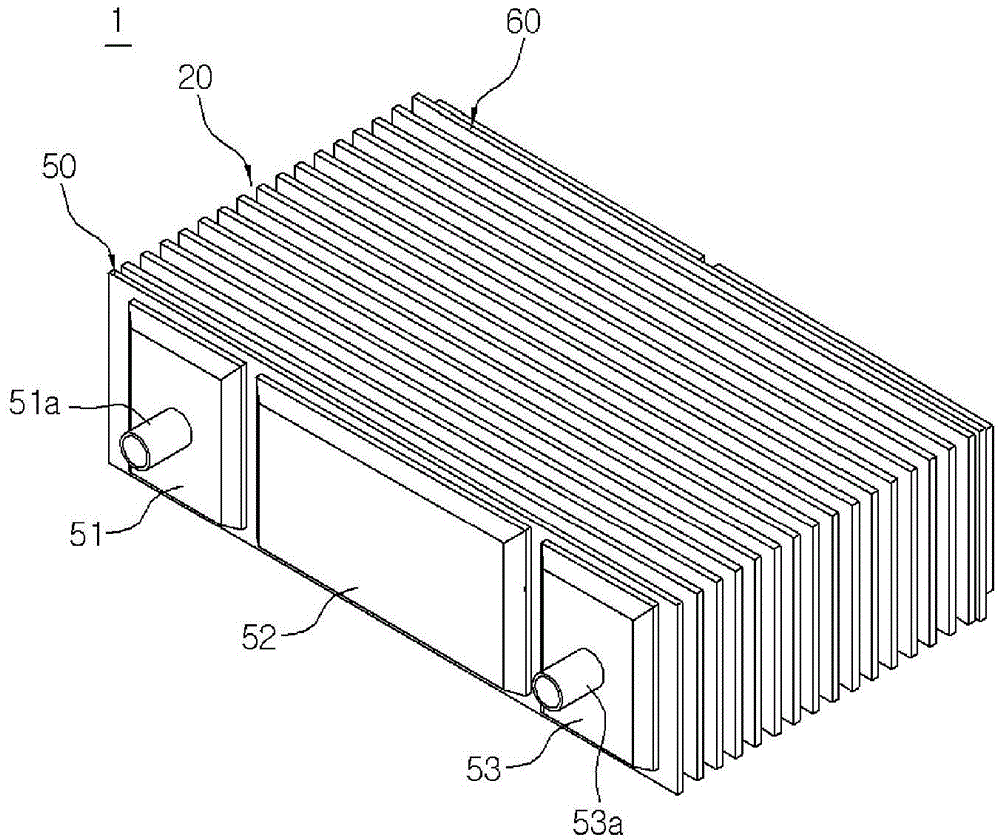

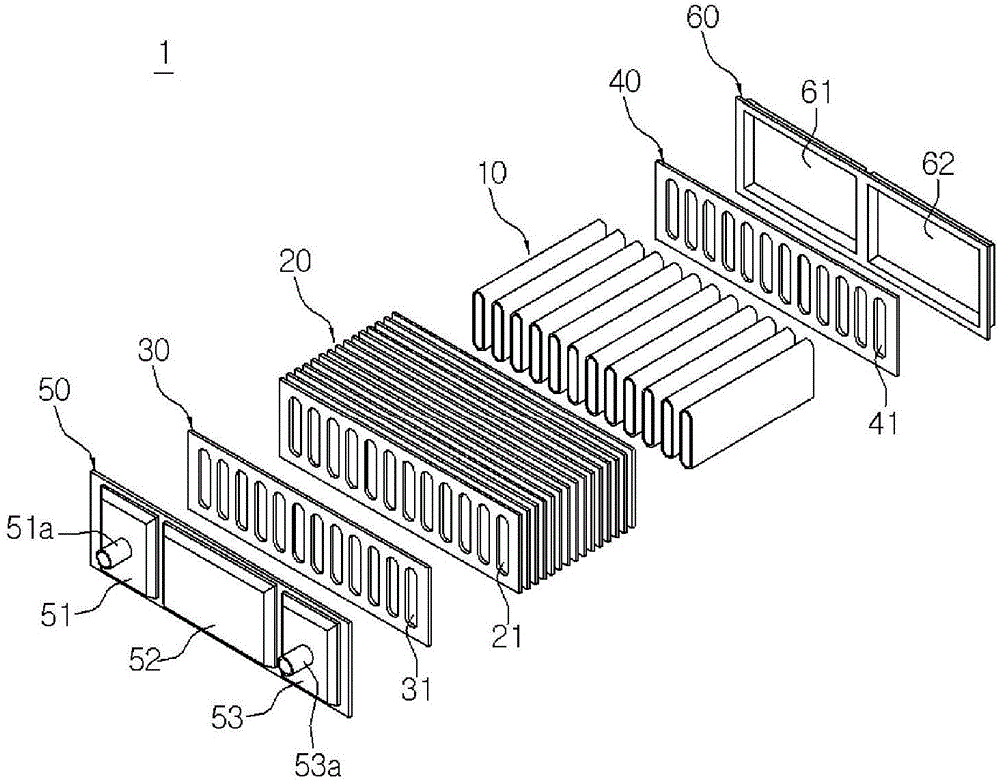

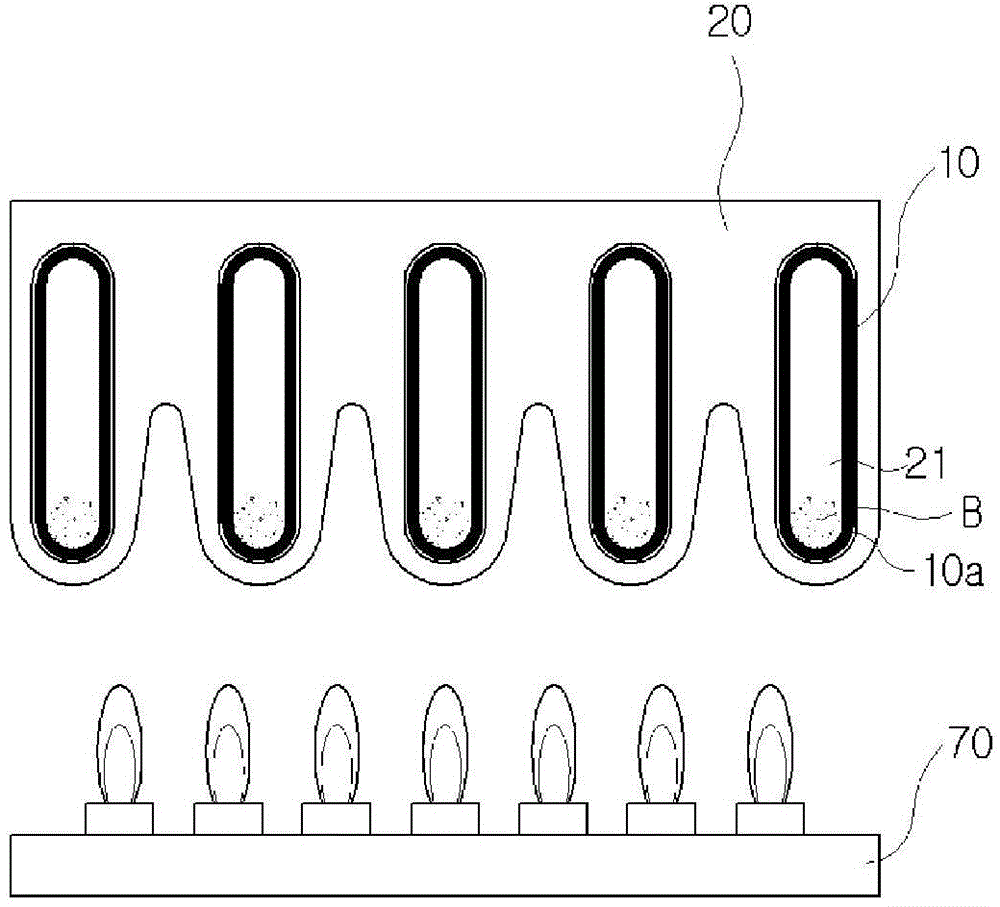

Fin-tube type heat exchanger

ActiveCN104884889APrevent localized overheatingIncreased turbulenceRecuperative heat exchangersHeat exhanger finsInterior spaceTubing types

The present invention relates to a pin-tube type heat exchanger, comprising: tubes through the inside of which a heat medium flows and which are arranged in parallel with a uniform distance therebetween, so that a combustion product can pass through space between the tubes; and heat transfer fins which are separately coupled to the outer surface of the tubes along the lengthwise direction thereof, so as to be parallel to the direction of flow of the combustion product, wherein inside the tubes a first turbulent flow-generating member is installed for creating turbulence in the flow of the heat medium, wherein the first turbulent flow-generating member comprises a flat plate portion, arranged in the lengthwise direction of the tubes, for dividing the inner space of the tubes into two sides, and first guide pieces and second guide pieces which are protrudingly provided at a tilted angle and are separately and alternately provided along the lengthwise direction of both sides of the flat plate portion.

Owner:KYUNGDONG NAVIEN

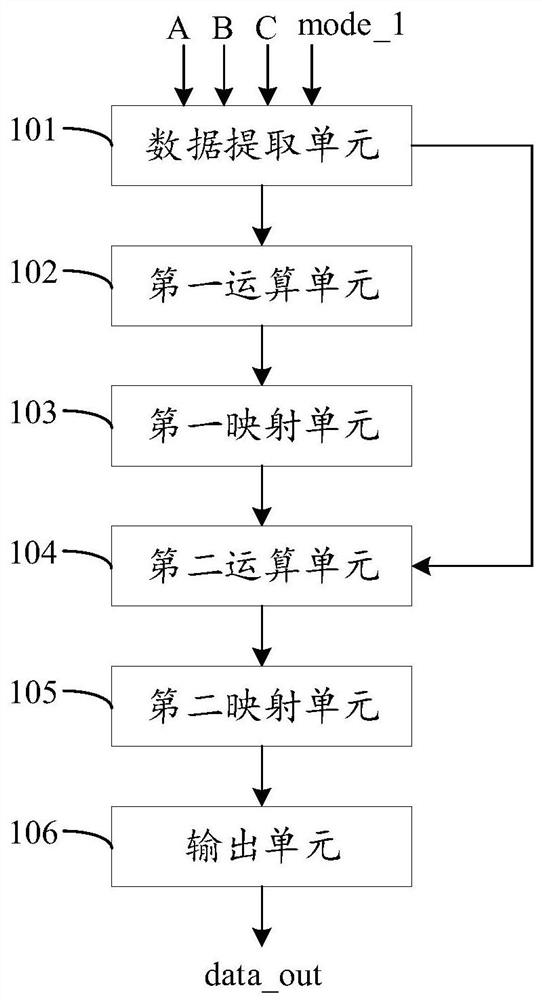

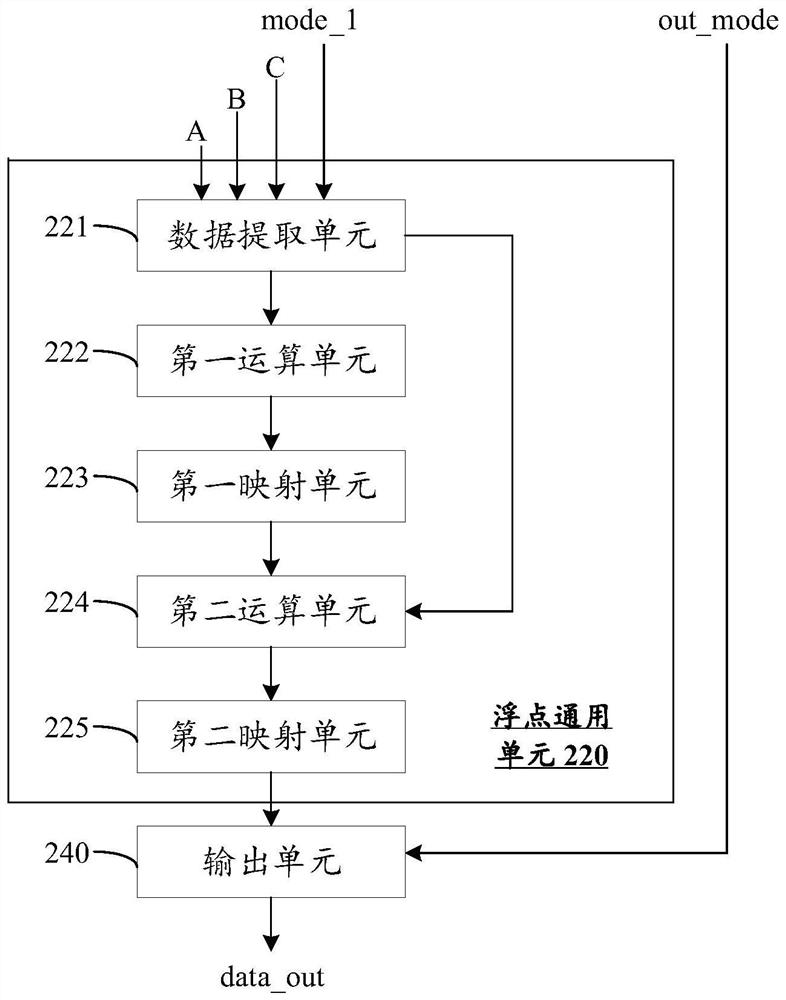

Chip comprising multiply accumulator, terminal and floating point operation control method

PendingCN111767025AReduce the number of settingsReduce areaDigital data processing detailsEmbedded systemHemt circuits

The invention discloses a chip comprising a multiply accumulator, a terminal and a floating point operation control method, and relates to the field of chips. The multiply accumulator comprises a floating point number input end, a first selection end, a floating point general unit and an output unit, wherein the floating point universal unit is connected with the floating point number input end, the first selection end and the output unit. According to the invention, in different floating point operation modes, the floating point number with high bit width can be split into sub-operands with low bit width to carry out multiply-accumulate operation, and according to the selecting of a floating point operation mode, the multiplier and the adder in the multiply accumulator are controlled to be split and recombined, so that the operational circuit in the multiply-accumulator becomes an operational circuit corresponding to the floating-point operation mode, the operational circuit can support multiply-accumulate operation of floating-point numbers with different bit widths, at least two sets of hardware structures do not need to be integrated on the chip, and the area and power consumption of the chip are effectively reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com