Patents

Literature

39results about How to "Mold resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

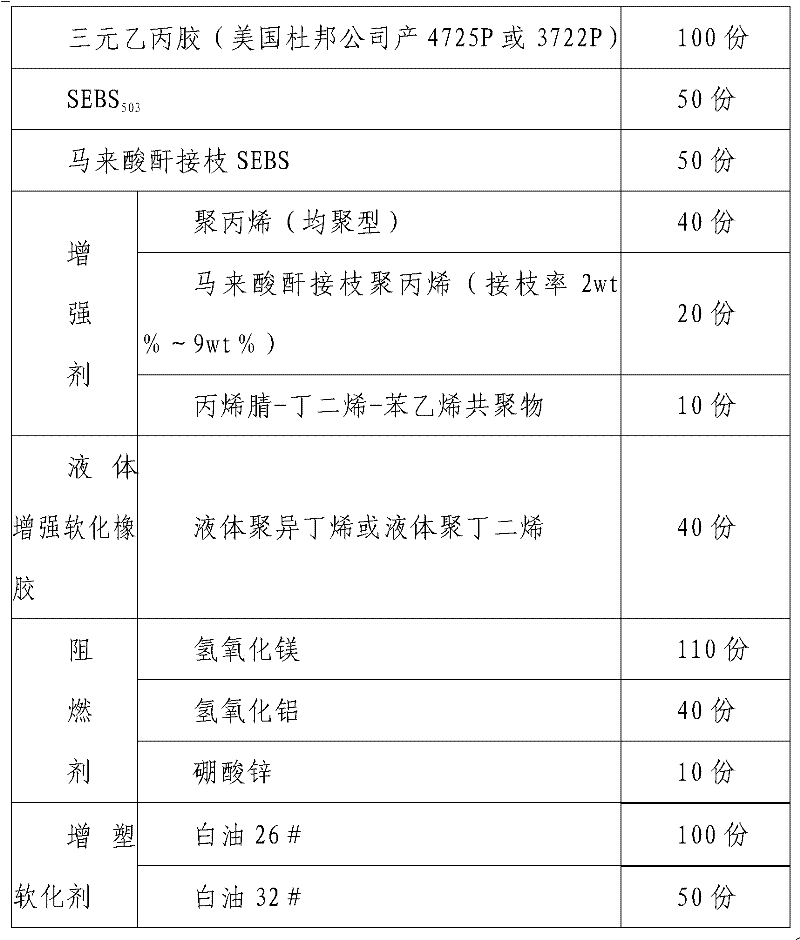

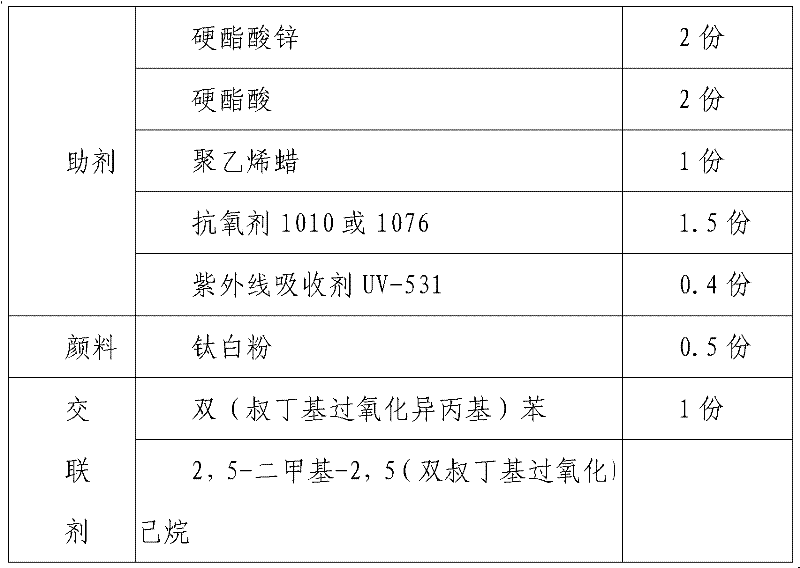

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437AChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

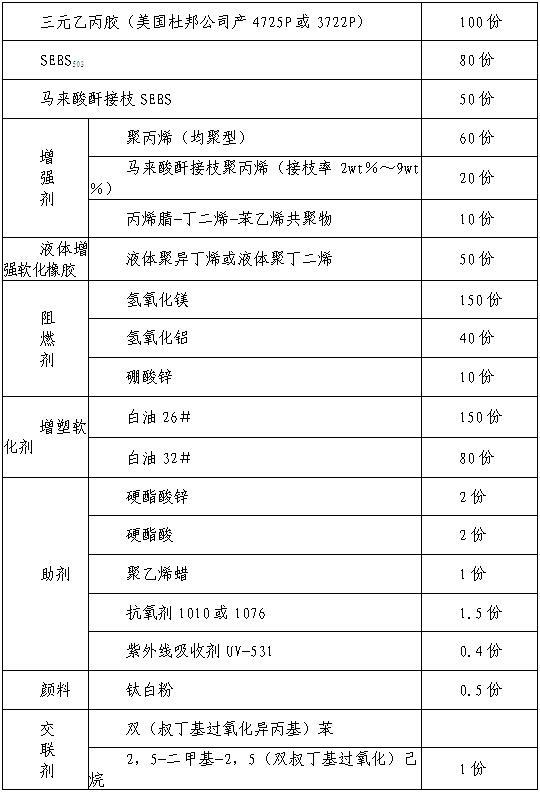

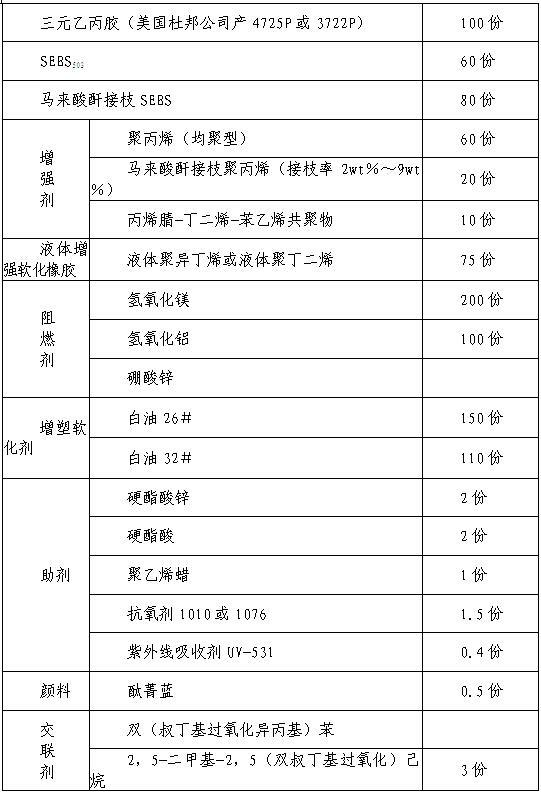

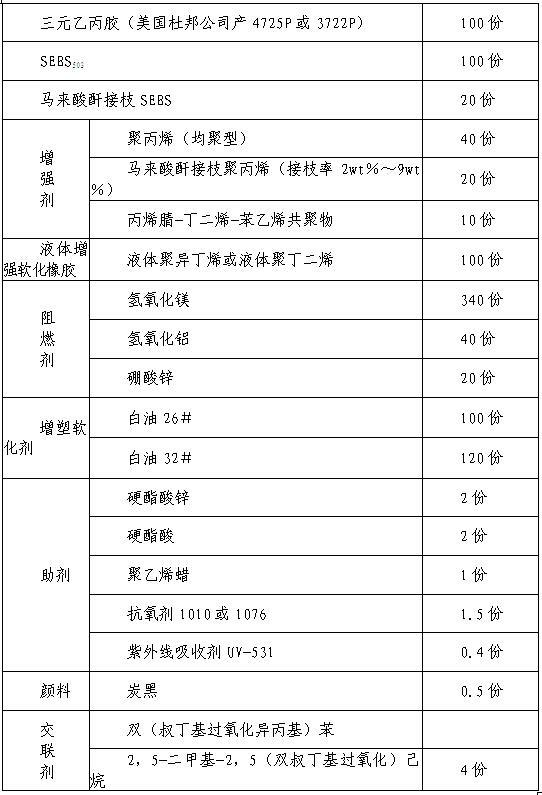

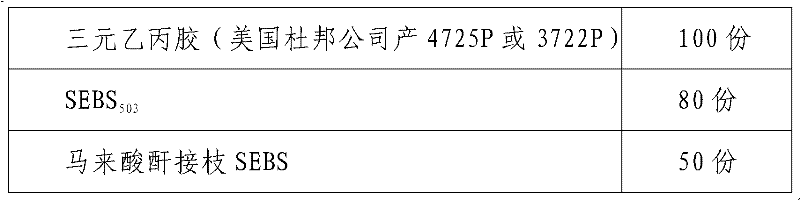

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

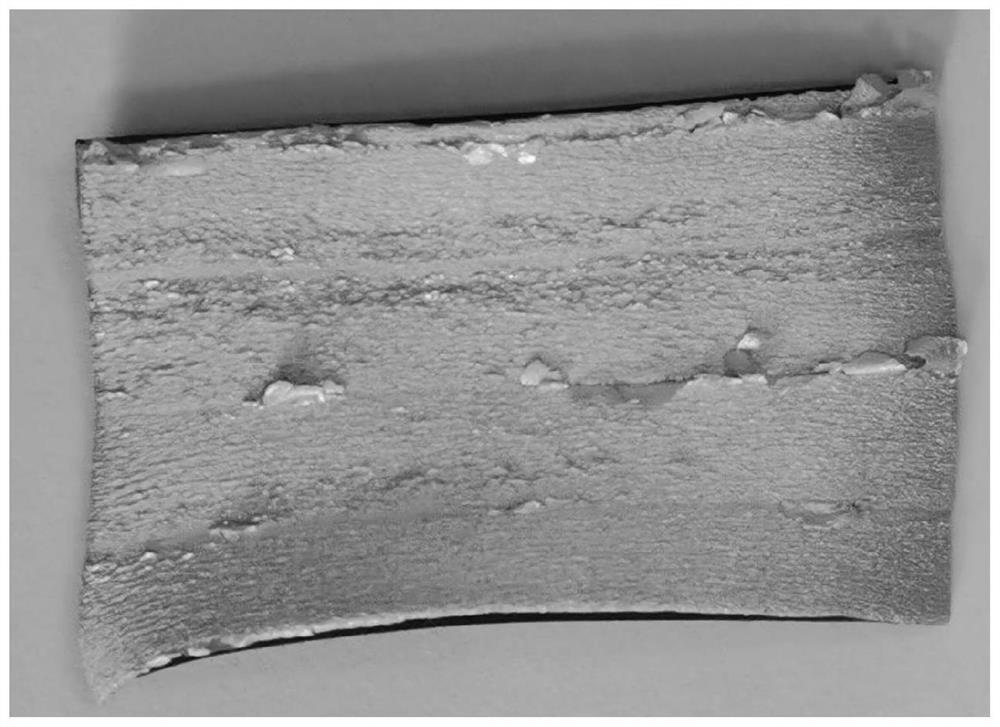

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789APromote environmental protectionReduce releaseWood treatment detailsWood veneer joiningEnvironmental resistanceVolumetric Mass Density

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

High temperature resistance multimode special optical fiber for aviation and manufacturing method thereof

InactiveCN104049330AHigh strengthWith high and low temperature resistanceFibre mechanical structuresAviationUltraviolet

The invention provides a high temperature resistance multimode special optical fiber for aviation and a manufacturing process of the optical fiber. The optical fiber structurally comprises a fiber core, an ultraviolet curing acrylic ester coating layer, an ethylene tetrafluoroethylene copolymer tight cladding, an aromatic polyamide fiber reinforcing layer and an ethylene tetrafluoroethylene copolymer restrictive coating. According to the manufacturing process, the fiber core of the optical fiber is a multimode, the coating layer is coated through the special ultraviolet curing acrylic ester, and the temperature of which the coating layer can withstand ranges from -55 DEG C to +125 DEG C. The outer diameter of the coating layer is 245 micron. According to the tight cladding, a high temperature extrusion molding machine is adopted to extrude out the high temperature ethylene tetrafluoroethylene copolymer in a double-layered mode. The reinforcing layer is knitted through the aromatic polyamide fiber having high tension resistance performance. According to the restrictive coating, the high temperature extrusion molding machine is adopted to extrude out the ethylene tetrafluoroethylene copolymer. The optical fiber has the advantages that the high-low temperature of which the coating layer can withstand ranges from -55 DEG C to +125 DEG C, and the optical fiber is high in intensity, resistant to bending, impact and aging, long in service life, resistant to mucedine, high in flame retardant, capable of providing highly reliable services in the severe environment and suitable for high-speed signal transmission under special environmental conditions such as the aerospace or electron or airborne environment.

Owner:NANJING QUANXIN CABLE TECH

Hot melt adhesive for acrylic hot-fix rhinestone and preparation method thereof

ActiveCN105273669AAdjust melt viscosityReduce crystallinityMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesPetroleum resinThermoplastic polyurethane

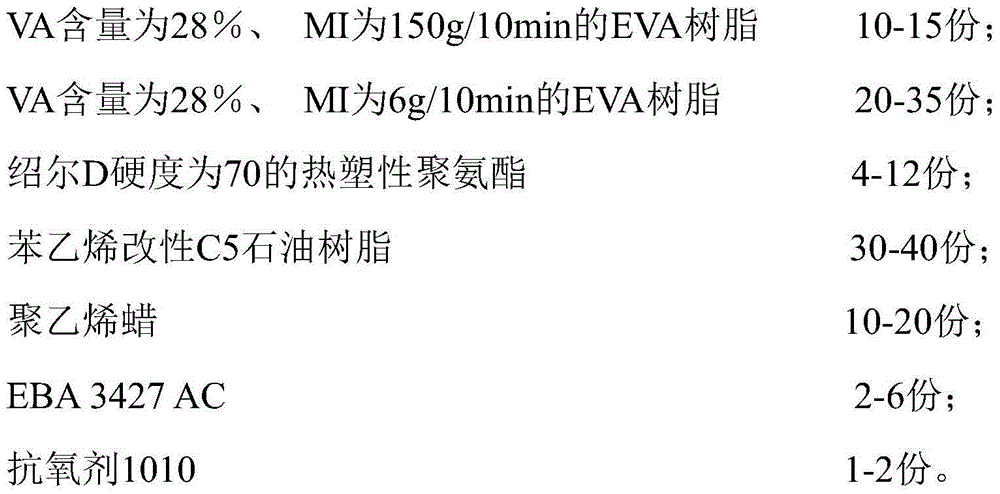

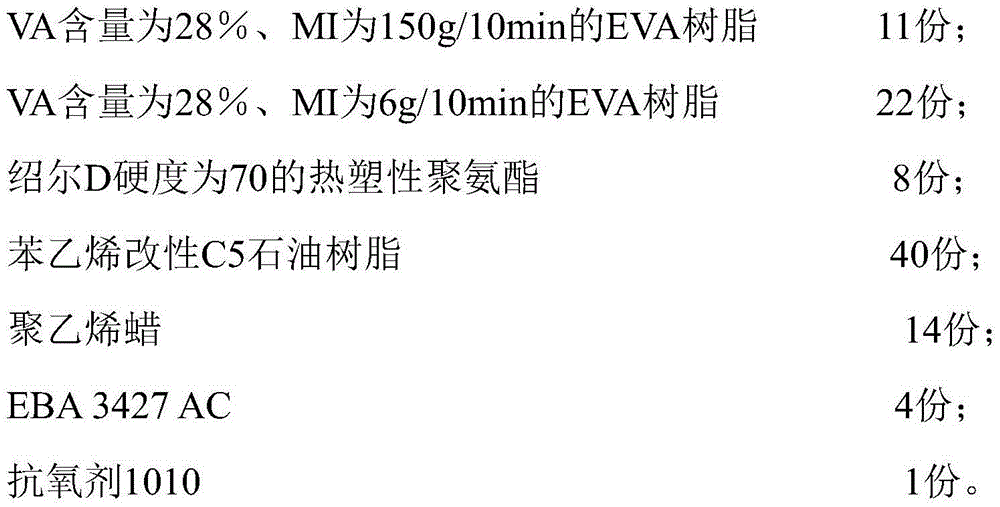

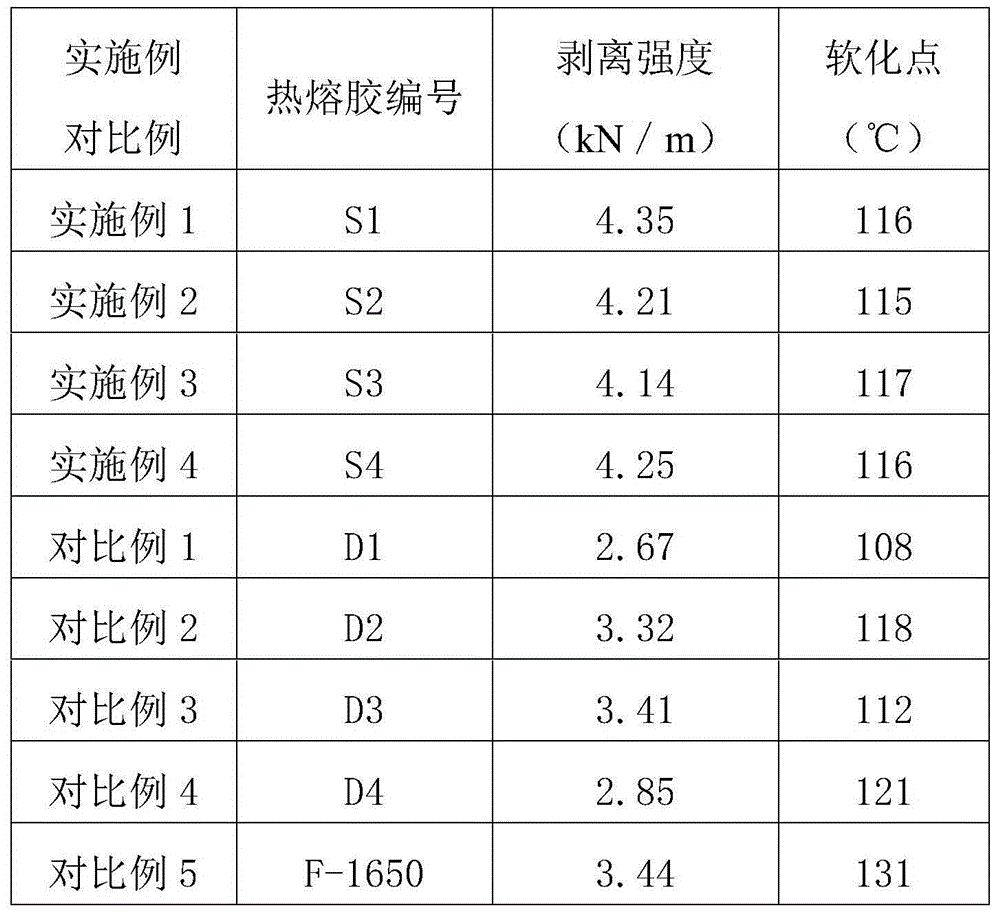

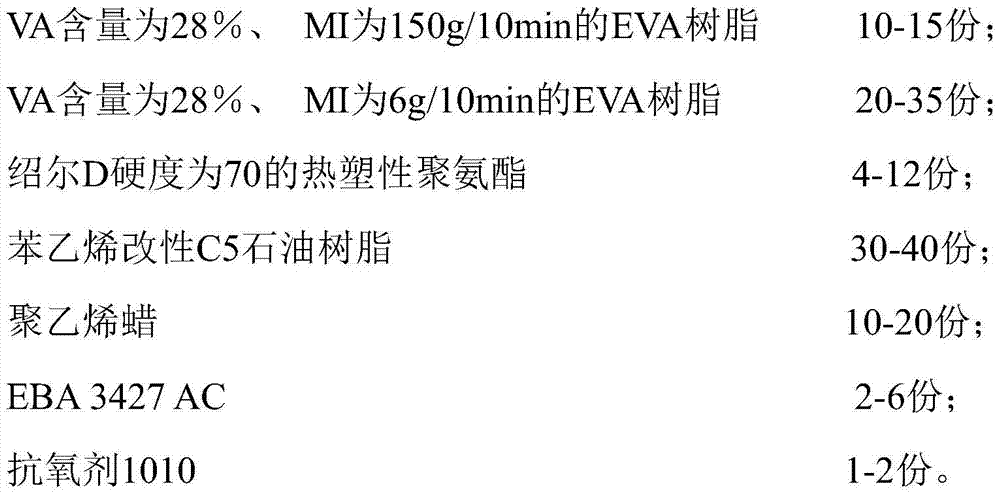

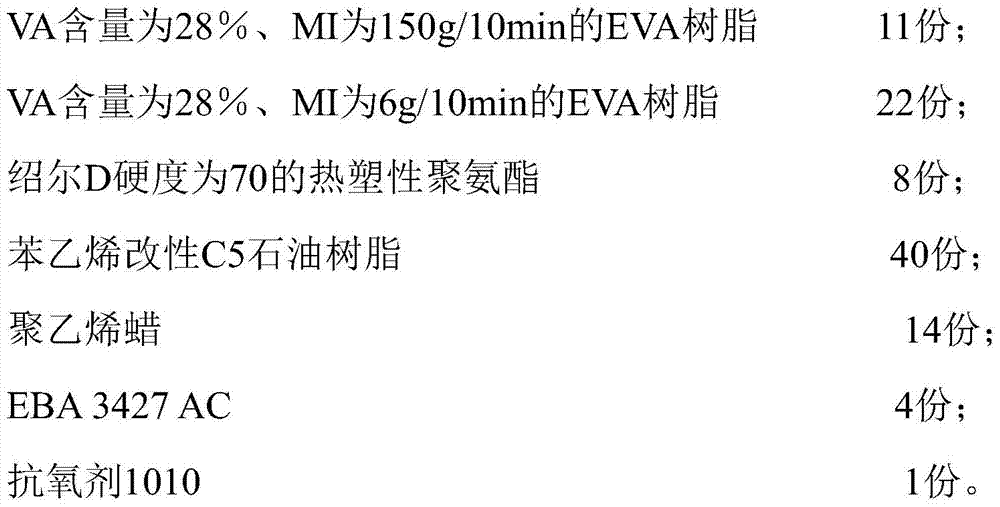

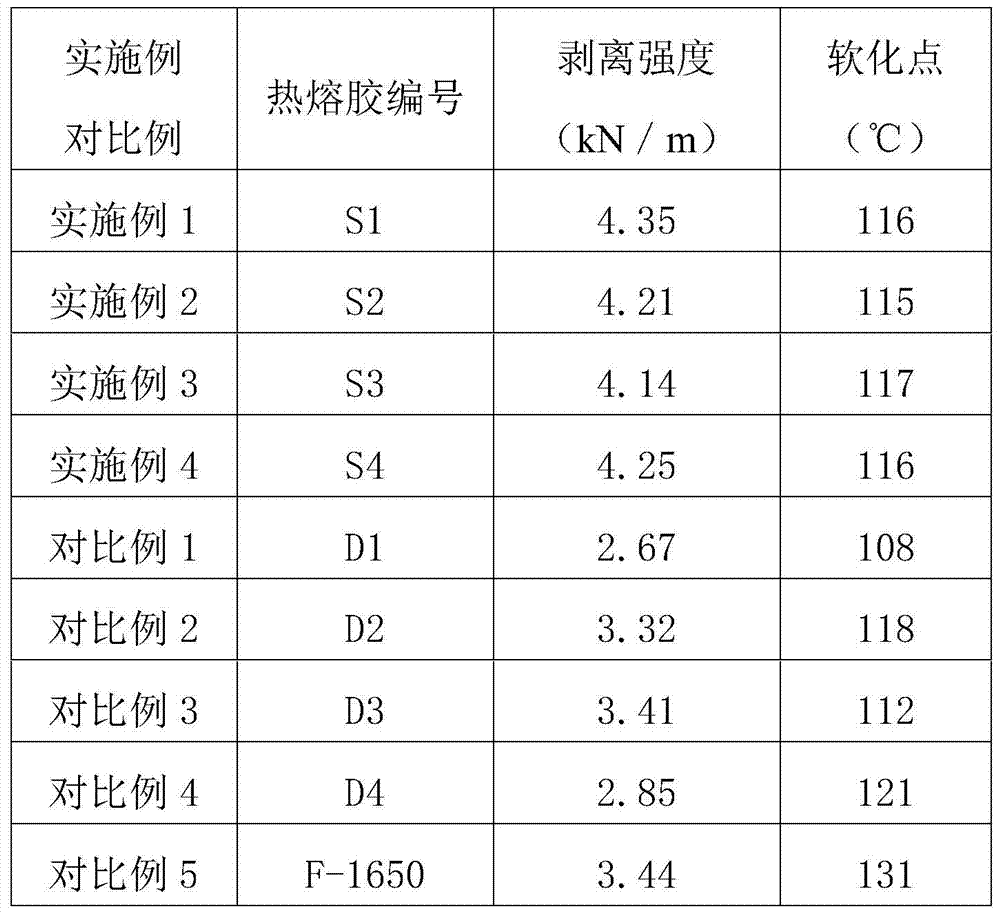

The invention provides a hot melt adhesive for an acrylic hot-fix rhinestone. The hot melt adhesive comprises the following components by weight: 10 to 15 parts of EVA resin with the VA content of 28% and the MI of 150 g / 10min, 0 to 35 parts of EVA resin with the VA content of 28% and the MI of 6 g / 10min, 4 to 12 parts of thermoplastic polyurethane with Shore D hardness of 70, 30 to 40 parts of styrene modified C5 petroleum resin, 10 to 20 parts of polyethylene wax, 2 to 6 parts of EBA3427AC and 1 to 2 parts of an antioxidant 1010. The hot melt adhesive for the acrylic hot-fix rhinestone provided by the invention has a hot-press temperature of 115 to 120 DEG C, is not prone to scalding the acrylic hot-fix rhinestone and fabrics, and has peeling strength of no less than 4.0kN / m , thereby having high bonding strength at the same time; meanwhile, the hot melt adhesive has the advantage of good adhesive force with a variety of fabrics and acrylic hot-fix rhinestones, and is an ideal hot melt adhesive for the acrylic hot-fix rhinestone.

Owner:HUANGSHAN XINDECHENG GLUE IND CO LTD

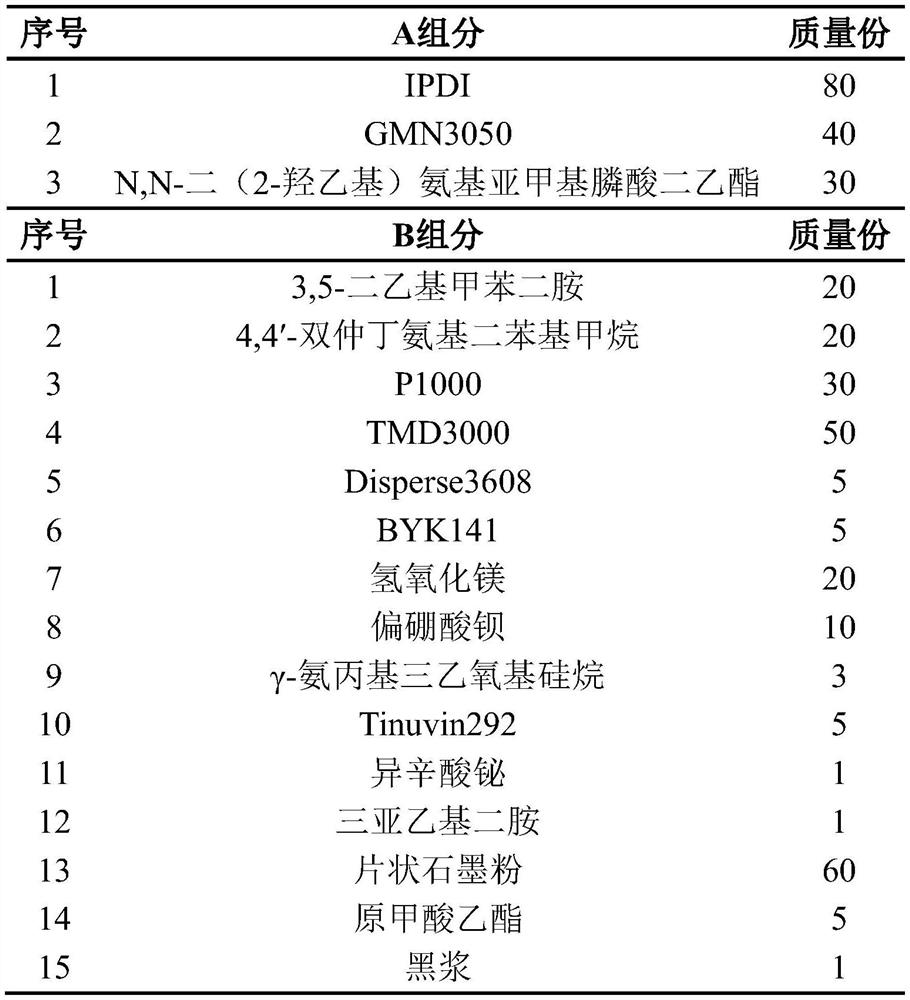

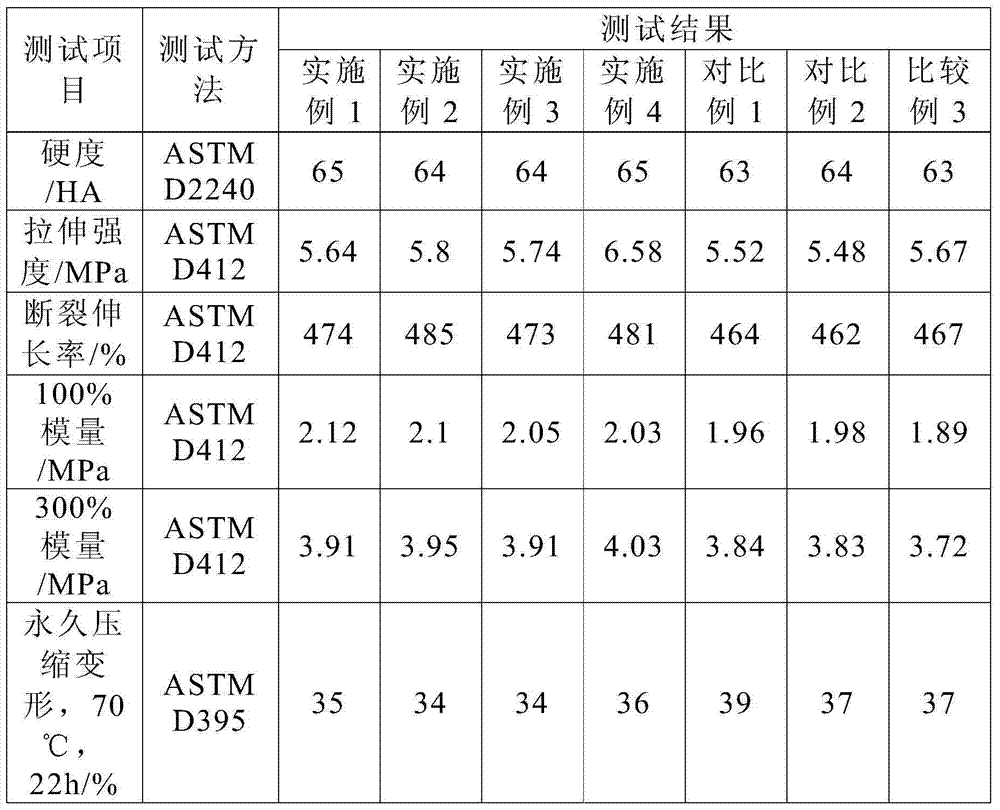

High-performance polyurea damping material and preparation method thereof

InactiveCN112375475AHigh solid contentImprove construction efficiencyFireproof paintsAntifouling/underwater paintsPolymer sciencePtru catalyst

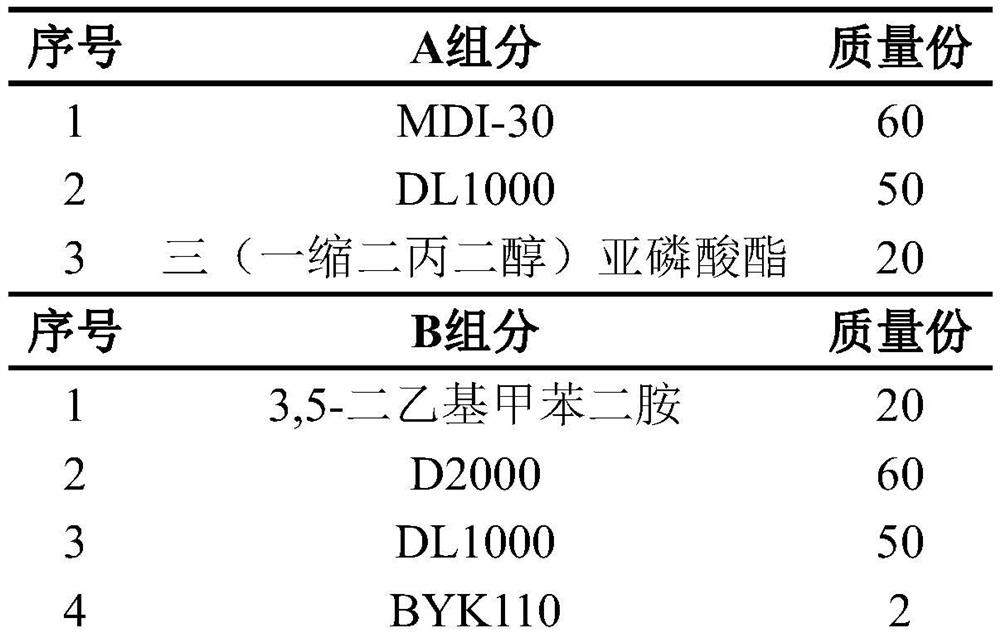

The invention provides a high-performance polyurea damping material, and belongs to the technical field of damping materials. The material is composed of a component A and a component B. The componentA is an isocyanate-terminated prepolymer, and is formed by reacting polyisocyanate, polyol and a reactive liquid flame retardant, and the -NCO content of the component A is 12-16%; the component B isformed by mixing a steric hindrance chain extender, amine-terminated polyether, polyhydric alcohol, a dispersing agent, a defoaming agent, an ultrafine powder flame retardant, a coupling agent, a weather-proof additive, a catalyst, a flaky functional filler, a water removal agent and color paste; and the isocyanate index alpha value of the component A and the component B is 0.9-1.1. The inventionfurther provides a preparation method of the high-performance polyurea damping material. The high-performance polyurea damping material provided by the invention has very excellent mechanical properties and very good damping performance, also has relatively good flame retardance, water resistance, liquid medium resistance, corrosion resistance, mold resistance and aging resistance, and is easy toconstruct, safe, environment-friendly and wide in application range.

Owner:QINGDAO AIR NEW MATERIALS

Assembly painting method for improving coating adhesion force

InactiveCN105521930AImprove adhesionImprove environmental adaptabilityPretreated surfacesCoatingsHeat resistanceSurface roughness

The invention discloses an assembly painting method for improving coating adhesion force. The method comprises the following steps: 1) roughing the surfaces of parts, controlling the roughness of the surfaces to be 1.6 to 6.3 microns, then washing through a solvent, and drying; 2) spraying epoxy primer, and controlling the thickness of a dried film to be 70 to 100 microns; 3) spraying fluorocarbon finish, and controlling the thickness of the dried film to be 30 to 50 microns; 4) assembling the parts to be an assembly, grinding and levelling a painted part of the assembly, removing dirt, spraying fluorocarbon finish, and controlling the thickness of the dried film to be 30 to 50 microns, so as to obtain the product. According to the method, the parts are painted, and then the assembly is sprayed with the paint, and the process parameters of each stage are controlled, so that the environmental suitability of the parts can be improved; besides the high adhesion force, a coating of the assembly is outstanding in salt mist resistance, moist heat resistance, mould resistance, high temperature resistance and low temperature resistance; the coating is uniform and consistent in appearance and high in decoration performance.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

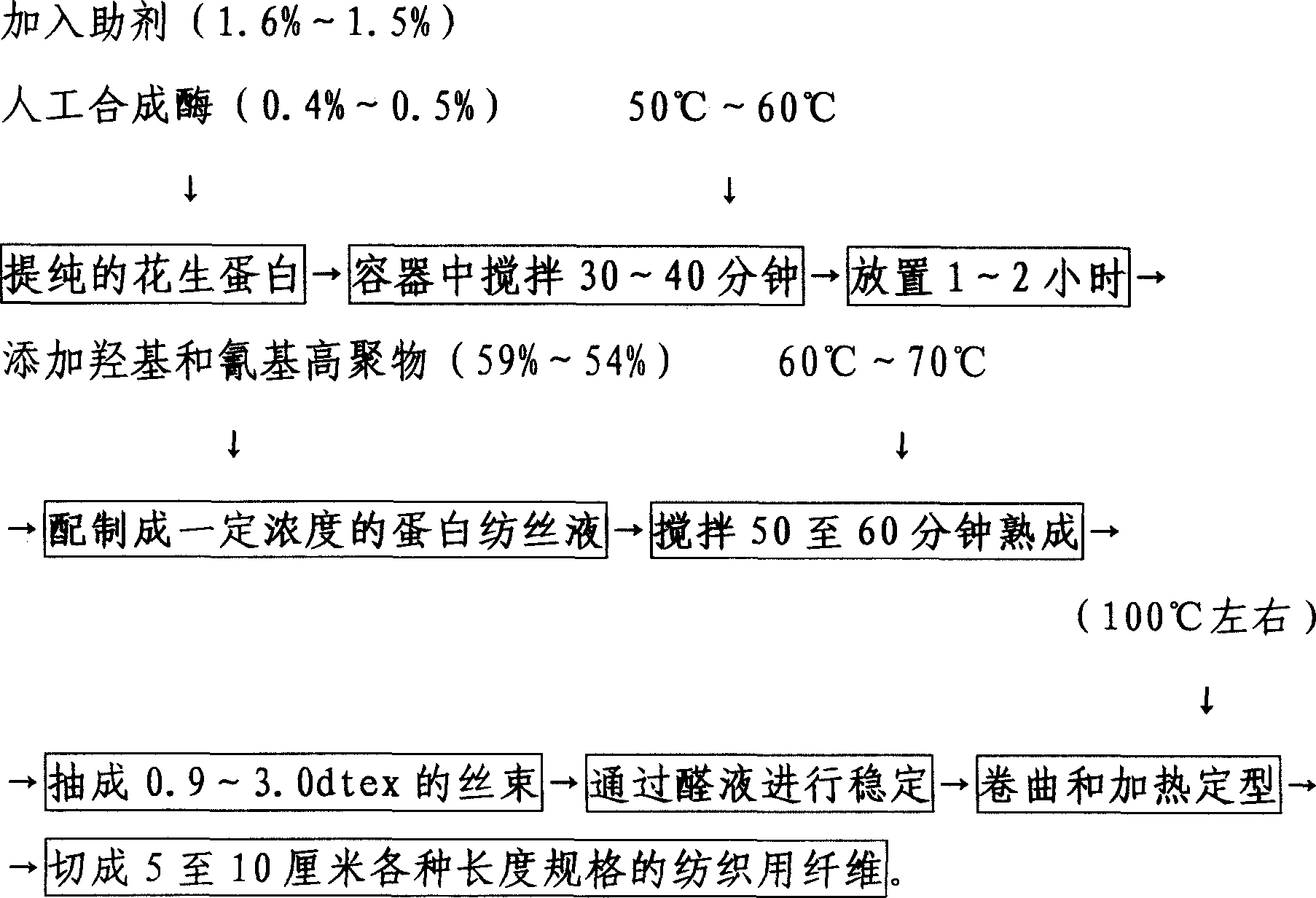

Process for producing fiber from peanut protein

InactiveCN1683615AImprove insulation effectMold resistantMonocomponent globulin artificial filamentFiberResource utilization

The process of producing fiber with peanut protein features the material comprising peanut globulin 39-44 wt%, polymer 54-59 wt%, artificial synthetase 0.4-0.5 wt%, and assistant 1.5-1.6 wt%. The present invention provides new way of utilizing peanut protein, raises the peanut resource utilization and is suitable for peanut globulin producing industry.

Owner:青岛润德粮油制品有限公司

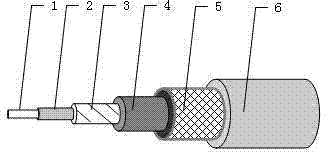

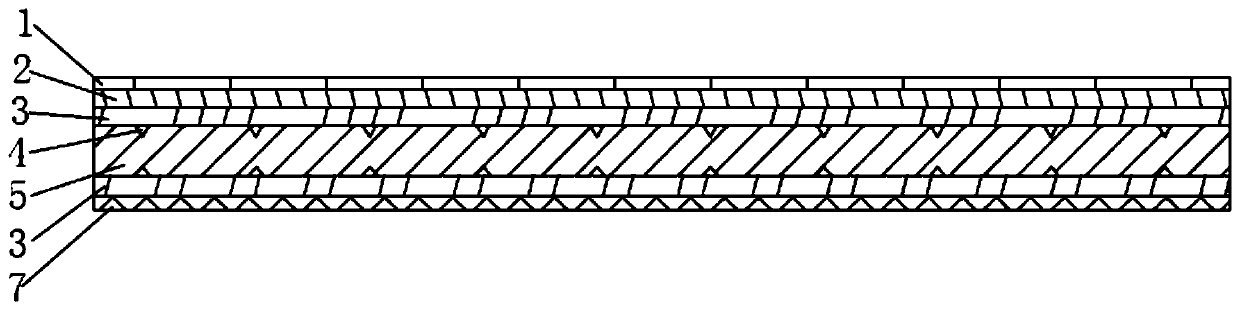

Aerial high-temperature-resistant loose optical cable and preparation method thereof

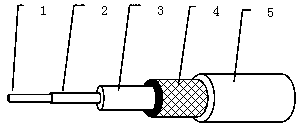

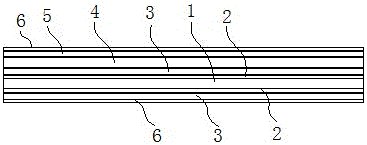

InactiveCN104777572ALong-term bending resistanceLong-term stress resistanceFibre mechanical structuresEngineeringPolytetrafluoroethylene

The invention discloses an aerial high-temperature-resistant loose optical cable and a preparation method thereof. A coating layer 2 is arranged outside an optical fiber core 1; a polytetrafluoroethylene PTFE lapping buffer layer 3 is arranged outside the coating layer 2; a polyether ether ketone PEEK loose layer 4 is arranged outside the polytetrafluoroethylene PTFE lapping buffer layer 3; an aromatic polyamide fiber reinforcing layer 5 is arranged outside the polyether ether ketone PEEK loose layer 4; an ethylene tetrafluoroethylene copolymer ETFE jacket layer 6 is arranged outside the aromatic polyamide fiber reinforcing layer 5. The aerial high temperature-resistant loose optical cable has the characteristics of resisting high / low temperature of -55-125 DEG C for a long time, resisting bending, compression, ageing, corrosion, salt mist, mould and damp heat and being long in service life and high in flame resistance, can be used for providing reliable service under severe environment and is suitable for the high-speed signal transmission under aerospace, electronics and onboard special environment conditions.

Owner:NANJING QUANXIN CABLE TECH

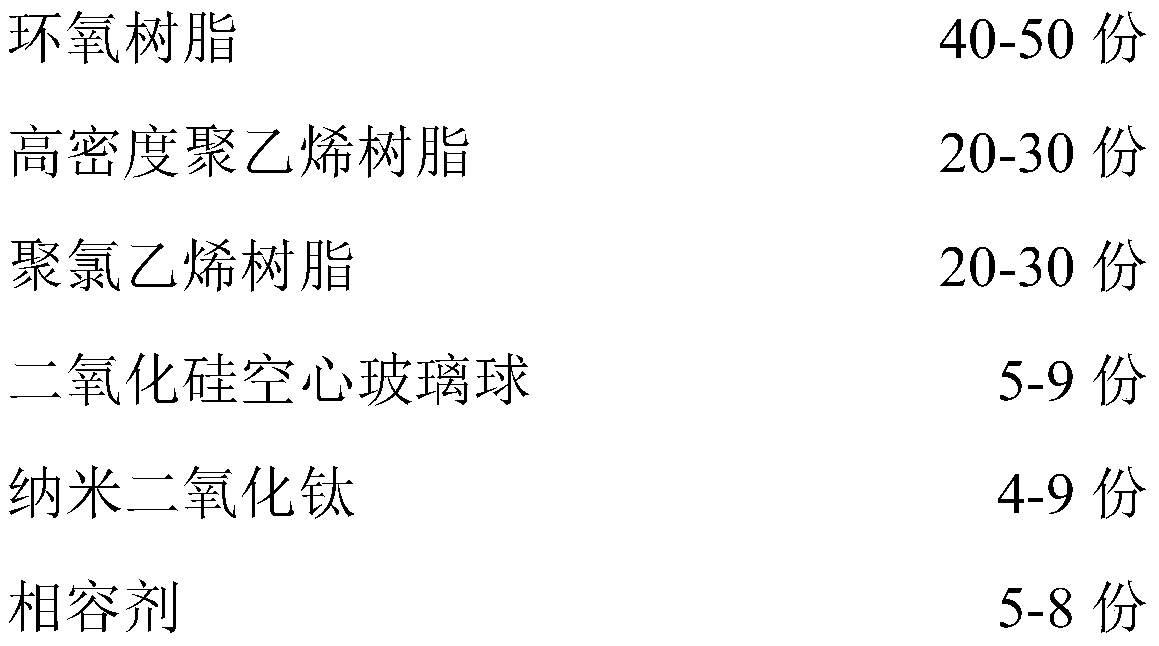

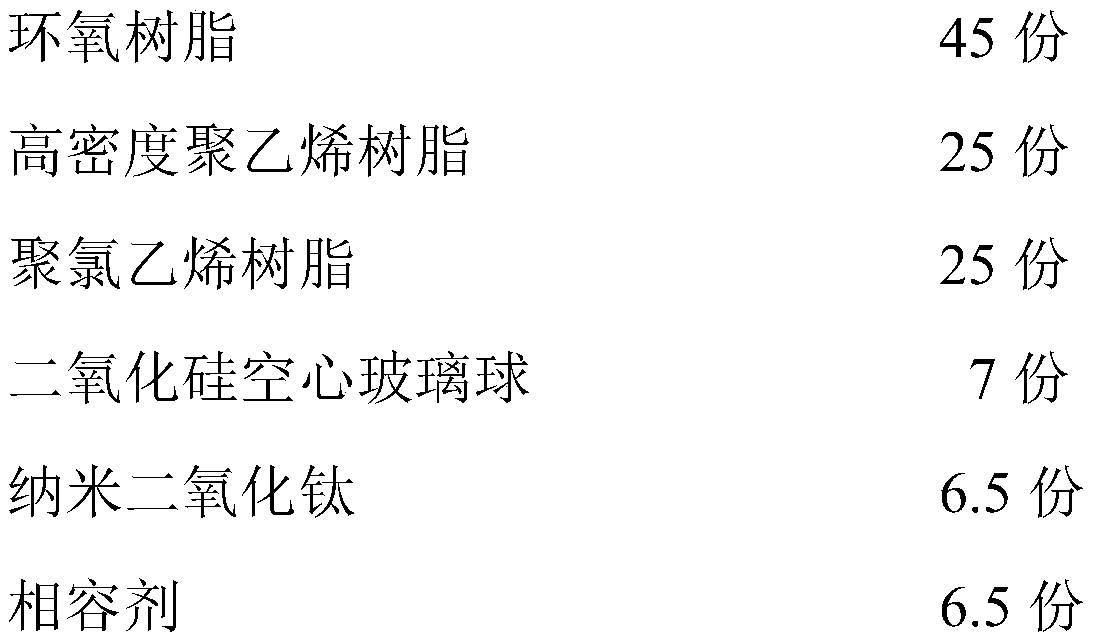

Nano modified high-performance dynamic vulcanization thermoplastic elastomer and preparation method thereof

The invention relates to a nano modified high-performance dynamic vulcanization thermoplastic elastomer and a preparation method thereof, belonging to the technical field of high-molecular materials. The nano modified high-performance dynamic vulcanization thermoplastic elastomer consists of the following components in parts by weight: 10-100 parts of polyolefin resin, 10-90 parts of elastomer, 2-20 parts of nano filler, 10-120 parts of filling oil, 1-30 parts of filler and 4-30 parts of processing aid, wherein the polyolefin resin is one or more of polyolefin resin homopolymer and polyolefin resin copolymer; the nano filler is one or more of nano modified montmorillonite, nano silicon dioxide, nano titanium dioxide and nano calcium carbonate; the particle size of the nano filler is 1-100nm. The invention also provides a preparation method of the nano modified high-performance dynamic vulcanization thermoplastic elastomer. The nano modified high-performance dynamic vulcanization thermoplastic elastomer provided by the invention has good physical properties and is widely applicable.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

Water-based protective coating with peeling property and preparation method thereof

InactiveCN110684450AExcellent peelabilityImprove controllabilityLiquid surface applicatorsAntifouling/underwater paintsDrying timeUltimate tensile strength

Owner:FUDAN UNIV

Preparation method of fiberboard for musical instrument bamboo fiber material

InactiveCN110576496AKeep the lookMaintain mechanical propertiesWood treatment detailsReed/straw treatmentCompression moldingAdhesive

The invention provides a preparation method of a fiberboard for a musical instrument bamboo fiber material. The preparation method comprises the following steps of 1), oxidizing and desugarizing natural plant fibers such as bamboo to obtain continuous bamboo natural fibers; 2), impregnating the surface modified continuous bamboo natural fibers with synthetic resin adhesive; and 3), carrying out compression molding on bamboo fibers impregnated with synthetic resin in a mold, taking forming curing temperature as the heat curing peak temperature of the synthetic resin adhesive, and preparing theplant fiber reinforced composite material after thermal curing molding. The preparation method of the fiberboard for the musical instrument bamboo fiber material has the advantages of low production cost, good mechanical property and good acoustic performance.

Owner:李刚

Modified wet film, production method of modified wet film and application of modified wet film in production of heat exchange device of air conditioner external unit

InactiveCN110743378AGood hygroscopicityIncreasing the thicknessSemi-permeable membranesMembranesOxide ceramicPolyvinyl alcohol

The invention provides a modified wet film. The modified wet film comprises the following raw materials: carboxymethyl cellulose, teflon, graphene oxide, a silane coupling agent KH550, oxide ceramics,a Li-containing metal salt, CaCl2, polyvinylpyrrolidone, polyvinyl alcohol, acetic acid, ethyl alcohol and water. The produced modified wet film has good self-cleaning performance after being used asthe heat exchange device of the air conditioner external unit, can guarantee cleanness of air which enters a room, has the advantages of non-toxicity, resistance to acids and alkalies, resistance tomould, flame retardation and the like, is a good use material of the heat exchange device of the external unit, and has wide application prospects.

Owner:吉金学

Preparation process of environmental-friendly cabinet board

ActiveCN109720021AHigh strengthImprove mechanical propertiesSynthetic resin layered productsLaminationEngineeringFormaldehyde free

The invention relates to the technical field of cabinet panels, in particular to a preparation process of an environmental-friendly cabinet board. The environmental-friendly cabinet board comprises adecorative layer, a sandwich plate layer, a foam plate core layer and a bottom plate layer which are sequentially compounded, a resin reinforcement layer is compounded between the sandwich plate layerand the foam plate core layer and between the foam plate core layer and the bottom plate layer, a plurality of conical bulges are arranged on the side surfaces of the resin reinforcement layer compounded with the foam plate core layer, the surface of the environmental protection cabinet board is sprayed with a waterproof and flame retardant paint, so that the cabinet board is environmentally friendly, pollution-free and formaldehyde-free, and has low water absorption, excellent tensile property and impact resistance.

Owner:GUANGDONG CACAR KITCHEN SCI & TECH CO LTD

Marine environment aviation tire tread rubber and preparation method thereof

The invention discloses marine environment aviation tire tread rubber and a preparation method thereof. The marine environment aviation tire tread rubber is prepared from, by mass, 16-18 parts of smoke sheet rubber, 1-2 parts of a silane coupling agent, 6-10 parts of stearic acid, 1-3 parts of a heat stabilizer, 4-6 parts of zinc oxide, 11-13 parts of palm oil, 1-3 parts of an accelerant,40-60 parts of butadiene styrene rubber, 1-2 parts of a fracturing preventive, 6-10 parts of insoluble sulfur, 1-3 parts of an anti-ageing agent, 4-6 parts of carbon black, 6-8 parts of white carbon black and 1-3 parts of an anti-reversion agent. According to the tire tread rubber, the rubber material has the advantages of resisting ultraviolet rays, resisting ozone, resisting atmospheric ageing, resisting salt spray and resisting mold erosion, and the aviation tire has the good overall performance, and is particularly suitable for an appropriate marine environment.

Owner:QINZHOU UNIV

Degradable thermoplastic polyurethane (TPU) cotton tablecloth with foaming layer

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Layer paving type selective laser sintering fast forming method of linen

InactiveCN102632617AThe overall thickness is thinImprove machining accuracySelective laser sinteringSurface roughness

The invention provides a layer paving type selective laser sintering fast forming method of linen and relates to a selective laser sintering method. The method aims at overcoming the defects that when composite powder is adopted as raw materials of the selective laser sintering, the uniform powder mixing and the mutual adhesion gathering are frequently generated, so the powder paving thickness is not uniform, composite powder loss even occurs in certain point positions, and the relative wrapping rate, the internal stress and the surface roughness of parts are influenced. The method comprises the steps that: 1, a computer is used for building a model; 2, the linen is paved layer by layer, the solidifying liquid is sprayed and coated, and the selective laser sintering is carried out; 3, the step 2 is repeated; and 4, semi-finished products are soaked in toluene, then, the vacuum drying is carried out, next, the semi-finished products are placed into copper ammonia solution to be soaked and are then taken out to be flushed by clean water, the drying is carried out for 1 hour at 120 DEG C, and the layer paving type selective laser sintering is completed. The method is used for preparing processing parts or manufacturing molds through the selective laser sintering.

Owner:河北英曼卡科技有限公司

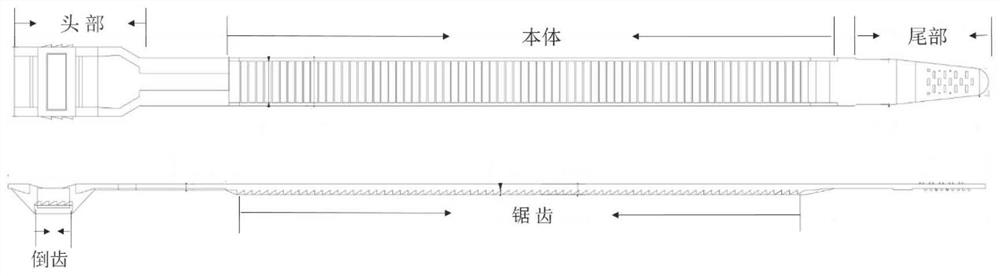

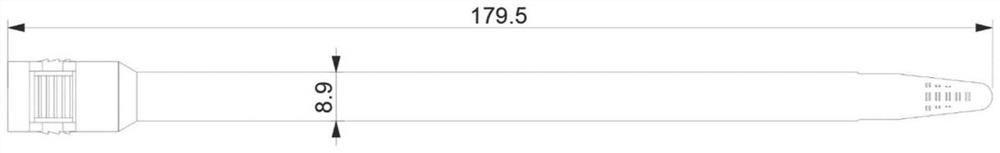

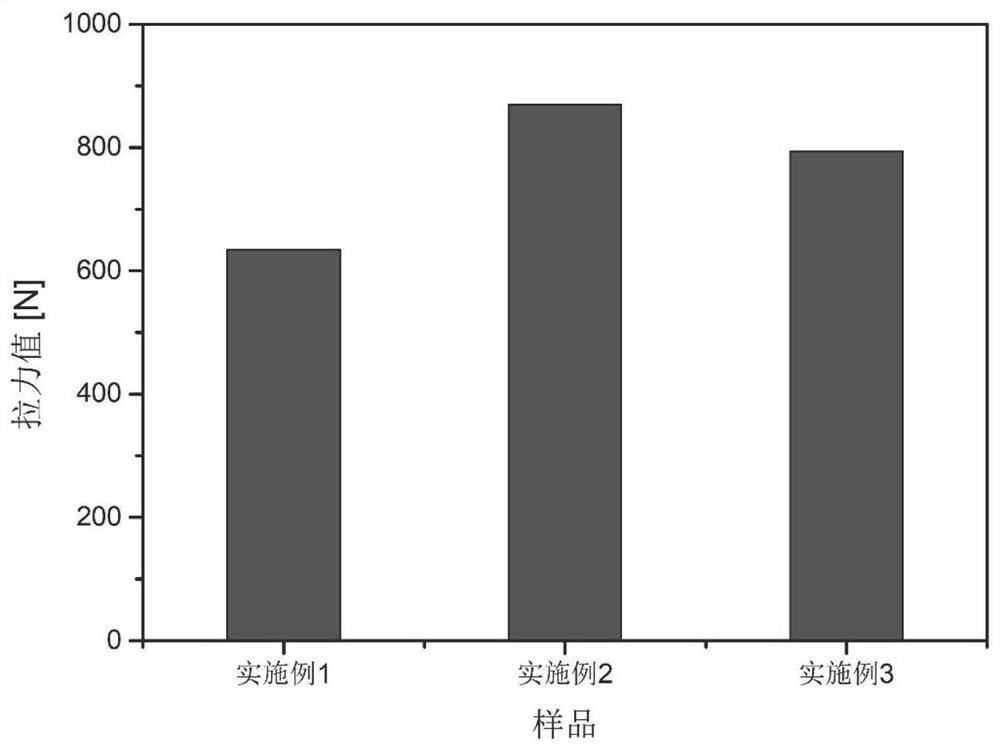

Self-locking nylon 66 plastic cable tie with high locking force and preparation method of self-locking nylon 66 plastic cable tie

InactiveCN113525922ALow temperature resistanceWith high and low temperature cycle resistanceFlexible elementsNylon 66Engineering

The invention provides a self-locking nylon 66 plastic cable tie with high locking force and a preparation method of the self-locking nylon 66 plastic cable tie, and belongs to the technical field of tightening pieces. The self-locking nylon 66 plastic cable tie comprises a head part, a body and a tail part, the head part is provided with inverted teeth, and a plurality of sawteeth are uniformly distributed on the inner side of the body; and the cable tie is made of toughened nylon 66. The cable tie is made of toughened nylon 66, has the advantages of low temperature resistance (can resist-55 DEG C), high-low temperature circulation resistance, high-frequency vibration resistance, mold resistance and the like, and still has high locking force under the harsh conditions. Furthermore, the width of the cable tie is increased compared with that of a conventional cable tie, and the locking force of the cable tie can be further improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

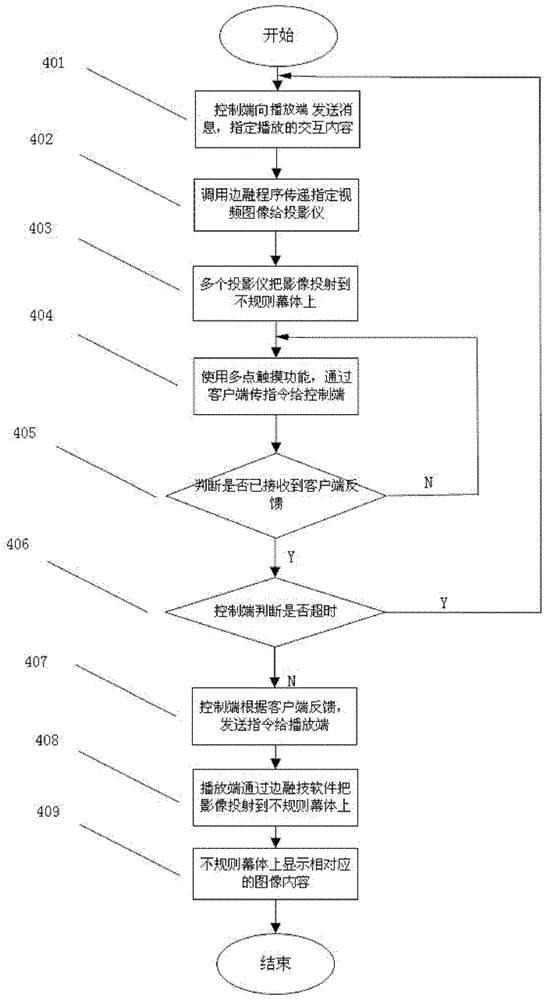

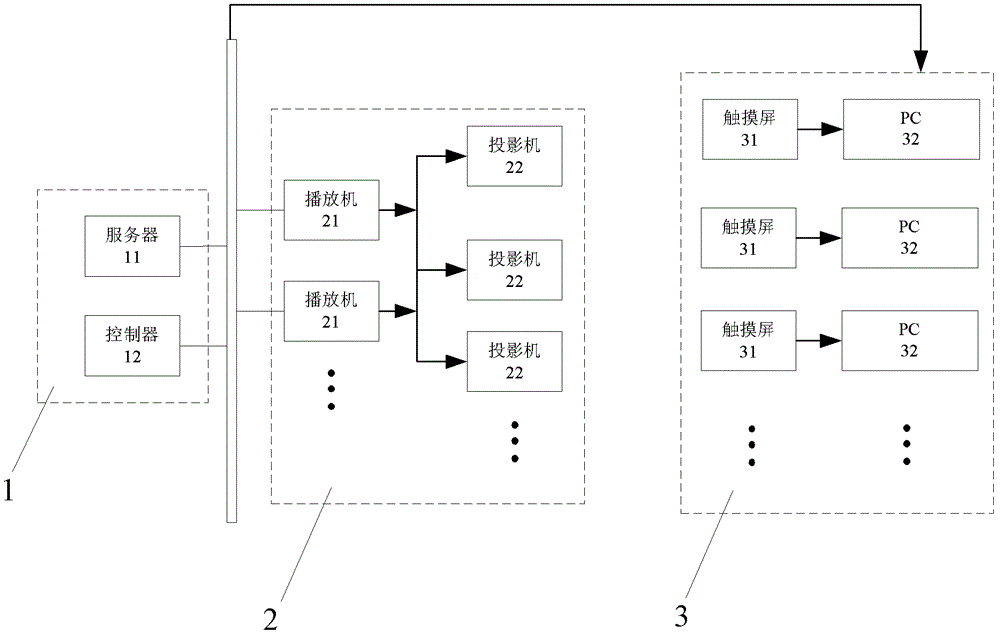

A human-computer interaction system based on irregular screen multi-touch

The invention relates to a human-computer interaction system based on irregular screen multi-touch, comprising: interactive content specified playback device; video image transmission device; image projection device; multi-touch device; client command judging device; control terminal timeout The judging device; the command sending device of the control terminal; the image projecting device of the playback terminal; the image content display device. Compared with the prior art, the present invention breaks the limitation that the projected images in the past can only be flat and regular graphics, and can conveniently project various image contents on irregular screens such as hemispherical and spherical, so that the audience has Immersive experience and other advantages.

Owner:SHANGHAI HUABO INFORMATION SERVICE

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789BGood adhesionWater resistantWood treatment detailsWood veneer joiningAdhesive cementWood veneer

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300Kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

Graphene coating and preparation method thereof

InactiveCN113025099AMold resistantImpact resistantAntifouling/underwater paintsPaints with biocidesPolymer scienceCarbamate

The invention provides a graphene coating and a preparation method thereof. The graphene coating is mainly prepared from polyurethane, 4-nitro-N-(3-triethoxysilylpropyl) benzamide, N-(3-trimethoxysilylpropyl) pyrrole, p-hydroxyphenylacrylic acid, methyl p-hydroxycinnamate, ethylene glycol monobutyl ether, tetraethylene glycol monobutyl ether, cinnamyl aldehyde grafted cassava starch and graphene / modified graphene. Graphene in the prepared graphene coating is good in dispersity, firm in combination and not prone to falling off, meanwhile, graphene interacts with other substances to form a complex net-shaped structure, and meanwhile the graphene coating has good antistatic performance and impact resistance. The whole preparation process is simple, the cost is low, no environmental pollution is caused in the production process, and the quality is stable.

Owner:尤纪超

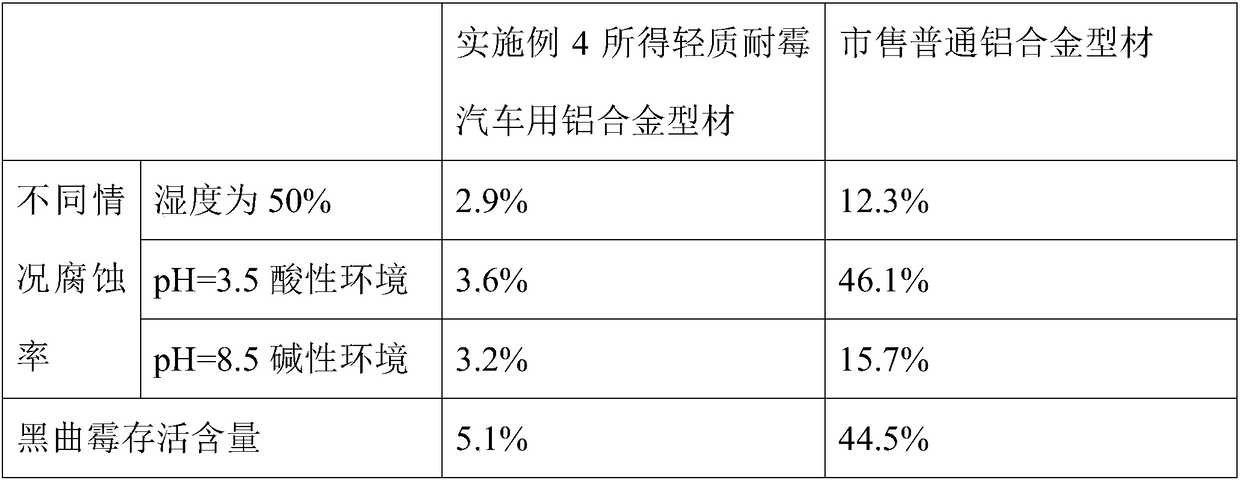

Aluminium alloy profile for lightweight mildew resistant vehicle

InactiveCN108250857AMold resistantAnti-pollutionAntifouling/underwater paintsPaints with biocidesCorrosionAluminium alloy

The invention discloses an aluminium alloy profile for a lightweight mildew resistant vehicle. The aluminium alloy profile comprises an aluminium alloy profile and a composite coating which coats thesurface of the aluminium alloy profile; the composite coating is prepared from the following raw materials in parts by weight: 30 to 50 parts of polyvinylidene fluoride, 4 to 8 parts of diethylene glycol ether, 3 to 7 parts of propylene glycol monomethyl ether, 6 to 12 parts of light calcium carbonate, 3 to 7 parts of broussonetia papyrifera powder, 4 to 8 parts of epoxidized soybean oil, and 4 to8 parts of magnesium stearate. The aluminium alloy profile for the lightweight mildew resistant vehicle provided by the invention has easily purchased raw materials, is novel in formula, light in weight, good in corrosion resistance and low temperature resistance, does not crack, fall off and mildew, and is long in service life, wherein the service life can reach 15 years.

Owner:安徽鑫铂铝业股份有限公司

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437BChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame-retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

A kind of acrylic hot-melt adhesive and preparation method thereof

ActiveCN105273669BHigh hardnessHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesThermoplastic polyurethaneHardness

Owner:HUANGSHAN XINDECHENG GLUE IND CO LTD

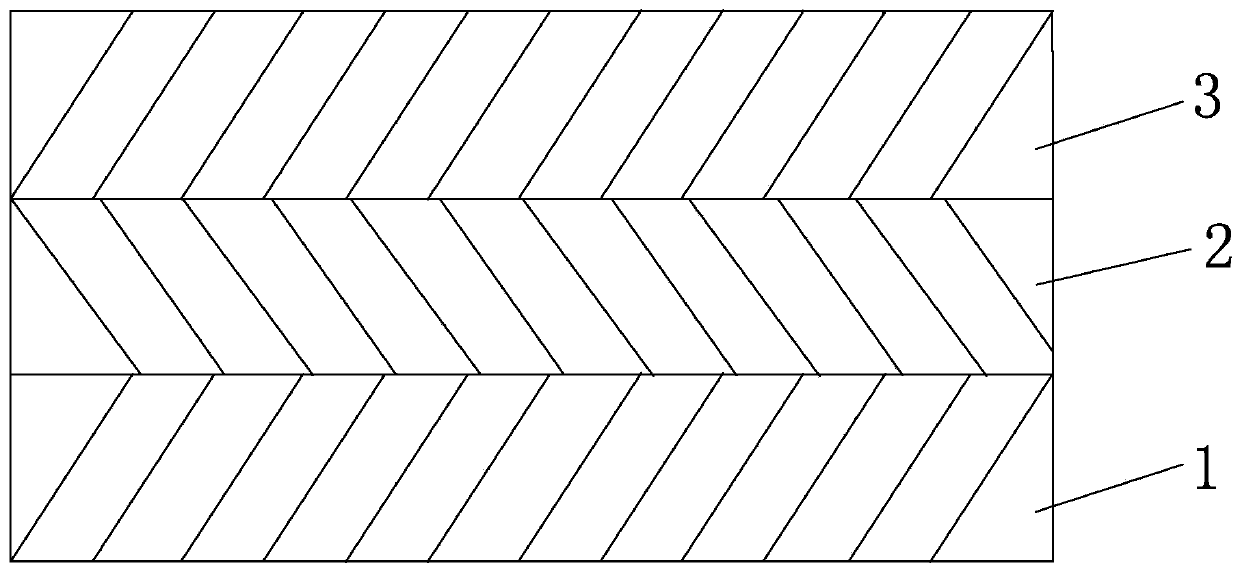

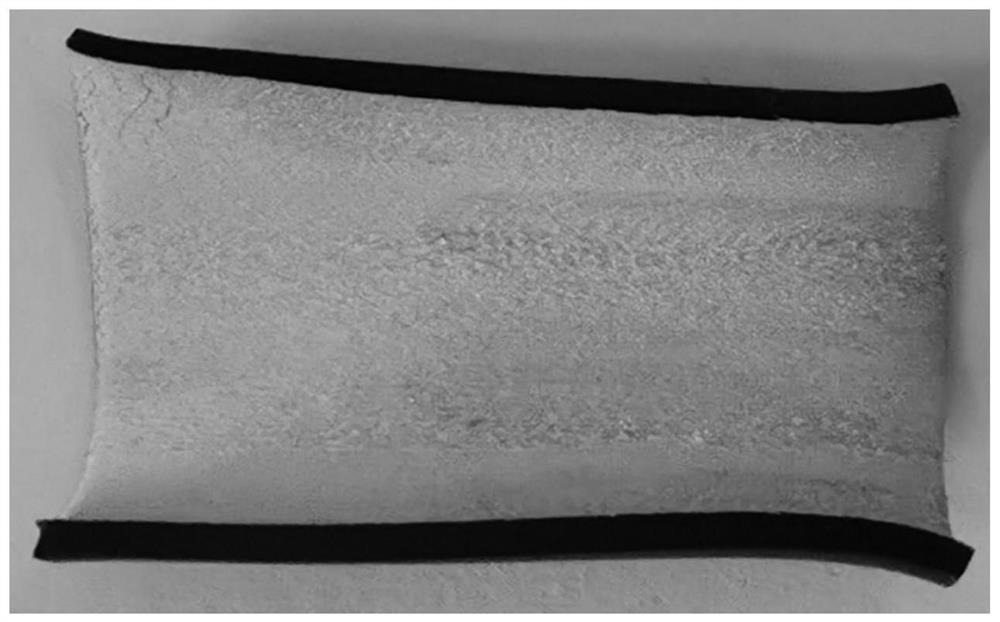

A high-strength coated Oxford cloth

ActiveCN104589750BInhibit productionExtended service lifeSynthetic resin layered productsCoatingsBreaking strengthGram

The invention discloses high-strength coating Oxford cloth. The high-strength coating Oxford cloth comprises base cloth, a silicon dioxide sol layer, an acrylic resin coating, an inorganic printing coating, a polyurethane resin coating and a film layer, wherein the base cloth is dipped into the silicon dioxide sol layer and the acrylic resin coating is arranged outside the silicon dioxide sol layer; the inorganic printing coating is arranged outside the acrylic resin coating; the polyurethane resin coating is arranged outside the inorganic printing coating; and the film layer is arranged outside the polyurethane resin coating. The gram weight of an Oxford cloth finished product is less than or equal to 300g / m<2>, the breaking strength in the warp direction is more than or equal to 2300N, the breaking strength in the weft direction is more than or equal to 2200N, the tearing strength in the warp direction is more than or equal to 300N, the tearing strength in the weft direction is more than or equal to 260N, the hydrostatic pressure flat part is more than or equal to 20kpa and the hydrostatic pressure fold part is more than or equal to 8kpa; the color fastness to light is more than or equal to 6-7 grades; and the high-strength coating Oxford cloth can resist sticking, has the advantages of resisting mold corrosion, inhibiting mold production, resisting salt mist corrosion and resisting natural ageing, so that the service life of a tent is more than 3 years.

Owner:YANGZHOU JIYUAN TEXTILE

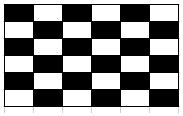

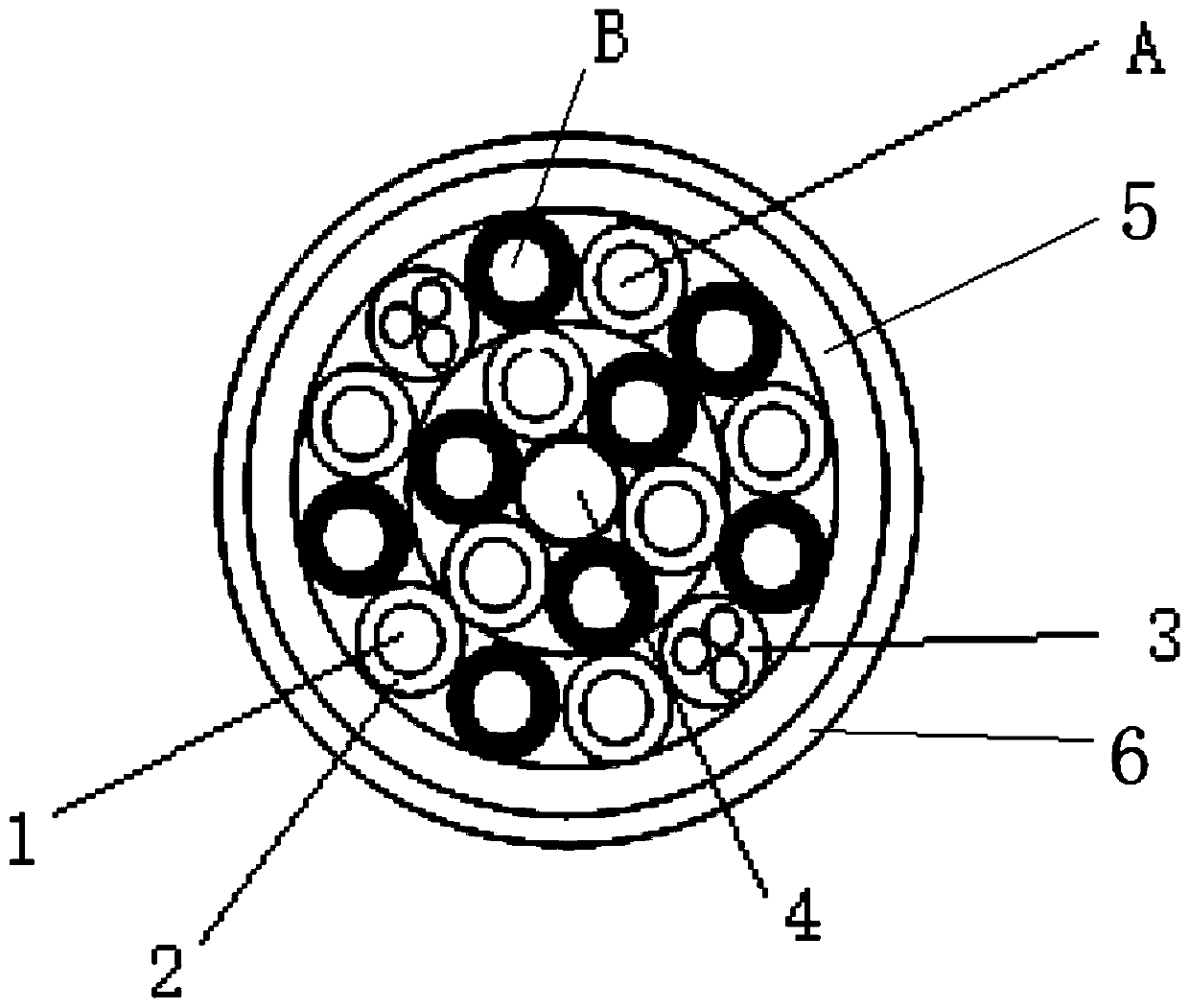

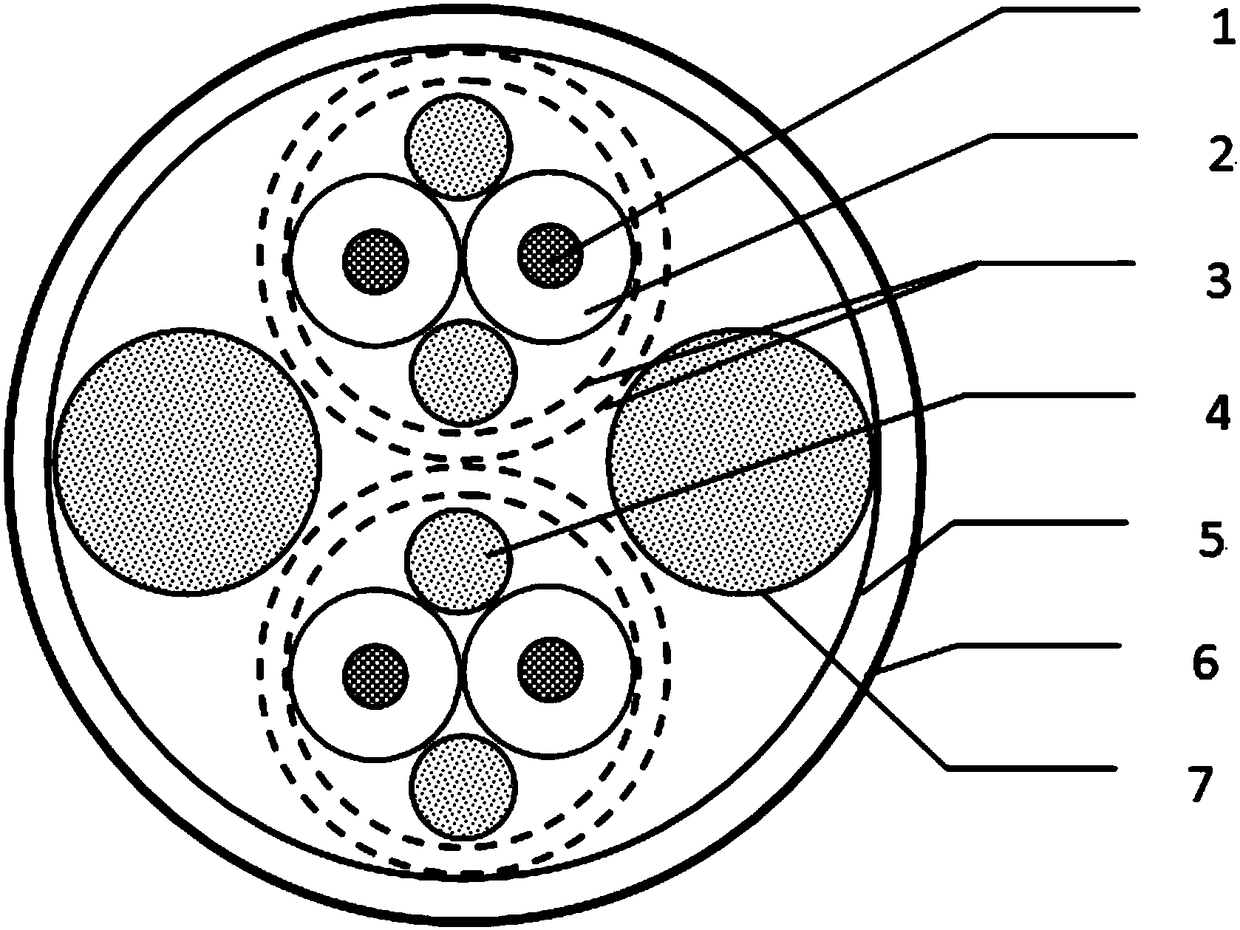

Anti-nuclear electromagnetic multi-core pulse direct-current cable

InactiveCN111489860AReduce Galvanic CorrosionGuarantee the quality of power transmissionPower cables including communication wiresPower cables with screens/conductive layersElectrical conductorPulsed DC

The invention belongs to the technical field of wires and cables and particularly relates to an anti-nuclear electromagnetic multi-core pulse direct-current cable which comprises conductors, insulators, a central filling core, a shielding layer and a sheath, the insulators wrap the conductors to serve as current-carrying wire cores, the multiple current-carrying wire cores are closely arranged andstranded outside the central filling core to form a cable with a multilayer structure, the cable is wrapped by the shielding layer, and the shielding layer is wrapped by the sheath, the current-carrying wire cores are divided into positive wire cores A and negative wire cores B, the positive wire cores A and the negative wire cores B on the same layer are alternately arranged, and adjacent positive wire core A and negative wire core B on the same layer form a group of loops; or all the positive wire cores A and the negative wire cores B in the cable are crossed and connected in parallel to form a loop. By optimizing the arrangement of the current-carrying wire cores, stray electromagnetic fields in any axial direction can be reduced or counteracted, the high-current power transmission quality is ensured, and the electric corrosion to equipment around the cable is reduced.

Owner:NANJING QUANXIN CABLE TECH

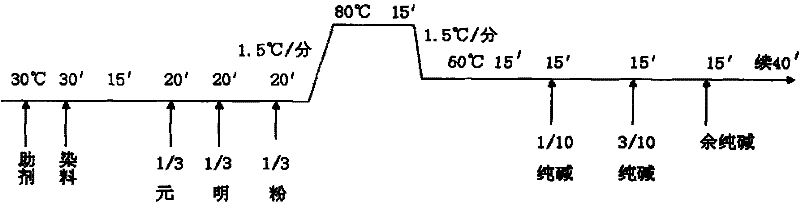

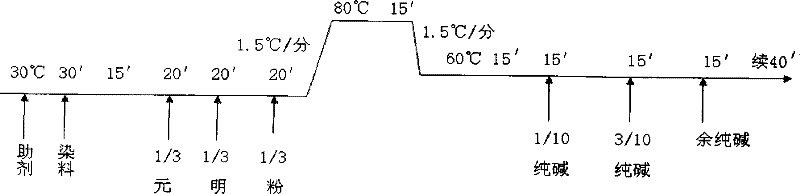

Production process of cotton coated viscose uniform material

InactiveCN101575763BWith comfortSun resistantWeft knittingHeating/cooling textile fabricsYarnViscose

The invention provides a process for manufacturing viscose yarn face and cotton back NBC protective school uniform material which is characterized by adopting an interlock structure and comprising the following components: 73-76 percent of 150D viscose yarn and 24-27 percent of combed cotton yarn, and environmental-friendly sunshine-resisting and sweat-resisting reactive dye is dyed into the viscose yarn face and cotton back NBC protective school uniform material. The viscose yarn face and cotton back NBC protective school uniform material is treated by water-proof finish aid, oil-proof finish aid and soil-releasing finish aidso that the water-proof finish aid, the oil-proof finish aid and the soil-releasing finish aid are adhered. The process comprises a weaving process, a dyeing process, a dehydration process, a width opening process, a drying process, a treatment process after heat setting and a test process. The viscose yarn face and cotton back NBC protective school uniform material manufactured by the inventive process has the characteristics of water-proof, oil-proof, soil-releasing properties, and the like and uneasy fluffiness and pilling. The invention can guarantee the level dyeing property and dye uptake of dye uptake fiber, increase colorizing force of the dye and improve the whole performance of the fabric.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Radiation-resistant light-weight symmetrical data transmission cable used for nuclear power plant and preparation method of cable

InactiveCN108288520AImpedance stabilitySmall attenuationInsulated cablesInsulated conductorsElectrical conductorSilver plate

The invention discloses a radiation-resistant light-weight symmetrical data transmission cable used for a nuclear power plant and a preparation method of the cable. The cable comprises multiple wire units, a wrapping layer and a sheath, wherein the wrapping layer is arranged on the exteriors of the multiple wire units; the sheath is arranged on the exterior of the wrapping layer in a sleeving manner; the space between the multiple wire units and the wrapping layer is filled with first fillers; each wire unit comprises multiple wires and a dual-layer silver-plated flat copper band woven shielding layer; the dual-layer silver-plated flat copper band woven shielding layer is arranged on the exterior of the corresponding wire in a sleeving manner; the space between the wire and the dual-layersilver-plated flat copper band woven shielding layer is filled with second fillers; each wire consists of a silver-pasted copper alloy twisted wire conductor and a crosslinked ethylene-tetrafluoroethylene copolymer insulating layer; and the exterior of the silver-pasted copper alloy twisted wire conductor is coated with the corresponding crosslinked ethylene-tetrafluoroethylene copolymer insulating layer. The cable has stable impedance, low attenuation, mould resistance, salt mist resistance, radiation resistance, high tensile strength, high external electromagnetic interference resistance, chemical corrosion resistance and dragging resistance.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

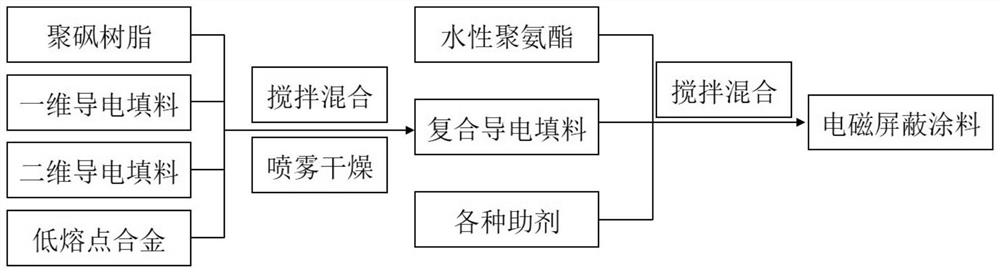

A kind of electromagnetic shielding coating suitable for heat shrinkable material and preparation method thereof

ActiveCN114058258BImprove shielding effectImprove shielding propertiesAntifouling/underwater paintsPaints with biocidesPolyurethane dispersionElectromagnetic shielding

The invention belongs to the field of coatings, and discloses an electromagnetic shielding coating suitable for heat shrinkable materials and a preparation method thereof. Add into the above solution, stir evenly to obtain conductive filler dispersion, then atomize the conductive filler dispersion, and obtain composite conductive filler after drying; (2) mix water-based polyurethane dispersion, anti-settling agent, composite conductive filler, Thickener and defoamer are mixed, and then stirred uniformly to obtain water-based polyurethane electromagnetic shielding coating. The low-melting-point alloy of the invention melts during the heating and shrinking process of the heat-shrinkable material, promotes the conductive filler to form a conductive network, increases the shielding performance of the shielding coating through the heat-shrinking process, and avoids wrinkling and cracking caused by the addition of excessive rigid metal fillers. Realize the low addition and high shielding properties of the coating.

Owner:广东粤港澳大湾区黄埔材料研究院

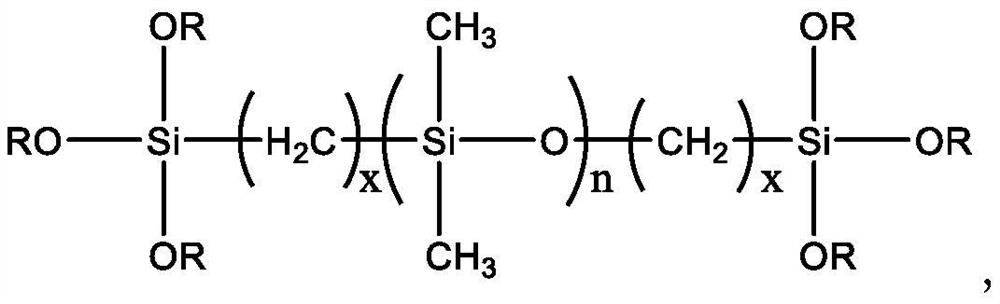

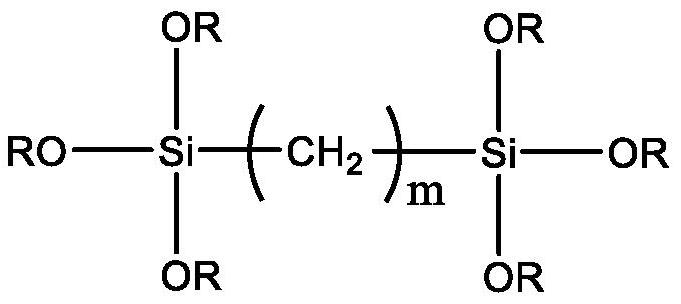

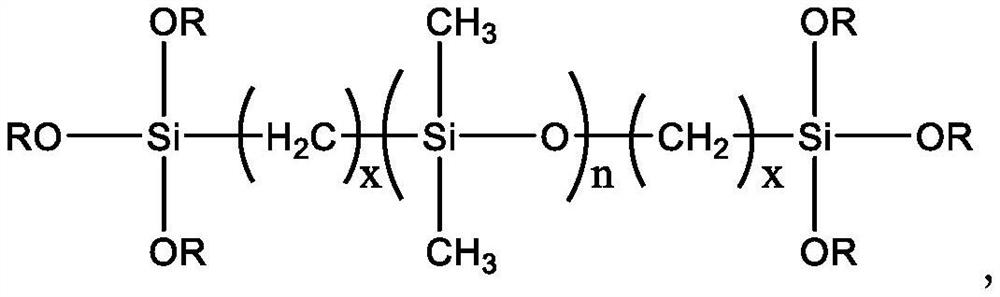

A low-viscosity transparent mildew-proof electronic coating adhesive and preparation method thereof

ActiveCN109504337BGood compatibilityDoes not affect transparencyNon-macromolecular adhesive additivesAlkanePtru catalyst

The invention discloses a low-viscosity transparent mildew-proof electronic coating adhesive and a preparation method thereof. The coating adhesive is polydimethylsiloxane, hexamethyldisilazide, and White carbon black treated with alkane, cross-linking agent, anti-fungal agent, tackifier and catalyst are mixed under vacuum condition according to a certain mass ratio. The draping glue prepared by the invention solves the problems of poor mildew resistance and poor stability of common draping glues, and the preparation method is simple and feasible. The components of the drape adhesive are well matched, and have the characteristics of low viscosity, environmental protection, solvent-free, and good stability; after curing, they have good electrical insulation, mildew resistance, and transparency, and have good adhesion to PCB circuit boards. Strong, able to meet the "three defenses" requirements of PCB circuit boards.

Owner:CHENGDU GUIBAO SCI & TECH

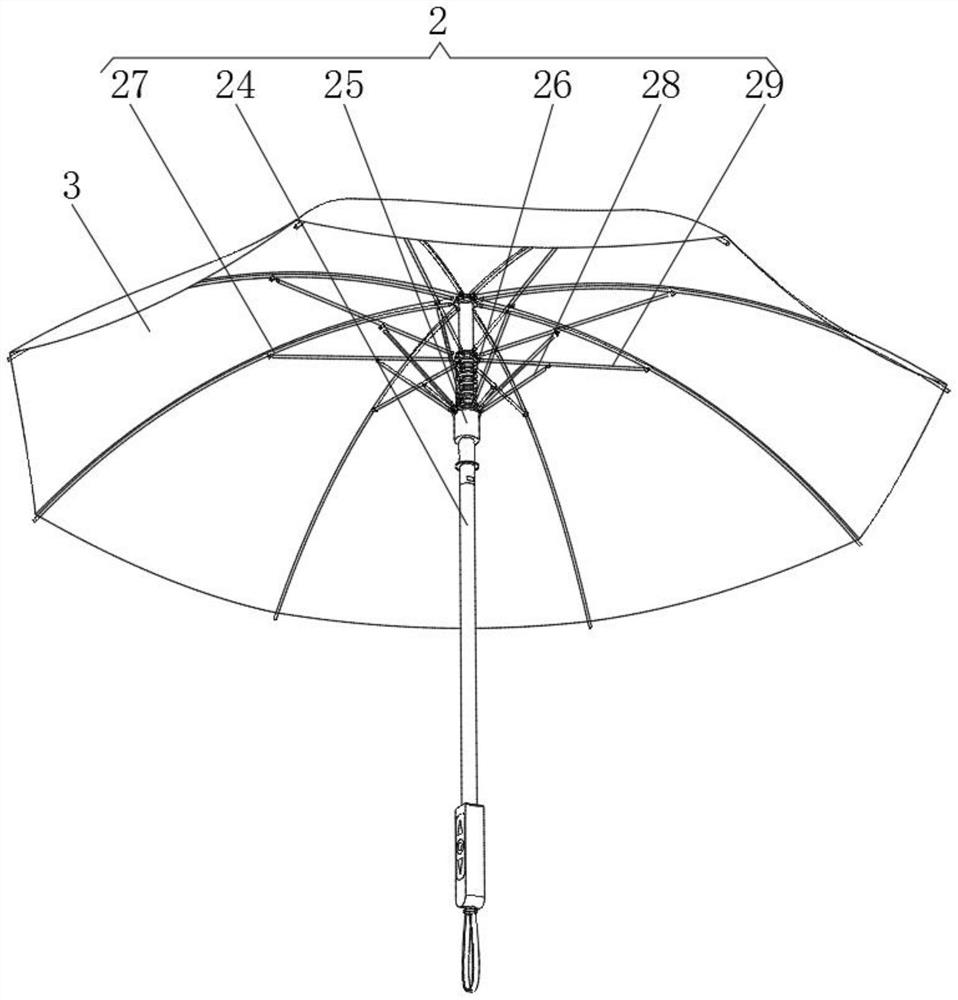

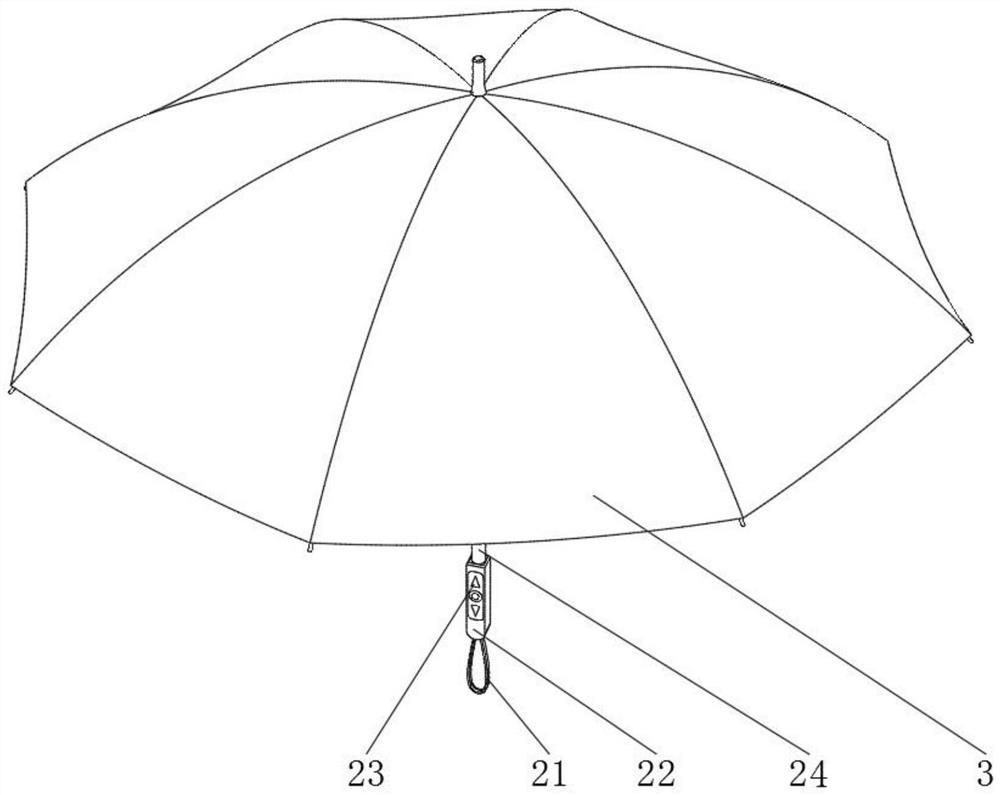

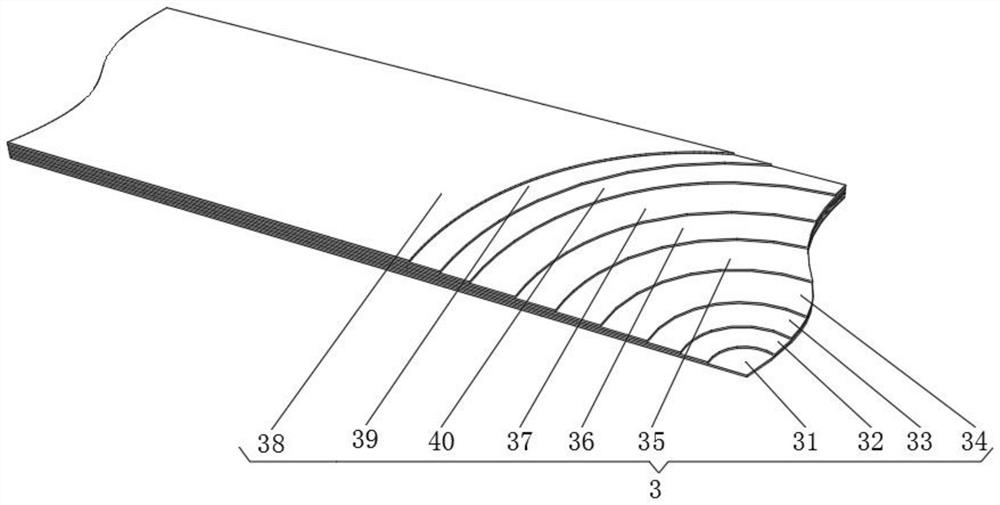

Novel umbrella cloth

PendingCN113940492AImprove textureWear-resistantWalking sticksSynthetic resin layered productsPolyesterFiber

The invention discloses novel umbrella cloth which comprises an umbrella and umbrella cloth, the top of the umbrella is movably connected with the bottom of the umbrella cloth, the umbrella cloth comprises a base layer, an acrylic surface layer, a water absorption layer and a water evaporation layer, and the base layer and the acrylic surface layer are mutually woven. An interwoven linen fabric is fine in texture, firm and durable, the polyester fiber filaments enable the umbrella cloth to have the advantages of being resistant to abrasion, easy to wash and dry, not prone to wrinkling, not prone to deformation and the like, the acrylic fabric of the acrylic surface layer can be protected against color fading for a year, and the whole umbrella cloth has the effects of resisting water, resisting mildew, preventing dust, resisting ultraviolet color fading and the like; and a wear-resistant protective layer can achieve a good ultraviolet-proof effect under the condition that it is guaranteed that the umbrella cloth is waterproof, the composite fiber layer enables the umbrella cloth to be more durable and wear-resistant, the water absorption layer is made of hydrophilic materials and has good water absorption performance, rainwater is evaporated through the water evaporation layer, the rainwater is not prone to being retained on the surface of the cloth, and a reflective coating has a good ultraviolet-proof effect, so that the umbrella cloth has good waterproof and sun-proof effects and is durable.

Owner:庞勇浪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com