Formula for fixing solid radioactive wastes by using cement mortar

A technology of radioactive waste and cement mortar, which is applied in the field of radioactive waste treatment, can solve the problems of high temperature and low compressive strength of fixed bodies, and achieve the effects of good impermeability, easy curing operation and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

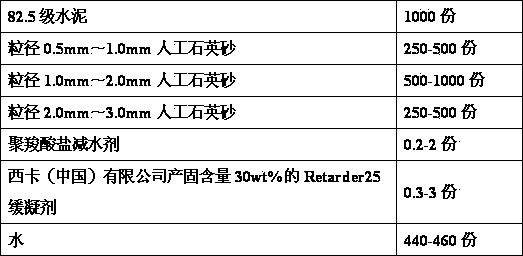

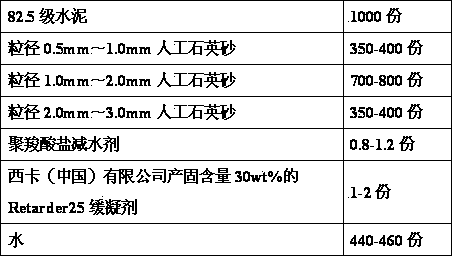

Method used

Image

Examples

Embodiment 1

[0017] Adopt solid radioactive waste cement mortar fixing formula and fixing process of the present invention, in 2m 3 Continuous pouring of 1.15m in the waste packing box 3 cement mortar, of which 0.85 m 3 The overpressure cake is fixed. The 82.5 grade cement in the formula is the product of Tangshan Polar Bear Building Materials Co., Ltd., and the water is ordinary civil tap water.

[0018] During this period, samples were taken to measure the fluidity of the cement mortar, and compression and impermeability samples were made (put them in the curing box for 28 days to measure their compressive and impervious strength).

[0019] The results show that the fluidity of the prepared cement mortar is about 320 mm, the highest temperature rise is 71.7 °C, the compressive strength of the sample block is 91 MPa after standard culture for 28 days, and the chloride ion migration is 589 C. crack.

Embodiment 2

[0021] Using the solid radioactive waste cement mortar fixing formula and fixing process of the present invention, the cement mortar is poured twice in the 200L waste barrel, and the metal elbows and metal wastes therein are fixed. The 82.5 grade cement in the formula is the product of Tangshan Polar Bear Building Materials Co., Ltd., and the water is ordinary civil tap water.

[0022] During this period, samples were taken to measure the fluidity of the cement mortar, and compression and impermeability samples were made (put them in the curing box for 28 days to measure their compressive and impervious strength).

[0023] The results show that the fluidity of the prepared cement mortar is 320 mm, the highest temperature rise is 78.7 °C, the compressive strength of the sample block is 90 MPa after standard curing for 28 days, the chloride ion migration is 600 °C, and the surface of the prepared fixed body is smooth without cracks .

[0024] Subsequently, the fixed body after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com