Die bonder and method for detecting positions of bonding tool and semiconductor die relative to each other

A bonding tool and relative position technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, instruments, etc., can solve problems such as complex optical system composition, and achieve the effect of simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

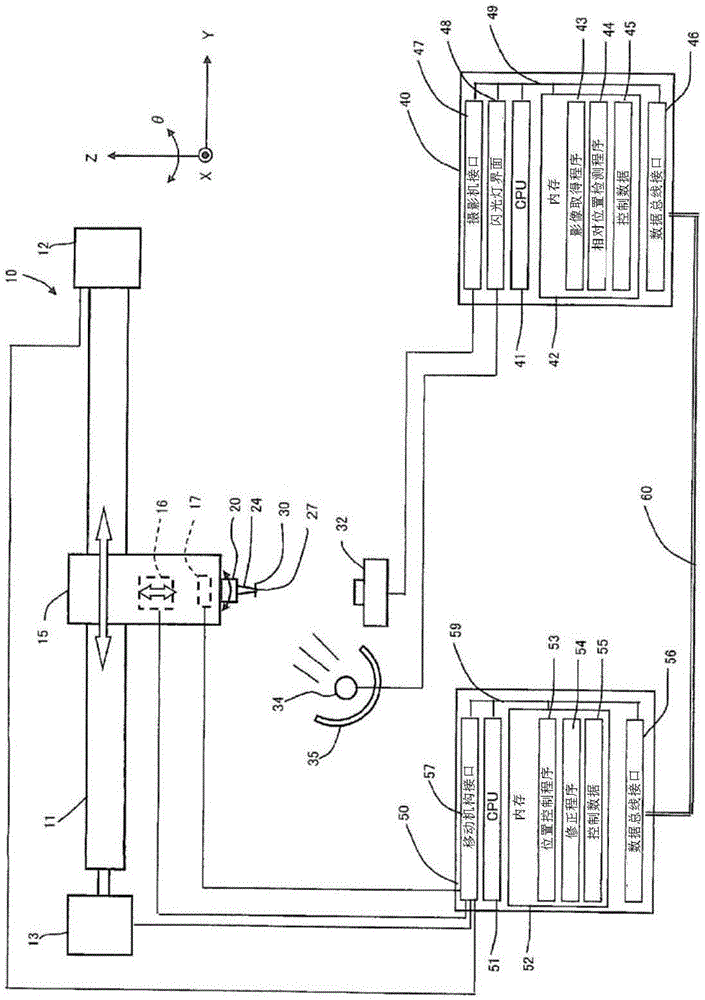

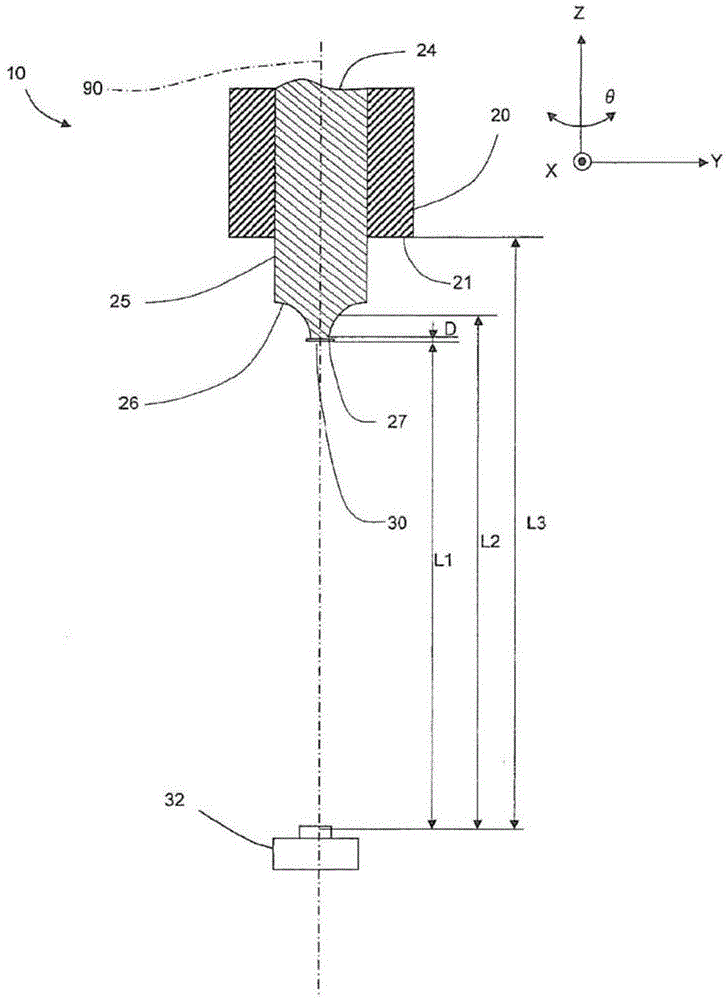

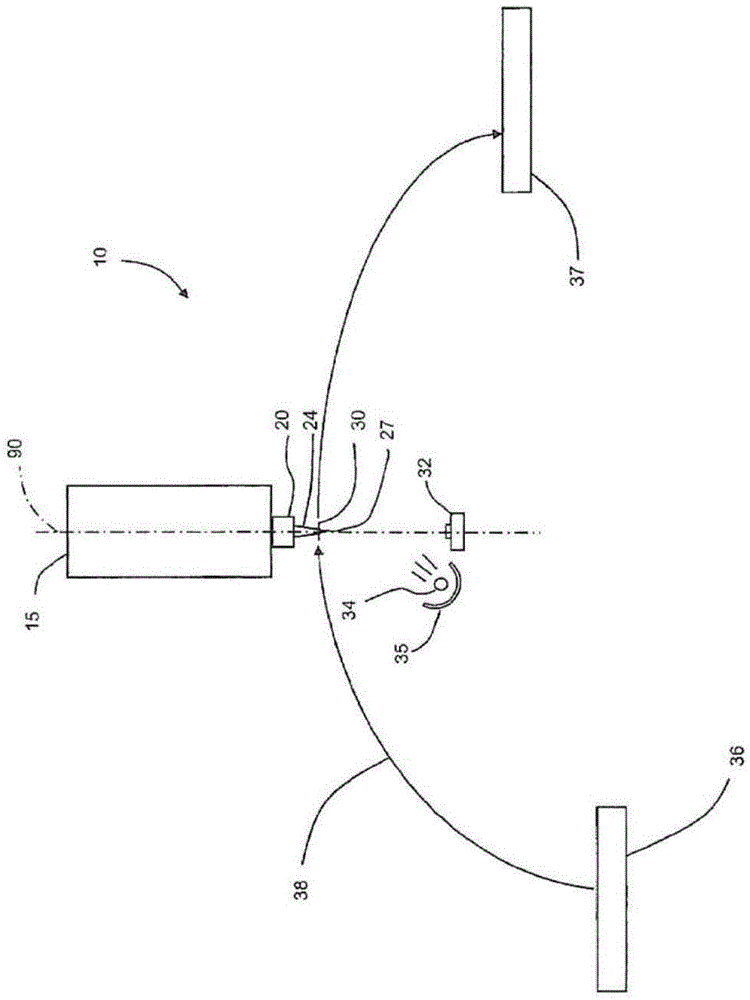

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings. like figure 1 As shown, the die bonder 10 of the present invention has a bonding head 15 on which a bonding tool 24 is installed through a crank 20, a guide rail 11 for guiding the bonding head 15 in the Y direction, and a Y direction for moving the bonding head 15 in the Y direction. Moving mechanism 13, X-direction moving mechanism 12 for moving guide rail 11 and bonding head 15 in X direction, camera 32 provided under bonding head 15, flashlight 34 as light source, image processing unit connecting camera 32 and flashlight 34 40, and the control unit 50 connected to the X and Y direction moving mechanisms 12 and 13. The bonding tool 24 has an adsorption surface 27 for adsorbing the semiconductor die 30 at its tip, and the strobe lamp 34 includes a reflector 35 for directing emitted light toward the bonding tool 24 . The bonding head 15 internally includes a Z-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com