Uniform distribution device for stone chips remained in municipal road construction

A technology for municipal roads and stone chips, which is applied in the field of stone chips uniform distribution device, can solve the problems of large difference in stone chip bulk density and inability to adjust the height of stone chip distribution, and achieve the same height, increased strength, and stone chip spray uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

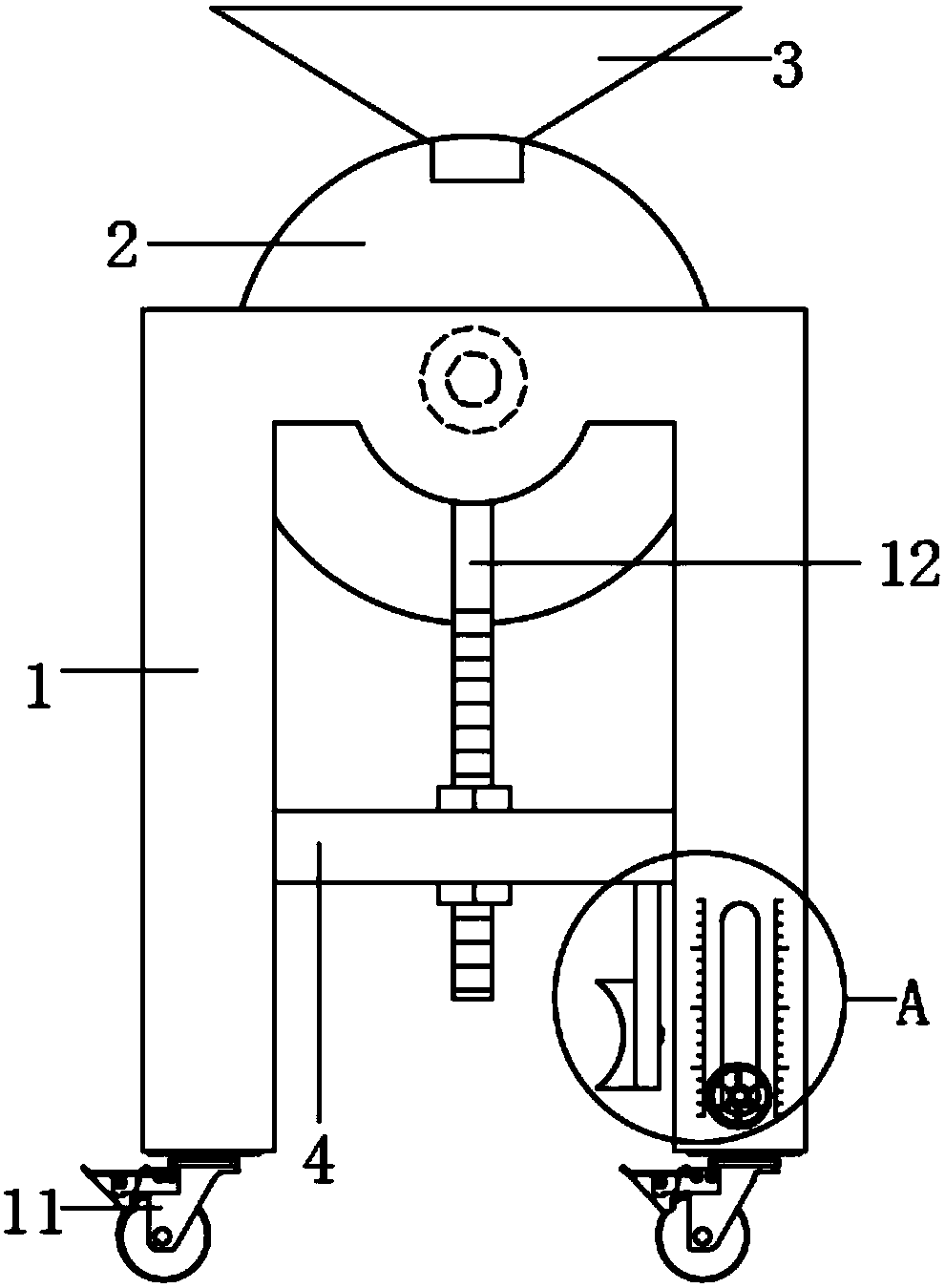

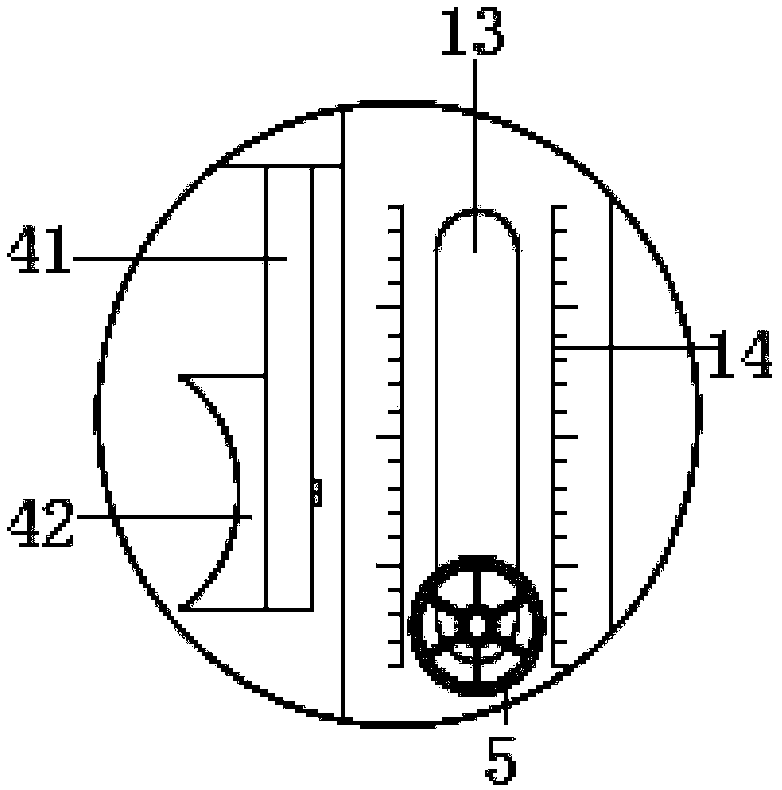

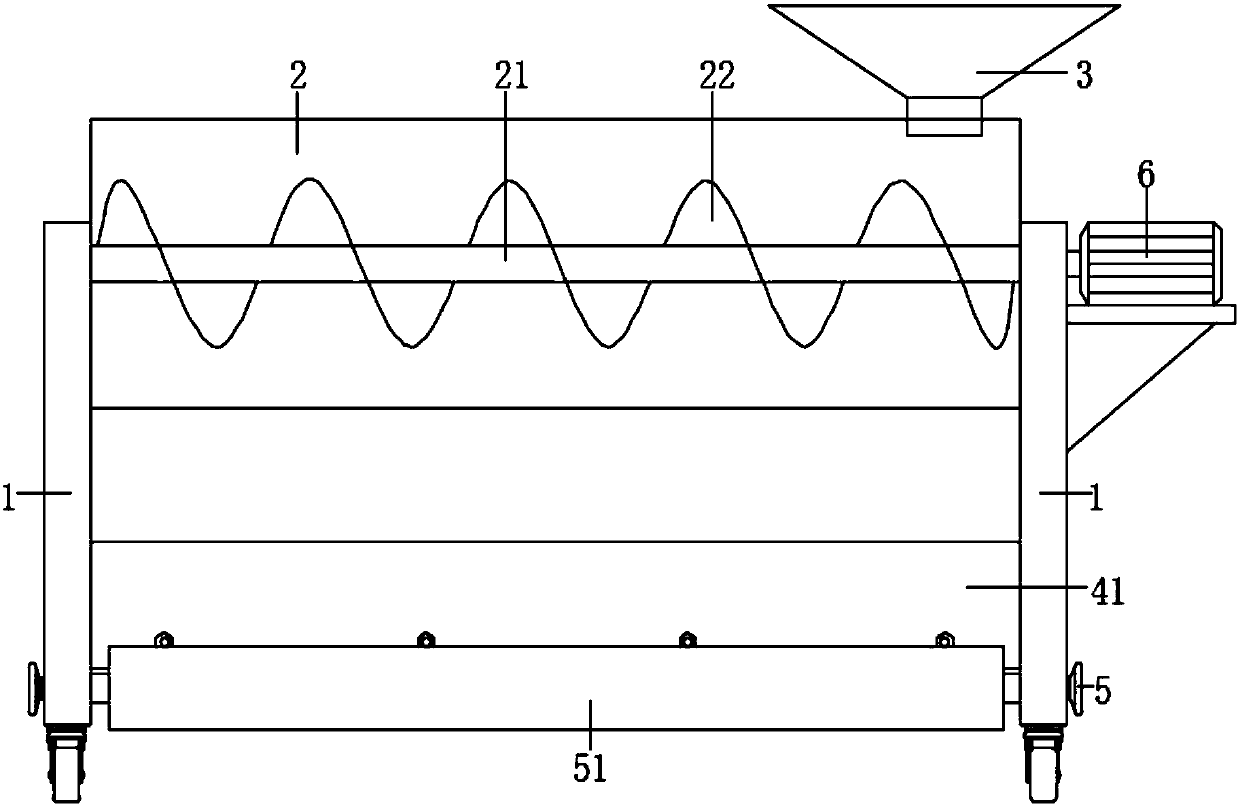

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a device for evenly spreading stone chips after municipal road construction, which includes a bracket 1, a sliding roller 11, a threaded rod 12, a round through hole 13, a scale line 14, a chute 15, a circular material bucket 2, and a conveying shaft 21. Spiral conveying blade 22, discharge hole 23, feeding hopper 3, sliding bar 4, scraping plate 41, scraping plow 42, penetration hole 43, T-shaped slider 44, locking handwheel 5, flattening Roller 51, Spike roller 52 and motor 6; The circular feed bucket 2 is fixedly mounted on the inside of the top of the two groups of brackets 1, and the feed hopper 3 is screwed to the internal threaded hole at the top end of the circular feed bucket 2 24, one end of the delivery shaft 21 crosses the circular barrel 2 and is connected to the bearing inside the top end of the support 1, and the other end of the delivery shaft 21 is connected with a motor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com