Aerial high-temperature-resistant loose optical cable and preparation method thereof

A high temperature resistant, loose sleeve technology, used in light guides, optics, optical components, etc., to achieve high hardness and strength, good reinforcement and protection, and enhanced pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Its preparation method includes the following processes:

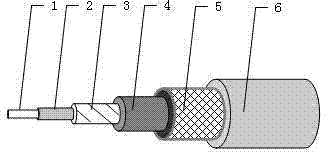

[0038] 1) Fiber core types are divided into multi-mode and single-mode, and the structure is divided into multi-mode 50 / 125μm, multi-mode 62.5 / 125μm, single-mode 9 / 125μm;

[0039] 2) Use coating equipment to coat special UV-curable acrylate, on the periphery of the optical fiber core, as coating layer 2, with a temperature resistance range of -65°C to +135°C, and an outer diameter of the coating layer of 245 μm;

[0040] 3) Use a wrapping machine to wrap a layer of polytetrafluoroethylene (PTFE) tape, and wrap it around the coating layer as a buffer layer 3. The temperature resistance range is -65℃~+250℃, and the outer diameter of the buffer layer is 400μm;

[0041]4) Polyetheretherketone (PEEK) is extruded by a high-temperature extruder and wrapped around the buffer layer 3 as the loose sleeve layer 4. The temperature resistance range is -65°C to +200°C, and the outer diameter of the loose sleeve layer is 900 μ...

example

[0044] Typical example: the outer diameter of the optical cable is 1.8mm, the outer diameter of the loose tube layer is 0.9mm, the core structure is 62.5μm / 125μm, and the high temperature resistant loose tube optical cable for aviation is 125°C, expressed as GLAE125-62.5 / 125-0.9-1.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com