Conveying chamber, substrate processing device, and substrate disorder detection method

A technology of a conveying device and a detection method, which is applied in the field of a conveying room, and can solve problems such as difficult detection and inability to apply position deviation detection of glass substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

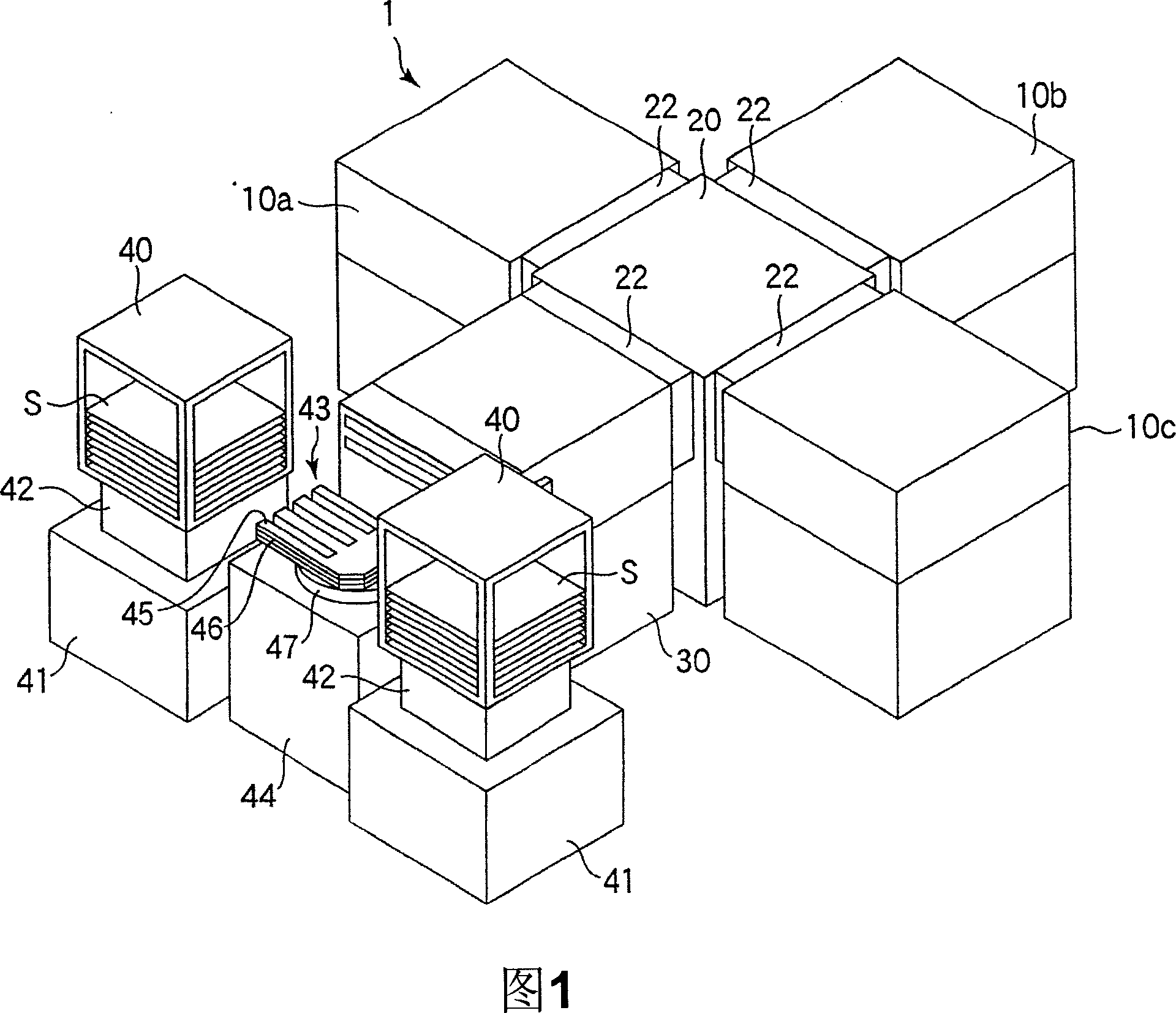

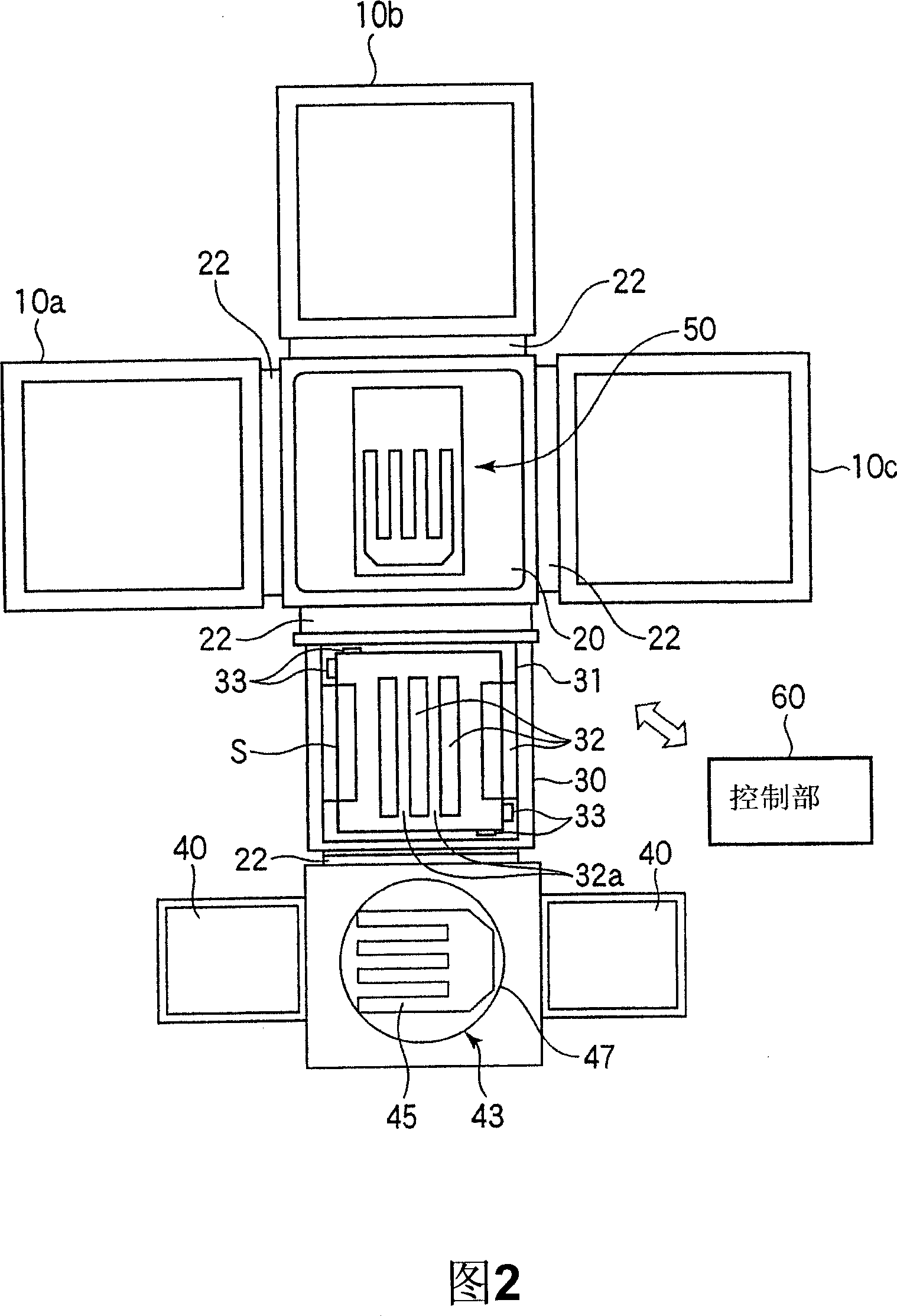

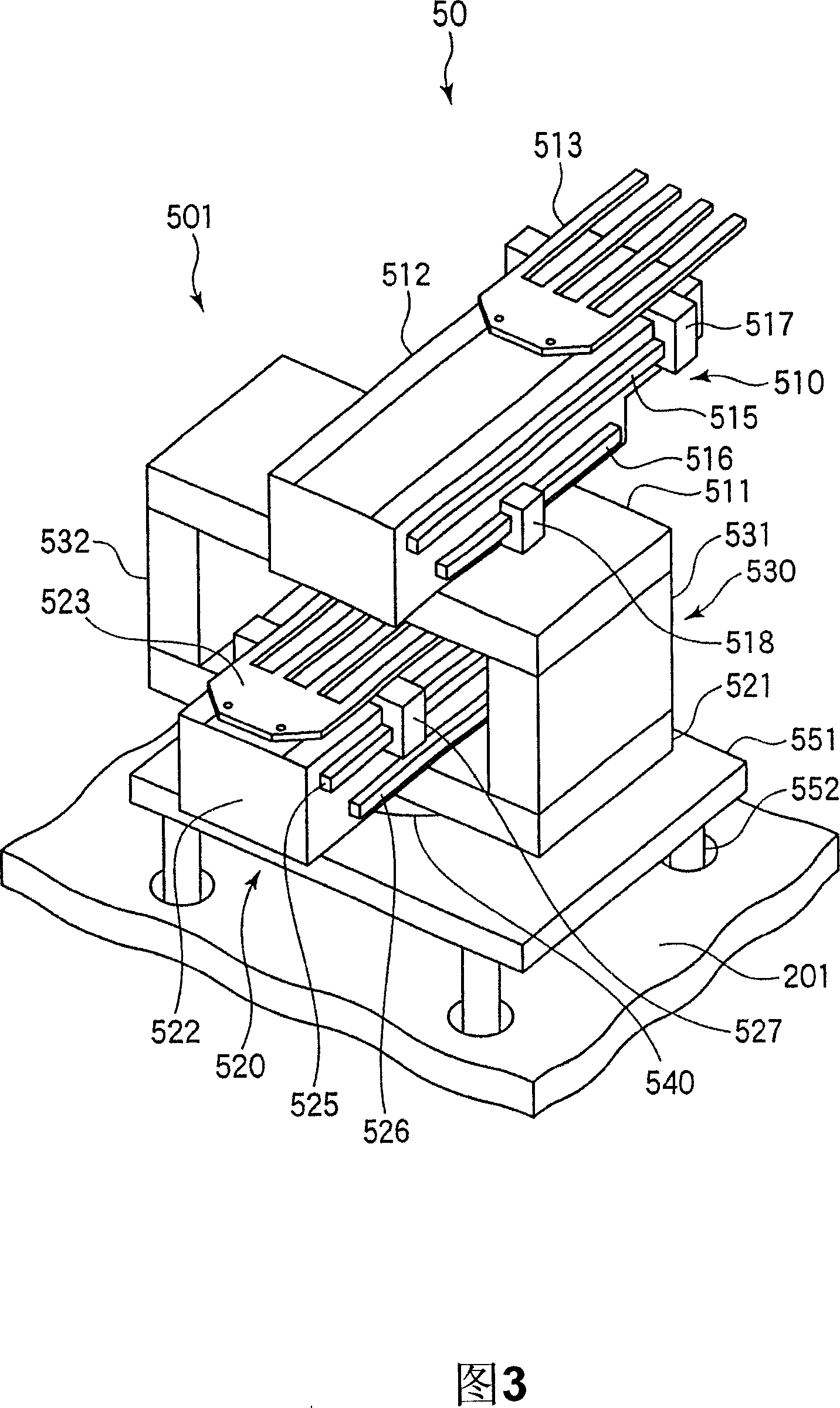

[0042] Next, preferred embodiments of the present invention will be described with reference to the drawings. Here, as a substrate processing apparatus, in a transfer chamber used in a multi-chamber plasma processing apparatus for performing plasma processing on a glass substrate for FPD (hereinafter simply referred to as a “substrate”) S, the substrate is abnormally treated. An example of detection will be described. Here, the FPD includes, for example, a liquid crystal display (LCD), a light emitting diode (LED) display, an electroluminescence (Electro Luminescence, EL) display, a fluorescent display tube (Vacuum Fluorescent Display, VFD), a plasma display panel (PDP), etc. .

[0043] FIG. 1 is a perspective view schematically showing a plasma processing apparatus according to one embodiment of the substrate processing apparatus of the present invention, and FIG. 2 is a horizontal cross-sectional view schematically showing its interior.

[0044] In this vacuum processing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com