Patents

Literature

244 results about "Skin thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Your Skin Basics. The actual thickness of your skin is different throughout the body. The thinnest skin — about 0.5 millimeter in thickness — is found on the eyelids, while the thickest skin, at about 4 mm, is on the palms of your hands and soles of your feet.

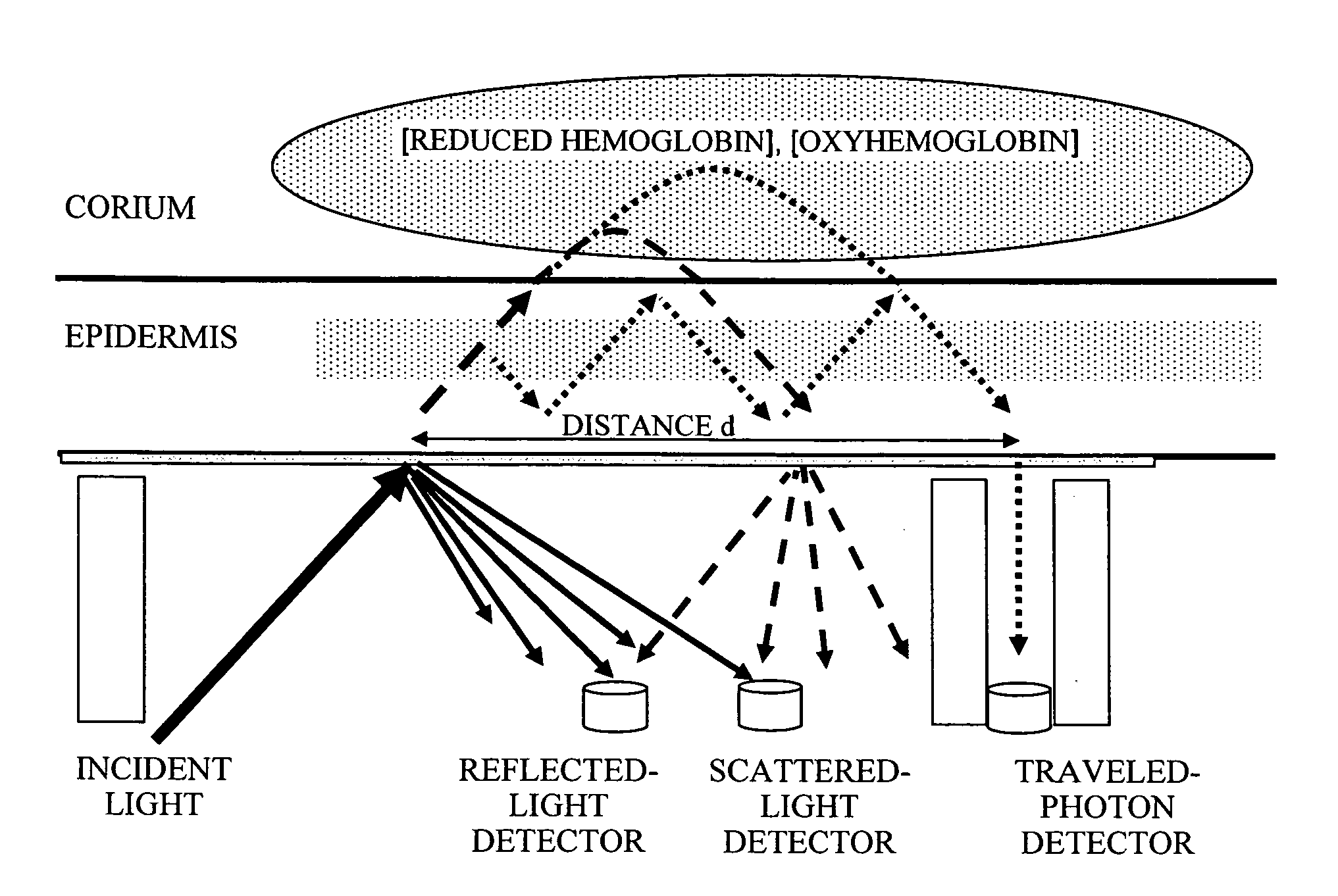

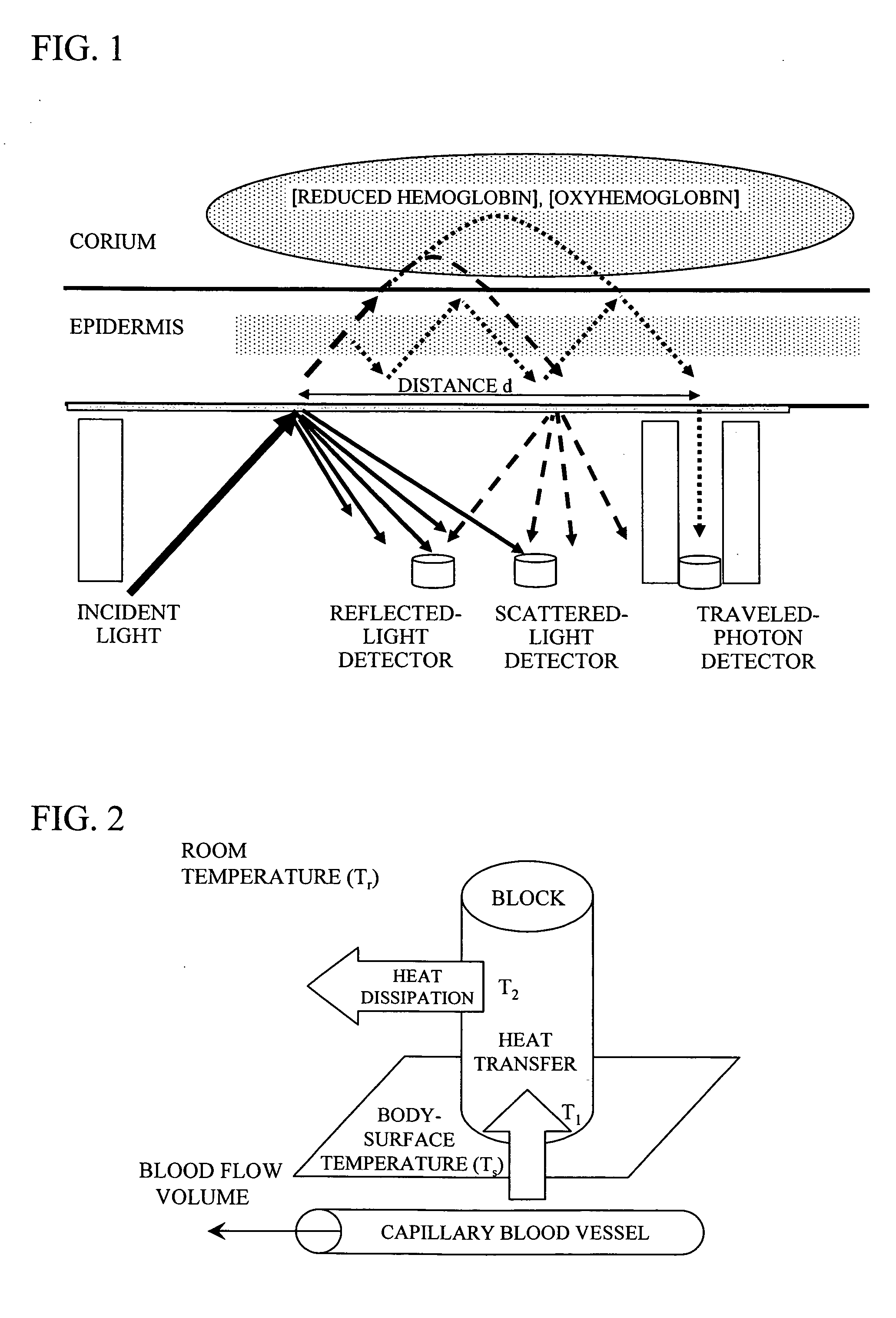

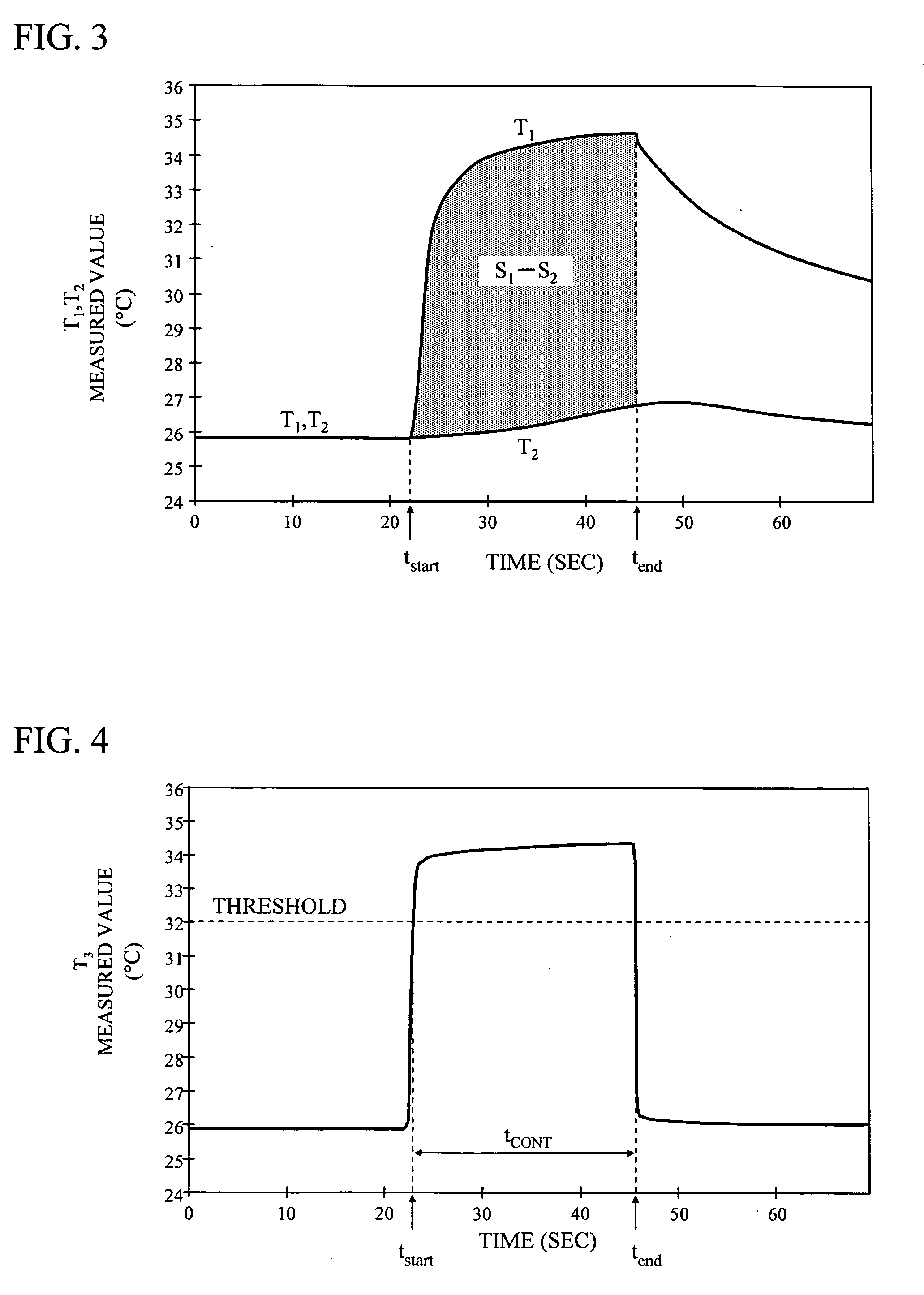

Optical measurements apparatus and blood sugar level measuring apparatus using the same

InactiveUS7254427B2Blood sugar levelScattering properties measurementsSensorsOptical measurementsBlood sugar

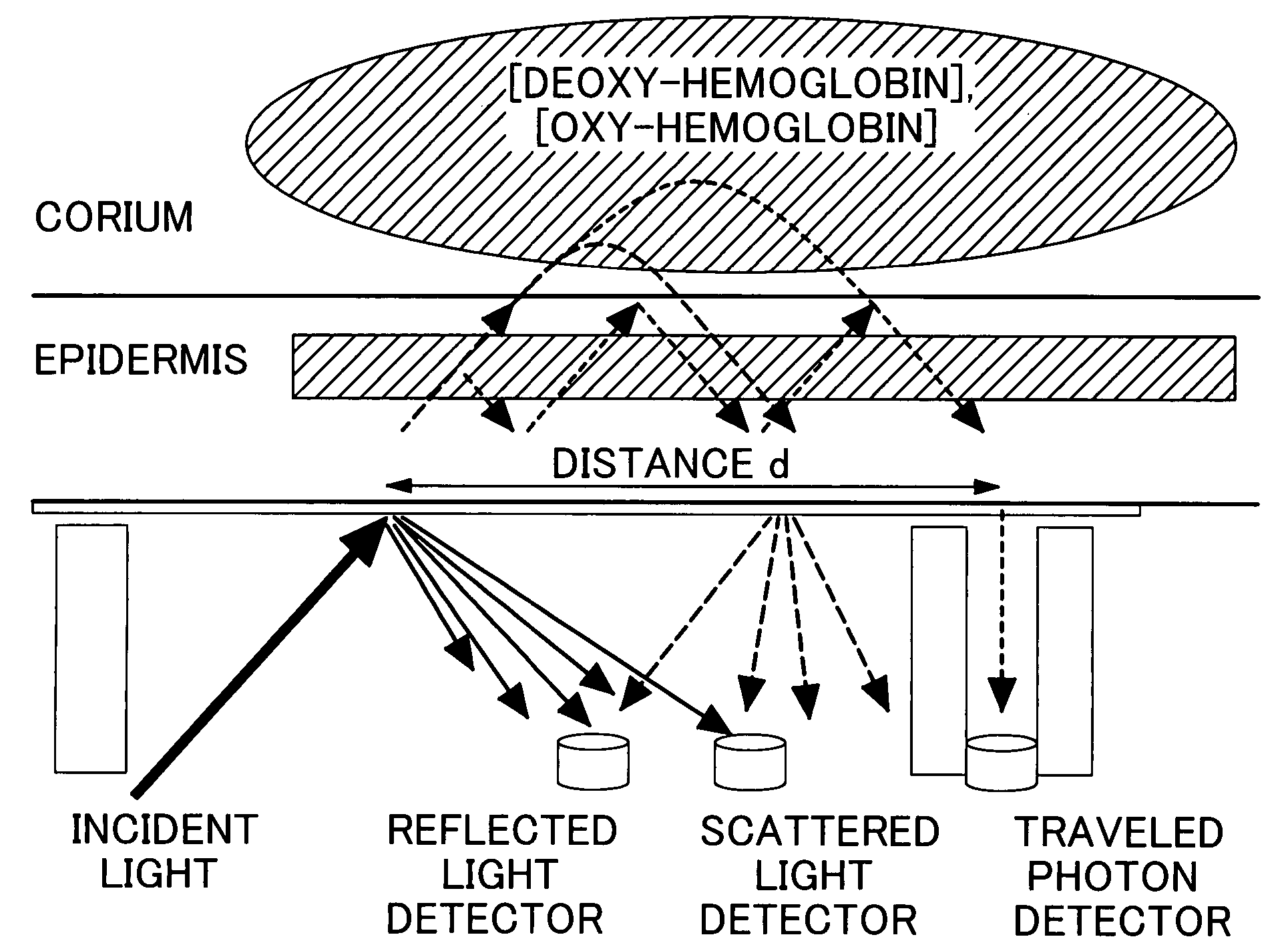

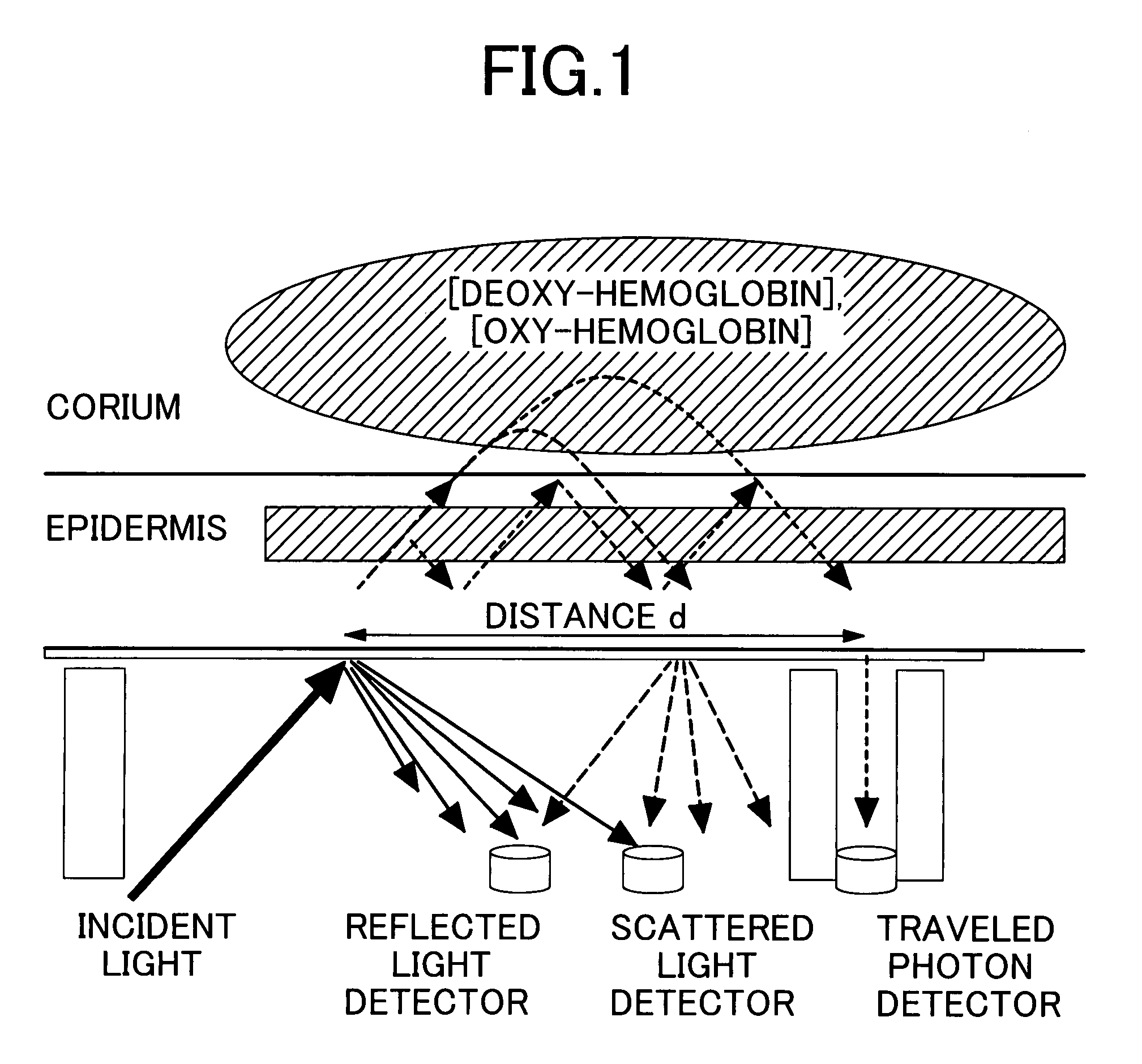

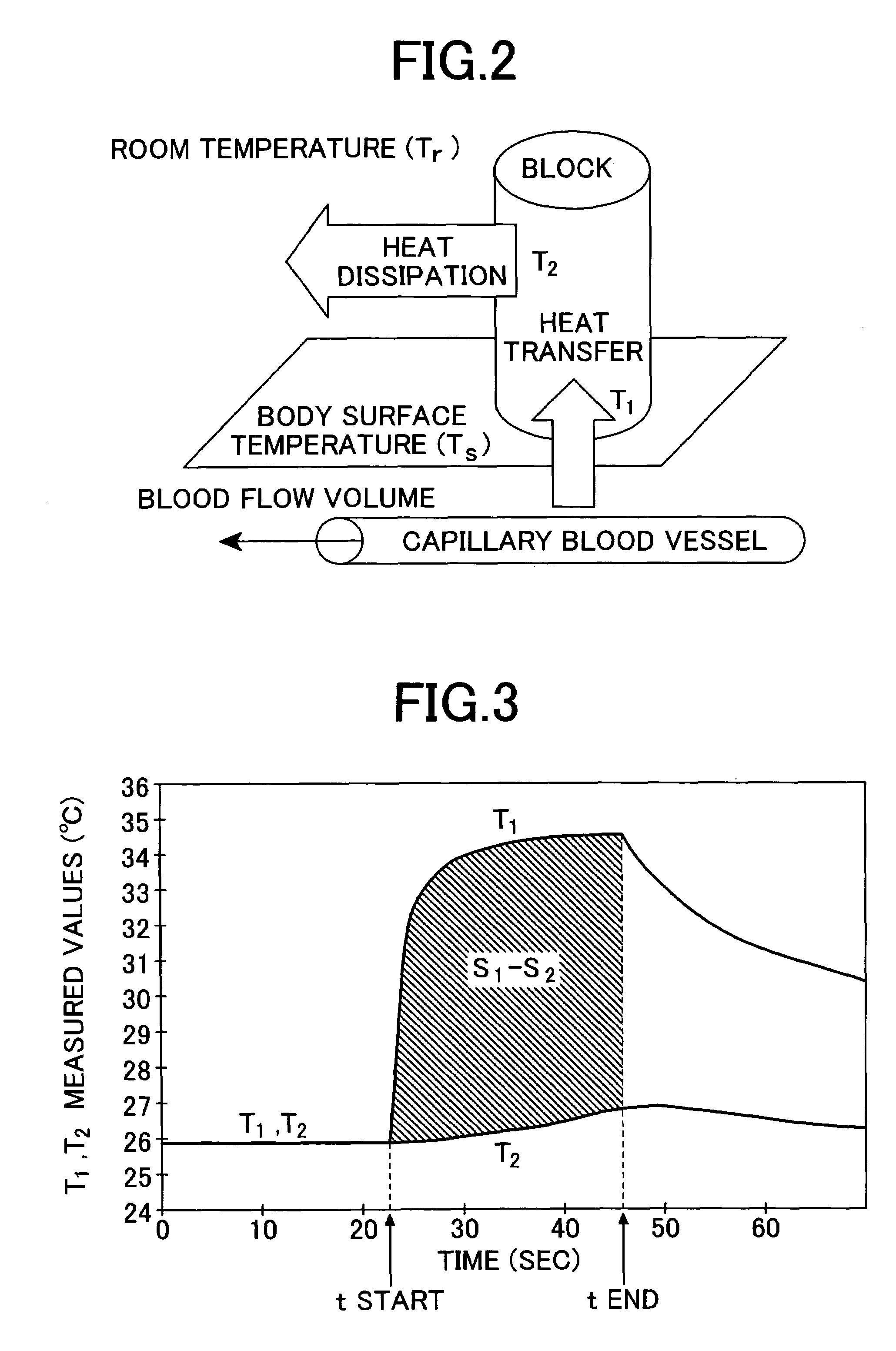

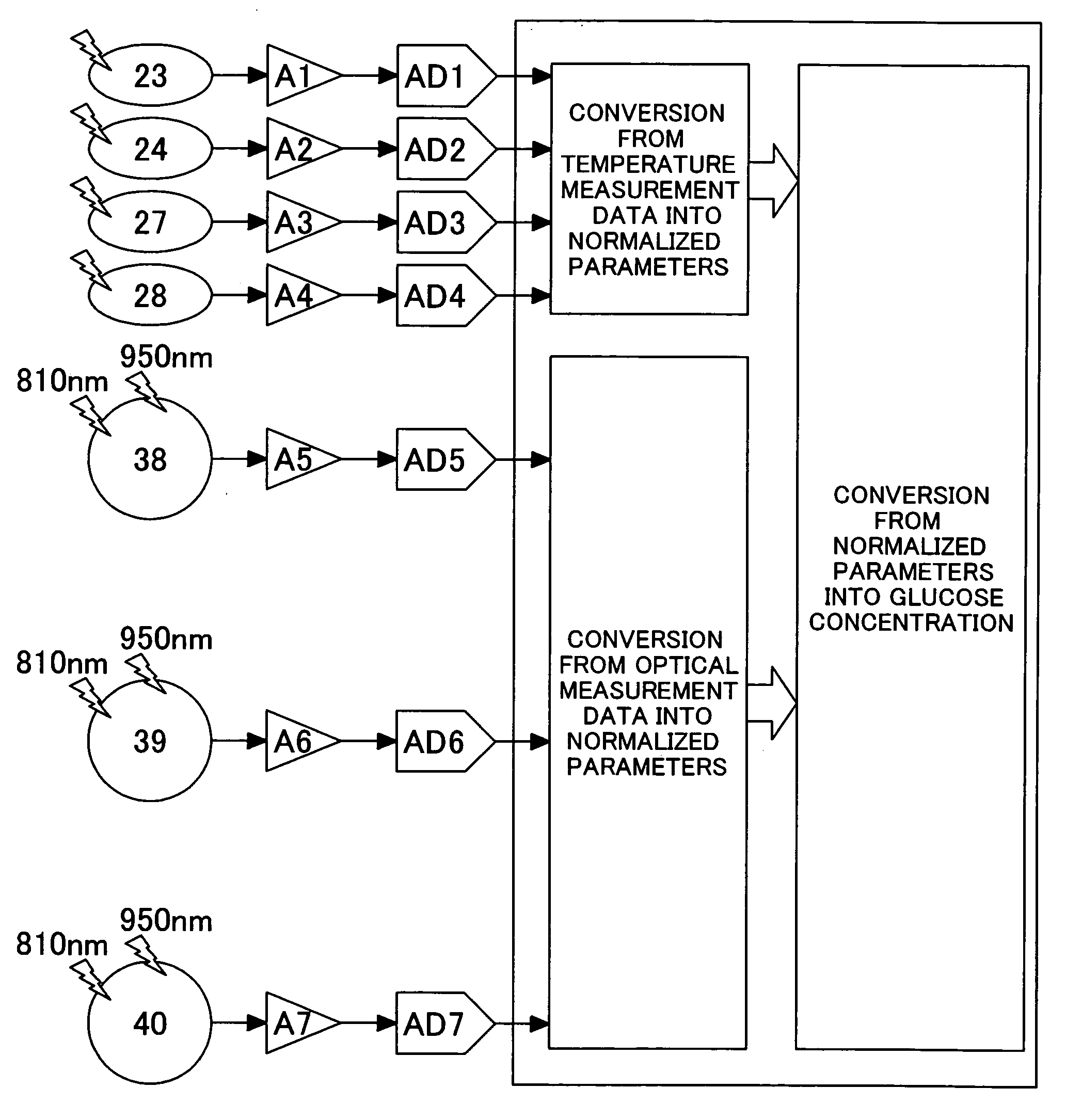

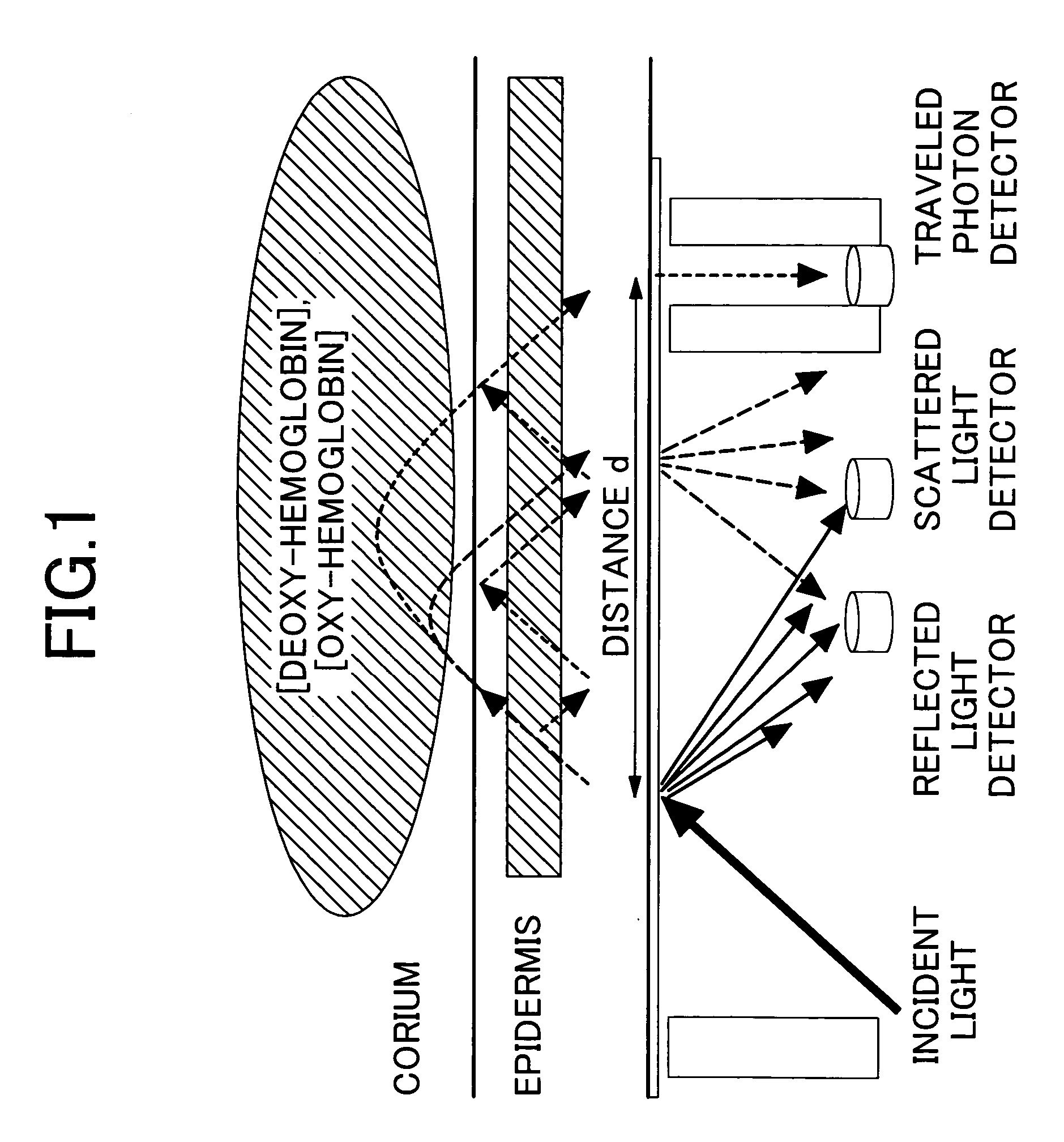

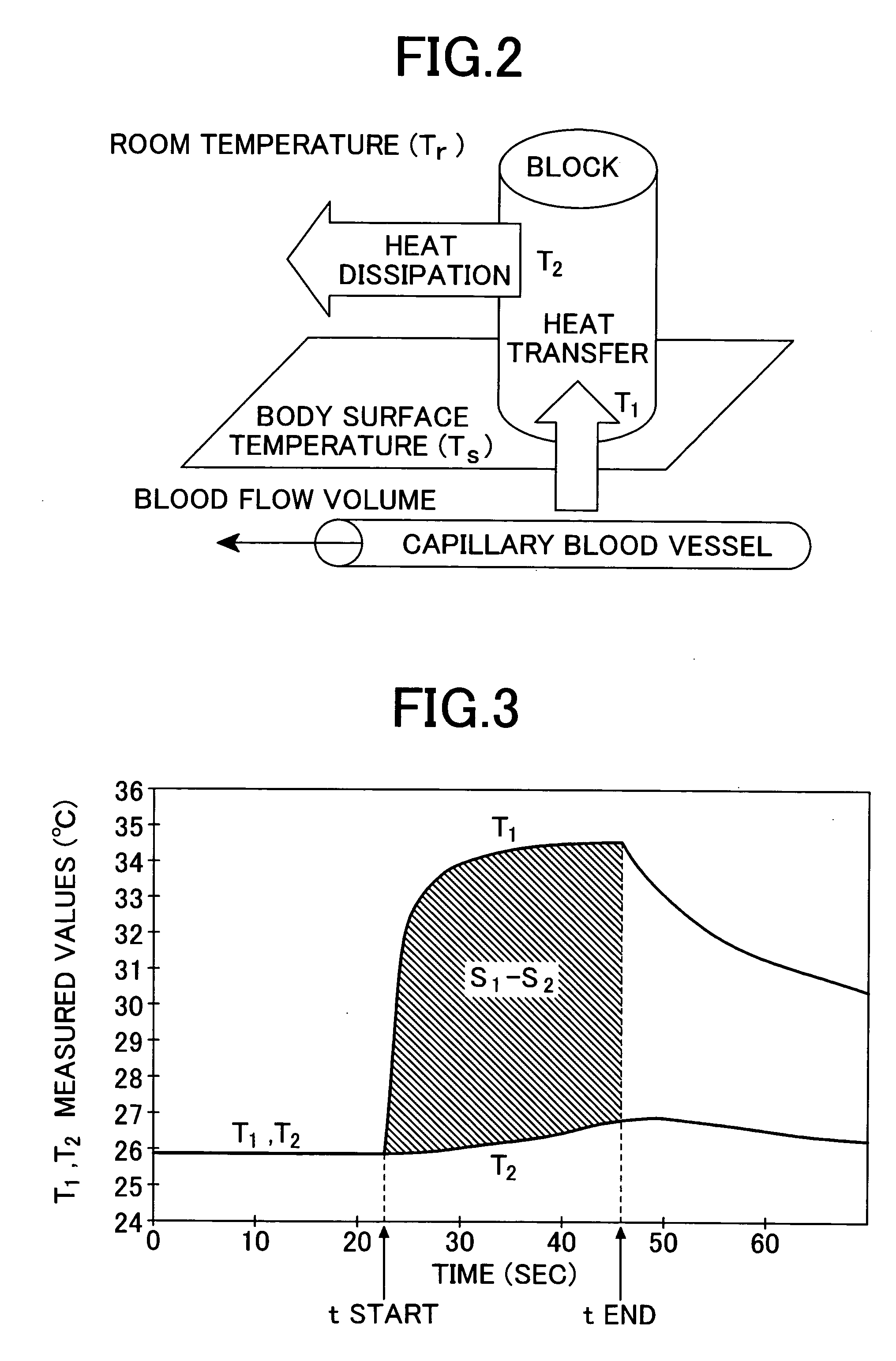

Blood sugar levels are measured non-invasively based on temperature measurement. Values of blood sugar levels non-invasively measured by a temperature measuring system are corrected using blood oxygen saturation and blood flow volume. Optical sensors are provided for detecting scattered light, reflected light, and light that enters into the skin which travels out of the body surface. The measurement data is stabilized by taking into consideration the influence of the thickness of skin on blood oxygen saturation.

Owner:HITACHI LTD

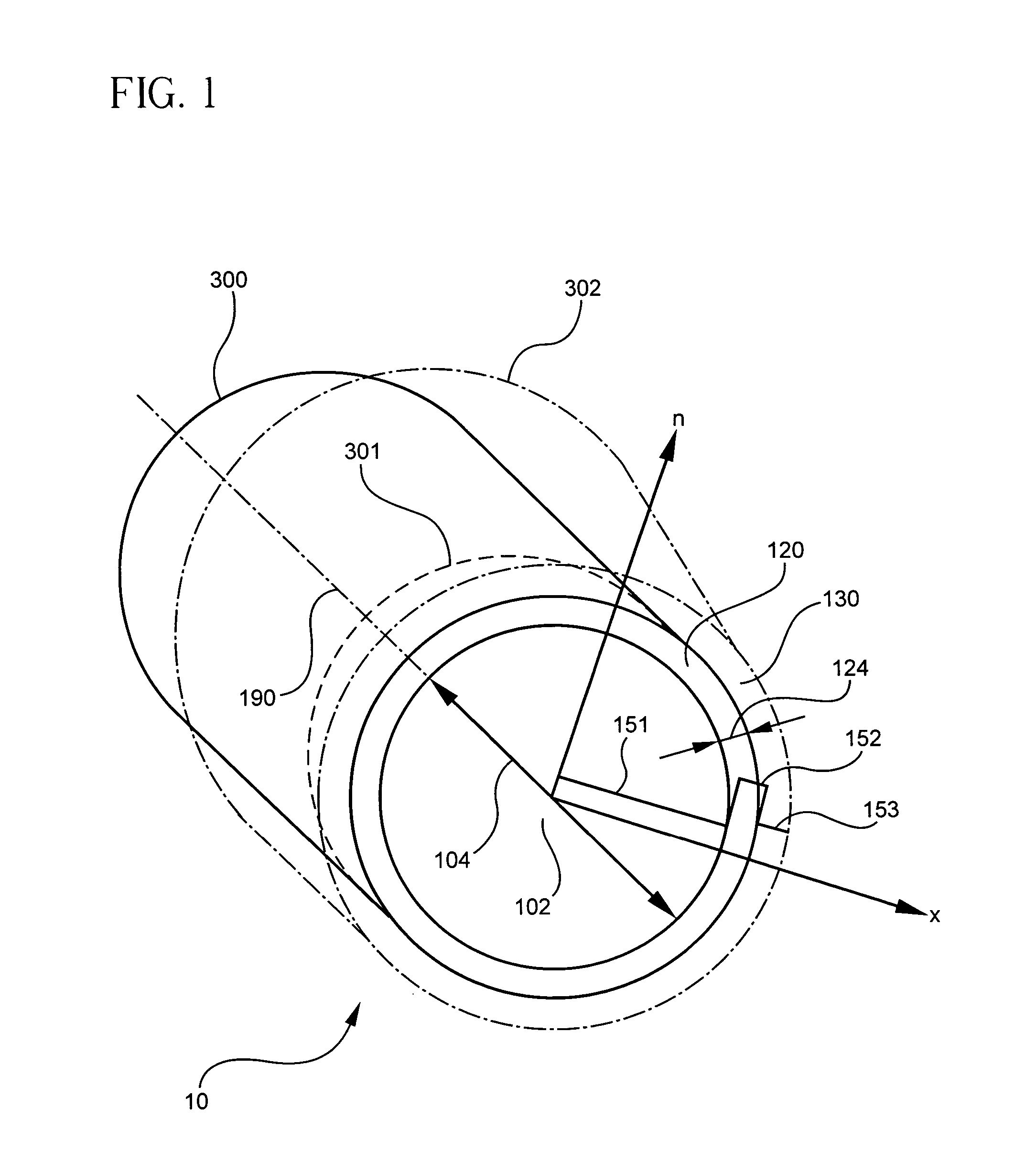

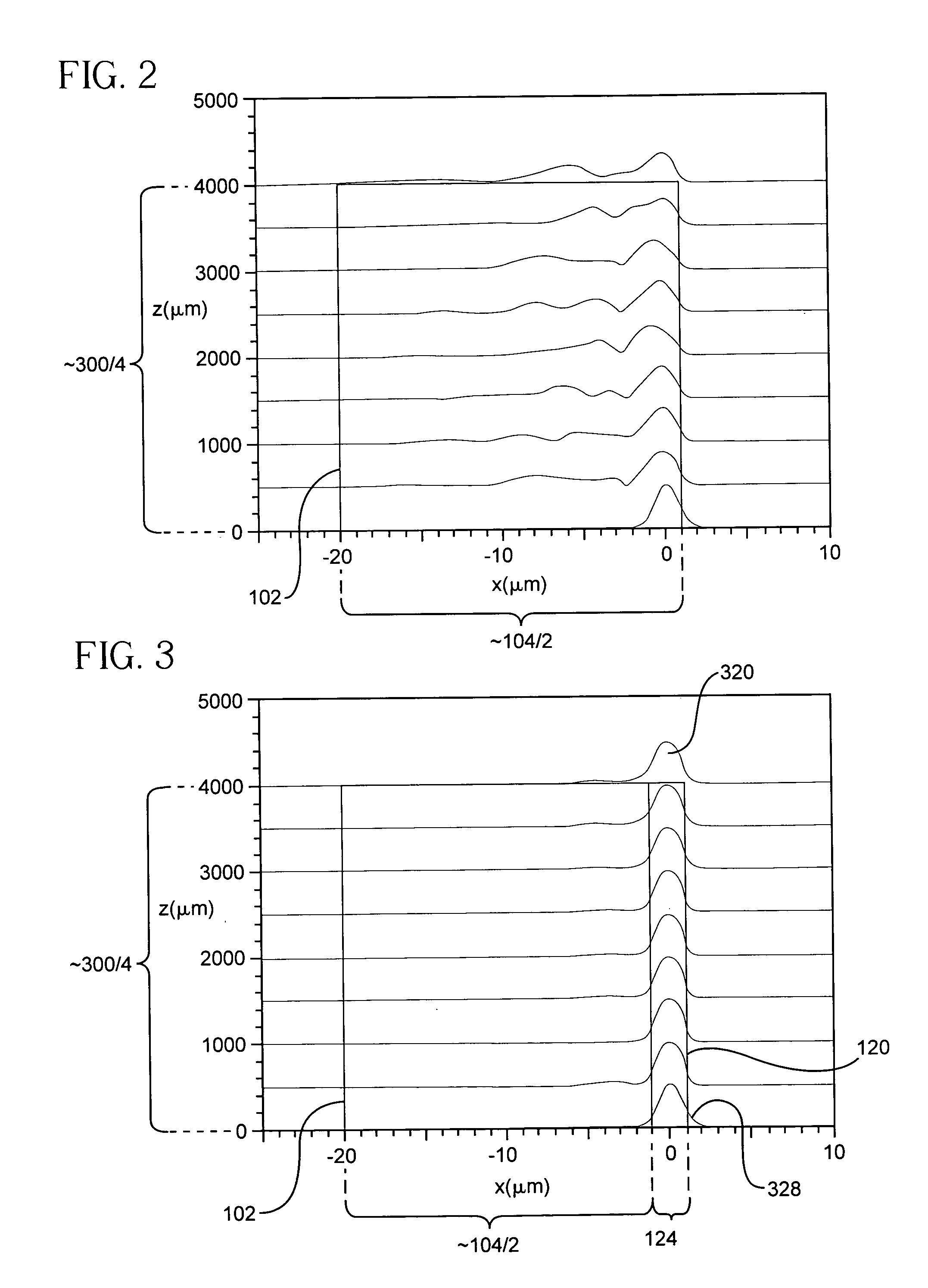

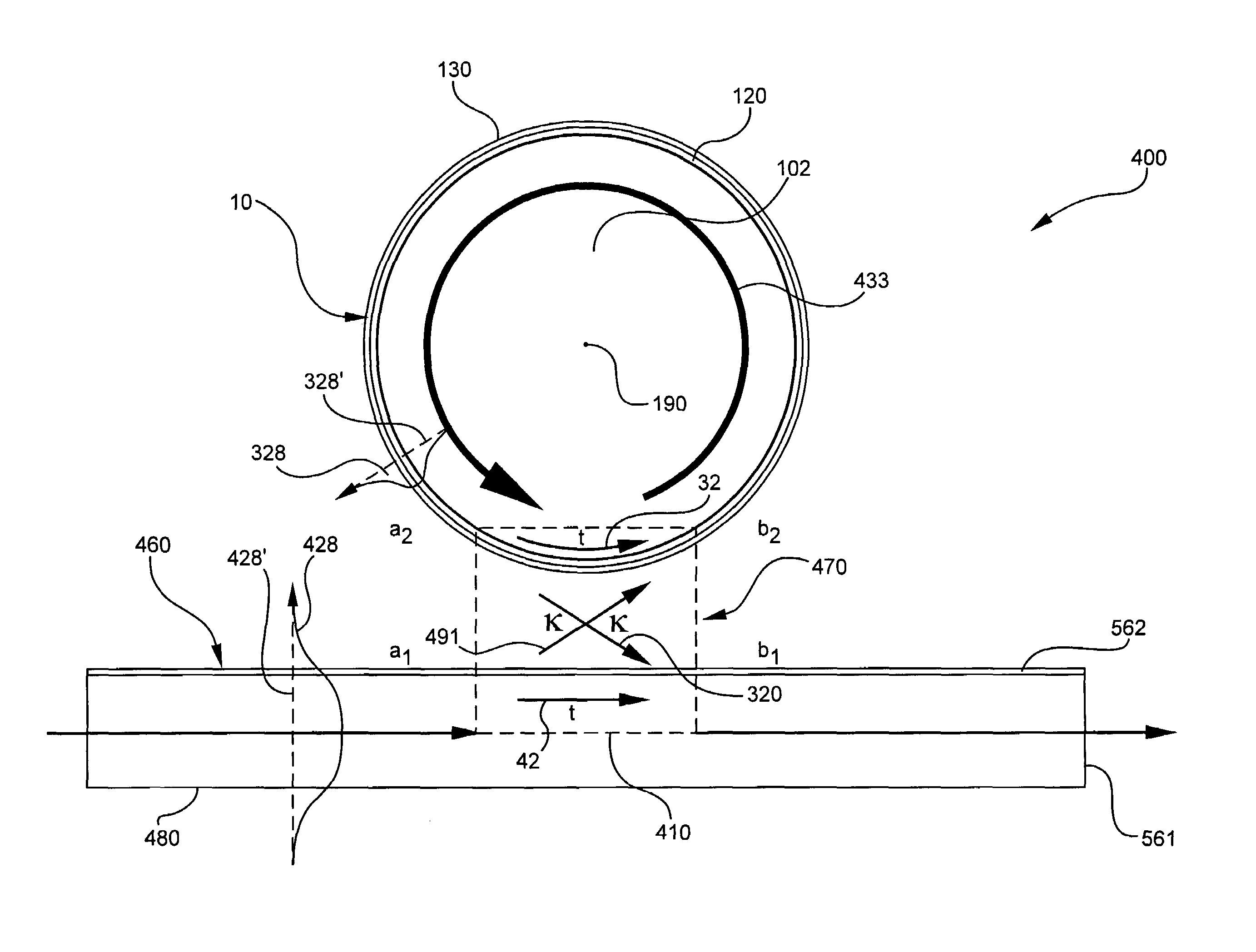

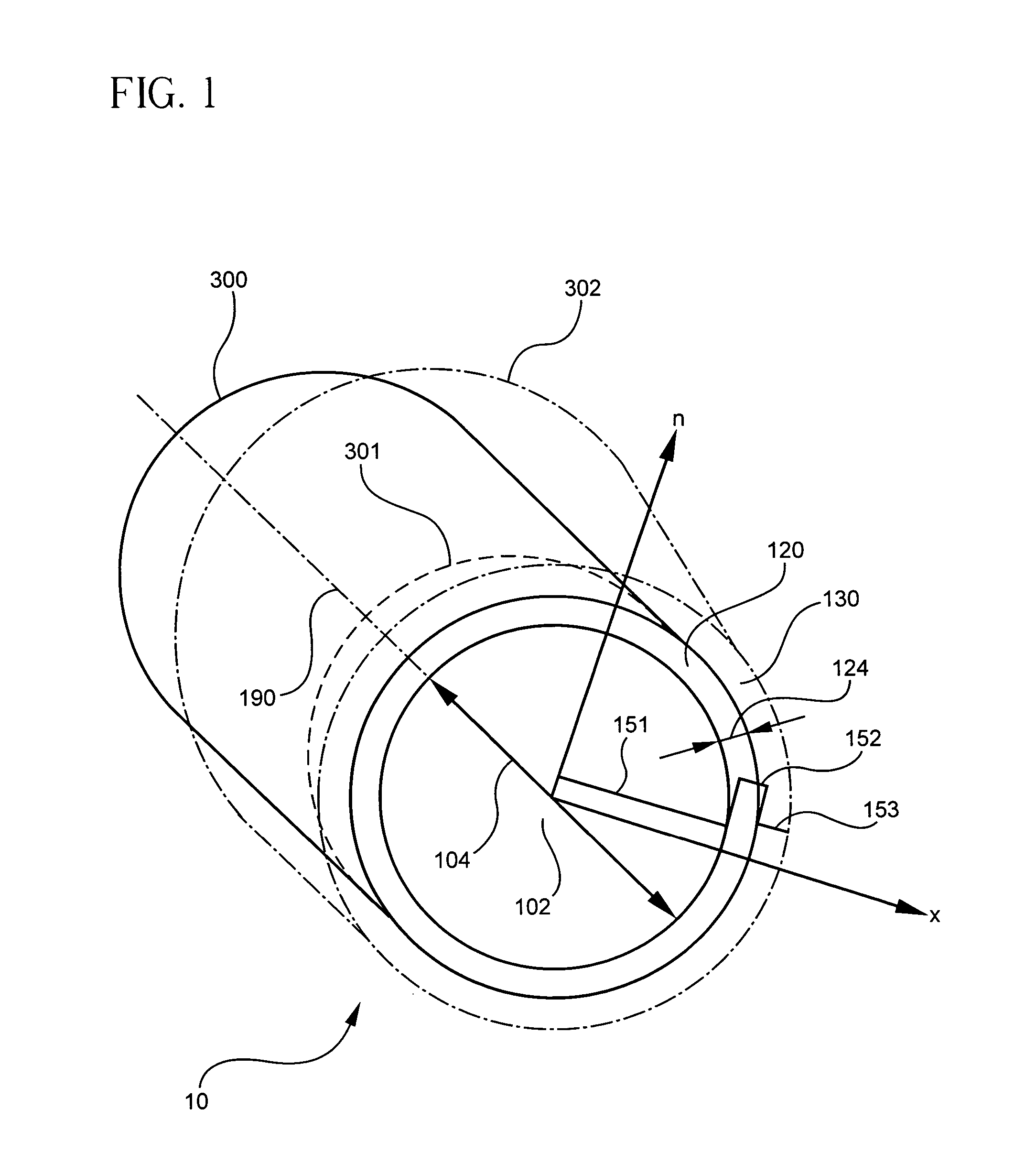

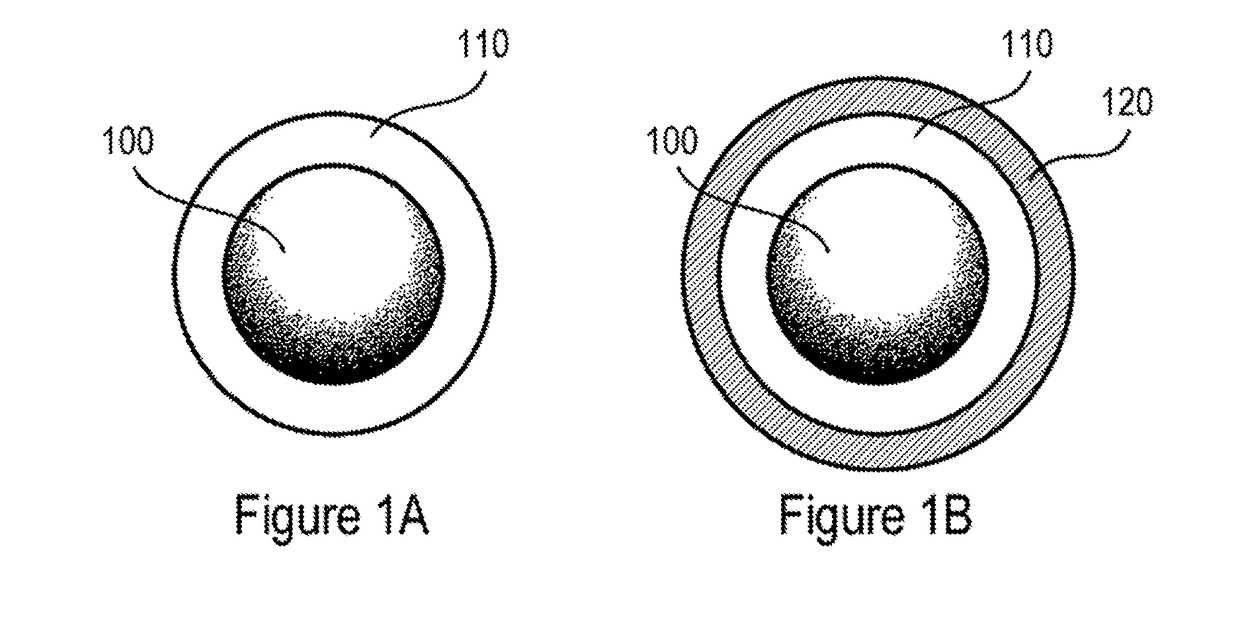

Transverse closed-loop resonator

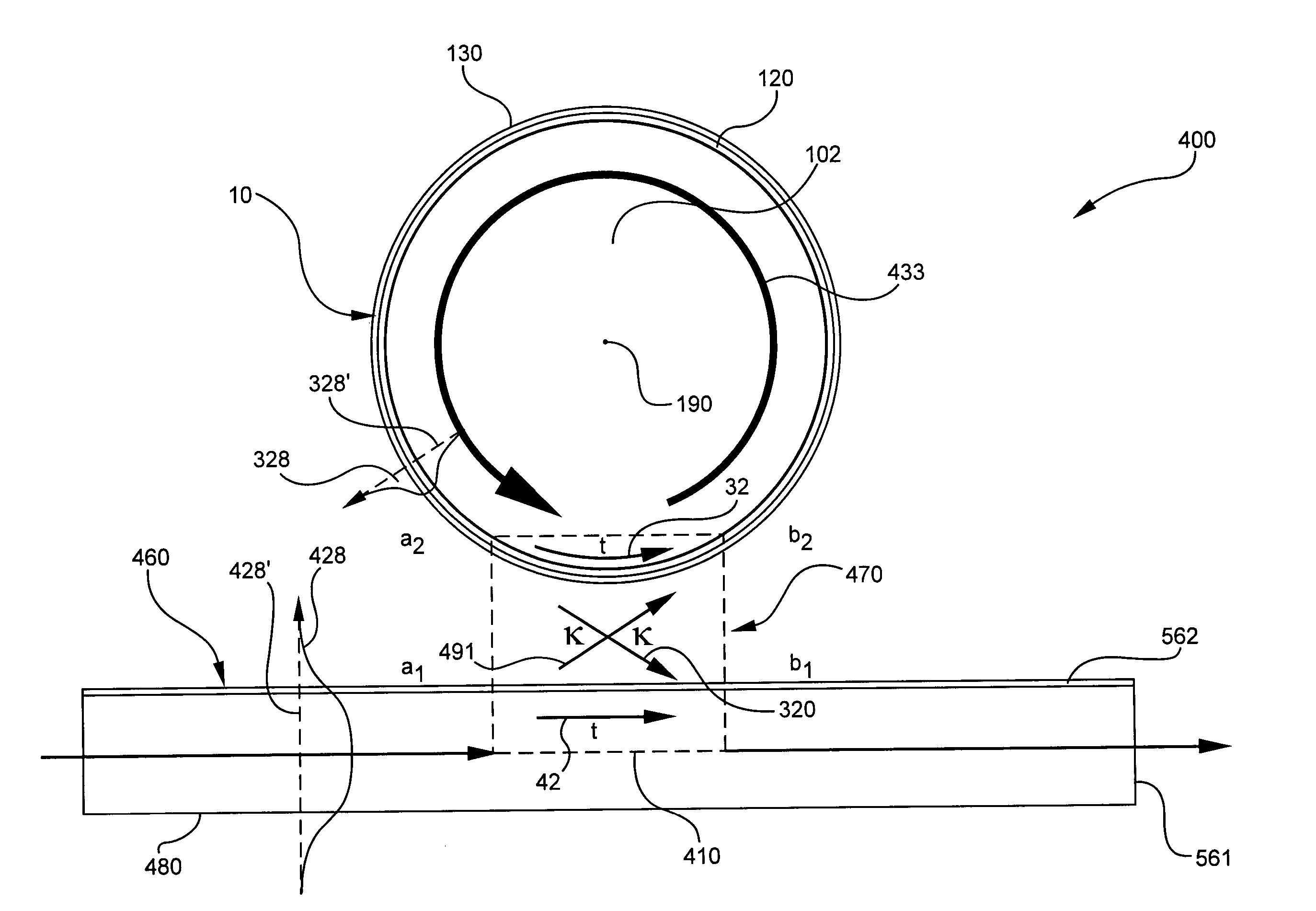

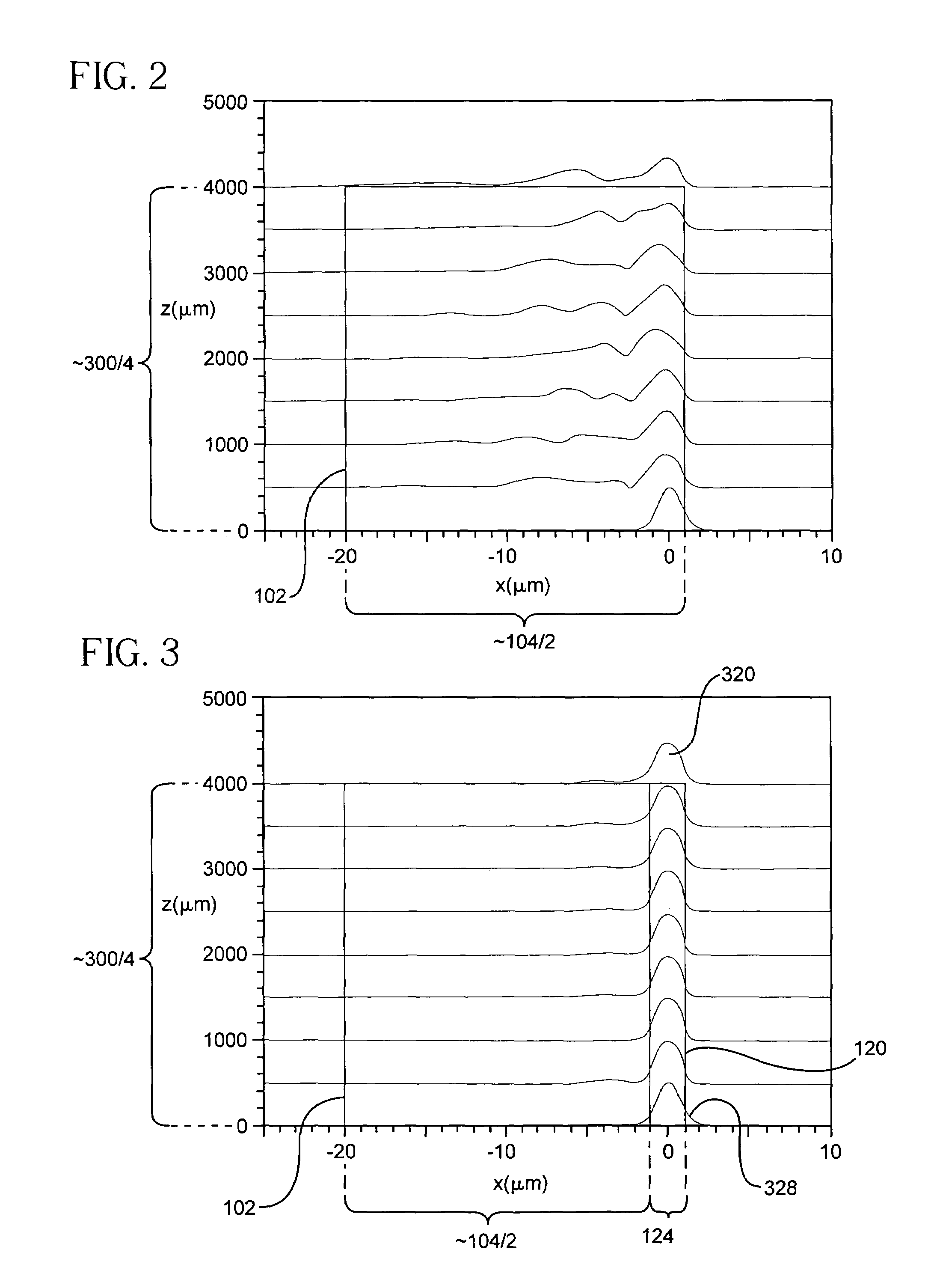

A transverse closed-loop fiber resonator (10) includes an inner cladding (102) having a surface (300) peripherally forming a closed-loop shape for confining light to the surface (300). The inner cladding has a first diameter thickness (104) and a first index of refraction profile in a cross-sectional portion of the transverse closed-loop fiber resonator (10). A ringed-core (120) corresponding to the closed-loop shape is disposed on the corresponding surface of the inner cladding (102). The ringed-core (120) has a second thickness (124) of material thinner than the first diameter thickness (104), and a second index of refraction profile greater than the first index of the inner cladding by an index delta in the cross-sectional portion of the transverse closed-loop fiber resonator such that the ringed-core can guide light within the ringed-core traversely around the closed-loop shape.

Owner:CORNING INC

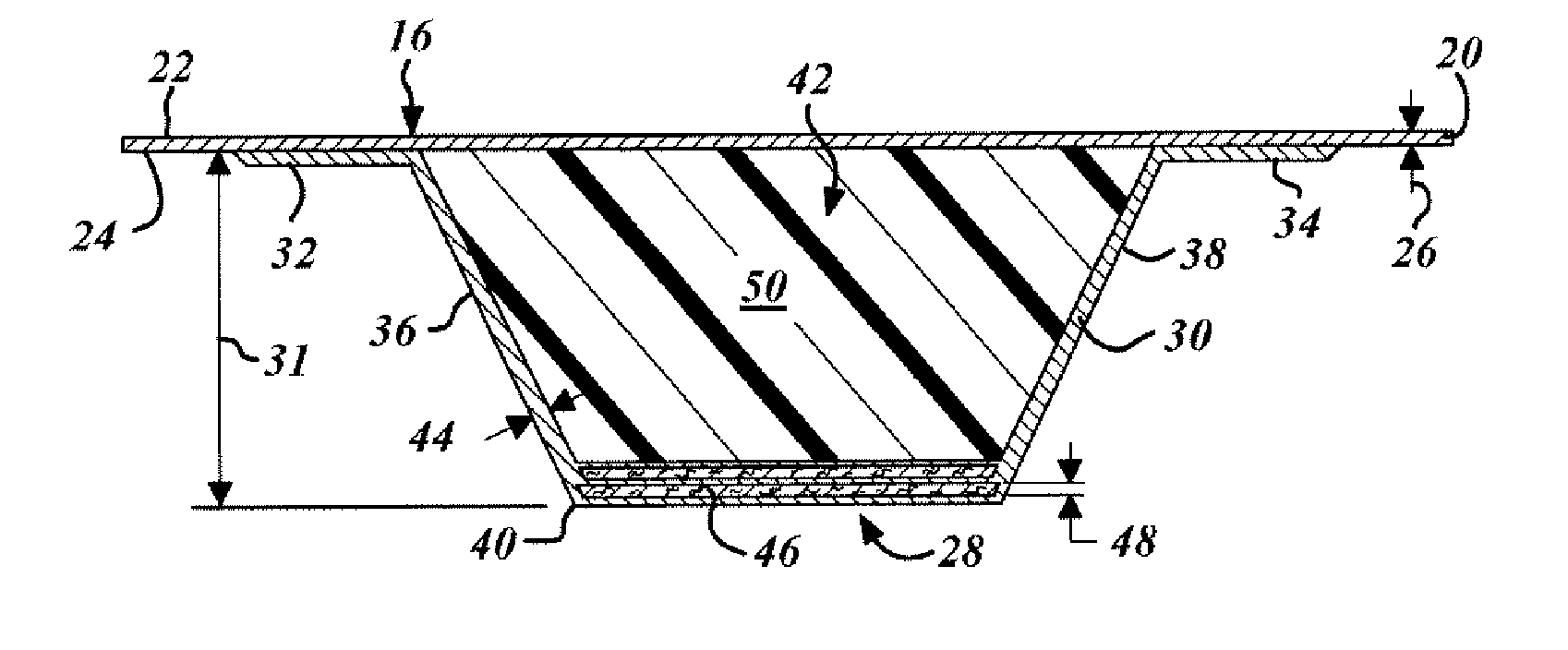

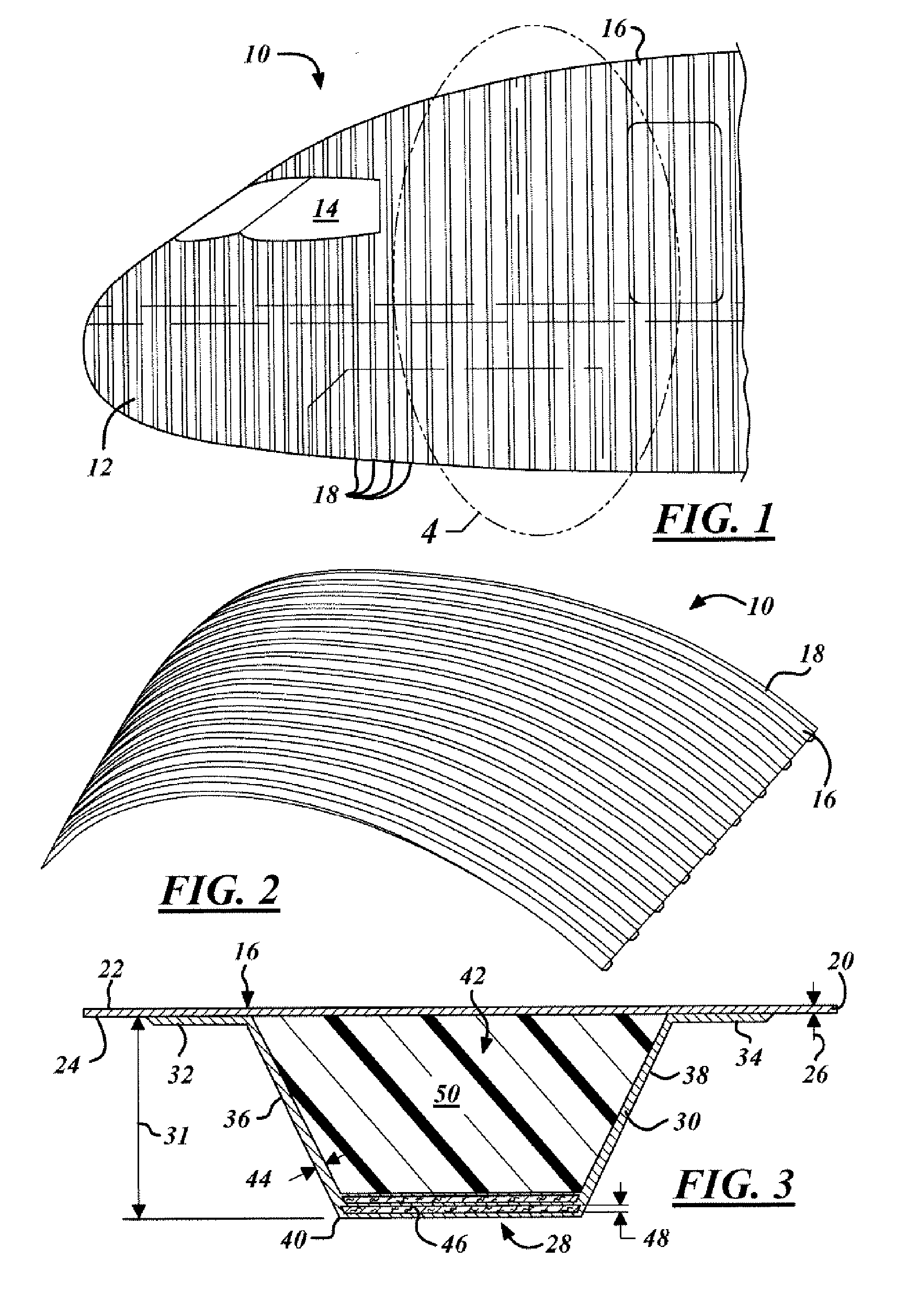

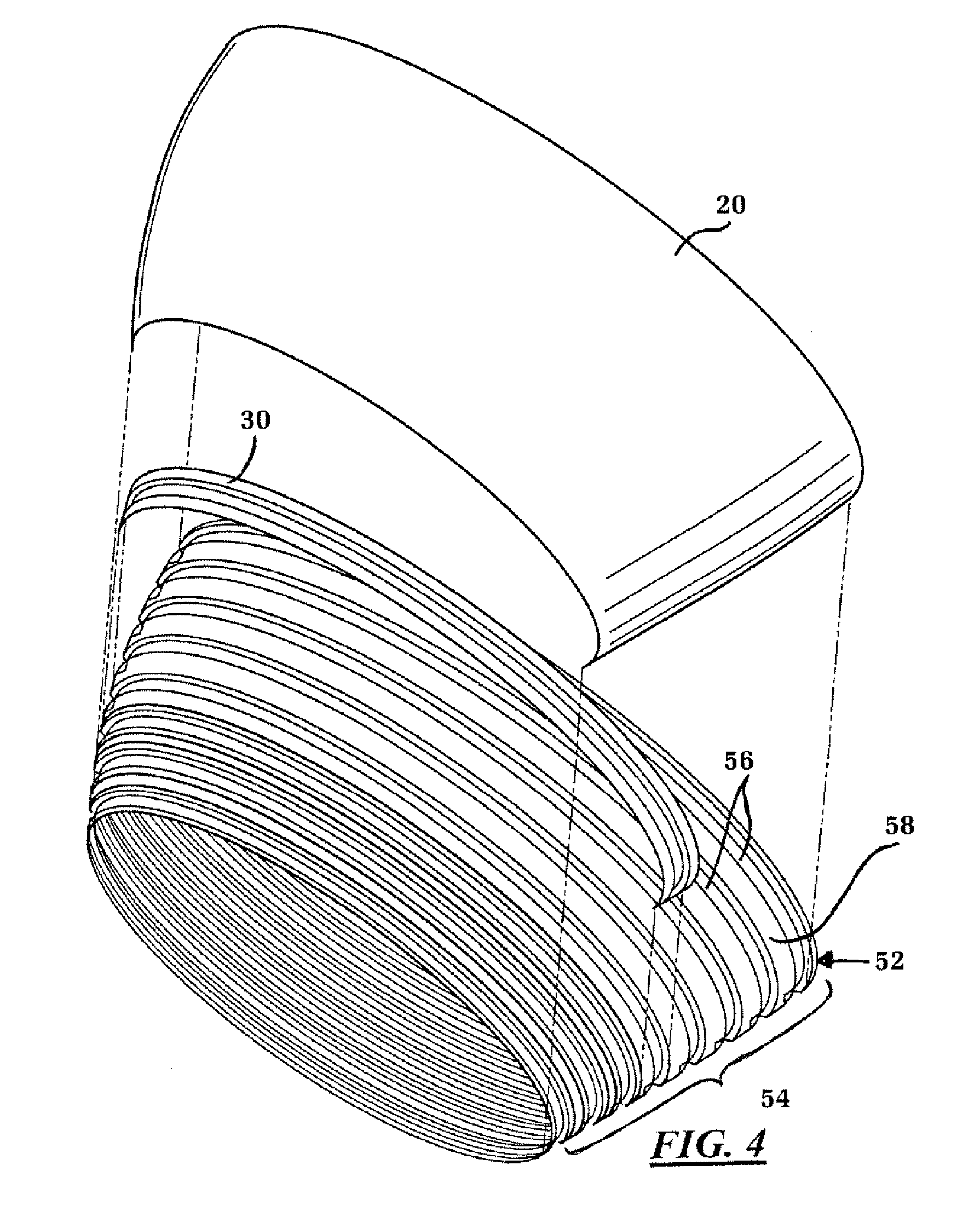

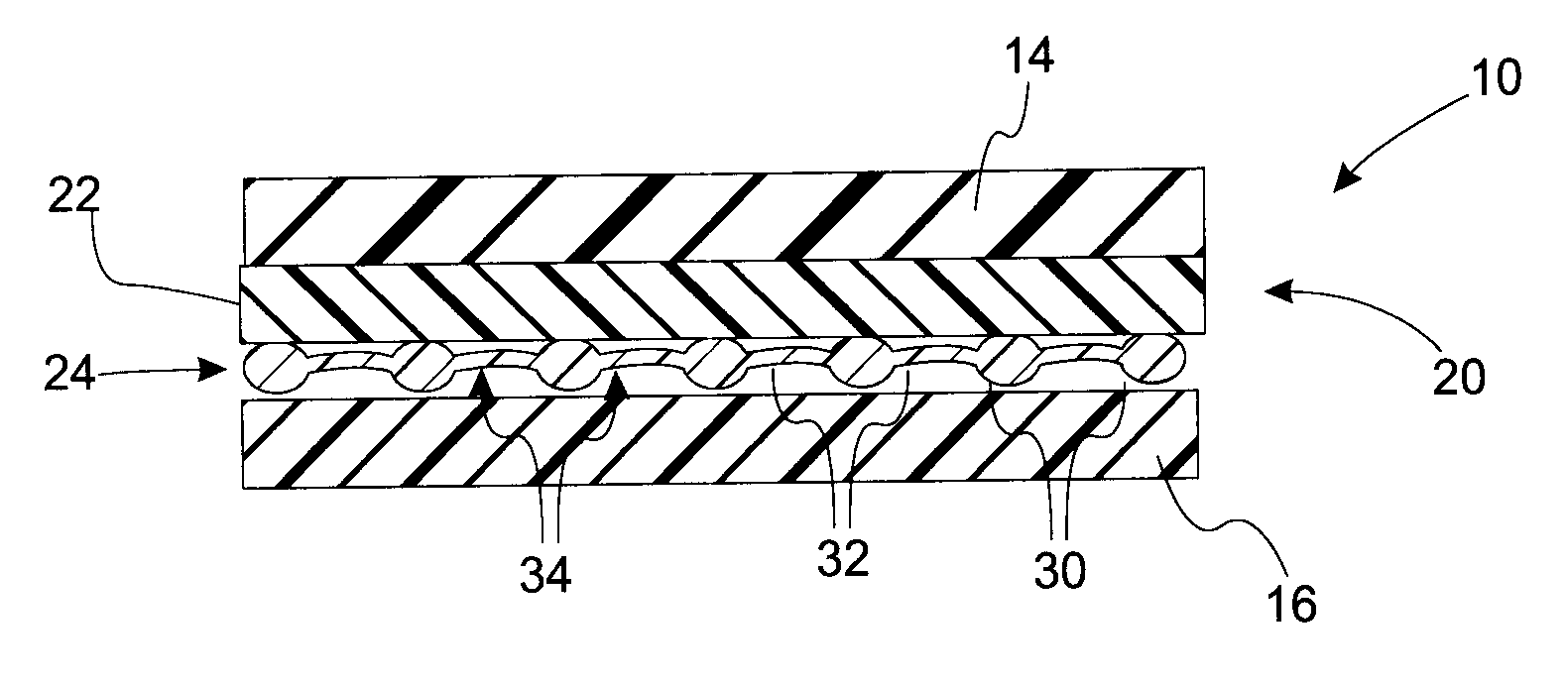

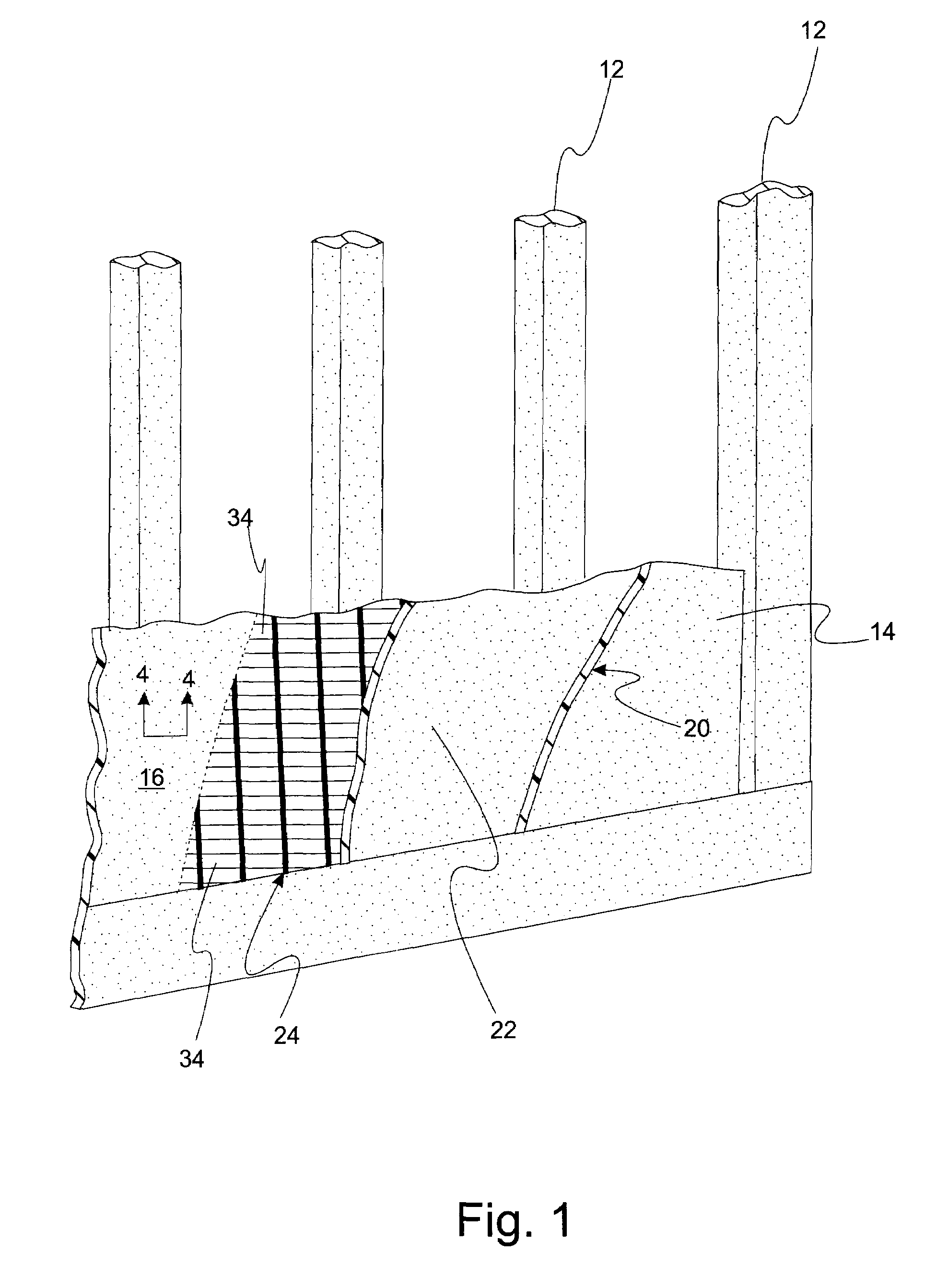

Single piece fuselage barrel

In accordance with the present invention an aircraft stringerless fuselage structure is provided comprising an impact compliant outer skin having a plurality of resin impregnated skin fibers forming an outer skin surface, an inner stringerless skin surface, and a skin thickness. A plurality of stiffeners is included, each comprising a plurality of resin impregnated stiffener fibers integrated into the inner stringerless skin structure. The plurality of resin impregnated skin fibers are not aligned with the plurality of resin impregnated stiffener fibers.

Owner:THE BOEING CO

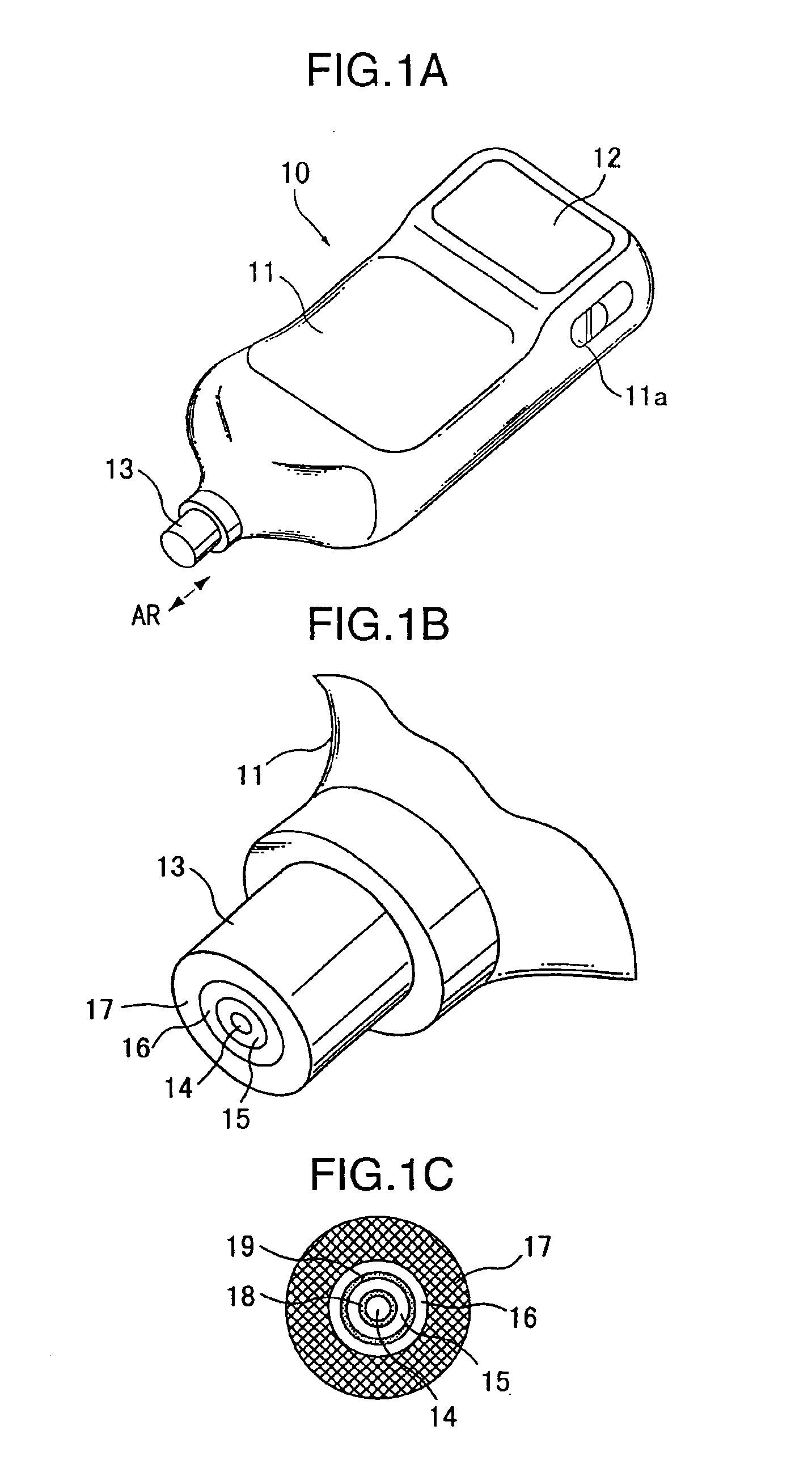

Transcutaneous bilirubin concentration measuring apparatus and a measurement data checking plate for use with the same

InactiveUS6847835B1High absorption coefficientDiagnostics using lightSensorsTranscutaneous bilirubinMeasurement device

Luminous fluxes from a xenon tube are introduced from one end of an optical fiber to an other end thereof and emerge therefrom. These luminous fluxes are incident of a skin of a person to be measured, and those diffused in the skin are incident on one end of an optical fiber through a first incident port and on one end of an optical fiber through a second incident port. The luminous fluxes from the one end are split by a dichroic mirror. The luminous fluxes reflected by the dichroic mirror are received by a photoelectric conversion element via a blue filter, and those having transmitted through the dichroic mirror are received by a photoelectric conversion element via a green filter. A concentration of bilirubin pigmented in fat of subcutaneous tissues can be accurately measured without being influenced by a difference in the thicknesses of epidermis and derma.

Owner:MINOLTA CO LTD

Process for formulating a customized skin care product

InactiveUS7349857B2Performance advantageStability of product can be controlledPigmenting treatmentVacuum evaporation coatingBiometric dataAdditive ingredient

The invention relates to a method and a process of determining individual skin structure and function at a point in time for the purpose of determining and formulating skin care products that remedy the deficiencies observed in the skin. Objective and repeatable dermal biometric instrumentation techniques can be used to measure skin moisture content, sebum content, firmness and elasticity properties, skin thickness, transepidermal water loss, skin pH and to perform a photo analysis of the face with UV and visible light. By customizing the skin care products, the individually added active ingredients can be controlled, the diluents can be modified, dermal penetration rates can be controlled, the surfactant systems can be adjusted, and the stability of the product can be controlled. To prevent the loss of active materials in the product, the skin care product is manufactured for an individual consumer and is only sold in a quantity of a three months supply. Additionally, a variety of ingredients can be combined that a mass produced product cannot contain due to stability / compatibility issues. This invention overcomes the limitations in formulating skin products for the mass market by providing a product designed with objective biometric data and created for the specific clinical condition of an individual's skin.

Owner:MANZO ROBERT P

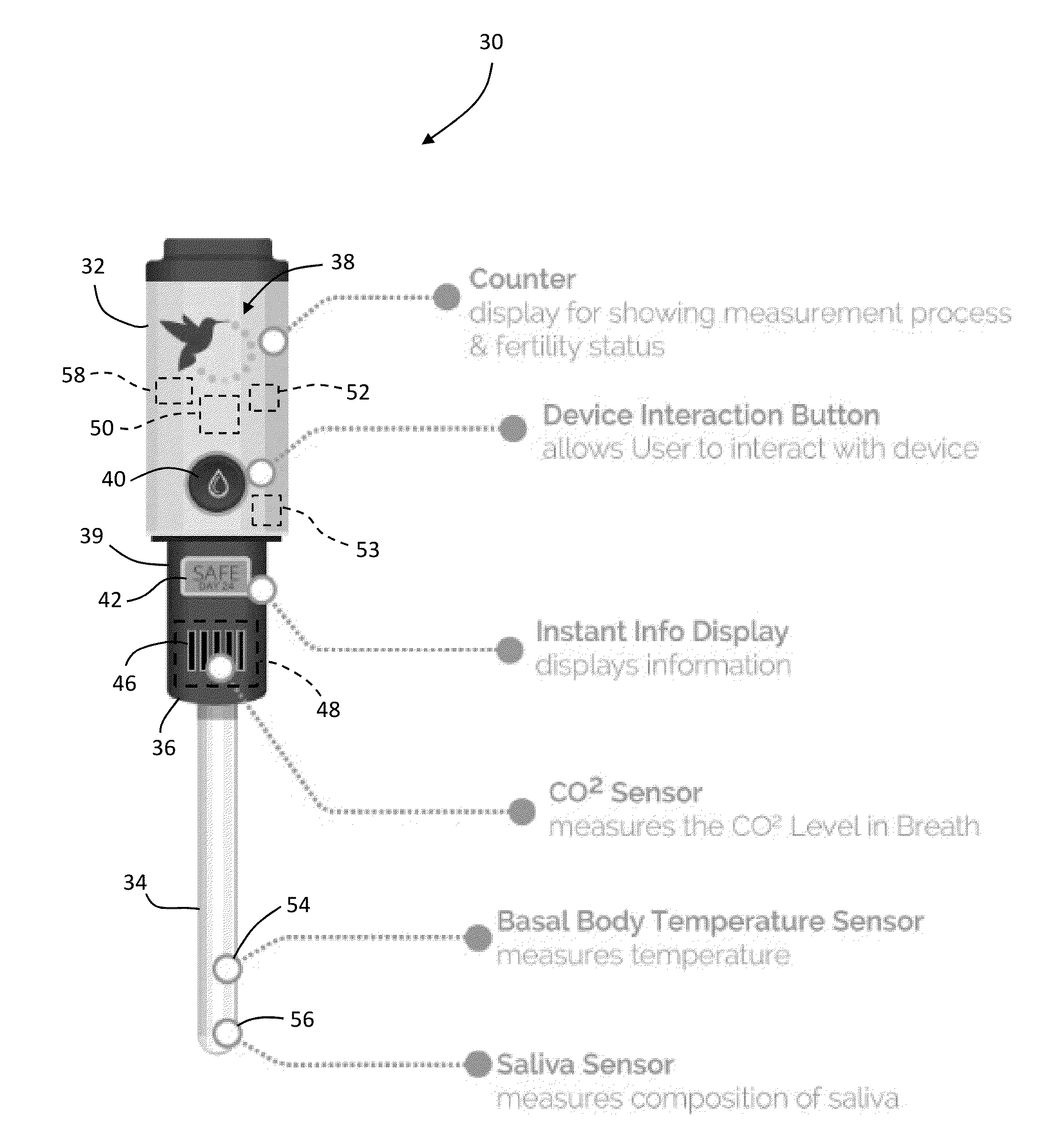

Health state monitoring device

A system and method for determining a user's physical condition such as a hormonal level are provided. The system includes a portable or wearable device that measures multiple biomarkers, such as basal body temperature, saliva salinity, saliva pH, sweat ions, skin thickness, vitamin levels or breath carbon dioxide. The system determines the physical condition, such as the fertility level of the user based on comparing the measured biomarkers with data models. The determined physical condition, such as the fertility level, is communicated to allow the user to know their status.

Owner:RAZZBERRY

Tension relieving body support apparatus

InactiveUS20100058541A1Prevent hyperextensionReduces nerveStuffed mattressesSpring mattressesVolumetric Mass DensityEngineering

Owner:MEDINNOVATIONS INT

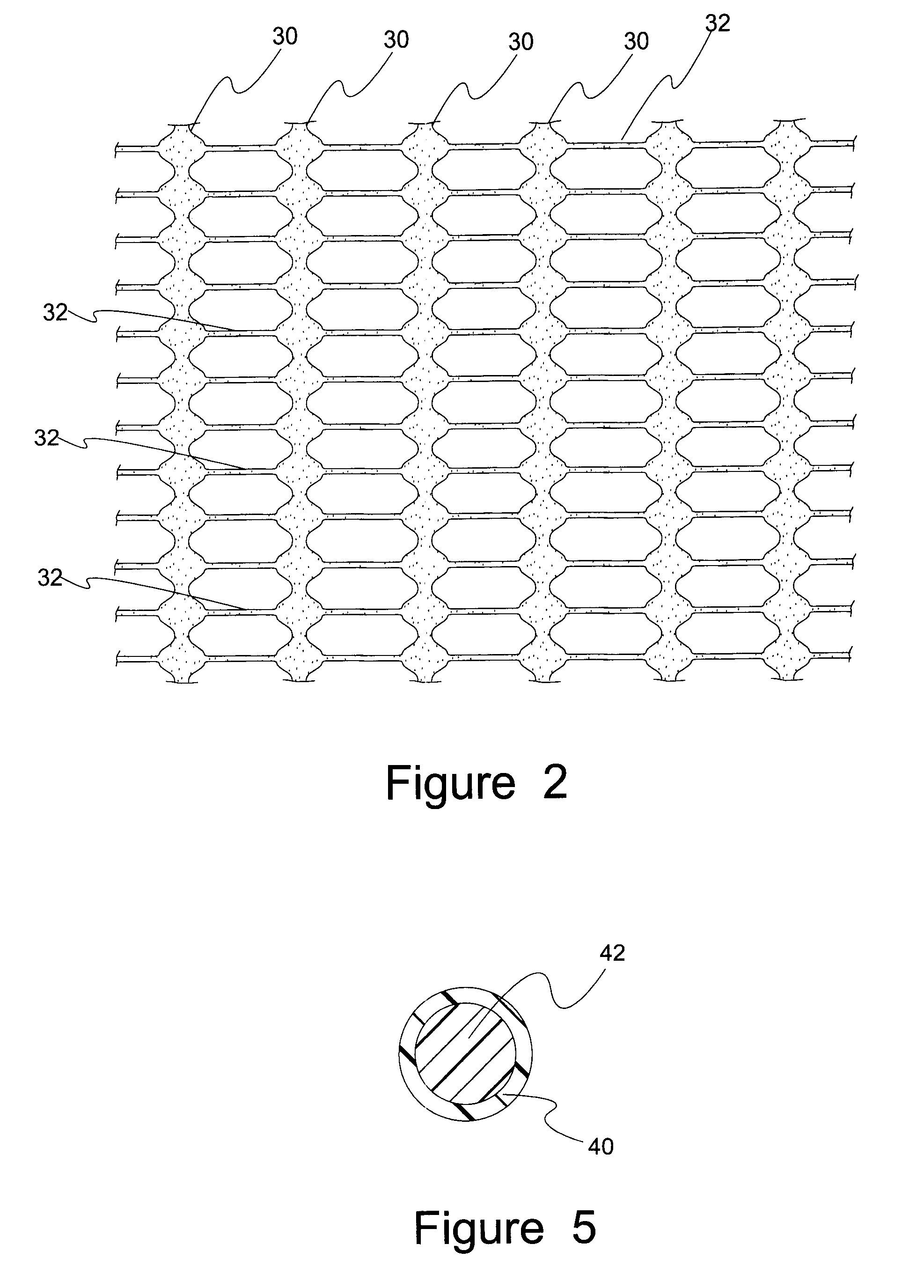

Water management building wrap

ActiveUS7520097B2Stable vertical water drainage channelsSynthetic resin layered productsConstructions elementsPolymerSkin thickness

Owner:CONWED PLASTICS

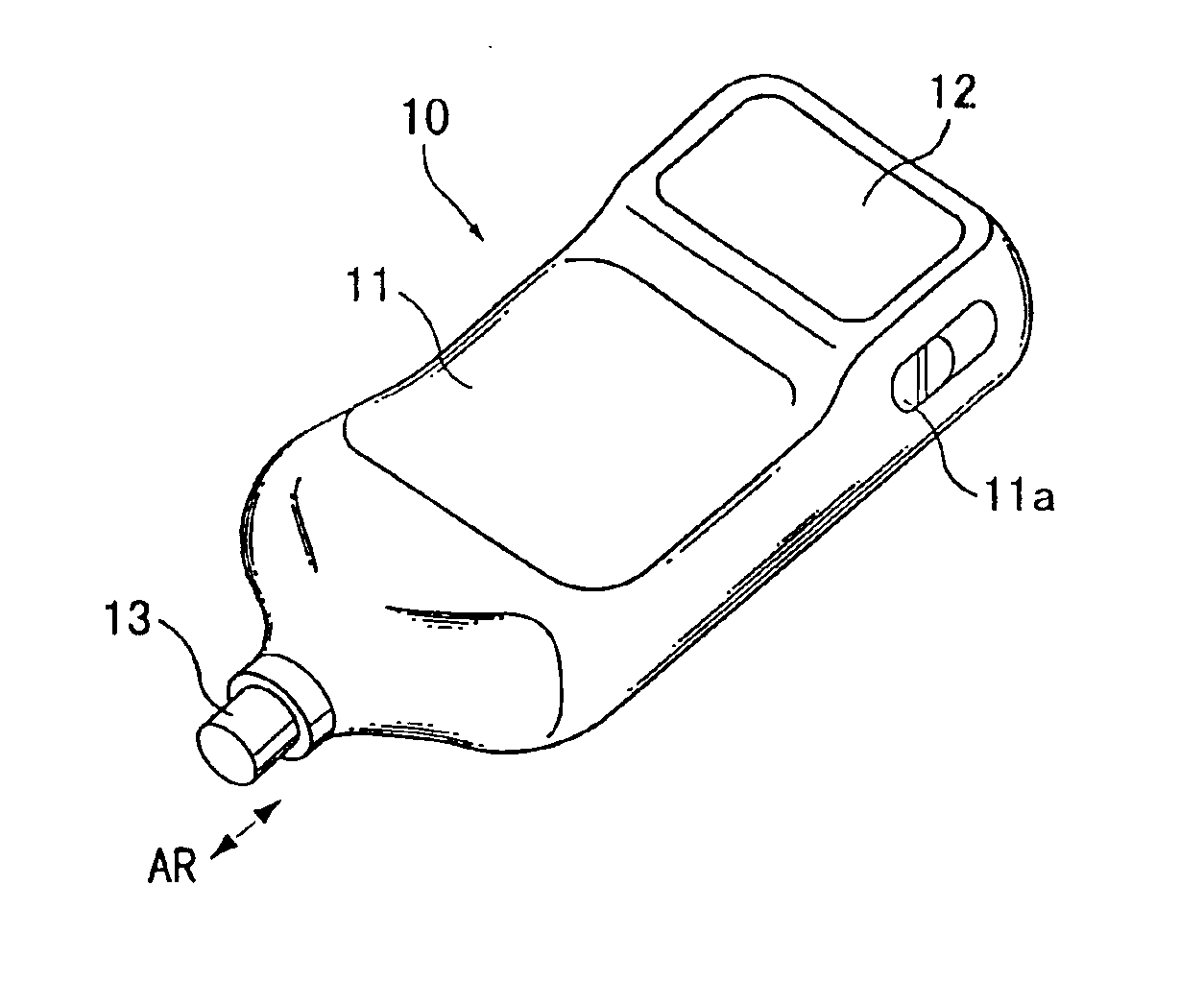

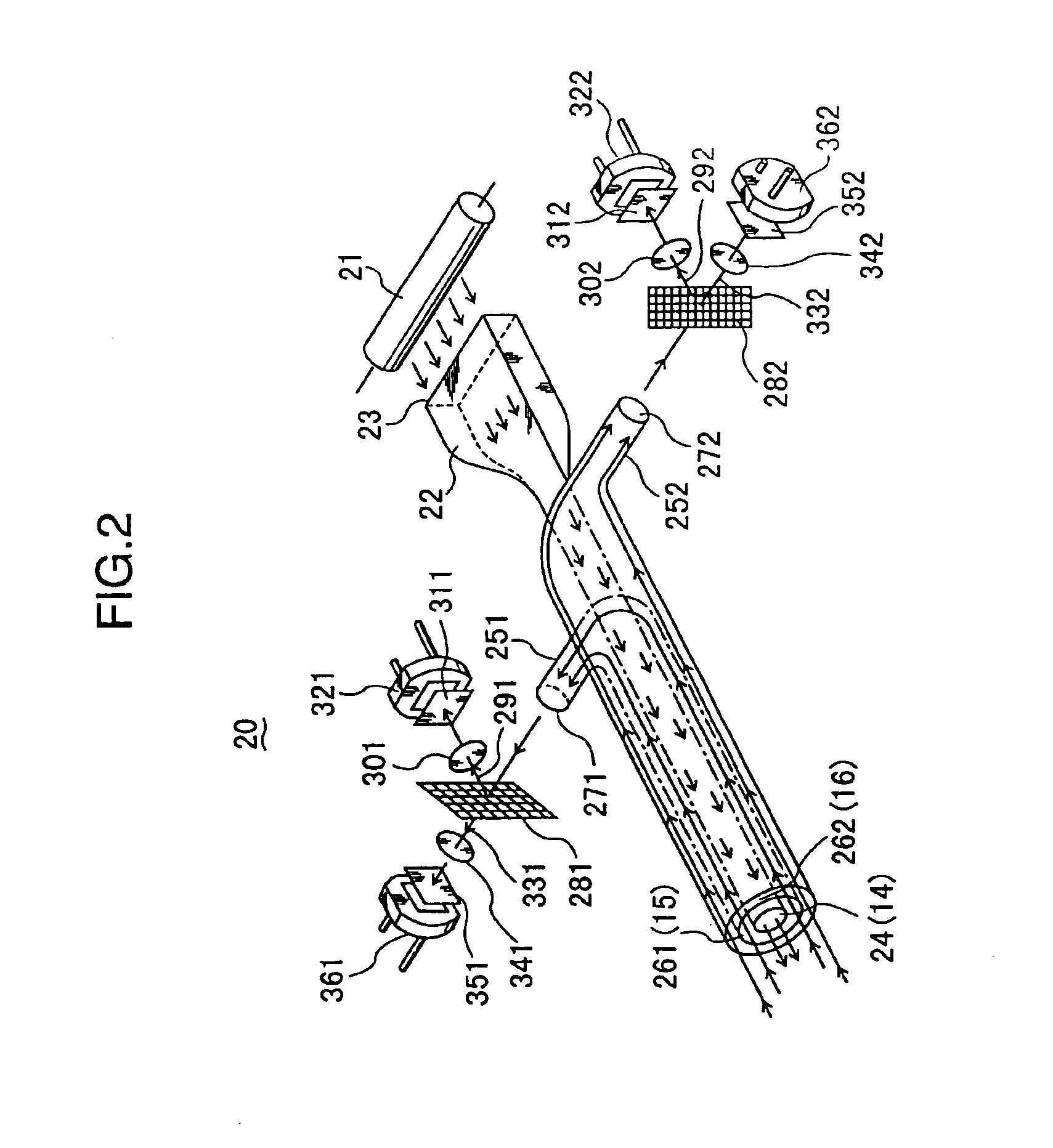

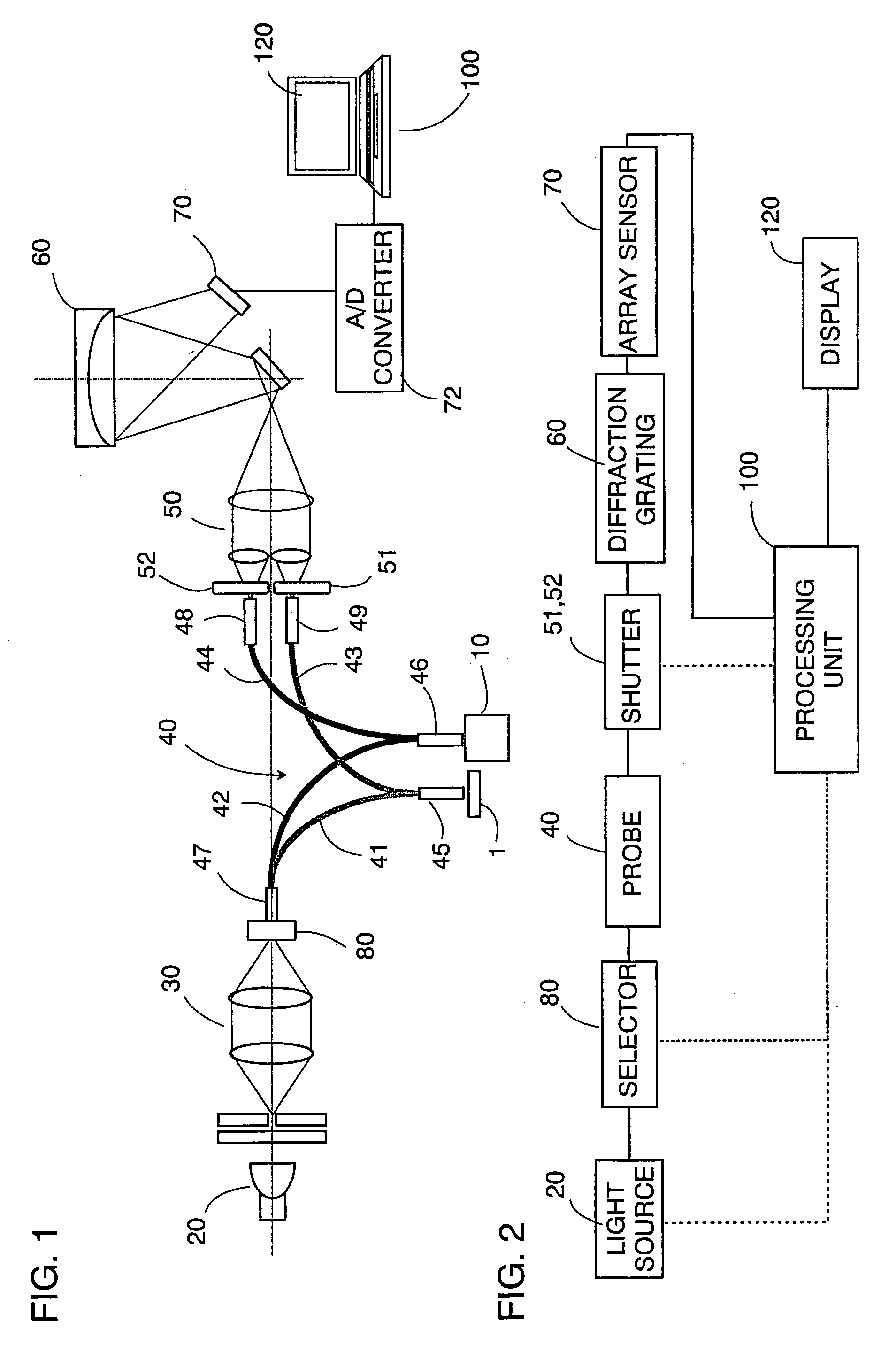

Optical measurement apparatus and blood sugar level measuring apparatus using the same

InactiveUS20060094941A1Improve accuracyBlood sugar levelDiagnostic recording/measuringSensorsOptical measurementsBlood sugar

An apparatus for non-invasively measuring blood sugar levels based on temperature measurements. A blood sugar level non-invasively measured by a temperature measuring method is corrected by blood oxygen saturation and blood flow volume. Optical sensors detect scattered light, reflected light, and light exiting from a body surface after penetrating the skin, so that measurement data can be stabilized by taking into consideration the influence of the thickness of the skin on blood oxygen saturation.

Owner:HITACHI LTD

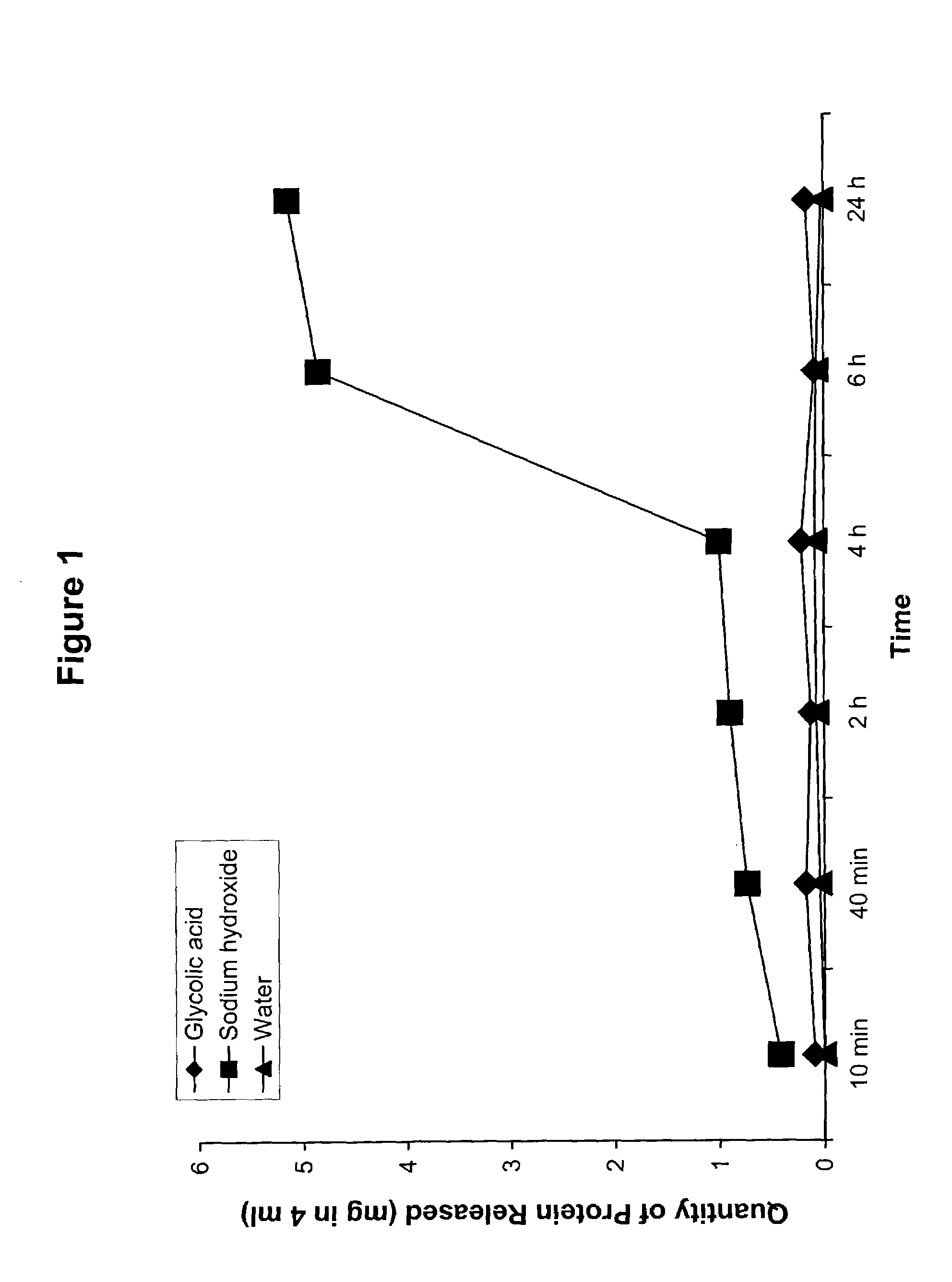

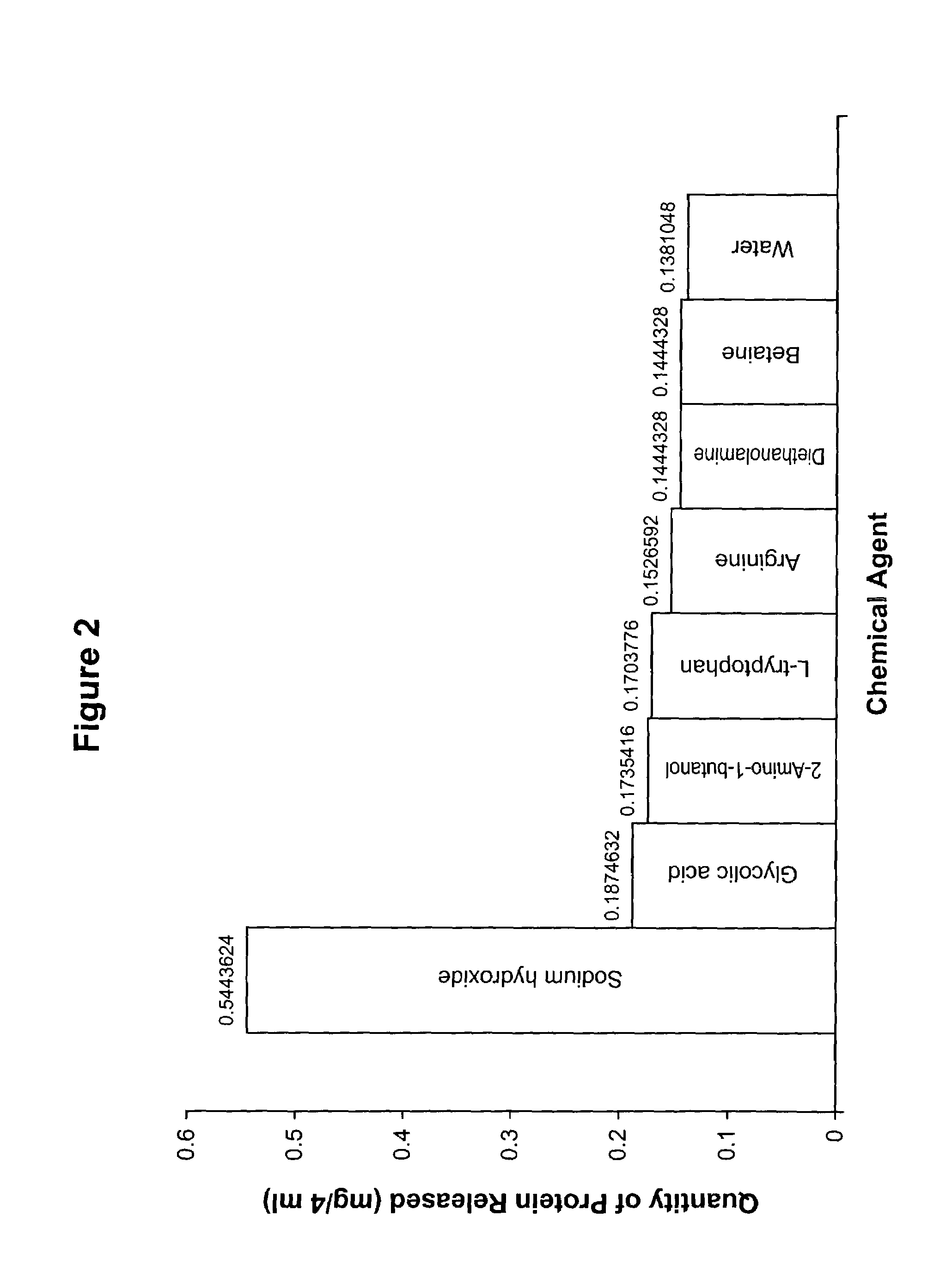

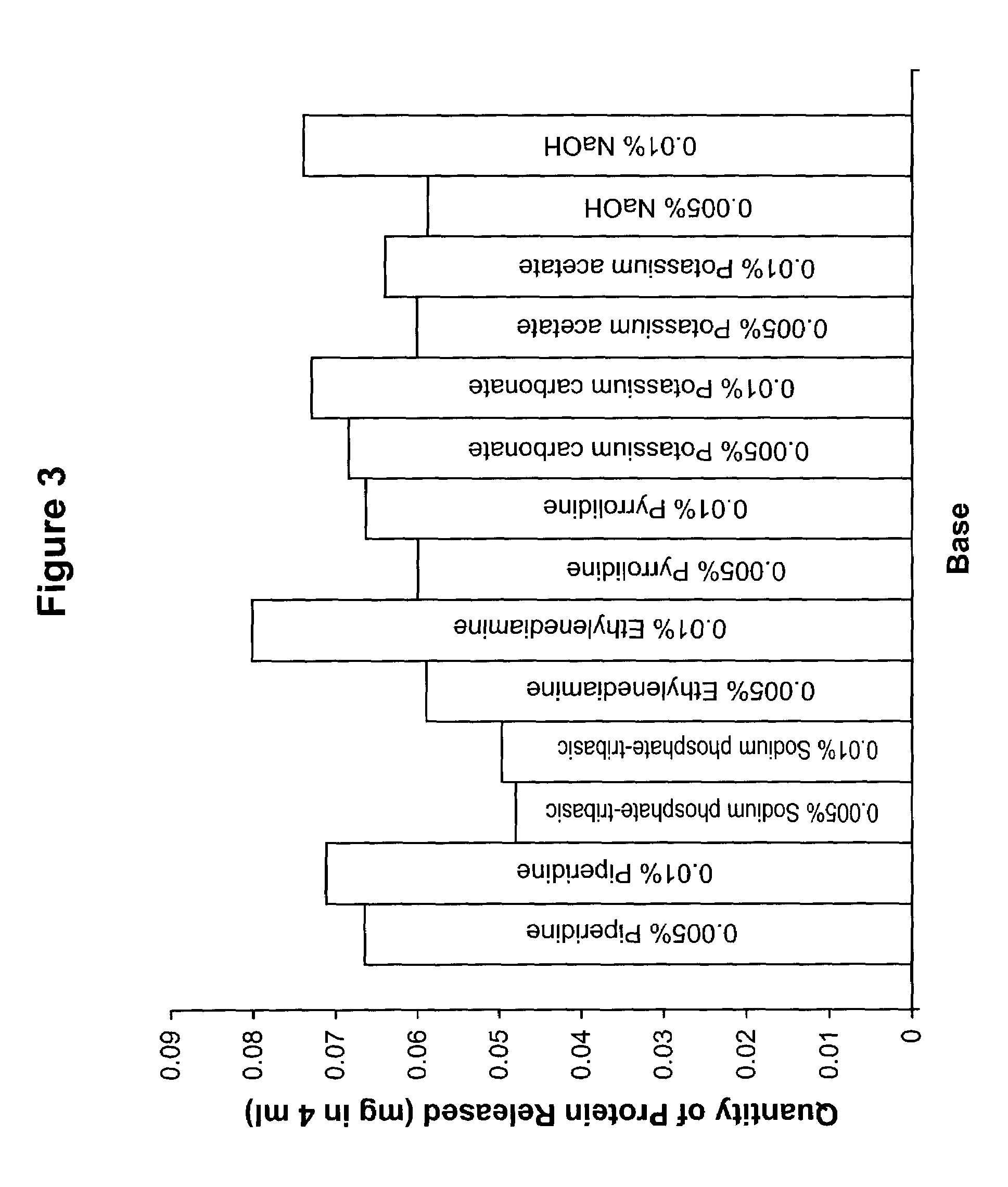

Method and topical formulation for treating skin conditions associated with aging

A composition and method are provided for alleviating the dermatological signs of intrinsic and extrinsic aging. A topical formulation containing a cosmeceutically active base, wherein the formulation provides a pH in the range of about 8.0 to 13.0 at the skin surface, is applied to the skin in order to prevent or treat aging-related skin conditions such as wrinkles, dry skin, age spots, sun damage (particularly UV radiation-induced oxidative stress), blemishes, hyperpigmented skin, age spots, increased skin thickness, loss of skin elasticity and collagen content, dry skin, lentigines and melasmas. The cosmeceutically active base is either an inorganic base, such as an inorganic hydroxide, an inorganic oxide, or a metal salt of a weak acid, or an organic base, particularly a nitrogenous base such as may be selected from primary amines, secondary amines, tertiary amines, amides, oximes, nitrites, aromatic and non-aromatic nitrogen-containing heterocycles, urea, and mixtures thereof.

Owner:DERMATRENDS INC

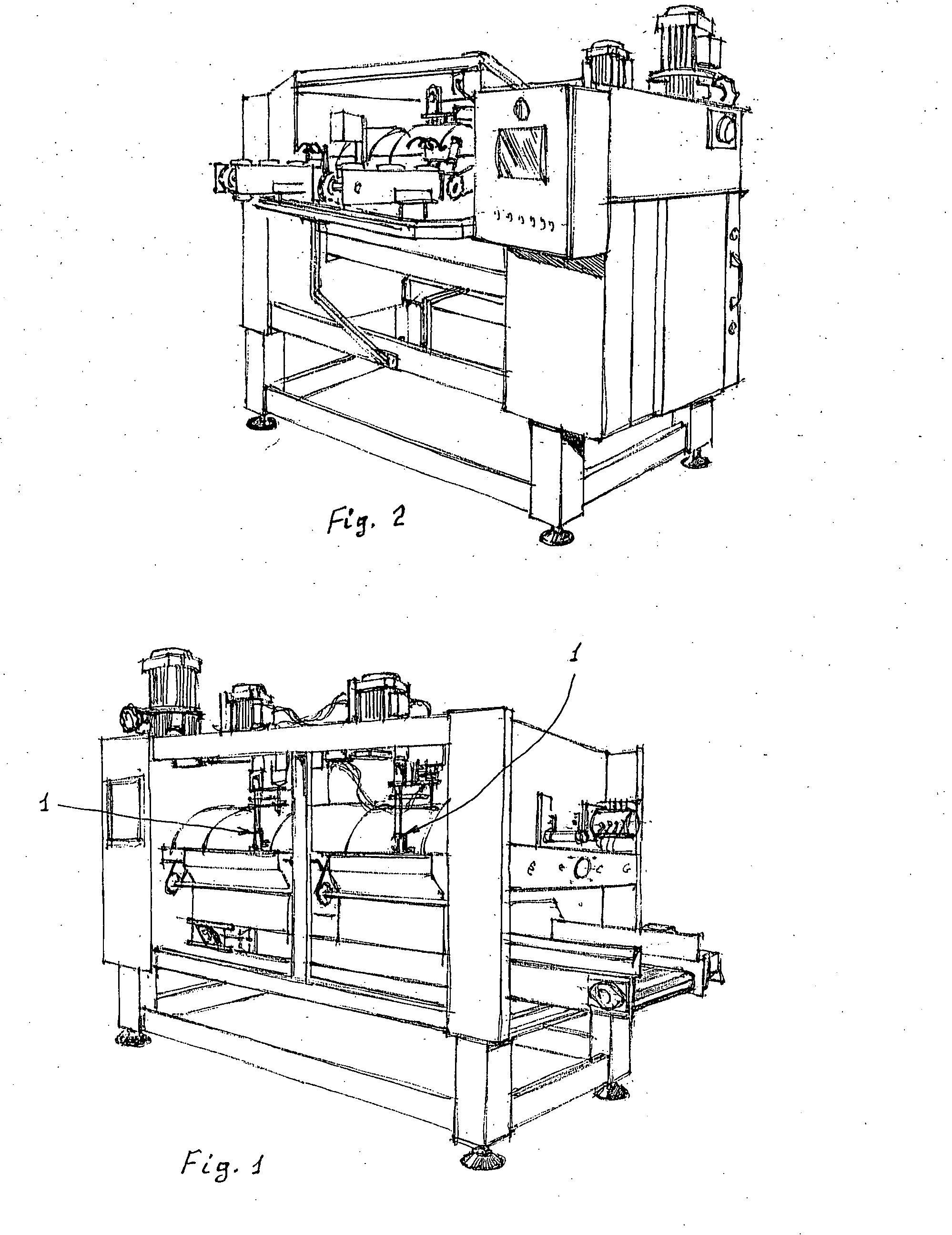

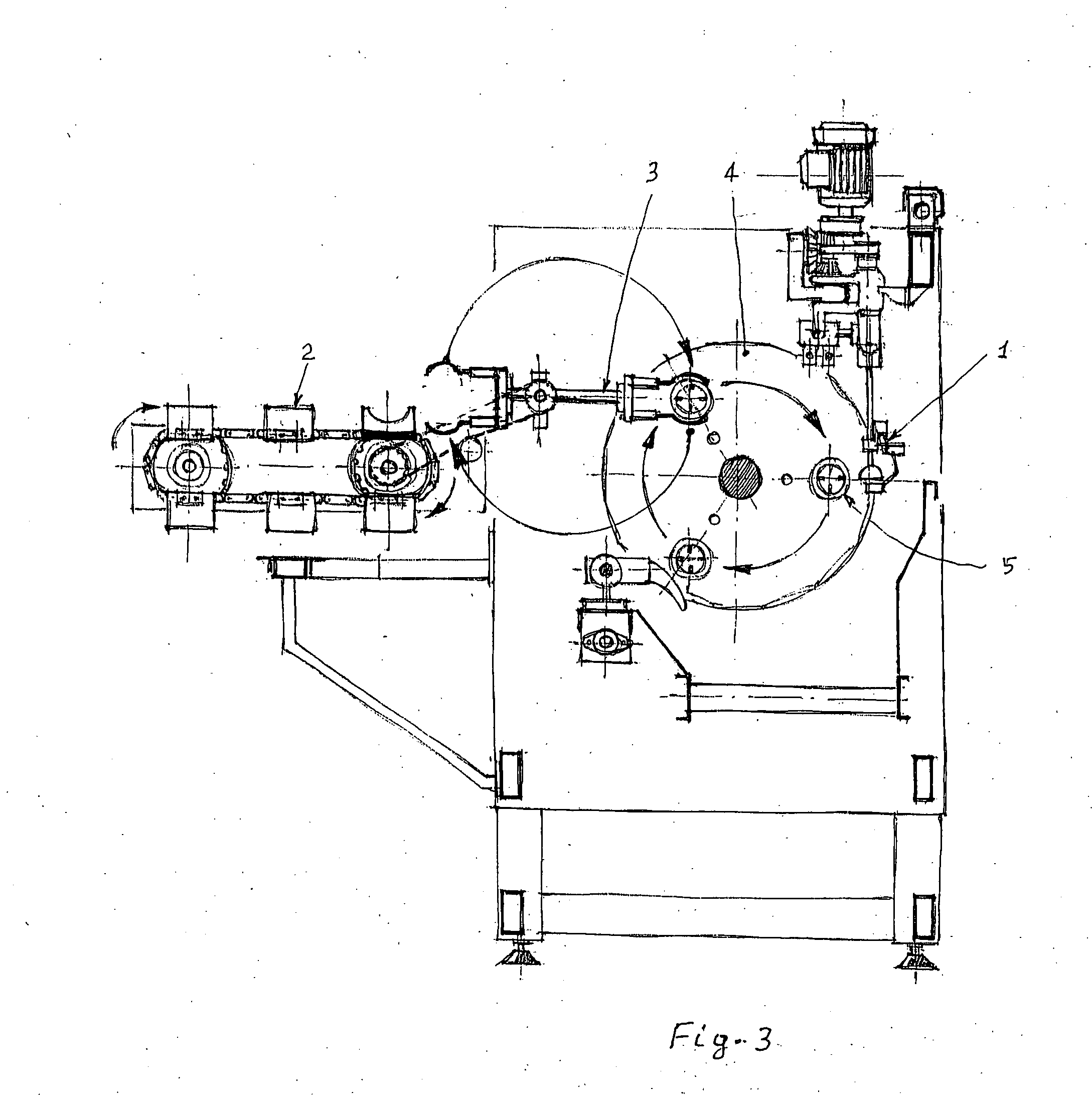

Device for peeling pulpy fruits, having an adjustable cutting depth

ActiveUS20050028686A1High yield percentage valueReduce wasteAutomatic control devicesFeeding apparatusPEARKiwi

A device for peeling pulpy fruits having an adjustable cutting depth The invention relates to a device suited to peel pulpy fruits, like citrus fruits, mango, kiwi, papaya, apples, pears, and particularly oranges and other fruits whose skin has not a uniform thickness. The peeling of fruits whose skin has an uneven thickness is made possible by the fact that the inventive device is equipped with a mechanism capable of varying continuously—according to a program—the amount of projection of the peeling tool relative to the feeler device, in the peeling step. The device is applicable to any kind of peeling machine, or to a machine that foresees a peeling step.

Owner:A B L SRL

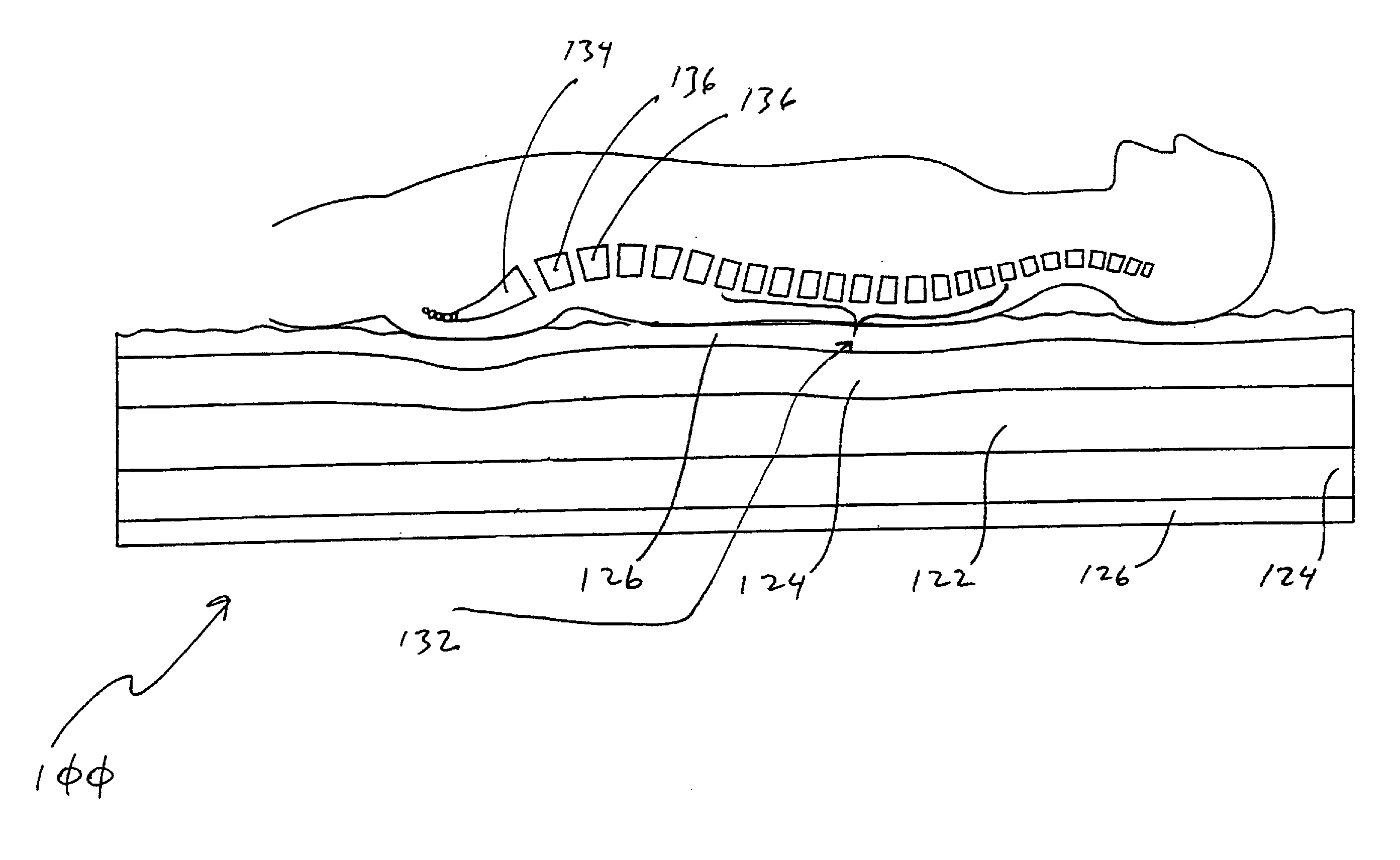

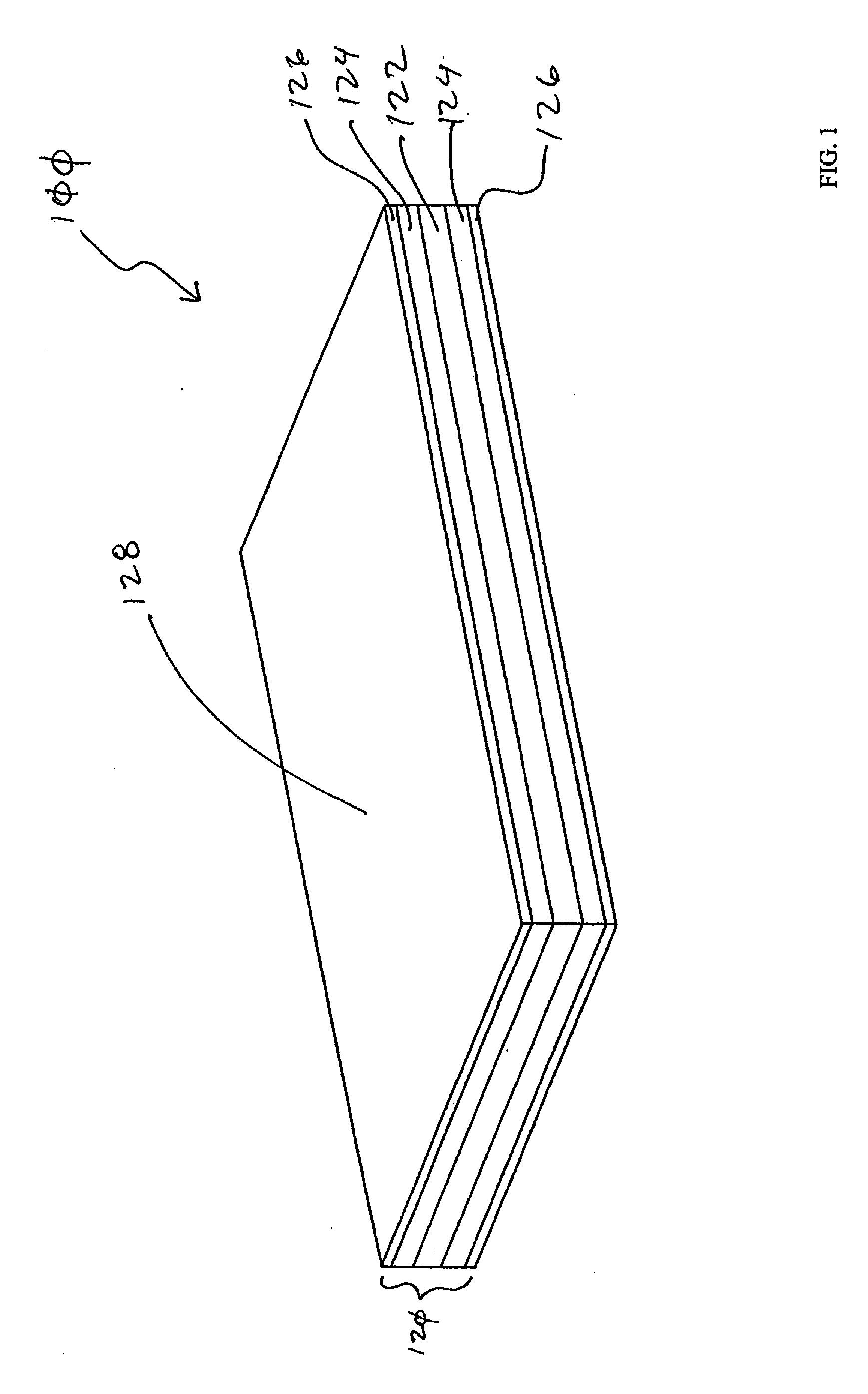

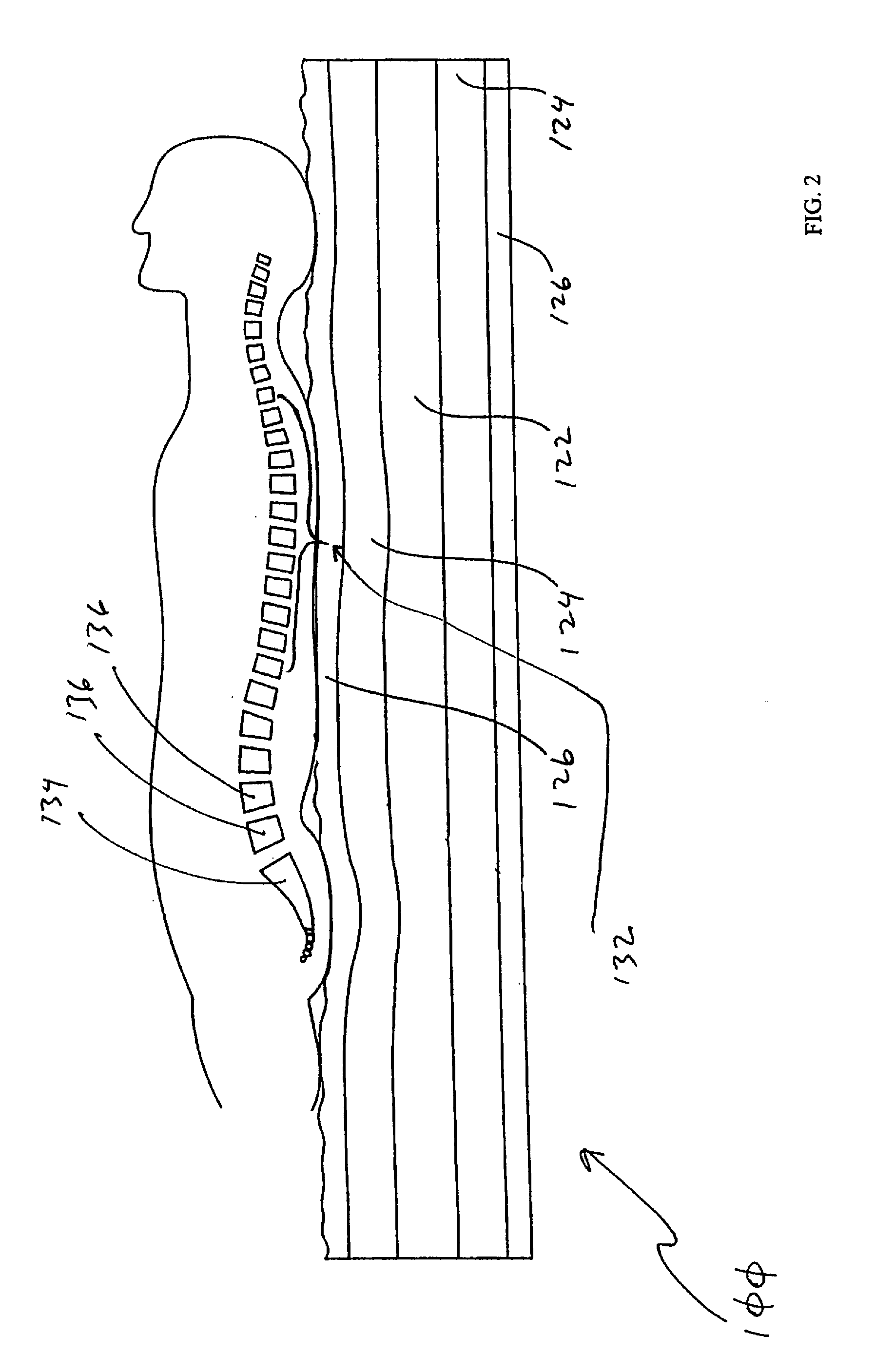

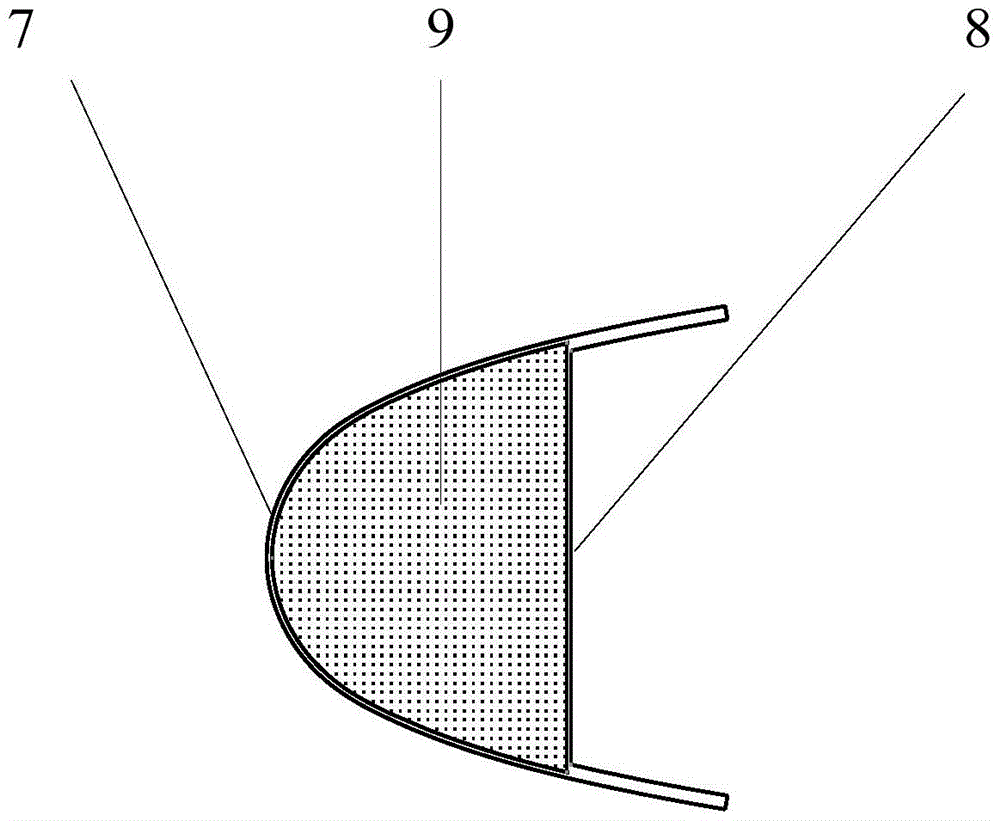

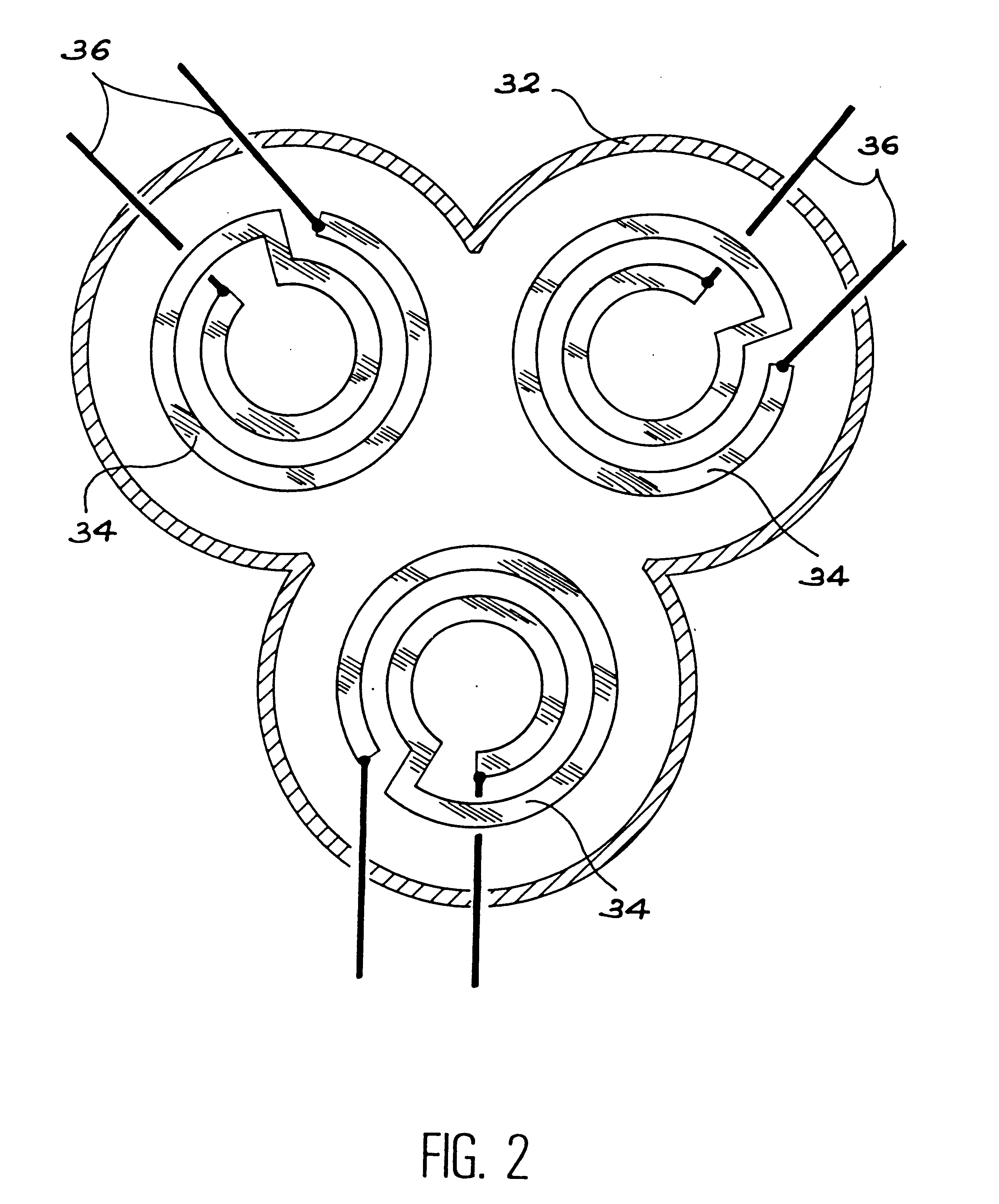

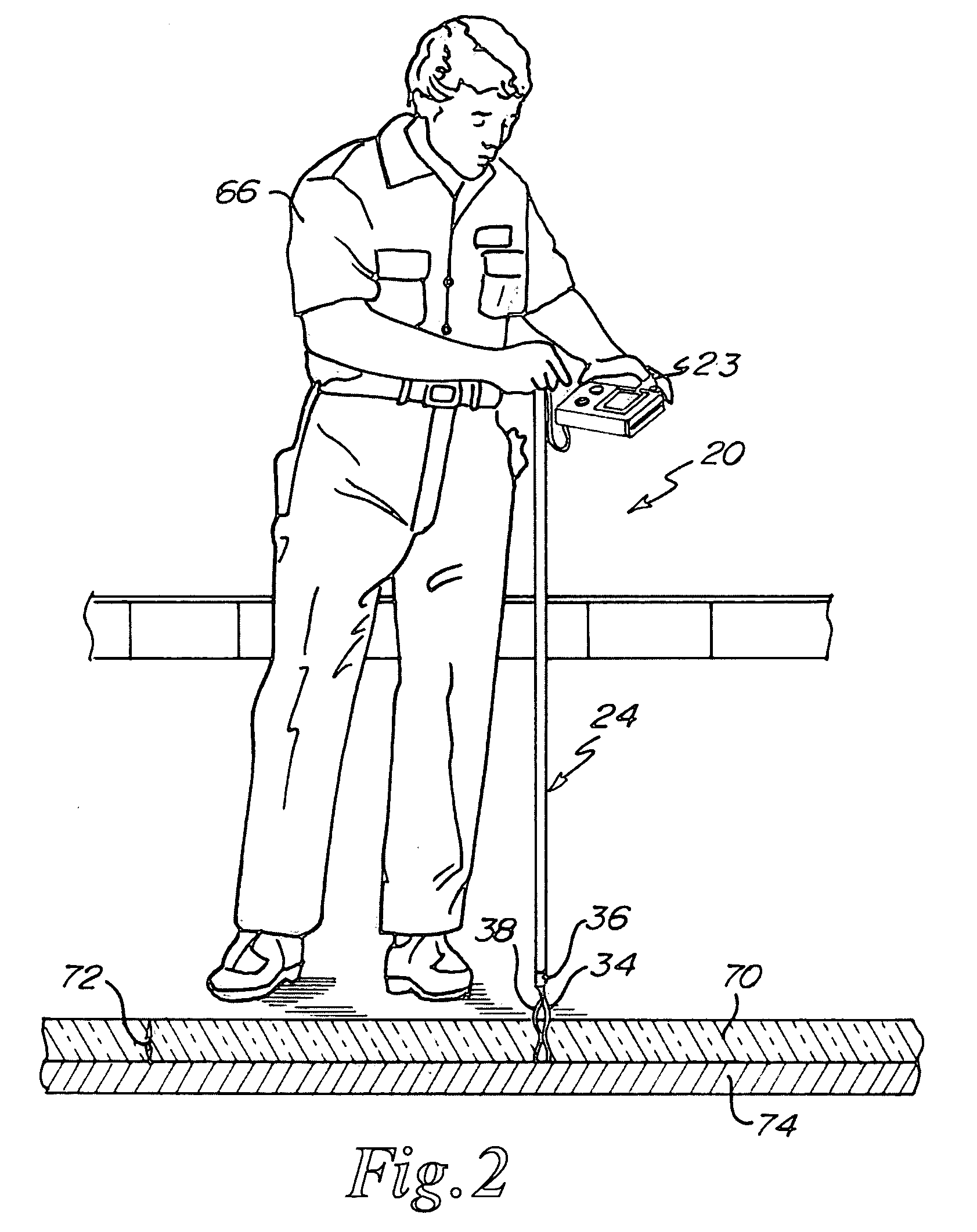

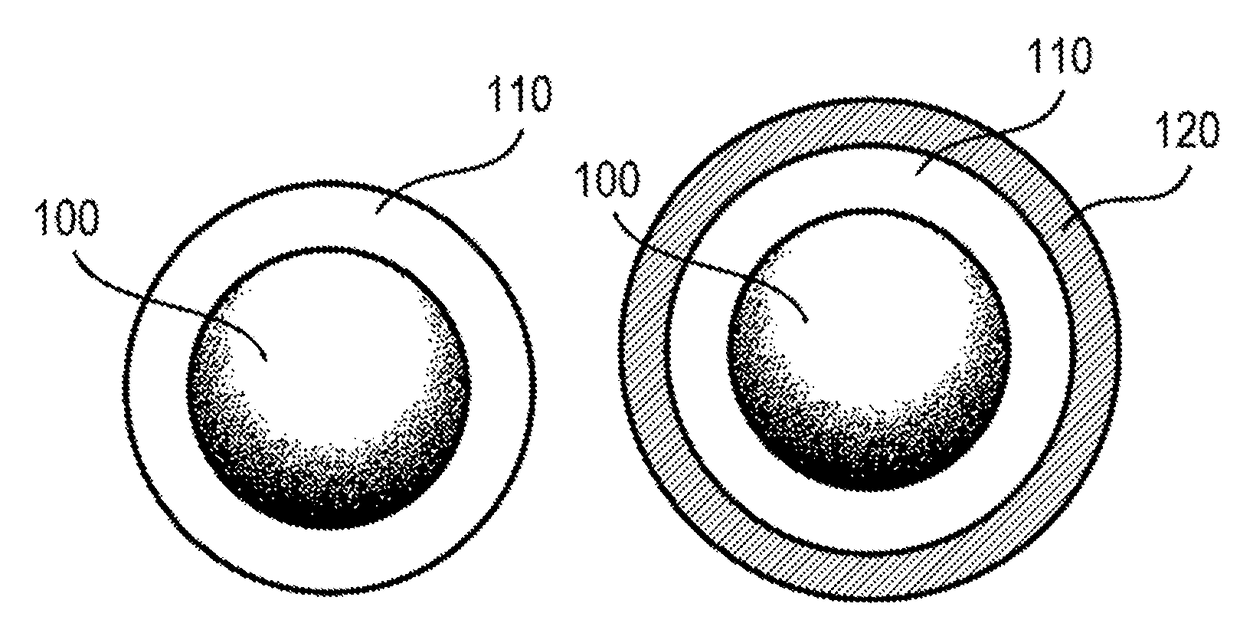

Transverse closed-loop resonator

A transverse closed-loop fiber resonator (10) includes an inner cladding (102) having a surface (300) peripherally forming a closed-loop shape for confining light to the surface (300). The inner cladding has a first diameter thickness (104) and a first index of refraction profile in a cross-sectional portion of the transverse closed-loop fiber resonator (10). A ringed-core (120) corresponding to the closed-loop shape is disposed on the corresponding surface of the inner cladding (102). The ringed-core (120) has a second thickness (124) of material thinner than the first diameter thickness (104), and a second index of refraction profile greater than the first index of the inner cladding by an index delta in the cross-sectional portion of the transverse closed-loop fiber resonator such that the ringed-core can guide light within the ringed-core traversely around the closed-loop shape.

Owner:CORNING INC

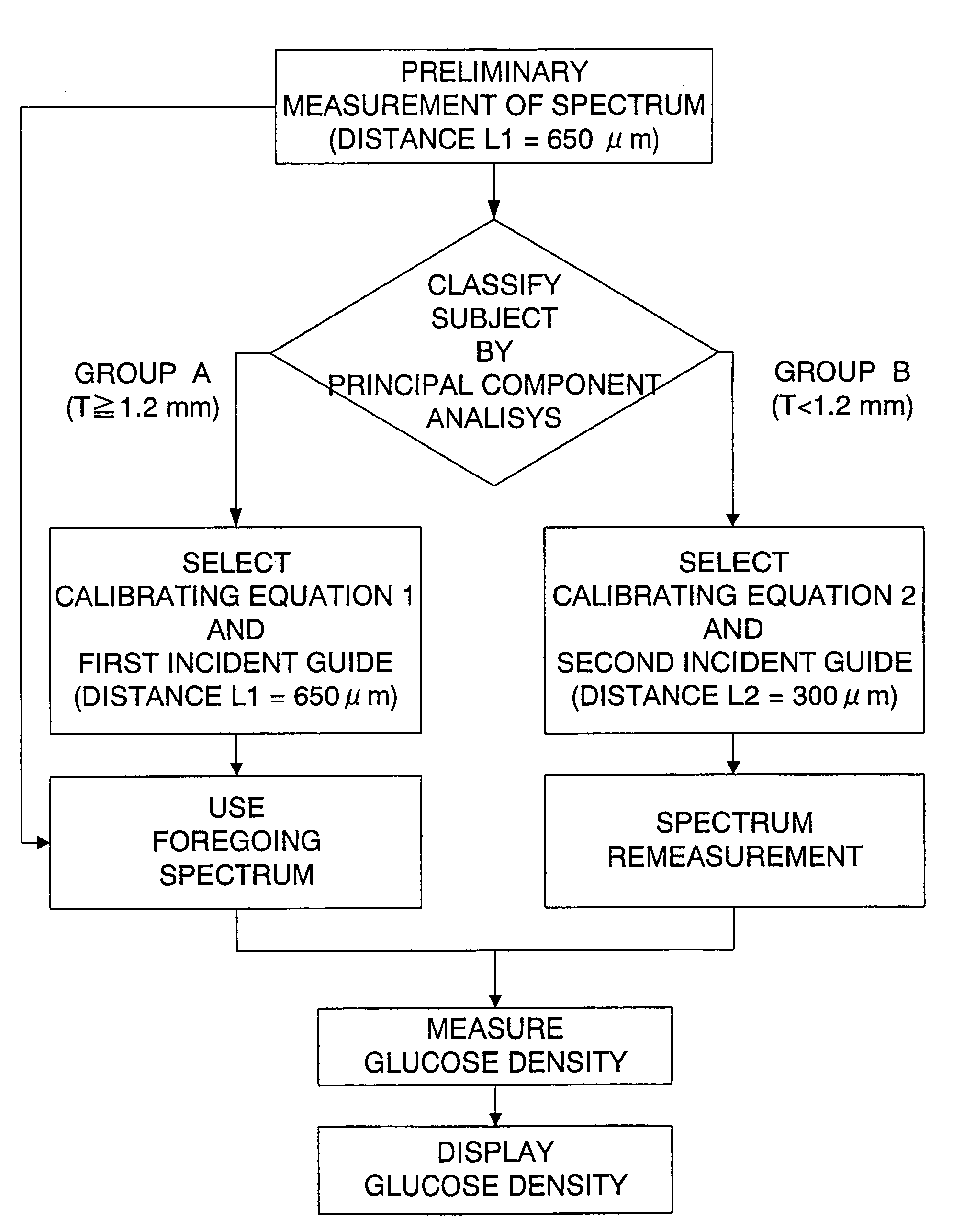

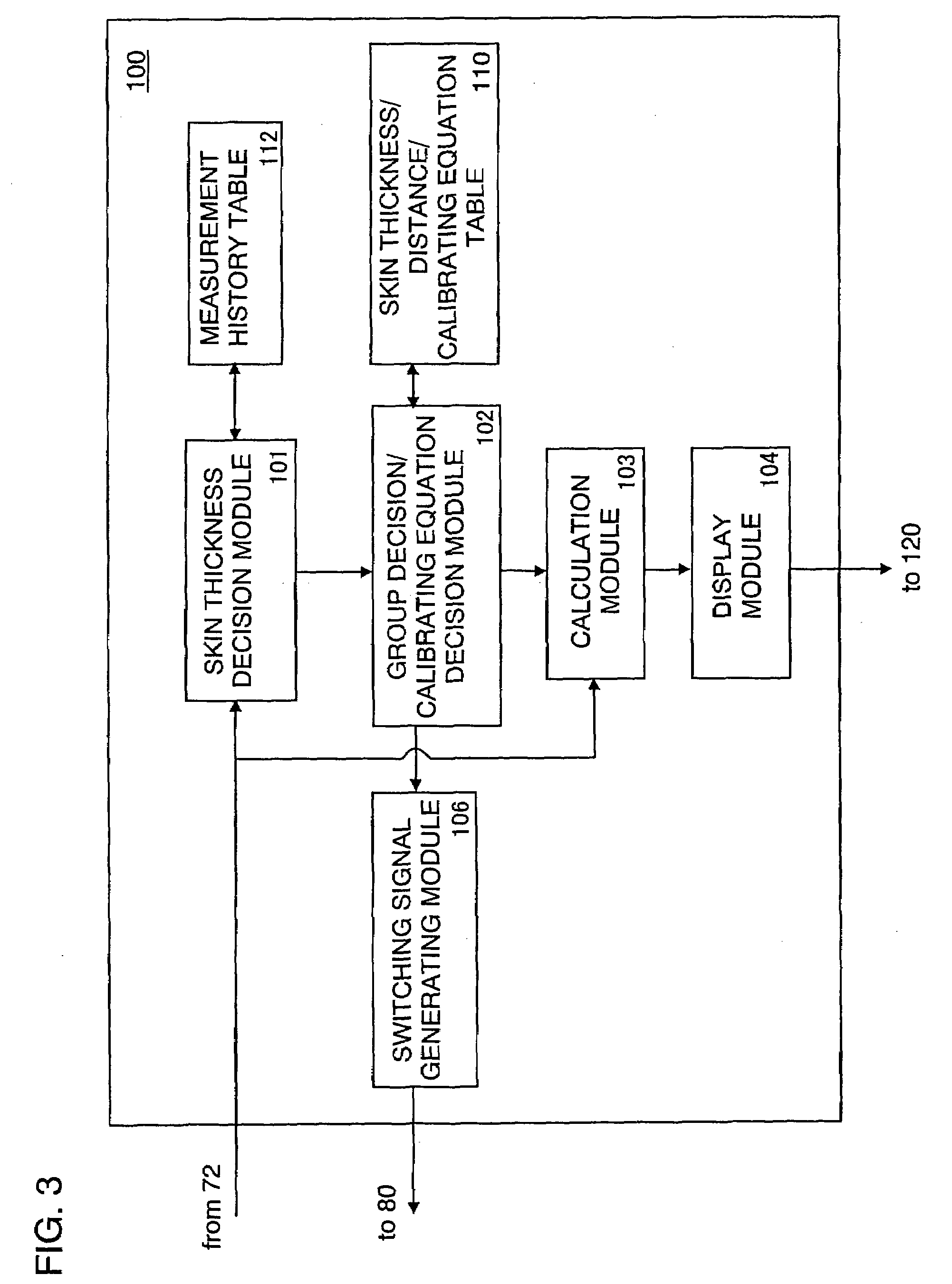

Method and device for calculating a biological component density of a subject

ActiveUS7333841B2Accurate measurementEasy to operateMicrobiological testing/measurementMedical automated diagnosisVolumetric Mass DensityD-Glucose

A method for calculating a biological component density of this invention comprises steps of irradiating a light of NIR spectrum to a skin of a subject, receiving the light of NIR reflected from the skin to obtain NIR spectrum data thereof, and substituting the NIR spectrum data into a predetermined calibrating equation to obtain a biological component density of the subject such as glucose density. This invention is characterized by preparing a plurality of the calibrating equations which are different from each other and are specific to each of plural groups which are classified in terms of a skin thickness parameter indicative of a skin thickness with respect to individuals of a species to which the subject belongs, determining the skin thickness parameter of the subject with a non-invasive technique and identifying the group of the subject in accordance with the determined skin thickness parameter, and deriving one of the calibrating equations in match with the identified group in order to calculate the biological component density of the subject.

Owner:PHC HLDG CORP

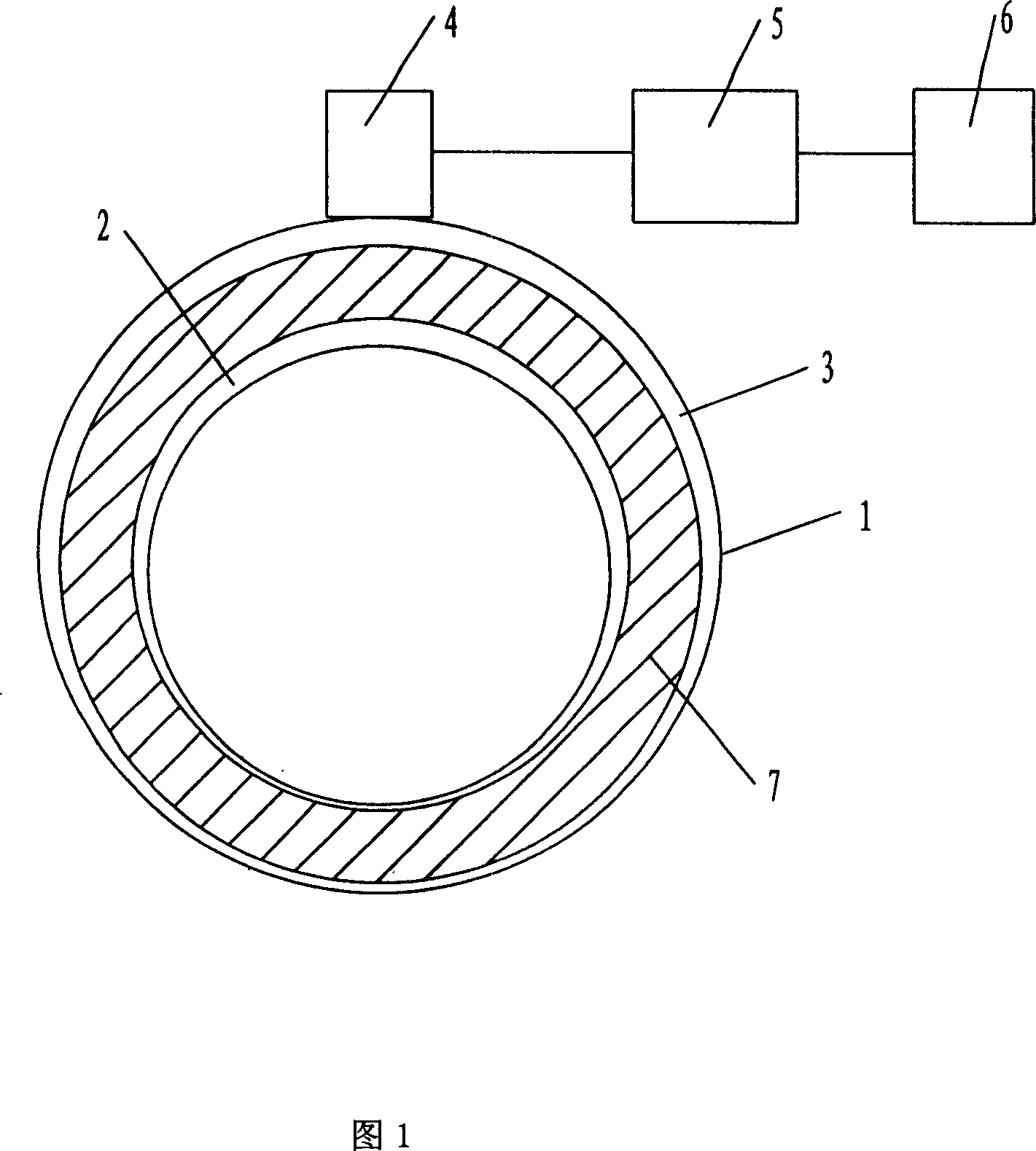

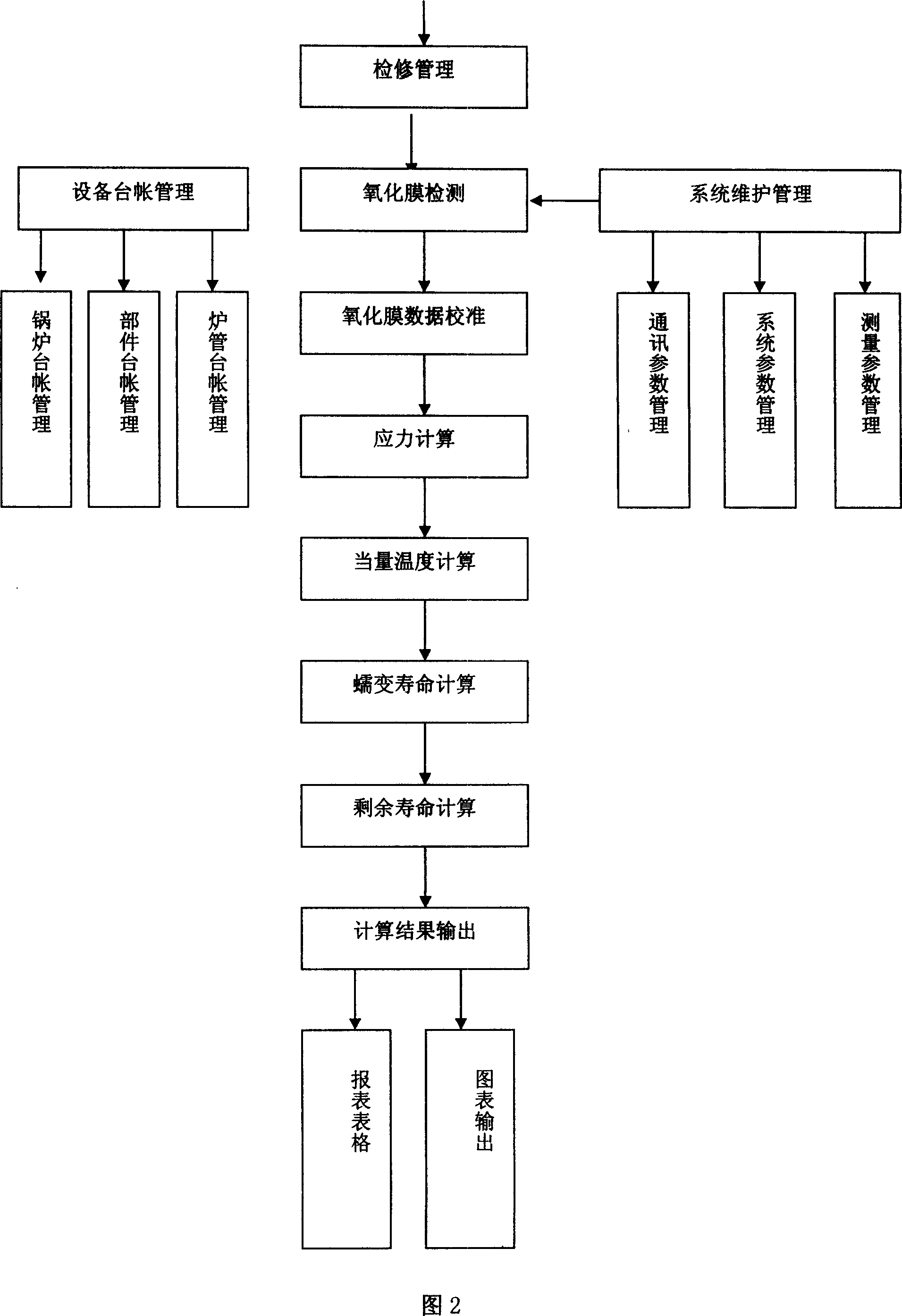

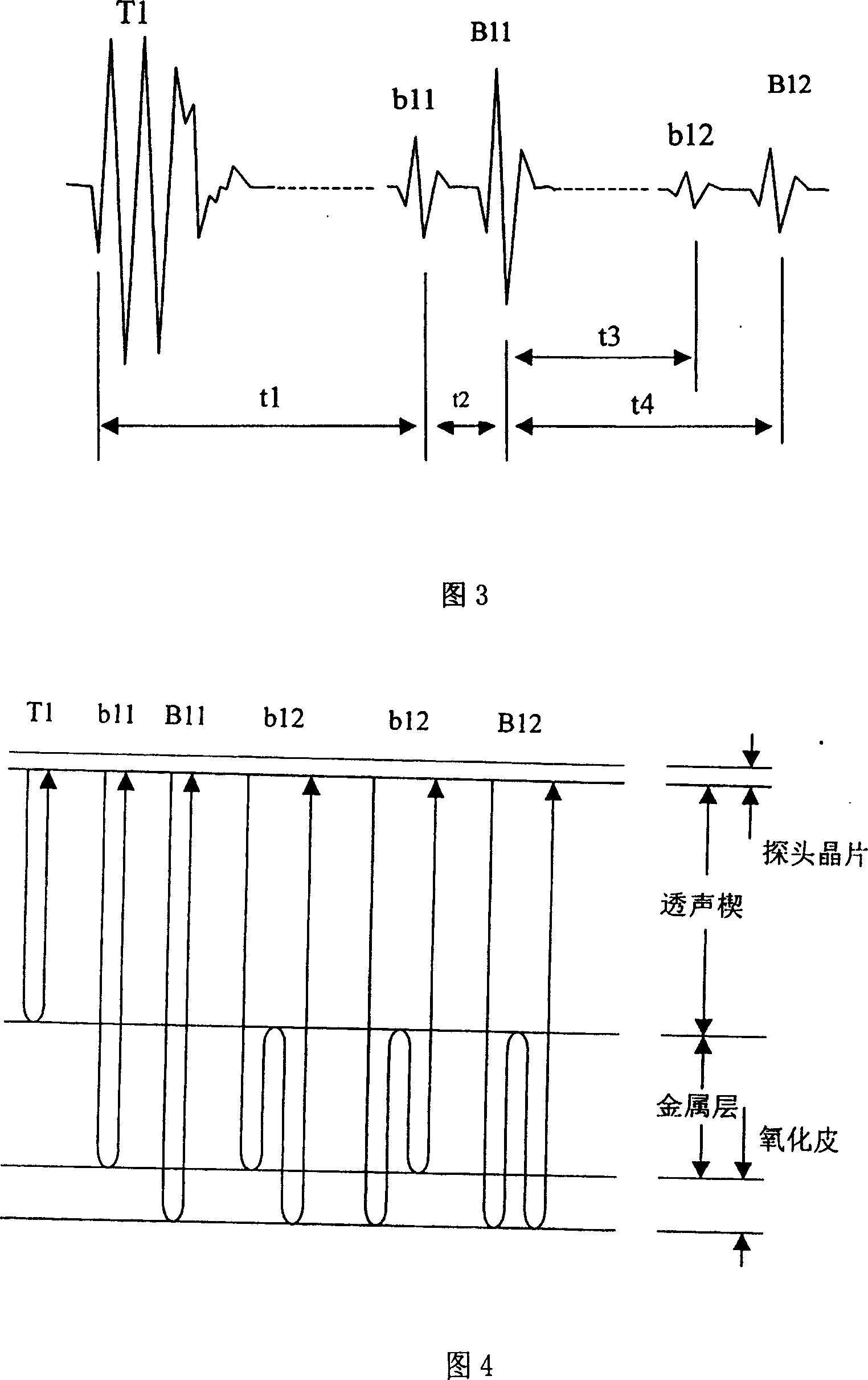

High temperature furnace pipe residue lifetime estimation method and device

InactiveCN101013067AAvoid Boiler AccidentsAvoid accidentsUsing subsonic/sonic/ultrasonic vibration meansStructural/machines measurementOxygenData treatment

The invention provides a high-temperature furnace tube remaining life assessment method, including the following steps: (a) according to the propagation velocity of the ultrasound in the oxygen skin, to calculate thickness of the inner wall oxygen skin; (2) according to the propagation velocity of the ultrasonic in the high temperature furnace tube matrix, to calculate the metal layer thickness; (3) establish the relationship database of the high temperature metal inner wall oxygen skin thickness, the running time and the equivalent temperature, to calculate the equivalent temperature when high temperature furnace tube running; (4) calculate the high-temperature furnace tube operation stress, and establish the relationship database of the high temperature furnace tube equivalent temperature, remaining life, and operation stress, and forecast the high temperature furnace tube remaining life. At the same time, it provides a high-temperature furnace tube remaining life assessment device, and the device includes the waveform acquisition device, the waveform display and receiving device, and the data-processing system. The invention can calculate and predict the high temperature furnace tube remaining life, and according to the remaining life, it can replace in advance the high-temperature furnace tube during the life end state.

Owner:JINAN FENGCAI ELECTRONICS TECH

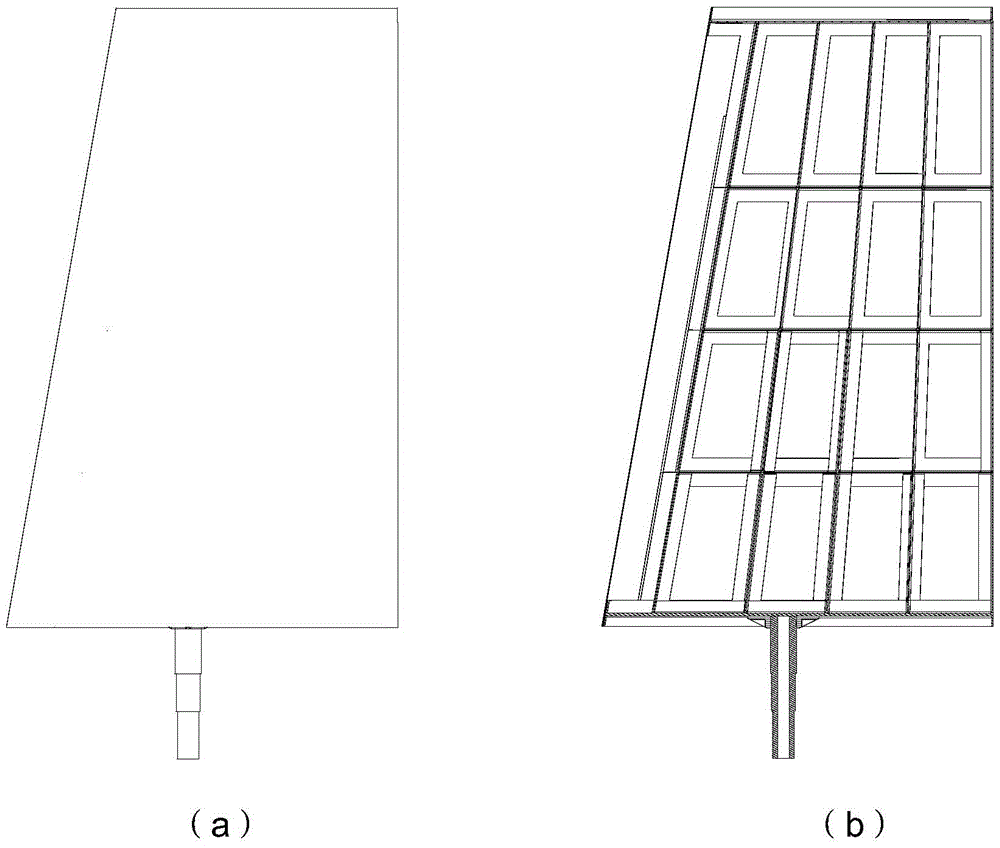

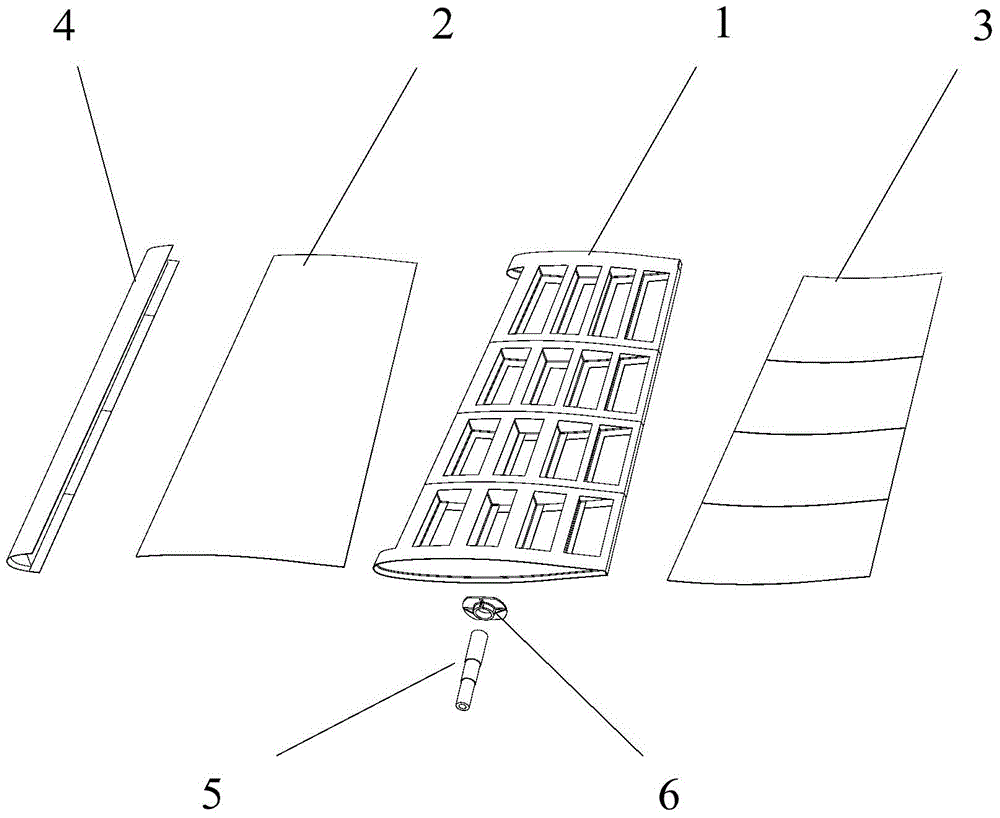

Composite material integrated control surface structure with progressive decrease in rigidity and processing method thereof

ActiveCN105035359AExcellent chatter characteristicsReduce structural weightCosmonautic vehiclesCosmonautic partsFiberEngineering

The invention discloses a composite material integrated control surface structure with progressive decrease in rigidity and a processing method thereof, wherein a design solution of a carbon fiber composite material integrated control surface structure is adopted; besides a control shaft and accessories thereof, the rest of the structure is carbon fiber reinforcedcomposite material; advanced optimization design technology is adopted; through several iterative calculations, the structure size design is optimized; the weight of the control surfacestructure is lightest; the rigidity of the optimized control surface structure is on the decrease progressively along an axial direction, that is, the thickness size of an internal skeleton web is on the decrease progressively towardswing tips and two sides; and the skin thickness is not the same and is on the decrease progressively towards the wing tips, thus the structure weight is further reduced; the control surface modal frequency is increased; and the control surface vibration property is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

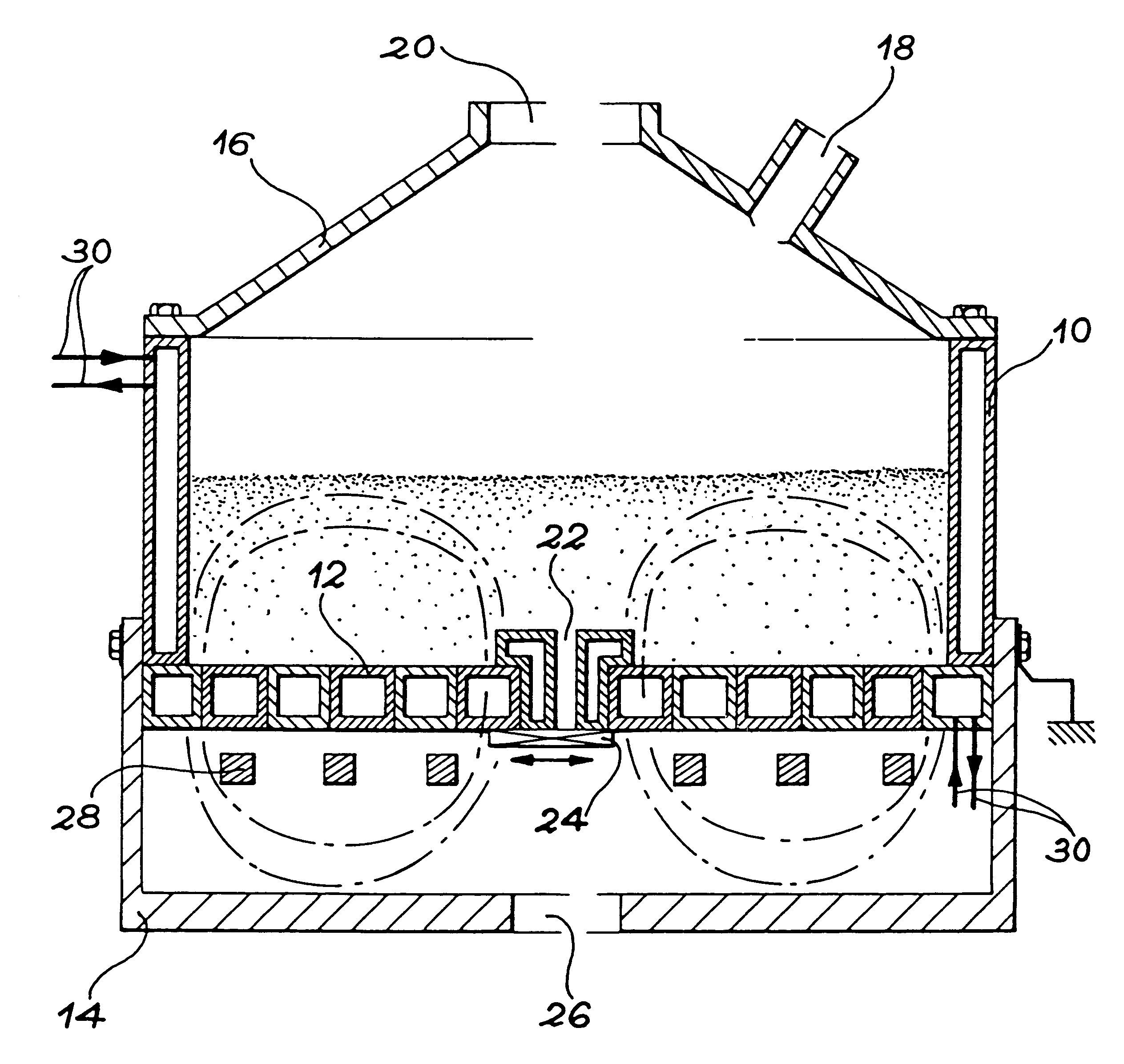

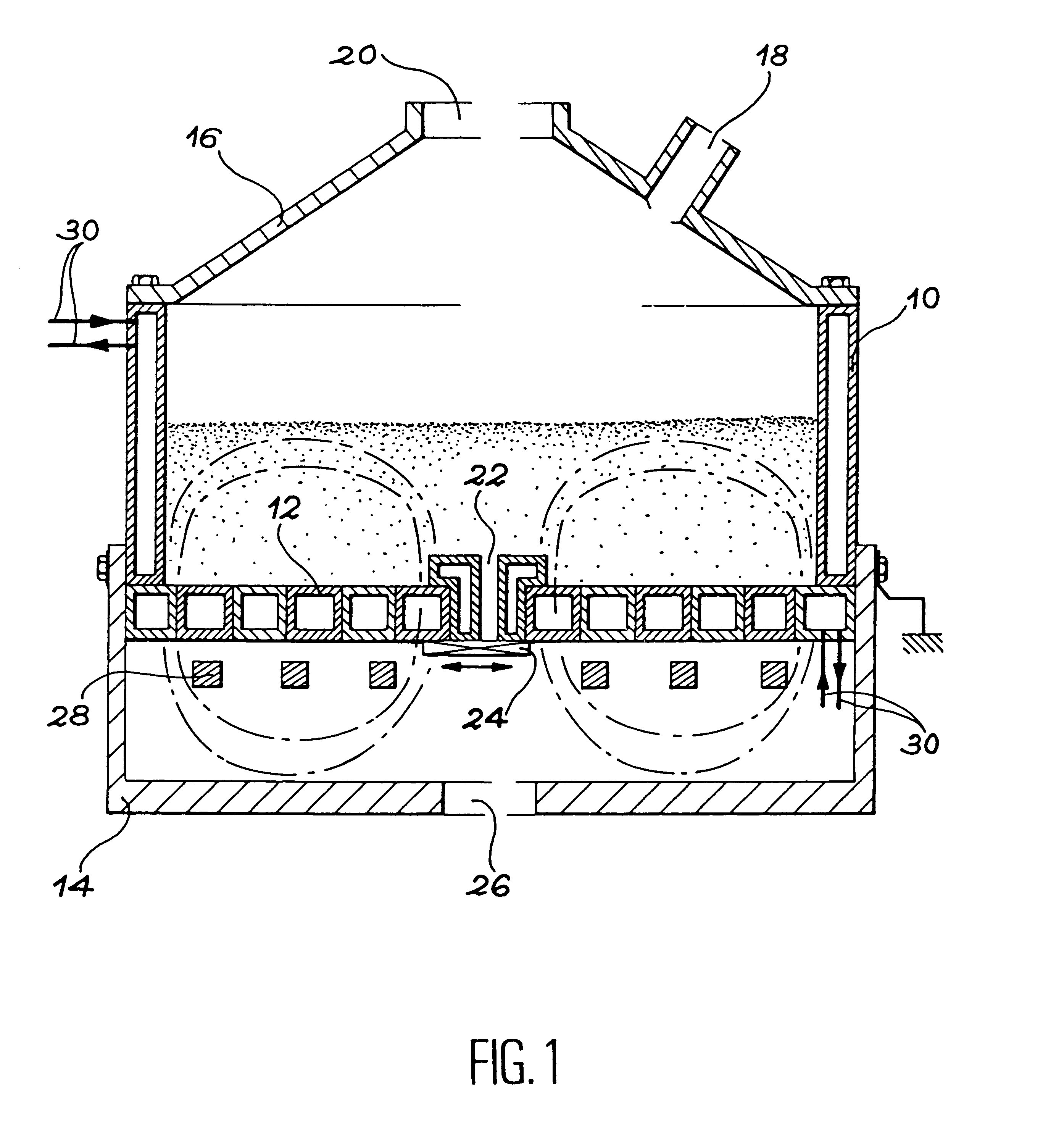

Glass induction melting furnace using a cold crucible

InactiveUS6185243B1Reduce inductanceLess expensiveFurnaces without endless corePot furnacesCrucibleMetal

A melting furnace for insulating materials is provided with a cooled crucible (10) having continuous metal side malls, a partitioned and cooled bottom (12) and at least one induction coil (28) placed under the bottom which serves as the sole heating means. The depth of the melting bath contained in the crucible and the excitation frequency of the induction coil are selected so that the depth and half of the inside radius of the crucible are less than the skin thickness of the bath.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

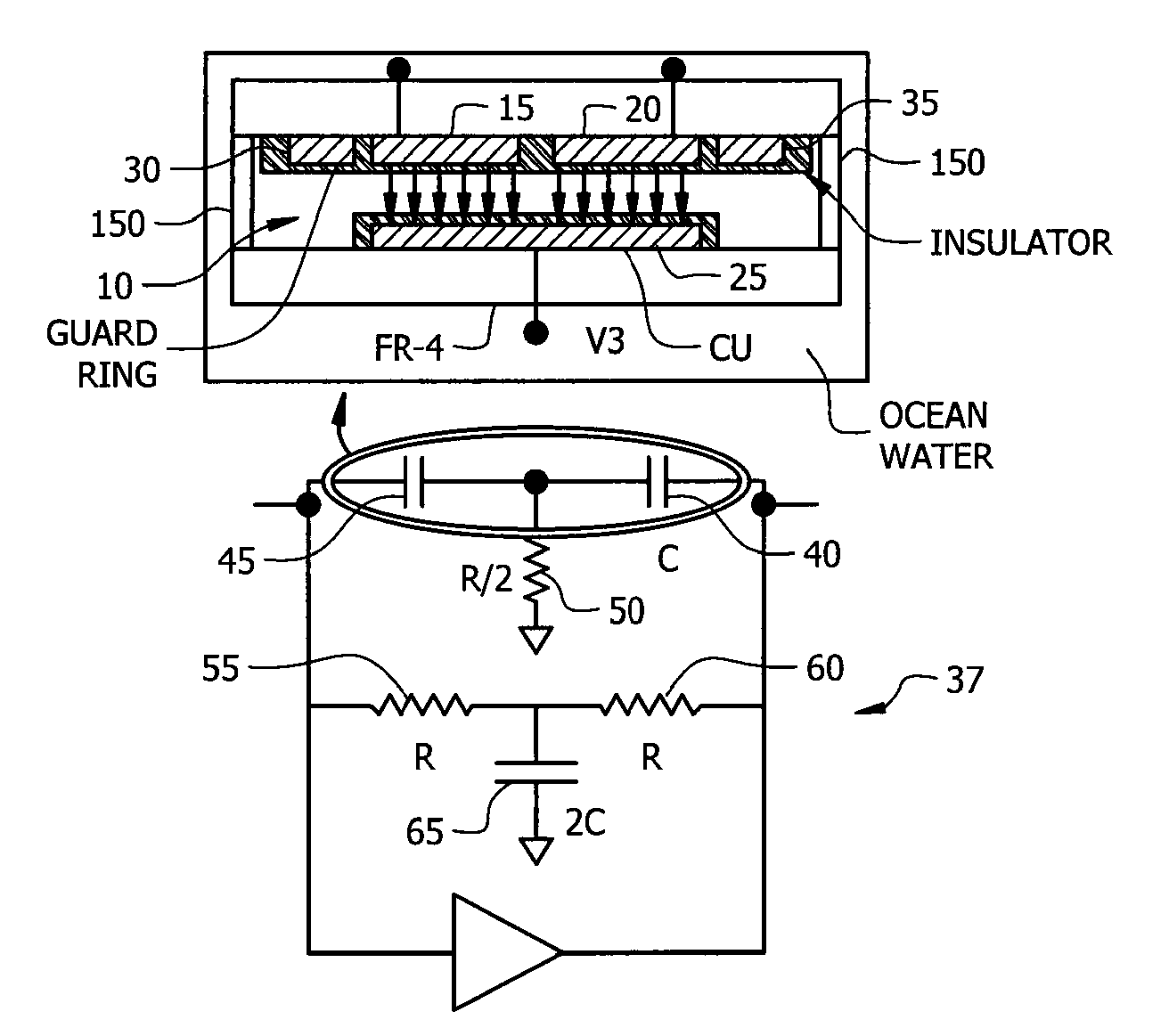

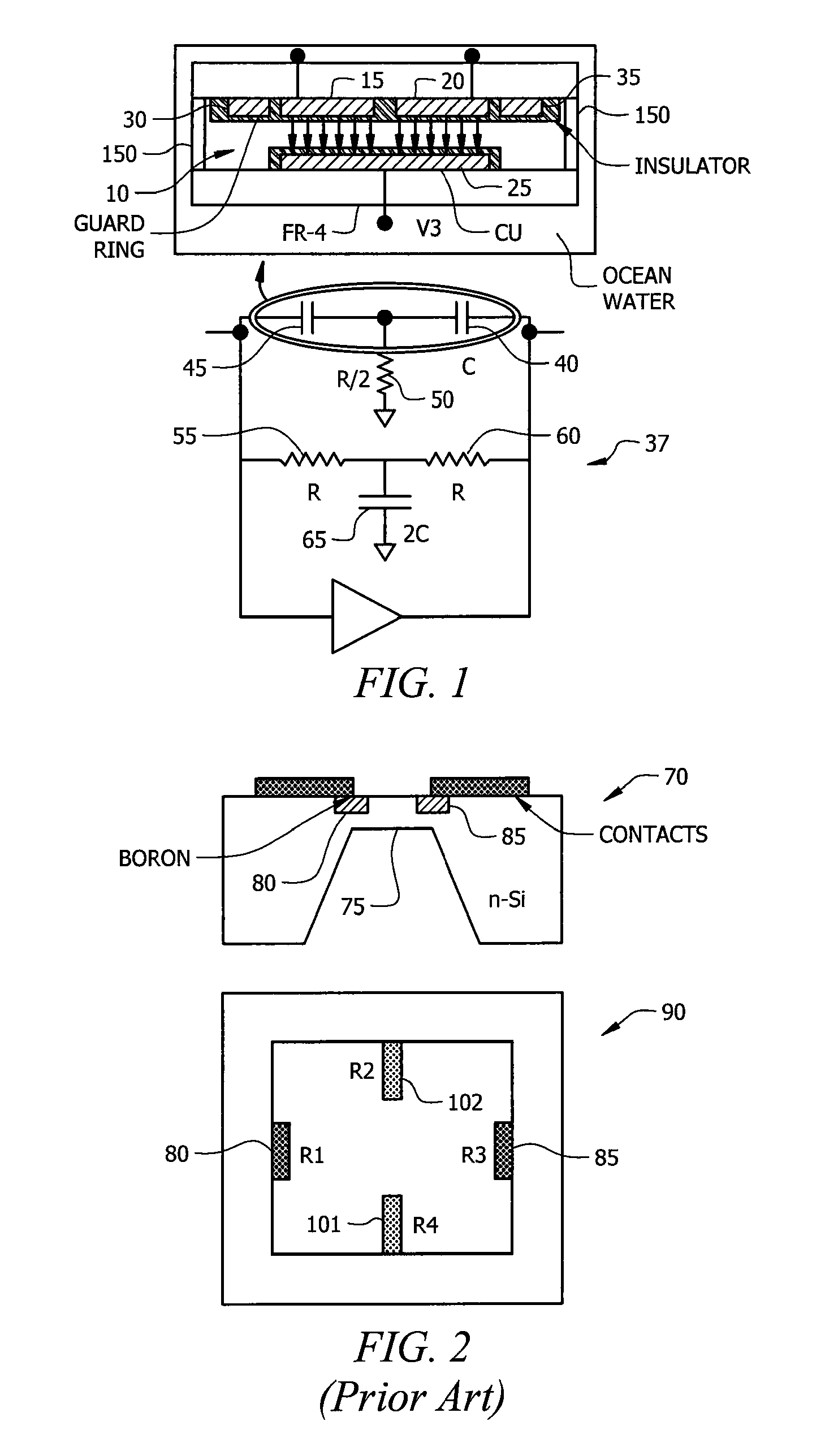

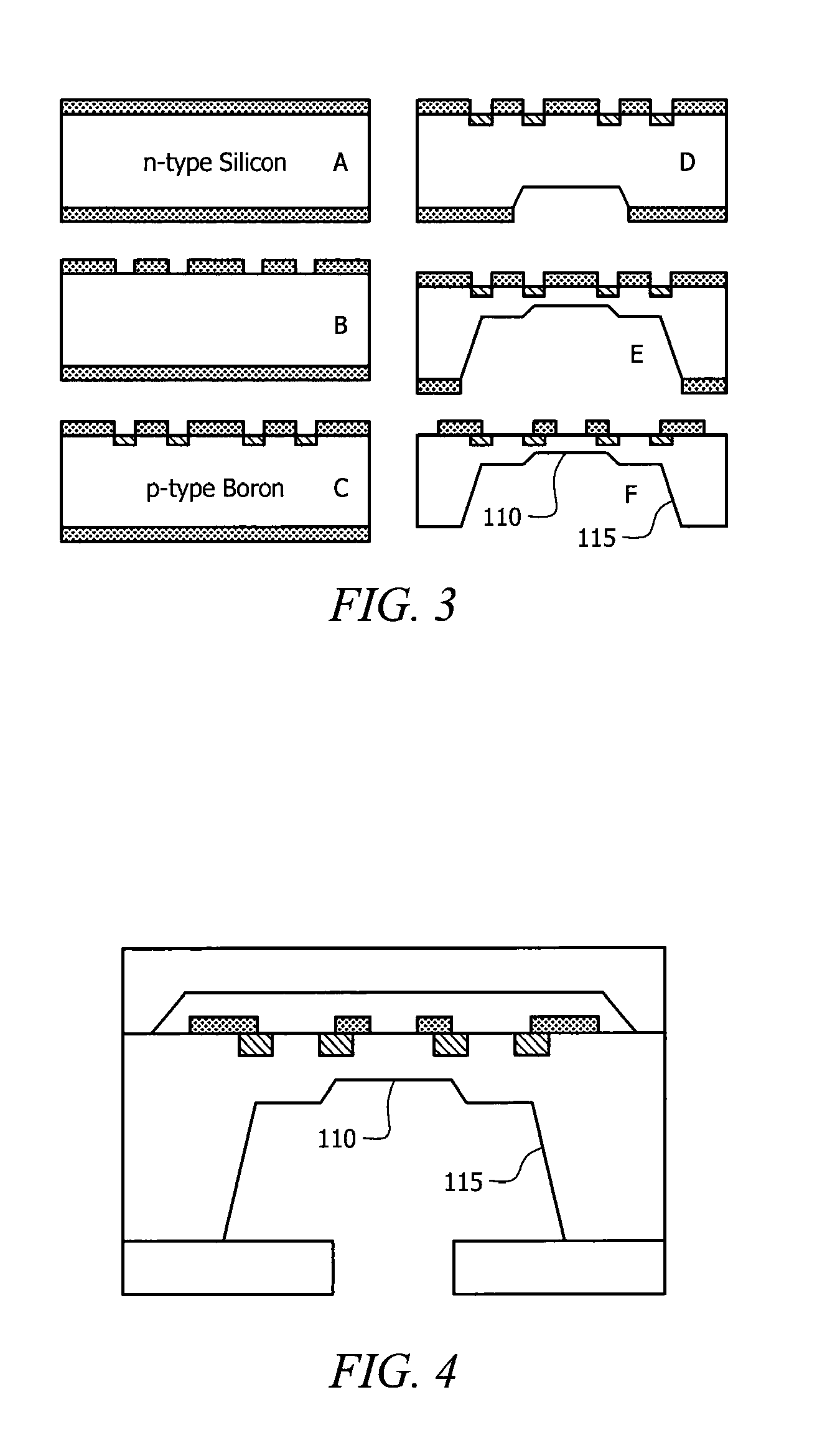

Reinforced piezoresistive pressure sensor

InactiveUS7856885B1Protect environmentHigh measurement accuracyMeasurement apparatus componentsFluid pressure measurement using ohmic-resistance variationEngineeringPiezoresistive pressure sensors

A MEMS-based silicon pressure sensor for the ocean environment is presented. The invention is a multiple diaphragm piezoresistive pressure sensor for measuring the pressure of a liquid, comprising an inner deformable diaphragm formed on a silicon substrate, the inner deformable diaphragm having a first thickness an outer deformable diaphragm formed on the silicon substrate, the outer deformable diaphragm having a second thickness which is greater than the first thickness, positioned below the inner deformable diaphragm to support the inner deformable diaphragm, a first piezoresistive bridge embedded in the inner deformable diaphragm, a second piezoresistive bridge embedded in the outer deformable diaphragm and possibly a third piezoresistive bridge embedded in the silicon substrate to compensate for temperature variations.

Owner:UNIV OF SOUTH FLORIDA

Optical measurement apparatus and blood sugar level measuring apparatus using the same

InactiveUS20050065415A1Accurately determineImprove accuracyScattering properties measurementsSensorsOptical measurementsBlood sugar

Blood sugar levels are measured non-invasively based on temperature measurement. Values of blood sugar levels non-invasively measured by a temperature measuring system are corrected using blood oxygen saturation and blood flow volume. Optical sensors are provided for detecting scattered light, reflected light, and light that enters into the skin which travels out of the body surface. The measurement data is stabilized by taking into consideration the influence of the thickness of skin on blood oxygen saturation.

Owner:HITACHI LTD

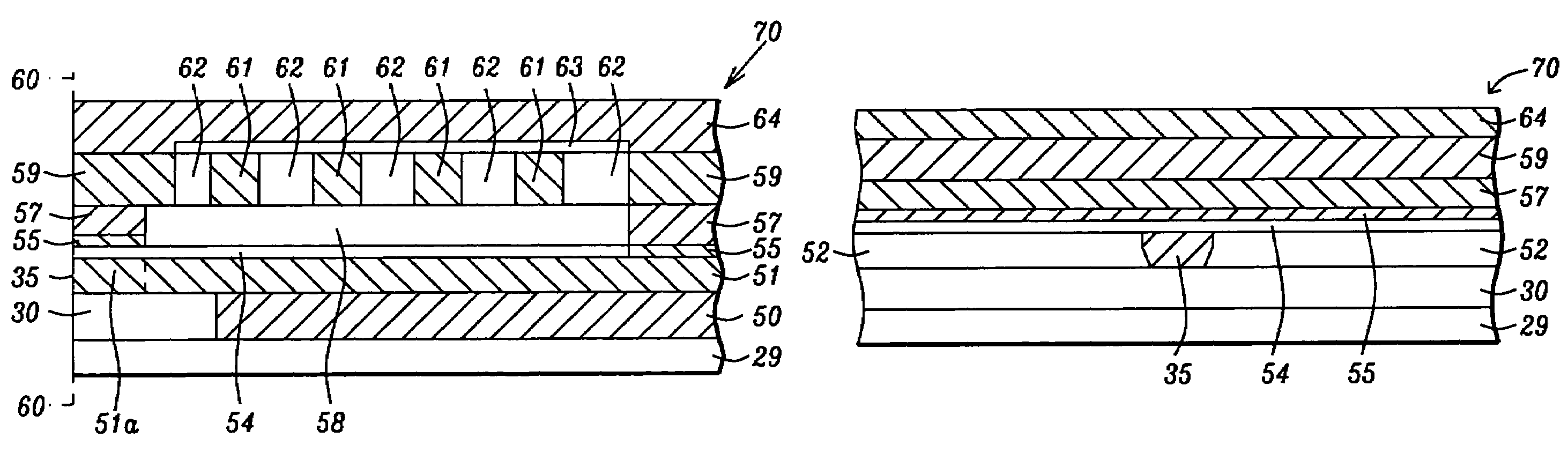

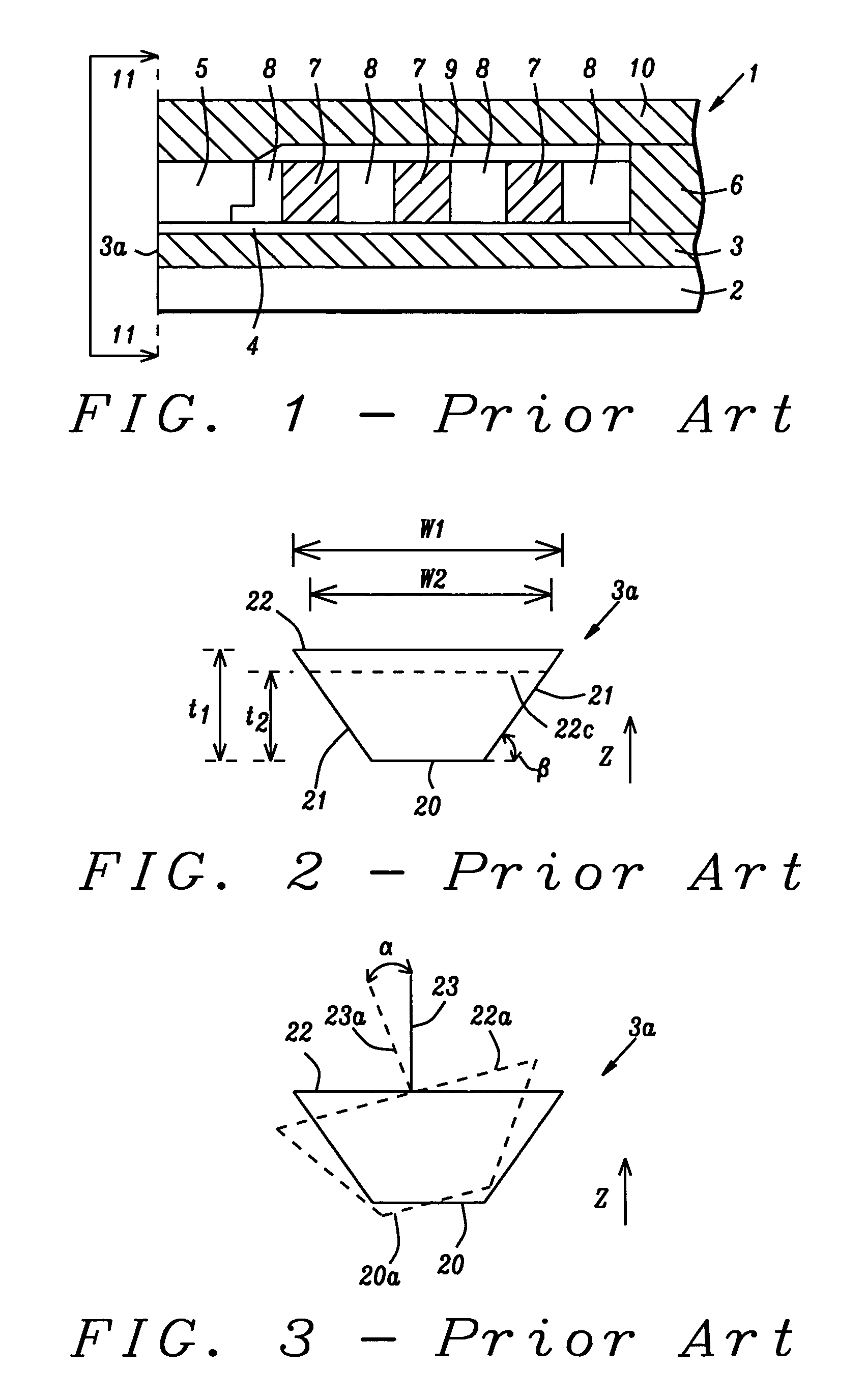

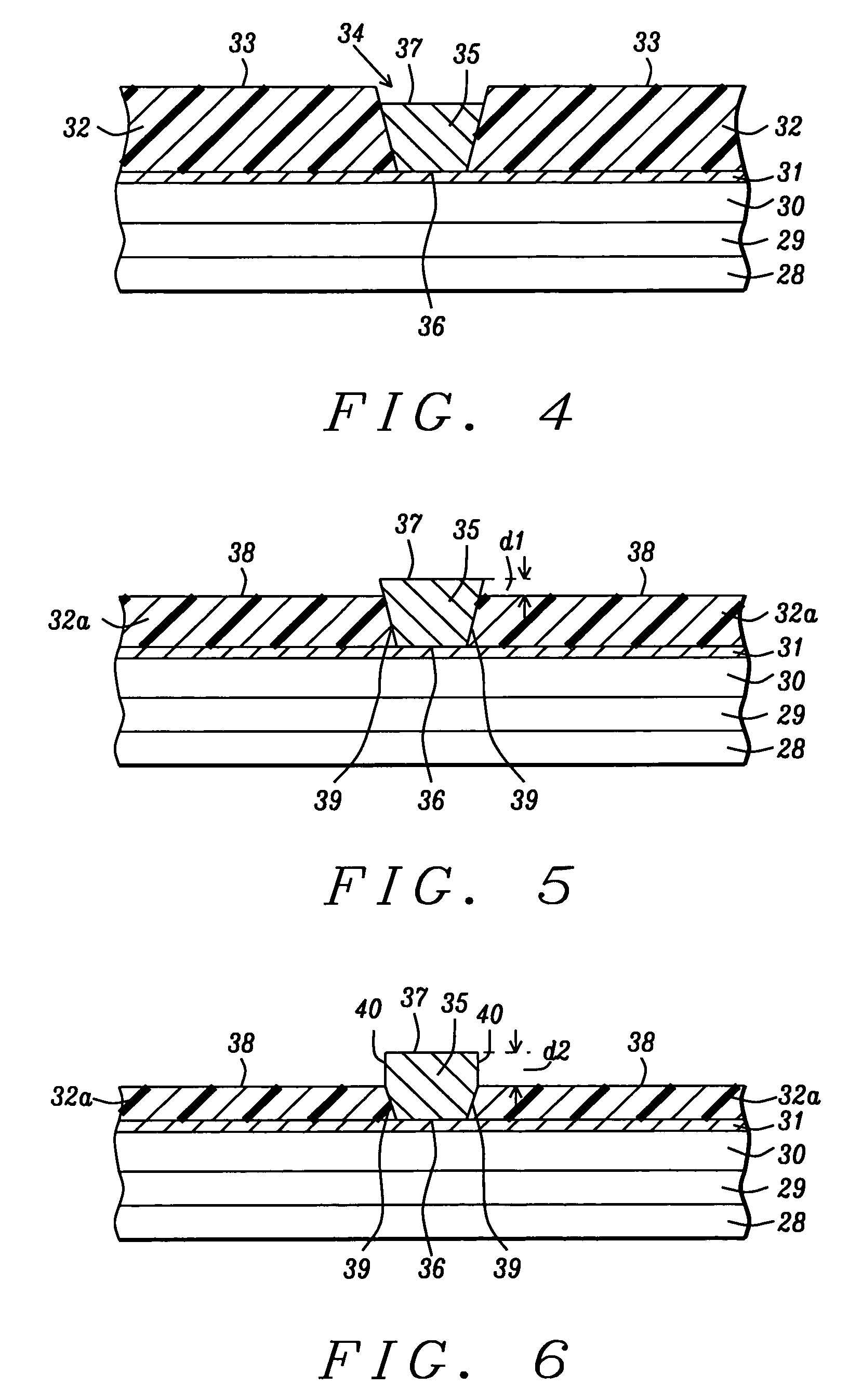

Pole width control on plated bevel main pole design of a perpendicular magnetic recording head

A main pole layer is deposited within an opening in a patterned photoresist layer on a substrate. The photoresist is thinned to expose an upper portion of a pole tip region that is then trimmed to a rectangular shape while a lower portion retains an inverted trapezoidal shape. Thereafter, a second trimming process forms a pole tip with a first width in the upper rectangular portion and a second thickness and second width which is less than the first width in the lower portion. A CMP step subsequently thins the upper portion to a first thickness of 0.04 to 0.08 microns while the second thickness remains at 0.16 to 0.32 microns. The bottom surface of the lower portion along the ABS becomes the trailing edge in a recording operation. The pole tip has a consistent first width (track width) that is not influenced by CMP process variations.

Owner:HEADWAY TECHNOLOGIES INC

Hard nanometer layered ZrO2/TiN coating

InactiveCN1888124AHigh hardnessImprove antioxidant capacityVacuum evaporation coatingSputtering coatingCeramic coatingArgon atmosphere

The present invention is one kind of multilayer hard nanometer ZrO2 / TiN coating and belongs to the field of ceramic coating technology. The multilayer hard nanometer ZrO2 / TiN coating includes alternately deposited ZrO2 layers of 2-8 nm thickness and TiN layers of 0.4-1.2 nm thickness on the substrate of hard alloy, ceramic or metal, and has total thickness of 2-5 microns. It is prepared through a double-target sputtering process in argon atmosphere. It has not only excellent high temperature oxidation resistance, but also hardness as high as 19.1-23 GPa. The multilayer hard nanometer ZrO2 / TiN coating of the present invention may be formed on high speed cutting tool and other high temperature wear and corrosion resistant workpieces.

Owner:SHANGHAI JIAO TONG UNIV

Pole width control on plated bevel main pole design of a perpendicular magnetic recording head

A main pole layer is deposited within an opening in a patterned photoresist layer on a substrate. The photoresist is thinned to expose an upper portion of a pole tip region that is then trimmed to a rectangular shape while a lower portion retains an inverted trapezoidal shape. Thereafter, a second trimming process forms a pole tip with a first width in the upper rectangular portion and a second thickness and second width which is less than the first width in the lower portion. A CMP step subsequently thins the upper portion to a first thickness of 0.04 to 0.08 microns while the second thickness remains at 0.16 to 0.32 microns. The bottom surface of the lower portion along the ABS becomes the trailing edge in a recording operation. The pole tip has a consistent first width (track width) that is not influenced by CMP process variations.

Owner:HEADWAY TECH INC

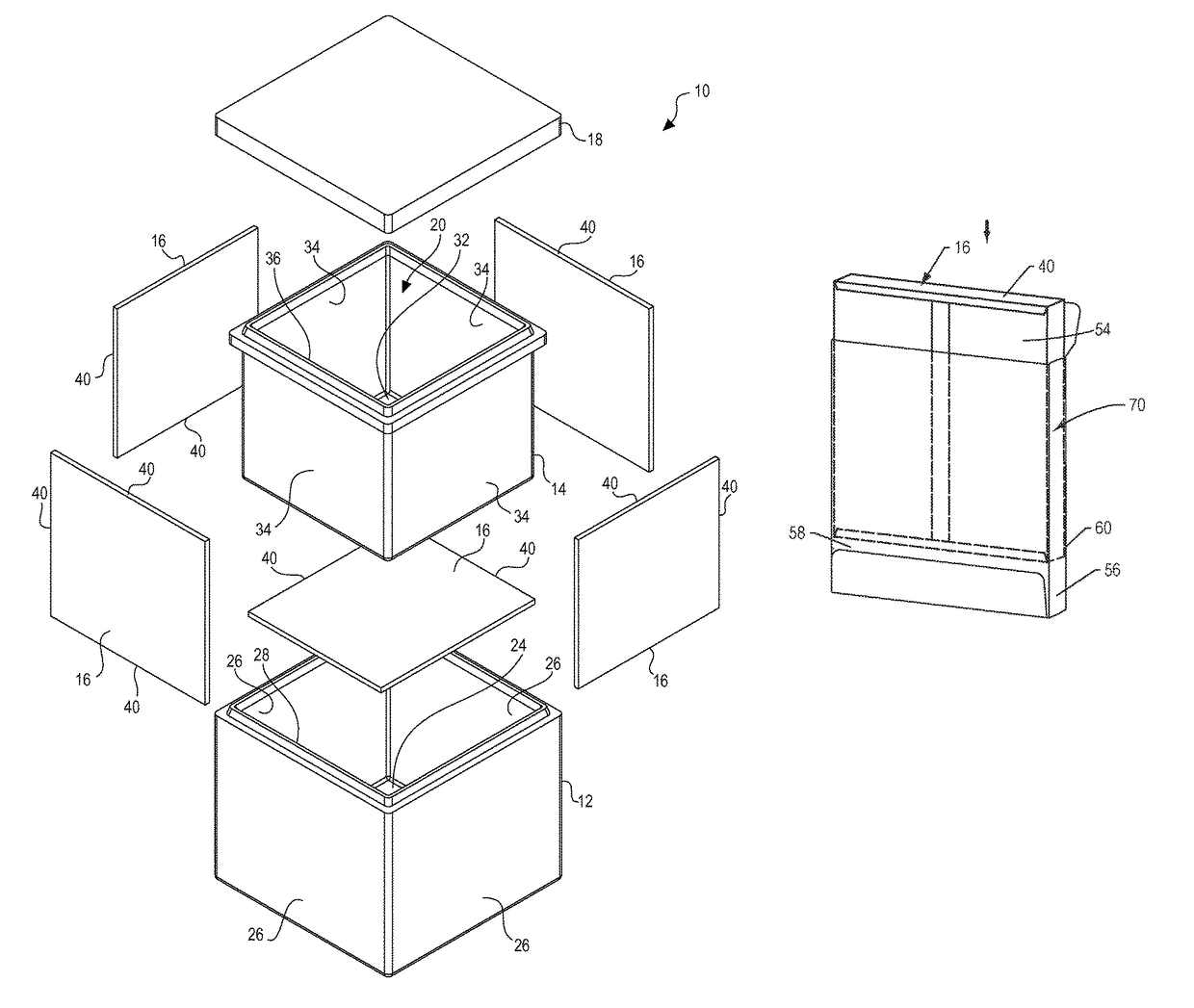

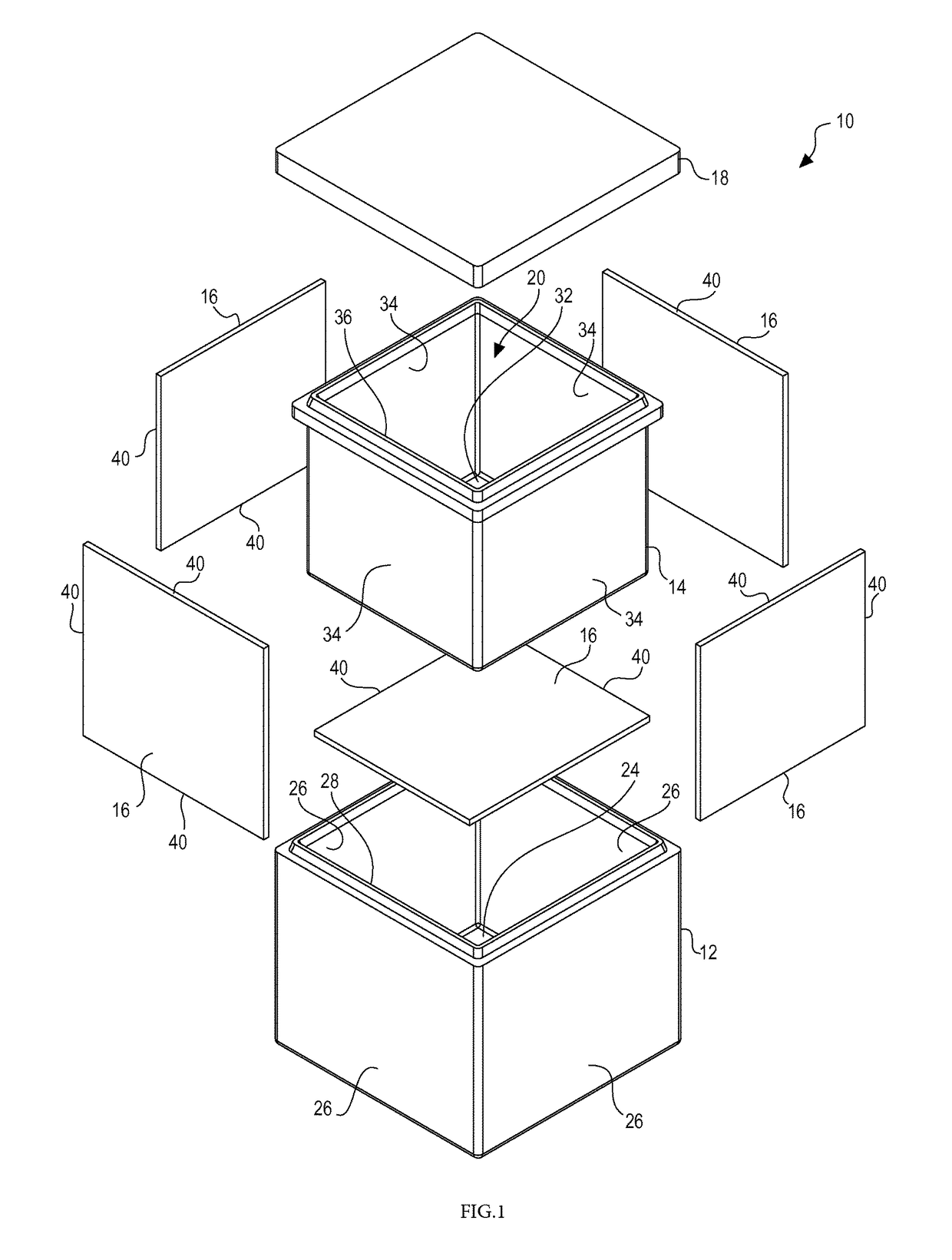

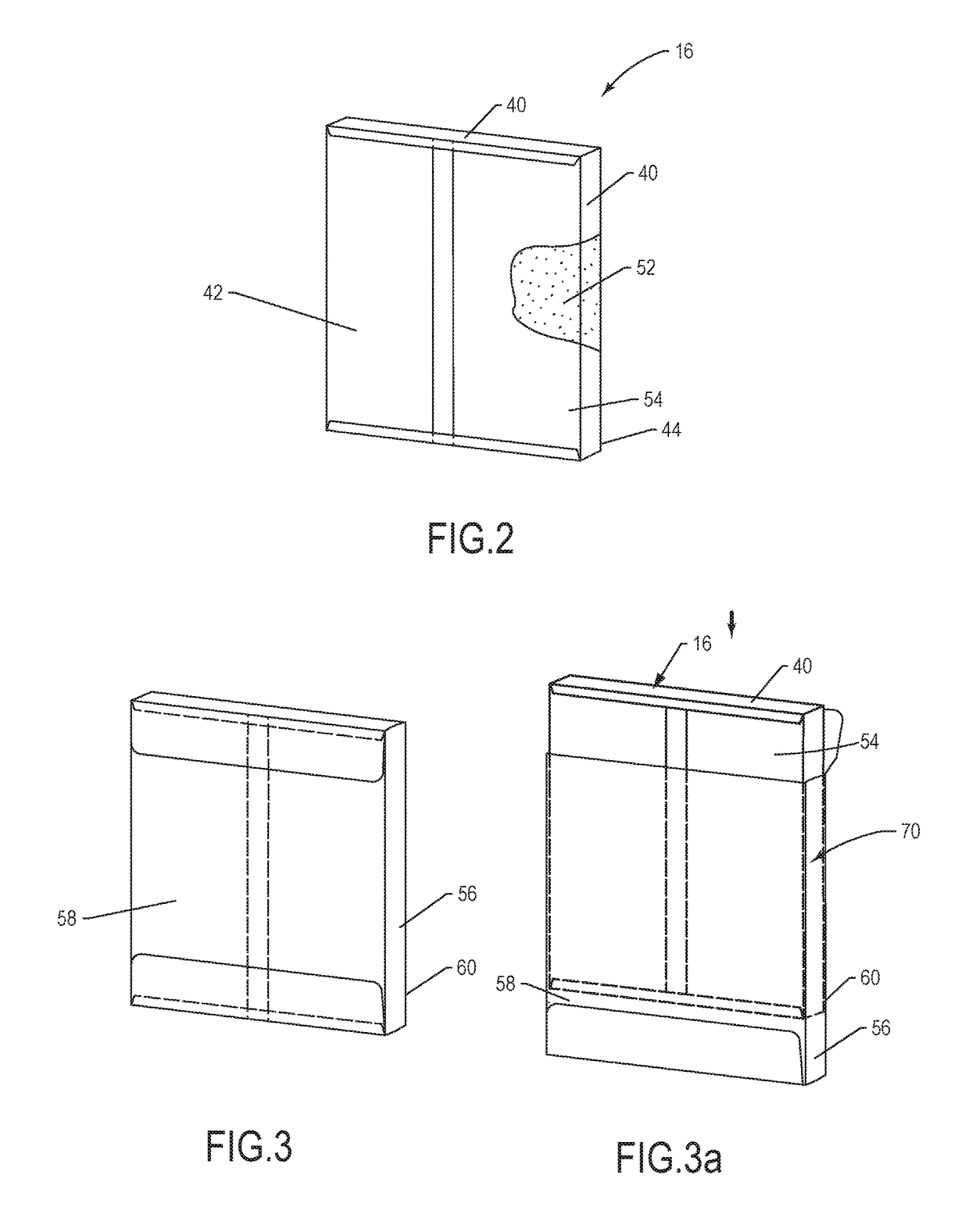

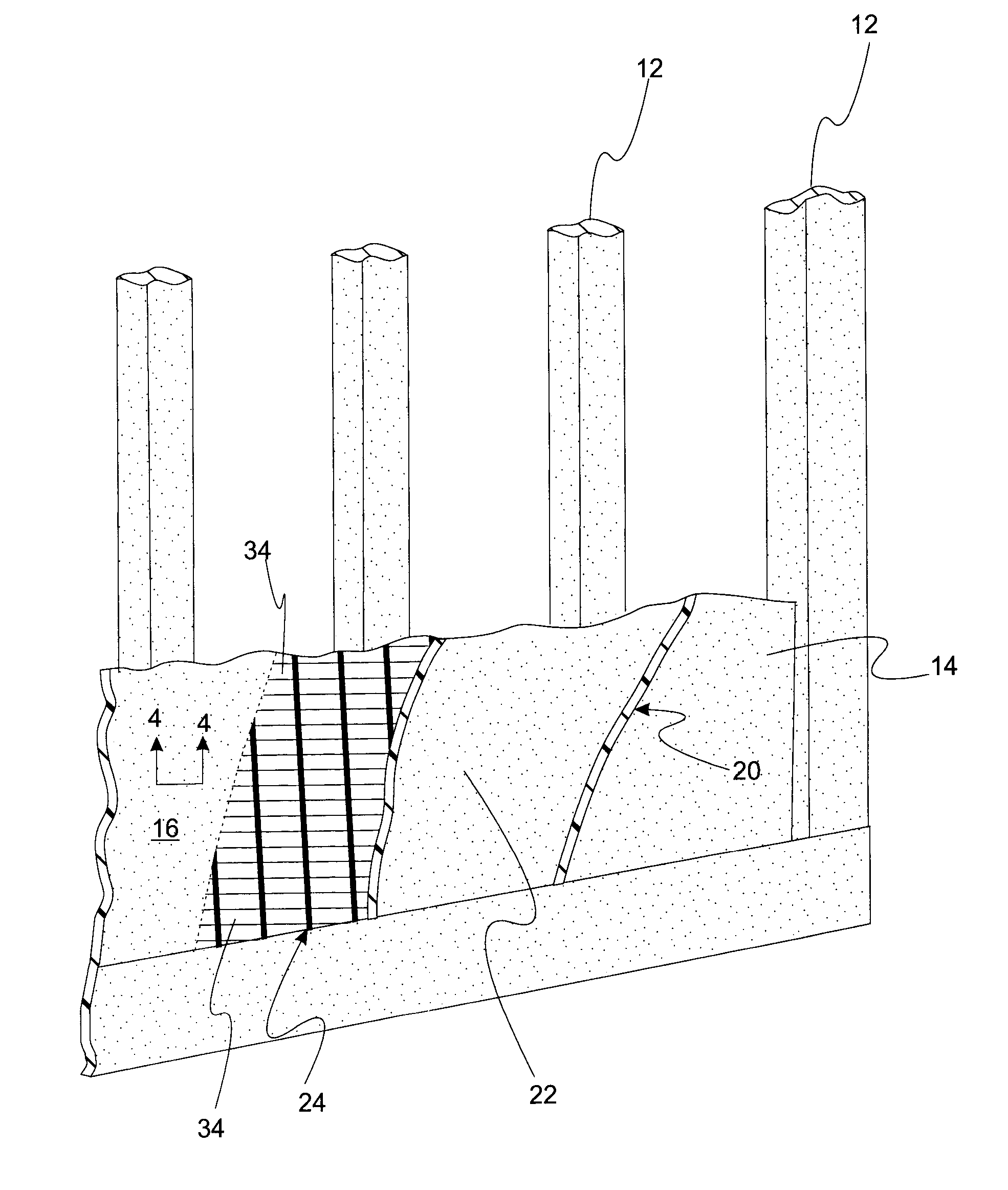

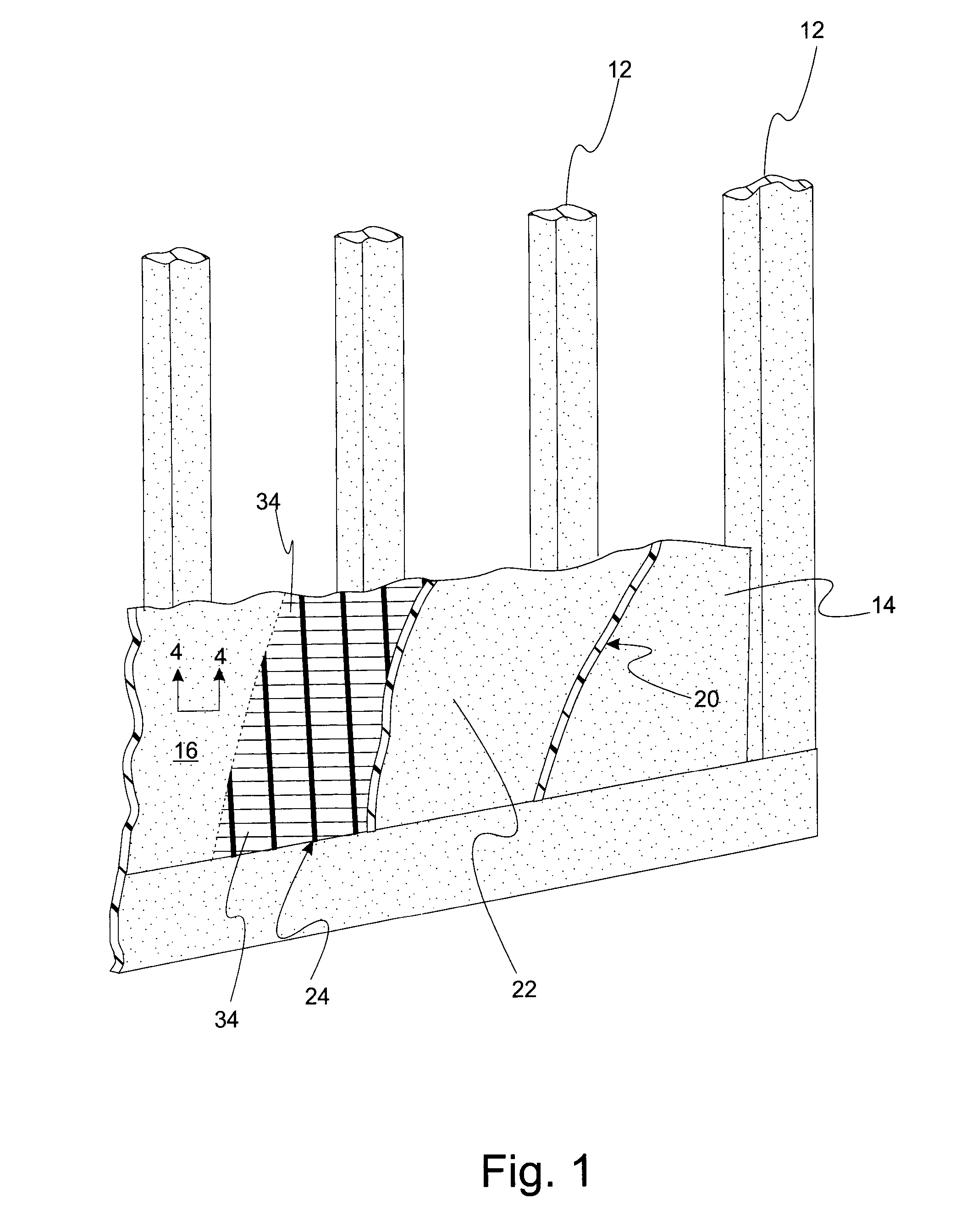

Double bag vacuum insulation panel for steam chest molding

A double bag vacuum insulation panel for use in a temperature assured shipper made in a steam chest molding machine is provided. The double bag VIP comprises a porous core, a heat sealable inner envelope and an outer bag. The inner envelope is made from a substantially gas impermeable first material having a first thickness and defines an interior having a pressure of less than or equal to about 30 millibar. The outer bag is made from a substantially gas impermeable second material having a second thickness. The outer bag encapsulates the inner envelope. The double bag vacuum insulation panel has an R value of at least about 28 hr-ft2-° F. / BTU-in and the R value drops less than about 10% after being exposed to a temperature of up to 95C for up to 7 seconds.

Owner:SONOCO DEV INC

Water management building wrap

ActiveUS20070144110A1Stable vertical water drainage channelsSynthetic resin layered productsConstructions elementsPolymerSkin thickness

Owner:CONWED PLASTICS

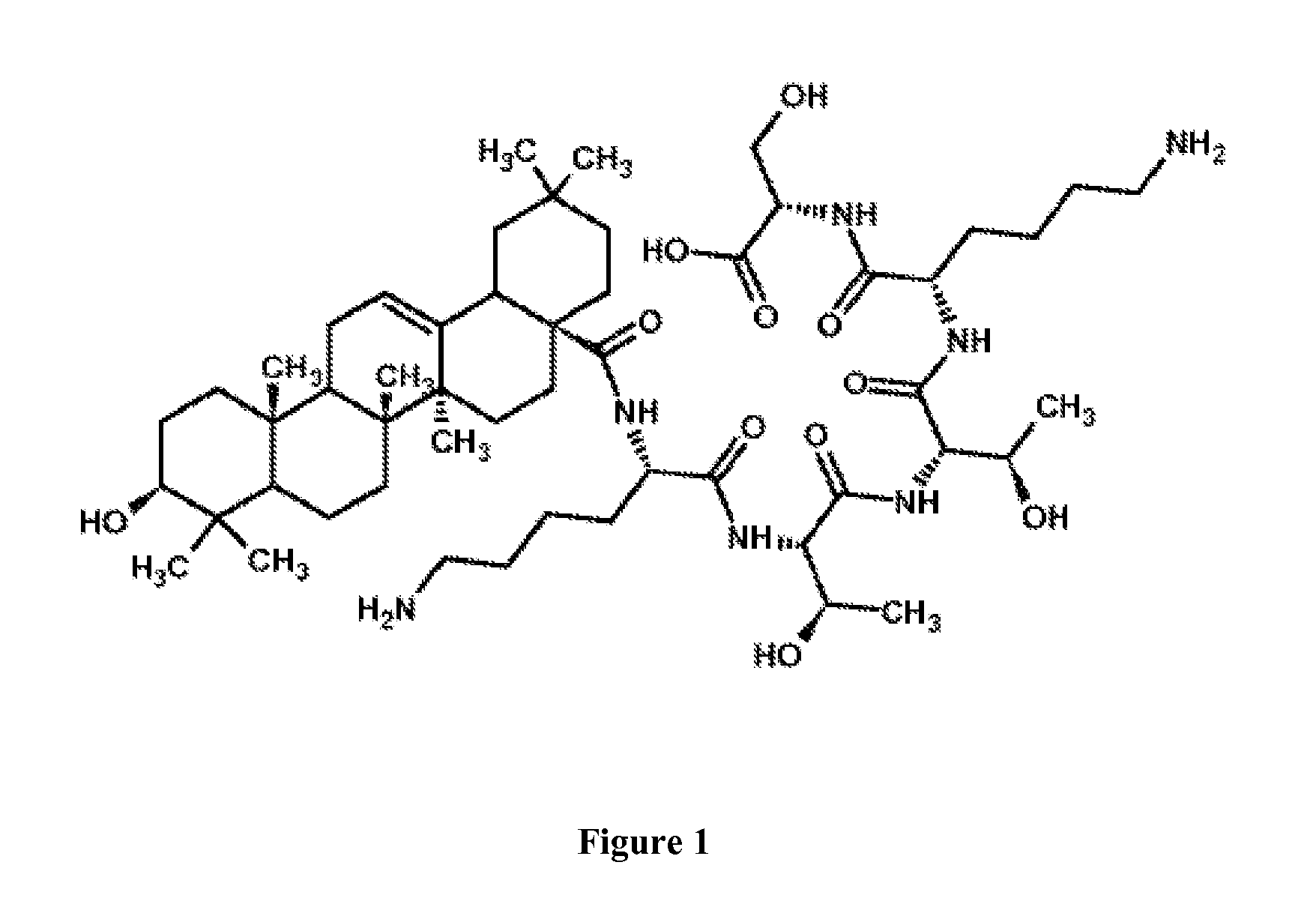

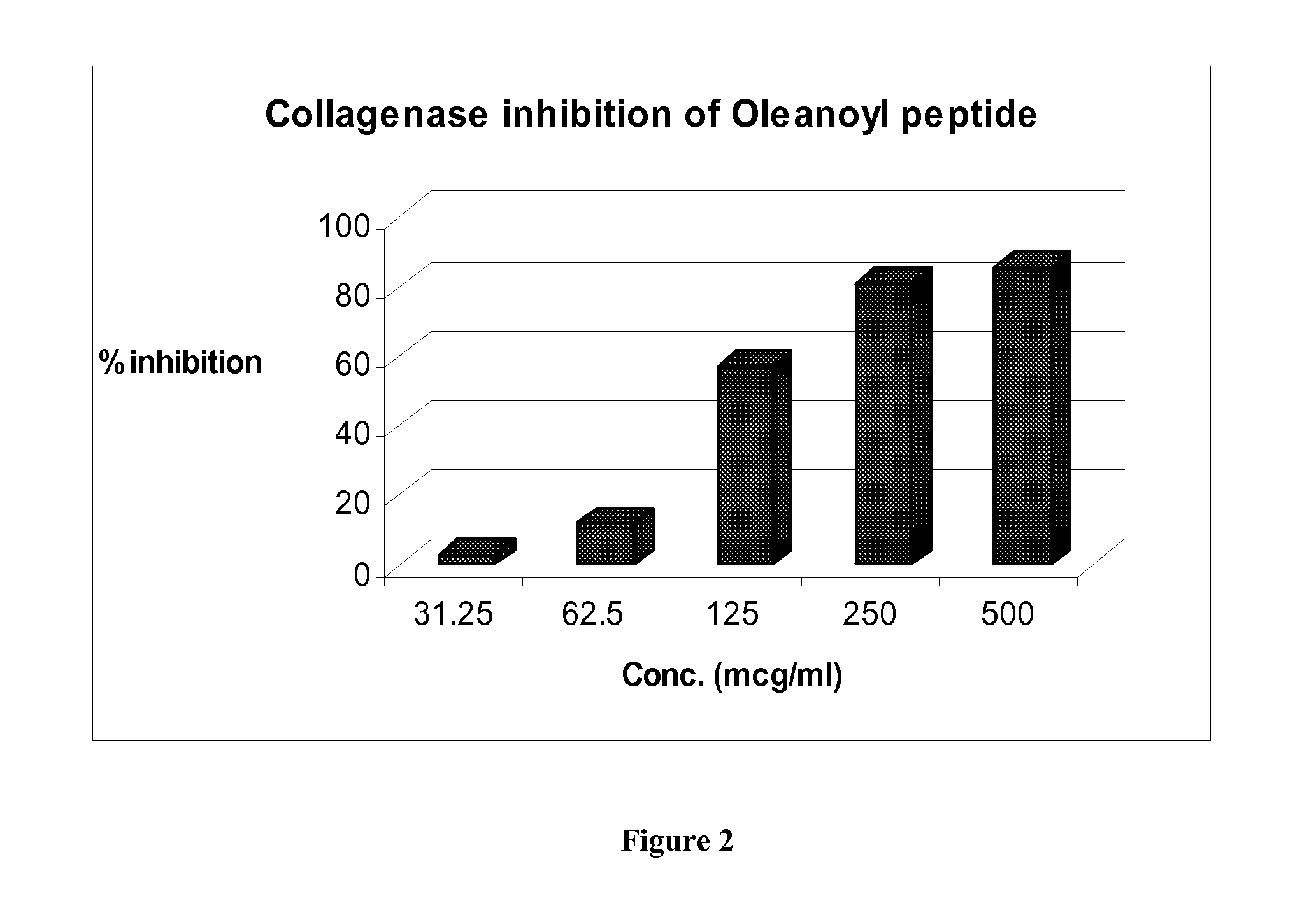

Oleanoyl peptide composition and a method of treating skin aging

ActiveUS20110091398A1Increase skin thicknessReduce hyperpigmentationBiocideCosmetic preparationsWrinkle skinPremature ageing

The present invention relates to a composition containing peptide of SEQ ID No. 1 linked to oleanolic acid and a method of treating skin aging. The composition effectively reduces signs of ageing due to oxidation, collagen insufficiency and excess activity of serine proteases like elastase and collagenase that result in wrinkling of skin, fine expression lines, reduced skin thickness, hyperpigmentation, under eye dark circles, and premature ageing.

Owner:SAMI LABS LTD

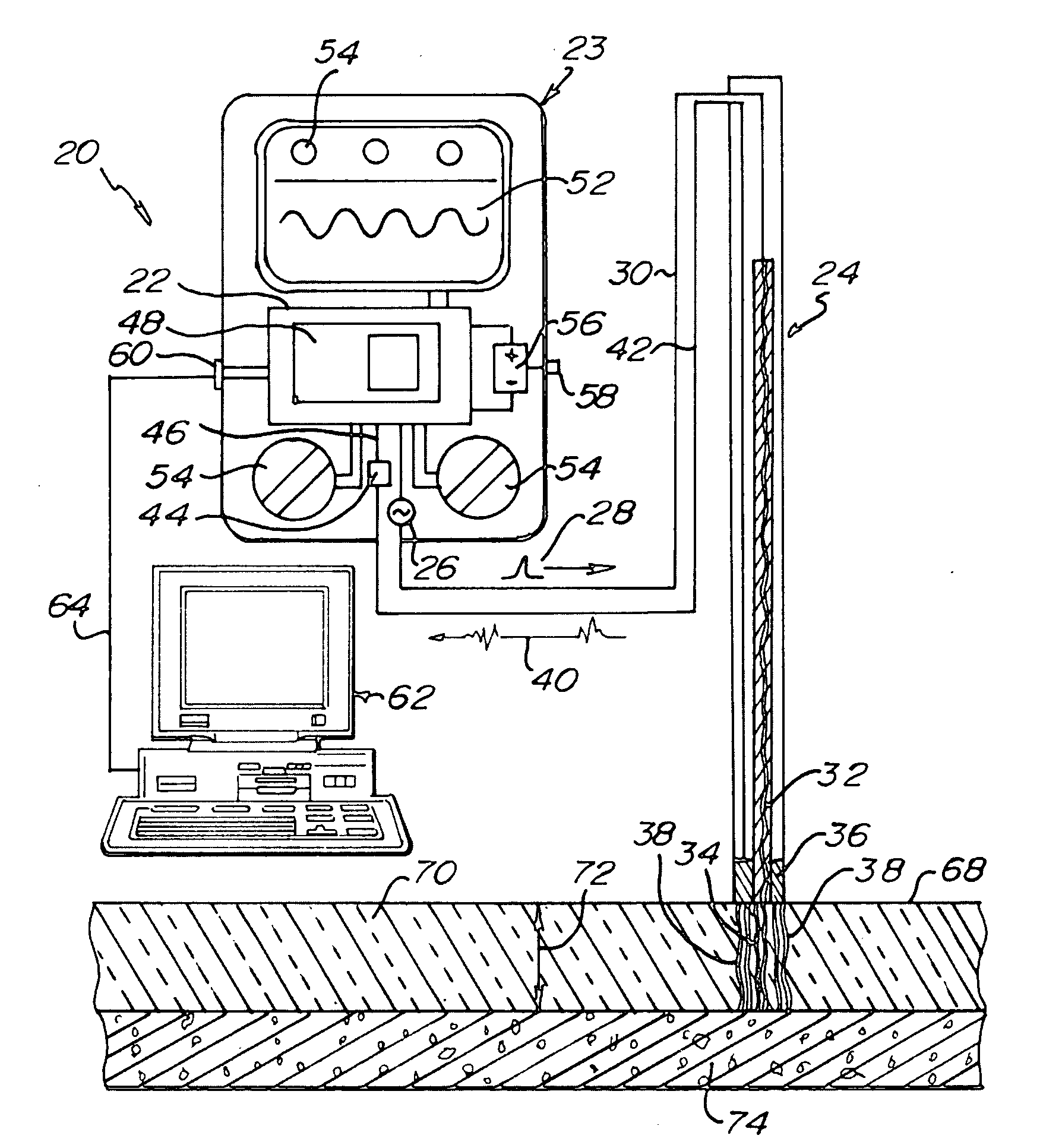

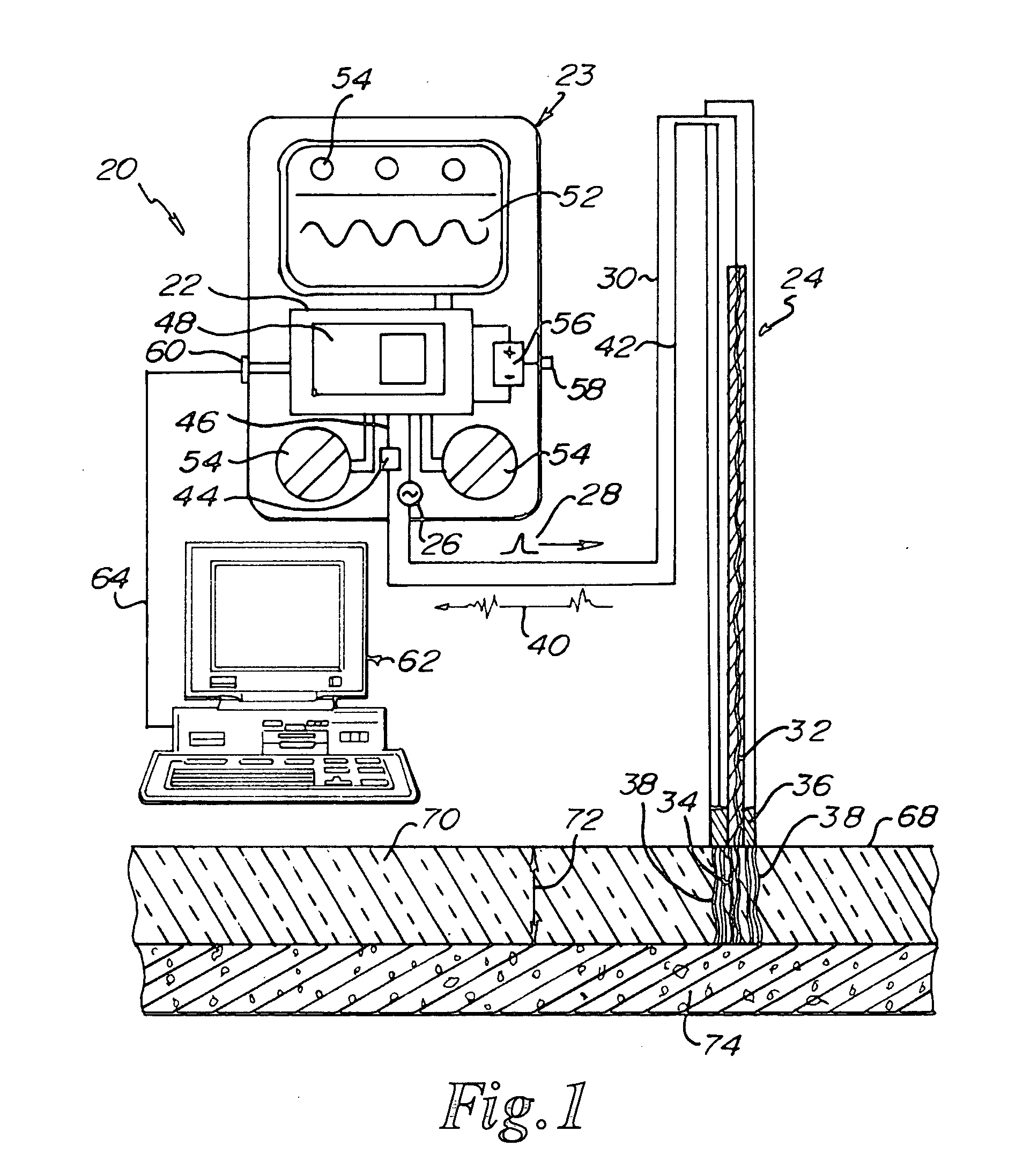

Ice thickness measuring system

InactiveUS20080295599A1Increase speedImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidGraphicsGraphical user interface

An ice thickness measurement system for determining thicknesses of an ice sheet such as an ice rink that is positioned on a solid or granular substrate. The system determines the thickness of the ice sheet using an acoustic technique, is portable, and may include a display graphic or graphical user interface on the portable unit to direct operators of the unit where to conduct an array of measurements on the ice sheet. The system may also be compatible with a computer for downloading of data and uploading of graphical displays.

Owner:PRECICE TECH

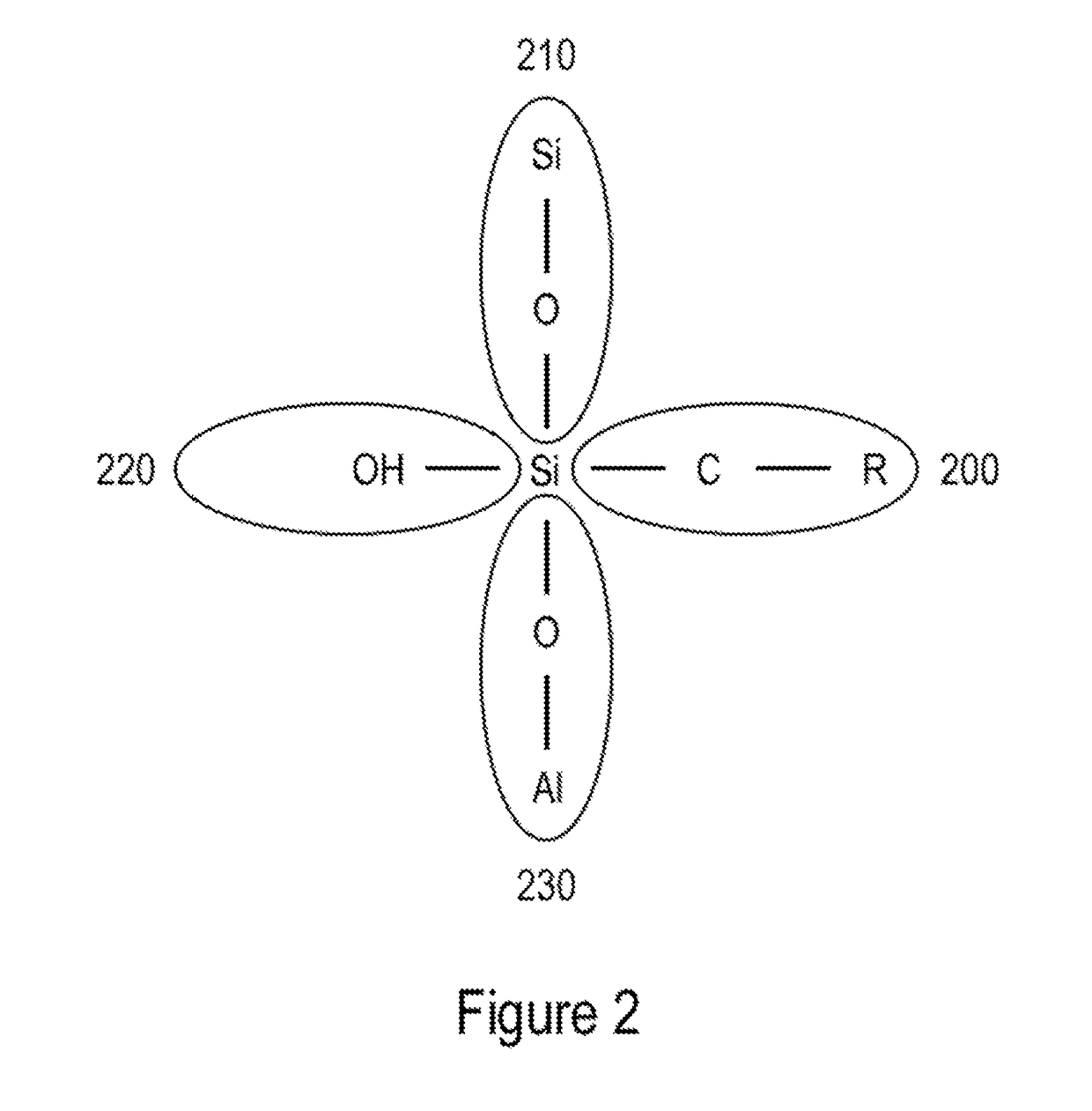

Encapsulated particles

The disclosed technology relates generally to material systems which include a plurality of particles and methods of making the same. The particles have a core and a shell which encapsulates the core and has at least one atomic element not included in the core. The cores of the particles have a median maximum dimension that is less than 10 microns and a median of at least one axial dimension that is between 10 nm and 500 nm. The shells of the particles have a median thickness that is less than 100 nm, a silicon concentration that is between 10% and 50% on the basis of the weight of the shells, and an aluminum concentration that is between 0.01% and 5% on the basis of the weight of the shells.

Owner:NANOCOMPOSIX LLC

Multilayer Film

InactiveUS20110097548A1Improve adhesionAssures adhesionWrappersOrnamental structuresPolymer resinPlasticizer

A multilayered formable packaging film and a method of manufacturing the film are disclosed. The film is suitable for making blisters either by thermoforming or cold forming. The visible surface of the film has unique features preventing counterfeiting, which features are retained on the film even after blister formation. The film has a thickness not exceeding 1050 microns. The film substrate has a 10-500 micron thickness, is devoid of plasticizer and comprises at least one polymeric resin. A coat of an ester acrylic based primer having a 0.1-1 micron thickness is on a first surface of the substrate. A metallized layer with non-uniform thickness between 0.001 to 0.3 micron is deposited on the coat and embossed. A base having a thickness of 50-1000 microns is on the second surface, the base comprising at least one polymeric resin.

Owner:BILCARE

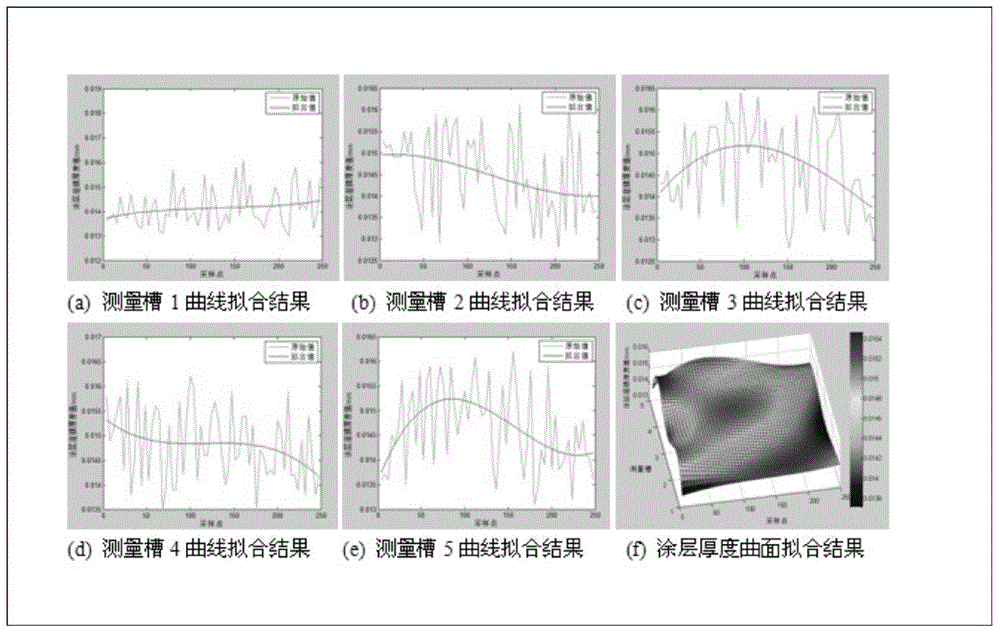

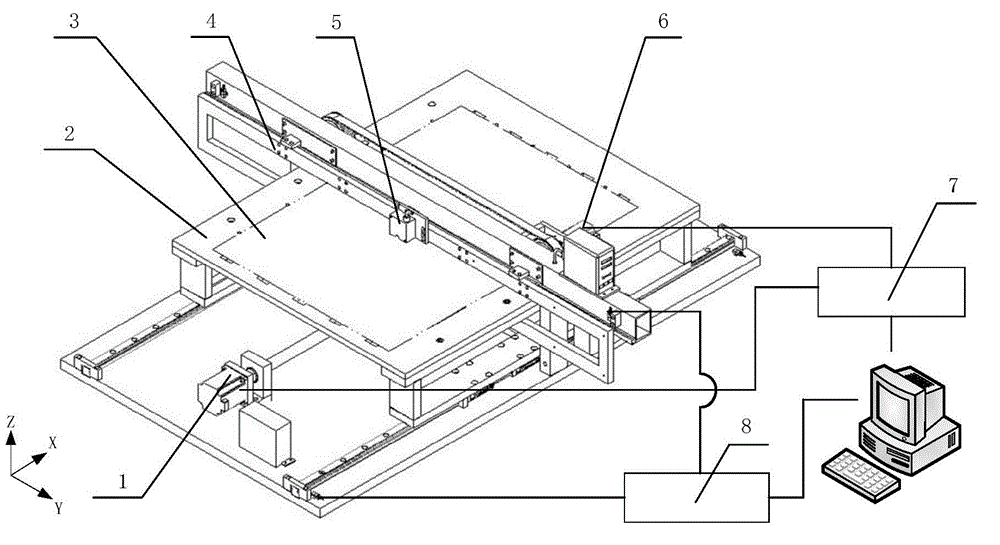

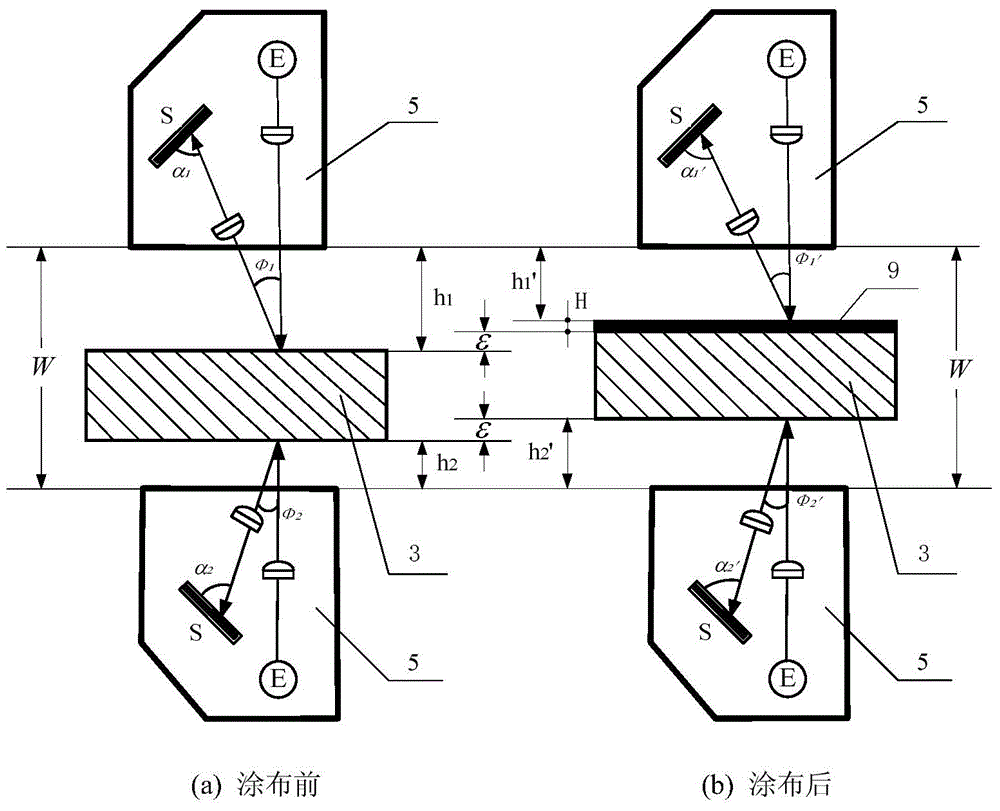

Wet film thickness difference measurement and evenness assessment method of metal sheet printing coating

ActiveCN104613883AEliminate the calibration link of the distance WEliminate the effects ofInvestigating moving sheetsUsing optical meansDifferential measurementThree dimensional graphics

The invention discloses a wet film thickness difference measurement and evenness assessment method of metal sheet printing coating. The method includes the following steps: (1) a metal sheet to be coated is placed on a thickness measuring platform which can be move in the X direction and a scanning thickness measuring mechanism which is provided with a laser double measuring heads can move along the Y direction so that the collection of multiple cloud data in the XOY plane of the metal sheet can be realized; (2) the coated metal sheet is placed on the same position of the thickness measuring platform and scanned and measured along the original route; (3) data processing is conducted on the data before and after the same metal sheet is coated according to the principle of difference measurement so that the coating thickness of the measured point can be obtained; (4) fitting is conducted on the measured thickness data according to the principle of least squares and the cubic spline interpolation algorithm so that a three-dimensional graphics of the surface coating thickness of the metal sheet can be obtained and the evenness of the surface coating thickness of the whole metal sheet can be assessed. The wet film thickness different measurement and evenness assessment method of the metal sheet printing coating can effectively assess the evenness of the printing coating thickness of the metal sheet and provides an evidence of the coating mechanism of the metal sheet.

Owner:上海三景制版有限公司

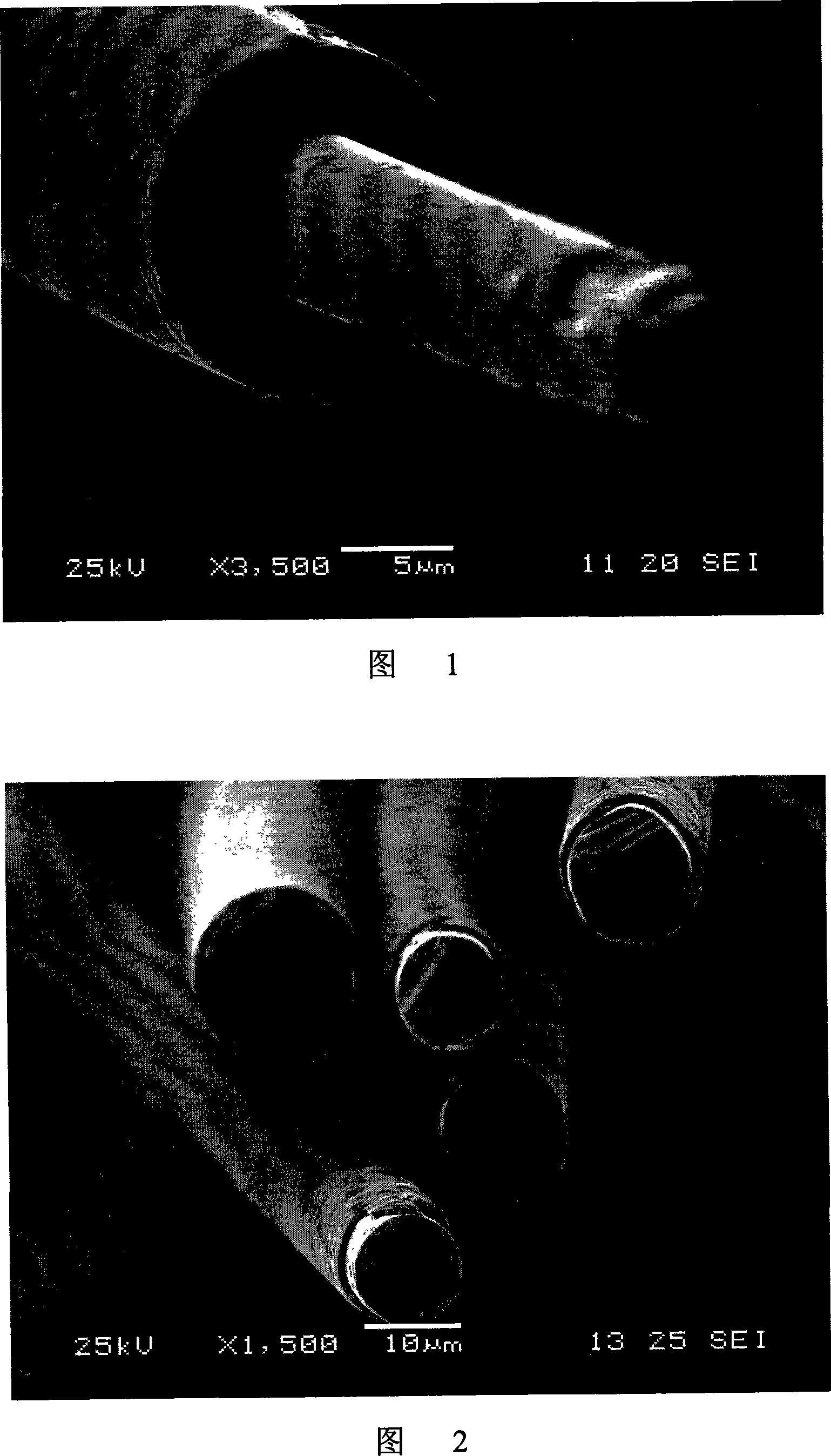

Core-skin structure micropore silicon carbide fiber and method for producing the same

InactiveCN101195938AArtificial filament heat treatmentFibre chemical featuresActivation methodChemical adsorption

The invention relates to skin-core structure micro-pore silicon carbide fiber and the preparation method, the fiber is characterized in that both the skin layer and the core part contain the micro-pore with pore diameter less than 2 nm, and the micro-pore volume content of the skin is higher than the core part; the ratio between the skin layer thickness and the radius is 0.1 to 0.9; according to the differences of the skin thickness, the specific surface area of the fiber is 400m<2> / g to 1400m<2> / g, and the average pore diameter is 1.30 to 1.60 nm; the C content of the skin layer is more than 90 wt percent, the residual is Si, or Si and O; the C content of the core part is 27 to 35 wt percent, the O content is 10 to 20 wt percent, and the residual is Si. The preparation method is characterized in that the Si element of the skin layer is etched through the KOH activation method and the skin-core structure is formed, simultaneously, the micro-pore with higher proportion is formed, the specific surface area and the conducting property of the fiber can be adjusted through the method. The skin-core structure micro-pore silicon carbide fiber of the invention can be used in the physico chemical adsorption field, catalyst carrier field, and wave-absorbed stealth field.

Owner:NAT UNIV OF DEFENSE TECH

Asymmetric gas separation membranes with superior capabilities for gas separation

InactiveUS20100244306A1Excellent permeation fluxHigh selectivityProductsSemi-permeable membranesCellulose diacetatePolyimide membrane

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes having a skin thickness of less than 100 nm, exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com