Tile with high whole body whiteness

A tile and whiteness technology, applied in the field of tiles, can solve the problems of inconsistent whiteness between the surface layer of the tile and the body, extremely poor post-processing performance, and high material cost, and achieve easy cleaning and maintenance, good product performance, and super flexural strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiment (billet unit is mass percent):

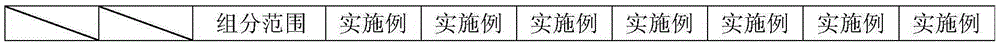

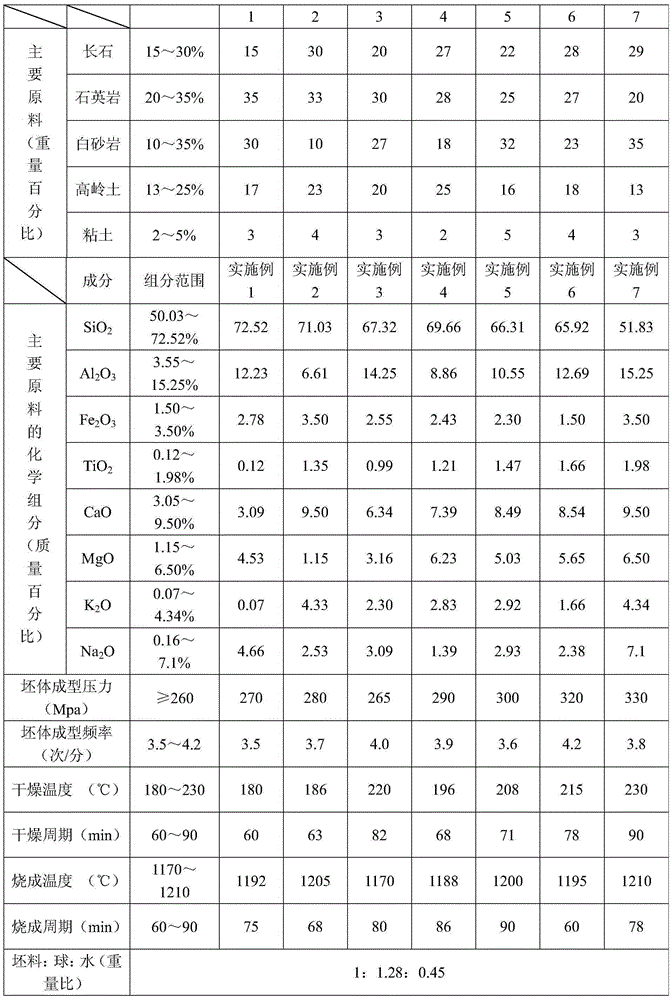

[0030]

[0031]

[0032]

[0033] The raw materials in the examples are processed according to the process steps: raw material procurement → raw material screening → formula formulation → batching ball milling → slurry → slurry stale → sieving iron removal → spray drying → powder → powder stale → distribution powder → cloth → Press molding→drying→firing→edging→grading→packaging→storage to make ceramic tiles with high whiteness.

[0034] The present invention introduces local high-quality kaolin and white sandstone into the powder of brick adobe without adding any chemical whitening. After firing at high temperature, the whole body of the tile has high whiteness, the texture of the surface layer and the whiteness of the body are consistent, and the structure is compact. Uniformity, extremely low radioactivity, good anti-fouling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com