Degradable thermoplastic polyurethane (TPU) cotton tablecloth with foaming layer

A foam layer and tablecloth technology, applied in the field of degradable TPU foam layer cotton tablecloth, can solve the problems of high-quality use demand of consumers, easy aging of PVC material, cumbersome production process, etc., to achieve more practical products Strong, exquisite pattern, comfortable hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

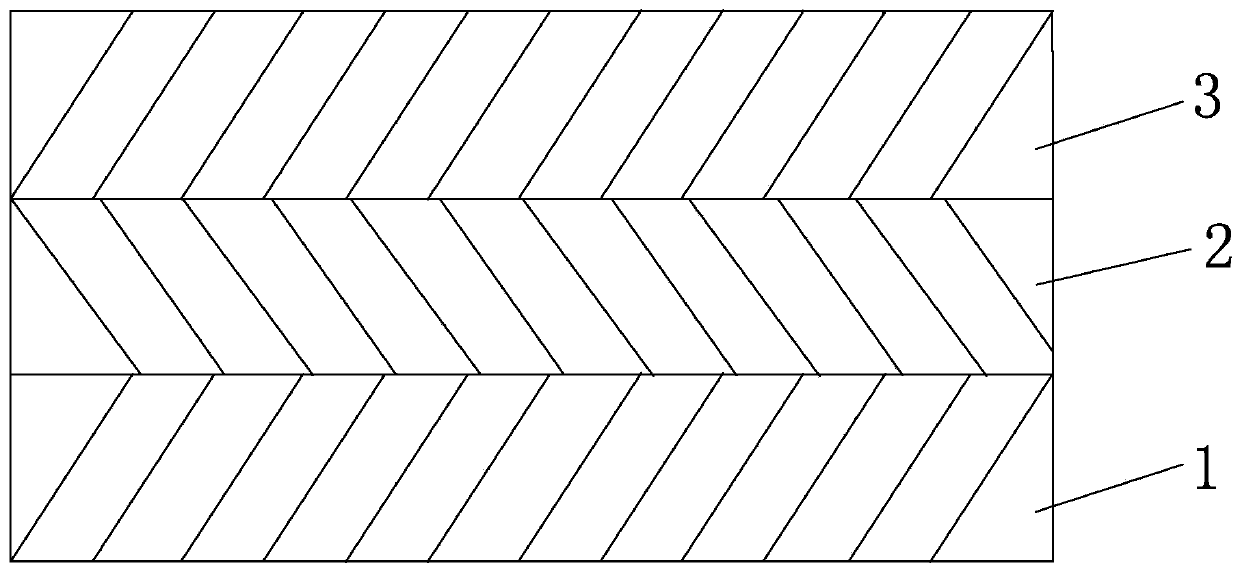

[0024] Embodiment 1: The present invention is a degradable TPU foam layer 2 cotton tablecloth, which includes a TPU bottom layer 1, a foam layer 2, and a three-dimensional cotton patch layer 3 from bottom to top, and the TPU bottom layer 1 adopts a three-liquid type quantitative Mixed, and made by continuous twin-screw extrusion. The twin-screw continuous extruding stage rotates in the same direction and is completely toothed. The TPU masterbatch includes the following components: high molecular polyester diol (PES) 65 parts, polyethylene adipate (PEA) 35 parts, polyethylene adipate lactide (PDA) 25 parts, polyethylene butylene adipate (PBA) 20 parts .

[0025] In the twin-screw continuous extrusion stage, vacuum buffering is simultaneously used to achieve the purpose of strong TPU masterbatch texture.

[0026] The polyethylene adipate (PEA) has a molecular weight of M=2000 and a hydroxyl value of 55±3 mgKOH / g, and the polyethylene adipate (PDA) has a molecular weight of M=20...

Example Embodiment

[0037] Embodiment 2: The present invention is a degradable TPU foam layer 2 cotton tablecloth, which includes a TPU bottom layer 1, a foam layer 2, and a three-dimensional cotton patch layer 3 from bottom to top, and the TPU bottom layer 1 adopts a three-liquid type quantitative Mixed, and made by continuous twin-screw extrusion. The twin-screw continuous extruding stage rotates in the same direction and is completely toothed. The TPU masterbatch includes the following components: high molecular polyester diol (PES) 70 parts, polyethylene adipate (PEA) 50 parts, polyethylene adipate lactide (PDA) 35 parts, polyethylene butylene adipate (PBA) 30 parts .

[0038]In the twin-screw continuous extrusion stage, vacuum buffering is simultaneously used to achieve the purpose of strong TPU masterbatch texture.

[0039] The polyethylene adipate (PEA) has a molecular weight of M=2000 and a hydroxyl value of 55±3 mgKOH / g, and the polyethylene adipate (PDA) has a molecular weight of M=200...

Example Embodiment

[0050] Embodiment 3: The present invention is a degradable TPU foam layer 2 cotton tablecloth, which includes a TPU bottom layer 1, a foam layer 2, and a three-dimensional cotton layer 3 from bottom to top, and the TPU bottom layer 1 adopts a three-liquid type quantitative Mixed, and made by continuous twin-screw extrusion. The twin-screw continuous extruding stage rotates in the same direction and is completely toothed. The TPU masterbatch includes the following components: high molecular polyester diol (PES) 68 parts, polyethylene adipate (PEA) 38 parts, polyethylene adipate lactide (PDA) 30 parts, polyethylene butylene adipate (PBA) 26 parts .

[0051] In the twin-screw continuous extrusion stage, vacuum buffering is simultaneously used to achieve the purpose of strong TPU masterbatch texture.

[0052] The polyethylene adipate (PEA) has a molecular weight of M=2000 and a hydroxyl value of 55±3 mgKOH / g, and the polyethylene adipate (PDA) has a molecular weight of M=2000 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com