Patents

Literature

205results about How to "Consistent density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

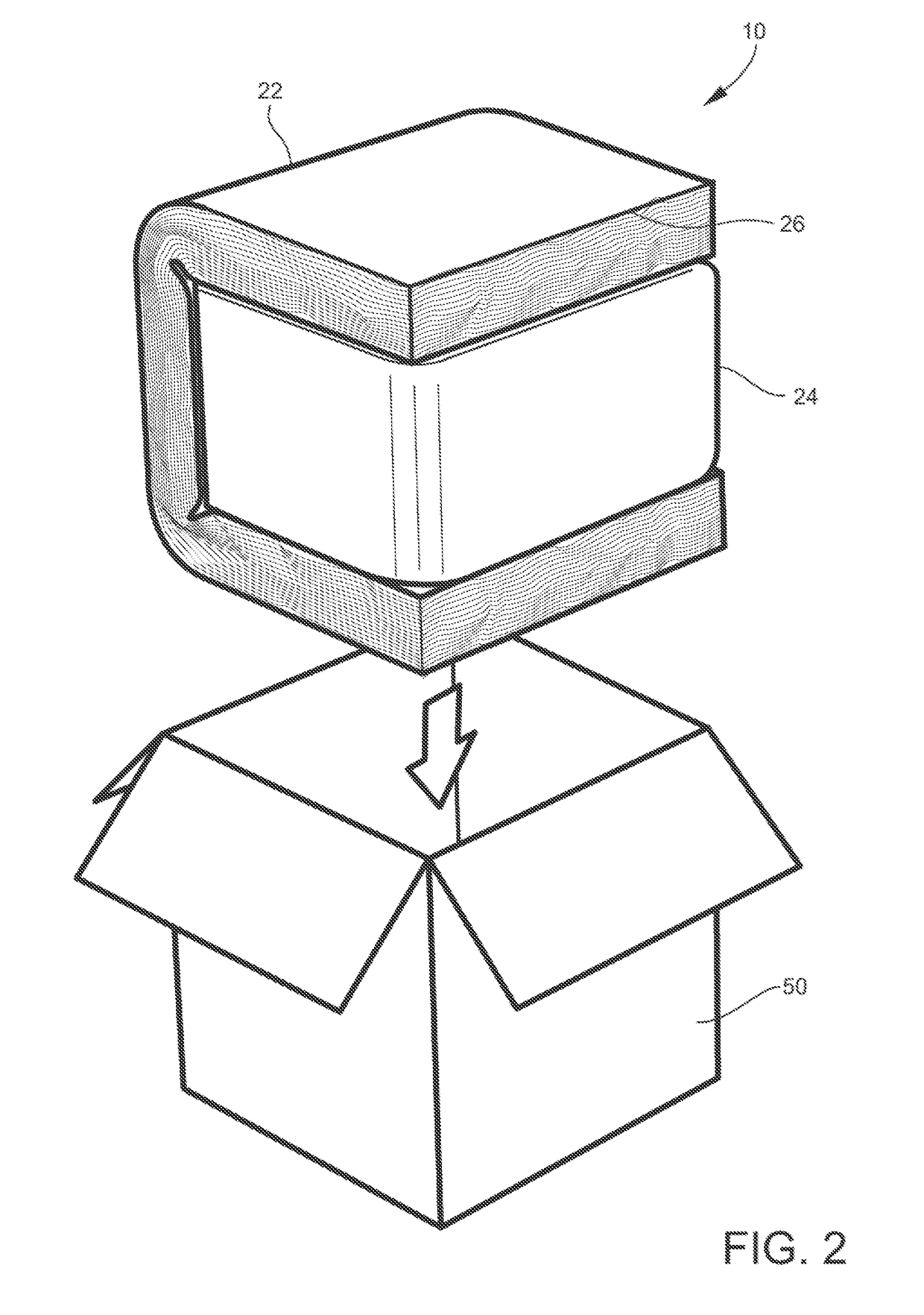

Insulated container

ActiveUS20170334622A1Efficient and economically manufacturedMinimize negative impactWrappersBoxes/cartons making machineryInsulation layerIsolation layer

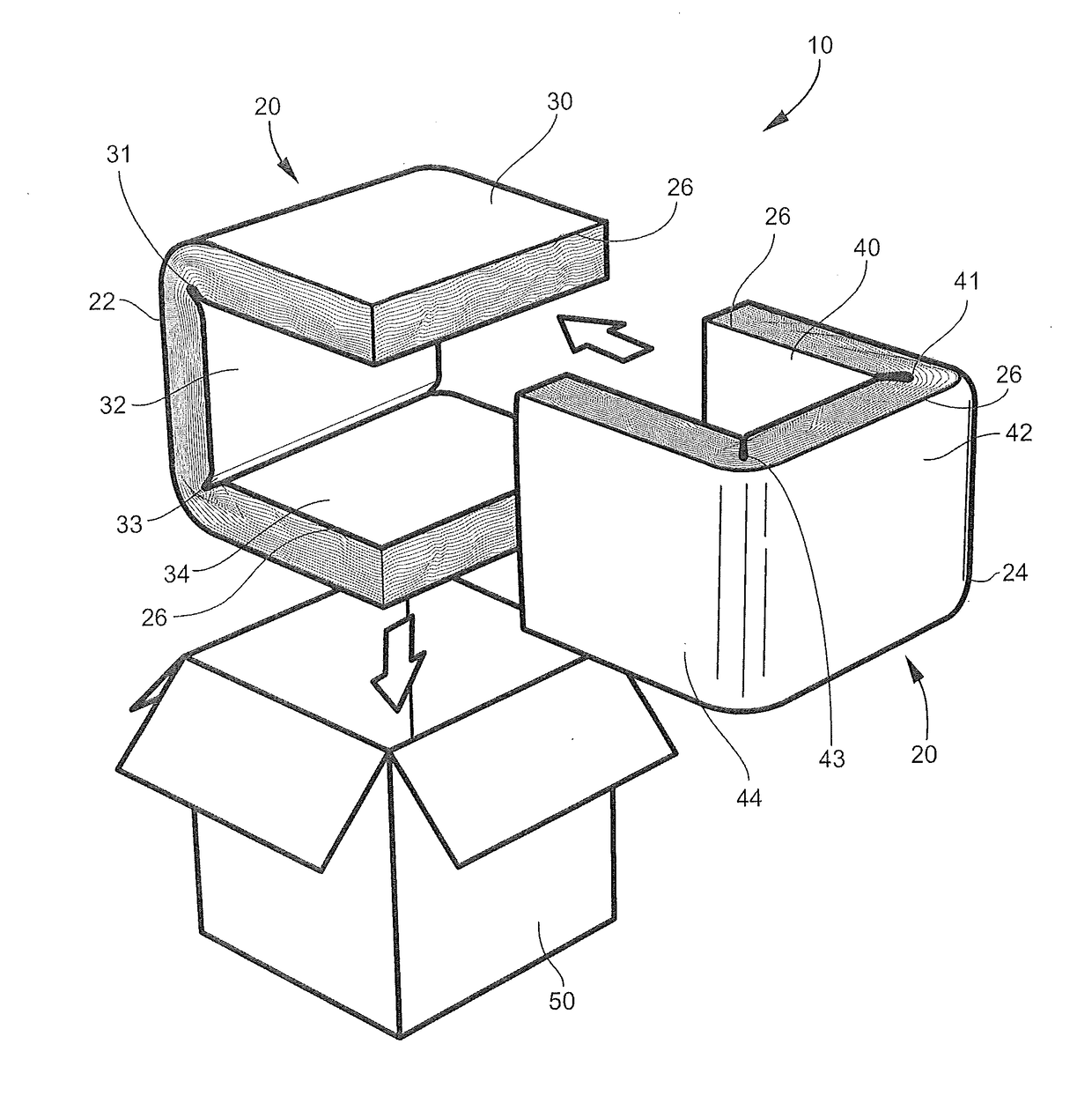

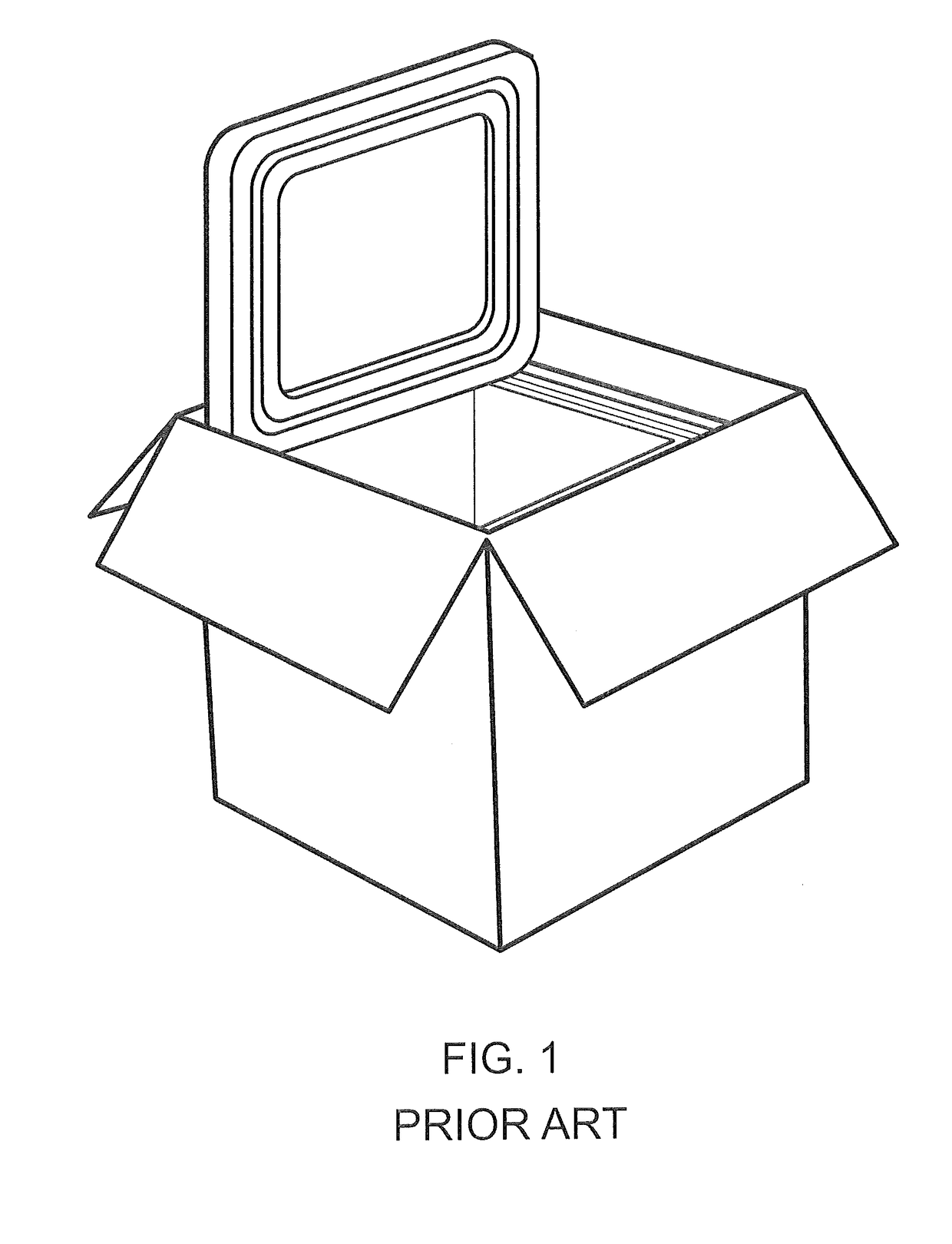

An insulated container may include a rigid container surrounding an insulation layer formed from a post-industrial, pre-consumer card waste. The insulation layer may be characterized by a lack of any wrapping material. The insulation layer may be manufactured using a variety of converting processes including, carding, airlay, and needle punch to form a non-woven material for providing consistent density throughout the insulation layer. The insulation layer may include a natural fiber lamination layer on an outer surface of the insulation layer. The insulation layer may be biodegradable in an anaerobic environment.

Owner:AIRLITE PLASTICS

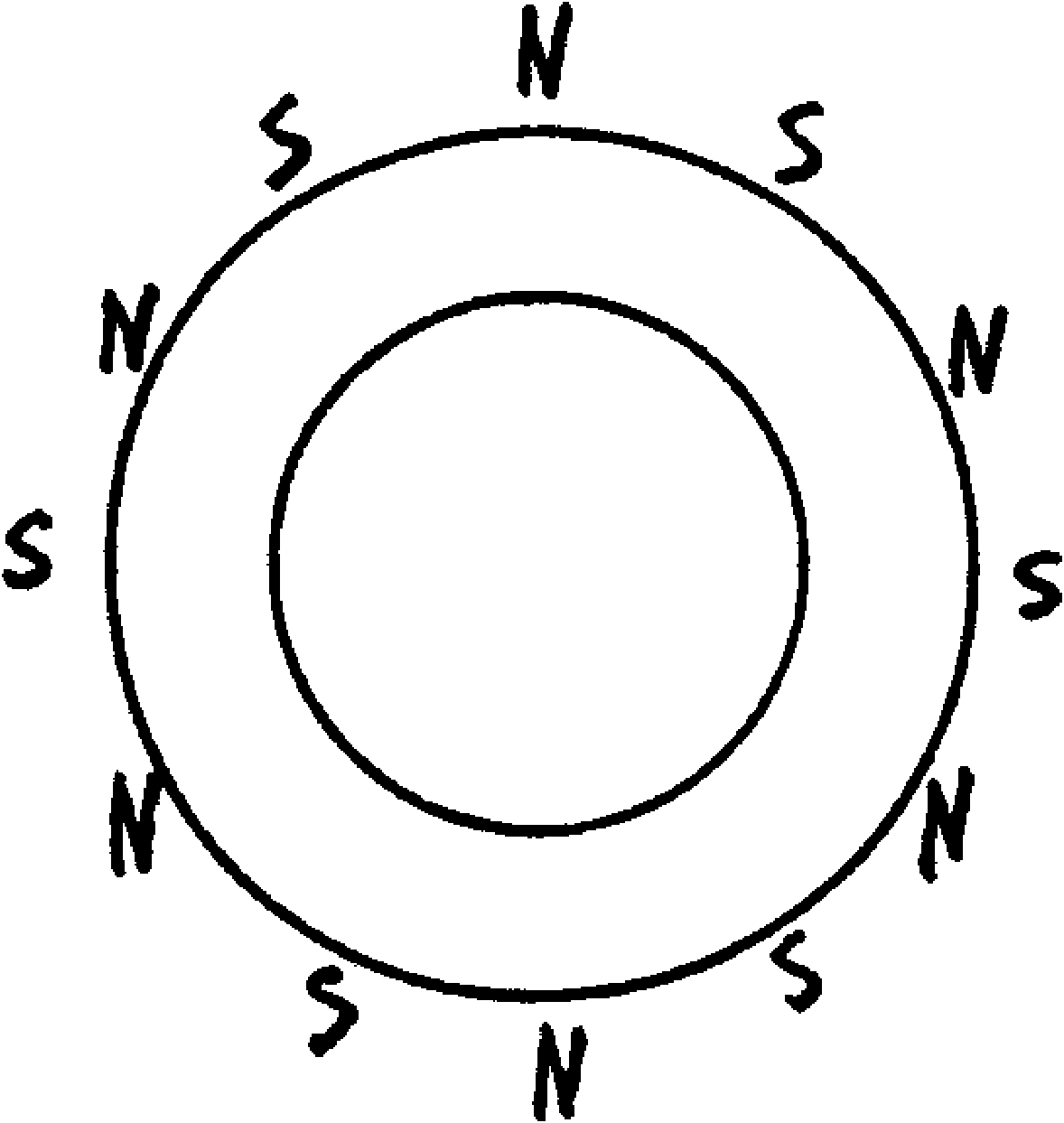

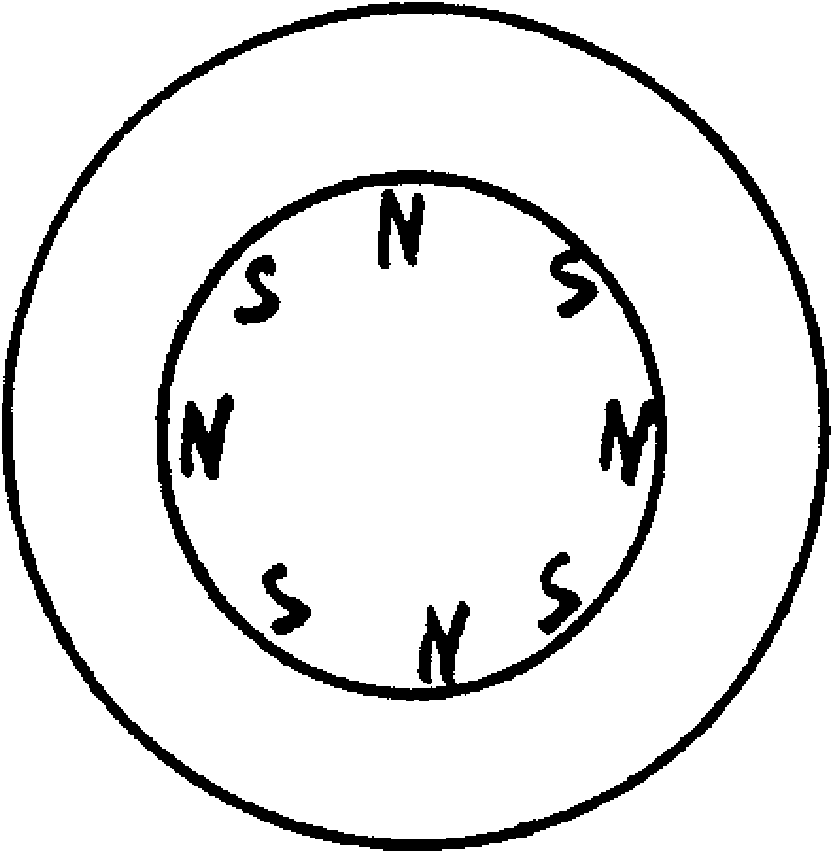

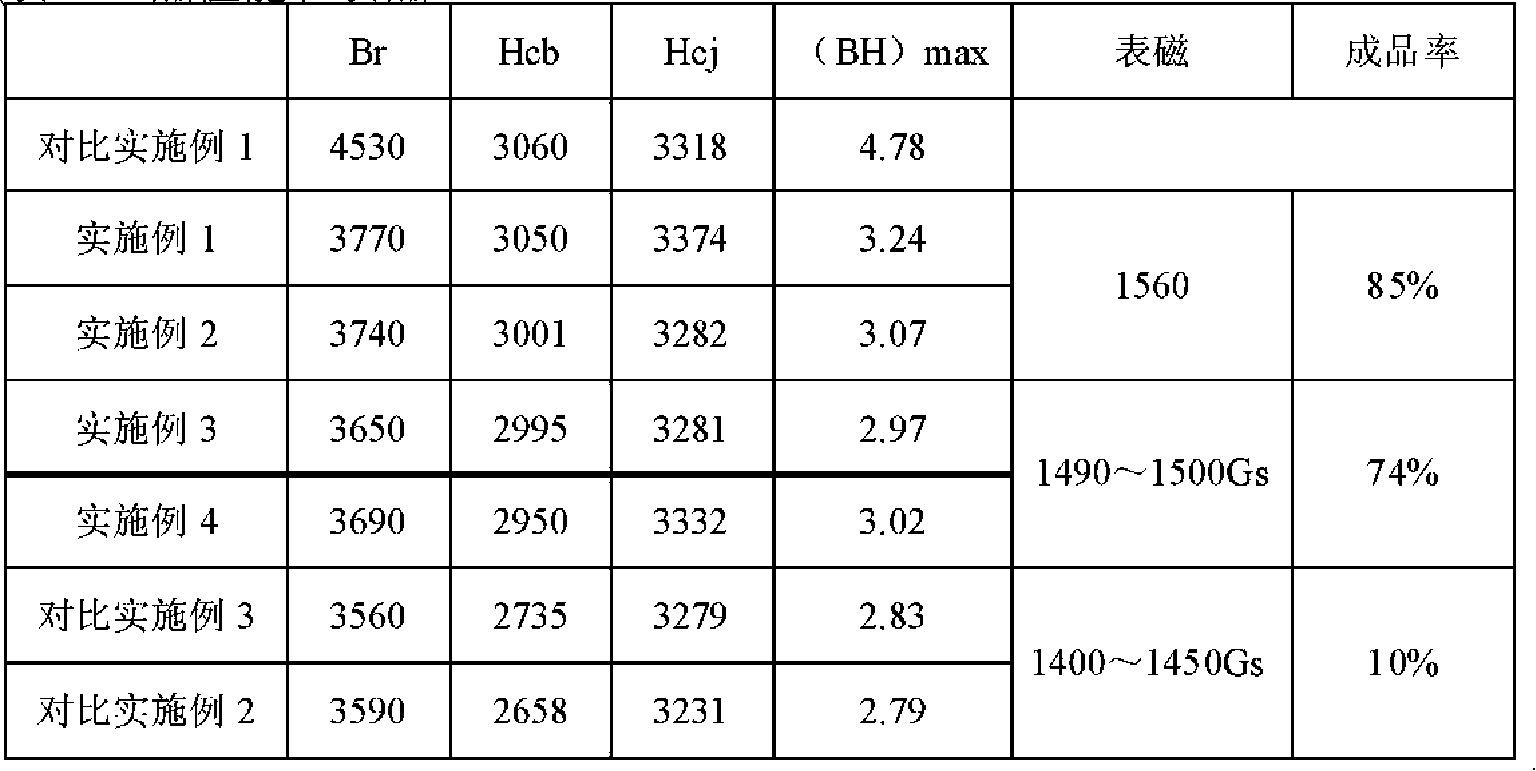

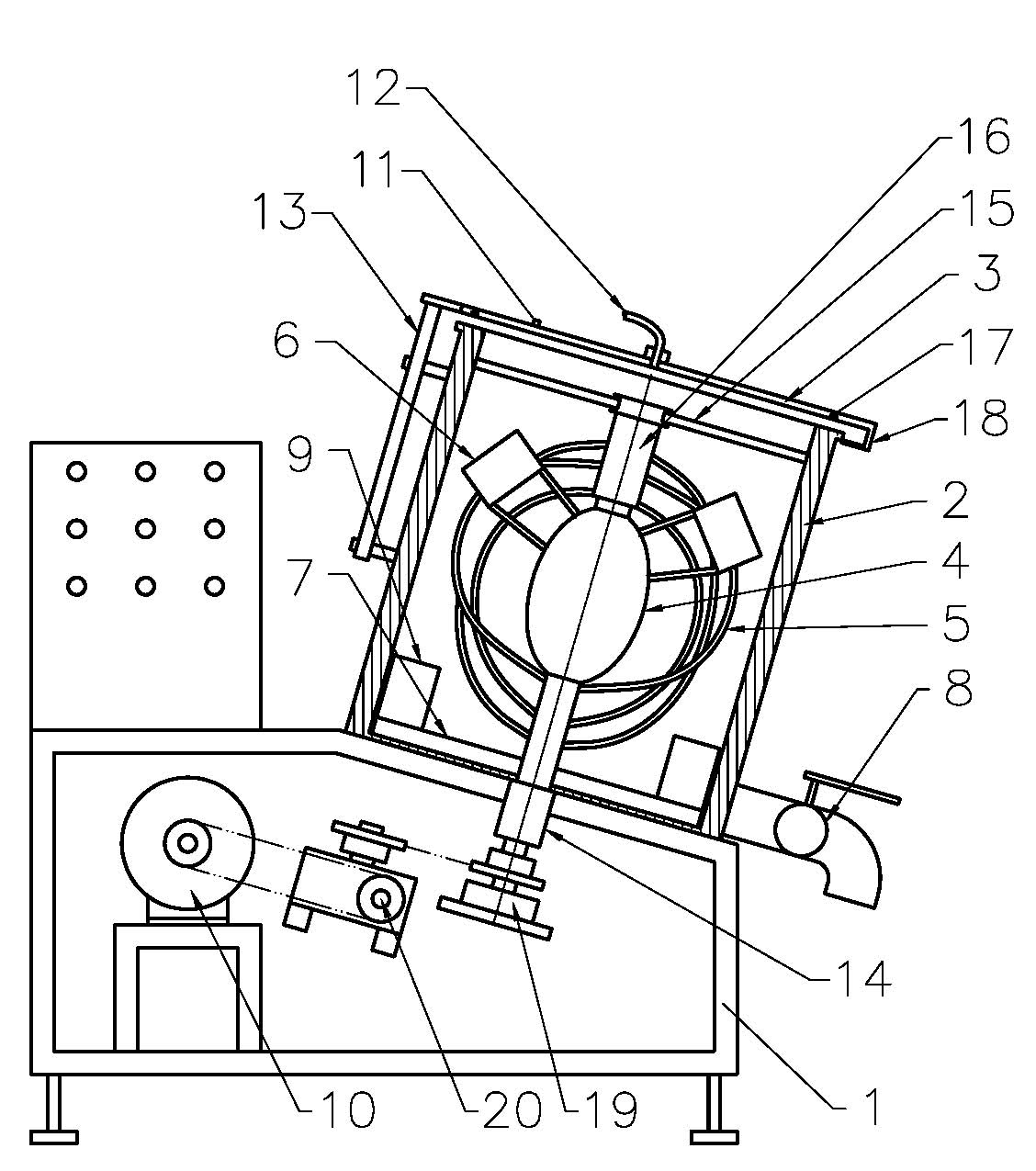

Method for manufacturing anisotropic multi-pole magnetic ring through dry-press forming

ActiveCN101599333AGood orientationWell formedCellulose derivative adhesivesWax adhesivesMetallurgyMagnetization

The invention relates to the field of magnetic materials, in particular to a method for manufacturing an anisotropic multi-pole magnetic ring through dry-press forming. Aiming at the problem that the multi-pole magnetic ring manufactured by the prior art through the dry-press forming is easy to crack, has low yield and the like, the invention provides the method for manufacturing the anisotropic multi-pole magnetic ring through the dry-press forming, and for the multi-pole magnetic ring manufactured by the method, the surface magnetism is more than 1,500 Gs, the Br is more than 3,600 Gs, and the Hcb is more than 3,000 Oe. The aim of the invention is achieved through the following technical proposal: performing wet method pulverization on magnetic powder; adding more than one binding agent and lubricating agent into the magnetic powder which is dried; then performing prepressing and pre-magnetization on the mixture, and then performing a mixing process for mixing the mixture by using a high-speed disintegrator; performing a double-sided equal pressure forming process on the powder in a radial magnetic field; and performing a sintering process for sintering the formed sample, wherein the magnetic powder contains a pre-sintering material and an additive.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

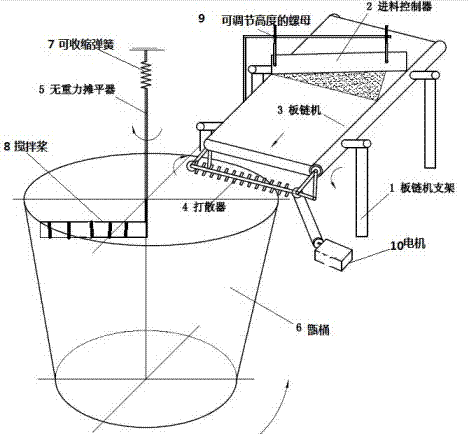

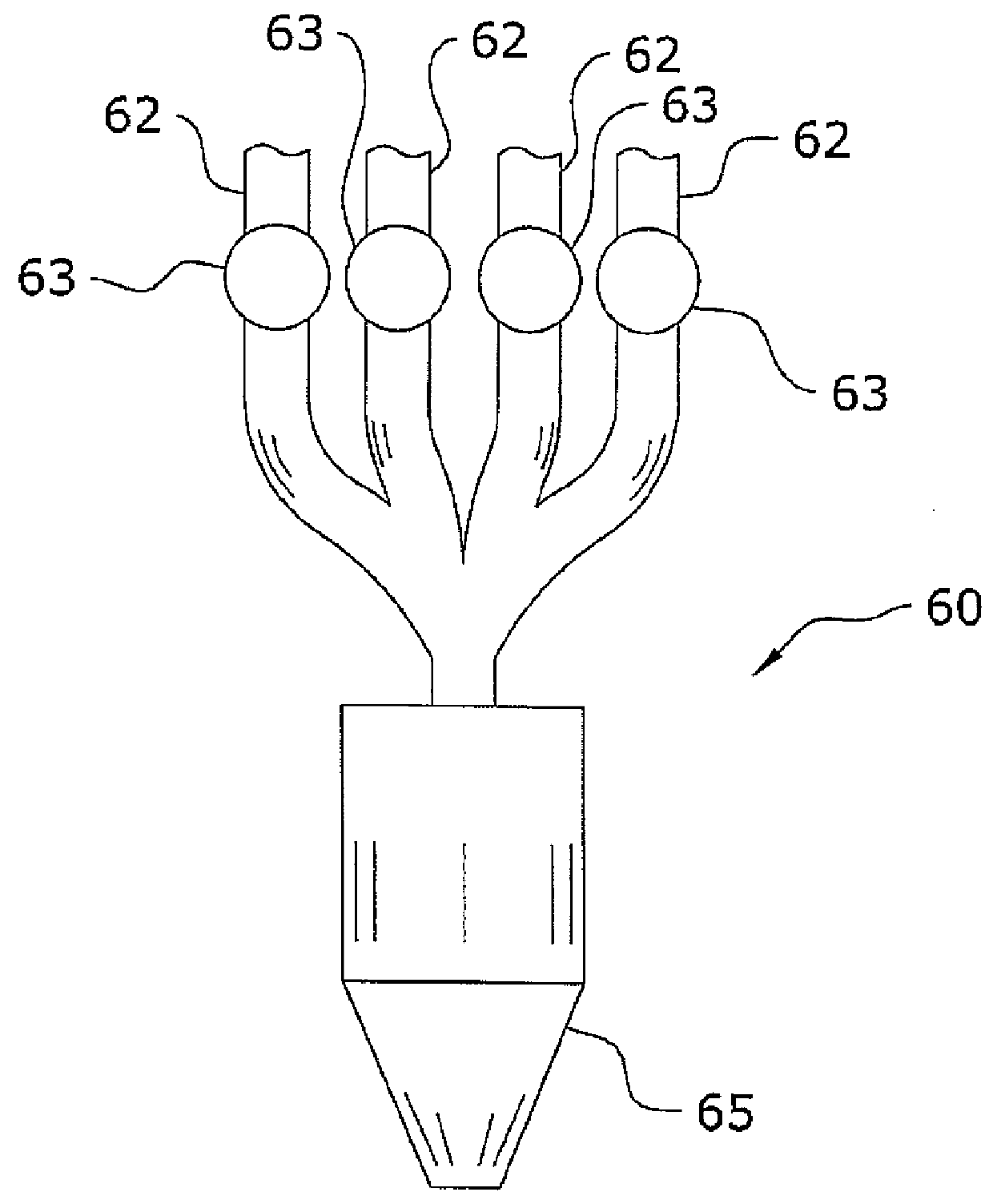

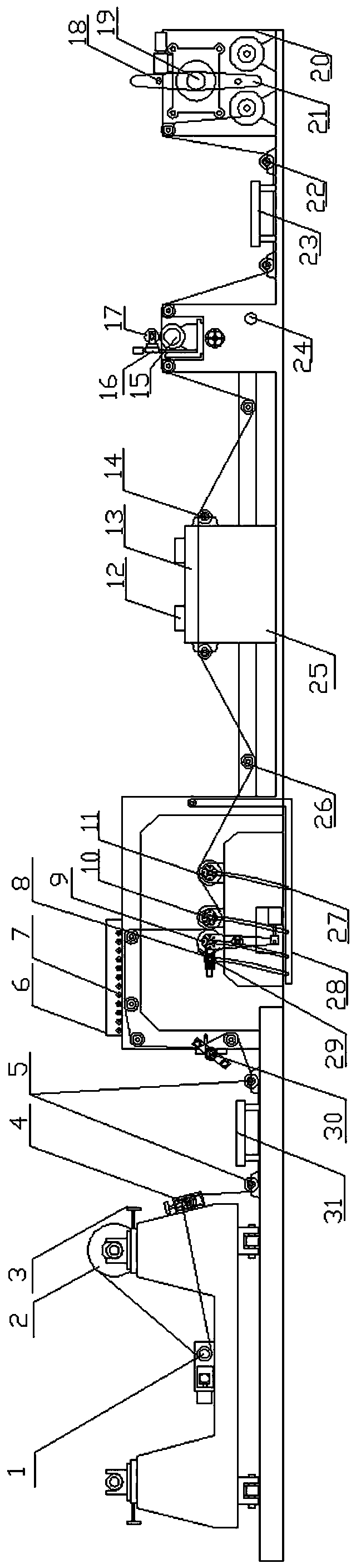

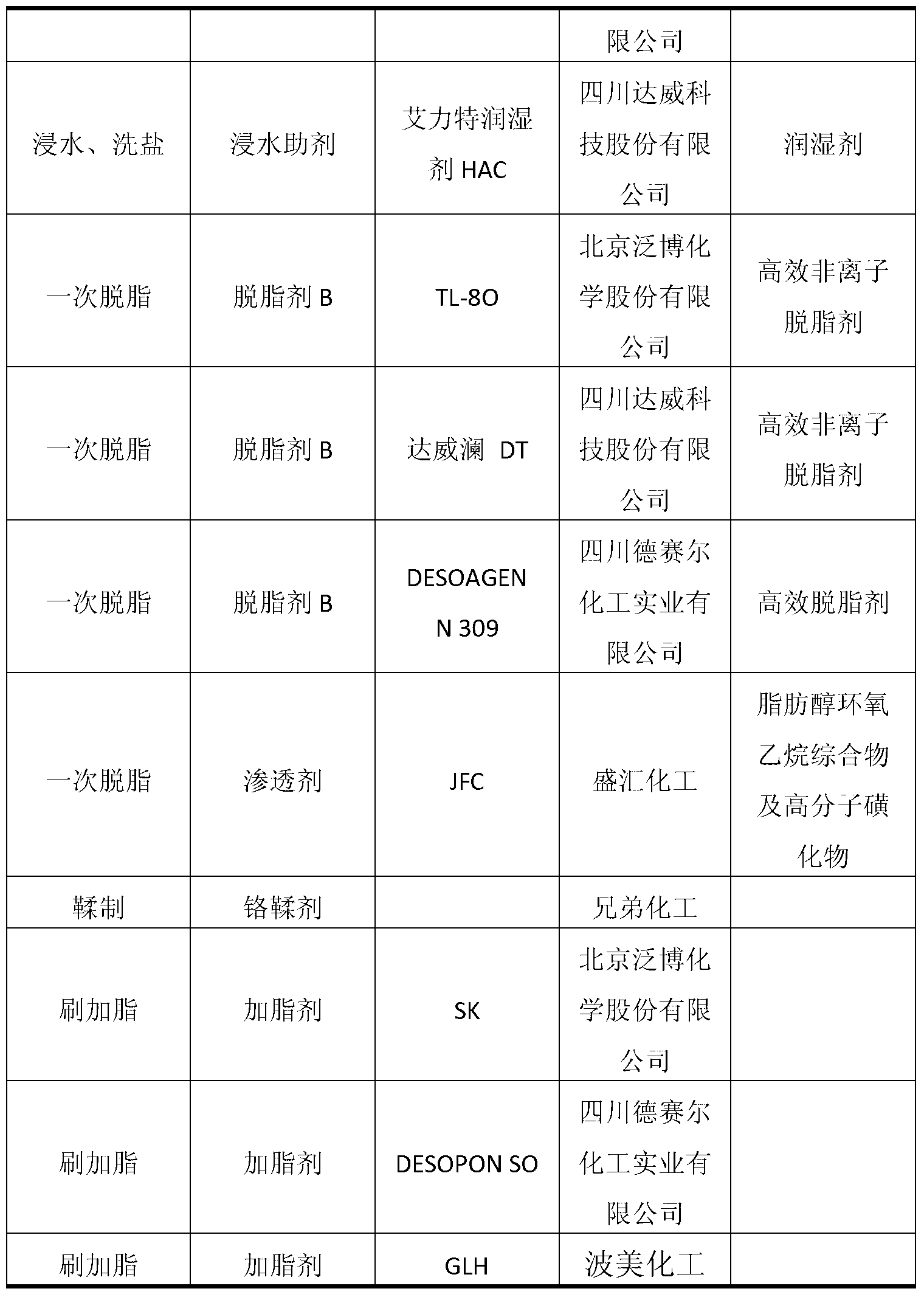

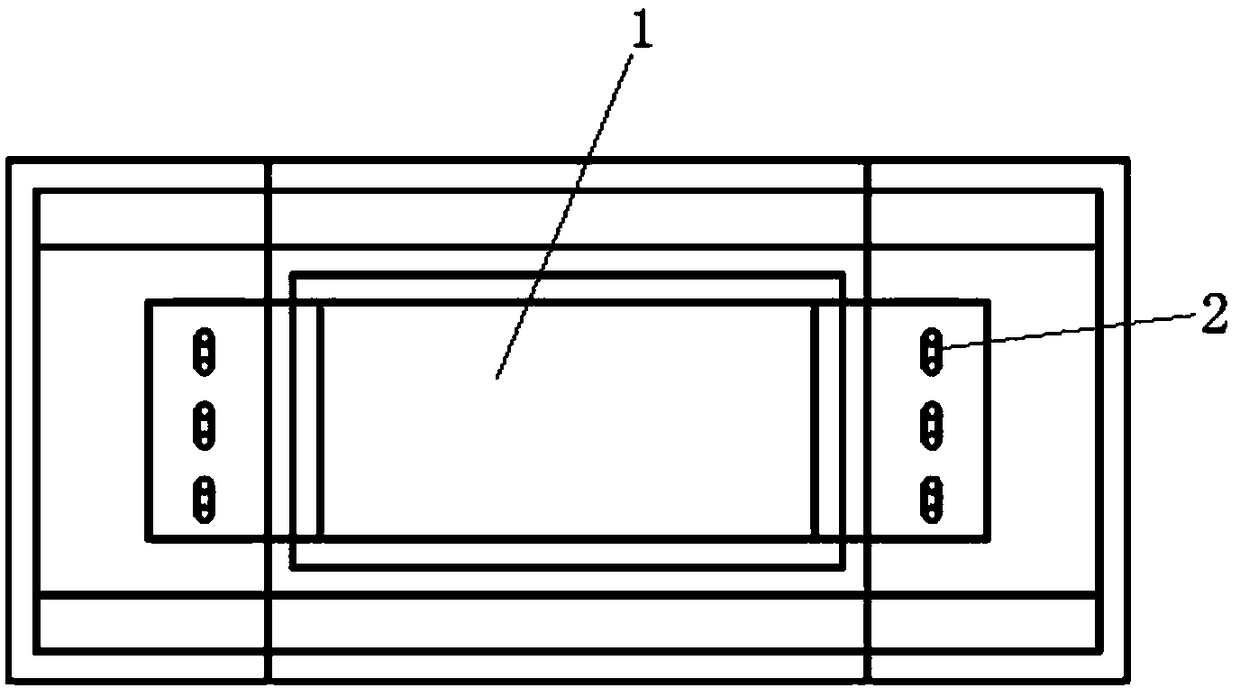

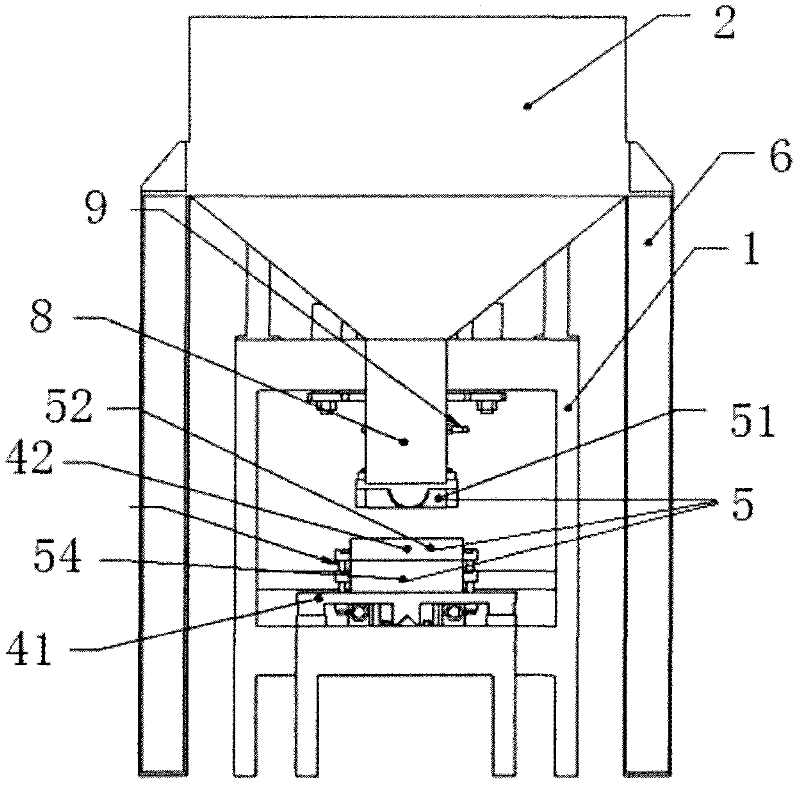

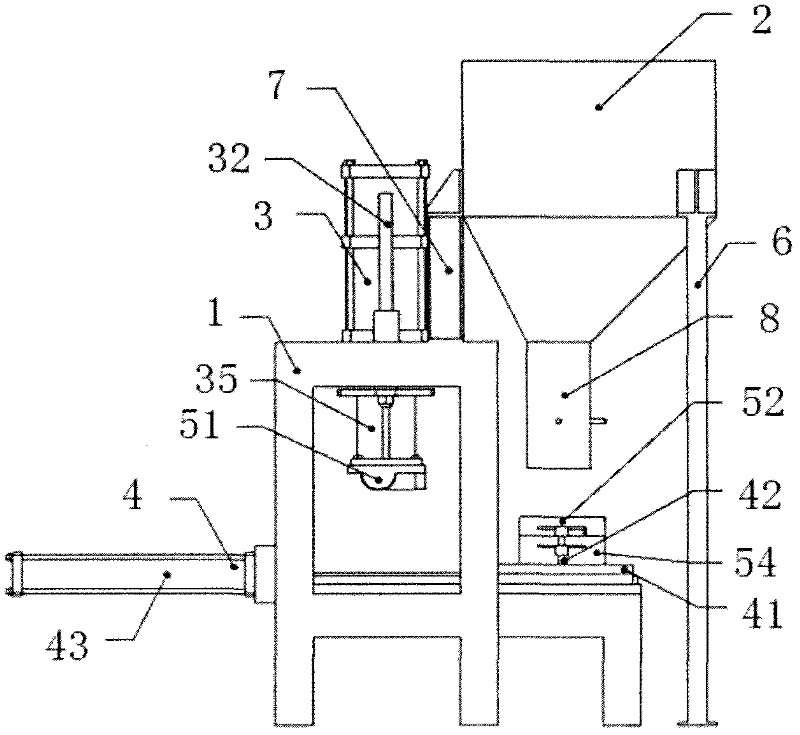

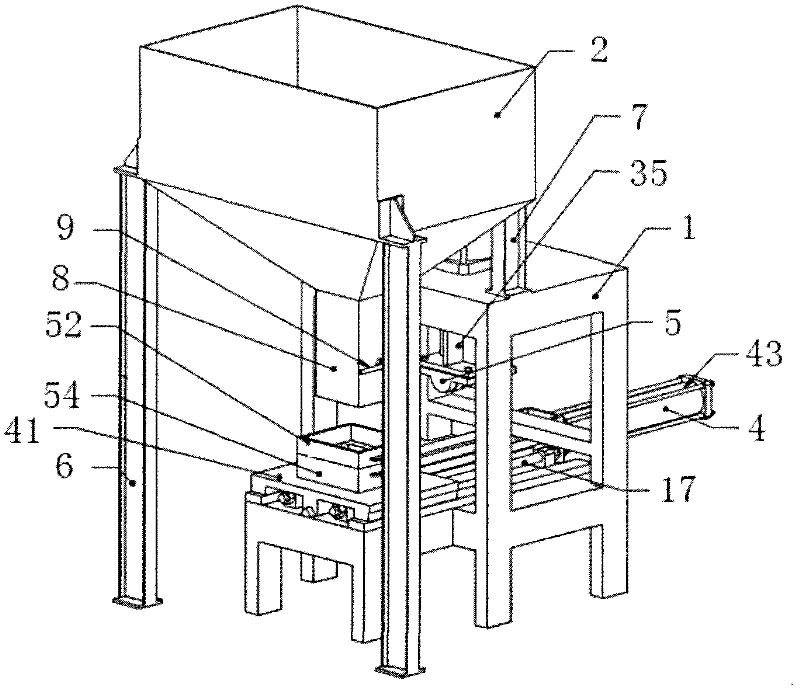

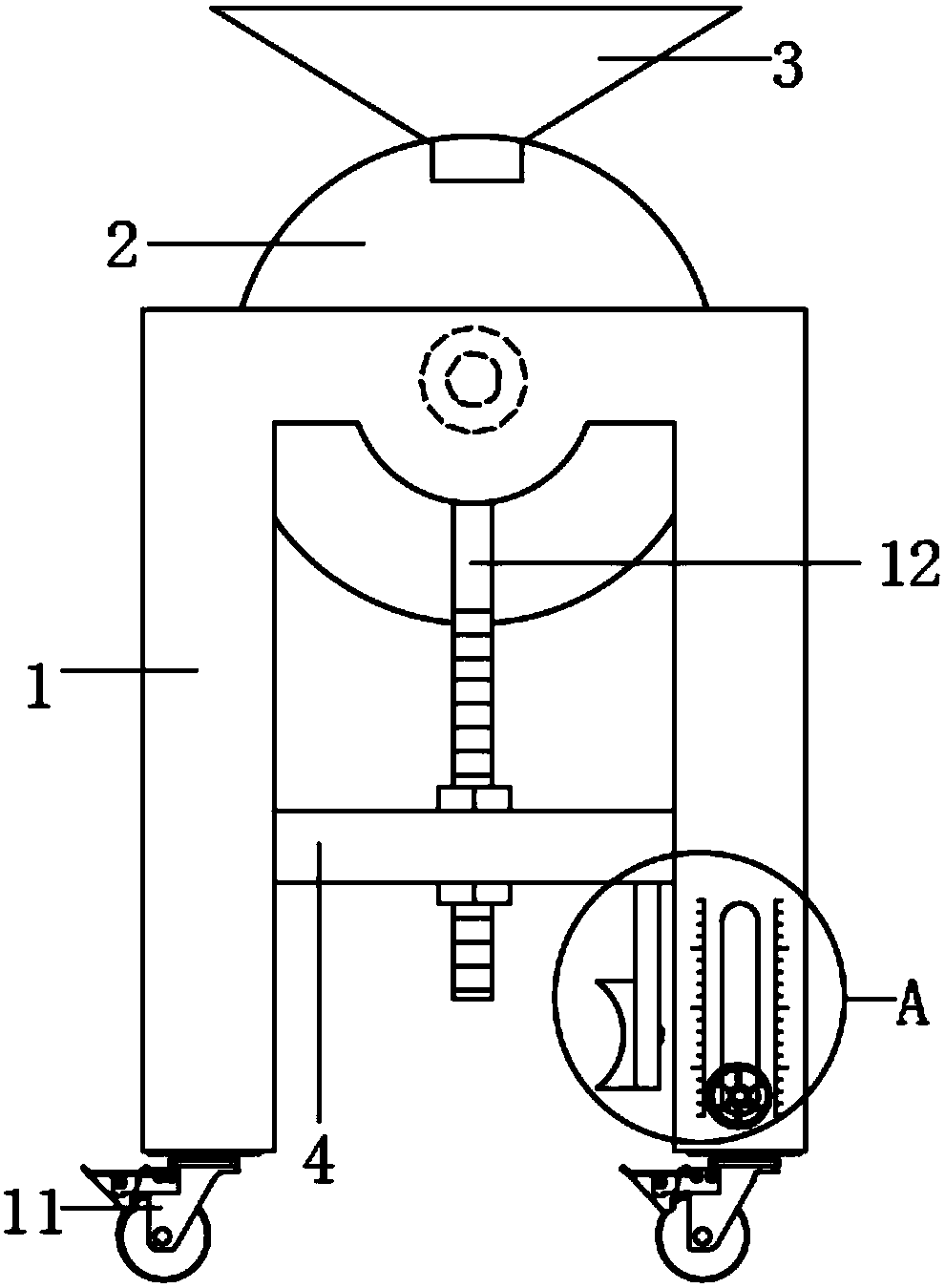

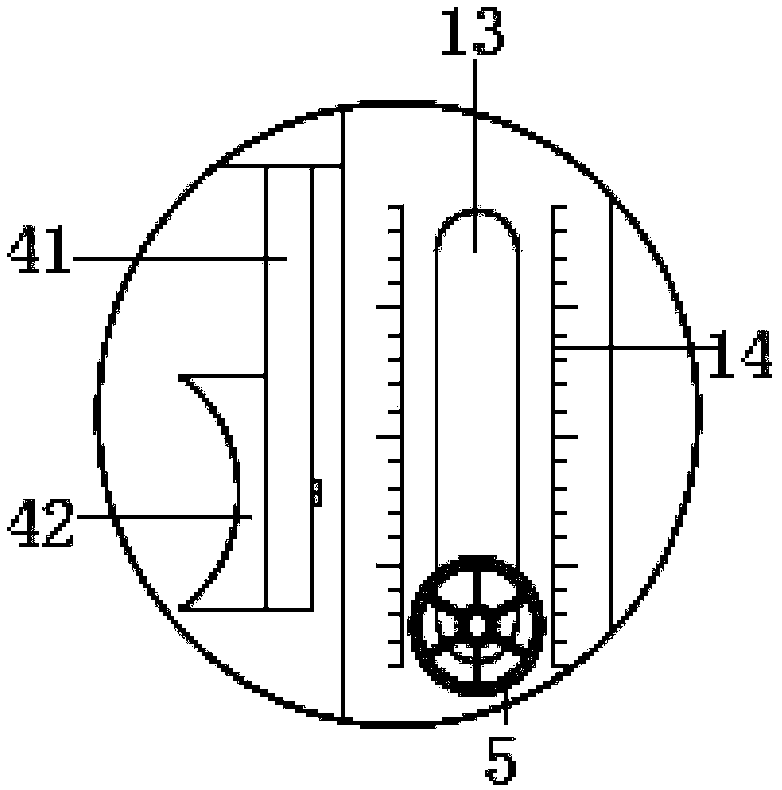

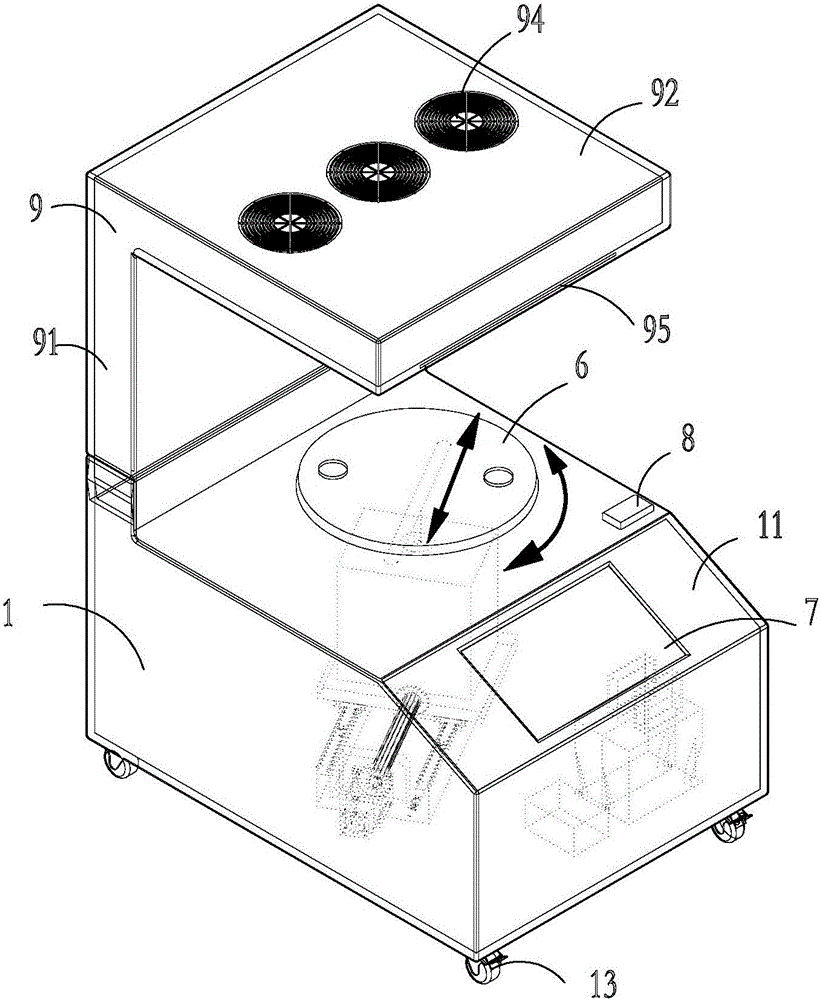

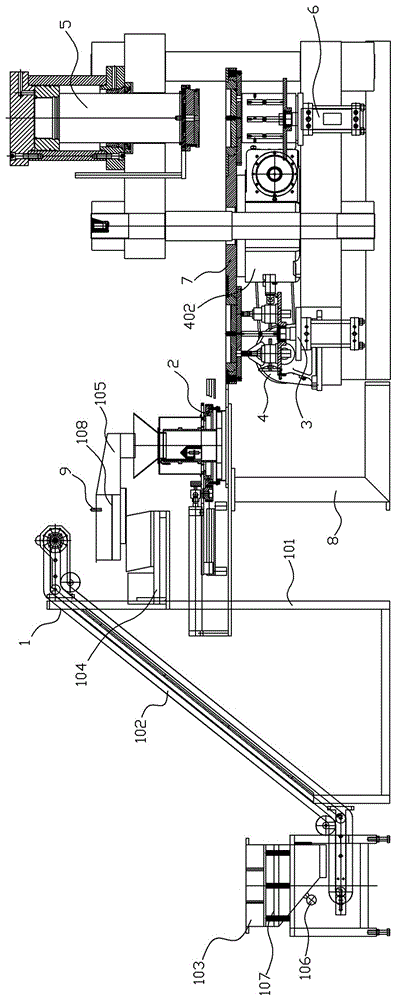

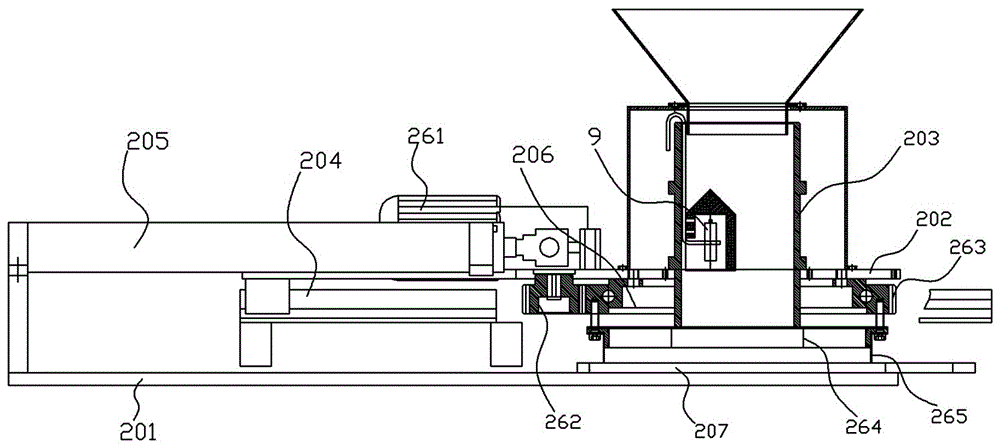

Method and device for automatically and uniformly loading materials into white spirit steaming barrel

The invention provides an automatic and uniform material loading method and an automatic and uniform material loading device which is used in the process of producing white spirit, and aims to achieve effects that the process which is manually performed in the prior art is completely or partially replaced by the method, the uniformity and the looseness of loading fermented grains are simultaneously guaranteed, and the shortcomings of the prior art are overcome. The automatic and uniform material loading device comprises a steaming barrel, a loading device and a uniformizing device, wherein the steaming barrel comprises a steaming barrel body and a bottom pot which are separable; the bottom of the steaming barrel is supported by a rotary supporting piece and can rotate; the loading device consists of a material conveying device, a charging controller and a scattering device; the uniformizing device consists of an agravic levelling device which is provided with a stirring paddle and liftable. By matching the steaming barrel, the loading device and the uniformizing device, materials are automatically loaded, and the uniform and stable looseness of loading the materials is guaranteed.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +2

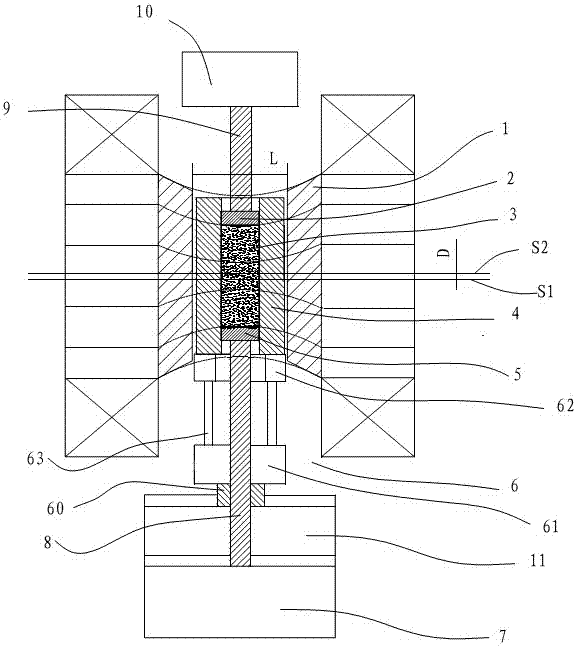

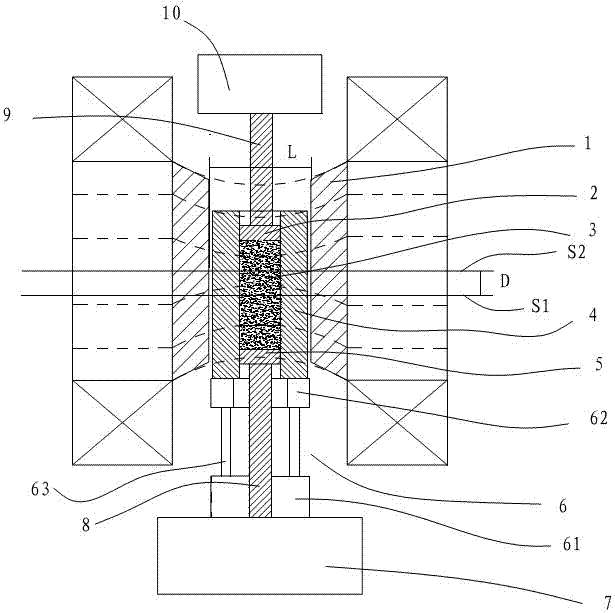

Preparation method and device for decreasing sintered NdFeB declination

ActiveCN104493158AImprove abilitiesReduce magnetic declinationMagnetic materialsMagnetic lineForming processes

The invention discloses a preparation method for decreasing sintered NdFeB declination. The preparation method includes preparing materials, performing smelting, processing powder, performing forming and performing sintering; to be specific, adding addition agent during powder processing to improve powder liquidity; increasing magnetic field intensity H during forming; reducing mold orientation length L; enlarging section area A in the vertical magnetic line direction; feeding mixture powder in a forming mold of a press; adjusting a center, on a coil pole, of the forming mold on a mold frame to allow the presses powder to stay in the center of the coil magnetic field during forming orientation pressing; by adjusting four relative parameters, the declination of the sintered NdFeB is decreased to 3 degrees from 10 degrees, use ratio of material with declination qualified is increased to 60% or above from 35%, production cost is remarkably decreased, and economic benefit is enhanced.

Owner:NINGBO KETIAN MAGNET +1

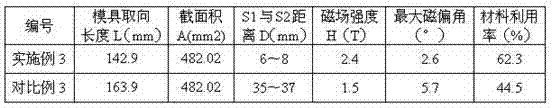

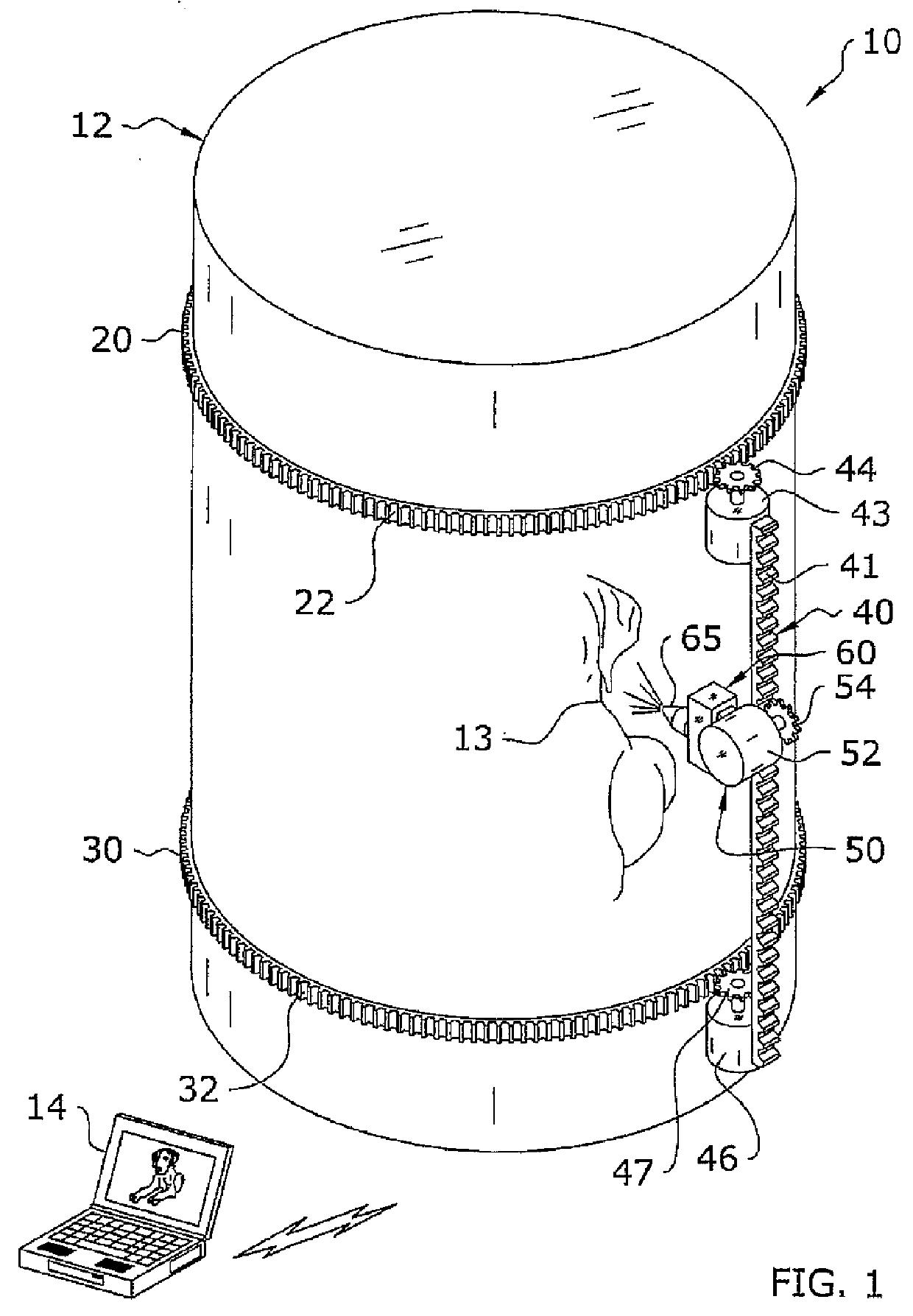

Automated Paint Application System and Related Method

InactiveUS20160052296A1Hindering quality and resolutionEasy to operateLiquid surface applicatorsDuplicating/marking methodsComputer graphics (images)High resolution image

An automated paint application system for automatically, safely and efficiently reproducing a high resolution image on an area of a surface located in an uncontrolled environment and a related method for reproducing a high resolution image on a surface in an uncontrolled environment are disclosed. The automated paint application system features a robotic painting machine which uses a vectorized format of the image to generate a plurality of paint paths which an applicator nozzle of the robotic painting machine follows about the surface in order to form the image. The robotic painting machine includes a plurality of paint conduits each connected by a valve to at least one applicator nozzle and usable for respectively transferring a different coloured paint in a manner such that the valves are controllable to dispense one of the different coloured paints or to form a combination colour thereof.

Owner:GRIMES JOHN

Gel cast fused quartz crucible and manufacturing method thereof

The invention discloses a gel cast fused quartz crucible which contains the following components by mass percentage: more than 99.74% of silica, less than 40ppm of ferric oxide, less than 1000ppm of alumina, and the balance inevitable impurities such as potassium, sodium, magnesium or calcium oxides. A green body of the gel cast fused quartz crucible is high in strength and density, and even in structure, and can be used for producing large-sized crucibles. The invention also discloses a manufacturing method of the gel cast fused quartz crucible.

Owner:龙立华

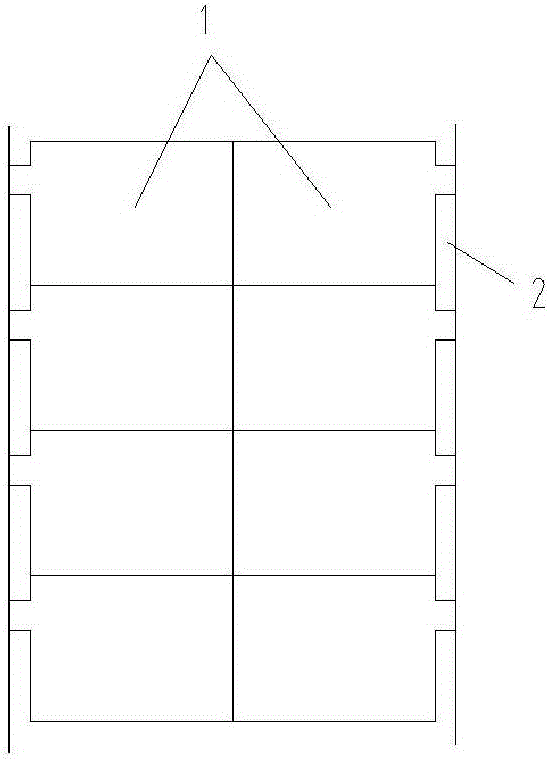

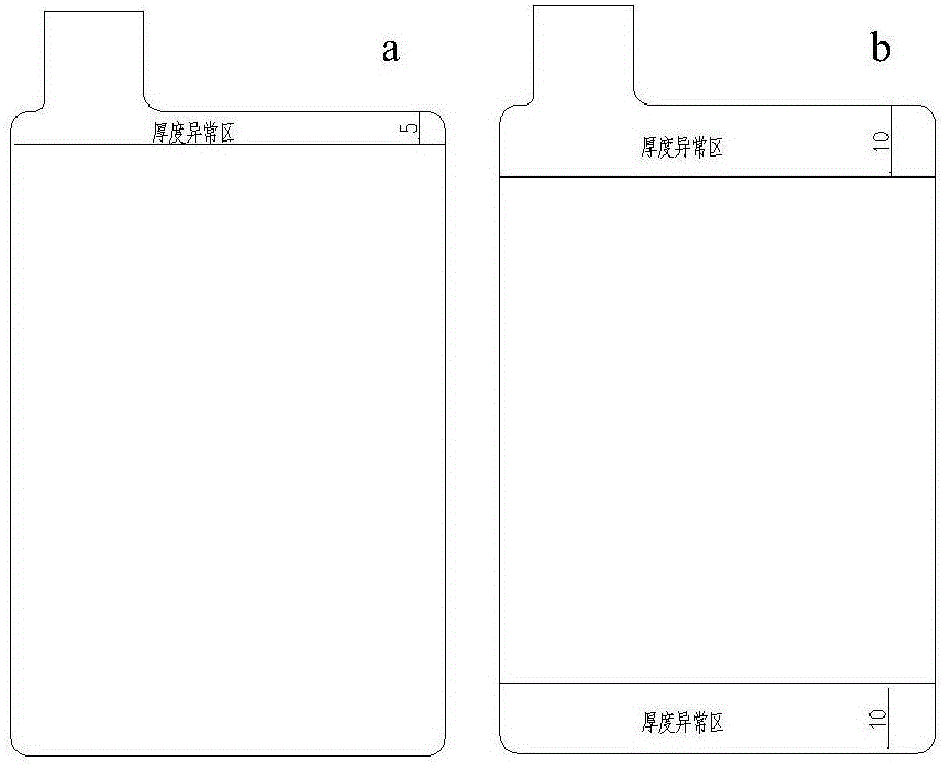

Preparation method of water system laminated type lithium-ion battery pole piece

ActiveCN106129326AQuality assuranceConsistent densityElectrode rolling/calenderingElectrode collector coatingMeasuring instrumentEngineering

The invention discloses a preparation method of a water system laminated type lithium-ion battery pole piece and belongs to the technical field of production of lithium-ion batteries. The method has the following advantages that (1) continuous coating is realized, the coating efficiency is improved, the range of a coating thickness abnormal region is reduced and the coating thickness is monitored online; (2) continuous roll pressing is realized, the roll pressing efficiency is improved, a roll pressing thickness is monitored online and frequent vibration loss of a roll pressing machine is alleviated; (3) the thicknesses of cut regions are the same in a cutting process, the cutting defects are small and the stability is good; (4) the slicing efficiency can be improved by utilizing high-speed slicing equipment, surface defects of the pole piece can be monitored online by utilizing a CCD (Charge Coupled Device) image measuring instrument and NG pole pieces are eliminated; and (5) the waste of raw material left overs is reduced and the utilization rate of positive and negative electrode foils and positive and negative electrode materials is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

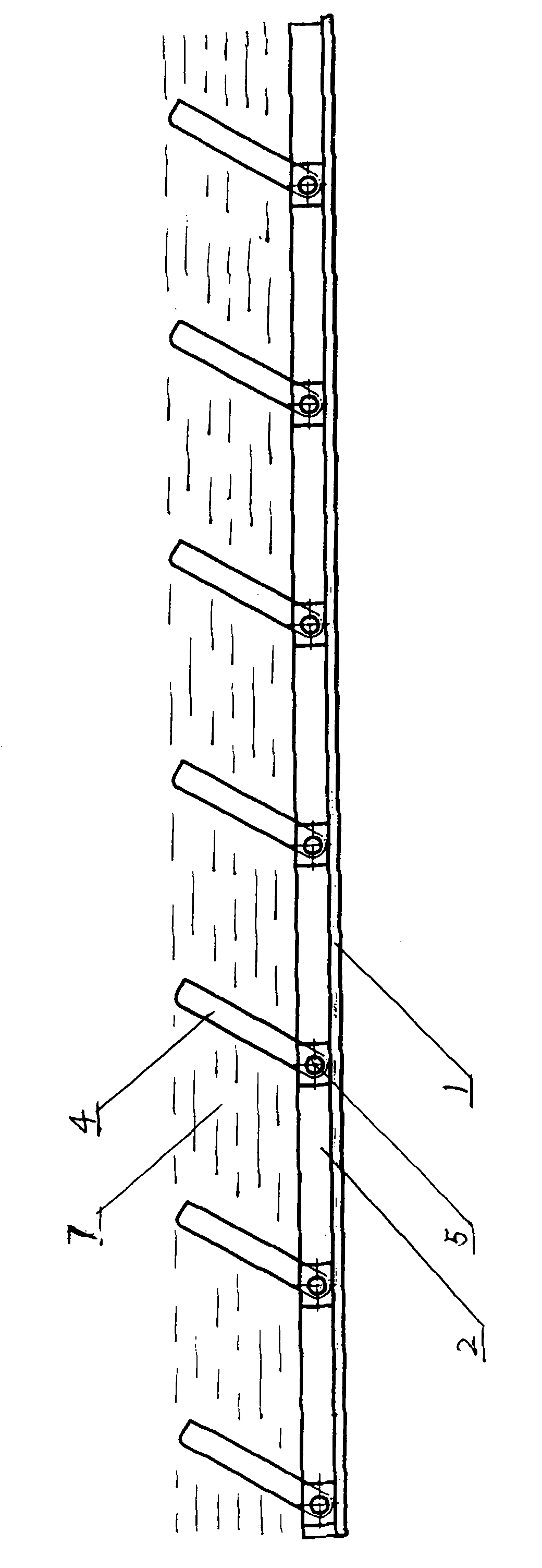

Swing type multi-rod blocking edge for blanking pad plate

InactiveCN103072178AConsistent densityConsistent strengthLaminationWood working apparatusEngineeringExtrusion

The invention discloses a swing type multi-rod blocking edge for a blanking pad plate, and relates to a multi-rod blocking edge for the blanking pad plate of a multi-layer hot press which is used for recombining a bamboo floor. The multi-rod blocking edge comprises a check block, a bottom rod and a plurality of movable blocking rods, wherein the check block is fixedly arranged on a pad plate and leans against the outside of the bottom rod in a blocking way, and the movable blocking rods are connected with the inside of the bottom rod through bolts. The movable blocking rods can be inclined at any angle or horizontally lie down, when the movable blocking rods horizontally lie down, and adjacent movable blocking rods are in end-to-end connection. The multi-rod blocking edge has the beneficial effects that when the pad plate placed with a blank is pushed between hot press plates of the hot press for compression, the height of the blank is gradually smaller and thinner under extrusion of an upper and lower hot press plates, meanwhile, under extrusion, the inclined angle and the height of each movable blocking rod of the swing type multi-rod blocking edge become smaller, and the vertical height of each movable blocking rod and the height of the blank synchronously become smaller. Since the swing type multi-rod blocking edge with a changeable height is always blocked on two sides of the blank, the blank is enabled not to collapse during a compression process, overall density and strength of a finished plate are enabled to be uniform, the quality is good, collapsed offcut does not occur, saving is realized, and the production cost is lowered.

Owner:QINGDAO GUOSEN MACHINERY

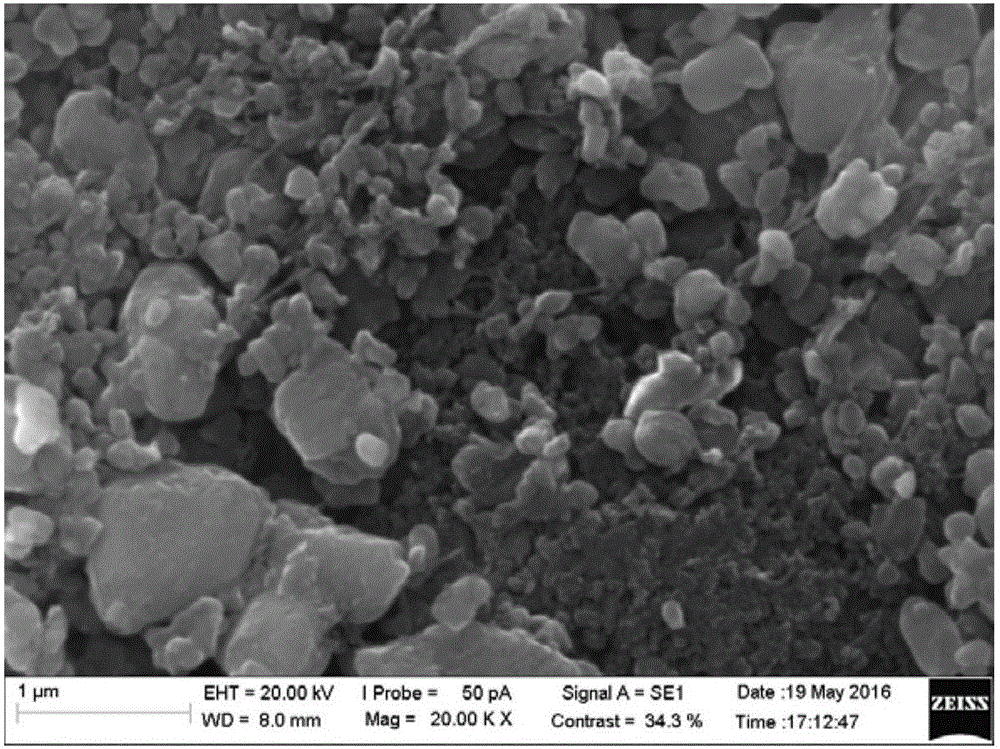

Preparation method of molybdenum titanium alloy material with high density, large size and high homogeneity

ActiveCN103740979AUniform microstructureSmall particle sizeVacuum evaporation coatingSputtering coatingSolventSpray nozzle

The invention discloses a preparation method of a molybdenum titanium alloy material with high density, large size and high homogeneity. The method comprises the following steps: 1) adding a solvent and a binder to Mo powder and Ti powder and grinding into slurry; 2) atomizing and pelletizing the slurry by using a spraying machine, wherein the inlet temperature is 250-300 DEG C, and the rotating speed of a spray nozzle is 8000-12000rpm, so as to obtain Mo-Ti composite powder; pressing the composite powder into blanks with regular sizes; 3) loading a plurality of blanks into a sheath, filling the Mo-Ti composite powder of 50-250 microns into the adjacent blanks to form a uniform composite powder layer, wherein the thickness of the composite powder layer is 0.5-1mm, and the condition that a gap between the inner wall of the sheath at any side and the outer wall of the adjacent blank is smaller than or equal to 0.5mm is ensured; and 4) welding and degassing the sheath and then carrying out hot isostatic pressing treatment at 750-900 DEG C and 120-160MPa and removing the sheath, wherein the heat-preserving and pressure-maintaining time is 4-6 hours. The target material fabricated by the method can be used as a cathode material of a magnetron sputtering technique.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Evaporation plating device and evaporation plating method

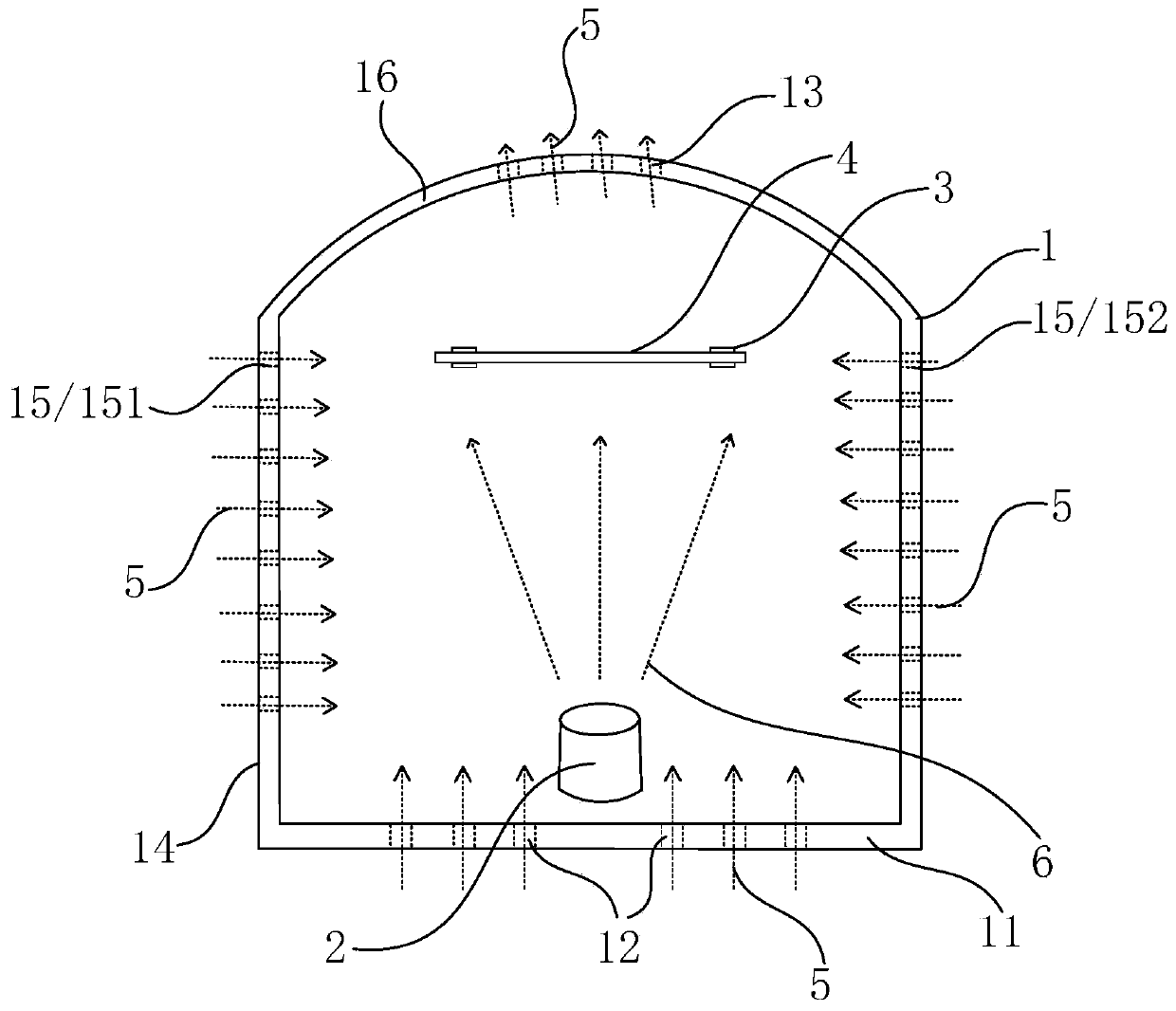

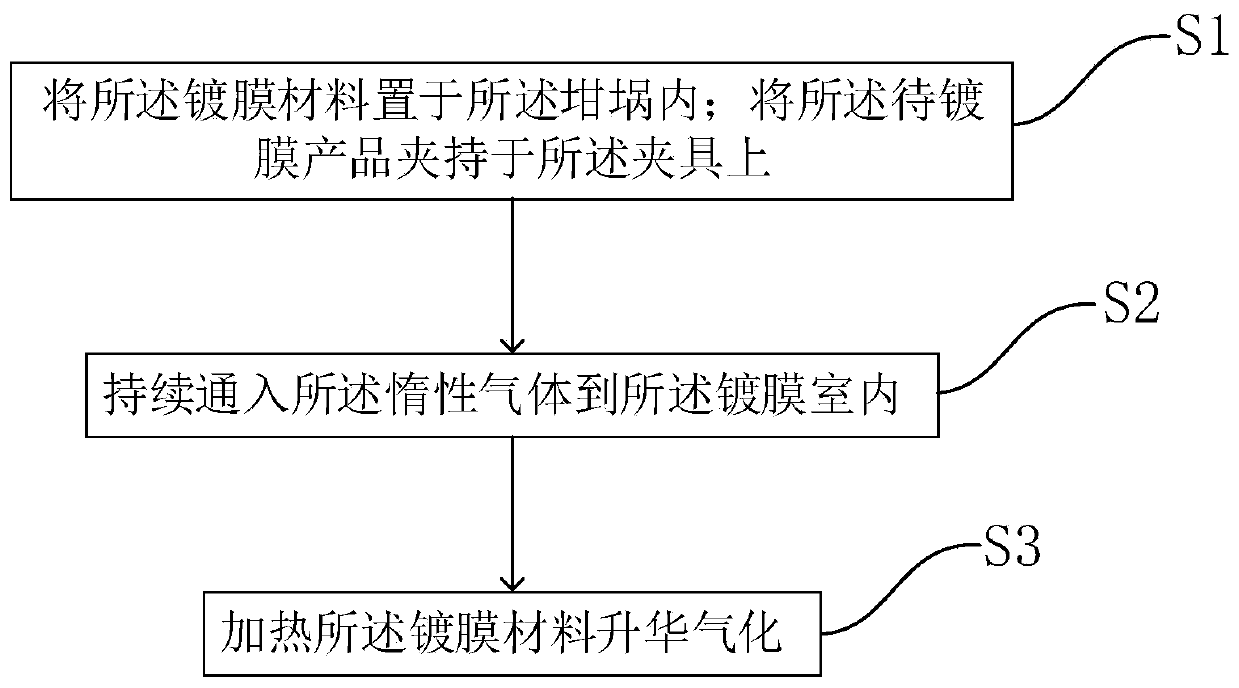

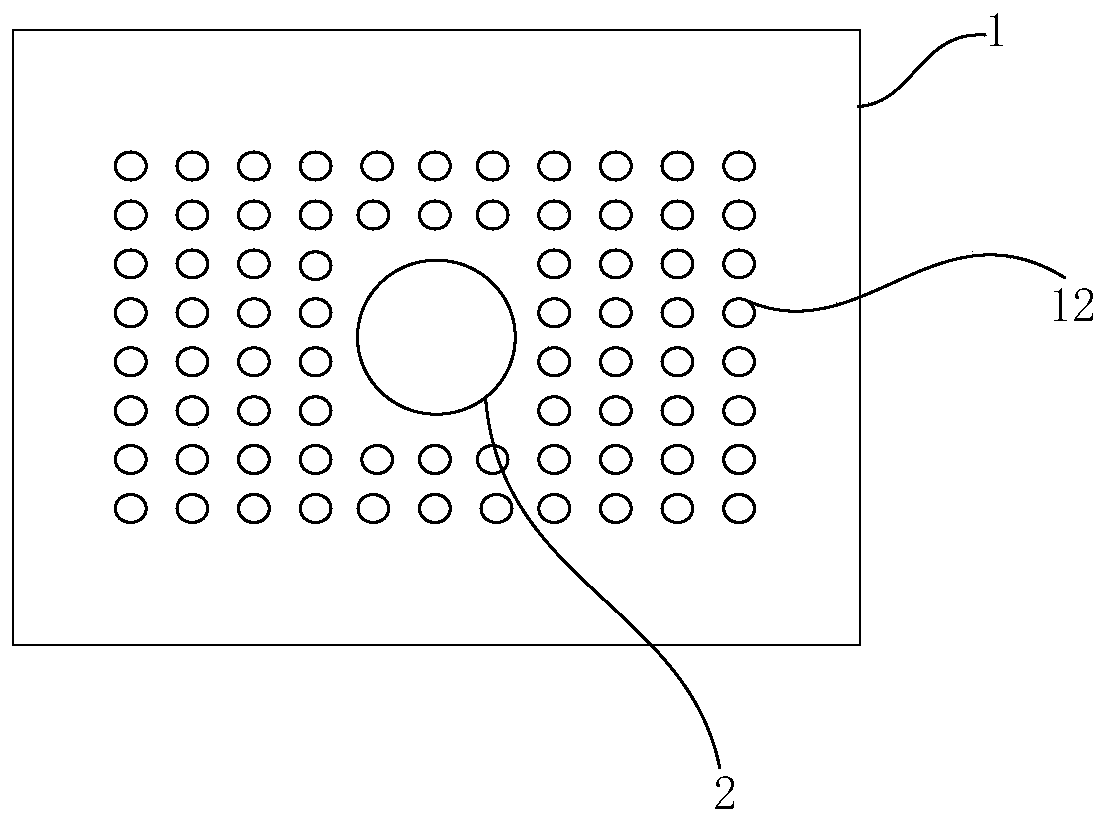

ActiveCN110344002AHigh speedConsistent densityVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention discloses an evaporation plating device and an evaporation plating method. The evaporation plating device comprises a film plating chamber, a crucible which is arranged at the bottom ofthe film plating chamber and used for containing and heating film plating materials and a fixture which is arranged on the top of the film plating chamber, is opposite to the crucible and is used forclamping a to-be-plated product; and the bottom of the film plating chamber is provided with at least one first air inlet hole, inert gas is introduced into the film plating chamber through the firstair inlet holes, and the film plating chamber is provided with at least one exhaust hole. The film plating materials are heated to be sublimated and gasified, diffused out from the crucible and then driven by the inert gas to quickly move towards the to-be-plated product, the film plating speed is higher, and the production efficiency is high. In the evaporation plating material gasifying and moving process, the evaporation plating materials can be mixed uniformly through the inert gas, therefore, the density of all areas of the evaporation plating materials is more consistent before the evaporation plating materials are plated on the to-be-plated product, the film plating uniformity is good, the film forming quality is better, and the precision is higher.

Owner:HKC CORP LTD +1

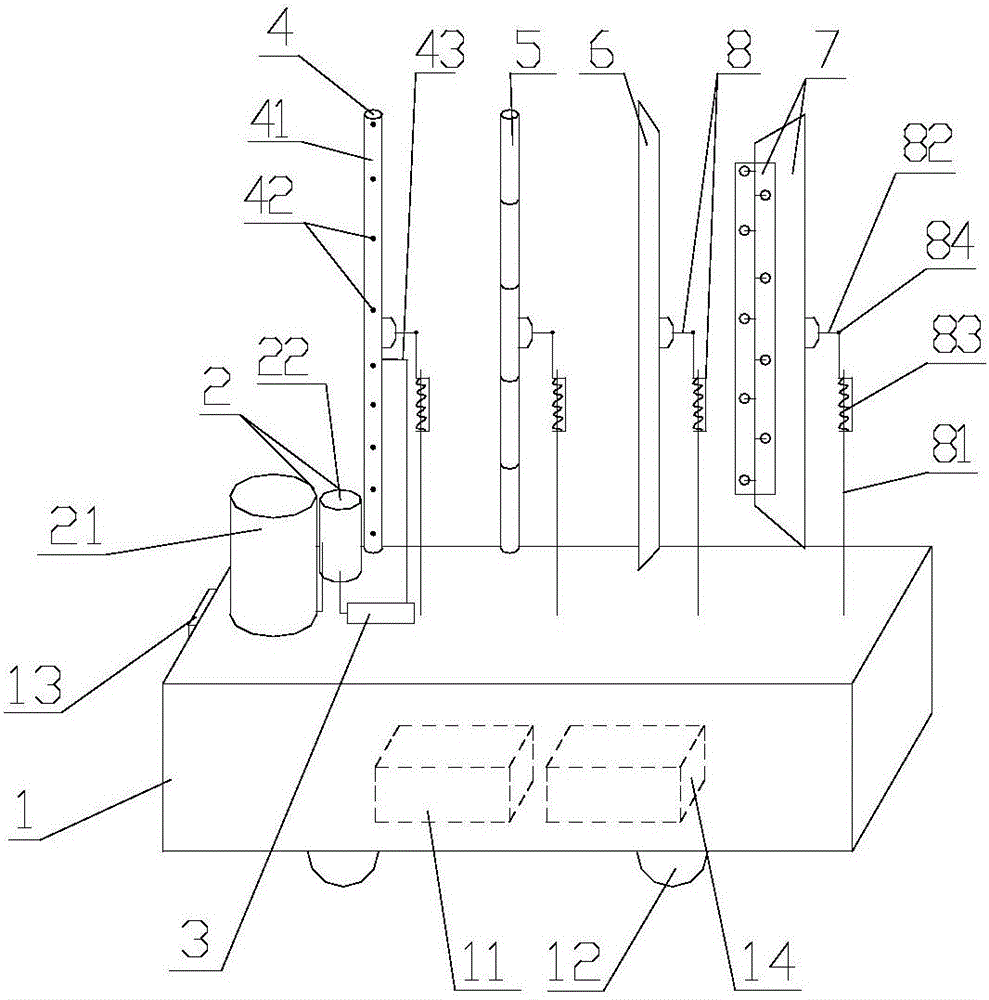

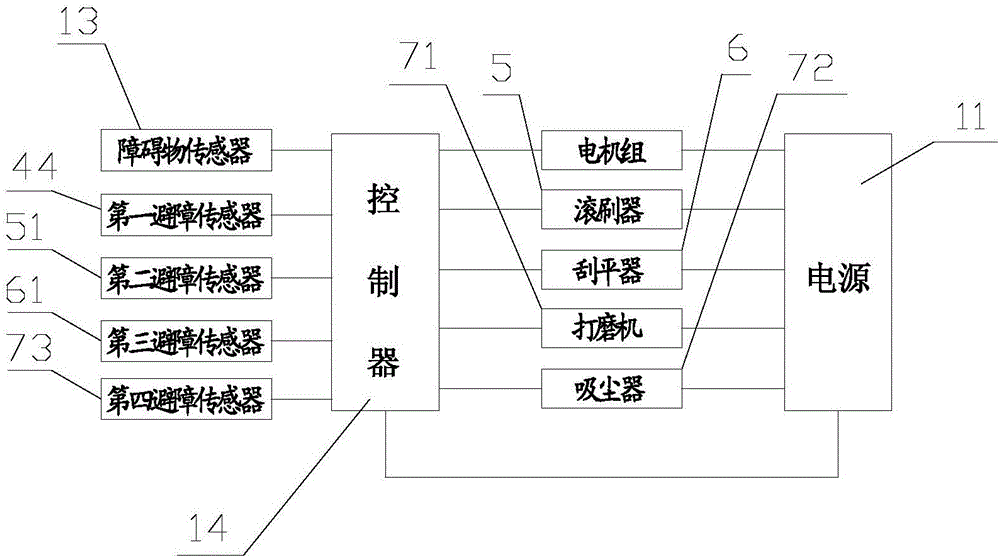

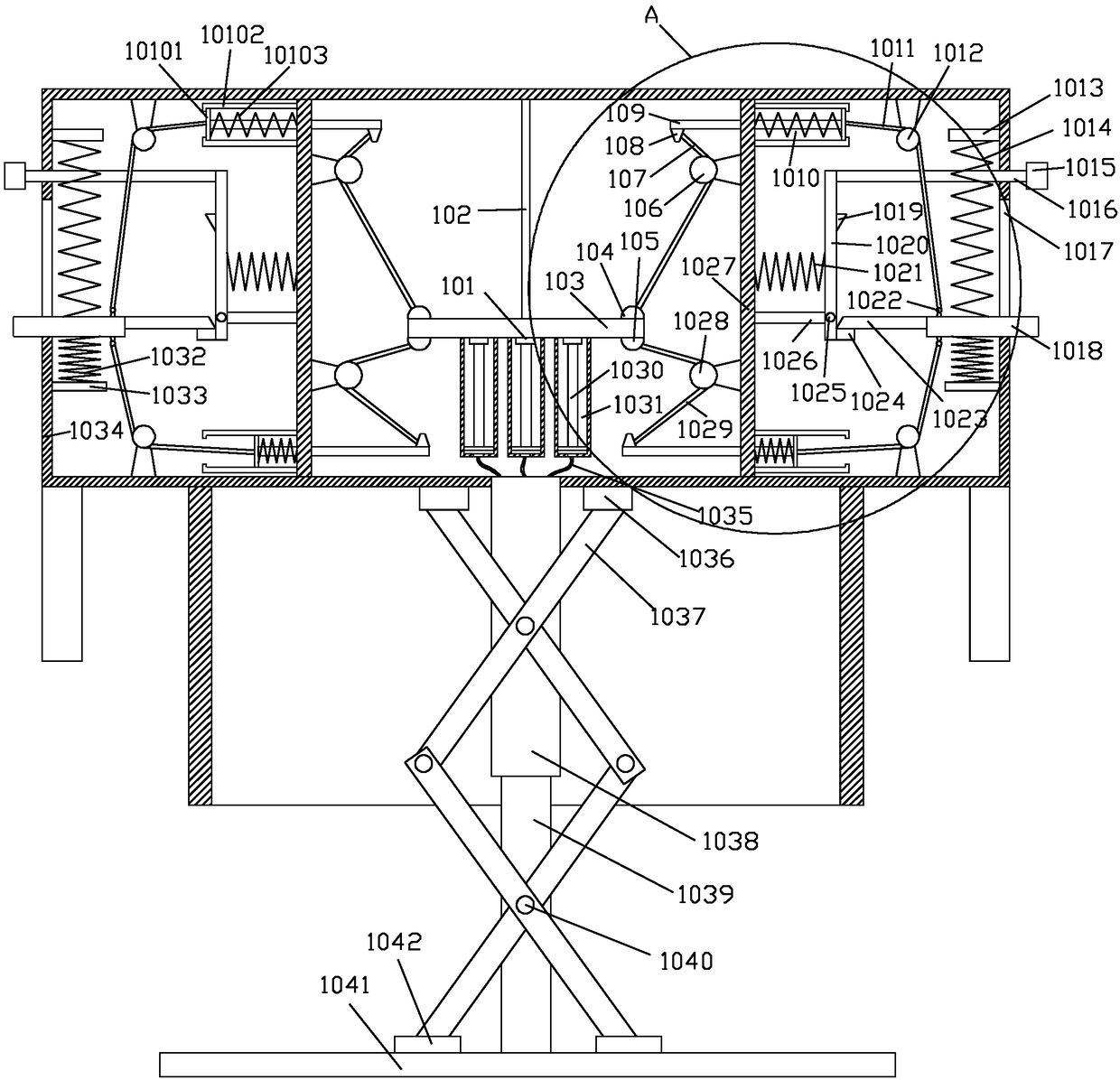

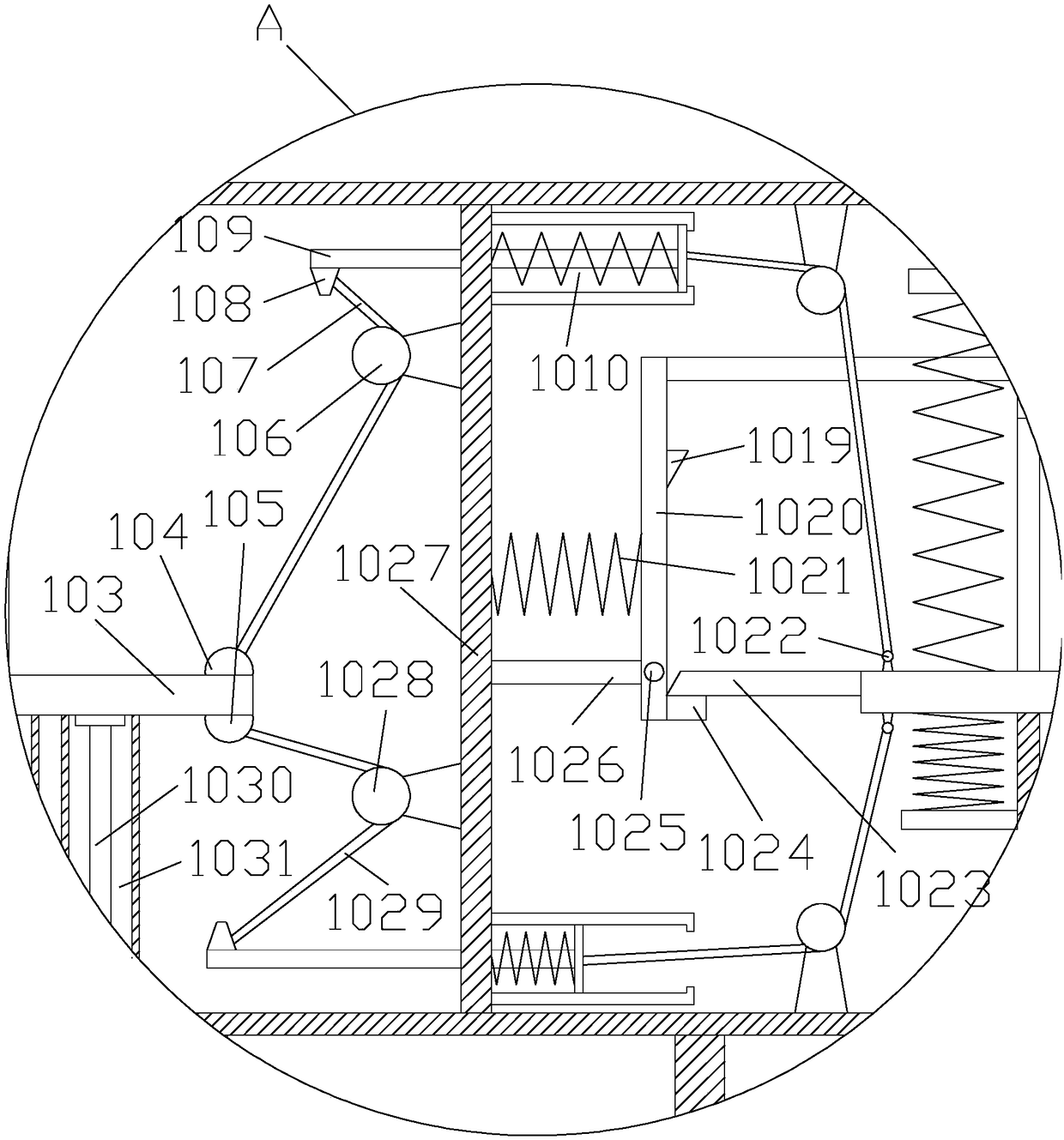

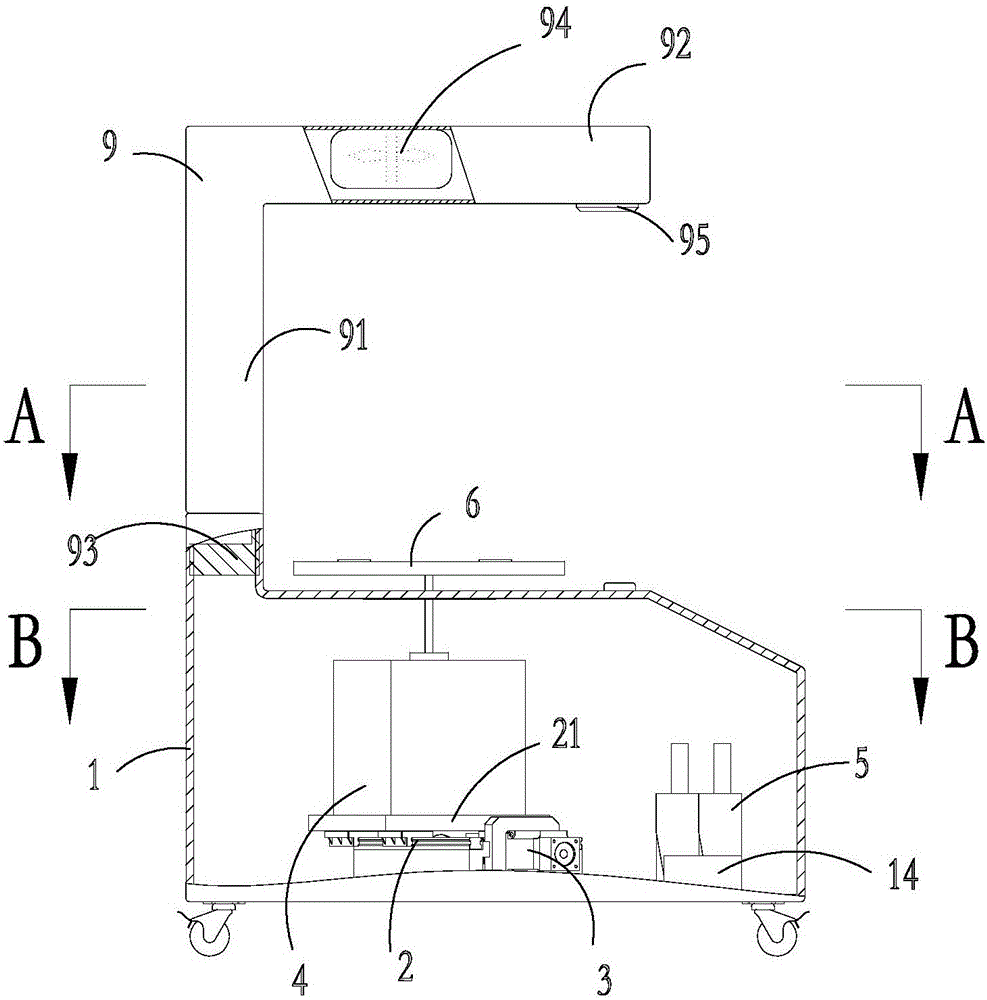

All-in-one full-automatic wall surface plastering unit and use method thereof

ActiveCN106499159AEasy to move and controllableHighly integratedBuilding constructionsElectricityControl system

The invention discloses an all-in-one full-automatic wall surface plastering unit and a use method thereof. The all-in-one full-automatic wall surface plastering unit comprises a transportation vehicle, four identical bracket structures arranged on the transportation vehicle in sequence, a plastering mechanism arranged above the bracket structure, and a control system, wherein a power supply for supplying power to the whole plastering unit is arranged in the transportation vehicle; the plastering mechanism comprises a spraying system, a roller device, a scraper device and grinding units which are connected with the power supply and are arranged above the four bracket structures in sequence; the control system comprises a controller arranged in the transportation vehicle and a motor set connected in series with the power supply and the controller; and the controller is further electrically connected with the roller device, the scraper device, small-size grinding machines and a dust collector. The plastering unit can replace a worker to realize at least 95 percent of the working amount in the construction project; the height and the width of construction can be controlled by the controller; and the all-in-one full-automatic wall surface plastering unit is high in construction speed, high in efficiency and suitable for popularization and application and can effectively avoid the risk caused by high-place work of personnel.

Owner:罗天才

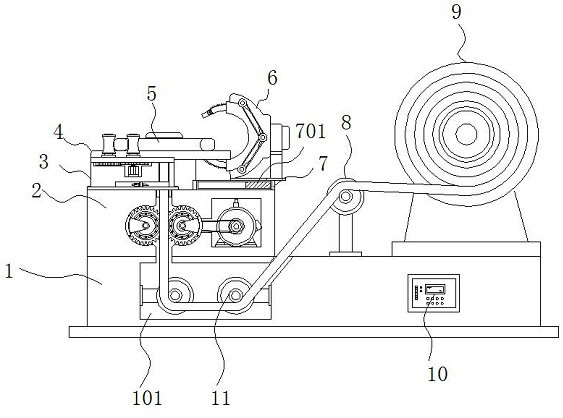

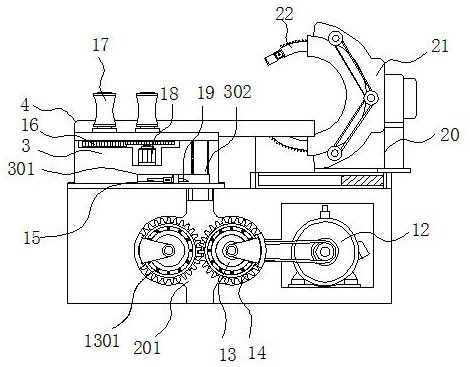

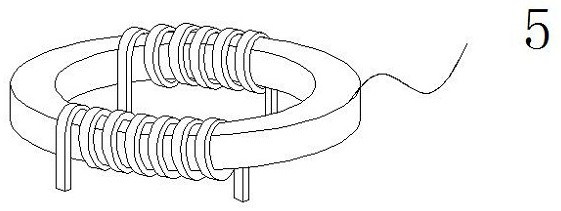

Automatic inductor winding device capable of controlling winding density

InactiveCN112259368AConsistent densityHigh precisionCoils manufactureWinding machineInductor windings

The invention discloses an automatic inductor winding device capable of controlling winding density. The automatic inductor winding device specifically comprises a base, a workbench, a coil placing frame, a winding mechanism and a rotating sleeve, wherein the workbench is mounted on one side of the top of the base, a winding wheel is fixed on the other side of the top of the base, a guide wheel ismounted on the base between the winding wheel and the workbench, and a positioning ring is fixed to the side, close to the guide wheel, in the winding wheel through a support. According to the automatic inductor winding device capable of controlling the winding density, the winding mechanism and a driving roller are arranged, the winding mechanism can drive an enameled wire to be wound on a coil,the driving roller clamps the coil and rotates relatively while winding is conducted so as to allow the coil to rotate at a constant speed, and therefore, uniform winding effect is obtained; comparedwith manual winding, the method has the advantages that efficiency is higher, the winding density can be controlled, it is guaranteed that the winding density is consistent, winding displacement is tidier, and winding precision is higher.

Owner:东莞市夯实科技有限公司

Method for manufacturing recombined hardwood

InactiveCN102172942AWiden tree age limitShort growth cyclePlywood pressesVeneer pressesSizingHardwood

The invention discloses a method for manufacturing recombined hardwood. The method is characterized by comprising the following steps of: a, selecting gum wood with thickness of between 0.5 and 3 millimeters and width of between 5 and 100 millimeters; b, sizing; c, assembling, namely arranging and assembling the gum wood along the length direction; d, performing cold pressing, namely conveying the gum wood into a die of a press to perform cold pressing, wherein the pressure is more than 20MPa; and e, curing, namely heating the die filled with the blank to cure the blank. The sheared or rotary-cut fast-growing low juvenile gum wood or aspen wood of a made forest is used as a production raw material in the method, and the production raw material can be felled in 4 to 8 years, so the using cycle is greatly shortened, and the economic benefit is improved.

Owner:李和麟

Graphene heating film and production method thereof

PendingCN107820340AGood flexibilityReduce manufacturing costWoven fabricsHeating element materialsYarnPolymer science

The invention provides a production method of a graphene heating film. The production method comprises the following steps: A, using a rapier loom to weave a graphene heating fabrc; B, using an ingredient mixing tank to prepare a macromolecule material; C, using a film forming device to fuse the macromolecule material so as to extrude a macromolecule material film; D, heat-sealing the macromolecule material film extruded in the step C to two sides of the heating fabric obtained in the step A in a double-faced synchronous heat-sealing manner; E, cooling an object obtained after lamination in the step D; and F, cutting deckle edges of an object obtained after cooling in the step E, and rolling to prepare the graphene heating film. The graphene heating film is simple in structure and convenient to use, a graphene heat conduction wire blending spinning silk yarn prepared fabric is used as a base material, and the macromolecule material layers are compounded on two sides of the fabric baselayer simultaneously to prepare the graphene heating film, so that the obtained graphene heating film is high in flexibility, low in manufacturing cost, free of stratification, light in weight and high in electrothermal efficiency.

Owner:青岛冠锐碳纤维科技有限公司

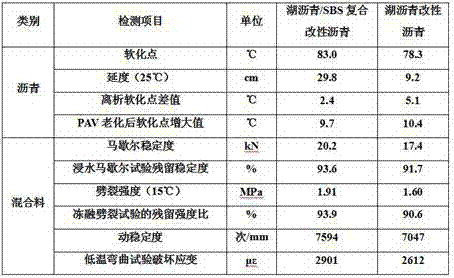

Lake asphalt/SBS compound modifier and preparation method and application thereof

InactiveCN106928731AImproves resistance to water damageImprove low temperature cracking resistanceBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBS compound modifier and a preparation method and application thereof. The lake asphalt / SBS compound modifier is a pre-dispersant which is prepared by the fusion and blending of lake asphalt, polymer SBS and compatilizers, and modified asphalt can be prepared by fusing and blending the lake asphalt / SBS compound modifier with petroleum asphalt and stabilizers. The obtained lake asphalt / SBS compound modifier is the pre-dispersant which can remarkably improve the high-temperature deformation resistance capability, low-temperature cracking resistance capability and water damage resistance capability of the petroleum asphalt, and by adding the pre-dispersant into the petroleum asphalt and taking use of the advantage of good compatibility between the pre-dispersant and the petroleum asphalt, the lake asphalt / SBS compound modified asphalt is prepared, wherein the modified asphalt is uniform in dispersion, and layered segregation does not occur easily on the modified asphalt. The modified asphalt is used for the construction of heavy-loaded traffic asphalt pavements in high temperature, damp and rainy areas, asphalt pavement diseases can be significantly reduced, the maintenance cost of the pavements is reduced, and the service life of the asphalt pavements is prolonged.

Owner:FUZHOU UNIV

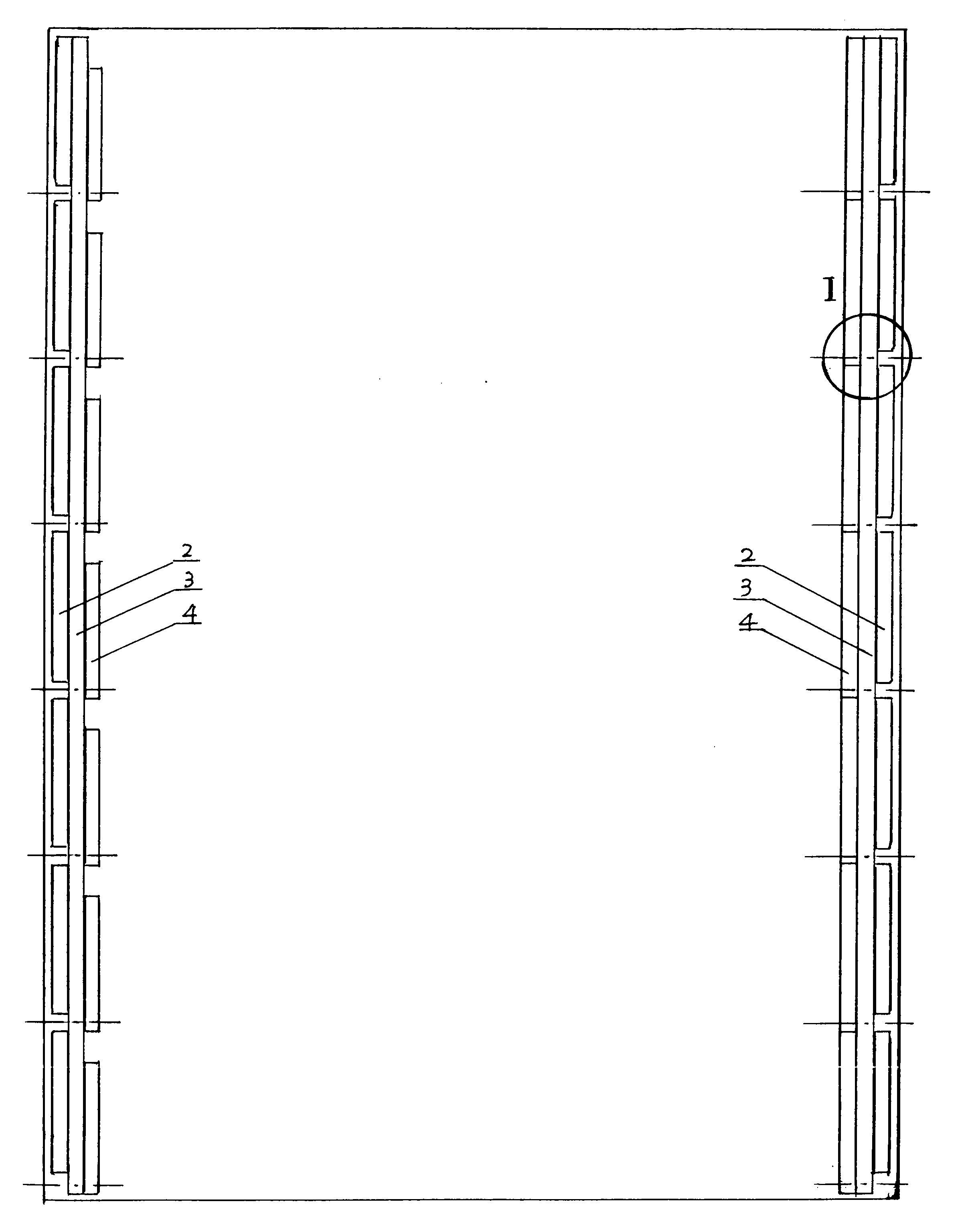

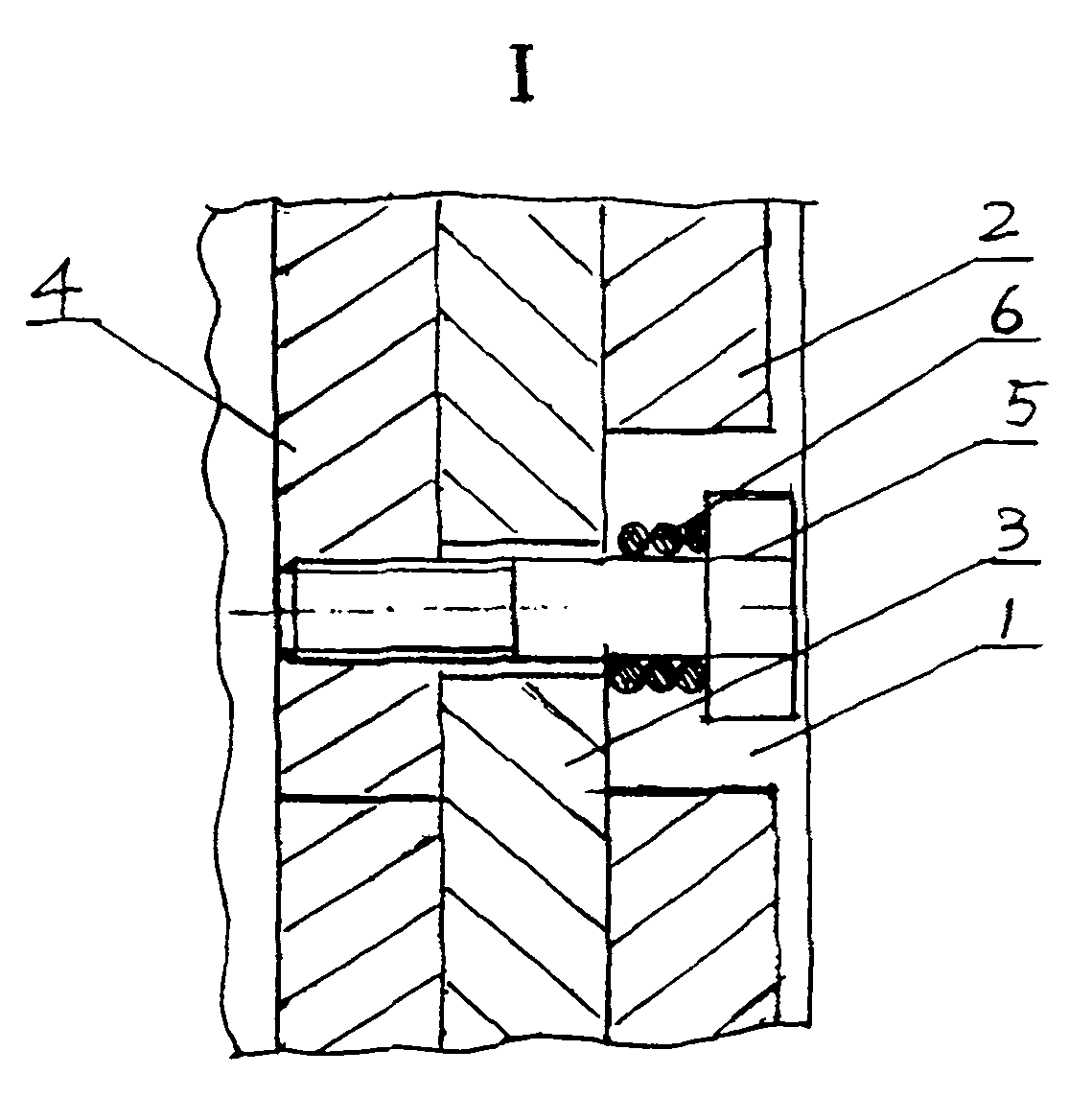

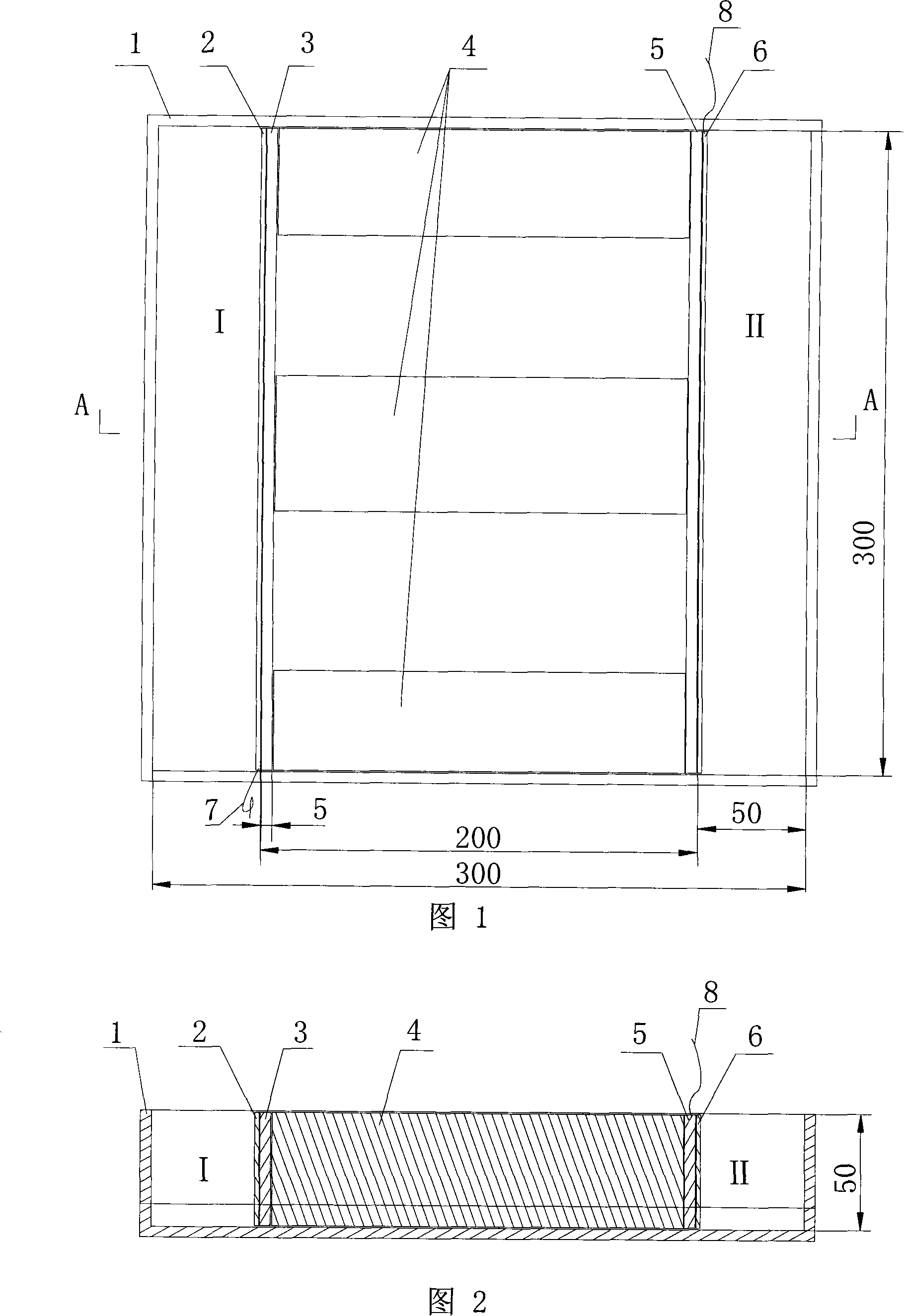

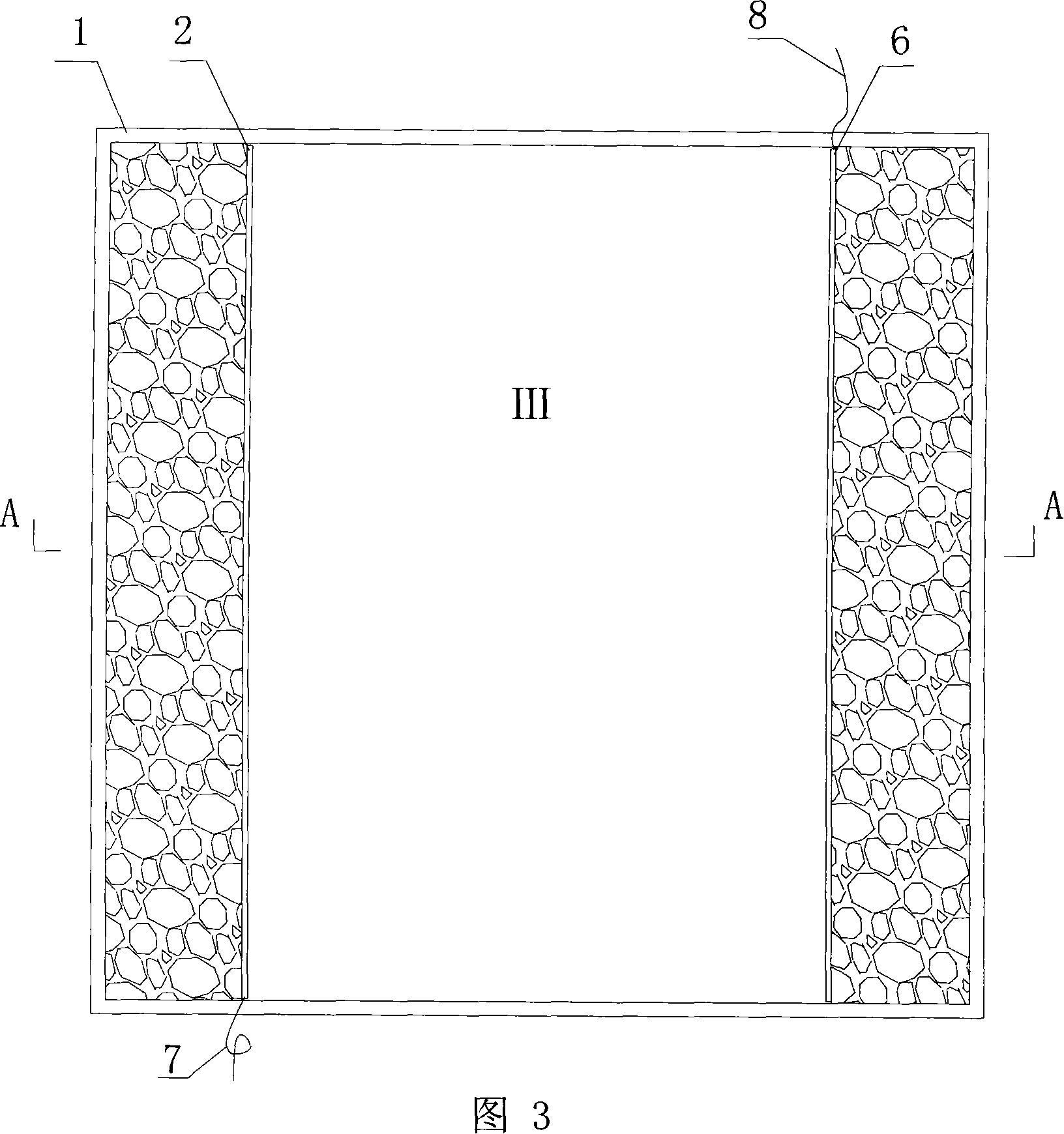

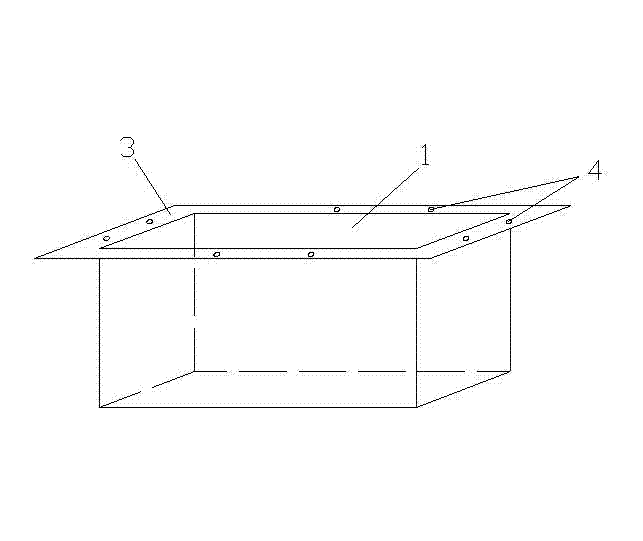

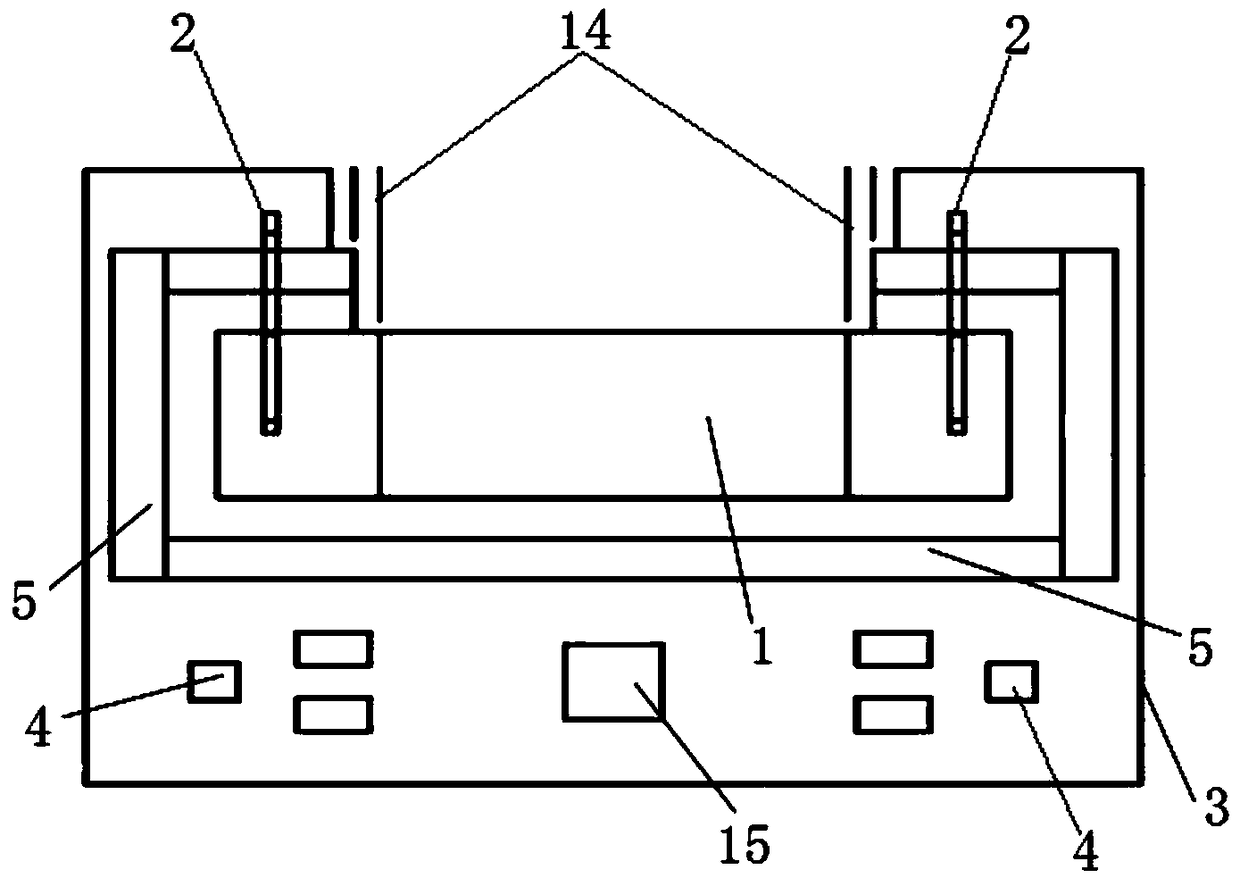

Conductive asphalt concrete resistance test method

InactiveCN101169457ASimple conductivityAccurate conductivityResistance/reactance/impedenceElectrical resistance and conductanceElectrical resistance survey

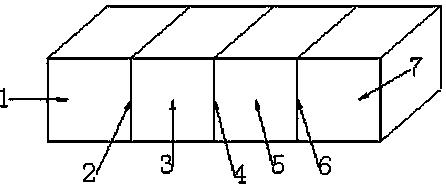

The invention relates to a resistance testing method of conduction asphalt concrete used for roads; the invention is characterized in that the testing method comprises the steps as following: firstly, the preparation of a testing device: the testing device is formed by a testing die (1), a first electrode (2), a first steel-made clapboard (3), a supporting block (4), a second steel-made clapboard (5), a second electrode (6), a first lead (7), a second lead (8) and a resistance measuring meter; secondly, leading the tested and heat mixed conduction asphalt concrete evenly to be filled into an area 1 and an area 2 of the testing die (1) according to the total amount of the conduction asphalt concrete needed for the area 1 and the area 2; thirdly, leading the tested and heat mixed conduction asphalt concrete to be evenly filled into an area 3 of the testing die (1) according to the total amount of conduction asphalt concrete needed for the area 3, and unmolding after the maintenance of indoor temperature within 24 hours; fourthly, leading the input end of a resistance meter to be respectively connected with the first lead (7) and the second lead (8) to measure the resistance value of the conduction asphalt concrete. The invention is simple and highly accurate.

Owner:WUHAN UNIV OF TECH

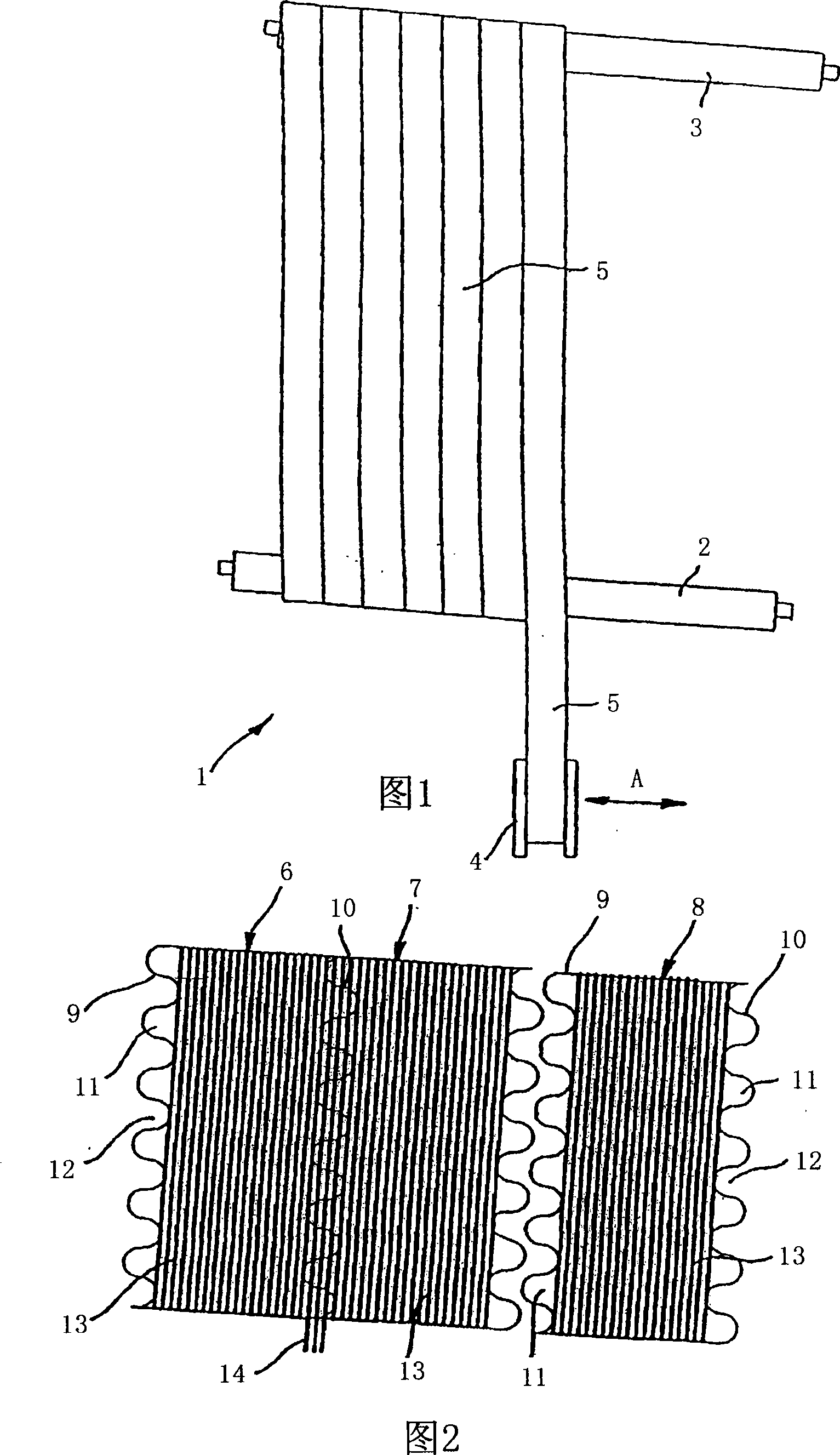

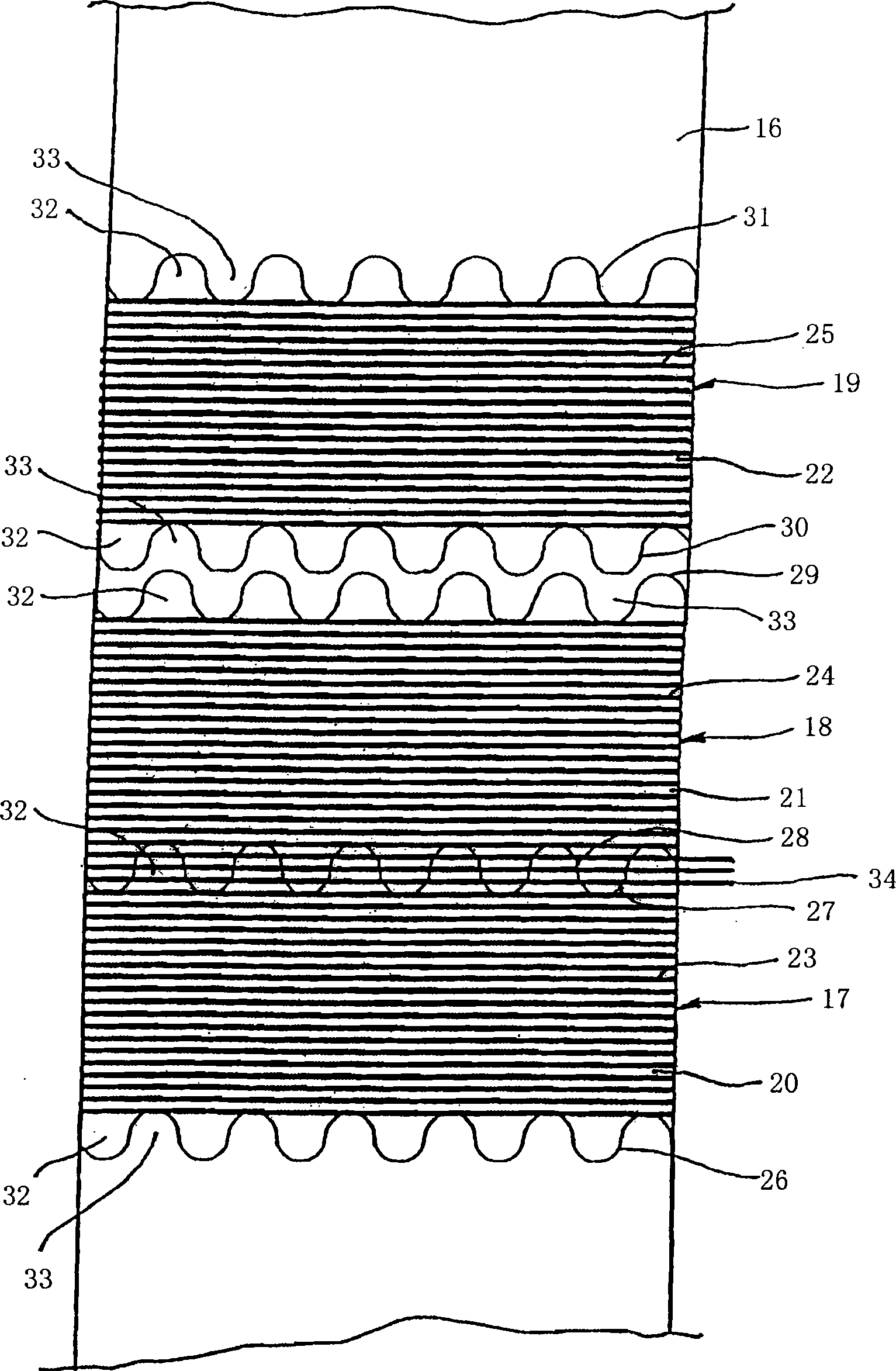

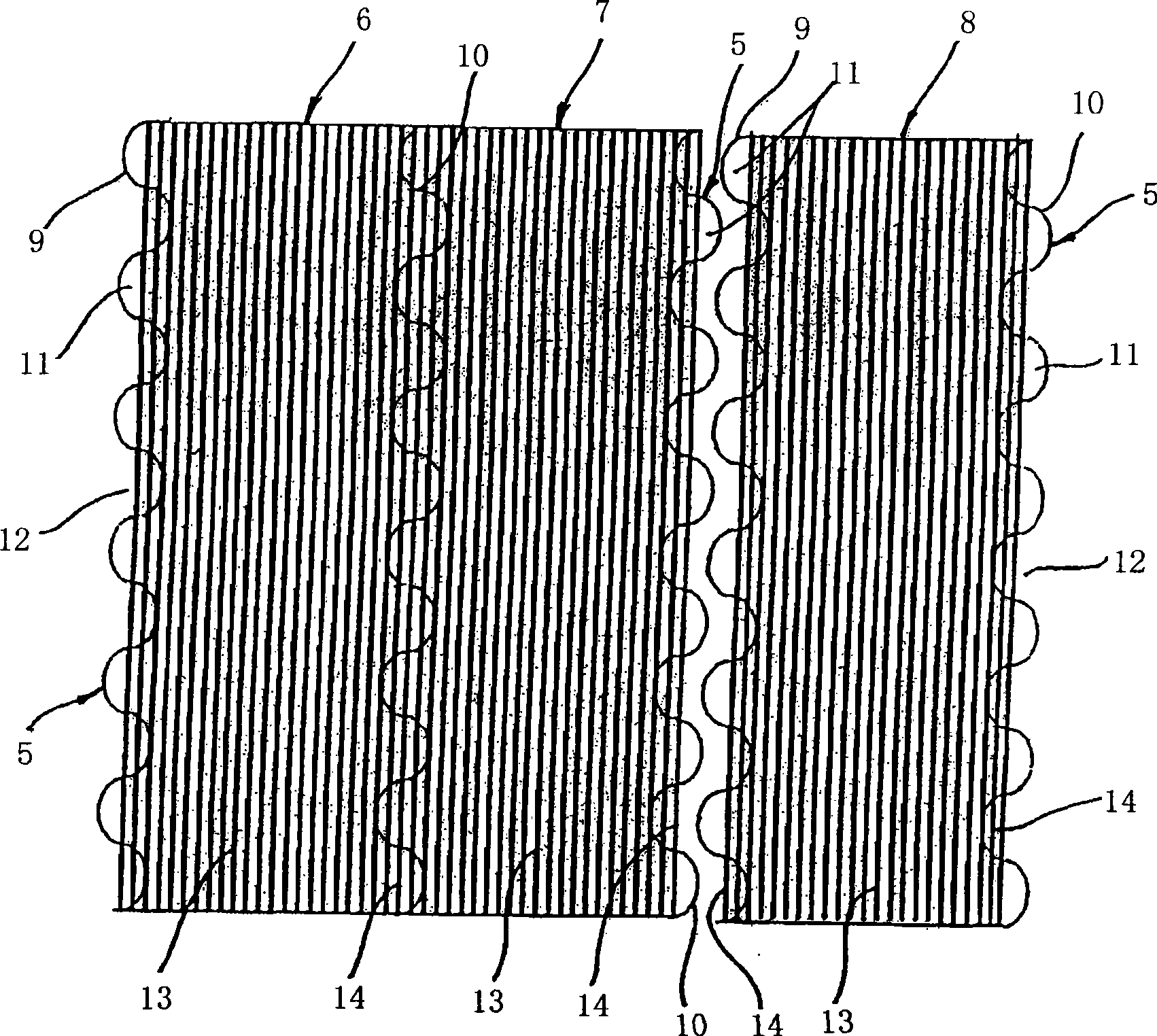

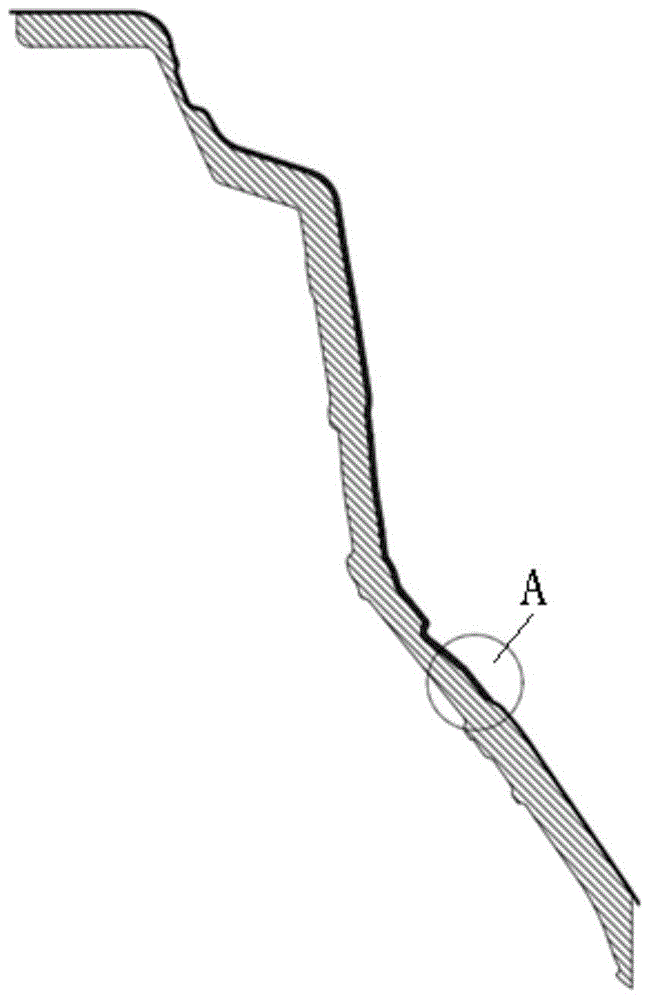

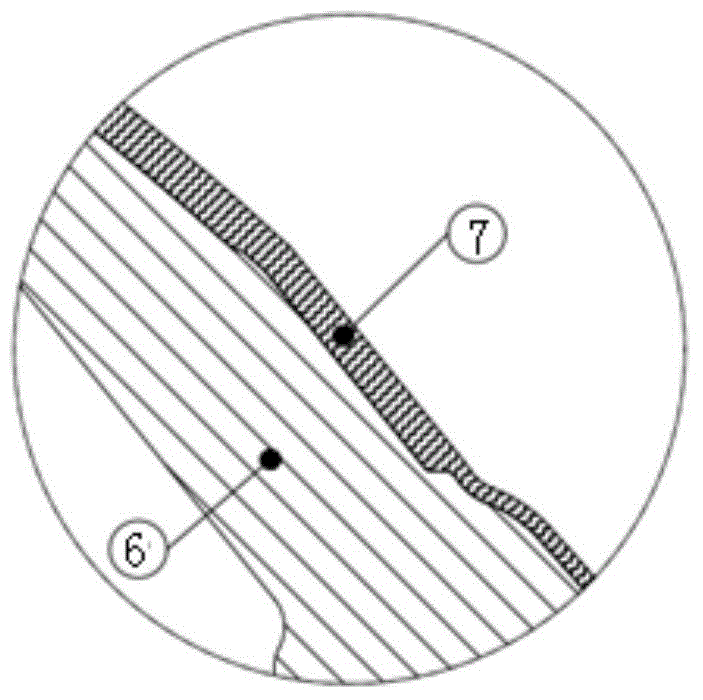

Method for manufacturing a machine felt and machine felt

The invention relates to a machine felt and a method for manufacturing the same. Firstly a tube having a longitudinal yarn layer is manufactured with a peripheral length double the length of the machine felt, and a width that corresponds to the width of the machine felt. The tube is compressed into a flattened tube with the formation of longitudinal yarn loops which are exposed by the removal of fibers of a fiber batt layer. An auxiliary substrate web is manufactured with a width that is less than that of the machine felt; for the longitudinal yarns and / or for the auxiliary substrate web, a material is used that absorbs laser energy; the longitudinal yarns are brought together with the auxiliary substrate web and connected by a laser beam; the auxiliary substrate web is helically wound until the tube is formed; and upon exposure of the longitudinal yarn loops, the auxiliary substrate web(s) are also removed.

Owner:HEIMBACH GMBH & CO KG

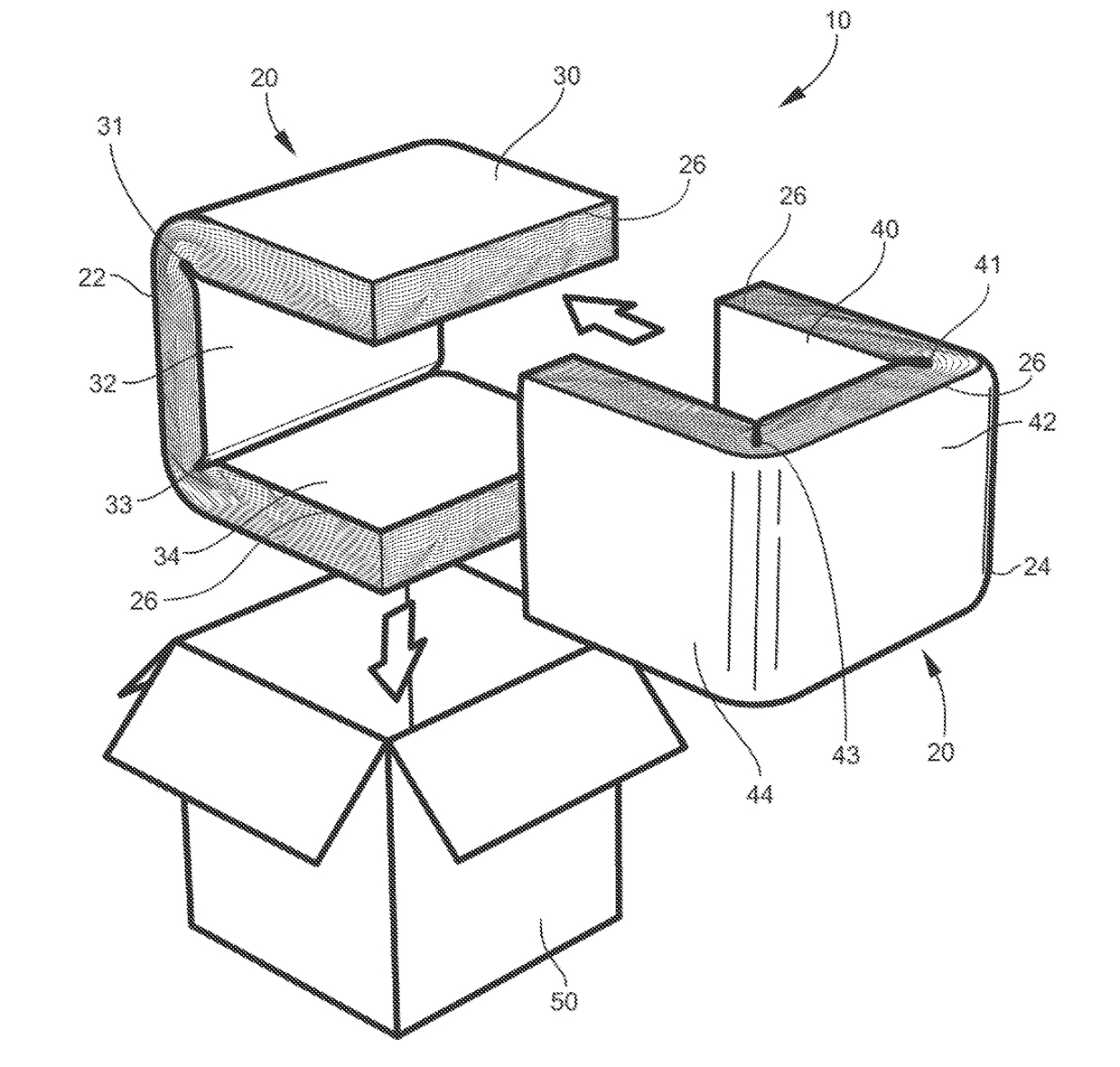

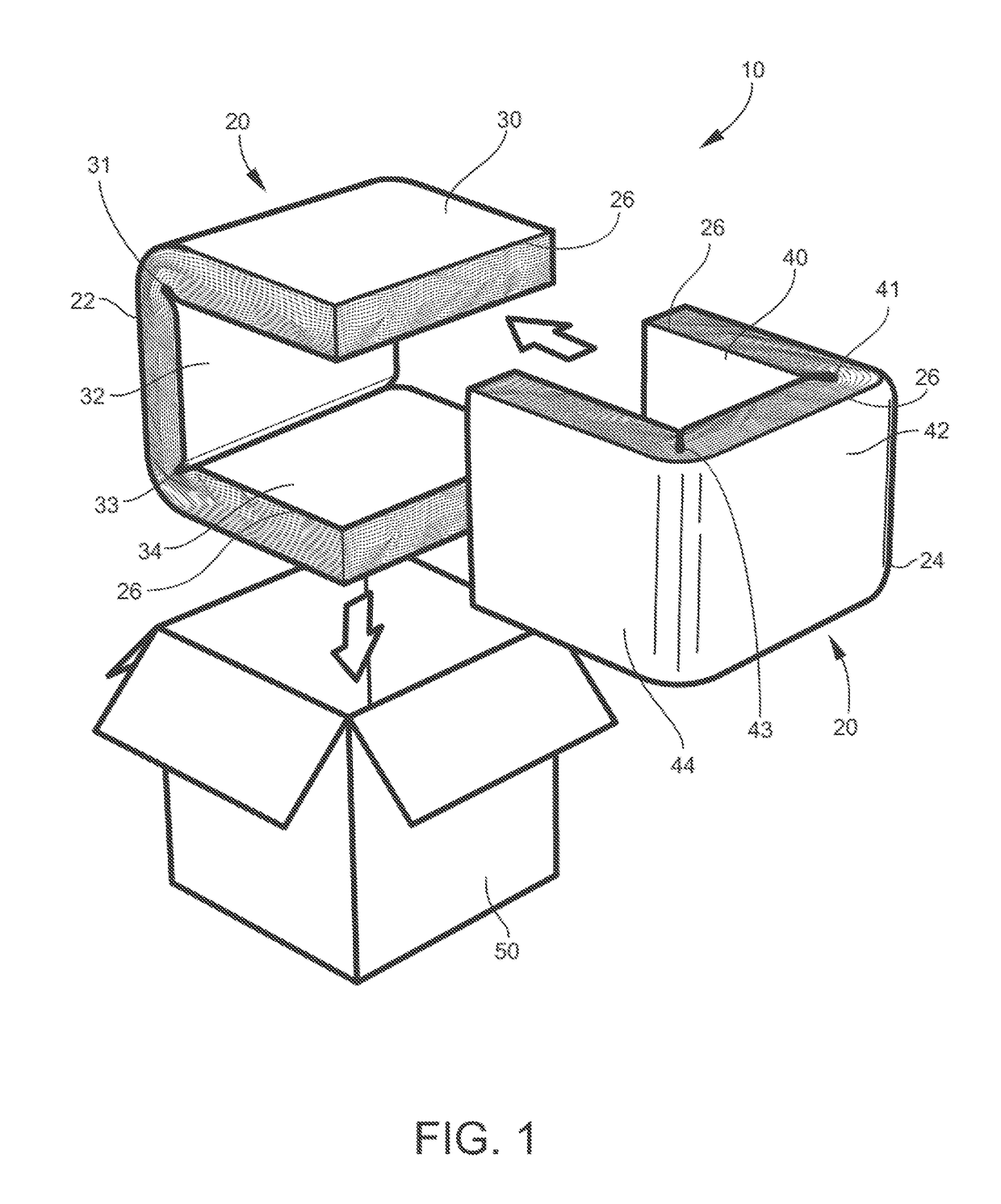

Insulated container

PendingUS20180257844A1Efficient and economically manufacturedMinimize negative impactFlexible coversWrappersInsulation layerEngineering

An insulated container may include a rigid container surrounding an insulation layer formed from a post-industrial, pre-consumer card waste. The insulation layer may include a natural fiber lamination layer on an outer surface of the insulation layer or may be housed in a biodegradable plastic. The insulated layer may be manufactured in a capital “T” shape such that it may be folded for compact transportation prior to end use. The folded insulation layer may bound by a separable band. The separable band may be removed when folded insulation layer is placed in the rigid container. The insulation layer and the band may be biodegradable in an anaerobic environment.

Owner:AIRLITE PLASTICS

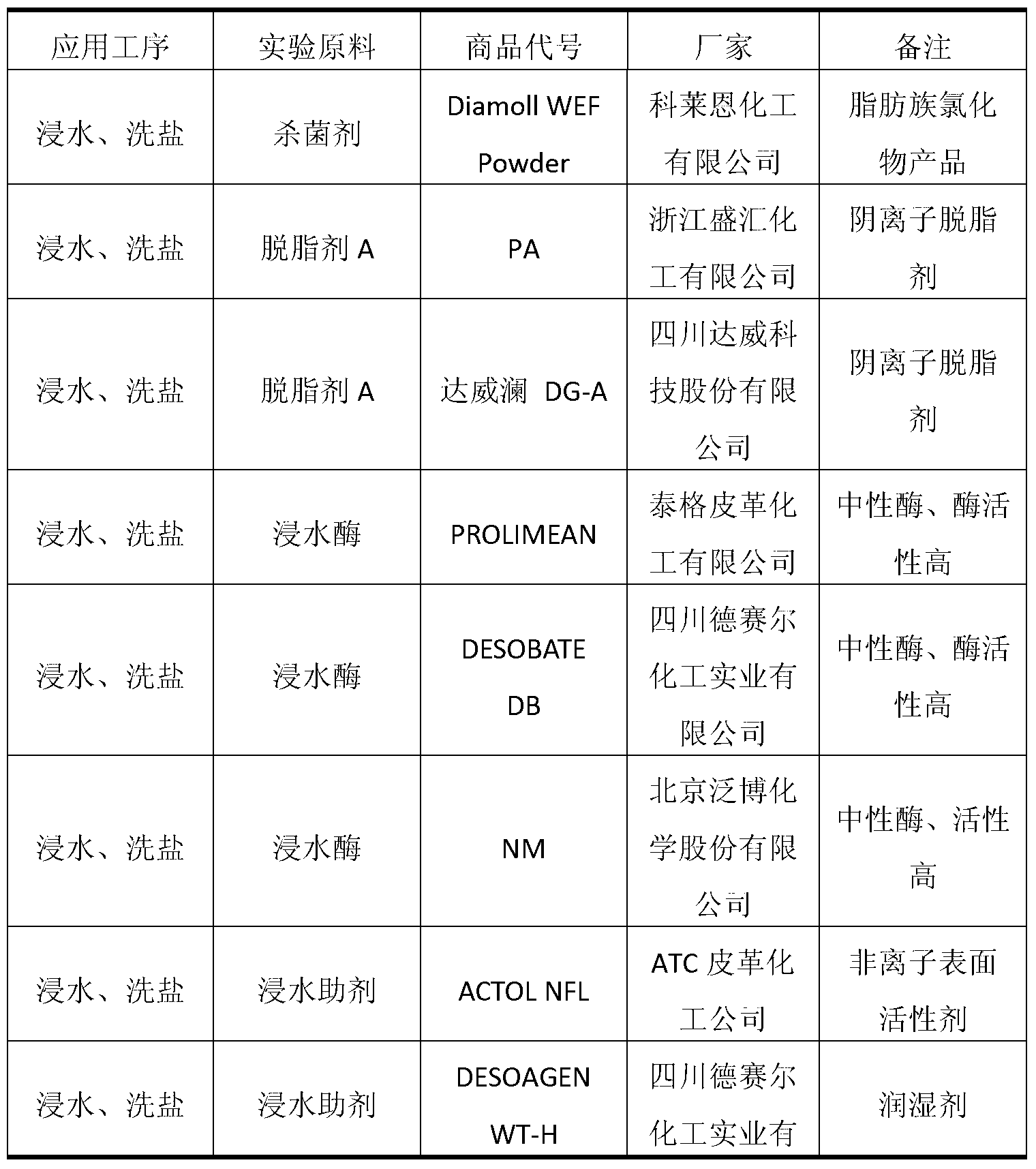

Production technology of cow rug

InactiveCN103290150AImprove bindingQuality assuranceTanning treatmentPre-tanning chemical treatmentCow dungChemistry

The invention discloses a production technology of a cow rug. The production technology of the cow rug comprises the following steps of: soaking and salt-leaching cow fur after original skin branching, and degreasing once after fleshing mechanically once; pickling, tanning, extracting alkaline, once washing the cow fur after degreasing once, and wringing, thereby obtaining the skin after being wrung; brushing and stuffing, drying, wetting back, staking and fluffing the skin after being wrung, thereby obtaining the cow rug. The production technology of the cow rug provided by the invention pays attention to original skin branching and selection, is suitable for producing skin of the high-grade cow rug, and guarantees the quality of the cow rug; the produced cow rug can be stored, and cannot be damaged by worms due to long-time placing and the like; the cow skin is subjected to degreasing and stuffing treatment pertinently, and oil grease in the fur is removed, and high-permeability stuffing agents are added, so that the flexibility degree of each part of the cow rug is consistent and each part has texture; a method for staking after stuffing is adopted, and the skin thickness difference is reduced.

Owner:伊犁霍尔果斯枣索制革厂 +1

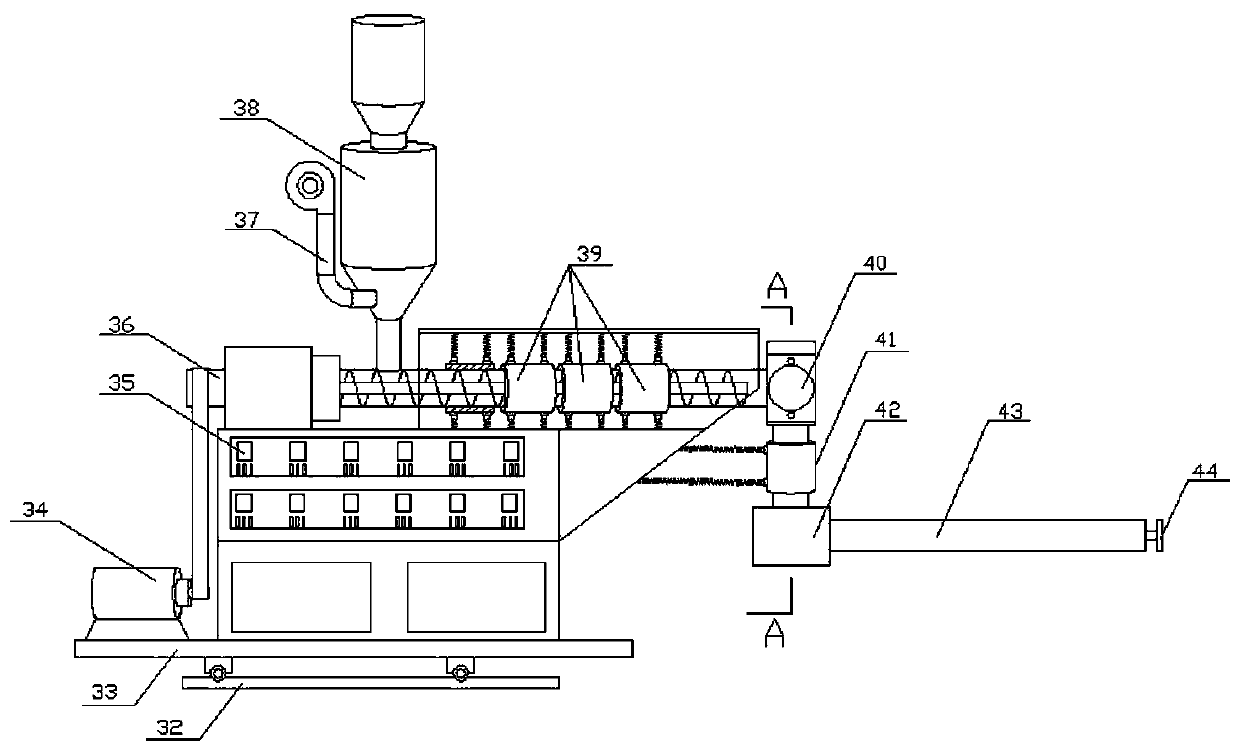

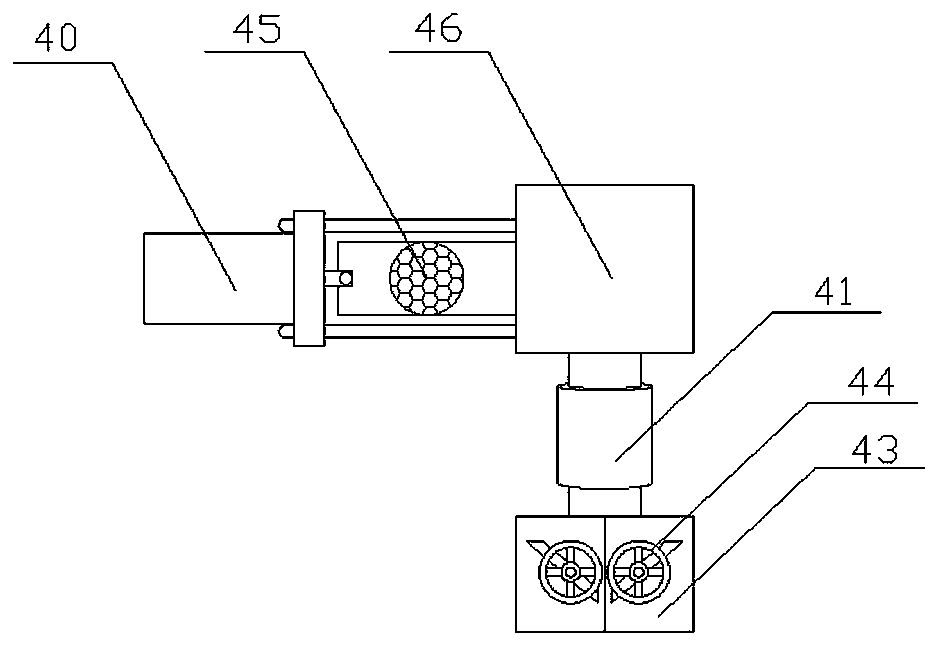

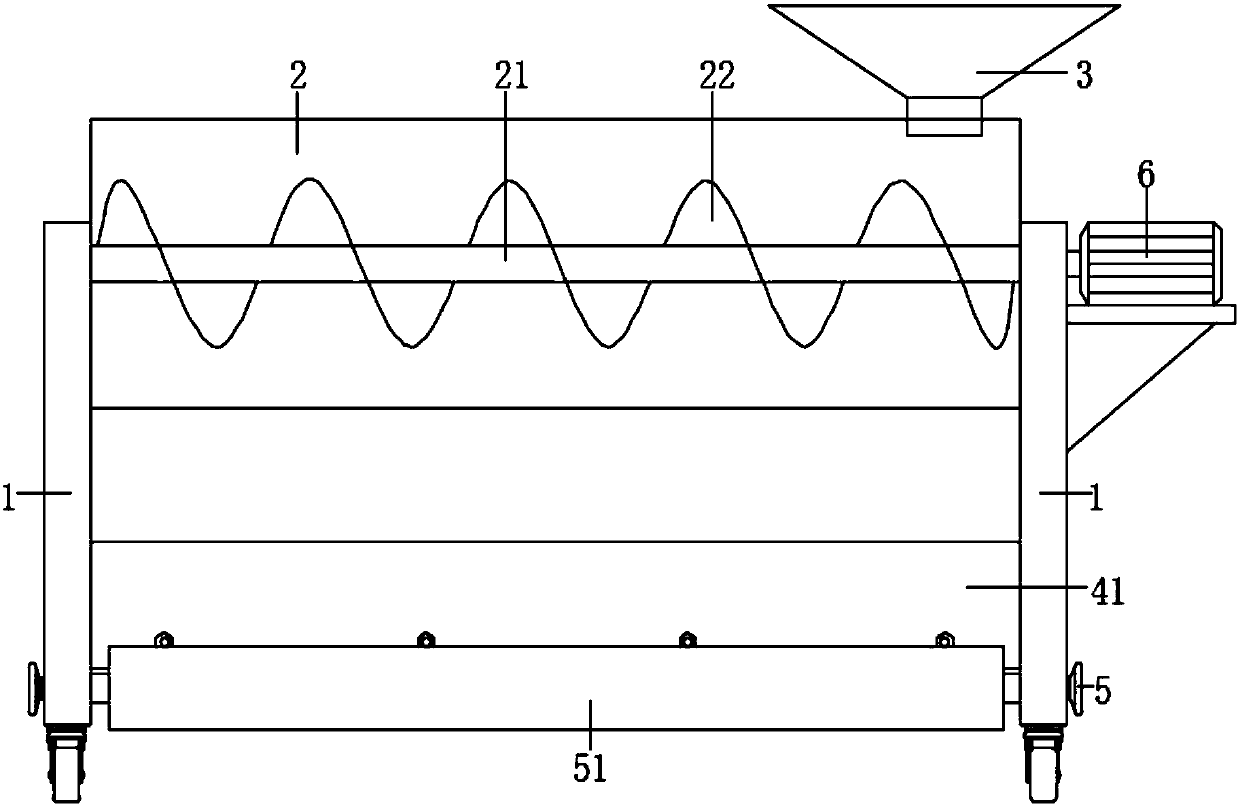

Mixing stirring machine

ActiveCN102091549AWell mixedConsistent densityRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention relates to the technical field of mixing stuffing and sizing agent, particularly to a mixing stirring machine used in the field of food processing. The invention provides a mixing stirring machine which is high in stirring efficiency, has good stirring effect and is simply and conveniently used. The mixing stirring machine comprises a stirring barrel, a stirring device, a driving mechanism and a frame, wherein the stirring device is arranged in the stirring barrel; the stirring barrel is arranged on the frame; the stirring device comprises a stirring ball, a barrel bottom scrapping plate and a side scrapping plate; the side scrapping plate is arranged on the end part of the barrel bottom scrapping plate; the barrel bottom scrapping plate is arranged on the bottom of the stirring barrel; the stirring ball and the barrel bottom scrapping plate are connected to the driving mechanism; the stirring ball comprises a sealing ball; steel wire strips are wound around the sealing ball; and a lower pressing plate is arranged on the steel wire strips. The mixed materials are turned up and down, left and right, under the action of the lower pressing plate on the stirring ball, the barrel bottom scrapping plate and the side scrapping plate. The effects of uniformly mixing and consistent density are achieved by continuously cutting through the steel wire strips. The operation is convenient and practical, the structure is simple and the cost is low.

Owner:DONGGUAN XUJI FOODSTUFF

Method for preparing honeycomb enhanced phenolic foam composite materials

The invention relates to a method for preparing honeycomb enhanced phenolic foam composite materials. The method is characterized by including the steps of: (1) pouring phenolic resin foam composite into a die; (2) vertically placing a honeycomb in the phenolic resin foam composite in the die; (3) placing the die with the phenolic resin foam composite and the honeycomb in the step (2) into a baking oven at the temperature of 50-100 DEG C for foaming for 5-10h, and obtaining the honeycomb enhanced phenolic foam composite material. Via one-time soaking and heating consolidation, the method is capable of preparing the honeycomb enhanced foam composite materials with phenolic foam ingredients in the honeycomb materials and phenolic foam filled in honeycomb lattice holes, the operation procedure is extremely simple, only the die and the baking oven are utilized as equipment, so that the method has the advantages of efficiency and low cost, meanwhile, the composite material products can be guaranteed to have the advantages of good combination properties like light weight, sound insulation, heat insulation, specific strength, specific modulus, water resistance and flame retardance.

Owner:ARAMICORE COMPOSITE

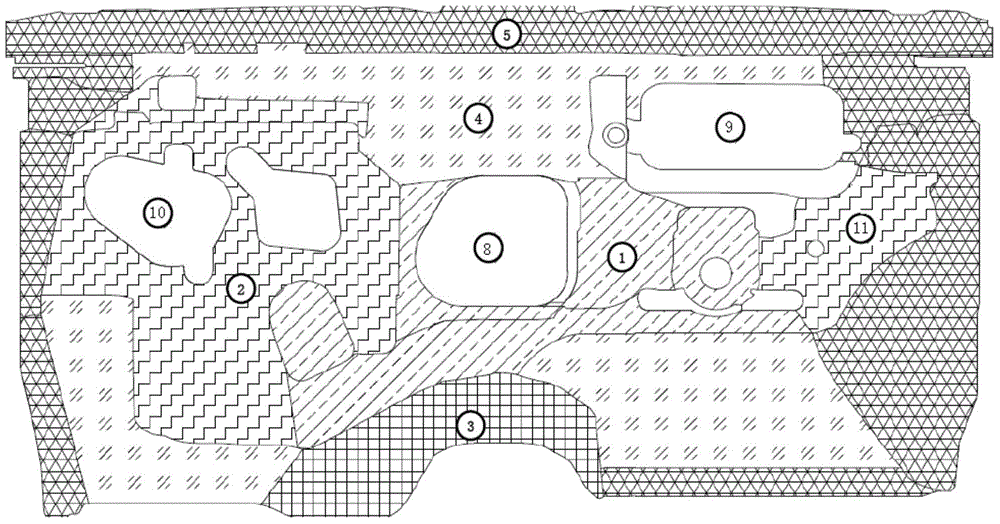

Injection molded automotive sound insulation pad and manufacturing method thereof

The invention relates to the technical field of an automotive sound insulation pad, and particularly to an injection molded automotive sound insulation pad and a manufacturing method thereof. The injection molded automotive sound insulation pad is characterized in that the sound insulation pad is provided with heavy layers with different densities; the central portion of the sound insulation pad is provided with a hole; the left side of the hole is provided with a first heavy layer with a density of 5.4kg / m<2>; a second heavy layer with a density of 6.3kg / m<2> is arranged at the right side and below the hole; the portion above the hole, the portion below the heavy layer and the right side below the second heavy layer are respectively provided with a third heavy layer with a density of 4.5kg / m<2>; a fourth heavy layer with a density of 3.6kg / m<2> is arranged below the second heavy layer; and a fifth heavy layer with a density of 2.7kg / m<2> is arranged outside the first heavy layer, the second heavy layer, the third heavy layer and the fourth heavy layer. Compared with a prior plastic uptake process, the process according to the injection molded automotive sound insulation pad is advantageous in that the number of leftover materials is reduced; and the dimension accuracy and consistency of the component are improved.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

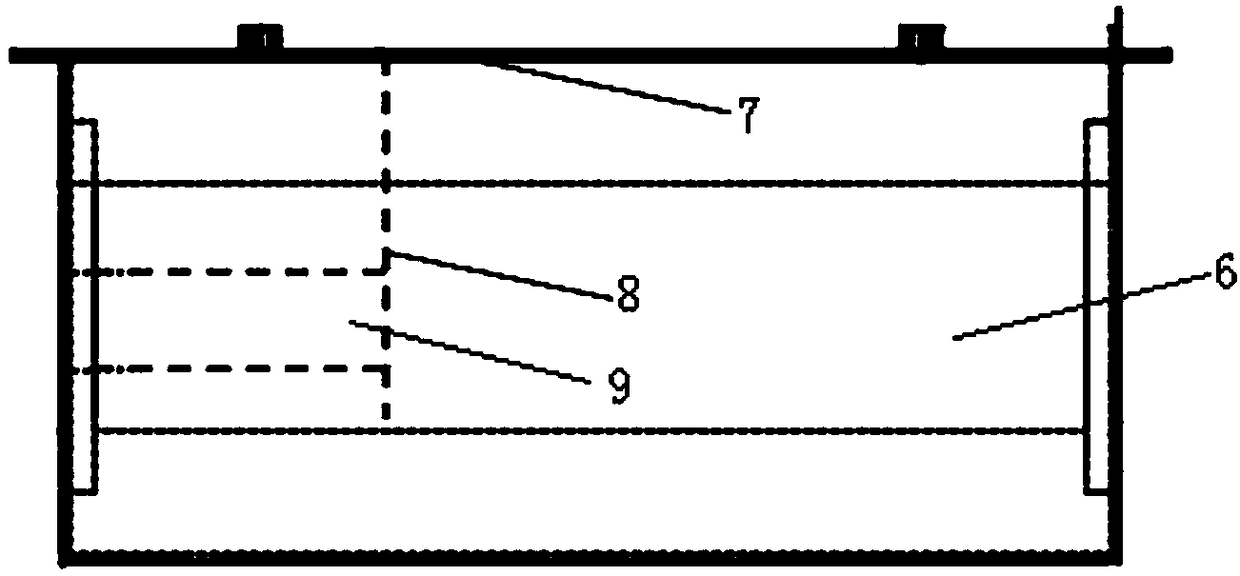

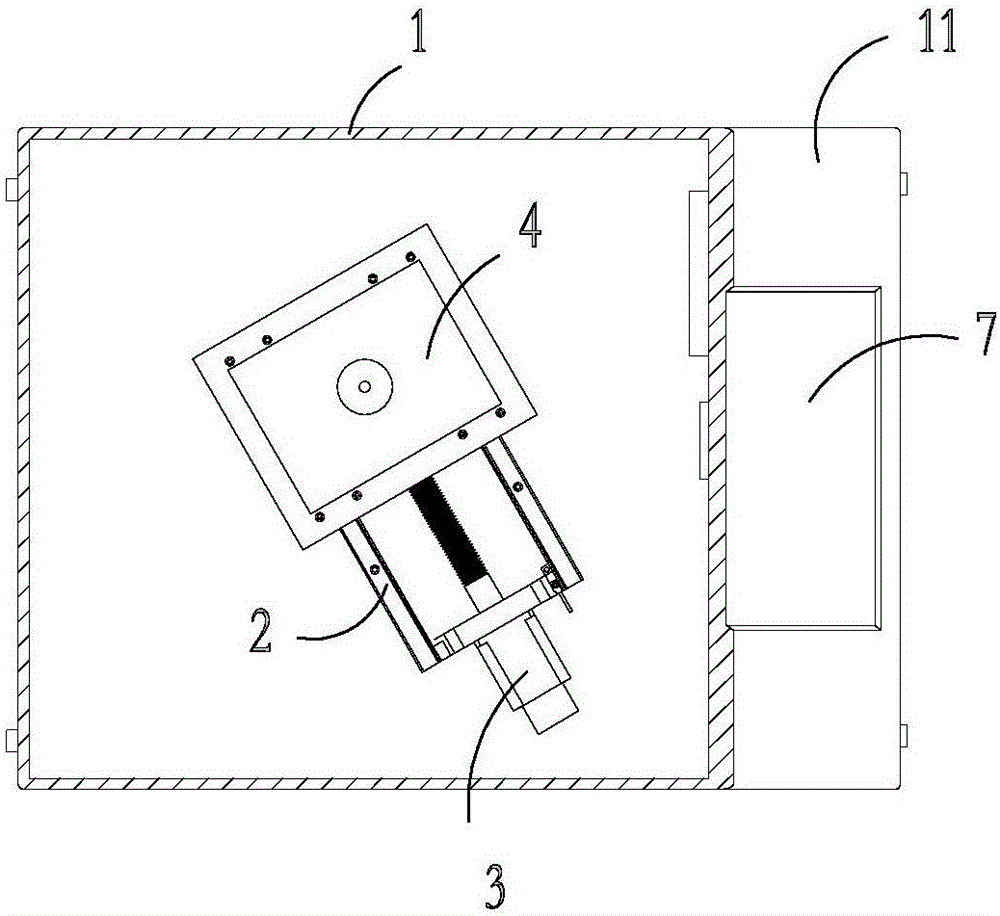

Experimental coke oven for small-scale production of coke and colloid layer samples and using method thereof

ActiveCN108398022ASimulation is accurateReal-time measurementCoke ovensFurnace typesCarbonizationColloid

The invention relates to an experimental coke oven for small-scale production of coke and colloid layer samples and a using method thereof. The experimental coke oven comprises a heating furnace, a reactor and a colloid layer sampler; the heating furnace is composed of a furnace shell, a heating furnace body, a carbonization chamber and a top split furnace door which are sequentially arranged fromoutside to inside; heating devices are arranged in the heating furnace body at the two ends of the carbonization chamber respectively; the reactor used for containing coal samples is arranged in thecarbonization chamber and is divided into a main reaction region and a colloid layer sampling region, and the main reaction region and the colloid layer sampling region are respectively close to two heating ends of the heating furnace body; and the colloid layer sampler is movably arranged in the colloid layer sampling region; and the top of the reactor is provided with a reactor upper cover, thereactor upper cover is provided with a gas outlet, a plurality of temperature sensors and a pressure sensor. The experimental coke oven can be used for accurately simulating the working conditions ofa large coke oven, and preparing the colloid layer samples and the coke samples for coking of single coal seed or coal blending; and meanwhile a colloid layer can be sampled at any time, and the experimental coke oven is simple in structure and convenient to operate.

Owner:UNIV OF SCI & TECH LIAONING

Suspension bleeding-proof water-based multicolor basic paint and preparation method thereof

The invention discloses a suspension bleeding-proof water-based multicolor basic paint and a preparation method thereof. The basic paint is prepared from the following materials by weight percent: 25-50% of deionized water, 0.3-1.4% of hydroxyethyl cellulose, 0.1-1.5% of PH regulator, 0.2-0.55% of dispersing auxiliary, 0.1-0.3% of wetting auxiliary, 0.1-0.5% of defoaming auxiliary, 1.0-5.0% of titanium dioxide, 10-40% of filler, 15-35% of self-crosslinking elastic emulsion, 0.2-0.6% of bactericidal and mildew-proof agent, 0.5-7.0% of hollow vitrified balls and 5.0-20% of protective colloid solution. The basic paint has the following beneficial effects that by adding the hollow vitrified balls, the density of the multicolor basic paint is greatly reduced and can keep consistent with that of the protective colloid solution, namely 1.03g / cm<3>.

Owner:重庆固安捷启中建材有限公司

Clay sand molding equipment and method

InactiveCN102416445AEasy to moveUniform hardnessMoulding machine componentsProduction lineProject area

The invention provides clay sand molding equipment and method, relating to the field of casting. In the clay sand molding equipment and method, a planker moving device is adopted, and a quantitative sand box and a molding sand box can be moved conveniently between a sand filling station and a compacting station, so that the defects of incapability of moving the sand box, the requirement of manual sand filling and high labor intensity existing in the conventional molding equipment are overcome; a molding mold body is arranged above, and structures with molding and compacting functions are arranged, so that the surface hardness of a sand mold is uniform; the quantitative sand box is adopted for filling sand, so that each box of sand mold has consistent sand mold density and compactness; a sand mold compacting device is adopted, so that the defects of overlarge size of a cylinder, insufficient compacting pressure and limitation on the molding projecting area existing in the conventional molding equipment are overcome; and a sand hopper structure is arranged above the sand filling station, so that manual sand filling is replaced, the labor intensity of workers is lowered, and convenience is brought to combination of a production line sand conveying system.

Owner:XUSHUI XINGHUA CASTING

Uniform distribution device for stone chips remained in municipal road construction

The invention provides a device for uniformly spreading stone chips after municipal road construction, which includes a threaded rod, a scraper, a scraper, a flattening roller and a spike roller; one end of the conveying shaft is connected across a circular material barrel In the bearing on the inner side of the top end of the support, a screw conveying leaf is also welded on the conveying shaft, and the threaded rod at the upper end of the inner side of the support passes through the hole to fix the sliding cross bar, and the flattening roller and the wolf tooth roller pass through the two. The fixed shaft at the end passes through the waist circle through hole and is screwed with a locking handwheel. The scraper plate is fixedly arranged on the bottom inner side of the two sets of sliding cross bars, and the front side of the lower end of the scraper plate is connected with a scraper plow by bolts. The height of the stone chips is adjusted by using the scraping plate and the scraping plow. At the same time, the scraping plow increases the strength of the scraping plate. The gap between the stone chips is adjusted through the teeth on the spike roller to ensure that the density of the stone chips after spreading is consistent. , and use the flattening roller to flatten the stone chips again, so that the stone chips on the road surface can be spread more evenly.

Owner:闻玉华

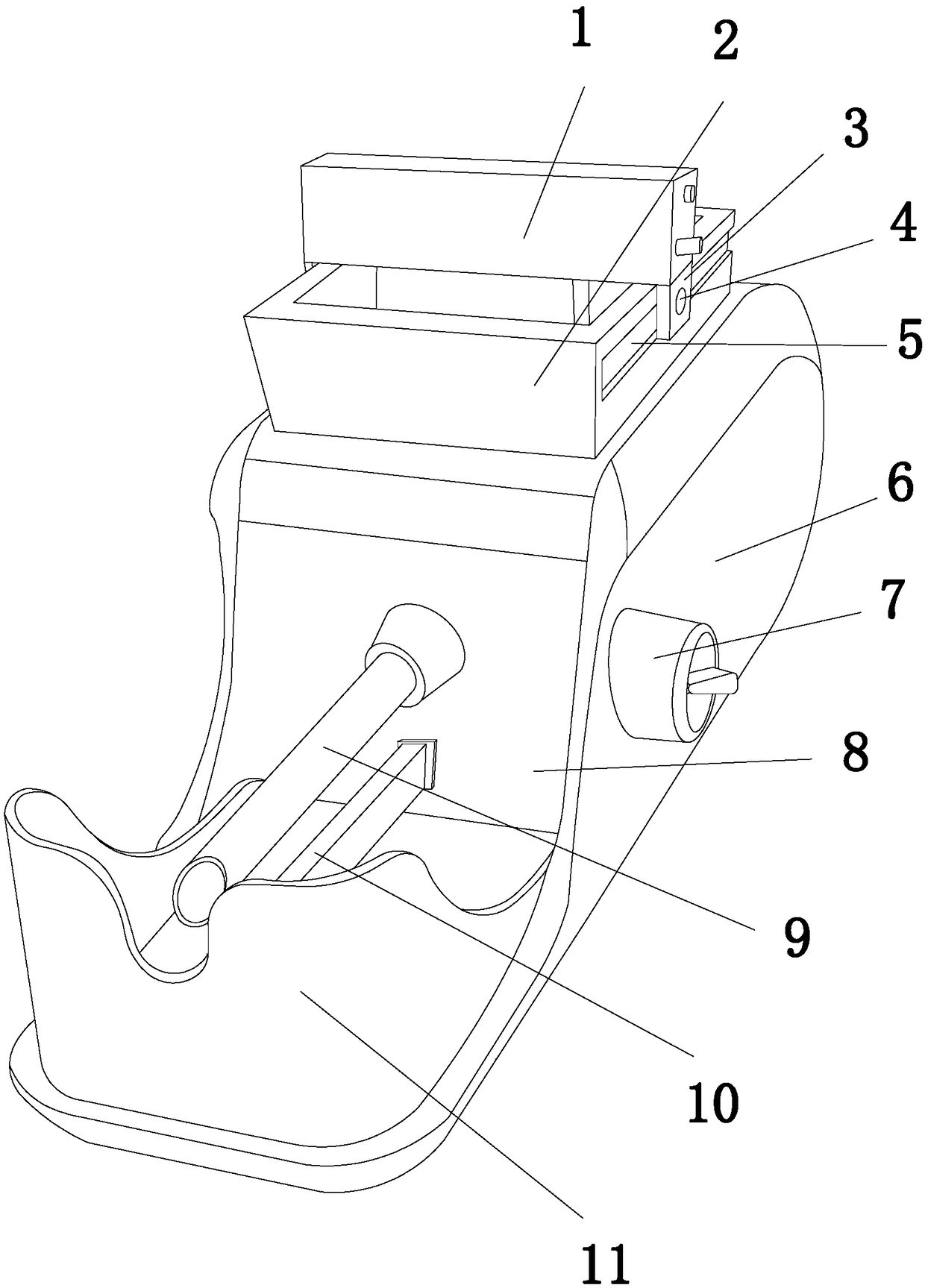

Cigarette making machine

InactiveCN108078001AQuality improvementRealize the push-down functionCigarette manufactureTelescopic cylinderEngineering

The invention discloses a novel cigarette making machine. The cigarette making machine comprises a stuffing groove, an intake chute, two movable stabilizer blades, a drive bolt, a drive chute, a shield, a control valve, a cigarette making machine body, a cut tobacco duct, a regulating lever, and an oddment box. The cigarette making machine has the advantages thatthe lifting pieceof the stuffing groove can lift up and down to control the main transmission rod to realize lifting function, and the main transmission rod can control the piston rod and the transmission cylinder for air compression.Then the liner of cylinder and the telescopic cylinder can be controlled, and the flexible mount can drive the pressing plate to expand and contract. Therefore, the press of the cut tobacco in the intake chute is effectively realized, ensuring the evenness of the cut tobacco, avoiding the appearance of hollows in the cigarette body, and improving the quality of cigarettes.

Owner:吴剑锋

Lake asphalt/SBR (styrene butadiene rubber) composite modifier and preparation method and application thereof

InactiveCN106893333AGood compatibilityGood dispersionBuilding insulationsCrack resistanceRoad surface

The invention relates to a lake asphalt / SBR (styrene butadiene rubber) composite modifier and a preparation method and application thereof. The lake asphalt / SBR composite modifier is a pre-dispersed material formed by the lake asphalt, polymer SBR and a compatilizer via melt blending, and the modified asphalt can be obtained by melt blending of petroleum asphalt and a stabilizer. The lake asphalt / SBR composite modifier is the pre-dispersed material capable of remarkably improving capacities of high-temperature deformation, low-temperature cracking resistance and anti-water damage, the pre-dispersed material is then added to the petroleum asphalt, and the lake asphalt / SBR composite modified asphalt uniform in dispersion and less prone to layered segregation by the aid of the advantage of good compatibility of the pre-dispersed material and the petroleum asphalt; the modified asphalt is applied to construction of heavy traffic asphalt pavement of high-temperature, moist and rainy regions, asphalt pavement diseases can be remarkably reduced, pavement maintenance cost is lowered, and service life of the asphalt pavement is prolonged.

Owner:FUZHOU UNIV

Microorganism streak inoculation instrument

InactiveCN105886383AGood spiral scribing effectConsistent densityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

A microorganism streak inoculation instrument comprises a shell, a guide rail, a linear movement motor, a rotary motor, a motor controller, a rotary platform, a control panel and a sensor, wherein the rotary platform, the control panel and the sensor are arranged at the upper end of the shell, the guide rail is horizontally arranged inside the shell, a strip-shaped hole is formed above the shell, and the strip-shaped hole extends in the direction the guide rail extends; an output shaft of the linear movement motor is connected with a guide plate arranged on the guide rail in a sliding mode, and an output shaft of the rotary motor penetrates through the strip-shaped hole in the vertical direction and then is fixedly connected with the rotary platform to drive the rotary platform to rotate; the linear movement motor, the rotary motor, the control panel and the sensor are electrically connected with the motor controller, signals are transmitted to the motor controller by the sensor, and the motor controller sends an instruction to the linear movement motor and the rotary motor to control the linear movement motor and the rotary motor to be opened and closed. By the adoption of the instrument, a good inoculating loop spiral streaking effect can be realized.

Owner:CHONGQING PANG TONG MEDICAL DEVICES

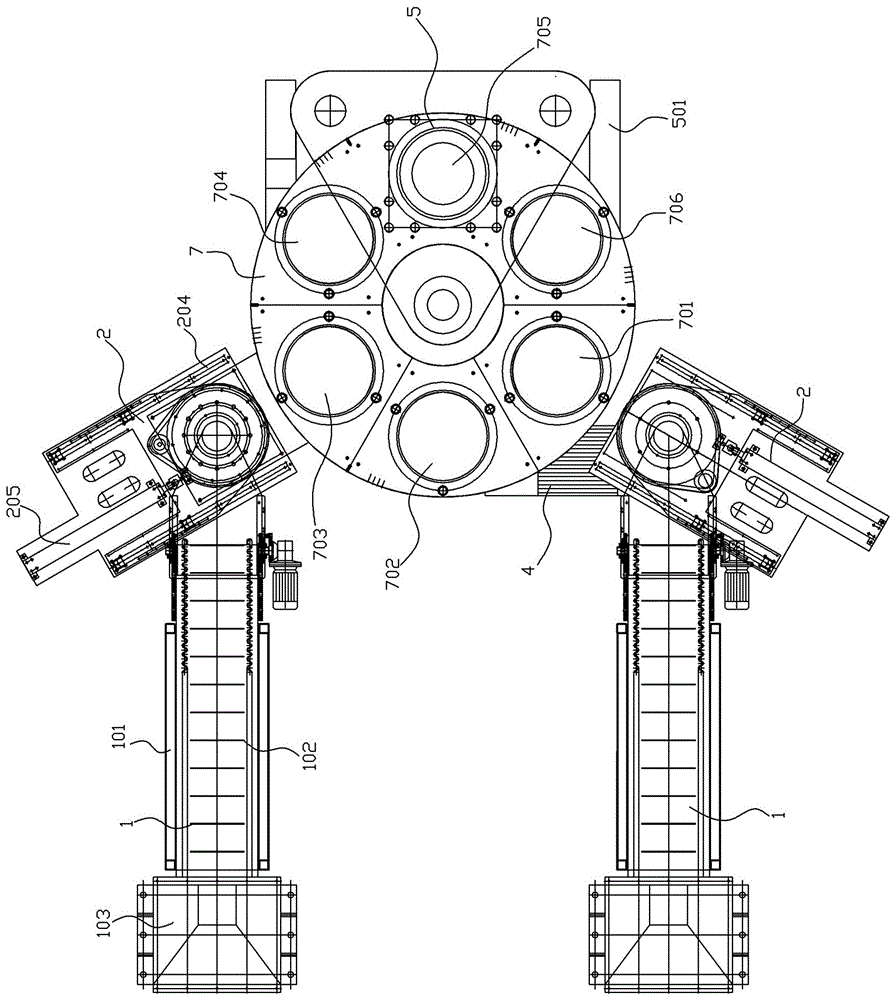

Full-automatic rotary multi-station grinding wheel forming machine

ActiveCN106041770AHigh purityQuality improvementGrinding devicesNumerical controlUltimate tensile strength

The invention relates to the technical field of grinding materials, grinding tools and grinding wheels, particularly to a full-automatic rotary multi-station grinding wheel forming machine which comprises lifting conveying mechanisms, pushing and scraping mechanisms, a constant-volume adjusting mechanism, a worktable transmission power mechanism, a compression forming mechanism, a demoulding ejection mechanism, a mould mounting frame and a numerical control unit, wherein a plurality of mould cavities are uniformly distributed on the mould mounting frame in a circumferential direction; each mould cavity correspond to one station, and the mould cavities correspond to a primary scraping station, a screen piece placing station, a secondary scraping station, a core ring placing station, a compression station and a demoulding station in sequence; and any one of the six stations is controlled to open or close according to needs. According to the full-automatic rotary multi-station grinding wheel forming machine, feeding, pushing and scraping, adjusting, compression and finished product ejection are all completed automatically, so that the equipment reliability and the degree of automation are greatly improved, and meanwhile the labor intensity of workers is lowered; and owing to automatic production the production efficiency, the product quality and the product conformity are all improved remarkably.

Owner:ZHENGZHOU HONGYI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com