Electric cabinet wear resistance anti-corrosion repair method

A repair method and technology of electric control cabinet, applied in the direction of substation/distribution device casing, etc., can solve the problems of exacerbation, high cost, hidden danger of production and use, etc., and achieve the effect of prolonging the service life, improving the anti-corrosion ability, and reducing the difficulty of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

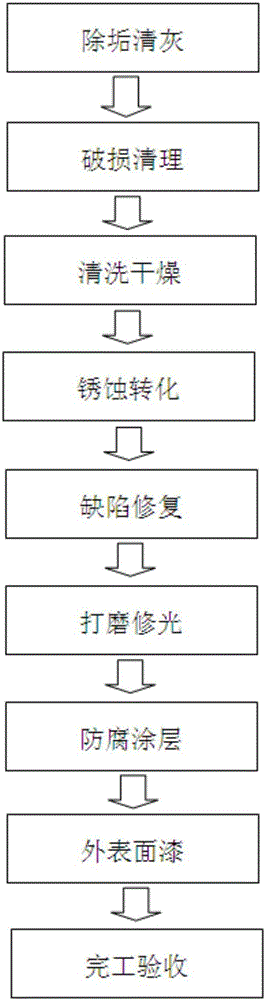

[0026] see figure 1 , the figure shows the process of repairing the wear-resistant and anti-corrosion electric control cabinet: descaling and dust removal → damage cleaning → cleaning and drying → rust conversion → defect repair → polishing → anti-corrosion coating → external surface paint → completion acceptance.

[0027] Working conditions for wear-resistant and anti-corrosion repair of electric control cabinets:

[0028] Temperature: the construction environment is above 10°C;

[0029] Site: Online or offline construction is acceptable;

[0030] Humidity: unlimited;

[0031] There is no need to cut off the power when the electric control cabinet is repaired;

[0032] During construction, construction conditions such as electricity and compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com