Cigarette making machine

A cigarette making machine, a new type of technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of pressing down the shredded tobacco with equal force, easy hollowing, inconsistent cutting speed of shredded tobacco, etc., and achieve the effect of ensuring the amount of tobacco leaves and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

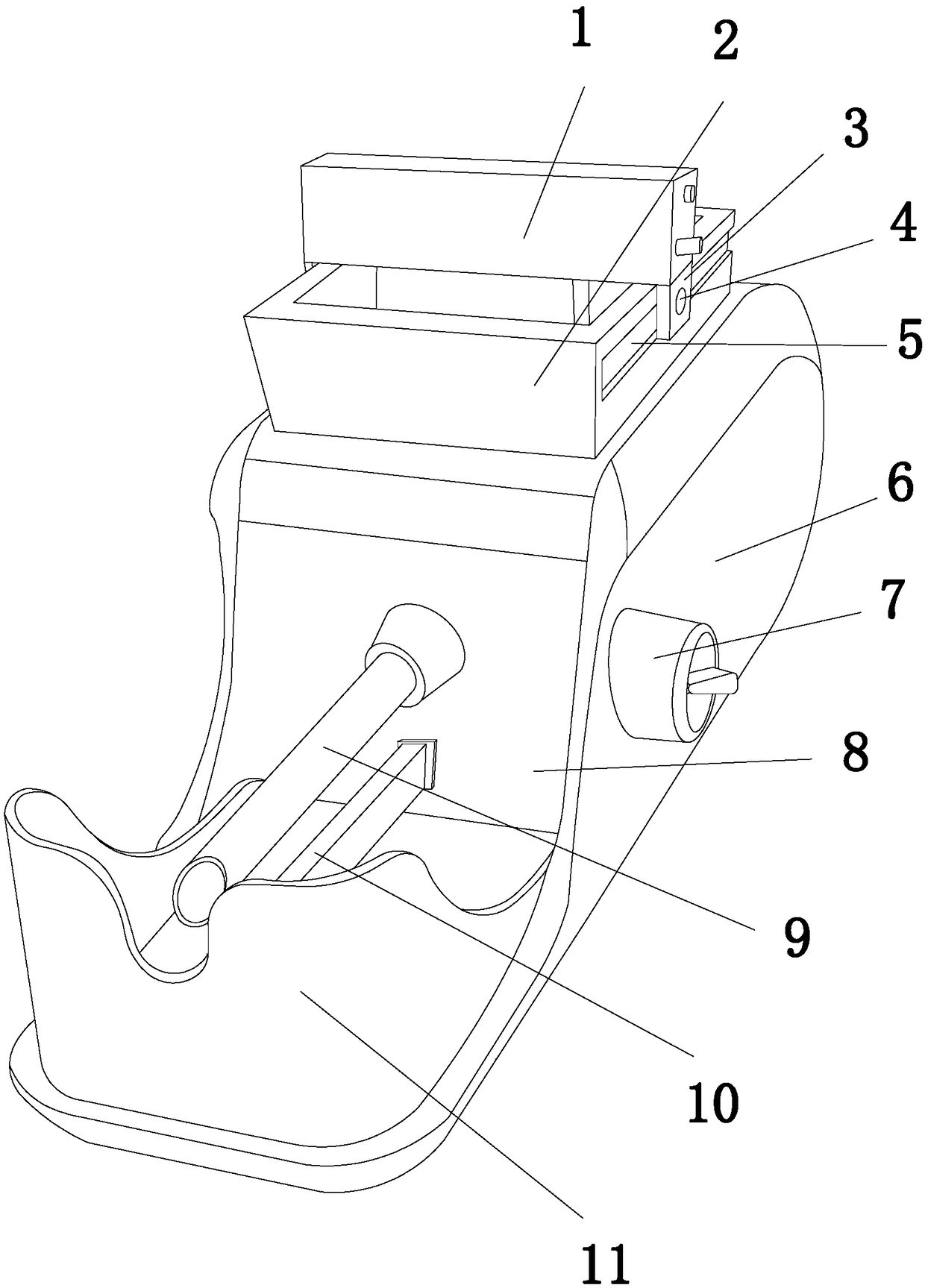

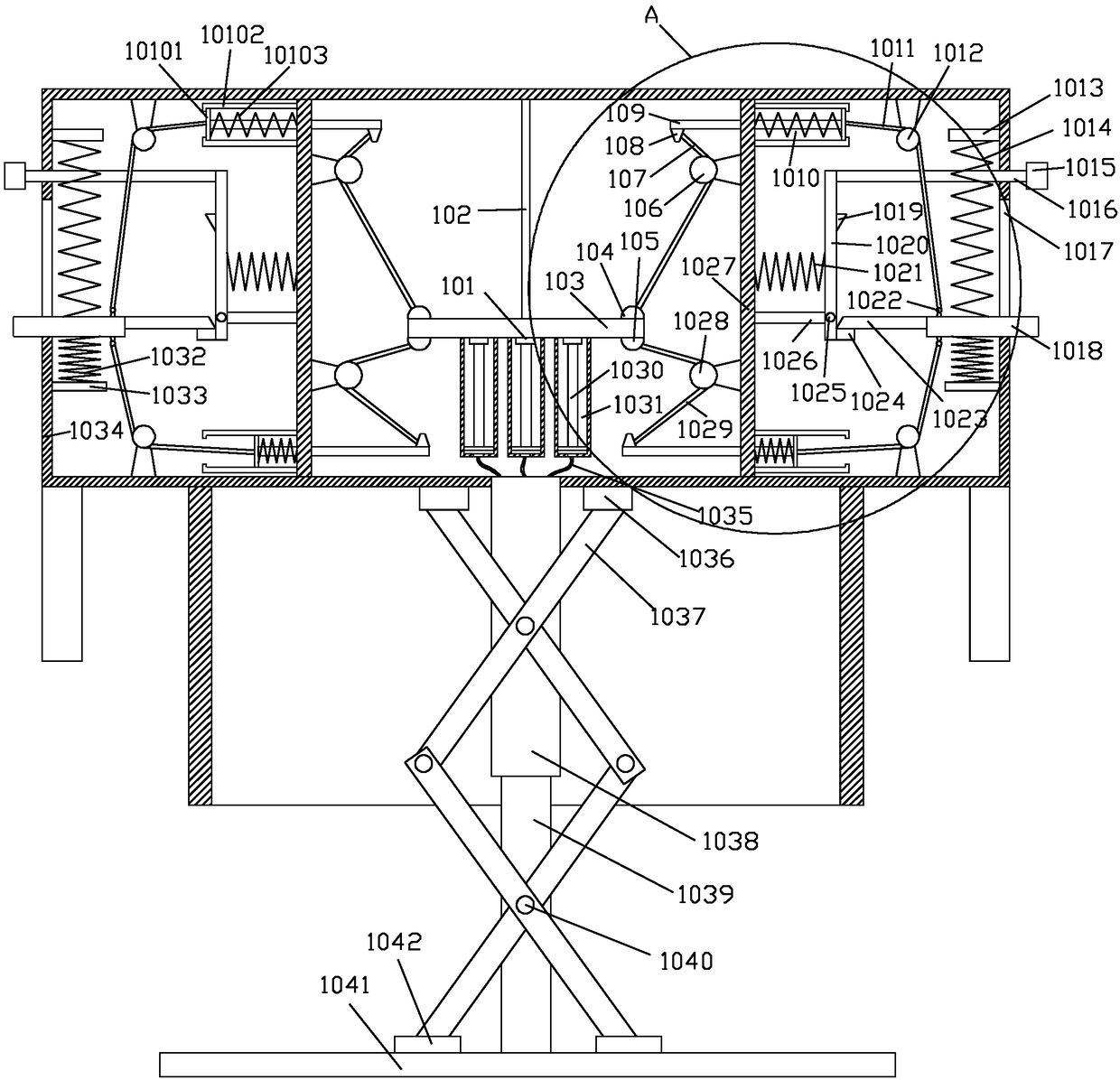

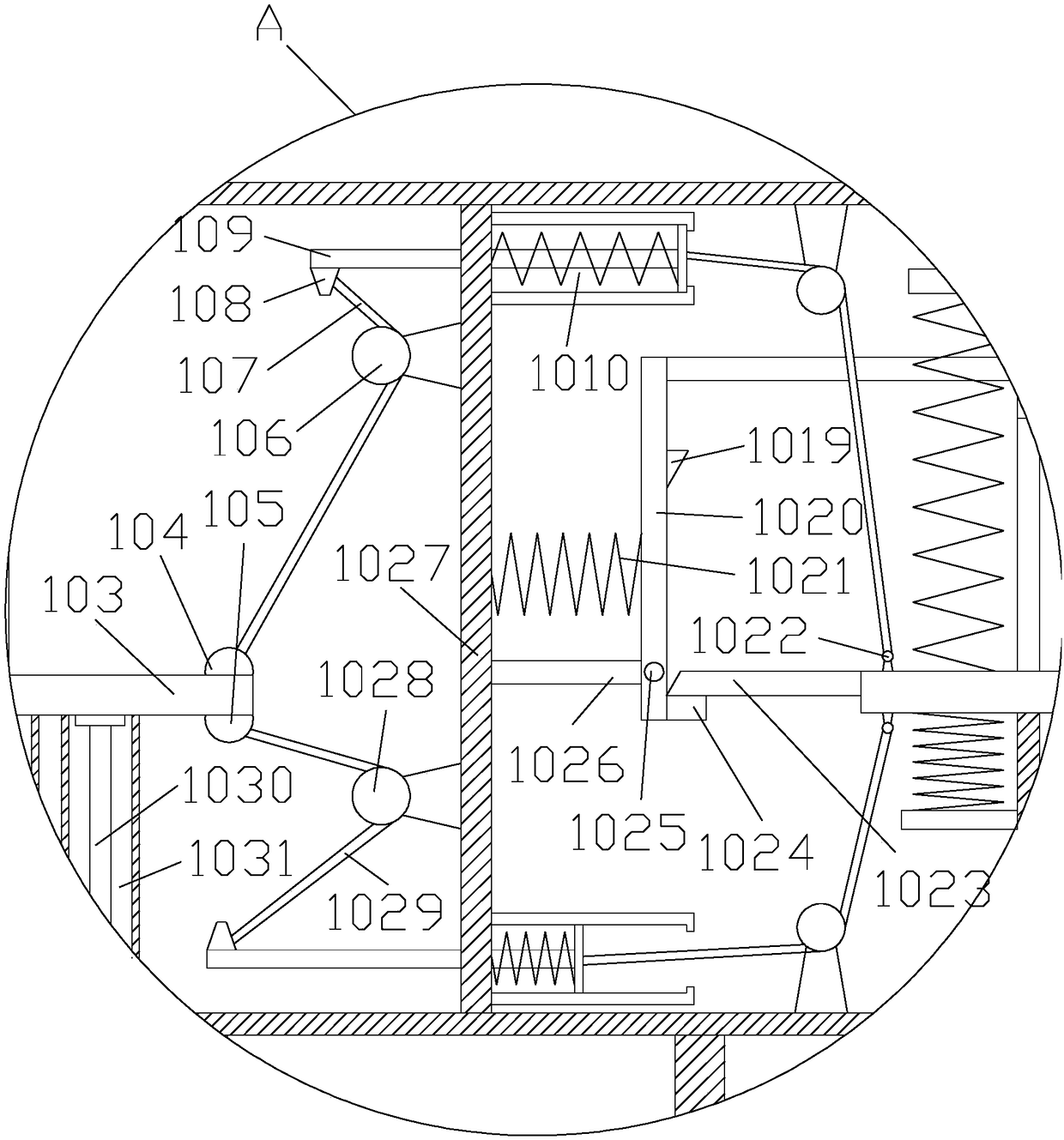

[0020] see Figure 1-Figure 4, the present invention provides a new type of cigarette making machine: its structure includes a presser 1, a feeding trough 2, a moving foot 3, a transmission bolt 4, a transmission groove 5, a protective cover 6, a regulating valve 7, a cigarette main unit 8, a cigarette pipe 9. Adjust the pressure rod 10 and the remaining material box 11. The left and right sides of the feed chute 2 are provided with transmission grooves 5 and are integrally formed. The two ends of the presser 1 are provided with moving feet 3 and integrated Forming structure, the two moving feet 3 are interlocked with the transmission groove 5 through the transmission bolt 4, the cigarette tube 9 is a cylindrical structure and the rear end is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com