Patents

Literature

203results about How to "Improve anti-corrosion ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal surface rust protection solution

InactiveCN102994995AGood anti-rust functionImprove bindingMetallic material coating processesLiquid wasteSodium phosphates

Owner:杨恒春

Foam concrete

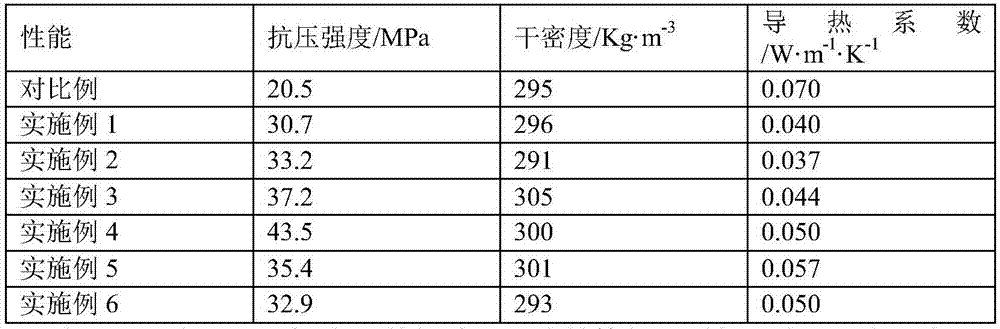

The invention discloses foam concrete. The foam concrete comprises following raw materials in parts by mass according to a formula: 210-300 parts of cement, 1.0-1.5 parts of a water reducing agent, 5.1-5.5 parts of an early strength agent, 2.1-2.9 parts of a coagulant, 1.7-3.4 parts of fibers, 12-20 parts of a chemical foaming agent, 0-90 parts of superfine slag powder and 100-160 parts of water, wherein the superfine slag powder is formed by aluminosilicate glass particles smaller than 15 mu m, and the specific surface area is 450-500 m<2>*kg<-1>. The compressive strength of the foam concrete is improved on the premise that the foam concrete keeps low density.

Owner:BEIJING MINJIA NEW BUILDING MATERIALS CO LTD

Anticorrosion epoxy primer and preparation method thereof

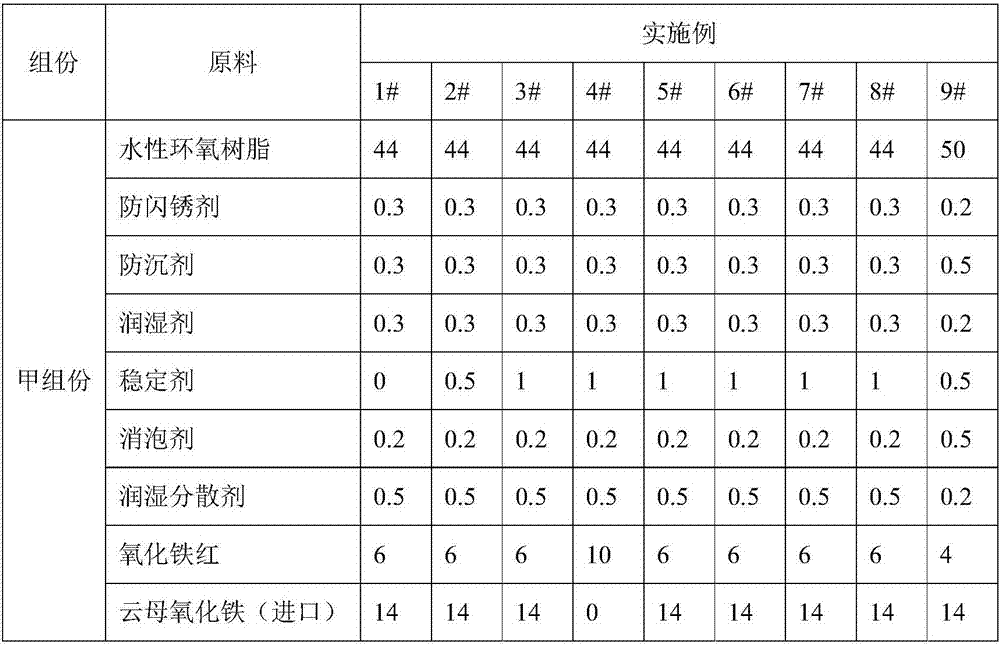

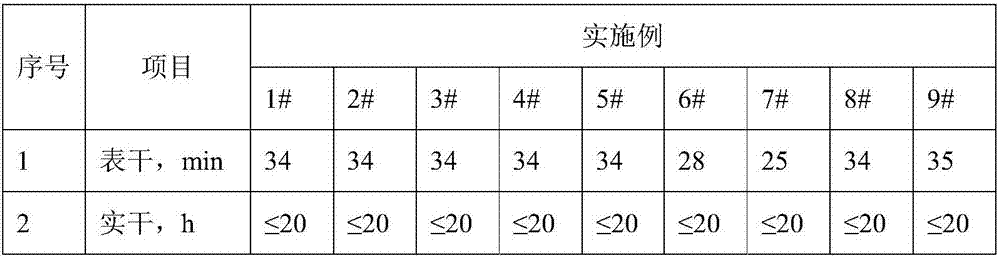

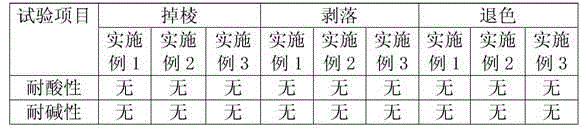

The invention discloses a water-borne anticorrosion epoxy primer and a preparation method thereof. The water-borne anticorrosion epoxy primer comprises a component A and a component B, wherein the component A comprises the following subcomponents in parts by weight: 34-50 parts of water-borne epoxy resin, 0.2-0.5 part of a flash rust preventer, 0.2-0.5 part of an anti-settling agent, 0.2-0.5 part of a wetting agent, 0.5-1.5 parts of a stabilizer, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of a wetting dispersant, 4-9 parts of iron oxide red, 12-19 parts of micaceous iron oxide, 4-9 parts of composite phosphate, 7-12 parts of talcum powder, 8-15 parts of distilled water and 0.5-2 parts of a nano-sized inorganic filler; the component B comprises the following subcomponents in parts by weight: 43-59 parts of a water-borne epoxy curing agent, 1.5-3 parts of a flash rust preventer and 39-54 parts of distilled water; the component A and the component B are blended according to a weight ratio of (3-7): 1. The water-borne anticorrosion epoxy primer adopts a unique formula and a proportion design; compared with the prior art, the water-borne anticorrosion epoxy primer has the advantage as follows: the overall performance, especially the salt spray resistance, of the water-borne anticorrosion epoxy primer is effectively improved.

Owner:SICHUAN OLIN PAINT IND

Fire-resistant heat-insulated and energy-saving glazed tile

InactiveCN105084860AImprove resource utilizationReduce land occupationClaywaresUltravioletAbsorption rate

The invention discloses a fire-resistant heat-insulated and energy-saving glazed tile and belongs to the technical field of building materials. According to the glazed tile, on the basis of an existing glazed tile production process, components of materials of a green body, base glaze and over glaze are adjusted and optimized, wherein partial industrial wastes are introduced into the preform body, so that energy resources can be saved, the production cost can be reduced, and the economic benefit can be increased; the base glaze contains materials such as cerium oxide, iron oxide, stannous chloride and the like, which can absorb ultraviolet rays and prevent radiation; and the over glaze contains materials such as sodium fluosilicate, sodium polyacrylate and the like, which can enhance the acid resistance, corrosion resistance and stability of the finished glazed tile. The glazed tile is good in body-glaze fitness and has the characteristics of fire resistance, heat insulation, noise insulation, weather resistance, freeze resistance, light weight, low possibility of breakage, high strength, long life, smooth and fine glaze surface, bright color and luster, low water absorption rate and the like.

Owner:贾耀玺

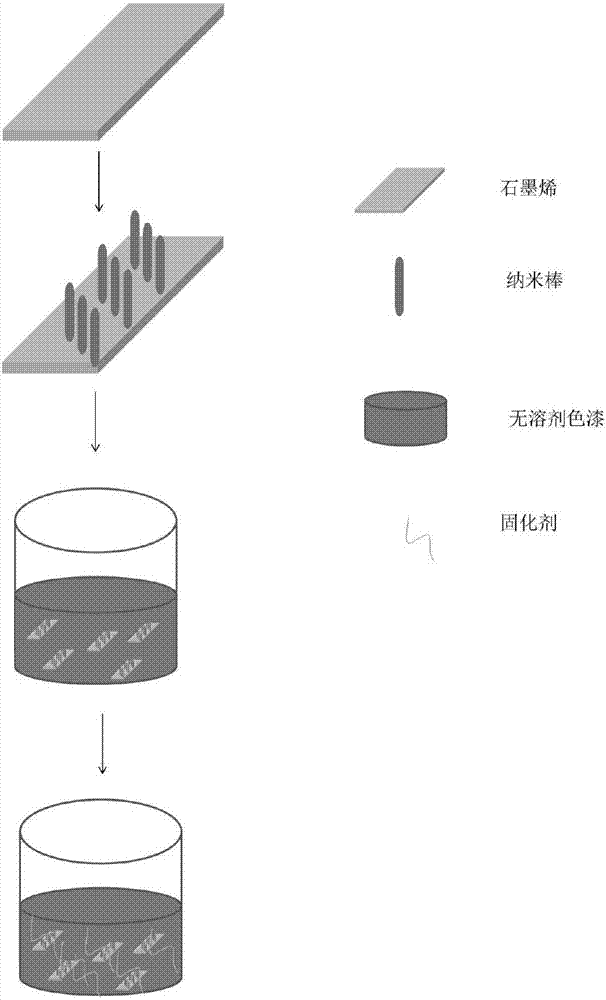

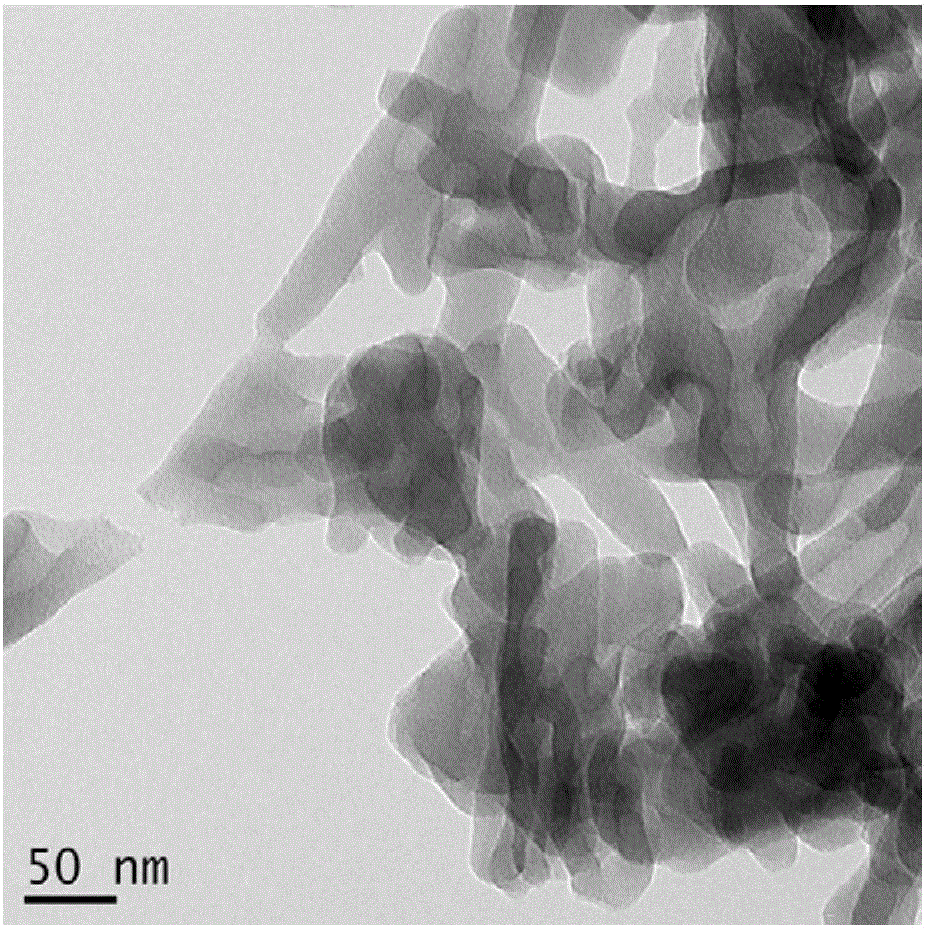

Humid rusted solvent-free graphene modified epoxy paint and preparation method thereof

ActiveCN106867363AGood self levelingUniform colorAnti-corrosive paintsEpoxy resin coatingsAdhesion forceSolvent free

The invention relates to humid rusted solvent-free graphene modified epoxy paint and a preparation method thereof. The paint is prepared from a material A and a material B, wherein the material A is colored paint; the material B is a curing agent; graphene-oxide nano-rods are added into the colored paint; in the aspect of selecting epoxy resin, two types of epoxy resin including solvent-free epoxy resin E-51 and organic zinc-enriched epoxy resin, which have complementary properties, are selected, so that the adhesion force and antirust effect of the paint and a substrate are enhanced; in the aspect of selecting the curing agent, two curing agents are adopted; a polyamide curing agent is added on the basis of a cashew nut shell oil modified phenolic aldehyde amine curing agent which is researched latest, so that the humid rusted solvent-free graphene modified epoxy paint is prepared.

Owner:邹亚静

Hexagonal boron nitride epoxy compound anticorrosion coating and preparation method and application thereof

ActiveCN106752673AGood storage stabilityNot easy to sinkAnti-corrosive paintsEpoxy resin coatingsEpoxyDispersed media

The invention discloses a hexagonal boron nitride epoxy compound anticorrosion coating and a preparation method and application thereof. The anticorrosion coating is mainly composed of hexagonal boron nitride, polyaniline nanofiber, epoxy resin, a disperse medium, a coating additive, an epoxy resin curing agent, a solvent, etc. The hexagonal boron nitride epoxy compound anticorrosion coating provided by the invention has good storage stability, is not easy to sink to the bottom, has simple preparation process, is low-cost, and is suitable for large-scale production. A coating layer formed by the coating has excellent barrier property and lasting corrosion resistance. The product has a good application prospect in the industries of chemical engineering, petroleum, electric power, ship, light textile, storage, transportation, spaceflight, etc.

Owner:XINHE NEW MATERIALS CO LTD

Aluminium wiredrawing lubricant and preparation method thereof

The invention provides an aluminium wiredrawing lubricant and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 0.3-0.4 parts of monoethanolamine, 0.6-0.8 parts of triethanolamine, 0.2-0.3 parts of mercapto benzimidazole, 1-2 parts of caprylic-capric acid blend, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of dibutyltin dilaurate, 1-2 parts of zinc acetate, 1-2 parts of tung oil, 2-3 parts of methyl trimethoxy silane, 3-4 parts of a film forming auxiliary agent and 150-160 parts of water. According to the invention, the tung oil is added to promote lubricity, water base is used to play a relatively good heat dissipating effect, the triethanolamine is added to improve an anti-corrosion effect, and the methyl trimethoxy silane is combined with the mercapto benzimidazole, the caprylic-capric acid blend and the film forming agent to improve a film forming performance and prolong an anti-corrosion time of the aluminium conductor after the wiredrawing.

Owner:安徽富华电子集团有限公司

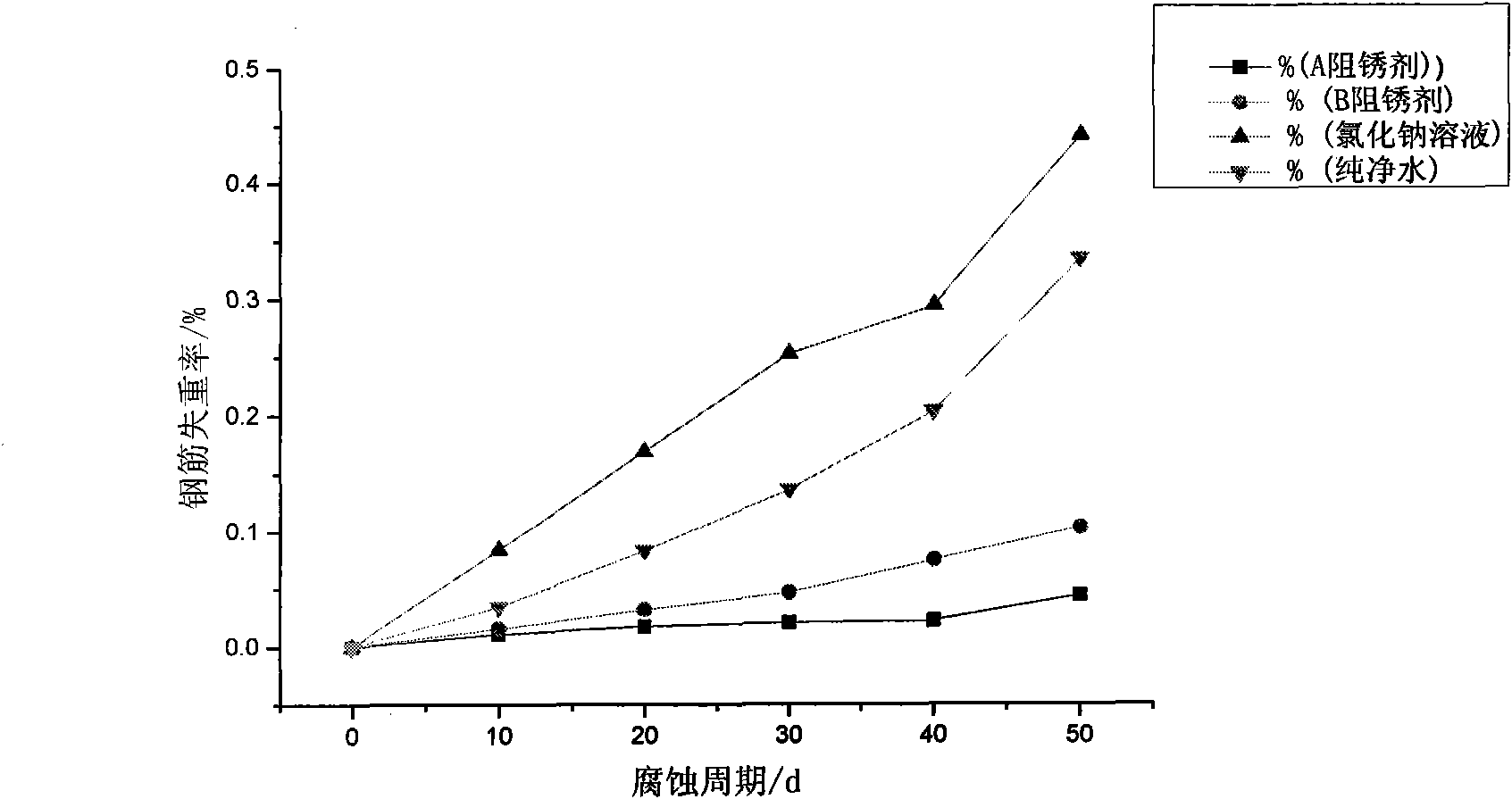

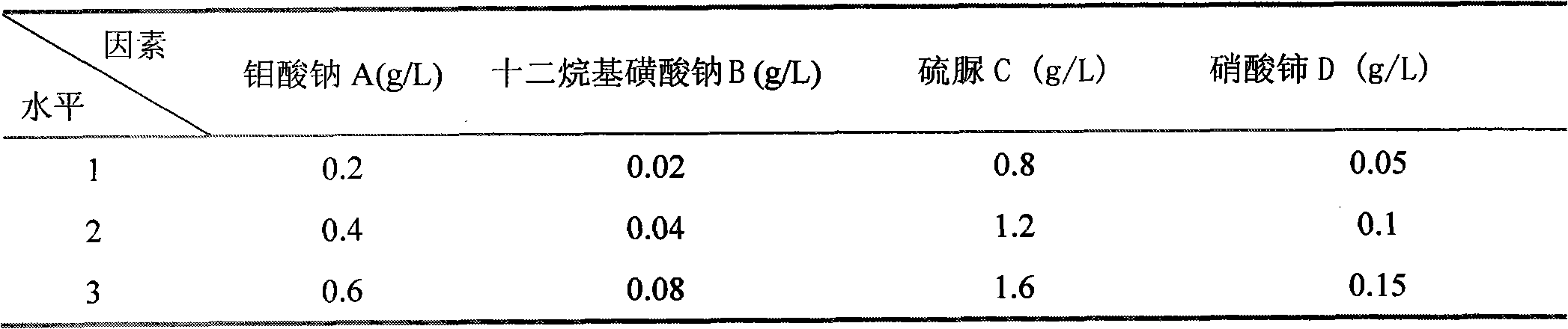

High corrosion resistance reinforced concrete corrosion inhibitor

The invention relates to a high corrosion resistance reinforced concrete corrosion inhibitor added with rare earth cerium ion, which comprises the following components in percentages by weight: 0.06-0.10% of sodium molybdate, 0.03-0.12% of sodium dodecyl sulfate, 0.25-0.45% of thiocarbamide, 0.03-0.12% of cerous nitrate and the balance of water. Each component is soluble in water, when the concrete is stirred, each component is added into a stirring device sequentially according to the adding sequence of the raw materials, but when water is added, each component is added in water to dissolve according to the requirement in the formulation. According to the invention, the corrosion of reinforcement in the reinforced concrete can be slowed down or restricted, the high corrosion resistance reinforced concrete corrosion inhibitor has the characteristics of high absorption force of the corrosion inhibitor and high corrosion inhibiting property, and is environment-friendly, the corrosion of reinforcement in the reinforced concrete can be inhibited effectively, especially the high corrosion resistance reinforced concrete corrosion inhibitor has great significance on the coastal reinforced concrete structures and the reinforced concrete structures having higher requirements on chloridion ion corrosion resistance.

Owner:李丽

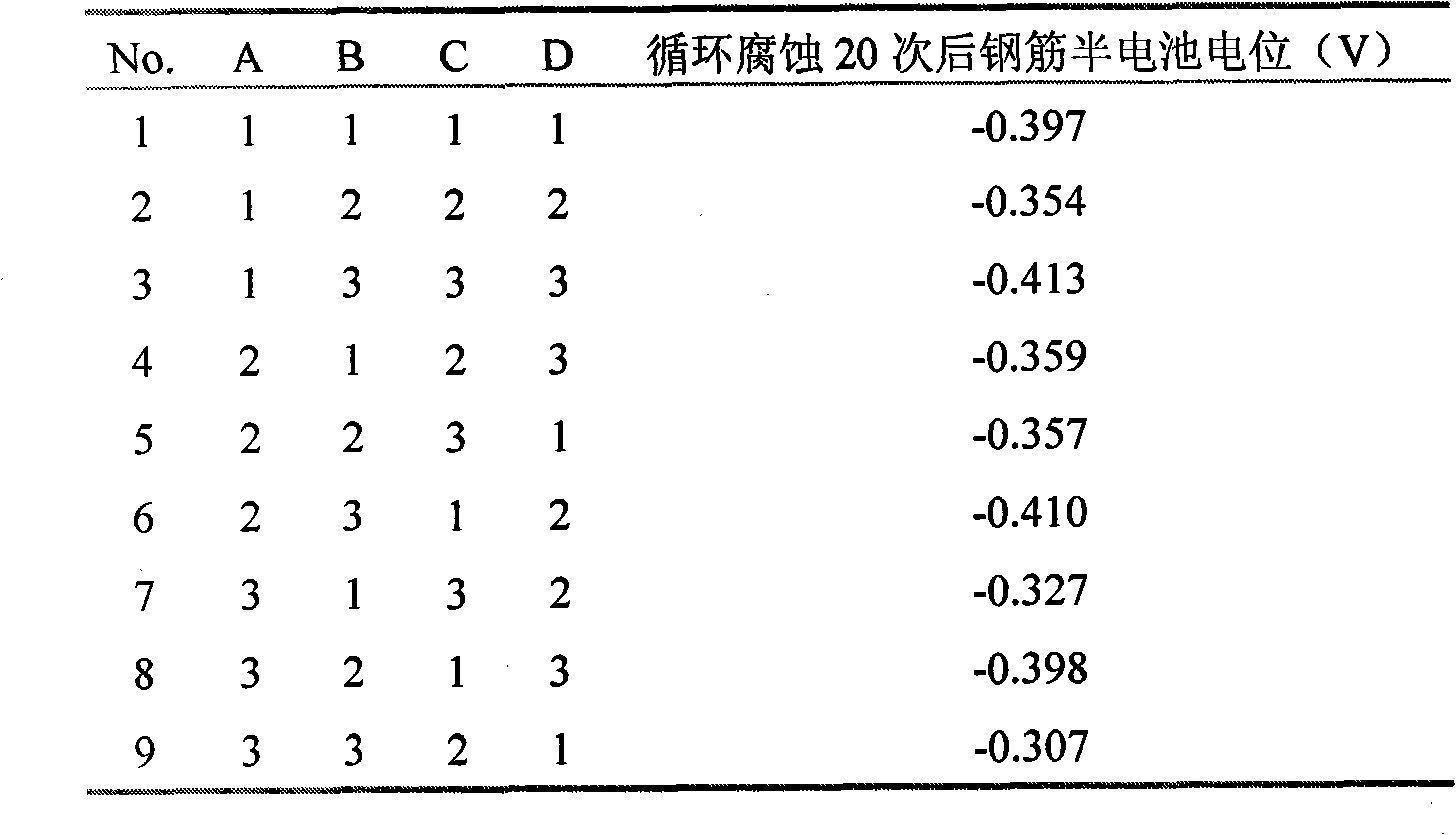

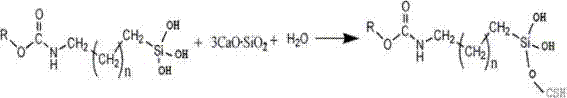

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

Functional gradient shield pipe sheet and producing method thereof

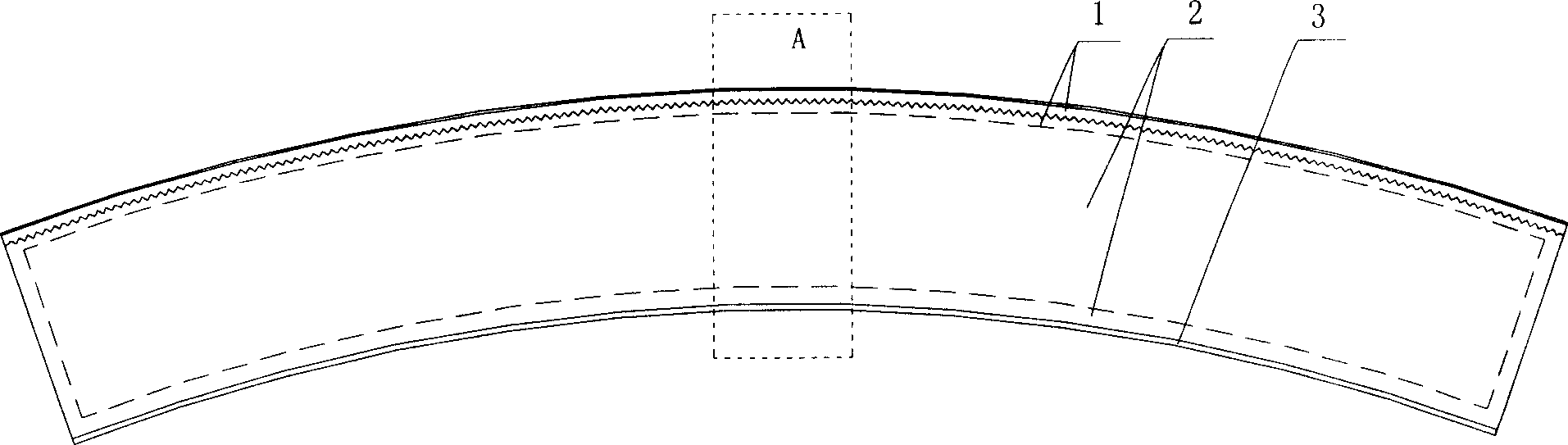

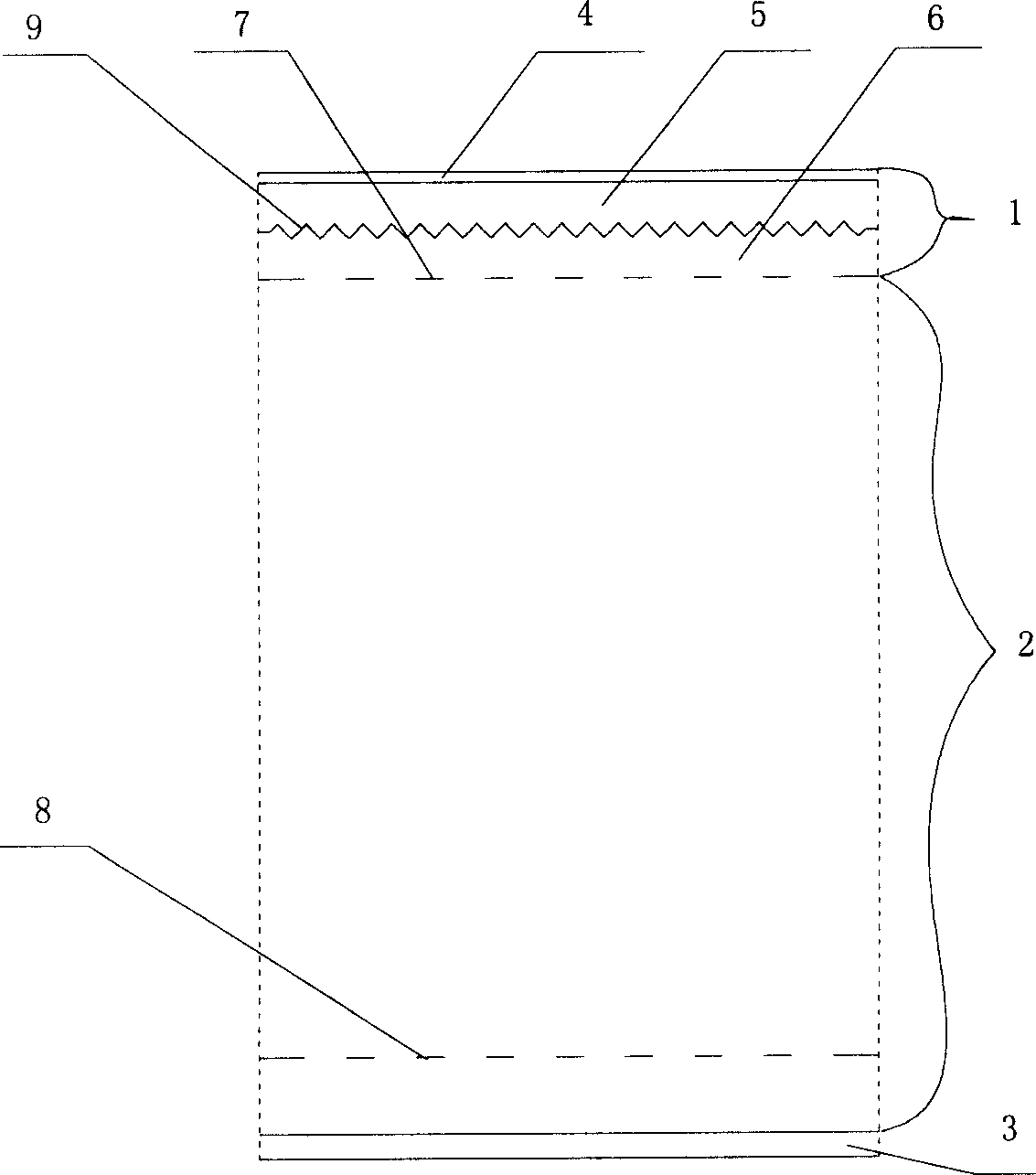

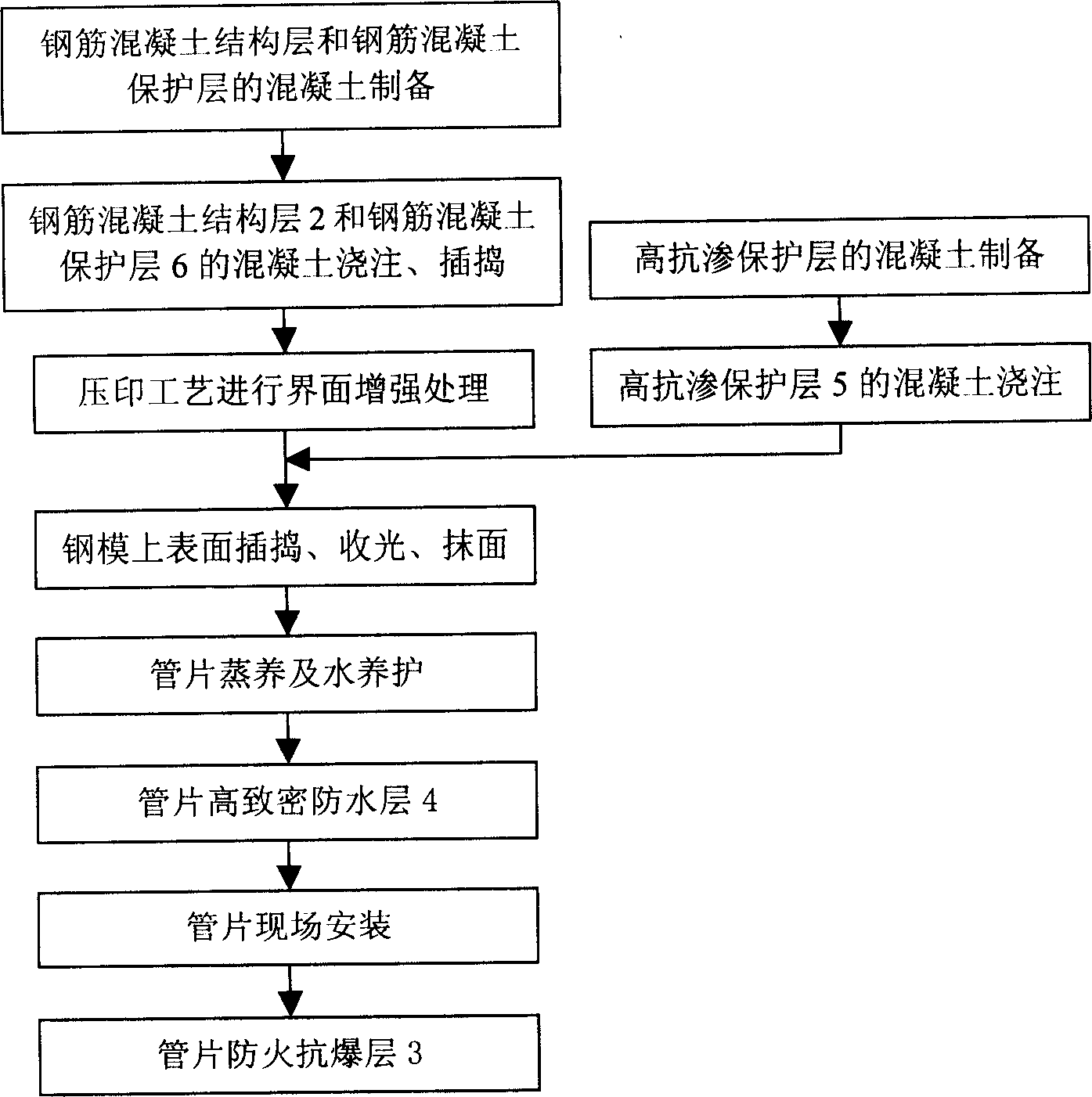

InactiveCN1888393AIncreased durabilityExtended service lifeUnderground chambersCeramic shaping apparatusReinforced concreteFireproofing

The present invention relates to a reinforced concrete segment for shield-driven tunnel and its preparation method. It is a functional gradient segment, and is characterized by that it is formed from segment exterior protecting layer, reinforced concrete structure layer and fireproofing explosion-resisting layer. The described segment exterior protecting layer is composed of high-compact water-proofing layer, high-impervious protecting layer and reinforced concrete protecting layer.

Owner:WUHAN UNIV OF TECH

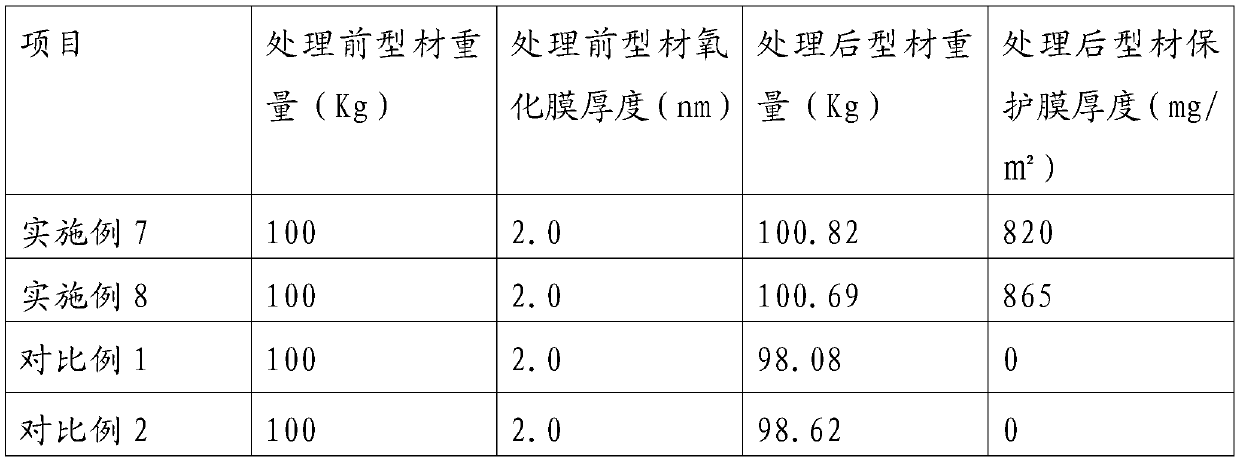

Aluminum alloy degreasing and polishing two-in-one treatment solution and method for degreasing and polishing aluminum alloy

The present invention discloses an aluminum alloy degreasing and polishing two-in-one treatment solution and a method for degreasing and polishing aluminum alloy. The aluminum alloy degreasing and polishing two-in-one treatment solution comprises the following components: 1-20 g / L of oxalic acid, 1-5 g / L of hydrofluoric acid or hydrofluoride, 0.001-0.01g / L of a surfactant and 0.05-0.15 g / L of an auxiliary agent. The method for treating the aluminum alloy by using the treatment solution comprises the following treatment steps: immersing to-be-treated aluminum alloy profiles into the two-in-onetreatment solution; initially reacting until bubbles begin to emerge; and then continuously immersing for three to five minutes to obtain the aluminum alloy profiles with smooth surfaces. The presentinvention is used to treat aluminum alloy profiles, which can not only complete degreasing and polishing in one step, but also improve the corrosion resistance and pollution resistance of the profiles, improve the high mirror reflection characteristics of the aluminum profiles and increase the weight of the profiles. Moreover, the treatment solution does not need to be replaced and can be recycled.

Owner:高瑞安 +1

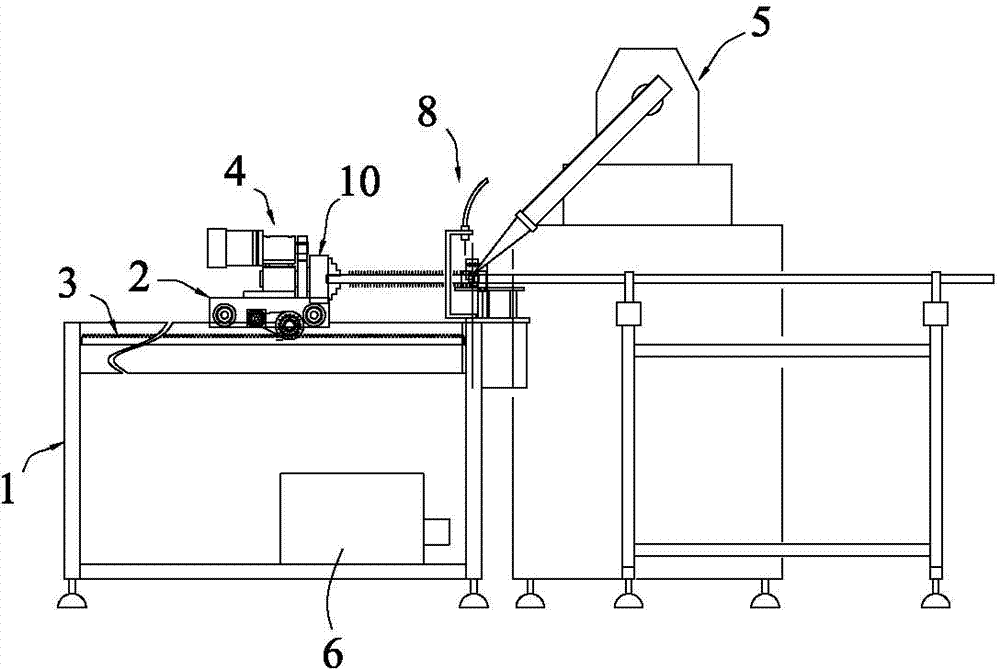

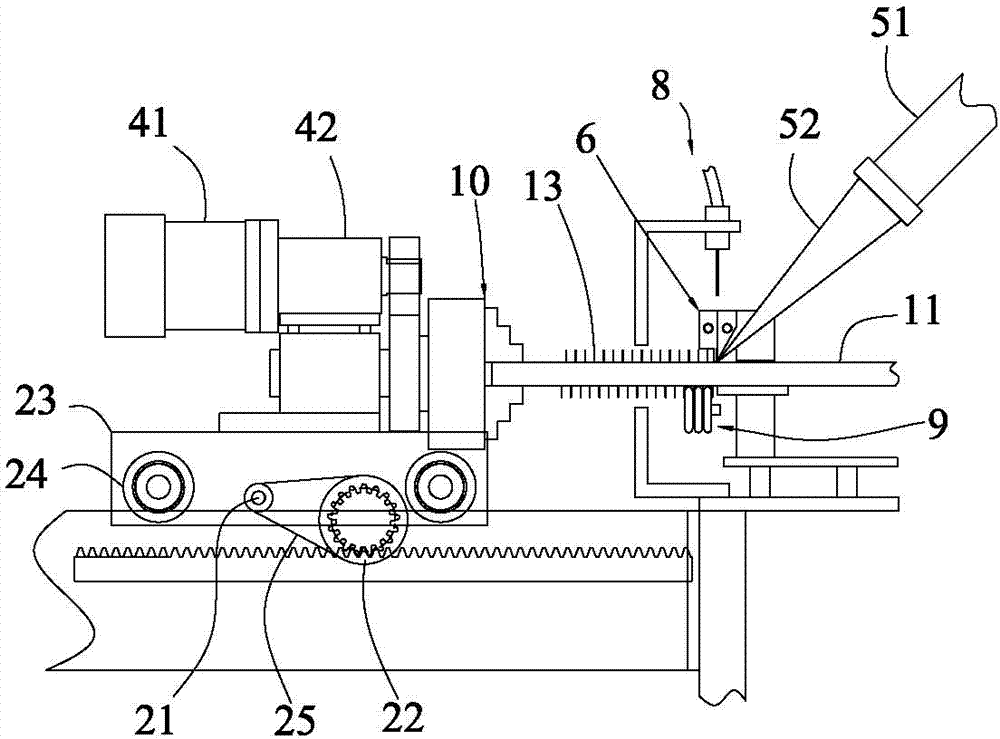

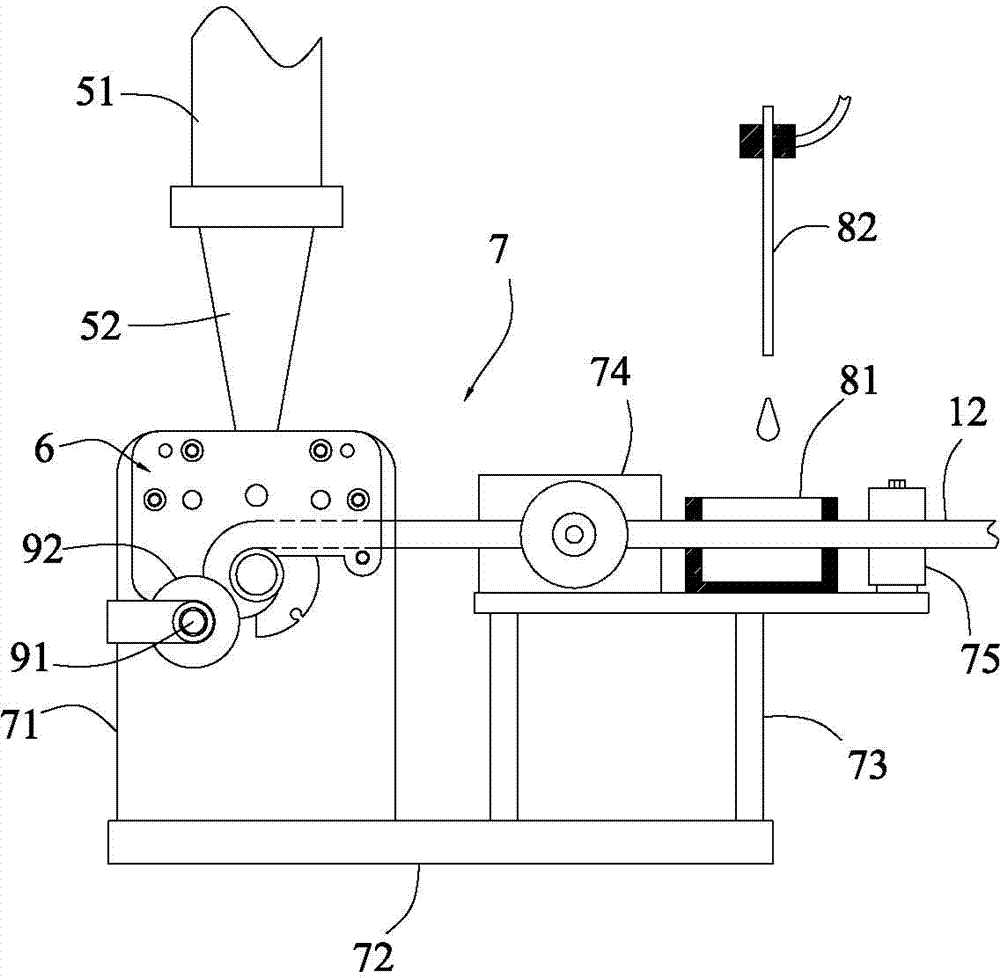

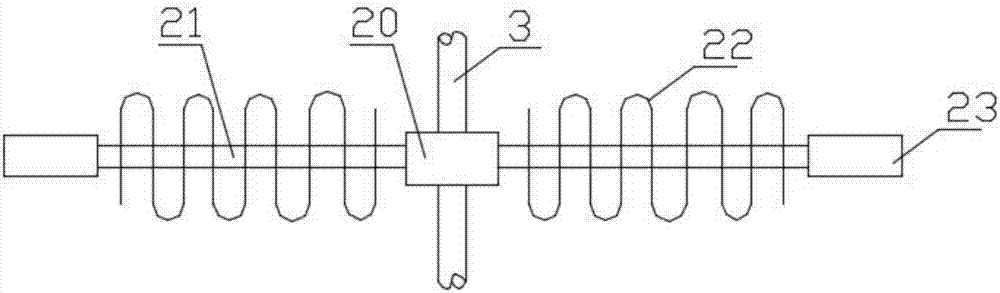

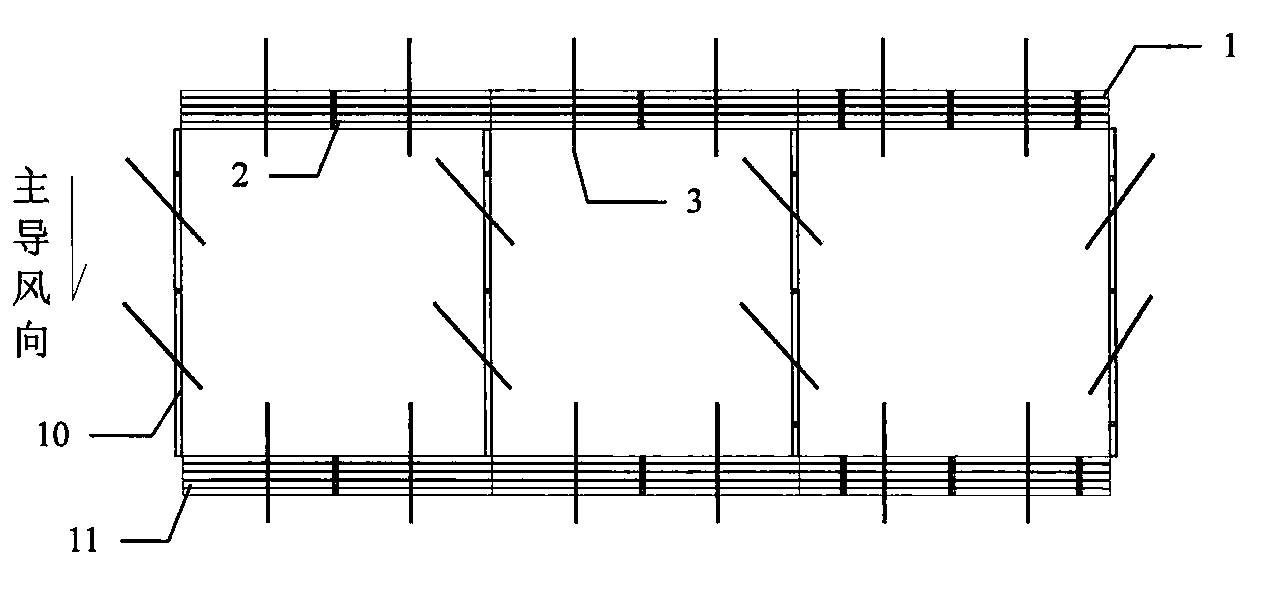

Numerical control helical finned tube laser welding molding equipment and welding molding method thereof

ActiveCN104325219AReasonable structural designExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlTransformation efficiency

The invention discloses numerical control helical finned tube laser welding molding equipment. The numerical control helical finned tube laser welding molding equipment comprises a frame, a linear walking trolley, a rack, a rotating device, a steel tube chuck, a laser, a steel belt conveying device, a refueling device and a correcting device. The invention further discloses a welding molding method of the numerical control helical finned tube laser welding molding equipment. The numerical control helical finned tube laser welding molding equipment provided by the invention is reasonable in structural design, a laser molding technology is combined skillfully, and the metallographic structure of metal is not changed; meanwhile, metallurgical bonding is adopted, so that the bonding effect between a fin and the steel tube is improved greatly, high strength is achieved, the product quality is ensured, high heat exchange efficiency, high corrosion resistance and long service life are achieved, welding operation steps are simple and convenient, and the working efficiency is high; the welding molding method provided by the invention is easy to implement, and has high efficiency; helical finned tubes with corrosion resistance, good combining effect, high heat transformation efficiency and long service lives can be produced rapidly.

Owner:BEIJING MEIJING HUAXIA ENVIRONMENTAL PROTECTION TECH

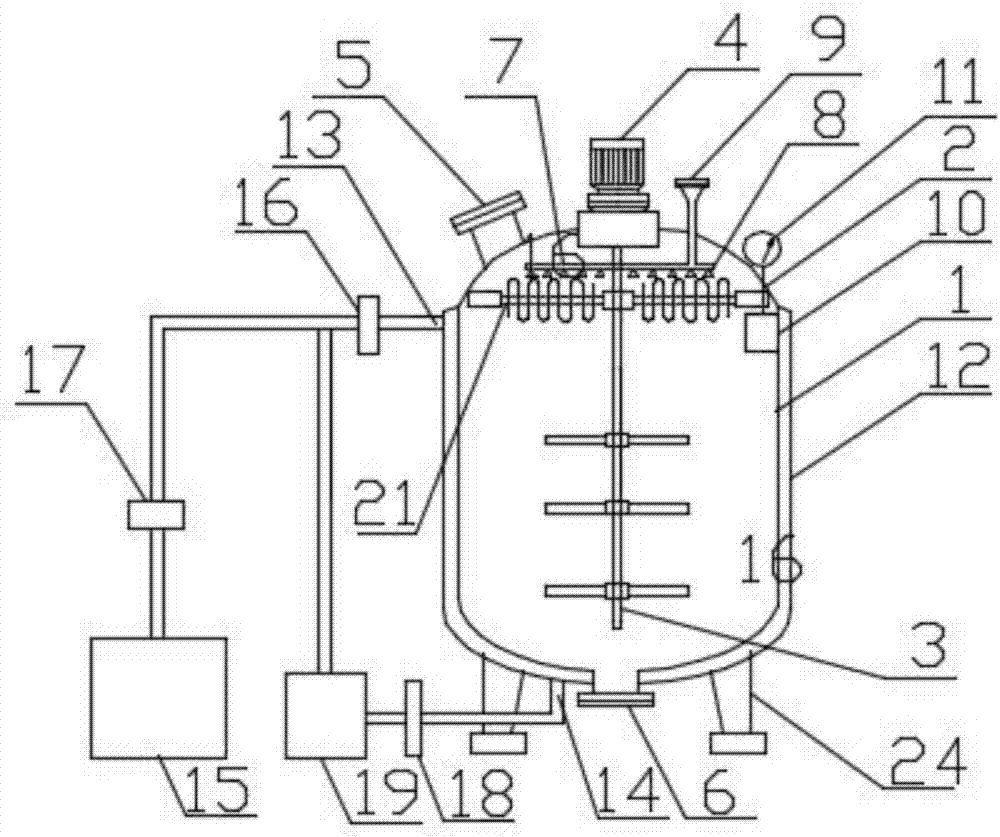

Multifunctional steam heating reaction kettle

InactiveCN107138118AManual steam controlAchieve recyclingProcess control/regulationChemical/physical/physico-chemical stationary reactorsSteam condensationWater storage tank

A multifunctional steam heating reaction kettle, including a kettle body, a kettle cover, a material inlet, a material outlet, a stirring shaft and a motor. A spray pipe is arranged on the upper part of the kettle body, and atomizing nozzles are evenly distributed on the spray pipe. The liquid inlet end of the pipe is located above the kettle body. There is a temperature sensor in the kettle body, and a temperature display connected to the temperature sensor through a wire outside the kettle body. There is a jacket outside the kettle body, and a steam inlet is arranged above the jacket. , there is a condensed water outlet under the jacket, a pressure sensor and a regulating valve are installed on the pipeline between the steam inlet and the steam generator in sequence, the condensed water outlet is connected to a water storage tank, and a purification device is installed between the condensed water outlet and the water storage tank. device, the top of the water storage tank is connected to the pipeline between the pressure sensor and the regulating valve, the upper end of the stirring shaft is also sleeved with a defoaming paddle through a sleeve, and a serpentine defoaming tube is arranged on the defoaming paddle, and the two free ends of the defoaming paddle With flexible sleeve. The invention not only can effectively control the reaction temperature, but also can recycle steam condensed water.

Owner:朱耿稳

Corrosion-resistant long-acting antirust liquid

InactiveCN106086851AStop the spreadInhibit migrationMetallic material coating processesPolyethylene glycolPhytic acid

The invention discloses corrosion-resistant long-acting antirust liquid. Raw materials of the corrosion-resistant long-acting antirust liquid comprise, by weight, 35-45 parts of compound corrosion inhibitor, 0.1-0.3 parts of a surface active agent, 0.2-0.4 part of hydroxy propyl cellulose, 0.3-0.5 part of polyethylene glycol, 0.1-0.3 part of a defoaming agent, 1-3 parts of sodium gluconate, 0.2-0.3 part of benzisothiazolones and 50-54 parts of water, wherein raw materials of the compound corrosion inhibitor comprise phytic acid, sodium molybdate, diethanol amine, monoethanolamine borate and 2-methyl benzimidazoline. According to the corrosion-resistant long-acting antirust liquid, by means of cooperation of the phytic acid, the sodium molybdate, the diethanol amine, the monoethanolamine borate and the 2-methyl benzimidazoline, the film forming speed of a protective film is increased, the corrosion speed is decreased, the thickness of the protective film is increased, corrosion media are prevented from making contact with metal, and the corrosion-resistant long-acting antirust liquid is made to have good corrosion-resistant performance and long-acting antirust performance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

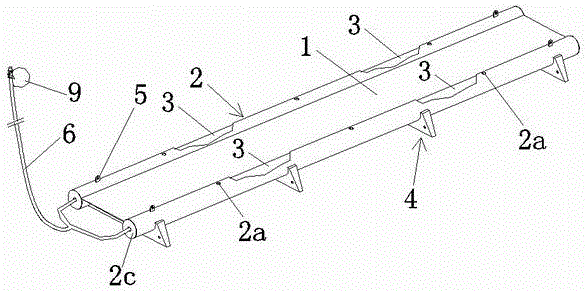

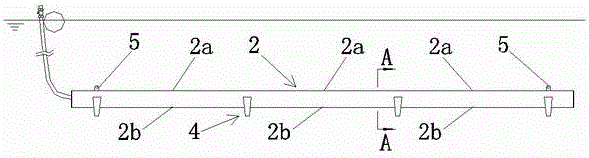

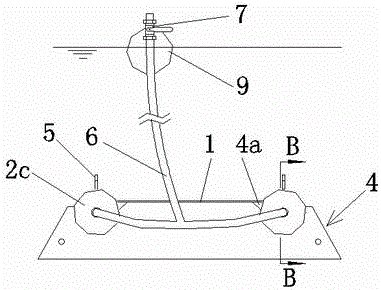

Double-cylinder and plate combined type ocean experimental platform and collecting and deploying method thereof

ActiveCN105691559ASimple structureSimple structure, novel form, light weight, excellent manufacturing processVessel designingFloating buildingsFiberManufacturing technology

The invention discloses a double-cylinder and plate combined type ocean experimental platform and a collecting and deploying method thereof, and belongs to the technical fields of ocean survey and ocean engineering equipment. The ocean experimental platform is characterized in that components mainly adopt fiber reinforced plastics as the material; instruments and devices can be mounted on a working panel, and a good working environment is provided; cylinders are arranged on the two sides of the working panel; airbags are mounted in the cylinders; a plurality of U-shaped diaphragm plates are longitudinally arranged on the platform; the structure form is simple and novel, and the longitudinal bending strength and sit-on bottom stability can be guaranteed; the platform rising and falling is controlled through adjusting the inflating volume of the airbags, and the method is economic and convenient; handing points are arranged at the two ends of each cylinder; and besides, the double-cylinder and plate combined type ocean experimental platform is equipped with a floating transportation platform for operation assistance, so that the sinking process of the platform is guaranteed to be controllable, and the damage of instant impact to the structure during platform bottom resting is avoided. According to the platform, the structure form is novel, the weight is light, the manufacturing technology is simple, the magnetism resistance is good, the erosion resistance is high, and the platform is a reliable, multi-functional, efficient and economic bottom resting type ocean experimental platform.

Owner:DALIAN UNIV OF TECH

Method for depositing boron carbon nitrogen film on stainless steel substrate

InactiveCN101768721AImprove featuresImprove corrosion resistanceVacuum evaporation coatingSputtering coatingSputteringMedium frequency

The invention discloses a method for depositing a boron carbon nitrogen film on a stainless steel substrate. The film can resist corrosion of the ionic liquid. The method adopts the medium frequency magnetron sputtering physical vapor deposition technology to directly deposit a layer of boron carbon nitrogen film on the stainless steel substrate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

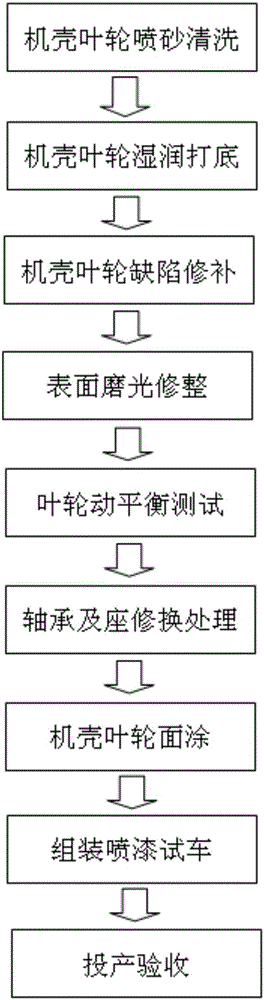

Wear and corrosion resisting repair method for draught fan

The invention discloses a wear and corrosion resisting repair method for a draught fan. The method comprises the process of descaling cleaning, sand blasting or shot blasting, cleaning and drying, wetting bottoming, cleaning and drying, defect repair, wear resisting repair, drying curing, grinding and polishing, impeller dynamic balancing, cleaning and drying, smearing of a first layer of finishing coat, drying curing, smearing of a second layer of finishing coat, drying curing and repair finishing. The wear and corrosion resisting repair method has the beneficial effects that the repair technology is superior to conventional welding repair and machining repair manners, deformation is avoided, no internal stress is generated, the aims of restoring the equipment use function and prolonging the service life are achieved, and the effects of reducing cost and achieving environment friendliness and energy saving are also achieved.

Owner:上海易乓乒智能科技股份有限公司

Preparation method of paper cushion for protecting stainless steel

InactiveCN1800489AAvoid pollutionImprove anti-corrosion abilitySpecial paperPulp beating methodsIonCushion

The invention discloses a method for preparing stainless steel pad paper, which comprises that: adding non-ionic intensifier into paper pulp and processing raw paper preparation and compression on the long-network multi-cylinder machine; compounding the high polymer with high vitrification temperature on the back surface of basic paper; mixing the morpholine oligomer vapour phase inhibitor in 20-30 deals, the dimethyl piperazine in 5-10 deals, the sodium tungstate in 5-10 deals, the blue dye in 0.001-0.01 deals and the deionized water in 50-70 deals to prepare the inhibitor; adding silicon porous absorption material, polyacrylic acid salt disperser and modified macromolecule film former to be plated on the surface of basic paper; drying paper with hot wind, to be burnished, coiled and cut. The invention utilizes the high polymer with high vitrification temperature to improve the mechanical strength and air tightness of basic paper with the functions of moisture-proof and anti-leakage. And the invention plates the metallic inhibitor suspend on the surface of basic paper, therefore, the time of anti-rust can reach 5-10 years.

Owner:SOUTH CHINA UNIV OF TECH

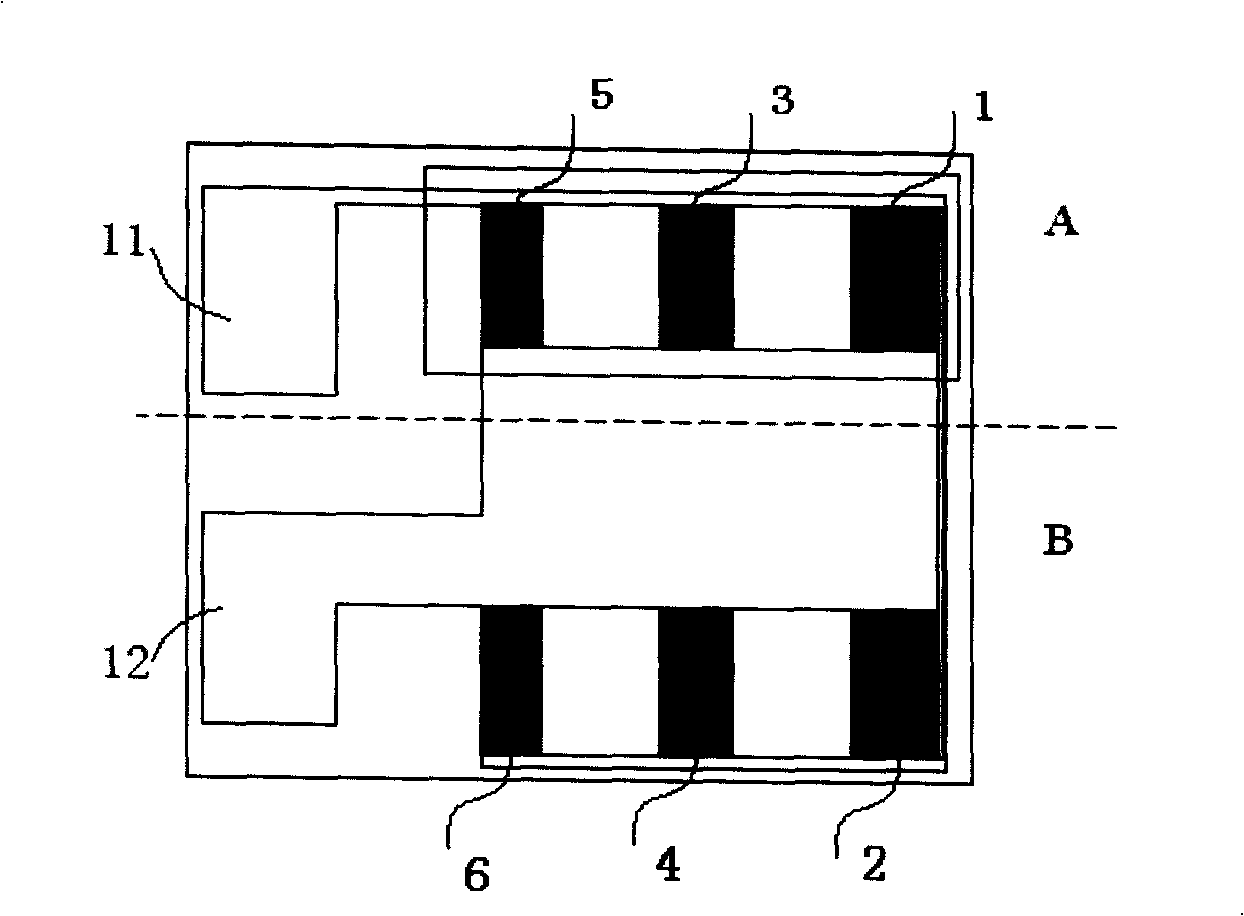

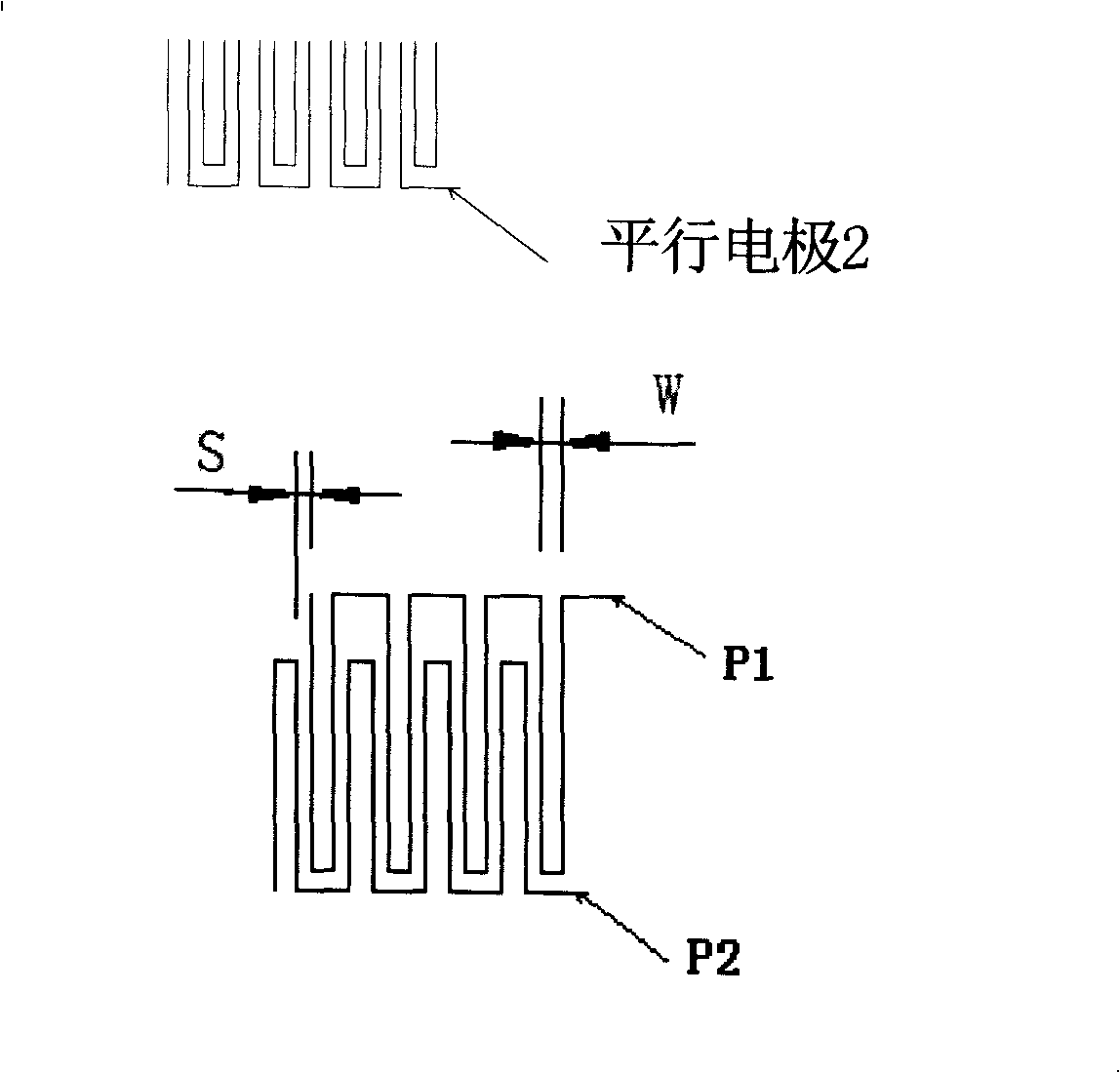

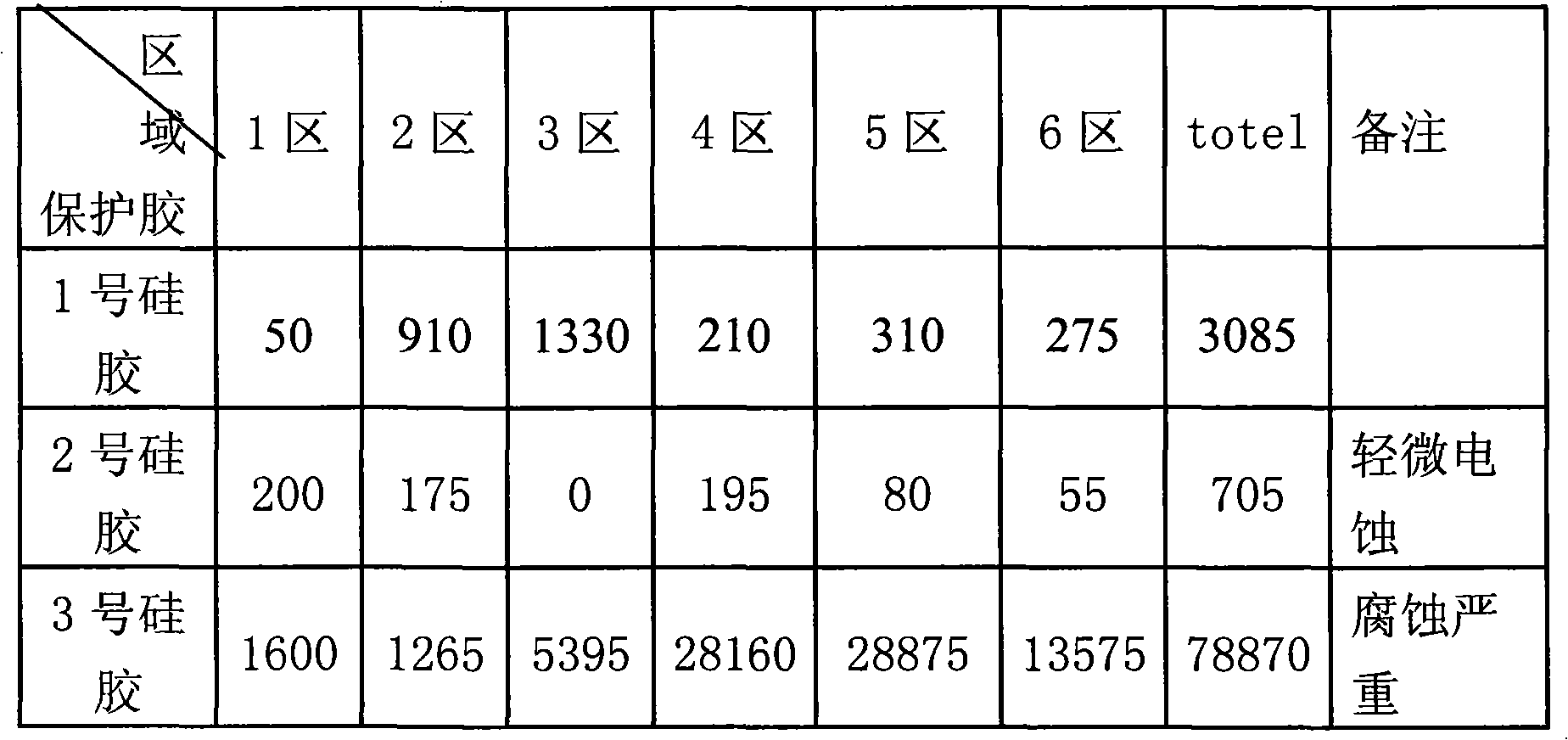

ITO test board and test method

ActiveCN101339302AImprove corrosion resistanceImprove anti-corrosion abilityElectronic circuit testingNon-linear opticsLiquid-crystal displayCorrosion

The invention discloses an ITO test board. The test board comprises a glass substrate, an ITO conducting layer and an insulating layer, wherein, the ITO conducting layer is coated on the glass substrate and the insulating layer is coated on part or the whole of the surface of the ITO conducting layer; and the ITO test board can simulate the ITO electrode routing of a SIN or a CSTN liquid crystal display. The invention also discloses a test method by using the ITO test board, which is as follows: the ITO test board is placed in environment with predetermined temperature and humidity, working voltage is conducted to the ITO electrode for a certain time, and the corrosion condition of the ITO test board is evaluated. The adoption of the scheme of the invention can effectively test and evaluate the factors which influence the corrosion of ITO glasses.

Owner:深圳市合力泰光电有限公司

Low-temperature oil casing steel surface pack cementation aluminizing technique

InactiveCN101775575AAvoid problemsLower activation energySolid state diffusion coatingAl powderSurface layer

The invention relates to a metal surface aluminizing technique, in particular to a low-temperature oil casing steel surface pack cementation aluminizing technique. The invention at least solves the following problems that: the complex change of the variety and content of aluminizing agent in the aluminizing technique needs to be reduced by changing aluminizing agent, the property stability can hardly be controlled, and the cost is high. The adopted technical scheme is as follows: the low-temperature oil casing steel surface pack cementation aluminizing technique sequentially includes the following steps that: the surface nanocrystallization of an oil casing steel sample: a SNC-2 metal surface nanocrystallization tester is utilized to nanocrystallize the surface of the oil casing steel sample in order to obtain a nano-structured surface layer with the thickness of 50Mu m to 90Mu m; the aluminization of the surface-nanocrystallized oil casing steel sample: aluminizing process parameters are as follows: the aluminizing temperature is 380 DEG C to 500 DEG C, and the aluminizing time is 6 hours to 10 hours; and the composition and content of the aluminizing agent are as follows: Al powder as metal source, Zn powder, NH4CL as activating agent and Al2O3 as filler. The aluminizing temperature is low; the variety of aluminizing agent is simple, the content can be easily controlled, and the process stability is high; and the effect is good.

Owner:XI'AN PETROLEUM UNIVERSITY

Anti-corrosion heat dissipation coating used for LED lights and preparation method thereof

ActiveCN103351809AImprove anti-corrosion abilityImprove high temperature resistanceAnti-corrosive paintsPolyamide coatingsXylylenePolyester

The invention provides an anti-corrosion heat dissipation coating used for LED lights and a preparation method thereof. The coating is characterized by comprising the following raw materials by weight parts: 45-48 parts of organic silicone resin, 24-26 parts of polyamide polyamine epichlorohydrin resin, 32-34 parts of aluminium nitride, 50-56 parts of xylene, 25-28 parts of butyl acetate, 2-3 parts of urotropine, 3-5 parts of phenyltriethoxysilane, 2-3 parts of aniline methyl triethoxysilane, 10-20 parts of carbon black N 339, 5-15 parts of carbon black N 660, 1-2 parts of triglycidyl isocyanurate, 5-8 parts of sebacic acid propanediol polyester, 3-5 parts of phthalic acid polyester, 2-3 parts of isoprene, 4-6 parts of 2-hydroxy propyl acrylate, 3-4 parts of propylene glycol, 1-2 parts of tert-butyl hydroperoxide, 1-2 parts of m-amino methylamine, 1-2 parts of ethylene diamine and 3-4 parts of a film forming agent. According to the invention, the urotropine is added into the raw materials to improve the anti-corrosion performance of the coating, so that the coating can be applied in various contaminated environments, and high temperature resistant and salt spray resistant capabilities of the coating can be improved.

Owner:TIANCHANG JINLING ELECTRONICS

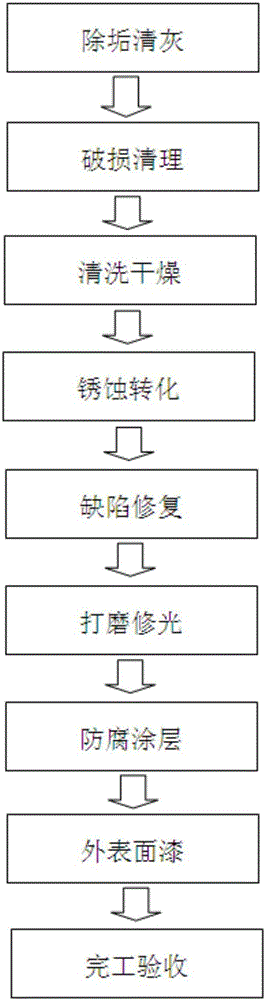

Electric cabinet wear resistance anti-corrosion repair method

ActiveCN105826823AReduce the difficulty of operationImprove anti-corrosion abilitySubstation/switching arrangement casingsDefect repairRepair method

The invention discloses an electric cabinet wear resistance anti-corrosion repair method. The method comprises steps of dirt cleaning, damage processing, cleaning and drying, corrosion conversion, defect repair, polishing and smoothing, anti-corrosion coating, surface painting and completion acceptance. The method is advantaged in that online conduction can be carried out when repair can be accomplished without power cut and without any influence on production, anti-corrosion service life of an electric cabinet after repair is improved by 2-3 times, and remarkable effects are realized.

Owner:上海易乓乒智能科技股份有限公司

Process for preparing corrosion resistant metal material through coating tantalum or niobium with PVD (physical vapor deposition) method

InactiveCN103695854AImprove corrosion resistance and wear resistanceExcellent abrasion resistanceVacuum evaporation coatingSputtering coatingNiobiumGas phase

The invention relates to a process for preparing a corrosion resistant metal material through coating tantalum or niobium with a PVD (physical vapor deposition) method. The process is characterized by comprising a step of coating a tantalum or niobium protective layer on the surface of a metal material substrate through a magnetron sputtering way. The method disclosed by the invention improves anticorrosion and wear-proof performances of metal through a coating technology, and a required corrosion resistant coating is coated on surface of stainless steel or other metal surfaces through a physical vapor deposition (PVD) method; the PVD method includes a magnetron sputtering method, a multi-arc ion plating method, electron gun evaporation and the like. The method disclosed by the invention can improve abrasion and corrosion resistance of surface of a plated metal part, so as to prolong service life of metal or a metal container, and simultaneously improve application safety factor.

Owner:NINGXIA ORIENT TANTALUM IND +1

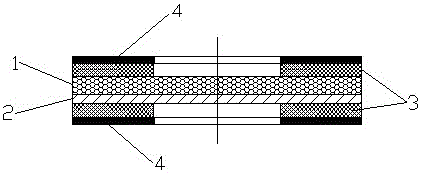

Acoustically transparent membrane module with high resistance to water pressure and manufacture method thereof

ActiveCN106671541AImprove anti-corrosion abilityClear sound without distortionPolymeric diaphragmsSynthetic resin layered productsHigh resistancePore water pressure

The invention discloses an acoustically transparent membrane module with high resistance to water pressure and a manufacture method thereof; the acoustically transparent membrane module with high resistance to water pressure comprises acoustically transparent expanded polytetrafluoroethylene coating film with high resistance to water pressure, pressure-sensitive tape and release paper; the acoustically transparent expanded polytetrafluoroethylene coating film with high resistance to water pressure comprises a coating layer with gas molecular micropores and an expanded polytetrafluoroethylene film layer, one side of the expanded polytetrafluoroethylene film layer is coated with the coating layer with gas molecular micropores, the outer side of the pressure-sensitive tape is provided with the release paper, and the pressure-sensitive tape is fitted to both the front and back of the acoustically transparent expanded polytetrafluoroethylene coating film. The manufacture method comprises: manufacturing hydrophobic oleophobic expanded polytetrafluoroethylene film; preparing coating liquid with gas molecular micropores; preparing the acoustically transparent expanded polytetrafluoroethylene coating film with high resistance to water pressure; preparing the acoustically transparent membrane module with high resistance to water pressure. The acoustically transparent membrane module with high resistance to water pressure has very high resistance to water pressure, can ensure conservations from a speaker are clear and distortionless, and has huge application market potential in terms of consumer electronics.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Water-soluble processing oil agent

ActiveUS20120058925A1Less adversely affects human body and ecological systemImprove anti-corrosion abilityOrganic chemistryLiquid carbonaceous fuelsWorking fluidEngineering

To provide a water-soluble working fluid which less adversely affects the human body and the ecological system as compared with conventional water-soluble working fluids, which has high rotting resistance, and which provides excellent working performance.The water-soluble working fluid of the invention contains methyldicyclohexylamine.

Owner:IDEMITSU KOSAN CO LTD

Repeatedly utilized grass grid sand fixing method

ActiveCN103541341ASave on preprocessing feesImprove anti-corrosion abilityClimate change adaptationSoil preservationBarrier methodEngineering

The invention discloses a repeatedly utilized grass grid sand fixing method. The method relates to a new grass grid sand-protecting barrier method and comprises the steps of: bundling up plant straws into grass bundles; paving the plant bundles on a sand surface to form a grid shape; fixing the plant straws on the sand surface by using a fixed drill rod; lifting the plant straws on the ground surface through a hook on a rake when lots of sands are accumulated in the square grids, wherein the anti-wind and sand-fixing capability of the grass grid sand-protecting barriers is recovered. The method is used for fixing flowing sand surfaces, can prevent hazards of sand storms of oasis cities and towns and engineering construction, can help afforestation in quicksand and can improve rate of survival of nursery stocks. The method can be widely applied to extremely droughty desert areas. If the straws are subjected to good preservative treatment, the method is also applicable to other windy and dusty areas with relatively great rainfalls. The repeatedly utilized grass grid sand fixing method solves the difficulty that the grass sand-protecting barrier after being buried in sands cannot be utilized repeatedly, is capable of saving raw material pre-treatment expense, enhancing erosion resistance of the straws and simplifying site construction besides fully utilizing the plant straw resource, and can be widely applied to the protection and treatment of hazards of sand storms in the extremely draughty desert areas.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

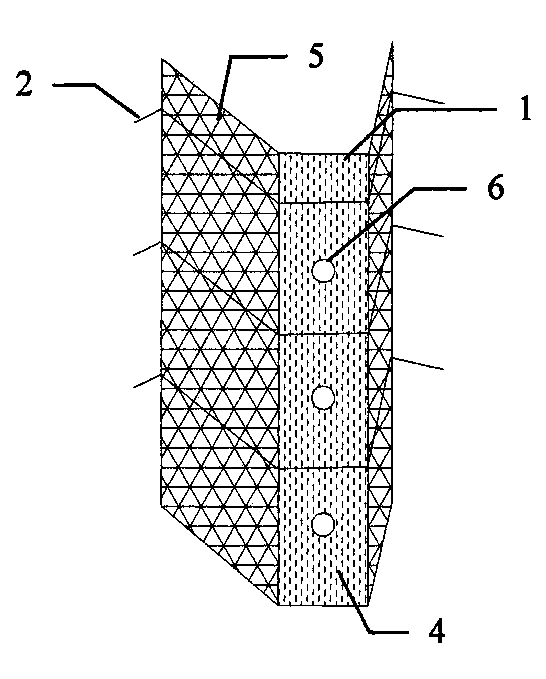

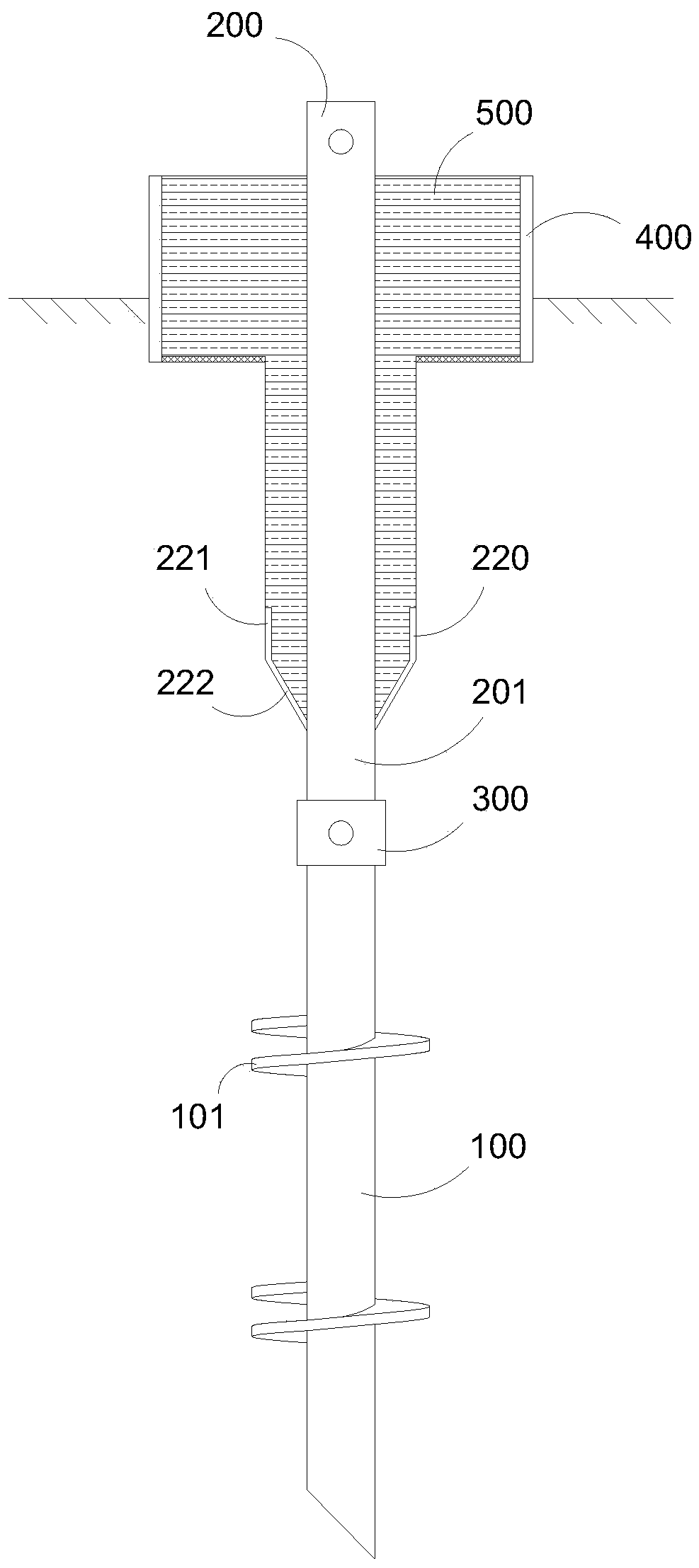

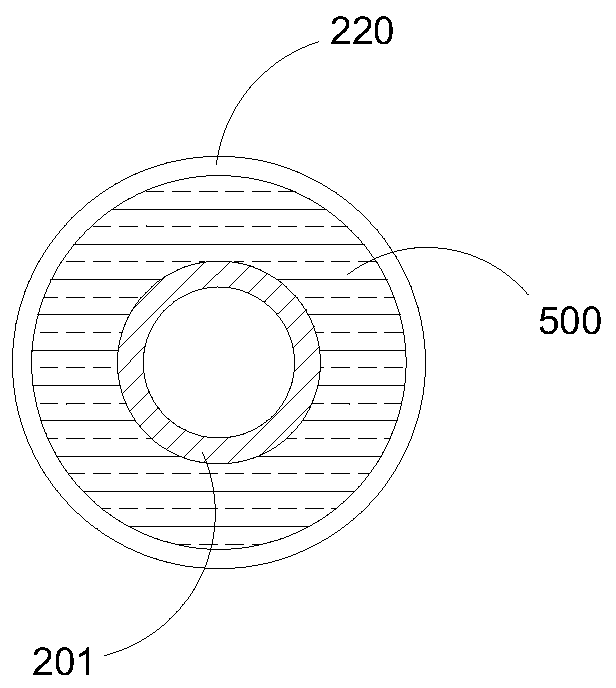

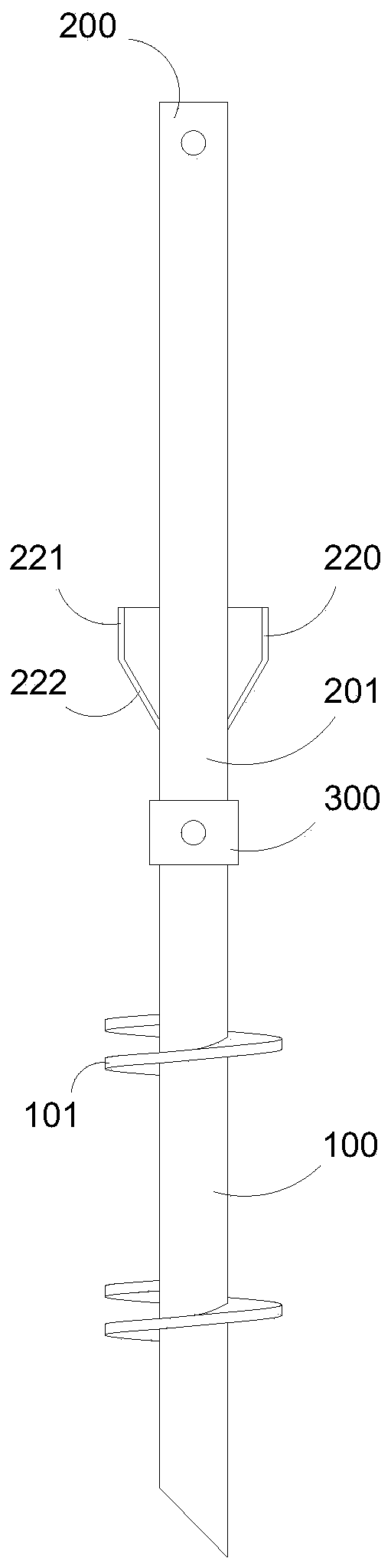

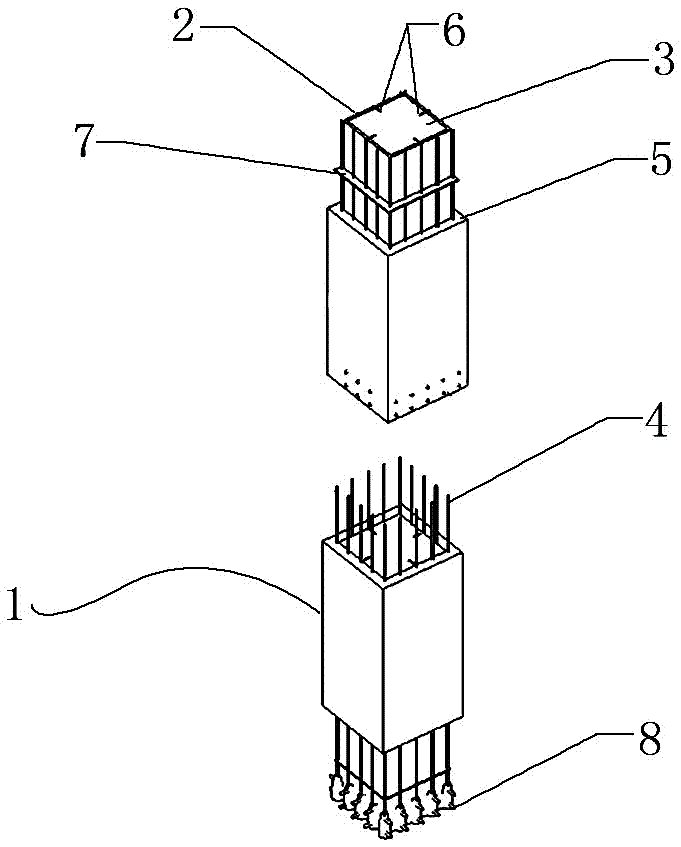

Spiral self-drilling steel pile capable of being reinforced through diameter increasing, and construction method of spiral self-drilling steel pile

PendingCN110067245AIncreased buckling stabilitySpeed up corrosionBulkheads/pilesCarrying capacityFunnel shape

The invention relates to the field of foundation treatment, in particular to a spiral self-drilling steel pile capable of being reinforced through diameter increasing, and a construction method of thespiral self-drilling steel pile. The spiral self-drilling steel pile capable of being reinforced through diameter increasing comprises a spiral pile with a center shaft being provided with spiral blades, and further comprises a lengthening rod composed of one or more lengthening sections; the upper end of the spiral pile is connected with the lower end of the lengthening rod, wherein diameter-increasing guiding discs are arranged on the one or more lengthening sections in the lengthening rod; and the diameter-increasing guiding discs are each in a funnel shape, openings of the diameter-increasing guiding discs face upwards, and the bottoms of the diameter-increasing guiding discs are connected with the rod wall of the lengthening rod in a sealed mode. Through pile side grouting, slurry reaches the diameter-increasing guiding discs to form a reinforced body, the vertical limit bearing capacity, critical buckling load and transverse carrying capacity of the pile are improved, and compared with the mode for improving the bearing capacity through methods of increasing the number of the blades, the diameter of the blades and the pile length, the more economical and applicable effects are achieved so as to enable a foundation to be more stable.

Owner:SOUTHWEST JIAOTONG UNIV

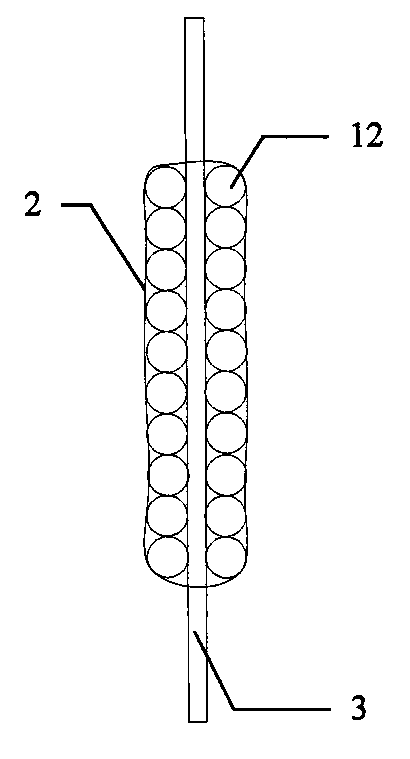

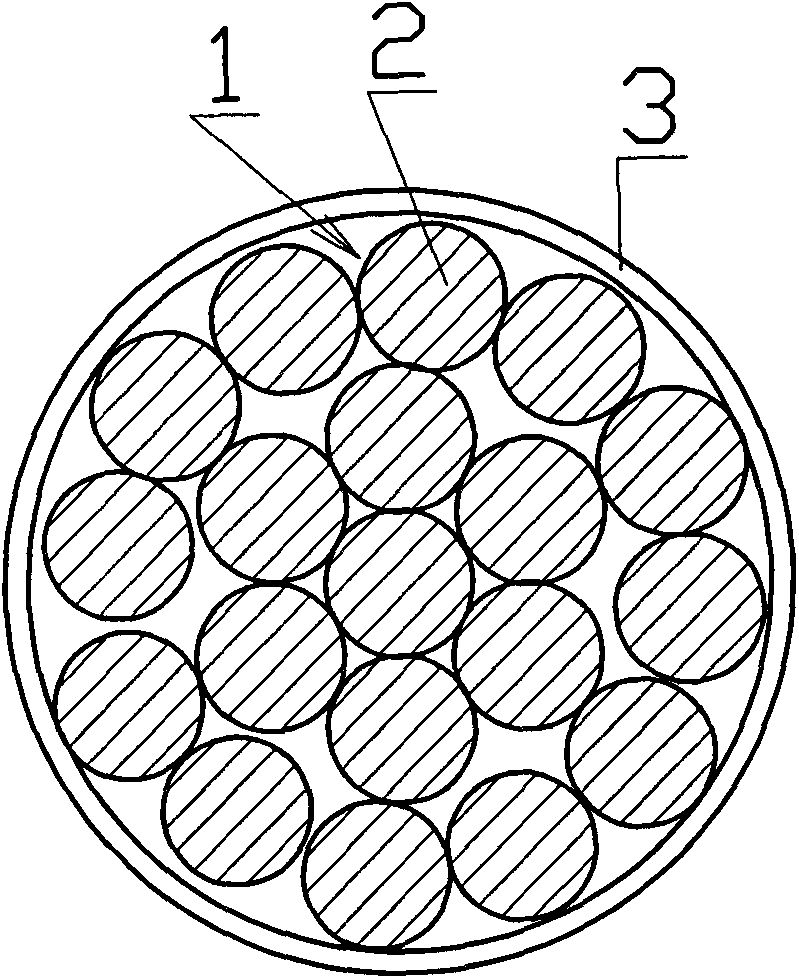

Special alloy-sheathed through earth wire for railway signal system and manufacturing method for special alloy-sheathed through earth wire

InactiveCN104464901AIncrease contact areaLower resistanceNon-insulated conductorsInsulated cablesCopper wireRailway signal

The invention discloses a special alloy-sheathed through earth wire for a railway signal system. The special alloy-sheathed through earth wire comprises a cable core which is of an integrated round structure formed by twisting a plurality of soft round copper wires, the cable core is coated with a brass band, and a tubular outer sheath is formed by the coating brass band. The manufacturing method for the through earth wire includes the following steps that the soft round copper wires with the same conductor diameter are selected and twisted into the cable core according to a specified pitch in a specified arrangement mode; stress of the required number of conductors is adjusted, and the conductors are shaped in a twisted mode; the twisted cable core is pressed through a die, so that the pressed round structure is formed for the cable core; a round metal tube is formed by the brass band through multiple dies, the cable core is coated with the metal tube, a sealed tube is formed by the metal tube after the argon arc welding process is conducted, and the welded brass band metal tube is drawn; the drawn through earth wire is placed in an annealing cavity with the temperature of 800 DEG C for annealing; the annealed through earth wire is passivated, and the passivated through earth wire is rinsed and dried.

Owner:JIANGSU DONGQIANG

Metal surface rust inhibitor and preparation method thereof

InactiveCN104213126AImprove anti-corrosion abilityMoisture proofDithiocarbamateHydroxypropylmethyl cellulose

The invention discloses a metal surface rust inhibitor and a preparation method thereof. The metal surface rust inhibitor comprises dodecenylsuccinic acid, benzotriazole, zinc naphthenate, N-ethyl-N-phenyl zinc dithiocarbamate, sodium oleate, ethylene glycol, inositol hexaphosphate, aluminium powder, barium sulfate, hydroxy propyl methyl cellulose, dimethylaminoethyl acrylate, sodium allysulfonate and water. The preparation method comprises the following steps: adding dodecenylsuccinic acid, benzotriazole and zinc naphthenate into water, stirring the mixture I uniformly, adding N-ethyl-N-phenyl zinc dithiocarbamate, sodium oleate, ethylene glycol, inositol hexaphosphate, aluminium powder, barium sulfate into the mixture I, adding hydroxy propyl methyl cellulose, dimethylaminoethyl acrylate and sodium allysulfonate into the mixture II, and adding rest components into the mixture III to obtain the rust inhibitor. The rust inhibitor provided by the invention can increase the corrosion resistance of a metal surface and improve the moist isolating property and the air isolating property of a protective layer.

Owner:汕头市融通机械实业有限公司

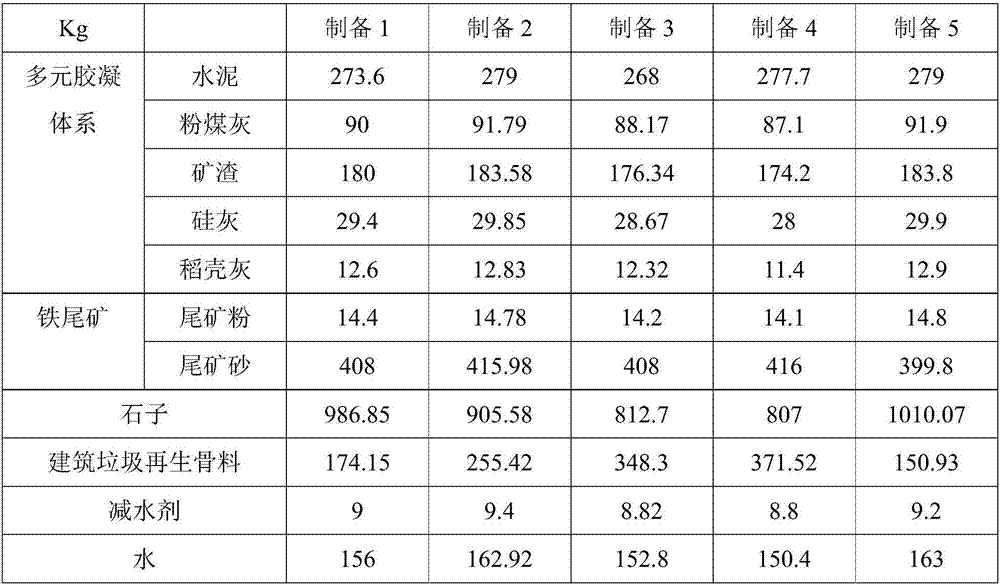

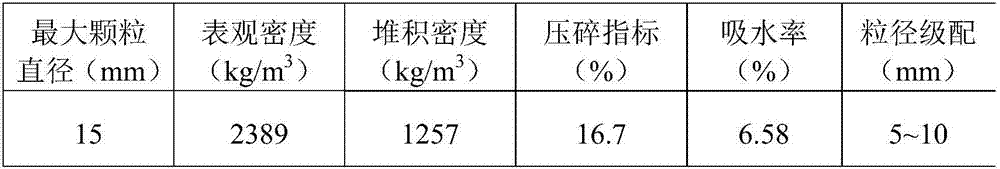

Assembled steel tube high-strength concrete columns and construction method thereof

ActiveCN107460994AIncreased durabilityImprove fire performanceStrutsSolid waste managementHigh strength concreteSteel tube

The invention relates to the technical field of assembled steel tube high-strength concrete columns, and discloses the assembled steel tube high-strength concrete columns and a construction method thereof. The assembled steel tube high-strength concrete columns are formed by sequential connecting of prefabricated standard column joints, and the standard column joints comprise steel tubes, high-strength concrete, stiffening ribs and ordinary concrete, wherein the high-strength concrete is poured in the steel tubes; the stiffening ribs are arranged on the outer side of the steel tubes in a surrounding mode, and the ordinary concrete is poured at the outside of the steel tubes; the high-strength concrete is high-strength concrete with added iron tailings and construction waste; vertical rib groups are fixed to the inner walls of the steel tubes in a welded mode; horizontal end plates are arranged on the outer circumferences of the steel tubes along the section direction in a surrounding mode; through holes are evenly formed in the horizontal end plates at intervals; the stiffening ribs penetrate through the through holes and are arranged in the length directions of the steel tubes in a full-length mode; one ends of the stiffening ribs extend out of the standard column joints, and the other ends of the stiffening ribs are provided with half grouting sleeves which are connected with the stiffening ribs extending out of the adjacent standard column joints. The assembled steel tube high-strength concrete columns are fireproofing, corrosion resisting, high in bearing capacity, and excellent in durability.

Owner:江苏悦港新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com