UV-curing light guide adhesive and preparation method thereof

A light-curing and light-adhesive technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of large equipment investment, large auxiliary raw material input, and high processing cost, so as to reduce packaging costs, reduce manufacturing processes, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

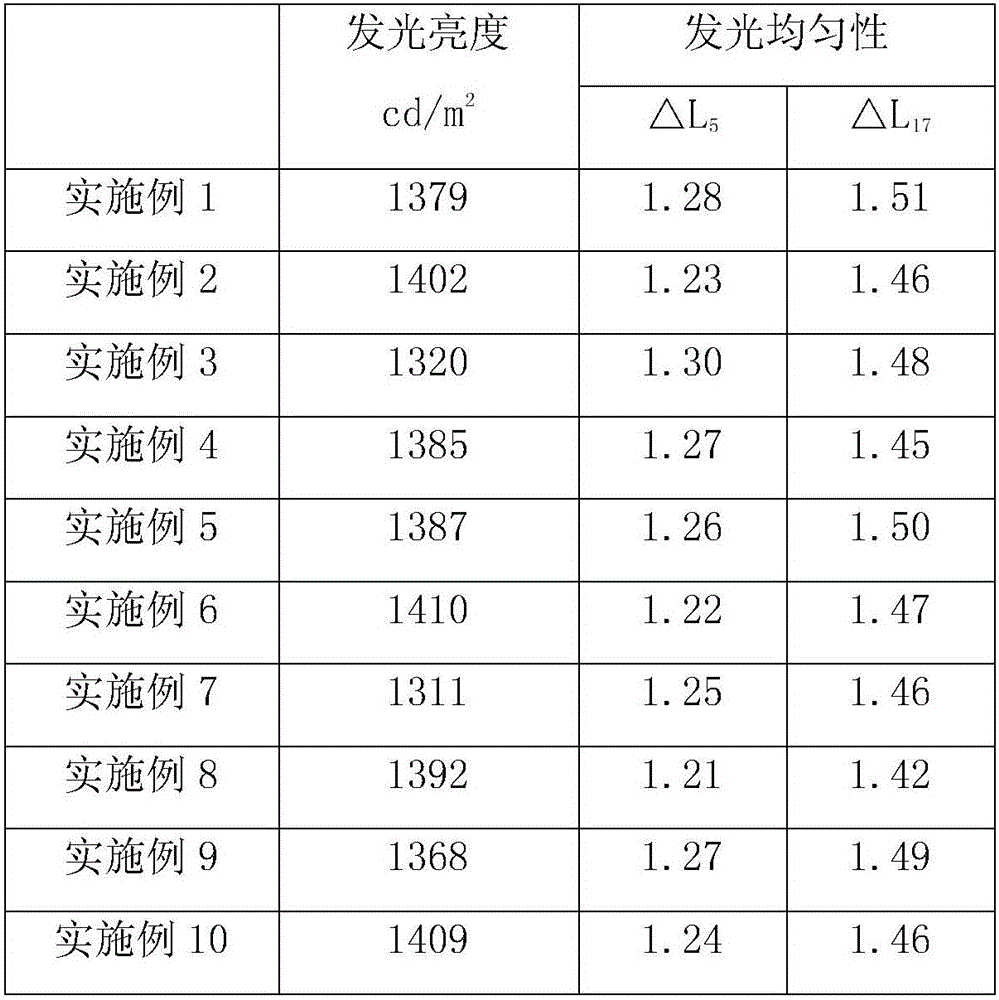

Embodiment 1

[0047] This embodiment provides a method for preparing a UV light-curing light-guiding adhesive, which is prepared according to the following preparation method:

[0048] (1) Weigh 14 parts of 3,3,5-trimethylcyclohexane methacrylate, 20 parts of polybutadiene dimethacrylate and 3 parts of vinyl tributylketoximosilane into the reactor In the process, the stirring speed is 1450r / min, and the reaction is carried out for 25min under the condition of maintaining the system temperature at 30°C;

[0049] (2) Weigh 0.05 parts of 2-hydroxy-2-methyl-1-phenylacetone, 0.05 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 47 parts of difunctional aliphatic polyurethane Add acrylate, 1.2 parts of polydimethylsiloxane, 1.1 parts of sodium polyacrylate and 1.8 parts of polyether-modified silicon into the reaction kettle, and react for 30 minutes at a reaction temperature of 35°C and a stirring speed of 1500r / min;

[0050] (3) Weigh 3 parts of nano-silica and 12 parts of organosil...

Embodiment 2

[0060] This embodiment provides a method for preparing a UV light-curing light-guiding adhesive, which is prepared according to the following preparation method:

[0061] (1) Weigh 14 parts of 3,3,5-trimethylcyclohexane methacrylate, 20 parts of polybutadiene dimethacrylate and 3 parts of vinyl tributylketoximosilane into the reactor In the process, the stirring speed is 1450r / min, and the reaction is carried out for 25min under the condition of maintaining the system temperature at 30°C;

[0062] (2) Weigh 0.05 parts of 2-hydroxy-2-methyl-1-phenylacetone, 0.05 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 47 parts of difunctional aliphatic polyurethane Add acrylate, 1.2 parts of polydimethylsiloxane, 1.1 parts of sodium polyacrylate and 1.8 parts of polyether-modified silicon into the reaction kettle, and react for 30 minutes at a reaction temperature of 35°C and a stirring speed of 1500r / min;

[0063] (3) Weigh 3 parts of nano-silica and 12 parts of organosil...

Embodiment 3

[0073] This embodiment provides a method for preparing a UV light-curing light-guiding adhesive, which is prepared according to the following preparation method:

[0074] (1) Weigh 8 parts of tetrahydrofuran methacrylate, 6 parts of isobornyl methacrylate, 20 parts of polybutadiene dimethacrylate and 3.5 parts of vinyl triethoxysilane into the reaction kettle, stir The speed is 1350 / min, and the reaction is maintained at a system temperature of 25°C for 20 minutes;

[0075] (2) Weigh 0.05 parts of 1-hydroxycyclohexyl phenyl ketone, 0.05 parts of 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, and 52 parts of trifunctional aliphatic polyurethane acrylic acid Ester, 2 parts of phosphate-modified acrylic acid, 1.5 parts of polyvinyl alcohol and 1.8 parts of polydimethylsiloxane were added to the reaction kettle, and the reaction temperature was 30°C, and the stirring speed was 1300r / min for 25 minutes;

[0076] (3) Weigh 4 parts of nano-titanium dioxide and 10 parts of org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com