Patents

Literature

120results about How to "Resistant to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

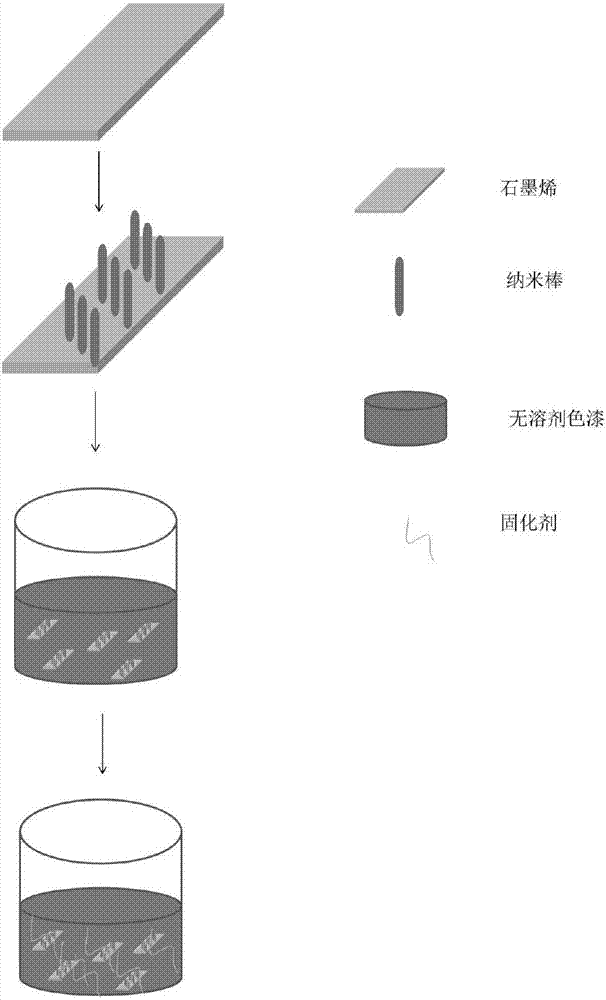

Humid rusted solvent-free graphene modified epoxy paint and preparation method thereof

ActiveCN106867363AGood self levelingUniform colorAnti-corrosive paintsEpoxy resin coatingsAdhesion forceSolvent free

The invention relates to humid rusted solvent-free graphene modified epoxy paint and a preparation method thereof. The paint is prepared from a material A and a material B, wherein the material A is colored paint; the material B is a curing agent; graphene-oxide nano-rods are added into the colored paint; in the aspect of selecting epoxy resin, two types of epoxy resin including solvent-free epoxy resin E-51 and organic zinc-enriched epoxy resin, which have complementary properties, are selected, so that the adhesion force and antirust effect of the paint and a substrate are enhanced; in the aspect of selecting the curing agent, two curing agents are adopted; a polyamide curing agent is added on the basis of a cashew nut shell oil modified phenolic aldehyde amine curing agent which is researched latest, so that the humid rusted solvent-free graphene modified epoxy paint is prepared.

Owner:邹亚静

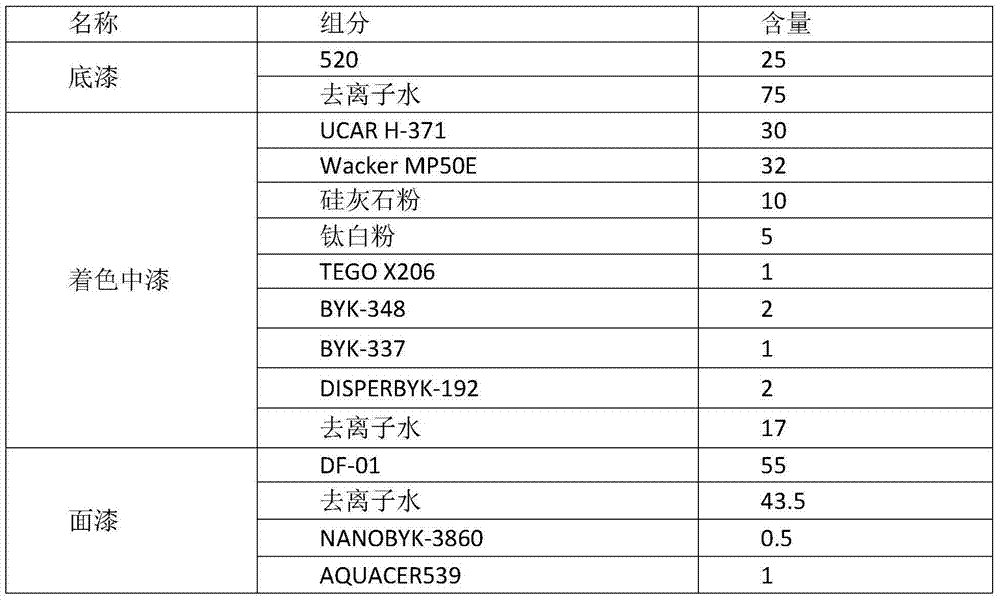

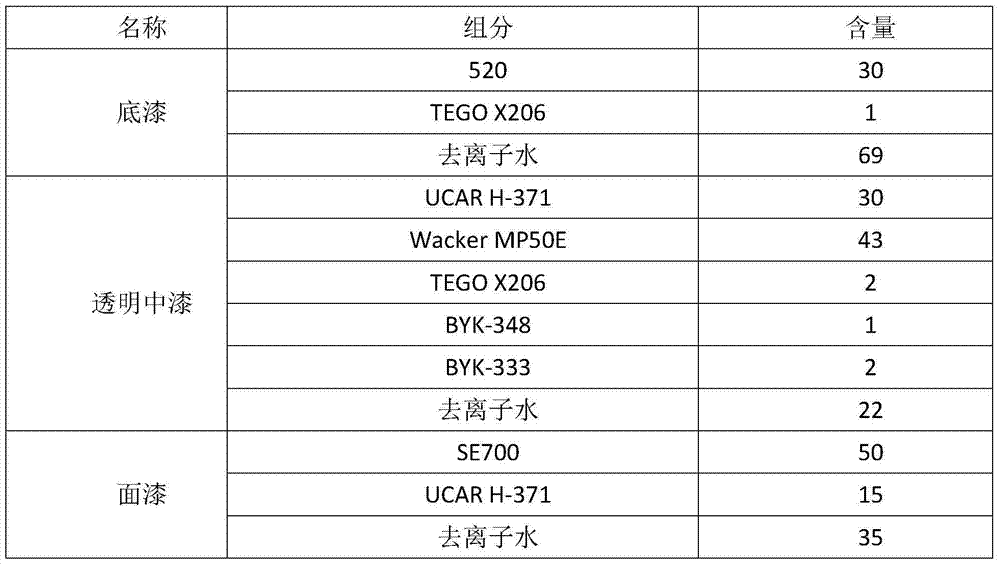

Protective agent for clear water concrete

InactiveCN103922800ARepair Surface Chromatic AberrationKeep natural textureCrosslinked polymersMaterials science

The invention discloses a protective agent for clear water concrete. The protective agent is composed of a priming paint, a medium paint and a finishing paint, wherein the priming paint is an organosilicon polymer, the medium paint is composed of a self-crosslinked polymer, water, pigment, a filling material and other auxiliary agents, and the finishing paint is a fluorosilicone resin polymer. According to the protective agent for the clear water concrete in the invention, three layers of the paints are combined and successively coat the surface of the clear water concrete, so surface color difference of the clear water concrete is repaired, nature quality and texture of the clear water concrete are maintained, the clear water concrete is endowed with a plurality of functions like water resistance, resistance to chemical attack, weatherability and self-cleaning performance, durability of the clear water concrete is substantially improved, and the service life of the clear water concrete is prolonged.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Vibration-damping heat-insulation paint and preparation method thereof

ActiveCN101709188AGood adhesionIncreased durabilityFireproof paintsAnti-corrosive paintsAdhesiveData recording

The invention discloses a vibration-damping heat-insulation paint which comprises the following components by mass percent: 9.5-11.5% of chlorine ether resin, 5-6% of adhesive, 3.5-4.5% of melamine urea copolymerization resin, 18-21% of environment-friendly solvent, 14.5-16.5% of soft filler I, 13-15% of soft filler II, 18-20% of soft filler III, 3.8-5.8% of plasticizer, 1.5-2.3% of titanium pigment and 4-6% of hollow micro-bead. The invention also discloses a preparation method of the vibration-damping heat-insulation paint. The high-efficiency vibration-damping heat-insulation paint can be coated on various substrates, has advantages in various aspects such as heat insulation, heat preservation, fire prevention, water prevention, crack prevention, noise prevention, weather resistance, acid / alkali resistance, salt-fog resistance, corrosion resistance, vibration damping, durability and the like, is suitable for thermal protection and vibration damping at the external surfaces of spaceflight instruments and data recording instruments of aerospacecrafts and can be used for damping the impact friction and the like of containers and the like.

Owner:WUXI HUHUANG PAINT

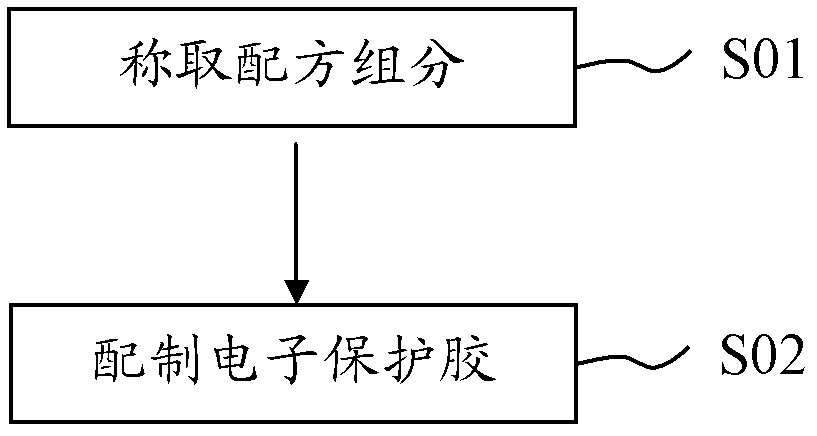

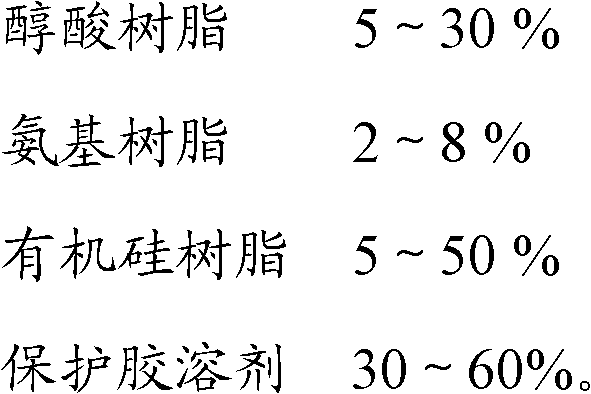

Electronic protecting glue, and preparation method and application thereof

ActiveCN102604585AImproves UV resistanceExcellent heat and humidity resistanceAldehyde/ketone condensation polymer adhesivesPolyester coatingsSolventSilicon

The invention discloses electronic protecting glue, and a preparation method and application thereof. The electronic protecting glue comprises, in weight percentage, 5-30% of alkyd resin, 2-8% of amino resin, 5-50% of organic silicon resin, and 30-60% of protecting glue solvent. The preparation method of the electronic protecting glue includes the steps: respectively weighing the components according to electronic protecting glue formulas described in claim one to six; adding and evenly dispersing the alkyd resin, the amino resin and the organic silicon resin into the protecting glue solvent,and packaging to obtain the electronic protecting glue. The electronic protecting glue is excellent in ultraviolet resistance and damp-heat resistance, fine in adhesive property, less prone to cracking, stable in performances, safe and environment-friendly. The defects of existing electronic protecting glue, such as proneness to cracking, poor adhesive property and low price, are overcome effectively. The preparation method of the electronic protecting glue is simple in process, low in cost, and applicable to industrial production and has low equipment requirements.

Owner:深圳市兴时达科技产品有限公司

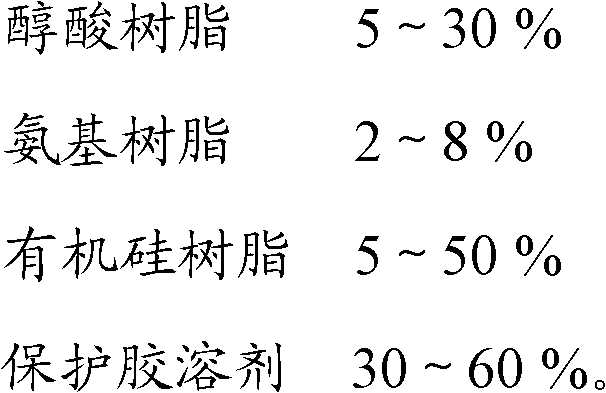

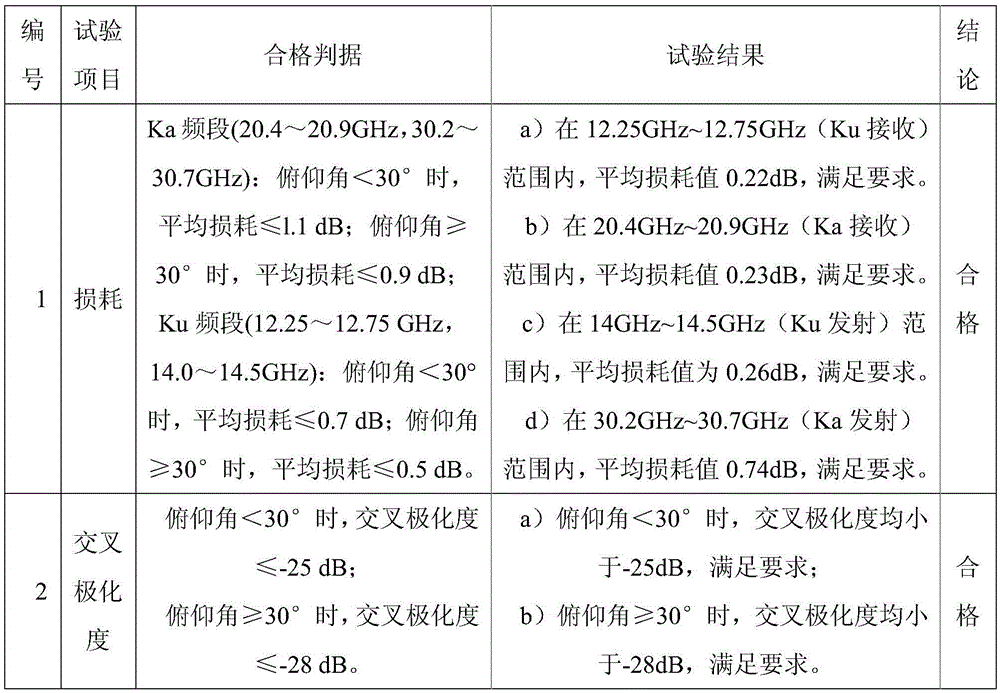

Composite material for airborne radomes, and preparation method thereof

ActiveCN105563964AImprove environmental resistanceStrong high and low temperature resistanceSynthetic resin layered productsRadiating element housingsRight trapezoidRadome

The invention discloses a composite material for airborne radomes, and a preparation method thereof. The composite material for airborne radomes comprises a surface coating layer, an outer skin layer, a sandwich layer and an inner skin layer, the sandwich layer is arranged between the outer skin layer and the inner skin layer, and the surface of the outer skin layer is coated with the surface coating layer; the thickness of the outer skin layer is 0.2-1mm; the sandwich layer is made of polymethacrylimide, and has a right trapezoid structure, the short edge thickness is 4-30mm, and the long edge thickness is 4.5-34mm; and the thickness of the inner coating layer is 0.2-1mm. The preparation method comprises the following steps: preparing an inner skin layer prepreg through manual pasting dipping, overlaying a sandwich layer material, solidifying, preparing an outer skin layer prepreg through manual pasting dipping, solidifying, spraying the surface coating layer, and solidifying. The composite material for airborne radomes has the advantages of excellent environment resistance, good whole bearing ability, and maintenance of a high wave penetration rate in double wavebands.

Owner:NAT UNIV OF DEFENSE TECH

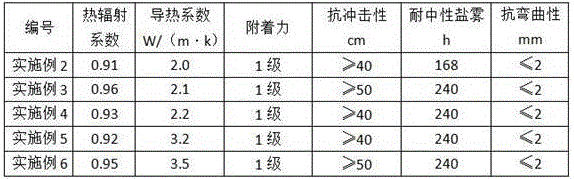

Graphene radiating material and preparation method thereof

InactiveCN106221396AImprove cooling effectImprove adhesionAntifouling/underwater paintsPaints with biocidesSolventGraphene

The invention discloses graphene radiating material and a preparation method thereof. The graphene radiating material comprises agent A and agent B mixed well at a mass ratio of 1:1, the agent A comprises the following components, by weight: 40-60% of fluorocarbon resin, 30-50% of a mixed solvent, 5-15% of graphene, 0.5-1.5% of a leveling agent, and a 0.5-1.5% of a dispersant; the agent B comprises a mixed solvent and a curing agent at a mass ratio of 10:1. The prepared coating has the advantages such as high thermal conductivity coefficient, high thermal radiation coefficient, god radiating effect, acid and alkali tolerance, salt spray tolerance, impact resistance and high matrix adhesion, and the radiating material is widely applicable and usable.

Owner:DEYANG CARBONENE TECH

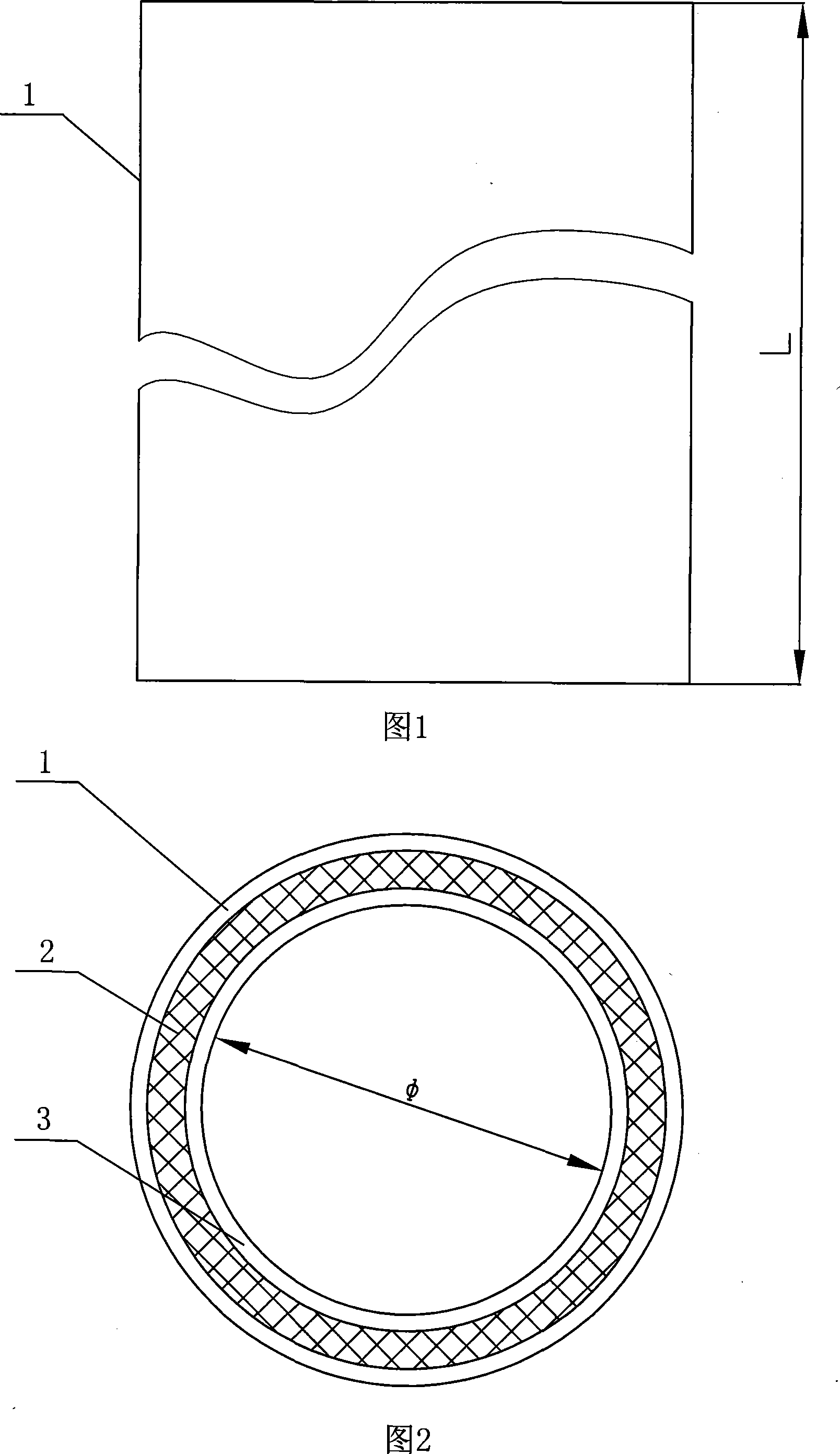

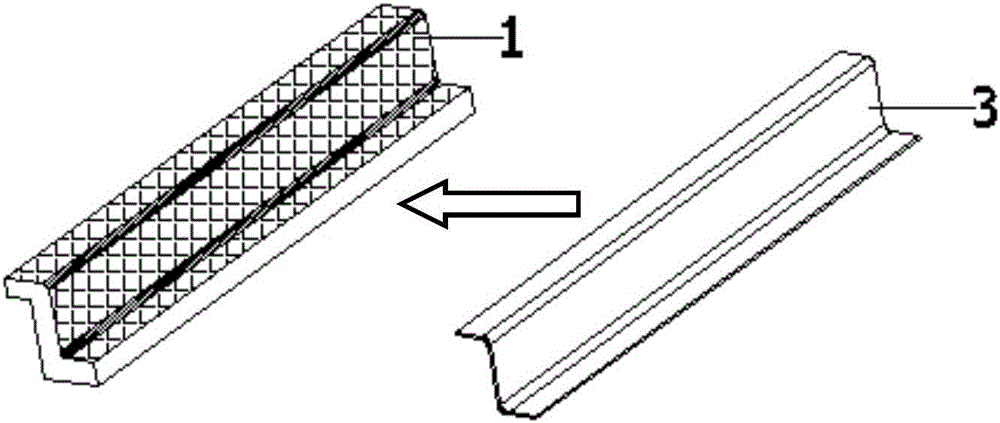

Fiber reinforcement resin radical compound material drive axle

A fiber enforced resin based compound material transmission shaft pertains to a compound material transmission shaft, and is mainly applied to the transmission systems and precision instruments of such fields as mechanics industry, aviation industry and aerospace industry. The invention solves the problems of the existing compound material transmission shaft, such as poor high temperature resistance, abrasion resistance, humidity resistance, salt spray resistance, and impact resistance, etc. The invention comprises a structure layer, a surface layer (1), and a lining layer (3); the structure layer is a hollow shaft body (2) made of fiber enforced resin based compound material, the lining layer (3) and the surface layer (1) are respectively stuck on the inner surface and the outer surface of the hollow shaft body (2) made of fiber enforced resin based compound material. The invention has the advantages of high temperature resistance, abrasion resistance, corrosion resistance, comparatively strength and hardness, humidity resistance, salt spray resistance, and impact resistance, etc.

Owner:HARBIN FRP INST

Ultraviolet-resisting metal anti-rust paint and preparation method thereof

The invention discloses ultraviolet-resisting metal anti-rust paint and a preparation method thereof. The anti-rust paint is prepared from slurrying raw materials and paint mixing raw materials; a paint film formed by the anti-rust paint has high hardness, scratching resistance, strong adhesion, salt fog resistance, saline resistance, acid-base resistance, water resistance, oil resistance and ultraviolet resistance; the paint can be used on the surface of an old paint film repeatedly; the damage to the paint film can be avoided; and super strong toughness of the paint film can be achieved. The service life of the paint film can reach 8 to 10 years generally.

Owner:广州瑞一环保科技有限公司

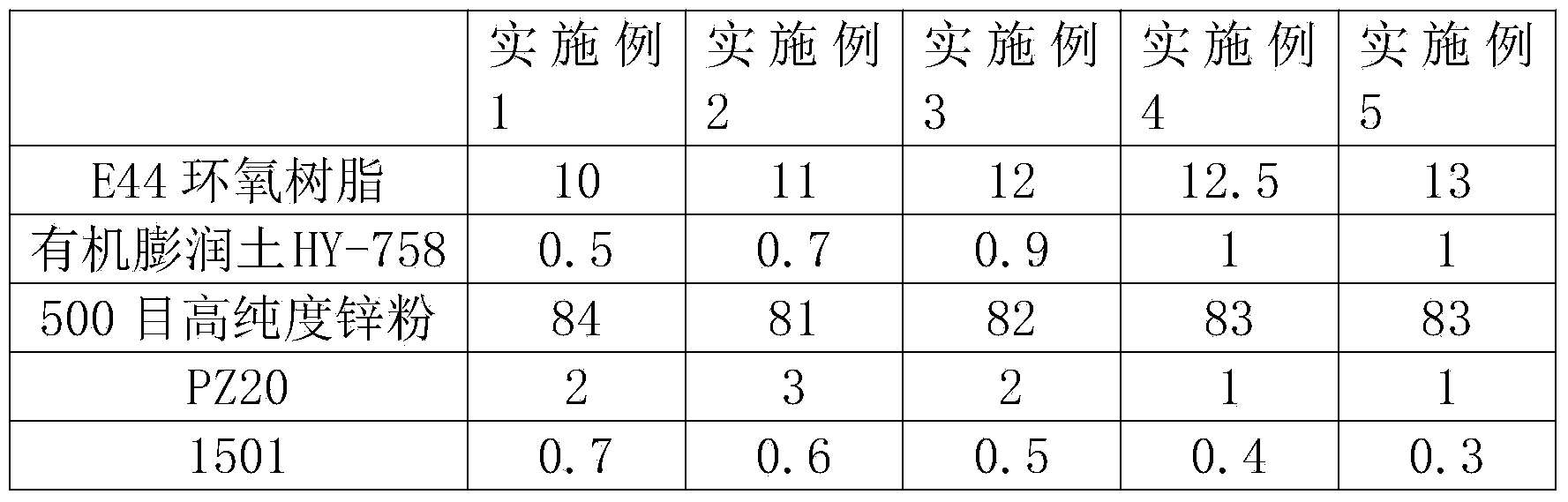

High-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer and preparation method thereof

InactiveCN104140735ANon-foamingNo rustAnti-corrosive paintsEpoxy resin coatingsZinc phosphateSodium Bentonite

The invention provides a high-specific-weight high-zinc-content heavy-duty epoxy zinc-rich primer. The primer contains a component A and a component B and is characterized in that the component A contains epoxy resin, high-purity zinc powder, environment-friendly zinc phosphate, an assistant A / B, organic bentonite and a mixed solvent; the component B contains cardanol modified polyamide resin, an assistant C and a mixed solvent. The product provided by the invention has the characteristics of salt mist resistance and high specific weight, the solid content reaches 95%, the zinc content reaches 80%, the primer solid proportion reaches 3.0g / ml, and the salt mist resistance can achieve that a primer film is free from bubbling, rusting and peeling for more than 5,000 hours; the product can be extensively applied to the field of metallic heavy-duty products in relatively adverse climates and seaboards, such as bridges, steel structures, ships and petroleum pipelines.

Owner:成都拜迪新材料有限公司

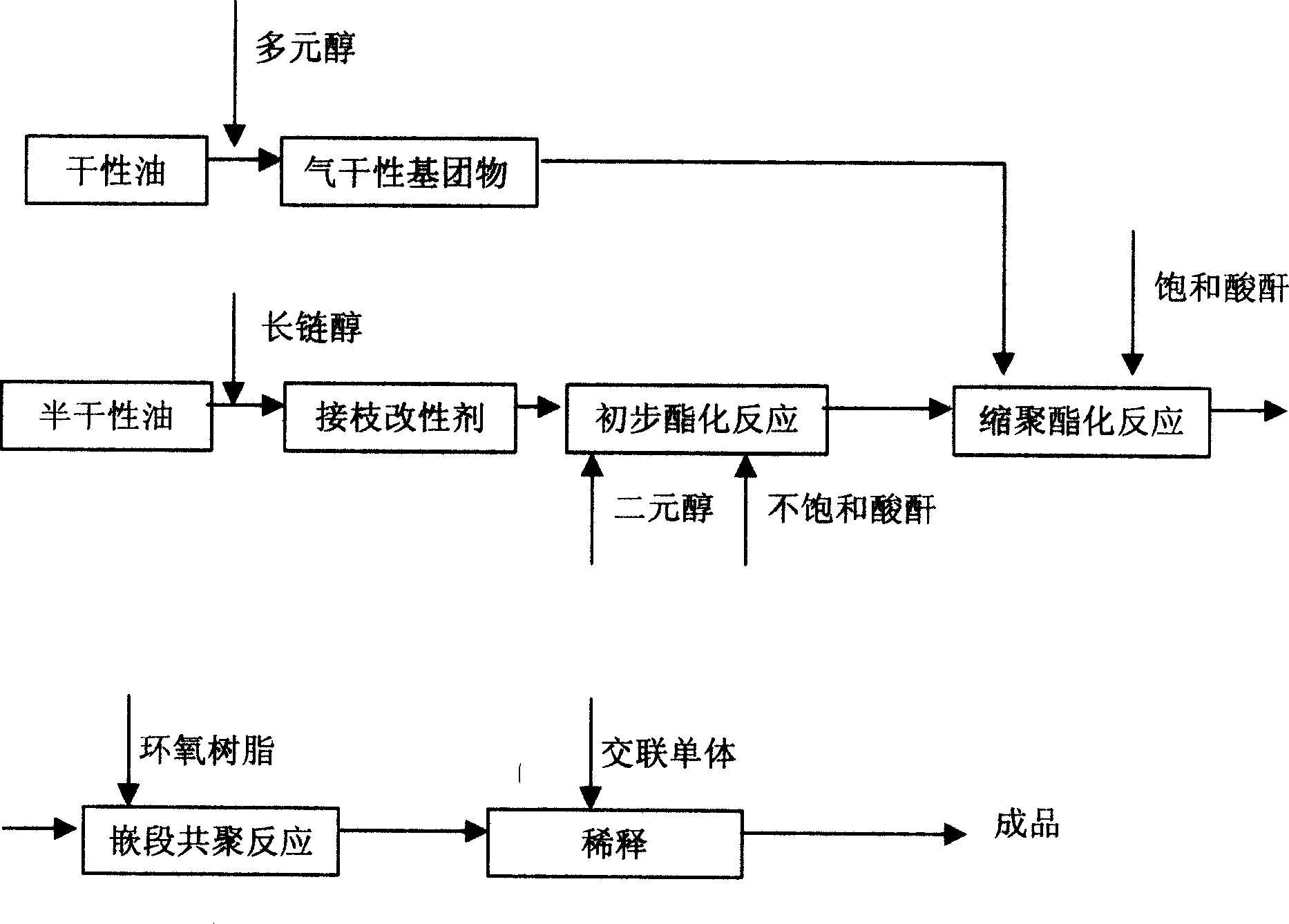

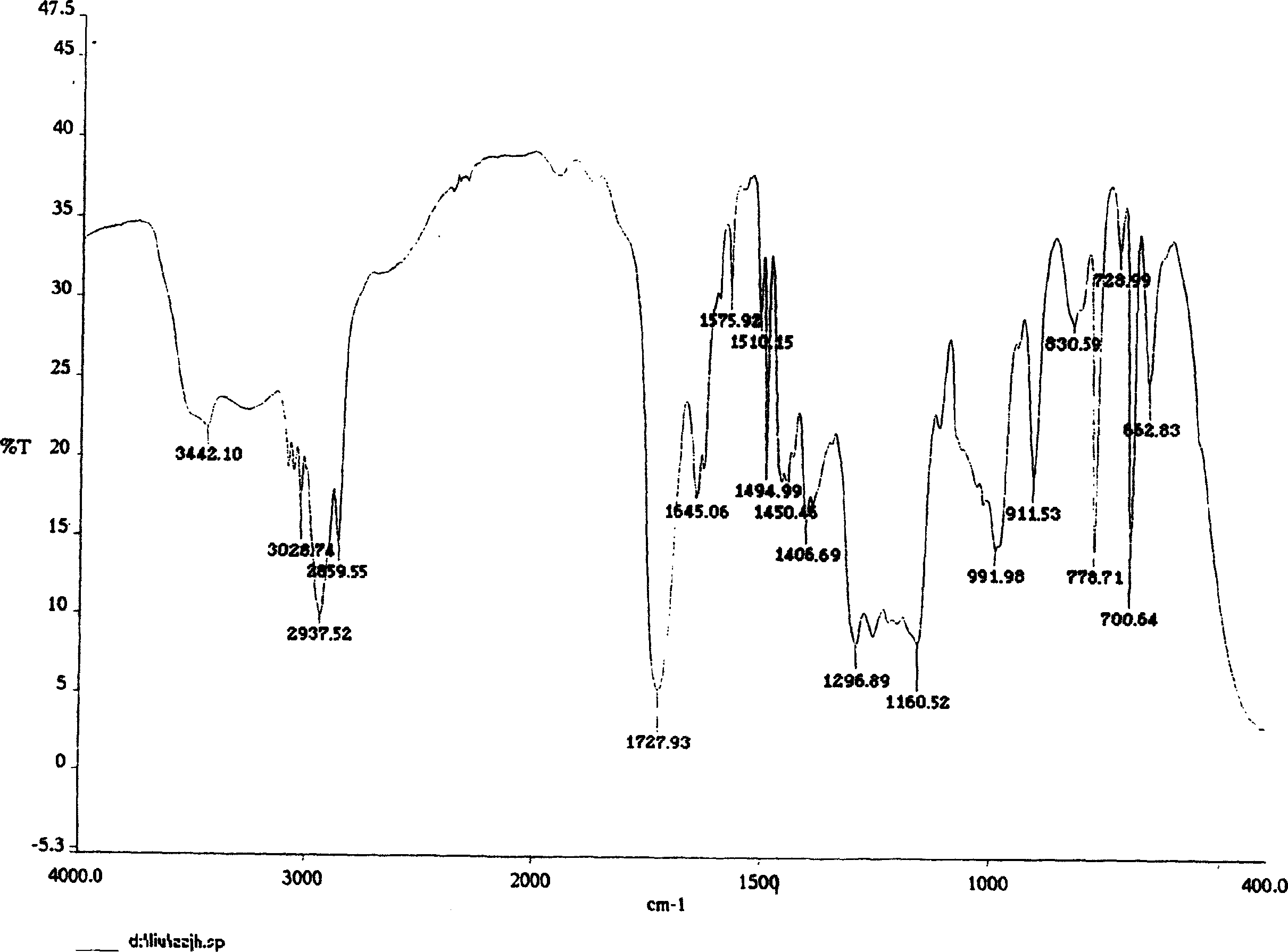

Epoxy modified unsaturated polyester resin special for putty and method for making same

InactiveCN1603352AStrong adhesionGood chemical resistanceFilling pastesChemical structureVegetable oil

This invention relates to homopolymer of multiple unsaturations aliphatic compounds and coating combination of homopolymer and their production method, especially to a lacquer putty special polyester resin and its production method. Single glyceride base group is made by graft copolymerization according to alkyd resin alcoholysis method on the basis of fundamental chain is unsaturation resin, and copolymerization epoxy base group is blocked. Molecular weight is 1000~2000, grafting ratio of alcoholic acid base group and epoxy base group is 25%~29%. The weight ratio of material recipe is that saturated anhydride 180~200 shares, unsaturation anhydride 260~320 shares, dihydric alcohol 180~200 shares, polyatomic alcohol 8~10 shares. Vegetable drying oil 23~30 shares, long chain alcohol 18~53 shares, half drying vegetable oil 32~97 shares, epoxy resin 35~42 shares, antioxidant 1.5~2.5 shares, catalyst 0.5~1 share, crosslinking monomer and diluent agent 450~500 shares. There is reasonable chemical structure in the invention, and the lacquer putty made can be strong adhesive force, good anti-chemical capability, quick drying, and it is easy to burnish and it can reach 1 hour in application.

Owner:株洲市九华新材料涂装实业有限公司

Metal antirust paint for ships and its preparation method

ActiveCN103396726AHigh hardnessScratch resistantAnti-corrosive paintsPolyester coatingsMethacrylateKetone

The invention discloses a metal antirust paint for ships. The metal antirust paint is composed of the following raw materials by weight part: 5-8 of zinc powder, 5-8 of ferroferric oxide, 20-30 of methyl ethyl ketone, 30-40 of medium oil alkyd resin, 1-2 of HDl biuret, 5-10 of dicyclopentenyl ethoxyl methacrylate, 5-10 of hexanediol butyl ether acetate, 4-6 of magnesium hydroxide, 3-5 of nano-attapulgite clay, 1-2 of stannous pyrophosphate, 3-5 of sodium tripolyphosphate, and 1-2 of a polysiloxane defoaming agent, etc. The preparation method of the antirust paint involved in the invention is designed as a two-step process. In the first step, the zinc powder reacts with other ingredients to form a grid structure. The formed paint film has high hardness, scratch resistance and strong adhesion, and resists salt fog, saline, acid and base, water as well as oil. No damage can be caused to the paint film. The paint film also has super strong flexibility, and a general service life of 6-8 years.

Owner:寿县风顺船舶修造有限责任公司

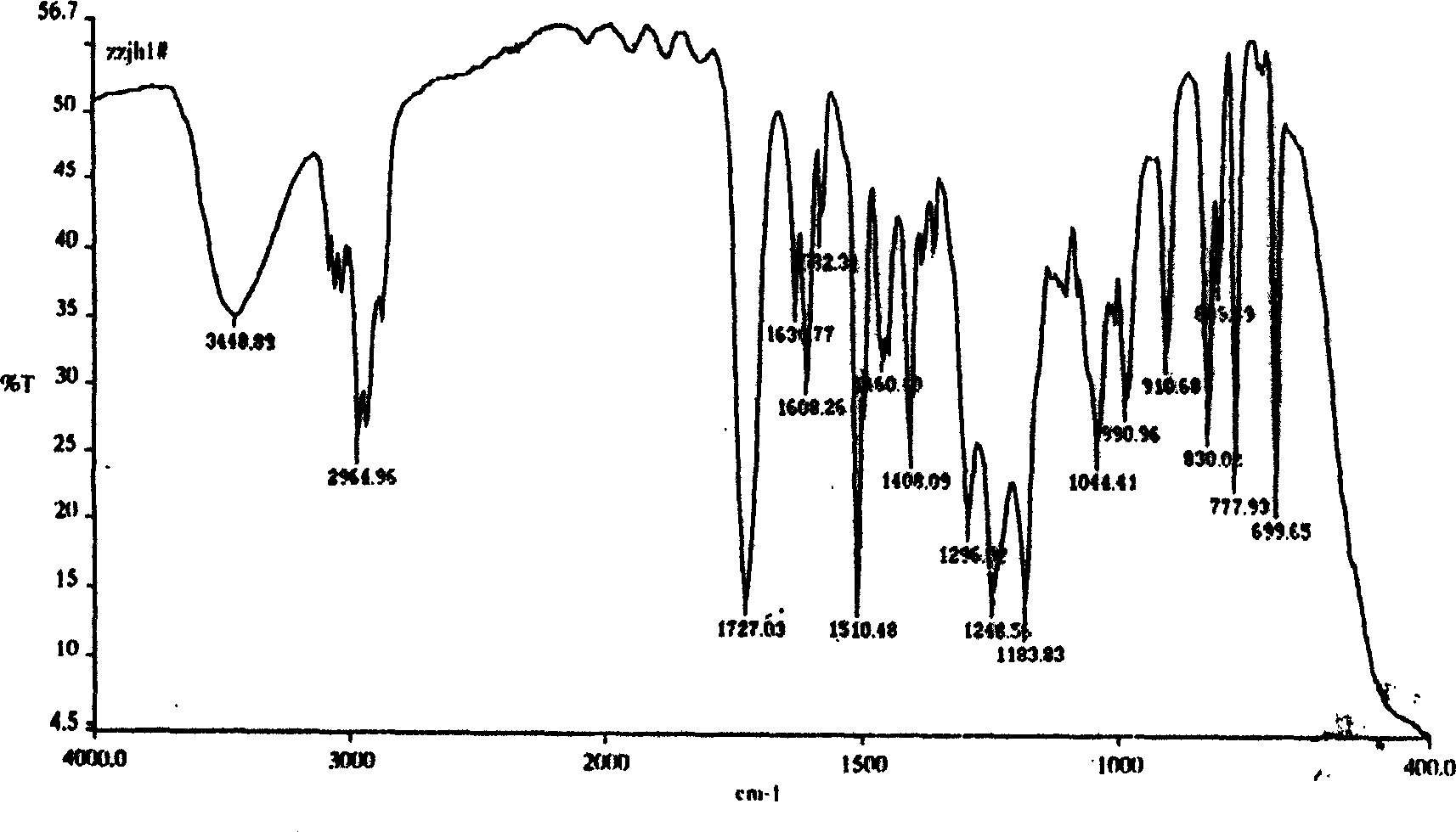

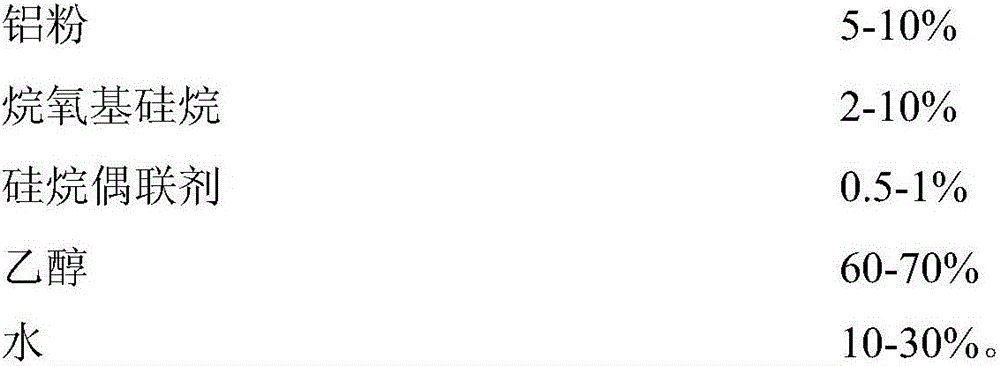

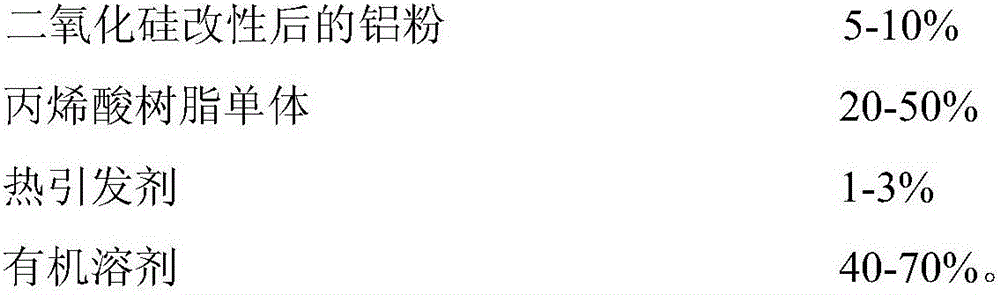

Aqueous aluminum powder paint and preparation method thereof

ActiveCN106010046AImprove protectionImprove corrosion resistanceAnti-corrosive paintsAcrylic resinSilanes

The invention discloses aqueous aluminum powder paint and a preparation method thereof. The preparation method comprises: (1) mixing aluminum powder, alkoxy silane, a silane coupling agent, ethanol and water; dropping hydrochloric acid to adjust the pH value to be 3 to 6; heating to react; after a reaction is finished, separating sediment and washing the sediment with alcohol and drying to obtain silicon dioxide modified aluminum powder; (2) adding the silicon dioxide modified aluminum powder into an organic solvent and dropping an acrylic resin monomer and a thermal initiator to carry out a polymerization reaction; after the reaction is finished, adjusting the pH value to be neutral; adding the water and emulsifying; removing the organic solvent to obtain an aluminum powder-acrylic resin compound; (3) mixing the aluminum powder-acrylic resin compound with amino resin, a flatting agent, a catalyst and the water and stirring and dispersing to prepare the aqueous aluminum powder paint. A paint film formed by the prepared aluminum powder paint has excellent performances including strong adhesive force, water resistance, salt fog resistance, good gloss retention and the like.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

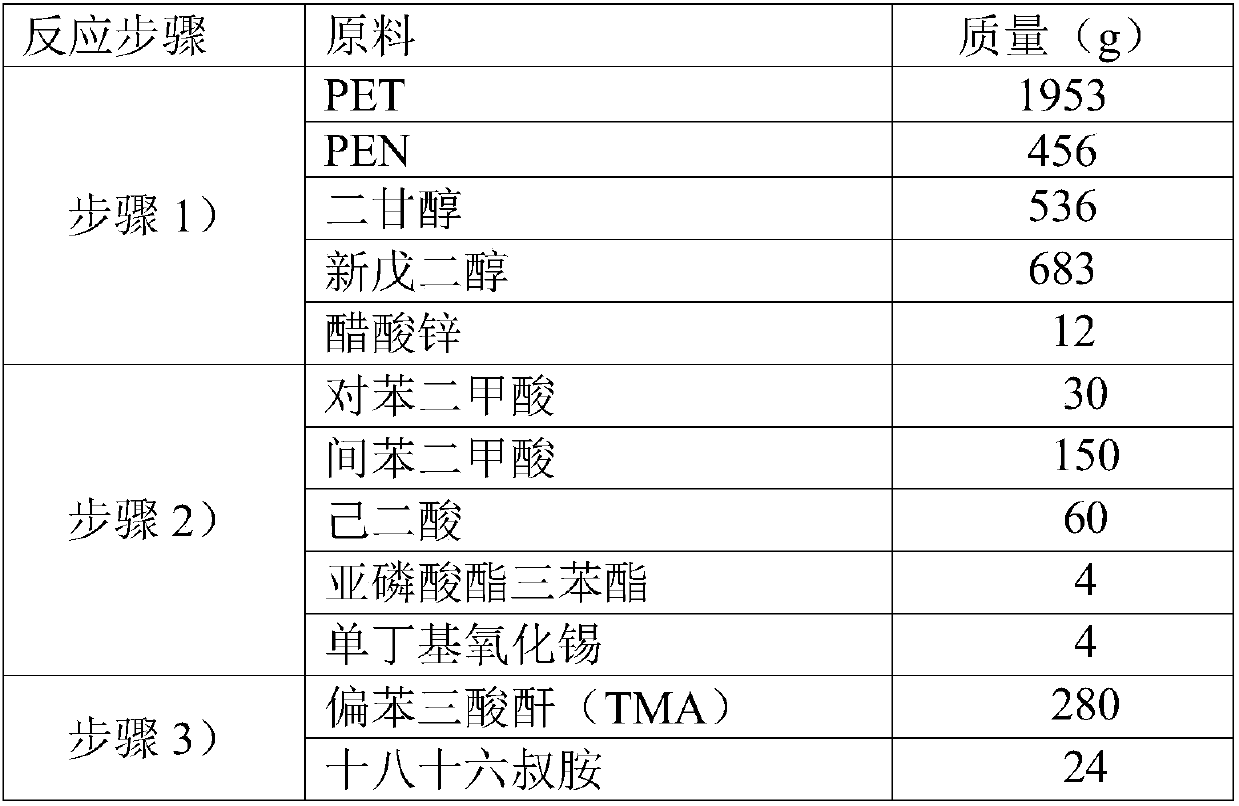

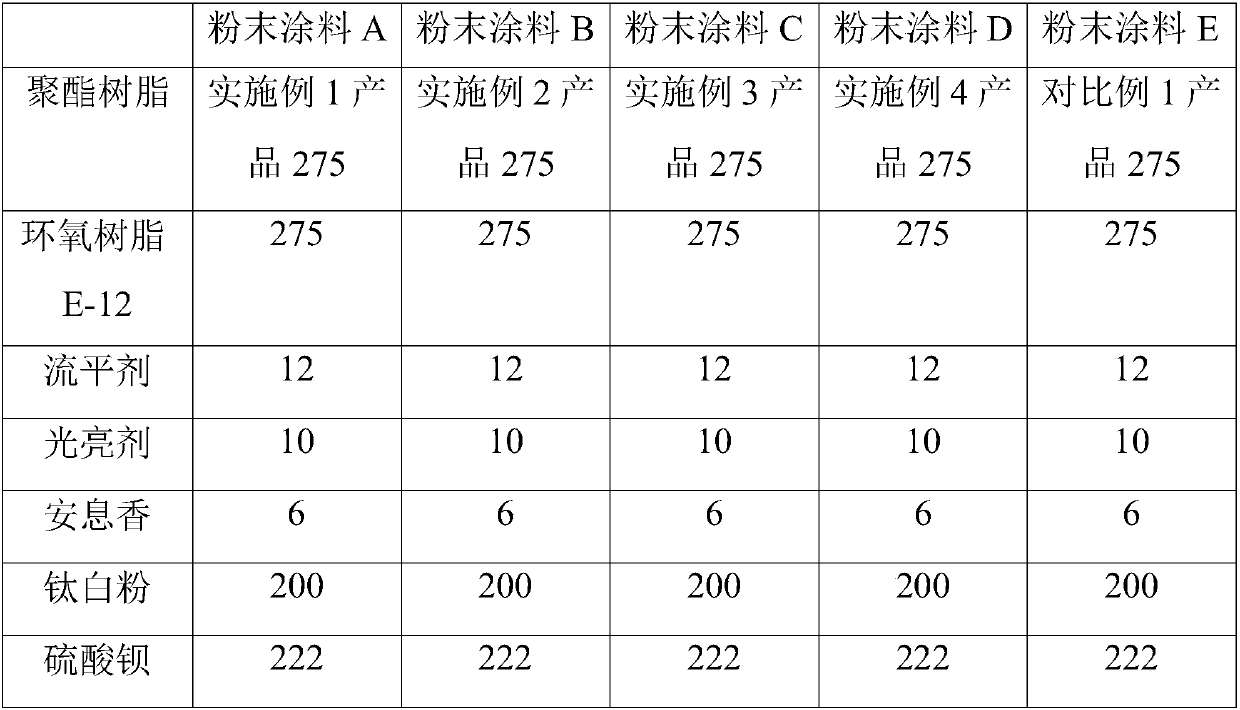

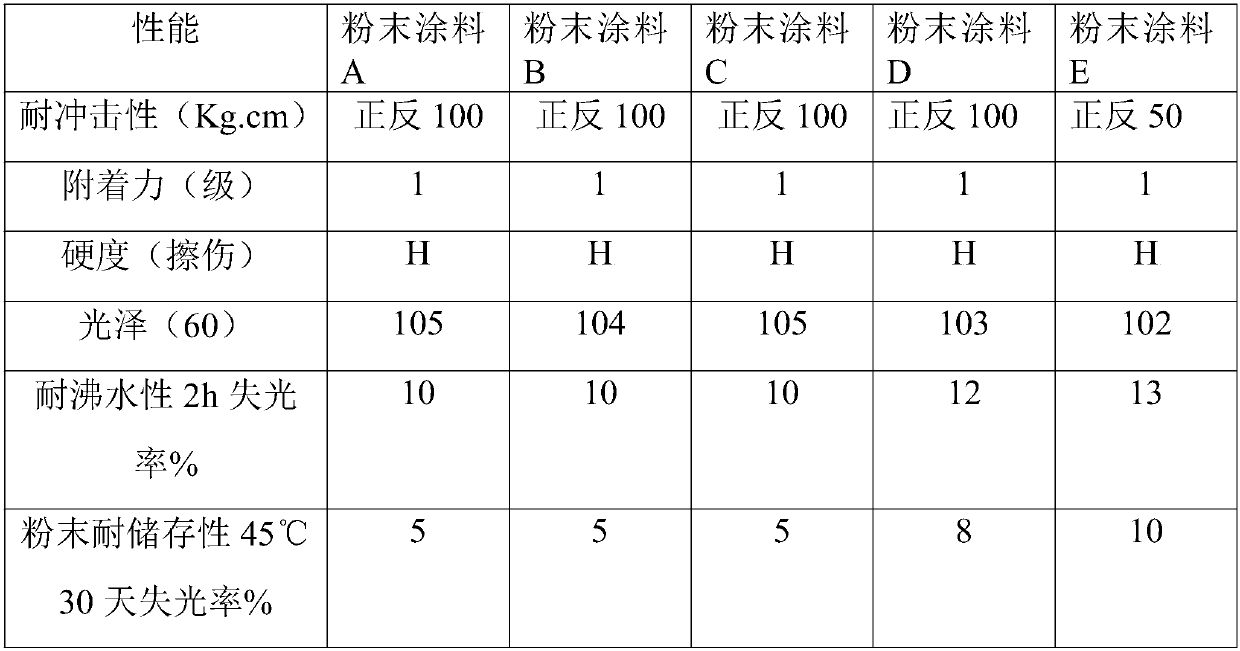

PEN modified polyester resin for epoxy polyester mixed powder paint and preparation method thereof

InactiveCN107603427AAchieve recyclingReduce generationPlastic recyclingPowdery paintsGlass transitionChemistry

The invention discloses a PEN modified polyester resin for epoxy polyester mixed powder paint. The PEN modified polyester resin for epoxy polyester mixed powder paint has an acid value of 68-75mgKOH / g, a viscosity of 2000-5500mPa.s / 200DEG C or an acid value of 48-55mgKOH / g, a viscosity of 3000-5500mPa.s / 200DEG C or an acid value of 32-35mgKOH / g, and a viscosity of 4000-6000mPa.s / 200DEG C. The preparation method includes: conducting alcoholysis on a mixture of PET and PEN in a mass ratio of 2.5-3:1 by polyol, then carrying out ester exchange reaction and / or esterification reaction with polyol,polyacid / anhydride, then carrying out decompression polycondensation reaction and trimellitic anhydride end-capping reaction, thus obtaining the polyester resin. The resin has the characteristics of ahigh glass transition temperature Tg above 58DEG C and high storage stability, and a board prepared from the polyester resin according to the standard formula has the characteristics of yellowing resistance, baking resistance, salt fog resistance and the like peculiar to powder paint produced by high quality polyester resin synthesis, and also has good gloss (greater than 105% (60DEG C glossmetertest)), and impact resistance (resistance to + / -100Kg.cm impact).

Owner:江苏宝田新材料股份有限公司

Anti-aging metal anti-rust paint and preparation method thereof

ActiveCN102888167AHigh hardnessScratch resistantAnti-corrosive paintsEpoxy resin coatingsHardnessToughness

The invention discloses anti-aging metal anti-rust paint and a preparation method thereof. The anti-rust paint is prepared from slurrying raw materials and paint mixing raw materials; a paint film formed by the anti-rust paint has high hardness, scratching resistance, strong adhesion, salt fog resistance, saline resistance, acid-base resistance, water resistance, and oil resistance; the paint can be used on the surface of an old paint film repeatedly; the damage to the paint film can be avoided; and super strong toughness of the paint film can be achieved. The service life of the paint film can reach 8 to 10 years generally.

Owner:FUJIAN HANSEN PAINT

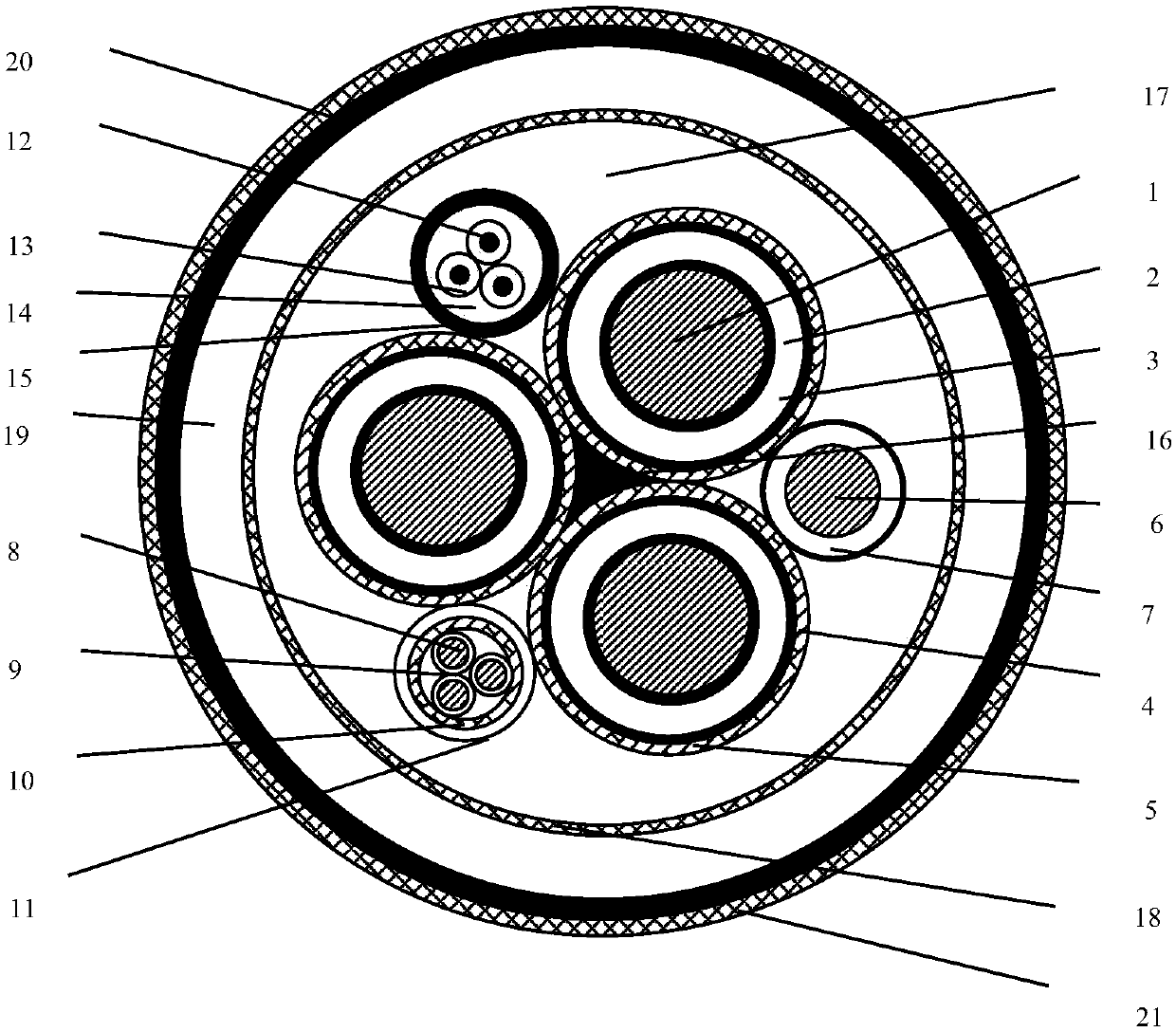

Pressure-resistant wear-resistant composite low-temperature-resistant ship shore power cable

InactiveCN109585059AReal-time video surveillanceRealize large-capacity power supplyCommunication cablesFibre mechanical structuresFiberElectrical conductor

The invention relates to a pressure-resistant wear-resistant composite low-temperature-resistant ship shore power cable and belongs to the technical field of cables. The shore power cable of the present invention comprises a main wire core, a ground wire core, a control wire core, a fiber combination unit and a filling core, wherein the main wire core comprises a main wire core conductor, a conductor shielding layer, an insulating layer and an insulating shielding layer; the ground wire core comprises a ground wire core conductor and a semiconducting layer extruded outside the ground wire coreconductor; the fiber combination unit comprises a fiber, a fiber loose sleeve, a fiber inner shield, a fiber outer shield. The main wire core, the ground wire core, the control wire core, a fiber combination unit, and the filling core are twisted together to form a cable, and then the inner sheath is extruded. The inner sheath is provided with a fiber weaving reinforcing layer and an outer sheath. The main wire core further includes a metal shielding layer. The outer sheath is also successively provided with a TPEE pressure-resistant protective layer and a Dyneema wrapping tape. The ship shore power cable of the invention can simultaneously transmit power, control signals and communication signals, realizes high-voltage large-capacity power supply on a ship, and realizes information management.

Owner:JIANGSU ZHONGMEI CABLE

Heat dissipation and high-temperature resistant nano anticorrosive paint and preparation method thereof

InactiveCN107141928AEasy to operateImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsEnvironmental resistanceLow temperature curing

Belonging to the technical field of paint, the invention relates to a heat dissipation and high-temperature resistant nano anticorrosive paint and a preparation method thereof. The heat dissipation and high-temperature resistant nano anticorrosive paint comprises the following components by weight percentage: 20-25% of high temperature resistant modified polymer resin, 60-65% of zinc powder and inorganic nano-powder combined filler, 3-6% of a suspending agent, 0.5-1.5% of a coupling agent, 1-1.5% of a defoaming agent and 5-20% of a solvent. The method provided by the invention adopts a compound technology, performs room temperature curing or low temperature curing, and is simple in operation, clean and environment-friendly. The nano anticorrosive paint provided by the invention can be used for a variety of metal and ceramic materials, etc., has excellent anti-corrosion and heat dissipation performance, also has the advantages of moisture protection, acid and alkali resistance, salt fog resistance, temperature resistance, insulation, wear resistance, solvent resistance and the like, and has strong adhesion and hardness superior to the usage requirements in the industry. The paint can be applied to a lot of devices requiring high power heat dissipation, and can provide different optimized ratios according to different power heat dissipation needs.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

Waterproof and weather-resistant two-component exterior wall emulsion paint with simple construction technology

InactiveCN109575708AFacilitate cross-linkingHydrophobicCovering/liningsEmulsion paintsWater basedUltraviolet

The invention relates to waterproof and weather-resistant two-component exterior wall emulsion paint with a simple construction technology. The waterproof and weather-resistant two-component exteriorwall emulsion paint is characterized by comprising a component A and a component B, wherein the component A comprises, by weight, 35-40 parts of water-based fluorocarbon resin dispersion, 1-5 parts ofcoalescing agents, 0.3-1.0 part of leveling agents, 0.1-0.3 part of thickening agents, 0.5-1 part of wetting dispersants, 0.25-0.30 part of defoaming agents, 0.20-0.25 part of sterilizing agents, 25-40 parts of pigments and fillers and 15-20 parts of water, and the component B comprises, by weight, 2-5 parts of titanate coupling agents and 1-3 parts of perhydropolysilazane. The waterproof and weather-resistant two-component exterior wall emulsion paint has high hardness and better acid resistance, hydrophobic and waterproof properties, ultraviolet resistance and dirt-removing power and is more applicable to engineering with high construction requirements and more severe environments.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

Fluorine/silicon-containing silicon paint and preparation method thereof

InactiveCN108727938AEasy to cleanSuperhydrophobic and oleophobicFireproof paintsAntifouling/underwater paintsSilicon oxygenSide chain

The invention discloses fluorine / silicon-containing silicon paint. The fluorine / silicon-containing silicon pain is prepared from the following components in parts by weight: 10 to 80 parts of fluorine-containing acrylate monomer, 9 to 60 parts of acrylate monomer, 5 to 30 parts of silane coupling agent, 2 to 28 parts of polysiloxane, 0.2 to 1.8 parts of initiator, and 40 to 80 parts of solvent. The organic fluorine and organic silicon are simultaneously used for modifying acrylate resin to obtain the fluorine / silicon-containing polymer which takes silicon oxygen bond as a main chain and fluorine-containing group as a side chain, and while keeping the heat resistance and cold resistance of the organic silicon material, the polymer also has the excellent performance such as weather resistance, aging resistance, solvent resistance, oil resistance and has lower surface energy. The product provided by the invention is suitable for various fields such as spaceflight, ocean, metal base materials, cultural relics, glass, ceramics, electronic products.

Owner:赵永锋

Water-based environment-friendly anti-rust internal wall building coating and preparation method thereof

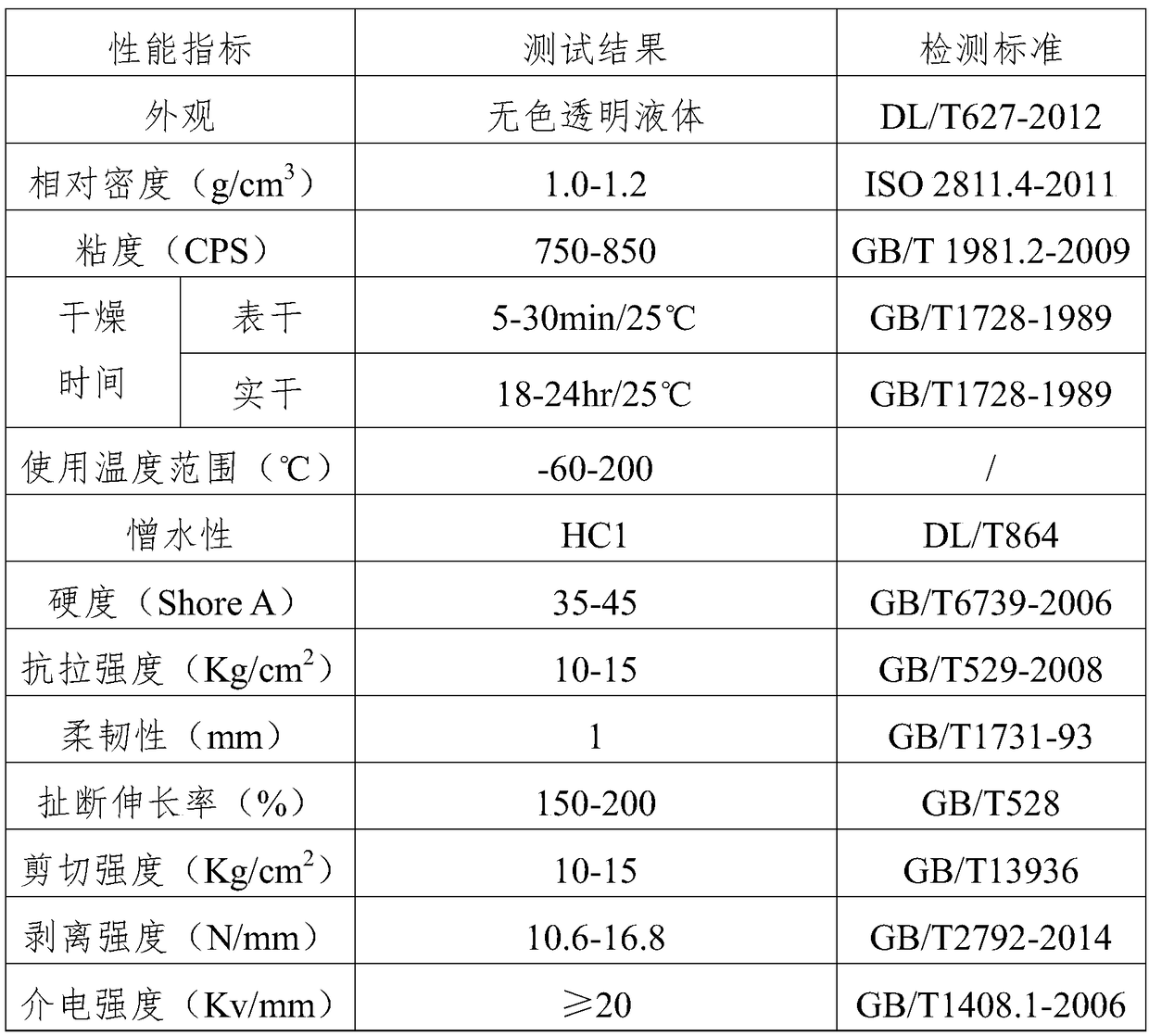

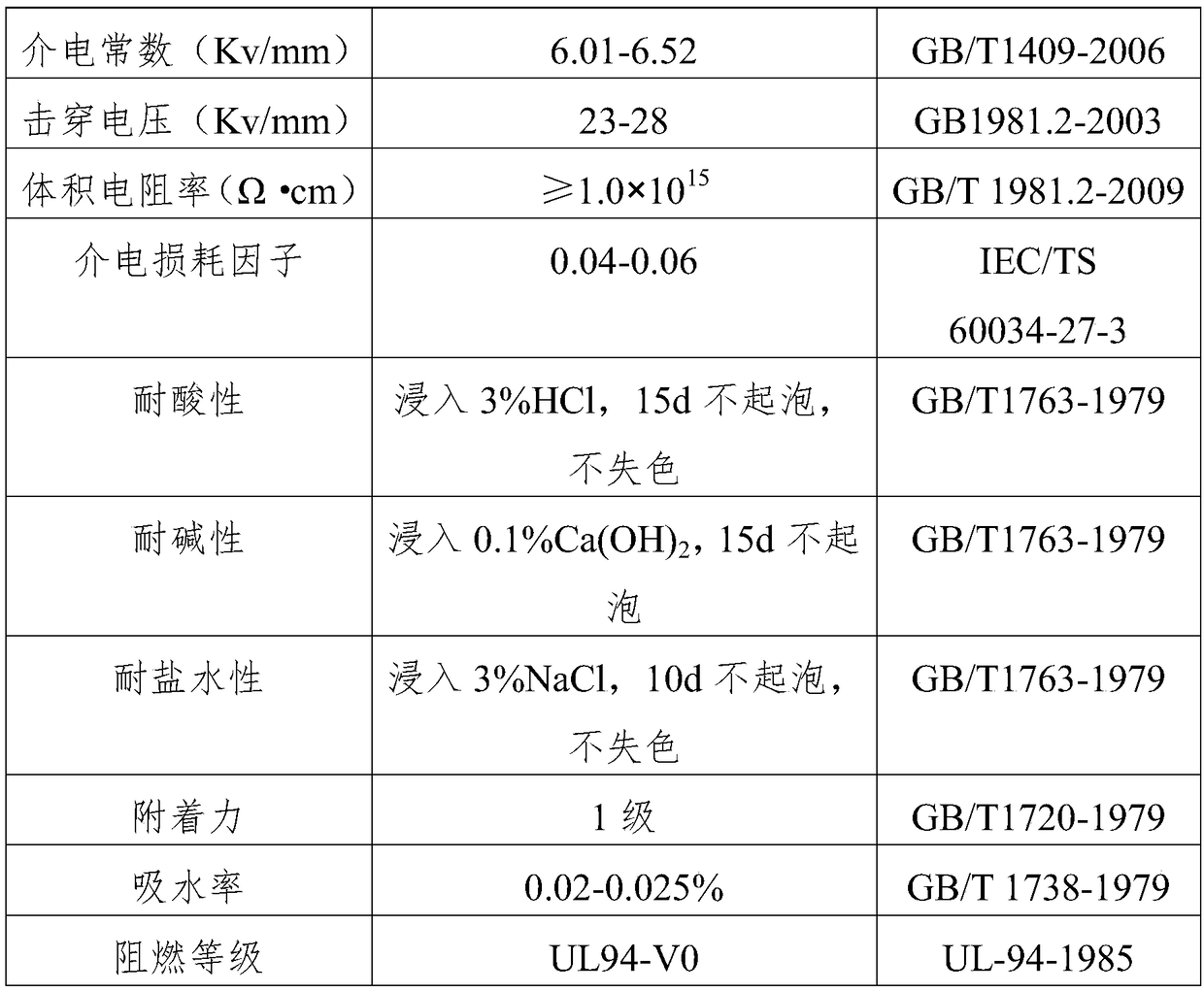

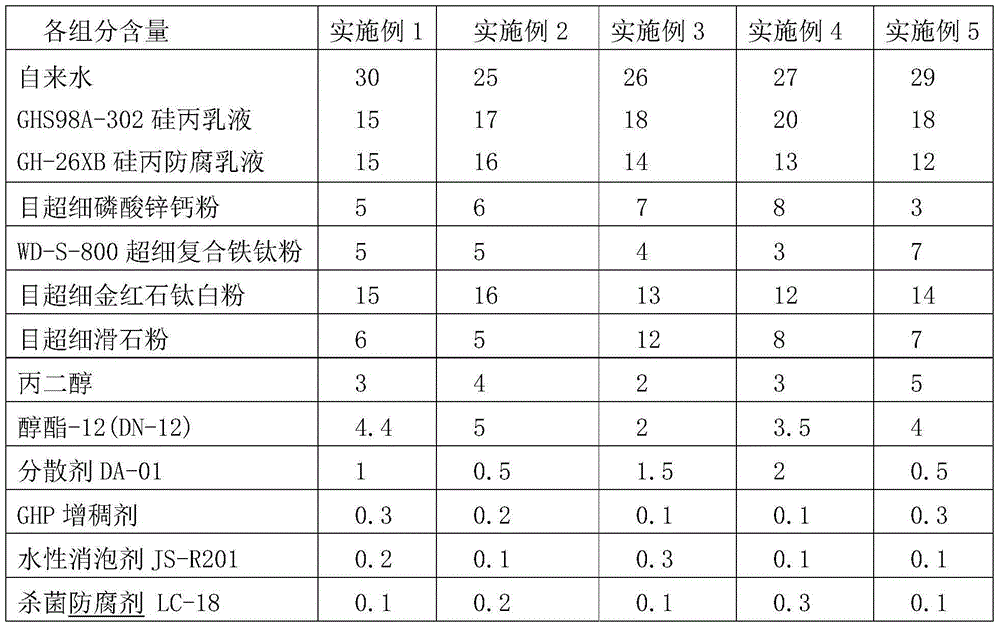

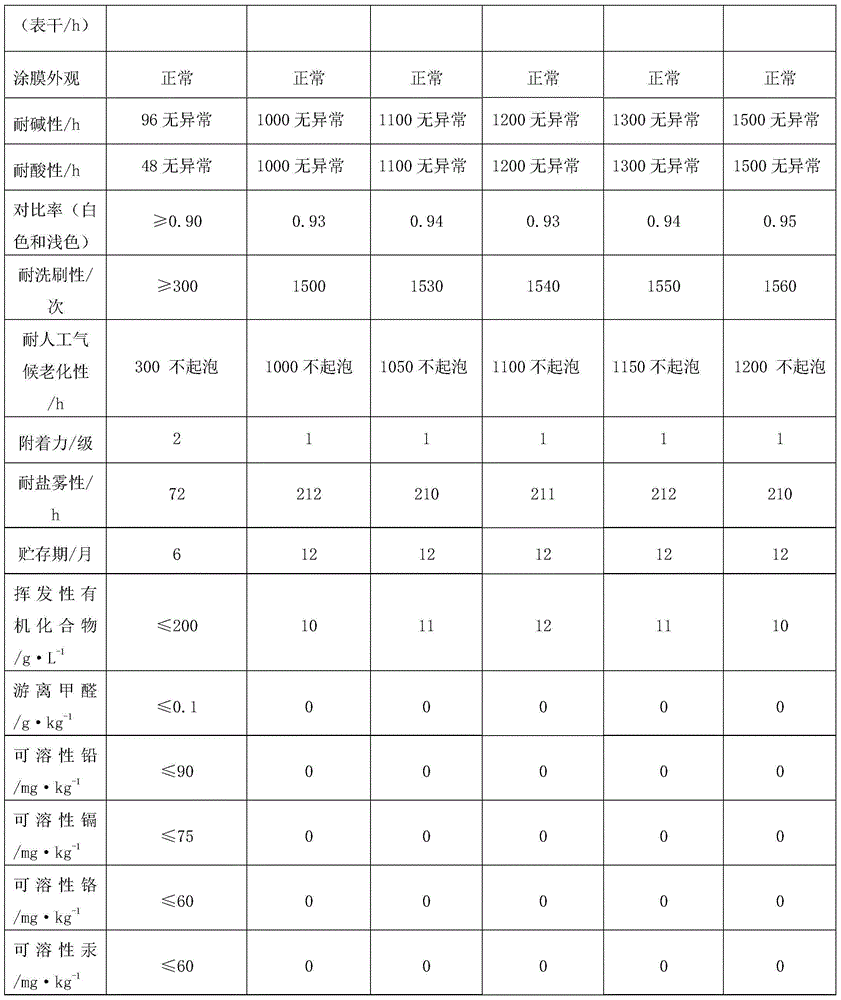

ActiveCN104059463ADry fastWater resistantAntifouling/underwater paintsPaints with biocidesWater basedRutile

The invention discloses a water-based environment-friendly anti-rust internal wall building coating and a preparation method thereof. The coating comprises the following components by weight percent: 25%-30% of water, 2%-5% of propanediol, 15%-20% of GHS98A-302 silicone acrylic emulsion, 12%-16% of GH-26XB silicone acrylic anticorrosion emulsion, 3%-8% of 1,000-mesh superfine calcium zinc phosphate powder, 3%-7% of 1000-mesh WD-S-800 superfine iron-titanium compound powder, 12%-16% of 1,000-mesh superfine rutile titanium dioxide powder, 5%-12% of 1,000-mesh superfine talcum powder, 2%-5% of alcohol ester-12(DN-12), 0.5%-2% of a DA dispersant, 0.1%-0.3% of a GHP thickening agent, 0.1%-0.3% of a water-based de-foaming agent JS-R201 and 0.1%-0.3% of a sterilizing preservative LC-18. The coating does not contain heavy metal, is environment-friendly, has the characteristics of high drying speed, water resistance, acid resistance, alkali resistance, chemical drug corrosion resistance, scrub resistance, artificial weathering aging resistance, good adhesion, salt mist resistance, good rust resistance and the like, and has good application prospects; the emission of VOC (volatile organic compounds) is zero.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Single-component wet gas curing polyurethane heavy-duty anticorrosion coating and preparation method thereof

ActiveCN110054980AHigh surface finishNo bubblesAnti-corrosive paintsPolyurea/polyurethane coatingsHigh surfaceTemperature resistance

The invention relates to a wet gas curing polyurethane heavy-duty anticorrosion coating which comprises, by mass, 70-99.9 parts of modified polyurethane prepolymer resin, 2-25 parts of pigment and filler, 0.5-3 parts of dispersant, 0.1-1 part of anti-settling agent, 0.2-2 parts of anti-flooding and anti-floating agent, 0.2-1 part of defoamer, 0.1-1 part of leveling agent, 5-15 parts of latent curing agent and 5-20 parts of water absorber. The polyurethane coating has a series of excellent performances like high storage stability, high surface smoothness, high curing film-forming speed, high adhesiveness with a substrate, high toughness and high chemical resistance, aging resistance and high-temperature resistance.

Owner:SWD HIGH TECH MATERIALS JIANGSU

Flame-retardant and fire-resistant silicone rubber material and preparation method and application thereof

The invention provides a flame-retardant and fire-resistant silicone rubber material as well as a preparation method and application thereof. The flame-retardant and fire-resistant silicone rubber material is prepared from the following raw materials in parts by weight: 50 to 100 parts of organic silicone rubber, 1 to 39 parts of organosiloxane, 20 to 50 parts of a reinforcing filler, 50 to 300 parts of a flame retardant, 90 to 300 parts of a fire-resistant filler and 1 to 19 parts of other auxiliary agents. The flame-retardant and fire-resistant silicone rubber material is good in flame-retardant and fire-resistant performance, easy to produce and process and low in cost.

Owner:苏州法思特新材料有限公司

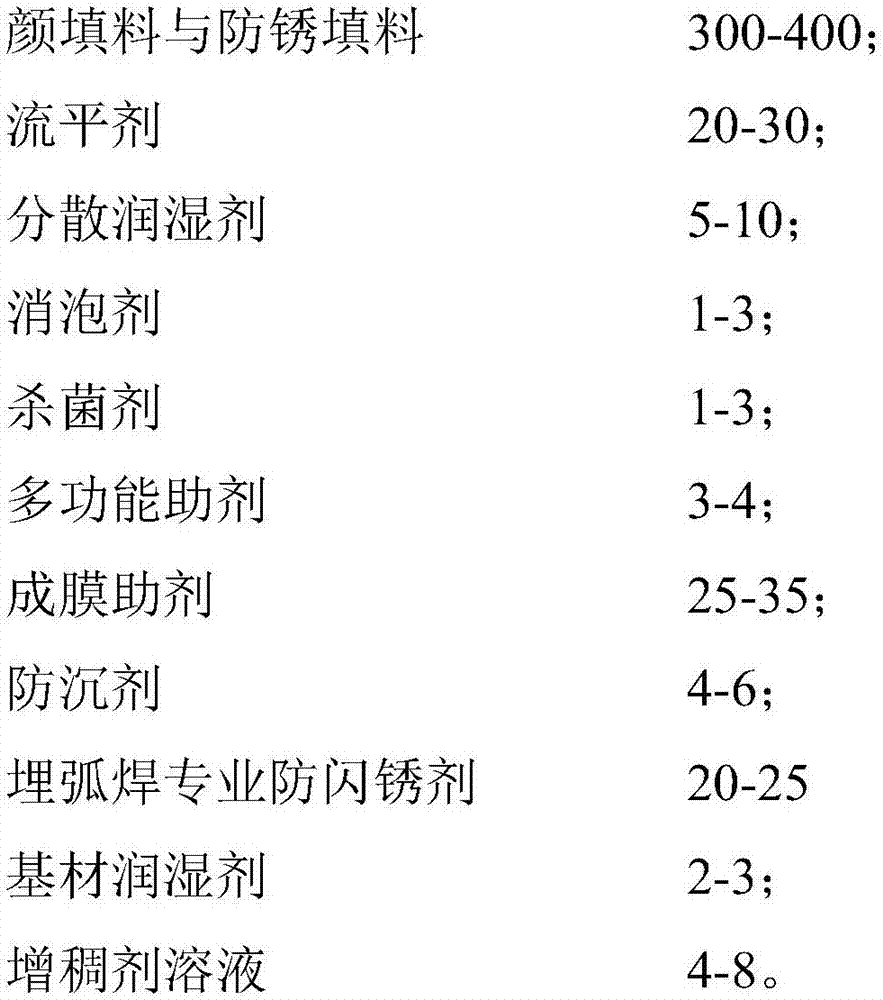

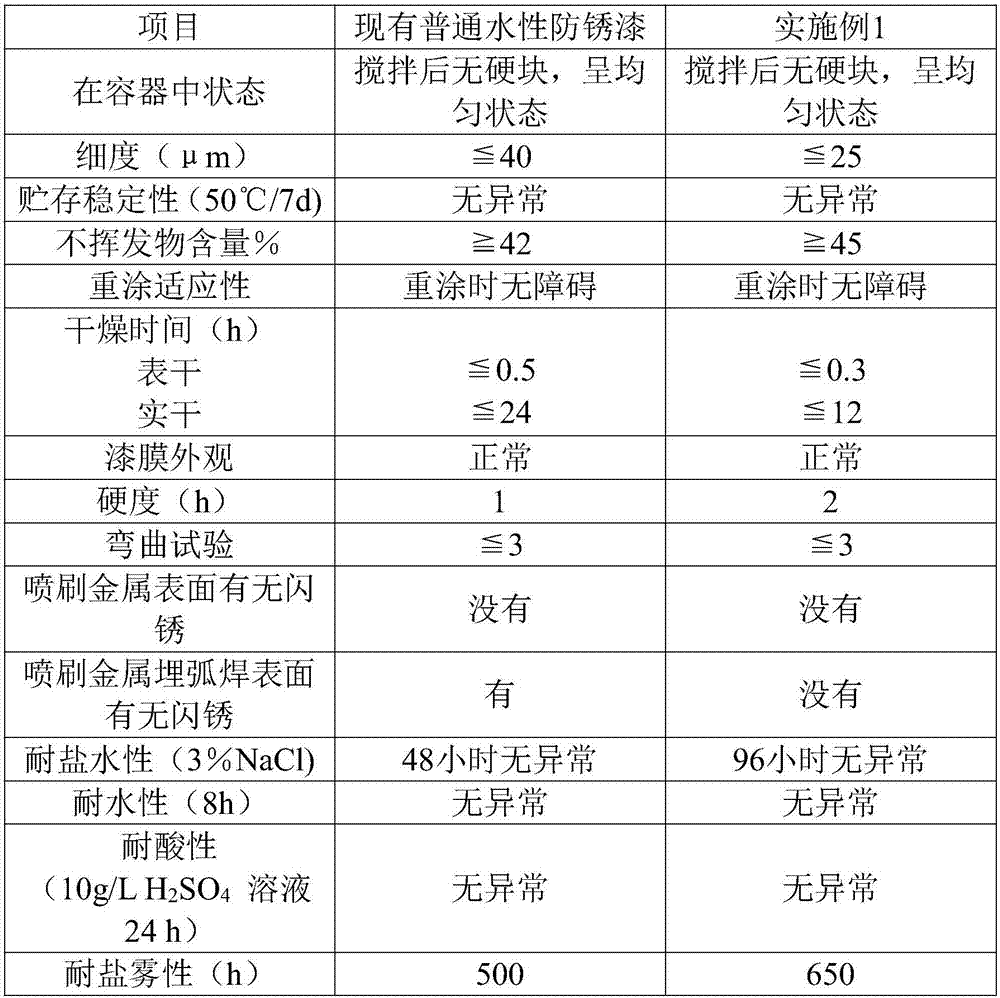

Special water-based anti-rust paint for submerged arc welding and preparation process thereof

InactiveCN106854406ALong-term flash rust problem solvingImprove rust resistanceAntifouling/underwater paintsPaints with biocidesWater basedWater dispersible

The invention discloses special water-based anti-rust paint for submerged arc welding. The water-based anti-rust paint comprises the following components in parts by weight: 400-500 parts of a film-forming material, 80-100 parts of deionized water, 300-400 parts of a pigment filler and an anti-rust filler, 20-30 parts of a levelling agent, 5-10 parts of a dispersing and wetting agent, 1-3 parts of a defoaming agent, 1-3 parts of a bactericide, 3-4 parts of a multifunctional auxiliary agent, 25-35 parts of a film-forming auxiliary agent, 4-6 parts of an anti-settling agent, 12-16 parts of a professional submerged arc welding flash rust preventer, 8-10 parts of a metal environment-friendly flash rust preventer, 2-3 parts of a substrate wetting agent and 4-8 parts of a thickening agent solution, wherein the film-forming material is an environment-friendly water-dispersible acrylic modified emulsion. The water-based anti-rust paint has the advantages of water-based environmental friendliness and good water resistance, salt fog resistance and weather resistance, has strong rust resistance, has good thermal stability, and is mainly applicable to rust prevention at a metal submerged arc welding position.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

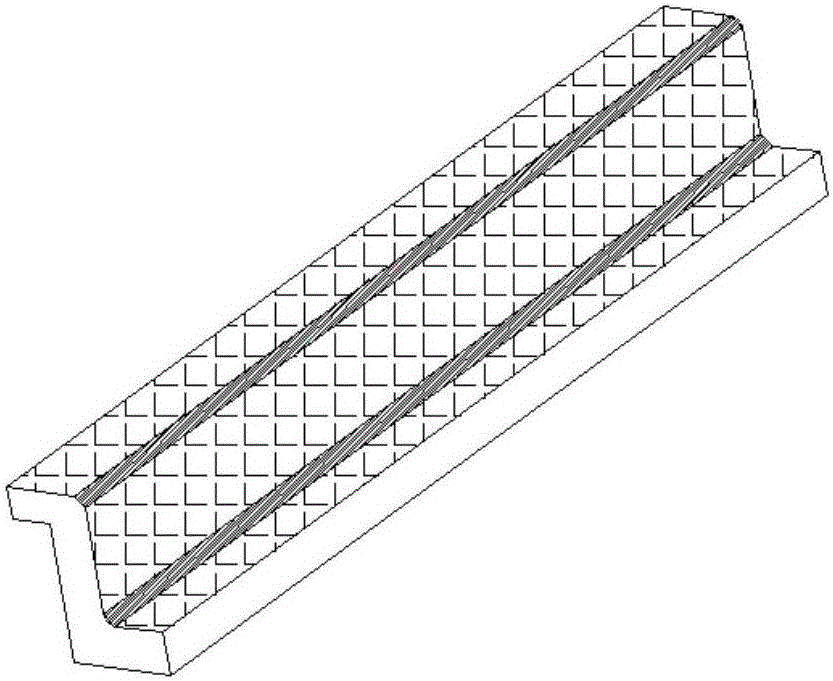

Technique for jet printing long term anti-corrosive paint on cable bridge rack

InactiveCN101097036AExtended service lifeSave human effortCorrosion preventionPipe protection against corrosion/incrustationFluorocarbonLife length

The invention discloses a method to spray long period anticorrosion paint for cable crane span structure, which is characterized by the following: basing on original cable crane span structure spraying paint craft; spraying fluorocarbon resin substratum, mesosphere and surface course. This invention possesses the advantages of high brightness, high strength and long durability.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

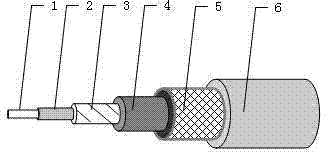

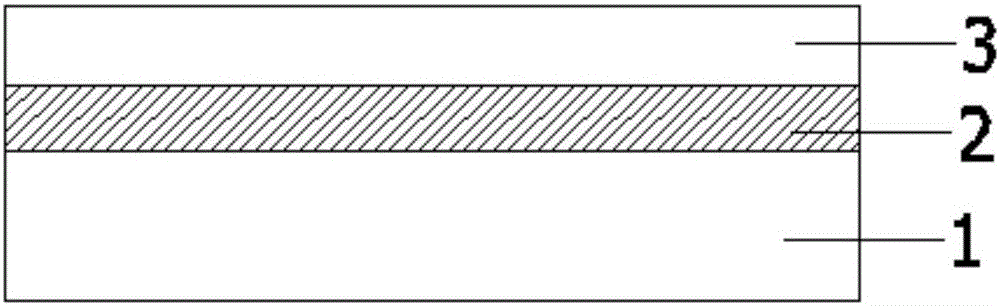

Aerial high-temperature-resistant loose optical cable and preparation method thereof

InactiveCN104777572ALong-term bending resistanceLong-term stress resistanceFibre mechanical structuresEngineeringPolytetrafluoroethylene

The invention discloses an aerial high-temperature-resistant loose optical cable and a preparation method thereof. A coating layer 2 is arranged outside an optical fiber core 1; a polytetrafluoroethylene PTFE lapping buffer layer 3 is arranged outside the coating layer 2; a polyether ether ketone PEEK loose layer 4 is arranged outside the polytetrafluoroethylene PTFE lapping buffer layer 3; an aromatic polyamide fiber reinforcing layer 5 is arranged outside the polyether ether ketone PEEK loose layer 4; an ethylene tetrafluoroethylene copolymer ETFE jacket layer 6 is arranged outside the aromatic polyamide fiber reinforcing layer 5. The aerial high temperature-resistant loose optical cable has the characteristics of resisting high / low temperature of -55-125 DEG C for a long time, resisting bending, compression, ageing, corrosion, salt mist, mould and damp heat and being long in service life and high in flame resistance, can be used for providing reliable service under severe environment and is suitable for the high-speed signal transmission under aerospace, electronics and onboard special environment conditions.

Owner:NANJING QUANXIN CABLE TECH

Processing technology of electric meter box body

The invention discloses a processing technology for the box body of an electric meter box, which comprises the following steps: material selection: selecting 20-40% polycarbonate particles and 60-80% ABS plastic particles, and fully mixing them through a mixer; feeding: a suction machine Inhale the mixed particles into the drying box; drying: dry the mixed particles in the drying box for 3-5 minutes; injection molding: the dried mixed particles are sent to the barrel through the suction machine, and injected The machine uses the mold to inject the mixed particles into shape; cooling: the water circulation is carried out on the mold to make the injection molded electric meter box cool and form. The processing technology of the present invention uses PC polycarbonate and ABS plastic particles to mix and extrude the box body through the injection molding machine, which has good insulation performance, anti-ultraviolet, aging resistance, acid rain resistance, salt spray resistance, high temperature resistance, low temperature resistance and impact resistance. The advantages of strong performance.

Owner:ANHUI ZHENGSHENG INTELLIGENT TECH CO LTD

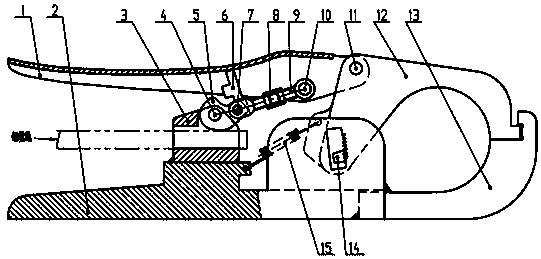

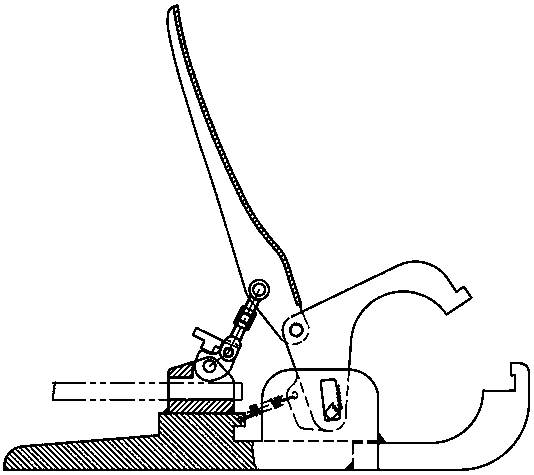

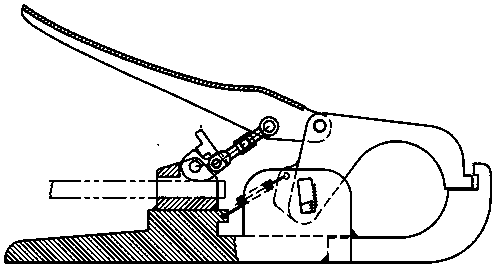

Rapid fixing connecting device of mooring rope for ship

InactiveCN108045502AQuick clampingQuick connectionWaterborne vesselsWear resistantMarine engineering

The invention discloses a rapid fixing connecting device of a mooring rope for a ship. The connecting device includes a moving handle, a fixing handle, a moving hook head, a fixing hook head, a wirerope positioning block, and a compact cam. The fixing hook head is welded to the front end of the fixing handle. The fixing handle is provided with a tooth-shaped long groove. The tooth-shaped long groove is internally provided with a positioning catch pawl in a matching and meshing mode. The lower end of the back side of the moving hook head is fixedly connected with the positioning catch pawl. Thefront end of the moving handle is connected with the upper end of the back side of the moving hook head in a hinging mode. The lower side of the moving handle is connected with the compact cam in a hinging mode through a connecting rod. The rapid fixing connecting device body of the mooring rope for the ship has a protection layer adopting NMIP nonmetallic ion infiltration surface treatment. Therapid fixing connecting device is suitable for marine fishing ship operation, and ship conveying operation; can make the wirerope to be fixedly connected rapidly; meanwhile, the fixing connecting device body adopts a surface treatment process and has moisture-resistant, salt-resistant and wear-resistant properties, and is suitable for the marine working environment.

Owner:WEIHAISHIWEILI TOP GRADE TOOL CO

Refrigerator handle and manufacturing method thereof

InactiveCN104963555ARaise the gradeMildew proofWing handlesLayered productsRefrigerator carEngineering

The invention discloses a refrigerator handle which is mainly composed of a refrigerator handle substrate, a bonding layer and a natural material layer. The refrigerator handle substrate is fixedly connected with the natural material layer through the bonding layer. The manufacturing method of the refrigerator handle comprises the following steps of refrigerator handle substrate forming, natural material layer manufacturing, preforming, attaching and pressure maintaining processing. The refrigerator handle and the manufacturing method thereof have the advantages that compared with a traditional imitation natural material technology, real natural materials are achieved on the refrigerator handle, the pursuit of people for the real natural material decoration effect is satisfied, and the product grade is improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

High-temperature-resistant anti-corrosive coating and preparation method

InactiveCN105295462AAnti-frictionImpact resistantAlkali metal silicate coatingsAnti-corrosive paintsLithium hydroxideSports equipment

Provided are a high-temperature-resistant anti-corrosive coating and a preparation method. The high-temperature-resistant anti-corrosive coating comprises, by weight parts, 812 parts of potassium silicate solution, 32 parts of lithium hydroxide solution, 337 parts of CH3Si (OCH3), 68 parts of water, 139 parts of wollastonite, 37 parts of boron nitride, 41 parts of fine grain aluminum oxide, 35 parts of superfine zinc oxide and 38 parts of titanium oxide. The high-temperature-resistant anti-corrosive coating can be used for base layer painting of automobiles, aerospace, toys and outdoor sports equipment. The high-temperature-resistant anti-corrosive coating has the advantages of being convenient to transport and construct and non-toxic, having no foreign smell and being free of pollution and has the advantages of being high in coating hardness and resistant to friction, impact, high temperature, corrosion, aging, weather, radiation, salt fog and water.

Owner:景晓丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com