Artificial pearl nucleus and preparation method and application thereof

A bead core and artificial technology, applied in the field of artificial bead core and its preparation, can solve the problems of being difficult to apply to industrial production, not adding antibacterial ingredients, and avoiding inflammation, etc., achieving low production cost, improving pearl quality, and good tissue compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

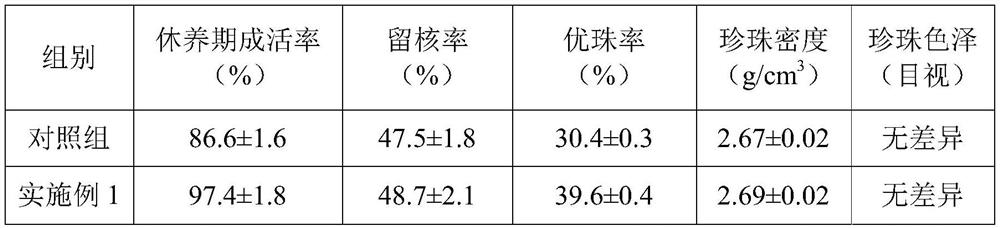

Embodiment 1

[0030] The preparation of embodiment 1 artificial bead nucleus

[0031] (1) Base material preparation: weigh polylactic acid and hydroxyapatite powder according to the mass ratio of polylactic acid and hydroxyapatite powder at 1:7, and weigh nano silver powder according to 0.01% of the total mass of polylactic acid and hydroxyapatite , mixing polylactic acid heated to 190°C to 210°C in a molten state, hydroxyapatite powder and nano-silver powder to make a base material;

[0032] (2) Bead core forming: adopt the method for injection molding to make the base material described in step (1) into bead core, the shape of bead core is spherical, ellipsoidal, drop-shaped for producing free pearls, and hemispherical for producing attached shell pearls , image shape, the produced bead core density is 2.65g / cm 3 ~2.67g / cm 3 , which is consistent with the core density of traditional shell beads.

[0033] (3) Purification of bead nuclei: wash the bead nuclei produced in step (2) and boi...

Embodiment 2

[0034] The preparation of embodiment 2 artificial bead nucleus

[0035] (1) Base material preparation: weigh polylactic acid and hydroxyapatite powder according to the mass ratio of polylactic acid and hydroxyapatite powder at 1:6.5, and weigh nano silver powder according to 0.02% of the total mass of polylactic acid and hydroxyapatite , mixing polylactic acid heated to 210°C in a molten state with hydroxyapatite powder and nano-silver powder to make a base material;

[0036] (2) Bead core forming: adopt the method for injection molding to make the base material described in step (1) into bead core, the shape of bead core is spherical, ellipsoidal, drop-shaped for producing free pearls, and hemispherical for producing attached shell pearls , image shape, the produced bead core density is 2.62g / cm 3 ~2.63g / cm 3 , which is basically the same as the core density of traditional shell beads;

[0037] (3) Purification of bead nuclei: wash the bead nuclei produced in step (2) and ...

Embodiment 3

[0038] The preparation of embodiment 3 artificial bead nucleus

[0039] (1) Base material preparation: weigh polylactic acid and hydroxyapatite powder according to the mass ratio of polylactic acid and hydroxyapatite powder at 1:7.5, and weigh nano silver powder according to 0.01% of the total mass of polylactic acid and hydroxyapatite , mixing polylactic acid heated to 200°C in a molten state with hydroxyapatite powder and nano-silver powder to make a base material;

[0040] (2) Bead core forming: adopt the method for injection molding to make the base material described in step (1) into bead core, the shape of bead core is spherical, ellipsoidal, drop-shaped for producing free pearls, and hemispherical for producing attached shell pearls , image shape, the produced bead core density is 2.69g / cm 3 ~2.70g / cm 3 , which is basically the same as the core density of traditional shell beads;

[0041] (3) Purification of bead nuclei: wash the bead nuclei produced in step (2) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com