Mixing stirring machine

A technology for mixers and mixing tanks, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., and can solve problems such as uneven thickness of fillings, difficulty in taking out, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

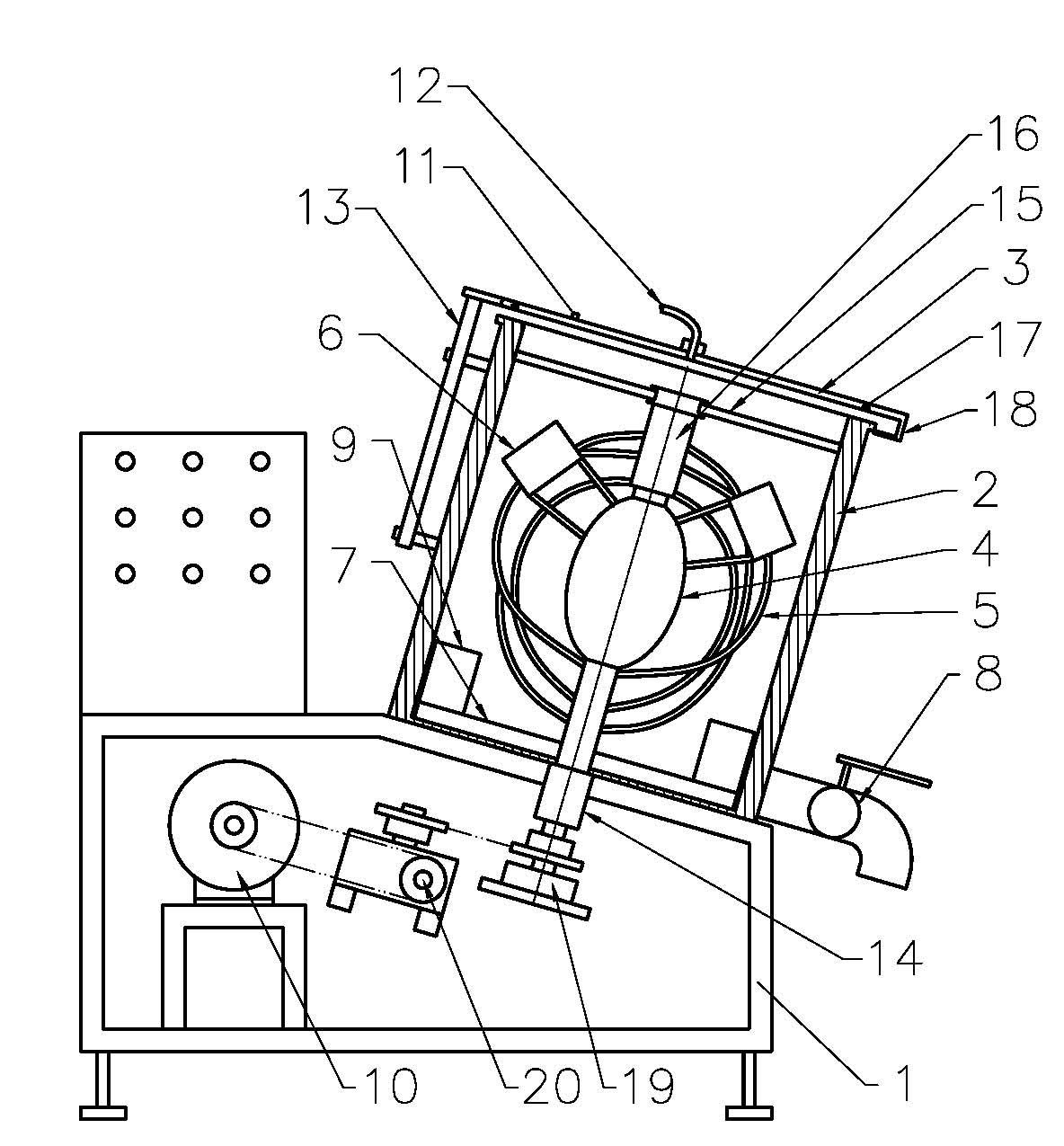

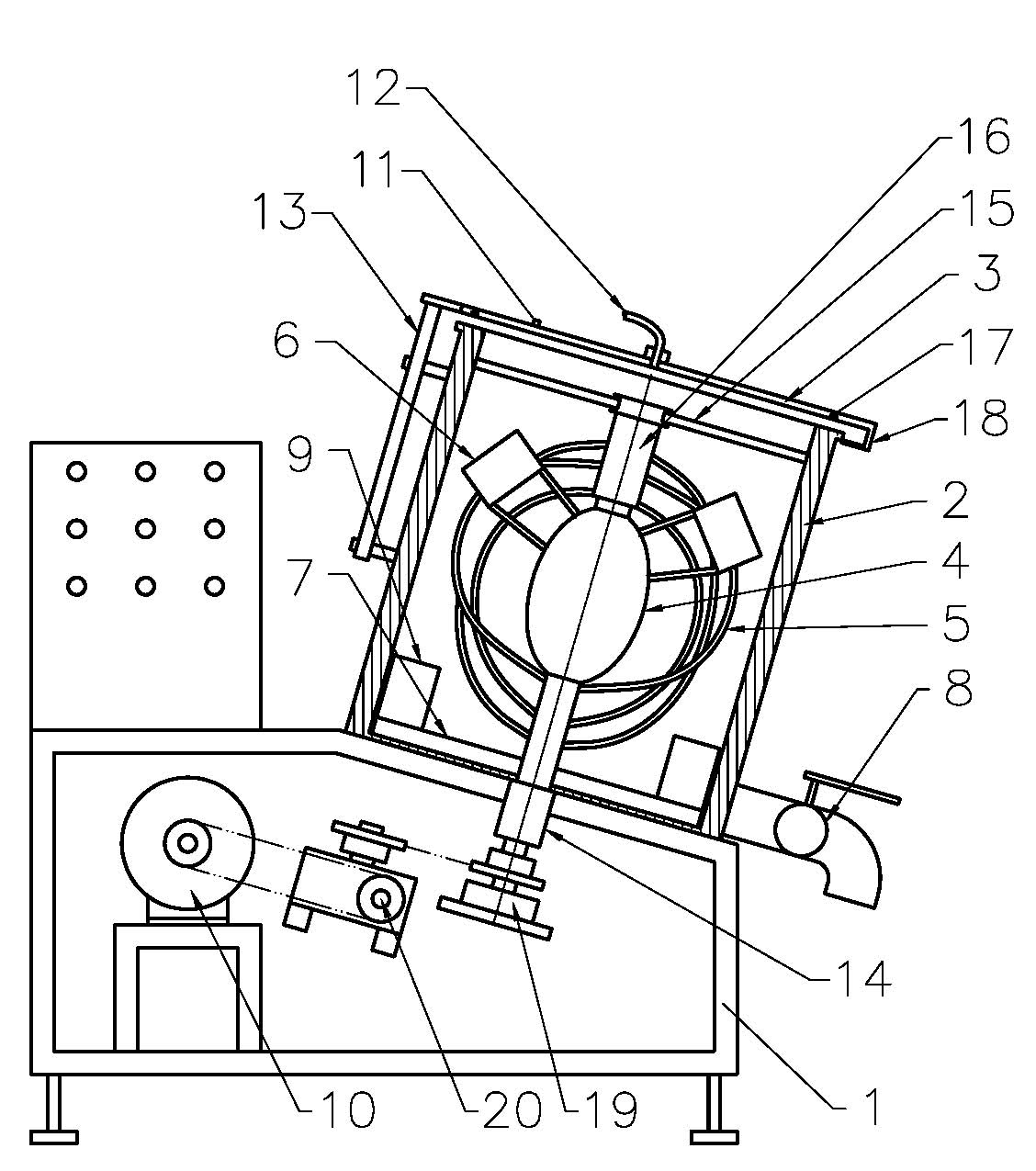

[0022] Embodiment 1, see figure 1 ,

[0023] A mixing mixer, which comprises a mixing tank, a stirring device, a driving mechanism and a frame 1, the stirring device is arranged in the mixing tank, the mixing tank is arranged on the frame 1, and the stirring device includes a stirring ball 16 and a scraper at the bottom of the bucket 7 and the side scraper 9, the side scraper 9 is arranged at the end of the bucket bottom scraper 7, the bucket bottom scraper 7 is arranged at the bottom of the mixing bucket, the stirring ball 16 and the bucket bottom scraper 7 are connected with the driving mechanism, and the mixing ball 16 includes a sealing ball 4 surrounded by a steel wire 5 , and a lower pressing plate 6 is arranged on the steel wire 5 .

[0024] The function of the sealing ball 4 is to push and spread the material statically accumulated in the center to the surrounding when stirring. The outer periphery of the sealing ball 4 is a stirring steel wire 5, which is used to st...

Embodiment 2

[0034] Embodiment 2, see figure 1

[0035] A kind of mixing mixer, it comprises mixing tank, stirring device and frame 1, and stirring device is arranged in the mixing tank, and mixing tank is arranged on frame 1, and described stirring device comprises stirring ball 16 and bucket bottom scraper 7 and side The scraper 9 and the side scraper 9 are arranged at the end of the scraper 7 at the bottom of the barrel, the scraper 7 at the bottom of the barrel is arranged at the bottom of the mixing barrel, the stirring ball 16 and the scraper 7 at the bottom of the barrel are connected with the driving mechanism, and the stirring ball 16 includes a sealing Steel wire strips 5 interwoven in different directions are arranged around the ball 4 and the sealing ball 4 , and a lower pressing plate 6 is arranged on the steel wire strips 5 .

[0036] The function of the sealing ball 4 is to push and spread the material statically accumulated in the center to the surrounding when stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com