High temperature furnace pipe residue lifetime estimation method and device

A technology for life assessment and high-temperature furnaces, applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as the inability to calculate the remaining life of the tube, the difficulty in supervising the operation of the high-temperature furnace tube, and the inability to effectively evaluate the operating status of the tube, etc. , to achieve the effect of avoiding boiler accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

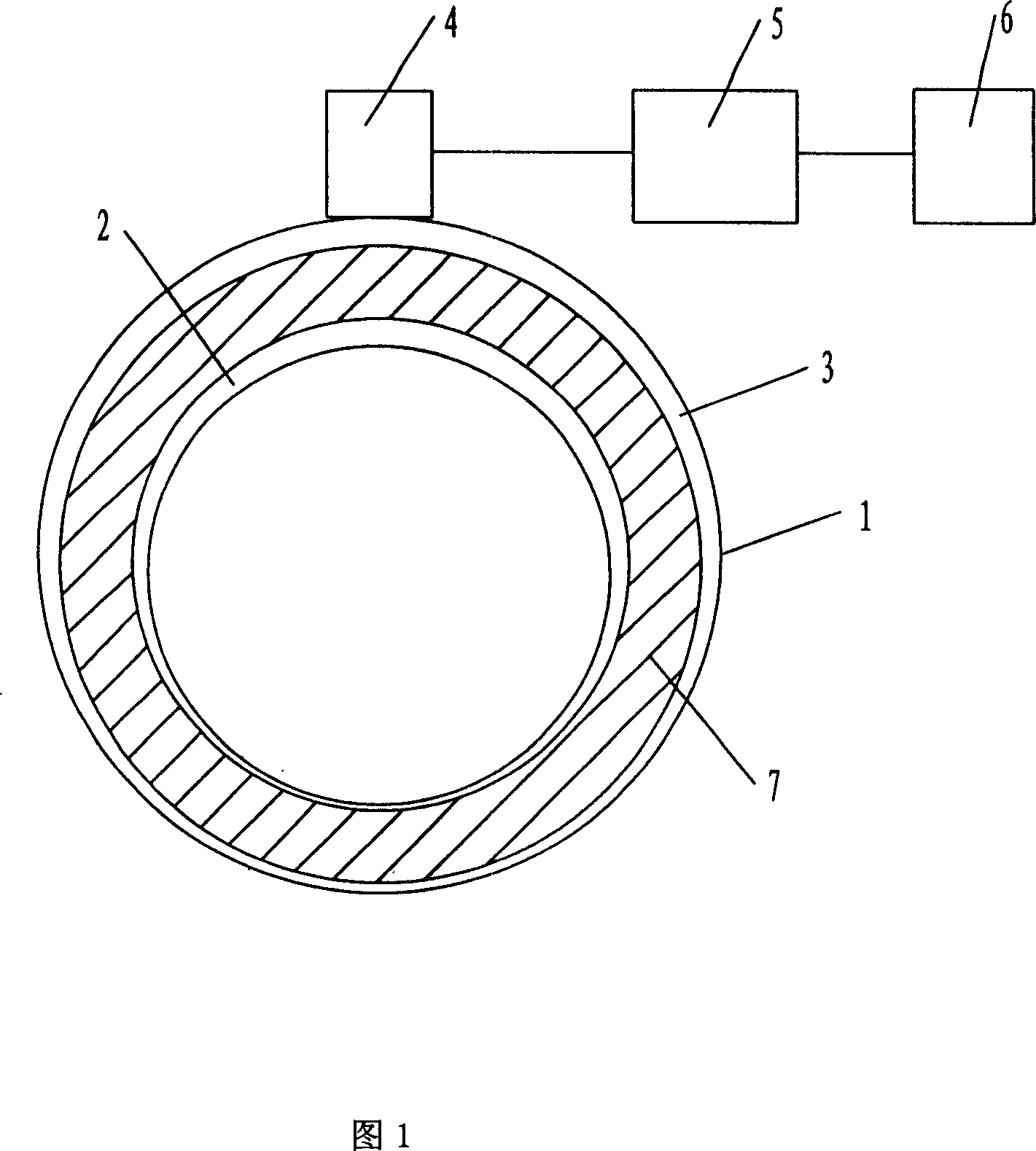

[0025] As shown in Fig. 1, the high-temperature furnace tube residual life evaluation device of the present invention includes: a high-frequency ultrasonic probe 4, a digital ultrasonic flaw detector 5 and a data processing system 6, which are sequentially connected together through communication cables. The high-frequency ultrasonic probe 4 is used to collect the waveform of the inner wall oxide layer 2 and the pure metal layer 7 of the high temperature furnace tube 1. When collecting the waveform of the pure metal layer 7, the outer wall oxide layer 3 should be removed, and the probe is in contact with the pure metal layer 7. The frequency of the high-frequency ultrasonic probe 4 is divided into several types such as a longitudinal wave probe of 15MHz, a longitudinal wave probe of 30MHZ and a transverse wave probe of 20MHz, and a general-purpose digital ultrasonic high-frequency probe can be used. The digital ultrasonic flaw detector 5 is used to receive the collected wavefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com