Swing type multi-rod blocking edge for blanking pad plate

A swing-type, padding technology, which is applied in lamination devices, lamination, household components, etc., can solve the problems of product board edge density, low strength, waste, edge collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

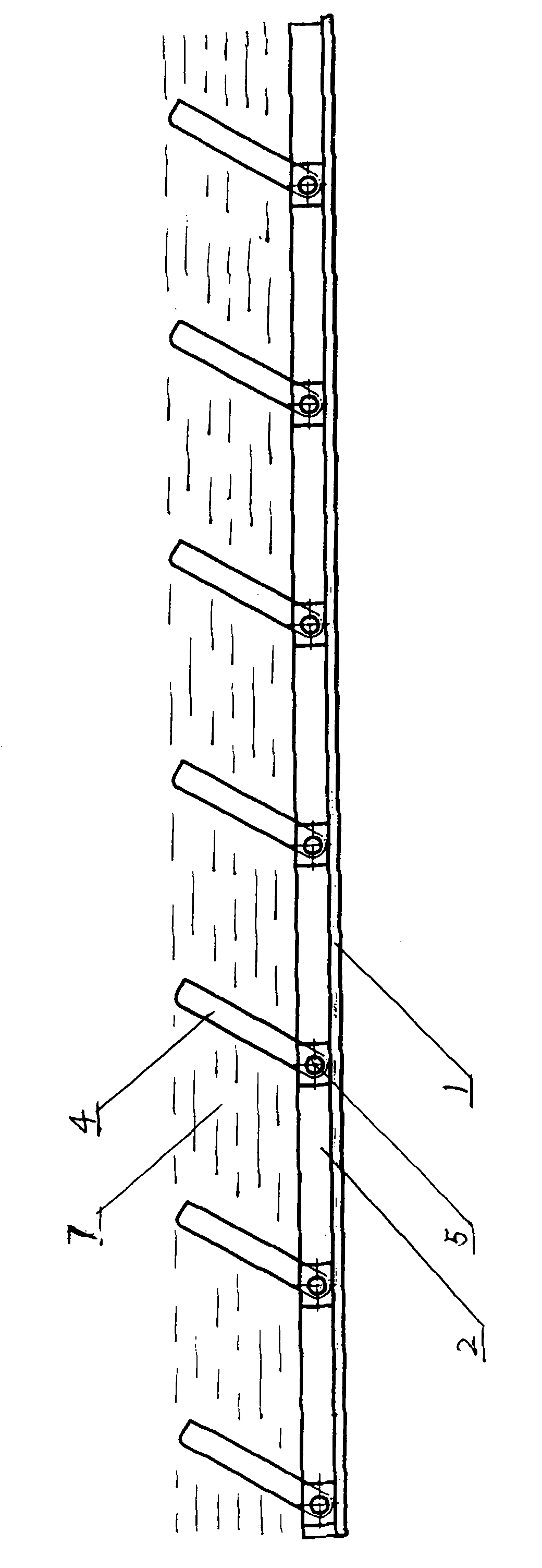

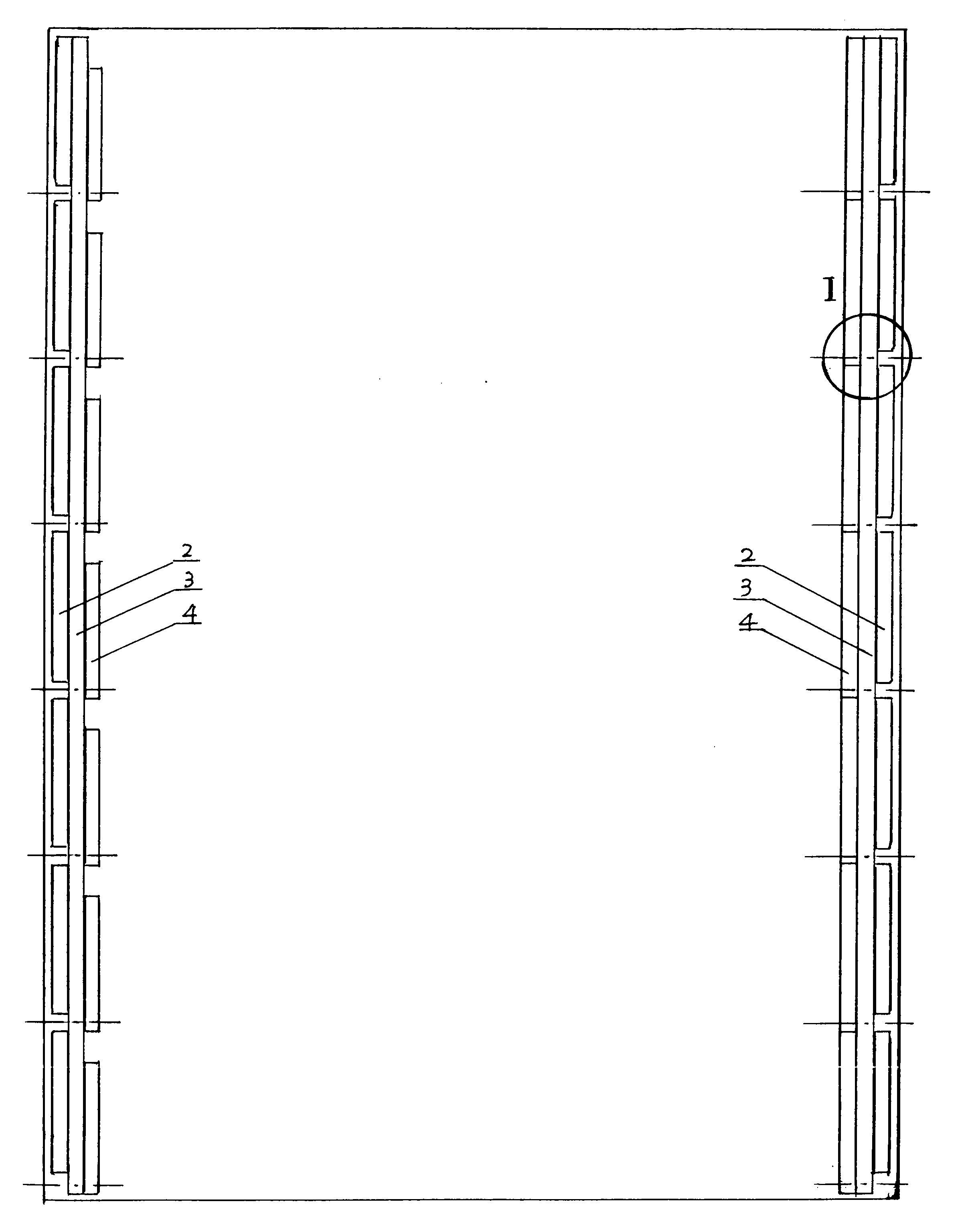

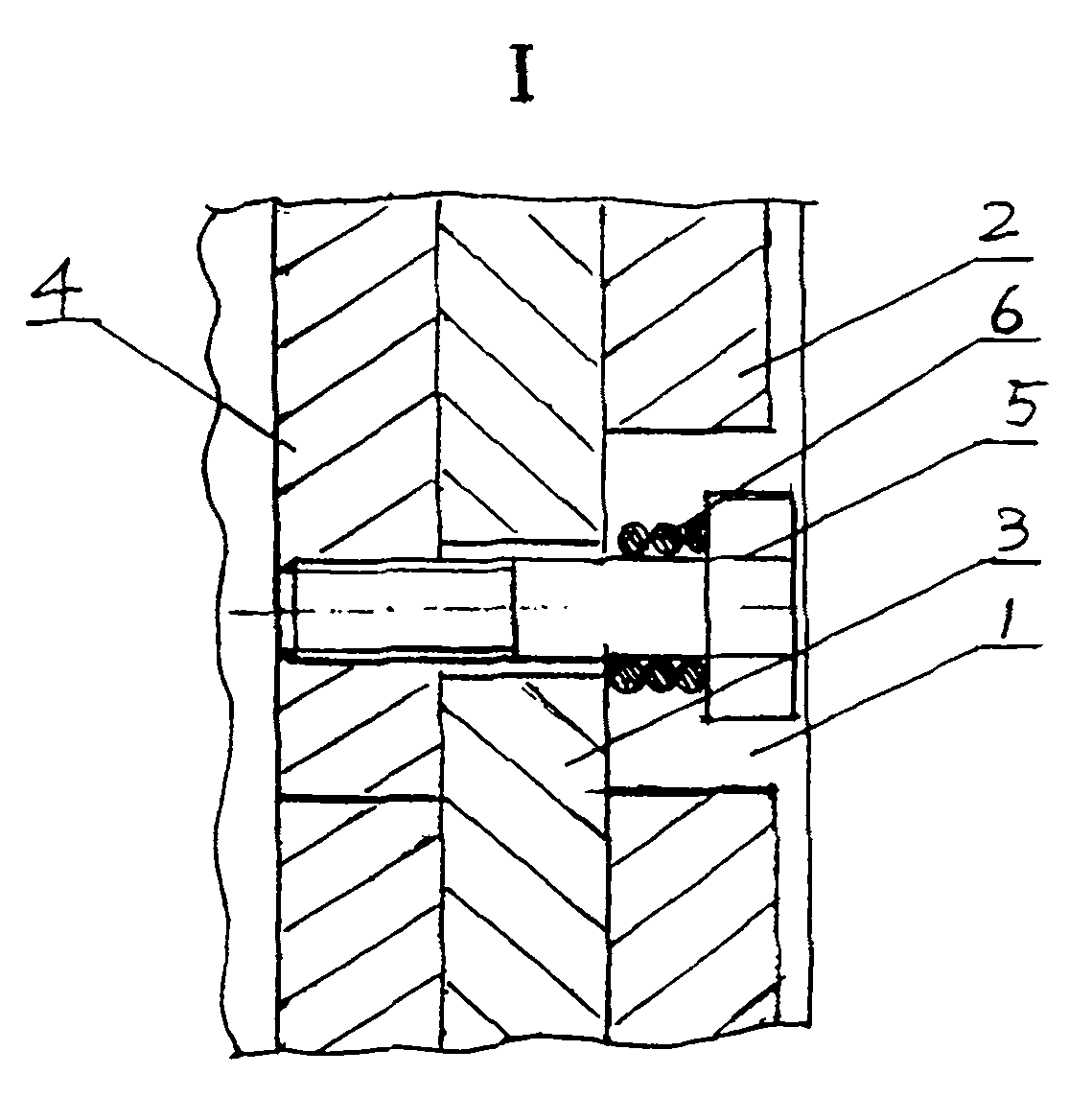

[0013] A specific embodiment of the present invention is as attached figure 1 , 2 , 3, and 4, including stoppers 2, bottom rods 3, and multiple movable stoppers 4 arranged sequentially from the outside to the inside along the longitudinal two sides of the surface of the blank backing plate 1, the stoppers 2 are fixed on the backing plate, and the stoppers On the outside of the bottom bar 3 , multiple movable stop bars 4 are connected to the inside of the bottom bar 3 by bolts 5 . The movable bar 4 can be tilted at any angle less than 90° or lie down horizontally. When lying down horizontally, the adjacent movable bar 4 is connected end to end, and the maximum inclination angle of the active bar in practical applications is 80°. The stoppers 2 are arranged in multiple pieces along the longitudinal direction of the backing plate 1, and are arranged at even intervals. The bolts 5 are arranged between two adjacent stoppers, and the bolts 5 connecting the bottom bar 3 and the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com