Humid rusted solvent-free graphene modified epoxy paint and preparation method thereof

A technology of graphene modification and epoxy coating, applied in the field of coatings, can solve the problems of poor solvent resistance and achieve the effects of improving anti-corrosion performance, good compatibility, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

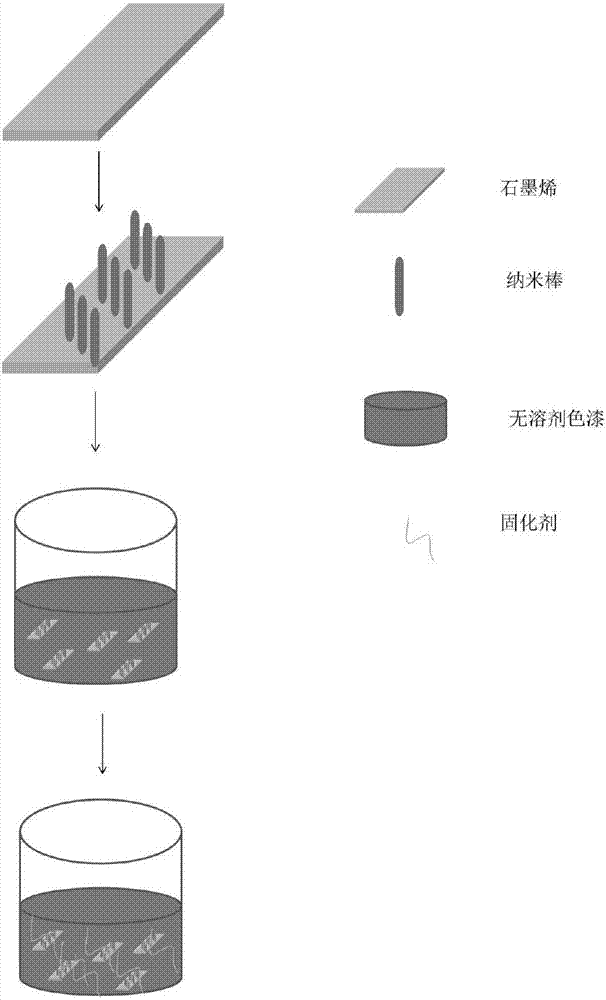

Image

Examples

Embodiment 1

[0050] A kind of damp band rust solvent-free graphene modified epoxy paint, comprises A material and B material; Its parts by weight are as follows:

[0051] Material A is

[0052] Solvent-free epoxy resin E-51 350 parts

[0053] 250 parts of organic zinc-rich epoxy resin

[0054] Epoxy wetting and dispersing additive 15 parts

[0055] 30 parts of graphene-iron oxide nanorod composite material

[0056] Mica iron oxide 110 parts

[0057] Talcum powder 55 parts

[0058] 7 parts organic bentonite

[0059] Metallic Ti nanometer parts 7 parts

[0060] 7 parts of silane coupling agent

[0061] Rheology additive 4 parts

[0062] Leveling agent 4 parts

[0063] Material B is

[0064] Cashew nut shell oil modified phenalkamine 25 parts

[0065] 3 parts of dispersing aid

[0066] Polyamide curing agent 25 parts

[0067] Accelerator 2 parts.

[0068] After testing, the coating has good self-leveling, uniform color and 100% solid content. It is an environmentally friendly co...

Embodiment 2

[0070] A kind of damp band rust solvent-free graphene modified epoxy paint, comprises A material and B material; Its parts by weight are as follows:

[0071] Material A is

[0072] Solvent-free epoxy resin E-51 350 parts

[0073] 250 parts of organic zinc-rich epoxy resin

[0074] Epoxy wetting and dispersing additive 15 parts

[0075] 20 parts of graphene-iron oxide nanorod composite material

[0076] Mica iron oxide 110 parts

[0077] Talcum powder 55 parts

[0078] 7 parts organic bentonite

[0079] Metallic Ti nanometer parts 7 parts

[0080] 7 parts of silane coupling agent

[0081] Rheology additive 4 parts

[0082] Leveling agent 4 parts

[0083] Material B is

[0084] Cashew nut shell oil modified phenalkamine 25 parts

[0085] 3 parts of dispersing aid

[0086] Polyamide curing agent 25 parts

[0087] Accelerator 2 parts.

[0088] After testing, the coating has good self-leveling, uniform color and 100% solid content. It is an environmentally friendly co...

Embodiment 3

[0090] A kind of damp band rust solvent-free graphene modified epoxy paint, comprises A material and B material; Its parts by weight are as follows:

[0091] Material A is

[0092] Solvent-free epoxy resin E-51 350 parts

[0093] 250 parts of organic zinc-rich epoxy resin

[0094] Epoxy wetting and dispersing additive 15 parts

[0095] 40 parts of graphene-iron oxide nanorod composite material

[0096] Mica iron oxide 110 parts

[0097] Talcum powder 55 parts

[0098] 7 parts organic bentonite

[0099] Metallic Ti nanometer parts 7 parts

[0100] 7 parts of silane coupling agent

[0101] Rheology additive 4 parts

[0102] Leveling agent 4 parts

[0103] Material B is

[0104] Cashew nut shell oil modified phenalkamine 25 parts

[0105] 3 parts of dispersing aid

[0106] Polyamide curing agent 25 parts

[0107] Accelerator 2 parts.

[0108] After testing, the coating has good self-leveling, uniform color and 100% solid content. It is an environmentally friendly co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com