Rubber powder modified cement concrete pavement and manufacturing method thereof

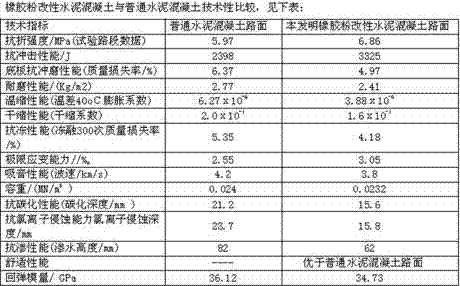

A technology of cement concrete and rubber powder, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of large load, temperature dry-wet deformation, large rigidity of concrete slabs, and unsuitable for large settlements, etc., to achieve Reduce black pollution, reduce engineering cost, improve the effect of high temperature micro-expansion and residual deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

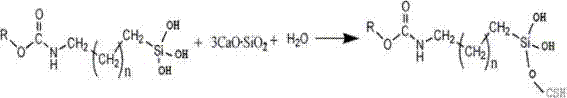

Method used

Image

Examples

Embodiment 1

[0055] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0056] Rubber powder 25kg / m³ 425 cement 300kg / m³

[0057] River sand 550kg / m³ gravel 1130kg / m³

[0058] Water 135kg / m³ Water reducer 5.5kg / m³

[0059] Phthalate coupling agent 3kg / m³ Rubber latex 2kg / m³

[0060] Hydrophobic modified cellulose 3kg / m³ lignin 15kg / m³ (recycled by banana stalks, see the content of the invention)

[0061] Granulated blast furnace slag powder 110kg / m³.

[0062] The fineness of the rubber powder is 20 mesh.

[0063] The fineness of the granulated blast furnace slag powder is 200 mesh.

[0064] The fineness modulus of the river sand is 2.2-3.5.

[0065] The grain size of the gravel is 5-37.5mm.

[0066] The manufacturing method comprises the following steps:

[0067] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and waste tires can be divided into tw...

Embodiment 2

[0071] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0072] Rubber powder 30kg / m³ 425 cement 330kg / m³

[0073] River sand 590kg / m³ gravel 1180kg / m³

[0074] Water 145kg / m³ Water reducer 6.5kg / m³

[0075] Phthalate coupling agent 4kg / m³ Rubber latex 3kg / m³

[0076] Hydrophobic modified cellulose 4kg / m³ Lignin 20kg / m³ (extracted by papermaking black liquor, see the content of the invention for the method)

[0077] Granulated blast furnace slag powder 100kg / m³.

[0078] The fineness of the rubber powder is 60 mesh.

[0079] The fineness of the granulated blast furnace slag powder is 280 mesh.

[0080] The fineness modulus of the river sand is 2.2-3.5.

[0081] The grain size of the gravel is 5-37.5mm.

[0082] The manufacturing method comprises the following steps:

[0083] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and waste t...

Embodiment 3

[0087] A rubber powder modified cement concrete pavement, the cement concrete pavement comprises the following raw materials in parts by weight:

[0088] Rubber powder 27kg / m³ 425 cement 315kg / m³

[0089] River sand 570kg / m³ gravel 1110kg / m³

[0090] Water 150kg / m³ Water reducer 6.2kg / m³

[0091] Phthalate coupling agent 3.5kg / m³ Rubber latex 2.5kg / m³

[0092] Hydrophobic modified cellulose 3.5kg / m³ Lignin 17.5kg / m³ (extracted by papermaking black liquor, see the content of the invention for the method)

[0093] Granulated blast furnace slag powder 95kg / m³.

[0094] The fineness of the rubber powder is 40 mesh.

[0095] The fineness of the granulated blast furnace slag powder is 240 mesh.

[0096] The fineness modulus of the river sand is 2.2-3.5.

[0097] The grain size of the gravel is 5-37.5mm.

[0098] The manufacturing method comprises the following steps:

[0099] (1) Production and selection of rubber powder; rubber powder (granules) comes from waste tires, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com